Page 1

Users manual

Wall-mounted

condensing gas boiler

Buderus 800 - 24/29/43/60 and

Buderus 800 - 24T25/29T25 H/V

7212 3900 (03/2010) GB

For the user

Please read thoroughly

before operating the unit

Page 2

Wall-mounted condensing gas boiler Buderus 800 - Subject to modifications resulting from technical improvements!

2

Subject to technical modifications !

Constant development efforts may result in minor deviations in

illustrations, functional steps and technical data.

Updating the documentation

If you have suggestions for improvement or have found

discrepancies, please do not hesitate to contact us.

Contents

1 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

1.1 Dimensions, connections and assembly . . . . . . . . .6

1.2 Boiler assembly - exploded view. . . . . . . . . . . . . . .8

1.3 Flue Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . .9

1.4 Items supplied with unit. . . . . . . . . . . . . . . . . . . . .11

1.5 Gas boiler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

1.6 Water circulation system. . . . . . . . . . . . . . . . . . . .12

1.7 Pipe connections. . . . . . . . . . . . . . . . . . . . . . . . . .12

1.8 Flue installation. . . . . . . . . . . . . . . . . . . . . . . . . . .15

1.9 Electrical connections . . . . . . . . . . . . . . . . . . . . . .18

2 Initial start-up . . . . . . . . . . . . . . . . . . . . . . . . . . .23

2.1 Preparing the boiler for operation . . . . . . . . . . . . .23

2.2 Start-up work. . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

3 Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

3.1 Preparing the heating boiler for inspection . . . . . .34

3.2 Checking for internal leaks . . . . . . . . . . . . . . . . . .34

3.3 Visual inspection . . . . . . . . . . . . . . . . . . . . . . . . . .34

4 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

4.1 Cleaning the heat exchanger, burner and syphon 35

5 Servicing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

5.1 Operating codes . . . . . . . . . . . . . . . . . . . . . . . . . .39

5.2 Fault codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

5.3 Checking and replacing parts . . . . . . . . . . . . . . . .48

6 Appendix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .63

6.1 Technical data. . . . . . . . . . . . . . . . . . . . . . . . . . . .63

6.2 Residual pump lift for wall-hung gas boilers . . . . .65

6.3 Short list of spare parts . . . . . . . . . . . . . . . . . . . . .66

7 Reports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .67

7.1 Start-up report. . . . . . . . . . . . . . . . . . . . . . . . . . . .67

7.2 Inspection and service reports . . . . . . . . . . . . . . .68

The boiler meets the basic requirements of the

appropriate standards and directives.

Conformity has been substantiated by the

proper documents which - together with the

declaration

of conformity - are filed with the manufacturer.

Page 3

Preface

Wall-mounted condensing gas boiler Buderus 800 - Subject to modifications resulting from technical improvements!

3

Preface

These installation and servicing instructions apply to:

Buderus wall-mounted condensing gas boilers

800 – 24/29/43/60 and 800 – 24T25/29T25 H/V.

Model B23, B33, C13, C33, C43, C53 and C

73

800 – 24/29/43: Category GB II

2H3P

20 mbar; 37 mbar

(natural gas

H and LPG)

In this document LPG = 3P-G31-37 mbar

800 – 60: Category GB I

2H

20 mbar

(natural gas

H)

Power rating: 230 VAC, 50 Hz, IP4X

Fuse rating: 1.25 slow blow

G. C. Aplliance No. :

Buderus 800 – 24 41-110-19

Buderus 800 – 29 41-110-20

Buderus 800 – 24 T25/V

Buderus 800 – 29 T25/V

Buderus 800 – 24 T25/H

Buderus 800 – 29 T25/H

Buderus 800 – 43 41-110-14

Buderus 800 – 60 41-110-15

Important general instructions for use

Only use the boiler in accordance with its designated

use and the installation and servicing instructions.

Servicing and repair must be carried out by Gas Safe

registered installer. Only use the boiler in combinations

and with the accessories and spare parts indicated in

the installation and servicing instructions. Other

combinations, accessories and consumables may only

be used if they are expressly provided for the designated

use and if system performance and safety are not

affected in any way.

The boiler is suitable for connection to fully pumped,

sealed water systems ONLY

. Adequate arrangements

for completely draining the system by provision of

draining valves must be provided in the installation

pipework.

Pipework from the boiler is routed downwards as

standard, but may be routed upwards behind the boiler

using the distance frame (supplied in a seperate kit).

Subject to technical modifications.

As a result of our policy of constant development, there

may be small differences between illustrations,

functional steps and technical data.

BENCHMARK' Log Book

All Buderus gas fired boilers now include an installation,

commissioning and service record log book. The details

of the log book will be required in the event of any

warranty work being requested. Please complete the

appropriate sections on completion of the installation

and commissioning.

REMEMBER: Please hand the log book back to the

user.

Regulations and directives

It is law that all gas appliances are installed and serviced

by a Gas Safe registered installer in accordance with the

regulations. Failure to install appliances correctly could

lead to prosecution. It is in your own interest, and that of

safety, to ensure the law is complied with.

The installation of the boiler MUST be in accordance

with the latest I.E.E. (

BS7671) Wiring Regulations, local

building

regulations, water regulations, the building regulations

and the Building Standard (Scotland) and any relevant

requirements of the local authority.

Detailed recommendations are contained in the

following British Standard Codes of Practice:

BS. 5440:1 Flues (for gas appliances of rated input

not exceeding 70 kW).

BS. 5440:2 Ventilation (for gas appliances of rated

input not exceeding 70 kW).

BS. 5449 Forced circulation hot water systems.

BS. 5546 Installation of gas hot water supplies for

domestic purposes (2nd. family Gases).

BS. 6798 Installation of gas fired hot water boilers

of rated input not exceeding 60 kW.

BS. 6891 Low pressure installation pipes.

IGE/UP/1b Tightness testing and purging domestic

sized gas installations.

Health and & Safety Document No. 635.

The Electricity at Work Regulations, 1989.

The manufacturer's notes must not be taken, in any way,

as overriding statutory obligations.

The design and construction of the Buderus wallmounted condensing gas boilers 800 – 24/29/43/60 and

800 – 24T25 /29T25 conforms to the basic

specifications listed in the European directive governing

gas-fired appliances 90/396/EEC, and with respect to

EN 625, EN 483 and EN 677.

Page 4

Preface

Wall-mounted condensing gas boiler Buderus 800 - Subject to modifications resulting from technical improvements!

4

Timber Framed Buildings

If the boiler is to be fitted in a timber framed building it

should be fitted in accordance with the Institute of Gas

Engineering document

IGE/UP/7:1998.

Bathroom Installations

This appliance is rated IP4X.

The boiler may be installed in any room or internal

space, although particular attention is drawn to the

requirements of the current IEE (

BS. 7671) Wiring

Regulations and, in Scotland, the electrical provisions of

the building regulations applicable in Scotland, with

respect to the installation of the boiler in a room or

internal space containing a bath or shower.

If the appliance is to be installed in a room containing a

bath or shower then, providing water jets are not going

to be used for cleaning purposes (as in communal

baths/showers), the appliance can be installed in Zone

3, as detailed in

BS. 7671.

Compartment Installations

A compartment used to enclose the boiler should be

designed and constructed especially for this purpose.

An existing cupboard or compartment may be used,

provided that it is modified for the purpose.

In both cases, details of essential features of cupboard/

compartment design, including airing cupboard

installation, are to conform to the following:

BS 6798 (No cupboard ventilation is required - see 'Air

Supply' for details).

It is not necessary to have a porpose-provided air vent

in the room or internal space in which the boiler is

installed. Neither is it necessary to ventilate a cupboard

or compartment in which the boiler is installed, due to

the low surface temperatures of the boiler casing during

operation; therefore the requirements of

BS 6798, Clause

12

, and BS 5440:2 may be disregarded.

The position selected for installation MUST allow

adequate space for servicing in front of the boiler.

For the minimum clearances required for safety and

subsequent service, see the wall mounting template.

In addition, sufficient space may be required to allow

lifting access to the wall mounting plate.

Wall-mounted condensing gas boilers must only be

operated with the combustion air/flue gas systems

especially devised and authorised for this type of boiler.

Observe the relevant standards, regulations and

legislation of the country of final use.

NOTE

Observe the corresponding technical rules

and the building supervisory and statutory

regulations when installing and operating

the system.

WARNING!

Keep the burner-control unit housing

CLOSED when working on water-bearing

components.

NOTE

It is mandatory to clean and service the

system once a year. This includes an

inspection of the entire system to see if it is

in full working order. Defects and faults

must be eliminated immediately.

