Buderus Logano G115 WS US/CA, Logano G115/3 WS, Logano G115/4 WS, Logano G115/5 WS Installation And Service Instructions Manual

Page 1

For heating contractors

Please read carefully prior

to installation and servicing.

Caution!

Observe the safety instructions of this installation

and maintenance manual before placing the boiler

in operation.

Danger!

If installation, adjustment, modification, operation or

maintenance of the heating system is carried out by

an unqualified person, this may result in danger to

life and limb or property damage.

The directions of this installation and maintenance

manual must be followed precisely.

Contact a qualified service company or service provider if support or additional information is required.

Caution!

The operating manual is a component of the technical documentation and must be handed over to the

operator of the heating system.

Discuss the content of this manual with the owner

or operator of the heating system to ensure that

they are familiar with all information required for

operation of the heating system.

Installation and Service

Instructions

Low-temperature

oil boiler

6 720 615 225-00.1RS

Logano G115 WS US/CA

6 720 615 225 - 08/2007 US/CA

Page 2

Contents

Logano G115 WS US/CA - Technical specifications are subject to change without prior notice.

2

Contents

1 Safety Considerations and Symbol

Descriptions 3

1.1 Regarding this Manual 3

1.2 Explanation of symbols 3

1.3 Observe the following Symbols 3

1.3.1 Installation Guidelines 4

1.3.2 Boiler Room Guidelines 4

1.4 Tools, Materials and Accessories 4

1.5 Disposal 4

2 Product description 5

2.1 Intended use 5

2.2 Certification and testing mark 5

2.3 Notes on installation and operation 5

2.4 Heating system water quality 5

2.5 Product description 6

2.6 Pack contents 7

2.7 Dimensions Specifications 8

2.7.1 Logano G115 WS dimensions 8

2.8 Conditions for operation 9

2.8.1 General operating conditions 9

2.8.2 Conditions for the boiler room and the

environment 10

2.8.3 Combustion air supply conditions 10

2.8.4 Conditions, Fuel 10

2.8.5 Conditions power supply 11

2.8.6 Conditions for hydraulic system and

water quality 11

3Moving the boiler 12

3.1 Reducing boiler weight for transportation

purposes 12

3.2 Lifting and carrying the boiler 13

3.3 Using transportation aids to transport

the boiler 13

4 Installing the boiler 14

4.1 Wall clearances 14

4.2 Reversing boiler door 15

4.3 Mounting the adjustable feet

(included with B-kit) 16

4.4 Positioning and leveling the boiler 16

5 Installing the boiler 17

5.1 Flue pipe installation 17

5.1.1 Chimney venting 17

5.2 Fitting the water connections 19

5.2.1 Fitting the B-kit 19

5.2.2 Installation of boiler drain (included in B-Kit) 20

5.2.3 Installing system components 20

5.3 Filling the heating system and checking

for leaks 21

5.4 Mounting the burner 23

5.5 Connecting the fuel supply 23

5.6 Installing aquastat 24

5.7 Blocked vent switch (required in Canada) 24

5.8 Electrical connections 24

5.8.1 Fitting the controls 25

5.8.2 Fitting temperature sensor assembly

and burner cable 26

5.8.3 Connecting the power supply and additional

components 27

5.8.4 Fitting cable ties 27

5.9 Fitting outer casing panels 27

6 Commissioning the heating system 28

6.1 Bringing the system up to operating pressure 28

6.2 Checking the safety valve 28

6.3 Checking position of heat exchanger baffles 29

6.4 Preparing the heating system for operation 29

6.5 Starting up the control and the burner 29

6.6 Notes on commissioning the burner 30

6.7 Raising flue gas temperature 30

6.7.1 Adjusting the position of heat exchanger

baffles 31

6.7.2 Removing heat exchanger baffles 31

6.7.3 Removing the heat exchanger barrier plate 32

6.8 Manual reset high limit (STB) 32

6.9 Installing the burner door jacket 32

6.10 Commissioning log 33

7 Shutting down the heating system 34

7.1 Shutting down normally 34

7.2 Shutting down the heating system in an

emergency 34

7.2.1 What to do in an emergency 34

8 Heating system servicing 35

8.1 Why is regular maintenance important? 35

8.2 Preparing the boiler for servicing 35

8.3 Cleaning the boiler 36

8.3.1 Cleaning the boiler with brushes 36

8.3.2 Wet cleaning (chemical cleaning) 37

8.4 Checking heating system operating pressure 37

8.5 Testing relief valve 38

8.6 Servicing and maintenance logs 39

9 Troubleshooting 42

10 Installation examples 43

11 Parts lists 45

12 Circuit diagrams 50

Page 3

1

Safety Considerations and Symbol Descriptions

Logano G115 WS US/CA - Technical specifications are subject to change without prior notice.

3

1 Safety Considerations and Symbol Descriptions

1.1 Regarding this Manual

This document contains important information regarding

safe and proper installation, operation and maintenance of

the boiler.

The high tech G115 WS boiler is designated as a hot

water heating boiler.

The Installation and Maintenance Instructions are directed

to the installing contractor who has professional knowledge regarding boiler installation and maintenance.

1.2 Explanation of symbols

Signal words are used to indicate the seriousness of the

ensuing risk if measures for minimising damage are not

taken.

– Caution indicates that minor damage to property may

occur.

– Warning indicates that minor personal injury or severe

damage to property may occur.

– Danger means that severe personal injury may occur.

Very serious cases may result in death.

Notes contain important additional information.

Notes do not contain any warnings or information about

hazards or risks.

1.3 Observe the following Symbols

All applicable local, state, and national codes and regulations must be observed for the installation of the boiler:

– The local building code requirements regarding place-

ment, combustion air and venting and chimney system

must be followed.

– Follow applicable electrical code requirements.

– Follow the local code and standards regarding safe

boiler operation.

Warnings are indicated by a warning triangle

and a grey background.

Notes are identified in the text by this symbol.

They are bounded by horizontal lines above

and below the text.

NOTICE

Use only original Buderus spare parts.

Buderus can not be held liable for damage

caused by non-Buderus parts.

NOTICE

The boiler installation must be performed by

a qualified installer in accordance with regulations put forth in NFPA-31 Installation of

Oil-Burning Equipment. The installation must

comply with all local and national codes, regulations and authorities having jurisdiction regarding the installation of oil fired boilers.

For Canada refer to the guidelines of CSA/

CGA-B139 Installation Codes.

Page 4

1

Safety Considerations and Symbol Descriptions

Logano G115 WS US/CA - Technical specifications are subject to change without prior notice.

4

1.3.1 Installation Guidelines

1.3.2 Boiler Room Guidelines

1.4 Tools, Materials and Accessories

For the installation and maintenance of the boiler you will

need typical tools used in this industry.

In addition, the following components are useful:

– Hand truck with strap or Buderus boiler cart.

– Wood blocking.

– Cleaning brushes and/or chemical cleaning agents for

wet cleaning.

1.5 Disposal

V Please dispose of any trash in an environmentaly

friendly fashion.

V Please discard properly of any heating system related

components.

Caution: DANGER TO LIFE

from electric shock.

V Do not work on electrical components un-

less you have the required qualification.

V Do not work on electrical components un-

less you have the required qualification.

V Prior to opening the control: shut down

the power supply by turning off the emergency shut-off switch or disengaging the

heating system circuit breaker, and prevent from accidental reactivation.

V Observe all applicable installation guide-

lines.

Caution: DANGER TO LIFE

from flue gas poisoning.

Insufficient combustion air can result in dangerous operation if combustion air is taken

from indoors.

V Please observe that combustion air open-

ings are not reduced in size or closed.

V Make sure that no mechanical air open-

ings or devices remove combustion air

from the boiler room such as central vacuum systems, dryers and air conditioning

appliances.

V Make sure that the boiler is connected to

a chimney or horizontal venting system

that is capable of handling the slight positive breeching pressure.

V If any of these problems have not been

corrected, the boiler must not be operated.

V Make the end-user aware of these guide-

lines and their potential danger.

Caution: FIRE DANGER

due to flammable or liquid materials.

V Make sure that flammable and liquid mate-

rials are not stored in the close vicinity of

the boiler.

Page 5

2

Product description

Logano G115 WS US/CA - Technical specifications are subject to change without prior notice.

5

2 Product description

This installation and maintenance manual contains important information for the safe and intended installation, initial start-up and maintenance of this boiler.

The special oil fired boiler Logano G115 WS is generally

referred to below as a boiler.

The installation and maintenance manual is provided for

technicians who have been trained and have experience

in working with heating systems and oil fired installations.

2.1 Intended use

The G115 WS is designed for central heating and

domestic hot water (DHW) systems, for instance in residential homes or apartment buildings, or small commercial applications.

2.2 Certification and testing mark

This appliance has been tested and certified to meet rules

and regulations in place for the US and Canadian markets.

2.3 Notes on installation and operation

When installing and operating the heating system, it is the

installer's responsibility to meet all applicable federal,

state, and local codes.

2.4 Heating system water quality

Poor water quality can damage heating systems due to

scale formation and corrosion.

Please refer to Chapter 2.8.6, Tab. 9 for further details of

the water quality.

Caution: Risk of system damage due to unsuitable boiler water.

V If oxygen-permeable pipes are used, e.g.

for radiant heating systems, the systems

must be separated from the boiler by a

heat exchanger. Unsuitable heating system water promotes sludge formation and

corrosion. This can result in heating system malfunction and boiler damage.

Page 6

2

Product description

Logano G115 WS US/CA - Technical specifications are subject to change without prior notice.

6

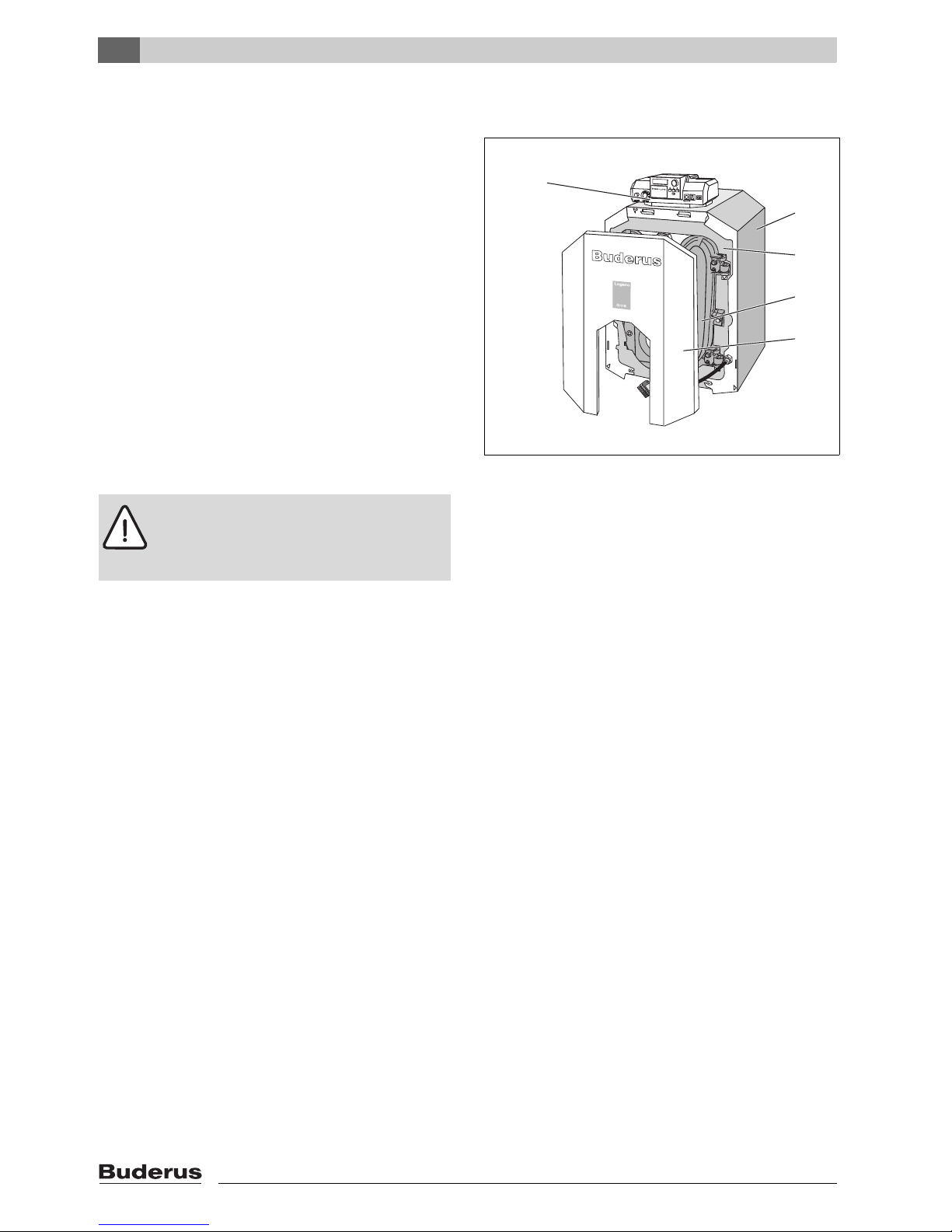

2.5 Product description

The boiler is a low-temperature oil-fired appliance with

automatic control panel or aquastat for boiler water temperature.

