Page 1

EM100

1

2

3

4

5

6

7

8

9

10

0

de Installationsanleitung für das Fachhandwerk.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

en Installation instructions for skilled labour . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

fl Installatiehandleiding voor de installateur. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

fr Notice d’installation pour le professionnel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

it Istruzioni per l'installazione per tecnico specializzato . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

EMS

EMS plus

5

6

4

7

3

8

2

9

1

100

6720891034 (2019/04) DE/BE/GB/FR/IT

Page 2

Inhaltsverzeichnis

Inhaltsverzeichnis 1 Symbolerklärung und

Sicherheitshinweise

1 Symbolerklärung und Sicherheitshinweise. . . . . . . . . 2

1.1 Symbolerklärung . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.2 Allgemeine Sicherheitshinweise . . . . . . . . . . . . . . . 3

2 Angaben zum Produkt. . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.1 Wichtige Hinweise zur Verwendung . . . . . . . . . . . . 4

2.2 Regelung des Wärmeerzeugers. . . . . . . . . . . . . . . . 4

2.2.1 Leistungsregelung . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.2.2 Vorlauftemperaturregelung. . . . . . . . . . . . . . . . . . . 5

2.3 Lieferumfang . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.4 Technische Daten. . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.5 Ergänzendes Zubehör . . . . . . . . . . . . . . . . . . . . . . . 5

2.6 Reinigung . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.1 Vorbereitung für die Installation im

Wärmeerzeuger . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.2 Installationsorte. . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.3 Installation eines Temperaturfühlers an der

hydraulischen Weiche oder hinter dem

Wärmetauscher . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.4 Elektrischer Anschluss . . . . . . . . . . . . . . . . . . . . . . 7

3.4.1 Anschluss BUS-Verbindung und

Temperaturfühler (Kleinspannungsseite). . . . . . . . 7

3.4.2 Anschluss Spannungsversorgung, Pumpe,

Magnetventil oder Störmeldung

(Netzspannungsseite) . . . . . . . . . . . . . . . . . . . . . . . 7

3.4.3 Überblick Anschlussklemmenbelegung . . . . . . . . . 8

4 Inbetriebnahme . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4.1 Kodierschalter einstellen. . . . . . . . . . . . . . . . . . . . . 9

4.2 Inbetriebnahme der Anlage und des Moduls . . . . . 9

4.3 Menü Einstellungen EM100 . . . . . . . . . . . . . . . . . . 9

1.1 Symbolerklärung

Warnhinweise

In Warnhinweisen kennzeichnen Signalwörter die Art und

Schwere der Folgen, falls die Maßnahmen zur Abwendung der

Gefahr nicht befolgt werden.

Folgende Signalwörter sind definiert und können im vorliegenden Dokument verwendet sein:

GEFAHR:

GEFAHR bedeutet, dass schwere bis lebensgefährliche

Personenschäden auftreten werden.

WARNUNG:

WARNUNG bedeutet, dass schwere bis lebensgefährliche Per-

sonenschäden auftreten können.

VORSICHT:

VORSICHT bedeutet, dass leichte bis mittelschwere Personen-

schäden auftreten können.

HINWEIS:

HINWEIS bedeutet, dass Sachschäden auftreten können.

Wichtige Informationen

Wichtige Informationen ohne Gefahren für Menschen oder Sachen werden mit dem gezeigten Info-Symbol gekennzeichnet.

5 Störungen beheben . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

6 Umweltschutz/Entsorgung. . . . . . . . . . . . . . . . . . . . . . 10

2

Weitere Symbole

Symbol Bedeutung

▶ Handlungsschritt

Querverweis auf eine andere Stelle im Dokument

• Aufzählung/Listeneintrag

– Aufzählung/Listeneintrag (2. Ebene)

Tab. 1

EM100 – 6720891034 (2019/04)

Page 3

1 Symbolerklärung und Sicherheitshinweise

1.2 Allgemeine Sicherheitshinweise

H Hinweise für die Zielgruppe

Diese Installationsanleitung richtet sich

an Fachkräfte für Gas- und Wasserinstallationen, Heizungs- und Elektrotechnik.

Die Anweisungen in allen Anleitungen

müssen eingehalten werden. Bei Nichtbeachten können Sachschäden und Personenschäden bis hin zur Lebensgefahr

entstehen.

▶ Installationsanleitungen (Wärmeer-

zeuger, Heizungsregler usw.) vor der

Installation lesen.

▶ Sicherheits- und Warnhinweise

beachten.

▶ Nationale und regionale Vorschriften,

technische Regeln und Richtlinien

beachten.

▶ Ausgeführte Arbeiten dokumentieren.

H

Bestimmungsgemäße Verwendung

▶ Produkt ausschließlich zur Regelung

von Heizungsanlagen verwenden.

Jede andere Verwendung ist nicht bestimmungsgemäß. Daraus resultierende

Schäden sind von der Haftung ausgeschlossen.

H Installation, Inbetriebnahme und

Wartung

Installation, Inbetriebnahme und Wartung

darf nur ein zugelassener Fachbetrieb

ausführen.

▶ Produkt nicht in Feuchträumen

installieren.

▶ Nur Originalersatzteile einbauen.

H Elektroarbeiten

Elektroarbeiten dürfen nur Fachleute für

Elektroinstallationen ausführen.

▶ Vor Elektroarbeiten:

– Netzspannung (allpolig) span-

nungsfrei schalten und gegen

Wiedereinschalten sichern.

– Spannungsfreiheit feststellen.

▶ Produkt benötigt unterschiedliche

Spannungen.

Kleinspannungsseite nicht an

Netzspannung anschließen und umgekehrt.

▶ Anschlusspläne weiterer Anlagenteile

ebenfalls beachten.

H Übergabe an den Betreiber

Weisen Sie den Betreiber bei der

Übergabe in die Bedienung und die

Betriebsbedingungen der Heizungsanlage ein.

▶ Bedienung erklären – dabei beson-

ders auf alle sicherheitsrelevanten

Handlungen eingehen.

▶ Darauf hinweisen, dass Umbau oder

Instandsetzungen nur von einem zugelassenen Fachbetrieb ausgeführt

werden dürfen.

▶ Auf die Notwendigkeit von Inspektion

und Wartung für den sicheren und umweltverträglichen Betrieb hinweisen.

▶ Installations- und Bedienungsanlei-

tungen zur Aufbewahrung an den

Betreiber übergeben.

EM100 – 6720891034 (2019/04)

3

Page 4

2

Angaben zum Produkt

H Schäden durch Frost

Wenn die Anlage nicht in Betrieb ist,

kann sie einfrieren:

▶ Hinweise zum Frostschutz beachten.

▶ Anlage immer eingeschaltet lassen,

wegen zusätzlicher Funktionen,

z. B. Warmwasserbereitung oder

Blockierschutz.

▶ Auftretende Störungen umgehend be-

seitigen lassen.

2 Angaben zum Produkt

• Das Modul kann über ein externes Steuersignal mit 0-10 V

(Gleichspannung) die Kessel-Vorlauftemperatur oder die

Leistung des Heizkessels anpassen.

• Das Modul meldet Störungen des Heizkessels sowie Anlagenstörungen, mit Ausnahme von Serviceanzeigen, Störungen externer Regler oder Wartung für den Installateur.

• Das Modul kann der Ansteuerung eines zweiten Magnetventils dienen und für Heizkessel in Flüssiggasausführung eingesetzt werden.

• Das Modul dient als Erweiterungsmodul für EMS- und

EMS plus-Kessel.

• Das Modul dient der modulierenden Drehzahlregelung

„Flow Control“ einer Kesselkreispumpe (0-10 V oder PWM)

in Verbindung mit hydraulischer Weiche oder Wärmetauscher.

Die Kesselkreispumpe passt den kesselseitigen Volumenstrom an und verhindert eine Rücklauftemperaturanhebung des Kessels. Ziel ist ein optimierter Brennwertnutzen

sowie Stromeinsparung. Durch die Auswahl 0-10V- oder

PWM-Signal ist die Funktion geeignet bei bodenstehenden

Kesseln und Wandgeräten GB162 >45 kW mit werkseitiger

Pumpengruppe.

3 Regelungsarten sind auswählbar:

1. Vorlauftemperaturregelung: Differenz Kesselvorlauf zu Anlagenvorlauf

2. Leistungsregelung: parallel zur Kesselleistung (wenn kein

Zusatzfühler möglich)

3. Differenz Kesselvorlauf zu Kesselrücklauf (empfohlen für

Wärmetauscher)

Die Kombinationsmöglichkeiten der Module sind aus den Anschlussplänen ersichtlich.

(empfohlen für hydraulische Weiche)

2.1 Wichtige Hinweise zur Verwendung

• Der Funktionsumfang ist von der installierten Bedieneinheit abhängig. Genaue Angaben zu Bedieneinheiten entnehmen Sie bitte dem Katalog, den Planungsunterlagen

und der Webseite des Herstellers.

• Der Installationsraum muss für die Schutzart gemäß den

technischen Daten des Moduls geeignet sein.

2.2 Regelung des Wärmeerzeugers

Diese Regelungsstrategie findet Anwendung, wenn die Heizungsanlage über eine Gebäudeleittechnik mit einem 0-10VReglerausgang geregelt wird ( Bild 22 am Dokumentende).

Eingangsspannung

0 V - 0,5 V 0 %/0 °C aus

0,6 V ca. 6 %/ca. 15 °C ein, wenn > min. Leistung

5,0 V ca. 50 %/ca. 50 °C ein

10,0 V ca. 100 %/ca. 90 °C ein/Maximum

Tab. 2 Regelung nach Leistung/Vorlauftemperatur

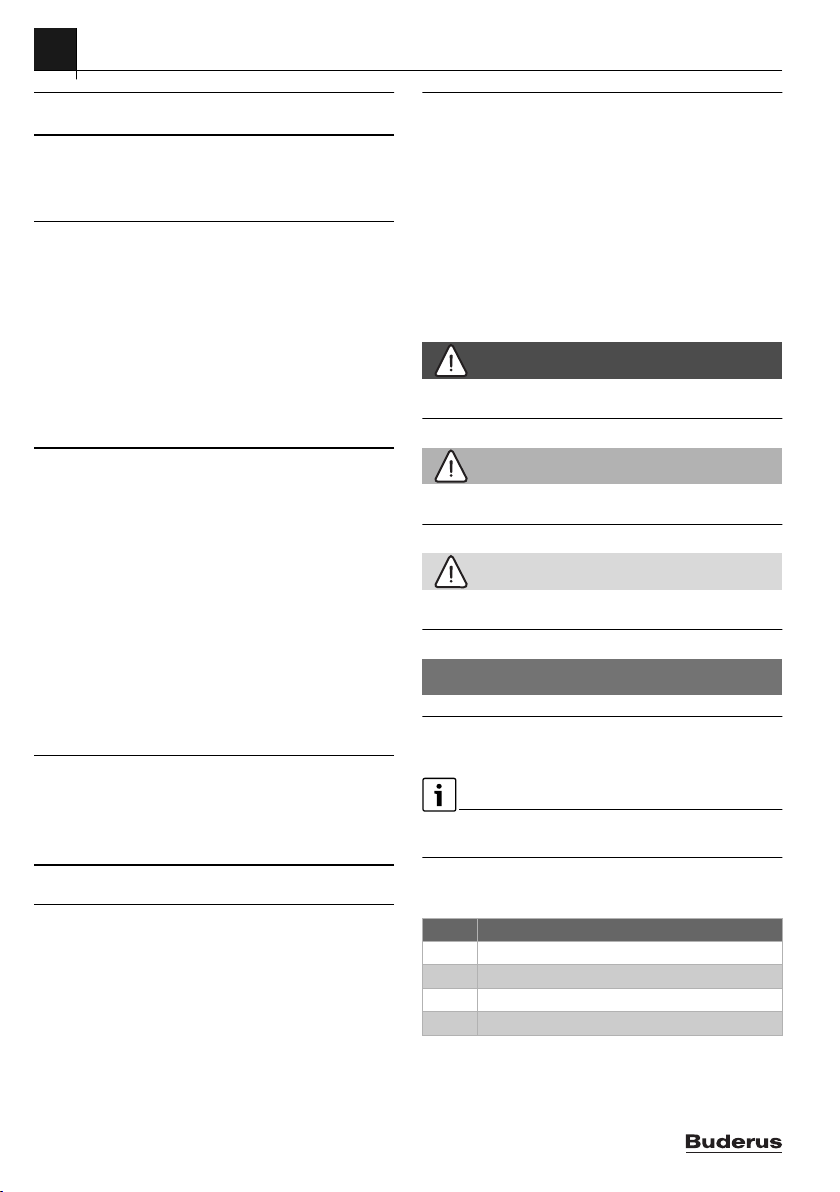

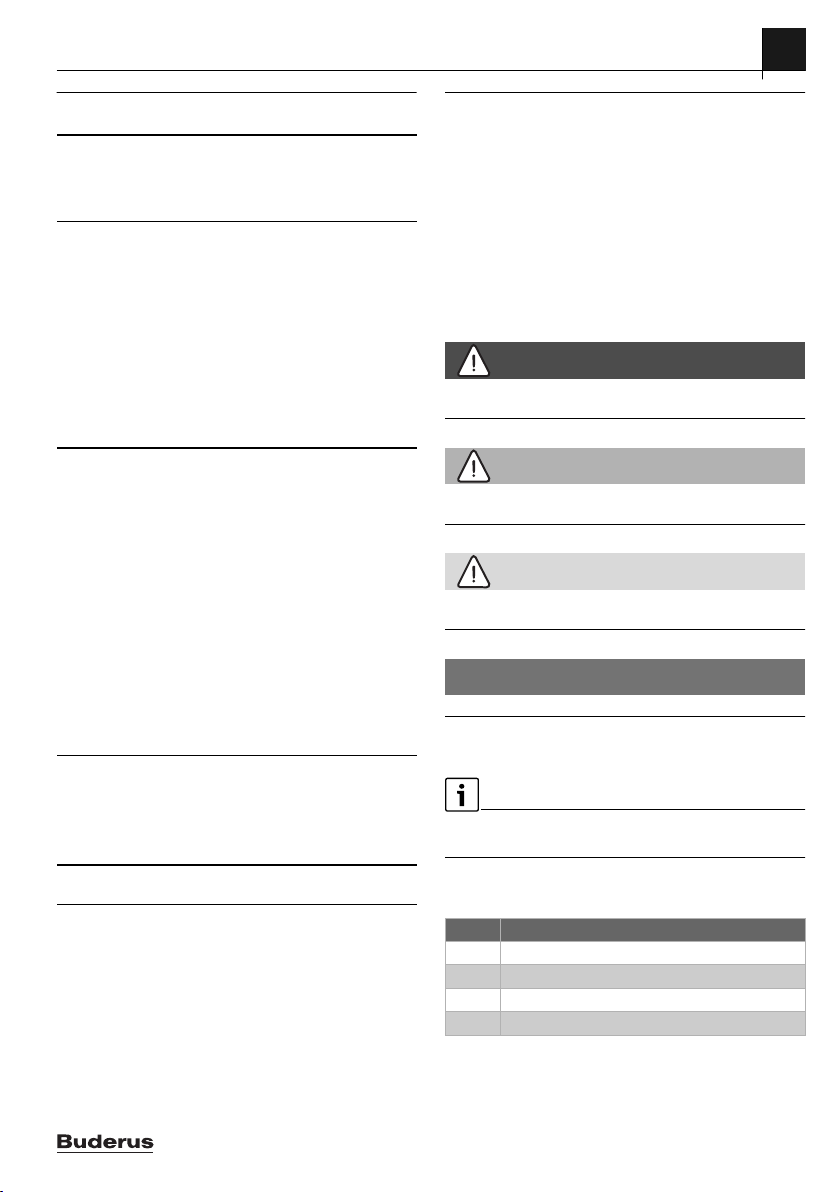

2.2.1 Leistungsregelung

Linearer Zusammenhang zwischen 0-10V-Signal (U in V) und

angeforderter Leistung (P in % bezogen auf die maximale

Leistung der Anlage):

P / %

100

10

Bild 1 Linearer Zusammenhang zwischen 0-10 V-Signal

Die angeschlossenen Wärmeerzeuger werden entsprechend

der angeforderten Leistung zu- und abgeschaltet.

