Buderus Logano G124X II/SP Installation And Maintenance Instructions Manual

6304 0308 – 04/2005 US For heating engineers

Installation and maintenance

instructions

Gas boiler

Logano G124X II/SP

CAUTION!

Observe the safety instructions of this

installation and maintenance manual

before placing the boiler in operation.

WARNING!

If installation, adjustment, modification,

operation or maintenance of the

heating system is carried out by an

unqualified person, this may result in

danger to life and limb or property

damage. The directions of this

installation and maintenance manual

must be followed precisely. Contact a

qualified service company, service

provider or the gas company if support

or additional information is required.

CAUTION!

The operating manual is a component

of the technical documentation handed

over to the operator of the heating

system. Discuss the instruction in this

manual with the owner or operator of

the heating system to ensure that they

are familiar with all information required

for operation of the heating system.

Note: Keep this installation and maintenance manual available for future

reference.

Please read carefully prior to installation and maintenance.

Contents

1Safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.1 Correct use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.2 Observe the following symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.3 Please observe these notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.4 Tools, materials and accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.5 Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2 Product description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3 Dimensions and connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

4 Scope of delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

5 Moving the boiler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

5.1 Moving the boiler with boiler cart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

5.2 Lifting and carrying the boiler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

6 Placing the boiler. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

6.1 Clearances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

6.2 Leveling the boiler. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

7 Boiler installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

7.1 Preparing for installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

7.2 Connecting the heating system. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

7.3 Electrical connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

7.4 Installation of Logamatic 2107 control (accessory). . . . . . . . . . . . . . . . . . . . . . 17

7.5 Fuel supply connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

7.6 Filling heating system and checking for leaks . . . . . . . . . . . . . . . . . . . . . . . . . 23

8 Check openings for combustion air supply and venting . . . . . . . . . . . . . 24

9 Requirements for connection to chimneys or venting systems . . . . . . . 25

10 Flue pipe installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

11 Placing the heating system in operation . . . . . . . . . . . . . . . . . . . . . . . . . 28

11.1 Start-up instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

11.2 Making G124X II and G124X SP boilers ready for operation . . . . . . . . . . . . . . . 31

11.3 Conducting final commissioning for G124X II boiler . . . . . . . . . . . . . . . . . . . . . 32

11.4 Conducting final commissioning for G124X SP boiler . . . . . . . . . . . . . . . . . . . . 36

11.5 Shutting off gas supply to boiler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

11.6 Instruct owner/operator and hand over technical documentation . . . . . . . . . . . . . 41

11.7 Start-up protocol. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

12 Taking the boiler out of operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

12.1 Normal boiler shut-down . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

12.2 Emergency shut-down . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

We reserve the right to make any changes due to technical modifications.

2

Installation and maintenance instructions Logano G124X II/SP special gas-fired boiler • Issue 04/2005

Contents

13 Boiler inspection and maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

13.1 Why is regular maintenance important? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

13.2 Testing the flue system, including combustion air, air inlets and ventilation openings . 44

13.3 Inspection of the boiler and burner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

13.4 Preparing boiler for cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

13.5 Cleaning the boiler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

13.6 Cleaning the burner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

13.7 Troubleshooting on the G124X II . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

13.8 Troubleshooting on the G124X SP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

13.9 Maintenance protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

14 Parts lists . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

15 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

16 Wiring diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

We reserve the right to make any changes due to technical modifications.

Installation and maintenance instructions Logano G124X II/SP special gas-fired boiler • Issue 04/2005

3

Safety1

1 Safety

Observe these instructions for your safety.

The burner and control must be correctly installed and

adjusted to ensure safe and economical operation of the

special gas-fired boiler.

Read this installation and maintenance manual carefully

and note the details on the boiler nameplate before

placing the boiler in operation.

1.1 Correct use

The Logano G124X II/SP special gas-fired boiler is

designed to heat water for a hot water heating system

for heating single or multiple occupancy buildings.

1.2 Observe the following symbols

Two levels of danger are identified and signified by the

following terms:

WARNING!

CAUTION!

Additional symbols for identification of dangers and user

instructions:.

RISK TO LIFE

Identifies possible dangers emanating

from a product, which might lead to serious

injury or death if appropriate care is not

taken.

RISK OF INJURY/

SYSTEM DAMAGE

Identifies potentially dangerous situations,

which might lead to medium or slight

injuries or to material losses.

RISK TO LIFE

from electric shock.

1.3 Please observe these notes

1.3.1 National regulations

The heating system must comply with the relevant

regulations issued by national authorities, or the

regulations issued by the National Fuel Gas Code, ANSI

Z 223.1. In Canada the regulations of CAN/CGA B 149.1

or 2, Installation Code for Gas Burning Appliances and

Equipment, must be observed.

If specified by the local regulatory authorities the heating

system must comply with the regulations of the

"Standard for Controls and Safety Devices for

Automatically Fired Boilers", ANSI/ASME CSD-1.

Carbon monoxide detoectors must be installed as

specified by the local regulations. The boiler must be

serviced annually

Boiler operating conditions

Maximum boiler temperature 220 °F

Maximum operating pressure 58 psi

The hot water pipe system must comply with the current

legislation and regulations. If an existing boiler is

replaced, the complete hot water pipe system must be

inspected to ensure that it is in perfect condition to

ensure safe operation.

WARNING!

(Î Chapter 13, page 44).

RISK TO LIFE

due to neglecting your own safety in case

of emergency, such as with a fire.

z Never put yourself at risk. Your own

safety must always take priority.

WARNING!

4

USER NOTE

Tip for the optimum utilization and setting

of the control(s) plus other useful

information.

We reserve the right to make any changes due to technical modifications.

Installation and maintenance instructions Logano G124X II/SP special gas-fired boiler • Issue 04/2005

Safety 1

WARNING!

CAUTION!

WARNING!

RISK TO LIFE

from explosion of flammable gases.

If you smell gas there is a danger of

explosion.

z Never work on gas lines unless you are

licensed for this type of work.

z Make sure that a qualified company

installs the boiler, connects gas and

venting, places the boiler in operation,

connects the electrical power, and

maintains and repairs the boiler.

z No open flame. No smoking. Do not

use lighters.

z Prevent spark formation.

Do not operate electrical switches,

including telephones, plugs or door

bells.

z Close main gas valve.

z Open doors and windows.

z Warn other occupants of the building,

but do not use door bells.

z Call gas company from outside the

building.

z If gas can be heard escaping, leave the

building immediately, prevent other

people from entering, notify police and

fire from outside the building.

SYSTEM DAMAGE

due to incorrect installation.

z Observe all current standards and

guidelines applicable to the installation

and operation of the heating system as

applicable in your country.

RISK TO LIFE

from electric shock.

z Disconnect the power supply to the

heating system before conducting any

work on it, e.g. switch off the heating

emergency switch outside the boiler

room.

z It is not sufficient just to switch off the

control.

SYSTEM DAMAGE

due to unsatisfactory cleaning and

CAUTION!

maintenance.

z Clean and service the system once a

year. Check that the complete heating

system operates correctly.

z Immediately correct all faults to prevent

system damage.

USER NOTE

Only use original Buderus spare parts.

Losses caused by the use of parts not

supplied by Buderus are excluded from the

Buderus warranty.

1.3.2 Installation notes

RISK TO LIFE

from explosion of flammable gases.

WARNING!

z Never work on gas lines unless you are

licensed for this type of work.

RISK TO LIFE

from electric shock.

WARNING!

z Do not carry out electrical work unless

you are qualified for this type of work.

z Before opening a unit: disconnect

electrical power completely and lock to

prevent accidental reconnection.

z Observe the installation regulations.

1.3.3 Information on the boiler room

RISK TO LIFE

by poisoning.

WARNING!

Insufficient ventilation may cause

dangerous flue gas leaks.

z Make sure that inlets and outlets are not

reduced in size or closed.

z If faults are not corrected immediately,

the boiler must not be operated.

z Inform the system operator of the fault

and the danger in writing.

We reserve the right to make any changes due to technical modifications.

Installation and maintenance instructions Logano G124X II/SP special gas-fired boiler • Issue 04/2005

5

Safety1

WARNING!

WARNING!

RISK TO LIFE

by poisoning.

When working on the flue gas monitoring

equipment leaking flue gas may endanger

the lives of people.

z Do not attempt to repair the flue gas

temperature sensor.

z Use only original parts when replacing

parts.

z When replacing the flue gas

temperature sensor install the new one

in the specified position.

RISK TO LIFE

by poisoning by leaking flue gas.

If the flue gas monitor trips frequently,

there may be a problem with the chimney

or the flue gas venting.

z If the flue gas monitor trips frequently

the fault must be corrected and a

function test must be conducted.

RISK TO LIFE

by poisoning by leaking flue gas.

WARNING!

z Make sure that the boiler is not fitted

with a thermally controlled flue gas

baffle after the back flow check.

FIRE DANGER

due to flammable materials or liquids.

WARNING!

z Make sure that there are no flammable

materials or liquids in the immediate

vicinity of the boiler.

1.4 Tools, materials and accessories

You need standard tools for the installation and

maintenance of the boiler as used in heating system

installation and oil, gas and water installations.

The following additional items will also be useful.

– Boiler cart with rope or Buderus boiler cart

– Cleaning brushes and/or chemical cleaning agents

for wet cleaning

1.5 Disposal

z Dispose of the packaging material in an

environmentally compatible fashion.

z Dispose of any components of the heating system

that require replacement in an environmentally

compatible fashion.

6

Installation and maintenance instructions Logano G124X II/SP special gas-fired boiler • Issue 04/2005

We reserve the right to make any changes due to technical modifications.