The boiler consists of:

– Boiler heat exchanger with insulation

– Boiler jacket

– Control panel or aquastat

The controls monitor and control all electrical boiler components.

The boiler can alternatively be fitted with a simple aquastat control.

The boiler jacket prevents heat loss and acts as a noise

insulator.

The boiler heat exchanger transfers the heat generated by

the burner to the heating water. The insulation prevents

energy loss.

Suitable burners

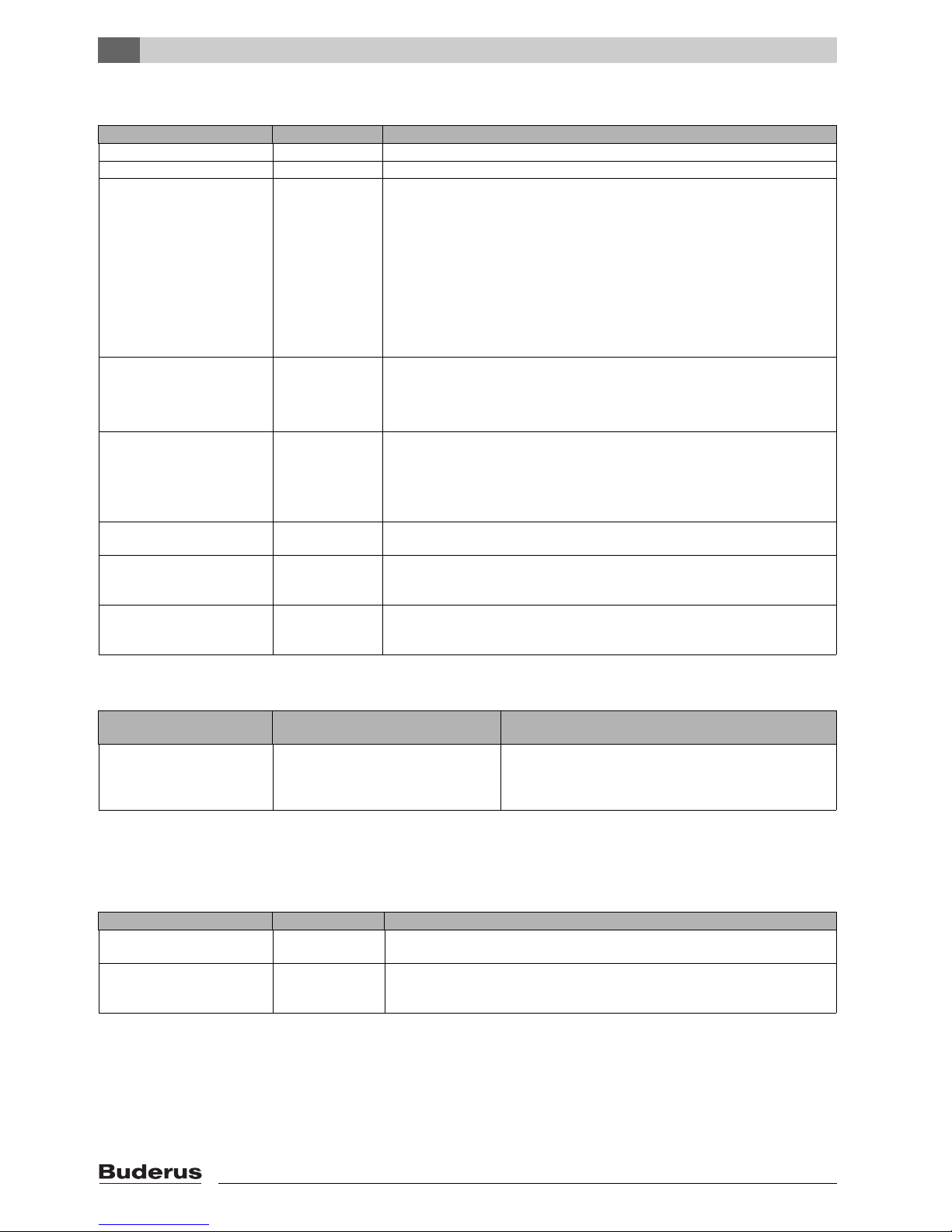

Fig. 1 Boiler without burner

1 Control panel

2 Boiler jacket

3 Boiler heat exchanger with insulation

4 Burner door

5 Burner door panel

Caution: Risk of system damage from use

of incorrect burner.

V Only the burner provided may be em-

ployed with this boiler.

6 720 615 225-01.1RS

1

2

3

4

5

Page 7

2

Product description

Logano G115 WS US/CA - Technical specifications are subject to change without prior notice.

7

2.6 Pack contents

Upon delivery, check that the packaging is complete and

undamaged.

Component Qty Packaging

Boiler heat exchanger 1 1 pallet

Boiler casing, factory-fitted to boiler heat

exchanger

Burner door and burner

door panel, factory-fitted

to boiler heat exchanger

B-kit components:

– 1 Supply manifold

G115"US"

– elbow 90 ° 1-1/4"

– elbow 90 ° 3/4"

– double nipple R1-1/4"-

1-1/4" NPT x 75

– boiler drain 3/4"

– relief valve 3/4" x 3/4"

30PSI

– temperature/pressure

gauge

– Bolt set B-Kit

G115"US"

– adjustable boiler feet

M10 x 51 packed

1 1 foil package

1)

1) in the combustion chamber in the boiler

Controller or, alternatively,

Aquastat

2)

2) Aquastat may be supplied with burner

11 box

Technical documentation 1 foil package

Tab. 1 Package Contents

Page 8

2

Product description

Logano G115 WS US/CA - Technical specifications are subject to change without prior notice.

8

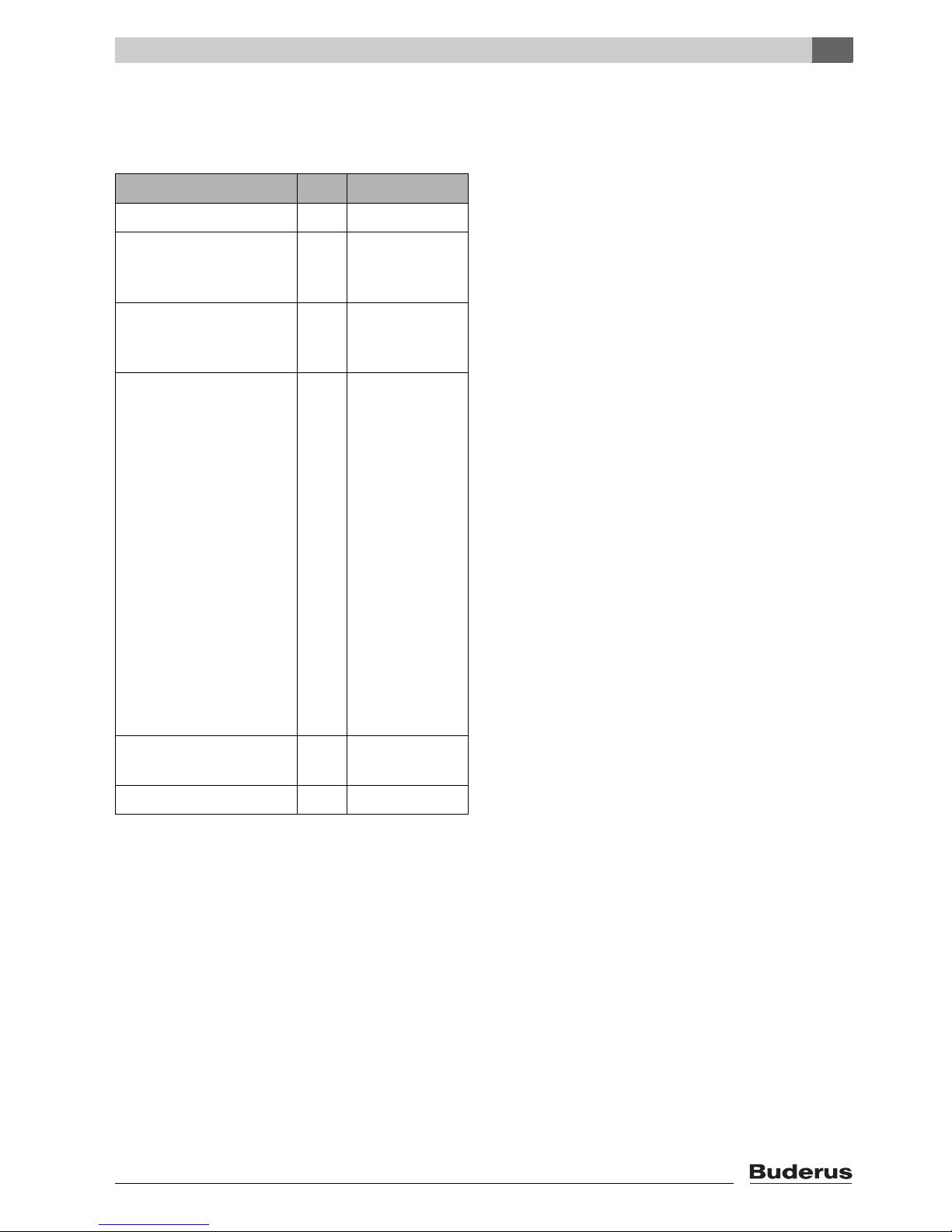

2.7 Dimensions Specifications

2.7.1 Logano G115 WS dimensions

Fig. 2 Connections and dimensions (measurements in inches)

VK = Boiler supply

RK = Boiler return

EL = Boiler drain (connection for drain valve)

Connections and dimensions:

7 747 019 141-02.1RS

23

5/8"

L

VK

L

K

F

L

39

5/8"

30

3/8"

1

3/4"

2

7/8"

8

7/8"

8

7/8"

Rp1

1/4"

EL

Rp

3/4"2 7/8"

25

1/4"

RK

1" NPT

3

1/4"

Ø 5"

20"

10

3/8"

12

1/4"

5

7/8"

4

3/8"

5/8"

- 1"

Boiler model Unit G115/3 WS G115/4 WS G115/5 WS

Boiler sections 345

Heating capacity (gross output) MBtu/hr 85 109 136

Thermal output (net IBR output) MBtu/hr 74 95 119

Boiler water content Gal 8.7 10.8 12.9

Gas capacity cu.ft. 1.20 1.75 2.21

Oil firing rate GPH 0.7 0.9 1.0

Flue gas back-pressure W.C. 0.04" - 0.06"

Permissible flow temperatureSafety

1)

1) Limit (safety temperature limiter, STB)

Maximum permitted flow temperature = Safety limit (STB) - 32 °F

Example: Safety limit (STB) = 212 °F, maximum permitted flow temperature = 212 ° - 32 ° = 180 °F

The safety limit must meet the national regulations of the country concerned.

°F 230

Allowable operating pressure psi 58

Maximum time constant of thermostat and

high limit safety cut-out (STB)

s 40

Tab. 2 Technical data for boilers without burners

Boiler model Unit G115/3 WS G115/4 WS G115/5 WS

Boiler overall length (L) Inch 23-5/8" 28-5/8" 33-3/8"

Boiler block length (LK) Inch 21-1/8" 25-¾" 30-½"

Combustion chamber length Inch 16" 20-½" 25-¼"

Combustion chamber length Inch 10-5/8"

Burner door thickness Inch 3-5/8"

Distance between boiler feet (FL) Inch 10-3/8" 16-1/8" 20-7/8"

Net weight1)– Lbs 330 403 476

Tab. 3 Dimensions, weight and other data for boilers without burners

1) Incl. packaging material approx. 6-8 % more

Page 9

2

Product description

Logano G115 WS US/CA - Technical specifications are subject to change without prior notice.

