BTI Wireless DAS1900M40RUS, DAS850M40RUM, DAS1900M20RUAM, DAS700U040RUS, DAS2100A80RUM Users Manual

mBSC-H DAS System

Installation Manual Issue 5

mBSC-H DAS SYSTEM

INSTALLATION AND

OPERATIONS MANUAL

mBSC-H DAS System

ISSUE

NO.

DESCRIPTION

DATE

1

INITIAL DRAFT

OCT. 28, 2009

2

UPDATE SPECIFICATIONS

JAN. 18, 2010

3

UPDATE SPECIFICATIONS, INSTALLATION, AND ILLUSTRATIONS

MAY 31, 2011

4

UPDATE SPECIFICATION, INSTALLATION, MAINTENANCE, AND

ILLUSTRATIONS

FEB 22, 2012

5

UPDATE SPECIFICATION WITH THE LATEST MECHANICAL DESIGN

AUG 31, 2013

6

ADD THE MESSAGE FOR FCC WARING LABEL ON PAGE 6

APR 28, 2014

7

Change the MPE Distance to 6 meters in page 6

JUN 10, 2014

Installation Manual Issue 7

COPYRIGHT

This document serves as the System Installation Manual for the BTI mBSC-H Fiber Distributed Antenna

System (DAS) system. BTI reserves the right to change the contents without prior notice. No part of this

document may be reproduced or utilized. © 2009-2013, BTI, All Rights Reserved

REVISION HISTORY

© 2009-2014, BTI Wireless Page 2

mBSC-H DAS System

Installation Manual Issue 7

Table of Contents

1 GENERAL INFORMATION ...................................................... 6

1.1 SAFETY PRECAUTIONS ............................................................................... 6

1.2 GLOSSARY AND ACRONYMS ...................................................................... 7

2 INTRODUCTION ...................................................................... 8

3 GENERAL DESCRIPTION ...................................................... 8

3.1 SYSTEM COMPONENTS DESCRIPTION ..................................................... 8

3.1.1 Host Unit ................................................................................................... 9

3.1.2 Network Management System ................................................................ 9

3.1.3 Remote Unit ............................................................................................ 11

3.2 USER INTERFACE ....................................................................................... 14

3.2.1 Host Unit Interface ................................................................................. 14

3.2.2 NMS Interface ......................................................................................... 14

3.2.3 Remote Unit Interface .......................................................................... 16

3.3 SPECIFICATIONS ........................................................................................ 18

3.3.1 Host Unit Specifications ........................................................................ 18

3.3.2 NMS Specifications ................................ .............................................. 18

3.3.3 Remote Unit Specification ................................................................... 19

4 INSTALLATION ...................................................................... 20

4.1 SYSTEM INSTALLATION OVERVIEW ........................................................ 20

4.2 REMOTE UNIT INSTALLATION ................................................................. 21

4.2.1 Remote Unit Installation Overview ....................................................... 21

4.2.2 Installation Hardware And Tools ........................................................... 21

4.2.3 Unpacking And Inspection .................................................................... 23

4.2.4 Mechanical Installation .......................................................................... 28

4.2.4.1 Mechanical Safety Precautions ....................................................................................... 28

4.2.4.2 Install The Mounting Panel .............................................................................................. 29

4.2.4.3 Install The Remote Unit On The Mounting Panel ............................................................ 30

4.2.4.4 Install The Shroud Cover ................................................................................................. 30

4.2.5 Electrical Installation ............................................................................. 32

4.2.5.1 Electrical Safety Precautions ........................................................................................... 32

4.2.5.2 Grounding ........................................................................................................................ 33

4.2.5.3 Route the Cables ............................................................................................................. 33

4.2.5.4 Fiber Optic Cable Connection ......................................................................................... 33

4.2.5.5 Antenna Cable Connection .............................................................................................. 34

4.2.5.6 AC Power Cable Connection ........................................................................................... 35

4.2.5.7 Slave Cable Connection .................................................................................................. 36

4.2.6 Remote Unit Installation Review ......................................................... 39

© 2009-2014, BTI Wireless Page 3

mBSC-H DAS System

Installation Manual Issue 7

4.2.6.1 Mechanical Installation Review ....................................................................................... 39

4.2.6.2 Electrical Installation Review ........................................................................................... 39

4.2.6.3 Field Status Test - Remote Unit LED Status Indicators ................................................... 39

4.2.7 Troubleshooting ..................................................................................... 40

4.3 HOST UNIT INSTALLATION ........................................................................ 41

4.3.1 Host Unit Installation Overview ............................................................ 41

4.3.2 Installation Hardware And Tools ........................................................... 41

4.3.3 Unpacking And Inspection .................................................................... 42

4.3.4 Electrical Installation ............................................................................. 43

4.3.4.1 Electrical Safety Precautions ........................................................................................... 43

4.3.4.2 Grounding ........................................................................................................................ 44

4.3.4.3 DC Power Cable Connection ........................................................................................... 48

4.3.4.4 Install the BIU and FIU modules ...................................................................................... 49

4.3.4.5 Alarm Installation ............................................................................................................. 49

4.3.4.6 Connect the BIU/FIU Modules ......................................................................................... 51

4.3.4.7 Optional Equipment Installation ....................................................................................... 52

4.3.4.8 Connect POI to BIU ......................................................................................................... 53

4.3.4.9 Connect the Fiber Optic Cable ........................................................................................ 53

4.3.5 Host Unit Installation Review .............................................................. 53

4.3.5.1 Electrical Installation Review ........................................................................................... 53

4.3.6 Troubleshooting ..................................................................................... 55

4.4 NMS INSTALLATION ................................................................................... 56

4.4.1 Installation Overview ............................................................................. 56

4.4.2 Installation Hardware and Tools ........................................................... 56

4.4.3 Unpacking And Inspection .................................................................... 57

4.4.4 Verify Server software ........................................................................... 57

4.4.5 Initial System Setup ............................................................................... 58

4.4.5.1 CD-ROM Install ................................................................................................................ 58

4.4.5.2 Launch NMS .................................................................................................................... 59

4.4.6 Initial Start-up Configuration ................................................................. 60

4.4.6.1 Modify Default Accounts .................................................................................................. 62

4.4.6.2 Set-up New User Accounts .............................................................................................. 65

4.4.6.3 Configure Software Parameters ...................................................................................... 67

4.4.7 Firmware Update .................................................................................. 68

4.4.8 Software Upgrade Installation ............................................................... 69

4.4.8.1 CD-ROM Install ................................................................................................................ 69