NOTE

When instructions aren’t followed, warranty

expires.

CAUTION

Use this device for its intended purpose

only.

Page 5

Preface

Wall-mounted condensing gas boiler Buderus 800 - Subject to modifications resulting from technical improvements!

5

DANGER!

Notes relating to the heating system water.

Thoroughly flush the system before it is

filled with water. Use only untreated water

or water treatment product such as Sentinal

X100 to fill and top up the system.

When using water treatment, only products

suitable for use with Buderus heat

exchangers are permitted (eg Sentinel

X100). Your warranty is at risk if an

incorrect water treatment product is used in

conjunction with this appliance. For more

information, contact Buderus Product

Support Department.

It is most important that the correct

concentration of the watertreatment product

is maintained in accordance with the

manufacturer's instructions.

If the boiler is used in an existing system

any unsuitable additives MUST be removed

by thorough cleaning.

BS.7593:1992 details

the steps necessary to clean a domestic

central heating system.

In hard water areas, treatment to prevent

lime scale may be necessary - however, the

use of artificially softened water is NOT

permitted.

Under no circumstances should the boiler

be fired before the system has been

thoroughly flushed.

Do not use water softened in a salt

bedding exchanger.

Do not use inhibitors, anti-freeze or

other additives.

The expansion vessel must be of

sufficient size.

When oxygen-permeable pipes are used

(e. g. for floor heating systems) the system

must be separated by means of heat

exchangers. Unsuitable heating water

promotes sludge formation and corrosion.

This may cause malfunctions and damage

in the heat exchanger.

NOTE:

Notes relating to domestic hot water.

The domestic hot water service must

be in accordance with

BS 5546 and BS

6700

.

The boilers are suitable for connection

to most types of washing machine and

dishwasher appliances.

When connecting to suitable showers,

ensure that:

a. The cold inlet to the boiler is fitted with

an approved anti-vacuum or syphon

non-return valve.

b. Hot and cold water supplies to the

shower are of equal pressure.

Where the water hardness exceeds

150 mg/litre, it is recommended that a

proprietary scale reducing device is

fitted into the boiler cold supply with

the requirements of the local water

company.

CAUTION

Provision must be made to accomodate

the expansion of DHW contained within

the appliance, if a non-return valve is fitted

to the DHW inlet, as detailed in

BS. 6798: 5.4.3.

Page 6

Installation1

Wall-mounted condensing gas boiler Buderus 800 - Subject to modifications resulting from technical improvements!

6

1 Installation

1.1 Dimensions, connections and

assembly

800 - 24T25V / 800 - 29T25V 800 - 24 / 800 - 29

800 - 43 / 800 - 60

CH flow

CH return

CWDO

GAS

CH flow

CH return

CWDO

GAS

CH flow

CH return

CWDO

GAS

DHW warm

DHW cold

1250 mm (49 ")

1

5

55 mm (2 ")

1

7

152 mm

(6")

152 mm

(6")

560 mm (22")

335 mm (13 ")

1

7

55 mm (2 ")

1

7

46 (1 ")

4

5

46 (1 ")

4

5

30 (1 ")

1

5

30 (1 ")

1

5

431 mm (17")

431 mm (17")

55

1

7

(2 ")

75

(3")

75

(3")

150

(6")

150

(6")

55

1

7

(2 ")

75

(3")

4 x 75

(3")

150

(6")

152 mm

(6")

46 (1 ")

4

5

30 (1 ")

1

5

431 mm (17")

75

(3")

55

1

7

(2 ")

323

209

(8 ")

1

4

(12 ")

4

3

335 mm

(13 ")

1

7

115 mm

(4 ")

1

2

900

mm (35 ")

1

2

(7 ")

1

2

190

(7 ")

1

2

190

(26 ")

1

5

665 mm

685 mm (27")

685 mm (27")

(7 ")

1

2

190

420 mm

1

2

(16 ")

420 mm

1

2

(16 ")

420 mm

1

2

(16 ")

560 mm (22")

335 mm (13 ")

1

7

DHW warm out = hot water outlet 15 mm dia.

DHW cold in = cold water inlet 15 mm dia.

GAS = gas connection R½ (800 - 24/29/43)

and (800 - 24T25V/29T25V)

gas connection R¾ (800 - 60)

CH return = boiler return line 28 mm dia.

CH flow = boiler flow line 28 mm dia.

CWDO = condensate water drain 32 mm dia.

Page 7

Installation 1

Wall-mounted condensing gas boiler Buderus 800 - Subject to modifications resulting from technical improvements!

7

800 - 24T25H / 800 - 29T25H

(7 ")

1

2

190

685 mm (27")

420 mm

1

2

(16 ")

75

(3")

40 (1 ")

1

2

30 (1 ")

1

5

431 mm (17")

75

(3")

55

1

7

(2 ")

335 mm

(13 ")

1

7

115 mm

(4 ")

1

2

900 mm (35 ")

1

2

75

(3")

300

(11 ")

5

4

152 mm

(6")

CH flow

CH return

CWDO

GAS

DHW warm

DHW cold

DHW warm

out

= hot water outlet 15 mm dia.

DHW cold in = cold water inlet 15 mm dia.

GAS = gas connection R½ (800 - 24T25H/29T25H)

CH return = boiler return line 28 mm dia.

CH flow = boiler flow line 28 mm dia.

CWDO = condensate water drain 32 mm dia.

Minimum side clearance required for all boilers is 100 mm (4")

Page 8

Installation1

Wall-mounted condensing gas boiler Buderus 800 - Subject to modifications resulting from technical improvements!

8

1.2 Boiler assembly - exploded view

Single unit (type 800 – 24 / 800 – 29)

Legend

10 Casing complete

20 Door

30 Casing clamp

40 Casing seal

50 Back panel

60 Mounting bracket

70 Seal lid for air vent

80 Heat exchanger

90 Revision set for air vent

100 Seal

110 Sight glas complete with

sealing rings

120 Restriction plate

130 Seal for condensate collector

140 Condensate collector incl. seal

150 Sensor complete with O-ring

160 Mounting clip

170 Seal for hot surface ignitor/

ionisation electrode

180 Hot surface ignitor

190 Ionisation electrode with cable and

connector

200 Safety sensor-ntc complete

210 Flue gas collector

220 Lip ring seal DN 80mm

230 Condensate by-pass

240 Syphon complete

260 Safety valve pipe

270 Seal set for syphon

280 Burner housing

290 Burner thermostat 107 °C

300 Burner seal

310 Gas/air distribution plate

320 Secondary gas/air distribution plate

330 Burner plaque assembly

340 Gas/air manifold

350 O-ring gas/air manifold to burner

360 Gas injector, natural gas (G20)

incl. O-ring

370 Air restrictor natural gas (G20)

375 Connection tube, fan/burner

380 Connection tube, fan/burner

430

420

360

340

350

290

280

370

230

220

330

320

310

300

210

70

100

110

90

80

120

260

270

240

60

530

550

560

565

540

545

570

520

510

470

500

480

490

40

30

630

540

640

590

620

610

650

580

600

375

380

410

390

400

460

430

440

170

180

190

200

160

130

140

20

10

150

150

50

660

390 Air inlet pipe incl. gasket

400 Support mounting bracket fan anti

vibration

410 Fan

420 Connection pipe gas valve/burner

430 Connection nipple 3/4"x1/2" with O-ring

440 Gas unit

460 Gas inlet pipe 1/2"

470 Control uba

480 Temperature / pressure gauge

490 Bracket for uba

500 Power switch

510 230V cable

520 Cable harness complete

530 Supply pipe heat exchanger

540 O-ring

550 Spring clip heat exchanger/supply

560 Pressure relief valve

570 Non return valve R 1/4''

580 Pump

590 Gasket for pump DN 44 x 2.5

600 Pump power cable complete with

connector

610 Ring

620 Nut for heat exchanger 1 1/2''

630 Nut for heat exchanger 1 1/2''

640 Return pipe

650 Filling-, draining valve

660 RTH converter

Page 9

Installation 1

Wall-mounted condensing gas boiler Buderus 800 - Subject to modifications resulting from technical improvements!

9

1.3 Flue Installation

1.3.1 Siting the flue terminal

The flue must be installed in accordance with the

recommendations of BS. 5440-1:2000.

Pluming will occur at the terminal so terminal positions

where this could cause a nuisance should be avoided.

The air supply and the flue gas exhaust must meet the

applicable general regulations. Please consult the

instructions provided with the flue terminal kits prior to

installation.

The boiler MUST be installed so that the terminal is

exposed to external air.

