Page 1

7210 1300 - 02/2006 GB(EN) For trade use

Servicing manual

Gas wall hung boiler condensing

600 Series - 11S / 19S / 24S / 24C

GB122

Please read thoroughly before attempting to diagnose fault

Page 2

List of contents

Preface

1 Messages – Universal Automatic Burner

(UBA) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.1 UBA status display . . . . . . . . . . . . . . . . . . . . . . . . 3

1.2 UBA operating level 1.5 . . . . . . . . . . . . . . . . . . . . . 4

1.3 Service tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.4 Operating messages . . . . . . . . . . . . . . . . . . . . . . . 5

1.5 Fault messages . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2 Faults that the UBA does not display . . . 8

3 Troubleshooting . . . . . . . . . . . . . . . . . . . . . 9

3.1 Troubleshooting tasks . . . . . . . . . . . . . . . . . . . . . 47

3.1.1 Unblocking the 600 Series 11S / 19S / 24S / 24C 47

3.1.2 Chimney-sweep mode . . . . . . . . . . . . . . . . . . . . . 47

3.1.3 Removing and refitting the outer casing . . . . . . . 48

3.1.4 Removing and refitting the combustion-

chamber cover . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

3.1.5 Checking the exhaust-gas sensor . . . . . . . . . . . . 49

3.1.6 Replacing the exhaust-gas sensor . . . . . . . . . . . 49

3.1.7 Checking the air intake and outlet openings . . . . 50

3.1.8 Replacing the UBA . . . . . . . . . . . . . . . . . . . . . . . 50

3.1.9 Checking the fan . . . . . . . . . . . . . . . . . . . . . . . . . 51

3.1.10 Replacing the fan . . . . . . . . . . . . . . . . . . . . . . . . . 51

3.1.11 Checking the wiring connections of the UBA . . . . 53

3.1.12 Checking the miniature fuses . . . . . . . . . . . . . . . 53

3.1.13 Checking the connections for the second

solenoid valve, modulating pump and floor

thermostat switching contact . . . . . . . . . . . . . . . . 53

3.1.14 Checking the circulation pump . . . . . . . . . . . . . . 54

3.1.15 Replacing the circulation pump . . . . . . . . . . . . . . 54

3.1.16 Checking the safety sensor . . . . . . . . . . . . . . . . . 55

3.1.17 Replacing the safety sensor . . . . . . . . . . . . . . . . 55

3.1.18 Checking the safety sensor connection lead . . . . 55

3.1.19 Checking the feed sensor . . . . . . . . . . . . . . . . . . 56

3.1.20 Replacing the feed sensor . . . . . . . . . . . . . . . . . . 56

3.1.21 Checking the feed sensor connection lead . . . . . 56

3.1.22 Checking the domestic hot water /

mains water supply . . . . . . . . . . . . . . . . . . . . . . . 57

3.1.23 Changing the domestic hot water /

mains water supply . . . . . . . . . . . . . . . . . . . . . . . 58

3.1.24 Checking the hot surface ingitor . . . . . . . . . . . . . 59

3.1.25 Replacing the hot surface ingitor . . . . . . . . . . . . . 59

3.1.26 Checking the gas-burner control system for

correct activation . . . . . . . . . . . . . . . . . . . . . . . . . 60

3.1.27 Replacing the gas burner fitting . . . . . . . . . . . . . . 60

3.1.28 Checking and adjusting the gas-to-air ratio . . . . . 62

3.1.29 Measuring the ionisation current . . . . . . . . . . . . . 63

3.1.30 Replacing the ionisation electrode . . . . . . . . . . . . 63

3.1.31 Checking the three-way motorised valve for

correct operation . . . . . . . . . . . . . . . . . . . . . . . . . 64

3.1.32 Replacing the motorised valve body control valve 64

3.1.33 Replacing the three-way valve . . . . . . . . . . . . . . 65

3.1.34 Checking the ERC/RC connections to the UBA . 66

3.1.35 Replacing the terminal strip . . . . . . . . . . . . . . . . . 66

3.1.36 Checking connections at the ERC or RC . . . . . . 67

3.1.37 Replacing the room-temperature control device . 67

Important general instructions for use

This device should only be operated in accordance with its

designated use and the indications given in the servicing

instructions. All maintenance and repair operations must be

carried out by a qualified service technician.

Always operate in conjunction with original accessories, and

use only genuine spare parts. Other combinations of units,

accessories and consumables are only to be used if they

completely fulfil the specifications involved, and if system

performance and safety are not affected in any way.

Note that all the servicing tasks described here must be carried

out by a qualified maintenance firm. Work on gas pipes and

fittings must only be carried out by a CORGI registered

engineer.

Subject to technical modifications

As a result of our policy of constant development, there may be

small differences between illustrations, functional steps and

technical data.

The boiler meets the basic requirements of the

appropriate standards and directives.

Conformity has been substantiated by the

proper documents which - together with the

declaration of conformity - are filed with the

manufacturer.

BENCHMARK' Log Book

All Buderus gas boilers now include an Installation, Commissioning and Service record log book. The details of the log

book will be required in the event of any warranty work being

requested.

Please complete the appropriate section at each service visit.

REMEMBER: Please hand the log book back to the user.

Subject to modifications resulting from technical improvements! Buderus Ltd. • http://www.buderus-domestic.co.uk

2 Servicing manual for wall-mounted condensing gas boiler 600 Series 11S/19S/24S/24C • Issued 02/2006

Page 3

Messages – Universal Automatic Burner (UBA) 1

Buderus

U122 K

1 Messages – Universal Automatic Burner (UBA)

1.1 UBA status display

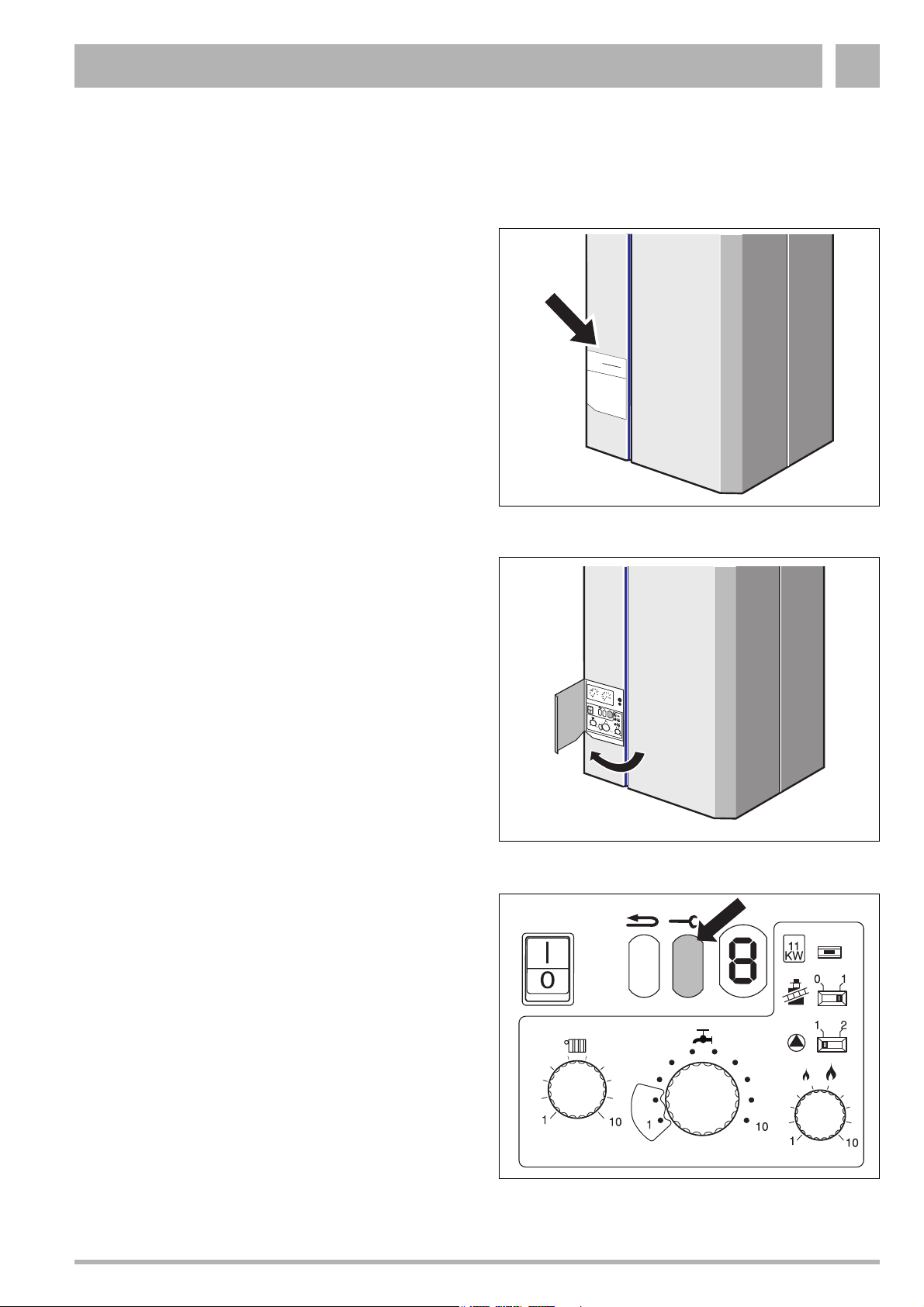

Operational condition and error messages appear on the

display of the Universal Automatic Burner (UBA).

The message consists of two characters.

The first character is displayed automatically.

Fig. 1 600 Series 11S / 19S / 24S / 24C: Display

To display the second character:

z Hinge the control panel cover to the left to open.

z Press the "Service" button.

Fig. 2 600 Series 11S / 19S / 24S / 24C:

Open the control panel cover

Fig. 3 "Service" button

Subject to modifications resulting from technical improvements! Buderus Ltd. • http://www.buderus-domestic.co.uk

Servicing manual for wall-mounted condensing gas boiler 600 Series 11S/19S/24S/24C • Issued 02/2006 3

Page 4

Messages – Universal Automatic Burner (UBA)1

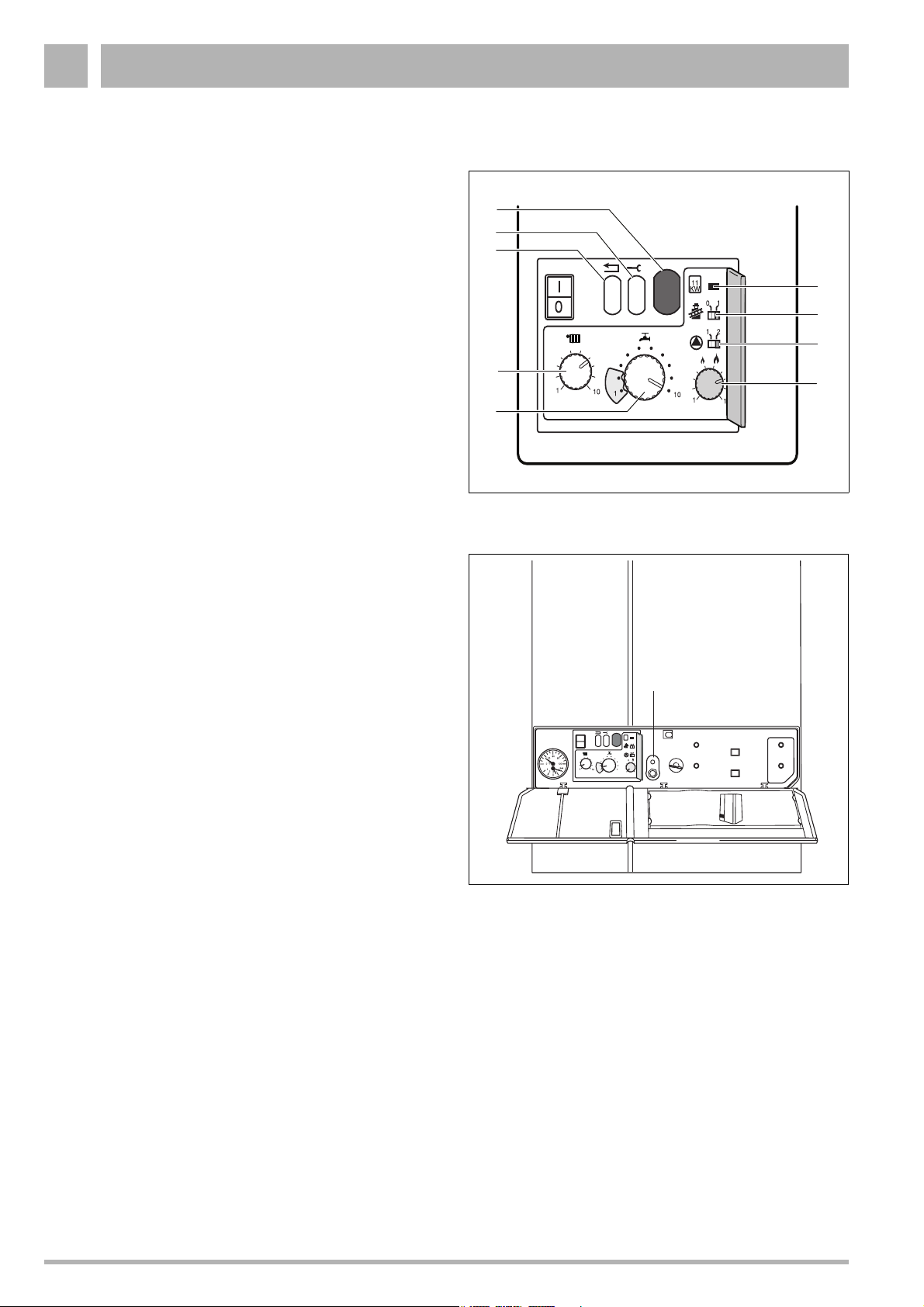

1.2 UBA operating level 1.5

UBA operating level 1.5 (fig. 4).

Key:

Item 1: Display

Item 2: Service button

Item 3: Reset button

Item 4: Boiler flow temperature

Item 5: Hot-water temperature

Item 6: Power adjustment

Item 7: Pump overrun switch

Item 8: Chimney-sweep switch

Item 9: 11 kW jumper

1

2

3

4

5

Fig. 4 UBA operating level 1.5

9

8

7

6

1.3 Service tool

The service tool allows you to determine the operating status

of the boiler, check components and carry out fast fault diagnosis.

z Open the cover at the front of the boiler unit and insert the

twin plug connector of the service tool into the sockets

provided (fig. 5, item 1).

1

11

KW

I

0

Fig. 5 Service tool connection

01

12

1

10

1

10

Subject to modifications resulting from technical improvements! Buderus Ltd. • http://www.buderus-domestic.co.uk

4 Servicing manual for wall-mounted condensing gas boiler 600 Series 11S/19S/24S/24C • Issued 02/2006

Page 5

Messages – Universal Automatic Burner (UBA) 1

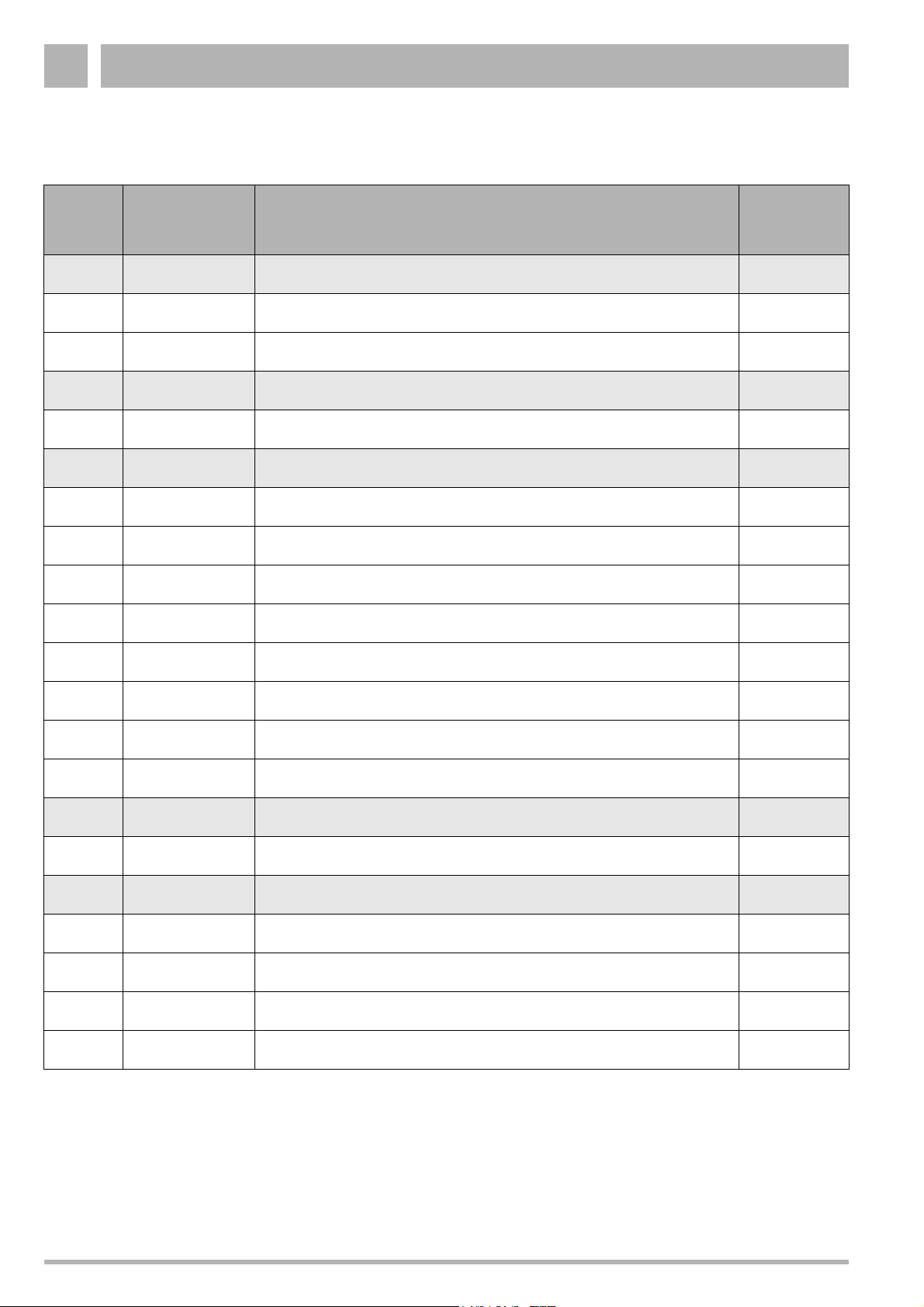

1.4 Operating messages

Display after

Display

pressing the

service button

Meaning

-.