4.4.9 NMS Upgrade Installation Review ....................................................... 70

4.4.10 Troubleshooting ................................................................................... 72

5 mBSC DAS SYSTEM START-UP .......................................... 73

5.1 SYSTEM COMMUNICATION ....................................................................... 73

5.1.1 Establishing a Host Unit communication ............................................ 73

5.2 INITIAL NETWORK CONFIGURATION ....................................................... 76

© 2009-2014, BTI Wireless Page 4

mBSC-H DAS System

Installation Manual Issue 7

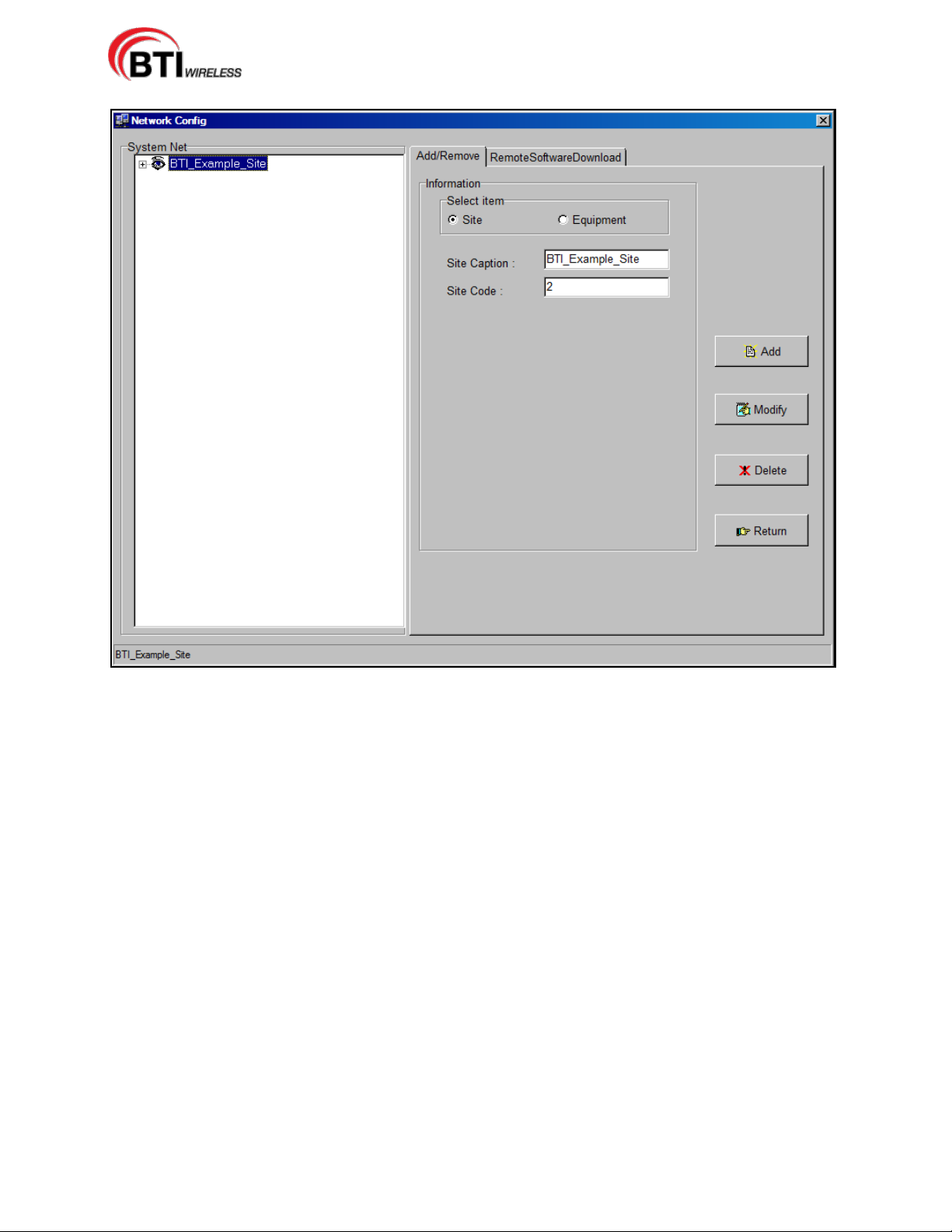

5.2.1 Add a Site ............................................................................................... 78

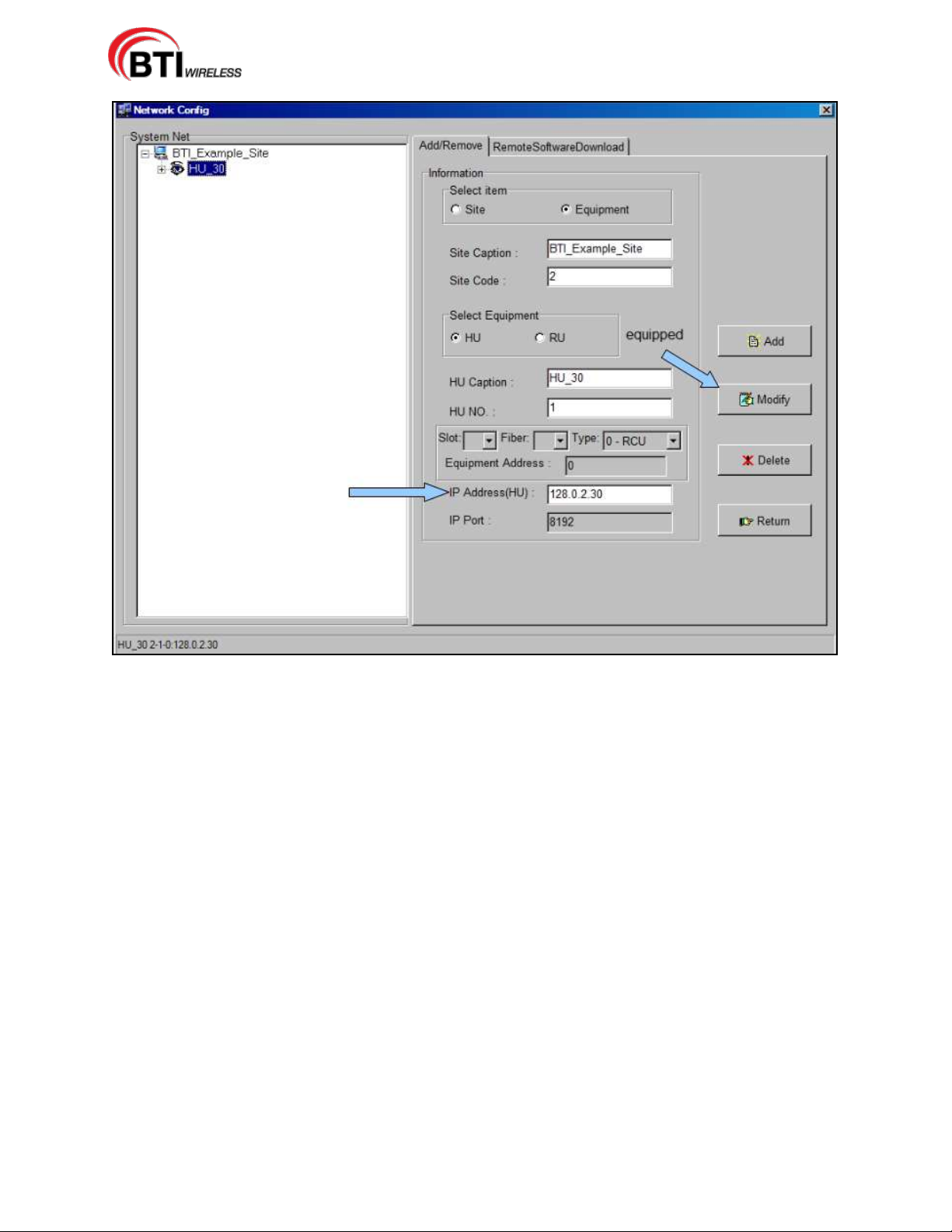

5.2.2 Add a Host Unit ................................ ...................................................... 80

5.2.3 Configuring the Host Unit Hardware Card ........................................... 82

5.2.4 Map the IP Address to the NMS Software ............................................ 86

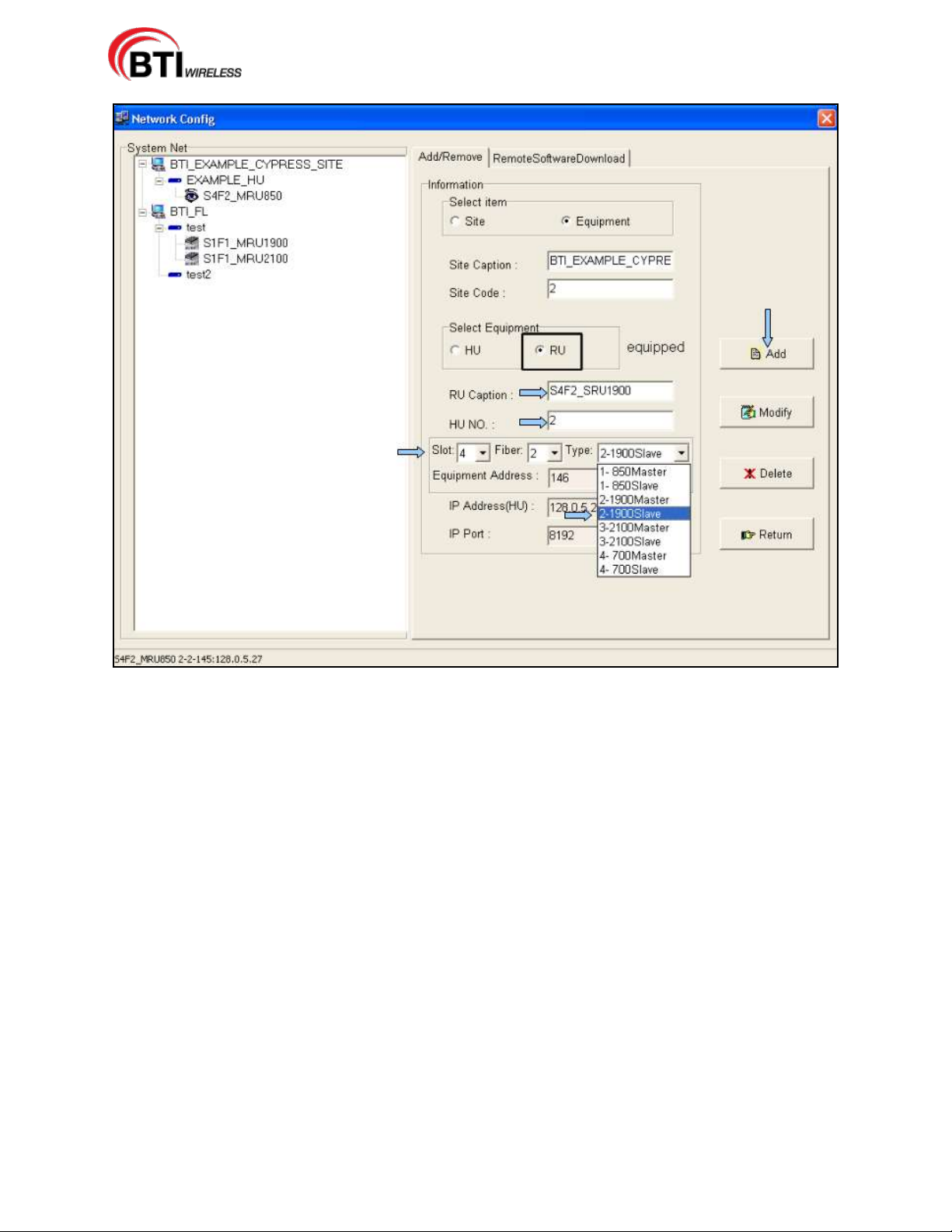

5.2.5 Adding a Master and/or a Slave Remote Unit ...................................... 88

5.2.5.1 Adding a Remote Unit...................................................................................................... 88

5.2.5.2 Modifying or Deleting a Remote Unit ............................................................................... 91

