Buderus Logano G125 BE US/CA, Logano G125/21-BE, Logano G125/28-BE, Logano G125/34-BE Installation And Service Instructions Manual

Installation and Service

Instructions

Low Emissions and

High Efficiency Oil

Boiler

C

Logano G125 BE US/CA

For trained and certified

installers

Read carefully prior to

installation, maintenance

and service.

6 720 804 880 (2012/10) EN-US

Table of Contents

1 Safety Considerations and Symbol Descriptions . . . . . . . . . . . . . . . . . . . 4

1.1 Regarding this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.2 Guideline of Notices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.3 Observe the following Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.3.1 Installation Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.3.2 Boiler Room Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.4 Tools, Materials and Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.5 Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2 Product Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.1 Product Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.2 Product Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3 Technical Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.1 Technical Data less Burner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.2 Operating Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.2.1 General Operating Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4 Packaging and Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

5 Moving the Boiler. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

5.1 Reducing Boiler Weight for Transportation. . . . . . . . . . . . . . . . . . . . . . . . . . . 13

5.2 Lifting and Carrying the Boiler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

5.3 Moving the Boiler with the Boiler Cart. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

6 Placing the Boiler. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

6.1 Clearances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

6.2 Reversing the Burner Door Swing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

6.3 Installation of boiler Feet (Components of B-Kit) . . . . . . . . . . . . . . . . . . . . . . . 17

6.4 Placement of the Boiler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

7 Boiler Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

7.1 Installation of Venting Systems. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

7.1.1 Vertical Venting Systems. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

7.1.2 Horizontal Venting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

7.2 Installation of Combustion Air Supply System. . . . . . . . . . . . . . . . . . . . . . . . . 28

7.3 Installation of Water Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

7.3.1 B-Kit Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

7.3.2 Installation of Boiler Drain (B-Kit Component) . . . . . . . . . . . . . . . . . . . . . . . . . . 32

7.3.3 Installation of System Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

7.4 Filling and Checking for Water Leaks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

7.5 Installation of Oil Line. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

7.6 Electrical Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

7.6.1 Installation of Aquasmart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

7.6.2 Control System Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

7.6.5 Strain Relief Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

7.6.6 Top Rear Panel Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

2

Logano G125 BE - Specifications subject to change without notice.

Table of Contents

8 Placing the Boiler in Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

8.1 Setting the Initial System Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

8.2 Checking the Relief Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

8.3 Check Position of Flue Baffles (Room Air Operation). . . . . . . . . . . . . . . . . . . . . 40

8.4 Check Position of Flue baffle Plates (Outside Air Operation) . . . . . . . . . . . . . . . . 41

8.5 Prepare System for Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

8.6 Start-up of Control and Burner. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

8.7 Guidelines for Burner Start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

8.8 Adjusting Stack Temperatures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

8.8.1 Adjusting/Removing Flue Baffles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

8.8.2 Removing Flue Blocking Plate. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

8.9 Testing of the Manual Reset High Limit (STB) of Logamatic controls . . . . . . . . . . . 44

8.10 Installation of Front Burner Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

8.11 Detailed Start-up Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

9 Taking the Boiler Out of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

9.1 Normal Boiler Shut-down . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

9.2 Emergency Shut-down . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

10 Boiler Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

10.1 Why do maintenance?. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

10.2 Prepare Boiler for Cleaning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

10.3 Boiler Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

10.3.1Cleaning the Boiler with Brushes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

10.3.2Wet Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

10.3.3Inspecting the combustion air hose (sealed combustion only) . . . . . . . . . . . . . . . . . . 50

10.4 Testing System Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

10.5 Testing Relief Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

10.6 Inspection and Maintenance Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

11 Restoring System Lock-outs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

12 Piping Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

13 Spare Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

14 Burner Wiring Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

15 Glossary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Logano G125 BE - Specifications subject to change without notice.

3

1

Î

Safety Considerations and Symbol Descriptions

1 Safety Considerations and Symbol Descriptions

1.1 Regarding this Manual

This document contains important information regarding

safe and proper installation, operation and maintenance

of the boiler.

The high tech G125 BE boiler is designated as a hot water heating boiler.

The Installation and Maintenance Instructions are directed to the installing contractor who has professional

knowledge regarding boiler installation and maintenance.

1.2 Guideline of Notices

Two levels of danger are identified by the following

warning labels:

DANGER

Denotes a possible severely dangerous

WARNING!

CAUTION!

situation where, without proper caution,

bodily injury or loss of life may result.

DANGER OF INJURY/SYSTEM

DAMAGE

Denotes a possible dangerous situation

that can lead to mild to moderate bodily injury or physical damage.

1.3 Observe the following Symbols

The local and state codes and regulations must be observed during the installation of the boiler:

– The local building code requirements regarding

placement, combustion air and venting and chimney

system must be followed.

– Follow applicable electrical code requirements.

– Follow the local code and standards regarding safe

boiler operation.

NOTICE

Use only original Buderus spare parts.

Buderus can not be held liable for damage caused by non-Buderus parts.

NOTICE

The boiler installation must be performed

by a qualified installer in accordance with

regulations put forth in NFPA-31 Installation of Oil-Burning Equipment. The installation must comply with all local and

national codes, regulations and authorities having jurisdiction regarding the installation of oil fired boilers.

For Canada refer to the guidelines of

CSA/CGA-B149.1 and 2 Installation

Codes.

NOTICE

Application comment for optimum use of

equipment and adjustment as well as

useful information.

Cross reference

Designated by means of an arrow Î , refers to a notice

in another document.

4

Logano G125 BE - Specification s subject to change without notice.

Safety Considerations and Symbol Descriptions

1

1.3.1 Installation Guidelines

DANGER TO LIFE

from electric shock

CAUTION!

z Do not work on electrical components

unless you have the required qualification and applicable certification.

z Do not work on electrical components

unless you have the required qualification and applicable certification.

z Prior to opening the control: shut

down the power supply and prevent

from accidental reactivation.

z Observe all applicable installation

guidelines.

1.3.2 Boiler Room Guidelines

DANGER TO LIFE

from poisoning.

CAUTION!

Insufficient combustion air can result in

dangerous operation if combustion air is

taken from indoors.

1.4 Tools, Materials and Accessories

For the installation and maintenance of the boiler you

will need typical tools used in .

In addition, the following components are useful:

– Boiler cart with rope or Buderus boiler cart.

– Wood blocking.

– Cleaning brushes and/or chemical cleaning agents

for wet cleaning.

1.5 Disposal

z Please dispose of any trash in an environmentaly

friendly fashion.

z Please discard properly of any heating system relat-

ed components.

CAUTION!

z Please observe that combustion air

openings are not reduced in size or

closed.

z Make sure that no mechanical air

openings or devices remove combustion air from the boiler room such as

central vacuum systems, dryers and

air conditioning appliances.

z Make sure that the boiler is connected

to a chimney or horizontal venting system that is capable of handling the

slight positive breeching pressure.

z If any of these problems have not been

corrected, one cannot operate the boiler.

z Make the end-user aware of these

guidelines and their potential danger.

FIRE DANGER

due to flammable or liquid materials.

z Make sure that flammable and liquid

materials are not in the close vicinity of

the boiler.

Logano G125 BE - Specifications subject to change without notice.

5

2

Product Description

2 Product Description

2.1 Product Applications

The boiler is designated for use as a hot water heating

boiler for space heating applications and to heat domestic hot water by means of an indirect fired tank for single

and multi-family homes and small commercial heating

applications.

Please observe the technical data on the rating label

and technical information (Î Chapter 3, page 7), to ensure proper application of this product.

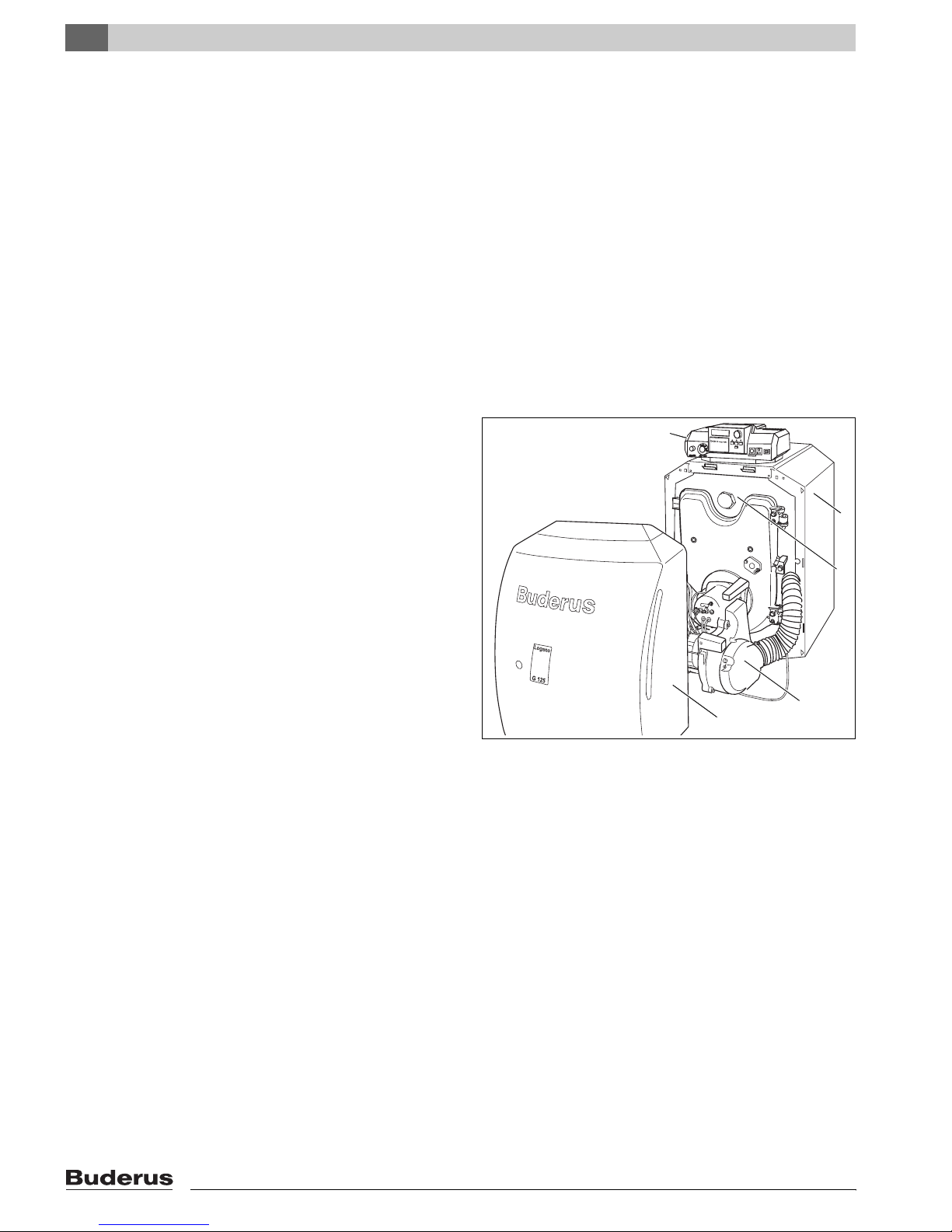

2.2 Product Description

The G125 BE is a oil fired low temperature boiler with

boiler water temperature regulation.