9

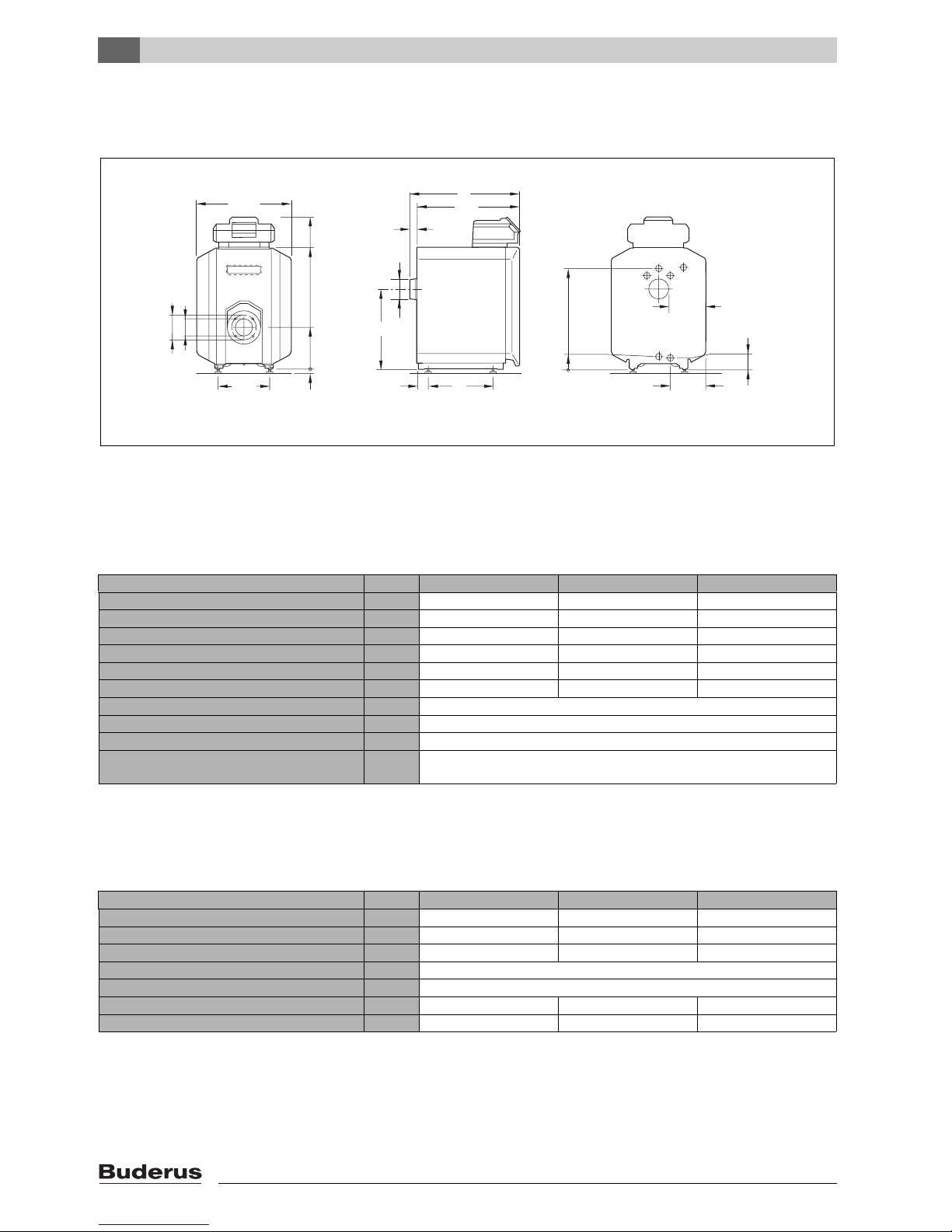

2.8 Conditions for operation

Maintaining the specified operating conditions will enable

the boiler to provide a high level of reliability and long service life. Some details relate only to operation with Buderus

Logamatic control panels.

2.8.1 General operating conditions

Caution: Ri sk of sys te m da ma ge if op er at in g

conditions are not maintained.

Irreversible damage to individual compo-

nents of the boiler as a whole or the heating

system may occur.

V The information on the rating plate is bind-

ing and must be observed.

Operating conditions

Min. boiler water tempera-

ture

Operating interruption

(complete boiler shutdown)

heating circuit with

heating circuit mixing valve

1)

Min. return temperature

In combination with Logamatic control for variable low-temperature operating modes, such as Logamatic 2107

no requirements operating

temperatures are ensured by

the Logamatic controls

2)

Automatically by Logamatic controls not required but recommended with

low-temperature heating system

design 130/113 °F

Required with:

– Underfloor heating systems

– Systems with high water content:

> 115° gal/MBH

(1 MBH = 100.000 Btu/hr)

In conjunction with a Logamatic controls for constant boiler water temperatures, e.g. Logamatic 2109 or with supplementary exter-

nal programmer and aquastat

150 °F

3)

possible if, after interruption of the

operation, there is at least 3 hours

heating operation

required Required with:

– Systems with high water content

> 115 gal/MBH: 130 °F

Tab. 4 General operating conditions

1) A heating circuit with a mixing valve improves controllability and is specifically recommended for systems with several heating zones.

2) If heating zones or a boiler circuit actuator cannot be regulated via the control device (for example pump logic), an operating temperature of

122 °F must be reached within 10 min of switching the burner ON by restricting the water volume flow.

3) Boiler water temperature control setting: when the boiler is in ON mode, the minimum boiler water temperature in the boiler must be reached

within 10 minutes, e.g. by flow rate limitation, and maintained as the minimum temperature.

Page 10

2

Product description

Logano G115 WS US/CA - Technical specifications are subject to change without prior notice.

10

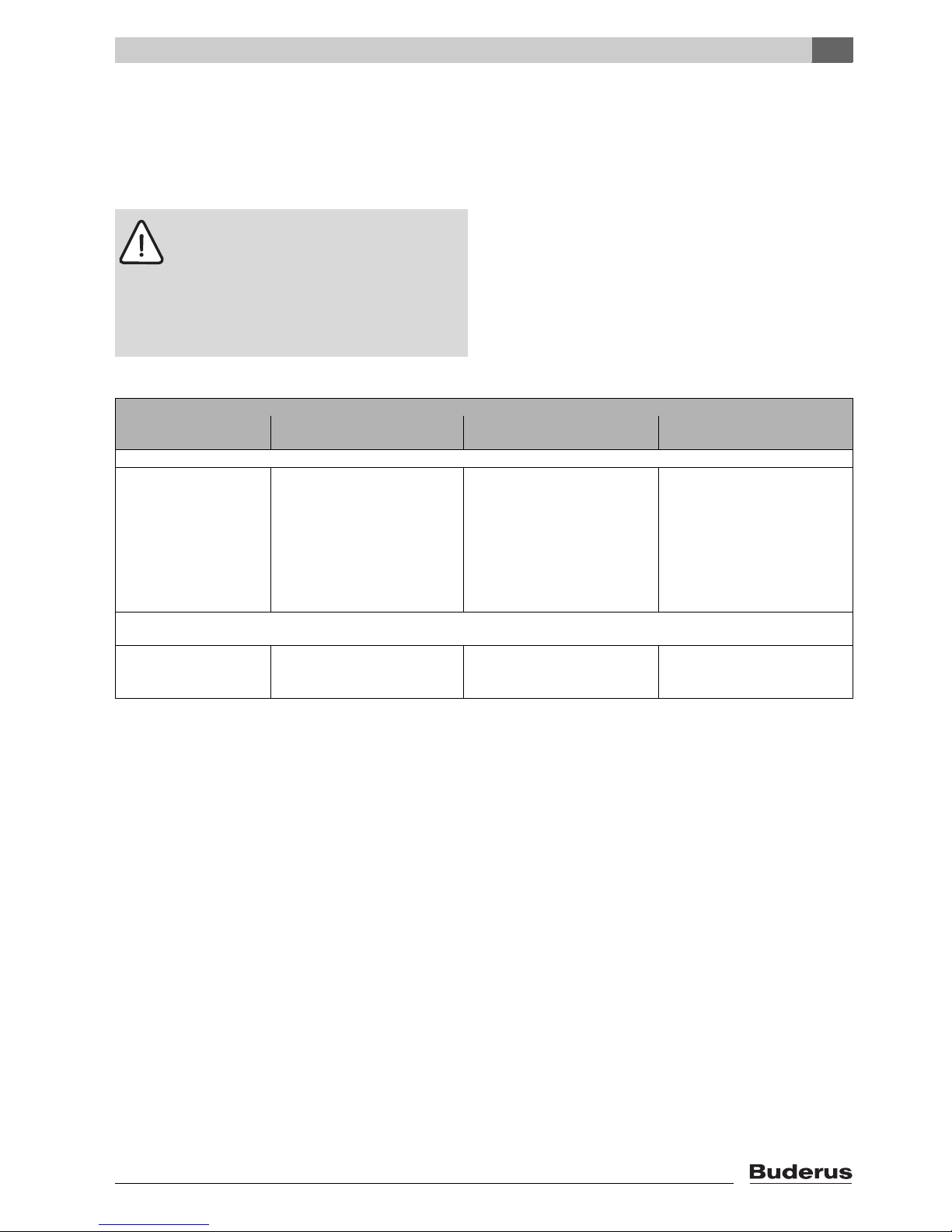

2.8.2 Conditions for the boiler room and the environment

2.8.3 Combustion air supply conditions

If the burner is to be operated with sealed combustion by drawing its combustion air solely from the outdoors, follow

burner manufacturer's specification.

2.8.4 Conditions, Fuel

Operating conditions Notes – Requirement in greater detail

Temperature in the boiler room +40 to +104 °F

relative humidity max. 90 % No condensation or precipitation inside the boiler room

Dust/airborne particles − Excessive dust inside the boiler room must be avoided when the boiler is operat-

ing, e. g.:

– Dust from building work

Combustion air supplied from outside must not be excessively loaded with dust

or airborne particles; if necessary, air filters should be fitted in case:

– Air supply contaminated with dust from dirt roads and paths.

– Air supply contaminated with dust from production and processing facilities, e. g. quar-

ries, mines, etc.

– Airborne particles from thistles and similar

Halogenated-hydrocarbon compounds

− The combustion air must be free from halogenated-hydrocarbon compounds.

– Identify the source of halogen-hydrocarbon compounds and seal it off. Where this is

impossible, route combustion air from areas that are not contaminated by halogen-

hydrocarbon compounds.

Fans that extract air from the

boiler room.

− During burner operation, no mechanical air handling equipment may be operated that could

extract combustion air from the boiler room, e.g.:

–Exhaust hood

– Tumble dryer

– Ventilation equipment

Small animals − Prevent small animals from entering the boiler room, particularly through the air inlet vents –

by fitting them with screens.

Fire safety − Maintain clearances between the boiler and flammable materials in accordance with local

regulations. A minimum clearance of 16" is required. Never store flammable materials or

liquids in the vicinity of the boiler.

Flooding − In case of an acute risk of flooding, disconnect the boiler in time from its fuel and power

supply before water enters the room. Any components or control equipment, which came

in contact with flood water, must be replaced before re-commissioning.

Tab. 5 Boiler room and ambient conditions

Operating conditions

Boiler output (in case of

multi-boiler systems = total output)

Ventilation air cross-section in square inches

(unrestricted aperture)

Air intake flow cross-section for

combustion air drawn from outside (divided between max. 2

apertures)

< 170,000 Btu/hr At least 23.25 square inches

Tab. 6 Observe national regulations for boilers which draw their air supply from the boiler room.

Operating conditions Notes – Requirement in greater detail

Permissible fuels for boilers without integral burners

− This boiler can be operated with #2 Fuel Oil ASTM D396-05 Type 2. Select a burner that

is suitable for this fuel typ.

Contamination − Free of contaminants (for example dust, mist, humidity), i. e. a constant operation will not

lead to accumulation of deposits, in valves, strainers and filters and could lead to service

calls.

Tab. 7 Fuels

Page 11

2

Product description

Logano G115 WS US/CA - Technical specifications are subject to change without prior notice.

11

2.8.5 Conditions power supply

2.8.6 Conditions for hydraulic system and water quality

Operating conditions Notes – Requirement in greater detail

Power supply voltage 120 V

AC nominal

Observe the voltage range of the burner and controls used. The outer casing/boiler must

be grounded for safety reasons and in order to function correctly.

Circuit breaker 10 A

Frequency 60 Hz

Enclosure rating − IP 40 (protected against contact by entry of foreign objects > 0.04 inches Ø

(> 1 mm Ø ), no water proofing)

Tab. 8 Power supply

Operating conditions Notes – Requirement in greater detail

Operating pressure (above

atmospheric)

15–58psi Maximum 30 psi with the supplied safety valve.

Permissible site test pressure 45 – 75 psi

Safety temperature limitation by

TR temperature control

122–194°F

Safety temperature limitation by

manual reset high limit (STB)

212 – 248 °F On some controls adjustable on site from 212 to 248 °F.

Water quality − The heating system may only be filled and topped up with water of domestic water quality.

We recommend a pH value of 8.2 – 9.5.

Tab. 9 System configuration and water quality

Page 12

3

Moving the boiler

Logano G115 WS US/CA - Technical specifications are subject to change without prior notice.

12

3 Moving the boiler

This chapter details how to move the boiler safely.