It is important that the position of the terminal allows the

free passage of air at all times.

Minimum acceptable spacing from the terminal to

obstructions and ventilation openings are specified in

table 1.

If the terminal is fitted within 1000 mm of a plastic or

painted gutter or within 500 mm of painted eaves, an

aluminium shield of at least 1000 mm long should be

fitted to the underside of the gutter or painted surface.

If the lowest part of the terminal is less than 2 metres

above the level of the ground, balcony, flat roof or place

to which any person has access, the terminal must be

protected by a guard. Protective guards are available

from Quinnell Barrett and Quinnell, Old Kent Road,

London.

Ensure that the guard is fitted centrally.

The flue assembly shall be so placed or shielded as to

prevent ignition or damage to any part of the building.

The air inlet/products outlet duct and the terminal of the

boiler MUST NOT be closer than 25 mm (1'') to

combustible material. Detailed recommendations on the

protection of combustible material are given in BS.

5440- 1:2000.

If this could occur the appliance MUST be turned off

(with the owners permission), and labelled as unsafe

until corrective action can be taken.

fig. 1 Flue terminal position

A

A

F

M

G

M

B,C

F

F

B,C

K

G

K

K

G

C

L

L

FJ

K

G

D

H, I

under carport

Terminal Position

Minimum

Spacing

A. Directly below or alongside an opening

window, air vent or other ventilation opening

300 mm (12")

B. Below guttering, drain pipes or soil pipes

75 mm (3")

C. Below eaves

200 mm (8")

D. Below balconies or a car port roof

200 mm (8")

E. From vertical drain pipes or soil pipes

150 mm (6")

F. From internal or external corners

300 mm (12")

G. Above adjacent ground, roof or balcony level

300 mm (12")

H. From a surface facing the terminal

600 mm (24")

I. From a terminal facing a terminal

1200 mm (48")

J. From an opening in a car port (e.g. door or

window) into dwelling

1200 mm (48")

K. Vertically from a terminal on the same wall

1500 mm (60")

L. Horizontally from a terminal on the wall

300 mm (12")

M. Adjacent to opening

300 mm (12")

table 1 Balanced flue terminal position

NOTE

It is absolutely essential to ensure, in

practice, that products of combustion

discharging from the terminal cannot reenter the building or any other adjacent

building through ventilators, windows,

doors, other sources of natural air

infiltration, or forced

ventilation/airconditioning.

Page 10

Installation1

Wall-mounted condensing gas boiler Buderus 800 - Subject to modifications resulting from technical improvements!

10

1.3.2 Air supply and flue gas exhaust in a closed

installation

To ensure optimal operation, the 800 Series appliances

must be connected to a Buderus wall-mounted or roofmounted flue terminal. These terminals have been

developed specifically for the 800 Series condensing

gas boilers and have been comprehensively tested. The

Buderus wall and roof-mounted flue terminal kits ensure

trouble-free operation.

The following items for the flue (see fig. 2) are included

in the delivery of the boiler:

– pos. 1: 1 Concentric bend 80/125;

– pos. 2: 1 Horizontal flue terminal 80/125;

– pos. 3: 1 Flue finishing kit.

1.3.3 Maximum Flue length

The maximum pipe length of the air supply and flue gas

exhaust pipes for the 800 Series condensing gas boilers

(see table 2) is determined by the total pressure loss of

all components in the flue gas exhaust / air supply

system.

Maximum wall thickness without extensions is 550 mm.

Maintain a minimum side wall clearance of 50 mm (see

fig. 3).

1.3.4 Additional flue parts

Additional flue parts (see table 3) can be ordered from

your supplier.

fig. 2 Horizontal flue pack

1

2

3

fig. 3 Side flue and rear flue installation

550 mm

50 mm

L

Boiler

Maximum

pipe length

For every 90° bend the

maximum pipe length has

to be reduced by

800 – 24 / 24T25 H/V L = 14 m 0 m

800 – 29 / 29T25 H/V L = 14 m 0 m

800 – 43 L = 14 m 1.5 m

800 – 60 L = 9 m 1.5 m

table 2 Pipe length

Flue parts Order No.

Concentric pipe, 500 mm long, adjustable NE 83713

Concentric pipe, 1000 mm long, adjustable NE 83714

Concentric bend 90° NE 83715

Concentric bend 45° NE 83716

24-43 kW adaptor plate NE 79061

60 kW adaptor plate NE 79064

table 3 Additional flue parts

Page 11

Installation 1

Wall-mounted condensing gas boiler Buderus 800 - Subject to modifications resulting from technical improvements!

11

1.4 Items supplied with unit

Check the contents against the packing list to ensure

that nothing is missing.

Requirements to be met by the place of installation

1.5 Gas boiler

Remove the packing and discard to ensure proper

recycling.

Do not remove the polystyrene foam bottom slab

protecting the connection nozzles. During installation

the gas boiler and the flue gas adapter must be

protected to prevent site dirt from entering, e.g. using

aluminum foil.

Fit the wall bracket.

Removing the casing:

Open the cover of the control panel (fig. 5, item 1).

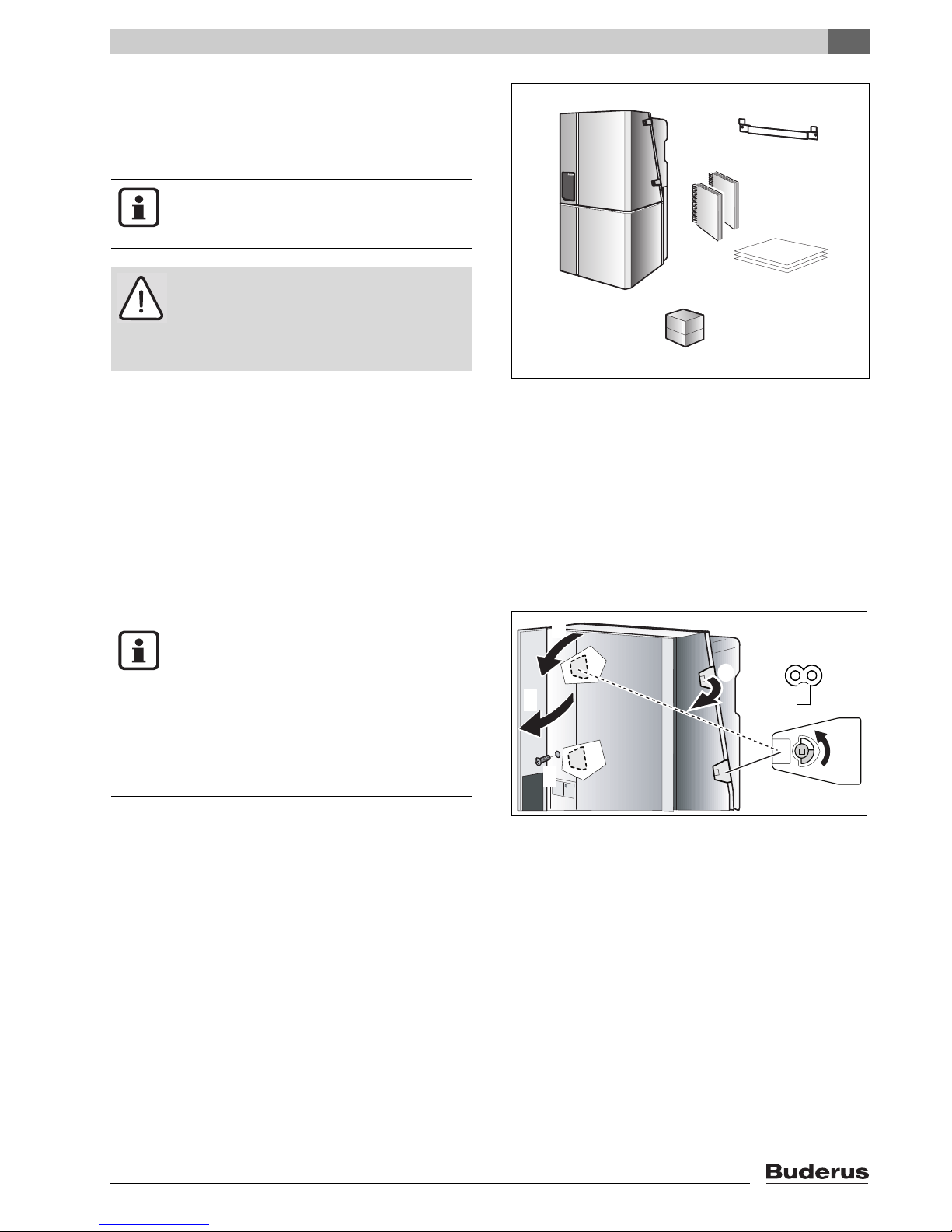

fig. 4 Items supplied with unit

Key to fig. 4:

1: wall-mounted condensing gas boiler

2: wall bracket

3: technical documents

4: wall-mounting template

5: screw fittings for connecting the boiler (heating system)

gas service valve ½" (800-24/29/43)

gas service valve ¾" (800-60)

2

3

5

1

4

6

NOTE

Observe all statutory building regulations

applying to the place of installation.

