Buderus 600-19R, 600-11R, 600-24R, 600 Series, 11R Installation And Servicing Instructions

...Page 1

7212 2900 - 05/2004 GB(EN) For trade use

Installation and servicing

instructions

Wall-mounted condensing gas boiler

Buderus 600 - 11R / 19R / 24R

Please read thoroughly before installing or servicing

Page 2

The boiler meets the basic requirements of the

appropriate standards and directives.

Conformity has been substantiated by the proper

documents which - together with the declaration of

conformity - are filed with the manufacturer.

Buderus 600 Series

CE-0063BO3062

CE-0063BO3062

Subject to technical modifications!

Constant development efforts may result in minor deviations in

illustrations, functional steps and technical data.

Updating the documentation

If you have suggestions for improvement or have found

discrepancies, please do not hesitate to contact us.

Subject to modifications resulting from technical improvements! Boulter Buderus Ltd. • http://www.boulter-buderus.co.uk

2 Installation and servicing instructions for wall-mounted condensing gas boiler Buderus 600 - 11R/19R/24R • 05/2004

Page 3

Contents

1 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.1 Dimensions and connections . . . . . . . . . . . . . . . . . 9

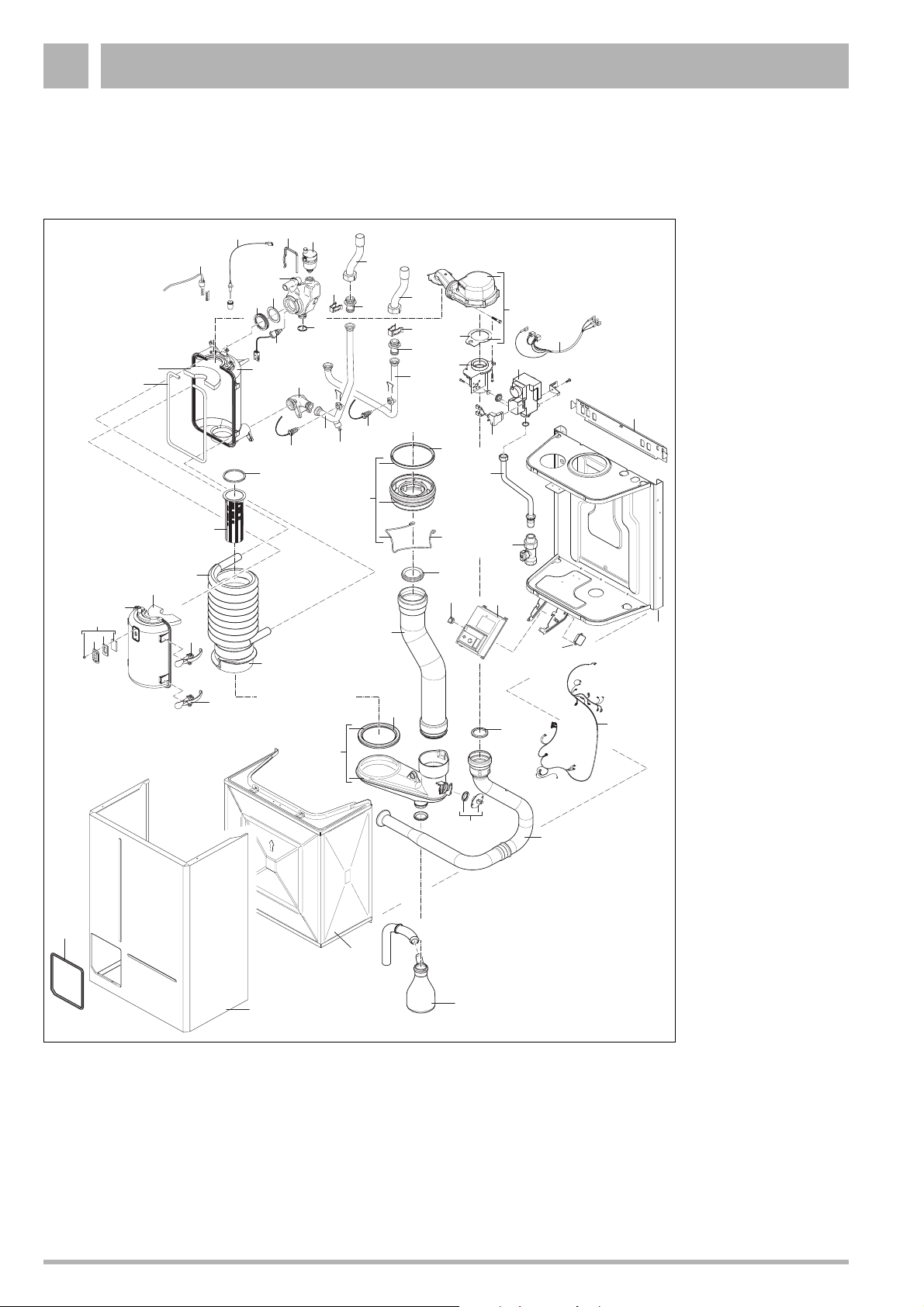

1.2 Boiler assembly - exploded view . . . . . . . . . . . . . 10

1.3 Flue Installation . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1.4 Items supplied with unit . . . . . . . . . . . . . . . . . . . . 13

1.5 Transport . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

1.6 Pipe connections . . . . . . . . . . . . . . . . . . . . . . . . . 14

1.7 Flue installation . . . . . . . . . . . . . . . . . . . . . . . . . . 15

1.8 Electrical connections. . . . . . . . . . . . . . . . . . . . . . 17

1.9 Timing and temperature control . . . . . . . . . . . . . . 19

2 Initial start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2.1 Preparing the boiler for operation. . . . . . . . . . . . . 20

3 Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

3.1 Preparing the heating boiler for inspection . . . . . . 26

4 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

4.1 Clean the heat exchanger, burner and

condensate trap . . . . . . . . . . . . . . . . . . . . . . . . . . 27

5 Servicing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

5.1 Operating codes . . . . . . . . . . . . . . . . . . . . . . . . . . 31

5.2 Fault codes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

5.3 Checking and replacing parts. . . . . . . . . . . . . . . . 40

6 Conversion to another type of gas. . . . . . . . . . 48

7 Appendix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

7.1 Technical specifications . . . . . . . . . . . . . . . . . . . . 50

7.2 Short list of spare parts . . . . . . . . . . . . . . . . . . . . 52

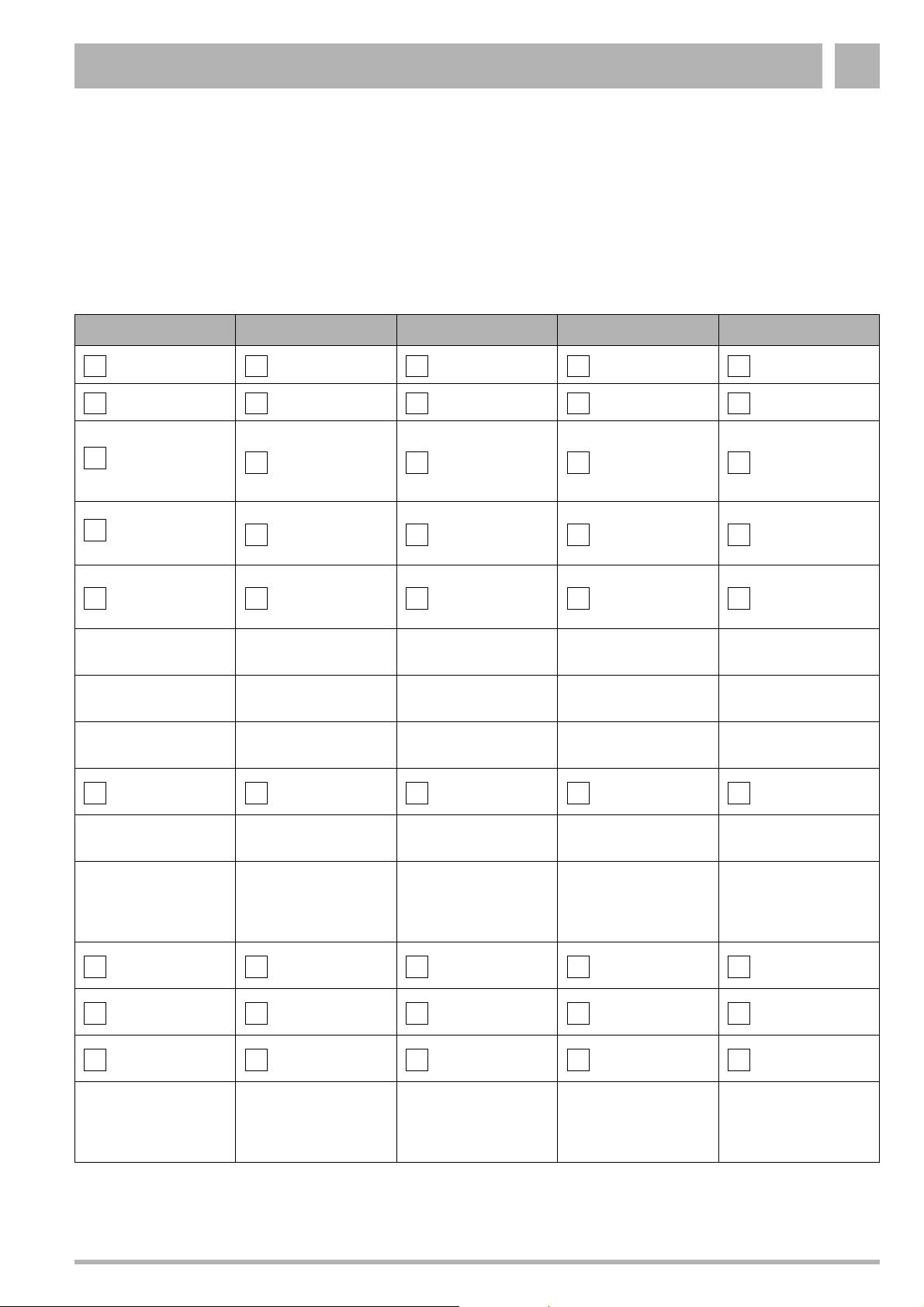

8 Reports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

8.1 Start-up report . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

8.2 Inspection and maintenance reports . . . . . . . . . . 54

Preface

These installation and servicing instructions apply to:

Buderus wall-mounted condensing gas boilers

600 - 11R / 19R / 24R.

Model: C13, C33, C

Type: GB II

Fuse rating: 1.25 Ampere slow blow

Power rating: 230 VAC, 50 Hz, IPX4D

Important general instructions for use

Only use the boiler in accordance with its designated use and

the installation and servicing instructions. Servicing and repair

must be carried out by CORGI registered installer. Only use

the boiler in combinations and with the accessories and spare

parts indicated in the installation and servicing instructions.

Other combinations, accessories and consumables may only

be used if they are expressly provided for the designated use

and if system performance and safety are not affected in any

way.

The boiler is suitable for connection to fully pumped, open

vented or sealed water systems.

Adequate arrangements for completely draining the system by

provision of draining valves must be provided in the installation

pipework.

Subject to technical modifications.

As a result of our policy of constant development, there may be

small differences between illustrations, functional steps and

technical data.

53

20 mbar, 37 mbar

2H3P

G. C. Aplliance No. :

Buderus 600 - 11R 41-110-21

Buderus 600 - 19R 41-110-22

Buderus 600 - 24R 41-110-23

BENCHMARK' Log Book

All Boulter Buderus gas fired boilers now include an installation, commissioning and service record log book. The details

of the log book will be required in the event of any warranty

work being requested.

Please complete the appropriate sections on completion of the

installation and commissioning.

REMEMBER: Please hand the log book back to the user.

Subject to modifications resulting from technical improvements! Boulter Buderus Ltd. • http://www.boulter-buderus.co.uk

Installation and maintenance instructions wall-mounted condensing gas boiler Buderus 600 - 11R/19R/24R • 05/2004 3

Page 4

Regulations and directives

It is law that all gas appliances are installed and serviced by a

CORGI registered installer in accordance with the regulations.

Failure to install appliances correctly could lead to prosecution.

It is in your own interest, and that of safety, to ensure the law

is complied with.

The installation must also be in accordance with the latest

I.E.E (BS.7671) Wiring Regulations, local building regulations,

water regulations, the building regulations and the Building

Standards (Scotland) and any relevant requirements of the

local authority.

Detailed recommendations are contained in the following

British Standard Codes of Practice:

BS. 5440:1 Flues (for gas appliances of rated input not

exceeding 70 kW).

BS. 5440:2 Ventilation (for gas appliances of rated input not

exceeding 70 kW).

BS. 5449 Forced circulation hot water systems.

BS. 5546 Installation of gas hot water supplies for domestic

purposes (2nd. family Gases).

BS. 6798 Installation of gas fired hot water boilers of rated

input not exceeding 60 kW.

BS. 6891 Low pressure installation pipes.

IGE/UP/1b Tightness testing and purging domestic sized gas

installations.

Health and & Safety Document No. 635.

The Electricity at Work Regulations, 1989.

The manufacturer's notes must not be taken, in any way, as

overriding statutory obligations.

The design and construction of the Buderus wall-mounted

condensing gas boiler 600 - 11R/19R/24R conforms to the

basic specifications listed in the European directive governing

gas-fired appliances 90/396/EEC, and with respect to EN 625,

EN 483 and EN 677.

NOTE

Observe the corresponding technical rules and

the building supervisory and statutory

regulations when installing and operating the

system.

WARNING!

Keep the burner-control unit housing CLOSED

when working on water-bearing components.

NOTE

It is mandatory to clean and service the system

once a year. This includes an inspection of the

entire system to see if it is in full working order.

Defects and faults must be eliminated

immediately.

NOTE

When instructions aren’t followed, warranty

expires.

Timber Framed Buildings

If the boiler is to be fitted in a timber framed building it should

be fitted in accordance with the Institute of Gas Engineering

document IGE/UP/7:1998.

Bathroom Installations

This appliance is rated IPX4D.

The boiler may be installed in any room or internal space,

although particular attention is drawn to the requirements of

the current IEE (BS.7671) Wiring Regulations and, in

Scotland, the electrical provisions of the building regulations

applicable in Scotland, with respect to the installation of the

boiler in a room or internal space containing a bath or shower.

If the appliance is to be installed in a room containing a bath or

shower then, providing water jets are not going to be used for

cleaning purposes (as in communal baths/showers), the

appliance can be installed in Zone 3, as detailed in BS.7671.

Compartment Installations

A compartment used to enclose the boiler should be designed

and constructed especially for this purpose.

An existing cupboard or compartment may be used, provided

that it is modified for the purpose.

In both cases, details of essential features of cupboard/

compartment design, including airing cupboard installation,

are to conform to the following:

BS 6798 (No cupboard ventilation is required - see 'Air Supply'

for details).

It is not necessary to have a purpose-provided air vent in the

room or internal space in which the boiler is installed. Neither

is it necessary to ventilate a cupboard or compartment in which

the boiler is installed, due to the low surface temperatures of

the boiler casing during operation; therefore the requirements

of BS 6798, Clause 12, and BS 5440:2 may be disregarded.

The position selected for installation MUST allow adequate

space for servicing in front of the boiler.

For the minimum clearances required for safety and

subsequent service, see the wall mounting template.

In addition, sufficient space may be required to allow lifting

access to the wall mounting plate.

Wall-mounted condensing gas boilers must only be operated

with the combustion air/flue gas systems especially devised

and authorised for this type of boiler.

Observe the relevant standards, regulations and legislation of

the country of final use.

CAUTION

Use this device for its intended purpose only.

Subject to modifications resulting from technical improvements! Boulter Buderus Ltd. • http://www.boulter-buderus.co.uk

4 Installation and maintenance instructions wall-mounted condensing gas boiler Buderus 600 - 11R/19R/24R • 05/2004

Page 5

DANGER!

Notes relating to the heating system water.

Thoroughly flush the system before it is filled

with water. Use only untreated water or water

treatment product such as Sentinal X100 to fill

and top up the system.

When using water treatment, only products

suitable for use with Boulter Buderus heat

exchangers are permitted (e.g. Sentinel X100).

Your warranty is at risk if an incorrect water

treatment product is used in conjunction with

this appliance. For more information, contact

Boulter Buderus Product Support Department.

It is most important that the correct

concentration of the water treatment product is

maintained in accordance with the

manufacturer's instructions.

If the boiler is used in an existing system any

unsuitable additives MUST be removed by

thorough cleaning. BS.7593:1992 details the

steps necessary to clean a domestic central

heating system.

In hard water areas, treatment to prevent lime

scale may be necessary - however, the use of

artificially softened water is NOT permitted.

Under no circumstances should the boiler be

fired before the system has been thoroughly

flushed.

Do not use water softened in a salt bedding

exchanger.

Do not use anti-freeze or other additives.

The expansion vessel must be of sufficient

size.

When oxygen-permeable pipes are used (e. g.

for floor heating systems) the system must be

separated by means of heat exchangers.

Unsuitable heating water promotes sludge

formation and corrosion. This may cause

malfunctions and damage in the heat

exchanger.

This appliance is not suitable for gravity

central heating nor are they suitable for the

provision of gravity domestic hot water.

The boiler must be vented.

Drain cocks must be located in accessible

positions, which permits the draining of the

entire system. They should be at least ½" BSP

nominal size and be in accordance with

BS. 2879.

The hydraulic resistance of the boilers is

shown in the graph below.

graph 1

350

300

250

200

150

resistance (mbar)

100

50

0

0 0,1 0,2 0,3 0,4 0,5 0,6 0,7 0,8 0,9 1 1,1 1,2 1,3

flow (m /h)

resistance heat exchanger

3

NOTE:

Notes relating to domestic hot water.