Vorlauftemperatur/

Leistung Sollwert

(Heizkessel)

0,5

110

(U in V) und angeforderter Leistung (P in %)

Status Heizkessel

U / V

0010013227-002

4

EM100 – 6720891034 (2019/04)

Page 5

2 Angaben zum Produkt

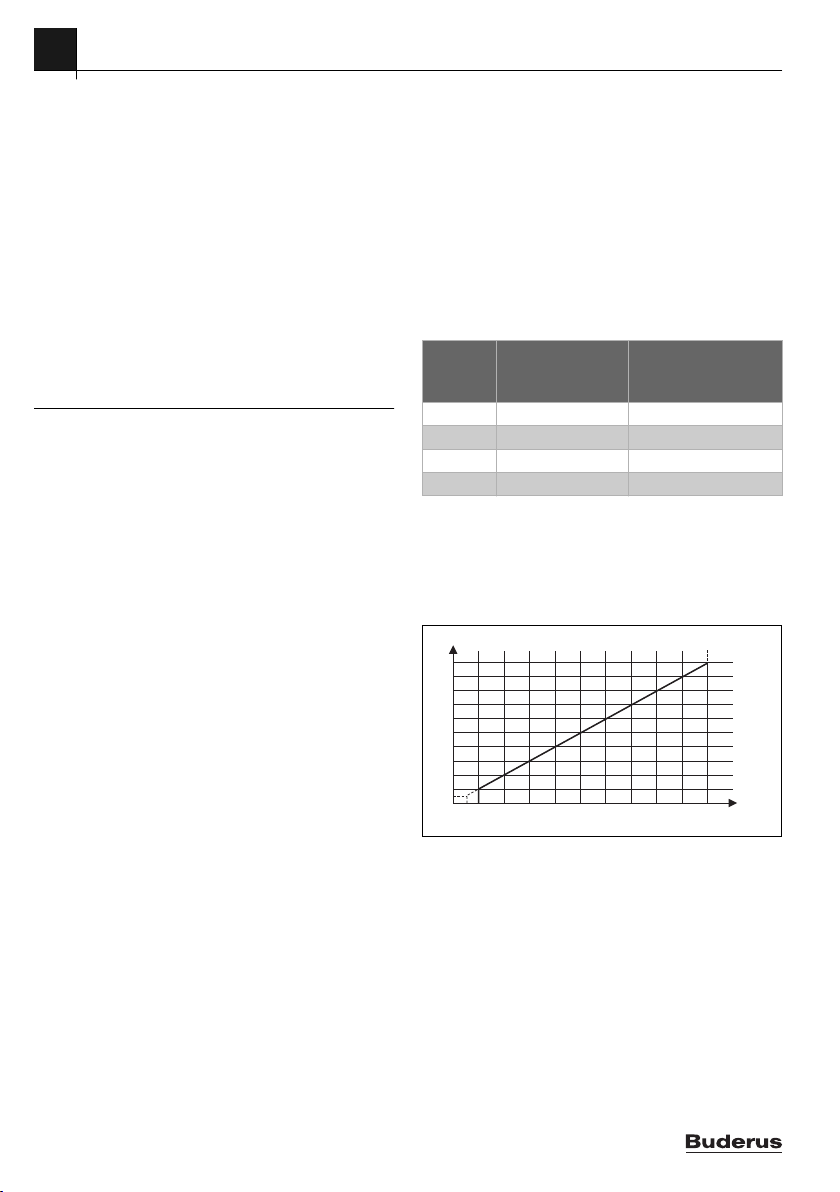

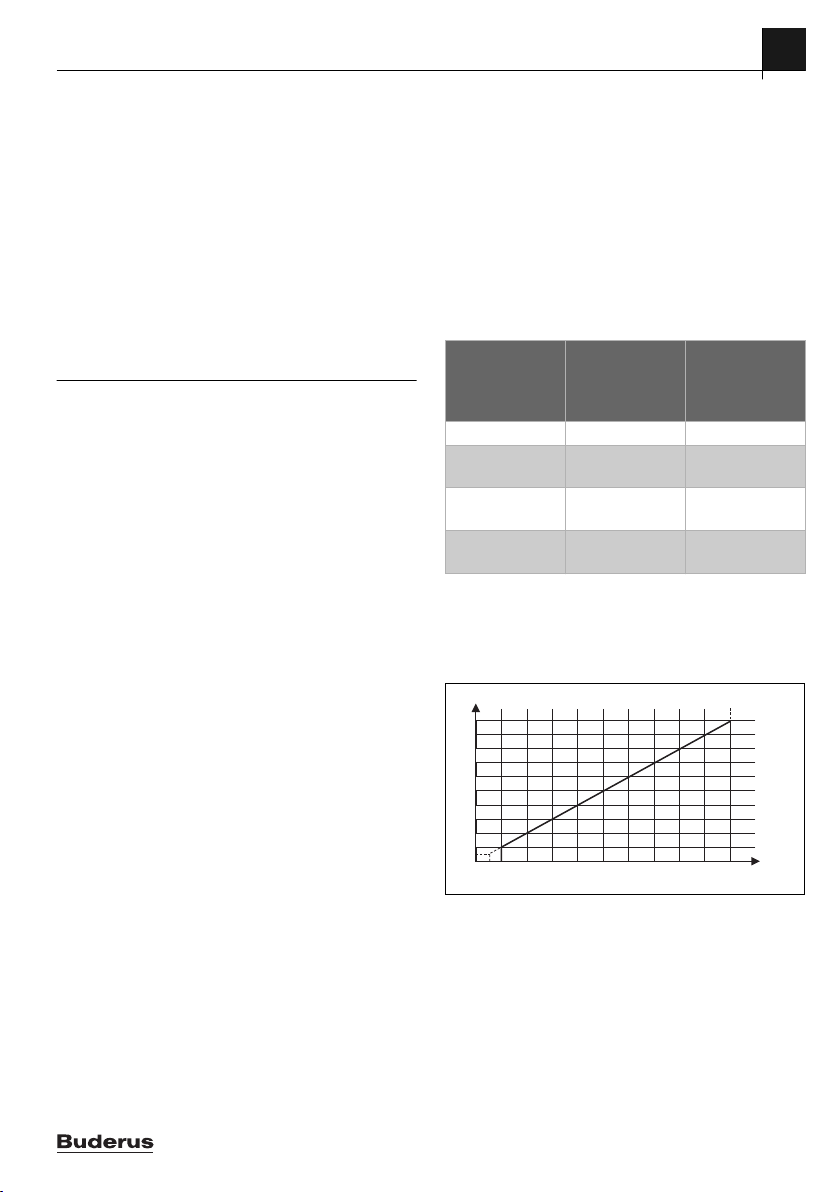

2.2.2 Vorlauftemperaturregelung

Linearer Zusammenhang zwischen 0-10V-Signal (U in V) und

angeforderter Vorlauftemperatur in °C bezogen auf den Be-

reich minimale Vorlauftemperatur bis maximale Vorlauftemperatur [Grundeinstellung 20 bis 90 °C]):

/ °C

90

20

0,5

110

U / V

0010024409-001

Bild 2 Linearer Zusammenhang zwischen 0-10V-Signal

(U in V) und angeforderter Vorlauftemperatur in °C)

Die angeschlossenen Wärmeerzeuger werden entsprechend

der angeforderten Vorlauftemperatur zu- und abgeschaltet.

2.3 Lieferumfang

Bild 6 am Dokumentende:

[1] Modul

[2] Beutel mit Zugentlastungen

[3] Installationsanleitung

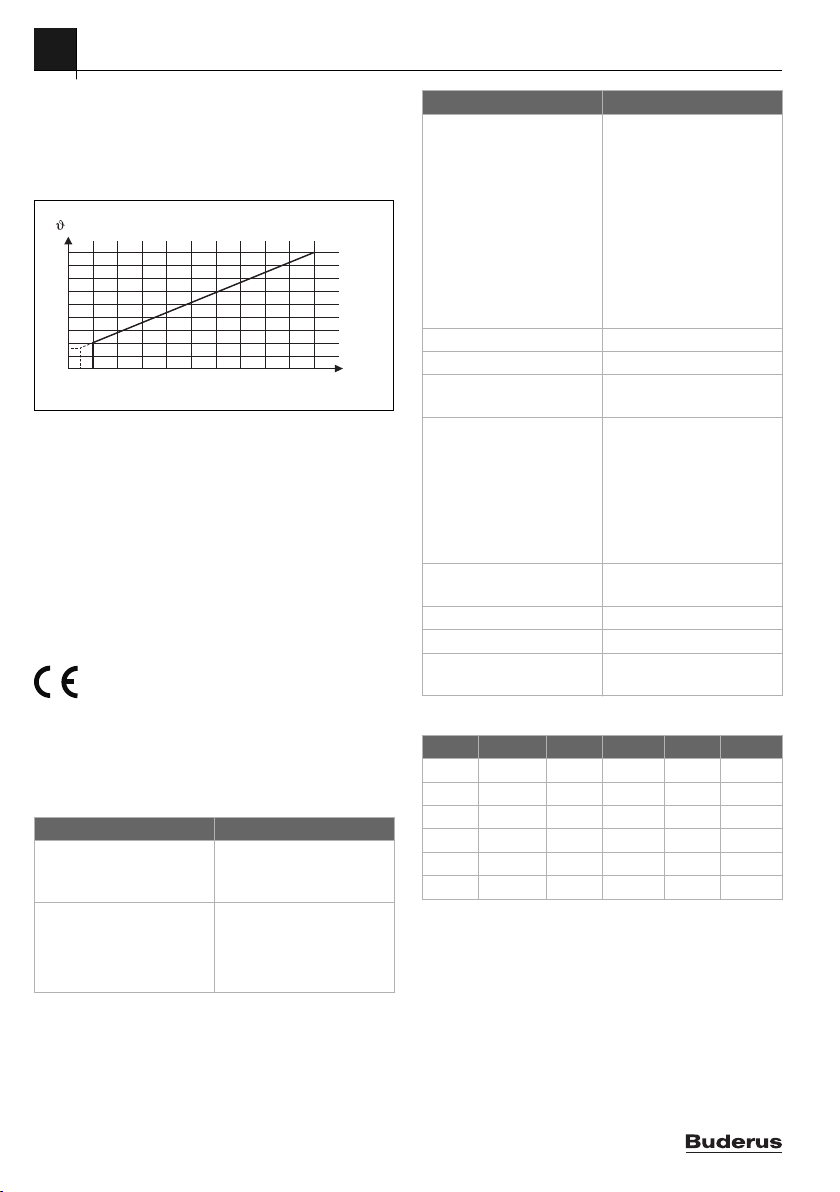

2.4 Technische Daten

Dieses Produkt entspricht in Konstruktion und Betriebsverhalten den europäischen Richtlinien sowie

Konformität wurde mit der CE-Kennzeichnung nachgewiesen.

Sie können die Konformitätserklärung des Produkts anfordern.

Wenden Sie sich dazu an die Adresse auf der Rückseite dieser

Anleitung.

den ergänzenden nationalen Anforderungen. Die

Technische Daten

Abmessungen

(B × H × T)

151 × 184 × 61 mm

(weitere Maße Bild 7 am

Dokumentende)

Maximaler Leiterquerschnitt

• Anschlussklemme

• 2,5 mm

230 V

• Anschlussklemme

• 1,5 mm

Kleinspannung

2

2

Technische Daten

Nennspannungen

• BUS • 15 V DC (verpolungssicher)

• Netzspannung Modul • 230 V AC, 50 Hz

• Bedieneinheit • 15 V DC (verpolungssicher)

• Pumpe, Magnetven-

• 230 V AC, 50 Hz

til, Störausgang

Sicherung 230 V, 5 AT

BUS-Schnittstelle EMS und EMS plus

Leistungsaufnahme –

< 3 W

Standby

max. Leistungsabgabe

• pro Anschluss (PC0)

• 400 W (Hocheffizienzpumpen

zulässig: < 30 A für 10 ms)

• 120 W (Hocheffizienzpumpen

• pro Anschluss (OE1)

zulässig: < 30 A für 10 ms)

zul. Umgebungstemp. 0 ... 60 °C

Schutzart IP 44

Schutzklasse I

Ident.-Nr. Typschild ( Bild 21 am

Dokumentende)

Tab. 3

°C °C °C

20 12486 50 3605 80 1256

25 10000 55 2989 85 1070

30 8060 60 2490 90 915

35 6536 65 2084 100 677

40 5331 70 1753 – –

45 4372 75 1480 – –

Tab. 4 Messwerte Weichentemperaturfühler (T0)

2.5 Ergänzendes Zubehör

Genaue Angaben zu geeignetem Zubehör entnehmen Sie bitte

dem Katalog oder der Internetseite des Herstellers.