=.

0

A

C

H

L

U

y

A

H

y

600 Series 11S / 19S / 24S / 24C is ready for operation

Burner interval circuit, 10 min from burner start-up

Waiting for the three-way valve and/or pump to switch

Standby activated, 600 Series 11S / 19S / 24S / 24C ready to provide heat or hot water

Initial safety period: self-testing of UBA during burner start-up

Post- or pre-flushing period of fan unit

Flow temperature at adjustment setting

600 Series 11S / 19S / 24S / 24C running in heating mode

“Chimney-sweep” mode, flow-temperature controller bypassed,

600 Series 11S / 19S / 24S / 24C heating to previously-entered flow temperature

Normal heating mode

Service mode

600 Series 11S / 19S / 24S / 24C running in hot-water mode

H

r

Table 1 Displayed UBA operating messages

Normal hot water mode

Reset

Subject to modifications resulting from technical improvements! Buderus Ltd. • http://www.buderus-domestic.co.uk

Servicing manual for wall-mounted condensing gas boiler 600 Series 11S/19S/24S/24C • Issued 02/2006 5

Page 6

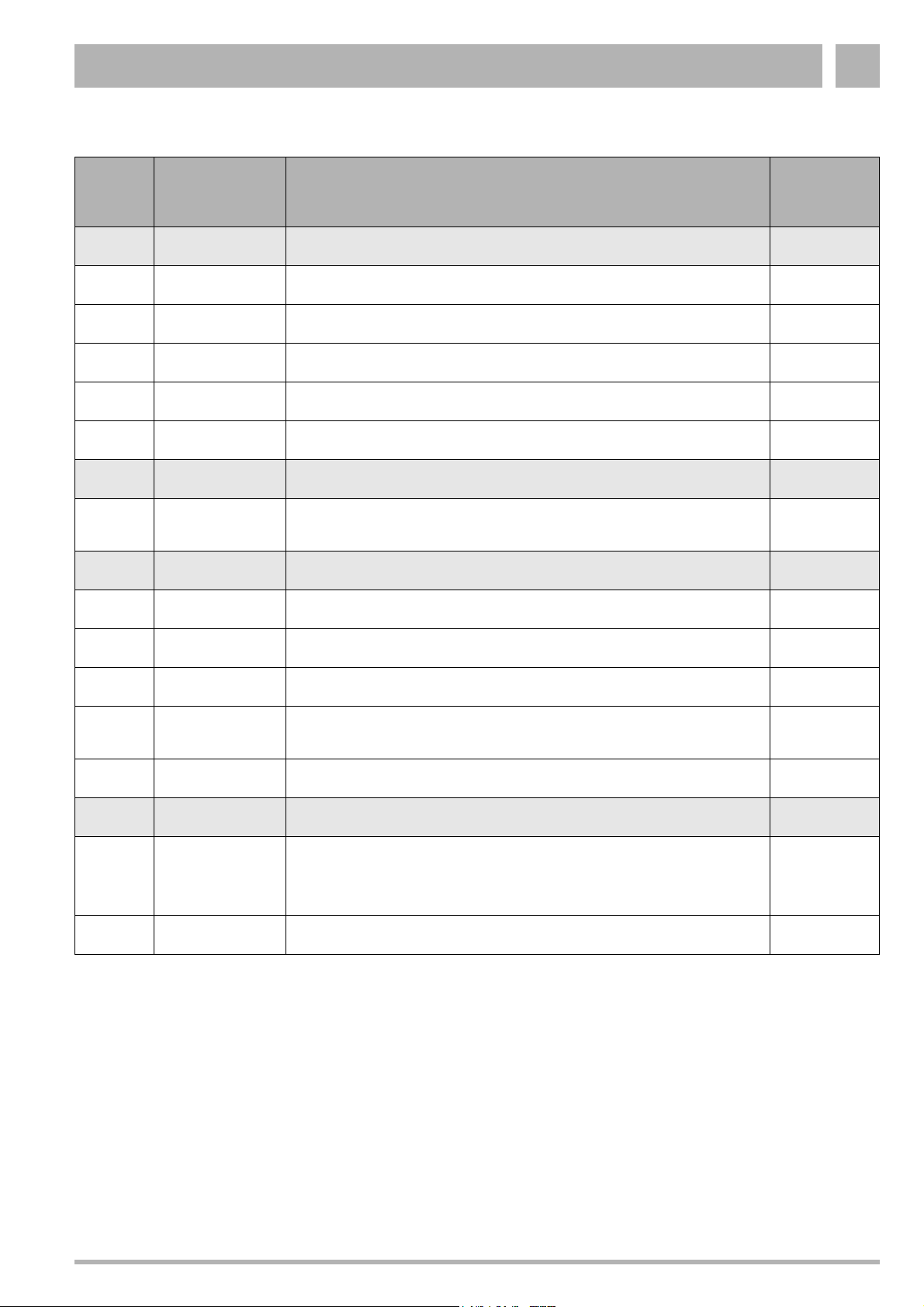

Messages – Universal Automatic Burner (UBA)1

1.5 Fault messages

Display

2

3

4

Display after

pressing the

service button

C

P

C

A

C

F

H

Trouble-

Meaning

Water flow

Safety sensor exceeds 100 °C page 10

Excessive temperature increase at safety sensor page 11

Air volume flow

Bad plug-in connection at cable loom, or damaged wiring page 12

Temperatures

Feed sensor above 100 °C page 13

F2 fuse malfunction, or exhaust-gas sensor tripped

Safety sensor exceeds 100 °C page 17

Dripping tap page 18

shooting

flow diagram

page 15

L

P

U

y

5

C

6

A

C

H

L

Short circuit in safety sensor page 19

Safety sensor, loose contact or defective page 20

Short circuit in feed sensor page 21

Feed sensor, loose contact or defective page 22

Communication

600 series has switched off after disconnection of diagnosis plug

Flame monitoring

F1 fuse defective, or no ionisation message after ignition page 24

Ionisation message, but no flame page 28

Flame dies out after gas valve is opened page 29

Flame goes out during warm-up phase page 30

page 23

Subject to modifications resulting from technical improvements! Buderus Ltd. • http://www.buderus-domestic.co.uk

6 Servicing manual for wall-mounted condensing gas boiler 600 Series 11S/19S/24S/24C • Issued 02/2006

Page 7

Messages – Universal Automatic Burner (UBA) 1

Display

7

8

9

Display after

pressing the

service button

A

C

F

H

L

y

A

Trouble-

Meaning

Mains voltage

Voltage in UBA too low or too high page 31

Mains voltage interrupted following a fault warning message page 32

F3 fuse defect, or UBA system error page 33

Voltage peaks in UBA page 34

UBA timer error page 35

General fault/gas-pressure

External switching contact, e.g. temperature monitor for floor heating, has

been tripped

System error

System error page 37

shooting

flow diagram

page 36

C

F, H, P

L

U

E

Any indication,

except

Incorrect cable connection at KIM, or KIM defective page 38

System error (UBA defective) page 39

Wiring to gas-burner assembly incorrect, or loose wiring connections

in UBA

KIM defective page 41

UBA system fault

UBA system fault

P

P

Table 2 Displayed UBA fault warning messages

Non-compatible UBA fitted page 42

page 40

Subject to modifications resulting from technical improvements! Buderus Ltd. • http://www.buderus-domestic.co.uk

Servicing manual for wall-mounted condensing gas boiler 600 Series 11S/19S/24S/24C • Issued 02/2006 7

Page 8

Faults that the UBA does not display2

2 Faults that the UBA does not display

Hot-water mode

Although the UBA is apparently ready for use, situations may

arise where a hot-water tap is opened and no hot water flows

out, or flows out for only a short period.

Troubleshooting flow diagram:

page 43/44.

Heating mode

Although the UBA is apparently ready for use, and the room

temperature has not yet reached the preset level, the

600 Series 11S / 19S / 24S / 24C wall-mounted condensing

gas boiler fails to go into heating mode.

Troubleshooting flow diagram:

page 45.

Subject to modifications resulting from technical improvements! Buderus Ltd. • http://www.buderus-domestic.co.uk

8 Servicing manual for wall-mounted condensing gas boiler 600 Series 11S/19S/24S/24C • Issued 02/2006

Page 9

Troubleshooting 3

3 Troubleshooting

The following flow diagrams are provided for the purpose of

systematic troubleshooting.

Take the opportunity, while carrying out fault diagnosis, to

check that all that plugs and wiring terminals on the UBA are

connected correctly.

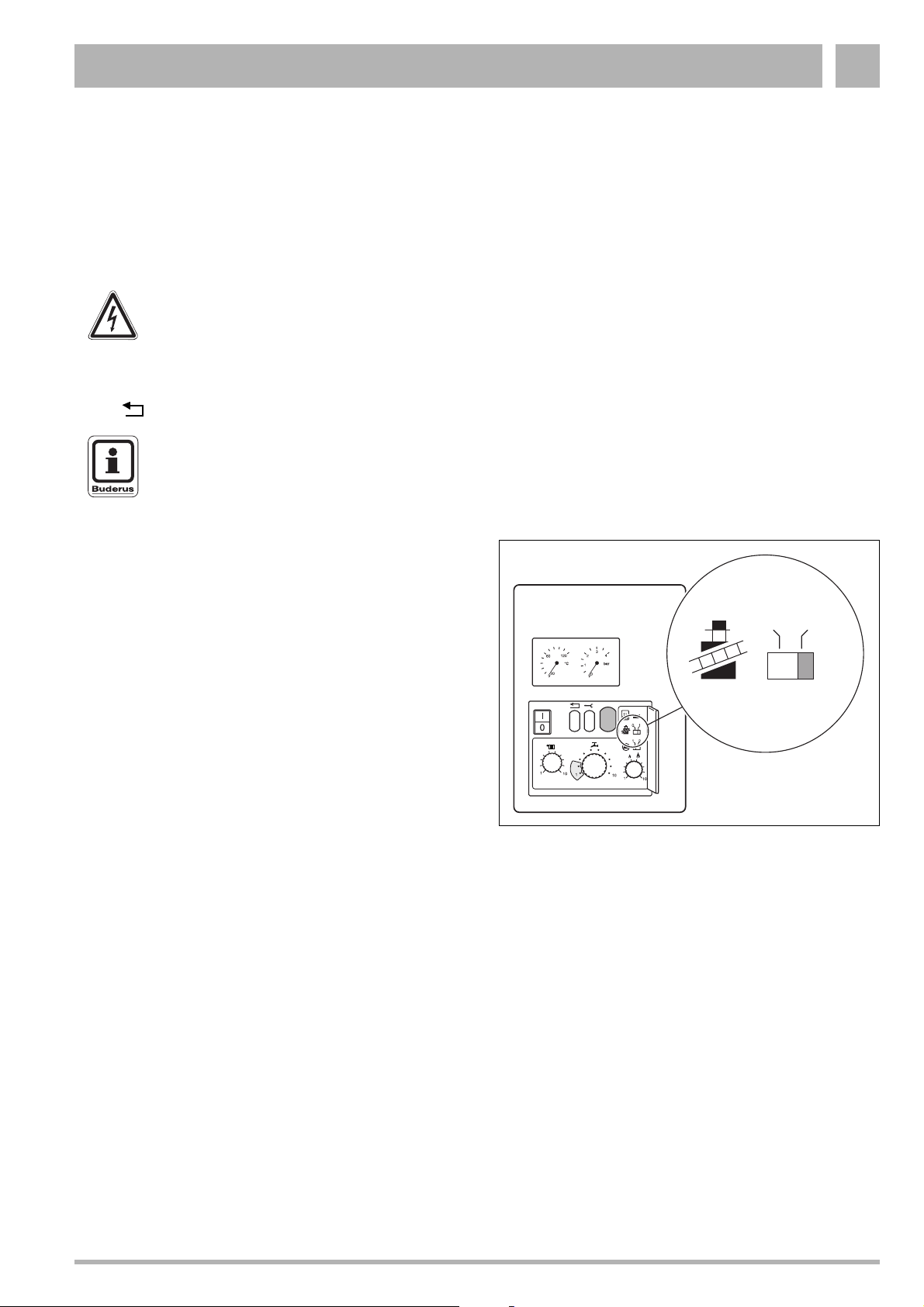

WARNING

Switch off the 600 Series 11S / 19S / 24S / 24C

BEFORE checking the connections.

Each time a fault has been rectified, push the “reset”

button " " to unblock the UBA and return it to standby mode.

NOTE

The system cannot be reset by disconnecting

at the master switch.

Certain troubleshooting tasks must be carried out with the

600 Series 11S / 19S / 24S / 24C in heating mode.

When doing so, the chimney-sweep switch should be set to "1"

(fig. 6).

Remember to return the chimney-sweep switch to “0” once

work is complete.