The boiler must not be used for direct hot water

supply.

The hot water storage cylinder must be of the

indirect type.

Single feed, indirect cylinders are not

recommended and must not be used on sealed

systems.

The hotwater cylinder and ancillary pipework,

not forming part of the useful heating surface,

should be lagged to prevent heat loss and any

possible freezing - particularly wher pipes run

throughroof spaces and ventilated underfloor

spaces.

The domestic hot water service must be in

accordance with BS 5546 and BS 6700.

Safe handling of substances

Care should be taken when handling the boiler's insulation,

which can cause irritation to the skin.

No asbestos, mercury or CFCs are included in any part of the

boiler and its manufacture.

Subject to modifications resulting from technical improvements! Boulter Buderus Ltd. • http://www.boulter-buderus.co.uk

Installation and maintenance instructions for wall-mounted condensing gas boiler Buderus 600 - 11R/19R/24R • 05/2004 5

Page 6

Open vent system requirements

The system should be vented directly off the boiler flow pipe, as

close to the boiler as possible. The cold feed entry should be

inverted and MUST be positioned between the pump and the vent,

and not more than 150 mm (6") away from the vent connection.

NOTE

Combined feed and vent pipes may also be

fitted.

Feed / expansion

cistern

Wate r

level

(cold)

22 mm

open vent

15 mm

cold

feed

450 (18")

minimum

1000 (40")

minimum

150 (6")

max.

There should be a minimum height, 450 mm (18"), of open vent

above the cistern water level. The vertical distance between the

highest point of the system and the feed/expansion cistern water

level MUST not be less than 1000 mm (40"). The pump must be

fitted on the flow side of the boiler.

A suitable pump is a domestic circulator capable of providing a

maximum 11 °C (20 °F) temperature differential across the boiler

with the whole of the heating circuit open. With the minimum flow

circuit allowed by the controls the differential must not exceed

25 °C (see also the graph on page 5).

The vertical distance between the pump and feed/expansion

cistern MUST comply with the pump manufacturer’s minimum

requirements, to avoid cavitation. Should these conditions not

apply either lower the pump position or raise the cistern above the

minimum requirements specified by Boulter Buderus. The

isolation valves should be fitted as close to the pump as possible.

Schematic pipework and system balancing

The boiler does not normally need a bypass but at least some

radiators on the heating circuit, of load at least 10% of the

minimum boiler output, must be provided with twin lockshield

valves so that this minimum heating load is always available (see

footnote re. thermostatic radiator valves).

Balancing

1. Set the programmer to ON for both CH and HW. Turn the

cylinder thermostat down. Close the manual or thermostatic

valves on all radiators leaving the twin lockshield valves (on

the radiators referred to above) in the open position. Turn up

the room thermostat and adjust these lockshield valves to give

boiler flow and return temperatures not more than 20 °C apart.

These valves should now be left as set.

2. Open all manual or thermostatic radiator valves and adjust the

lockshield valves on remaining radiators to give around 11 °C

temperature drop at each radiator.

3. Turn up the cylinder thermostat and adjust the cylinder

balancing valve so that the cylinder achieves a maximum flow

consistent with adequate flow to the radiators. Check that with

only the domestic hot water loop in circuit a differential

temperature of 20 °C across the boiler is not exceeded.

4. Adjust room and cylinder thermostats and programmer to

NORMAL settings.

System

flow to

pump

Connection

to boilers

fig. 1 Open vent system

22 mm

open vent

15 mm

cold

feed

Elbow

then

tee

Flow

Return

BOILER

fig. 2 Schematic pipework and system

System

return

Air vent

Alternative

2x2 port

valves

Radiators

Inverted cold

feed entry

3 port

valve

Cylinder

balancing

valve

Subject to modifications resulting from technical improvements! Boulter Buderus Ltd. • http://www.boulter-buderus.co.uk

6 Installation and maintenance instructions wall-mounted condensing gas boiler Buderus 600 - 11R/19R/24R • 05/2004

Page 7

Thermostatic radiator valves

k

Boulter Buderus support the recommendations made in

BS. 5449, and by leading manufacturers of domestic heating

controls, that heating systems utilising the thermostatic

radiator valve control of temperature in individual rooms shall

also be fitted with a room thermostat, controlling the

temperature in a space served by radiators not fitted with such

a valve.

Such an arrangement will provide for potentially more efficient

control of the environment and will also avoid the continuous

running of the circulation pump during programmed heating

ON periods - thus saving electrical energy.

It is, therefore, strongly recommended that, when thermostatic

radiator valves are used, space heating temperature control

over a living/dining area or a hallway having a heating

requirement of at least 10% of the minimum boiler heat output,

is achieved using a room thermostat whilst other rooms are

individually controlled by thermostatic radiator valves.

Sealed system requirements

NOTE

The method of filling, refilling, topping up or

flushing sealed hot water circuit from the mains

via a temporary hose connection is only

allowed if acceptable to the local water

authority.

1. General

The installation must comply with the requirements of

BS. 6798 and BS. 5449.

The installation should be designed to work with flow

temperatures of up to 80 °C.

All components of the system, including the heat exchanger of

the indirect cylinder, must be suitable for a working pressure of

3 bar (45 lb/in

2

) and temperature of 110 °C. Care should be

taken in making all connections so that the risk of leakage is

minimised.\

2. Safety valve

A spring loaded safety valve complying with the relevant

requirements of BS. 6759 must be fitted in the flow pipe as

close to the boiler as possible and with no intervening valve or

restriction. The valve should have the following features:

– A non-adjustable preset lift pressure not exceeding 3 bar

(45 lb/in

2

);

– A manual testing device;

– Provision for connection of a discharge pipe. The valve or

discharge pipe should be positioned so that the discharge

of water or steam cannot create a hazard to the occupants

of the premises or cause damage to electrical components

and wiring.

Make-up vessel

(max. capacity 3 litres)

Hose union

bib tap

Water

supply

Hose connector

Nonreturn

valve

Automatic

air vent

Hosepipe

(disconnect

after refilling)

BS. 1010:2

stop tap

HEATING

CIRCUIT

Test cock

Air vent

Pump

Double check valve

Pressure gauge

Expansion

vessel

Safety valve

BOILER

Drain coc

fig. 3 Sealed system

3. Pressure gauge

A pressure gauge covering at least the range of 0-4 bar

(0-60 lb/in

2

) must be fitted to the system. The gauge should be

easily seen from the filling point and should preferably be

connected at the same point as the expansion vessel.

4. Expansion vessel

A diaphragm type expansion vessel must be connected to a

point close to the inlet side of the pump, the connecting pipe

being not less than 15 mm (½" nominal) size and not

incorporating valves of any sort.

The vessel capacity must be adequate to accept the

expansion of the system water when heated to 110 °C

(230° F).

The charge pressure must not be less than the static water

head above the vessel. The pressure attained in the system

when heated to 110 °C (230° F) should be at least 0.35 bar

2

(5 lb/in

) less than the lift pressure of the safety valve.

For guidance on vessel sizing refer to table 1.

For further details refer to BS. 5449 and BS. 7074:1 and the

British Gas Corporation publication: "Material and Installation

Specifications for Domestic Central Heating and Hot Water".

5. Cylinder

The cylinder must be either of the indirect coil type or a direct

cylinder fitted with an immersion calorifier which is suitable for

operating on a gauge of 0.35 bar (5 lb/in

2

) in excess of the

safety valve setting. Single feed indirect cylinders are not

suitable for sealed systems.

6. Make-up water

provision must be made for replacing water loss from the

system, either:

– from a manually filled make-up vessel with a readily visible

water level. The vessel should be mounted at least 150 mm

(6") above the highest point of the system, and be

connected through a non-return valve to the system, filled

at least 300 mm (12") below the make-up vessel on the

return side of the domestic hot water cylinder or radiators.

or

– where access to a make-up vessel would be difficult by

pre-pressurisation of the system. Refer to "Filling", below.

Subject to modifications resulting from technical improvements! Boulter Buderus Ltd. • http://www.boulter-buderus.co.uk

Installation and maintenance instructions for wall-mounted condensing gas boiler Buderus 600 - 11R/19R/24R • 05/2004 7

Page 8

7. Mains Connection

There must be no direct connection to the mains water supply

or to the water storage tank supplying domestic water, even

through a non-return valve, without the approval of the local

water authority.

8. Filling

The system may be filled by one of the following methods:

a. Through a cistern, used for no other purpose, via a ball

valve permanently connected directly to a service pipe

and/or a cold water distributing pipe. The static head

available from the cistern should be adequate to provide

the desired initial system design pressure. The cold feed

pipe from the cistern should include a non-return valve and

a stop valve with an automatic air vent connected between

them, the stop valve being located between the system and

the automatic air vent. The stop valve may remain open

during normal operation of the system if automatic water

make-up is required.

b. Through a self-contained unit comprising a cistern,

pressure booster pump (if required) and, if necessary, an

automatic pressure reducing valve and flow restrictor. The

cistern should be supplied through a temporary connection

from a service pipe or cold water distributing pipe.

This unit may remain permanently connected to the

heating system to provide limited automatic water makeup. Where the temporary connection is supplied from a

service pipe or distributing pipe which also supplies other

draw-off points at a lower level then a double check valve

shall be installed upstream of the draw-off point.

c. Through a temporary hose connection from a draw-off tap

supplied from a servicing pipe under mains pressure.

Where the mains pressure is excessive a pressure

reducing valve shall be used to facilitate filling.

The following fittings shall form a permanent part of the system

and shall be fitted in the order stated:

– A stop valve complying with the requirements of

BS. 1010, Part 2 (the hose from the draw-off tap shall

be connected to this fitting);

– A test cock;

– A double check valve of an approved type.

z Thoroughly flush out the whole of the system with cold

water, without the pump in position.

z With the pump filled, fill and vent the system until the

pressure gauge registers 1.5 bar (21.5 lb/in

2

). Examine

for leaks.

z Check the operation of the safety valve by manually

raising the water pressure until the valve lifts. This

should occur within ± 0.3 bar (4.3 lb/in

2

) of the preset lift

pressure.

z Release water from the system until the initial system

design pressure is reached.

z Light the boiler and heat the system to the maximum

working temperature. Examine for leaks.

z Turn off the boiler and drain the system while still hot.

z Refill and vent the system.

z Adjust the initial pressure to the required valve.

Sizing procedure for expansion vessel

The volume of the expansion vessel (litres) fitted to a sealed

system shall not be less than that given by the table below,

multiplied by a factor of 0.8 (for flow temperatures of less than

80 °C).

Safety valve setting 3.0 bar 2.5 bar 2.0 bar

Vessel charge and initial system

pressure

Total water content of system (litres) Expansion vessel volume litres

25 2.1 2.7 3.9 2.3 3.3 5.9 2.8 5.0

50 4.2 5.4 7.8 4.7 6.7 11.8 5.6 10.0

75 6.3 8.2 11.7 7.0 10.0 17.7 8.4 15.0

100 8.3 10.9 15.6 9.4 13.4 23.7 11.3 20.0

125 10.4 13.6 19.5 11.7 16.7 29.6 14.1 25.0

150 12.5 16.3 23.4 14.1 20.1 35.5 16.9 30.0

175 14.6 19.1 27.3 16.4 23.4 41.4 19.7 35.0

200 16.7 21.8 31.2 18.8 26.8 47.4 22.6 40.0

225 18.7 24.5 35.1 21.1 30.1 53.3 25.4 45.0

250 20.8 27.2 39.0 23.5 33.5 59.2 28.2 50.0

275 22.9 30.0 42.9 25.8 36.8 65.1 31.0 55.0

300 25.0 32.7 46.8 28.2 40.2 71.1 33.9 60.0

Multiplying factors for other

system volumes

Table 1 Expansion vessel volumes

0.5 1.0 1.5 0.5 1.0 1.5 0.5 1.0

bar bar bar bar bar bar bar bar

0.0833 0.109 0.156 0.094 0.134 0.237 0.113 0.20

Subject to modifications resulting from technical improvements! Boulter Buderus Ltd. • http://www.boulter-buderus.co.uk

8 Installation and maintenance instructions wall-mounted condensing gas boiler Buderus 600 - 11R/19R/24R • 05/2004

Page 9

Installation 1

1 Installation

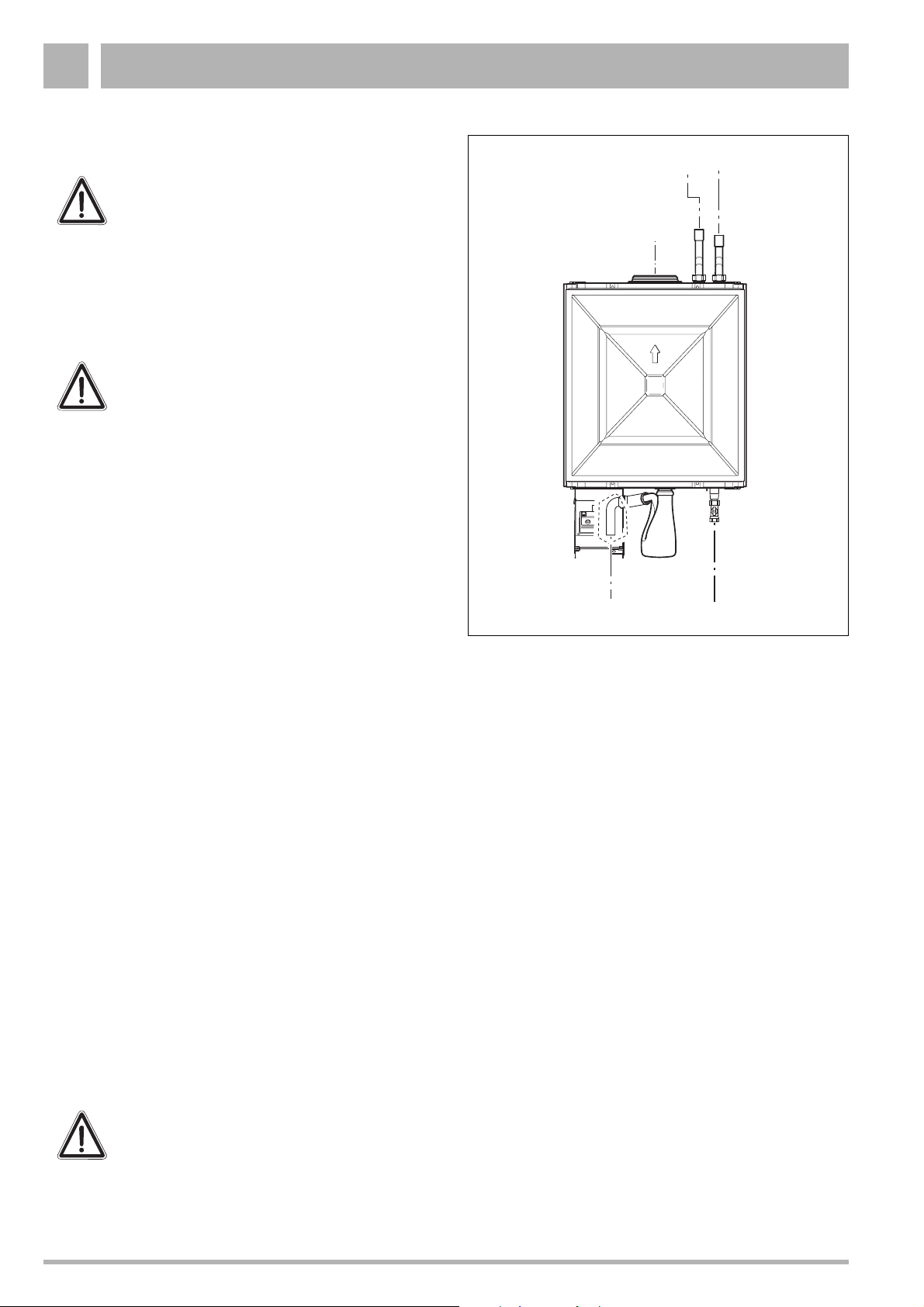

1.1 Dimensions and connections

CH FLOW

CH RETURN

460 mm (18")

290 mm (11,4")

105 mm (4")

230 mm (9")

50 (2")

70 (2.8")

130 (5")

145 (5,7")

619 mm (24")

604 mm (23,7")

Ø100 (4")

3

Ø60 (2 ")

328 mm (13")

376 mm (15")

25 mm (1")

8

20 (0.8")

700 mm (27½")

119 mm (4,7")

82 mm (3")

CWDO

GAS

CH Flow = Ø22 mm Compression (0.87")

CH return = Ø22 mm Compression (0.87")

GAS = Gas connection G½" INSIDE

CWDO = Condensate water drainage outlet Ø21.5 mm (0.8") OUTSIDE

NOTE

See the wall-mounting template for the necessary clearances.

