User Manual

CPM

Communication Platform

Copyright© 2019 BTG Instruments AB

The contents of this document are subject to revision without notice due to continued progress

in methodology, design, and manufacturing. BTG shall have no liability for any error or

damages of any kind resulting from the use of this document.

All rights reserved. No part of this document may be copied, photocopied, published,

reproduced, translated or converted into electronic or machine-readable form

without written permission of BTG Instruments AB.

Original Instructions

BTG Instruments AB, 2019

Important Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1 Product Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

1.2 Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.3 Dimensions and Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.4 Type Plate Explanations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

1.5 CE-Declaration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2 Installation Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.1 Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.2 Assembly of Product Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.3 Mounting Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

2.4 Cabling Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2.5 Connection Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2.5.1 AC Connection to Power Supply Unit . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.5.2 HCM-8000 / 8010 Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2.5.2.1 HCM-8000 Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2.5.2.2 HCM-8010 Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2.5.3 FCM-8000 / 8010 Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2.5.3.1 FCM-8000 Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2.5.3.2 FCM-8010 Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

2.5.4 Sensor Control Module SCM-8000 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

2.5.5 Connection to Transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

2.5.6 24 V On/Off Switch. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

2.6 Backup Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

2.7 RS-485 Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

3 Service Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

3.1 Maintenance Routines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

4 Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

4.1 CPM Kits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

© BTG 2019 User Manual CPM M2066/10en I

5 Appendix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

5.1 HCM-8000 Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

5.2 HCM-8010 Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

5.3 FCM-8000 Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

5.4 FCM-8010 Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

II User Manual CPM M2066/10en © BTG 2019

Important Information

This user manual contains all necessary instructions for installation,

maintenance, and basic service of the Communication Platform (CPM).

Safety instructions and regulations for installation and service are found in the

BTG Safety Manual, M2076.

NOTE!

Always read the safety instructions before installation and service of the

instrument!

NOTE!

If the CPM is used in a manner not specified by BTG the protection provided

by the equipment may be impaired.

For operation instructions, see the CPM operation manual for the appropriate

instrument. CPM operation manuals are available for the following

instruments:

Instrument CPM Operation manual

ACT-2500

MBT-2500

MEK-2500

MEK-3000

DRT-5500 OM2005

TCR-25xx OM2006

MBT-4500 OM2007

TCT-25x1

RET-25x2

RET-55x3 OM2010

BT-5500 OM2011

BLT-5500 OM2012

SPK-5500 OM2013

DLT-5500 OM2014

RT-5500 OM2015

TCS-2531 OM2016

OCT-25x1 OM2017

SPM-5500 OM2018

SPC-5500 OM2019

OM2003

OM2009

© BTG 2019 User Manual CPM IN2066en Rev.B 1

Recycling

Recycle the instrument and all replaced parts according to local, first and

foremost national, laws and regulations. Contact BTG to get detailed

information on how to disassemble and recycle the instrument safely. BTG

should have no liability for any error or damage of any kind due to disassembly

or recycle work done.

the unit is not falling under the RoHS/WEEE CE-directives according to:

RoHS According to Article 2 (4) and (4e) alt. (4d) and

according to Article 3 (3) alt. (4), the unit shall not

apply to RoHS.

WEEE According to Article 2 (3b) and (4c; f), and according

to Article 3 (1b) and (1c, I, II, III), the unit shall not

apply to WEEE.