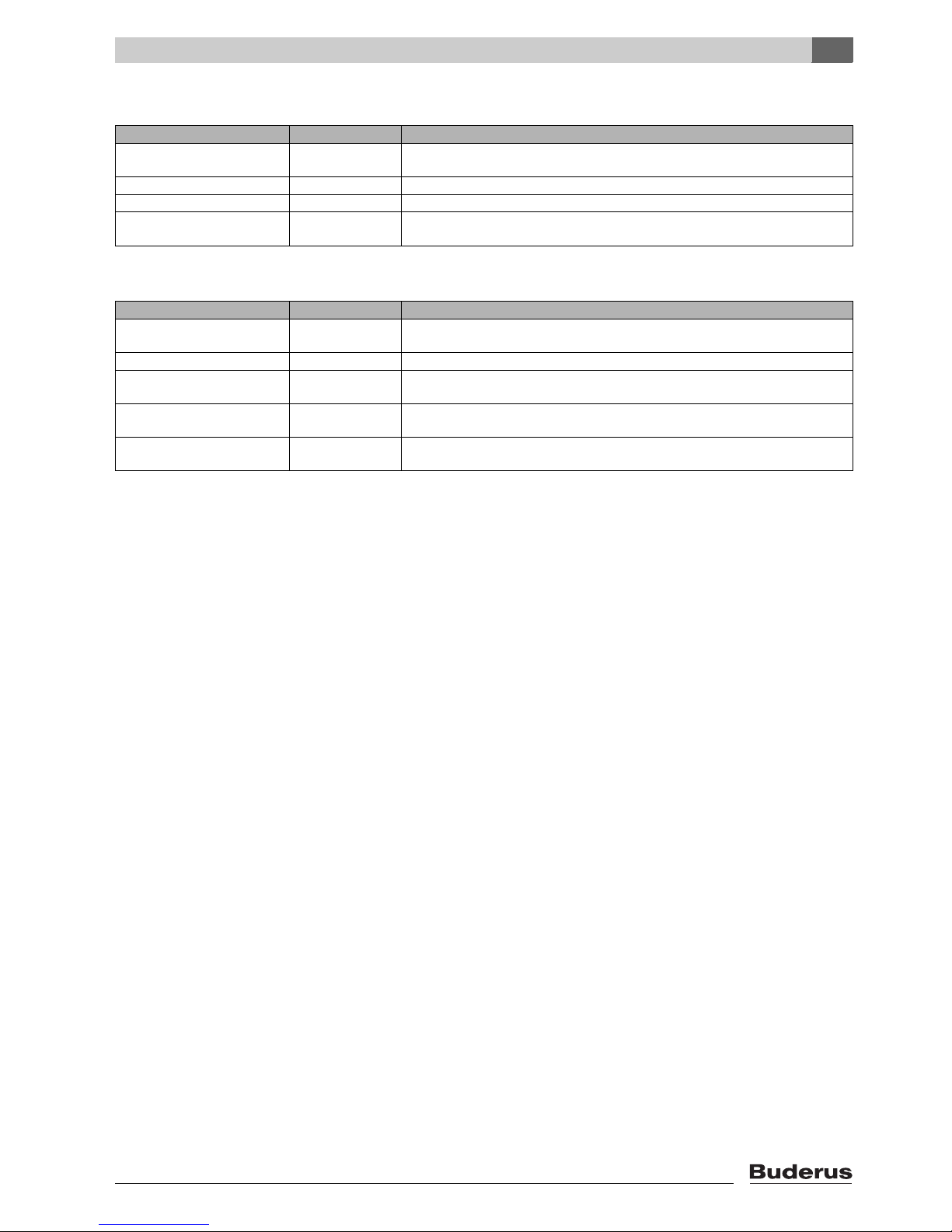

3.1 Reducing boiler weight for transportation purposes

If required, you can reduce the weight of the boiler by

removing the burner hood and door.

V Unscrew the burner door-panel screws.

V Lift burner door panel slightly and draw forward to

remove.

Fig. 3 Removing burner door panel

V Unscrew two hex-head bolts at the sides.

V Open burner door.

V Lift the burner door off its hinges.

Fig. 4 Removing the burner door

Caution: Risk of system damage from impact.

Fragile components could be damaged.

V Observe the transport instructions on the

packaging.

Protect boiler connections from damage and

dirt if the boiler is not installed immediately.

Dispose of packaging in an environmentally

responsible manner.

6 720 615 225-02.1RS

Prevent the burner door from falling over and

damaging the burner and blast tube.

7 747 019 141-04.1RS

Page 13

3

Moving the boiler

Logano G115 WS US/CA - Technical specifications are subject to change without prior notice.

13

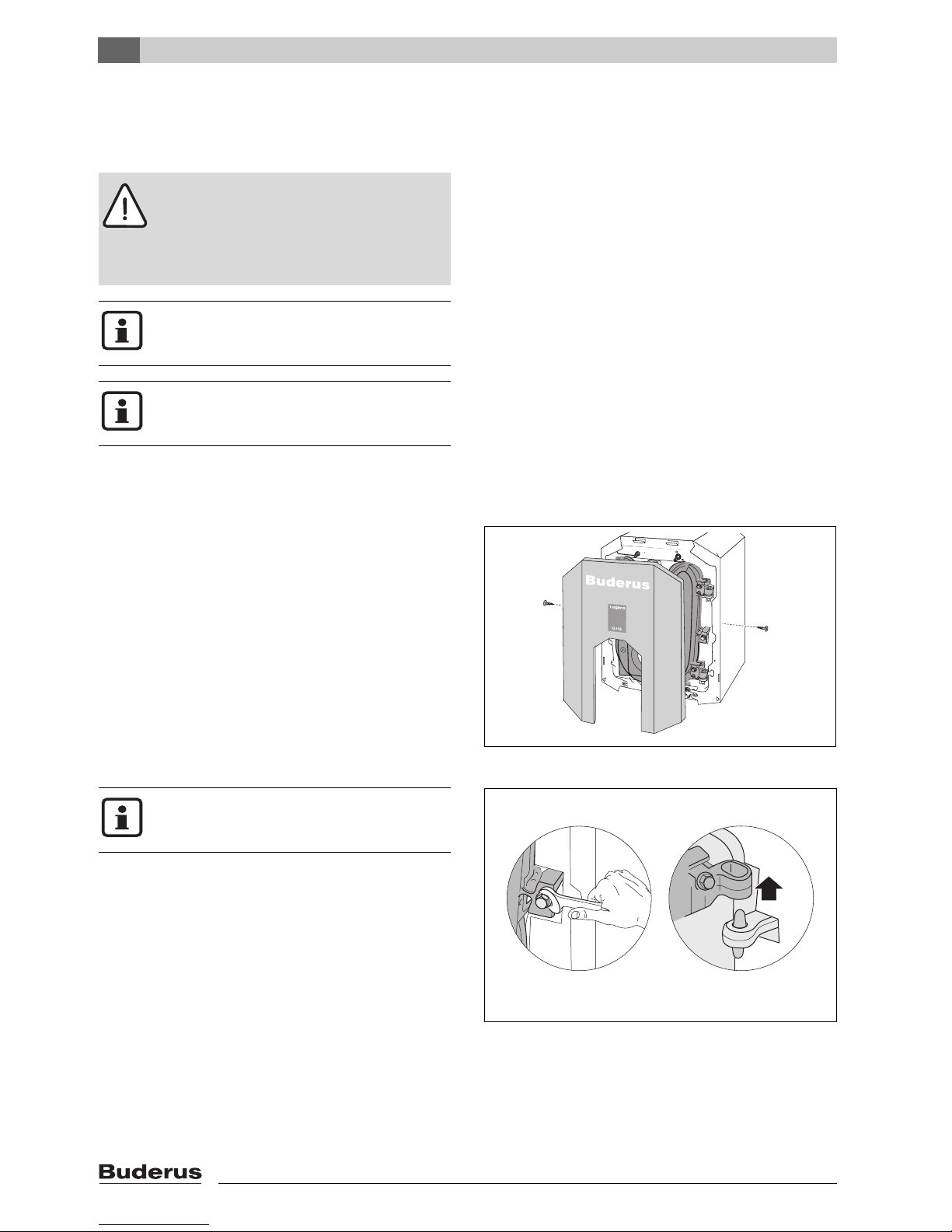

3.2 Lifting and carrying the boiler

The boiler can be held and carried at the grip positions

shown.

V Undo the transit screws.

Fig. 5 Lifting and carrying the boiler

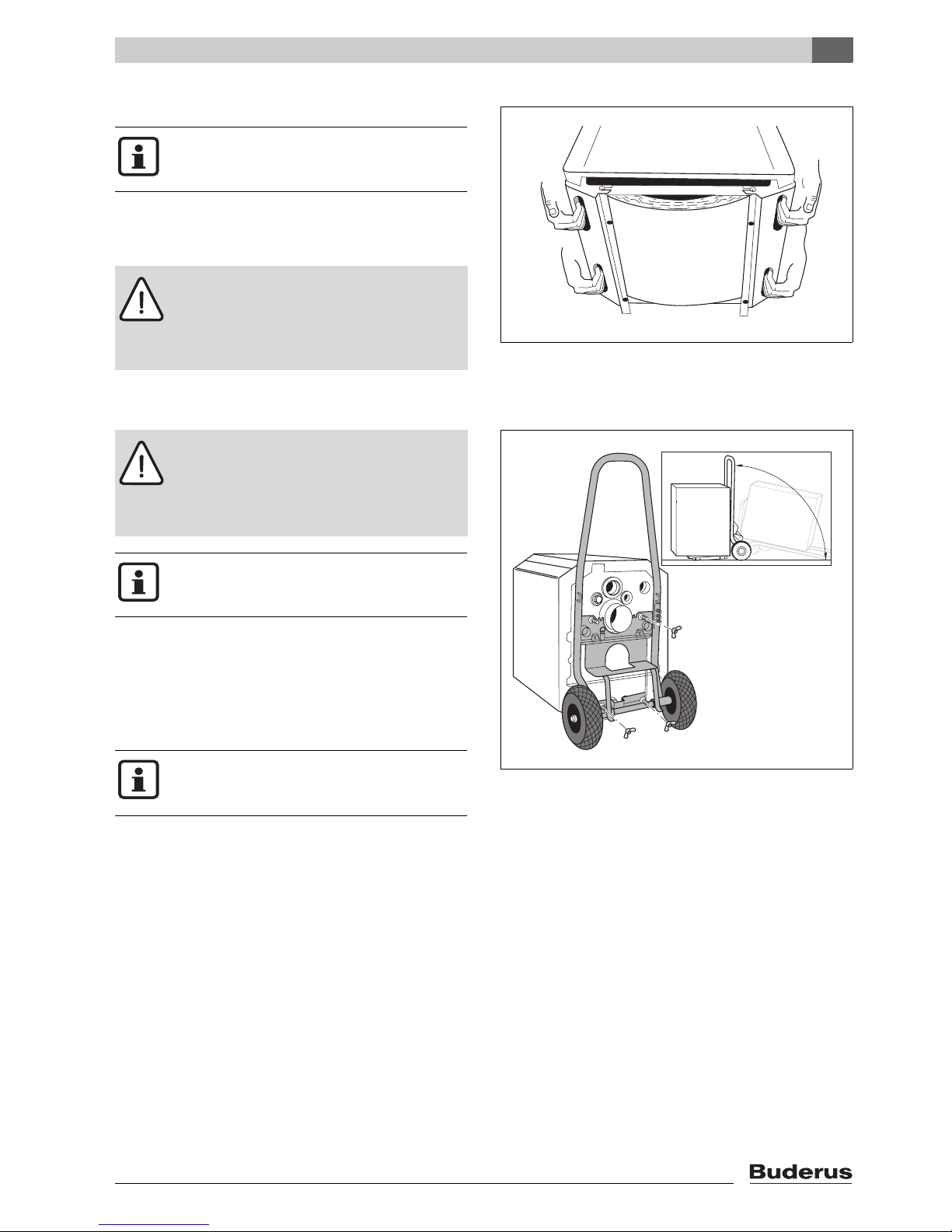

3.3 Using transportation aids to transport the boiler

Moving the boiler with hand truck

V Place the hand truck (e.g. boiler trolley or sack truck) at

the back of the boiler.

V Secure boiler to hand truck using the boiler bolts or

strapping.

V Move the boiler to the installation location.

Fig. 6 Moving the boiler with a boiler hand truck

The boiler is secured to the pallet by 2

screws for transportation purposes.

Caution: Risk of injury from carrying heavy

loads.

V Always lift and move the equipment with

the assistance of another person using the

handle positions shown.

7 747 019 141-05.1RS

Caution: Risk of injury if load is inadequately

secured during transportation.

V Use suitable means of transportation, e.g.

the Buderus boiler hand truck with strap.

V Secure the load against falling.

You can order the boiler hand truck from your

Buderus distributor.

The boiler trolley can also be used to facilitate

work underneath the boiler, e.g. fitting the adjustable feet (Æ Chapter 4.3, page 16).

7 747 019 141-06.1RS

Page 14

4

Installing the boiler

Logano G115 WS US/CA - Technical specifications are subject to change without prior notice.

14

4 Installing the boiler

This chapter describes how to install and place the boiler

in the boiler room.

4.1 Wall clearances

Position the boiler with the recommended wall clearances. Reducing the minimum clearances makes the

boiler more difficult to access during installation, maintenance and cleaning.

The boiler base or foundation must be perfectly flat and

level.

The burner door is factory-fitted with the hinges on the

right. The burner door can be converted to open to the left

(Chapter 4.2, page 15).