5.2.6 Connect Host Unit to Server ................................................................. 92

5.3 MANAGING AND MONITORING ALARMS ................................................. 92

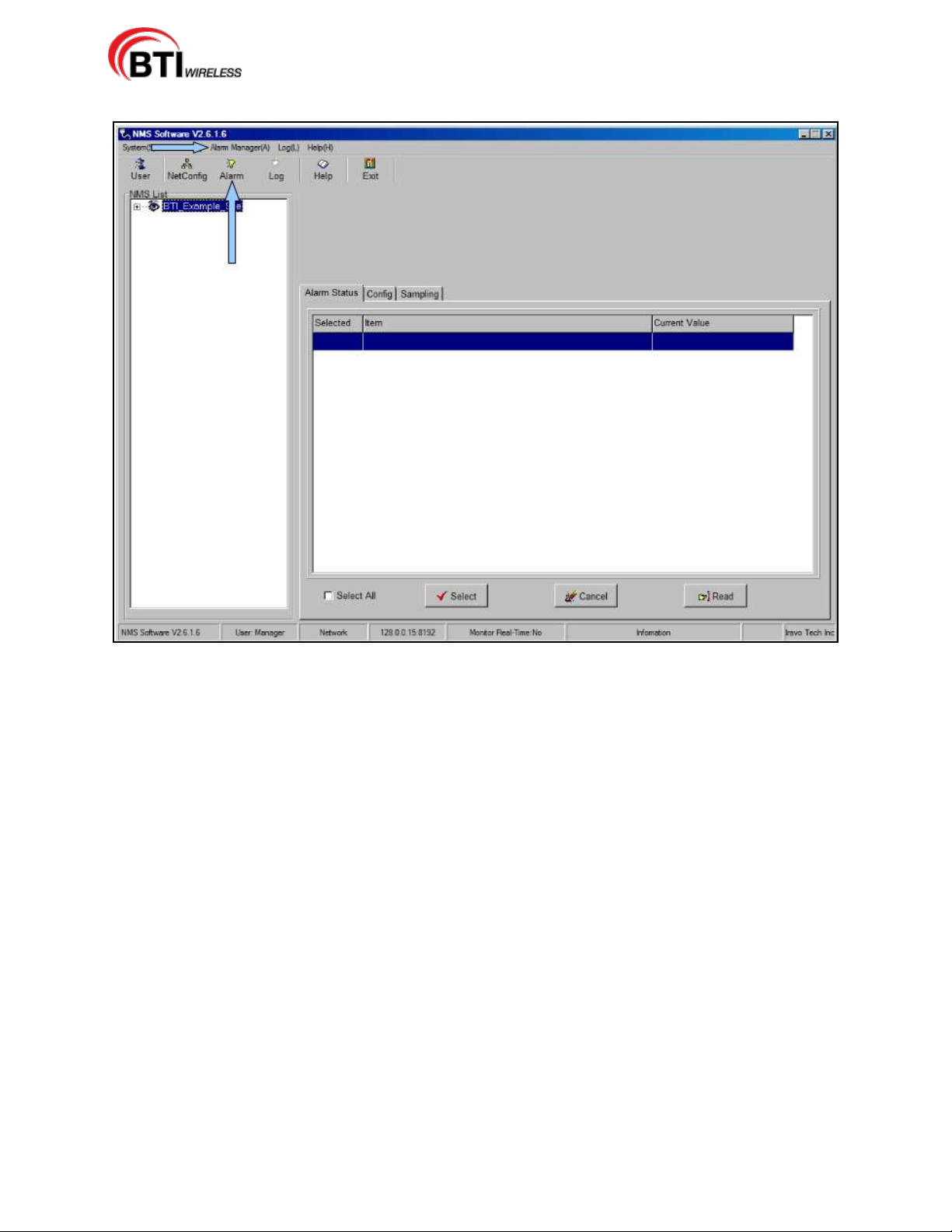

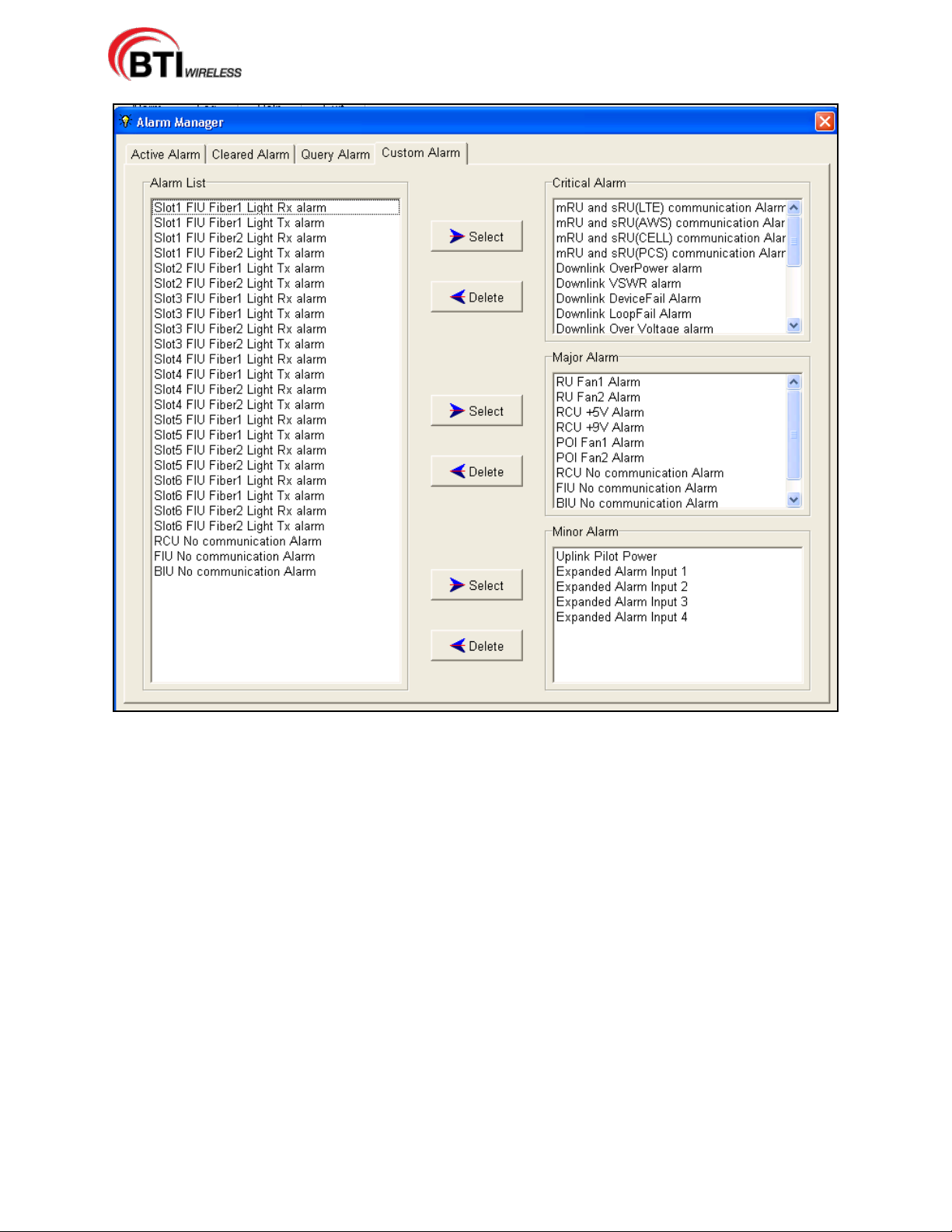

5.3.1 Alarm Manager ....................................................................................... 92

5.3.2 Configuring Standard Alarm Defaults .................................................. 93

5.3.3 System Activation Review ................................................................... 97

5.3.4 Troubleshooting ................................................................................... 98

6 Maintenance .......................................................................... 99

6.1 General ........................................................................................................ 99

6.2 Host Unit ...................................................................................................... 99

6.3 NMS 100

6.4 Remote Units ............................................................................................. 100

6.4.1 Fans....................................................................................................... 100

7 CUSTOMER SERVICE CONTACT INFORMATION ............ 101

© 2009-2014, BTI Wireless Page 5

mBSC-H DAS System

Danger: Danger is used to indicate the presence of a hazard that will cause serious personal

injury, death or substantial property damage if the hazard is not avoided.

Warning: Warning is used to indicate the presence of a hazard that may cause serious

personal injury, possible death or substantial property damage if the hazard is not avoided.

Caution: Caution is used to indicate the presence of a hazard that will or may cause minor

personal injury or substantial property damage if the hazard is not avoided.

Installation Manual Issue 7

1 GENERAL INFORMATION

1.1 SAFETY PRECAUTIONS

1. For general safety, only appropriately qualified personnel familiar with all recommended and

regulatory safety practices and installation methods may be allowed to work on this system.

2. All general and regional safety and installation regulations relating to high voltage installations,

proper use of tools and recommended individual protective equipment must be obeyed.

3. Operating instructions must be kept accessible and available for all users.

4. The network provider is responsible for implementing protective measures to avoid the health

hazards associated with radiation from the Unit antenna(s).

5. Warning: This is NOT a CONSUMER device. It is designed for installation by FCC

LICENSEES and QUALIFIED INSTALLERS. You MUST have an FCC LICENSE or

express consent of an FCC License to operate this device. Unauthorized use may result in

significant forfeiture penalties, including penalties in excess of $100,000 for each continuing

violation. Warning label messages will be also shown in online and point-of-sale marketing

materials and on outside packaging of device

6. For US and Canadian installations: FCC RF exposure compliance requires the

following antenna installation and device operation configurations be satisfied: A

separation distance of at least 6 meters must be maintained between the antenna of this device

and all persons. RF exposure compliance may need to be addressed at the time of licensing, as

required by the responsible FCC Bureau(s), including antenna co-location requirements of

1.1307(b)(3). Maximum permissible antenna gain is 17 dBi.

7. Access should be restricted to appropriately qualified personnel.

8. Operation of this Unit is restricted to the license holders of the respective frequency range.

9. Use of this equipment is only for the purpose specified by the manufacturer. Modifications or

the use of any spare parts which are not provided by or recommended by the manufacturer are

prohibited as this may cause fires, electric shock or other injuries or damage.

10. High temperatures due to power dissipation may occur, do not operate the equipment on or

near combustible materials.

11. Ascertain that the mains supply is disconnected before opening the Unit as well as

connecting or disconnecting the mains connector at the Remote Unit.

12. Observe ESD precautions. Use the available grounding system to connect ESD protection

measures before commencing maintenance work.

© 2009-2014, BTI Wireless Page 6

mBSC-H DAS System

Abbreviation

Description

AISG

Antenna Interface Standard Group

BIU

Base station Interface Unit

BTS

Base Station

CFR

Crest Factor Reduction

CL-OS

Closed-Loop Operating System

DAS

Distributed Antenna System

EDGE

Enhanced Data for GSM Evolution

FIU

Fiber Interface Unit

FIU-S

Fiber Interface Unit - Simulcast

FIU-NS

Fiber Interface Unit - Non-Simulcast

HPA

High Power Amplifier

HU

Host Unit

LMU

Location Measurement Unit

LNA

Low Noise Amplifier

mBSC

Multi-Band Multi-System Multi-Carriers

MIMO

Multi-input multi-output

MTBF

Mean Time Between Failure

NMS

Network Management System

PA

Power Amplifier

PCU

Power Controller Unit

PWM

Pulse Width Modulation

RCU

Remote Control Unit

RF

Radio Frequency

RU

Remote Unit

RX

Receive Signal

TDTD

Time delay TX diversity

TMA

Tower Mounted Amplifier

TX

Transmit Signal

UMTS

Universal Mobile Telecom System

VSWR

Vertical Standing Wave Radio

Installation Manual Issue 7

13. This Unit complies with European standard EN60950.

14. Verify that all regulatory requirements have been met and that all system settings have been set

according to the intended use. (Please see appropriate manufacturer product information

materials.)

15. Grounding the antenna cables close to the antenna connectors of the Remote Unit for

protection against atmospheric discharge is highly suggested, even though the Remote Unit is

internally protected against over-voltage.

16. Class 1 – Laser Radiation warning: Do not look into the beam, view it directly, or

indirectly with or without optical instruments.

1.2 GLOSSARY AND ACRONYMS

The acronyms and abbreviations used in this manual are detailed in the following list.

© 2009-2014, BTI Wireless Page 7

mBSC-H DAS System

Installation Manual Issue 7

2 INTRODUCTION

This document provides the installation procedures for the BTI DAS system consisting of the DAS Host

Unit, Remote Unit equipment and the Network Management System (NMS). It also provides for the initial

configuration set-up, operation procedures and the software upgrade installation process for the Network

Management System.

For Host Unit and Remote Unit installation, the reader should be familiar with the use of Distributed

Antenna Systems, power system distribution for both AC and DC, all safety guidelines and regulations,

and the required tools to accomplish the installation in a safe manner.

For NMS software installation and configuration as well as firmware update and software upgrade

installations, the reader should be familiar with server administration, software install, firmware update, and

software upgrade procedures at the administrator level.

3 GENERAL DESCRIPTION

Figure 3-1. BTI DAS System

The system consists of an Indoor HU (Host Unit) and an Outdoor RU (Remote Unit) and Network

Management Software.

3.1 SYSTEM COMPONENTS DESCRIPTION

The Host Unit is designed to be mounted in a 19” rack and should only be utilized in an indoor environment

(0C - 45C) or in a place were an indoor-type environment can be provided.

The NMS (Network Management System) runs on a centralized server that provides access to the entire

network of hub sites and Remote nodes. The NMS is designed to configure, monitor, and manage all

system functionality.

© 2009-2014, BTI Wireless Page 8

mBSC-H DAS System

Installation Manual Issue 7

The Remote Units may consist of combinations of 700MHz, 850MHz, 1900MHz and 2100MHz frequencies

and are available in 20 Watt, 40 Watt or 80 Watt output configurations. Each RU is designed to support a

Single Frequency Band. For multi-frequency use, the system can be configured as multiple Master/Slave

Remote Units. Each Master Unit can support a maximum of two slave RUs with a maximum of three RUs

supported per fiber connection. The primary transport between the HU and the RU is fiber optic. The Fiber

Optic also provides the RU alarms and configuration communication between the NMS and the Remote Unit.

The downlink and uplink optical signals are duplexed so only one fiber is required.

3.1.1 Host Unit

The Host Unit provides a multiple slot assembly, consisting of 9 slots numbered from left to right: 1 through

9. Slots 7 through 9 are used and specifically keyed for the Remote Control Unit (RCU) and two

redundant Power Supply Units (PSU) only. The Host Unit also houses the Base Station Interface Units

(BIU) and Fiber Interface Units (FIU), Figure 3-2. The BIU comes in Diversity (BIU-D) and Non-Diversity

(BIU-ND) and the FIU comes in Simulcast (FIU-S) and Non-Simulcast (FIU-NS) modules. The HU allows

multiple combinations of BIU and FIU modules with up to 3 band downlink and uplink RF signals per BIU

from the BTS and converts them to analog over RF for fiber transport.

The Host Unit, through interface combinations, provides the following functions:

Converts the BTS RF signal to fiber signal.

Supplies connectivity between the BTS and the Remote Unit.

Manages and monitors the system alarms and configurations.

Supports 1 to 3 Sectors system configurations.

Supports a single sector with 1:1, 2:1, 3:1 and 4:1 Simulcast configuration.

Supplies fiber connectivity to the Remote Unit with in-band message signaling.

Figure 3-2. Host Unit Multiple-Slot Assembly

3.1.2 Network Management System

The Network Management System (NMS), shown in Figure 3-3, is a software-based Network

Management System tool that provides control and monitoring functions for the BTI mBSC DAS system.

NMS is used to provision and configure a new system for operation, set the system operating parameters,

get system alarms and status messages, and update the system firmware.

The Network Management System provides the following functions:

Manages SNMP v2 messaging to the Network Operating Center (NOC).

Provides a detailed graphic User Interface to manage, monitor and configure multiple DAS

system.

Configure multiple DAS systems custom alarms.

Provides a firmware update interface.

© 2009-2014, BTI Wireless Page 9

mBSC-H DAS System

Installation Manual Issue 7

Figure 3-3. Network Management System Software Components Folder and Desktop Icon

3.1.3 Remote Unit

The Single-Band Master Remote Unit, shown in Figure 3-4a, 3-4b, 3-4c and 3-4d, consists of an optical

module (O/E), a downlink power amplifier, an LNA, and duplexer. The Optical module converts the

downlink optical signal from the FIU module in the HU and splits the RF signal into 3 RUs. It also converts

the uplink RF signal to an optical signal and simultaneously sends it to the FIU module in the HU for

distribution to the BIU modules. Each optical module can support 3 RUs in any combination of different

bands.

The Single-Band Master Remote Unit provides the following functions:

Converts the forward optic signal to RF signal.

Boosts the forward RF signal from the HU to a higher power level (max output: 80W).

Amplifies the uplink signal from the antenna to improve the system receive sensitivity.

Supplies in-band messaging between the HU and RU for RU Alarms and configuration.

The Remote Unit has been designed for minimal maintenance. Maintenance recommendations include a

once yearly inspection and cleaning, if needed. A fan alarm will be generated should the fan current drop

below one third of its required current.