Subject to modifications resulting from technical improvements! Boulter Buderus Ltd. • http://www.boulter-buderus.co.uk

Installation and maintenance instructions for wall-mounted condensing gas boiler Buderus 600 - 11R/19R/24R • 05/2004 9

Page 10

Installation1

1.2 Boiler assembly - exploded view

Single unit (11R / 19R / 24R)

350

10

380

310

340

420

440

360

320

290

330

250

370

280

260

270

120

520

510

400

390

410

430

450

460

470

480

480

20

Legend

10. Casing

230

110

130

230

250

240

300

200

70

60

100

500

80

170

530

180

40

560

540

160

90

190

210

220

490

140

150

240

290

50

30

20. Door complete

30. Ventilation cover

40. Bracket

50. Concentric adaptor

60. Clip adaptor

70. Lipring 100mm

80. Fan

90. Sealing Fan / Venturi

100. Lipring 60mm

110. Flue gas pipe

120. Condensate collector

130. Seal flue gas pipe

140. Flue gas sensor

150. Condensate trap

160. Suction pipe

170. Lipring 50mm

180. Gas valve

190. Rectifier

200. Venturi

210. Gas pipe

220. Gas service valve

550

230. Pipe return/flow top

240. Pipe connection

250. Clip

260. Return pipe

270. Drain cock

280. Connection return

290. Sensor

300. Flow pipe

310. Connection supply

320. Hairpin heat exchanger

330. Automatic air vent

340. O-ring

350. Lipring

360. Safety sensor

370. Sealing ring

380. Backpart heat

exchanger

390. Seal heat exchanger

400. Insulation backpart heat

exchanger

410. Burner 11 kW

Burner 19 kW

Burner 24 kW

420. Sealing burner

430. Heat exchanger helix

440. Combustion divider

450. Insulation front heat exchanger

460. Frontpart heat exchanger

470. Sight glass

480. Fasteners

490. UBA

500. Main switch

510. Hot surface ignitor

520. Ionisation electrode

530. Cable fan

540. Cable harness

550. Frame

560. RTH converter 230V

Subject to modifications resulting from technical improvements! Boulter Buderus Ltd. • http://www.boulter-buderus.co.uk

10 Installation and maintenance instructions for wall-mounted condensing gas boiler Buderus 600 - 11R/19R/24R • 05/2004

Page 11

Installation 1

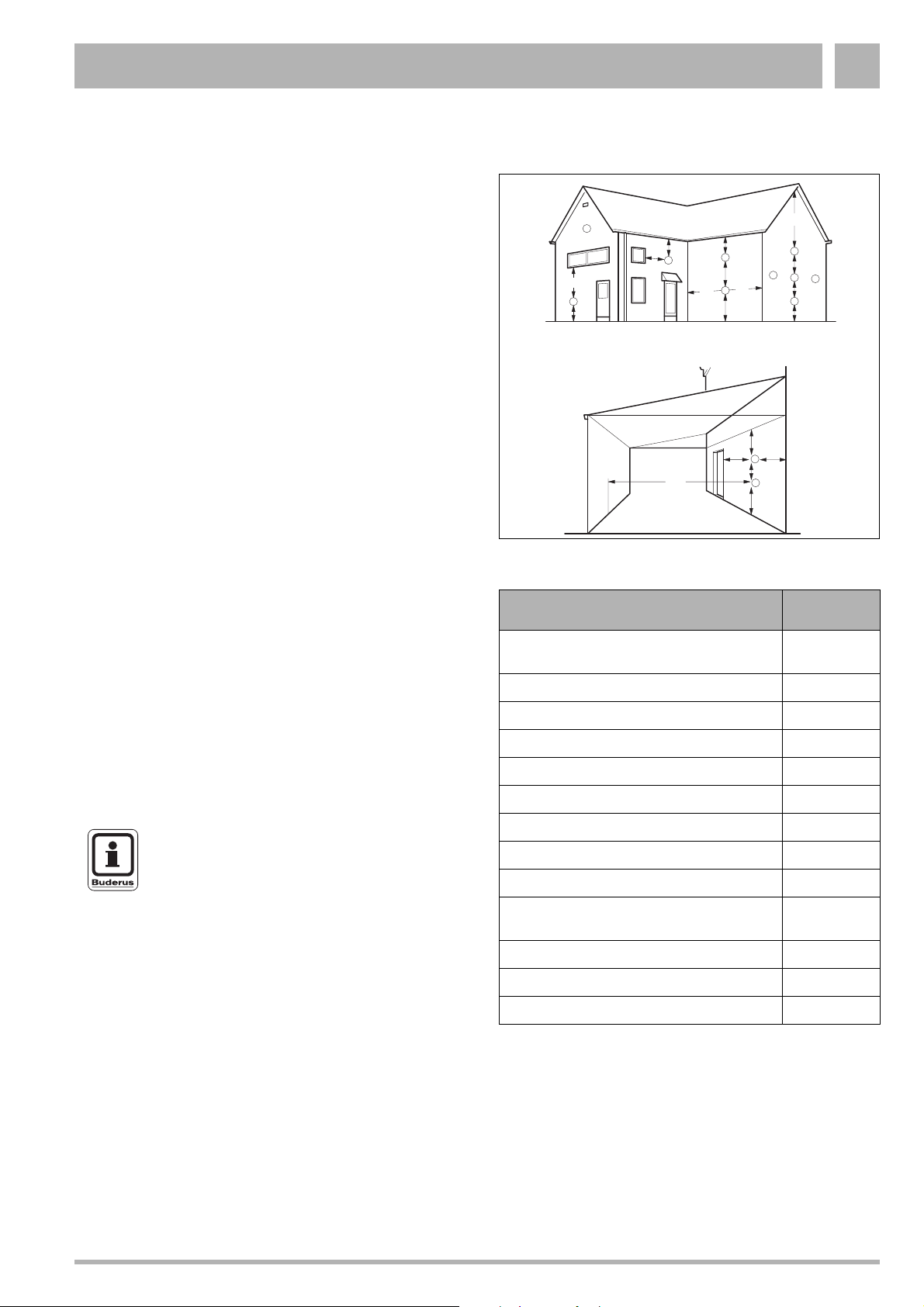

1.3 Flue Installation

1.3.1 Siting the flue terminal

The flue must be installed in accordance with the

recommendations of BS. 5440-1:2000.

Pluming will occur at the terminal so terminal positions where

this could cause a nuisance should be avoided.

The air supply and the flue gas exhaust must meet the

applicable general regulations. Please consult the instructions

provided with the flue terminal kits prior to installation.

The boiler MUST be installed so that the terminal is exposed

to external air.

It is important that the position of the terminal allows the free

passage of air at all times.

Minimum acceptable spacing from the terminal to obstructions

and ventilation openings are specified in table 1.

If the terminal is fitted within 1000 mm of a plastic or painted

gutter or within 500 mm of painted eaves, an aluminium shield

of at least 1000 mm long should be fitted to the underside of

the gutter or painted surface.

If the lowest part of the terminal is less than 2 metres above the

level of the ground, balcony, flat roof or place to which any

person has access, the terminal must be protected by a guard.

Protective guards are available from Quinnell Barrett and

Quinnell, Old Kent Road, London.

Ensure that the guard is fitted centrally.

The flue assembly shall be so placed or shielded as to prevent

ignition or damage to any part of the building.

The air inlet/products outlet duct and the terminal of the boiler

MUST NOT be closer than 25 mm (1'') to combustible material.

Detailed recommendations on the protection of combustible

material are given in BS. 5440 - 1:2000.

NOTE

It is absolutely essential to ensure, in practice,

that products of combustion discharging from

the terminal cannot re-enter the building or any

other adjacent building through ventilators,

windows, doors, other sources of natural air

infiltration, or forced ventilation/airconditioning.

If this could occur the appliance MUST be turned off (with the

owners permission), and labelled as unsafe until corrective

action can be taken.

A

B,C

M

A

F

M

G

under carport

H, I

B,C

K

F

F

G

D

K

G

Fig. 1 Flue terminal position

Terminal Position

A. Directly below or alongside an opening

window, air vent or other ventilation opening

B. Below guttering, drain pipes or soil pipes

C. Below eaves

D. Below balconies or a car port roof

E. From vertical drain pipes or soil pipes

F. From internal or external corners

G. Above adjacent ground, roof or balcony level

H. From a surface facing the terminal

I. From a terminal facing a terminal

J. From an opening in a car port (e.g. door or

window) into dwelling

K. Vertically from a terminal on the same wall

L. Horizontally from a terminal on the wall

M. Adjacent to opening

C

K

L

L

K

G

FJ

Minimum

Spacing

300 mm (12")

75 mm (3")

200 mm (8")

200 mm (8")

150 mm (6")

300 mm (12")

300 mm (12")

600 mm (24")

1200 mm (48")

1200 mm (48")

1500 mm (60")

300 mm (12")

300 mm (12")

Table 1 Balanced flue terminal position

Subject to modifications resulting from technical improvements! Boulter Buderus Ltd. • http://www.boulter-buderus.co.uk

Installation and maintenance instructions for wall-mounted condensing gas boiler Buderus 600 - 11R/19R/24R • 05/2004 11

Page 12

Installation1

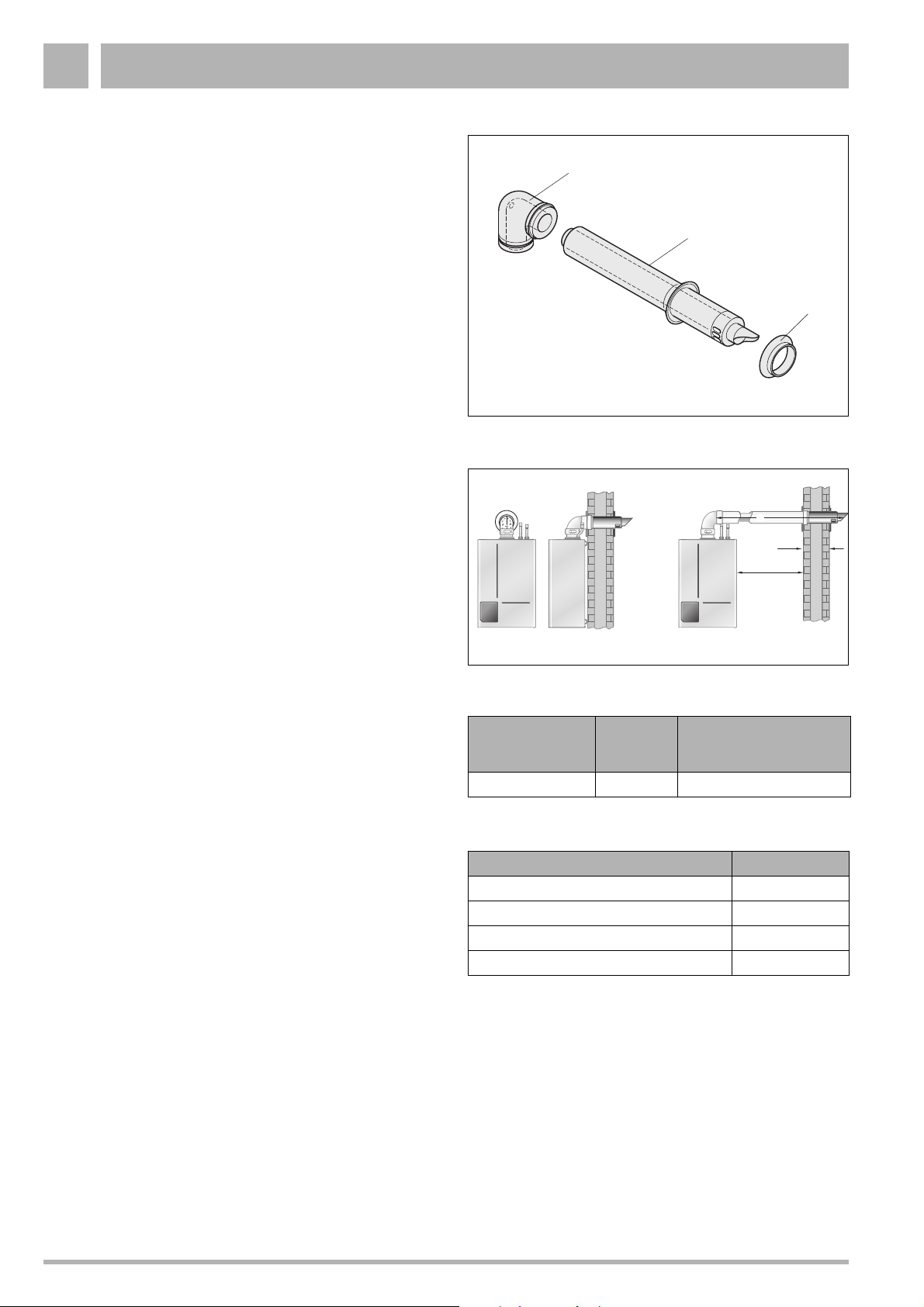

1.3.2 Air supply and flue gas exhaust in a closed installation

A ventilation cover is integrated into the 600 Series condensing

gas boilers. This cover houses a number of components, such

as the burner and the heat exchanger. Since this ventilation

cover is part of the air supply system, it is vital that it is always

installed correctly.

To ensure optimal operation, the 600 Series appliances must

be connected to a Buderus wall-mounted or roof-mounted flue

terminal. These terminals have been developed specifically for

the 600 Series condensing gas boilers and have been

comprehensively tested. The Buderus wall and roof-mounted

flue terminal kits ensure trouble-free operation.

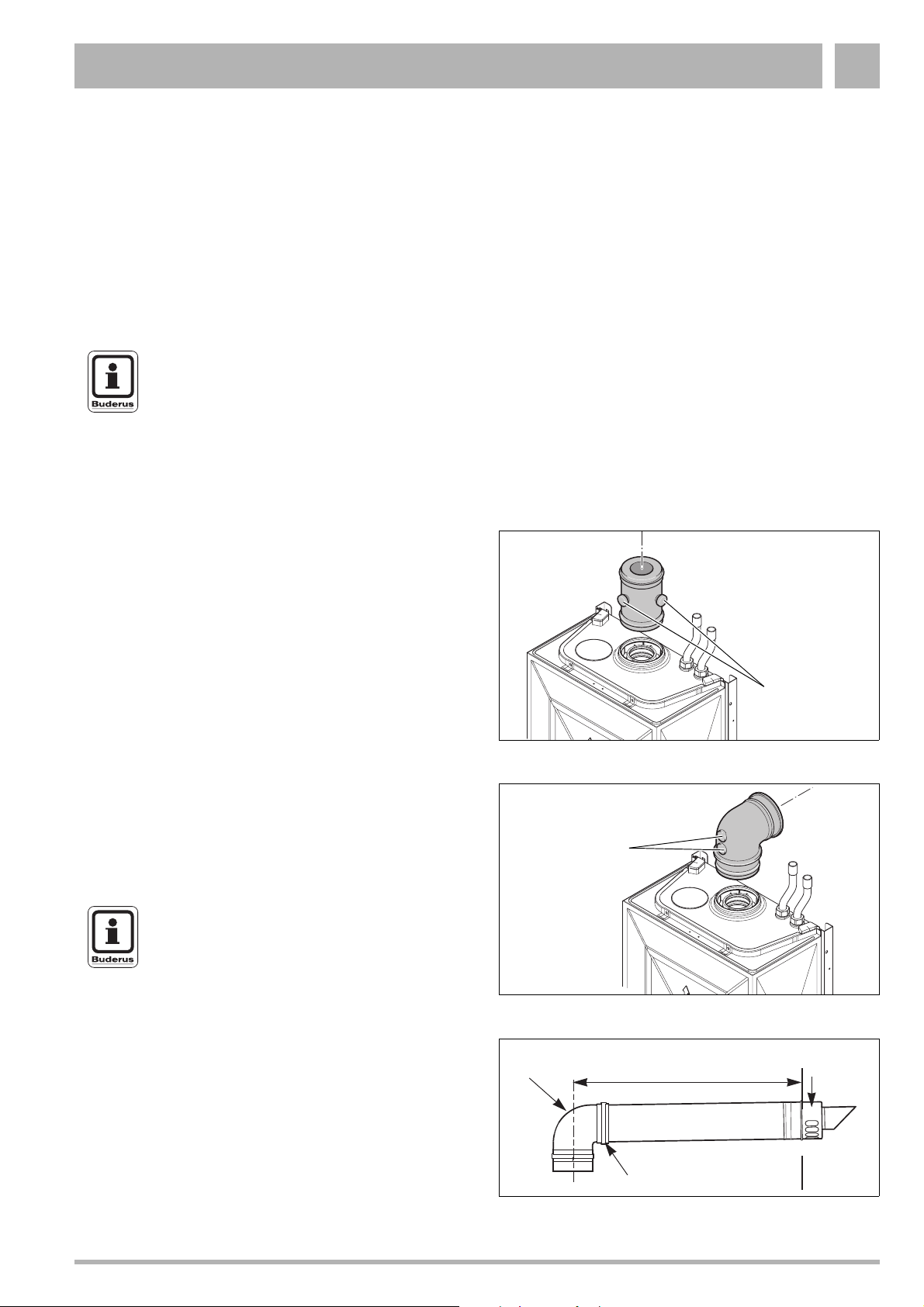

The following items for the flue (see fig. 2) are included in the

delivery of the boiler:

– pos. 1: 1 Concentric bend 60/100;

– pos. 2: 1 Horizontal flue terminal 60/100;

– pos. 3: 1 Flue finishing kit.

1.3.3 Maximum Flue length

The maximum pipe length of the air supply and flue gas

exhaust pipes for the 600 Series condensing gas boilers (see

table 2) is determined by the total pressure loss of all

components in the flue gas exhaust / air supply system.

1

Fig. 2 Horizontal flue pack

2

3

L

550 mm

50 mm

Take the flue conduit clearances into account when planning

the layout of the place of installation (see subsection 1.3.1:

"Siting the flue terminal" on page 11).

Maximum wall thickness without extensions is 550 mm.

Maintain a minimum side wall clearance of 50 mm (see fig. 3).

1.3.4 Additional flue parts

Additional flue parts (see table 3) can be ordered from your

supplier.

Fig. 3 Side flue and rear flue installation

Boiler

600 Series L = 7.5 m 1.2 m

Table 2 Pipe length

Flue parts Order No.