Product description 2

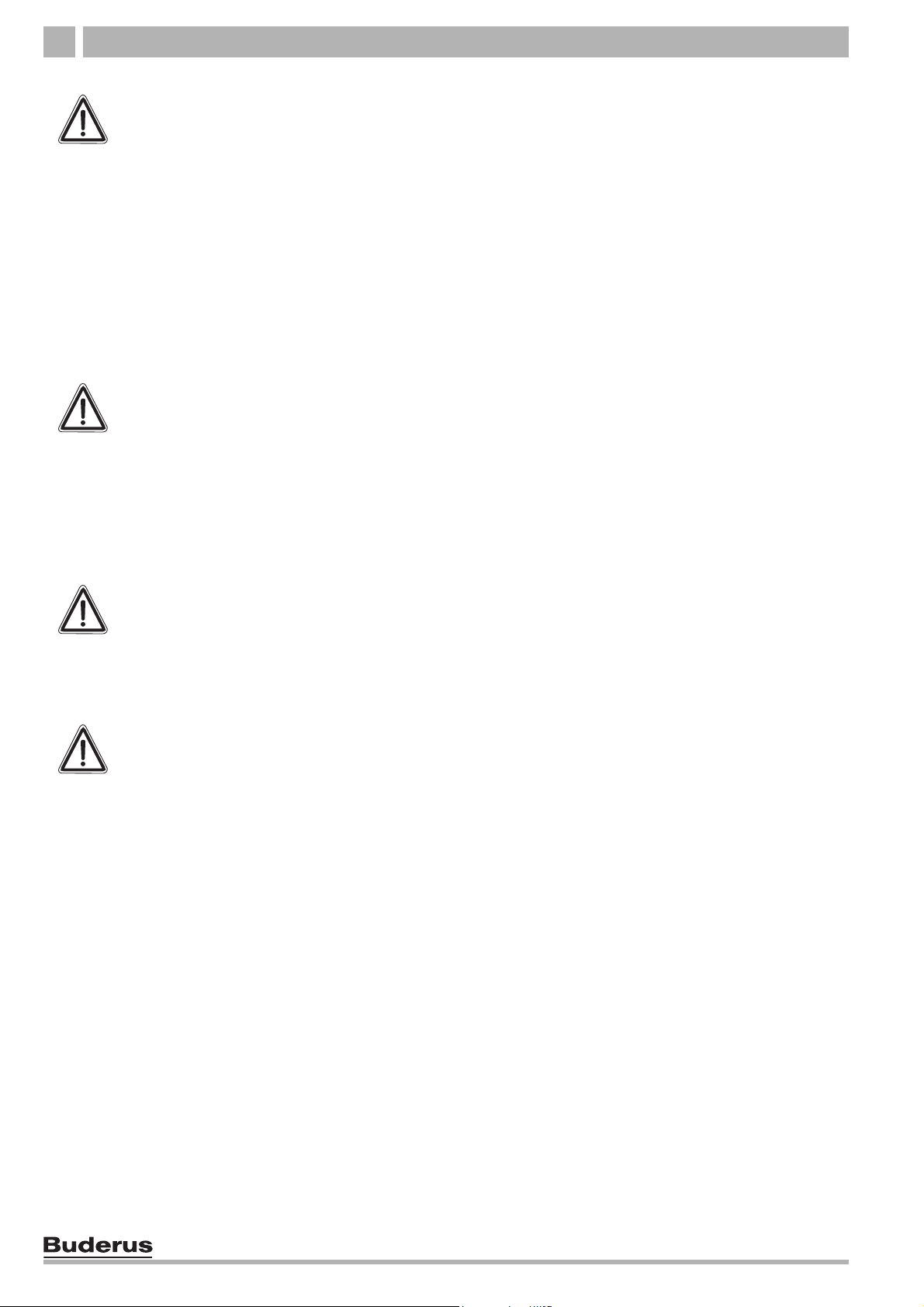

2 Product description

The boiler is a low temperature gas-fired boiler.

USER NOTE

The boiler is fully functional with the

factory-installed aquastats. The

Logamatic 2107 control can also be

installed in addition to the factory-installed

aquastats.

The boiler consists of:

– Automatic igniter (G124X II only) and aquastat

– Logamatic 2107 control (optional)

– Boiler jacket and front panel

– Boiler block with insulation

– Burner

The automatic igniter, the aquastat and, if applicable,

the Logamatic 2107 monitor and control all electrical

components of the boiler.

The boiler jacket prevents energy loss and acts as

soundproofing.

The boiler block transfers the heat generated by the

burner to the heater water. The insulation prevents

energy loss.

1

Fig. 1 Logano G124X II boiler

1 Boiler front panel

2 Logamatic 2107 control (accessory)

3 Ignition Module

4 Aquastat (control unit)

5 Boiler jacket

6 Boiler block with insulation

7 Burner

2

3

4

5

6

7

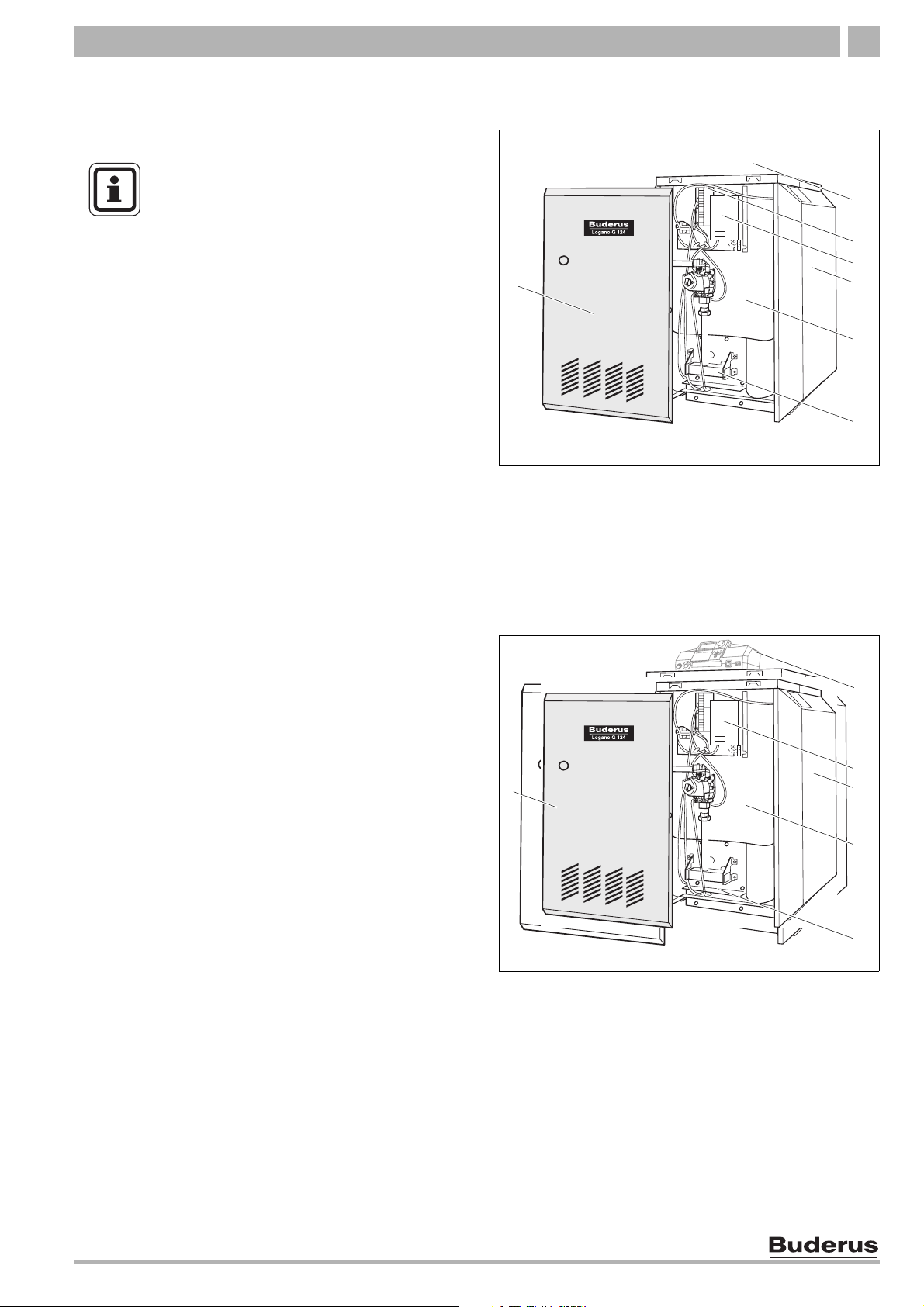

1

Fig. 2 Logano G124X SP boiler

1 Boiler front panel

2 Logamatic 2107 control (accessory)

3 Aquastat

4 Boiler jacket

5 Boiler block with insulation

6 Burner

2

3

4

5

6

We reserve the right to make any changes due to technical modifications.