• Weichentemperaturfühler; Anschluss an T0

• Primärkreispumpe; Anschluss an PC0

Installation des ergänzenden Zubehörs

▶ Ergänzendes Zubehör entsprechend den gesetzlichen Vor-

schriften und der mitgelieferten Anleitungen installieren.

2.6 Reinigung

▶ Bei Bedarf mit einem feuchten Tuch das Gehäuse abreiben.

Dabei keine scharfen oder ätzenden Reinigungsmittel verwenden.

EM100 – 6720891034 (2019/04)

5

Page 6

3

Installation

3 Installation

GEFAHR:

Lebensgefahr durch elektrischen Strom!

Das Berühren von elektrischen Teilen, die unter Spannung stehen, kann zum Stromschlag führen.

▶ Vor Installation dieses Produktes: Wärmeerzeuger und

alle weiteren BUS-Teilnehmer allpolig von der

Netzspannung trennen.

▶ Vor Inbetriebnahme: Abdeckung anbringen

( Bild 20 am Dokumentende).

3.1 Vorbereitung für die Installation im Wärmeerzeuger

▶ Über die Installationsanleitung des Wärmeerzeugers überprü-

fen, ob dieser die Möglichkeit bietet, Module (z. B. EM100)

im Wärmeerzeuger zu installieren.

▶ Wenn das Modul ohne Hutschiene im Wärmeerzeuger

installiert werden kann, Modul vorbereiten ( Bild 8 und 9

am Dokumentende).

3.2 Installationsorte

▶ Modul an einer Wand ( Bild

an einer Hutschiene ( Bild

Baugruppe oder im Wärmeerzeuger installieren.

▶ Bei der Installation des Moduls in einem Wärmeerzeuger,

die Anleitung des Wärmeerzeugers beachten.

▶ Modul von der Hutschiene entfernen

( Bild 13 am Dokumentende).

3.3 Installation eines Temperaturfühlers an der

hydraulischen Weiche oder hinter dem Wärmetauscher

Der Weichentemperaturfühler T0 sollte vorrangig mit EM100

verbunden sein. Bei Heizgeräten mit EMS plus kann der Fühler

auch am Gerät oder einem MM100 angeschlossen werden.

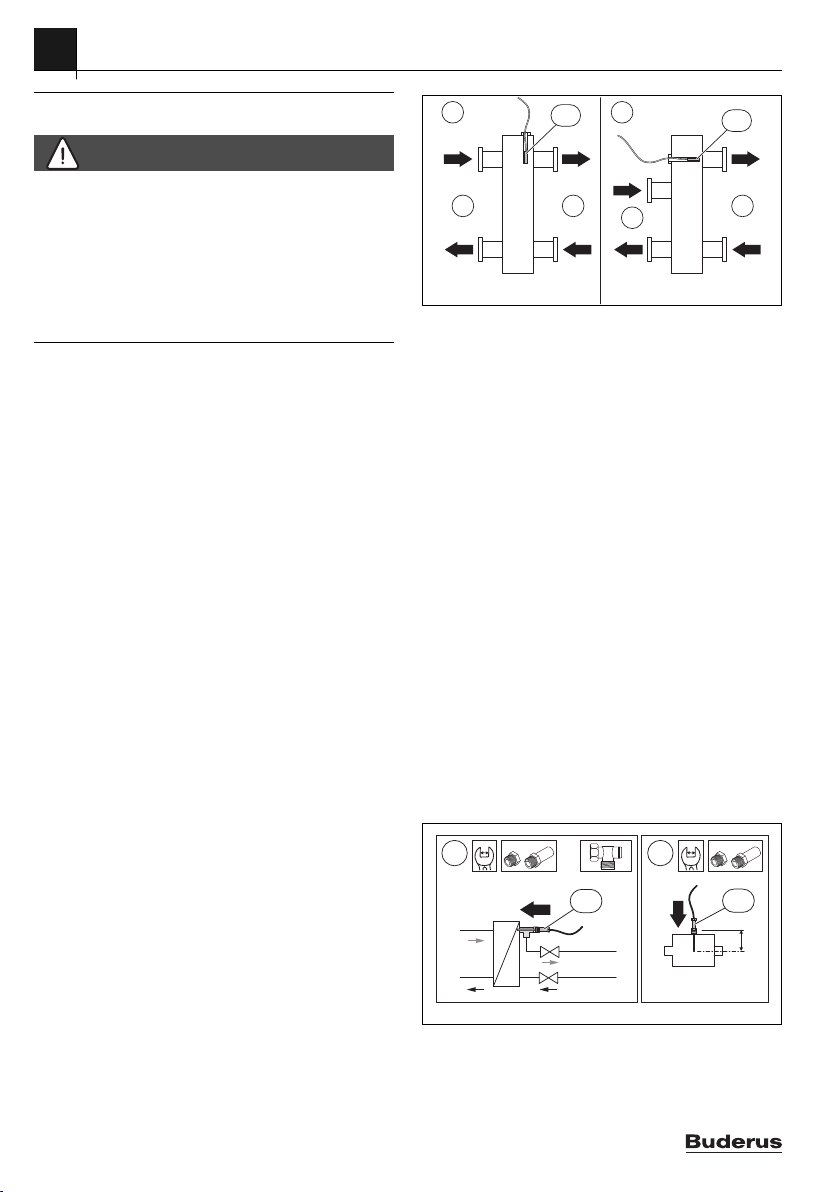

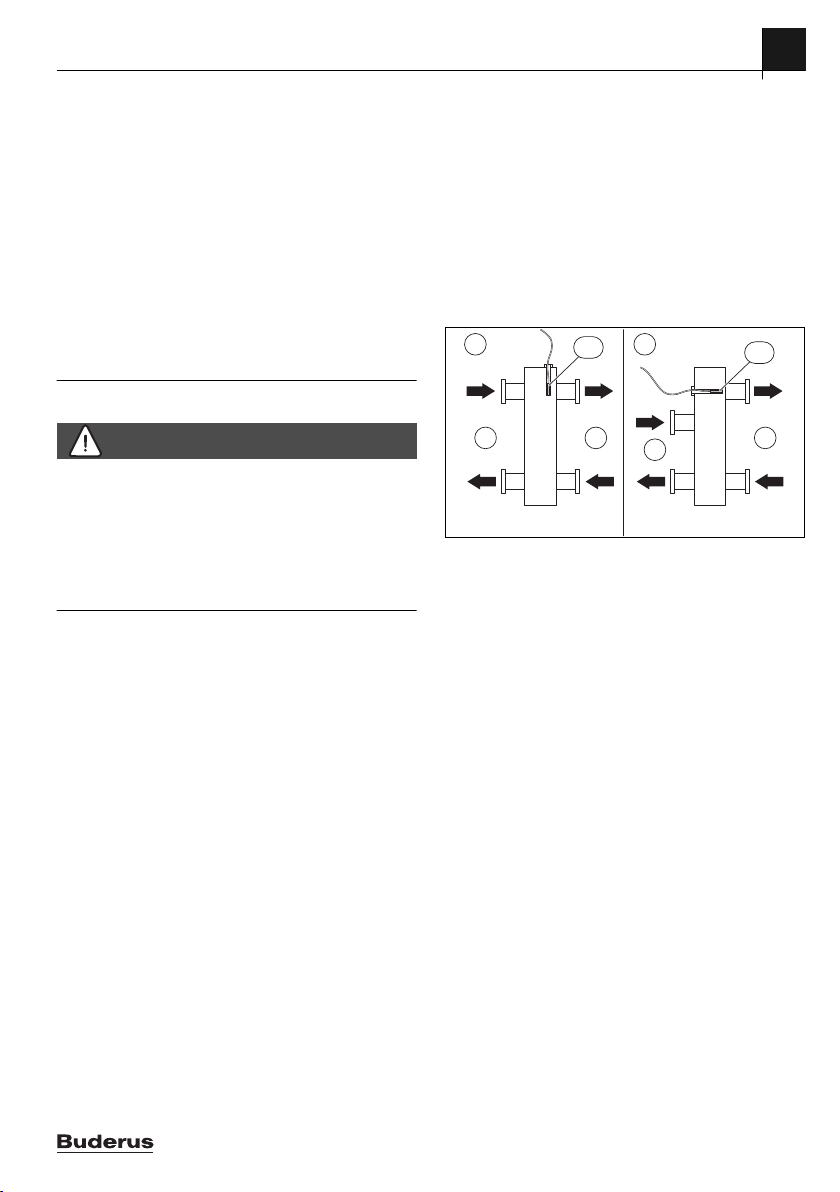

Installation an der hydraulischen Weiche

( Bild 23 und 25 am Dokumentende)

Position Temperaturfühler Vorlauf (T0):

10

und

11

12

am Dokumentende),

am Dokumentende), in einer

A

ϑ

1

T0

12

ϑ

2

B

ϑ

3

ϑ

1

1

ϑ

ϑ

4

2

T0

ϑ

2

ϑ

4

0 010 013 230-001

3

Bild 3 Position Temperaturfühler Vorlauf (T0)

[1] alle Wärmeerzeuger

[2] alle Heizkreise

A hydraulische Weiche Bauform 1

B hydraulische Weiche Bauform 2

1gemeinsame Vorlauftemperatur aller Wärmeerzeuger

gemeinsame Rücklauftemperatur aller Wärmeerzeuger

2

gemeinsame Vorlauftemperatur aller Heizkreise

3

gemeinsame Rücklauftemperatur aller Heizkreise

4

T0 Temperaturfühler Vorlauf an der hydraulischen Weiche

T0 ist so zu positionieren, dass

strom auf der Seite aller Wärmeerzeuger [1] erfasst wird. Nur

unabhängig vom Volumen-

3

so kann die Regelung auch bei kleinen Lasten stabil arbeiten.

Für ein optimales Regelverhalten sollte der Temperaturfühler

umströmt werden. Dies kann durch Kombination von T-Stück,

Hahnverlängerung und Fühlerset erreicht werden.

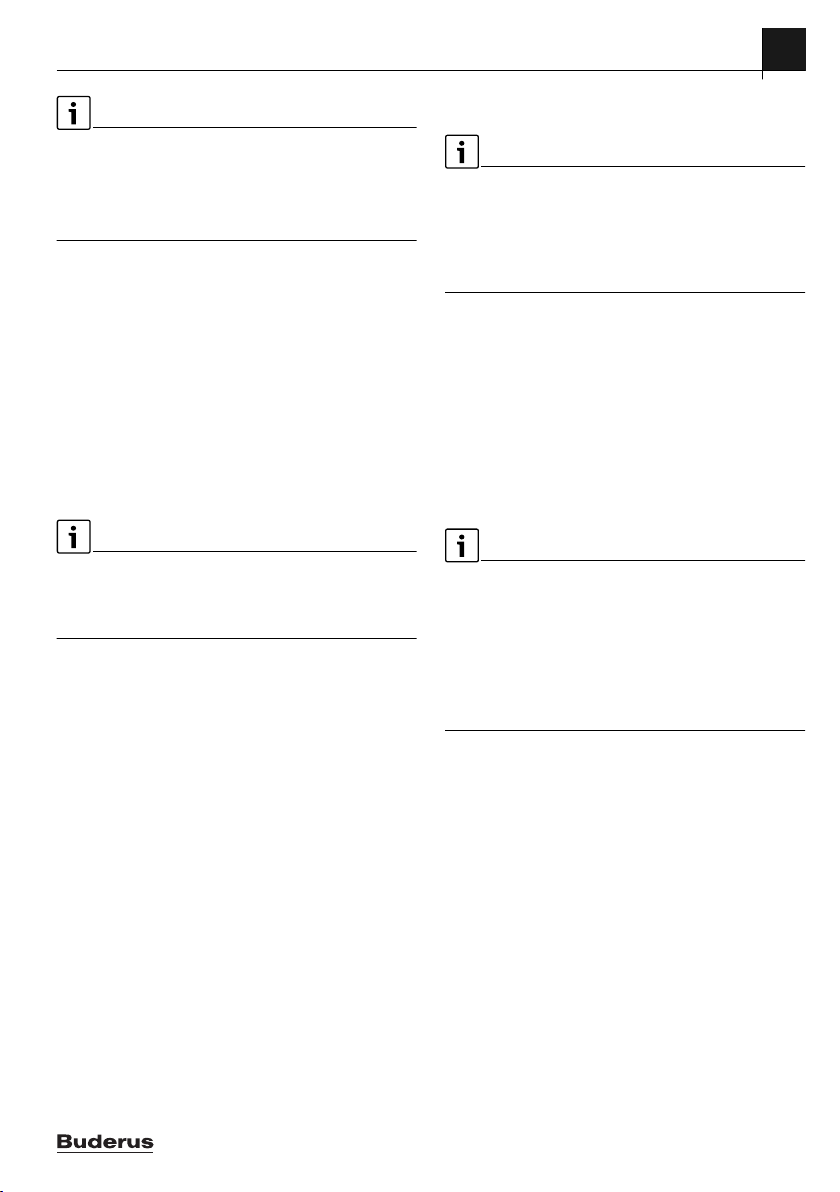

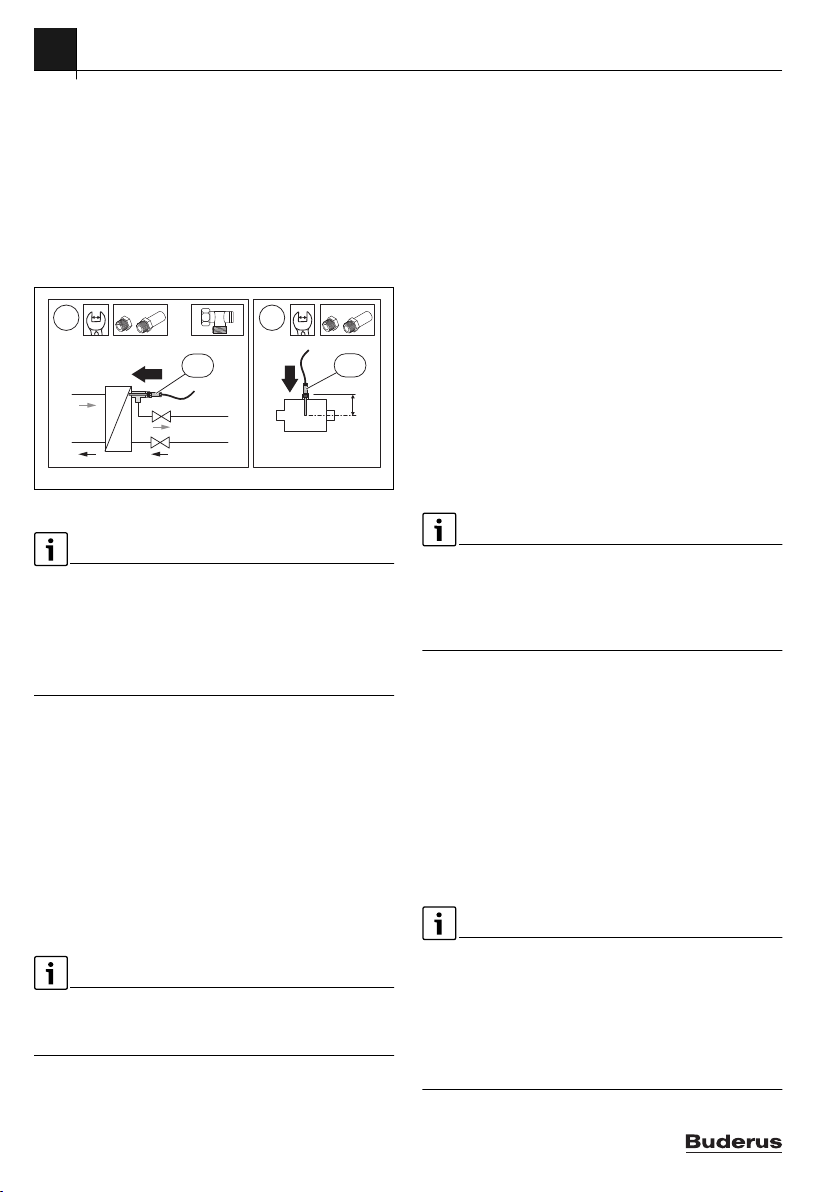

Optimierte Fühlermontage hinter dem Wärmetauscher

Der Temperaturfühler (T0) muss am Vorlauf nach dem

Wärmetauscher sekundärseitig (Nassfühler) angebracht

werden ( Bild 24 am Dokumentende).