01

Fig. 6 Chimney sweeper switch on UBA

Subject to modifications resulting from technical improvements! Buderus Ltd. • http://www.buderus-domestic.co.uk

Servicing manual for wall-mounted condensing gas boiler 600 Series 11S/19S/24S/24C • Issued 02/2006 9

Page 10

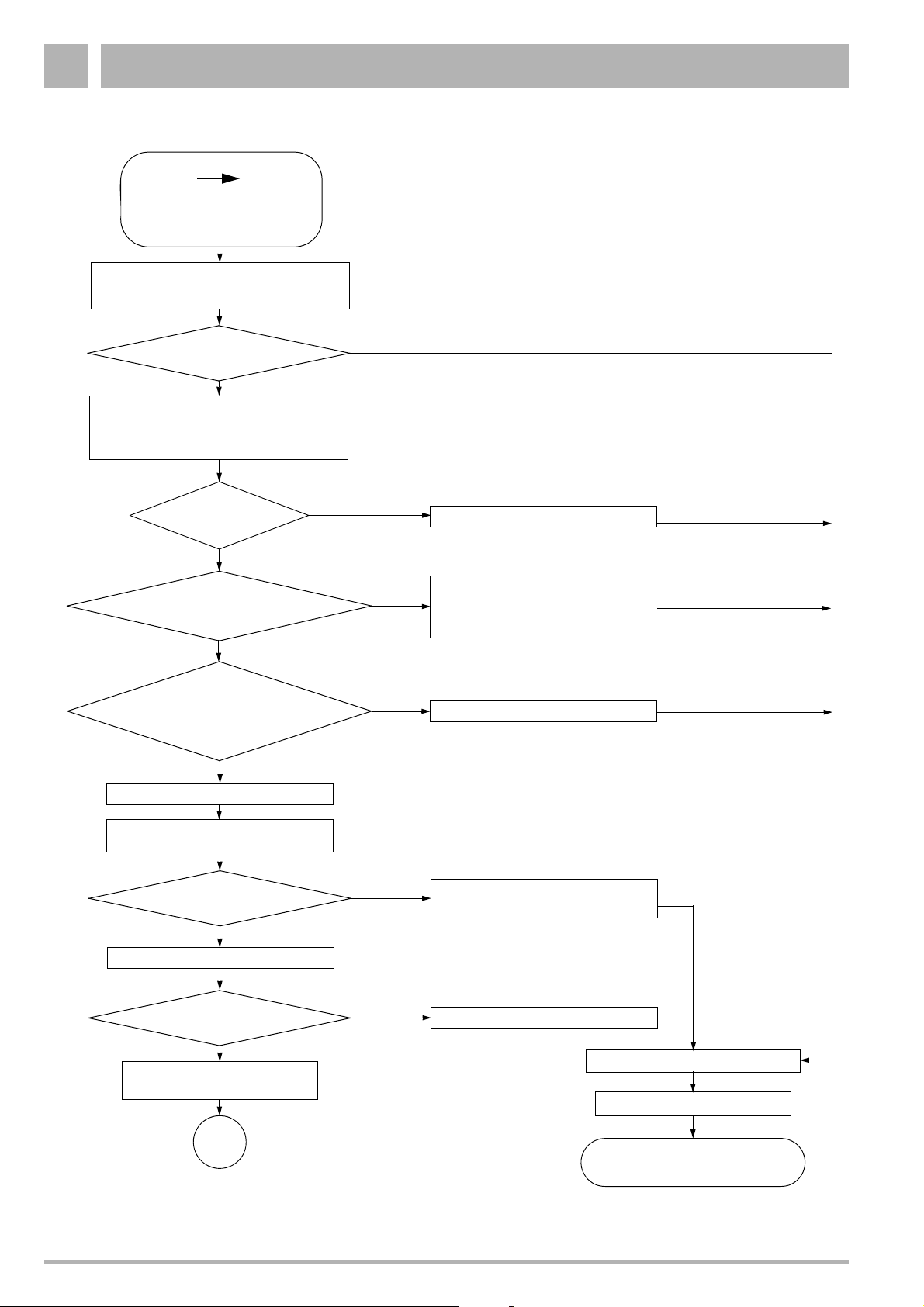

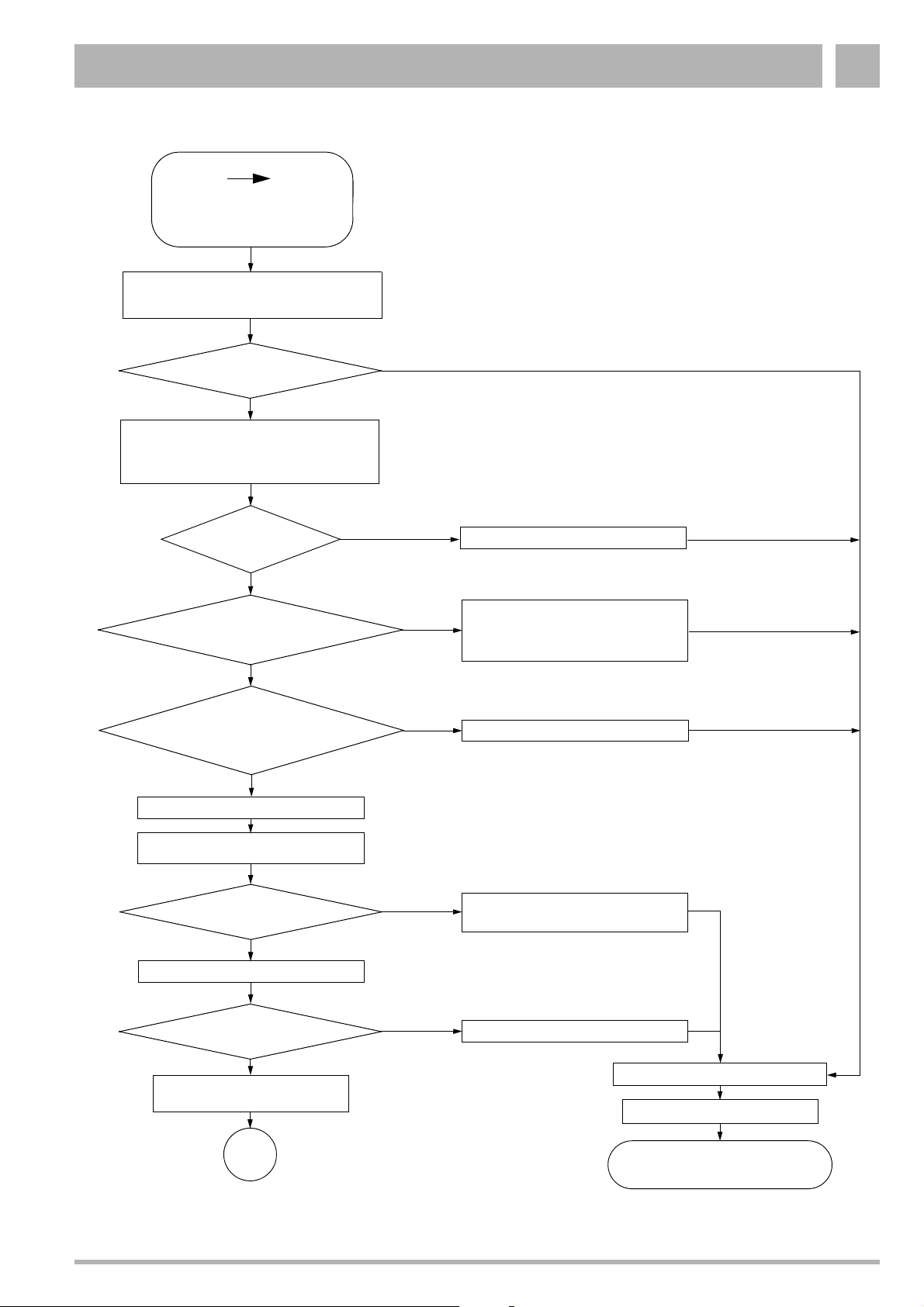

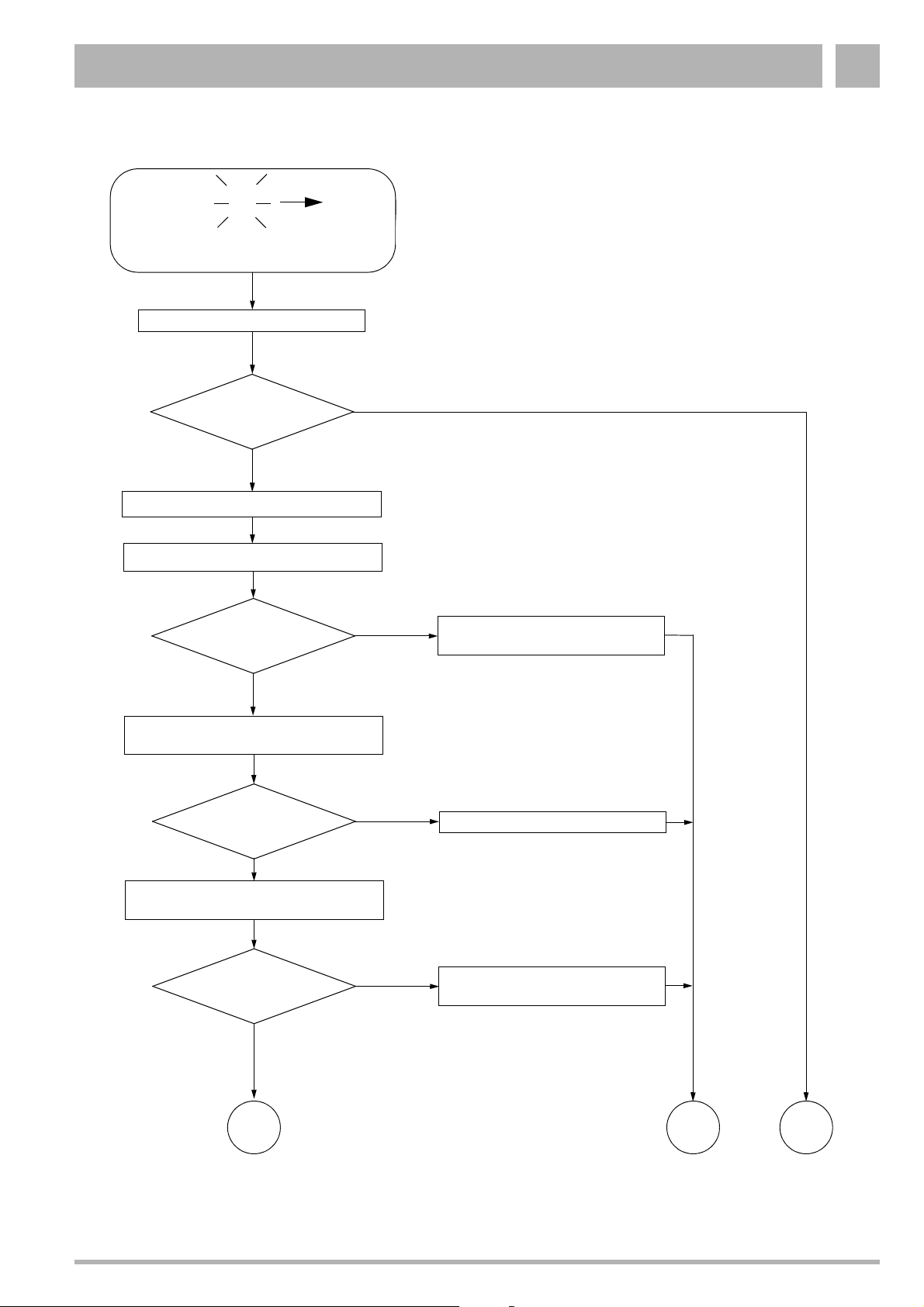

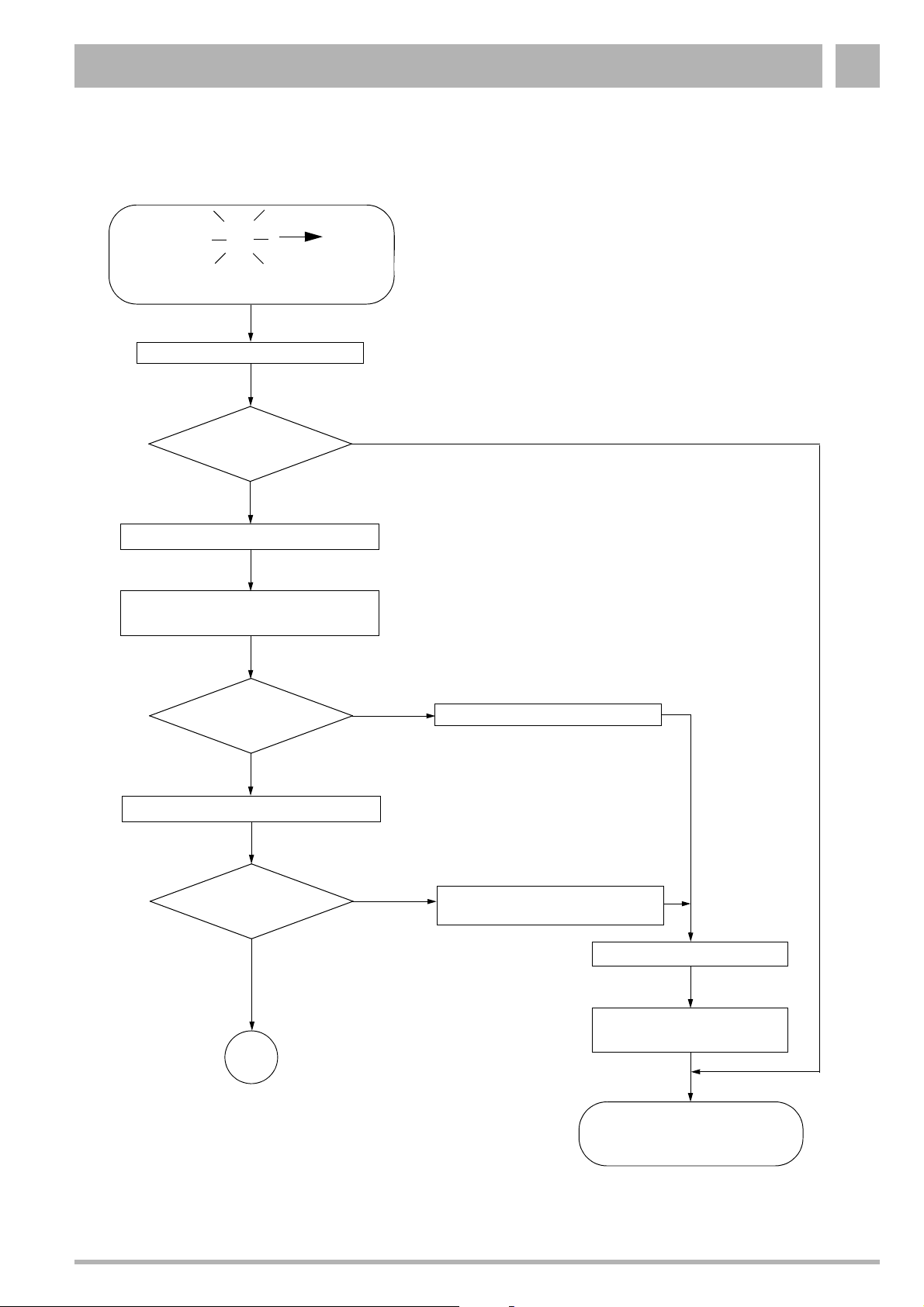

Troubleshooting3

2

Safety sensor temp. exceeds

100 °C

Wait approx. 30 sec for the boiler to return

automatically to normal operation

New fault warning message

2C?

Check system and heat exchanger, as

indicated in the installation and servicing

instructions, for signs of airlocks and dirt -

purge and/or clean as required

Are all

maintenance shutoff

valves open?

Is the water

pressure in the system at

least 1 bar?

C

Yes

Yes

No

No

No

Open maintenance shutoff valves

Fill up with water as indicated in the

installation and servicing instruc-

tions, and purge the system of air

Yes

Is at least one

thermostatic valve open (to

control the amount of water

circulating)?

Yes

Remove the casing (page 48)

Check safety sensor and wiring

(page 55)

Safety sensor OK?

Yes

Check circulation pump (page 54)

Circulation pump OK?

Yes

Filter to catch dirt fitted?

If yes, is it unclogged?