Installation and maintenance instructions Logano G124X II/SP special gas-fired boiler • Issue 04/2005

7

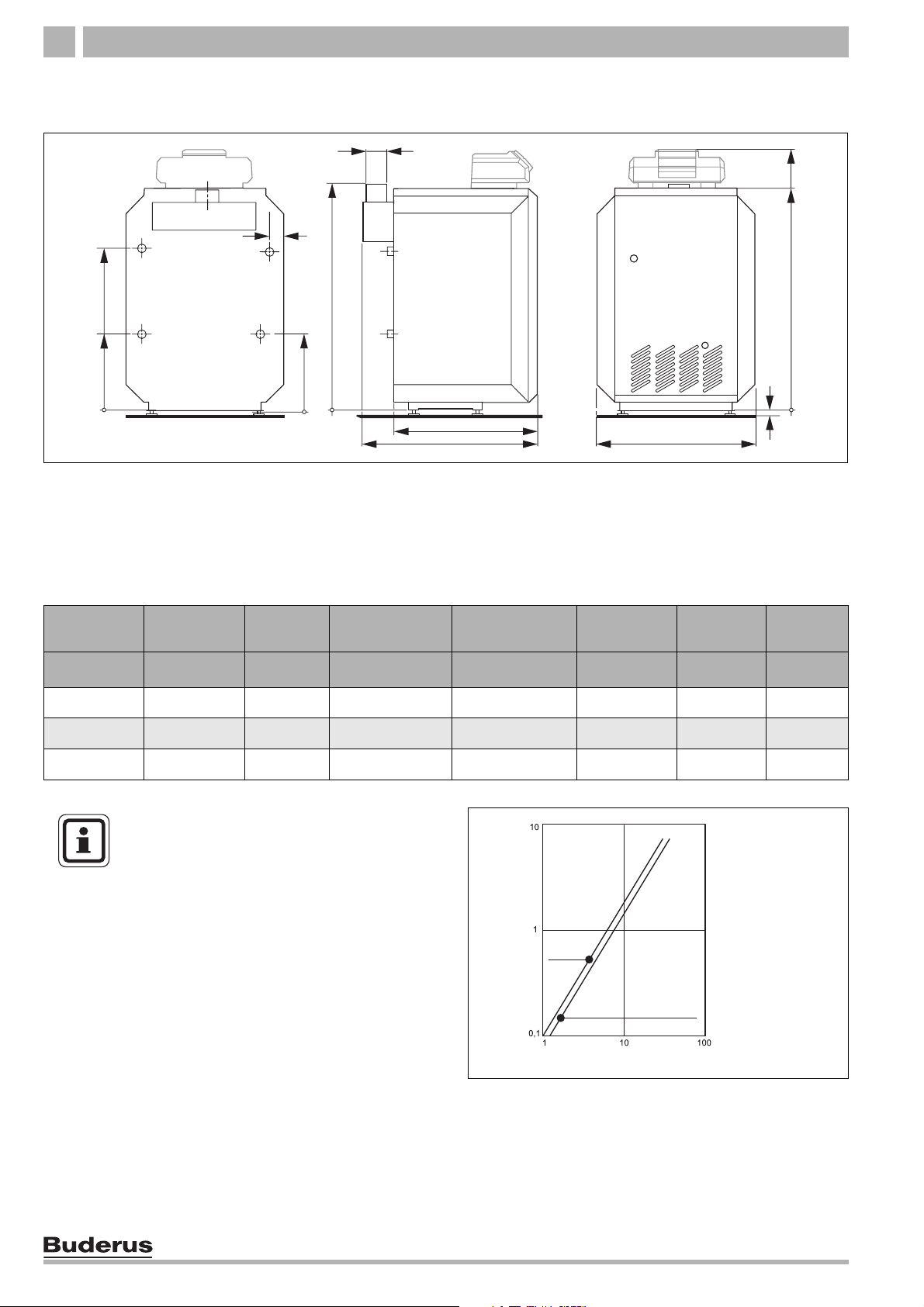

Dimensions and connections3

3 Dimensions and connections

Vent

37"

1 2/5"

23 7/8"

VK 1"

10 7/8"

RK 1"

GAS

EL ¾"

½"

10 7/8"

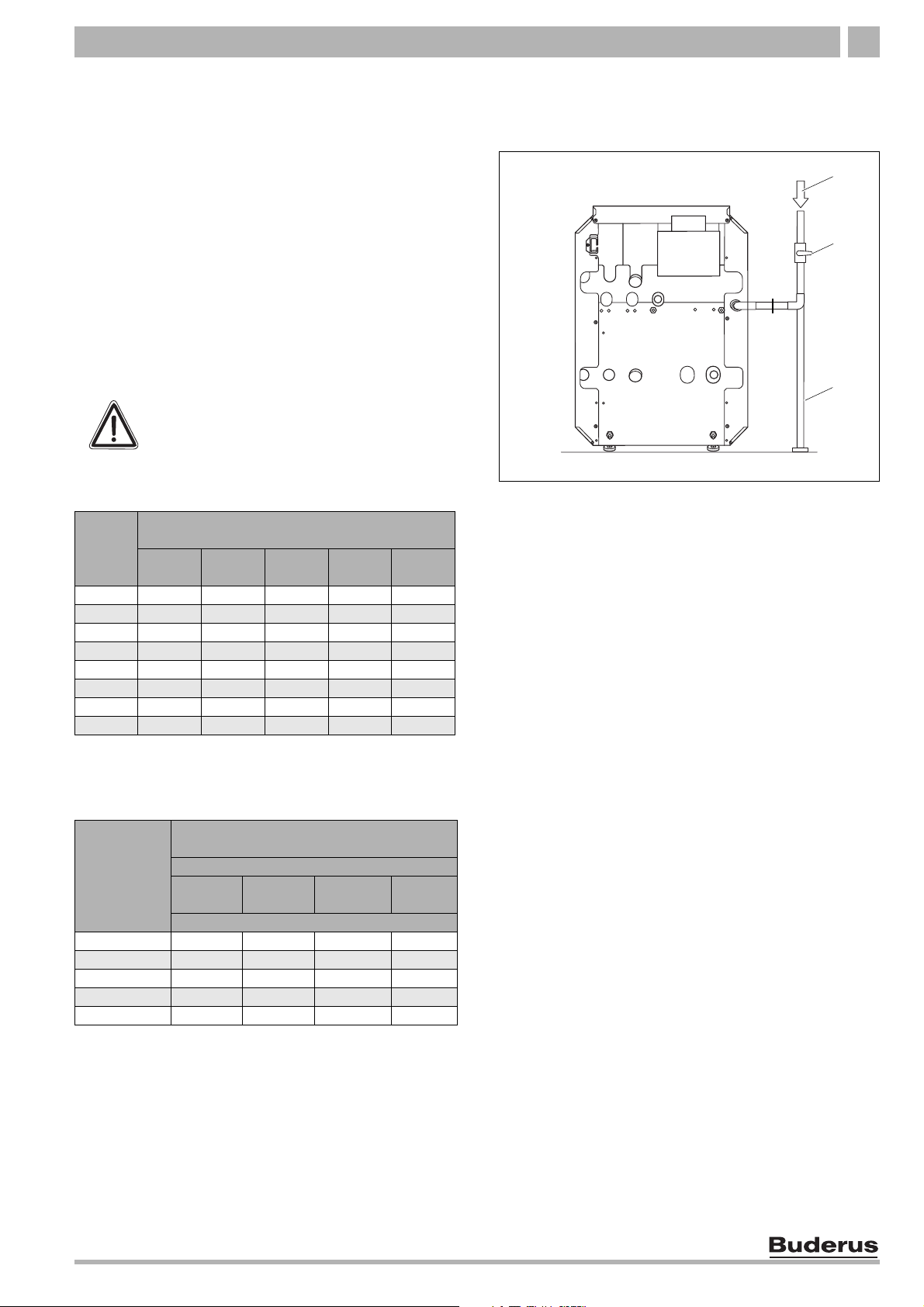

Fig. 3 Back, side and front view, measurements in inches

Connections (measurements see the following tables):

VK = Boiler supply

RK = Boiler return

EL = Drain

GAS = Gas connection

38 1/2"

33 1/3"

22"

A

23 2/3"

2/3" - 1 2/5"

Boiler size Boiler output A Flue connection

II/SP

Min. overflow

valve capacity

Number of

Nozzles

Water

volume

MBtu/hr Inches Inches lb/hr Qty US gal. lbs

18 74 29 2/5" 5" 62 2 2.4 229

25 103 30 1/5" 5" 86 3 2.9 240

32 132,5 30 7/8" 6" 110 4 3.4 337

Tab. 1 Dimensions

USER NOTE

For the size and dimensions of the main

gas orifices see

Î Chapter 15, page 73.

pressure drop

flow rate in GPM

Empty

weight

Fig. 4 Pressure drop

We reserve the right to make any changes due to technical modifications.

8

Installation and maintenance instructions Logano G124X II/SP special gas-fired boiler • Issue 04/2005