The boiler consists of:

– Optional Logamatic control

– Boiler jacket

– Boiler block with insulation

– Burner

The optional Logamatic control manages most control

functions in a heating system.

As an alternative, a Aquasmart control can be used for

boiler control.

The boiler jacket serves to reduce energy loss and as a

noise reducing agent.

The boiler block transfers the heat generated by the

burner to the boiler water. The insulation reduces the

stand-by losses.

1

Fig. 1 Boiler G125 BE US/CA

1 Control panel

2 Boiler jacket

3 Boiler block with insulation

4 Burner door cover

5 Burner

2

3

5

4

7 747 010 678-01.1RS

6

Logano G125 BE - Specification subject to change without notice.

3 Technical Information

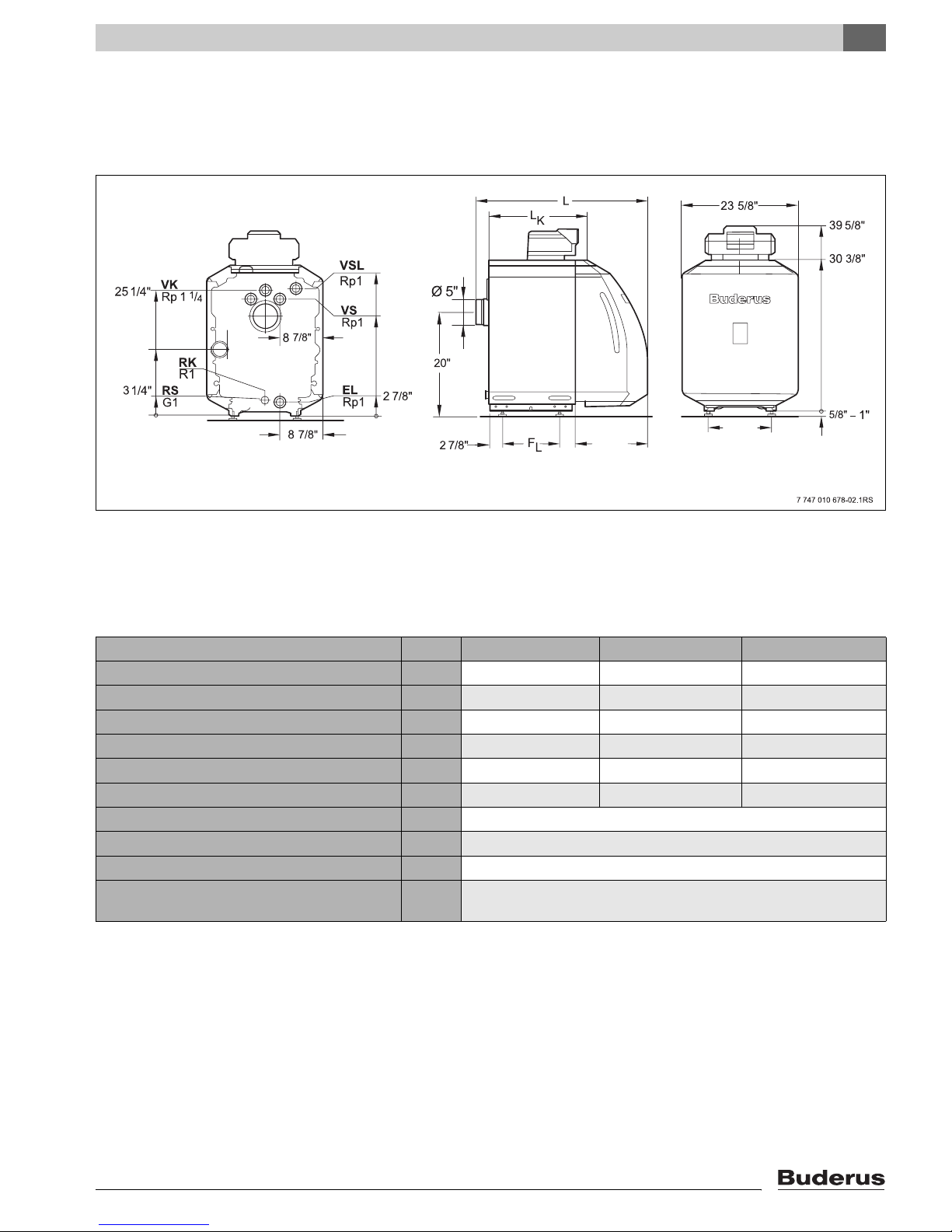

3.1 Technical Data less Burner

25 1/2"

23 1/2"

14 1/2"

Technical Information

12 1/4"

3

Fig. 2 Dimensions and connections (measurements in inches)

Connections (For Measurements see following tables):

VK = Boiler supply VS = Connection (plugged)

RK = Boiler return RS = Connection (plugged)

EL = Boiler drain (Connection for drain valve) VSL = Connection (plugged)

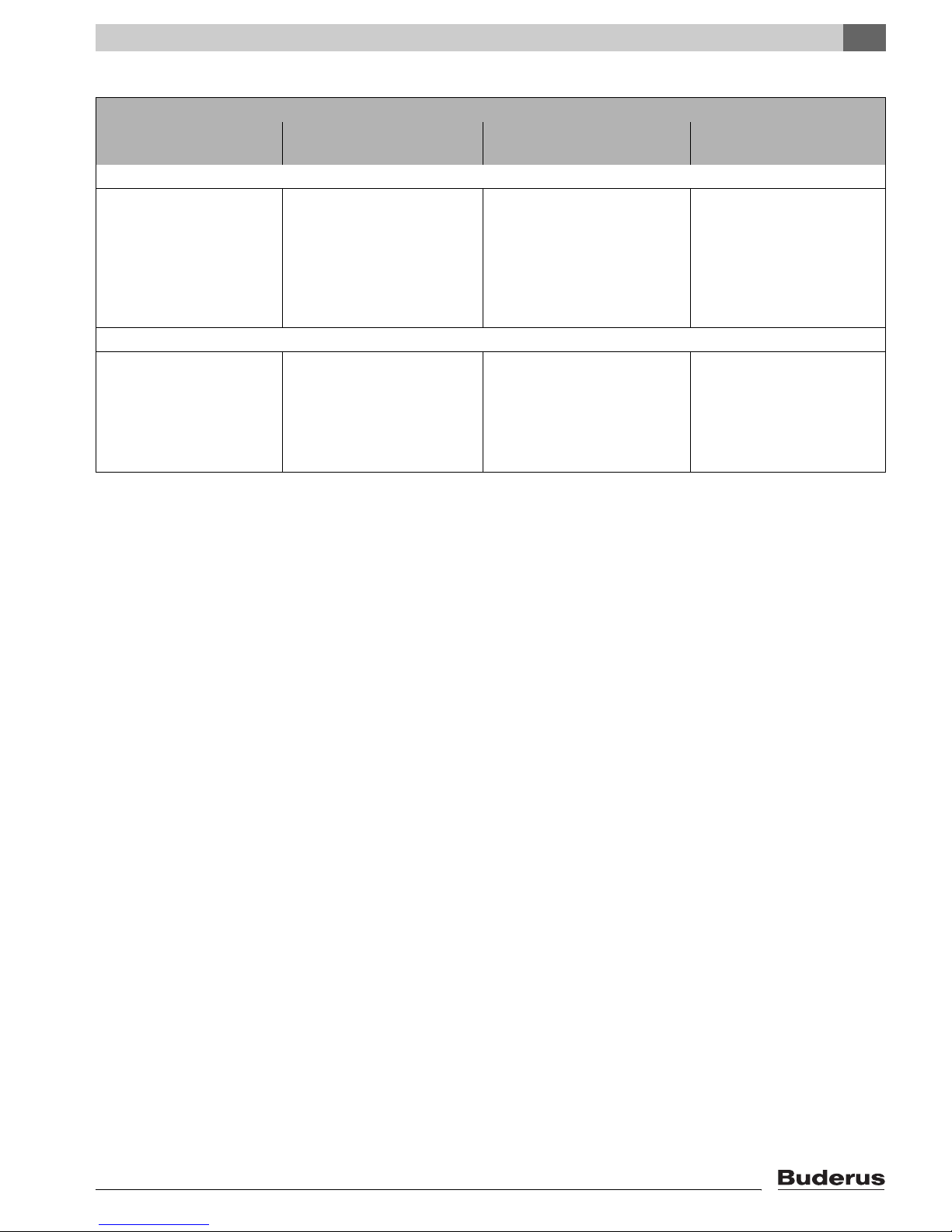

Boiler Model G125/21-BE G125/28-BE G125/34-BE

Number of boiler blocks 34 5

Heating Capacity (Gross Output) MBtu/hr 72 96 116

Net IBR MBtu/hr 63 83 101

Boiler water content Gal 8.7 10.8 12.9

Fireside volume cu.ft. 1.20 1.75 2.21

Oil firing rate GPH .60 .80 1.0

Fireside pressure drop psi 0.00058 – 0.00145

Permissible max. supply temperature

1

°F 230

Allowable operating pressure psi 58

Maximum Reset High Limit for temperature

s 40

sensor and overheat thermostat (STB)

Table 1 Technical Data for G125 BE less burner

1

High limit (overheat thermostat STB)

Permissible maximum supply temperature = High limit (STB) – 32 °F

e.g.: High limit (STB) = 212 °F, maximum permissible supply temperature = 212 – 32 = 180 °F

Select your high limit (STB setting) according to your local codes and requirements.

Logano G125 BE - Specifications subject to change without notice.

7

3

Technical Information

Boiler Model G125/21-BE G125/28-BE G125/34-BE

Total boiler length (L) 34 5/8” 39 3/8” 44”

Boiler block length (LK) 21 1/8” 25 3/4” 30 1/2”

Combustion chanber length 16” 20 1/2” 25 1/4”

Firebox diameter 10 5/8”

Burner door thickness 3 1/2”

Distance between boiler feet (FL) 11 3/8” 16 1/8” 20 7/8”

Dry weight

Table 2 Dimensions, Weight and other Data for G125 BE less burner

1

Weight incl. packaging material approx 6 – 8% more.

1

386lbs 459lbs 513lbs

3.2 Operating Conditions

Maintain the operating requirements listed on the following page for long and trouble free operation of the boiler.

Proper and timely maintenance procedures must be followed.

SYSTEM DAMAGE

CAUTION!

If these operating requirements are not

followed, it can lead to premature failure

can result and cause permanent damage

to the boiler.

z Follow the instructions on the rating la-

bel and those in the manual.

8

Logano G125 BE - Specifications subject to change without notice.