No

No

No

Open one thermostatic valve

Replace safety sensor (page 55)

Replace circulation pump (page 54)

Fit the casing (page 48)

"reset"

A

page 46

Fig. 7 Fault warning message 2C: Safety sensor temp. exceeds 100 °C

Subject to modifications resulting from technical improvements! Buderus Ltd. • http://www.buderus-domestic.co.uk

10 Servicing manual for wall-mounted condensing gas boiler 600 Series 11S/19S/24S/24C • Issued 02/2006

600 Series 11S / 19S / 24S / 24C

OK

Page 11

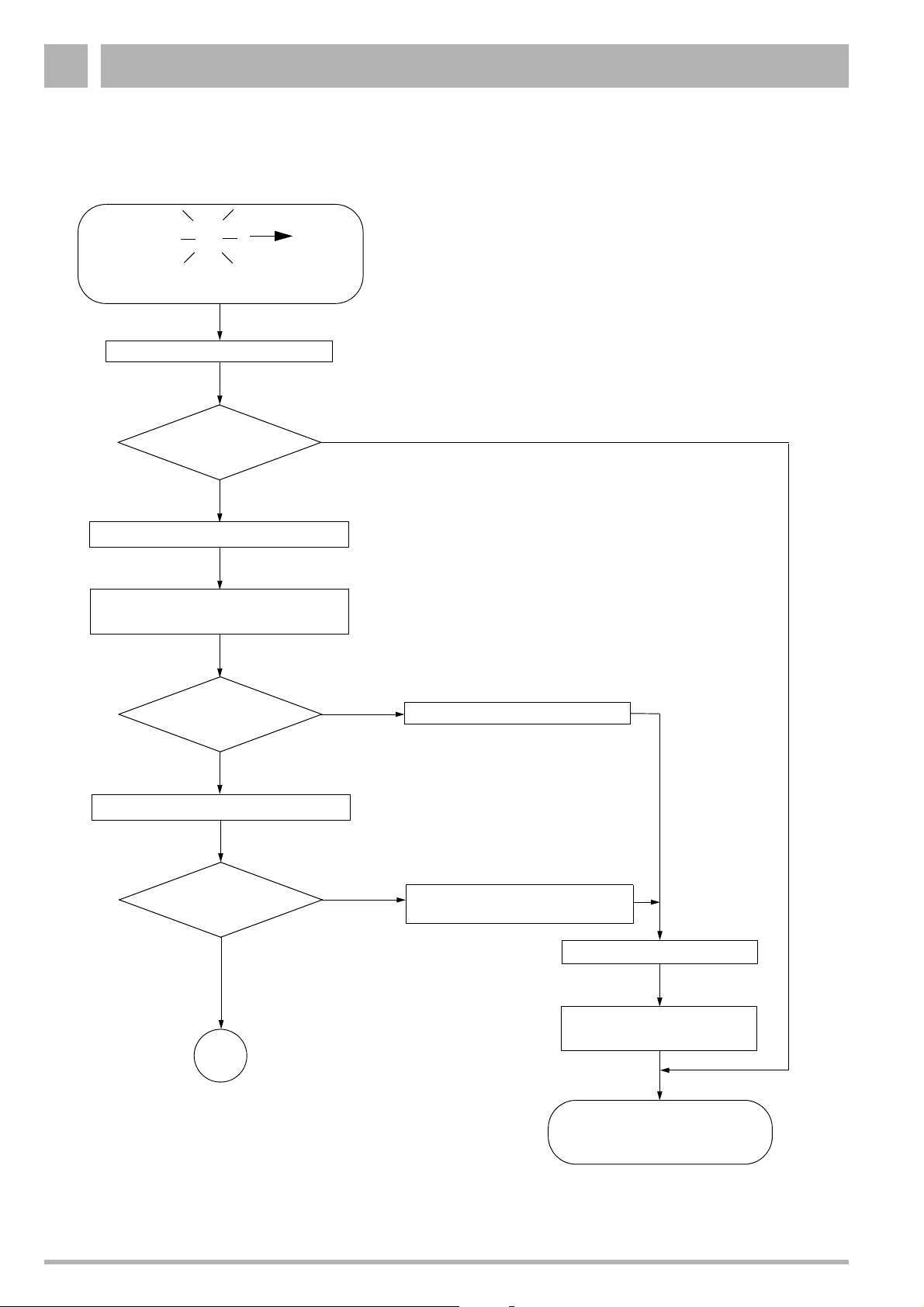

Troubleshooting 3

2

Excessive temperature

increase at safety sensor

Wait approx. 30 sec for the boiler to return

automatically to normal operation

New fault warning message

Check system and heat exchanger, as

indicated in the installation and servicing

instructions, for signs of airlocks and dirt -

purge and/or clean as required

Are all

maintenance shutoff

valves open?

Is the water

pressure in the system at

least 1 bar?

P

2P?

Yes

Yes

No

No

No

Open maintenance shutoff valves

Fill up with water as indicated in the

installation and servicing instruc-

tions, and purge the system of air

Yes

Is at least one

thermostatic valve open (to

control the amount of water

circulating)?

Yes

Remove the casing (page 48)

Check safety sensor and wiring

(page 55)

Safety sensor OK?

Yes

Check circulation pump (page 54)

Circulation pump OK?

Yes

Filter to catch dirt fitted?

If yes, is it unclogged?

No

No

No

Open one thermostatic valve

Replace safety sensor

(page 55)

Replace circulation pump (page 54)

Fit the casing (page 48)

"reset"

A

page 46

Fig. 8 Fault warning message 2P: Excessive temperature increase at safety sensor

Subject to modifications resulting from technical improvements! Buderus Ltd. • http://www.buderus-domestic.co.uk

Servicing manual for wall-mounted condensing gas boiler 600 Series 11S/19S/24S/24C • Issued 02/2006 11

600 Series 11S / 19S / 24S / 24C

OK

Page 12

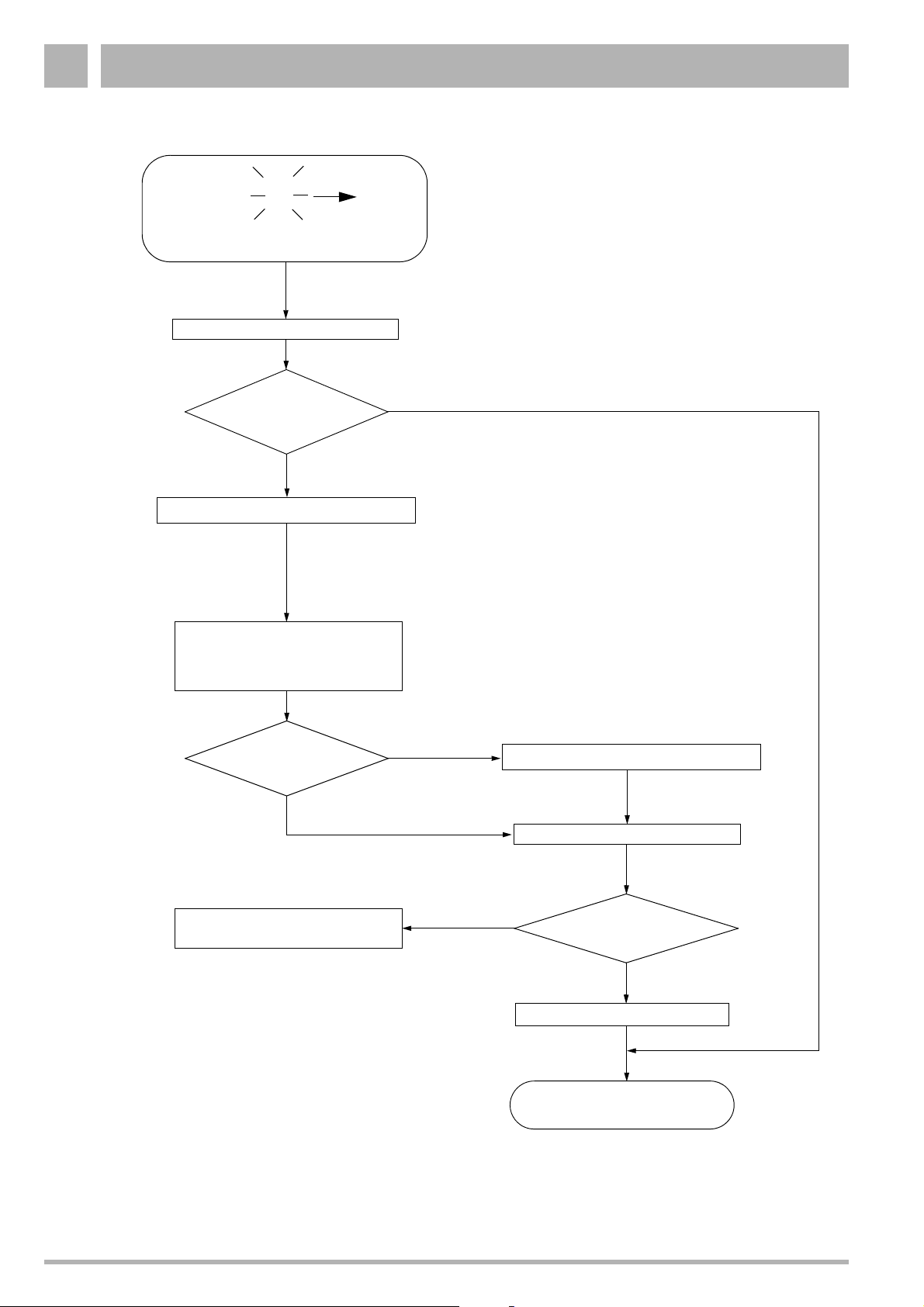

Troubleshooting3

Flashing

3

C

Bad plug-in connection at cable loom,

or damaged wiring

"reset"

New fault warning

message 3C?

Yes

Remove the casing (page 48)

Check for a damaged or broken

connection lead between plugs

03-20 and 04-20 of the 20-core

lead to the UBA

No

Wiring OK?

Yes

Use the corresponding flow diagram

to diagnose and deal with the fault.

No

Replace cable

"reset"

Yes

600 Series 11S / 19S / 24S / 24C

New fault warning

message?

No

Fit the casing (page 48)

OK

Fig. 9 Fault warning message 3C: Bad plug-in connection at cable loom, or damaged wiring

Subject to modifications resulting from technical improvements! Buderus Ltd. • http://www.buderus-domestic.co.uk

12 Servicing manual for wall-mounted condensing gas boiler 600 Series 11S/19S/24S/24C • Issued 02/2006

Page 13

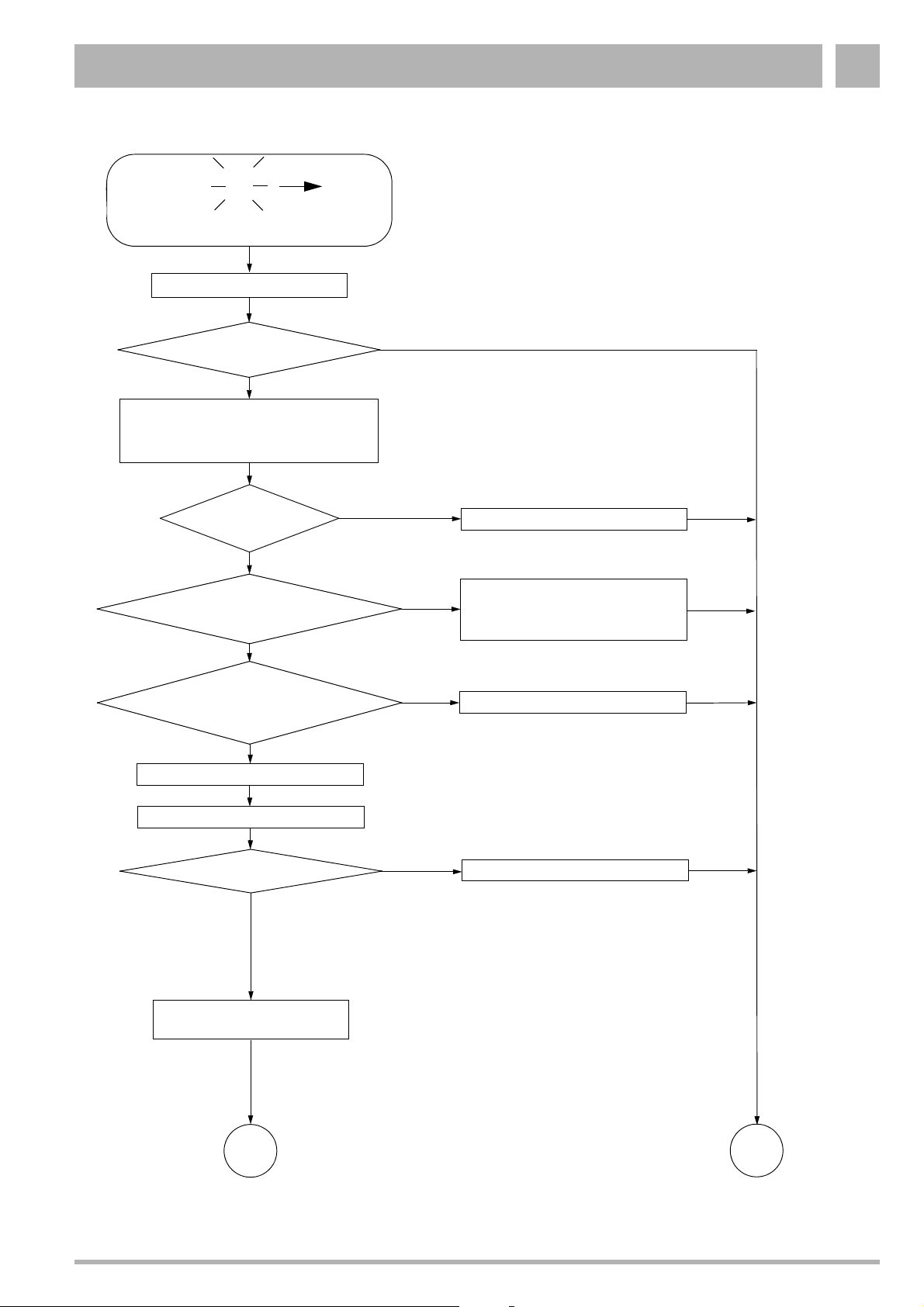

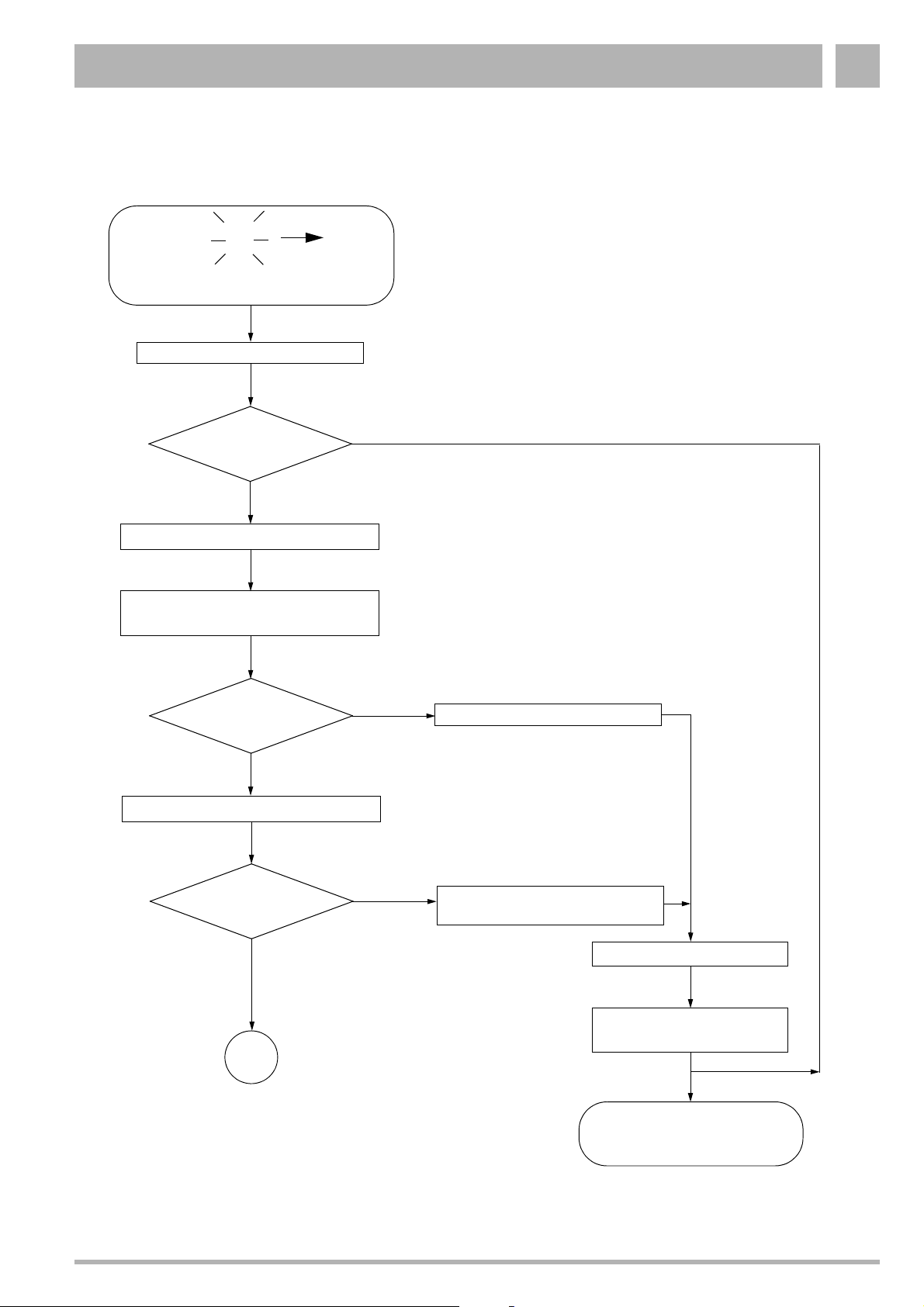

Troubleshooting 3

Flashing

4

Feed sensor above 100 °C

"reset"

New fault warning message

4A?

Yes

Check system and heat exchanger, as

indicated in the installation and servicing

instructions, for signs of airlocks and

dirt - purge and/or clean as required.

Are all

maintenance shutoff

valves open?

Yes

Is the water

pressure in the system at

least 1 bar?

Yes

A

No

No

No

Open maintenance shutoff valves

Fill up with water as indicated in the

installation and servicing instruc-

tions, and purge the system of air

Is at least one

thermostatic valve open (to control

the amount of water cir-

culating)?

Yes

Remove the casing (page 48)

Check circulation pump (page 54)

Circulation pump OK?

Yes

Filter to catch dirt fitted?

If yes, is it unclogged?