Concentric pipe, 500 mm long, adjustable NE 83703

Concentric pipe, 1000 mm long, not adjustable NE 83704

Concentric bend 90° NE 83705

Concentric bend 45° NE 83706

Table 3 Additional flue parts

Maximum

pipe length

For every 90° bend the

maximum pipe length has

to be reduced by

Subject to modifications resulting from technical improvements! Boulter Buderus Ltd. • http://www.boulter-buderus.co.uk

12 Installation and maintenance instructions for wall-mounted condensing gas boiler Buderus 600 - 11R/19R/24R • 05/2004

Page 13

Installation 1

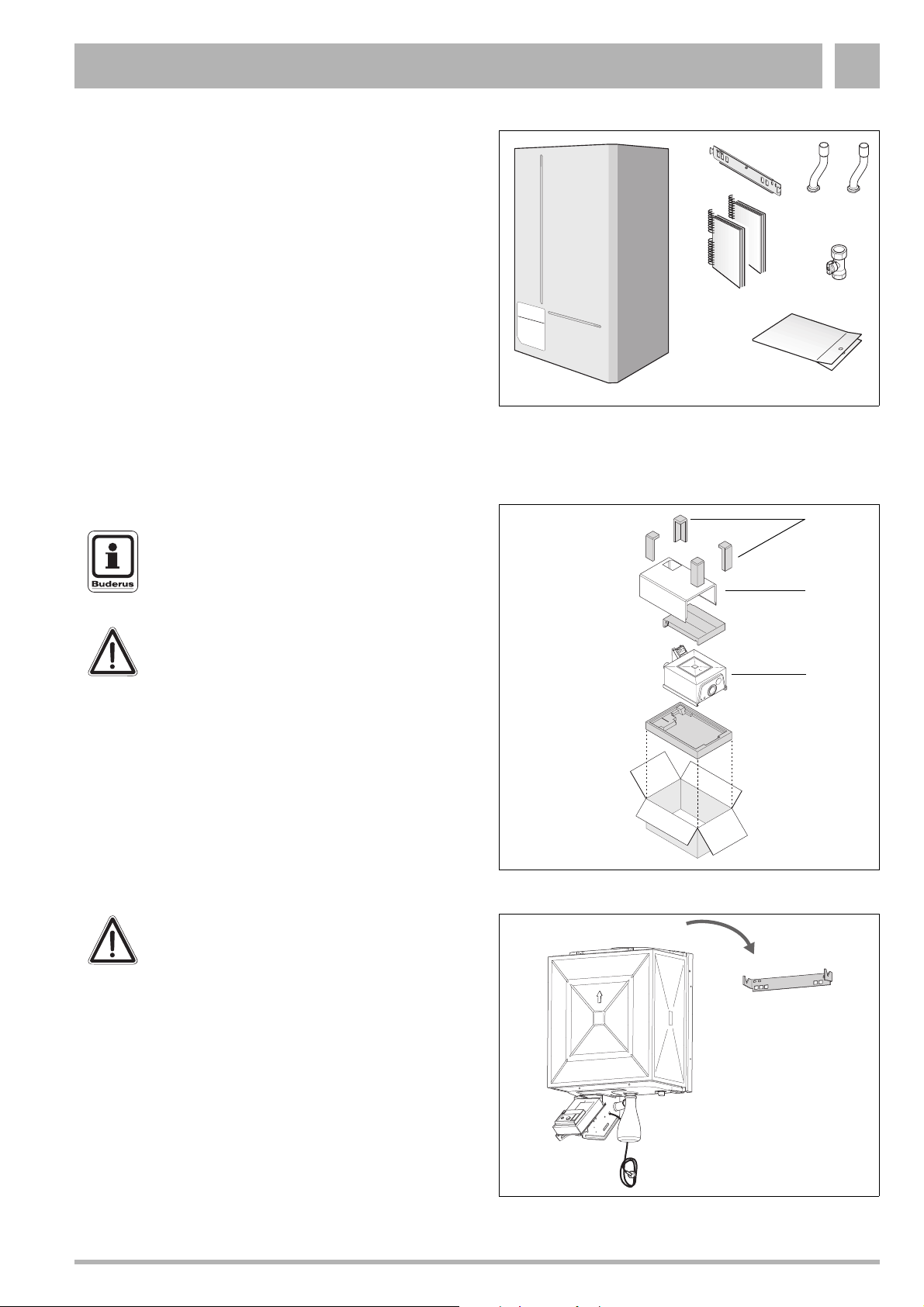

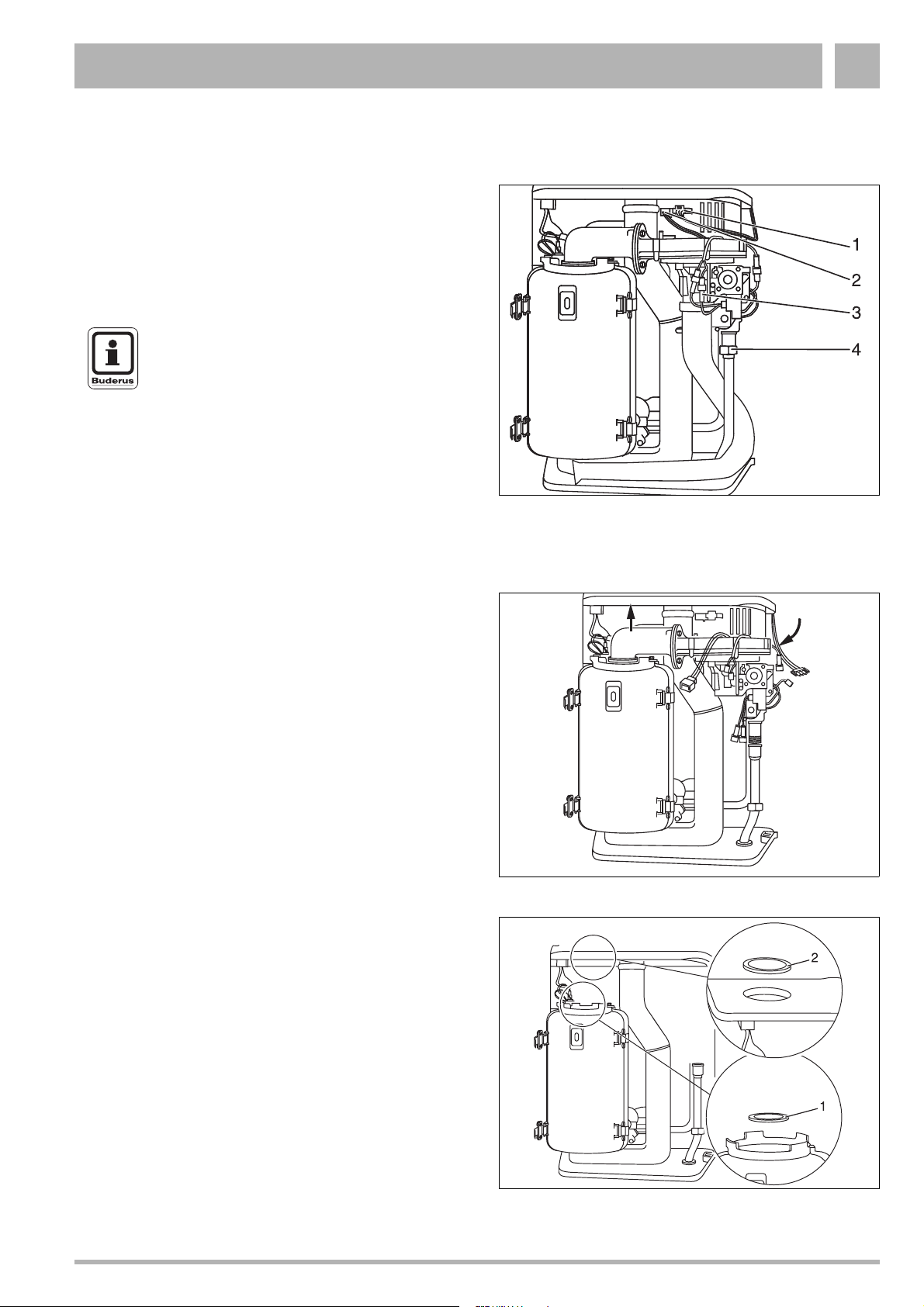

1.4 Items supplied with unit

z Check the contents against the packing list to ensure that

nothing is missing.

Key to fig. 4:

1: Wall-mounted condensing gas boiler

2: Wall bracket

3: Technical documents

4: CH Flow connection pipe

5: CH Return connection pipe

6: Gas service valve

7: Plastic bag containing the following accessories:

2 x wall fixing-screws

2 x wall plugs

2 x washers

Seals (2 x ¾“)

Square wrench

Initial start-up sticker

Second identification plate

Requirements to be met by the place of installation

NOTE

Observe all statutory building regulations

applying to the place of installation.

1

Fig. 4 Items supplied with unit

2

5

4

3

6

7

1

2

DANGER!

Inflammable materials or liquids must not be

stored or used near wall-mounted condensing

gas boilers. The site of installation must be

frost-protected.

1.5 Transport

The boiler is transported in a horizontal position.

z Open the box and remove the four foam supports (fig. 5,

item 1). The casing is not attached to the boiler.

z Take out the casing (fig. 5, item 2) and put aside during

installation.

CAUTION!

Do not carry the boiler by the casing at any

time.

z Take out the wall bracket (fig. 4, item 2) and attach to the

wall using the wall mounting template.

z Take out the condensing gas boiler (fig. 5, item 3) and

hang onto the wall bracket (fig. 6).

z Dispose of packaging.

3

Fig. 5 Unpacking the box

Fig. 6 Installation

Subject to modifications resulting from technical improvements! Boulter Buderus Ltd. • http://www.boulter-buderus.co.uk

Installation and maintenance instructions for wall-mounted condensing gas boiler Buderus 600 - 11R/19R/24R • 05/2004 13

Page 14

Installation1

1.6 Pipe connections

CAUTION!

Ensure that all pipework is routed so as to

minimise any strain on the boiler fittings.

1.6.1 Gas Supply

The gas installation must be installed in accordance with

BS.6891.

CAUTION!

Pipework from the meter to the boiler MUST be

of adequate size.

The complete installation MUST be tested for gas tightness

and purged as described in IGE/UP/1b.

1.6.2 Gas connection

12

z A gas service valve is supplied with the unit. Take it out of

the box and connect it to the boiler see fig. 7, item 3 with

P.T.F.E.-tape. Connect to gas supply according to the

relevant standards.

1.6.3 Heating system connections

The central heating system should be in accordance with

BS.6798 and, in addition, for smallbore and microbore

systems, BS.5449.

z Take the CH flow connection pipe and the CH return

connection pipe out of the box and connect to the

condensing gas boiler see fig. 7, item 1 and 2.

z Connect the central heating system to these pipe

connections according to the relevant standards.

1.6.4 Condensate drain

A condensate drain is integrated in the boiler. The drain outlet

is a standard (21.5 mm) overflow pipe. This drain needs to be

connected to a drainage point. All pipework and fittings in the

condensate drainage system MUST be made of plastic - no

other materials may be used.

The routing of the drain must be made to allow a minimum fall

of 1 in 20 away from the boiler, throughtout its length.

4

Fig. 7 Pipe connections

Key to fig. 7:

1: CH flow

2: CH return

3: Gas

4: Condensate water drainage outlet (CWDO)

3

Excessive external pipe runs should be avoided in order to

prevent possible freezing.

Any external pipework should be a minimum of 32 mm internal

diameter.

WARNING!

Any external run must be insulated.

Ensure that the condensate trap is filled with water.

Subject to modifications resulting from technical improvements! Boulter Buderus Ltd. • http://www.boulter-buderus.co.uk

14 Installation and maintenance instructions for wall-mounted condensing gas boiler Buderus 600 - 11R/19R/24R • 05/2004

Page 15

Installation 1

1.7 Flue installation

The only flue systems that may be used are those supplied by

Boulter Buderus. The flue system must be installed in

accordance with the requirements of BS.5440:1. 2000.

Standard 100 mm flue systems

The standard concentric flue system provides for a max.

horizontal straight length of upto 7.5 m (see subsection 1.3.3).

Full instructions for fitting this flue are in subsection 1.7.2:

"Installation of the horizontal flue" on page 15.

IMPORTANT

Any horizontal flue system fitted to a

condensing boiler must be inclined towards the

appliance at an angle of 3% (30 mm per metre

length) to prevent condensate dripping from

the flue terminal.

This means that the clearance above the

appliance must be increased to match the duct

length. See figure on page 9.

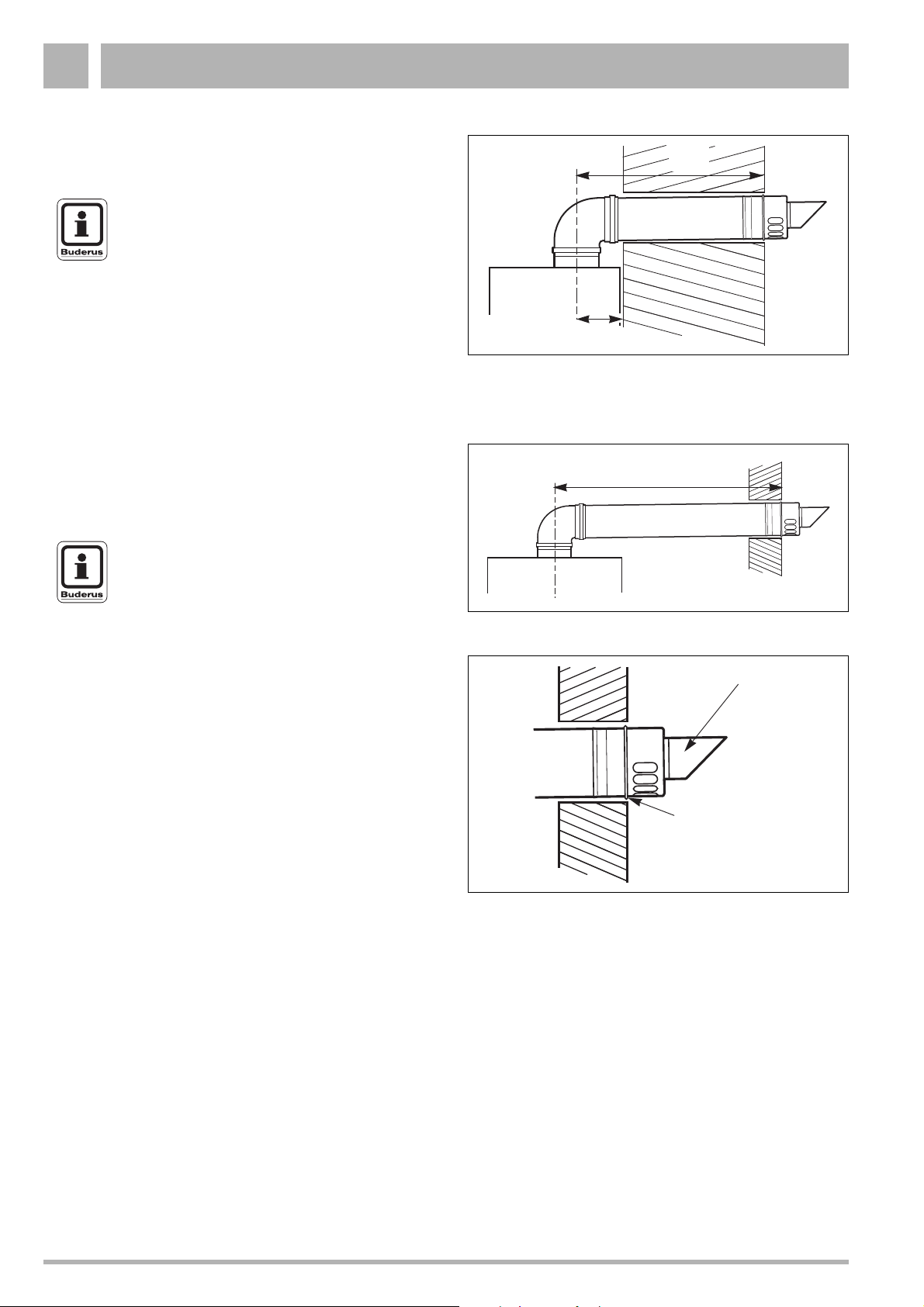

1.7.1 Connecting the vertical flue gas duct

z Fit the vertical flue gas duct (fig. 8) onto the appliance flue

connector.

z For remaining installation of the vertical flue assembly,

refer to the relevant installation instructions.

1.7.2 Installation of the horizontal flue

The standard 100 mm diameter horizontal flue system is

siutable for lengths upto 560 mm (see fig. 10).

For longer flue runs upto 7.5 m, extension air/flue ducts are

available (see page 12, table 3).

NOTE

Use the wall-mounting template to help you

mark the position of the side flue opening

Flue gas

testing point

Fig. 8 Vertical flue connection

Flue gas

testing point

Fig. 9 Elbow with flue gas testing point

Flue

Turret

Maximum 560 mm

No Clamp

Terminal

assembly

Outer

Wall

Fig. 10 Standard flue

Subject to modifications resulting from technical improvements! Boulter Buderus Ltd. • http://www.boulter-buderus.co.uk

Installation and maintenance instructions for wall-mounted condensing gas boiler Buderus 600 - 11R/19R/24R • 05/2004 15

Page 16

Installation1

1.7.3 Flue duct preparation and assembly

z Measure the flue length L. Refer to figures 11 and 12.

NOTE

The flue must be inclined to the boiler.

z Mark of the lengths shown onto the ducts and cut the

length. The cuts must be square and free from burrs.