Technical Information

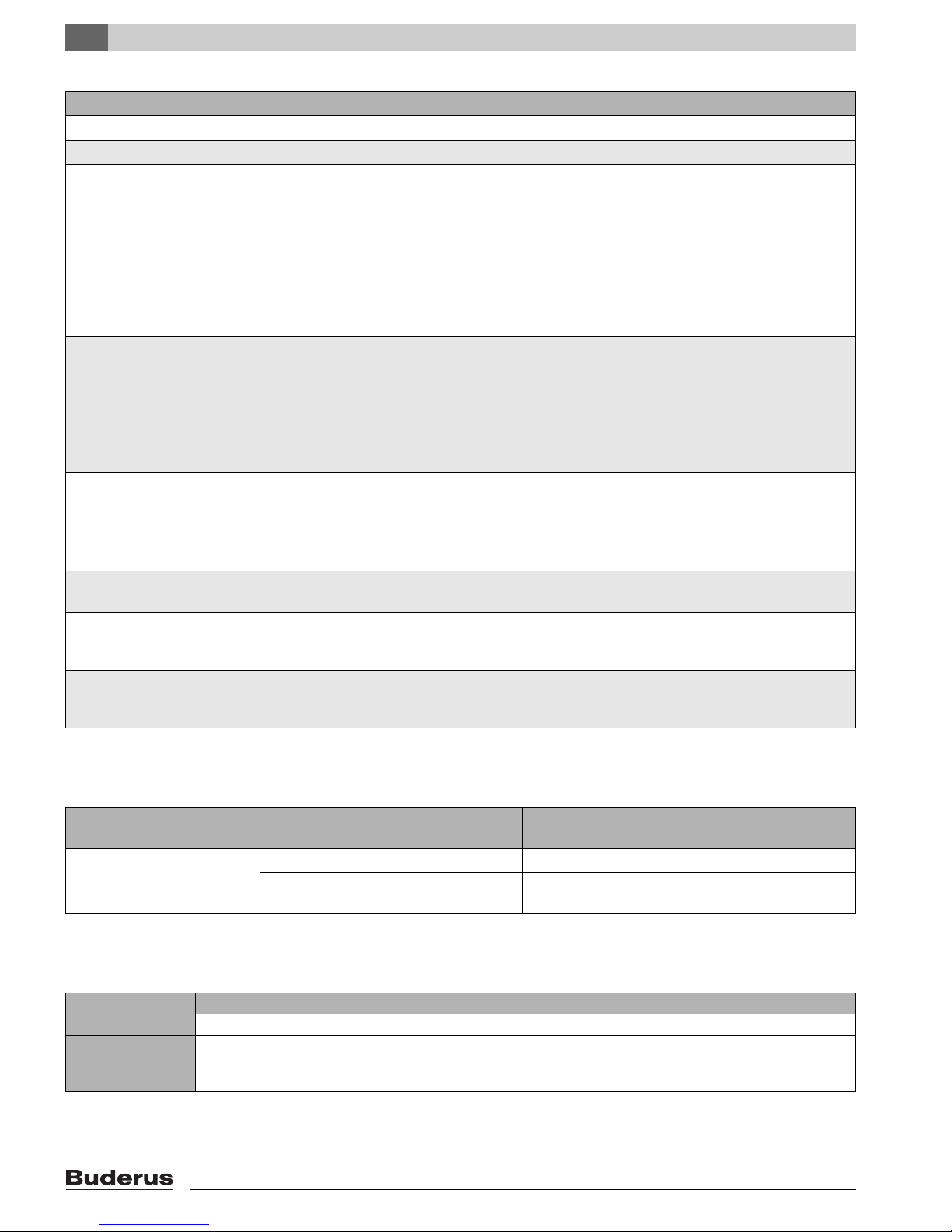

3.2.1 General Operating Requirements

Operating Conditions

Minimum Boiler tempera-

ture

Systems controlled by R2107 controls for outdoor reset operation

No requirements

Operating conditions are met

with R2107 control

150 °F

2

3

Table 3 General Operating Requirements

1

A heating circuit equipped with a motorized mixing valve improves the controllability of that sub-system and is specifically recommended when

requiring different water temperatures.

2

In case the control system has no influence over the flow in a heating circuit (for instance using the Pumplogic feature of the R2107), then one

should achieve a minimum supply temperature of 122 °F within 10 minutes after burner start-up by means of reducing (or interrupting) the water

flow through the boiler.

3

Minimum setting on the adjustable high limit or Aquasmart: During burner operation one should achieve the minimum boiler temperature within

10 minutes after burner start-up by means of flow reduction and one should maintain this temperature.

Boiler Shutdown Boiler Shutdown/

Mixed temperature

Automatic with Logamatic

R2107

No requirement, yet beneficial

with low temperature boiler with

130/113 °F system design

Necessary with:

– Radiant floor applications

– Systems with large water con-

tent > 115 gal/100,000 Btu/hr

Systems controlled by Aquasmart or R2109

Possible, provided the boiler op-

erates after total shut-down for

at least 3 hours.

1

Minimum return temperature

No requirement

Necessary Necessary for:

– Systems with large water

content > 115 gal/100,000

Btu/hr: 130 °F

– Firing with modulating burn-

ers: 130 °F

3

Logano G125 BE - Specifications subject to change without notice.

9

3

Technical Information

3.2.2 Requirements for Boiler Room and Surroundings

Operating Conditions Comments – Detailed Information

Boiler room temperature +40 to +104 °F

Relative humidity max. 90 % No condensate or dampness in boiler room.

Dust – No excess amounts of dust should be present in the boiler room, e.g.:

– No sheet rock or construction dust.

The available combustion air can not contain dust or other particles/ use of an air

filter might be needed, e.g.:

– Combustion air from nearby roads with high dust levels.

– Combustion air from nearby production facilities such as chemical plants &

shops.

– Airborne particulates.

Halogenated Hydrocarbons

contamination

Fans, removing air from boiler

room

Animals – The boiler room and especially the air inlet openings for combustion air must be

Fire Protection – Maintain proper clearances to combustible materials as required per local code.

Flood Zone Conditions – Separate the fuel supply and electrical power supply from the boiler during flood

– Combustion air must be free of halogenated hydrocarbons components.

– Eliminate any chemical compound such as paints, lacquers, thinners, clean-

ing agents. If not possible, provide fresh outside air for combustion.

Please observe the following:

– Product information of Buderus catalog.

– Also observe guidelines in K3 chapter of Buderus catalog.

– Avoid forced air removal by mechanical means during boiler operation such as:

– Bathroom exhaust fans

– Dryer

– Air-conditioning equipment

kept free from animals entering by means of grills.

Maintain a minimum distance of 16”. Do not store flammable materials near the

boiler.

conditions. Replace the boiler components such as insulation, electrical and control components afterwards.

Table 4 Boiler room and surroundings

3.2.3 Combustion Air Requirements

Operating Conditions Boiler capacity (combine total boiler ca-

pacity for multiple units)

Two air inlet openings from outside: one top, one near bottom

Table 5 Observe local codes and regulations for combustion air requirements

< 170,000 Btu/hr At least 43 square inch

> 170,000 Btu/hr At least 43 square inch plus 2.5 square inch per 10,000

Btu/hr, if the output is higher than 170,000 Btu/hr.

3.2.4 Fuel Conditions

Country All Countries

Fuel #2 Fuel Oil ASTM D396-05 Type 2

Comments No other fuel may be used with this burner.

Burner requires annual service and cleaning. Verify each time that the complete heating system is in working

order. Defects must be remedied immediately.

Table 6 Permitted fuel types

Cross area required

10

Logano G125 BE - Specifications subject to change without notice.

Technical Information

3

3.2.5 Requirements for Power Supply

Operating Conditions Comments – Detailed Information

Main power supply 120 V Provide proper grounding for equipment and personal protection.

High amp protection 10 A

Frequency 60 Hz

Protection – Group all equipment per local code

Table 7 Power supply

3.2.6 Conditions Pertaining to Piping and Water Quality

Operating Conditions Comments – Detailed Information

Operating pressure (over pressure)

Allowable test pressure 45 – 75 psi

Adjustable temperature limit TR122 – 194 °F

Manual reset high limit 210 °F In combination with Beckett AquaSmart the limit value (210 °F) may not be excee-

Water quality – Initial fill water and make-up water should be potable water type quality. A pH

12 – 58 psi Maximum pressure is 30 psi based on supplied relief valve

ded.

range of 8.2 to 9.5 is desired.

Table 8 Piping and water quality

Logano G125 BE - Specifications subject to change without notice.

11

4

Packaging and Components

4 Packaging and Components

z Check the packaging for concealed damage.

z Check the packaging for completeness. Contact your

wholesaler in case of missing parts.

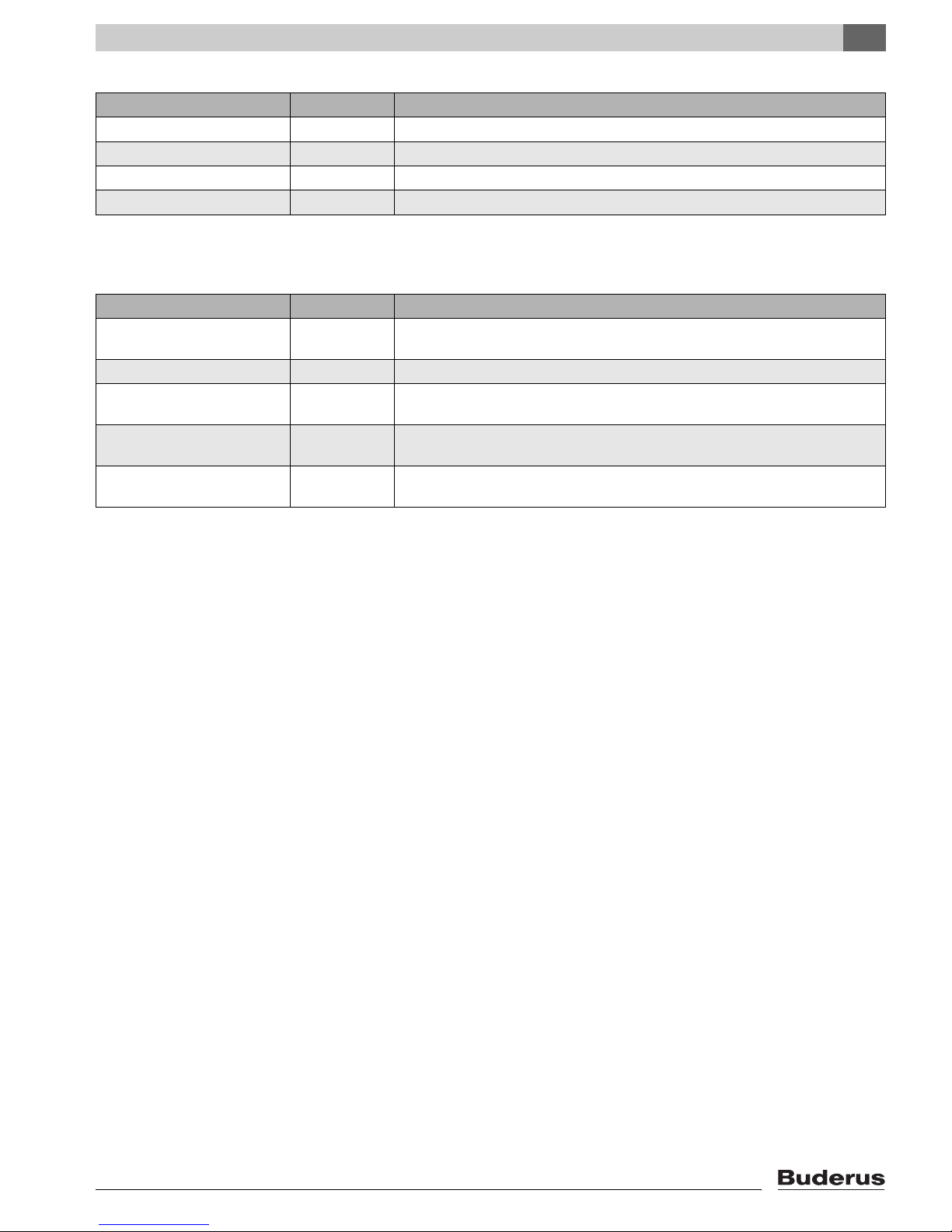

Component Qty Packaging

Boiler block 1 Pallet

Boiler jacket, installed on boiler

Burner door and burner door cover

installed on boiler block

Buderus oil burner mounted on customized burner door

B-Kit-Components:

Supply manifold (1¼" NPT)

30 psi relief valve

(¾") boiler drain

Pressure/temperature gauge

(1¼" NPT × R1¼) conversion nipple

(parallel to NPT)

90°-elbow (1¼" NPT)

90°-elbow (¾" NPT)

Burner mounting studs and washers

Screw in feet

14Plastic pack-

aging with boiler

Control panel, alternative Aquasmart control (ordered separately)

Tigerloop oil filter 1 included with

Taco 007 circulator pump w/flanges

Technical documents 1 Plastic pack-

Table 9 Packaging and components

Cardboard

box

boiler package

aging w/boiler

12

Logano G125 BE - Specifications subject to change without notice.