DANGER!

Inflammable materials or liquids must not be

stored or used near wall-mounted

condensing gas boilers. The site of

installation must be frost-protected.

fig. 5 Removing the casing

6

1

2

5

5

5

4

3

NOTE!

Note the clearance required to install the

flue system (see chapter 1.8 "Flue

installation").

Note the side wall minimum clearance of

100 mm. If a storage-type water heater is

installed underneath, take care that the

minimum clearances according to the

installation instructions are adhered to.

Page 12

Installation1

Wall-mounted condensing gas boiler Buderus 800 - Subject to modifications resulting from technical improvements!

12

Remove the screw (fig. 5, item 2).

Open the locks (fig. 5, item 3) with the radiator key

(fig. 5, item 4).

Release the clasps (fig. 5, item 5).

Remove the boiler casing forwards (fig. 5, item 6).

Do not carry the casing by the clasps !

Combination unit type 800 - 24T25V / 29T25V:

Vertical boilers:

Pull forward the casing of the hot water reservoir and

lift it clear from the top holders. This is only possible

with the upper casing removed.

Attach the gas boiler to the wall bracket (fig. 6).

1.6 Water circulation system

The central heating system should be in accordance

with BS.6798 and, in addition, for smallbore and

microbore systems, BS.5449.

1.7 Pipe connections

1.7.1 Heating circuit connection

On type 800 – 60 an automatic air-release valve must

be fitted in the return line.

A servicing valve has to be installed in the flow and

return lines to allow the gas boiler to be serviced and

repaired.

Make sure that the expansion vessel, pressure relief

valve and draining valve are installed between the

service valve and the boiler.

In order to ensure an optimum and efficient operation of

the heating system, care must be taken that the heating

boiler always has the required minimum amount of

circulation water.

In single-circuit systems the required minimum amount

of circulation water can be provided e.g. by means of an

bypass valve.

A bypass valve is not needed when a hydraulic shunt is

installed.

fig. 6 Installation

Page 13

Installation 1

Wall-mounted condensing gas boiler Buderus 800 - Subject to modifications resulting from technical improvements!

13

Thoroughly flush pipes and radiators !

For sizes of pipe connections please refer to the wall

mounting template.

Fit expansion vessel in compliance with the separate

installation instructions

or

install the expansion vessel in the boiler return line.

Fit the service valve in the flow and return lines (see

subsection 1.1 on pages 6 and 7).

Connect pipes free of tension.

1.7.2 Gas Supply

The gas installation must be installed in accordance with

BS6891.

The complete installation MUST be tested for gas

tightness and purged as described in IGE/UP/1b.

1.7.3 Gas connection

For the size of the pipe connection please refer to the

wall mounting template.

Connect the boiler to the gas supply in accordance

with the relevant standards. Fit the supplied service

valve in the gas feed line. Connect the pipe free of

tension (fig. 7).

Fit a gas service valve with a size of R¾ on type 800 –

60.

1.7.4 Hot water connection

On type 800 – 24/29/43/60:

Connect the external storage-type water heater in

accordance with the appropriate installation instructions

using the connection kit.

fig. 7 Gas connection

CAUTION!

Pipework from the meter to the boiler MUST

be of adequate size.

CAUTION!

Work on gas-bearing components may only

be carried out by a Gas Safe registered

installer.

Page 14

Installation1

Wall-mounted condensing gas boiler Buderus 800 - Subject to modifications resulting from technical improvements!

14

On type 800 – 24T25 H/V and 800 – 29T25 H/V:

When using plastic pipes, note the information provided

by the pipe manufacturer. This particularly applies to the

mode of connection recommended by manufacturer.

In certain situations to prevent hammering within the

system when closing taps, controls can be installed

to counter act this action. For further information

please contact Buderus.

For the size of pipe connections please refer to the

wall mounting template.

1.7.5 Condensate water drain

When shorter aluminium flue-gas systems are used

There is no integrated condensate water outlet in the

flue gas adapter of the aluminium exhaust flue.

The condensate water from the exhaust flue flows via

the gas boiler and into the boiler's odour trap (syphon,

see fig. 10).

fig. 8 Hot water connection vertical boilers

(type 800 – 24T25V / 800 – 29T25V)

CAUTION!

Do not use galvanised pipes or fittings. The

hot water heat exchanger is made of copper

and risks electrolytic corrosion.

fig. 9 Hot water connection horizontal boilers

(type 800 – 24T25H / 800 – 29T25H)

fig. 10 Condensate water outlet for exhaust flue systems

made of aluminium

NOTE!

The condensate water collecting in the gas

boiler and possibly in the flue gas line must

be drained. Local regulations must also be

noted.

CAUTION!

If the flue gas adapter is made of aluminium,

the sealing cap (fig. 12, item 1) MUST NOT

be removed.

Page 15

Installation 1

Wall-mounted condensing gas boiler Buderus 800 - Subject to modifications resulting from technical improvements!

15

When longer aluminium flue-gas systems are used

There is no integrated condensate water outlet in the

flue gas adapter of the aluminium exhaust flue.

The condensate water from the exhaust flue flows via

the external condensate water outlet with odour trap

(syphon, see fig. 11).

This additional component is required:

– from 10 m expanded overall length of exhaust flue

with 800 Series to boiler size of 24 kW or

– from 5 m expanded overall length of exhaust flue with

type

800 – 29, 800 – 43 and 800 – 60.

1.8 Flue installation

The only flue systems that may be used are those

supplied by Buderus. The flue system must be installed

in accordance with the requirements of BS5440:1. 2000.

Standard 125 mm flue systems

See subsection 1.3.3 for the maximum horizontal

straight length of each type boiler. Full instructions for

fitting this flue are in Section 1.8.2: "Installation of the

horizontal flue“ on page 16.

fig. 11 Condensate water outlet for longer exhaust flue

systems made of aluminium

CAUTION!

If the flue gas adapter is made of aluminium,

the sealing cap (fig. 12, item 1) MUST NOT

be removed.

fig. 12 Remove sealing cap on condensate water bypass

(applies only to boiler connection pieces made of

plastic)

1

2

Page 16

Installation1

Wall-mounted condensing gas boiler Buderus 800 - Subject to modifications resulting from technical improvements!

16

1.8.1 Fitting the boiler's adaptor plate

Place the boiler's adaptor plate onto the boiler

(fig. 13).

Secure with 6 screws.

1.8.2 Installation of the horizontal flue

The standard 125 mm diameter horizontal flue system is

suitable for length upto 595 mm. Flue length above this

will require extension duct assemblies.

See table 2 on page 10 for the maximum pipe length for

each type boiler.

fig. 13 Adaptor plate

IMPORTANT

Any horizontal flue system fitted to a

condensing boiler must be incline towards

the appliance at an angle of 3% (30 mm per

metre length) to prevent condensate

dripping from the flue terminal.

This means that the clearance above the

appliance must be increased to match the

duct length. See figure on page 6.

fig. 14 Elbow with flue gas testing point

fig. 15 Standard flue

Flue

Turret

Maximum 595 mm

Terminal

assembly

Outer

Wall

NOTE

Use the wall-mounting template to help you

mark the position of the side flue opening

Page 17

Installation 1

Wall-mounted condensing gas boiler Buderus 800 - Subject to modifications resulting from technical improvements!

17

1.8.3 Flue duct preparation and assembly

Measure the flue length L. Refer to figure 16.

Mark of the lengths shown onto the ducts and cut the

length. The cuts must be square and free from burrs.

Terminal assembly outer (air) duct - L-70 mm, inner (flue)

duct - L-50 mm. The measurement is made from the ridge

at the terminal indicating the outer face of the wall.

Refer to figure 18.

Extension air duct - L-70 mm, flue duct - L-50 mm.

The measurement is from the formed end.

Assemble flue system completely. Push the ducts

fully together. The slope of the terminal outlet must

be face downwards.

The assembly will be made easier if a solvent free

grease is lightly applied to the male end of the ducts.

Push the assembly through the wall and slide the tur-

ret onto the flue connector. Refer to figure 14.