© 2009-2014, BTI Wireless Page 10

mBSC-H DAS System

Installation Manual Issue 7

Figure 3-4a. 20 Watt and 40 Watt Fan Cooled Remote Unit

Figure 3-4b. 80 Watt Fan Cooled Remote Unit

© 2009-2014, BTI Wireless Page 11

mBSC-H DAS System

Module Name

Port Name

Description

Remark

FIU-S/FIU-NS

TX1, TX2

Downlink interface ports to be

connected to BIU output

RF signal

RX1, RX2

Uplink interface ports to be

connected to BIU input

RF signal

Fiber 1, Fiber 2

Fiber optic interface ports to be

connected to the RU

Optical signal

E9111, E9111-2

The RX coupling uplink signal for

LMU (TDOA location only)

RF signal

E9111, E9111-2

The RX coupling uplink signal for

LMU (TDOA Location only)

RF signal

E9111, E9111-2

The RX coupling uplink signal for

LMU (TDOA Location only)

RF signal

BIU-ND/BIU-D

TX1, TX2, TX3, TX4

Input signals from the BTS to

provide the combined downlink

signal to FIUs

RF signal

RX1, RX2, RX3, RX4

The combined uplink signal from

FIUs

RF signal

TX1 and TX2 out

Downlink RF interface to FIU

RF signal

RX1, RX2, RX3, and

RX4 out

Uplink RF interface from the FIU

RF signal

Installation Manual Issue 7

3.2 USER INTERFACE

The user interface for each segment of the mBSC DAS System is designed to provide the most efficient

interaction, installation and ease of use for the user.

3.2.1 Host Unit Interface

Each interface module of the Host Unit, shown in Figure 3-5, is described in Table 3-1 below.

Figure 3-5. Host Unit Interface

Table 3-1. Host Unit User Interface

3.2.2 NMS Interface

A simple login access, Figure 3-6, allows for quick access. A graphical user interface, Figure 3-7, provides

real time user access to the configuration, performance monitoring, and alarm status. The system also

© 2009-2014, BTI Wireless Page 12

mBSC-H DAS System

Installation Manual Issue 7

uses SNMPv2.0 protocol to transmit automated traps to the operator's Network Operations Center for

remote alarming and system queries. These two capabilities provide for centralized configuration and

alarm monitoring of the entire system.

Operational parameters, such as uplink and downlink, and gain can be set through the NMS server. Status

information at each node is easily available. The customer can readily access power output, ALC status,

VSWR, PA temperature, and other basic operating parameters, The BTI NMS simplifies the configuration

of the network by providing accurate downlink power and uplink gain updates. This allows the system

operator to maximize the efficient use of field personnel when diagnosing system performance issues.

Figure 3-6. NMS Login Interface

© 2009-2014, BTI Wireless Page 13

mBSC-H DAS System

Menu

Parameter Name

Default Value

System Parameter

SNMP

No

User

Manager

Name: Manager; Password: 1; Level: Supervisor

User

User

Name: User; Password: 1; Level: Observer

Installation Manual Issue 7

Figure 3-7. NMS Command Console

Table 3-2. Default Parameter Values

3.2.3 Remote Unit Interface

The interface of the Remote Unit consists of connectors and LEDs that are located on the bottom of the

RU enclosure. The Master RU user interface points are indicated in Figure 3-8 and Table 3-3. The Slave

RU user interface points are indicated in Figure 3-9 and Table 3-4.

Remote Units are classified as either MASTER or SLAVE. Master and Slave Units have exactly the same

mechanical dimensions. Functionality is the main difference as the MASTER Remote Unit has the

connection for the fiber optic cable. For supporting multiple bands, only the MASTER Remote Unit needs

to have the fiber optic connection with the Host Unit. Other Remote Units are interfaced with SLAVE ports

for receiving RF downlink signal and sending RF uplink signal with the Master Remote Unit.

MASTER Remote Unit:

Has the Fiber Optic Cable connection with the Host Unit

Provides the RF downlink signal to the SLAVE Remote Unit through “TX_IN” or “TX_OUT” port.

Receives the RF uplink signal from the SLAVE Remote Unit “RF_IN” or “RF_OUT” port.

© 2009-2014, BTI Wireless Page 14

SLAVE Remote Unit:

Label Name

Description

ANT

Interface port for Antenna Feed line

OPERATE

LED indicator for normal or critical fault status of the RU.

Normal: Green ON, Critical fault: Red ON

TX_Out

RF output port to provide the input signal to the Slave Remote Unit when Dual or

Triple Band application is configured.

RX_In

RF input port to provide the output signal to the Master Remote Unit when Dual

or Triple Band application is configured.

FIBER

Fiber Optic Cable interface port for combined downlink and uplink signal

POWER

Interface port for the AC 110/220V power cable

DC_FAN

Provides power to the fan

VENT

Port for the balance of pressure inside and outside of the enclosure

Label Name

Description

ANT

Interface port for Antenna Feed line

OPERATE

LED indicator for normal or critical fault status of the RU.

Normal: Green ON, Critical fault: Red ON

No Fiber Optic Cable connection with the Host Unit

Interfaces with the Master Unit for downlink and uplink signal

Unused ports (TX_OUT, RX_IN) are blocked with a cover.

mBSC-H DAS System

Installation Manual Issue 7

Figure 3-8. User Interface of MASTER Remote Unit

Table -3-3. Master Remote Unit User Interface

Figure 3-9. User Interface of SLAVE Remote Unit

Table -3-4. Slave Remote Unit User Interface

© 2009-2014, BTI Wireless Page 15

mBSC-H DAS System

TX_Out (Slave 1)

RF output port to provide the input signal to the Slave Remote Unit when Dual or

Triple Band application is configured

RX_In (Slave 2)

RF input port to provide the output signal to the Master Remote Unit when Dual

or Triple Band application is configured.

POWER

Interface port for the AC 110/220V power cable

DC_FAN

Provides power to fan

VENT

Port for the balance of pressure inside and outside of the enclosure

Host Unit Specification

Description

Notes

System

Support Multi-Frequency bands with Multi-Air Interface

standards

(GSM / EDGE / CDMA / WCDMA / AWS / LTE)

Max No. of Plug-in

module

• 3 fixed slots for two (PSU) and a single (RCU)

• 6 module slots for BIU and FIU

PSU (Power Supply

Unit)

• -48Vdc and optional AC 110/220 DC converter

• 2 PSU are installed for redundancy

RCU (Remote

Controller Unit)

Main process board for DAS system

BIU (Base station

Interface Unit)

• Support multi-frequency bands DL and UL interface

• Support RX Diversity

• QMA connector for RF Interface

• Support 4 downlink and uplink interface ports

FIU (Fiber Interface

Unit)

• Support 2 Fiber ports per FIU

• Support Non-Simulcast or Simulcast

NMS Specification

Specification

Notes

Max No. of Nodes

1080

A combination of BIU, FIU and Remote Units

SNMP based management

Yes

Real time alarm display

Yes

Display various system level

values

Yes

Voltages, RF power, etc.

Remote firmware download

Yes

Firmware update interface for DAS components.

Server

Specification

Specification

Notes

Processor

One Quad-core Intel® Xeon® 3400 series processor

Installation Manual Issue 7

3.3 SPECIFICATIONS

3.3.1 Host Unit Specifications

The specifications for the Host Unit of the mBSC DAS system are listed in Table 3-5:

Table 3-5. Host Unit Specifications

3.3.2 NMS Specifications

The specifications for the Network Management System (NMS) of the mBSC system are listed in Table

3-6.

Table 3-6. NMS Specifications

The NMS also requires a dedicated server to connect to the RCU. The Server specifications are

Table 3-7. Server Specifications

© 2009-2014, BTI Wireless Page 16

mBSC-H DAS System

Server

Specification

Specification

Notes

Operating

System

Microsoft® Windows® XP Professional

Memory

4GB (4 DIMM slots) DDR3

Storage

Cabled Hard Drive Options:

2.5" SATA SSD, SAS (10K), nearline SAS (7.2K)

Maximum Internal Storage:

250G

Power

Single cabled power supply (250W)

Video Card

Matrox G200eW w/ 8MB memory

Network

Controller

One dual-port Broadcom BCM 5716

System Specification

Downlink

Uplink

Optic Wavelength

1310/1550nm

Antenna Port

7/16 DIN female

Optical connector

E2000

Power Supply

AC 110V / 220V ± 20%

Current

< 1A @ Full power, ~220V AC input

< 2A @ Full power, ~110V AC input

Weight

varies per type

Waterproof

IP65

Installation Manual Issue 7

3.3.3 Remote Unit Specification

The specifications for the Remote Unit of the mBSC system are listed in Table 3-8.

Table 3-8. Remote Unit Specifications

© 2009-2014, BTI Wireless Page 17

mBSC-H DAS System

Installation Manual Issue 7

4 INSTALLATION

4.1 SYSTEM INSTALLATION OVERVIEW

This section provides instructions for installing the mBSC DAS system in an efficient, productive and

customer friendly order. Each component of the mBSC DAS system is covered in its own installation

section as follows:

4.2.REMOTE UNIT INSTALLATION

The Remote Unit installation section provides instructions for the mechanical and electrical installation of

the mBSC Remote Unit including: mounting the Remote Unit, connecting the fiber optics cables; Antenna

feed line; and AC power cables.

The procedures in this section assume that the required Fiber Optic cables have been routed between the

Host Unit and the Single-Band RU and that the required antenna has been installed.

4.3.HOST UNIT INSTALLATION

The Host Unit installation section provides instructions for the electrical installation of the mBSC Host Unit

including verifying the DC power cable connection, connecting the network cable, the alarm connectors,

and other required connections and cables.

The procedures in this section assume that the Host Unit has been inspected, the Remote Unit(s)

installation is complete and that a dedicated IP address for the Host Unit has been designated.

4.4.NMS INSTALLATION

The Network Management System (NMS) installation section provides instructions for setting up the

pre-installed software component of the mBSC NMS. The instructions will allow a qualified user to install

the NMS software, set-up accounts, change passwords for security, and upgrade the system software and

hardware.

The procedures in this section assume that the NMS server has been received, the Host Unit is installed,

and that security software has been installed on the designated NMS computer(s).

© 2009-2014, BTI Wireless Page 18

mBSC-H DAS System

Danger: Wet conditions increase the potential for receiving an electrical shock when

installing or using electrical power equipment. To avoid electrical shock, never install or use

the electrical equipment in a wet location.

Danger: Do not look into the end of the fiber optic cables. Exposure to laser radiation may

result. Do not assume that the laser power is turned off or that the fiber optic cable is

disconnected at the other end.

Danger: Use extreme caution when working with high voltage AC power. Ensure all power is

disconnected before working on power circuit.

Caution: Always make sure there is sufficient cable length to permit the routing of the fiber

optic cables to prevent the cable damage. The optic cables may be damaged if bent or coiled

too tightly.