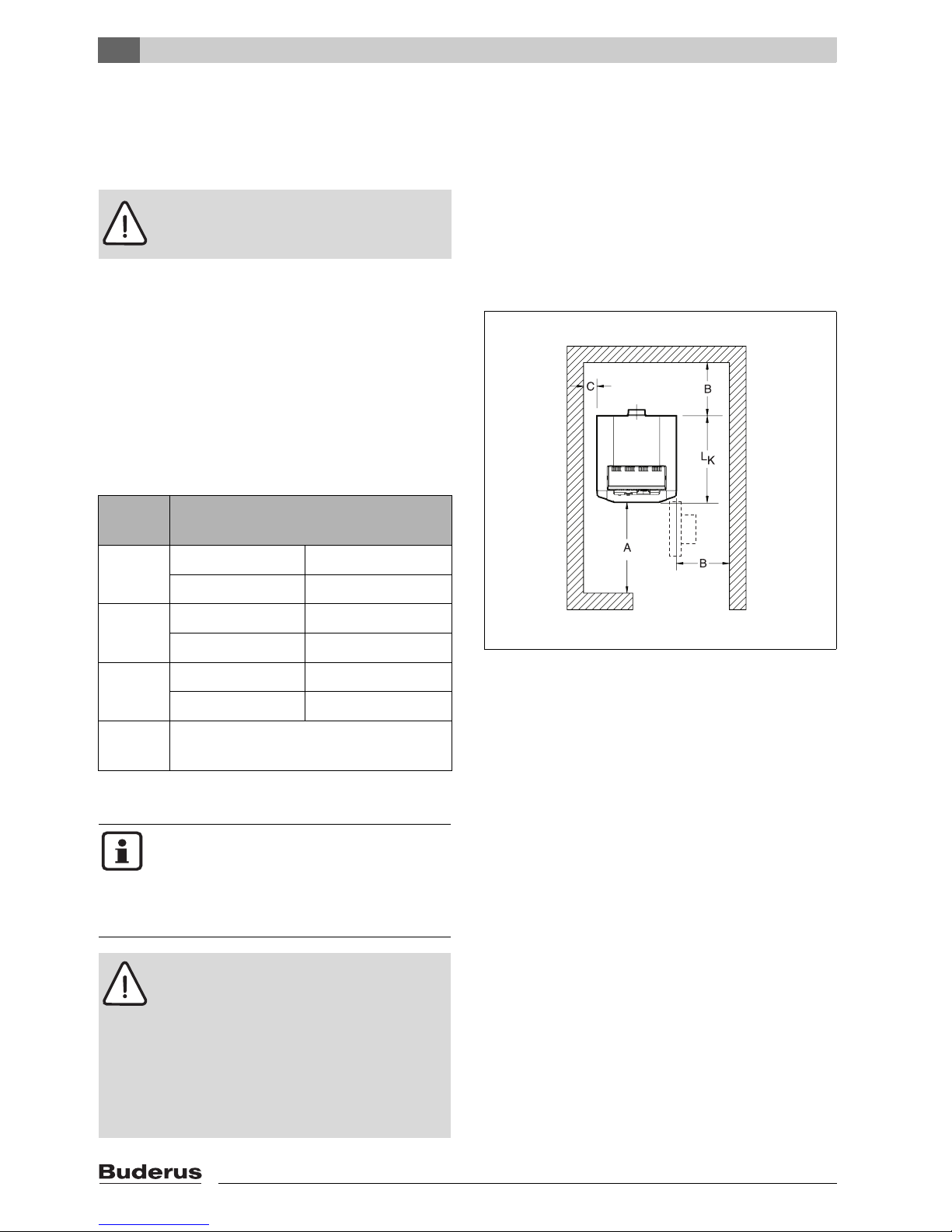

Fig. 7 Boiler room clearances (boiler positioned on the

l.h. or r.h. side)

Caution:

Risk of system damage from freezing.

V Install the heating system in a frost-free

room.

Dimension

Wall clearance

A Recommended 51-1/8"

minimum 39-3/8"

B Recommended 27-½"

minimum 15-¾"

C Recommended 15-¾"

minimum 3-7/8"

L

K

Æ Chapter 2.7.1 "Logano G115 WS

dimensions", page 8

Tab. 10 Recommended and minimum wall clearances

(dimensions in inches).

7 747 019 141-07.1RS

The boilers are designed for a side clearance

of 6".

Where applicable, allow extra wall clearances for additional components such as DHW

tank, pipe connections, flue gas silencer or

other flue components, etc.

Caution: Risk of fire from flammable materials or liquids.

V Clearances less than 6" must comply with

local and statutory codes.

V Make sure that there is a sufficient clear-

ance between combustible materials and

the chimney connection as specified by

NFPA 31 (distance of 18 ").

V The floor must comply with the require-

ments of NFPA 31.

Page 15

4

Installing the boiler

Logano G115 WS US/CA - Technical specifications are subject to change without prior notice.

15

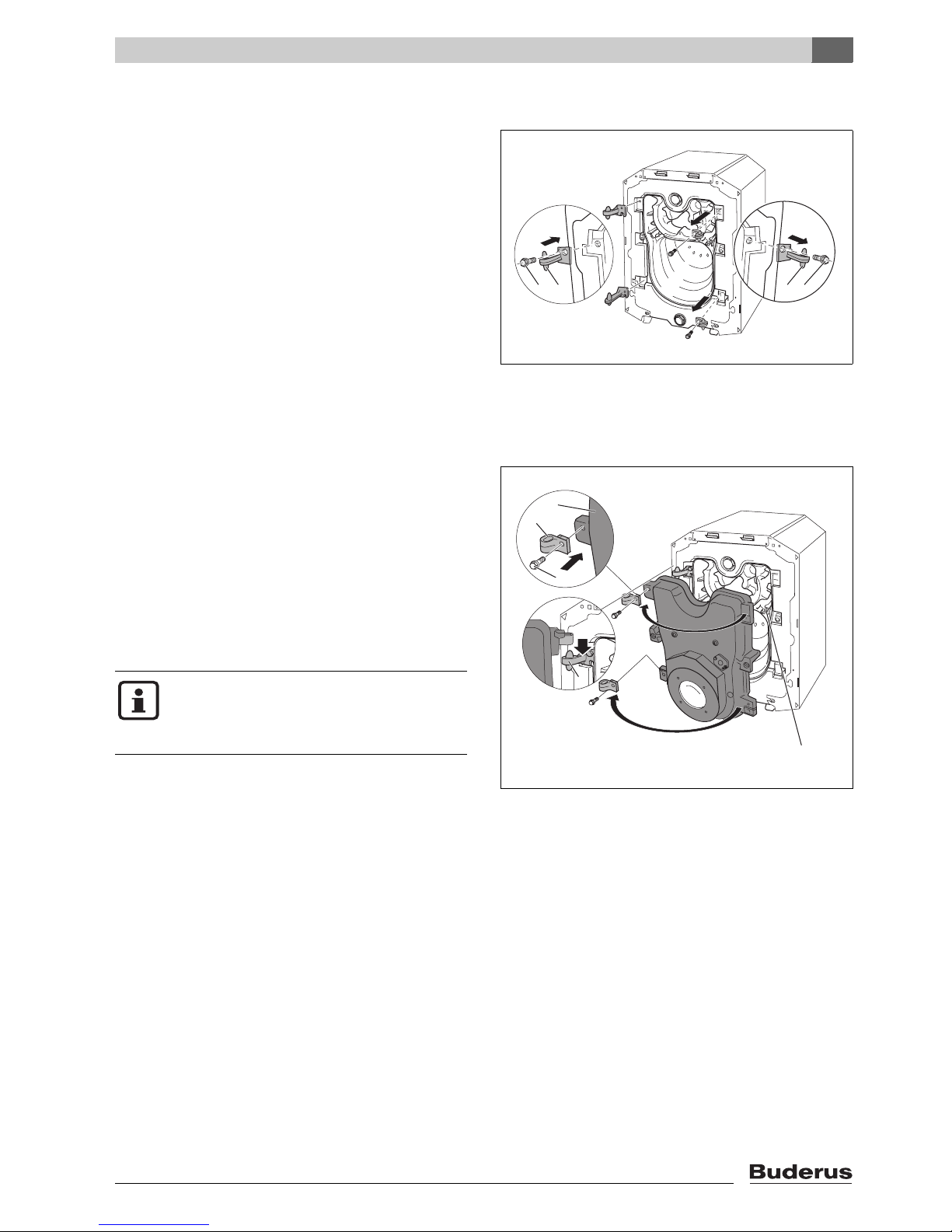

4.2 Reversing boiler door

The burner door is factory-fitted with the hinges on the

right – the burner door opens to the right.You can change

the burner door hinges over to the left-hand side if desired

to suit the installation site.

Remove the burner hood/burner door panel first

(Æ Chapter 3.1, page 12).

V Removing the burner door (Æ Chapter 3.1, page 12).

V Unscrew the hinge bolts and remove the hinges.

V Mount the hinges on the left-hand side of the boiler

using the hinge bolts.

Fig. 8 Reversing the burner door (boiler heat

exchanger attachments)

1 Hinge bolts

2 Hinges

V First remove the hinge lobe bolts and then the hinge

lobes. Mount the hinge barrels on the left-hand side of

the boiler using the hinge-barrel bolts.

V Hook the burner door with the hinge lobes onto the

hinges.

V Check that the heat exchanger baffles are placed hori-

zontally (Æ Chapter 6.3, page 29).

V Close the burner door and secure with the two hexa-

gon-head bolts.Tighten the hexagon-head bolts evenly

(approx. 90 Lbs/inch) so that the burner door seals

properly.

Fig. 9 Reversing the burner door (door attachments)

1 Hinge-barrel bolts

2 Hinge lobes

3 Burner door

4 Hinges

5 Heat exchanger baffle plates

7 747 019 141-08.1RS

12 21

If the burner door hinges have been changed

over to the left-hand side, the burner cable

must be disconnected from the burner before

opening the burner door.

7 747 019 141-09.1RS

1

4

5

2

3

Page 16

4

Installing the boiler

Logano G115 WS US/CA - Technical specifications are subject to change without prior notice.

16

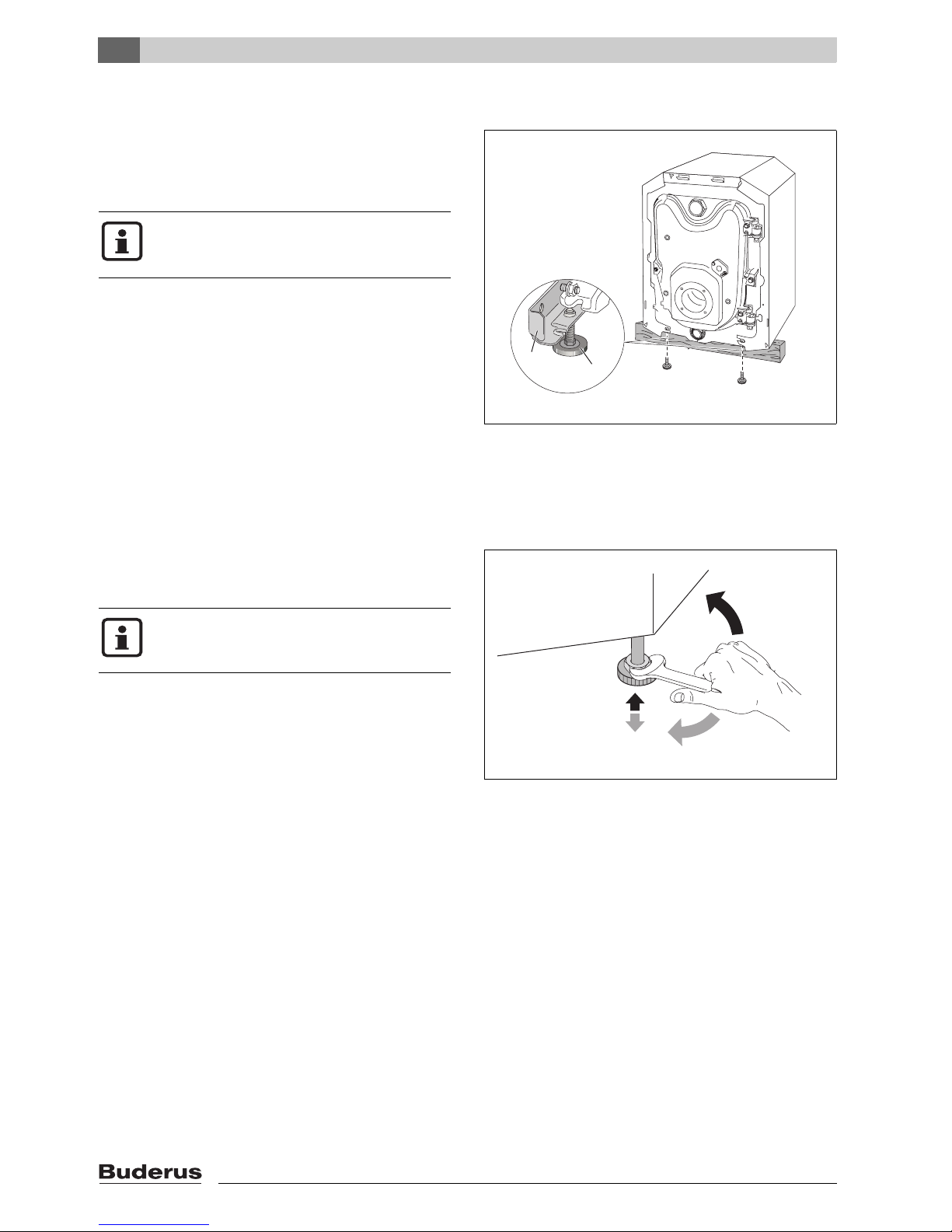

4.3 Mounting the adjustable feet (included with B-kit)

Level the boiler with the adjustable feet to prevent air

pockets forming inside the boiler.

Requirement: the burner hood/burner door panel must

have been removed first (Æ Chapter 3.1, page 12).