No

No

Open one thermostatic valve

Replace circulation pump (page 54)

16

page 14

Fig. 10 Fault warning message 4A: Feed sensor above 100 °C

Subject to modifications resulting from technical improvements! Buderus Ltd. • http://www.buderus-domestic.co.uk

Servicing manual for wall-mounted condensing gas boiler 600 Series 11S/19S/24S/24C • Issued 02/2006 13

17

page 14

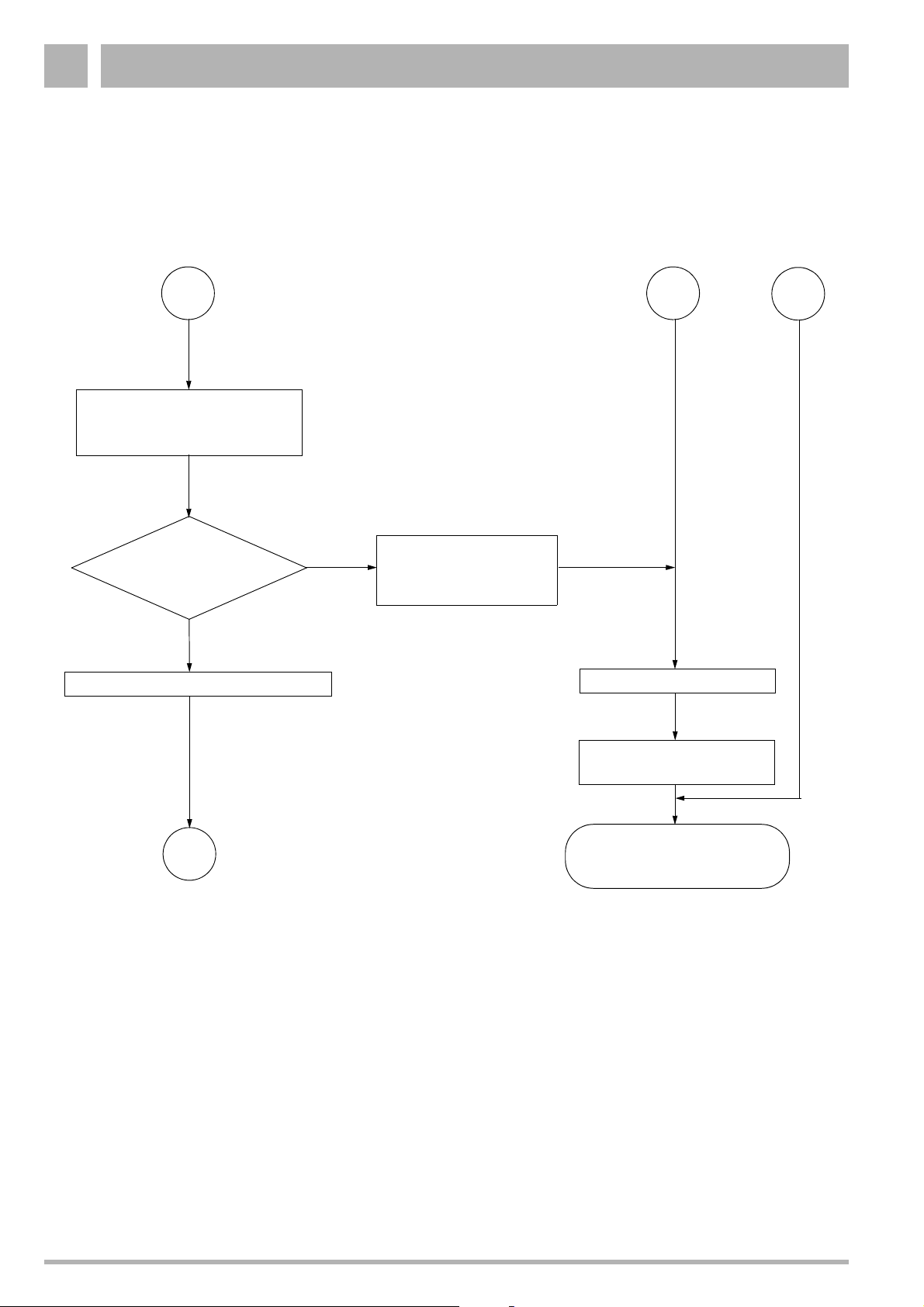

Page 14

Troubleshooting3

page 13

16

Check feed sensor and feed-sensor

connection wiring (page 56)

Flow sensor

and wiring

OK?

Yes

A

No

page 13

17

Replace feed sensor or cable

(page 56)

"reset"

page 46

Fit the casing (page 48)

600 Series

11S / 19S / 24S / 24C

OK

Fig. 11 Continuation of fault warning message 4A: Feed sensor above 100 °C

Subject to modifications resulting from technical improvements! Buderus Ltd. • http://www.buderus-domestic.co.uk

14 Servicing manual for wall-mounted condensing gas boiler 600 Series 11S/19S/24S/24C • Issued 02/2006

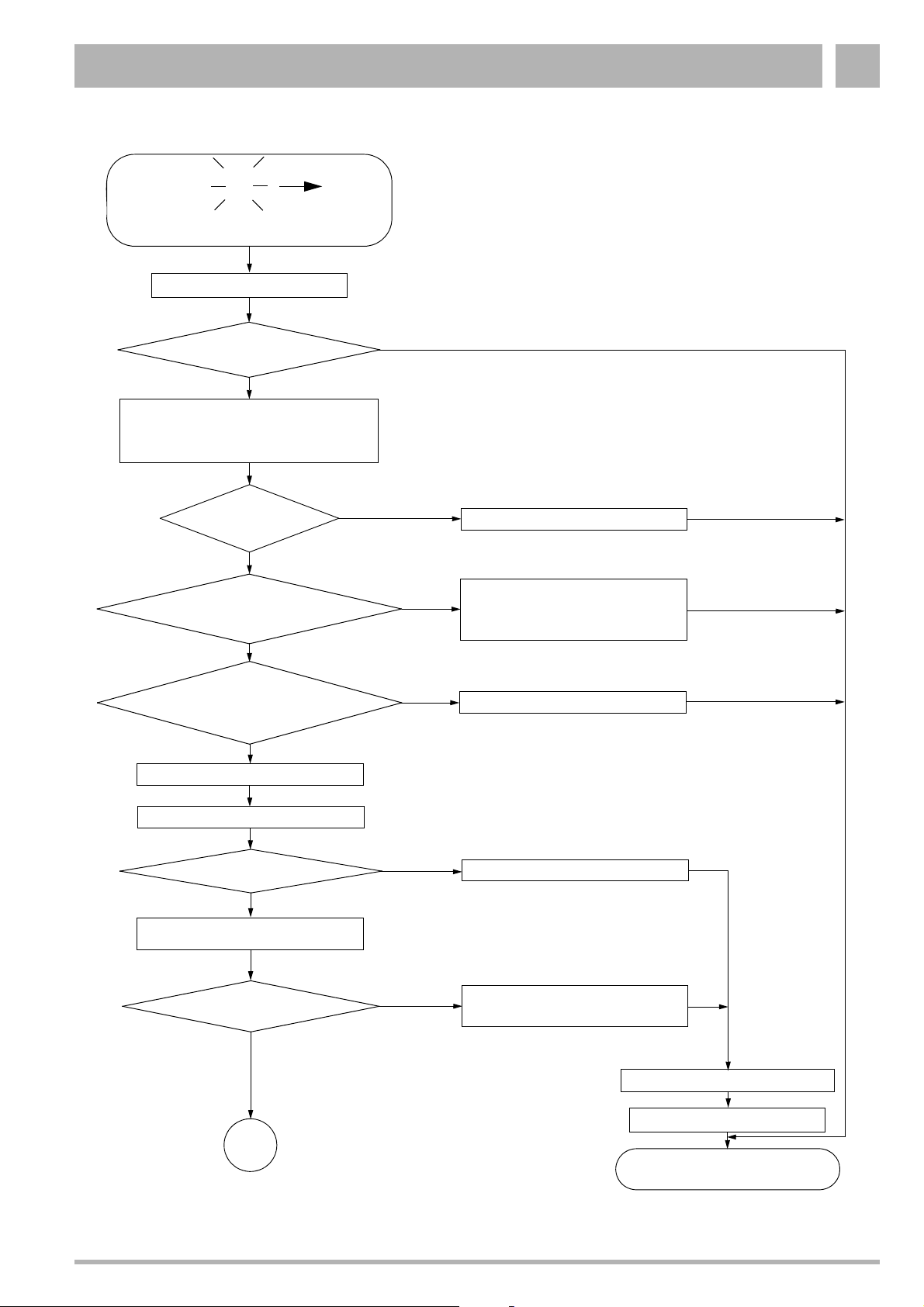

Page 15

Troubleshooting 3

Flashing

4

F2 fuse malfunction, or exhaust-gas

sensor tripped

"reset"

New fault

warning message

4C?

Yes

Remove the casing (page 48)

Check miniature fuse F2 (page 53)

Miniature fuse F2 OK?

C

No

No

Fuse (1.25 AT) should be

replaced

Yes

Check wiring connection of UBA

(page 53)

Wiring connection

OK?

Yes

Check exhaust-gas sensor

(page 49)

Exhaust-gas

sensor OK?

Yes

18

No

No

Connect lead correctly

Replace exhaust-gas sensor

(page 49)

19

20

page 16

Fig. 12 Fault warning message 4C: F2 fuse malfunction, or exhaust-gas sensor tripped

Subject to modifications resulting from technical improvements! Buderus Ltd. • http://www.buderus-domestic.co.uk

Servicing manual for wall-mounted condensing gas boiler 600 Series 11S/19S/24S/24C • Issued 02/2006 15

page 16

page 16

Page 16

Troubleshooting3

page 15

18

Open the heat exchanger and

burner, as indicated in the installation

and servicing instructions, and check

for dirt

Are the heat exchang-

er and burner soiled?

No

Shut the heat exchanger and burner

Yes

Clean the heat exchanger

and burner, as indicated in

the installation and servicing

instructions

page 15

19

"reset"

page 15

20

A

page 46

Fit the casing

(page 48)

600 Series

11S / 19S / 24S / 24C

OK

Fig. 13 Continuation of fault warning message 4C: F2 fuse malfunction, or exhaust-gas sensor tripped

Subject to modifications resulting from technical improvements! Buderus Ltd. • http://www.buderus-domestic.co.uk

16 Servicing manual for wall-mounted condensing gas boiler 600 Series 11S/19S/24S/24C • Issued 02/2006

Page 17

Troubleshooting 3

Flashing

4

Safety sensor temp. exceeds 100 °C

"reset"

New fault

warning message 4F?

Yes

Check system and heat exchanger, as

indicated in the installation and servicing

instructions, for signs of airlocks and

dirt - purge and/or clean as required

Are all

maintenance shutoff

valves open?

Yes

Is the water

pressure in the system at

least 1 bar?

F

No

No

No

Open maintenance shutoff valves

Fill up with water as indicated in the

installation and servicing instruc-

tions, and purge the system of air

Yes

Is at least one

thermostatic valve open (to

control the amount of water

circulating)?

Yes

Remove the casing (page 48)

Check circulation pump (page 54)

Circulation pump OK?

Yes

Check safety sensor

(page 55)

Safety sensor

OK?

Yes

No

No

No

Open one thermostatic valve

Replace circulation pump (page 54)

Replace safety sensor

(page 55)

Fit the casing (page 48)

"reset"

A

600 Series 11S / 19S / 24S / 24C

page 46

Fig. 14 Fault warning message 4F: Safety sensor temp. exceeds 100 °C

Subject to modifications resulting from technical improvements! Buderus Ltd. • http://www.buderus-domestic.co.uk

Servicing manual for wall-mounted condensing gas boiler 600 Series 11S/19S/24S/24C • Issued 02/2006 17

OK

Page 18

Troubleshooting3

Flashing

4

Dripping tap

There is constant heat monitoring

over a period of 4 hours, but the

boiler has been heating up for less

than 20 minutes. The hot water

requirement is now blocked for one

hour, or the restriction lifted if a heat

requirement arises.

Is there a

dripping tap somewhere in

the hot-water system?

Yes

H

No

Please deal with this item

Yes

"reset"

New fault warning

message 4H?

No

600 Series

11S / 19S / 24S / 24C

OK

Fig. 15 Fault warning message 4H: Dripping tap

Subject to modifications resulting from technical improvements! Buderus Ltd. • http://www.buderus-domestic.co.uk

18 Servicing manual for wall-mounted condensing gas boiler 600 Series 11S/19S/24S/24C • Issued 02/2006

Page 19

Troubleshooting 3

Flashing

4

Short circuit at safety sensor

"reset"

New fault warning

message 4L?

Yes

Remove the casing (page 48)

Check wiring to safety sensor for short

circuits (page 55)

L

No

Wiring OK?

Yes

Check safety sensor (page 55)

Safety sensor

OK?

Yes

A

page 46

No

No

Replace cable

Replace safety sensor

(page 55)

"reset"

Fit the casing

(page 48)

600 Series

11S / 19S / 24S / 24C

OK

Fig. 16 Fault warning message 4L: Short circuit in safety sensor

Subject to modifications resulting from technical improvements! Buderus Ltd. • http://www.buderus-domestic.co.uk

Servicing manual for wall-mounted condensing gas boiler 600 Series 11S/19S/24S/24C • Issued 02/2006 19

Page 20

Troubleshooting3

Flashing

4

Safety sensor, loose contact

or defect

"reset"

New fault warning

message 4P?

Yes

Remove the casing (page 48)

Check wiring to safety sensor for loose

contacts (page 55)

P

No

Wiring OK?

Yes

Check safety sensor (page 55)

Safety sensor

OK?

Yes

A

page 46

No

No

Replace cable (page 55)

Replace safety sensor (page 55)

"reset"

Fit the casing

(page 48)

600 Series

11S / 19S / 24S / 24C

OK

Fig. 17 Fault warning message 4P: Safety sensor, loose contact or defect

Subject to modifications resulting from technical improvements! Buderus Ltd. • http://www.buderus-domestic.co.uk

20 Servicing manual for wall-mounted condensing gas boiler 600 Series 11S/19S/24S/24C • Issued 02/2006

Page 21

Troubleshooting 3

Flashing

4

Short circuit in feed sensor

"reset"

New fault warning

message 4U?

Yes

Remove the casing (page 48)

Check wiring to feed sensor for short

circuits (page 56)

U

No

Wiring OK?

Yes

Check feed sensor (page 56)

Feed sensor

OK?

Yes

A

page 46

No

No

Replace cable

Replace feed sensor

(page 56)

"reset"

Fit the casing

(page 48)

600 Series

11S / 19S / 24S / 24C

OK

Fig. 18 Fault warning message 4U: Short circuit in feed sensor

Subject to modifications resulting from technical improvements! Buderus Ltd. • http://www.buderus-domestic.co.uk

Servicing manual for wall-mounted condensing gas boiler 600 Series 11S/19S/24S/24C • Issued 02/2006 21

Page 22

Troubleshooting3

Flashing

4

Feed sensor, loose contact or

defective

"reset"

New fault warning

message 4Y?

Yes

Remove the casing (page 48)

Check wiring to feed sensor for loose

contacts (page 56)

Y

No

Wiring OK?

Yes

Check feed sensor (page 56)

Flow sensor

OK?

Yes

A

page 46

No

No

Replace cable

Replace feed sensor

(page 56)

"reset"

Fit the casing

(page 48)

600 Series

11S / 19S / 24S / 24C

OK

Fig. 19 Fault warning message 4Y: Feed sensor, loose contact or defective

Subject to modifications resulting from technical improvements! Buderus Ltd. • http://www.buderus-domestic.co.uk

22 Servicing manual for wall-mounted condensing gas boiler 600 Series 11S/19S/24S/24C • Issued 02/2006

Page 23

Troubleshooting 3

Flashing

5

600 Serie has switched off

after connection of diagnosis plug

"reset"

600 Series

11S / 19S / 24S / 24C

OK

C

Fig. 20 Fault warning message 5C: 600 Series has switched off after disconnection of diagnosis plug

Subject to modifications resulting from technical improvements! Buderus Ltd. • http://www.buderus-domestic.co.uk

Servicing manual for wall-mounted condensing gas boiler 600 Series 11S/19S/24S/24C • Issued 02/2006 23

Page 24

Troubleshooting3

Flashing

6

F1 fuse defective, or no ionisation

message after ignition

"reset"

Is the gas-supply shutoff

valve open?

Yes

Remove the casing (page 48)

Did the incandes-

cent firing electrode glow

during ignition?

Yes

Did the gas valve

open during ignition? (Noise

from switch)

A

No

No

No

Open gas-supply shutoff valve

21

22

page 25

page 26

Yes

Is the fan running?