5 Moving the Boiler

This chapter describes how to move the boiler.

SYSTEM DAMAGE

due to bumps.

CAUTION!

z Protect the boiler from bumps and

rough treatment.

NOTICE

z Protect the boiler from connections

from damage and dirt, when the boiler

is not installed immediately.

NOTICE

Please dispose of the packaging in an environmentally friendly fashion.

Moving the Boiler

5

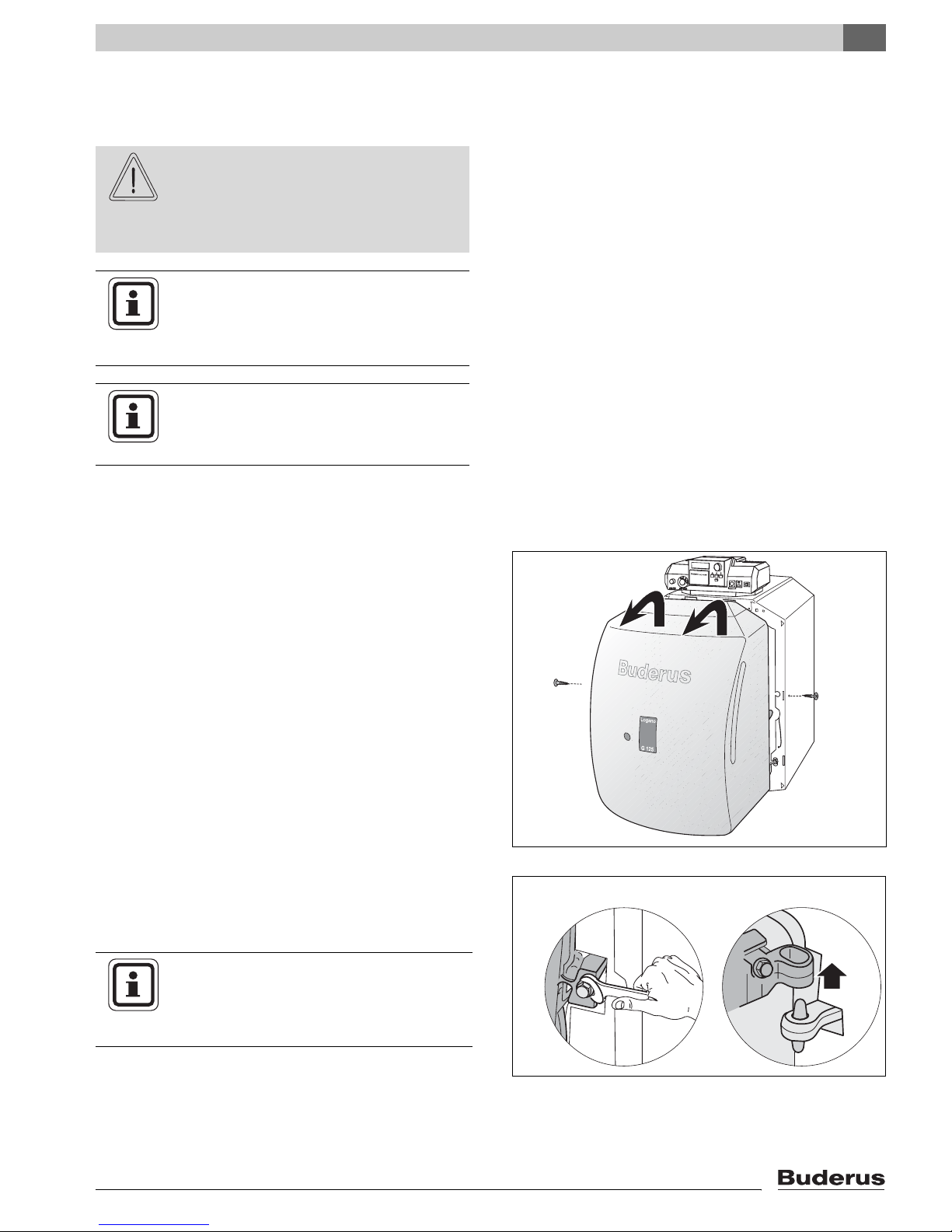

5.1 Reducing Boiler Weight for Transportation

One can reduce boiler weight by removing the front cover and burner door itself.

z Remove the screws holding the front cover in place.

z Lift up the front cover slightly and remove.

z Disconnect burner cable from burner control before

removing the burner door.

z Open burner door by removing the two burner door

bolts.

z Lift burner door from hinges.

NOTICE

Fig. 3 Removing the front cover

z Protect the burner door and the burner

tube from damage and dirt when the

burner door is removed from the boiler.

Logano G125 BE - Specifications subject to change without notice.

Fig. 4 Removal of burner door

13

5

Moving the Boiler

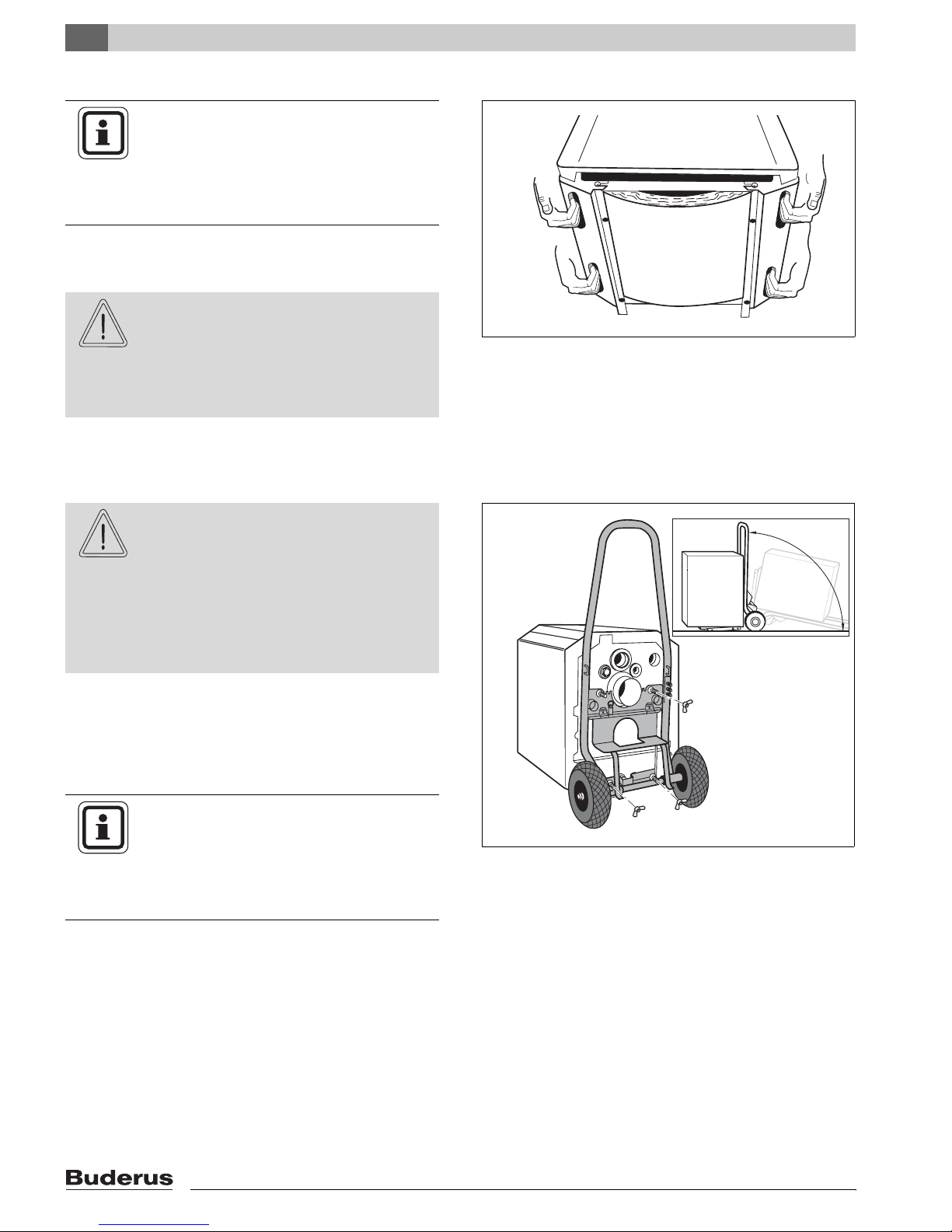

5.2 Lifting and Carrying the Boiler

NOTICE

The boiler is secured to the pallet with two

bolts.

z Remove the bolts from pallet before

lifting the boiler.

The boiler can be picked up at the hand grips located

along the lower jacket panels.

BODILY DANGER

due to carrying of heavy loads.

CAUTION!

z Lift and carry the boiler with at least

two people at the designated hand

grip positions.

5.3 Moving the Boiler with the Boiler Cart

BODILY DANGER

if the product is not properly secured to

CAUTION!

z Lift up the boiler from the rear side by using moving

equipment (e.g. Buderus card or other dolly).

z Secure the boiler to the cart.

z Move the boiler to the job location.

the cart.

z Use proper moving equipment such as

the Buderus cart or other dolly.

z Secure the boiler to the cart and move

the boiler to the job location.

Fig. 5 Lifting and carrying the boiler

NOTICE

By tipping the cart you can install the boiler feet (Î Chapter 6.3, page 17).

You can order a Buderus cart from your

local wholesaler.

14

Fig. 6 Moving the boiler with a Buderus cart

Logano G125 BE - Specifications subject to change without notice.

6 Placing the Boiler

This chapter discusses how to place the boiler in the

boiler room.

SYSTEM DAMAGE

due to freezing temperatures

CAUTION!