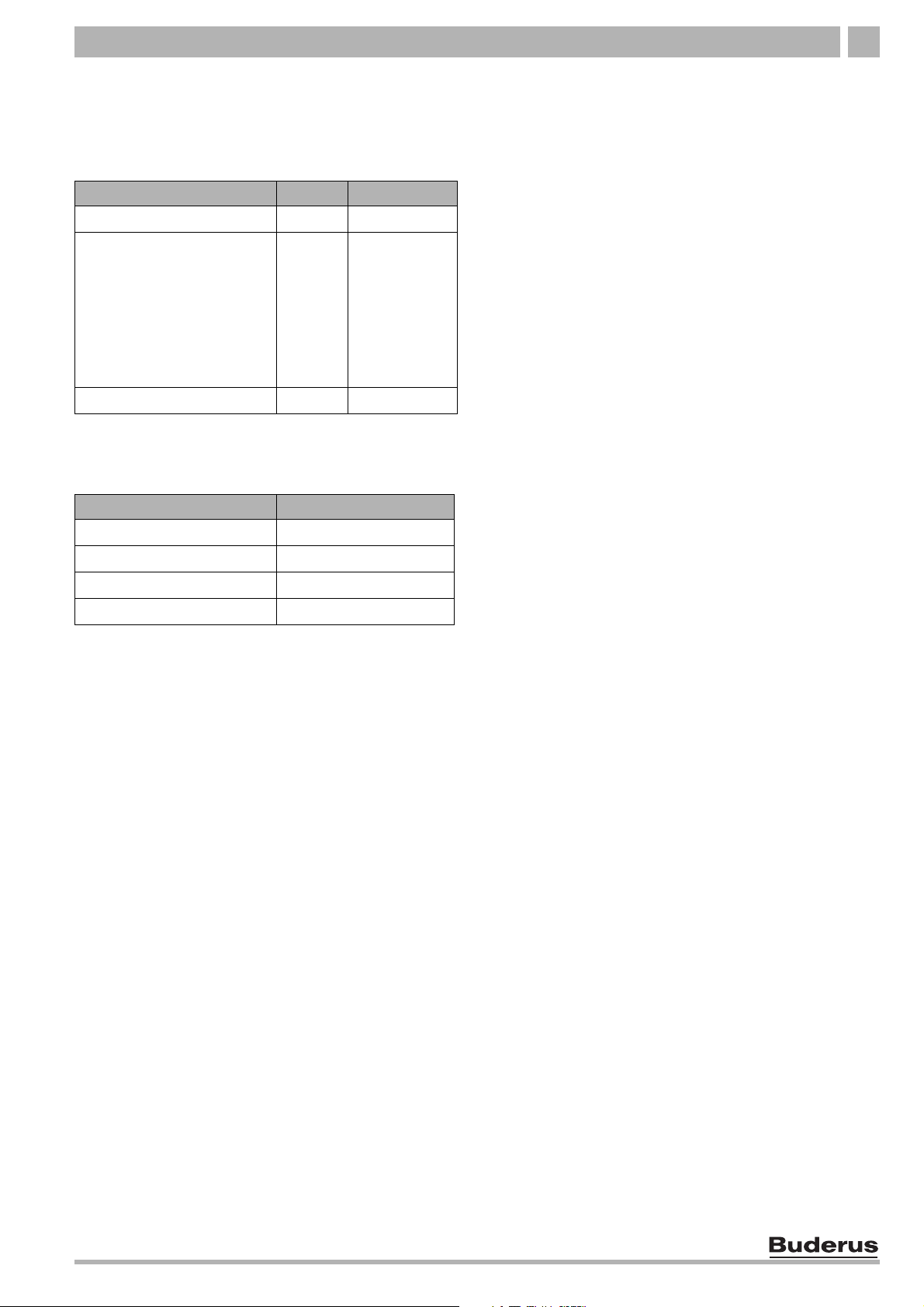

Scope of delivery 4

4 Scope of delivery

z Check packaging on delivery for damage.

z Check delivery for completeness.

Component Qty Packaging

Boiler, complete 1 1 pallet

B-kit components:

- supply manifold

- 30 psi relief valve

- boiler drain (¾")

- pressure/temperature gauge

- 90° elbow (1" NPT)

- 90° elbow (¾" NPT)

- screw-in feet (4)

Technical documents 1 foil package

Tab. 2 Scope of delivery

1

On pallet

1 1 foil package

1

Accessories

Logamatic 2107 control 1

Heat circulation pump 1

Cleaning brush 1

Vertical flue system 1

Tab. 3 Scope of delivery

1

Accessories available by separate order

1

Unit

We reserve the right to make any changes due to technical modifications.

Installation and maintenance instructions Logano G124X II/SP special gas-fired boiler • Issue 04/2005

9

Moving the boiler5

5 Moving the boiler

This chapter describes how to move the boiler safely,

SYSTEM DAMAGE

due to bumps.

CAUTION!

z Check the transport diagrams on the

packaging to protect the sensitive

components from damage by bumping.

USER NOTE

z Protect the boiler connections from dirt

if the boiler is not installed immediately.

USER NOTE

Dispose of the packaging material in an

environmentally compatible fashion.

5.1 Moving the boiler with boiler cart

Move the boiler with packaging and on pallet as much as

possible.

RISK OF INJURY

if the boiler is not properly secured to the

CAUTION!

z Position transport equipment (e.g. boiler cart) at the

back of the boiler.

z Secure boiler to cart.

z Move the boiler to the installation location.

z Remove the straps and the cardboard packaging.

z Remove the bolts from the pallet.

z Lift the boiler at the sides and slide to the edge of the

pallet. Place a pipe under the boiler and roll it on

additional pipes to the installation location.

z Place the boiler in its final position.

trolley.

z Use suitable transport equipment, such

as a boiler cart with a belt.

z Secure the boiler to prevent it from

falling.

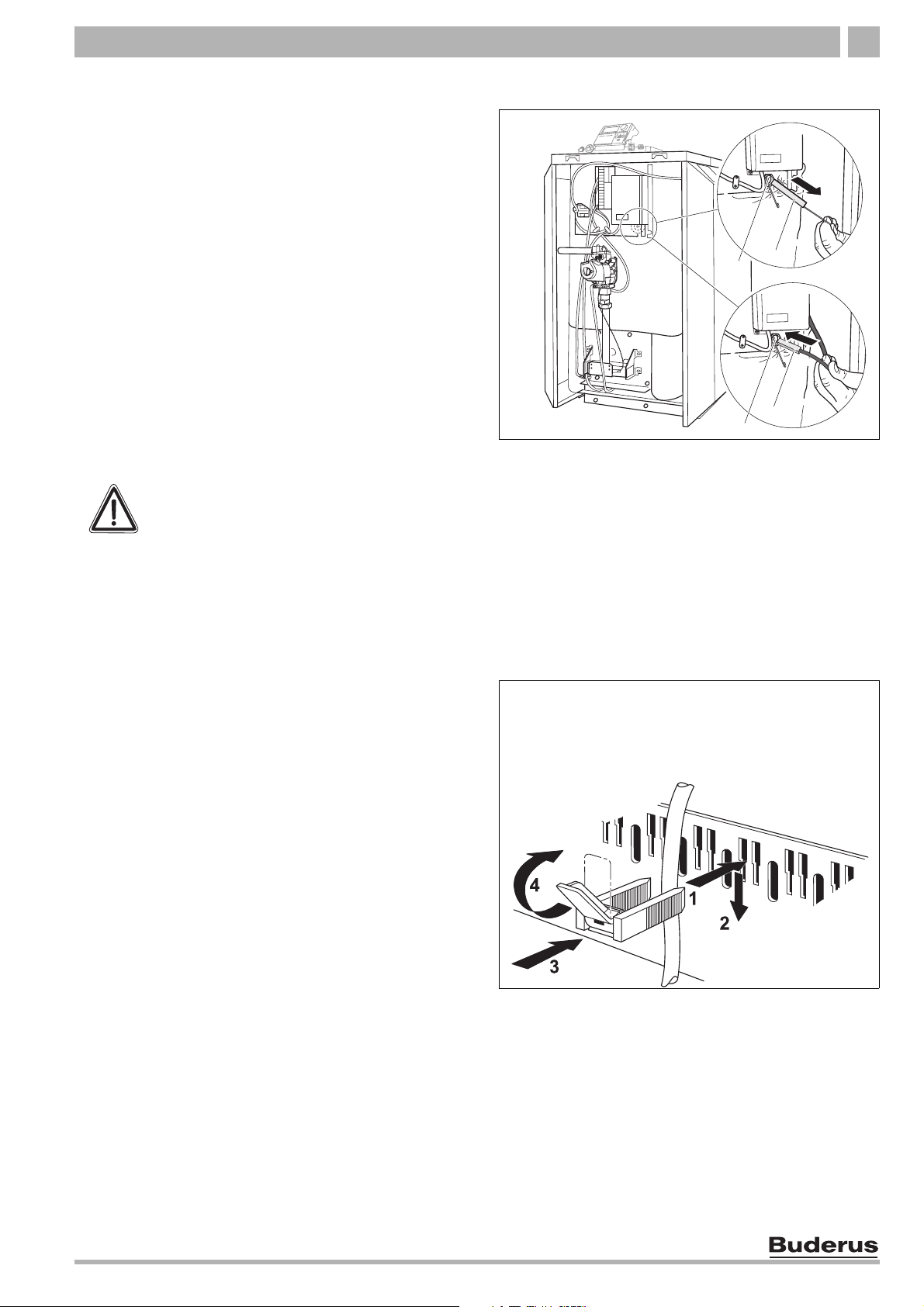

Fig. 5 Moving boiler with boiler cart

10

Fig. 6 Moving the boiler

We reserve the right to make any changes due to technical modifications.

Installation and maintenance instructions Logano G124X II/SP special gas-fired boiler • Issue 04/2005

Moving the boiler 5

5.2 Lifting and carrying the boiler

The boiler can be picked up at the hand grips shown.

RISK OF INJURY

due to carrying heavy loads.

CAUTION!

z Lift and carry the boiler with at least four

people at the designated hand grip

positions.

Fig. 7 Lifting and carrying the boiler

We reserve the right to make any changes due to technical modifications.

Installation and maintenance instructions Logano G124X II/SP special gas-fired boiler • Issue 04/2005

11

Placing the boiler6

6 Placing the boiler

This chapter explains how to place the boiler and

position it in the boiler room.

SYSTEM DAMAGE

through frost.

CAUTION!

The boiler is very heavy when full. Check that the floor

can bear the weight before installation.

6.1 Clearances

A space of at least 33 inches is required in front of the

boiler with the door open to allow sufficient access

space for operation and maintenance. When the door is

closed, a minimum clearance of 2 inches is required at

the front and sides, 2 inches clearance is also required

for the flue pipe and 30 inches clearance to the ceiling.

The installation location and the base must be smooth

and horizontal. The boiler may be installed on a

flammable base, but not on carpet.

z Place the boiler in a frost-free room.

min. 6"

2"

3

min.

1

6.2 Leveling the boiler

z Screw the four rubber feet 0.25 to 1.0 inches into the

bottom rails.

z Place boiler on the feet.

z Level boiler horizontally and vertically by screwing

the feet in and out.

min. 2"

33"

Fig. 8 Required clearances in the boiler room

1 Door closed

2 Door open

3 Flue pipe

min. 2"

2

12

Fig. 9 Unscrewing screw-in feet

We reserve the right to make any changes due to technical modifications.

Installation and maintenance instructions Logano G124X II/SP special gas-fired boiler • Issue 04/2005

Boiler installation 7

7 Boiler installation

This chapter describes how to install the boiler. This

includes the following tasks:

– Connecting the heating system

– Electrical connection

– Fuel supply connection

7.1 Preparing for installation

z Unpack all boxes and containers and check all parts

against the packing lists to make sure that everything

has been supplied.

USER NOTE

Every boiler is carefully inspected and

tested before it leaves the factory.

However, if you discover any damage or

missing parts, please inform the supplier

immediately. Before disposing of packing

material, make sure that no parts are still

in it.