V Tilt the boiler with the aid of a hand truck or trolley

(Æ Chapter 3.3, page 13) or place a wooden batten

underneath it.

V Screw in adjustable feet ¼" – 3/8".

V Gently set the boiler down.

Fig. 10 Fitting adjustable feet

1 Angle bracket

2 Adjustable feet

4.4 Positioning and leveling the boiler

V Position the boiler in its final location.

V Level the boiler horizontally by turning the adjustable

feet and using a level.

Fig. 11 Leveling the boiler horizontally

If the boiler is mounted on top of a horizontal

hot water tank, the adjustable feet are not

needed.

7 747 019 141-10.1RS

1

2

Protect boiler connections from damage and

dirt if the boiler is not installed immediately.

7 747 019 141-11.1RS

Page 17

5

Installing the boiler

Logano G115 WS US/CA - Technical specifications are subject to change without prior notice.

17

5 Installing the boiler

This chapter details how to install your boiler correctly.

The individual steps involved are:

– Connecting the flue

– Connecting the water pipes

– Making the electrical connections

– Fitting the burner

– Connecting the fuel supply

5.1 Flue pipe installation

5.1.1 Chimney venting

Connect boiler to vertical chimney with a 5" vent pipe.

Use only venting systems that comply with local codes

and regulations.

If local codes are not existent, refer the the following regulations:

– NFPA 31, Installation of Oil-Burning Equipment,

– NFPA 211, Standard for Chimneys, Fire Places and

Solid Fuel Burning Appliances,

– In Canada refer to CSA B139, Installation Code for Oil-

Burning Equipment,

– NFPA 211 requires chimney to be lined before con-

necting boiler.

Inspecting and cleaning existing flue

Before installing the new boiler, check and clean the old

flue system.

V Remove blockages and dirt from the chimney.

V Clean chimney.

V Repair or replace faulty sections.

V If necessary, repair chimney with mortar and joints.

Down drafts

To prevent down drafts extend chimney at

least 3 feet above the roof opening and at

least 2 feet above any part of the roof within

a radius of 10 feet.

Page 18

5

Installing the boiler

Logano G115 WS US/CA - Technical specifications are subject to change without prior notice.

18

Minimum clearances to combustible material

Minimum size of chimney

The minimum recommended chimney size is 8" x 8"

(6 ¾" x 6 ¾" inside liner) or 6" diameter with a minimum

height of 15 feet. Use a 5" flue pipe for connection to an

existing chimney.

Installing the flue pipe

V Insert flue pipe 5" onto the breach and secure with

3 screws.

V Install flue connections between boiler and chimney to

slope up at least ¼" per foot to the chimney.

V Connect the flue pipe to the chimney above the bottom

of the chimney to prevent blockages.

V Install cleaning and service hatches.

After starting the burner, set breeching draft to -0.01 to

-0.02 inches WC using a draft gauge. The overfire pressure can be positive. If necessary, install a barometric

damper in the flue system to maintain the underpressure

in the system or to meet code requirements. Always install

the draft controller in vertical position. Use a draft gauge

when making adjustments.

Fig. 12 Installing the flue pipe

1 Flue pipe

2 Boiler flue socket

Flue pipe Type Minimum clearance

Double-wall L 6"

Single-wall L 18"

Tab. 11 Minimum clearances to combustible objects for

flue systems

Danger: Risk of death from escaping flue

gases.

If the resistance to flue gas flow is too great

and/or the flue pipe diameter is smaller than

the recommended size and/or the flue pipe is

too short:

V Seal all vent pipe joints.

V Install a CO alarm. Positive pressure com-

bustion ensures that the flue gas can exit

the flue system.

Avoid long horizontal flue pipe runs and keep

the number of elbows to a minimum.

Page 19

5

Installing the boiler

Logano G115 WS US/CA - Technical specifications are subject to change without prior notice.

19

5.2 Fitting the water connections

5.2.1 Fitting the B-kit

The safety relief valve and the pressure/temperature

gauge are mounted on the supply manifold (included in BKit) on the VK boiler supply connection as follows:

V Fit and seal unmarked end of double nipple into con-

nection VK on the boiler.

V Converter is paint-marked pink and stamped with the

designation NPT on the end with the 1¼" NPT thread.

Fig. 13 Checking thread length on double nipple

V Seal 90° 1¼" NPT street elbow on double nipple.

V Fit and seal manifold to 90° elbow. The manifold can

face in different directions (Æ Fig. 14).

V Seal pressure/temperature gauge to supply manifold.

Fig. 14 Installing B-Kit

1 90° 1¼" NPT street elbow

2 Double nipple

3 Supply manifold

4 Pressure/temperature gauge

5 Pressure relief valve

6 90° ¾" NPT elbow

Caution: Risk of system damage from leak-

ing connections.

V Support the pipes to the boiler to prevent

them from being under stress.

Do not fit the safety valve until the leak test

(Æ Chapter 5.3, page 21) has been completed.

The relief valve must be installed in a vertical

position.

We recommend installing a dirt filter (optional) in the boiler return connection to reduce

build-up of debris on the water side.

Page 20

5

Installing the boiler

Logano G115 WS US/CA - Technical specifications are subject to change without prior notice.

20

5.2.2 Installation of boiler drain (included in B-Kit)

V Seal boiler drain to connection EL.

Fig. 15 Installation of boiler drain

RK Return

EL Drain

5.2.3 Installing system components

See the installation diagram for installation of the heating

system components.

For more installation examples refer to Æ Chapter 10,

page 43.

Fig. 16 Installation diagram

1 Pressure relief valve

2 Pressure/temperature gauge

3 Ball or stop valve

4 Air eliminator (in main supply)

5 System pump

6 Flow check valve

7 Expansion tank

8 Automatic feed valve

9 Flow check valve

10 Purge station

11 Water feed

VK Boiler supply

EL Drain

RK Return

Install a fill connection in the supply piping to

the boiler.

7 747 019 141-15.1RS

RK

EL

7 747 019 141-16.1RS

1

2

33 563

3

7

3

98

VK

RK

11

EL

4

10

Page 21

5

Installing the boiler

Logano G115 WS US/CA - Technical specifications are subject to change without prior notice.

21

5.3 Filling the heating system and checking for leaks

The boiler is tested for leaks at the factory. Before putting

the heating system into operation, it must be checked to

ensure that no leaks will occur during operation.

Carry out the leak test at 1.5 times the standard operating

pressure and in accordance with the codes.

V Seal pressure relief valve connection (Æ Fig. 14

"Installing B-Kit", page 19) and all other open connection with blind plugs.

V Isolate the expansion tank from the system by closing

the valve.

V Open the mixing and shut-off valves on the heating

water (primary) side.

V Slowly fill the boiler with tap water.

Fig. 17 Pressure/temperature gauge

Caution: Risk of system damage from excess pressure when testing for leaks.

Pressure, control and safety equipment may

be damaged by excessive pressure.

V When you carry out a leakage test, make

sure that no pressure, control or safety

equipment that cannot be isolated from

the boiler water chamber is fitted.

Caution: Risk of damage to system due to

temperature stresses.

If you fill the heating system when it is hot, the

resulting temperature stresses can cause

stress cracks. The boiler will then leak.

V Only fill the heating system when cold (the

flow temperature should be no more than

100 °F).

V Pay attention to the water quality as spec-

ified in the operator's log, and record the

volume and quality of the water used to fill

the system.

Maximum

operating pressure

Maximum

on-site testing pressure

30 psi (with safety valve

supplied)

45 psi

58 psi (with 50 psi relief

valve)

75 psi

Tab. 12 Maximum testing pressure

7 747 019 141-17.1RS

Page 22

5

Installing the boiler

Logano G115 WS US/CA - Technical specifications are subject to change without prior notice.

22

V Open the cap of the automatic air vent by one full turn

to allow air to escape.

V Slowly fill the heating system. Observe the pressure

gauge whilst filling.

V Check the connections and pipework for leaks.

V Bleed the system via the radiator bleed valves if appli-

cable.

V Top with water if the pressure drops as a result of

bleeding the system.

V Installing pressure relief valve (Æ Fig. 14 "Installing B-

Kit", page 19)

Caution: Health risk from contaminated domestic water.

V Always observe the regulations and stand-

ards applicable in your jurisdiction for the

prevention of contamination of drinking

water (e.g. by water from heating systems).

Page 23

5

Installing the boiler

Logano G115 WS US/CA - Technical specifications are subject to change without prior notice.

23

5.4 Mounting the burner

Only burners that comply with the boiler specification can

be used with this boiler. (Æ Chapter 2.7, page 8).

V Screw studs included with the B-Kit to the burner door.

V Install burner with the correct nozzle and settings (air,

pump pressure, turbulator settings, flange position).

V Place the seal on the studs and secure the burner with

the included nuts.

V Follow the manufacturer’s direction for installation, fine

adjustment and regular maintenance procedures.

Fig. 18 Burner door mounting holes

5.5 Connecting the fuel supply

Make the fuel connection in accordance with all applicable local and national codes and regulations. We recommend fitting a fuel filter and de-aerator.

V Visually inspect the fuel pipe and clean or replace, if

necessary.

V Install a shut-off valve into the fuel supply pipe.

V Connect the fuel pipe free of stress to the boiler.

V Check the fuel line for leaks.

Caution: Risk of system damage from use of

incorrect fuel.

V Only use burners which meet the techni-

cal boiler requirements.

Approved burners with accessories (such as

aquastat and circulator) are also available as

a package from Buderus.

For details of the correct burner settings

Æ flue system documentation and

Æ burner documentation.

7 747 019 141-18.1RS

Page 24

5

Installing the boiler

Logano G115 WS US/CA - Technical specifications are subject to change without prior notice.

24

5.6 Installing aquastat

An aquastat controls the boiler supply temperature.

V Install aquastats in the sensor well as specified by the

installation manual.

For operating the boiler with aquastat Æ Chapter 6,

page 28.

Fig. 19 Aquastat installation

1 Immersion sleeve

5.7 Blocked vent switch (required in Canada)

For Canadian installations fit a blocked vent switch per

the vent switch manufacturer’s instructions and as close

as possible to the boiler breach.

See pages 50 - 52 for wiring diagrams.

5.8 Electrical connections

This section only applies to boilers using Buderus controls.

V Remove rear boiler jacket.

– Unscrew the fixing screws.

V Remove cover panel. Wiring from the control panel to

the burner is passed through the hole in the front boiler

top panel.

Fig. 20 Removing rear boiler cover and cover plate.

1

7 747 019 141-19.1RS

Danger: Risk of death from electric shock.

V Electrical work may only be carried out by

qualified technicians. Before opening any

electrical equipment, isolate it from the

power supply by turning off the emergency shut-off switch or disengaging the heating system circuit breaker, and prevent

from accidental reactivation. Follow the installation instructions.

Page 25

5

Installing the boiler

Logano G115 WS US/CA - Technical specifications are subject to change without prior notice.

25

5.8.1 Fitting the controls

V Position the tabs of the controls in the slots.

V Slide the controls forwards towards the burner door.

V Let the flexible hooks of the control panel click into the

openings by pushing the control panel down.

Fig. 21 Fitting the controls

1 Flexible catches

2 Locating tabs

3 Slots

4 Locating holes

V Remove the controls cover.

– Unscrew the cover screws.

V Secure the controls with self-tapping screws.

Fig. 22 Cover, removing

1 Cover screws

2 Self-tapping screws

1

2

3

7 747 019 141-21.1RS

1

2

7 747 019 141-22.1RS

Page 26

5

Installing the boiler

Logano G115 WS US/CA - Technical specifications are subject to change without prior notice.

26

5.8.2 Fitting temperature sensor assembly and burner cable

V Route capillary tubes and sensor wiring through the

cable opening of the front boiler jacket and connect to

test port.

V Roll up surplus capillary tubes and sensor lead and lay

them on the thermal insulation.

V Route the burner cable through the cable entry in the

front boiler cover to the control panel.

V Connect the burner cable to the control in accordance

with the terminal markings.

Fig. 23 Routing and connecting cables

1 Cable entry in the front boiler cover

2 Capillary tube and sensor cable

3 Immersion well (sensing point)

4 Burner cable

V Insert the temperature sensor assembly and balancing

spring in the immersion well and insert completely. The

plastic spiral is then pushed back automatically.

V Push the sensor retaining clip (supplied with the con-

trols) onto the top of the immersion well from the side.

Fig. 24 Fitting the temperature sensor assembly

1 Immersion well (sensing point)

2 Plastic coil

3 Balancing spring

4 Sensor retaining clip

Caution: Risk of system damage due to se-

vere kinking or sharp burrs on capillary tubes.

Capillary tubes can get damaged from se-

vere kinking or sharp burrs.

V Route capillary tubes carefully, avoiding

bending them excessively.

The boiler comes factory equipped with the

sensor immersion well for the Aquastat.

V If a Buderus Logamatic controls is being

installed, the factory-fitted immersion well

must be replaced by the Logamatic well

supplied with the controls.

Ensure good contact between the sensor

surfaces and the sensor well to achieve accurate readings. Use the balancing spring.

1

1

4

2

3

7 747 019 141-24.1RS

Page 27

5

Installing the boiler

Logano G115 WS US/CA - Technical specifications are subject to change without prior notice.