Yes

Measure connection pressure (18 - 25 mbar),

as indicated in installation and servicing

instructions

Gas connection pressure

OK?

Yes

Carry out the following tasks as shown in the

Installation and Servicing Instructions: Check

exhaust-gas system (operation independent of

room-air), Check gas-air ratio of supply

Gas-air ratio OK?

Yes

No

No

No

23

Contact local gas-supply

Adjust gas/air ratio as indicated in the

installation and servicing instructions

page 27

utility

"reset"

Fit the casing (page 48)

24

page 25

Fig. 21 Fault warning message 6A: F1 fuse defective, or no ionisation message after ignition

Subject to modifications resulting from technical improvements! Buderus Ltd. • http://www.buderus-domestic.co.uk

24 Servicing manual for wall-mounted condensing gas boiler 600 Series 11S/19S/24S/24C • Issued 02/2006

600 Series 11S / 19S / 24S / 24C

OK

Page 25

Troubleshooting 3

page 24

21

Check fuse F1 (page 53)

Fuse OK?

No

Fuse (1.25 AT) should be

replaced

Yes

Replace hot surface ingitor

(page 59)

A

page 46

Check hot surface ingitorhot surface

ingitor (page 59)

No

Measure ionisation current

Yes

Replace ionization electrode

hot surface

ingitor OK?

Yes

(page 63)

Ionization

electrode OK?

No

(page 63)

24

page 24

Has fuse

been replaced twice in

quick succession?

Yes

No

"reset"

Fit the casing

(page 48)

A

page 46

600 Series

11S / 19S / 24S / 24C

OK

Fig. 22 Continuation of fault warning message 6A: F1 fuse defective, or no ionisation message after ignition

Subject to modifications resulting from technical improvements! Buderus Ltd. • http://www.buderus-domestic.co.uk

Servicing manual for wall-mounted condensing gas boiler 600 Series 11S/19S/24S/24C • Issued 02/2006 25

Page 26

Troubleshooting3

page 24

22

Check switching contact of floor

thermostat (page 53)

Switch contact

OK?

Yes

Check lead connections on gas

burner subassembly

Wiring connec-

tions OK?

Yes

Check gas-burner subassembly for

correct activation (page 60)

No

No

Connect switch contact

correctly

Connect wiring correctly

Activation

OK?

No

Yes

A

page 46

Fig. 23 Continuation of fault warning message 6A: F1 fuse defective, or no ionisation message after ignition

Subject to modifications resulting from technical improvements! Buderus Ltd. • http://www.buderus-domestic.co.uk

Replace gas-burner assembly

(page 60)

"reset"

Fit the casing

(page 48)

600 Series

11S / 19S / 24S / 24C

OK

26 Servicing manual for wall-mounted condensing gas boiler 600 Series 11S/19S/24S/24C • Issued 02/2006

Page 27

Troubleshooting 3

page 24

23

Check that the fan-unit connection

plug is correctly inserted

Plug OK?

Yes

Replace fan unit

(page 51)

"reset"

Fit the casing

(page 48)

600 Series

11S / 19S / 24S / 24C

OK

No

Insert plug correctly

Fig. 24 Continuation of fault warning message 6A: F1 fuse defective, or no ionisation message after ignition

Subject to modifications resulting from technical improvements! Buderus Ltd. • http://www.buderus-domestic.co.uk

Servicing manual for wall-mounted condensing gas boiler 600 Series 11S/19S/24S/24C • Issued 02/2006 27

Page 28

Troubleshooting3

6

Ionisation message,

but no flame

Remove the casing (page 48)

Check gas burner subassembly

(page 60)

Gas burner

assembly activates without

instructions having been issued to

the effect (Display

UBA

C

0H)

Yes

A

No

Replace ionization electrode

(page 63)

"reset"

page 46

Fit the casing

(page 48)

600 Series

11S / 19S / 24S / 24C

OK

Fig. 25 Fault warning message 6C: Ionisation message, but no flame

Subject to modifications resulting from technical improvements! Buderus Ltd. • http://www.buderus-domestic.co.uk

28 Servicing manual for wall-mounted condensing gas boiler 600 Series 11S/19S/24S/24C • Issued 02/2006

Page 29

Troubleshooting 3

6 H

Flame dies out after main gas

valve is opened

"reset"

Is the gas-supply shutoff valve

completely open?

Yes

Remove the casing (page 48)

Measure the gas connection

pressure

Put system into chimney sweeper mode

(page 47)

Are the minimum-

pressure specifications being

observed (17 mbar min. for

natural gas)?

Yes

No

No

If the required connection

pressure is not available, con-

tact your gas utility company

Open gas valve

completely

"reset"

Fit the casing

(page 48)

Check gas/air ratio as indicated in

the installation and servicing

instructions

Gas-air ratio

OK?

Yes

Check gas-air injector for correct

fitting; check for correct diameter

Fig. 26 Fault warning message 6H: Flame dies out after main gas valve is opened

Subject to modifications resulting from technical improvements! Buderus Ltd. • http://www.buderus-domestic.co.uk

Servicing manual for wall-mounted condensing gas boiler 600 Series 11S/19S/24S/24C • Issued 02/2006 29

No

Adjust gas/air ratio as indi-

cated in the installation and

servicing instructions

600 Series

11S / 19S / 24S / 24C

OK

Page 30

Troubleshooting3

6 L

Flame goes out during warm-up

phase

"reset"

Is the gas-supply shutoff

valve completely open?

Yes

Remove the casing (page 48)

Measure the gas connection

pressure

Put system into chimney sweep mode

(page 47)

Are the minimum-

pressure specifications being

observed (17 mbar min. for

natural gas)?

Yes

No

No

If the required connection

pressure is not available,

contact your gas utility

company

Open gas valve

completely

"reset"

Fit the casing

(page 48)

Check gas/air ratio as indicated in the

installation and servicing instructions

Gas-air ratio

OK?

Yes

Check gas-air injector for correct fitting

and possible clogging; check for correct

diameter

Fig. 27 Fault warning message 6L: Flame goes out during warm-up phase

Subject to modifications resulting from technical improvements! Buderus Ltd. • http://www.buderus-domestic.co.uk

30 Servicing manual for wall-mounted condensing gas boiler 600 Series 11S/19S/24S/24C • Issued 02/2006

No

Adjust gas/air ratio as

indicated in the installation

and servicing instructions

600 Series

11S / 19S / 24S / 24C

OK

Page 31

Troubleshooting 3

Flashing

7

Voltage in UBA too low/high

"reset"

A

Yes,

on second and

third attempts

to start up

New fault warning

message 7A?

Yes, on fourth attempt to start up

Check Mains voltage

(195 V to 253 V)

Mains voltage

OK?

Yes

Remove the casing (page 48)

No

No

Contact local energy-supply

utility

Is regulator connected to

incorrect terminals?

Yes

Connect correctly

Fig. 28 Fault warning message 7A: Voltage in UBA too low or too high

Subject to modifications resulting from technical improvements! Buderus Ltd. • http://www.buderus-domestic.co.uk

Servicing manual for wall-mounted condensing gas boiler 600 Series 11S/19S/24S/24C • Issued 02/2006 31

No

A

page 46

600 Series

11S / 19S / 24S / 24C

OK

Page 32

Troubleshooting3

Flashing

7

Mains voltage interrupted following a

fault warning message

Keep "reset" button pressed for at

least 5 sec.

Use the corresponding flow diagram

to diagnose and deal with the

original fault

C

Fig. 29 Fault warning message 7C: Mains voltage interrupted following a fault warning message

Subject to modifications resulting from technical improvements! Buderus Ltd. • http://www.buderus-domestic.co.uk

32 Servicing manual for wall-mounted condensing gas boiler 600 Series 11S/19S/24S/24C • Issued 02/2006

Page 33

Troubleshooting 3

Flashing

7

F3 fuse defect, or UBA system error

Remove the casing (page 48)

Check miniature fuse F3 (page 53)

F

Is F3 defective?

No

A

page 46

Yes

Fuse (1.25 AT) should be

replaced

Has fuse been replaced

twice in quick succession?

Yes

Check electrical control system of

three-way valve (page 64)

Operation

OK?

Yes

Replace three-way valve

(page 65)

No

No

A

page 46

"reset"

Fit the casing (page 48)

600 Series

11S / 19S / 24S / 24C

OK

Fig. 30 Fault warning message: 7F: F3 fuse defect, or UBA system error

Subject to modifications resulting from technical improvements! Buderus Ltd. • http://www.buderus-domestic.co.uk

Servicing manual for wall-mounted condensing gas boiler 600 Series 11S/19S/24S/24C • Issued 02/2006 33

Page 34

Troubleshooting3

Flashing

7

Voltage peaks in UBA

"reset"

H

Yes,

on second and

third attempts

to start up

New fault warning

message 7H?

Yes, on fourth attempt to start up

Check Mains voltage

(195 V to 253 V)

Mains voltage

OK?

Yes

Remove the casing (page 48)

No

No

Contact electricity supplier

and Buderus

Customer Service

A

page 46

600 Series

11S / 19S / 24S / 24C

Fig. 31 Fault warning message 7H: Voltage peaks in UBA

Subject to modifications resulting from technical improvements! Buderus Ltd. • http://www.buderus-domestic.co.uk

34 Servicing manual for wall-mounted condensing gas boiler 600 Series 11S/19S/24S/24C • Issued 02/2006

OK

Page 35

Troubleshooting 3

Flashing

7

UBA timer error

"reset"

L

New fault warning

message 7L?

Yes

Remove the casing (page 48)

A

page 46

No

600 Series

11S / 19S / 24S / 24C

OK

Fig. 32 Fault warning message 7L: UBA timer error

Subject to modifications resulting from technical improvements! Buderus Ltd. • http://www.buderus-domestic.co.uk

Servicing manual for wall-mounted condensing gas boiler 600 Series 11S/19S/24S/24C • Issued 02/2006 35

Page 36

Troubleshooting3

Flashing

8

External switching contact,

e.g. temperature monitor for floor

heating, has been tripped

Y

Switch

contact OK?

No

Replace switch contact

Yes

Yes

Remove the casing (page 48)

Is there

an external switching

contact?

Contacts in cable

loom OK?

Yes

No

No

Connect contacts correctly

"reset"

New fault warning

message 8Y?

Yes

No

Fit the casing

(page 48)

600 Series

A

page 46

Fig. 33 Fault warning message 8Y: External switching contact, e.g. temperature monitor for floor heating, has been tripped

Subject to modifications resulting from technical improvements! Buderus Ltd. • http://www.buderus-domestic.co.uk

36 Servicing manual for wall-mounted condensing gas boiler 600 Series 11S/19S/24S/24C • Issued 02/2006

11S / 19S / 24S / 24C

OK

Page 37

Troubleshooting 3

Any charac-

9

A

E

ter, except

P

Yes, on second or

third attempt to

start up

System error

"reset"

New fault warning

message 9A?

No

Other fault

warning message?

Yes

System error

Yes,

on fourth

attempt to

start up

Use the corresponding flow diagram

to diagnose and deal with the fault

B

page 46

600 Series

11S / 19S / 24S / 24C

OK

Fig. 34 Fault warning message 9A (with any character except P): System error

Subject to modifications resulting from technical improvements! Buderus Ltd. • http://www.buderus-domestic.co.uk

Servicing manual for wall-mounted condensing gas boiler 600 Series 11S/19S/24S/24C • Issued 02/2006 37

Page 38

Troubleshooting3

Flashing

9

Incorrect cable connection at UBA,

or KIM defective

Remove the casing (page 48)

Check cable connections at

KIM

Check wiring connection in UBA

(page 53)

C

Connections OK?

Yes

A

page 46

No

Connect all terminals

correctly

"reset", Fit the casing

600 Series

11S / 19S / 24S / 24C

OK

Fig. 35 Fault warning message 9C: Wiring to KIM connected incorrectly

Subject to modifications resulting from technical improvements! Buderus Ltd. • http://www.buderus-domestic.co.uk

38 Servicing manual for wall-mounted condensing gas boiler 600 Series 11S/19S/24S/24C • Issued 02/2006

Page 39

Troubleshooting 3

Flashing

9

Timer error (UBA defective)

F,H,P

At second

attempt

At third

attempt

B

page 46

Yes

"reset"

New fault warning

message 9P?

No

New fault warning

message 9F or 9H?

No

Yes

B

page 46

Use the corresponding flow diagram

to diagnose and deal with the fault

"reset"

Yes

New fault warning

message 9P?

No

600 Series

11S / 19S / 24S / 24C

Fig. 36 Fault warning message 9F,H,P: System error (UBA defective), or KIM defective

Subject to modifications resulting from technical improvements! Buderus Ltd. • http://www.buderus-domestic.co.uk

Servicing manual for wall-mounted condensing gas boiler 600 Series 11S/19S/24S/24C • Issued 02/2006 39

OK

Page 40

Troubleshooting3

Flashing

9

Wiring to gas-valve assembly incorrect,

or loose wiring connections in UBA

Remove the casing (page 48)

Check connection lead to gas burner

assembly

Check wiring connection in UBA

(page 53)

L

Connections OK?

Yes

A

page 46

No

Connect all terminals correctly

"reset"

Fit the casing

(page 48)

600 Series

11S / 19S / 24S / 24C

Fig. 37 Fault warning message 9L: Wiring to gas-valve assembly incorrect, or loose wiring connections in UBA.

Subject to modifications resulting from technical improvements! Buderus Ltd. • http://www.buderus-domestic.co.uk

40 Servicing manual for wall-mounted condensing gas boiler 600 Series 11S/19S/24S/24C • Issued 02/2006

OK

Page 41

Troubleshooting 3

Flashing

9

Wiring to gas-valve assembly incorrect,

or loose wiring connections in UBA

Remove the casing (page 48)

U

Set the mains switch to "0".

Check wiring connection in UBA

(page 53)

Connections OK?

No

Connect all terminals correctly

Set the mains switch to "1".

Yes

Yes

page 46

A

KIM connected

correctly?

"reset"

No

"reset"

"reset"

Set the mains switch to "1".

New fault warning

message 9U?

No

Yes

Use the corresponding flow diagram

to diagnose and deal with the

fault

Fig. 38 Fault warning message 9U: Incorrect cable connection at UBA (KIM defective)

Subject to modifications resulting from technical improvements! Buderus Ltd. • http://www.buderus-domestic.co.uk

Servicing manual for wall-mounted condensing gas boiler 600 Series 11S/19S/24S/24C • Issued 02/2006 41

Other fault warning

message ?

No

Fit the casing

(page 48)

600 Series

11S / 19S / 24S / 24C

OK

Yes

Contact Buderus

Customer Service

Fit the casing

(page 48)

Page 42

Troubleshooting3

E P

Non-compatible UBA installed

UBA software

version 3.5

or better?

No

Install version 3.5 (or better) of

UBA software

Fit the casing

(page 48)

"reset"

600 Series

11S / 19S / 24S / 24C

OK

Yes

A

page 46

Fig. 39 Fault warning message EP: Non-compatible UBA installed

Subject to modifications resulting from technical improvements! Buderus Ltd. • http://www.buderus-domestic.co.uk

42 Servicing manual for wall-mounted condensing gas boiler 600 Series 11S/19S/24S/24C • Issued 02/2006

Page 43

Troubleshooting 3

No mains water, despite system being

ready for operation

Is the chimney

sweep switch set

to "0"?

Yes

Remove the casing (page 48)

Check three-way valve for correct

activation (page 64) ?

Activation

OK?

Yes

Check three-way valve

No

No

Set the chimney-sweep switch

to "0"

600 Series

11S / 19S / 24S / 24C

OK

A

page 46

Three-way valve

OK?

Yes

26

page 44

Fig. 40 Malfunction: No mains water, despite system being ready for operation

Subject to modifications resulting from technical improvements! Buderus Ltd. • http://www.buderus-domestic.co.uk

No

Replace three-way valve (page 65)

27

page 44

Servicing manual for wall-mounted condensing gas boiler 600 Series 11S/19S/24S/24C • Issued 02/2006 43

Page 44

Troubleshooting3

page 43

27

Check mains-water sensor (page 57)

Mains-water

sensor OK?