Step

Operation Type

Operation Action

1

MECHANICAL

INSTALL THE RU MOUNTING PANEL TO THE TOWER

2

MECHANICAL

VERIFY THAT THE SIDE MOUNTING BRACKETS ARE

SECURELY ATTACHED TO THE REMOTE UNIT

3

MECHANICAL

INSTALL THE MASTER REMOTE UNIT ON THE MOUNTING

PANEL

4

MECHANICAL

MOUNT THE SHROUD COVER OVER THE ENCLOSURE AND

SECURE IT

5

INSTALLATION

REVIEW

CONFIRM THE MECHANICAL INSTALLATION USING TABLE 4-4

MECHANICAL INSTALLATION CHECKLIST

6

ELECTRICAL

GROUND THE UNIT

7

ELECTRICAL

ROUTE THE CABLES TO BE CONNECTED

8

ELECTRICAL

CONNECT THE FIBER OPTIC CABLES

9

ELECTRICAL

CONNECT THE ANTENNA FEED LINE

10

ELECTRICAL

INSTALL THE AC POWER CABLE

11

ELECTRICAL

CONNECT ANY SLAVE REMOTE UNIT TO THE MASTER

REMOTE UNIT

12

INSTALLATION

REVIEW

CONFIRM THE ELECTRICAL INSTALLATION USING TABLE 4-5

ELECTRICAL INSTALLATION CHECKLIST

13

FIELD STATUS TEST

CHECK THE REMOTE UNIT LED STATUS INDICATORS USING

TABLE 4-6 RU LED STATUS INDICATOR AND THE

TROUBLESHOOTING GUIDE

4.2 REMOTE UNIT INSTALLATION

4.2.1 Remote Unit Installation Overview

Installation Manual Issue 7

The installation of the Remote Unit, both single enclosure and multi-enclosure, consists of the following

steps:

Table 4-1. Remote Unit Installation Overview

4.2.2 Installation Hardware And Tools

The Remote Units are shipped with the standard mounting hardware required for a BTI pole-mount

© 2009-2014, BTI Wireless Page 19

mBSC-H DAS System

Hardware and Fasteners

Quantity

Rec'd

MOUNTING PANEL

(Configurable)

1

I-BEAM or U-BEAM/CHANNEL

MOUNTING BRACKETS

2

SHROUD COVER 1

M5 SCREW

8

M5 LOCK WASHER 8

M5 FLAT WASHER 8

M6 SCREW

8

M6 LOCK WASHER 8

M6 FLAT WASHER 8

M8 SCREW

8

M8 LOCK WASHER 8

M8 FLAT WASHER 8

M12 SCREW

4

M12 LOCK WASHER 4

M12 FLAT WASHER 4

JUNCTION BOX 1

RF CABLE (Designated Slave Unit)

2

FIBER OPTIC COWL 1

POWER CABLE (10 FEET)

1

FAN CONNECTOR (OPTIONAL)

1

Type

Screws

Hex Nuts

Spacers

Spring/Lock Washers

Spacers

Flat Washers

Thread

M5

M8

M12

M5

M8

M12

M5

M8

M12

Specified

Torques

(lb. - ft.)

2

12

40 2 12

40 2 12

40

Installation Manual Issue 7

installation. Table 4-2 lists the mounting hardware provided by the manufacturer for a standard BTI pole

mount installation kit. Additional hardware may be needed, depending on the site requirements, and may

be ordered through Customer Service (Section 6).

Table 4-2. Single-Band RU Mounting Hardware and Fasteners

for a standard BTI pole mount installation kit

The following is a list of tools and any additional materials required for mounting every Single-Band

Remote Unit configuration:

DIN male connectors

Tool kit for attaching DIN connectors to coaxial cable

Tools for installing exterior AC circuit

Tools for securing M5 screw

© 2009-2014, BTI Wireless Page 20

Table 4-3. Specified Hardware Torque

mBSC-H DAS System

Installation Manual Issue 7

Wire cutters

Wire Stripper

Open End Wrench 1.25 inch/33mm (used for DIN connector)

Hex Wrench 5mm (M6 screw)

SAE Wrench 5/16 inch/8mm (the Slave Remote Unit connectors)

4.2.3 Unpacking And Inspection

This section provides the instruction for receiving the equipment shipment, verifying all parts have been

received and checking that no damage has occurred during transportation. The Remote Unit includes the

following items:

Remote Unit(s)

Hardware and Fasteners described in Table 4-2, Section 4.2.2

Use the following procedure to unpack and inspect the Remote Unit and accessories:

1. Open the shipping container, Figure 4-1 and carefully remove any accessories from the protective

packing material, Figure 4-2.

Figure 4-1. Open the Shipping Container Figure 4-2. Remove Accessories

2. Remove the Shroud from the Remote Units(s), Figure 4-3.

Figure 4-3. Remove the Shroud

© 2009-2014, BTI Wireless Page 21

mBSC-H DAS System

Installation Manual Issue 7

3. Begin removing the Remote Unit(s) from the Mounting Panel by unscrewing the two (2) M8 fasteners

at the bottom bracket Interface end of the Remote Unit(s), Figure 4-4.

Figure 4-4. Remove the two M8 Fasteners

4. Remove the single (1) M8 fastener from the top bracket Fan end of the Remote Units and then remove

the two (2) M5 fasteners from the metal shipping bracket and discard the metal shipping bracket,

Figure 4-5.

Figure 4-5. Remove the M8 Fastener and the two M5 Fasteners

5. Remove the Remote Unit(s) from the shipping crate.

6. Unpack the Mounting Panel from the crate.

© 2009-2014, BTI Wireless Page 22

mBSC-H DAS System

Installation Manual Issue 7

7. Verify receipt of hardware and fasteners using Table 4-2

8. Check each Remote Unit and accessories for broken or missing parts. If there is any damage or

missing parts, contact BTI (Section 6) for an RMA and to reorder parts, if any replacement parts are

required.

NOTE: Check particularly for any damage to the power connection, the fins/fans,

and the fiber optic cable connection on the Remote Unit Interface.

© 2009-2014, BTI Wireless Page 23

mBSC-H DAS System

Installation Manual Issue 7

4.2.4 Mechanical Installation

4.2.4.1 Mechanical Safety Precautions

Please read the general Safety Precautions contained in Section 1.2 Safety Precautions

1. Follow the procedures provided by the manufacturer when installing the Remote Unit. Do not

install the Unit in a place or in a manner that does not meet the manufacturer's provided

specifications.

2. Use the mounting hardware supplied by the manufacturer. If non-standard mounting hardware

is used, it must meet the requirements for mounting the Unit as specified by the manufacturer.

NOTE: It is important that specified load limits for the Unit are not exceeded as this may

void the warranty.

3. Safety measures for lifting heavy materials should be followed to prevent injury.

4. High temperatures may occur due to power dissipation. Please follow the specifications for

proper Remote Unit ventilation as indicated by the manufacturer.

5. Check that the mains supply is disconnected, before connecting or disconnecting the main

power connector at the Remote Unit.

6. Do not block airflow ventilation outlets during installation or Remote Unit(s) may sustain

critical damage.

© 2009-2014, BTI Wireless Page 24

mBSC-H DAS System

Installation Manual Issue 7

4.2.4.2 Install The Mounting Panel

Use the following procedure to install the mounting panel on the pole:

1. Take one M12 screw and insert it loosely in one of the two top holes in the panel. Place the mounting

panel against the pole as shown in Figure 4-6.

2. Place one of the two I-Beam or U-Beam brackets on the back side of the pole so that it aligns with the

M12 screw.

3. Hand tighten the screw to hold it in place

4. Place the second M12 screw in the next hole at the top of the panel and loosely fasten the screw as

well. Continue until all four screws are in place as shown in Figure 4-7.

5. Use a wrench to securely fasten the screws through both panel and brackets until the panel is securely

attached to the pole.

Figure 4-6. Attach the Mounting Panel and Bracket to a Pole

© 2009-2014, BTI Wireless Page 25

mBSC-H DAS System

Installation Manual Issue 7

Figure 4-7. The Mounting Panel secured tightly to a Pole

4.2.4.3 Install The Remote Unit On The Mounting Panel

Use the following procedure to install the RU on the mounting Panel.

1. Verify that the attached side mounting brackets, as shown in Figure 4-8 are secure.

2. Grasp the Remote Unit at the top and bottom of the casing and carefully slide the top two hooks onto

the mounting panel, Figure 4-9, followed by the lower hooks and allow the Unit to slide down into place.

3. After hanging the enclosure on the mounting panel, use the M8 screws, lock and flat washers to secure

the rear mounting bracket (top and bottom) so the RU does not move.

Figure 4-8. The Side Mounting Bracket to the Mounting Panel

© 2009-2014, BTI Wireless Page 26

mBSC-H DAS System

Installation Manual Issue 7

Figure 4-9. Secure Enclosure To the Side Mounting Bracket

4.2.4.4 Install The Shroud Cover

The Remote Unit has a Shroud cover for thermal protection.

Use the following procedure to install the Shroud cover on the enclosure:

1. Line up the slots at the top of the Shroud cover to the tabs at the top of the mounting panel as shown in

Figure 4-10.

2. Gently lower the slots over the tabs and slide the cover down. The cover will be at an angle, Figure

4-11.

3. Lay the cover flush against the mounting bracket, then carefully, place the M5 screw through the middle

hole, aligning it to the hole on the bracket. Loosely fasten the screw. Working on the opposite side,

again place an M5 screw through the middle hole and loosely fasten the screw.

4. Loosely fasten the remaining M5 screws to all four corners of the cover and then tighten all the screws

securely.

© 2009-2014, BTI Wireless Page 27

mBSC-H DAS System

Installation Manual Issue 7

Figure 4-10. Install the Shroud Cover to the RU

Figure 4-11. Secure Shroud Cover to the mounting panel

© 2009-2014, BTI Wireless Page 28

mBSC-H DAS System

Installation Manual Issue 7

4.2.5 Electrical Installation

4.2.5.1 Electrical Safety Precautions

Please read the general Safety Precautions presented in Section 1.2 Safety Precautions

1. This Unit uses high voltages. Follow the instructions for installation provided in this

manual to prevent serious accidents including loss of life, severe personal injury or

extensive property damage.

2. The Unit must be grounded before connecting any power supply. Grounding is a

required precautionary measure. Grounding instructions are provided and should be

followed for safety.

3. The Unit is internally protected against over-voltage, but in areas with strong and frequent

lightning strikes additional lightning protection is strongly recommended. Grounding the

antenna cables close to the antenna connectors will help prevent damage from atmospheric

discharge.

4. Verify that there is a suitable circuit breaker and an over-current limiting device connected

between the mains and the Remote Unit.

5. Check that the mains supply is disconnected, before connecting or disconnecting the main

power connector at the Remote Unit.

6. An easily reached emergency disconnect device should be provided in the mains circuit if the

power feeds to the Remote Unit(s) are not within close reach.

7. The Remote Unit should be installed in close proximity to a power source with a circuit

breaker to ensure safe installation and for ease of power connectivity.

8. Electrical and electronic components can be destroyed by incorrectly wired connections.

9. Cable connector materials must meet manufacturer specifications to avoid corrosion at the

connectors.

10. Check cable connections to ensure that water cannot penetrate the Unit.

11. Caution should be used when attaching the antenna. Hand tightening should be sufficient for

connecting the antenna during installation. Manufacturer's recommendation for torque

specification should be used during installation. Use the appropriate tool to complete the

Antenna installation, but do not use tools, such as pliers, as they may cause damage to the

Remote Unit.

12. A voltage limiting device is strongly recommended for electrical networks that often produce

spikes.

13. Compliance with the surge requirement of EN 61000-4-5 (fine protection) has been met by this

Unit. Installing additional external surge protection, depending on the individual application,

via local supply connection and/or coarse protection is recommended to avoid damage

caused by electrical surges.

© 2009-2014, BTI Wireless Page 29

mBSC-H DAS System

4.2.5.2 Grounding

The Unit must be grounded and the integrity of the protective earth must be ensured. Connect an

earth-bonding cable to the provided grounding connection on the equipment. Do not connect any

additional external devices to the grounding connection.

Installation Manual Issue 7

Figure 4-12. Grounding Connection

1. Uncover the RU interface by removing the Vandalism Protective Shield from the bottom of the Shroud

Cover.

2. Loosen the hex nut located on the grounding connection as shown in Figure 4-12.

3. Connect the earth-bonding cable between the two lock and flat washers.

4. Tighten the hex nut, making sure the cable is securely connected before moving to the next phase of

the installation.

4.2.5.3 Route the Cables

Prepare and route all cables according to standard field installation procedures.

The mains cable and mains plug is used as a disconnect device. For PLUGGABLE EQUIPMENT, the

socket-outlet shall be installed near the equipment and shall be easily accessible.

Care should be taken to prevent wear or field damage to cables during install. Particular attention should

be paid to the Fiber Optics Cable as damage may occur if cable is tightly coiled or bent.