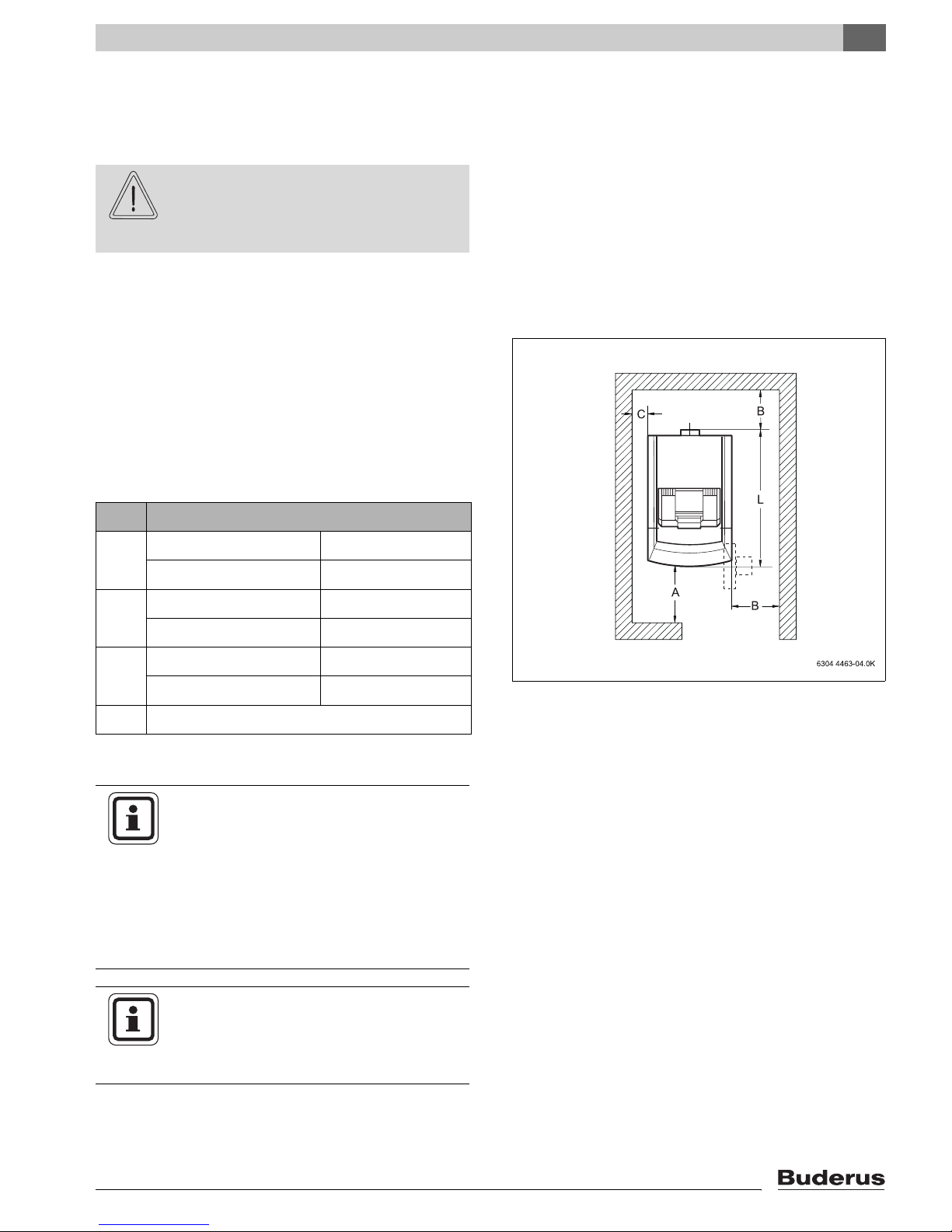

6.1 Clearances

Position the boiler while observing the clearances in

(Î Fig. 7). Access to the boiler is reduced when reducing these clearances.

The boiler foundation must be level and sufficiently

strong.

The burner door is factory installed right swinging. Youcan reverse the door swing in the field.

z Place the boiler in a frost free room.

Placing the Boiler

6

Distance

A Recommended 51 1/8"

minimum 39 3/8"

B Recommended 27 1/2"

minimum 15 3/4"

C Recommended 15 3/4"

minimum 3 7/8"

L see Chapter 3 „Technical Information“

Table 10 Recommended and minimum clearances

(Measurement in Inches)

NOTICE

Smaller clearances must abide with state

and local code. The boiler is approved for

6" side clearances. A minimum distance

of 18" to combustible materials must be

maintained per NFPA 31.

Floor material must comply with

NFPA 31.

Fig. 7 Clearance dimensions for G125 boilers

NOTICE

Observe required distances to other components such as water piping, venting

and other components.

Logano G125 BE - Specifications subject to change without notice.

15

6

Placing the Boiler

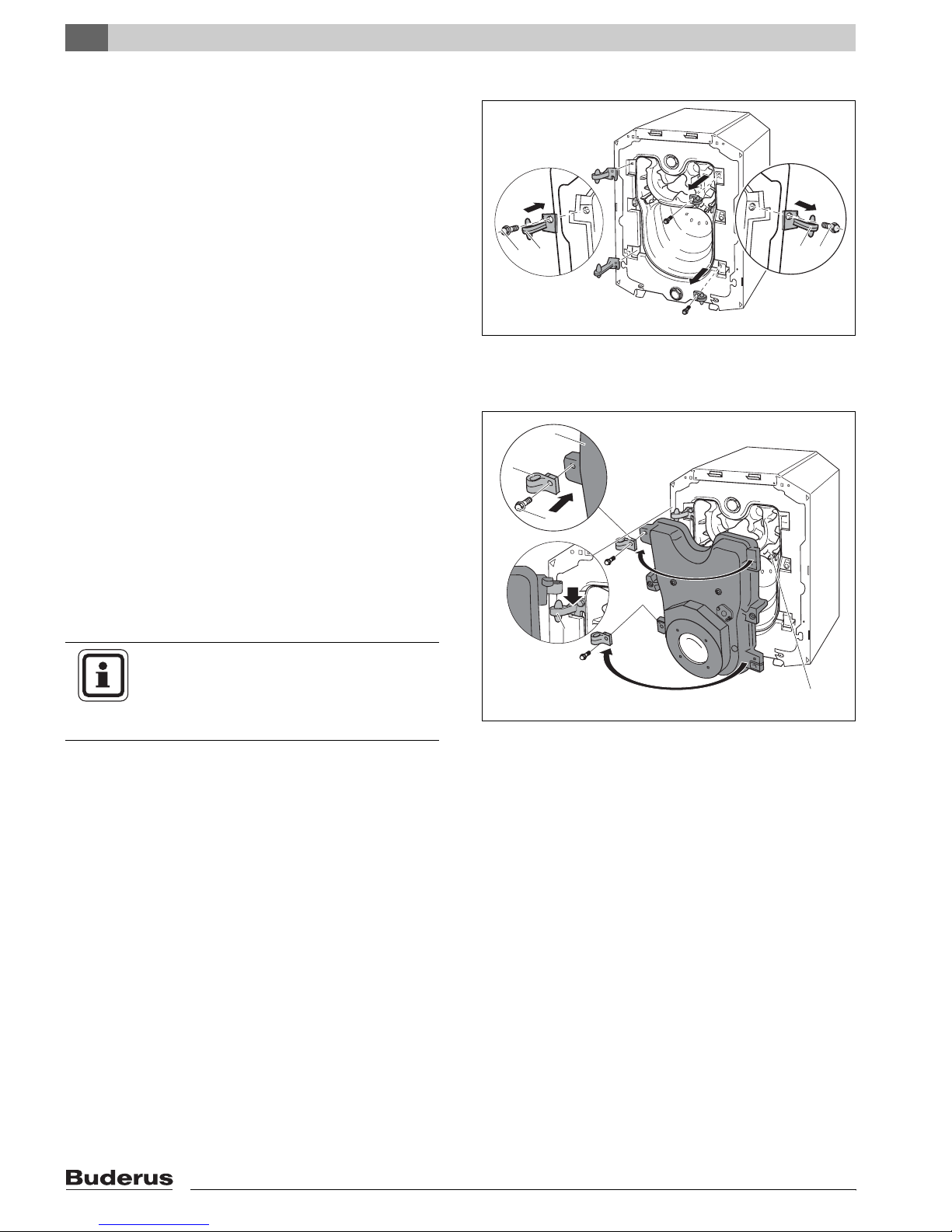

6.2 Reversing the Burner Door Swing

The burner door hinges are factory installed on the right

handside the burner door swings to the right. You can

adjust the hinges so that the burner door swings to the

left in the field.

Note: the front panel must first be removed.

(Î Chapter 5.1, page 13).

z Remove burner door (Î Chapter 5.1, page 13).

z Remove hex head bolts of burner door hinges and re-

move hinges.

z Install the hinges on the left side of the boiler with the

hex head bolts.

z Remove the eyelets from the burner door by remov-

ing the hex head bolts.

z Locate and secure with hex head bolts these eyelets

to the left side of the burner door.

z Hang the burner door on the hinges.

z Check to make sure that the flue baffle plates are

horizontally in the boiler (Î Chapter 8.3, page 40).

z Secure the burner door with the burner door bolts.

Make sure to tighten the burner door bolts evenly

with about 7.5 ft-lbs torque.

NOTICE

When reversing the swing of the burner

door, make sure to remove the burner cable and oil line from the burner first.

2

1

Fig. 8 Reversing burner door (boiler block)

1 Hex head bolts for hinges

2 Door hinges

3

2

1

4

Fig. 9 Reversing burner door (on burner door)

1 Hex head bolts for door eyelets

2 Door eyelet

3 Burner door

4 Door hinges

5 Flue baffles

1

2

5

16

Logano G125 BE - Specifications subject to change without notice.