We reserve the right to make any changes due to technical modifications.

Installation and maintenance instructions Logano G124X II/SP special gas-fired boiler • Issue 04/2005

13

Boiler installation7

7.2 Connecting the heating system

BOILER DAMAGE

through moisture.

CAUTION!

z Protect the components of the gas

ignition system from moisture (dripping,

spray, rain) during installation of the

boiler, during operation and during

maintenance work (such as replacing

the pump, replacing the control, etc.).

3

CAUTION!

CAUTION!

SYSTEM DAMAGE

due to overheating as a result of low water.

z Note that a boiler installed above the

level of the heating system must be

fitted with a low-water cutoff. The lowwater cutoff must be installed during

installation of the boiler

(Î Fig. 10).

SYSTEM DAMAGE

due to high temperature variations in the

heating system.

z If the boiler is operated in connection

with a refrigeration system, make sure

that the pipes for the refrigerated liquid

are connected in parallel to the boiler

system with suitable valves to prevent

the refrigerated liquid from entering the

boiler.

z The pipe system of a boiler connected

to the heating coils of hot-air heating

systems that may be exposed to the

circulation of cooled air must be fitted

with a flow-control valve or some other

automatic system for preventing the

boiler water from circulating by gravity

during the cooling cycle.

1

2

2

1

Fig. 10 Low-water alarm

1 Boiler

2 Radiator

3 Heating system with low-water cutoff

4 Heating system without low-water cutoff

2

2

4

2

2

14

We reserve the right to make any changes due to technical modifications.

Installation and maintenance instructions Logano G124X II/SP special gas-fired boiler • Issue 04/2005

Boiler installation 7

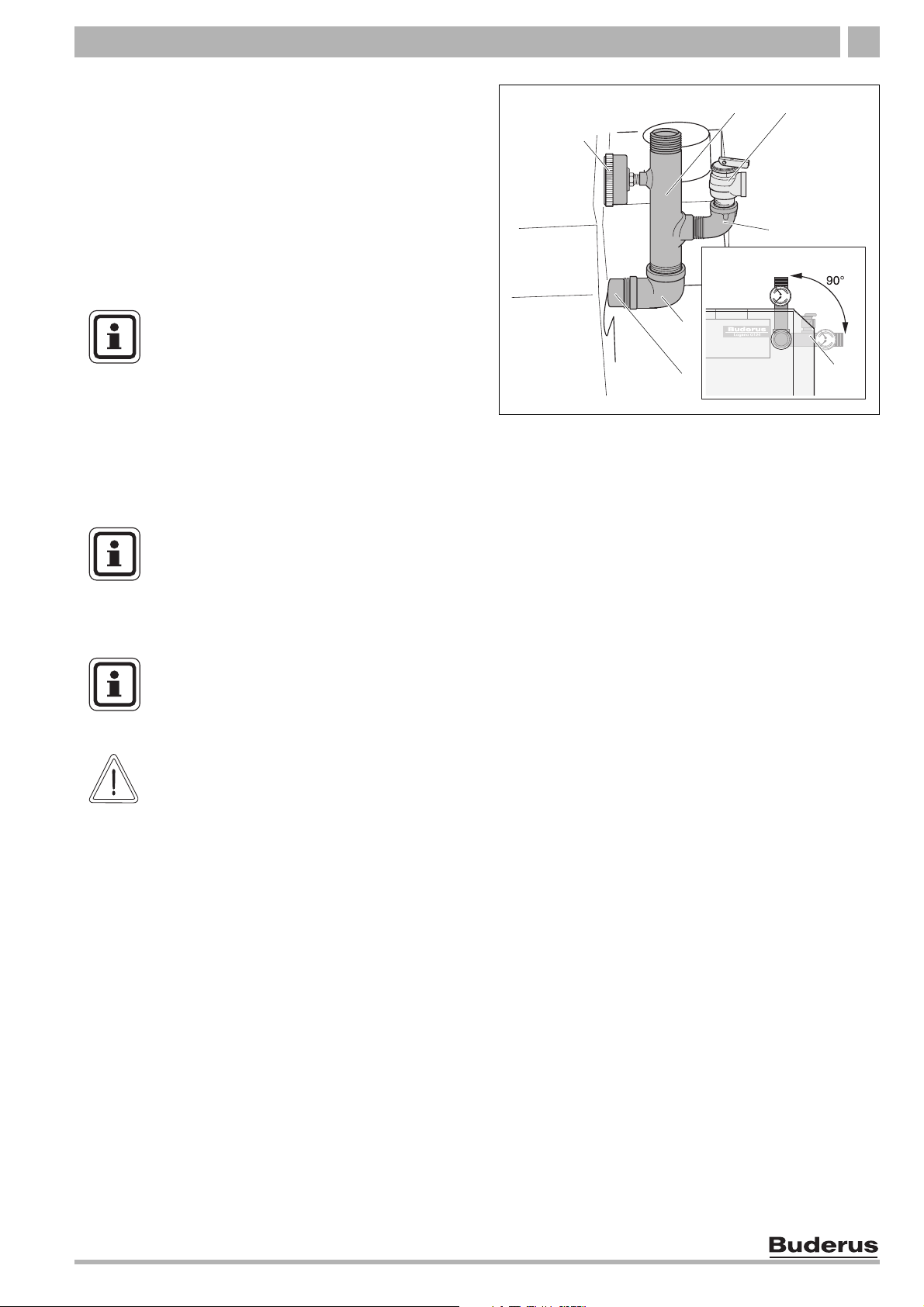

Installation of B-kit

The relief valve and the pressure/temperature gauge are

mounted on the boiler supply VK over the

supply manifold (included in B-kit).

z Seal 90° 1" NPT elbow on VK.

z Seal supply manifold on 90° 1" NPT elbow. The

supply manifold can be mounted vertically or rotated

90° to the right.

z Seal temperature/pressure gauge on supply

manifold.

USER NOTE

Install the relief valve after the leak test

(Î Chapter 7.6, page 23).

The relief valve must be installed in a

vertical position.

The relief valve must also be installed in

accordance with the requirements of the

ANSI/ASME Boiler and Pressure Vessel

Code, Section IV.

USER NOTE

We recommend installing a dirt filter

(accessory) in the heater return

connection to reduce build-up of debris on

the water side.

1

5

6

Fig. 11 Installation of B-kit

1 Pressure/temperature gauge

2 Supply manifold

3 Relief valve 3/4"

4 90° 3/4" elbow

5 90° 1" NPT elbow

6 Boiler supply VK

7 B-kit rotated 90° right

2

3

4

7

CAUTION!

USER NOTE

Observe the local regulations for

connection of boiler systems.

FIRE DANGER

through frost.

z Note that a minimum clearance of two

inches is required between pipes

carrying hot water and flammable walls

in the boiler room.

We reserve the right to make any changes due to technical modifications.

Installation and maintenance instructions Logano G124X II/SP special gas-fired boiler • Issue 04/2005

15

Boiler installation7

7.3 Electrical connection

The electrical connections of the boiler must be

manufactured as specified by the local codes and the

current regulations of the National Electrical Code,

ANSI/NFPA–70.

In Canada the regulations of CSA C 22.1 Canadian

Electrical Code, Part 1, must be observed.

The boiler must be grounded as specified by the

regulations of the relevant local authorities; otherwise

follow the regulations of the National Electrical Code,

ANSI/NFPA–70.

USER NOTE

When making the electrical connections

follow the circuit diagrams on

to Î page 78.

Install an ON/OFF switch near the boiler.

RISK TO LIFE

from electric shock.

WARNING!

z When conducting maintenance work

label all cables before disconnecting

them.

z If cables are connected incorrectly the

system may not operate correctly with

possibly dangerous consequences.

Î page 74

z Check that the heating system functions correctly

after any maintenance work.

16

We reserve the right to make any changes due to technical modifications.

Installation and maintenance instructions Logano G124X II/SP special gas-fired boiler • Issue 04/2005

Boiler installation 7

7.4 Installation of Logamatic 2107 control (accessory)

The boiler is fully functional with the factory-installed

aquastats. The Logamatic 2107 control can also be

installed in addition to the factory-installed aquastats.

USER NOTE

Note the following when making electrical

connections:

z Lay out cables and capillaries carefully.

z Do not bend the capillaries during

installation.

z Never carry out any electrical work on

the heating system unless you are

licensed for this type of work. If you are

not a licensed electrician, have a

specialist electrical company make the

electrical connections.

z Observe the local regulations.