The remote unit is connected to a external antenna or dish, and the antenna ports (mounted on the

rear side of the EUT) is considered a Cable Distribution System circuit (CDS). Circuits for connection to the

CDS are classified as TNV-1.

4.2.5.4 Fiber Optic Cable Connection

One fiber optic cable must be routed from an external splice enclosure or fiber access terminal to the

Master Remote Unit enclosure. The RU is equipped so only one cable is required per Master Remote Unit

for the optic port. A hardened optical E2000 connector is used for the optic port.

© 2009-2014, BTI Wireless Page 30

mBSC-H DAS System

Warning: Do not look into the end of the fiber optic cable. Do not look directly into the optical

transmitter of any Unit or exposure to laser radiation may result. An optical power meter

should be used to check the active fibers.

Installation Manual Issue 7

Use the following procedure to connect the fiber optic cable:

1. Connect or splice the drop Fiber cable to the outside plant cable. Verify that there is sufficient cable

length to reach from the splice enclosure or fiber access terminal (not provided) to the bottom of the

Master Remote Unit

2. Route the free end of the drop cable to the enclosure through the junction box as shown in Figure 4-13.

3. Leave sufficient slack to allow the cable to be connected and disconnected from the enclosure fiber

optic port without bending or crimping the fiber optic cable.

4. Remove the cap from the interface port labeled "FIBER". Connect the fiber optic cable to the port on the

bottom of the enclosure.

Figure 4-13. Junction Box

4.2.5.5 Antenna Cable Connection

The antenna feed line(s) must be routed from the antenna to each Remote Unit. The cable must have the

appropriate antenna connector termination to connect to the RU antenna port (ANT), shown in Figure

4-14.

Figure 4-14. Antenna port

Use the following procedure to install the antenna cable:

© 2009-2014, BTI Wireless Page 31

mBSC-H DAS System

Danger: Use extreme caution when working with high voltage AC power. Ensure all power is

disconnected before working on power circuit.

Warning: Verify that the Unit has been ground with an earth-bonding cable to the grounding

connector.

Installation Manual Issue 7

NOTE: When using multiple RU enclosures to support more than one RF band,

each RU is supporting a different frequency. When routing the coaxial antenna

cable, it is critical that the appropriate frequency band cable be connected to the

same frequency type RU.

1. Remove the dust cap from the DIN female connector located on the bottom of the enclosure. The port

is labeled with “ANT”.

2. Route the coaxial antenna cables from the antenna to the bottom of the enclosures.

3. Cut the antenna cable to the required length and terminate with the appropriate connector.

4. Connect the antenna cable to the antenna port labeled with “ANT”, Figure 4-15.

Figure 4-15. DIN Female Connector

4.2.5.6 AC Power Cable Connection

Use the following procedure to install the AC Power cable:

1. Route the power cable between the AC power port, located on the bottom of the enclosure and the

nearest AC power junction box as shown Figure 4-16.

© 2009-2014, BTI Wireless Page 32

mBSC-H DAS System

Danger: To avoid serious personal injury and equipment damage, always turn the AC power

off on the circuit breaker before connecting the any power cable to the AC power port.

Installation Manual Issue 7

Figure 4-16. Junction Box AC Power Cable Routing

2. Secure the cable between the AC power port and the AC power junction box. Leave sufficient slack in

the cable to allow it to be easily connected and disconnected from the AC power port.

3. Install any AC power supply wires that may be required between the AC junction box and the AC circuit

breaker box.

4. At the AC circuit breaker box, connect the AC power supply load wire to the circuit breaker.

5. Place the circuit breaker in the ON position and then test the connected end of the AC power cable for

proper voltage levels and correct polarity.

6. When testing is complete, PLACE THE CIRCUIT BREAKER IN THE OFF POSITION.

7. Connect the power cable connector to the AC power port labeled “POWER”.

8. Tighten the coupling nut.

4.2.5.7 Slave Cable Connection

When two RU or more enclosures are installed for supporting multi-band. One is designated the Master

Remote Unit and each additional RU, up to two Units, are designated as slave Remote Units. The Master

and slave Unit(s) is specified by the frequency band. The Master Unit will separate the bi-directional signal

related to the frequency and provide the RF input signal to each slave Remote Unit. The connection

between Master and Slave is interfaced with the RF cable provided with the Remote Units.

Use the following procedure to install the antenna cable:

All designated slave RUs arrive with two RF cables.

Connect one RF cable to the port labeled “TX_OUT” on the MASTER Remote Unit User Interface.

© 2009-2014, BTI Wireless Page 33

mBSC-H DAS System

Installation Manual Issue 7

Connect the other end of the RF cable to the port labeled “TX_IN” on the SLAVE Remote Unit User

Interface as shown in Figure 4-17.

Connect the second cable to the port labeled "RX_IN" on the MASTER RU.

Connect the other end of the second RF cable to the port labeled "RX_OUT on the SLAVE RU.

Figure 4-17. RF cable connection between Master and Slave Remote Unit

1 Slave to Slave Connection: Connect an RF cable into the port labeled "TX_OUT" on the first SLAVE

RU User interface.

2 Connect the other end of the RF cable to the port labeled "TX_IN" on the next SLAVE RU Unit.

Continue connecting all SLAVE RUs in this manner, as shown in Figure 4-18.

3 Connect an RF cable into the port labeled "RX_OUT" on the first SLAVE RU.

4 Connect the other end of the RF cable to the port labeled "RX_IN" on the next SLAVE RU. Continue

connecting all SLAVE RUs in this manner.

5 Power may now be applied to all Master and Slave Units used in this configuration.

© 2009-2014, BTI Wireless Page 34

mBSC-H DAS System

Installation Manual Issue 7

Figure 4-18. RF cable connection between Slave to Slave Remote Units

© 2009-2014, BTI Wireless Page 35

mBSC-H DAS System

Items

Description

1

Confirm that the Unit is mounted firmly and is stable.

2

Verify that the Unit is affixed per manufacturer's specifications.

3

Check that all screws and nuts are secure, that spring washers sit flush upon the flat

washers, and that there are no missing flat washers and spring washers.

4

Examine each part and cable for breakage or damage.

5

Make sure the Unit is clean and free of dust and other contaminants

Items

Description

1

Verify that the grounding cable is secure.

2

Make sure that all the cable sheathings are not damaged.

3

Confirm that the connection to the cables are stable and are not loose or damaged.

4

Check that the cables are completely connected, but make sure there is enough slack, if

needed. Do not cross the cables and the cables should be bundled together in the same

direction.

5

Check that the connected cables are not bent more than the manufacturer's specified

maximum bending radius.

LED Indicator

Colors

Cycles

Test the LED

Red and Green Blink

1 flash per second

Master RU Fiber Alarm

Red Fast Blink

2 times per second

mRU and sRU Comm Fail

Red and Green Blink

1 time per second

PA/LNA shutdown or Other

Red Fast Blink

2 times per second

Normal Operation

Green Blink

1 times per second

Installation Manual Issue 7

4.2.6 Remote Unit Installation Review

Use the following steps listed in Tables 4-3 and 4-4 to review the installation completion status

4.2.6.1 Mechanical Installation Review

Table 4-4. Remote Unit Mechanical Installation Check Lists

4.2.6.2 Electrical Installation Review

Table 4-5. Remote Unit Electrical Installation Check List

4.2.6.3 Field Status Test - Remote Unit LED Status Indicators

Perform a visual review of the LED Status indicators on the installed Remote Unit. The Remote Unit (RU)

status LED consists of a bi-colored LED of RED and GREEN. The high intensity LED is viewable from

ground level under most circumstances when using the BTI RU shroud system.

Table 4-6. Remote Unit LED Status Indicators

© 2009-2014, BTI Wireless Page 36

mBSC-H DAS System

Installation Manual Issue 7

4.2.7 Troubleshooting

© 2009-2014, BTI Wireless Page 37

mBSC-H DAS System

Installation Manual Issue 7

© 2009-2014, BTI Wireless Page 38

mBSC-H DAS System

Danger: Wet conditions increase the potential for receiving an electrical shock when

installing or using electrical power equipment. To avoid electrical shock, never install or use

the electrical equipment in a wet location.

Warning: Verify that the Unit has been ground with an earth-bonding cable to the grounding

connector.

Step

Operation Type

Operation Action

1

ELECTRICAL

VERIFY THAT THE UNIT IS GROUNDED

2

ELECTRICAL

CONFIRM THAT THE DC POWER CABLE IS INSTALLED AND

SECURE

3

ELECTRICAL

INSTALL THE BIU AND FIU MODULES

4

ELECTRICAL

INSTALL THE ALARM CONNECTORS (Optional)

5

ELECTRICAL

CONNECT THE BIU AND FIU

6

ELECTRICAL

CONFIRM THAT THE POI AND FAN (Opt. Equip.) ARE

CONNECTED

7

ELECTRICAL

CONNECT OPTIONAL EQUIPMENT TO THE BIU (if present)

8

ELECTRICAL

CONNECT THE FIBER OPTIC CABLES

9

INSTALLATION

REVIEW

CONFIRM THE ELECTRICAL INSTALLATION, TABLE 4-10

HOST UNIT ELECTRICAL INSTALLATION CHECKLIST

10

TROUBLESHOOTING

INSTALLATION TROUBLESHOOTING GUIDE

Single Host Unit

Hardware and Fasteners

Customer Install

Factory Install

Rec'd

CABINET (Optional)

1

HU DC POWER CABLE

1

ALARM CONNECTORS

8

FIU-S INTERFACE CABLE

3

FIU-NS INTERFACE CABLE

4

GROUNDING CABLES

1

POI GROUNDING CABLE

(Optional)

1

4.3 HOST UNIT INSTALLATION

4.3.1 Host Unit Installation Overview

The installation of the Host Unit consists of the following steps:

Table 4-6. Host Unit Installation Overview

Installation Manual Issue 7

4.3.2 Installation Hardware And Tools

The Host Units may be shipped individually or shipped factory pre-installed in optional cabinets. Table 4-7

lists the cables and hardware provided by the manufacturer. Additional hardware may be needed,

depending on the site requirements, and may be ordered through Customer Service (Section 6).

Table 4-7. Host Unit Cables and Hardware

© 2009-2014, BTI Wireless Page 39

mBSC-H DAS System

Single Host Unit

Hardware and Fasteners

Customer Install

Factory Install

Rec'd

POI INTERFACE CABLE

4

Installation Manual Issue 7

The following is a list of tools and any additional materials required for the Host Unit installation:

Small Phillips screwdriver

Wire cutters

Wire Harness (Required for Expanded Third Party Alarm)

4.3.3 Unpacking And Inspection

This section provides the instruction for receiving the equipment shipment, verifying all parts have been

received and checking that no damage has occurred during transportation. The Host Unit includes the

following items:

Optional Cabinet with Host Unit installed as shown in Figure 4-19.

Hardware and Fasteners described in Table 4-7, Section 4.3.2

Use the following procedure to unpack and inspect the Host Unit and accessories:

1. Open the shipping packet and carefully unpack the cabinet or individual Host Unit from the protective

packing material.

2. Verify receipt of hardware and fasteners using Table 4-7

3. Check each optional cabinet for broken or missing parts. Check each Host Unit module for any

damage, particularly the Fiber Optic Port. If there is any damage or missing parts, contact BTI (Section

6) for an RMA and to reorder parts, if any replacement parts are required.

© 2009-2014, BTI Wireless Page 40

Figure 4-19. Host Unit Cabinet

mBSC-H DAS System

Installation Manual Issue 7

NOTE: Check particularly for any damage to the fiber optic connectors on the FIU

module. Check the power connectors located at the back of the Host Unit and check

the back plane connectors located inside the Host Unit for any damage.

.

4.3.4 Electrical Installation

4.3.4.1 Electrical Safety Precautions

Please read the general Safety Precautions presented in Section 1.2 Safety Precautions

1. Follow the instructions for installation provided in this manual to prevent serious

accidents including loss of life, severe personal injury or extensive property damage.