Für eine optimierte Fühlermontage hinter dem Wärmetauscher

gibt es zwei Möglichkeiten ( Position [1] mit Eck-Verschraubung und Position [2], Bild 4 "Optimierte Fühlermontage"):

24

B

A

1

T0

24

B

A

2

T0

0010024454-001

Bild 4 Optimierte Fühlermontage

6

EM100 – 6720891034 (2019/04)

Page 7

Der Temperaturfühler muss mittig im Rohr messen.

▶ Die Einbautiefe des Weichen-Temperaturfühlers mit Hahn-

verlängerungen anpassen ( Installationsanleitung Fühlerset hydraulische Weiche). Bei ordnungsgemäßer Montage

ragt der Fühler 1-2 cm in den Wärmetauscher hinein.

3.4 Elektrischer Anschluss

▶ Unter Berücksichtigung der geltenden Vorschriften für den

Anschluss mindestens Elektrokabel der Bauart H05 VV-...

verwenden.

3.4.1 Anschluss BUS-Verbindung und Temperaturfühler

(Kleinspannungsseite)

▶ Bei unterschiedlichen Leiterquerschnitten Verteilerdose

für den Anschluss der BUS-Teilnehmer verwenden.

▶ BUS-Teilnehmer [B] über Verteilerdose [A] in Stern

( Bild 18 am Dokumentende) oder über BUS-Teilnehmer

mit 2 BUS-Anschlüssen in Reihe schalten.

3 Installation

3.4.2 Anschluss Spannungsversorgung, Pumpe, Magnetventil oder Störmeldung (Netzspannungsseite)

Die Belegung der elektrischen Anschlüsse ist von der installierten Anlage abhängig. Die am Dokumentende in Bild 14 bis 17

dargestellte Beschreibung ist ein Vorschlag für den Ablauf des

elektrischen Anschlusses. Die Handlungsschritte sind teilweise

nicht schwarz dargestellt. Damit ist leichter zu erkennen, welche Handlungsschritte zusammengehören.

▶ Nur Elektrokabel gleicher Qualität verwenden.

▶ Auf phasenrichtige Installation des Netzanschlusses achten.

Netzanschluss über einen Schutzkontaktstecker ist nicht

zulässig.

▶ An den Ausgängen nur Bauteile und Baugruppen gemäß

dieser Anleitung anschließen. Keine zusätzlichen Steuerungen anschließen, die weitere Anlagenteile steuern.

▶ Kabel durch die Tüllen führen, gemäß den Anschlussplänen

anklemmen und mit den im Lieferumfang enthaltenen Zugentlastungen sichern ( Bild

14

bis

17

am Dokumentende).

Wenn die maximale Gesamtlänge der BUS-Verbindungen zwischen allen BUS-Teilnehmern überschritten wird oder im BUSSystem eine Ringstruktur vorliegt, ist die Inbetriebnahme der

Anlage nicht möglich.

Maximale Gesamtlänge der BUS-Verbindungen:

2

• 100 m mit 0,50 mm

• 300 m mit 1,50 mm

Leiterquerschnitt

2

Leiterquerschnitt

▶ Um induktive Beeinflussungen zu vermeiden: Alle Klein-

spannungskabel von Netzspannung führenden Kabeln getrennt verlegen (Mindestabstand 100 mm).

▶ Bei induktiven äußeren Einflüssen (z. B. von PV-Anlagen)

Kabel geschirmt ausführen (z. B. LiYCY) und Schirmung

einseitig erden. Schirmung nicht an Anschlussklemme für

Schutzleiter im Modul anschließen, sondern an Hauserdung, z. B. freie Schutzleiterklemme oder Wasserrohre.

Bei Verlängerung der Fühlerleitung folgende Leiterquerschnitte

verwenden:

• Bis 20 m mit 0,75 bis 1,50 mm

• 20 bis 100 m mit 1,50 mm

2

Leiterquerschnitt

2

Leiterquerschnitt

▶ Kabel durch die bereits vormontierten Tüllen führen und ge-

mäß den Anschlussplänen anklemmen.

EM100 – 6720891034 (2019/04)

Die maximale Leistungsaufnahme der angeschlossenen Bauteile und Baugruppen darf die in den technischen Daten des Moduls angegebene Leistungsabgabe nicht überschreiten.

▶ Wenn die Netzspannungsversorgung nicht über die Elektro-

nik des Wärmeerzeugers erfolgt, bauseits zur Unterbrechung der Netzspannungsversorgung eine allpolige

normgerechte Trennvorrichtung (nach EN 60335-1) installieren.

7

Page 8

3

0

1

2

3

4

5

6

7

8

9

10

0

1

2

3

4

5

6

7

8

9

10

Installation

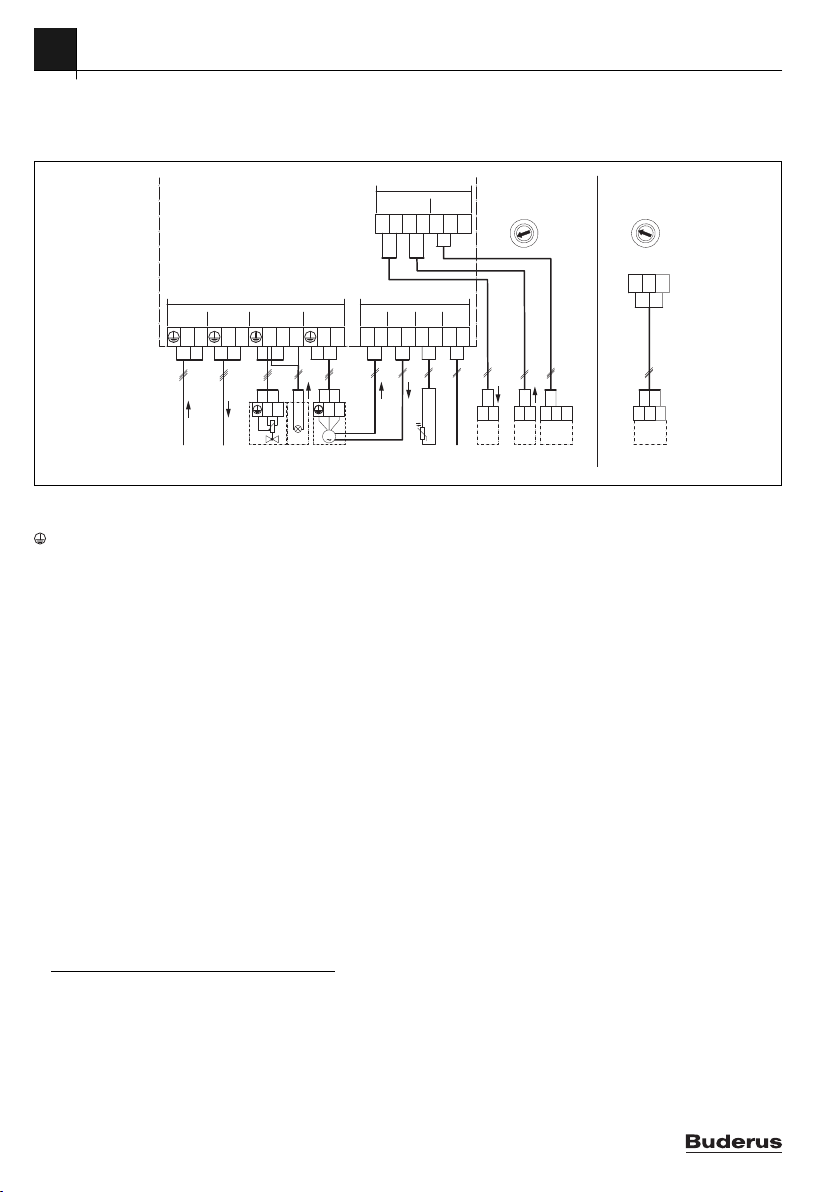

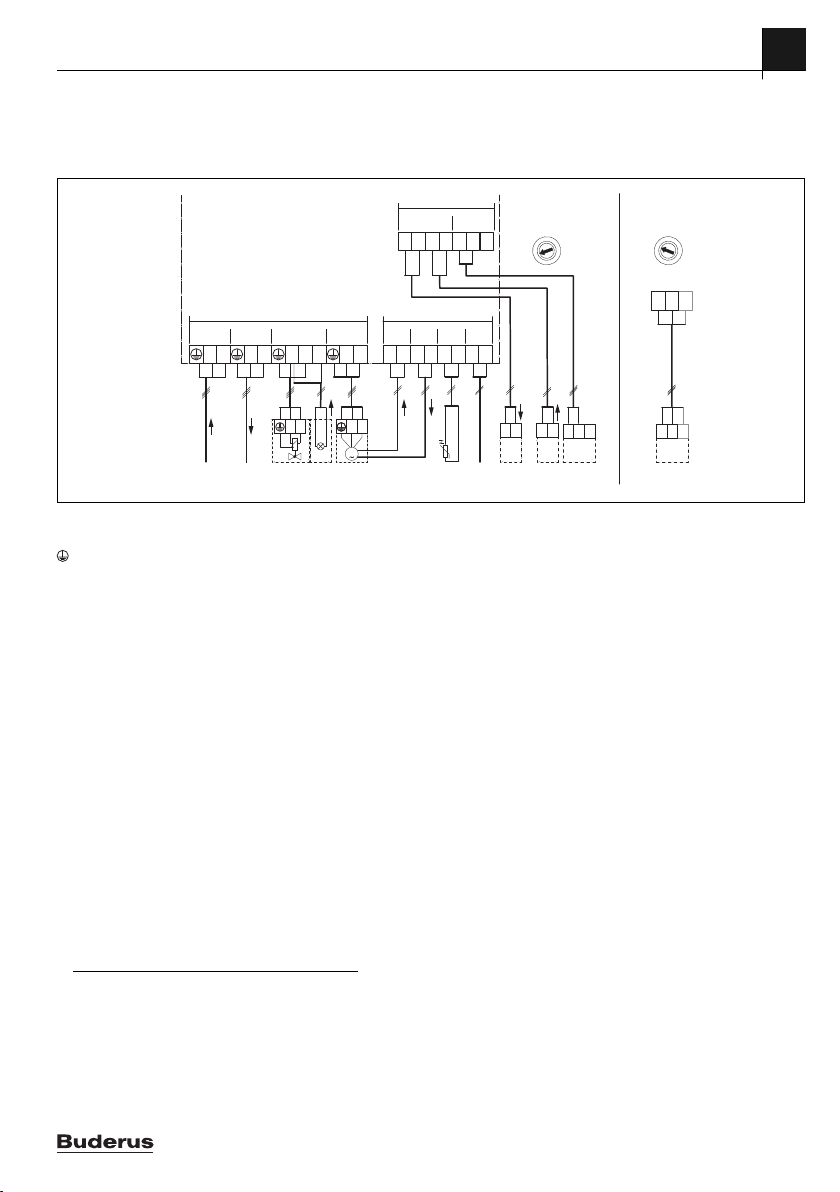

3.4.3 Überblick Anschlussklemmenbelegung

Dieser Überblick zeigt, welche Anlagenteile angeschlossen

werden können.

EM100

120/230 V AC

230 VAC

OE1 PC0

N

L

OE1 OE1

120/230VAC120/230VAC

NL N N74 N6375L

230 VAC

Legende zum Bild oben und zu den Anschlussplänen mit

Anlagenbeispielen am Dokumentende:

Schutzleiter

Anschlussklemmenbezeichnungen:

230 V AC Anschluss Netzspannung

BUS Anschluss BUS-System

BMS Gebäudeleittechnik (Building Management System)

mit 0-10V-Schnittstelle

HS Wärmeerzeuger (Heat Source) an BUS-System

OE1-74 Ausgang Netzspannung Magnetventil

OE1-75 Ausgang Störung (230 V)

PC0 Ausgang Netzspannung Pumpe (230 V)

IE0 Alarmausgang Pumpe

OP0 Pumpe an/aus (Ausgang/potenzialfreier

T0 Eingang Weichentemperaturfühler

Kontakt ≤ 24 V)

2)

IO1-1,2 Ausgang Rückmeldung Wärmeerzeuger (0-10 V)

IO1-3,4 Eingang Ansteuerung Wärmeerzeuger (0-10 V)

OC0 1-2 Ausgang Kontrollsignal Pumpe (0-10 V/PWM)

OC0 1-3 Eingang Rückmeldung Pumpe (PWM), optional

CON Bedieneinheit mit BUS-System (Controller)

MC Steuergerät Kessel (Master Controller)

MM 100 Heizkreismodul (EMS/EMS plus)

EM100 Erweiterungsmodul

IE0 OP0

1212 12

NL

M

PC0

1)

3)

3)

Je nach Verwendung des Moduls (Kodierung am Modul und

Konfiguration über die Bedieneinheit) sind die Anlagenteile gemäß dem jeweiligen Anschlussplan anzuschließen.