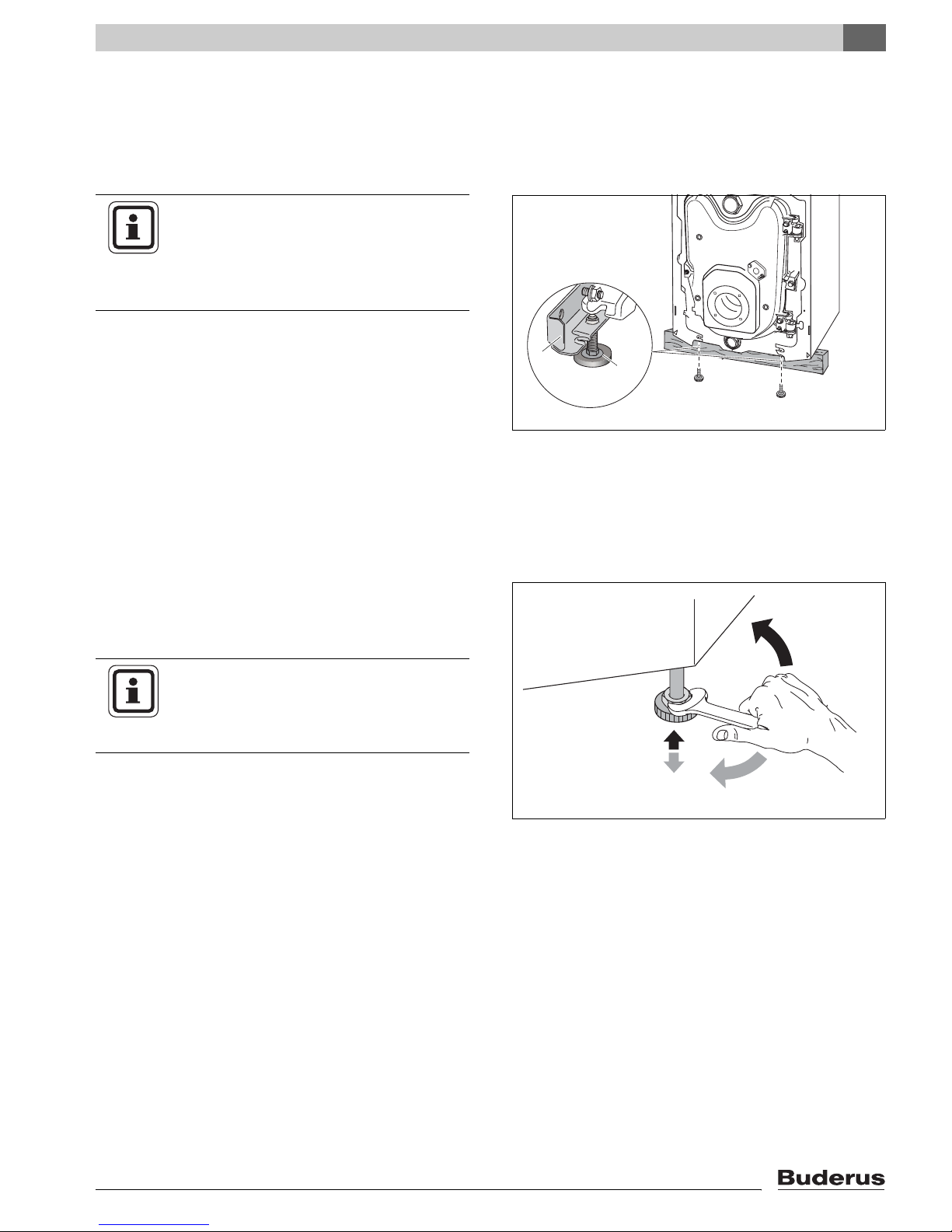

6.3 Installation of boiler Feet (Components of B-Kit)

You can level the boiler using the screw-in boiler feet, so

that air can not collect in the boiler.

Requirement: remove front panel from boiler

(Î Chapter 5.1, page 13).

NOTICE

When installing a G125 BE boiler on top

of a horizontal Buderus DHW indirect

tank, do not use the boiler feet on the boiler, but rather use the feet to level the tank.

z Tip the boiler slightly using the boiler cart

(Î Chapter 5.3, page 14) or put a piece of wood under one side.

z Screw in the boiler feet 1/4" – 3/8".

1

Placing the Boiler

6

2

z Level the boiler.

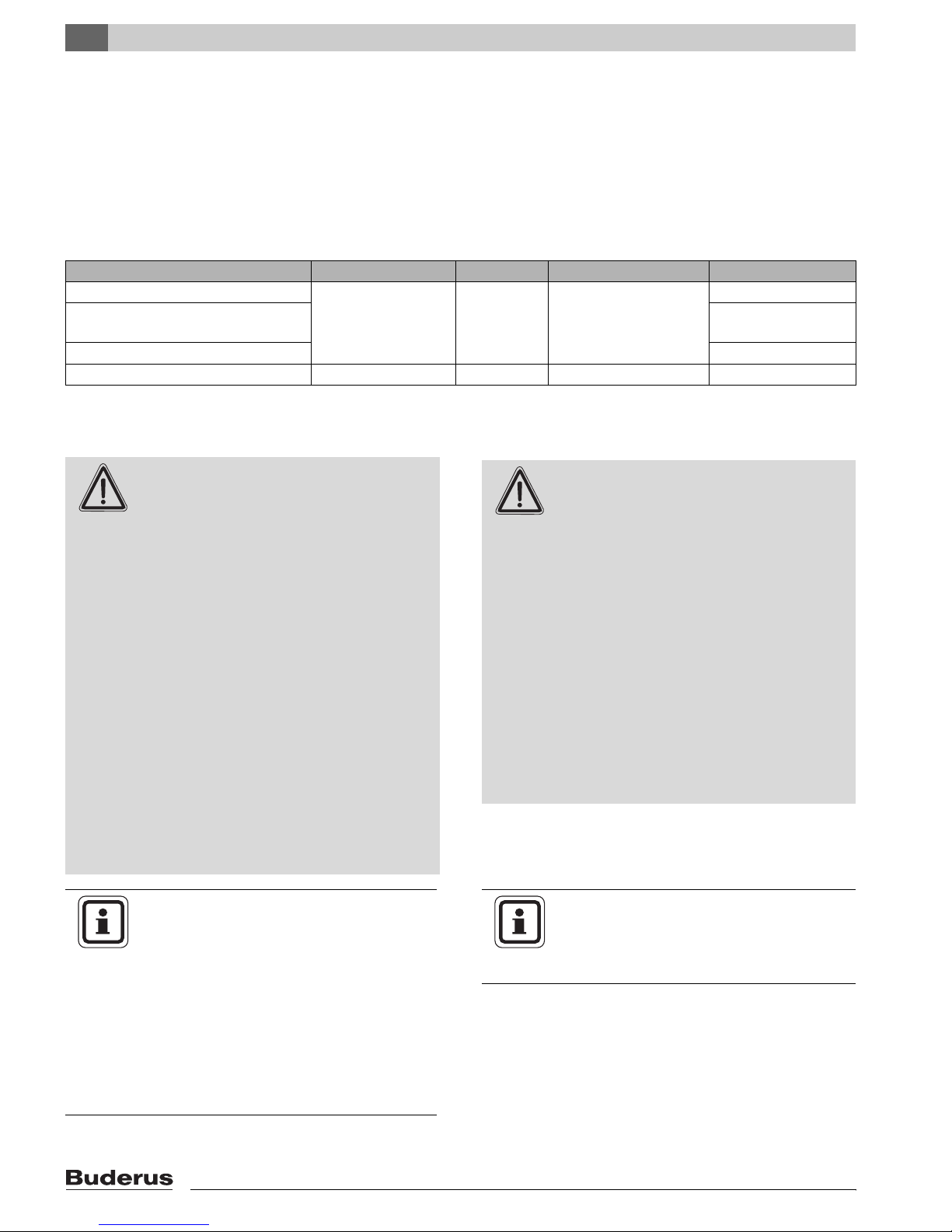

6.4 Placement of the Boiler

z Bring the boiler to its final location.

z Put a level on the boiler and adjust boiler feet to level

the boiler.

NOTICE

z Protect the boiler connections from

dust and debris, if the boiler will not be

connected right away.

Fig. 10 Installation of boiler feet

1 Boiler rail

2 Boiler feet

Fig. 11 Leveling the boiler

Logano G125 BE - Specifications subject to change without notice.

17

7

Boiler Installation

7 Boiler Installation

7.1 Installation of Venting Systems

This chapter describes the installation of the venting

system and the combustion air supply system for the

G125 BE boiler.

Following venting options are available:

Venting system Comment Draft Combustion air Chapter

Masonry chimney (no liner) Barometric

Masonry chimney

w/ 5" liner

Vertical vent 5" 7.1.1.3, Page 21

Side wall Sealed vent Positive Outside air only 7.1.2, Page 22

Table. 11Venting options

damper

required

Negative Outside air or room air 7.1.1.1, Page 19

7.1.1.2, Page 20

WARNING!

DANGER TO LIFE

from toxic flue gases.

z Never connect more than one appli-

ance to a venting system - regardless of

vertical or horizontal venting.

z Common venting of appliances can

cause property damage and put life at

risk.

z Chimney liners must be a single contin-

uous piece inside an existing chimney

and can not have any connections inside the chimney chase.

z The venting system shall not be routed

into, through, or within any other vent,

such as an existing masonry or factorybuilt chimney that is used to vent any

other appliance.

z Always follow vent manufacturer’s in-

structions.

NOTICE

WARNING!

FIRE DANGER

from insufficient clearance between vent

system components and combustible surfaces.

z Maintain 18" clearance to combustible

surfaces when using galvanized or

stainless pipe in vertical or horizontal

venting.

z Maintain 1" clearance to combustible

surfaces when using flexible oil vent for

horizontal venting.

z Both the Aerocowl (AT-4) exhaust ter-

mination and Fields (FT-4) concentric

exhaust/intake terminations are approved with zero clearance to combustible surfaces.

NOTICE

The boiler installation must be performed

by a qualified installer in accordance with

regulations put forth in NFPA-31 Installation of Oil-Burning Equipment. The installation must comply with all local and

national codes, regulations and authorities

having jurisdiction regarding the installation of oil fired boilers.

For Canada refer to the guidelines of

CSA/B139 Installation Codes.

18

z Avoid excessively long venting sys-

tems and keep the number of elbows to

a minimum.

Logano G125 BE - Specifications subject to change without notice.

NOTICE

Due to tight construction of modern

homes, Buderus recommends drawing

combustion air from outdoors. The boiler is

factory prepared for connecting 4" rigid

pipe ducted directly to the increaser at the

rear of the boiler. For further directions

Î Chapter 7.2, page 28.

Except for direct venting, and provided

ample combustion air is available in the

boiler room, combustion air can also be

drawn from the room (Î Chapter 7.2,

page 28 for details).

NOTICE

For Canada the G125 BE is approved

without a Blocked Vent Switch.

Should local authorities require a Blocked

Vent Switch Î Chapter Fig. 63, page 68.