Ensure that the turret is fully entered into the socket

on the boiler. From the outside fix the flue finishing kit

to the terminal and, after ensuring the duct is properly

inclined towards the boiler, fix the finishing kit to the

wall.

If the terminal is within 2 m of the ground where there

is access then an approved terminal guard must be

fitted.

The guard must give a clearance of at least 50 mm

around the terminal and be fixed with corrosion resistant screws.

fig. 16 Flue length - rear

152

L

NOTE

The flue must be inclined to the boiler.

fig. 17 Flue length - side

L

NOTE

An inner wall sealing plate is provided which

should be fitted to the ducts before

assembly.

fig. 18 Flue terminal position

Outer

Wall

Face

Flue Terminal

Raised Ring

locating the

terminal relative

to the outside

wall face

Page 18

Installation1

Wall-mounted condensing gas boiler Buderus 800 - Subject to modifications resulting from technical improvements!

18

1.9 Electrical connections

1.9.1 Mains connection

A mains supply of 230 V - 50Hz is required.

External controls are suitable for volt free or 230 V

installation.

Wiring to the boiler MUST be in accordance with the

current I.E.E. (BS.7671) Wiring Regulations and any

local regulations.

Wiring should be a 3 core PVC insulated cable, not less

than 0.75 mm

2

(24 x 0.2 mm), and to table 16 of

BS.6500.

Connection must be made in a way that allows complete

isolation of the electrical supply such as a double pole

switch having 3 mm (1/8'') contact separation in both

poles, or by a three pin connector, serving only the boiler

and system controls. This boiler is equipped with a

double pole switch see fig. 19, item 1. The means of

isolation must be accessible to the user after installation.

The electrical connection to the mains supply should be

readily accessible and adjacent to the boiler.

If the supply cord is damaged, it must be replaced by a

registered Gas Safe installer to avoid a hazard and must

be an original spare part.

The electrical supply for both the boiler and the system

must

be taken from the same fused spur outlet.

fig. 19 UBA

1

NOTE

All Buderus boilers require a permanent

live.

WARNING!

Do not connect 230V to the connection

block on the UBA.

Page 19

Installation 1

Wall-mounted condensing gas boiler Buderus 800 - Subject to modifications resulting from technical improvements!

19

1.9.2 Wiring Diagram

fig. 20 Wiring diagram

24 VAC

0 VAC

0

max 6 VA

12

RC

1)

12

Incandescent

firing electrode

Remove bridge when

carrying out connection

12

1234

M

N

L

12

M

231

1 2 3 4 5 6 7 8 9

10 11 12 13 14 15 16 17 18 19 20

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18

20 pin connection strip 18 pin connection strip

12 34 56 78 9 1110

24V output (AC)

External sensor

Fuse, main switch, emergency OFF switches and safety

measures to comply with local regulations and standards

STB

MV2

MV1

HT1

HT2

24Vdc

ATB

PA

FR FS

FB

FK

Flame-monitoring electrode

Note:

Circulation pump (PH)

(max. 2A)

KIM

Ventilator

230V 50Hz

Mains power source

~

1) Only one room-temperature regulating

device may be connected.

ATB Flue-gas temperature-limiting device

FB Mains-water temperature sensor

FK Boiler water-temperature sensor (supply)

FR Return-temperature sensor (return)

FS Safety-temperature sensor (safety)

HT Hand-held terminal

KIM Boiler identification module

MV1 1. Solenoid valve

MV2 2. Solenoid valve

PA Potential-free connection (br idge connector)

STB Burner thermostat

Internal three-way

reversing valve

for mains water

(AC operation)

Digital Room

Controller

I/O

communication port

Turn-on voltage for

external, customer-supplied

three-way reversing valve

(AC operation)

Bridge is conductive

(remove when connecting)

Loop is non-conducting

(remove when connecting)

UBA connection block

Burner-control unit (UBA)

Fuse 1.25 slow blow

21

2

1

1

2

12

external

230V controls

Volt free external

control device

*) remove wirebridge

when used

Volt free room

thermostat

when used with

230V timer *)

IMPORTANT

The wires in this mains lead are coloured in accordance with the following code:

GREEN AND YELLOW - EARTH ; BLUE - NEUTRAL ; BROWN - LIVE

As the colours of the wires in the mains lead of of the appliance may not correspond with the coloured markings identifying the terminals in your plug proceed as follows:

The wire coloured green and yellow must be connected to the terminal on the plug marked with the letter E or by the earth symbol or coloured green or green-and-yellow. The wire coloured brown must be connected to the terminal marked with

the letter L or coloured red. The wire coloured blue must be connected to the terminal marked with the letter N or coloured black.

WARNING

THIS APPLIANCE MUST BE EARTHED

Ensure that your appliance is connected correctly - if you are in any doubt consult a qualified electrician.

WARNING!

Do not connect 230V to the connection block on the UBA.

Page 20

Installation1

Wall-mounted condensing gas boiler Buderus 800 - Subject to modifications resulting from technical improvements!

20

1.9.3 Connecting a three-way valve of an external

storage-type water heater

Three-way valve with plug:

Connect the plug-and-socket connector to the plug of

the external storage-type water heater (fig. 21).

Three-way valve without plug:

Connect the three-way valve to terminals 9 and 11 of

the terminal strap (fig. 22, item 5).

1.9.4 External controls

The wall-mounted condensing gas boiler can be fitted

with the following control devices:

– Buderus programmable room thermostat

(see subsection 1.9.5).

– A room-temperature control device at 230V

connected to the RTH converter (see subsection

1.9.6);

– ON/OFF temperature controller, volt free

(see subsection 1.9.7);

fig. 21 Connecting a three-way valve of an external storage-

type water heater

Page 21

Installation 1

Wall-mounted condensing gas boiler Buderus 800 - Subject to modifications resulting from technical improvements!

21

If the boiler has to be temporarily put into operation

without control unit, place a conducting bridge in

terminal 12 and set the feed temperature and the

required heating capacity on the UBA.

1.9.5 Buderus room temperature control device

connection

Remove the bridge in terminal 34 (fig. 22, item 2)

and connect the control unit to the terminal strap.

Remove the wire in terminal 12 (fig. 22, item 1).

1.9.6 230V room-temperature control device connection

Remove the cover of the RTH converter (fig. 22,

item 6).

Lead the control device wire through the cable lead

(fig. 22, item 8).

Fix the wire to terminal 1 and 2 of the 230 Volt con-

nection (fig. 22, item 9).

Secure the wire with the bracket and the two screws

onto the RTH converter.

1.9.7 Volt free external control device connection

Remove the cover of the RTH converter (fig. 22,

item 6).

Lead the control device wire through the cable lead.

Fix the wire to terminal 1 and 2 of the volt free con-

nection (fig. 22, item 10).

1.9.8 Service tool

The service tool allows you to determine the operating

status of the boiler, check components and carry out fast

fault

diagnosis.

Open the flap at the front of the boiler unit and insert

the twin plug connector of the service tool into the

sockets provided (fig. 23, item 1).

fig. 22 Connecting the control unit

Key to fig. 22:

item 1: ON/OFF temperature controller (non-conducting

bridge)

item 2: Room temperature controller iRT (digital)

item 3: I/O port/communication port

item 4: Outdoor temperature sensor

item 5: Power supply 24 VAC/max: 6 VA switching voltage

three-way valve (9+11)

item 6: RTH converter

item 7: 24 VAC connection

item 8: 230 VAC connection

item 9: Volt free connection

2

4

5

6

7

8

10

11

12

1

3

1

2

3

4

9

5

6

0 VAC

0 V

24 VAC

- max. 6VA

1

2

3

4

5

6

10

9

7

8

NOTE

RTH converter is no longer in use.

fig. 23 Service-tool connection

1

Page 22

Installation1

Wall-mounted condensing gas boiler Buderus 800 - Subject to modifications resulting from technical improvements!