≤ 24 V

IO141OC0

213 23

OC0

3

≤ 24 V

OP0IE0

T0

12

T0

BUS

BUS

(+) (–)12(+) (–)

IO1

0-10 V

34

123

0-10V

IO1

OC0

0-10 V

21

123

PWM

OC0

0010025508-001

1) Die Pumpe kann auch direkt an den

Haussicherungsautomaten angeschlossen werden, wenn

Dauerstrom notwendig ist.

2) Beim Wärmetauscher ist T0 der Vorlauftemperaturfühler.

3) Kodierschalterstellung beachten.

8

EM100 – 6720891034 (2019/04)

Page 9

4 Inbetriebnahme

0

1

2

3

4

5

6

7

8

9

10

4 Inbetriebnahme

Alle elektrischen Anschlüsse richtig anschließen und erst danach die Inbetriebnahme durchführen!

▶ Installationsanleitungen aller Bauteile und Baugruppen der

Anlage beachten.

▶ Spannungsversorgung nur einschalten, wenn der Kodier-

schalter eingestellt ist.

▶ Wenn eine Bedieneinheit angeschlossen ist, wird empfoh-

len, den Konfigurationsassistenten zu starten.

HINWEIS:

Anlagenschaden durch zerstörte Pumpe!

▶ Vor dem Einschalten die Anlage befüllen und entlüften, da-

mit die Pumpen nicht trocken laufen.

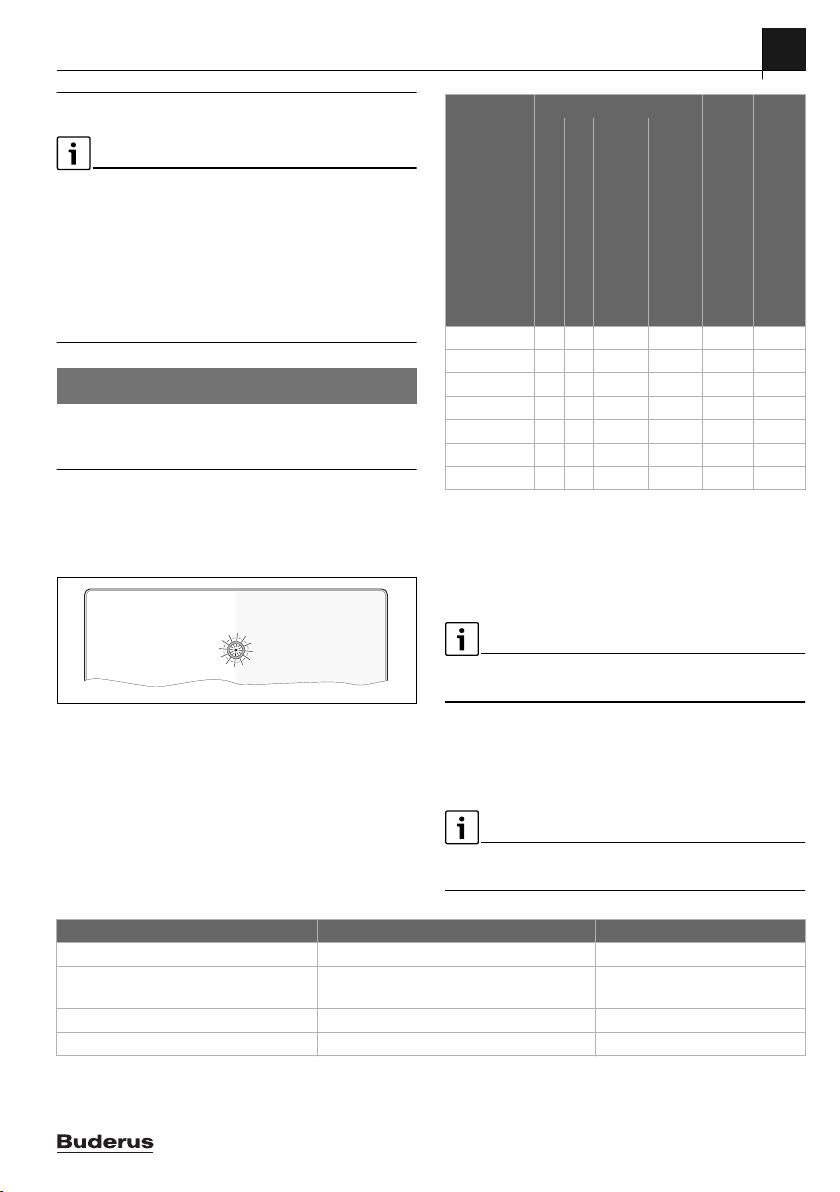

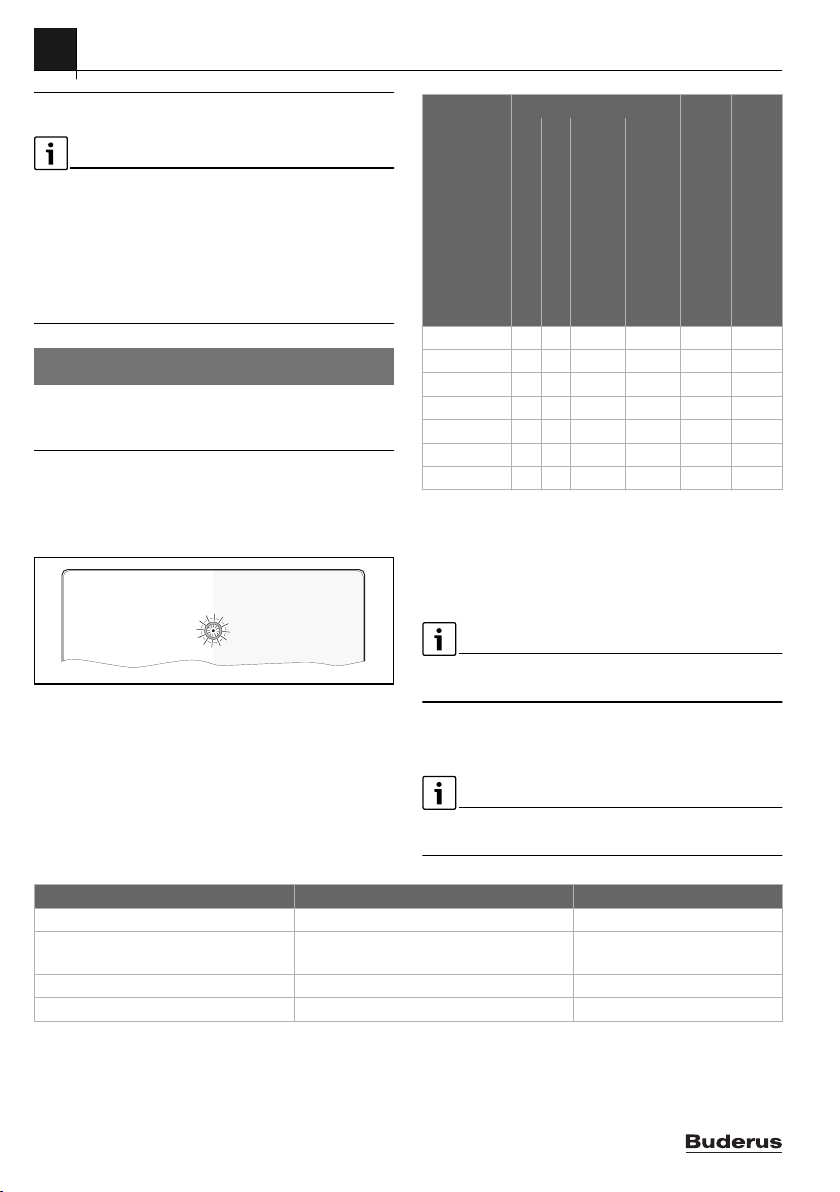

4.1 Kodierschalter einstellen

Kodierschalter mit Betriebsanzeige des Moduls und Zustandsanzeige der angeschlossenen Wärmeerzeuger oder Module:

0 010 013 313-001

Bild 5 Kodierschalter mit Zustandsanzeige des Moduls und

Zustandsanzeige der angeschlossenen Wärmeerzeuger oder Module

Kodierung Funktion des Moduls

Ausgang Störung

Leistungssteuerung des

Ansteuerung 2. Magnetventil

1)

0

– – – – – –

Vorlauftemperaturregelung des

Pumpenregelung über

Pumpenregelung über 0-10 V

Wärmeerzeugers

Wärmeerzeugers

1 – –

2 – –

3 – – –

4 – – –

5 – – – –

2)

6-10

– – – – – –

1) Aus (Lieferzustand)

2) Ungenutzt

Tab. 5 Kodierung und Funktion

4.2 Inbetriebnahme der Anlage und des Moduls

Falls eine Bedieneinheit angeschlossen ist, automatischen Konfigurationsassistenten starten.

4.3 Menü Einstellungen EM100

Die Einstellungen von EM100 können über die Bedieneinheit

( Tab. 6 "Menü EM100") vorgenommen werden.

PWM-Signal

Grundeinstellungen sind in der folgenden Tabelle hervorgehoben dargestellt.

Menüpunkt Einstellungen/Einstellbereich Bemerkung/Einschränkung

PM10 Pumpenmodulation Ja | Nein

PM10 Regelungsart Leistung | 0,5 ... 2,5 ... 10 K Auswahl von Leistungsregelung

oder Temperaturregelung.

PM10 Spg. min. Volumen 0 ... 10 V

PM10 Spg. max. Volumen 0 ... 10 V

Tab. 6 Menü EM100

EM100 – 6720891034 (2019/04)

9

Page 10

5

0

1

2

3

4

5

6

7

8

9

10

Störungen beheben

5 Störungen beheben

Nur Originalersatzteile verwenden. Schäden, die durch nicht

vom Hersteller gelieferte Ersatzteile entstehen, sind von der

Haftung ausgeschlossen.

▶ Wenn sich eine Störung nicht beheben lässt, bitte an den

zuständigen Servicetechniker wenden.

Wenn der Kodierschalter bei eingeschalteter Spannungsversorgung > 2 s auf 0 gedreht wird, werden alle Ausgänge des Moduls auf Grundstellung zurückgesetzt und Störungen gelöscht.

▶ Das Modul erneut in Betrieb nehmen.

Die Betriebsanzeige zeigt den Betriebszustand des Moduls.

0 010 013 313-001

Betriebsanzeige

Dauernd rot Ungültige Schalter-

Blinkt rot Temperaturfühler

Dauernd

gelb

Blinkt grün Keine Kommunikati-

Dauernd

grün

Dauernd

aus

Tab. 7

Mögliche Ursachen Abhilfe

▶ Modul austauschen

position oder interne

Störung

oder gültige Schalterposition wählen.

▶ Temperaturfühler

defekt oder Alarmausgang Pumpe

tauschen bzw. Pumpenfehler beheben.

Kodierschalter auf 0 ▶ Richtige Kodierstel-

lung auswählen.

▶ BUS-Verbindung

on zum BUS-System

zum EMS-Bus herstellen bzw. überprüfen.

Keine Störung,

▶ –

Normalbetrieb

Keine Spannungsversorgung

▶ Modul mit Netzspan-

nung versorgen.

6 Umweltschutz/Entsorgung

Umweltschutz ist ein Unternehmensgrundsatz der Bosch

Gruppe.

Qualität der Produkte, Wirtschaftlichkeit und Umweltschutz

sind für uns gleichrangige Ziele. Gesetze und Vorschriften zum

Umweltschutz werden strikt eingehalten.

Zum Schutz der Umwelt setzen wir unter Berücksichtigung

wirtschaftlicher Gesichtspunkte bestmögliche Technik und Materialien ein.

Verpackung

Bei der Verpackung sind wir an den länderspezifischen Verwertungssystemen beteiligt, die ein optimales Recycling gewährleisten.

Alle verwendeten Verpackungsmaterialien sind umweltverträglich und wiederverwertbar.

Elektro- und Elektronik-Altgeräte

Nicht mehr gebrauchsfähige Elektro- oder

Elektronikgeräte müssen getrennt gesammelt und

einer umweltgerechten Verwertung zugeführt

werden (Europäische Richtlinie über Elektro- und

Elektronik-Altgeräte).

Nutzen Sie zur Entsorgung von Elektro- oder Elektronik-Altgeräten die länderspezifischen Rückgabe- und Sammelsysteme.

10

EM100 – 6720891034 (2019/04)

Page 11

Table of contents 1 Explanation of symbols and safety

instructions

1 Explanation of symbols and safety instructions. . . .11

1.1 Explanation of symbols . . . . . . . . . . . . . . . . . . . . .11

1.2 General safety instructions . . . . . . . . . . . . . . . . . .12

2 Product Information . . . . . . . . . . . . . . . . . . . . . . . . . . .13

2.1 Important notices on use . . . . . . . . . . . . . . . . . . .13

2.2 Controls of the heat source. . . . . . . . . . . . . . . . . .13

2.2.1 Output control. . . . . . . . . . . . . . . . . . . . . . . . . . . .13

2.2.2 Flow temperature control. . . . . . . . . . . . . . . . . . .14

2.3 Supplied parts . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

2.4 Specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

2.5 Additional accessories . . . . . . . . . . . . . . . . . . . . .15

2.6 Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

3 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

3.1 Preparation for the installation in the heat

source . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

3.2 Installation locations . . . . . . . . . . . . . . . . . . . . . . .15

3.3 Installation of a temperature sensor on the

low loss header or downstream of the heat

exchanger. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.4 Electrical connection. . . . . . . . . . . . . . . . . . . . . . .16

3.4.1 Establishing the BUS connection and

temperature sensor (extra-low voltage side). . . .16

3.4.2 Connecting the power supply, pump,

solenoid valve or fault display (mains voltage

side) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.4.3 Overview of the terminal assignment . . . . . . . . .17

4 Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

4.1 Setting the coding switch . . . . . . . . . . . . . . . . . . .18

4.2 Commissioning of the system and module . . . . .18

4.3 Settings menu EM100 . . . . . . . . . . . . . . . . . . . . .18

1.1 Explanation of symbols

Warnings

In warnings, signal words at the beginning of a warning are used

to indicate the type and seriousness of the ensuing risk if

measures for minimising danger are not taken.

The following signal words are defined and can be used in this

document:

DANGER:

DANGER indicates that severe or life-threatening personal

injury will occur.