2 User Manual CPM IN2066en Rev.B © BTG 2019

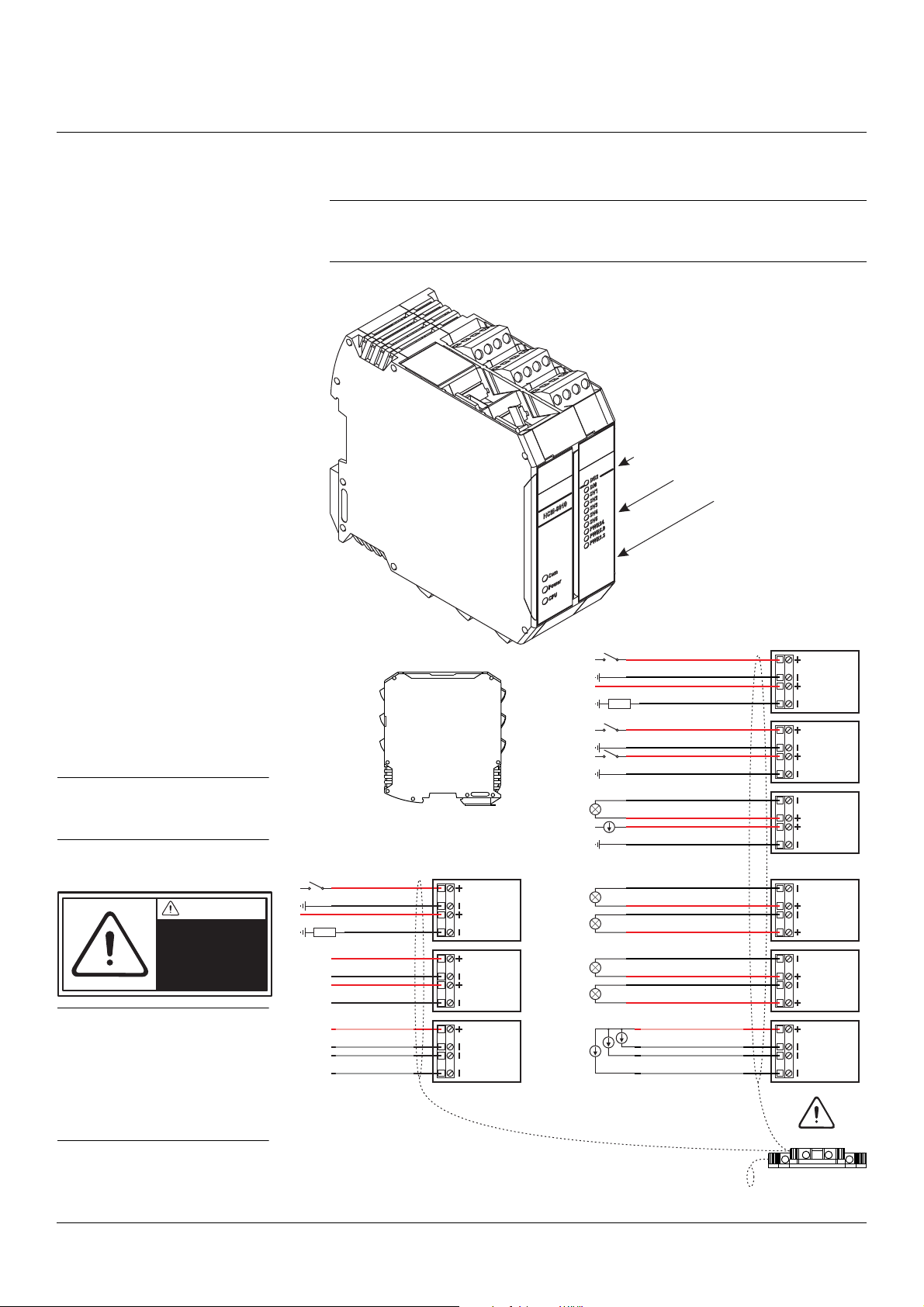

Product Introduction

Fig 1 CPM overview

1 Protective cover

2 Front cover

3 Scroll keys

4 LCD display with

backlight

5 Function keys

6 Closing screw

7 Cable glands

8 Transmitter cable

2

3

4

6

7

5

1

8

1 Product Introduction

1.1 General

The CPM is delivered as a complete unit from BTG, normally in conjunction with an

instrument.

The CPM has the following functions:

• Local display and console for full configuration and operation of the

instrument

• Large illuminated display for easy reading

• Protected from splash and sun

© BTG 2019 User Manual CPM PI2066en Rev.B 3

Product Introduction

1.2 Technical Data

General

Type

CPM Communication Platform.

Manufacturer

BTG, Säffle, Sweden.

Quality Assurance

Quality-assured in accordance with ISO 9001.

Product Safety

Fulfills all relevant CE-directive requirements and all Australian TIC requirements.

Function Specifications

Communication Modules:

HCM-8000/8010

Hart communication module using HART® protocol.

Equipped with slot for SD memory card.

Analog output (AO1- AO5)

4 - 20 mA. Galvanic isolated. Current limited to min. 3.9 and max. 20.5 mA.

Loop load signal: Voltage supply/load 24 V DC

Active or passive output for HCM-8000

Active output only for HCM-8010

Superimposed signal over 4 - 20 mA current loop according to standard HART® protocol.

Analog input (AI1 - AI4)

4 - 20 mA 250 Ω input resistance

Digital input (DI1 - DI4)

Galvanic isolated

High-ohmic = logical 0

+24 V ≥ 12 mA = logical 1

Digital output (DO1 - DO2)

Galvanic isolated

Maximum 120 mA

Maximum 30 V DC

Solenoid valve (SV1 - SV5)

Open drain output for solenoids

Maximum 500 mA

Maximum 30 V DC

FCM-8000/8010

Fieldbus communication module programmed for PROFIBUS.

Equipped with slot for SD memory card.