Terminal assembly outer (air) duct - L-70 mm, inner (flue)

duct - L-50 mm. The measurement is made from the ridge

at the terminal indicating the outer face of the wall.

Refer to figure 13.

Extension air duct - L-70 mm, flue duct - L-50 mm.

The measurement is from the formed end.

z Assemble flue system completely. Push the ducts fully

together. The slope of the terminal outlet must be face

downwards.

The assembly will be made easier if a solvent free grease

is lightly applied to the male end of the ducts.

NOTE

An inner wall sealing plate is provided which

should be fitted to the ducts before assembly.

L

105

Fig. 11 Flue length - rear

L

z Push the assembly through the wall and slide the turret

onto the flue connector. Refer to figure 9.

z Ensure that the turret is fully entered into the socket on the

boiler. From the outside fix the flue finishing kit to the

terminal and, after ensuring the duct is properly inclined

towards the boiler, fix the finishing kit to the wall.

If the terminal is within 2 m of the ground where there is

access then an approved terminal guard must be fitted.

The guard must give a clearance of at least 50 mm around

the terminal and be fixed with corrosion resistant screws.

Fig. 12 Flue length - side

Outer

Wall

Face

Fig. 13 Flue terminal position

Flue Terminal

Raised Ring

locating the

terminal relative

to the outside

wall face

Subject to modifications resulting from technical improvements! Boulter Buderus Ltd. • http://www.boulter-buderus.co.uk

16 Installation and maintenance instructions for wall-mounted condensing gas boiler Buderus 600 - 11R/19R/24R • 05/2004

Page 17

Installation 1

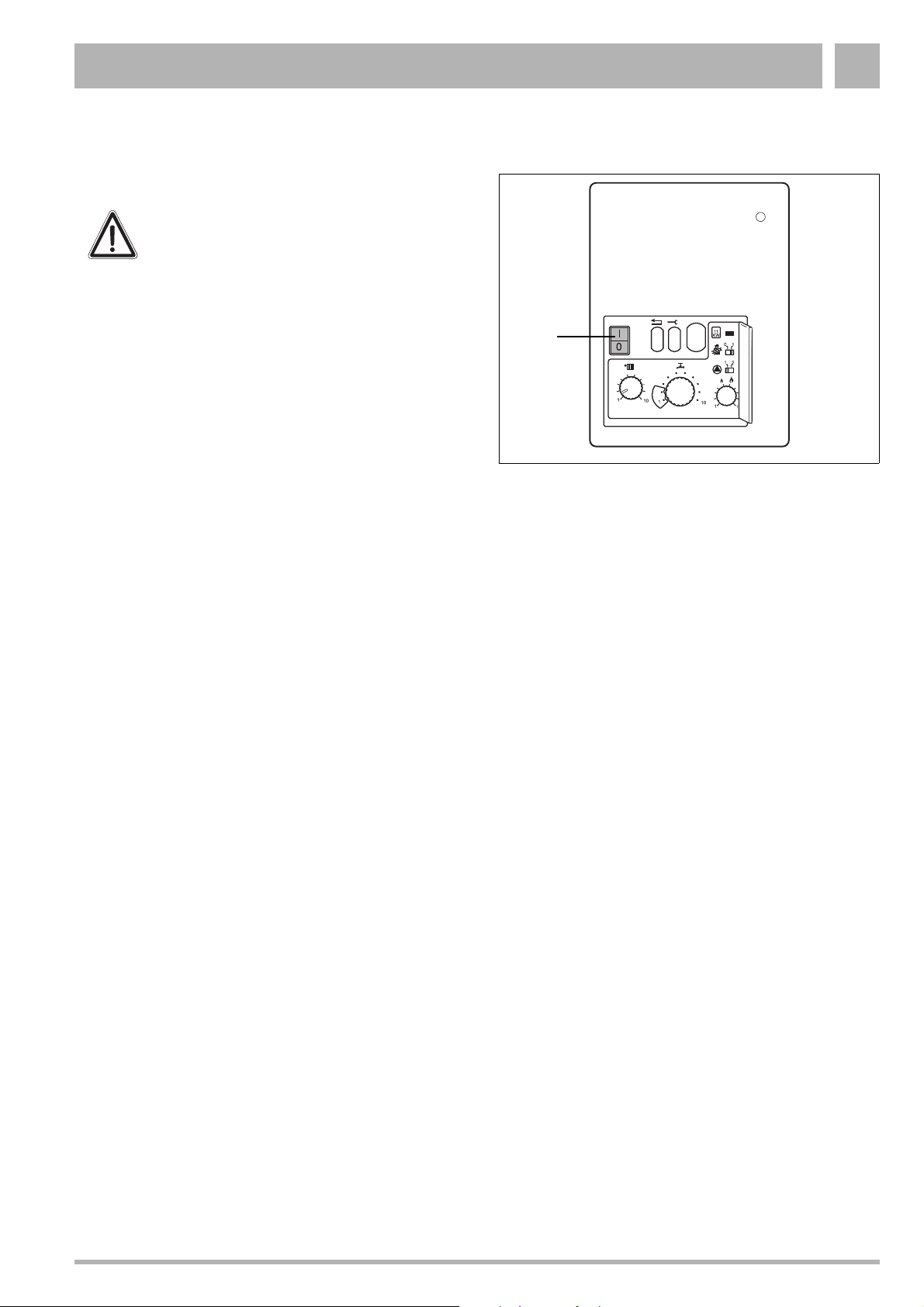

1.8 Electrical connections

1.8.1 Mains connection

CAUTION

This appliance MUST be earthed.

A mains supply of 230 V - 50Hz is required.

External controls are suitable for volt free or 230 V installation.

Wiring to the boiler MUST be in accordance with the current

I.E.E. (BS.7671) Wiring Regulations and any local regulations.

Wiring should be a 3 core PVC insulated cable, not less than

0.75 mm

Connection must be made in a way that allows complete

isolation of the electrical supply such as a double pole switch

having 3 mm (1/8'') contact seperation in both poles, or a plug

and socket, serving only the boiler and system controls. This

boiler is equipped with a double pole switch see fig. 14, item 1.

The means of isolation must be accessible to the user after

installation.

The electrical connection to the mains supply should be readily

accessible and adjacent to the boiler.

If the supply cord is damaged, it must be replaced by a

registered Corgi installer to avoid a hazard.

2

(24 x 0.2 mm), and to BS.6500 Table 16.

1

Fig. 14 UBA

Subject to modifications resulting from technical improvements! Boulter Buderus Ltd. • http://www.boulter-buderus.co.uk

Installation and maintenance instructions for wall-mounted condensing gas boiler Buderus 600 - 11R/19R/24R • 05/2004 17

Page 18

Installation1

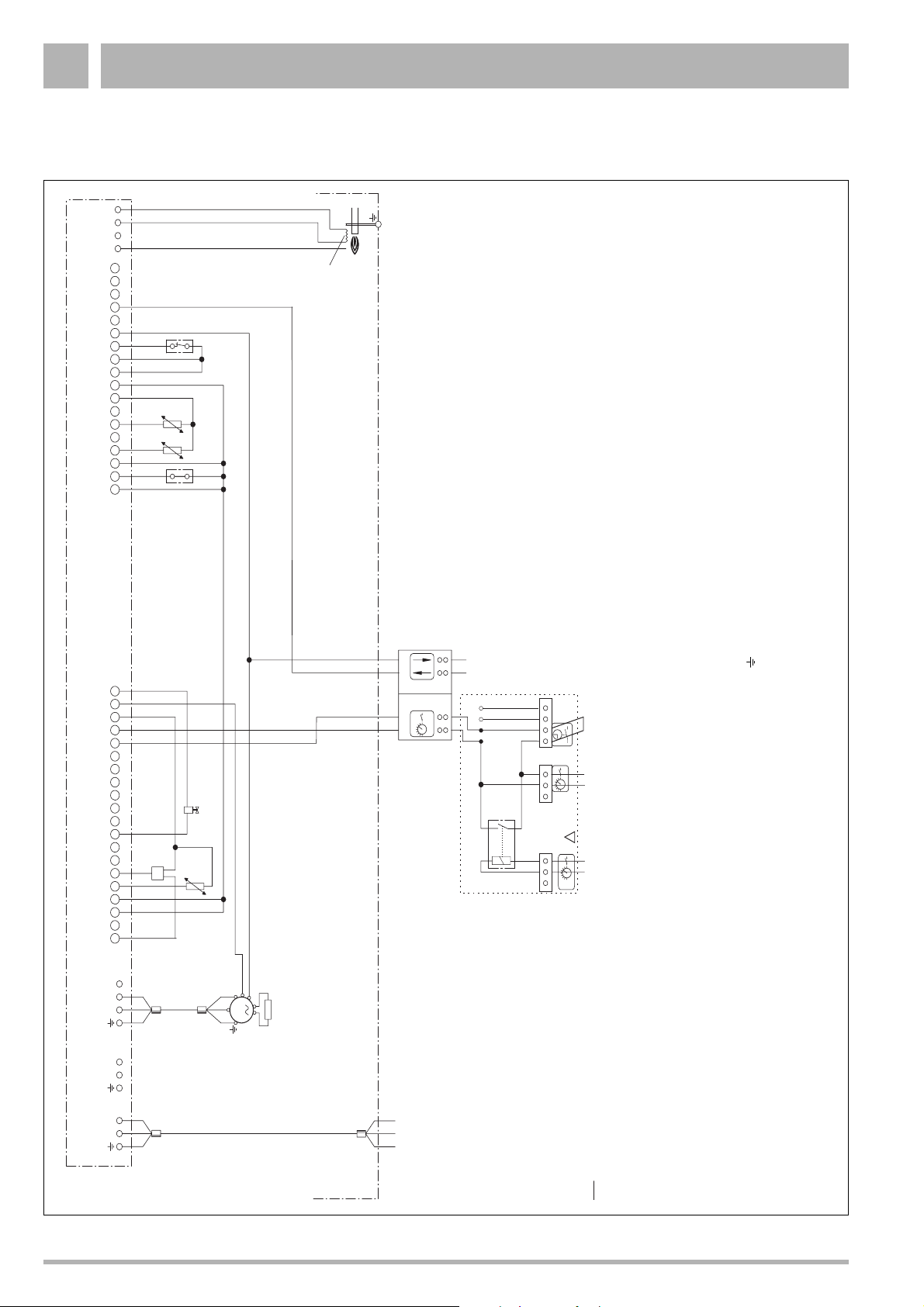

1.8.2 Wiring Diagram

4

12 3

18-pin connection strip

FS

FR

PA

Burner-control unit (UBA)

Flame-monitoring electrode

ignitor

Hot surface

STB

Fuse, main switch, emergency OFF switches and

safety measures to comply with local regulations and standards

port

I/O

Communication

24Vac

12 34

MV

1234

To Boiler

1234

RTH

321

Loop

1)

ON/OFF-

potential free

room thermostat

!

20-pin connection strip

KIM

FK

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18

3

2

1

12 1 2

N

M

L

Ventilator

50 Hz

~

230V

Mains power source

Max. permitted

10A

fuse rating

STB Flue gas monitor

230Vac

321

230 Vac ON/OFF-

room thermostat

device may be connected.

FR Return-temperature sensor (return)

FS Safety-temperature sensor (safety)

FK Supply-temperature sensor (supply)

KIM Boiler identification module

MV Solinoid valve

Note:

1) Only one room-temperature regulating

IMPORTANT

The wires inthis mains lead are coloured in accordance with the following code:

GREEN AND YELLOW - EARTH ; BLUE - NEUTRAL ; BROWN - LIVE

As the colours of the wires in the mains lead of of the appliance may not correspond with the coloured markings identifying the terminals in your plug proceed as follows:

The wire coloured green and yellow must be connected to the terminal on the plug marked with the letter E or by the earth symbol or coloured green or green-and-yellow. The wire coloured brown must be connected to the terminal marked with

the letter L or coloured red. The wire coloured blue must be connected to the terminal marked with the letter N or coloured black.

FOR LOCATION OF INDIVIDUAL COMPONENTS, SEE TROUBLESHOOTING GUIDE IN THE SERVICE SECTION OF THIS MANUAL.".

WARNING

THIS APPLIANCE MUST BE EARTHED

Ensure that your appliance is connected correctly - if you are in any doubt consult a qualified electrician.

Subject to modifications resulting from technical improvements! Boulter Buderus Ltd. • http://www.boulter-buderus.co.uk

18 Installation and maintenance instructions for wall-mounted condensing gas boiler Buderus 600 - 11R/19R/24R • 05/2004

Page 19

Installation 1

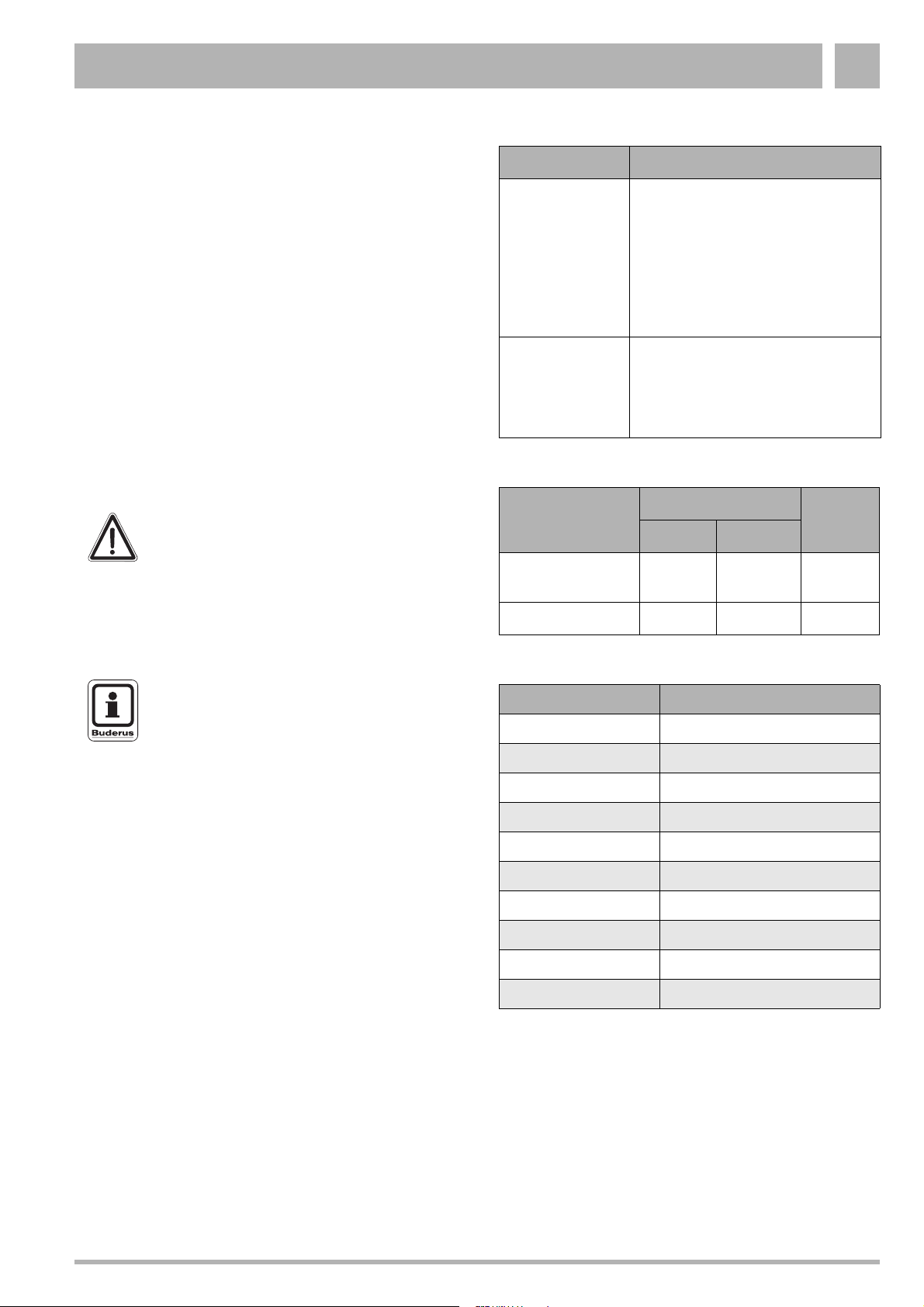

1.9 Timing and temperature control

The wall-mounted condensing gas boiler can be fitted with the

following control devices:

– ON/OFF temperature controller, volt free;

– A room-temperature control device at 230V connected to

the RTH converter see fig. 15, item 2.