WARNING:

WARNING indicates that severe to life-threatening personal

injury may occur.

CAUTION:

CAUTION indicates that minor to medium personal injury may

occur.

NOTICE:

NOTICE indicates that material damage may occur.

Important information

The info symbol indicates important information where there is

no risk to people or property.

Table of contents

5 Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

6 Environmental protection/disposal . . . . . . . . . . . . . .19

EM100 – 6720891034 (2019/04)

Additional symbols

Symbol Meaning

▶ a step in an action sequence

a reference to a related part in the document

• a list entry

– a list entry (second level)

Table 1

11

Page 12

1

Explanation of symbols and safety instructions

1.2 General safety instructions

H Notes for the target group

These installation instructions are

intended for gas, plumbing, heating and

electrical contractors. All instructions

must be observed. Failure to comply

with instructions may result in material

damage and personal injury, including

danger to life.

▶ Read the installation instructions

(heat source, heating controller, etc.)

before installation.

▶ Observe the safety instructions and

warnings.

▶ Observe national and regional

regulations, technical rules and

guidelines.

▶ Record all work carried out.

H Determined use

▶ Use the product only to control

heating systems.

Any other use is considered

inappropriate. We take no responsibility

for damage caused through incorrect use.

H Installation, commissioning and

maintenance

Installation, commissioning and

maintenance must only be carried out by

a competent person.

▶ Never install the product in wet rooms.

▶ Only use genuine spare parts.

H Electrical work

Electrical work must only be carried out

by a qualified electrician.

▶ Before starting electrical work:

– Isolate all poles of the mains power

supply and secure against

reconnection.

– Make sure the mains voltage is

disconnected.

▶ The product requires different

voltages.

Do not connect the extra-low voltage

side to the mains voltage or vice versa.

▶ Also observe the connection

diagrams of other system

components.

H Handover to the user

When handing over, instruct the user

how to operate the heating system and

inform the user about its operating

conditions.

▶ Explain how to operate the heating

system and draw the user's attention

to any safety relevant action

▶ Explain that conversions and repairs

must only be carried out by a

competent person.

▶ Point out the need for inspections and

maintenance for safe and

environmentally-compatible operation.

▶ Leave the installation instructions and

the operating instructions with the

user for safekeeping.

12

EM100 – 6720891034 (2019/04)

Page 13

2 Product Information

H Damage caused by frost

The system can freeze if it is switched off:

▶ Observe the notices regarding frost

protection.

▶ Due to the additional functions, e.g.

DHW heating or pump anti-seizure

protection, the system should always

be left on.

▶ Have faults rectified immediately.

2 Product Information

• The module can adjust the boiler flow temperature or the

boiler output via an external control signal with 0–

10 V (direct voltage).

• The module signals faults in the floor standing boiler and

system faults, apart from service displays, faults in external

controllers or maintenance for the installer.

• The module can be used to activate a second solenoid valve

and for boiler versions operated with liquid gas.

• The module serves as an expansion module for EMS and

EMS plus boilers.

• The module serves as the modulating speed control “Flow

Control” of a boiler circulation pump (0-10 V or PWM) in

combination with a low loss header or heat exchanger.

The boiler circulation pump adapts the flow rate on the

boiler side and prevents an increase in the return

temperature of the boiler. The objective is to optimise the

utilisation of calorific value and to save power. The choice of

0-10 V or PWM signal makes the function suitable for floor

standing heat sources and wall-mounted indoor units

GB162 >45 kW with factory-installed pump assembly.

3 control types can be selected:

1. Flow temperature control: difference between heating flow

and system flow

2. Power regulation: parallel to boiler output (if additional

sensor is not possible)

3. Difference between heating flow and return

(recommended for heat exchangers)

The combination options for the modules are shown in the

connection diagrams.

(recommended for low loss header)

2.1 Important notices on use

• The range of functions depends on the control unit

installed. Detailed information on control units can be

found in the technical guide and on the website of the

manufacturer.

• The installation room must be appropriate for the IP rating

stated in the technical data of the module.

2.2 Controls of the heat source

This control strategy is used when the heating system is

controlled using a building management system with a 0–10 V

controller output ( Fig. 22 at the end of the document).

Input voltage Flow

0 V - 0.5 V 0 %/0 °C off

0.6 V approx. 6 %/

5.0 V approx. 50 %/

10.0 V approx. 100 %/

Table 2 Control based on output/flow temperature

2.2.1 Output control

Linear relationship between the 0–10 V signal (U in volts) and

the required performance (P in percent)

P / %

100

10

0,5

110

Fig. 1 Linear relationship between the 0–10 V signal (U in

The connected heat sources are enabled and disabled

according to the required output.

volts) and the required performance P (in percent

with reference to the maximum system

performance)

temperature/

output setpoint

(boiler)

approx. 15 °C

approx. 50 °C

approx. 90 °C

Boiler status

on if > min. output

on

on/maximum

U / V

0010013227-002

EM100 – 6720891034 (2019/04)

13

Page 14

2

Product Information

2.2.2 Flow temperature control

Linear relationship between the 0–10 V signal (U in volts) and

the required flow temperature in °C with reference to the

minimum flow temperature range to the maximum flow

temperature range [default setting 20 to 90 °C]):

/ °C

90

20

0,5

110

U / V

0010024409-001

Fig. 2 Linear relationship between the 0–10 V signal (U in

volts) and the required flow temperature in °C)

The connected heat sources are enabled and disabled

according to the required flow temperature.

2.3 Supplied parts

Fig. 6 at end of document:

[1] Module

[2] Bag with strain relief

[3] Installation Manual

2.4 Specification

This product conforms to European directives and

supplementary national requirements in design and

marking.

You can request the conformity declaration of the product. If

you require this, contact the address on the back cover of these

instructions.

operation. Compliance is demonstrated by the CE

Specification

Dimensions (W × H × D)

151 × 184 × 61 mm (for more

dimensions Fig.

document)

Maximum conductor crosssection

• 230 V terminal • 2.5 mm

• Extra-low voltage terminal • 1.5 mm

7

at end of

2

2

Specification

Rated voltages

• BUS • 15 V DC

(reverse polarity

protected)

• Module mains voltage • 230 V AC, 50 Hz

• User interface • 15 V DC

(reverse polarity

protected)

• Pump, solenoid valve,

• 230 V AC, 50 Hz

interference output

Fuse 230 V, 5 AT

BUS interface EMSand EMS plus

Power consumption –

< 3 W

Standby

Max. power output

• per connection(PC0)

• 400 W (high-efficiency

pumps permissible:

<30 A for 10 ms)

• per connection(OE1)

• 120 W (high-efficiency

pumps permissible:

< 30 A for 10 ms)

Permitted ambient

0 ... 60 °C

temperature

IP rating IP 44

Protection class I

ID no. Data plate ( Fig. 21 at the

end of document)

Table 3

°C °C °C

20 12486 50 3605 80 1256

25 10000 55 2989 85 1070

30 8060 60 2490 90 915

35 6536 65 2084 100 677

40 5331 70 1753 – –

45 4372 75 1480 – –

Table 4 Measurements of low loss header temperature

sensor (T0)

14

EM100 – 6720891034 (2019/04)

Page 15

3 Installation

2.5 Additional accessories

For detailed information about suitable accessories, refer to

the catalogue or Internet page of the manufacturer.

• Low loss header temperature sensor; connection to T0

• Primary pump; connection to PC0

Installation of additional accessories

▶ Install the additional accessories in accordance with legal

regulations and the instructions supplied.

2.6 Cleaning

▶ Wipe the casing with a damp cloth when necessary. Never

use aggressive or caustic cleaning agents for this.

3 Installation

DANGER:

Danger to life from electric shock!

Touching live electrical parts can cause an electric shock.

▶ Before installing this product: Disconnect the heat source

and all other BUS nodes from the mains voltage across all

poles.

▶ Before commissioning: Mount the cover

( Fig. 20 at end of document).

3.1 Preparation for the installation in the heat

source

▶ Check by referring to the installation instructions of the

heat source whether it is possible to install modules

(e.g. EM100) in the heat source.

▶ If the module can be installed in the heat source without a

mounting rail, prepare the module ( Fig. 8 and 9 at end

of document).

3.2 Installation locations

▶ Install the module on a wall, ( Fig. 10 and 11 at end

of document), on a mounting rail ( Fig. 12 at end of

document), in an assembly or in the heat source.

▶ When the module is installed in a heat source, observe the

heat source instructions.

▶ Remove the module from the mounting rail

( Fig. 13 at end of document).

3.3 Installation of a temperature sensor on the

low loss header or downstream of the heat

exchanger

The low loss header temperature sensor T0 should as a priority

be connected to EM100. In wall mounted boilers equipped with

EMS plus, the sensor can also be connected to the device or a

MM100.

Installation on the low-loss header

( Fig. 23 and 25 at the end of the document)

Position of flow temperature sensor (T0):

A

ϑ

1

T0

12

ϑ

2

Fig. 3 Position of flow temperature sensor (T0)

[1] all heat sources

[2] all heating circuits

A low loss header model 1

B low loss header model 2

overall flow temperature of all heat sources

1

overall return temperature of all heat sources

2

overall flow temperature of all heating circuits

3

overall return temperature of all heating circuits

4

T0 flow temperature sensor on the low loss header

T0 must be positioned so

sources [1] independently of the flow rate. This is the only way

also to ensure stable operation of the control with small loads.

To ensure optimum control response, the flow should circulate

around the temperature sensor. This can be achieved by a

combination of tee, tap extension and sensor set.

B

ϑ

3

ϑ

1

1

ϑ

ϑ

4

2

0 010 013 230-001

is detected on the side of all heat

3

T0

ϑ

ϑ

3

2

4

EM100 – 6720891034 (2019/04)

15

Page 16

3

Installation

Optimised sensor installation downstream of the heat

exchanger

The temperature sensor (T0) must be mounted on the flow

downstream of the heat exchanger on the secondary side

(wet sensor) ( Fig. 24 at end of document).

There are two ways to ensure optimised sensor installation

downstream of the heat exchanger ( Item [1] with angled

screw connection and Item [2], Fig. 4 "Optimised sensor

installation"):

24

B

A

1

T0

24

B

A

2

T0

0010024454-001

Fig. 4 Optimised sensor installation

The temperature sensor must be positioned so the

measurement is taken at the centre of the pipe.

▶ Use tap extensions to adjust the installation depth of the low

loss header temperature sensor ( Installation instructions

of low loss header sensor set). If installed correctly, the

sensor projects 1-2 cm into the heat exchanger.

3.4 Electrical connection

▶ Obser ve electrical regulations and use at least

cable H05 VV-...

3.4.1 Establishing the BUS connection and temperature

sensor (extra-low voltage side)

▶ If the conductor cross-sections vary, use a junction box to

connect the BUS nodes.

▶ Switch BUS nodes [B] via the junction box[A] in star

( Fig. 18 at end of document) or via BUS nodes with 2

BUS connections in series.

If the maximum total length of the BUS connections between all

BUS nodes is exceeded or the BUS system has a ring structure,

commissioning of the system is not possible.

Maximum total length of BUS connections:

• 100 m with 0.50 mm

• 300 m with 1.50 mm

2

conductor cross-section

2

conductor cross-section

▶ To avoid inductive interference: Make sure all low-voltage

cables are routed separately from supply voltage carrying

cables (min. clearance 100 mm).

▶ In the case of external inductive effects (e.g. from PV systems)

use shielded cable (e.g. LiYCY) and ground one end of the

shield. |Connect the shield to the building's earthing system,

e.g. to a free earth conductor terminal or water pipes, and not

to the connecting terminal for earth leads in the module.

When extending the sensor leads, use the following conductor

cross-sections:

• 0.75 to 1.50 mm

• 1.50 mm

2

conductor cross-section for up to 20 m

2

conductor cross-section for 20 m to 100 m

▶ Route cables through the grommets provided and connect

them as shown in the connection diagrams.

3.4.2 Connecting the power supply, pump, solenoid valve

or fault display (mains voltage side)

The assignment of the electrical connection depends on which

system is installed. The description at the end of the document

in Fig. 14 to 17 is a possible suggestion for the electrical

connection. Not all steps are shown in black. This makes it

easier to see, which steps belong together.

▶ Only use electric cables of the same quality.

▶ Make sure the power supply is connected to the correct

phases.

A power supply via an earthed safety plug is not permissible.

▶ Connect only components and assemblies to the outputs as

described in these instructions. Do not connect any

additional controls that operate other system components.

▶ Route cables through the grommets, connect them as

shown in the connection diagrams and secure them with

the strain relief devices included in the scope of delivery

( Fig. 14 to 17 at the end of this document).

The maximum power consumption of the connected

components and assemblies must not exceed the power output

stated in the specifications for the module.

▶ If the mains voltage is not supplied via the electronic system

of the heat source: Install a standard all-pole isolator

(in accordance with EN 60335-1) on site to interrupt the

mains voltage.

16

EM100 – 6720891034 (2019/04)

Page 17

3 Installation

0

1

2

3

4

5

6

7

8

9

10

0

1

2

3

4

5

6

7

8

9

10

3.4.3 Overview of the terminal assignment

This overview indicates which system parts can be connected.

EM100

120/230 V AC

230 VAC

OE1 PC0

N

L

OE1 OE1

120/230VAC120/230VAC

NL N N74 N6375L

230 VAC

Caption to the figure above and connection diagrams with

system schematics at end of document:

Earth connection

Connecting terminal designations:

230 V AC Mains voltage connection

BUS BUS system connection

BMS Building Management System with 0-10 V interface

HS Heat Source on BUS system

OE1-74 Mains voltage output, solenoid valve

OE1-75 Fault output (230 V)

PC0 Mains voltage output, pump (230 V)

IE0 Pump alarm output

OP0 Pump on/off (output/potential-free contact ≤ 24 V)

T0 Low loss header temperature sensor input

IO1-1,2 Heat source feedback output (0–10 V)

IO1-3,4 Heat source activation input (0–10 V)

OC0 1-2 Pump control signal output (0-10 V/PWM)

OC0 1-3 Pump check-back signal input (PWM), optional

CON Control unit with BUS system (Controller)

MC Boiler control device (Master Controller)

MM 100 Heating circuit module (EMS/EMS plus)

EM100 Extension module

IE0 OP0

1212 12

NL

M

PC0

1)

2)

3)

3)

Depending on what the module is used for (coding at the

module and configuration via the control unit), connect the

system parts as specified in the corresponding connection

diagram.