27

5.8.3 Connecting the power supply and additional components

Establish a permanent connection to the mains power

supply in accordance with the locally applicable regulations.

V Route all cables through the cable entries to the control

panel and connect in accordance with the wiring diagram.

5.8.4 Fitting cable ties

Secure all cable runs with cable ties (included with the

control):

V Insert the cable ties together with the cable from the

top into the slots in the frame (step 1).

V Slide the cable ties downward (step 2).

V Push against the ties (step 3).

V Flip the toggle up (step 4).

Fig. 25 Securing cables with cable ties

5.9 Fitting outer casing panels

V Position and secure the control device cover.

V Fit the rear boiler cover.

V Secure by reinstalling cover screws and jacket panel

screws.

Fig. 26 Fitting the rear boiler cover

1 Controls cover

2 Rear boiler cover

Warning: Fire hazard from hot boiler compo-

nents.

Hot boiler components may damage electri-

cal cables.

V Ensure that all wiring is routed in the ducts

provided or on the boiler insulation.

7 747 019 141-25.1RS

Page 28

6

Commissioning the heating system

Logano G115 WS US/CA - Technical specifications are subject to change without prior notice.

28

6 Commissioning the heating system

This chapter describes the initial start-up procedure

regardless of the installed control device.

V Complete the start-up protocol during this process

(Æ Chapter 6.10, page 33).

Further information on boiler room layout and clearances,

combustion air requirements and venting systems and

boiler operational requirements can be found in

Æ Chapter 2.8, page 9.

6.1 Bringing the system up to operating pressure

Bring the system up to the normal operating pressure

before commissioning.

V Top up the heating water or drain via the boiler drain

valve until the required operating pressure has been

reached: minimum 15 psi, maximum 30 psi pressure.

V Bleed air from the heating system while filling.

6.2 Checking the safety valve

V Make sure that no persons are in the discharge area of

the pressure relief valve.

V Raise the lever on the pressure relief valve.

The pressure relief valve must open and release pressure.

If the pressure relief valve does not discharge, it must be

replaced, because system components can be damaged

by excessive pressure.

Fig. 27 Pressure/temperature gauge for showing oper-

ating pressure and supply temperature

Caution: Risk of boiler damage from excessive dust and airborne particle levels.

V Do not operate the boiler when there is a

lot of dust in the boiler room, e.g. due to

construction work.

V Install an air filter if the combustion air sup-

ply is very dusty (e.g. due to dirt roads and

paths or dust-generating working environments such as quarries, mines etc.) or

contains airborne seeds from composite

plants.

Caution: Risk of damage to system due to

material stresses caused by temperature differentials.

V Only fill the heating system when cold (the

flow temperature should be no more than

100 °F).

7 747 019 141-17.1RS

Page 29

6

Commissioning the heating system

Logano G115 WS US/CA - Technical specifications are subject to change without prior notice.

29

6.3 Checking position of heat exchanger baffles

Prior to commissioning, check that the heat exchanger

baffles are in a horizontal position:

V Open burner door by removing the two hexagon-head

bolts at the sides.

V Slightly withdraw the flue gas baffles from the heat

exchanger.

V Adjust the heat exchanger baffles to a horizontal posi-

tion and push them back into the heat exchanger.

V Close burner door with the two hexagon bolts (approx.

90 inch-lbs). Tighten the hexagon bolts evenly to properly seal the burner door.

Fig. 28 Opening the burner door

1 Flue gas baffles in the heat exchanger

6.4 Preparing the heating system for operation

V Open the fuel supply at the main shut-off valve.

V Switch on the heating system emergency shut-off

switch and/or the appropriate circuit-breaker.

6.5 Starting up the control and the burner

For further start-up steps, follow the burner start-up

sequence.To do so, it is essential that you consult the

burner Æ documentation.

Use the on/off switch on the controls to switch the heating system on. The burner starts up if the system is calling

for heat or if you set the controls to manual mode.

Æ service instructions for the controls.

V Select "Manual" mode .

V Set the boiler water temperature control to the desired

temperature.

V Switch the on/off switch on (position "I").

Fig. 29 Switching on the controller

(e. g. Logamatic 2000)

1 Boiler water thermostat

2 On/off switch

1

7 747 019 141-27.1RS

1

2

7 747 019 141-28.1RS

Page 30

6

Commissioning the heating system

Logano G115 WS US/CA - Technical specifications are subject to change without prior notice.

30

6.6 Notes on commissioning the burner

Allow burner to operate for 15 to 20 minutes before performing a combustion test. Earlier combustion tests can

lead to incorrect readings as a result of burning off the

sealing rope. We recommend rechecking the burner after

a few weeks of operation.

Required instruments:

–CO

2

measuring equipment

– Draft measuring equipment

– Oil pressure gauge

– Stack thermometer

–Smoke tester

V Check the combustion chamber pressure at the test

port.

V Check the breeching draft at a test port drilled in the

vent connector (chimney vent models only).

Fig. 30 Pressure test port on burner door

1 Pressure test port

6.7 Raising flue gas temperature

For the set flue gas temperature for the boiler see the

technical data (Æ Chapter 2.7, page 8).

You may raise the flue gas temperature if you discover

during tests that the flue gas temperature is too low for

the type of chimney used (risk of condensation) by one or

several of the following measures:

Incorrect burner adjustment can cause contamination of the boiler (e.g. soot), leading to

low efficiency, high emissions, and a greater

risk of service calls.

V Always check combustion with the follow-

ing instruments.

V Never adjust burner visually.

1

7 747 019 141-29.1RS

Caution: Risk of burning by touching hot

boiler parts.

V Wear appropriate protective gloves or use

pliers.

Page 31

6

Commissioning the heating system

Logano G115 WS US/CA - Technical specifications are subject to change without prior notice.

31

V Adjusting the position of heat exchanger baffles

-orV Removing heat exchanger baffles

-orV Removing the heat exchanger barrier plate

6.7.1 Adjusting the position of heat exchanger baffles

Only adjust or remove heat the exchanger baffles in pairs.

V Open burner door by removing the two hexagon-head

bolts at the sides.

V Adjusting the position of heat exchanger baffles.

V Slightly withdraw the flue gas baffles from the heat

exchanger.

V Turn the heat exchanger baffles to a slanting position

and push them back into the heat exchanger.

V Close burner door with the two hexagon bolts (approx.

90 inch-lbs). Tighten the hexagon bolts evenly to properly seal the burner door.

V Re-check the flue gas temperature.

Fig. 31 Adjusting the position of heat exchanger baffles

6.7.2 Removing heat exchanger baffles

You can remove the baffle plates in pairs to raise the flue

gas temperature.

V Open burner door by removing the two hexagon-head

bolts at the sides.

V Remove the baffle plates towards the front.

V Close burner door with the two hexagon bolts (approx.

90 inch-lbs) Tighten the hexagon bolts evenly to properly seal the burner door.

V Re-check the flue gas temperature.

Fig. 32 Removing heat exchanger baffles

7 747 019 141-30.1RS

7 747 019 141-31.1RS

Page 32

6

Commissioning the heating system

Logano G115 WS US/CA - Technical specifications are subject to change without prior notice.

32

6.7.3 Removing the heat exchanger barrier plate

You can remove the blocking plate to further raise the flue

gas temperature if the flue gas temperature is still too low

after removing of the baffles.

V Open burner door by removing the two hexagon-head

bolts at the sides.

V Remove diverter plate by loosening bolt.

V Re-check the flue gas temperature.

Fig. 33 Removing the heat exchanger barrier plate

6.8 Manual reset high limit (STB)

The manual reset high limit interrupts the power supply if

the maximum permissible flow temperature is exceeded.

To enable a boiler reset and re-starting, the fault must be

removed and the system temperature must have fallen

below the limit.

V Check the function of the manual reset high limit

(Æ controls maintenance instructions).

6.9 Installing the burner door jacket

V Position the burner door panel on the hooks on the

boiler casing.

V Secure the burner door panel with the two screws at

the sides.

V The Logano G115 WS must be fitted with a burner that

has an operating range that matches the specifications

of the Logano G115 WS.

V Mount the selected burner to the hole circle in the

burner door.

V Connect burner cable to burner. (Æ Installation instruc-

tions of burner).

Fig. 34 Installing the burner door jacket

7 747 019 141-32.1RS

Danger: Risk of fatal injury from electric

shock.

V Only operate the boiler with the burner

hood/door panel fitted.

Caution: Risk of system damage from use

of incorrect fuel.

V Only use burners which meet the techni-

cal requirements of the Logano G115 WS

(Æ Chapter 2.7, page 8).

7 720 615 225-03.1RS

Page 33

6

Commissioning the heating system

Logano G115 WS US/CA - Technical specifications are subject to change without prior notice.

33

6.10 Commissioning log

V Initial and date the commissioning steps carried out.

Commissioning operations Page Readings taken Comments

1. Fill heating system and check for leaks 21

____________ psi

– Heating system pressure

2. Bringing the system up to operating pressure

V bleeding heating system

V Testing relief valve

V adjust the expansion tank pressure (Æ see the expansion tank

manufacturer’s documentation)

28

____________ psi

3. Checking combustion air supply and flue system

4. Checking position of heat exchanger baffles 29

5. Switching on the controls and burner (Æ controls' documentation)

29

6. Checking flue gas temperature and raising if required 30

____________ °F

7. Checking the manual reset high limit (STB) 32

8. Adjusting the controls settings to suit the customer's requirements (Æ controls' documentation)

9. Informing the end user and handing over technical documentation

Confirmation of properly completed commissioning Company stamp/signature/date

Inform the customer about the correct fuel

and correct operating pressure. Enter the details in the table (Æ boiler operating instructions).

Page 34

7

Shutting down the heating system

Logano G115 WS US/CA - Technical specifications are subject to change without prior notice.

34

7 Shutting down the heating system

7.1 Shutting down normally

V With Buderus controls: switch off the on/off switch on

the controls (position "0"). This switches off the boiler

and all its components (e.g. burner).

Fig. 35 Switching off the heating system

(Logamatic 2000)

1 On/off switch

V When using the aquastat: Shut off main heating system

by turning off the emergency shut-off switch (position

"OFF"). This switches off the boiler with all its components.

V Further shut-down procedure Æ refer to aquastat doc-

umentation.

Fig. 36 Heating system emergency shut-off switch

V Shut off fuel supply by closing main valve.

7.2 Shutting down the heating system in an emergency

7.2.1 What to do in an emergency

Explain to the customer what to do in an emergency, e.g.

a fire.

V Never put yourself at risk of fatal injury. Your own safety

must always take the highest priority.

V Disconnect the heating system from the electrical

power supply by means of the emergency shutoff

switch or the heating system circuit-breaker.

Caution: Risk of system damage from freezing.

If the heating system has been switched off,

it may freeze up in cold weather conditions.

V Leave the heating system switched on as

long as possible.

V Protect a disabled heating system from

freezing by draining the heating system

and hot water pipes at the lowest point.

1

7 747 019 141-34.1RS

7 747 019 141-35.1RS

Use the heating system emergency shut-off

switch located outside the boiler room or the

heating system circuit-breaker for emergency

shutdown.

Page 35

8

Heating system servicing

Logano G115 WS US/CA - Technical specifications are subject to change without prior notice.

35

8 Heating system servicing

8.1 Why is regular maintenance important?

Heating systems should be regularly maintained for the

following reasons:

– to achieve a high level of efficiency and to operate the

system economically (low fuel consumption),

– to achieve a high level of operational reliability,

– to maintain the cleanest possible combustion,

– to ensure reliable operation and long service life.

Servicing work may only be carried out by a qualified service technician. If parts are replaced, only Buderus

approved components may be used. A service must be

carried out once a year. The results of the services must

be recorded in the servicing and maintenance log.

8.2 Preparing the boiler for servicing

V Shut down the heating system. (Æ Chapter 7.1,

page 34)

V Remove the burner door panel or the burner hood from

the boiler. (Æ Chapter 3.1, page 12)

V Disconnect electrical supply to burner.

Spare parts can be ordered from Buderus using the parts list.

Danger: Risk of death from electric shock.

V Before working on the boiler and prior to

opening control panel:

shut down the power supply by turning off

the emergency shut-off switch or disengaging the heating system circuit breaker,

and prevent from accidental reactivation.

Page 36

8

Heating system servicing

Logano G115 WS US/CA - Technical specifications are subject to change without prior notice.

36

8.3 Cleaning the boiler

The boiler can be cleaned with brushes and/or by a wet

method. Cleaning equipment is available as accessory.

V Open burner door by removing the two hexagon bolts

on the sides.

8.3.1 Cleaning the boiler with brushes

V Note the position of the heat exchanger baffles for later.

V Remove the hot gas baffle plates from the hot gas pas-

sages.

V Clean the hot gas baffle plates with one of the two

cleaning brushes.

Fig. 37 After opening the burner door

1 Flue gas baffles in the heat exchanger

V Clean the hot gas passages by turning the round clean-

ing brush.

Fig. 38 Brushing out the hot gas flues

V Clean the combustion chamber with a flat brush.

Remove the debris from the combustion chamber, the

hot gas flues and the flue connection.

V Refit the heat exchanger baffles in their original posi-

tions.