22

1.9.9 System examples

Prog

reference room / main living area

other rooms

CT

ZV

TRV

LSV

LSV

LSV

Cylinder

radiator radiator

AV

WC

RT

CHF CHR

ZV

Condensing gas boiler

Buderus 800

PL

JB

CB

EV

PRV

Prog

reference room / main living area

other rooms

CT

DV

TRV

LSV

LSV

LSV

Cylinder

radiator radiator

AV

WC

RT

CHF

CHR

Condensing gas boiler

Buderus 800

PL

JB

CB

EV

PRV

Boulter Buderus

programmable

room thermostat

reference room / main living area

other rooms

Condensing gas boiler

Buderus 800

PL

JB

CB

BCT

BDV

TRV

LSV

LSV

LSV

Cylinder

radiator radiator

AV

CHF

CHR

EV

PRV

Key to abbreviations :

AV = Air Vent

BCT = Buderus cylinder thermostat

BDV = Buderus diverter valve

CB = Connection Block

CHF = Central Heating Flow

CHR = Central Heating Return

EV = expansion vessel

JB = Junction Box / RTH Relay

LSV = Lockshield Valve

PL = Permanent Live

PRV = Pressure relief valve

TRV = Thermostatic radiator valve

Buderus 800 with Buderus controls

Buderus 800 with external 230V connection

Key to abbreviations :

AV = Air Vent

CB = Connection Block

CHF = Central Heating Flow

CHR = Central Heating Return

CT = Cylinder thermostat

DV = Diverter valve

EV = expansion vessel

JB = Junction Box / RTH Relay

LSV = Lockshield Valve

PL = Permanent Live

Prog = Programmer

PRV = Pressure relief valve

RT = Room Thermostat

TRV = Thermostatic radiator valve

WC = Wiring Centre

Buderus 800 with external 230V connection and two port zone

Key to abbreviations :

AV = Air Vent

CB = Connection Block

CHF = Central Heating Flow

CHR = Central Heating Return

CT = Cylinder thermostat

EV = expansion vessel

JB = Junction Box / RTH Relay

LSV = Lockshield Valve

PL = Permanent Live

Prog = Programmer

PRV = Pressure relief valve

RT = Room Thermostat

TRV = Thermostatic radiator valve

WC = Wiring Centre

ZV = Two port Zone Valve

Page 23

Initial start-up 2

Wall-mounted condensing gas boiler Buderus 800 - Subject to modifications resulting from technical improvements!

23

2 Initial start-up

2.1 Preparing the boiler for operation

2.1.1 Filling the heating system

When using oxygen-permeable pipes (e.g. for floor

heating), heat exchangers must be used to separate the

system.

Move the mechanical switch on the three-way valve

to centre position (fig. 24) (applicable for 800-24T25

and

800-29T25 only) and systems with an external storage-type water heater.

If necessary open the CH flow and CH return mainte-

nance valves.

Connect temporary hose of the filling loop (for pipe

locations see page 6 and 7).

Open both stop valves.

Fill the system to a pressure of 1.0 to 1.2 bar (fig. 26,

item 1). Max. water pressure is 2.0 bar.

Shut both stop valves and disconnect the filling loop.

fig. 24 Mechanical switch on the three-way valve

WARNING

The wall-mounted condensing gas boiler

must not be activated at this stage.

fig. 25 Connecting temporary hose

temporary

hose

stop

valve

stop

valve

double

check

valve

DHW

cold

CH

return

fig. 26 Pressure display

12

10

1

01

11

KW

10

1

10

1

I

0

Page 24

Initial start-up2

Wall-mounted condensing gas boiler Buderus 800 - Subject to modifications resulting from technical improvements!

24

To drain the system take the following steps:

Close the CH flow and the CH return service valve.

Place hose on the draining tule.

Turn to drain the system.

2.1.2 Preparing the automatic air release valve

Open the protective cap on the automatic air release

valve one full turn (fig. 27).

Should the air purging operation cause the pressure

to drop below minimum, top up water.

2.1.3 Filling the hot water reservoir

Open the cold water inlet on the service valve.

Open the hot water valve until a full jet of water is

flowing.

2.1.4 Filling the syphon with water

Pull the hose from the condensate plate (fig. 28,

item1).

Fill the syphon with water.

Fit the hose to the condensate plate.

2.1.5 Checking for leaks

Disconnect the system from power supply.

Check all sections of gas pipework and connections

for signs of leaks before starting up system for the

first time.

If a leak is detected during tightness testing, use an

approved leak detector to check all connections for

possible escapes.

The product must be certified as a gas leak-testing

agent.

DO NOT allow the product to come into contact with

electrical wiring.

fig. 27 Automatic air release valve

fig. 28 Filling the syphon with water

1

2

3

4

5

6

7

8

9

10

24 VAC

- max 6 VA

0

24 VAC

1

2

3

4

5

6

12

11

1

Page 25

Initial start-up 2

Wall-mounted condensing gas boiler Buderus 800 - Subject to modifications resulting from technical improvements!

25

2.1.6 Purging air from the gas supply pipe

Loosen the screw plug on the gas connection and air

purging test nipple on Honeywell gas units two turns

(fig. 29, item 1), fully unscrew the plug on SIT gas

units (fig. 30, item 1) and fit the hose.

Purge system and appliance as per relevent proce-

dures, IGE/UP/1b. Ensuring all safety requirments

are met.

fig. 29 Purging the gas supply pipe (Honeywell gas units)

fig. 30 Purging the gas supply pipe (SIT gas units)

Page 26

Initial start-up2

Wall-mounted condensing gas boiler Buderus 800 - Subject to modifications resulting from technical improvements!

26

2.2 Start-up work

2.2.1 Checking the boiler equipment

Type of gas Factory setting of gas burners

Natural

gas E

(includes

natural

gas H)

When delivered ready for operation and set

to Wobbe index 14.1 kWh/m

3

(referred to

15 °C, 1013 mbar), applicable for Wobbe

index range 11.3 to 15.2 kWh/m

3

.

Inscription on type of gas label:

Category setting: G 20 2E_20 mbar

Formerly: set to Wobbe index 15.0 kWh/m3

(referred to 0 °C, 1013 mbar), applicable for

Wobbe index range 12.0 to 15.7 kWh/m3.

LPG

After change-over (see Installation

Instructions: “Changing to another type of

gas”) suitable for LPG.

Inscription on type of gas label:

Category setting: 3P G 31_30-50 mbar

table 4 Gas burner factory settings

Gas boiler Type of gas

Gas injector

diameter

[mm]

Air injector

diameter

[mm]

800-24

(24T25 H/V)

Natural gas H 4.65 21.55

LPG 3.45 20.10

800-29

(29T25 H/V)

Natural gas H 5.00 23.30

LPG 3.90 23.00

800-43

Natural gas H 6.40 29.30

LPG 4.85 27.40

800-60 Natural gas H 8.00 36.40

table 5 Gas and air injector diameters

NOTE

The burner must only be put into operation

with the correct injectors (table 5).

Page 27

Initial start-up 2

Wall-mounted condensing gas boiler Buderus 800 - Subject to modifications resulting from technical improvements!

27

2.2.2 Settings

Setting the flow temperature

Set the controller (fig. 31, item 2) to the desired max-

imum flow temperature in accordance with the system design and table 6.

Factory setting = 80 C (controller poition 10).

With external storage-type water heater:

set the hot water temperature

Use the controller (fig. 31, item 3) to set the desired

domestic hot water temperature in accordance with

table 7.

fig. 31 Controls

Key to fig. 31

item 1: Main switch

item 2: Flow temperature controller

item 3: Domestic hot water temperature controller

item 4: Jumper 11/50 kW to limit capacity

item 5: Pump over-run time switch

item 6: Heating capacity controller

item 7: Cover for second control level

12

10

01

11

kW

10

10

1

1

123

7

4

5

6

Controller position Flow temperature in °C

140

2 44

348

4 53

558

6 62

767

8 71

976

10 80

table 6 Flow temperature

Controller

position

Domestic hot water temperature of

external reservoir in °C

127

2 31

334

4 38

541

6 45

749

8 52

956

10 60

table 7 Domestic hot water temperature

Page 28

Initial start-up2

Wall-mounted condensing gas boiler Buderus 800 - Subject to modifications resulting from technical improvements!

28

Setting the heating capacity

Open the cover of second control level (fig. 31, item

7).

Set the heating capacity in accordance with the re-

quired heat demand (table 8) on the controller

(fig. 31, item 6). Take into account the appropriate

losses caused by the flue gas system (table 9).

Setting the pump over-run time

Move the switch

( (fig. 31, item 4) to position "1".

Pump over-run time 4 minutes.

Move the switch

( to position "2" when the system is

controlled in accordance with the room temperature

and if parts of the system outside the detection area

of the room temperature controller are at risk of freezing (e.g. radiators in the garage).

Pump over-run time 24 hours (constant operation).

Connecting the hot water sensor FW

Remove the bridge plug (fig. 32, item 1).

Cable colours: black/white and lilac.

Connect 3-m long extension cable (fig. 32, item 2) for

the hot water sensor to the plug and fit sensor in the

reservoir.