≤ 24 V

IO141OC0

213 23

OC0

3

≤ 24 V

OP0IE0

T0

12

T0

BUS

BUS

0-10 V

(+) (–)12(+) (–)

IO1

0-10 V

34

IO1

123

0-10V

OC0

21

123

PWM

OC0

0010025508-001

1) The pump can also be connected directly to the building

circuit breaker if continuous current is required.

2) With the heat exchanger, T0 is the flow temperature

sensor.

3) Observe coding switch position.

EM100 – 6720891034 (2019/04)

17

Page 18

4

0

1

2

3

4

5

6

7

8

9

10

Commissioning

4 Commissioning

First make all electrical connections and then carry out the

commissioning!

▶ Observe the installation instructions for all components

and assemblies in the system.

▶ Only switch on the power supply if the coding switch is set up.

▶ If a control unit is connected, it is recommended to start the

configuration wizard.

NOTICE:

Risk of damage to system through pump failure!

▶ Fill and vent the system before switching it on so that the

pumps do not run dry.

4.1 Setting the coding switch

Coding switch with On/Off indicator of the module and a status

display of the connected heat sources or modules:

0 010 013 313-001

Fig. 5 Coding switch with module status display, and a status

display of the connected heat sources or modules

Coding Function of module

Fault output

Output control of the

2nd solenoid valve activation

1)

0

– – – – – –

Flow temperature control of the

Pump control via

Pump control via 0-10 V

heat source

heat source

1 – –

2 – –

3 – – –

4 – – –

5 – – – –

2)

6-10

– – – – – –

1) Off (delivered condition)

2) Unused

Table 5 Coding and function

4.2 Commissioning of the system and module

If a control unit is connected, start the automatic configuration

wizard.

PWM signal

4.3 Settings menu EM100

The settings of the EM100 can be made via the control unit

( Table 6 "EM100 menu").

The basic settings are depicted as highlighted in the following

table.

Menu item Settings/adjustment range Remark/restriction

PM10 pump modulation Yes | No

PM10 control type Output | 0.5 ... 2.5 ... 10 K Selection of output control or

PM10 voltage min. vol. 0 ... 10 V

PM10 voltage max. vol. 0 ... 10 V

Table 6 EM100 menu

18

EM100 – 6720891034 (2019/04)

temperature control.

Page 19

5 Troubleshooting

0

1

2

3

4

5

6

7

8

9

10

5 Troubleshooting

Use only original spare parts. Damage caused by the use of

spare parts not supplied by the manufacturer is excluded from

the warranty.

▶ If a fault cannot be rectified, please contact your local

service engineer.

If the coding switch is set to 0 for > 2 s when the power supply

is switched on, all outputs of the module are reset to their

default settings and faults are deleted.

▶ Restart the module.

The On/Off indicator indicates the operating condition of the

module.

0 010 013 313-001

Status

indicator

Constantly

red

Red

flashing

Constantly

yellow

Green

flashing

Constantly

green

Constantly

OFF

Table 7

Possible causes Remedy

Invalid switch position

or internal fault

▶ Replace the module

or select valid

switch position.

Temperature sensor

faulty or pump alarm

output

▶ Replace

temperature sensor

or eliminate pump

fault.

Coding switch set to 0 ▶ Select the correct

encoding position.

No communication

with the BUS system

▶ Establish the BUS

connection to the

EMS BUS.

No fault, normal

▶ –

operation

Lack of electrical

supply

▶ Supply the module

with mains voltage.

6 Environmental protection/disposal

Environmental protection is a key commitment of the Bosch

Group.

Quality of products, efficiency and environmental protection

are equally important objectives for us. Environmental

protection laws and regulations are strictly observed.

To protect the environment, we use the best possible

technology and materials while taking into account economic

considerations.

Packaging

Where packaging is concerned, we participate in countryspecific recycling processes that ensure optimum recycling.

All of our packaging materials are environmentally compatible

and can be recycled.

Old electrical and electronic appliances

Electrical or electronic appliances that are no

longer serviceable must be collected separately

and sent for environmentally compatible recycling

(in accordance with the European Directive on

Waste Electrical and Electronic Equipment).

To dispose of old electrical or electronic appliances, you should

use the return and collection systems put in place in the country

concerned.

EM100 – 6720891034 (2019/04)

19

Page 20

Inhoudsopgave

Inhoudsopgave 1 Toelichting bij de symbolen en

veiligheidsinstructies

1 Toelichting bij de symbolen en

veiligheidsinstructies . . . . . . . . . . . . . . . . . . . . . . . . . . 20

1.1 Symboolverklaringen. . . . . . . . . . . . . . . . . . . . . . . 20

1.2 Algemene veiligheidsvoorschriften. . . . . . . . . . . . 21

2 Gegevens betreffende het product. . . . . . . . . . . . . . . 22

2.1 Belangrijke adviezen voor het gebruik . . . . . . . . . 22

2.2 Regeling van de warmteproducent . . . . . . . . . . . . 22

2.2.1 Vermogensregeling . . . . . . . . . . . . . . . . . . . . . . . . 22

2.2.2 Aanvoertemperatuurregeling . . . . . . . . . . . . . . . . 22

2.3 Leveringsomvang . . . . . . . . . . . . . . . . . . . . . . . . . . 23

2.4 Technische gegevens . . . . . . . . . . . . . . . . . . . . . . . 23

2.5 Aanvullend toebehoren . . . . . . . . . . . . . . . . . . . . . 23

2.6 Reiniging. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

3 Installatie . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

3.1 Voorbereiding voor installatie in de cv-ketel. . . . . 24

3.2 Installatieplaatsen . . . . . . . . . . . . . . . . . . . . . . . . . 24

3.3 Installatie van een temperatuursensor op de

evenwichtsfles, of achter de warmtewisselaar . . . 24

3.4 Elektrische aansluiting. . . . . . . . . . . . . . . . . . . . . . 25

3.4.1 Aansluiting BUS-verbinding en

temperatuursensor (laagspanningszijde). . . . . . . 25

3.4.2 Aansluiting voedingsspanning pomp,

magneetventiel of storingsindicatie

(netspanningszijde). . . . . . . . . . . . . . . . . . . . . . . . 25

3.4.3 Overzicht bezetting aansluitklemmen . . . . . . . . . 26

4 Inbedrijfstelling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

4.1 Codeerschakelaar instellen . . . . . . . . . . . . . . . . . . 27

4.2 Inbedrijfstelling van de installatie en de

module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

4.3 Menu instellingen EM100 . . . . . . . . . . . . . . . . . . . 27

1.1 Symboolverklaringen

Waarschuwingen

Bij waarschuwingen geven signaalwoorden de soort en de ernst

van de gevolgen aan indien de maatregelen ter voorkoming van

het gevaar niet worden opgevolgd.

De volgende signaalwoorden zijn vastgelegd en kunnen in dit

document worden gebruikt:

GEVAAR:

GEVAAR betekent dat zwaar tot levensgevaarlijk lichamelijk

letsel zal ontstaan.

WAARSCHUWING:

WAARSCHUWING betekent dat zwaar tot levensgevaarlijk

lichamelijk letsel kan ontstaan.

VOORZICHTIG:

VOORZICHTIG betekent, dat licht tot middelzwaar persoonlijk

letsel kan ontstaan.

OPMERKING:

OPMERKING betekent dat materiële schade kan ontstaan.

Belangrijke informatie

Belangrijke informatie, zonder gevaar voor mens of materialen,

wordt met het getoonde info-symbool gemarkeerd.

5 Storingen verhelpen . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

6 Milieubescherming/afvalverwerking . . . . . . . . . . . . . 28

20

Aanvullende symbolen

Symbool Betekenis

▶ Handelingsstap

Kruisverwijzing naar een andere plaats in

het document

• Opsomming/lijstpositie

– Opsomming/lijstpositie (2e niveau)

Tabel 1

EM100 – 6720891034 (2019/04)

Page 21

1 Toelichting bij de symbolen en veiligheidsinstructies

1.2 Algemene veiligheidsvoorschriften

H Instructies voor de doelgroep

Deze installatiehandleiding is bedoeld

voor installateurs van gas- en waterinstallaties, verwarmings- en elektrotechniek.

Houd de instructies in alle handleidingen

aan. Indien deze niet worden aangehouden kunnen materiële schade, lichamelijk

letsel en zelfs levensgevaar ontstaan.

▶ Lees de installatiehandleidingen

(warmteproducent, verwarmingsregelaar enz.) voor de installatie.

▶ Neem de veiligheidsinstructies en

waarschuwingsaanwijzingen in acht.

▶ Neem de nationale en regionale voor-

schriften, technische regels en richtlijnen in acht.

▶ Documenteer uitgevoerde werkzaam-

heden.

H Gebruik volgens de voorschriften

▶ Gebruik het product uitsluitend voor

het regelen van cv-installaties.

Ieder ander gebruik komt niet overeen met

de voorschriften. Daaruit resulterende

schade valt niet onder de fabrieksgarantie.

H Installatie, inbedrijfstelling en

onderhoud

Installatie, inbedrijfstelling en onderhoud

mogen alleen door een erkend installateur worden uitgevoerd.

▶ Installeer het product niet in vochtige

ruimten.

▶ Gebruik alleen originele reserve-on-

derdelen.

Elektrotechnische werkzaamheden

H

Elektrotechnische werkzaamheden mogen alleen door elektrotechnici worden

uitgevoerd.

▶ Vóór elektrotechnische

werkzaamheden:

– Schakel de netspanning (over alle

polen) spanningsloos en zorg ervoor

dat ze niet per ongeluk opnieuw kunnen worden ingeschakeld.

– Spanningsloosheid vaststellen.

▶ Het product heeft verschillende span-

ningen nodig.

Sluit de laagspanningszijde niet aan

op de netspanning en omgekeerd.

▶ Respecteer de aansluitschema's van

de overige installatiedelen ook.

H Overdracht aan de eigenaar

Instrueer de eigenaar bij de overdracht

in de bediening en bedrijfsomstandigheden van de cv-installatie.

▶ Leg de bediening uit – ga daarbij in

het bijzonder in op alle veiligheidsrelevante handelingen.

▶ Wijs erop, dat ombouw of herstellin-

gen alleen door een erkend installateur mogen worden uitgevoerd.

▶ Wijs op de noodzaak tot inspectie en

onderhoud voor een veilig en milieuvriendelijk bedrijf.

▶ Geef de installatie- en bedienings-

handleidingen aan de eigenaar in

bewaring.

EM100 – 6720891034 (2019/04)

21

Page 22

2

Gegevens betreffende het product

H Schade door vorst

Wanneer de installatie niet in bedrijf is,

kan deze bevriezen:

▶ Respecteer de instructies voor

vorstbeveiliging.

▶ Laat de installatie altijd ingeschakeld,

vanwege extra functies zoals bijvoorbeeld warmwaterbereiding of blokkeerbescherming.

▶ Laat optredende storingen direct

oplossen.

2 Gegevens betreffende het product

• De module kan via een extern stuursignaal met 0-10 V (gelijkspanning) de aanvoertemperatuur van de cv-ketel of het

vermogen van de cv-ketel aanpassen.

• De module meldt storingen van de cv-ketel en ook systeemstoringen, met uitzondering van de servicedisplays, storingen van externe regelaars of onderhoud voor de installateur.

• De module kan bij de sturing van een tweede magneetventiel worden gebruikt en bij cv-ketels met vloeibaar gas worden toegepast.

• De module is bedoeld als uitbreidingsmodule voor EMS- en

EMS plus-cv-ketel.

• De module is bedoeld voor de modulerende toerentalregeling “Flow Control” van een ketelcircuitpomp (0-10 V of

PWM) in combinatie met een evenwichtsfles of warmtewisselaar.

De ketelcircuitpomp past het debiet van de cv-ketel aan en

voorkomt een retourtemperatuurverhoging van de cv-ketel.

Het doel is een geoptimaliseerde condensatiebenutting en

stroombesparing. Door 0-10 V of PWM-signaal te selecteren, is de functie geschikt bij op de vloerstaande cv-ketels

en wandtoestellen GB162 >45 kW met een pompgroep af

fabriek.

Er kan uit 3 regeltypen worden gekozen:

1. Regeling van de cv-aanvoertemperatuur: Verschil cv-aanvoer

met installatie-aanvoer

2. Vermogensregeling: parallel aan het ketelvermogen

(als er geen extra sensor mogelijk is)

3. Verschil cv-aanvoer met cv-retour (aanbevolen voor

warmtewisselaar)

De combinatiemogelijkheden van de module zijn te vinden in de

aansluitschema's.

(aanbevolen voor evenwichtsfles)

2.1 Belangrijke adviezen voor het gebruik

• De functionaliteit is afhankelijk van de geïnstalleerde bedieningseenheid. Meer informatie over de bedieningseenheden vindt u in in de catalogus, de planningsdocumenten en

de website van de fabrikant.

• De opstellingsruimte moet voor de beschermingklasse conform de technische gegevens van de module geschikt zijn.

2.2 Regeling van de warmteproducent

Deze regelstrategie wordt toegepast, als de cv-installatie via

een gebouwautomatiseringssysteem met een 0-10 V-regelaaruitgang wordt geregeld ( afbeelding 22 aan het einde van het

document).

Ingangsspanning Gewenste waarde

0 V - 0,5 V 0 %/0 °C uit

0,6 V ca. 6 %/ca. 15 °C aan, wanneer >

5,0 V ca. 50 %/ca. 50 °C aan

10,0 V ca. 100 %/ca. 90 °C aan / maximum

Tabel 2 Regeling volgens vermogen/aanvoertemperatuur

2.2.1 Vermogensregeling

Lineaire relatie tussen 0-10 V-signaal (U in Volt) en gevraagde

vermogen (P in procenten gerelateerd aan het maximale

vermogen van de installatie):

P / %

100

10

0,5

Afb. 1 Lineaire relatie tussen 0-10 V-signaal (U in Volt) en

De aangesloten warmteproducenten worden conform het

gevraagde vermogen in- of uitgeschakeld.

2.2.2 Aanvoertemperatuurregeling

Lineaire relatie tussen 0-10 V-signaal (U in Volt) en gevraagde

aanvoertemperatuur in °C gerelateerd aan het bereik mini-

male aanvoertemperatuur tot maximale aanvoertemperatuur

[fabrieksinstelling 20 tot 90 °C]):

aanvoertemperatuur/

vermogen (cv-ketel)

110

gevraagde vermogen (P in procenten)

Status cv-ketel

min. vermogen

U / V

0010013227-002

22

EM100 – 6720891034 (2019/04)

Page 23

2 Gegevens betreffende het product

/ °C

90

20

0,5

110

U / V

0010024409-001

Afb. 2 Lineaire relatie tussen 0-10 V-signaal (U in Volt) en

gevraagd vermogen van de aanvoertemperatuur

in °C)

De aangesloten warmteproducenten worden conform de gevraagde aanvoertemperatuur in- of uitgeschakeld.