2. The Unit must be grounded before connecting any power supply. Grounding is a

required precautionary measure. Grounding instructions are provided and should be

followed for safety.

3. Electrical and electronic components can be destroyed by incorrectly wired connections.

4. Cable connector materials must meet manufacturer specifications to avoid corrosion at the

connectors.

5. Compliance with the surge requirement of EN 61000-4-5 (fine protection) has been met by this

Unit. Installing additional external surge protection, depending on the individual application, via

local supply connection and/or coarse protection is recommended to avoid damage caused by

electrical surges.

© 2009-2014, BTI Wireless Page 41

mBSC-H DAS System

Installation Manual Issue 7

4.3.4.2 Grounding

The Unit must be grounded. The Host Unit is grounded during a factory installation in the optional

cabinet with an earth-bonding cable connected to the provided grounding connection. Do not

connect external devices to the grounding connection.

Please verify the Unit is securely grounded. If it is no longer securely grounded, please use the following

procedure to ground the Unit:

Figure 4-20. Host Unit Grounding Connection

1. Find the screw at the bottom right corner of the Host Unit as shown in Figure 4-20.

2. Loosen the screw located on the grounding connection.

3. Connect the cabinet mounted earth-bonding cable between the two lock and flat washers as shown in

Figure 4-21. Ensure the grounding surface is clean and free of paint, insulating material or

contaminants.

© 2009-2014, BTI Wireless Page 42

mBSC-H DAS System

Danger: Please use caution when working with DC power. Ensure all power is disconnected

before working on power circuit.

Warning: Verify that the Unit has been ground with an earth-bonding cable to the grounding

connector.

Installation Manual Issue 7

Figure 4-21. Grounded Host Unit (shown with optional POI Unit, also grounded)

4. Tighten the screw, making sure the cable is securely connected before moving to the next phase of the

installation.

4.3.4.3 DC Power Cable Connection

The DC power cable is connected during factory pre-installation.

© 2009-2014, BTI Wireless Page 43

mBSC-H DAS System

Installation Manual Issue 7

Figure 4-22. Factory Installed DC Power Cable

1. Confirm electrical polarity of the power cables to match the customer provided DC power system.

2. Verify the DC power cable is attached securely, as shown Figure 4-22.

3. If the DC power cable is not secure, turn off all associated DC power to the Host Unit, and secure the

power cables as shown.

4.3.4.4 Install the BIU and FIU modules

Figure 4-23. BIU and FIU modules

1. Remove the blank module covers for the chosen module slot locations.

2. Slide the BIU and FIU modules in to each separate designated module slot, Figure 4-23.

3. Secure the screws at the top and bottom of each module.

4.3.4.5 Alarm Installation

The Alarm interface is an optional customer centered configuration.

The Alarm Input configuration gives the user the means to monitor third party alarms, such as battery or

intrusion alarms.

The Alarm Output configuration provides the customer with the means to monitor major or minor alarms

via Form C relay.

The alarm interface is located at the back of the Host Unit as shown in Figure 4-24.

© 2009-2014, BTI Wireless Page 44

mBSC-H DAS System

NMS Alarm Status

Alarm

No Alarm

Expanded Alarm 1 (User Defined)

IN1/GND

IN1

Expanded Alarm 2 (User Defined)

IN2/GND

IN2

Expanded Alarm 3 (User Defined)

IN3/GND

IN3

Expanded Alarm 4 (User Defined)

IN4/GND

IN4

Installation Manual Issue 7

Figure 4-24. Alarm Interface

1. With wire cutting tools, prepare the connecting wires.

2. Loosen the screws in each connector.

3. Use the Input Alarm configurations shown in Table 4-8 and the Output Alarm configurations in Table

4-9 to determine the wire placement.

4. Slide the bared wires into the slot under the screw and tighten securely.

5. Plug all the alarm connectors into the Alarm Input interface as shown in Figure 4-25 and Figure 4-26.

Table 4-8. Input Alarm Configuration

© 2009-2014, BTI Wireless Page 45

mBSC-H DAS System

Alarm Type

On

Off

Major

COM1/NC1

COM1/NO1

Minor

COM2/NC2

COM2/NO2

Installation Manual Issue 7

Figure 4-25. Input Alarm Installation (Alarm On)

Table 4-9. Output Alarm Configuration

Figure 4-26. Output Alarm Installation (Alarm On)

4.3.4.6 Connect the BIU/FIU Modules

Connect the BIU to the FIU-S with the provided interface cable using the following procedure:

1. Connect one end of the interface cable to the BIU port labeled "Tx1 Out".

2. Connect the other end of the cable to the FIU-S port labeled "Tx1".

3. Connect a second interface cable to the BIU port labeled "Rx4".

© 2009-2014, BTI Wireless Page 46

mBSC-H DAS System

Installation Manual Issue 7

4. Connect the other end of the cable to the FIU port labeled "Rx1", Figure 4-27.

Figure 4-27. Connect the BIU to the FIU

For a two BIU and FIU-NS configuration, use the additional provided interface cables and the following

procedure:

5. Connect the one end of the interface cable to the FIU-NS port labeled "Tx1".

6. Connect the end of the second interface cable to the FIU-NS port labeled "Tx2".

1. Connect one end of the interface cable to the BIU port labeled "Tx1 Out".

2. Connect the end of the second interface cable to the port labeled "Tx1 Out" of the second BIU.

3. Connect the end of the third interface cable to the FIU-NS port labeled "Rx1".

4. Connect the other end of the fourth interface cable to the FIU-NS port labeled "Rx2"

5. Connect the third interface cable to the BIU port labeled "Rx4".

6. Connect the fourth interface cable to "Rx4" of the second BIU.

4.3.4.7 Optional Equipment Installation

The POI and Fan, (if ordered) are factory installed. Please verify the POI and Fan are securely connected

as shown in Figure 4-28.

Figure 4-28 POI and FAN Installation

© 2009-2014, BTI Wireless Page 47

mBSC-H DAS System

Installation Manual Issue 7

4.3.4.8 Connect POI to BIU

The Point of Interface (POI) is an optional component. The POI is connected to the BIU, Figure 4-29,

using the following procedure:

1. Connect one end of a POI interface cable into the BIU port labeled "Tx1 In".

2. Connect the other end of the cable to the POI port labeled "Tx-L".

3. Connect the one end of a POI interface cable into the BIU port labeled "Rx4 Out".

4. Finally, connect the other end of the cable to the POI port labeled "Rx-L".

Figure 4-29. POI to BIU Connection

4.3.4.9 Connect the Fiber Optic Cable

The Fiber optic cable is connected to the FIU module by attaching the cable to the port labeled "Fiber-1" as

shown in Figure 4-30.

Figure 4-30. Fiber Optic Cable Connection to the FIU Module

4.3.5 Host Unit Installation Review

4.3.5.1 Electrical Installation Review

© 2009-2014, BTI Wireless Page 48

mBSC-H DAS System

Items

Description

1

Verify that the grounding cable is secure.

2

Confirm that the power cable connection is stable and is neither loose or damaged and

that the electrical polarity is correct.

3

Verify that the fiber optic cable is securely connected.

4

Check that all installed cables are securely connected.

5

Confirm that the alarm connectors are securely connected.

Installation Manual Issue 7

Table 4-10. Host Unit Electrical Installation Check List

© 2009-2014, BTI Wireless Page 49

4.3.6 Troubleshooting

mBSC-H DAS System

Installation Manual Issue 7

© 2009-2014, BTI Wireless Page 50

mBSC-H DAS System

Caution: Network security may be compromised when accessing external Internet

connectivity. The use of established security software is recommended.

Step

Operation Type

Operation Action

1

SYSTEM SET-UP

VERIFY SERVER SOFTWARE IS OPERATIONAL

2

SYSTEM SET-UP

INSTALL SYSTEM SOFTWARE ON TO CUSTOMER

MONITORING EQUIPMENT

3

SYSTEM SET-UP

LAUNCH NMS SOFTWARE

4

CONFIGURE

CONFIGURE MANAGER ACCOUNT

5

CONFIGURE

SET-UP USER ACCOUNTS

6

CONFIGURE

SOFTWARE SYSTEM PARAMETERS

7

UPDATE/UPGRADE

SOFTWARE/FIRMWARE UPGRADE INSTALL

8

INITIAL SOFTWARE

INSTALLATION

REVIEW

CONFIRM SOFTWARE SET-UP INSTALLATION, TABLE 4-13

NMS INITIAL SOFTWARE INSTALLATION CHECKLIST

9

UPGRADE

INSTALLATION

REVIEW

CONFIRM FIRMWARE UPDATE AND SOFTWARE UPGRADE

INSTALLATION, TABLE 4-14 NMS UPGRADE SOFTWARE

INSTALLATION CHECKLIST

10

TROUBLESHOOTING

INSTALLATION TROUBLESHOOTING GUIDE

NMS ACCESSORY

Quantity

Received

SOFTWARE CD-ROM

1

Installation Manual Issue 7

4.4 NMS INSTALLATION

The NMS software is pre-installed on the Network Management Server and the NMS server arrives

pre-installed in the optional Host Unit cabinet. This section provides instruction for installing the NMS

software on a customer laptop or desktop and setting initial software parameters.

Figure 4-31. NMS Server

4.4.1 Installation Overview

The installation of the Network Management System consists of the following steps:

Table 4-11. NMS Installation Overview

4.4.2 Installation Hardware and Tools

The NMS server is shipped pre-installed in the optional Host Unit cabinet. Table 4-12 lists the accessories

provided by the manufacturer. Additional accessories may be needed, depending on the site requirements,

and may be ordered through Customer Service (Section 6).

Table 4-12. NMS Cables and Accessories

© 2009-2014, BTI Wireless Page 51

mBSC-H DAS System

NMS ACCESSORY

Quantity

Received

AC POWER CABLE

1

Installation Manual Issue 7

The following is a list of tools and any additional materials required for NMS software installation:

Laptop, Desktop PC and/or Terminal

Crossover Cable

Hub and/or Router

4.4.3 Unpacking And Inspection

This section provides the instructions for receiving the equipment shipment and verifying that no damage

has occurred during shipping. The NMS software is pre-installed on the server which is shipped with the

following:

Optional cabinet with NMS server and Host Unit installed as shown in Figure 4-32.

Installation cables and accessories as described in Table 4-12, Section 4.4.2.

Use the following procedure to unpack and inspect the NMS server and accessories:

1. Open the shipping packet and carefully unpack the cabinet from the protective packing material.

2. Verify receipt of accessories using Table 4-12

3. Check the server for visual damage. If there is any damage, contact BTI (Section 6) for further

instructions including an RMA, if necessary.