Con-trol-

ler posi-

tion

Heating capacity in kW (±5 %)

800-24

24T25

800-29

29T25

800-43 800-60

1 6.6 8.4 12.1 22.0

2 8.4 10.8 15.2 25.3

3 10.2 13.0 18.3 29.7

4 11.9 15.2 21.4 33.5

5 13.6 17.5 24.5 37.3

6 15.3 19.7 27.7 41.2

7 17.0 21.9 30.8 45.0

8 18.7 24.1 35.9 48.8

9 20.4 26.3 37.0 52.7

10 22.0 28.0 40.2 56.5

table 8 Heating capacity

Pressure loss of

flue gas system

in Pa

Available portion of

maximum capacity

in %

800-24/29/43 800-60

20 98.5 98.5

30 97.8 98.0

40 97.1 97.4

50 96.4 96.9

60 95.6 96.3

70 94.8 95.8

80 – 95.2

90 – 94.7

table 9 Capacity losses

fig. 32 Hot water sensor FW for external storage-type water

heater

1

2

Page 29

Initial start-up 2

Wall-mounted condensing gas boiler Buderus 800 - Subject to modifications resulting from technical improvements!

29

type 800 – 24T25 H/V and 800 – 29T25 H/V

Setting the hot water flow limiter

Set the desired value on the flow volume limiter

(fig. 33), e.g. for 60 °C at 6 liters/min for type 800 –

24T25 or 8 liters/min for type 800 – 29T25.

2.2.3 Measuring the gas supply pressure (flow pressure)

Open at least one radiator thermostat valve.

The gas boiler must not be turned on yet.

Move the chimney sweeper switch (fig. 34) to posi-

tion "1".

On type 800 – 60 the full capacity is achieved after

approx. one minute. Therefore measurements

should be carried within one minute of boiler operation.

Loosen the screw plug on the gas distribution pres-

sure test nipple on Honeywell gas units (fig. 35,

item 1) two turns, fully unscrew the plug on SIT gas

units (fig. 36, item 1).

Fit the measuring hose of the pressure gauge to the

test nipple (fig. 35, item 2 or fig. 36, item 2).

Slowly open the gas service valve.

Insert the mains plug and move the mains switch to

"I". After about 30 seconds the burner will fire.

Measure the gas distribution pressure and enter into

the certificate.

The gas distribution pressure must be

min. 17 mbar, max. 25 mbar, rated distribution

pressure 20 mbar for natural gas H and

min. 30 mbar, max. 50 mbar, rated distribution

pressure 37 mbar for LPG.

Pull off the measuring hose and tighten up the screw

plug on the test nipple.

fig. 33 Hot water flow volume limiter

Turning to the right = reducing the flow volume

Turning to the left = increasing the flow volume

fig. 34 Chimney sweeper switch

12

10

01

11

KW

10

1

10

1

01

1

I

0

fig. 35 Measuring the gas distribution pressure

(Honeywell gas units)

Page 30

Initial start-up2

Wall-mounted condensing gas boiler Buderus 800 - Subject to modifications resulting from technical improvements!

30

Ensure all disturbed joints and connections are checked

for gas tightness on completion of tasks.

2.2.4 Checking and setting the gas/air ratio

The gas/air ratio can be checked and set in two different

ways:

– using a pressure gauge;

– in accordance with the CO

2

content.

Setting the gas/ratio using a pressure gauge:

Move the mains switch and chimney sweeper switch

to "0".

Pull off the bottom hose attached P1 (fig. 38, item 1)

and fit a hose with Tee in between.

Connect the Tee to the negative port of the pressure

gauge.

Loosen the screw in the burner pressure measuring

nipple on Honeywell gas units (fig. 38, item 2) two

turns, completely unscrew the screw on SIT gas units (fig. 39, item

1).

Connect the positive port of the pressure gauge with

a hose to the burner pressure measuring nipple

(fig. 38, item 2 or fig. 39, item 1).

Move the mains switch to "I" and the chimney sweep-

er switch to "1".

When the burner has fired after approx. 30 seconds,

press the service button (fig. 37) until "Y" is shown on

the display.

fig. 36 Measuring the gas distribution pressure (SIT gas

units)

NOTE

If the required connection pressure is not

available or too high, contact your gas

supplier or TRANSCO.

fig. 37 Service button

fig. 38 Checking and adjusting the gas/air ratio (Honeywell

gas unit)

2

3

1

Page 31

Initial start-up 2

Wall-mounted condensing gas boiler Buderus 800 - Subject to modifications resulting from technical improvements!

31

Move the hot water temperature controller to "1".

Read the differential pressure.

The differential pressure (p

Gas

- p

Air

) must be -5 Pa

(±5 Pa) (display on the meter: -10 to 0 Pa).

In case of gas/air ratio deviations, adjust by using the

setscrew (fig. 38, item 3 or fig. 39, item 2).

Set mains switch and chimney sweeper switch to "0".

Remove the measuring equipment, tighten up the

screw in the burner pressure measuring nipple, put

the hose back on P1.

Set the hot water temperature controller back to the

original value.

Move the mains switch to "I".

Adjustment according to the CO

2

content (natural

gas):

The mains switch must be set to "I" and the chimney

sweeper switch to "1".

Press the service button (fig. 37) until "Y" is shown on

the display.

Full load

Move the hot water temperature controller to "10".

Measure and record the CO

2

content on the flue gas

measuring point (fig. 40).

Partial load

Set the hot water temperature controller to "1".

Measure and record the CO

2

content.

The CO

2

content under partial load must be 0.7 %

lower than the one under full load.

If the measured value is too high or too low, use the

setscrew of the gas burner unit (fig. 38, item 3 or

fig. 39, item 2) to set the gas/air ratio under partial

load.

Set the hot water temperature controller to the origi-

nal value.

Set the chimney sweeper switch to "0".

2.2.5 Checking for leaks in operational condition

Check with the burner running, all joints across the

entire gas route of the burner using a foaming agent.

The agent must be certified as a gas leak test agent.

Do not apply the agent to electrical connection cables.

fig. 39 Checking and adjusting the gas/air ratio (SIT gas

unit)

1

2

fig. 40 Flue gas measuring point

Page 32

Initial start-up2

Wall-mounted condensing gas boiler Buderus 800 - Subject to modifications resulting from technical improvements!

32

2.2.6 Measuring the carbon monoxide content

Measuring point see fig. 40 on page 31.

The carbon monoxide values under vacuum must be

smaller than 400 ppm and/or 0.04 Vol%.

Values around or exceeding 400 ppm indicate a faulty

burner adjustment, a dirty gas burner or heat exchanger

or a defective burner.

Find and eliminate the cause.

2.2.7 Checking the operation

During commissioning and the annual inspection and

servicing routine the working order of all control,

regulating and safety devices must be checked to see if

they are correctly set (provided these devices can be

adjusted).

Measuring the ionisation current

Move the mains switch to "0".

Loosen the plug-and-socket connector of the moni-

toring cable and connect the measuring device in series (fig. 41).

Select on the measuring device the µA direct current

range. The measuring device must have a resolution

of at least 1 µA.

Move the mains switch to "I" and the chimney sweep-

er switch to "1".

After the burner has fired, press the service button

(fig. 37) until "Y" is shown on the display.

Move the hot water temperature controller to "1".

Measure the ionisation current. The ionisation cur-

rent must be > 2 µA direct current under partial load.

Enter the measurement in the certificate.

Move the mains switch to "0".

Remove the measuring device and restore the origi-

nal condition of the plug-and-socket connection.

Move the chimney sweeper switch to "0".

Close the cover of the 2nd control level.

Set the temperature on the hot water temperature

controller to the desired value.

Move the mains switch to "I".

When the display shows "7" and the service button is

pressed, the display turns to "c".

Press the reset button until "r" is shown on the display.

Close the cover.

fig. 41 Measuring the ionisation current

Page 33

Initial start-up 2

Wall-mounted condensing gas boiler Buderus 800 - Subject to modifications resulting from technical improvements!

33

2.2.8 Fitting the boiler casing

Put the casing in place (fig. 42, item 1).

Close (fig. 42, item 2) and lock the clasps (fig. 42,

item 3) with the radiator key (fig. 42, item 4).

Turn in the screw (fig. 42, item 5).

Close the cover of the control panel (fig. 42, item 6).

Do not carry the casing by the clasps !

2.2.9 Handing over

After completing the installation and commissioning of

the system the installer should hand over to the

householder by the following actions:

Fill out the form at the end of this manual. This con-

firms that the system is properly set up, installed and

commissioned and that it has been handed over in

good working order.

Hand the User Manual to the householder and ex-

plain his/her responsibilities under the relevant national regulations.

Explain and demonstrate the lighting and shutting

down procedures.