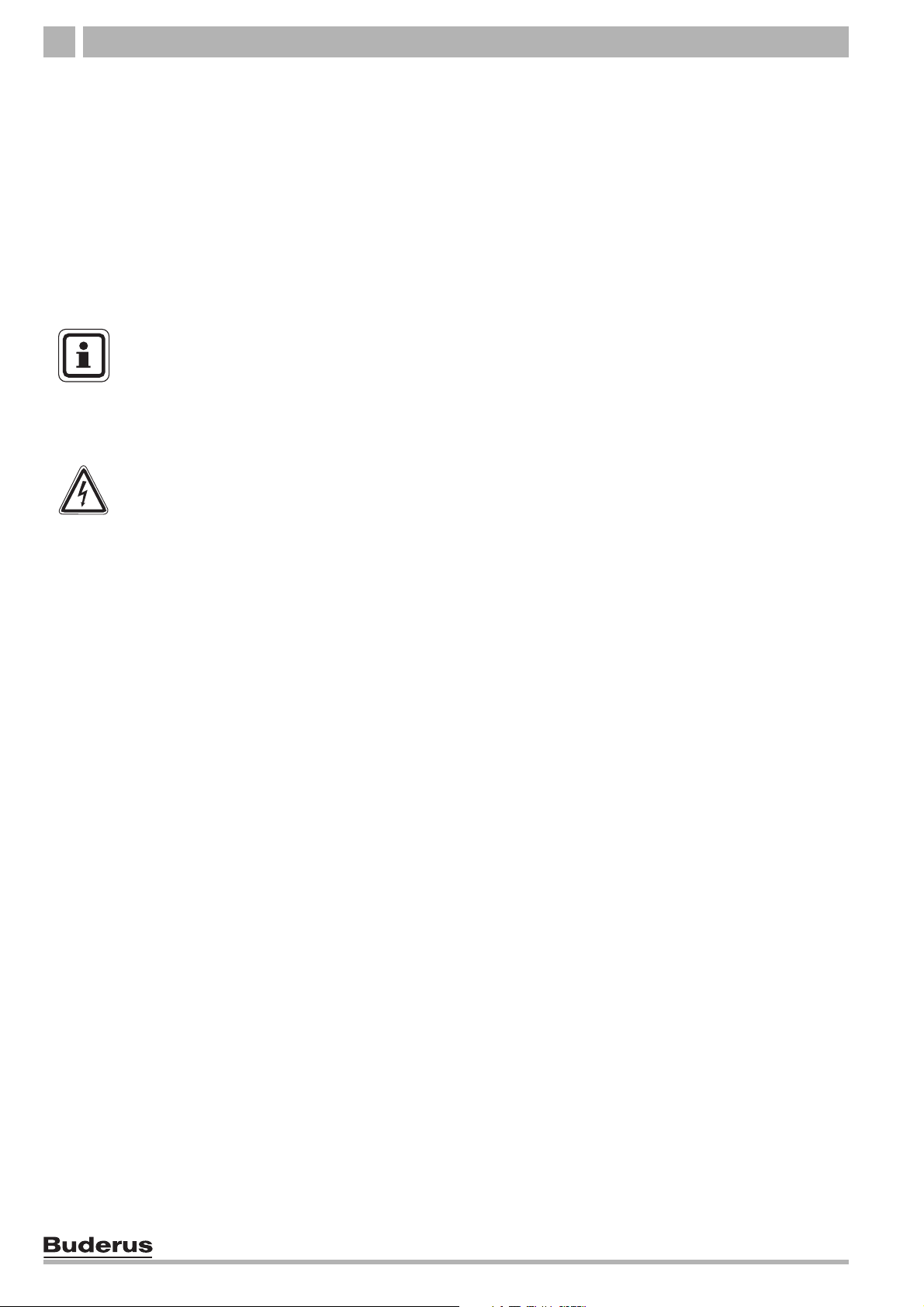

1. Unscrew left and right screws in the side panels, lift

front panel up, pull down and remove to the front.

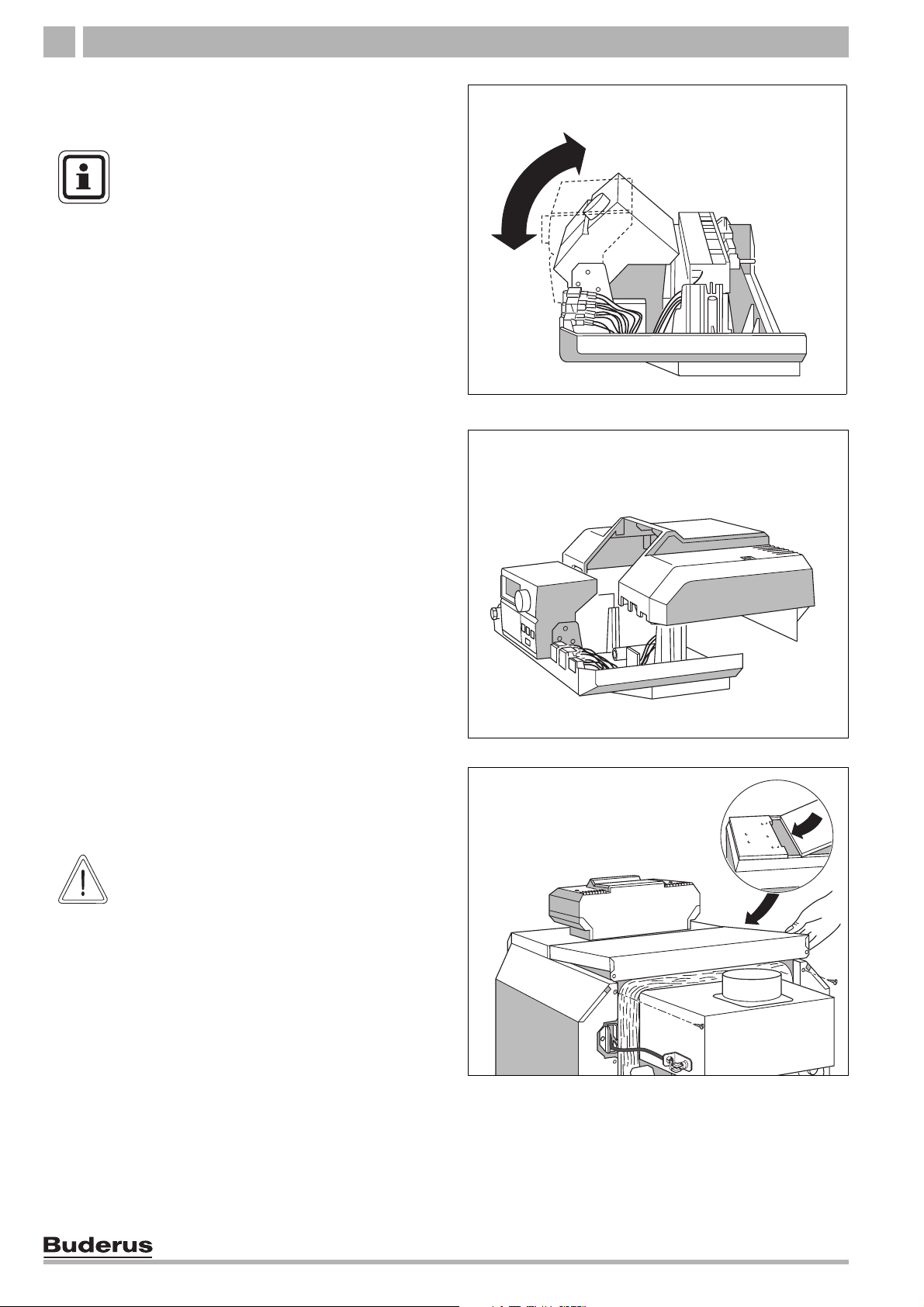

Fig. 12 Removing front panel of boiler

2. Unscrew the two fastening screws on the back boiler

jacket. Lift the back boiler jacket and remove to the

back.

Fig. 13 Removing boiler jacket

We reserve the right to make any changes due to technical modifications.

Installation and maintenance instructions Logano G124X II/SP special gas-fired boiler • Issue 04/2005

17

Boiler installation7

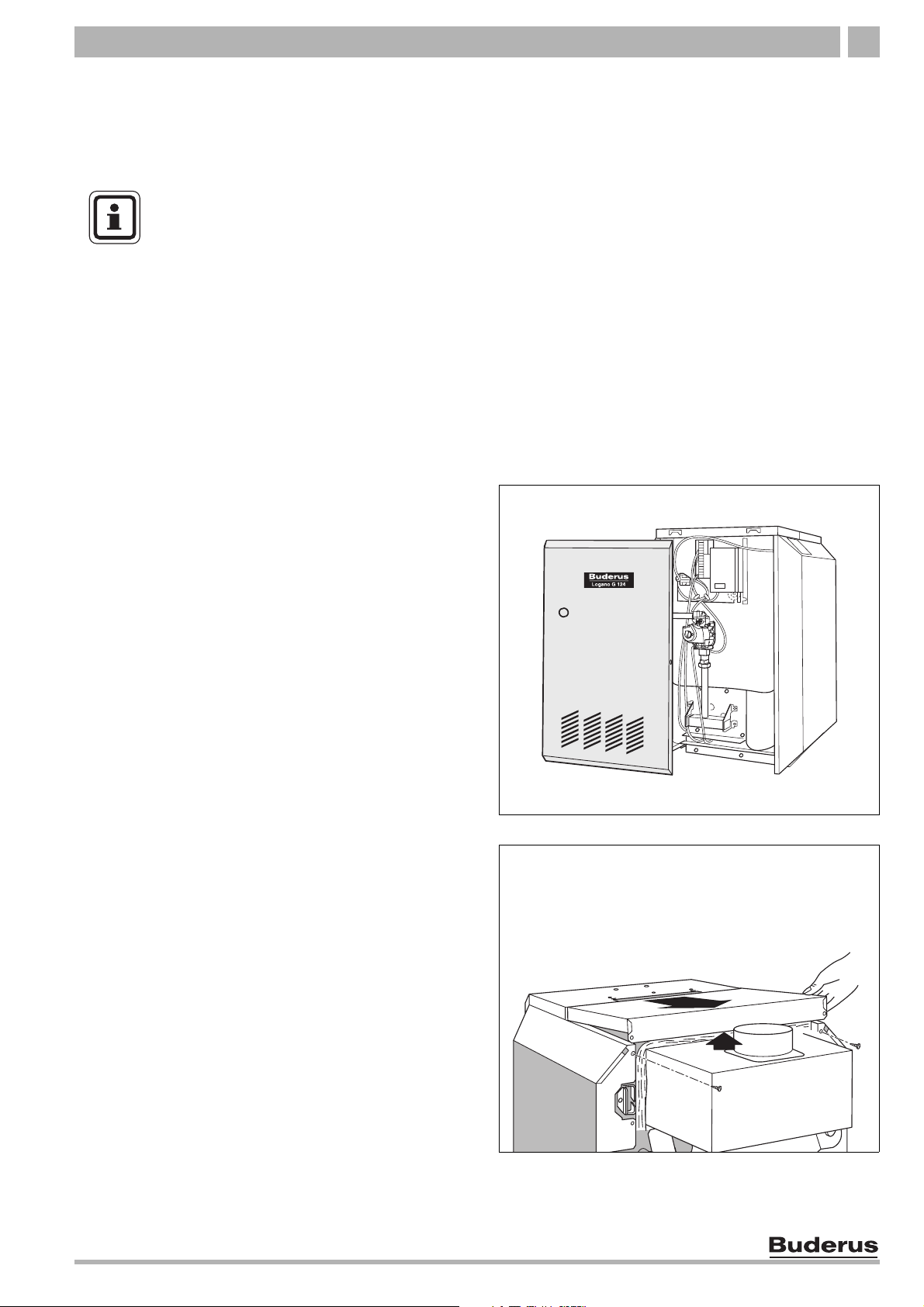

3. Slide the insertion tabs of the control into the oval

openings.