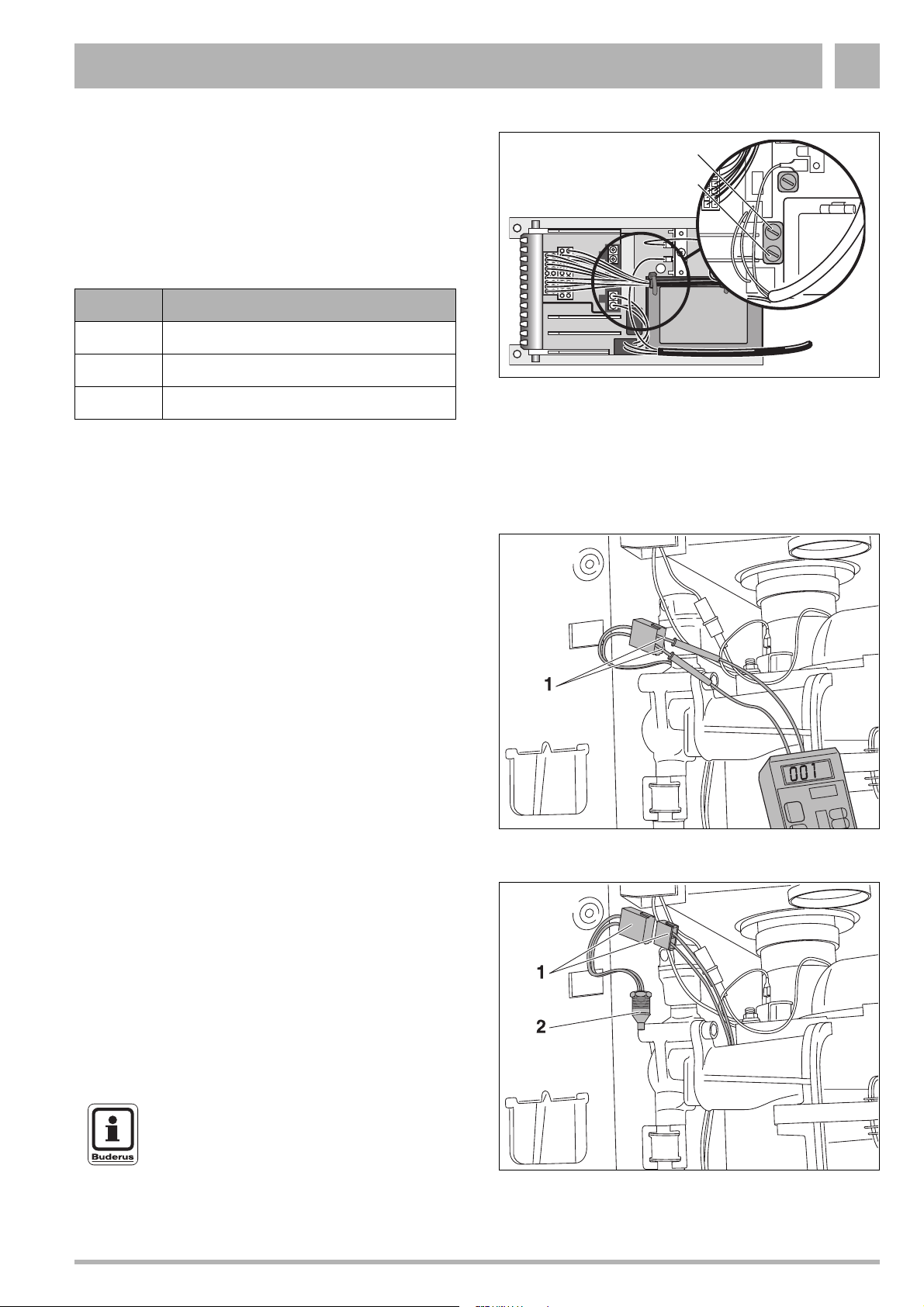

1.9.1 230V Room-temperature control device connection

CAUTION

DO NOT activate the condensing gas boiler at

this stage.

z Lead the 230V control device wire through the cable lead

(see fig. 15, item 1).

z Fix the 230V wire to position 1 and 2 of the 230V

connection (see fig. 15, item 2).

z Secure the 230V wire with the bracket and the two screws

onto the RTH converter.

1.9.2 Volt free room-temperature control device connection

z Remove the cover of the connextion box (fig. 16, item 1).

z Lead the control device wire through the cable lead

(see fig. 16, item 2).

z Fix the wire to position 1 and 2 of the volt free connection

(see fig. 16, item 3).

z Secure the wire with the bracket and the two screws onto

the RTH converter (see fig. 16, item 4).

Fig. 15 Connecting the control device

2

1

1

2

3

Fig. 16 RTH converter - Volt free connection

Subject to modifications resulting from technical improvements! Boulter Buderus Ltd. • http://www.boulter-buderus.co.uk

Installation and maintenance instructions for wall-mounted condensing gas boiler Buderus 600 - 11R/19R/24R • 05/2004 19

Page 20

Initial start-up2

12

10

01

11

KW

10

1

1

2 Initial start-up

2.1 Preparing the boiler for operation

CAUTION

DO NOT operate the condensing gas boiler if

large amounts of dust are present, e.g. due to

building work in and around the place of

installation.

2.1.1 Checking for leaks

z Disconnect the system from the power supply.

z Check all sections of gas pipework and connections for

signs of leaks before starting up system for the first time.

If a leak is detected during tightness testing, use an

approved leak detector to check all connections for

possible escapes. The product must be certified as a gas

leak-testing agent. DO NOT allow the product to come into

contact with electrical wiring.

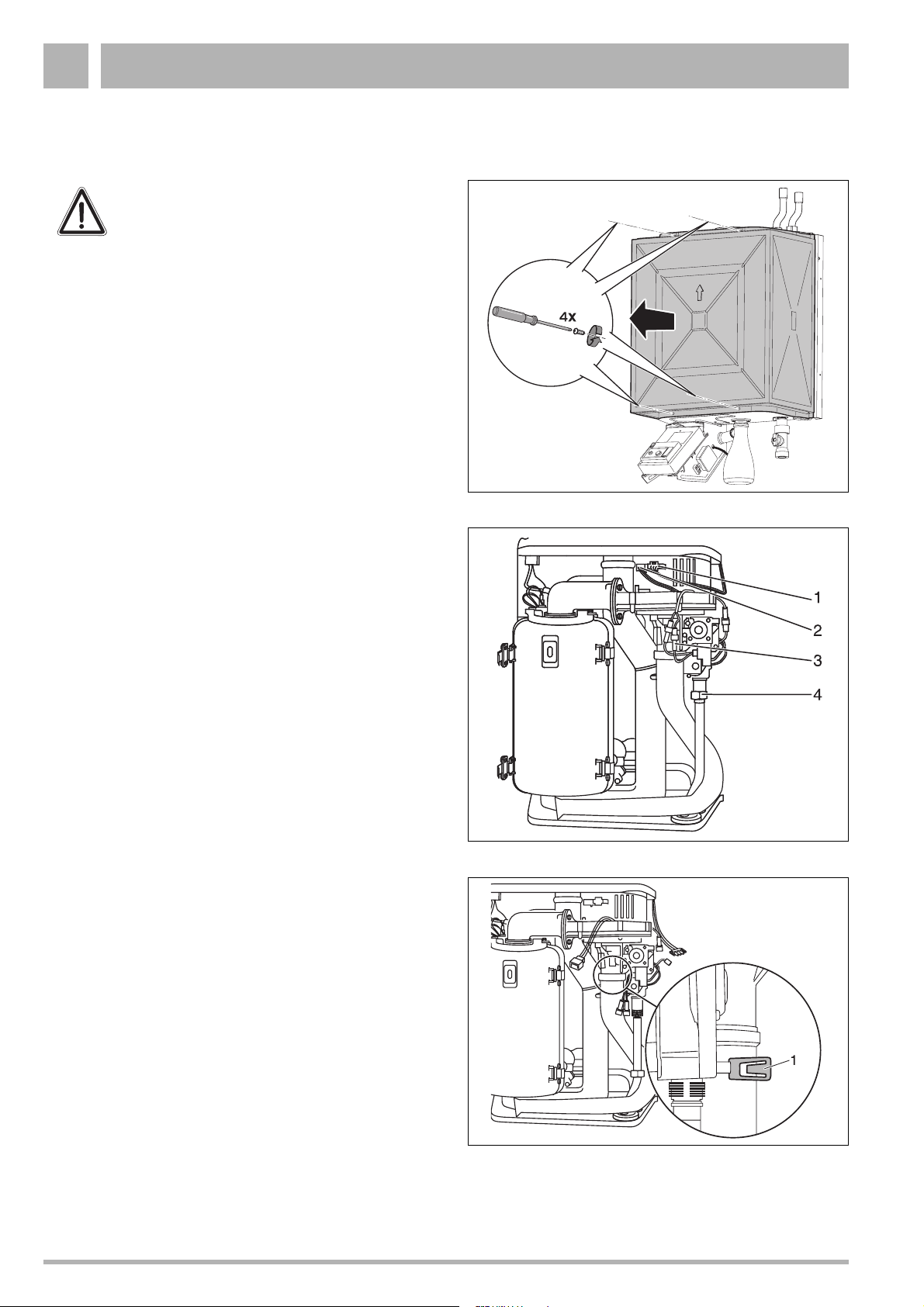

Fig. 17 Unscrew ventilation cover

2.1.2 Purging air from the gas supply system

z Loosen the 4 crosshead screws on the ventilation cover

(fig. 17).

z Remove the ventilation cover.

z Close the gas service valve.

z Unscrew the sealing closure of the gas connection-

pressure testing nipple by two turns (fig. 18).

z Purge system and appliance as per relevent procedures,

IGE/UP/1b. Ensuring all safety requirments are met.

z Open gas service valve.

z Close the gas service valve once more.

z Shut the sealing closure of the test nipple once more.

z Open cover for 2nd operating level (fig. 19, item 1).

z Make sure that system pump is running.

z Start boiler up and move chimney sweep switch (fig. 19,

item 3) to position “1”.

The display shows (fig. 19, item 2) “

-.” or “ =.” to indicate that

the gas supply system is purged of air. Return chimney sweep

switch to position “0”.

Fig. 18 Purging air from the gas supply system

2

3

1

Subject to modifications resulting from technical improvements! Boulter Buderus Ltd. • http://www.boulter-buderus.co.uk

20 Installation and maintenance instructions for wall-mounted condensing gas boiler Buderus 600 - 11R/19R/24R • 05/2004

Fig. 19 Display and chimney-sweep switch

Page 21

Initial start-up 2

2.1.3 Check combustion air/flue gas connection

Check to ensure that the correct combustion air/flue gas

system has been fitted.

Check that the instructions included in the appropriate flue gas

system installation manual have been followed.

2.1.4 Checking the type of gas and supply

CAUTION

The burner must only be put into operation with

the correct nozzles (table 5).

Type of gas Factory settings of gas burners

When delivered ready for operation

and set to Wobbe index 14.1 kWh/m

(referred to 15 °C, 1,013 mbar),

Natural gas H

applicable for Wobbe index range

11.3 to 15.2 kWh/m

3

.

Inscription on gas-type indicating

label:

Category setting: G 20 - 2E_20 mbar

After adaptation by a CORGI

registered installer, the unit can be

Propane P

run on propane.

Inscription on gas-type indicating

label: 3P G 31_30-50 mbar

Table 4 Gas-supply types

Type of gas

supply

Natural gas H

(G20)

Gas nozzles ∅ [mm]

11R 19R/24R

Venturi

tubes

5.55 6.5 Standard

3

NOTE

Observe stickers attached to Venturi tubes.

Propane P 3.40 4.15 Standard

Table 5 Gas-nozzle diameter

Controller setting Flow temperature [°C]

1 40

2 44

3 48

4 53

5 58

6 62

7 67

8 71

9 76

10 80

Table 6 Flow temperature

Subject to modifications resulting from technical improvements! Boulter Buderus Ltd. • http://www.boulter-buderus.co.uk

Installation and maintenance instructions for wall-mounted condensing gas boiler Buderus 600 - 11R/19R/24R • 05/2004 21

Page 22

Initial start-up2

12

10

01

11

KW

10

1

1

2.1.5 Adjusting the flow temperature

z Open the cover to the 2nd operating level (fig. 20, item 1).

z Adjust the knob (fig. 20, item 2) to the desired flow

temperature (table 6) for your particular installation.

NOTE

Factory setting of the controller is "10"

(around 83 °C).

NOTE

If the flow temperature is set too low, there is

the risc that an external hot water cylinder

cannot achieve a comfortable enough

temperature.

2

1

Fig. 20 Control box

Key to Fig. 20:

1: Cover for second operating level

2: Flow temperature knob

3: Heat-capacity jumper

4: Heating capacity knob

5: only used when boiler is in service mode

6: only used when boiler is in service mode

3

56

4

2.1.6 Setting the heating capacity

Set the heating capacity (table 7), according to the amount of

heat required, at the controller (fig. 20, item 4).

NOTE

The controller is factory-adjusted to position “6”

Controller

setting

Heating capacity [kW] (±5 %)

11 R 19 R 24 R

14.99.79.7

2 5.6 10.7 11.3

3 6.3 11.8 12.9

4 6.9 12.8 14.5

5 7.6 13.8 16.0

6 8.3 14.9 17.6

7 9.0 15.9 19.2

8 9.6 16.9 20.8

9 10.3 18.0 22.4

10 11.0 19.0 24.0

Table 7 Heating capacity

Subject to modifications resulting from technical improvements! Boulter Buderus Ltd. • http://www.boulter-buderus.co.uk

22 Installation and maintenance instructions for wall-mounted condensing gas boiler Buderus 600 - 11R/19R/24R • 05/2004

Page 23

Initial start-up 2

12

10

01

11

KW

10

1

1

2.1.7 Measure gas-supply pressure (flow pressure)

z Open at least one radiator thermostat valve.

CAUTION

The condensing gas boiler must not be

activated at this stage.

z Make sure that the system pump is running.

z Turn the chimney-sweep switch (fig. 21, item 4) to

position “1”.

z Loosen the screw plug on the gas test nipple (fig. 22) by

two turns.

z Attach the pressure-gauge connection hose to the gas test

nipple (fig. 23).

z Slowly open the gas service valve.

z Turn the power switch (fig. 21, item 2) to position “I”.

The burner should ignite after about 30 seconds.

z Measure the gas connection pressure and note it down on

the report form.

The gas-connection pressure must be

for natural gas H min. 17 mbar, max. 25 mbar, nominal

connection pressure 20 mbar.

for propane P min. 30 mbar, max. 50 mbar, nominal

connection pressure 37 mbar.

z Detach the gauge-connection tube once more and close

the test nipple at the screw plug.

.

NOTE

If the required connection pressure is not

available or too high, contact your gas supplier

or TRANSCO.

Ensure all disturbed joints and connections are checked for

gas tightness on completion of tasks.

3

4

2

1

Fig. 21 Mains switch, service button and chimney-sweep

switch

Fig. 22 Measure the gas connection pressure

2.1.8 Check the gas/air ratio and adjust as required

z Turn mains power switch (fig. 21, item 2) and chimney-

sweep switch (fig. 21, item 4) to “0”.

z Unscrew the sealing closure of the burner-pressure testing

nipple by one turn (fig. 22).

z Connect the positive port of the pressure gauge with a

hose to the burner pressure measuring nipple (fig. 23).

z Make sure that the system pump is running.

z Turn mains power switch to “I” and chimney-sweep switch

to “1”.

z If the burner has fired after approx. 30 seconds, keep the

service button (fig. 21, item 3) pressed until “Y” appears on

the display.

z Turn the hot-water temperature controller (fig. 21, item 1)

Fig. 23 Check the gas/air ratio

to “1”.

z Read the differential pressure.

The differential pressure (p

(±5 Pa = 0,05 bar) (display on measuring gauge: -10 Pa to

GAS–pAIR

) should total -5 Pa

0Pa).

Subject to modifications resulting from technical improvements! Boulter Buderus Ltd. • http://www.boulter-buderus.co.uk

Installation and maintenance instructions for wall-mounted condensing gas boiler Buderus 600 - 11R/19R/24R • 05/2004 23

Page 24

Initial start-up2

z If the gas/air ratio does not conform to specifications,

readjust at the setscrew (fig. 23, item 1).

z Turn mains power switch and chimney-sweep switch to “0”.

z Remove the measuring equipment and retighten the screw

in the burner-pressure measuring nipple.

z Readjust the hot-water temperature controller to its original

setting.

z Turn the mains power switch to “I”.

2.1.9 Record readings

z Unscrew the corresponding sealing closure (fig. 24) on the

connection adapter for the combustion-air/flue-gas system

and replace it once the measuring operation in question

has been carried out.

Carbon monoxide content

CAUTION

The carbon monoxide values under vacuum

must be smaller than 400 ppm or 0.04 Vol%.

Values around or exceeding 400 ppm indicate

a faulty burner adjustment, a dirty gas burner

or heat exchanger, or a defective burner.

Ensure that the cause of the fault is remedied

immediately.

2.1.10 Function testing

NOTE

During initial start-up and annual servicing,

make sure that all control, regulating and

safety devices are in full working order and, if

applicable, check for correct adjustment.