Yes

A

page 46

No

Replace mains-water sensor

(page 58)

26

page 43

Fit the casing

(page 48)

600 Series

11S / 19S / 24S / 24C

OK

Fig. 41 Continued malfunction: No mains water, despite system being ready for operation

Subject to modifications resulting from technical improvements! Buderus Ltd. • http://www.buderus-domestic.co.uk

44 Servicing manual for wall-mounted condensing gas boiler 600 Series 11S/19S/24S/24C • Issued 02/2006

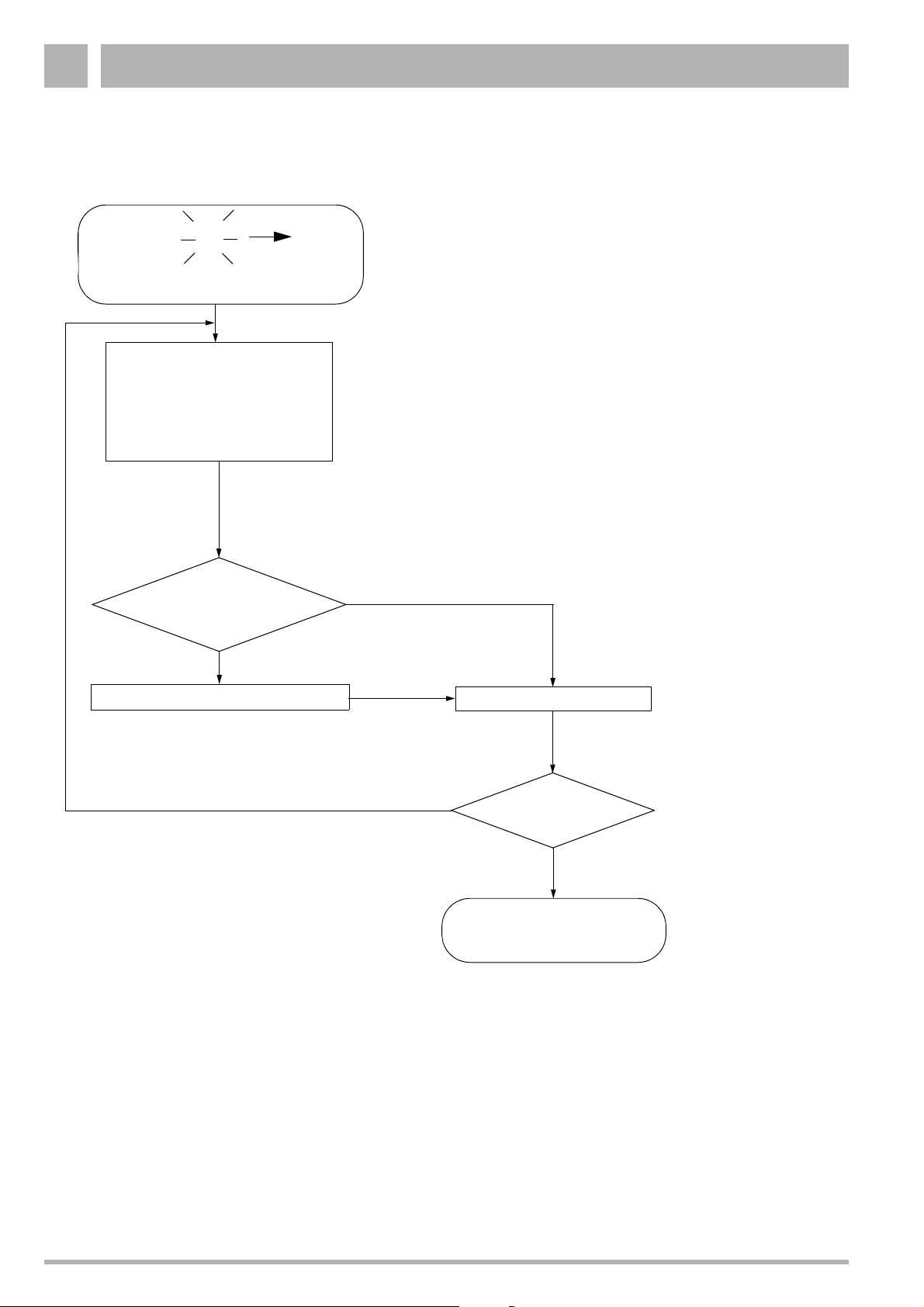

Page 45

Troubleshooting 3

No heating operation, despite request for

activation and display message indicating that

system is ready for use

Check control-unit configuration and

wiring connections to unit

Configuration OK?

Yes

Remove the casing

(page 48)

Check control-unit connection to UBA

(page 66)

Connections in

UBA OK?

Yes

Connections at the

ERC/RC OK?

No

No

Adjust settings and press "reset"

Configure connections correctly

Fit the casing

(page 48)

600 Series

Replace lead or control unit

Still no heating

operation?

11S / 19S / 24S / 24C

OK

A

page 46

Fig. 42 Malfunction: No heating operation, despite request for activation and display message indicating that system is ready for use

Subject to modifications resulting from technical improvements! Buderus Ltd. • http://www.buderus-domestic.co.uk

Servicing manual for wall-mounted condensing gas boiler 600 Series 11S/19S/24S/24C • Issued 02/2006 45

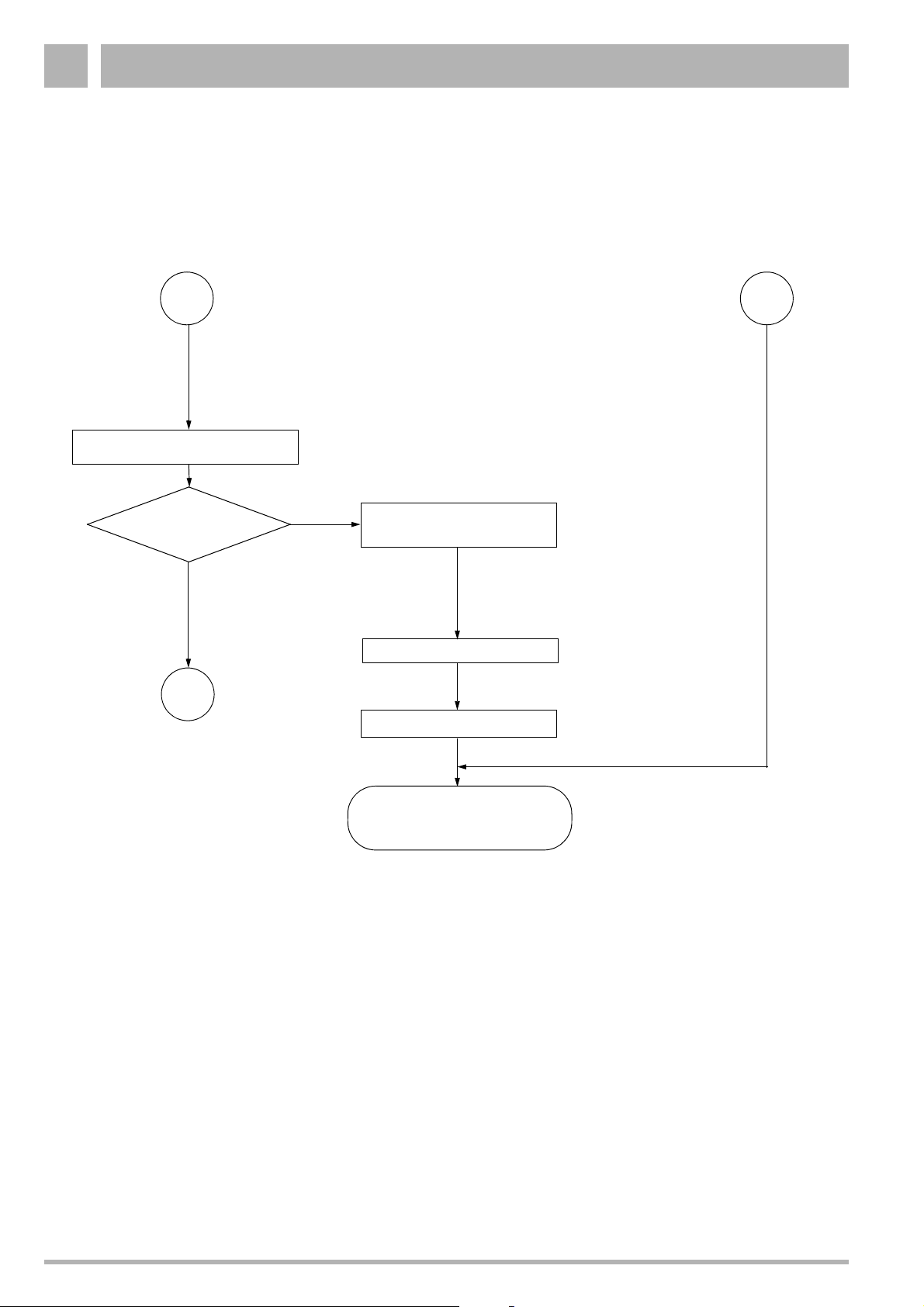

Page 46

Troubleshooting3

A

Check all plug-in connections on UBA and

all plug-in connections in general

B

Connection plug

and plug-in con-

nections OK?

Yes

Replace UBA (page 50) or contact

Buderus Customer Service

Use the corresponding flow diagram

to diagnose and correct the fault

No

Correct contact malfunction

"reset"

Yes

New fault warning

message?

Fit the casing

(page 48)

No

600 Series

11S / 19S / 24S / 24C

OK

Fig. 43 Continued malfunction: No heating operation, despite request for activation and display message indicating that system is ready for use

Subject to modifications resulting from technical improvements! Buderus Ltd. • http://www.buderus-domestic.co.uk

46 Servicing manual for wall-mounted condensing gas boiler 600 Series 11S/19S/24S/24C • Issued 02/2006

Page 47

Troubleshooting 3

12

10

01

11

KW

10

1

1

1

3.1 Troubleshooting tasks

CAUTION

All work on the gas supply must be carried out

by a CORGI registered engineer.

All work on water and electrical supplies must

be carried out by a competent person.

3.1.1 Unblocking the 600 Series 11S / 19S / 24S / 24C

Press the “reset” button (fig. 44) after rectifying each fault.

A letter “r” will appear on the display.

This unblocks the UBA and returns it to standby mode.

NOTE

The system cannot be unblocked by

disconnecting at the master switch.

If the "reset" button is not kept pressed for long enough, the

display will first show a "7" and, after the Service button is

pressed, a "C".

Unblock by pressing the “reset” button once more and keeping

it pressed for the required time.

Fig. 44 "Reset" button

3.1.2 Chimney-sweep mode

Certain troubleshooting tasks must be carried out with the

600 Series 11S / 19S / 24S / 24C in heating mode.

z Before proceeding, open the cover of the second operating

level on the UBA (fig. 45).

z Set the chimney-sweep switch to “1”.

z Remember to return the chimney-sweep switch to “0” once

work is complete.

z Close the cover of the second operating level on the UBA.

NOTE

The system cannot be used to supply hot water

while it is in chimney-sweep mode. With

chimney sweep mode activated, the boiler

heats up to its preset feed temperature.

01

Fig. 45 Chimney-sweep switch

Subject to modifications resulting from technical improvements! Buderus Ltd. • http://www.buderus-domestic.co.uk

Servicing manual for wall-mounted condensing gas boiler 600 Series 11S/19S/24S/24C • Issued 02/2006 47

Page 48

Troubleshooting3

3.1.3 Removing and refitting the outer casing

z Note current display.

z Set the mains switch to “0”.

z Loosen the fixing screw (fig. 46, item 1).

z Detach the outer casing.

z To refit the casing, follow the above procedure in reverse

order. Then return the mains switch to “I”.

3.1.4 Removing and refitting the combustion-chamber cover

1

Fig. 46 Remove outer casing

z Open the clip fastenings (fig. 47, item 1).

z Remove combustion-chamber cover.

z To refit the cover, follow the above procedure in reverse

order.

1

1

Fig. 47 600 Series 11S / 19S / 24S / 24C:

Remove combustion-chamber cover

Fig. 48 600 Series 24C: Combi-unit

Subject to modifications resulting from technical improvements! Buderus Ltd. • http://www.buderus-domestic.co.uk

48 Servicing manual for wall-mounted condensing gas boiler 600 Series 11S/19S/24S/24C • Issued 02/2006

Page 49

Troubleshooting 3

3.1.5 Checking the exhaust-gas sensor

z Detach plug-and-socket connection on cable to exhaust-

gas sensor. Ensure that no cable is earthed (grounded) at

any point.

z Allow the exhaust-gas sensor to cool down.

Activation temperature:

600 Series 11S / 19S / 24S / 24C: 105 °C

z Check exhaust-gas sensor for free throughput. If

throughput is not free, the exhaust-gas sensor is defective.

z Replace any exhaust-gas sensor found to be defective.

Ensure you use only genuine Buderus spare parts.

z If the exhaust-gas sensor is working correctly, plug it in

once more.

Fig. 49 600 Series 11S / 19S / 24S / 24C:

Checking the exhaust-gas sensor

3.1.6 Replacing the exhaust-gas sensor

z Unscrew the flow-backup mounting.

z Detach the cable plug at the exhaust-gas sensor.

z Loosen both retaining screws on the exhaust-gas sensor.

z Remove the exhaust-gas sensor and replace with a new

unit (fig. 50).

z Retighten the retaining screws.

z Reconnect the cable plug.

z Screw the mounting into place.

Fig. 50 600 Series 11S / 19S / 24S / 24C:

Replacing the exhaust-gas sensor

Subject to modifications resulting from technical improvements! Buderus Ltd. • http://www.buderus-domestic.co.uk

Servicing manual for wall-mounted condensing gas boiler 600 Series 11S/19S/24S/24C • Issued 02/2006 49

Page 50

Troubleshooting3

3.1.7 Checking the air intake and outlet openings

z Check to ensure that the air intake and outlet openings are

of sufficient size, and that they are not obstructed or

clogged.

3.1.8 Replacing the UBA

z Disconnect the system from the power supply.

z Loosen crosshead screw (fig. 51, item 1) on UBA housing.

z Swivel UBA housing downwards.

1

z Open the UBA housing (fig. 52).

z Note the position of the cable plugs, disconnect all cable

plugs.

z Open the mains connection box by loosening the screw.

z Loosen the four screws and remove the strain-relief clamp.

z Carefully lift the UBA and remove by pulling forwards (snap

lock) (fig. 53).

z Fit new UBA.

z Reconnect all plug-in cables to their correct sockets.

z Feed the mains lead in through the strain-relief clamp in the

connection box and connect to the terminals as per the

wiring diagram.

z Retighten the strain-relief clamp and shut the connection

box.

z Shut the mains connection box.

z Shut the UBA housing.

z Swivel the UBA housing upwards and screw into place.

z Fit the casing.

z Connect system to mains power supply.

Fig. 51 Swivel UBA housing downwards

Fig. 52 Opening the UBA housing

Fig. 53 Carefully lift the UBA to remove

Subject to modifications resulting from technical improvements! Buderus Ltd. • http://www.buderus-domestic.co.uk

50 Servicing manual for wall-mounted condensing gas boiler 600 Series 11S/19S/24S/24C • Issued 02/2006

Page 51

Troubleshooting 3

3.1.9 Checking the fan

z Set the mains switch to “0”.

z Disconnect the fan's plug and socket connection.

z Connect a multimeter (230 V AC).

z Turn the mains power switch to “I”.

z Take voltage reading at measuring device.

If the voltage reading is 230 V, the power supply is in order.

z Set the mains switch to “0”.

z If the power supply is in order, plug the unit in once more.

z Turn the mains power switch to “I”.

z If the fan now fails to run, it must be replaced.

z If the fan runs at only partial load (i.e. effective operation of

the boiler is not possible), troubleshooting should start at

the connection cable to the UBA or UBA.

3.1.10 Replacing the fan

Fig. 54 Checking the fan

z Shut the gas cock.

z Disconnect the system from the power supply.

z Disconnect the fan, using the plug and socket from the

power supply (fig. 55, item 1), loosen the UBA control line

at the fan (fig. 55, item 2) and the gas burner fitting (fig. 55,

item 3).

z Loosen the union nut (fig. 55, item 4) on the gas burner

fitting.

1

2

3

4

Fig. 55 Replacing the fan on the 600 Series:

Loosen plug and union nut

Subject to modifications resulting from technical improvements! Buderus Ltd. • http://www.buderus-domestic.co.uk

Servicing manual for wall-mounted condensing gas boiler 600 Series 11S/19S/24S/24C • Issued 02/2006 51

Page 52

Troubleshooting3

z Push the safety plate out of the way (fig. 56, item 1).

z Turn air suction tube and pull off from below.

1

Fig. 56 Replacing the fan on the 600 Series:

Remove the air suction tube

z Swivel the "CombiVENT" gas combination unit forward

(fig. 57, item 1)

z Remove the "CombiVENT" gas combination unit from its

bayonet connector and pull upwards to detach

(fig. 57, item 2).

z Detach the fan by loosening the 2 x 2 screws on the

connection unit.

z Replace the fan.

z Refit by following the above procedure in reverse.