The operation of the boiler and the use and adjust-

ment of all system controls should be fully explained

to the householder, to ensure the greatest possible

fuel economy consistent with the household requirements of heating. Advise the User of the precautions

necessary to prevent damage to the system and to

the building in the event of the system remaining inoperative during frosty conditions.

Explain the function and the use of the boiler heating

controls.

Explain the function of the boiler fault mode. Empha-

sise that if a fault is indicated, the boiler should be

turned off and a registered local heating installer consulted.

Explain and demonstrate the function of time and

temperature controls, radiator valves etc., for the

economic use of the system.

fig. 42 Fitting the boiler casing

6

5

2

2

2

4

3

1

Page 34

Inspection3

Wall-mounted condensing gas boiler Buderus 800 - Subject to modifications resulting from technical improvements!

34

3 Inspection

3.1 Preparing the heating boiler for

inspection

Disconnect the system.

Remove the burner housing or cover from the heat-

ing boiler (fig. 5 on page 11).

3.2 Checking for internal leaks

Check all internal pipework and controls for leaks using

the appropriate methods as in IGE/UP/1b, using the

correct leak detection fluid. Please ensure that any leak

detector fluid DO NOT come into contact with any

electrical components.

3.3 Visual inspection

Check all gas-bearing and water-bearing pipes for

signs of corrosion (fig. 43).

Replace corroded pipes if necessary.

For further information, please refer to subsection 7.2

"Inspection and service reports" on page 68 and fill out

the

Benchmark.

DANGER OF FATAL INJURY

due to electric shock when system is

opened.

Before opening the system:

disconnect the heating unit at the emergency OFF switch or the corresponding

circuit breaker of the house power supply.

Ensure that the heating system cannot

be reconnected by accident.

NOTE

If the gas supply pipes are to be

disconnected from the burner, the housing

MUST ONLY be removed by a qualified

service technician and checked for

tightness on reassembly.

fig. 43 Visual inspection for signs of corrosion

Page 35

Maintenance 4

Wall-mounted condensing gas boiler Buderus 800 - Subject to modifications resulting from technical improvements!

35

4 Maintenance

For further information, please refer to subsection 7.2

"Inspection and service reports" on page 68 and fill out

the Benchmark.

Preparations

Disconnect the system from the power supply.

Close the gas service valve.

Remove the boiler casing (fig. 5 on page 11).

4.1 Cleaning the heat exchanger, burner

and syphon

The heat exchanger can be cleaned with a brush and

compressed air.

Loosen the screw couplings of the gas injector

(fig. 44, item 1).

Pull off the hose leading to the fan (fig. 44, item 2).

Pull off the hoses at the differential pressure measur-

ing point (fig. 44, item 3).

Pull off the wiring of the burner thermostat (fig. 44,

item 4).

Pull off the plug of the fan (fig. 45, item 1).

Turn and pull out the safety retainer of the fan

(fig. 45, item 2).

fig. 44 Disconnecting

1

2

10

0

1

11

KW

1

0

1

1

0

1

4

1

3

2

1

2

fig. 45 Removing the fan

1

2

Page 36

Maintenance4

Wall-mounted condensing gas boiler Buderus 800 - Subject to modifications resulting from technical improvements!

36

Push up the fan (fig. 46, item 1).

Pivot the lower end of the fan forward (fig. 46, item 2)

and take it out downwards and forwards (fig. 46, item

3).

Loosen both retaining clamps (fig. 47, item 2) of the

burner cover and remove the burner cover and burner

(fig. 47, item 3).

Cleaning by using a brush and compressed air

Pull the syphon away from the condensate plate

(fig. 47, item 1).

Loosen the connection to the condensate water by-

pass

(fig. 47, item 6).

Loosen the retaining clamps (fig. 47, item 4) of the

condensate plate and remove the condensate plate

(fig. 47, item 5).

Pull out the baffle plate (fig. 48).

fig. 46 Removing the fan

1

2

3

fig. 47 Removing the cover and condensate plate

3

2

1

2

3

4

5

6

7

8

9

10

24 VAC

- max 6 VA

0

24 VAC

1

2

3

4

5

6

12

1

5

11

4

6

fig. 48 Baffle plate

Page 37

Maintenance 4

Wall-mounted condensing gas boiler Buderus 800 - Subject to modifications resulting from technical improvements!

37

Clean the burner with a soft brush and compressed

air (fig. 49).

Clean the heat exchanger with a rib comb and com-

pressed air.

Put all components back in place in reversed order.

Remove and clean the syphon (fig. 51).

Take care that the syphon cap is screwed on correctly.

Fill with water before putting the syphon back in

place.

Put all components back in place in reversed order.

When plastic boiler connectors are used:

check the operation of the condensate water bypass

Inject water (e.g. using a spray bottle) into the left-

hand flue gas measuring point (fig. 51) and check

that the

condensate water bypass is not obstructed.

fig. 49 Cleaning the burner

1

NOTE

The perforated plate (fig. 49, item 1) is only

provided on type 800 – 24 and 800 – 24T25

models.

fig. 50 Cleaning the heat exchanger

1

DANGER!

The hot surface ignitor (fig. 50, item 1) is

made of fragile material.

fig. 51 Checking the operation of the condensate water

bypass

1

2

3

4

5

6

7

8

9

10

24 VAC

- max 6 VA

0

24 VAC

1

2

3

4

5

6

12

11

Page 38

Maintenance4

Wall-mounted condensing gas boiler Buderus 800 - Subject to modifications resulting from technical improvements!

38

When aluminium boiler connectors are used:

check the sealing cap of the condensate water

bypass.

Visual inspection to see if there is a white sealing cap

on the condensate water bypass (fig. 52).

fig. 52 Condensate water bypass sealing cap

1

2

10

0

1

1

1

K

W

10

1

10

1

1

Page 39

Servicing 5

Wall-mounted condensing gas boiler Buderus 800 - Subject to modifications resulting from technical improvements!

39

5 Servicing

5.1 Operating codes

NOTE

If the code displayed on the burner-control

unit is not listed under the operating codes

or fault warnings, the burner-control unit

itself is malfunctioning.

Display

Display after

pressing the ser-

vice button

Meaning

0

800 Series is ready for operation

A

Burner interval circuit, 10 minutes from start of burner

C

Waiting for the three-way valve and/or pump to switch

H

Ready for operation

L

First safety period

P; U

Safety period

Y

Flow water temperature setting reached (switching difference +2 K)

-.

800 Series runs in heating mode

A

Chimney sweep mode

H

Normal heating mode

Y

Service mode

=.

800 Series runs in hot water mode

H

Normal hot water mode

r

Reset (after reset button has been pressed for 5 sec. UBA is reset to the switch-on

condition)

Page 40

Servicing5

Wall-mounted condensing gas boiler Buderus 800 - Subject to modifications resulting from technical improvements!

40

5.2 Fault codes

Code Meaning

1C Flue gas thermostat (STB) has been tripped

Possible

cause

Action

1 Water pressure is too low in the installation Top up the system (see subsection 2.1.1)

2 Connection in cable harness defective or is getting too

hot

Check cable harness and press "reset" until "r" appears in

the display

3 Flue gas thermostat if present is defective or is getting

too warm

Check the cable connections and press "reset" until "r"

appears in the display. Replace if necessary

Code Meaning

2C Safety sensor exceeds 95 °C, blocked for 30 sec.

Possible

cause

Action

1 Resistance in the installation is too high Check if not all (thermostatic) radiator valves are clogged

with dirt. Bypass is installed incorrectly

2 Safety sensor is faulty Measure if resistance over the sensor is correct.

If not replace safety sensor temporarily with another one

(see subsection 5.3.9 and subsection 5.3.10)

3 Problem with the pump or pump cabling

(no circulation)

Check if the pump cabling is faulty or if the pump is stuck

(see subsection 5.3.7)

4 Water pressure is too low in the installation Top up the system (see subsection 2.1.1)

Code Meaning

2F Temperature difference between the safety sensor and flow sensor is greater than or equal to 15 °K,

blocked for 30 sec.

Possible

cause

Action

1 Resistance in the installation is too high Check if not all (thermostatic) radiator valves are closed or

clogged with dirt

2 Safety sensor is dirty or faulty Check the safety sensor for dirt. Measure if resistance over

the sensor is correct. If not replace safety sensor

temporarily with another one (see subsection 5.3.9 and

subsection 5.3.10)

3 Flow sensor is dirty or faulty Check the sensor, replace if necessary by temporarily

connecting another one (see subsection 5.3.9 and

subsection 5.3.10)

4 Problem with the pump or pump cabling

(no circulation)