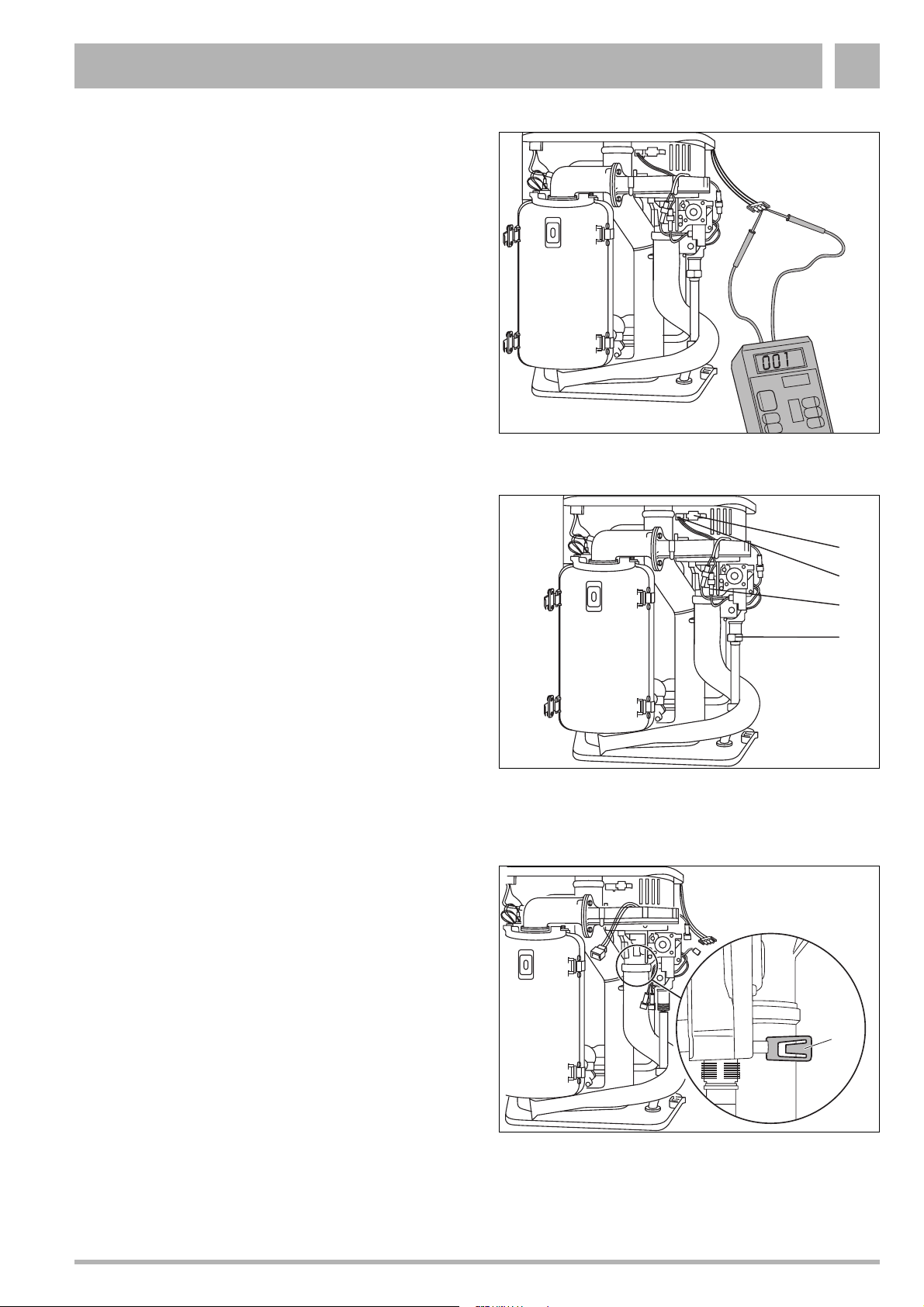

Measuring the ionisation current (fig. 25)

z Disconnect the system from the power supply.

z Loosen the plug-and-socket connector of the ionisation

electrode and connect the multimeter in series.

On the measuring device, select the µ-direct current range.

The measuring device must have a resolution of at

least 1 µA.

z Make sure that the system pump is running.

z Reconnect the system to the power supply and turn the

chimney-sweep switch to “1”.

z Measuring the ionisation current. The ionisation current

being checked must measure >2 µA direct current.

z Enter the reading on the report form.

z Disconnect the system from the power supply.

z Remove multimeter and restore the plug-and-socket

connection to its original state.

z Turn the chimney sweep switch to position “0”.

z Reconnect the system to the power supply.

When the display shows “7” and the service button is

pressed, the display turns to “c”. Press the Reset button.

The display shows “r”.

Fig. 24 Measuring points on exhaust conduit

Key to Fig. 24:

1: Exhaust-fume temperature, CO

2: Combustion-air temperature

, CO, NO

2

x

Fig. 25 Measuring the ionisation current

12

Subject to modifications resulting from technical improvements! Boulter Buderus Ltd. • http://www.boulter-buderus.co.uk

24 Installation and maintenance instructions for wall-mounted condensing gas boiler Buderus 600 - 11R/19R/24R • 05/2004

Page 25

Initial start-up 2

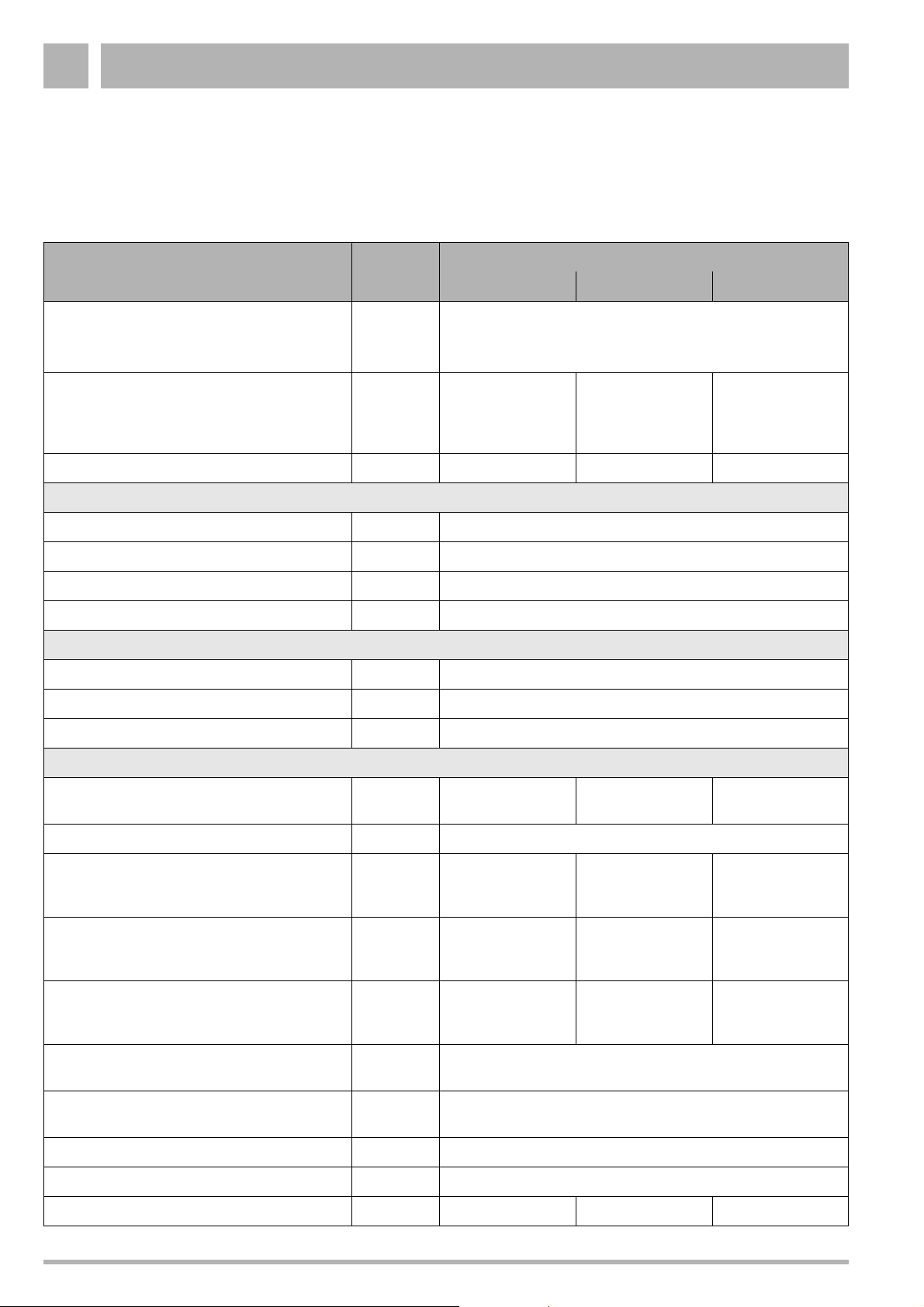

z Place the casing (see fig. 26, item 1).

z Tighten the fixing screw (see fig. 26, item 2).

2.1.11 Handing over

After completing the installation and commissioning of the

system the installer should hand over to the householder by

the following actions:

z Hand the User Manual to the householder and explain

his/her responsibilities under the relevant national

regulations.

z Explain and demonstrate the lighting and shutting down

procedures.

z The operation of the boiler and the use and adjustment of

all system controls should be fully explained to the

householder, to ensure the greatest possible fuel economy

consistent with the household requirements of heating.

Advise the user of the precautions necessary to prevent

damage to the system and to the building in the event of the

system remaining inoperative during frosty conditions.

z Explain the function and the use of the boiler heating

controls.

z Explain the function of the boiler fault mode. Emphasise

that if a fault is indicated, the boiler should be turned off and

a registered local heating installer consulted.

z Explain and demonstrate the function of time and

temperature controls, radiator valves etc., for the economic

use of the system.

Fig. 26 Place casing

1

2

Loss of system water pressure

z Explain that when there is a significant loss of pressure the

user should contact a Corgi registered installer.

WARNING

Do not fire the boiler if the pressure has

reduced to zero from the original setting.

z After installation, commissioning and customer handover

instructions please complete the BENCHMARK appliance

log book and leave this with the customer.

z IMPORTANT

A comprehensive service should be carried out annually.

Stress the importance of regular servicing by a Corgi

registered installer.

Subject to modifications resulting from technical improvements! Boulter Buderus Ltd. • http://www.boulter-buderus.co.uk

Installation and maintenance instructions for wall-mounted condensing gas boiler Buderus 600 - 11R/19R/24R • 05/2004 25

Page 26

Inspection3

3 Inspection

3.1 Preparing the heating boiler for inspection

z Disconnect the system.

DANGER OF FATAL INJURY

due to electric shock when system is

opened.

z Before opening the system:

disconnect the heating unit at the

emergency OFF switch or the

corresponding circuit breaker of the house

power supply.

z Ensure that the heating system cannot be

reconnected by accident.

z Remove the burner housing or cover from the heating

boiler.

NOTE

If the gas supply pipes are to be disconnected

from the burner, the housing MUST ONLY be

removed by a qualified service technician and

checked for tightness on reassembly.

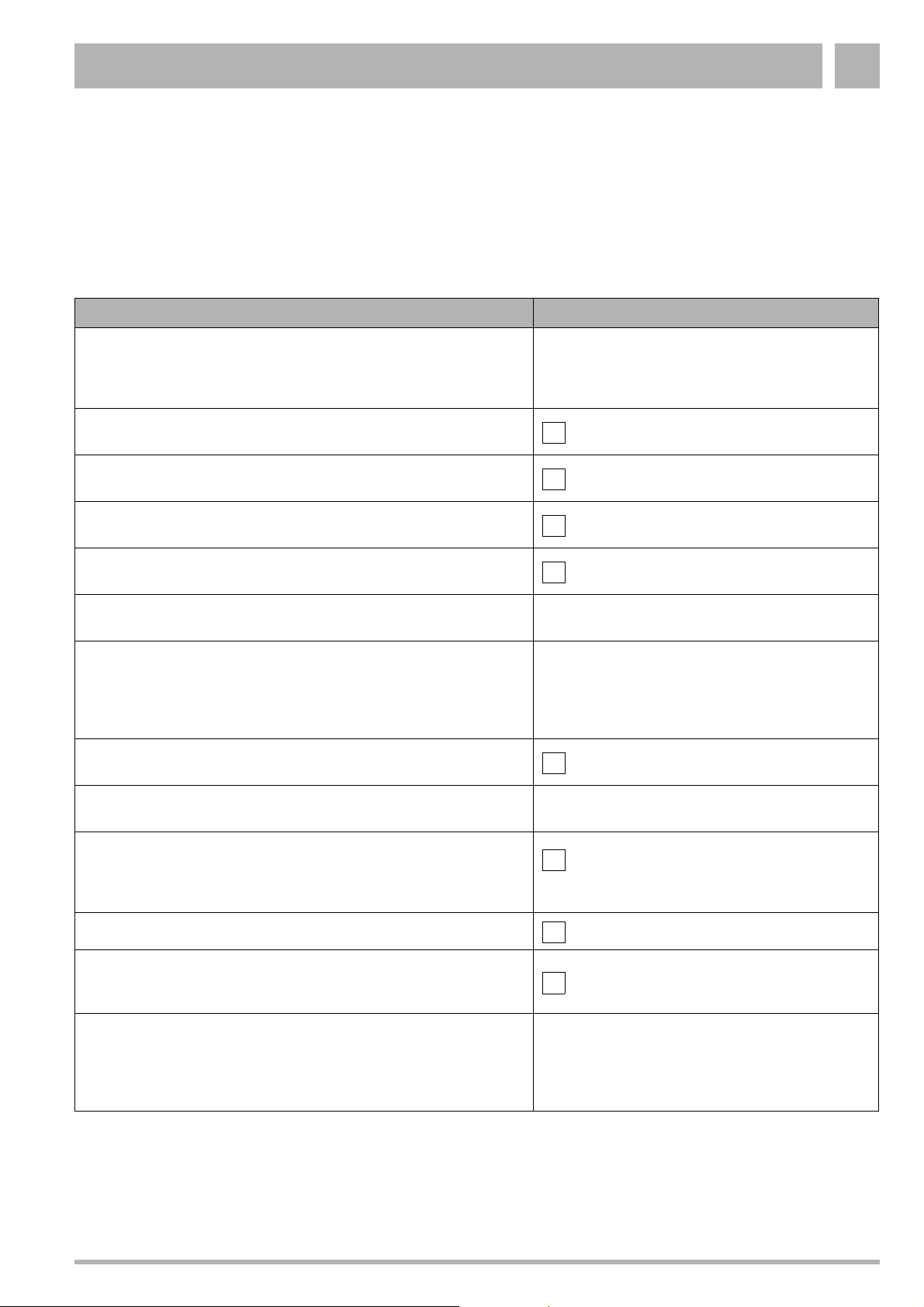

For further information, please refer to subsection 8.2

"Inspection and maintenance reports" on page 54 and fill out

the Benchmark.

Subject to modifications resulting from technical improvements! Boulter Buderus Ltd. • http://www.boulter-buderus.co.uk

26 Installation and maintenance instructions for wall-mounted condensing gas boiler Buderus 600 - 11R/19R/24R • 05/2004

Page 27

Maintenance 4

4 Maintenance

For further information, please refer to subsection 8.2

"Inspection and maintenance reports" on page 54 and fill out

the Benchmark.

4.1 Clean the heat exchanger, burner and condensate trap

NOTE

The cleaning of the burner and heat exchanger

described here should be carried out whenever

there are signs of heavy soiling on the wallmounted condensing gas boiler. It is sufficient,

during annual servicing, to clean the burner

and heat exchanger with the help of an

appropriate cleaning product and a soft brush

and compressed-air hose (see following

section).

The heat exchanger can be dismantled

completely for thorough cleaning if required

(see “Cleaning the heat exchanger after

dismantling” on page 28).

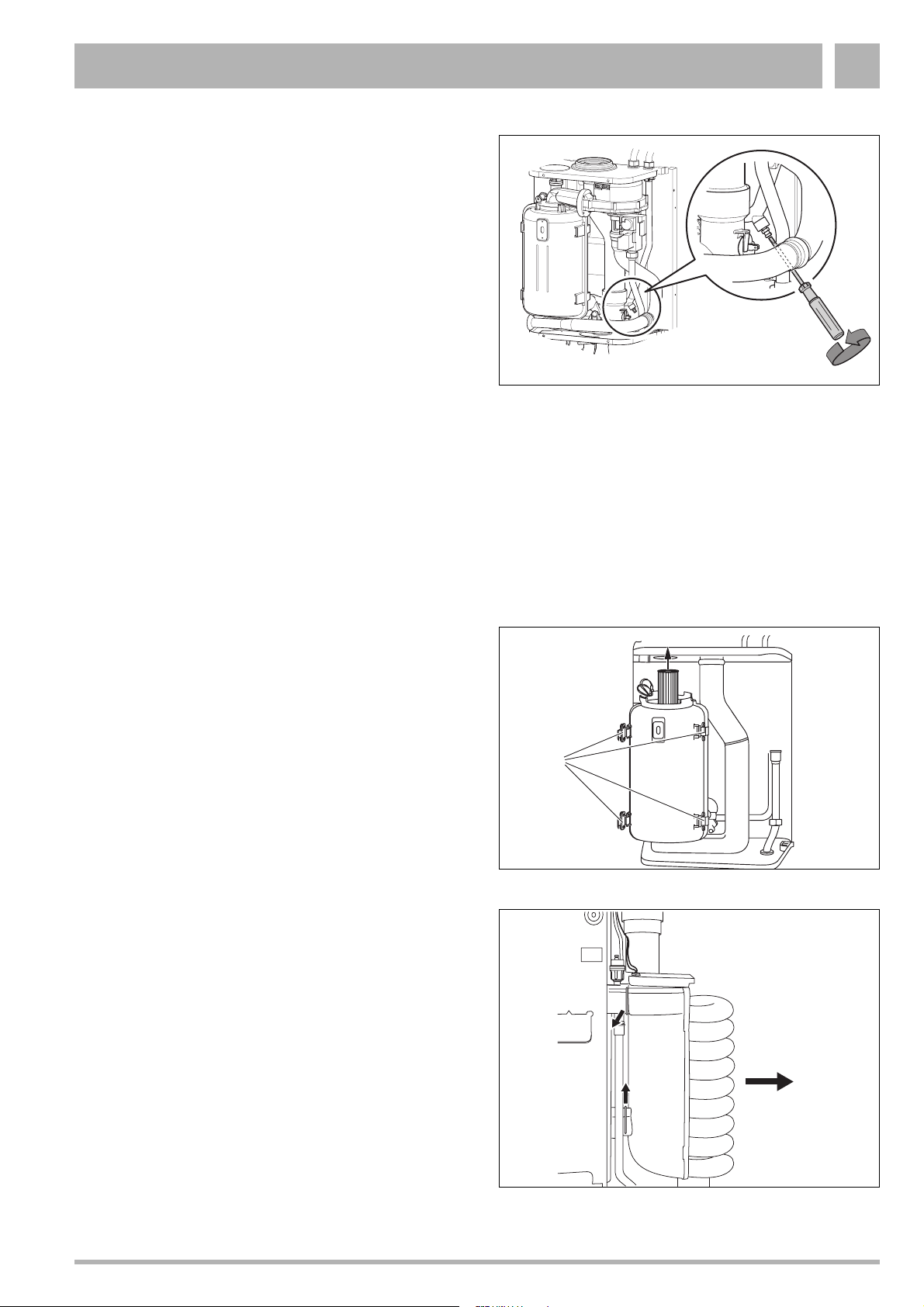

Fig. 27 Loosen the union nut and remove the cable

4.1.1 Cleaning the heat exchanger without dismantling

z Disconnect the system from the power supply.

z Close the gas service valve.

z Loosen the fixing screws, remove casing and ventilation

cover.

z Release plug-in connection of fan power lead (fig. 27,

item 1), burner-control unit fan control lead (fig. 27, item 2)

and gas-burner assembly (fig. 27, item 3).

z Loosen union nut on gas valve assembly (fig. 27, item 4).

z Push safety plate out of way.

z Turn air suction tube and pull off from below.