4.4.4 Verify Server software

© 2009-2014, BTI Wireless Page 52

Figure 4-32. NMS Server

mBSC-H DAS System

Installation Manual Issue 7

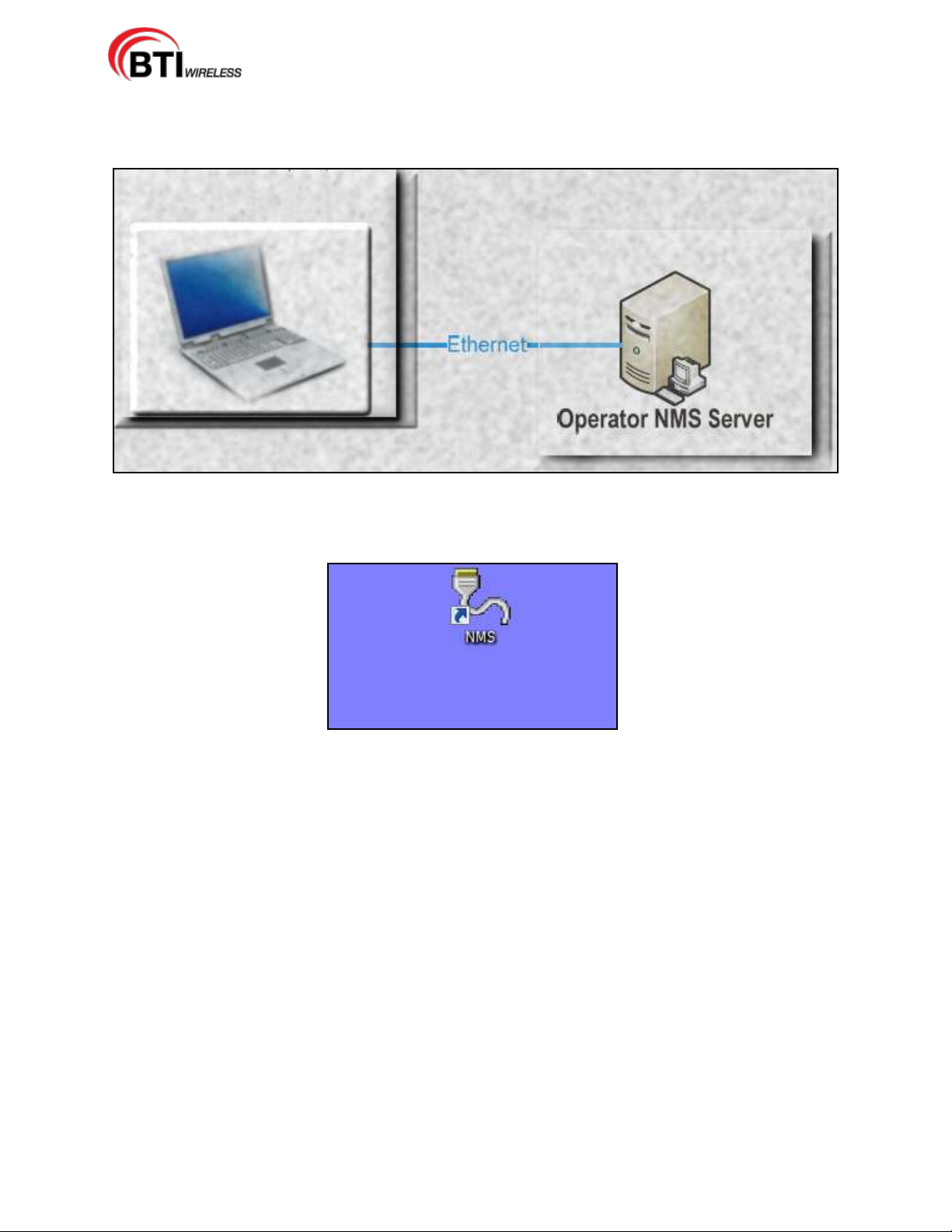

1. Connect the laptop, PC or terminal to the server through the hub using a crossover cable, Figure 4-33.

The monitoring device may also be plugged directly into the server with a crossover cable.

Figure 4-33. Connecting the Monitoring Device to the Server

2. Locate the NMS icon on the screen of the monitoring device, Figure 4-34.

Figure 4-34. Locate NMS Icon

4.4.5 Initial System Setup

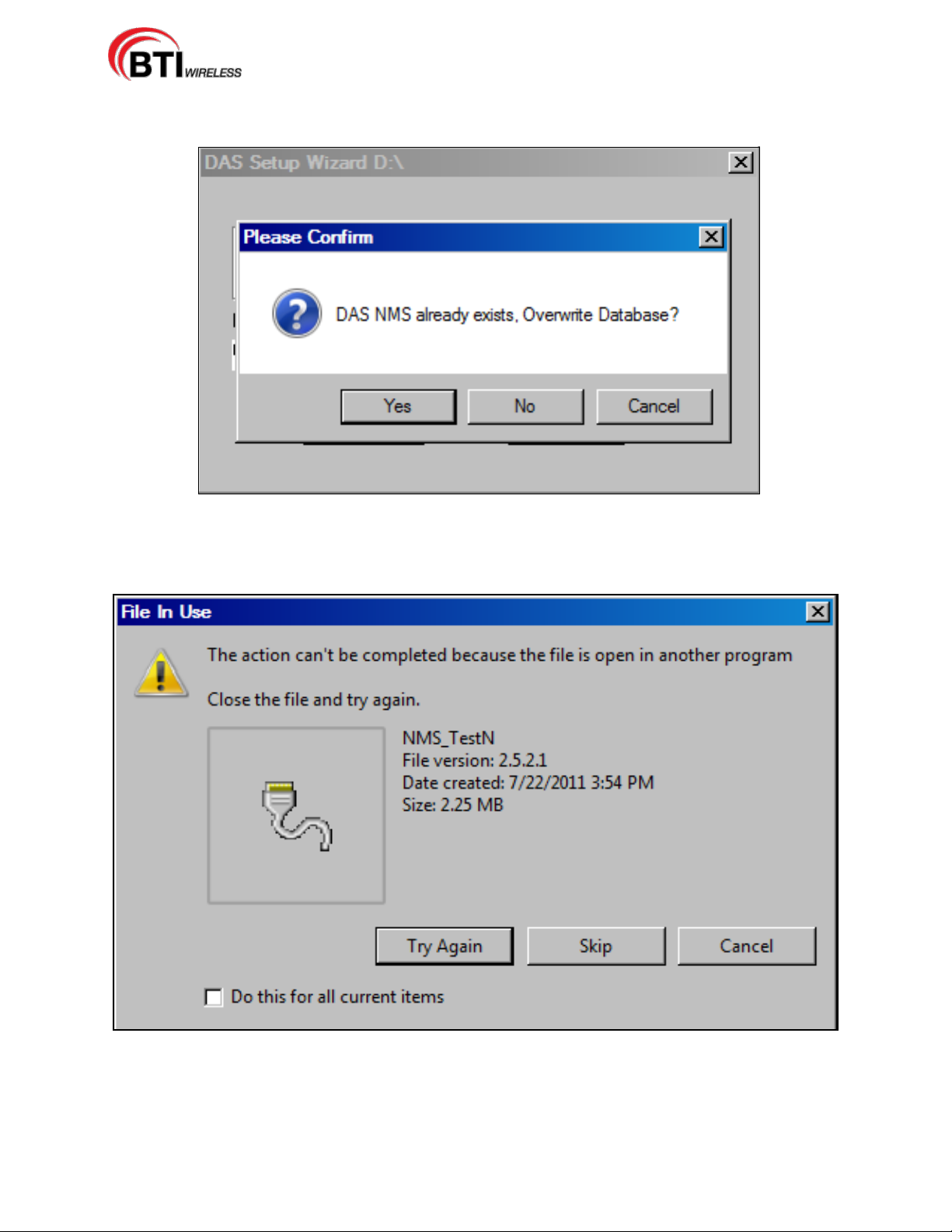

4.4.5.1 CD-ROM Install

The CD-ROM install is used to install NMS on to a Laptop or Desktop Computer. Use the following

procedure to install the application on to the computer:

1. Open the CD drive on the machine.

2. Place the CD into the drive and close the drive.

3. The CD will begin the install wizard, Figure 4-35.

4. The wizard copies the files to the %ProgramFiles% folder. The default destination directory may be

changed, if desired.

© 2009-2014, BTI Wireless Page 53

mBSC-H DAS System

Figure 4-35. DAS Setup Wizard

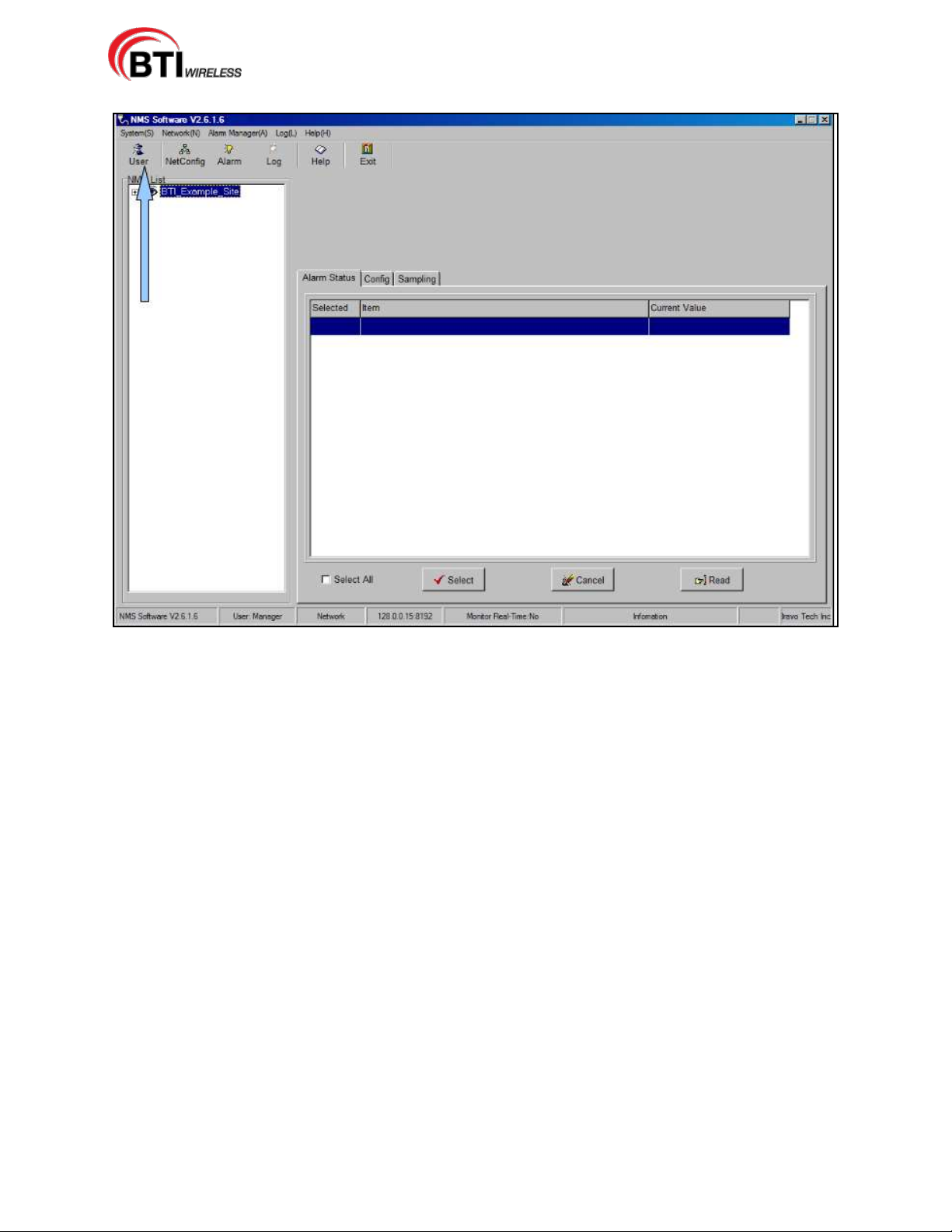

4.4.5.2 Launch NMS

1. After copying the files, the Wizard will ask to launch NMS, Figure 4-36.

Installation Manual Issue 7

2. Select Yes.

3. The Wizard simultaneously places a shortcut on to the desktop of the computer as shown in Figure

4-37. Double clicking on the NMS icon on the desktop also launches the NMS Login screen.

Figure 4-36. NMS Launch from Wizard Installation

© 2009-2014, BTI Wireless Page 54

mBSC-H DAS System

Installation Manual Issue 7

Figure 4-37. NMS Desktop Shortcut

NOTE: Occasionally, there are compatibility problems that cause a configuration

conflict when setting up the NMS. Follow the steps shown in the Troubleshooting

Guide. If this does not resolve the issue, contact Customer Service (Section 6).

4. Verify that the Advance box is checked and then click in the password field, Figure 4-38.

5. Enter the following default password: 1

6. Click on OK. The NMS Command Console is then launched.

Figure 4-38. NMS Login Screen

4.4.6 Initial Start-up Configuration

Once NMS is installed on the machine, the command console or main screen is used to navigate through