V Check sealing rope on burner door. Replace damaged

or hardened gasket cord.

V Close burner door with the two hexagon bolts (approx.

90 inch-lbs). Tighten the hexagon bolts evenly.

Fig. 39 Brushing out the combustion chamber

Caution: Risk of burning by touching hot

boiler parts.

V Wear appropriate protective personal

safety equipment.

1

7 747 019 141-27.1RS

7 747 019 141-37.1RS

You can obtain suitable gasket cord from

your local Buderus sales office.

7 747 019 141-38.1RS

Page 37

8

Heating system servicing

Logano G115 WS US/CA - Technical specifications are subject to change without prior notice.

37

8.3.2 Wet cleaning (chemical cleaning)

For wet cleaning use a cleaning agent appropriate for the

degree of soiling (soot or scale). Proceed with the wet

cleaning in the same order as described for cleaning with

brushes (Æ Chapter 8.3.1, page 36).

V Cover the control panel with plastic to prevent spray

from entering the control panel.

V Spray cleaning agent evenly into the heat exchanger

heater passages.

V Close burner door and start up the heating system.

V Heat the boiler to a temperature of at least 160 °F.

V Shut down the heating system.

V Brush out the heat exchanger heater.

8.4 Checking heating system operating pressure

The system pressure for closed systems must be

15 – 30 psi (1.0 – 2.1 bar).

V Check system pressure.

V If the pressure gauge shows less than 15 psi, the pres-

sure is too low. Top up the system with water.

Fig. 40 Pressure/temperature gauge for showing oper-

ating pressure and feed temperature

Follow the instructions for the cleaning product. You may need to proceed differently

from the method described here in some circumstances.

Caution: Risk of system damage due to frequent topping up.

If you have to top up the heating water frequently, the heating system may suffer damage from corrosion or scaling, depending on

the water quality.

V Ensure that your heating system is bled

properly.

V Check the heating system for leaks and

proper operation of the expansion vessel.

7 747 019 141-17.1RS

Page 38

8

Heating system servicing

Logano G115 WS US/CA - Technical specifications are subject to change without prior notice.

38

V Add water through the feed valve.

V Bleed the heating system.

V Check the operating pressure again.

8.5 Testing relief valve

The functioning of the pressure relief valve must be

checked at regular intervals (1-3 years as specified by

local codes).

V Make sure that no persons are in the discharge area of

the pressure relief valve.

V Raise the lever on the pressure relief valve.

The pressure relief valve must open and release pressure.

If the pressure relief valve does not discharge, it must be

replaced, because system components may be damaged

by excessive pressure.

Caution: Risk of damage to system due to

material stresses caused by temperature differentials.

V Only fill the system when cold (the flow

temperature at the temperature/pressure

gauge should be no more than 100 °F).

Page 39

8

Heating system servicing

Logano G115 WS US/CA - Technical specifications are subject to change without prior notice.

39

8.6 Servicing and maintenance logs

V Initial and date the servicing operations completed. The inspection and servicing logs can also be used as

copy masters.

Service work Page Date:______ Date:______ Date:______

1. Check general condition of heating system

2. Visual inspection and function check of the heating

system

3. Checking fuel and water-carrying components of the

system for:

– leaks during operation

–leak test

– visible signs of corrosion

– signs of ageing

4. Check the combustion chamber and the heating surface for contamination; shut down the system for this

step

34

5. Checking the burner (Æ burner documentation)

6. Check the combustion air supply and flue gas routing

for function and safety

7. Check the operating pressure, relief valve and expansion tank inlet pressure

37

8. Checking function of DHW tank and sacrificial anode

(Æ DHW tank documentation)

9. Checking controls settings (Æ controls' documentation)

10. Record the final checks of the inspection work, incl.

measurements and test results

Confirmation of properly completed servicing Company

stamp/signature

Company

stamp/signature

Company

stamp/signature

Page 40

8

Heating system servicing

Logano G115 WS US/CA - Technical specifications are subject to change without prior notice.

40

Date:______ Date:______ Date:______ Date:______ Date:______ Date:______ Date:______

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

Company

stamp/signature

Company

stamp/signature

Company

stamp/signature

Company

stamp/signature

Company

stamp/signature

Company

stamp/signature

Company

stamp/signature

If any condition requiring maintenance work

is identified in the course of servicing, that

work must be carried out as necessary to ensure safe and proper operation.

Page 41

8

Heating system servicing

Logano G115 WS US/CA - Technical specifications are subject to change without prior notice.

41

On-demand maintenance procedures Page Date:______ Date:______ Date:______

1. Shutting down the heating system 34

2. Removing and cleaning the heat exchanger baffles 36

3. Cleaning heat exchanger heater flue (heating surfaces)

and combustion chamber and afterwards refitting heat

exchanger baffles in original positions

36

4. Checking seals/cord gaskets on burner door and

burner and replacing as necessary

36

5. Commissioning the heating system 29

6. Final check of the servicing work

7. Checking safe and proper operation

Confirmation of properly completed servicing Company

stamp/signature

Company

stamp/signature

Company

stamp/signature

Date:______ Date:______ Date:______ Date:______ Date:______ Date:______ Date:______

1.

2.

3.

4.

5.

6.

7.

Company

stamp/signature

Company

stamp/signature

Company

stamp/signature

Company

stamp/signature

Company

stamp/signature

Company

stamp/signature

Company

stamp/signature

Page 42

9

Troubleshooting

Logano G115 WS US/CA - Technical specifications are subject to change without prior notice.

42

9 Troubleshooting

Two type of fault are distinguished:

– Burner faults and

– Control and heating system faults.

If there is a burner fault the fault indicator lamp on the

burner comes on (Æ burner documentation). Such faults

can generally be reset by pressing the reset button on the

burner. Controls and heating system faults are indicated

on the controls display if it has one. For further information

see Æ controls' documentation.

Correcting burner faults

V Press reset button on burner.

Fig. 41 Resetting the burner

1 Burner

Caution: Risk of system damage due to too

many resets

Too many resets can damage the burner's ig-

nition transformer.

V Do not press the reset button more than

three times in a row.

V If the fault does not reset after the third at-

tempt, try to localize and rectify the fault

with the help of the burner documentation.

V Notify a service engineer if necessary.

Caution: Risk of system damage from freezing.

The heating system can freeze up in cold

weather if it has been disabled by a fault

shutdown.

V Rectify the fault immediately and restart

the heating system.

V If this is not possible, protect your heating

system from freezing by draining the heating system and hot water pipes at the lowest point.

1

6 720 615 225-04.1RS

Page 43

10

Installation examples

Logano G115 WS US/CA - Technical specifications are subject to change without prior notice.

43

10 Installation examples

Key to abbreviations

Fig. 42 Multiple circuits with circuit valves

1 Baseboard

Fig. 43 Multiple circuits with circuit valves

1 Baseboard

KR Check valve SH Heating circuit adjuster

MAG Expansion tank SV Pressure relief valve

PH System pump THV Thermostatic radiator valve

PW Hot water pump WH Water compensation pipe (diversion)

7 747 019 141-40.1RS

SV

PH

MAG

THV

G125 WS/NA

1

1

1

G115 WS/NA

7 747 019 141-41.1RS

SV

PH

KR

MAG

G125 WS/NA

1

1

1

G115 WS/NA

Page 44

10

Installation examples

Logano G115 WS US/CA - Technical specifications are subject to change without prior notice.

44

Fig. 44 Multiple circuits of water diversion for systems with a high water volume

1 Radiator

2 Boiler bypass

Fig. 45 Multiple circuits with pumps and motor-actuated 3-way mixing valve

1 Baseboard

7 747 019 141-42.1RS

SV

PH

THV

MAG WH

G125 WS/NA

3/4"

1

1

1

2

G115 WS/NA

7 747 019 141-43.1RS

SV

R2107

PH

PH

SH

180˚

100˚

100˚120˚

160˚180˚

M

PS

KR

KR

MAG

G125 WS/NA

1

G115 WS/NA

Page 45

11

Parts lists

Logano G115 WS US/CA - Technical specifications are subject to change without prior notice.

45

11 Parts lists

The following parts are available from Buderus. If there are

several Buderus article numbers for one item number, the

numbers for the various models are listed in the relevant

columns. Otherwise the table shows the number of components for each model.

Legend for tables 13 and 14:

x = no spare part

(x) = component of a set, only available with set

0 = no picture available

Boiler block and burner door (Æ Fig. 46)

Item no. Description Part number

G115/3 WS

3 section

G115/4 WS

4 section

G115/5 WS

5 section

10 Boiler block G115 WS 63036027 63036028 63036029

Available front section components

21 Plug G1 1/4" right 86055310

22 Gasket D 41.7x55x1.5mm AFM 34, left 86159710

23 Barrier plate with countersunk bolt, M8x16 63015342

24 Countersunk bolt DIN 7991 -M 8 x 16 -Ms (x)

Available back section components

50 Gasket D33x44x2mm 63005462

51 Plug G 1 05317712

52 Stud bolt, M10x65 5.6 as per drawing 05555070

20 Spacer sleeve R3/8"x39 (x)

54 Hexagon nut ISO4032-M10-8-A3K (x)

55 Washer DIN115-A10.5-A3K (x)

57 Reducer nipple G1"xG3/4" 63027607

60 Sensor sleeve PMW -3 SEE (4 1/2")"US" 7747022364

70 Anchor bolt set, M8x310mm 05127574 - 70 Anchor bolt set, M8x440mm - 05127578 70 Anchor bolt set, M8x555mm - - 05127580

80 Flue connection complete 05354074

Available flue connection components

81 Sealing rope 8x1050 GP 63020961

0 Gasket compound brown (cartridge 310 ml) for gluing sealing rope 63014361

90 Feed-in connector assy. 1 1/4-NPT1, G115/G115 WS 63028062 63028062 63028061

91 Seal 55x41.7x1.5 mm 05752540

Spare parts that are supplied with the spare boiler block

120 Heat exchanger baffle 05347085 05347087 05347089

130 Angle bracket 420mm long 7747000018 – –

130 Angle bracket 540mm long – 7747000019 –

130 Angle bracket 660mm long – – 7747000020

131 Washer DIN126-9 (x)

132 Hexagon bolt ISO 4017 -M8x25-8.8 (x)

133 Hexagon nut DIN 6923-M8-8.8-A3K (x)

140 Hinge bracket G105/G115 05327033

141 Washer DIN125-A10.5-A3K (x)

142 Hexagon bolt ISO4017-M10x25-8.8 (x)

150 Hexagon bolt ISO4014-M10x65-8.8 (x)

160 Washer DIN125-A10.5-A3K (x)

180 Boiler feet M10x51mm complete 05236440

190 Flue pipe sealing collarDN130 complete 05354010

Tab. 13 Boiler block and burner door

Page 46

11

Parts lists

Logano G115 WS US/CA - Technical specifications are subject to change without prior notice.

46

200

Flue silencer DN130 complete, without condensate drain; higher sound

absorption

05074020

or:

210

Flue silencer D130 with an adaptor of 100mm length, with condensate drain;

lower sound absorption

05074022

Flue silencer components

190 Flue pipe sealing collarDN130 complete 05354010

220 Flue pipe sealing collar assy. DN130 (stepped) 05354030

230 Sealing rope 10x2000 GP 63020963

250 Burner door complete 63023858

Available burner door components

260 Hinge G 215 05327020

270 Washer DIN125 A10,5 A3K (x)

280 Hexagon bolt ISO4017 M10x25 8. (x)

290 Inspection window seal assy. V3 63023634

Obtainable individual parts of inspection window seal

300 Gasket 30x30x3 63014382

310 Inspection window glass, Tempax 30x30x3.3mm 05447620

320 Inspection window cover x

330 Hexagon bolt ISO4017 M6x12 8.8 A3K (x)

340 Pressure testing nozzle M6 SW10 V2 (x)

350 Heat insulation for burner door BE/non-Buderus burner size 21/334/5 63002401

Available heat insulation components

360 Heat insulation for burner door panel 24mm thick 63004169

370 Insulation ring for burner door panel 10mm thick 63004170

380 Washer DIN9021 A6,4 A3K (x)

390 Sheet metal screw DIN7981 C ST6,3x25 A3T (x)

400 Sealing rope 14x1650 GP 63020965

0 Gasket compound brown (cartridge 310 ml) for gluing sealing rope 63014361

(x)

Mounting material for boiler block G115 WS

63031288

Contents:

1 countersunk bolt M8x16 Ms

2 spacer sleeves R3/8"x39

2 hexagon nuts ISO4032 M10 8 A3K

8 washers DIN125 A10.5 A3K

4 washers DIN126 9

4 hexagon bolts ISO4017 M8x25 8.8

4 hexagon nuts DIN6923 M8 8.8 A3K

4 hexagon bolts ISO4017 M10x25 8.8

2 hexagon bolts DIN6921 M10x65 8.8

1 hexagon bolt ISO4017 M6x12 8.8A3K

2 washers DIN9021 A6.4 A3K

2 sheet metal screws DIN7981 C ST6,3x25 A3T

0

B-KIT G115 WS

63029762

Contents:

1 Supply manifold G115"US"

1 elbow 90DEG11/4

1 elbow 90DEG 3/4 I/A