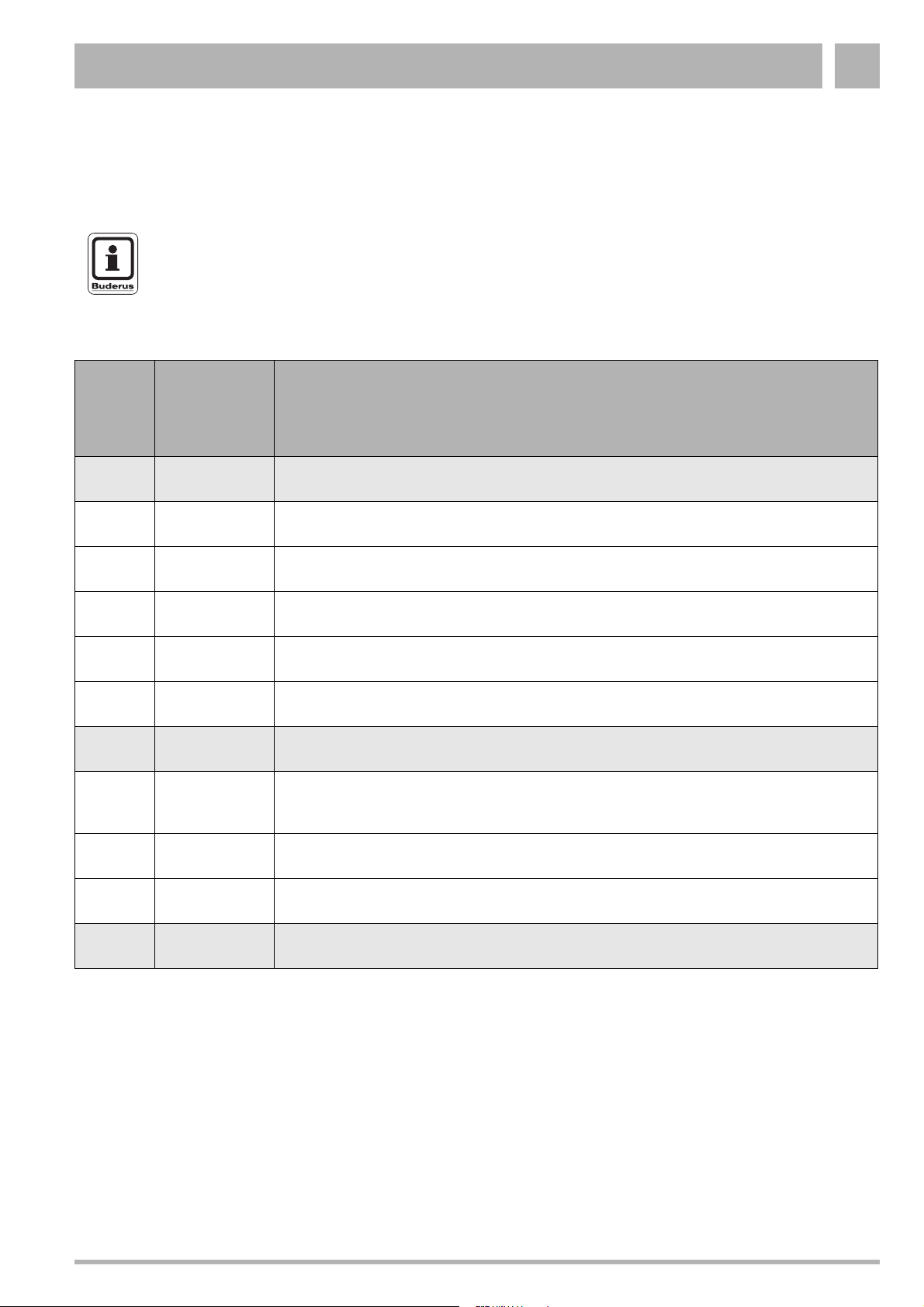

z Swivel the air combination unit forward (fig. 28, item 1).

z Pull the air combination unit up and out of bayonet

connector (fig. 28, item 2) and remove via front of unit.

z Remove burner gasket (fig. 29, item 1).

z Remove rubber seal in heat exchanger by pushing

upwards from inside (fig. 29, item 2).

2

Fig. 28 Remove the air combination unit

1

Fig. 29 Remove burner gasket and rubber seal

Subject to modifications resulting from technical improvements! Boulter Buderus Ltd. • http://www.boulter-buderus.co.uk

Installation and maintenance instructions for wall-mounted condensing gas boiler Buderus 600 - 11R/19R/24R • 05/2004 27

Page 28

Maintenance4

z Remove heat exchanger by pulling upwards through the

opening (fig. 30).

NOTE

Maintain the specified clearance of approx.

25 cm between the ceiling and the ventilation

cover.

z Remove the front of the heat exchanger. This is done by

releasing the four snap catches at the sides.

z Remove the hot surface ignitor (fig. 31, item 1) and

ionisation electrode (fig. 31, item 2).

In the case of the hot surface ignitor: loosen the fixing

screw of the hot surface ignitor, detach both earth (ground)

leads and remove the retaining plate of the hot surface

ignitor by pulling it upwards, withdraw the hot surface

ignitor by pulling it upwards.

In the case of the ionisation electrode: Swivel the

retaining plate to one side and carefully remove the

ionisation electrode by pulling it upwards.

z Clean the burner and both parts of the heat exchanger with

compressed-air or brush.

z Refit the heat exchanger by following the above procedure

in reverse order.

CAUTION

The gasket between the two halves of the

casing shell should normally be replaced.

Fit the new gasket by pressing in from the top

on both sides, and without stretching.

DO NOT attempt to cut the gasket to size.

Fig. 30 Remove burner

1

2

CAUTION

The burner gasket must match the shape of

the groove in the housing.

CAUTION

Check the heat-exchanger for leaks BEFORE

reassembling the casing shells.

4.1.2 Cleaning the heat exchanger after dismantling

z Disconnect the system from the power supply.

z Close the gas service valve.

z Loosen the retaining screw and remove the casing.

z Close the heating shutoff valves and drain the system.

CAUTION

Cut hot water on supply side by closing the

heating shutoff valve.

Fig. 31 Remove the hot surface ignitor and ionisation

electrode

Subject to modifications resulting from technical improvements! Boulter Buderus Ltd. • http://www.boulter-buderus.co.uk

28 Installation and maintenance instructions for wall-mounted condensing gas boiler Buderus 600 - 11R/19R/24R • 05/2004

Page 29

Maintenance 4

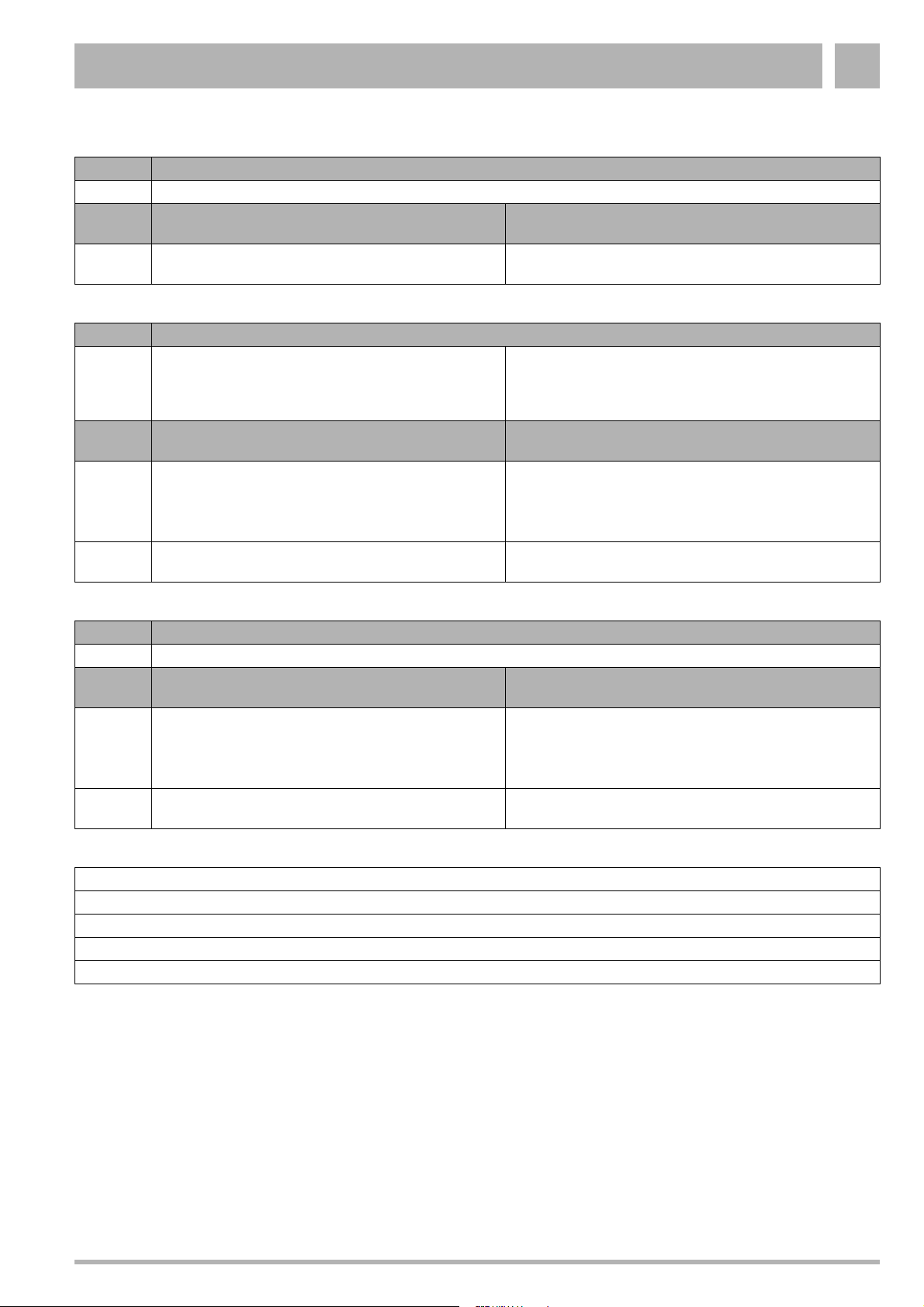

To drain the boiler take the following steps:

z First drain the system.

z In case of frost, drain the boiler.

z Loosen the draining nipple with a screwdriver see fig. 32.

z Attach temporary hose to the nipple. Connect the other

side of the temporary hose to a draining pipe.

z When the boiler is drained then tighten the draining nipple

screw.

z Release plug-in connection of fan power lead (fig. 27,

item 1, page 27), burner-control unit fan control lead

(fig. 27, item 2, page 27) and gas-burner assembly (fig. 27,

item 3, page 27).

z Loosen union nut on gas valve assembly (fig. 27, item 4,

page 27).

z Push safety plate out of way.

z Turn air suction tube and pull off from below.

z Swivel the air combination unit forward (fig. 28, item 1,

page 27).

z Pull the air combination unit up and out of bayonet

connector (fig. 28, item 2, page 27) and remove via front of

unit.

z Remove rubber seal in combustion chamber from top

(fig. 29, item 2, page 27).

Fig. 32 Draining the boiler

z Remove burner and burner gasket (fig. 29, item 1,

page 27) by pulling upwards through the opening (fig. 33,

item 1).

z Remove the front of the heat exchanger by releasing the

four retaining clips (fig. 33, item 2).

z Remove the hot surface ignitor (fig. 31, item 1) and

ionisation electrode (fig. 31, item 2).

In the case of the hot surface ignitor:

Loosen the fixing screw of the hot surface ignitor, detach

both earth (ground) leads and remove the retaining plate of

the hot surface ignitor by pulling it upwards, withdraw the

hot surface ignitor by pulling it upwards.

In the case of the ionisation electrode:

Swivel the retaining plate to one side and carefully remove

the ionisation electrode by pulling it upwards.

z Remove securing pin on flow and return connection

conduit (fig. 34) of heat exchanger.

z Remove spiral heat exchanger by pulling towards front

(fig. 34). Drain any water remaining in the heat exchanger

into the condensate trap.

1

2

Fig. 33 Remove burner and release retaining clips

Fig. 34 Securing pin on spiral heat exchanger

Subject to modifications resulting from technical improvements! Boulter Buderus Ltd. • http://www.boulter-buderus.co.uk

Installation and maintenance instructions for wall-mounted condensing gas boiler Buderus 600 - 11R/19R/24R • 05/2004 29

Page 30

Maintenance4

z Remove the diffusion head (fig. 35, item 2) on the

underside of the heat exchanger by withdrawing the

securing pin (fig. 35, item 1) and unscrewing the diffusion

head.

z Clean the front and back cover of the heat exchanger and

the heat exchanger with water or compressed air.

z Clean the burner with compressed air only.

Take care not to damage the fins of the heat exchanger.

Refitting (fig. 36) :

NOTE

Excessive flue gas temperatures may be an

indication of an incorrectly-fitted diffusion

head.

12

z Screw the diffusion head in as far as it will go on the

underside of the heat exchanger (the final turn of the heat

exchanger increases the clearance between the pipes) and

insert securing pin.

CAUTION

Take care not to damage the insulation on the

diffusion head.

z Check to ensure that the heat exchanger has been fitted

the right way round. The upper securing-pin groove must

be horizontal (fig. 36, item 1).

z Refit the heat exchanger by following the above procedure

in reverse. Note the following:

z The gasket between the front and back cover of the heat

exchanger should normally be replaced. Fit the new gasket

by pressing in from the top on both sides, and without

stretching. DO NOT attempt to cut the gasket to size.

z Check the heat exchanger for leaks BEFORE

reassembling the front and back cover of the heat

exchanger.

z Check O-ring seals (spiral), and replace as required.

z Smear the O-ring seal with a thin layer of silicone grease.

Fig. 35 Removing the diffusion head

1

Fig. 36 Refitting the heat exchanger

4.1.3 Cleaning the condensate trap

z Remove the trap and withdraw it from the outlet see fig. 37.

z Clean the condensate trap.

z Fill the condensate trap with water and then reassemble in

reverse order.

z Measuring the gas input pressure (flow pressure).

z Check the gas/air ratio.

z Leak test in operational condition.

z Measuring the carbon monoxide content.

z Carry out function testing.

Subject to modifications resulting from technical improvements! Boulter Buderus Ltd. • http://www.boulter-buderus.co.uk

30 Installation and maintenance instructions for wall-mounted condensing gas boiler Buderus 600 - 11R/19R/24R • 05/2004

Fig. 37 Removing the condensate trap

Page 31

Servicing 5

5 Servicing

5.1 Operating codes

NOTE

If the code displayed on the burner-control unit

is not listed under the operating codes or fault

warnings, the burner-control unit itself is

malfunctioning.

Display Display after

pressing the

service

button

0 Buderus 600 - 11R / 19R / 24R is ready for operation

A Burner interval circuit, 10 min. from burner start-up

H Standby activated, Buderus 600 - 11R / 19R / 24R ready to provide heat

L Initial safety period: self-testing of burner-control unit during burner start-up

U Post- or pre-purging period of fan unit

Y Flow temperature over setpoint

-. Buderus 600 - 11R / 19R / 24R running in heating mode

A

Meaning

“Chimney-sweep” mode, flow-temperature controller bypassed, Buderus 600 - 11R / 19R / 24R

heating to previously-entered flow temperature.

H Normal heating mode

Y Service mode

r Reset

Subject to modifications resulting from technical improvements! Boulter Buderus Ltd. • http://www.boulter-buderus.co.uk

Installation and maintenance instructions for wall-mounted condensing gas boiler Buderus 600 - 11R/19R/24R • 05/2004 31

Page 32

Servicing5

5.2 Fault codes

Code Meaning

2C Safety sensor exceeds 95 °C

Possible

cause

1 Resistance in the installation is too high Check if not all (thermostatic) radiator valves are clogged

2 Heating capacity is too large for the installation Adjust the heating capacity (see subsection 2.1.6)

3 Safety sensor is faulty Measure if resistance over the sensor is correct.

4 Problem with the pump or pump cabling (no circulation) Check if the pump cabling is faulty or if the pump is stuck

5 Water pressure is too low in the installation Top up the system

Code Meaning

2F Temperature difference between the safety sensor and flow sensor is greater than or equal to 15 °K

Possible