Boiler Installation

7

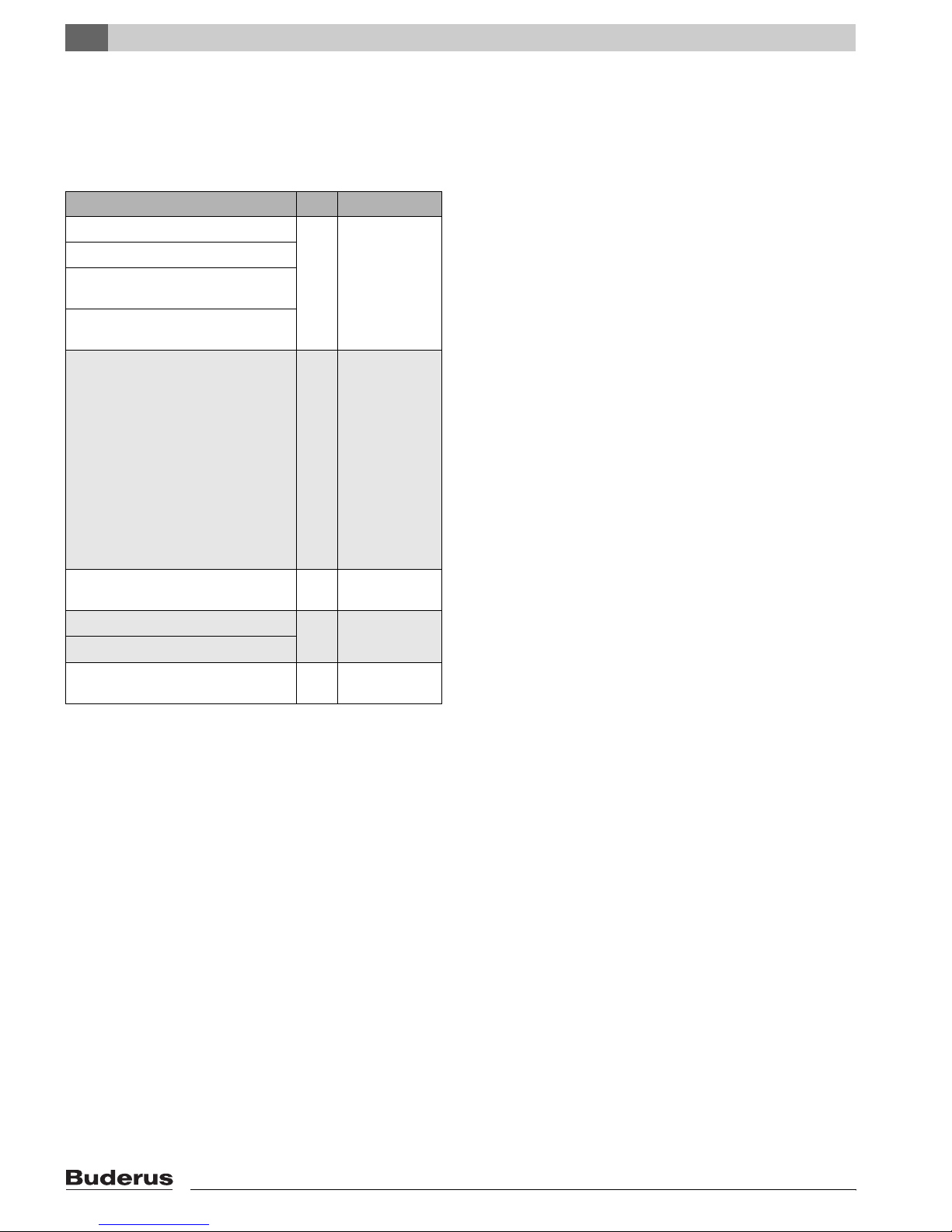

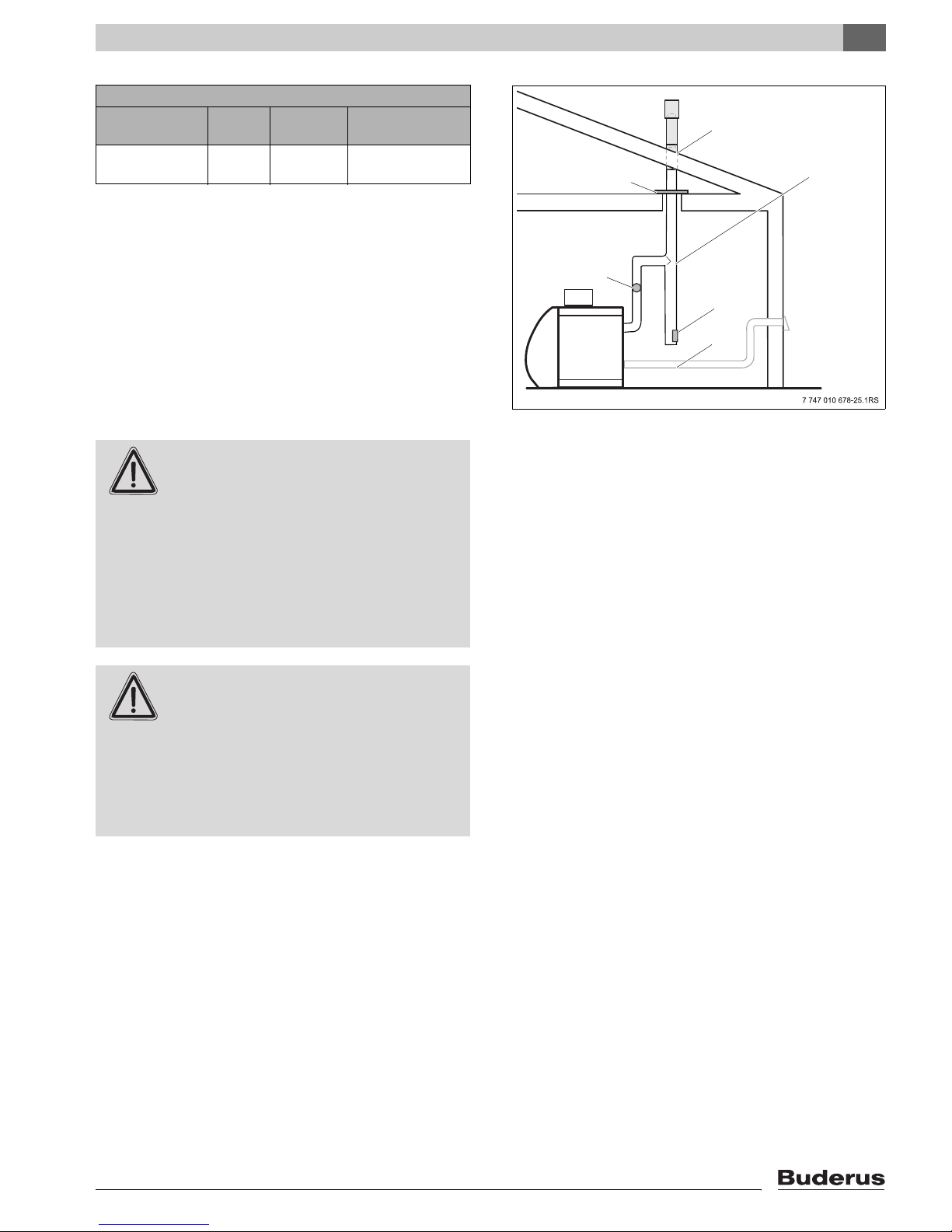

7.1.1 Vertical Venting Systems

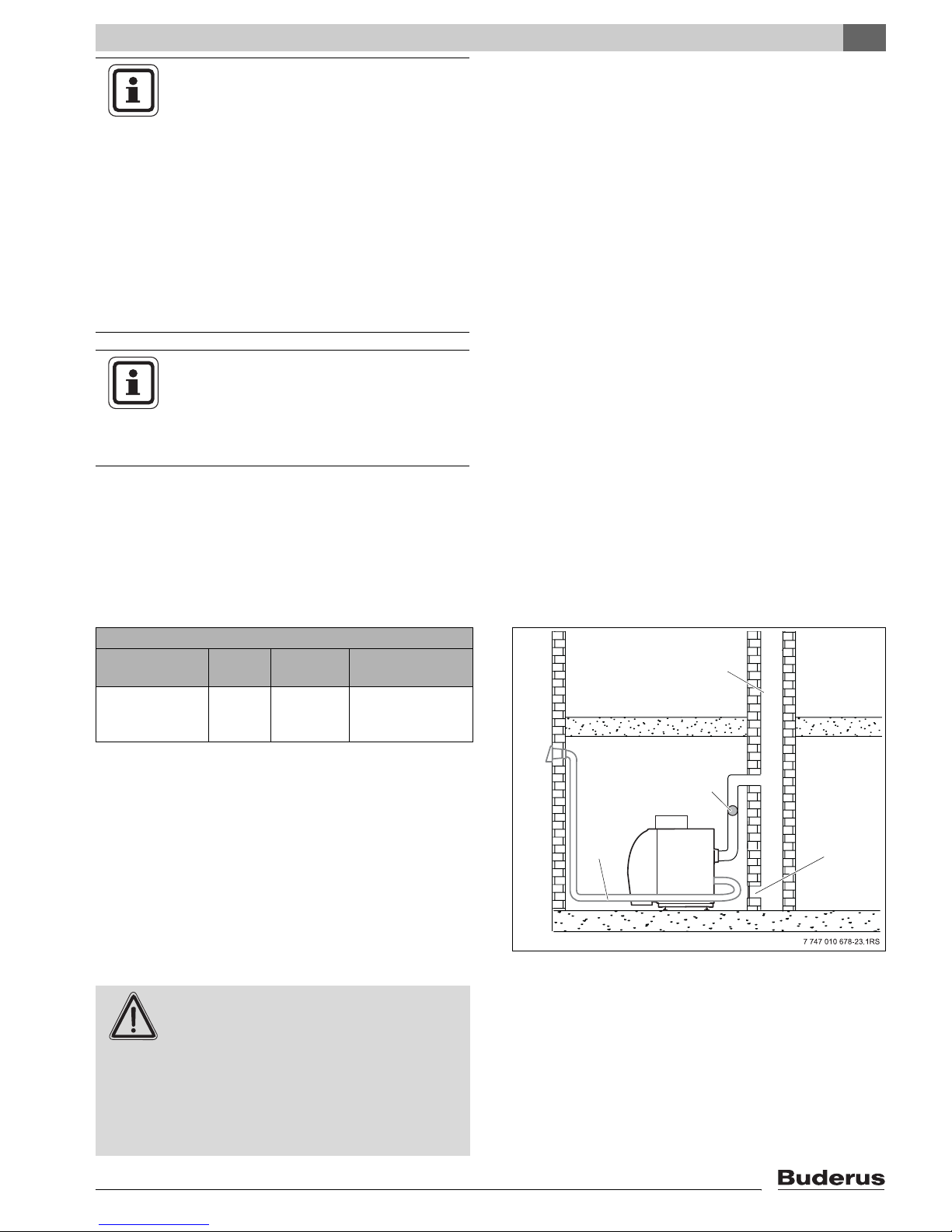

The G125 BE boiler can be vented vertically using an

existing masonry chimney or a factory built All-Fuel or Lvent chimney.

7.1.1.1 Masonry Chimney

Venting system: Masonry Chimney

Comment Draft Combus-

tion air

Barometric

damper

required

Negative Outside air

or room air

Max. vent length

60 ft.

Refer to NFPA 31 for requirements on chimney venting.

Old, cold or over-sized chimneys require the use of an

approved 5" chimney liner (Î Page 20).

The maximum vent length of a masonry chimney is 60 ft.

A masonry chimney is operated under slight negative

pressure, and requires a barometric damper.

z Follow damper manufacturer’s instructions as to

placement.

z Adjust draft for negative 0.02 – 0.04" W.C.

DANGER TO LIFE

from toxic flue gases.

WARNING!

z Verify that all vent pipe connections

have been installed properly.

1

2

4

Fig. 12 Masonry chimney installation

1 Chimney

2 Barometric damper

3 Clean-out

4 Horizontal air connection for combustion air

(optional, see 7.2)

3

z Have the entire venting system cleaned

and inspected annually by a qualified

service company.

Logano G125 BE - Specifications subject to change without notice.