2.3 Leveringsomvang

Afb. 6 aan het einde van het document:

[1] Module

[2] Zak met trekontlastingen

[3] Installatiehandleiding

2.4 Technische gegevens

Dit product voldoet qua constructie en werking aan

de Europese richtlijnen evenals aan de bijkomende

toond door het CE-kenmerk.

De conformiteitverklaring van het product kunt u aanvragen.

Neem daarvoor contact op met het adres vermeld op de achterkant van deze handleiding.

nationale vereisten. De conformiteit wordt aange-

Technische gegevens

Afmetingen (B × H × D) 151 × 184 × 61 mm (overige

maten afb. 7 aan het eind

van het document)

Maximale geleiderdiameter

• Aansluitklem 230 V • 2,5 mm

• Aansluitklem laagspanning

• 1,5 mm

2

2

Nominale spanningen

• BUS

• 15 V DC

(beveiligd tegen ompolen)

• Netspanning module • 230 V AC, 50 Hz

• Bedieningseenheid

• 15 V DC

(beveiligd tegen ompolen)

• Pomp, magneetventiel,

• 230 V AC, 50 Hz

storingsuitgang

Zekering 230 V, 5 AT

BUS-interface EMS en EMS plus

Technische gegevens

Opgenomen vermogen –

< 3 W

standby

max. vermogen

• Per aansluiting (PC0)

• 400 W (hoogrendementpompen toegelaten:

< 30 A gedurende 10 ms)

• Per aansluiting (OE1)

• 120 W (hoogrendementpompen toegelaten:

< 30 A gedurende 10 ms)

Toegest. omgevingstemp. 0 ... 60 °C

Beschermingsklasse IP 44

Veiligheidsklasse I

Identificatienummer Typeplaat ( afb. 21 aan ein-

de van het document)

Tabel 3

°C °C °C

20 12486 50 3605 80 1256

25 10000 55 2989 85 1070

30 8060 60 2490 90 915

35 6536 65 2084 100 677

40 5331 70 1753 – –

45 4372 75 1480 – –

Tabel 4 Meetwaarden evenwichtsflestemperatuursensor (T0)

2.5 Aanvullend toebehoren

Exacte informatie over geschikt toebehoren is opgenomen in de

catalogus of de internetpagina van de fabrikant.

• Evenwichtsflestemperatuursensor: aansluiting op de T0

• Primaire pomp: aansluiting op de PC0

Installatie van de aanvullende toebehoren

▶ Installeer de aanvullende toebehoren overeenkomstig de

wettelijke voorschriften en de meegeleverde handleidingen.

2.6 Reiniging

▶ Indien nodig met een vochtige doek de behuizing schoon

wrijven. Gebruik daarbij geen scherpe of bijtende reinigingsmiddelen.

EM100 – 6720891034 (2019/04)

23

Page 24

3

Installatie

3 Installatie

GEVAAR:

Levensgevaar door elektrische stroom!

Aanraken van elektrische onderdelen die onder spanning staan

kan een elektrische schok veroorzaken.

▶ Voor de installatie van dit product: warmteproducent en

alle andere BUS-deelnemers over alle polen losmaken van

de netspanning.

▶ Voor de inbedrijfstelling: breng de afdekking aan

( afb. 20 aan het einde van het document).

3.1 Voorbereiding voor installatie in de cv-ketel

▶ Via de installatiehandleiding van de warmteproducent con-

troleren, of deze de mogelijkheid biedt, een module (bijvoorbeeld EM100) in de warmteproducent te installeren.

▶ Wanneer de module zonder rail in de warmteproducent kan

worden geïnstalleerd, de module voorbereiden

( afbeelding 8 en 9 aan het einde van het document).

3.2 Installatieplaatsen

▶ De module aan een wand ( afbeelding 10 en 11 aan het

einde van het document), aan een rail ( afbeelding 12

aan het einde van het document), in een bouwgroep of in de

warmteproducent installeren.

▶ Respecteer de handleiding bij montage van de module in

een cv-ketel.

▶ Verwijder de module van de rail

( afb. 13 aan einde document).

3.3 Installatie van een temperatuursensor op

de evenwichtsfles, of achter de

warmtewisselaar

De evenwichtsflestemperatuursensor T0 moet met prioriteit

met de EM100 worden verbonden. Bij cv-ketels met EMS plus

kan de sensor ook op het toestel of een MM100 worden aangesloten.

Installatie op de evenwichtsfles

( afbeelding 23 en 25 aan het einde van het document)

Positie temperatuursensor aanvoer (T0):

A

ϑ

1

T0

12

ϑ

2

B

ϑ

3

ϑ

1

1

ϑ

ϑ

4

2

T0

ϑ

2

ϑ

4

0 010 013 230-001

3

Afb. 3 Positie aanvoertemperatuursensor (T0)

[1] Alle warmtebronnen

[2] Alle cv-circuits

A Evenwichtsfles model 1

B Evenwichtsfles model 2

Gemeenschappelijke aanvoertemperatuur van alle

1

warmtebronnen

Gemeenschappelijke retourtemperatuur van alle

2

warmtebronnen

Gemeenschappelijke aanvoertemperatuur van alle

3

cv-circuits

Gemeenschappelijke retourtemperatuur van alle

4

cv-circuits

T0 Temperatuursensor aanvoer op de evenwichtsfles

T0 moet zodanig worden geplaatst, dat

het debiet aan de zijde van alle warmteproducenten [1] wordt

onafhankelijk van

3

geregistreerd. Alleen zo kan de regeling ook bij kleine belastingen stabiel werken.

Voor een optimaal regelgedrag, moet er aan alle zijden van de

temperatuursensor stroming zijn. Dit kan worden bereikt door

een combinatie van een T-stuk, een kraanverlenging en een

sensorset.

Geoptimaliseerde sensormontage achter de

warmtewisselaar

De temperatuursensor (T0) moet op de aanvoer naar de warmtewisselaar aan de secundaire zijde (vochtsensor) worden gemonteerd ( afbeelding 24 aan het einde van het document).

Voor een geoptimaliseerde sensormontage achter de warmtewisselaar bestaan er twee mogelijkheden ( positie [1] met

hoekschroefverbinding en positie [2], Afb. 4 "Geoptimaliseerde sensormontage"):

24

EM100 – 6720891034 (2019/04)

Page 25

3 Installatie

24

B

A

1

T0

24

B

A

2

T0

0010024454-001

Afb. 4 Geoptimaliseerde sensormontage

De temperatuursensor moet in het midden van de buis meten.

▶ De inbouwdiepte van de evenwichtsfles-temperatuursen-

sor met kraanverlengingen aanpassen

( installatiehandleiding sensorset evenwichtsfles).

Bij een correcte montage steekt de sensor 1-2 cm in de

warmtewisselaar.

3.4 Elektrische aansluiting

▶ Gebruik rekening houdend met de geldende voorschriften

voor de aansluiting minimaal elektrische kabel

model H05 VV-....

3.4.1 Aansluiting BUS-verbinding en temperatuursensor

(laagspanningszijde)

▶ Gebruik bij verschillende geleiderdiameters een verdeel-

doos voor de aansluiting van de BUS-deelnemers.

▶ Schakel BUS-deelnemers [B] via de verdeeldoos [A] in ster

( afbeelding 18 aan het einde van het document) of via

BUS-deelnemers met 2 BUS-aansluitingen in serie.

Wanneer de maximale totale lengte van de BUS-verbinding tussen alle BUS-deelnemers wordt overschreden of in het BUS-systeem een ringstructuur bestaat, is de inbedrijfstelling van de

installatie niet mogelijk.

Maximale totale lengte van de BUS-verbindingen:

• 100 m met 0,50 mm

• 300 m met 1,50 mm

▶ Installeer alle laagspanningskabels van netspanning gelei-

dende kabels afzonderlijk (minimale afstand 100 mm) om

inductieve beïnvloeding te vermijden.

2

geleiderdiameter

2

geleiderdiameter

▶ Voer bij externe inductieve invloeden (bijvoorbeeld van fo-

tovoltaïsche installaties) de kabel afgeschermd uit (bijvoorbeeld LiYCY) en aard de afscherming eenzijdig. Sluit de

afscherming niet aan op de aansluitklem voor de randaarde

in de module, maar op de huisaarde, bijvoorbeeld vrije afleiderklem of waterleiding.

Gebruik bij verlenging van de sensorkabel de volgende geleiderdiameters:

• Tot 20 m met 0,75 tot 1,50 mm

• 20 m tot 100 m met 1,50 mm

2

geleiderdiameter

2

geleiderdiameter

▶ Installeer de kabel door de al voorgemonteerde tulen en

conform de aansluitschema's.

3.4.2 Aansluiting voedingsspanning pomp, magneetventiel of storingsindicatie (netspanningszijde)

De bezetting van de elektrische aansluitingen is afhankelijk van

de geïnstalleerde installatie. De aan het einde van het document in afb. 14 t/m 17 getoonde beschrijving is een voorstel

voor de procedure van de elektrische aansluiting. De handelingsstappen zijn deels niet zwart weergegeven. Daarmee kan

gemakkelijker worden herkend, welke handelingsstappen bij

elkaar horen.

▶ Gebruik alleen elektriciteitskabels van dezelfde kwaliteit.

▶ Let erop dat de fasen van de netaansluiting correct worden

geïnstalleerd.

Netaansluiting via een stekker met randaarde is

niet toegestaan.

▶ Sluit op de uitgangen alleen componenten en bouwgroepen

aan conform deze handleiding. Sluit geen extra besturingen

aan die andere installatiedelen aansturen.

▶ Voer de kabels door de tulen, sluit ze conform de aansluit-

schema's aan en borg ze met de meegeleverde trekontlastingen ( afb. 14 t/m 17 aan het eind van het document).

Het maximale opgenomen vermogen van de aangesloten componenten en bouwgroepen mag niet hoger worden dan het

maximaal vermogen zoals gespecificeerd in de technische gegevens van de module.

▶ Installeer lokaal een genormeerde scheidingsinrichting

(conform EN 60335-1) voor de onderbreking van de netspanning over alle polen wanneer de netspanning niet via

de elektronica van de warmeproducent verloopt.

EM100 – 6720891034 (2019/04)

25

Page 26

3

0

1

2

3

4

5

6

7

8

9

10

0

1

2

3

4

5

6

7

8

9

10

Installatie

3.4.3 Overzicht bezetting aansluitklemmen

Dit overzicht toont, welke installatiedelen kunnen worden aangesloten.

EM100

120/230 V AC

230 VAC

OE1 PC0

N

L

OE1 OE1

120/230VAC120/230VAC

NL N N74 N6375L

230 VAC

Legenda bij afbeelding boven en bij de aansluitschema's

met installatievoorbeelden aan het eind van het document:

Randaarde

Identificatie aansluitklemmen:

230 V AC Aansluiting netspanning

BUS Aansluiting BUS-systeem

BMS Gebouwautomatiseringssysteem (building manage-

ment system) met 0-10 V-interface

HS Warmteproducent (heat source) op het

BUS-systeem

OE1-74 Uitgang netspanning magneetventiel

OE1-75 Uitgang storing (230 V)

PC0 Uitgang netspanning pomp (230 V)

1)

IE0 Alarmuitgang pomp

OP0 Pomp aan/uit (uitgang/potentiaalvrij contact ≤ 24 V)

T0 Ingang evenwichtsflestemperatuursensor

IO1-1,2 Uitgang terugmelding warmteproducent (0-10 V)

IO1-3,4 Ingang sturing warmteproducent (0-10 V)

OC0 1-2 Uitgang controlesignaal pomp (0-10 V/PWM)

OC0 1-3 Ingang terugmelding pomp (PWM), optioneel

CON Bedieningseenheid met BUS-systeem (controller)

MC Sturing cv-ketel (master controller)

1) Wanneer er geen continue stroom wordt benodigd, kan de

pomp ook direct op de aanwezige zekeringsautomaat

worden aangesloten.

2) Bij de warmtewisselaar is T0 de

aanvoertemperatuursensor.

3) Let op de stand van de codeerschakelaar.

IE0 OP0

1212 12

NL

M

PC0

2)

3)

3)

Afhankelijk van het gebruik van de module (codering op de module en configuratie via de bedieningseenheid) moeten de installatiedelen volgens het bijbehorende aansluitschema

worden aangesloten.

≤ 24 V

IO141OC0

213 23

OC0

3

≤ 24 V

OP0IE0

T0

12

T0

BUS

BUS

(+) (–)12(+) (–)

IO1

0-10 V

34

IO1

0-10 V

123

0-10V

OC0

21

123

PWM

OC0

MM 100 Cv-circuitmodule (EMS/EMS plus)

EM100 Uitbreidingsmodule

0010025508-001

26

EM100 – 6720891034 (2019/04)

Page 27

4 Inbedrijfstelling

0

1

2

3

4

5

6

7

8

9

10

4 Inbedrijfstelling

Sluit alle elektrische aansluitingen correct aan en voer pas daarna de inbedrijfstelling uit!

▶ Neem de installatiehandleidingen van alle componenten en

bouwgroepen van de installatie in acht.

▶ Schakel de voedingsspanning alleen in als de codeerscha-

kelaar is ingesteld.

▶ Wanneer een bedieningseenheid is aangesloten, wordt

aanbevolen de configuratie-assistent te starten.

OPMERKING:

Schade aan de installatie door een defecte pomp!

▶ Vul en ontlucht de installatie voor het inschakelen, zodat de

pompen niet drooglopen.

4.1 Codeerschakelaar instellen

Codeerschakelaar met bedrijfsindicatie van de module en toestandsindicatie van de aangesloten warmteproducent of module:

0 010 013 313-001

Afb. 5 Codeerschakelaar met toestandsindicatie van de

module en toestandsindicatie van de aangesloten

warmteproducent of module

Codering Functie van de module

Uitgang storing

Sturing 2e magneetventiel

1)

0

– – – – – –

Aanvoertemperatuurregeling van de

warmteproducent

warmteproducent

Pompregeling met 0-10 V

Vermogenssturing van de

PWM-signaal

Pompregeling met

1 – –

2 – –

3 – – –

4 – – –

5 – – – –

2)

6-10

– – – – – –

1) Uit (uitleveringstoestand)

2) Niet gebruikt

Tabel 5 Codering en functie