2

Fig. 57 Replacing the fan on the 600 Series:

Remove the gas connection unit

1

NOTE

Once installation has been completed

successfully, carry out leak testing as per

"Installation and Servicing Instructions" supplied with 600 Series 11S / 19S / 24S / 24C.

Fig. 58 Replacing the fan on the 600 Series:

Replace the fan

Subject to modifications resulting from technical improvements! Buderus Ltd. • http://www.buderus-domestic.co.uk

52 Servicing manual for wall-mounted condensing gas boiler 600 Series 11S/19S/24S/24C • Issued 02/2006

Page 53

Troubleshooting 3

3.1.11 Checking the wiring connections of the UBA

z Disconnect the system from the power supply.

z Loosen crosshead screw on UBA housing.

z Swivel UBA housing downwards.

z Open the UBA housing.

z Check all cable terminals for tightness and

resecure/retighten as required.

z Shut the UBA housing.

z Swivel the UBA housing upwards and screw into place.

z Connect system to mains power supply.

Fig. 59 Checking the wiring connections of the UBA

3.1.12 Checking the miniature fuses

2

z Disconnect the system from the power supply.

z Loosen crosshead screw on UBA housing.

z Swivel UBA housing downwards.

z Open the UBA housing.

z Check miniature fuses (fig. 60) for correct functioning,

or carry out visual inspection. If defective, fit new fuse

(1.25 AT).

3

Fuse Function

1 Hot surface ingitor

2 UBA, sensors, thermostat valve

3 UBA, three-way valve

z Shut the UBA housing.

z Swivel the UBA housing upwards and screw into place.

z Connect system to mains power supply.

3.1.13 Checking the connections for the second solenoid valve, modulating pump and floor thermostat switching contact

z Pull on mains connection box to detach.

z Check connections of second solenoid valve (fig. 61,

item 1), modulating pump (fig. 61, item 2) and floor

thermostat switching contact (fig. 61, item 3).

1

Fig. 60 Checking the miniature fuse

1

2

3

Fig. 61 Connections for the second solenoid valve,

modulating pump

Subject to modifications resulting from technical improvements! Buderus Ltd. • http://www.buderus-domestic.co.uk

Servicing manual for wall-mounted condensing gas boiler 600 Series 11S/19S/24S/24C • Issued 02/2006 53

and external switching contact

Page 54

Troubleshooting3

2

3.1.14 Checking the circulation pump

z Remove screw plug on circulation pump (fig. 62).

z Turn the UBA mains power switch to “I”.

z Check to ensure that the circulation pump is running.

The circulation pump’s running mechanism may become

blocked if the heating system has been out of use for an

extended period. Use a screwdriver to rotate the circulation

pump in its normal running direction and release the

blockage in question. If this procedure does not work,

replace the circulating pump.

z If the circulation pump is working correctly, screw the plug

back in.

Fig. 62 600 Series 11S / 19S / 24S / 24C:

Checking the circulation pump

3.1.15 Replacing the circulation pump

z Disconnect the system from the power supply.

z Shut the servicing cock.

z Drain the 600 Series 11S / 19S / 24S / 24C as per the

"Installation and Servicing Instructions".

z Loosen the screw on the terminal box (fig. 63, item 2) of the

circulation pump and open the terminal box. Note the

wiring layout, and loosen the cables (fig. 63, item 1).

z Loosen the screw-in connections on the circulation pump

(fig. 63, item 3) and remove the pump.

z Fit new pump and connect to system.

z Connect cables in previously-noted order inside terminal

box, close terminal box and screw shut.

z Connect system to mains power supply.

z Open servicing cocks.

NOTE

Fill the 600 Series 11S / 19S / 24S / 24C and

purge the system of air as indicated in the

installation and servicing instructions.

3

1

Fig. 63 600 Series 11S / 19S / 24S / 24C:

Replacing the circulation pump

Subject to modifications resulting from technical improvements! Buderus Ltd. • http://www.buderus-domestic.co.uk

54 Servicing manual for wall-mounted condensing gas boiler 600 Series 11S/19S/24S/24C • Issued 02/2006

Page 55

Troubleshooting 3

3.1.16 Checking the safety sensor

z Unplug cable connection from sensor.

z Measure resistance of sensor (fig. 64, item 1).

z Use a second-reading thermometer to measure the

temperature around the sensor.

z Compare readings with values shown intable 3 on

page 57. If there is any mismatch (i.e. > 5%), the sensor is

defective.

z If the sensor is working correctly, plug it in once more.

Fig. 64 600 Series 11S / 19S / 24S / 24C:

Checking the safety sensor

3.1.17 Replacing the safety sensor

z Shut the servicing cock.

z Drain the 600 Series 11S / 19S / 24S / 24C as per the

"Installation and Servicing Instructions".

z Loosen the plug-in connection (fig. 65, item 1).

z Unscrew the sensor (fig. 65, item 2) and replace with a new

unit.

z Plug in cable connection.

z Open servicing cocks.

NOTE

Fill the 600 Series 11S / 19S / 24S / 24C and

purge the system of air as indicated in the

installation and servicing instructions.

3.1.18 Checking the safety sensor connection lead

Check to ensure that all plug-in connections on the sensor and

UBA are in order. Note that an incorrectly-inserted plug can

lead to the generation of error messages. Start up the boiler by

pressing the “reset” button.

z Set the mains switch to “0”.

z Disconnect the system from the power supply.

z Unplug cable connection from feed sensor.

z Disconnect 18-pin plug from UBA.

z Use a continuity tester to check the cable between the

plug-in connection and the 18-pin plug in the UBA.

The test should be carried out on connections 06-18 and

08-18 (fig. 66).

z If the cables are in order, plug them in.

z Connect system to mains power supply.

z Turn the mains power switch to “I”.

Fig. 65 600 Series 11S / 19S / 24S / 24C:

Replacing the safety sensor

Fig. 66 600 Series 11S / 19S / 24S / 24C:

Checking the safety sensor connection lead

Subject to modifications resulting from technical improvements! Buderus Ltd. • http://www.buderus-domestic.co.uk

Servicing manual for wall-mounted condensing gas boiler 600 Series 11S/19S/24S/24C • Issued 02/2006 55

Page 56

Troubleshooting3

3.1.19 Checking the feed sensor

z Unplug cable connection from sensor.

z Measure resistance of sensor (fig. 67, item 1).

z Use a second-reading thermometer to measure the

temperature around the sensor.

z Compare readings with values shown in table 3 on

page 57. If there is any mismatch (i.e. > 5%), the sensor is

defective.

z If the sensor is working correctly, plug it in once more.

3.1.20 Replacing the feed sensor

z Shut the servicing cock.

z Drain the 600 Series 11S / 19S / 24S / 24C as per the

"Installation and Servicing Instructions".

z Loosen the plug-in connection (fig. 68, item 1).

z Unscrew the sensor (fig. 68, item 2) and replace with a new

unit.

z Plug in cable connection.

z Open servicing cocks.

1

Fig. 67 600 Series 11S / 19S / 24S / 24C:

Checking the feed sensor

1

1

2

NOTE

Fill the 600 Series 11S / 19S / 24S / 24C and

purge the system of air as indicated in the

installation and servicing instructions.

3.1.21 Checking the feed sensor connection lead

Check to ensure that all plug-in connections on the sensor and

UBA are in order. Note that an incorrectly-inserted plug can

lead to the generation of error messages. Start up the boiler by

pressing the “reset” button.

z Set the mains switch to “0”.

z Disconnect the system from the power supply.

z Unplug cable connection from feed sensor.

z Disconnect 20-pin plug from UBA.

z Use a continuity tester to check the cable between the

plug-in connection and the 20-pin plug in the UBA.

The test should be carried out on connections 05-20 and

18-20 (fig. 69).

z If the cables are in order, plug them in.

z Connect system to mains power supply.

z Turn the mains power switch to “I”.

Fig. 68 600 Series 11S / 19S / 24S / 24C:

Replacing the feed sensor

Fig. 69 600 Series 11S / 19S / 24S / 24C:

Checking the feed sensor connection lead

Subject to modifications resulting from technical improvements! Buderus Ltd. • http://www.buderus-domestic.co.uk

56 Servicing manual for wall-mounted condensing gas boiler 600 Series 11S/19S/24S/24C • Issued 02/2006

Page 57

Troubleshooting 3

3.1.22 Checking the domestic hot water / mains water supply

z Disconnect the plug-and-socket connection on the hot-

water sensor cable (fig. 70, item 1) and/or the mains-water

sensor (fig. 70, item 2).

z Measure resistance, take a temperature reading at the

thermal pressure gauge (tolerance ± 5 K) and compare

with the values listed in table 3. If there is any marked

mismatch, the hot-water sensor is defective.

z If the hot-water/mains-water sensor is in order, plug it back

in.

2

Temperature [°C] Resistance [Ω]

0 29490

5 23462

10 18787

15 15136

20 12268

25 10000

30 8197

35 6754

40 5594

45 4656

50 3893

55 3271

60 2760

1

Fig. 70 Checking the domestic hot water / mains water

supply

65 2339

70 1990

75 1700

80 1458

85 1255

90 1084

95 939,6

100 817,2

Table 3 Resistance values for hot-water/mains-water sensor

Subject to modifications resulting from technical improvements! Buderus Ltd. • http://www.buderus-domestic.co.uk

Servicing manual for wall-mounted condensing gas boiler 600 Series 11S/19S/24S/24C • Issued 02/2006 57

(approximate values)

Page 58

Troubleshooting3

3.1.23 Changing the domestic hot water / mains water supply

z Shut the servicing cock.

z Drain the 600 Series 11S / 19S / 24S / 24C as per the

"Installation and Servicing Instructions".

z Disconnection plug-and-socket connection on cable to hot-

water/mains-water sensor.

z Remove insulation mounting (fig. 71, item 1) and detach

insulation.

1

Fig. 71 Changing the domestic hot water / mains water

supply

z Pull out the sensor fuses (fig. 72).

z Unscrew hot-water/mains-water sensor and replace with

new unit.

z Refit insulation and corresponding mounting elements.

z Plug cable connection in once more.

z Open servicing cocks.

z Fill the 600 Series 11S / 19S / 24S / 24C and purge the

system of air as indicated in the installation and servicing

instructions.

1

2

Fig. 72 Changing the domestic hot water / mains water

supply

Subject to modifications resulting from technical improvements! Buderus Ltd. • http://www.buderus-domestic.co.uk

58 Servicing manual for wall-mounted condensing gas boiler 600 Series 11S/19S/24S/24C • Issued 02/2006

Page 59

Troubleshooting 3

1

2

3

3.1.24 Checking the hot surface ingitor

z Disconnect the system from the power supply.

z Loosen crosshead screw on UBA housing.

z Swivel UBA housing downwards.

z Open the UBA housing.

z Unplug and remove hot surface ingitor from UBA housing

(fig. 73).

z Check hot surface ingitor for free throughput.

If throughput is free, the hot surface ingitor is in order.

z If the hot surface ingitor is in order, plug the cable into the

UBA housing.

z Shut the UBA housing.

z Swivel the UBA housing upwards and screw into place.

z Connect system to mains power supply.

Fig. 73 Checking the

hot surface ingitor

3.1.25 Replacing the hot surface ingitor

z Disconnect the system from the power supply.

z Remove combustion-chamber cover.

z Remove the earth (ground) lead from the hot surface

ingitor (fig. 74, item 1).

z Loosen crosshead screw on UBA housing.

z Swivel UBA housing downwards.

z Open the UBA housing.

z Unplug hot surface ingitor connection cable from UBA

housing (fig. 75).

z Loosen nut on clamp used to secure earth (ground) lead

(fig. 74, item 2).

z Detach retaining plate of hot surface ingitor (fig. 74, item 3)

and remove hot surface ingitor.

Fig. 74 Replacing the

hot surface ingitor

Subject to modifications resulting from technical improvements! Buderus Ltd. • http://www.buderus-domestic.co.uk

Servicing manual for wall-mounted condensing gas boiler 600 Series 11S/19S/24S/24C • Issued 02/2006 59

Fig. 75 Disconnect the plug-in cable from the UBA housing

Page 60

Troubleshooting3

3.1.26 Checking the gas-burner control system for correct activation

z Set the mains switch to “0”.

z Connect the multimeter (AC) to the plug-and-socket power-

supply connection to the gas burner fitting.

z Turn the mains power switch to “I”.

z Set the chimney-sweep switch to “I”.

z Start up the device. Take a reading after about 30 seconds

of running time.

z If the voltage reading is 24 V, the control system of the gas

burner fitting is in order.

z When the test is complete, set the mains switch to “0”.

Fig. 76 600 Series 11S / 19S / 24S / 24C:

Checking the gas-burner assembly for correct

activation

3.1.27 Replacing the gas burner fitting

DANGER !

All work on the gas supply must be carried out

by a CORGI registered engineer.

z Shut the gas cock.

z Disconnect the system from the power supply.

z Disconnect the fan using the plug and socket (fig. 77,

item 1), loosen the UBA control line at the fan (fig. 77,

item 2) and the gas burner fitting (fig. 77, item 3).

z Loosen the union nut (fig. 77, item 4) on the gas burner

fitting.

1

2

3

4

Fig. 77 Replacing the gas burner fitting on the 600 Series:

Loosen plug and union nut

Subject to modifications resulting from technical improvements! Buderus Ltd. • http://www.buderus-domestic.co.uk

60 Servicing manual for wall-mounted condensing gas boiler 600 Series 11S/19S/24S/24C • Issued 02/2006

Page 61

Troubleshooting 3

z Push the safety plate out of the way (fig. 78, item 1).

z Turn air suction tube and pull off from below.

Fig. 78 Replacing the gas burner fitting on the 600 Series:

Remove the

air suction tube

1

z Swivel the "CombiVENT" gas combination unit forward

(fig. 79, item 1)

z Remove the "CombiVENT" gas combination unit from its

bayonet connector and pull upwards to detach (fig. 79,

item 2).

z Loosen the three screws (fig. 80).

z Screw the air suction tube safety plate into place (not

supplied with new gas burner fitting).

2

Fig. 79 Replacing the gas burner fitting on the 600 Series:

Remove the gas connection unit

1

12

Fig. 80 Replacing the gas burner fitting on the 600 Series:

Replace the gas burner fitting

Subject to modifications resulting from technical improvements! Buderus Ltd. • http://www.buderus-domestic.co.uk

Servicing manual for wall-mounted condensing gas boiler 600 Series 11S/19S/24S/24C • Issued 02/2006 61

Page 62

Troubleshooting3

12

10

01

11

KW

10

10

1

1

3.1.28 Checking and adjusting the gas-to-air ratio

z Set mains switch (fig. 82, item 1) and chimney-sweep

switch (fig. 82, item 3) to "0".

z Unscrew the sealing closure of the burner-pressure testing

nipple by one turn (fig. 81).

z Set pressure gauge to zero.

z Connect the positive terminal of the pressure gauge with

a hose to the burner pressure measuring nipple (fig. 81).

NOTE

The negative terminal of the pressure gauge

MUST NOT be connected.

z Turn the mains power switch to “I” and the chimney-sweep

switch to “1”.

z When the burner has fired (after approx. 30 seconds), push

the service button (fig. 82, item 2) and keep it pressed until

“Y” is shown on the display.

z Set the heating-capacity controller (fig. 82, item 4) to "1".

z Read the differential pressure. The differential pressure

(p

gas–pair

10 PA to 0 PA).

z In the event of any anomaly in the gas-to-air ratio, readjust

at the setscrew (fig. 81, item 1).

) must be -5 Pa (±5 Pa) (display on meter: -

1

Fig. 81 Check the gas-air ratio

2

3

NOTE

Remove the cover fixing screw before

readjusting. The cover fixing screw must be

secured before readings can be taken.

z Turn mains power switch and chimney-sweep switch to “0”.

z Remove the measuring equipment and retighten the screw

in the burner-pressure measuring nipple.

z Readjust the heating capacity controller to its original

(factory default) setting.

z Turn the mains power switch to “I”.

1

4

Fig. 82 Check the default gas-air ratio settings

Subject to modifications resulting from technical improvements! Buderus Ltd. • http://www.buderus-domestic.co.uk

62 Servicing manual for wall-mounted condensing gas boiler 600 Series 11S/19S/24S/24C • Issued 02/2006

Page 63

Troubleshooting 3

3.1.29 Measuring the ionisation current

z Disconnect the system from the power supply.

z Loosen the plug-and-socket connector of the monitoring

cable and connect the measuring device in series.

Select the µA direct current range on the multimeter.

The multimeter must have a resolution of at least 1 µA.

z Reconnect the system to the power supply and turn the

chimney-sweep switch to “1”.

z Measure the ionisation current.

The ionisation current must be > 2 µA DC.

z Enter the reading on the report form.

z Disconnect the system from the power supply.