19

7

Boiler Installation

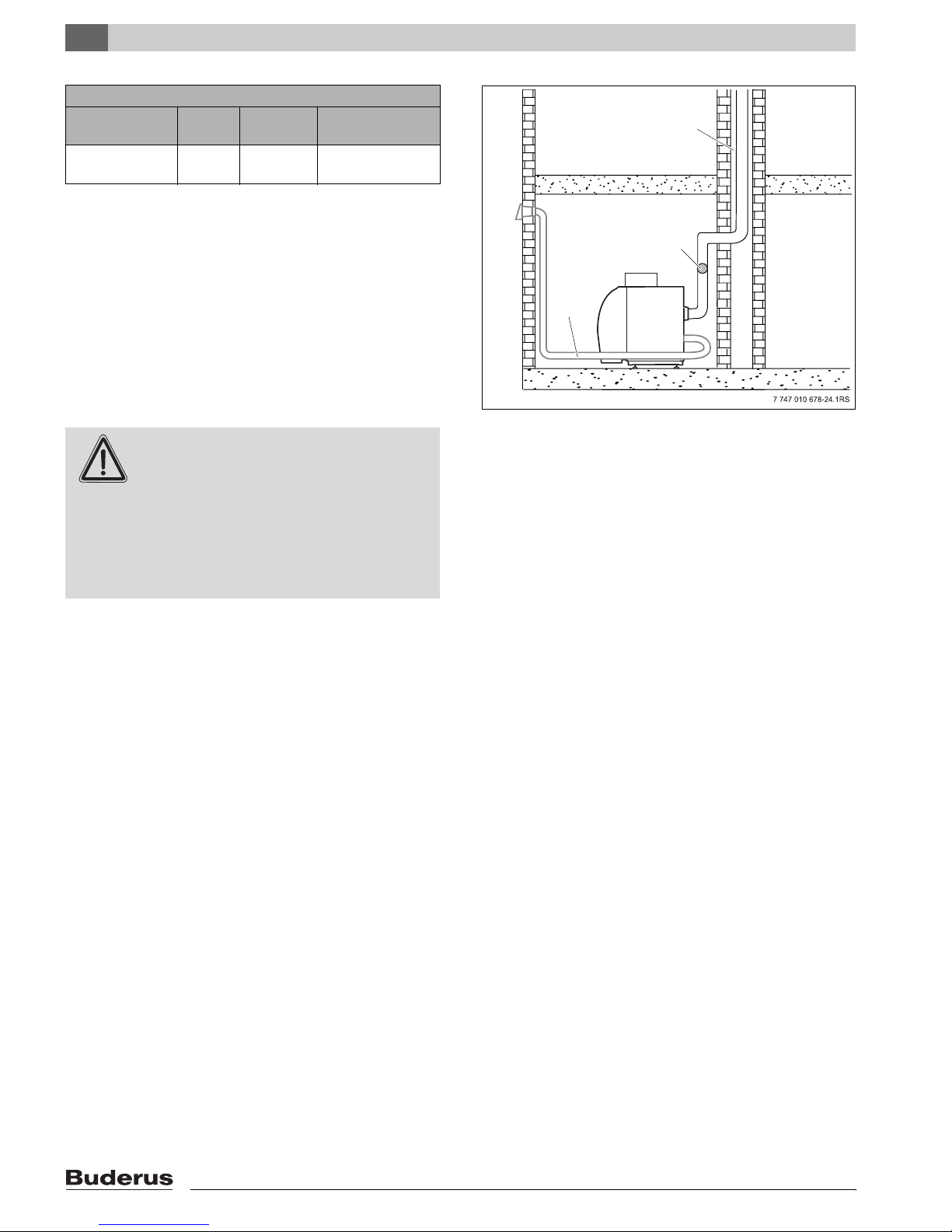

7.1.1.2 Chimney with 5" Liner

Venting system: Chimney with 5" Liner

Comment Draft Combus-

tion air

Barometric

damper required

Negative Outside air

or room air

Max. Vent length

60 ft.

Install liner according to manufacturer’s instructions.

Follow all applicable local and national codes and regulations.

The maximum vent length of 5" liner in a masonry chimney is 60 ft.

The 5" liner in a chimney is operated under slight negative pressure, which requires a barometric damper.

z Follow damper manufacturer’s instructions as to

placement.

1

2

3

z Adjust draft for negative 0.02 – 0.04" W.C.

DANGER TO LIFE

from toxic flue gases.

WARNING!

z Verify that all vent pipe connections

have been installed properly.

z Have the entire venting system cleaned

and inspected annually by a qualified

service company.

Fig. 13 5" Chimney liner installation

1 5" Chimney liner

2 Barometric damper

3 Horizontal air connection for combustion air

(optional, see 7.2)

20

Logano G125 BE - Specifications subject to change without notice.

7.1.1.3 Vertical Vent

Venting system: 5" Vertical Vent

Comment Draft Combus-

tion air

Barometric

damper required

Negative Outside air

or room air

Max. Vent length

60 ft.

Extend the vertical vent pipe sufficiently far above the

roof per NFPA 31. Follow all applicable local and national codes and regulations.

Boiler Installation

7

1

2

3

The maximum length of the vertical 5" venting system is

60 ft.

The 5" vertical venting system operates under a slight

negative pressure, which requires a barometric damper.

z Follow damper manufacturer’s instructions as to

placement.

z Adjust draft for negative 0.02 – 0.04" W.C.

DANGER TO LIFE

from toxic flue gases.

WARNING!

z Vertical vent pipe must have an ap-

proved fire stop at each ceiling penetration and the stack must be properly

supported at its base.

z Each venting section must be support-

ed at each elbow and at least every 48"

of straight pipe.

DANGER TO LIFE

from toxic flue gases.

WARNING!

z Verify that all vent pipe connections

have been installed properly.

4

5

6

Fig. 14 Vertical venting system installation (supports are not

shown for clarity)

1 Roof Penetration

2 Fire stop

3 All-Fuel or L vent flue pipe

4 Barometric Damper

5 Clean-out

6 Horizontal air connection for combustion air

(optional, see 7.2)

z Have the entire venting system cleaned

and inspected annually by a qualified

service company.

Logano G125 BE - Specifications subject to change without notice.

21

7

Boiler Installation

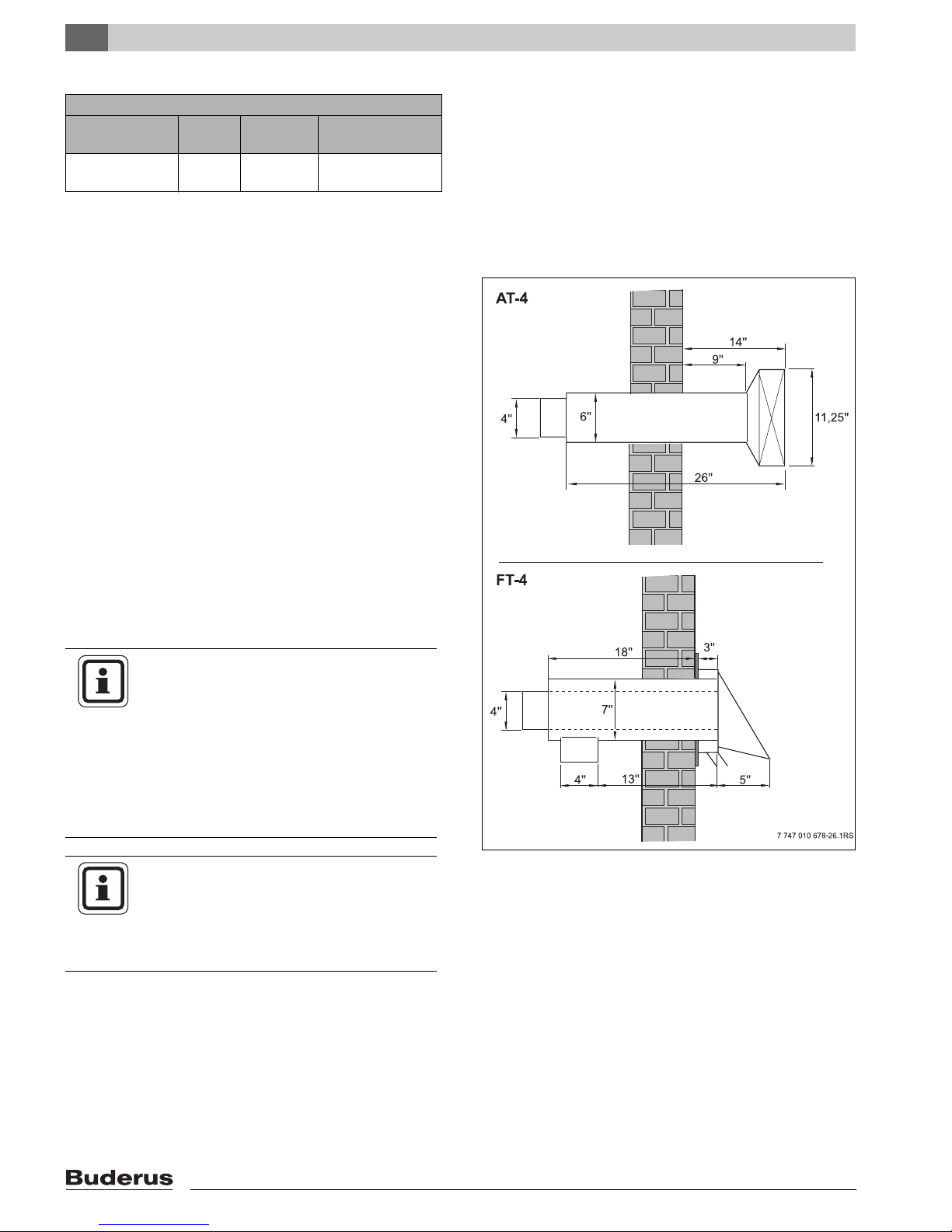

7.1.2 Horizontal Venting

Venting system: Side wall

Comment Draft Combus-

tion air

Sealed vent Positive Outside air

only

Max. Vent length

20 ft.

The maximum length of the direct vent system is 20 ft. of

linear pipe including 3 x 90° elbows. With 4 elbows the

maximum pipe length is 10 ft.

The following two direct vent terminations are approved

with the G125 BE, and are available for purchase from

your Buderus supplier.

Both exhaust terminations are approved for use with two

different exhaust vent pipe options.

– Option 1:

Flexible, insulated 4" stainless steel oil vent. The insulated oil vent is rated for 1" clearance to combustibles. Wrap the adapters with 3" of ceramic wool

covered with foil tape or sheet metal to maintain 1"

clearance. For installation instructions Î Chapter

„7.1.2.6 Installation of Insulated Flexible Oil Vent“,

page 26.

– Option 2:

Standard, 26 gauge galvanized 4" vent pipe. Maintain 18" clearance to combustibles with galvanized

vent pipe (Î Chapter „7.1.2.7 Installation of Galvanized Vent Pipe“, page 27).

NOTICE

Horizontal vent systems operate under

positive pressure, which requires all

seams to be sealed. Use high temperature

silicone (500°F rated, G.E. 106 or equivalent) to seal any joints, screw penetrations,

or combustion test holes, and seal at each

pipe connection and all joints on adjustable elbows. Refer to 7.1.2.2 for details.

NOTICE

Installations in Canada less than 7 ft.

above ground are required to have a

cage/screen over the termination to prevent injury from touching hot surfaces.

Fig. 15 Aerocowl (AT-4) and Concentric (FT-4) termination

22

Logano G125 BE - Specifications subject to change without notice.

Loading...

Loading...