4. Slide control toward the boiler front panel.

5. Push to snap plastic tabs of the control into the

knock-outs.

6. Remove top cover of control Remove screws from

the top cover.

Fig. 14 Removing terminal cover

7. Fasten control with sheet-metal screws.

8. Route boiler water sensor cable through the cable

opening and unroll to the required length.

1

Fig. 15 Installation of Logamatic 2000 control system

1 Screws

18

We reserve the right to make any changes due to technical modifications.

Installation and maintenance instructions Logano G124X II/SP special gas-fired boiler • Issue 04/2005

Boiler installation 7

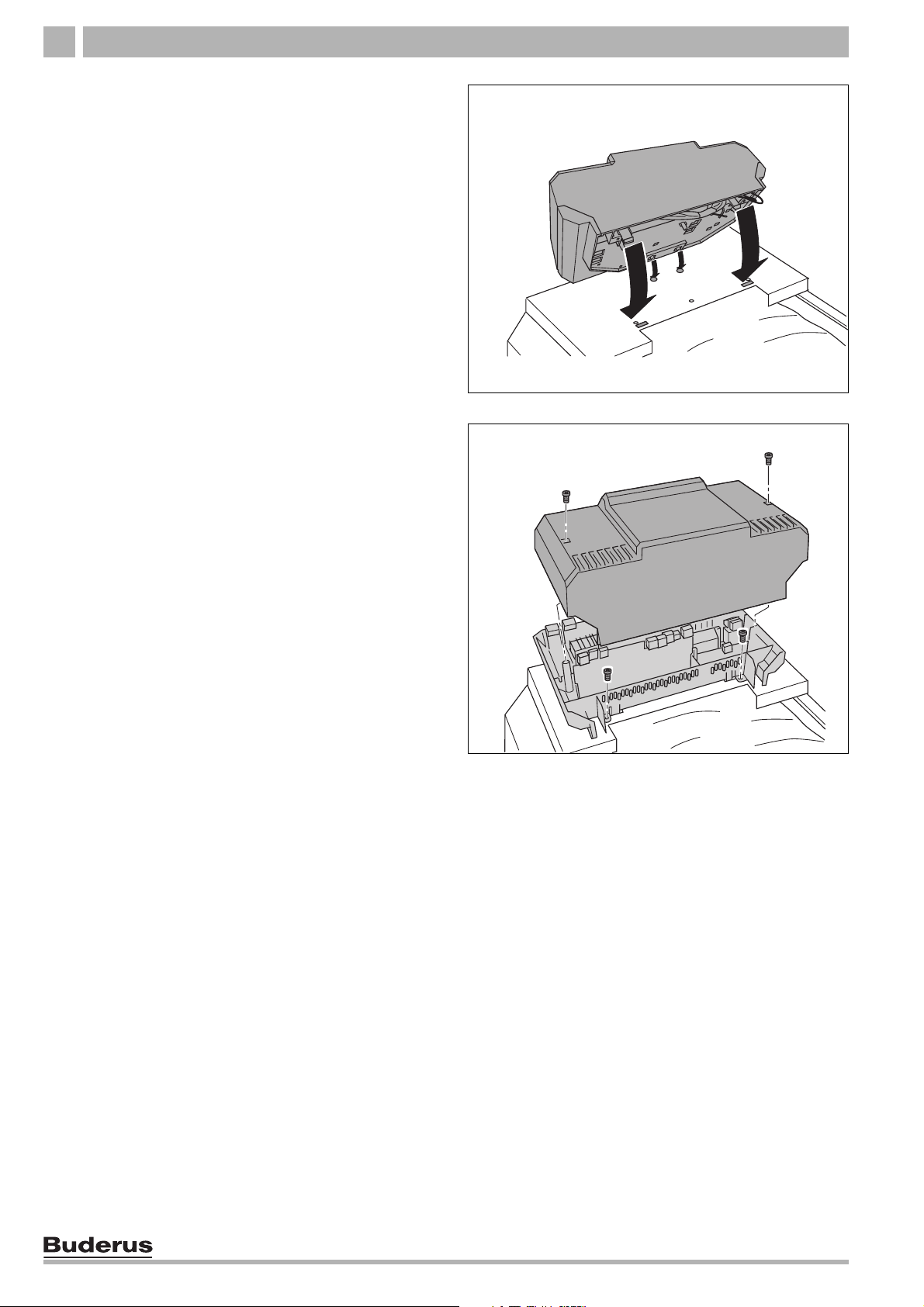

Installation of Logamatic boiler water sensor

9. Trace boiler water capillary package wiring under

the front boiler cover to the measuring point

(immersion well).

10. Remove all spacers from the immersion well.

11. Remove carefully the copper sleeves from the

Logamatic capillaries and slide Logamatic

capillaries together with Honeywell capillary into

boiler immersion well.

12. Press sensor clip (included with control) from the

side or from above to the head of the immersion well.

13. Carefully roll up unnecessary wiring and capillaries

and stow in the Logamatic 2107 control.

Power connection and connections of additional

components

Connect to the power supply as specified by the local

code.

FIRE DANGER

Hot boiler components may damage

WARNING!

electrical wiring.

z Make sure that all cables are routed in

the ducts or on the boiler insulation.

Fig. 16 Front of boiler

1 Measuring point (immersion well)

2 Spacers (blanking piece)

3 Boiler water sensor (Logamatic 2107 control)

2

1

3

1

14. Route all wiring to the control through the wiring

opening and connect as specified by the circuit

diagram.

Install strain relief

Secure all wiring with wiring clips (included with control):

– Insert wiring clip with wiring from above into the slot

of the clip frame; the lever bar must point upwards

(step 1).

– Slide wiring clip down (step 2).

– Press (step 3).

– Move lever up (step 4).

1

Fig. 17 Secure wiring with wiring clip

We reserve the right to make any changes due to technical modifications.

Installation and maintenance instructions Logano G124X II/SP special gas-fired boiler • Issue 04/2005

19

Boiler installation7

Install panel components

15. Swivel display unit to the desired position.

USER NOTE

We recommend positioning the display

unit straight on combinations with an Ltank.

16. Position terminal cover and screw to control.

Fig. 18 Swivel display unit

17. Slide tabs of rear boiler cover under the front boiler

cover and press down at back.

18. Screw rear boiler cover to rear panel of boiler.

SYSTEM DAMAGE

due to dirt.

CAUTION!

If the boiler is assembled and not in use,

note the following:

z Protect the boiler connections from dirt

by closing the connections.

Fig. 19 Positioning terminal cover

Fig. 20 Installing rear boiler cover

20

We reserve the right to make any changes due to technical modifications.

Installation and maintenance instructions Logano G124X II/SP special gas-fired boiler • Issue 04/2005

Boiler installation 7

7.5 Fuel supply connection

7.5.1 Gas connections

For the gas pipe diameter required for the installation

please see

Tab. 4 and Tab. 5. Make sure that the pipe

fitting has the correct thread size.

Make sure that a sediment trap is installed at the inlet for

the gas supply pipe to the boiler. A gas cock shut-off

must be installed outside the boiler jacket if required by

the local code. We recommend installing a gas cock

shut-off in the main gas pipe to the boiler. The gas pipe

must be fastened outside the boiler.

The local codes must be observed during installation of

the gas connection, otherwise the regulations of the

National Fuel Gas Code, ANSI Z 223.1.

DANGER OF EXPLOSION

Leakage from the gas pipes and gas

WARNING!

connections may cause an explosion.

z Use soap solution to find leaks.

Length

Ironpipe

in feet

Gas pipe supply volume in cubic feet of gas

of

per hour

1

1/2 3/4 1 1 1/4 1 1/2

10 132 278 520 1060 1600

20 92 190 350 730 1100

30 73 152 285 590 890

40 63 130 245 500 760

50 56 115 215 440 670

75 45 93 175 360 545

100 38 79 160 305 480

150 31 64 120 250 380

Tab. 4 Gas pipe supply volume

1 Maximum gas supply volume in cubic feet per hour, based on a

specific gas weight of 0.60 and a gas pressure of 0.5 psi or less

and a pressure rise corresponding to a water column of 0.3

inches.

Equivalent lengths for pipe fittings in

Nominal

diameter of

iron pipe

(inches)

90° angle T-piece Ball valve

feet

Pipe fitting type

Gas

valve

Equivalent lengths in feet

1/2 1.4 2.7 0.3 0.80

3/4 2.1 4.1 0.5 1.25

1 2.6 5.2 0.6 1.6

1 1/4 3.5 6.9 0.8 2.15

1 1/2 4.0 8.0 0.9 2.50

Tab. 5 Equivalent lengths for pipe fittings

Disconnect the boiler with the gas shut-off rom the gas

supply pipe system the system is pressure tested with a

test pressure greater than 1/2 psi.

Fig. 21 Pipe connection to gas fittings – back view

1 Gas supply

2 Shut-off

3 Sediment trap

1

2

3

We reserve the right to make any changes due to technical modifications.

Installation and maintenance instructions Logano G124X II/SP special gas-fired boiler • Issue 04/2005

21

Boiler installation7

If the gas supply pipe system is pressure tested at a test

pressure of 1/2 psi or less, it is sufficient to disconnect

the boiler from the pipe system by closing the stop valve.

z The boiler and its gas connections must be tested for

leaks before placing it into operation,

Use only sealant that is resistant to corrosion by LPG for

pipe connection. Only a small amount of sealant must be

applied to the external thread of the pipe connections.

If you wish to convert the boiler to propane, please

contact Buderus for the required conversion

components. Do not attempt to convert the boiler without

the approved Buderus parts and the relevant technical

documentation. The technical documentation is

included with the conversion parts.

7.5.2 Installation at high altitudes

The boiler is designed for installation at altitudes below

8500 feet above sea level. The boiler must be converted

appropriately for installation above altitudes of 8500

feet. The conversion consists of replacing the main gas

nozzles.

(Î page 29).

USER NOTE

If the installation location is over 8500 feet

above sea level, please contact Buderus

for the required conversion components.

Do not attempt to convert the boiler

without the approved Buderus parts and

the relevant technical documentation.

The technical documentation is included with the

conversion parts (accessory).

22

We reserve the right to make any changes due to technical modifications.

Installation and maintenance instructions Logano G124X II/SP special gas-fired boiler • Issue 04/2005

Boiler installation 7

7.6 Filling heating system and checking for leaks

The boiler is tested for leaks at the factory. Before

placing the heating system tank into use, check it for

soundness to avoid leaks occurring during operation.

Water treatment

USER NOTE

Have the water analyzed before filling the

heating system. The water may require

treatment as a result of the analysis.

Please consult the local water supply

company if the water is extremely hard or

CAUTION!

has a pH level below 7.0.

SYSTEM DAMAGE

due to overpressure during the leak test.

Pressure, control or safety components

may be damaged by high pressure.

z Before conducting the leak test make

sure that no pressure, control or safety

components that cannot be

disconnected from the water

compartment of the boiler are installed.

Fig. 22 Temperature/pressure gauge

Carry out the leak test at 1.5 times the normal operating

pressure and as specified by the local codes as follows:

Maximum

operating pressure

30 psi (with the included relief

valve)

58 psi (with a different relief

valve)

Tab. 6 Test pressures

Maximum

construction site test

pressure

45 psi

75 psi

z Close connection for relief valve (Î Fig. 11,

page 15) and all other open connections with plugs.

z Disconnect the expansion tank from the system by

closing the cap valve.

z Open mixing and stop valves on hot water side.

z Fill boiler slowly with water from the building

connection.

z Turn cap of automatic vent one revolution to allow the

air to escape.

z Slowly fill heating system. Observe pressure display

on pressure gauge during this process.

z Check connections and pipes for leaks.

z Bleed heating system through the bleed valves on

the radiators.

z If the pressure falls while bleeding, water must be

added.

z Install relief valve (Î Fig. 11, page 15).

We reserve the right to make any changes due to technical modifications.

Installation and maintenance instructions Logano G124X II/SP special gas-fired boiler • Issue 04/2005

23

Check openings for combustion air supply and venting8

8 Check openings for combustion air supply and venting

BOILER DAMAGE AND OPERATING

FAULTS

CAUTION!

due to missing or inadequate openings for

combustion air and venting of the boiler

room.

Inadequate venting of the boiler room may

result in excessive ambient temperatures.

This can damage the boiler.

Inadequate combustion air supply may

cause operating faults.

z Make sure that inlets and outlets are

not reduced or closed and that they are

adequately dimensioned.

z If faults are not corrected immediately,

the boiler must not be operated.

z Inform the system operator of the fault

and the danger.

To ensure an adequate combustion air supply and

venting of the heating system suitable measures must

be taken in accordance with the National Fuel Gas

Code, Section 5.3, Air for Combustion and Ventilation,

or the local codes.

In Canada the regulations in accordance with the

CSA/CGA–B 149.1 or 2 Installation Codes apply.

BOILER DAMAGE

due to contaminated combustion air.

CAUTION!

z Never use cleaning agents that contain

chlorine and halogenated

hydrocarbons (e.g. spray bottles,

solvents and cleaning agents, paints,

glues).

z Do not store or use these substances in

the boiler room.

z Prevent excessive dust levels.

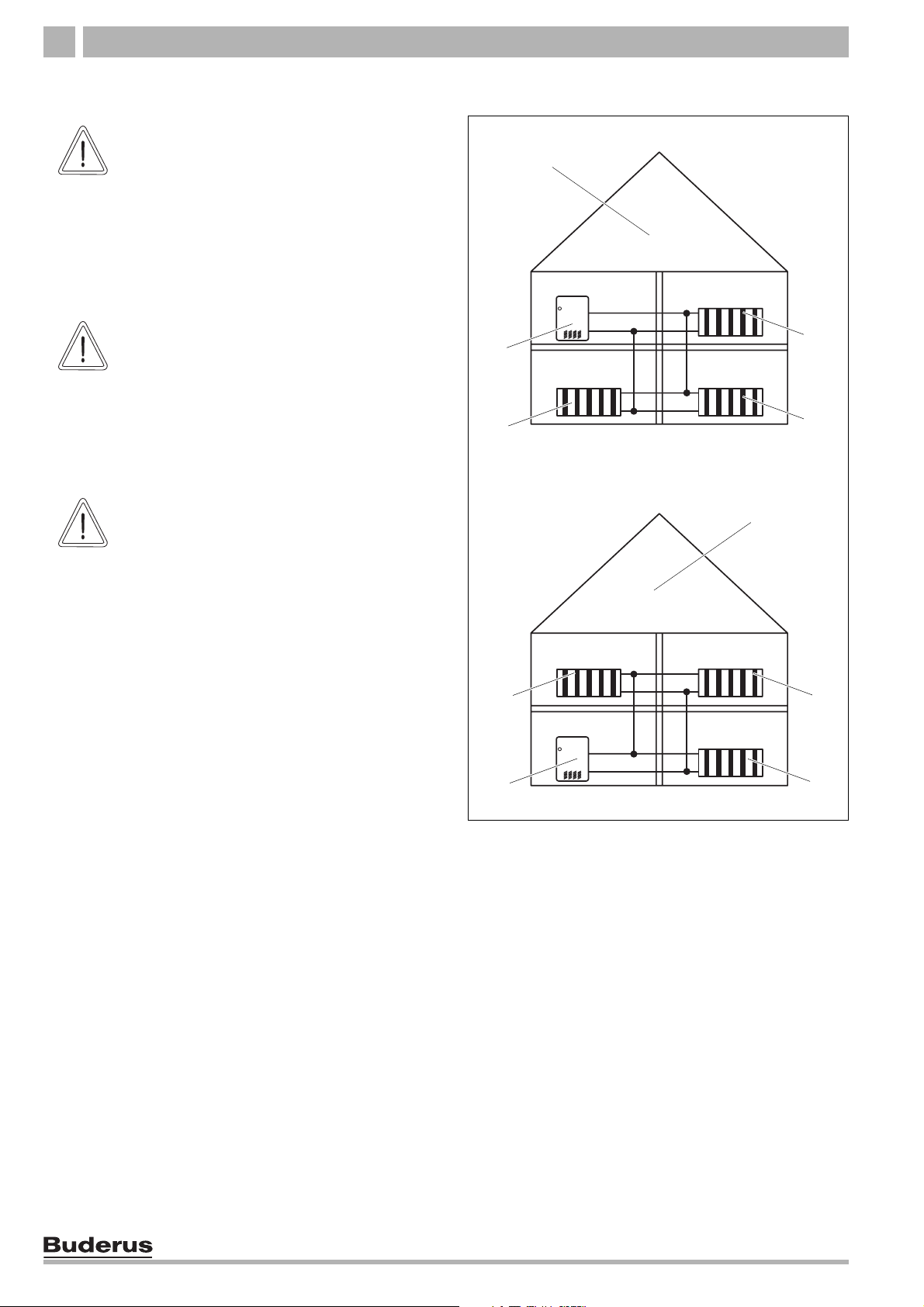

Total air supply from inside the building

Make sure that the boiler room has two permanent

openings that are connected with one or more other

rooms. When calculating the cross-section areas of the

openings, the total combustion output of all gas-fired

appliances in the connected rooms must be taken into

account. Each opening must have a minimum crosssection of one square inch per 1000 Btu/h of the total

combustion output of all gas-fired appliances inside the

connected rooms. Note that the minimum cross-section

of every opening must not be less than 100 square

inches. One opening must not be more than 12 inches

from the ceiling and the other must not be more than 12

inches from the floor of the boiler room, calculated from

the outer edge of the opening. The shortest dimension

of all inlet and outlet openings must not be less than

three inches.

Total air supply from outside the building

Make sure that the boiler room has two permanent

openings, one of which must not be more than 12 inches

from the ceiling and the other must not be more than 12

inches from the floor of the boiler room, calculated from

the outer edge of the opening. The openings have a

direct connection or a connection through ventilation

ducts to the outside or to rooms that have an

unobstructed connection to the outside (crawl space or

attic). The shortest dimension of all inlet and outlet

openings must not be less than three inches.

1. If there is a direct connection to the outside, each

opening must have a minimum cross-section of one

square inch per 4000 Btu/h of the total combustion

output of all gas-fired appliances inside the closed

room.

2. If there is a connection to the outside through

vertical ventilation ducts, each opening must have a

minimum cross-section of one square inch per 4000

Btu/h of the total combustion output of all gas-fired

appliances inside the closed room.

WARNING!

24

3. If there is a connection to the outside through

FIRE DANGER

due to flammable materials or liquids.

z Do not store flammable materials or

horizontal ventilation ducts, each opening must have

a minimum cross-section of one square inch per

2000 Btu/h of the total combustion output of all gasfired appliances inside the closed room.

liquids in the immediate vicinity of the

heat generator.

4. If the openings are connected to ventilation ducts,

the ducts must have the same cross-section area as

the openings.

We reserve the right to make any changes due to technical modifications.

Installation and maintenance instructions Logano G124X II/SP special gas-fired boiler • Issue 04/2005

Loading...

Loading...