Output / Input signal

PROFIBUS (PA)

User Interface

Illuminated display. Key pad for adjustment of instrument settings.

4 User Manual CPM PI2066en Rev.B © BTG 2019

Product Introduction

Support System Specifications

Supply Voltage

Power supply unit 100 - 240 V AC, 50-60 Hz.

AC input range: 90 - 264 V continuous operation.

Disconnecting Device

An external 2-pole switch close to the CPM is required. The switch must be approved in

accordance with the IEC 60947-2 and IEC 60947-3 requirements.

Power Consumption

Maximum: 135 VA (CPM-1300), 515 VA (CPM-1400), 160 VA (CPM-1500)

Altitude

0 to 2000 m (0-6560ft) without any restrictions.

2000 to 6000 m (6560 to 20000ft) reduce output power or ambient temperature.

Altitude de-rating = 5 W / 1000 m or 5 °C / 1000 m.

Humidity

5 to 95% r.h (IEC 60068-2-30)

Over-voltage Category

Category III: IEC 62103, EN 50178, altitudes up to 2000 m

Category II: altitudes from 2000 m to 6000 m

Degree of Pollution

2: IEC 62103, EN 50178, not conductive

Physical Specifications

Materials

Casing: Polycarbonate thermo plastic

Cable fittings: Polyamide thermo plastic

Storage Temperature

Max. 80 °C (176 °F)

Min. -25 °C (-13 °F)

Operation Temperature

Max. 50 °C (122 °F)

Min. 0 °C (32 °F)

Degree of Protection

IP 65, comparable to NEMA 4x and better, the CPM is intended for use indoors.

Weight

CPM: 2 - 2.5 kg (4.4 - 5.5 lbs) depending on configuration

Cables

Power supply flexible cable: 0.3 - 2.5 mm

Signalling cable: 0.2 - 2.5 mm2 (AWG = 24-12)

Transmitter Cable

CPM-1300: Standard length: 10 m [33 ft] (option up to 55 m [180 ft])

Cable diameter: 5.5 mm [0.22"]

Connector diameter: 15 mm [0.6"]

CPM-1400: Standard length: 10 m [33 ft] (option up to 20 m [66 ft])

Cable diameter: 13 mm [0.5"]

No fixed connector

CPM-1500: Standard length: 10 m [33 ft] (option up to 20 m [66 ft])

Cable diameter: 5.5 mm [0.22"]

No fixed connector

2

(AWG = 28-12)

Cable Inlets

There are cable glands for signal cables (diameter 4-8 mm) and for power supply cable

(diameter 4-12 mm) in the bottom of the CPM.

© BTG 2019 User Manual CPM PI2066en Rev.B 5

Product Introduction

210

8.4"

10 (4x)

0.4"

5 (4x)

0.2"

10

0.4"

180

7.2"

240

9.6"

270

10.8"

180

7.2"

152

6"

162

6.5"

222

8.9"

50

2"

Quick GuideQuick

Guide

180

7.2"

Fig 2 Dimensions

300

12"

200

8"

200

8"

Quick GuideQuick

Guide

200

8"

Fig 3 Recommended

clearances

1.3 Dimensions and Mounting

6 User Manual CPM PI2066en Rev.B © BTG 2019

Product Introduction

N1619

NiMH

Certified to CAN/CSA-C22.2 No.61010-1 2nd ed

BTG Instruments AB

Industrigatan 1-3

66129 Säffle

SWEDEN

PRODUCT

VOLTAGE

FREQUENCY

NO

TYPE

3068754

INSTALLATION CATEGORY

FACTORY IDENTIFICATION

APPARENT POWER

Fig 4 Type plate

HA/Q0/C0/S/10/I230 A

123456

50-60 Hz

12345

6

7

8

9

10 11

12

50 W

III

CPM-1300

100-240 V AC

15

13

14

16

1.4 Type Plate Explanations

1. Manufacturer

2. CE-marking

The CPM is approved in accordance with CE directives.

3. C-TIC marking

The CPM is approved in accordance with Australian C-TIC N1619

directives.

4. ETL-marking

The CPM is approved by ETL.

5. Warning sign

The CPM is designed for industrial use. Installation, handling and service

must only be carried out by trained and authorized personnel and in

accordance with relevant standards. Read the manual for detailed

information and pay particular attention to the warning signs!

© BTG 2019 User Manual CPM PI2066en Rev.B 7

Product Introduction

CPM-1300

ABC

6. Product

The instrument model is specified according to the code system explained

below:

A Product Group

CPM Communication platform

B Power type

13 50 W Power supply

14 240 W Power supply

15 80 W Power supply

C Input/Output Unit

If field D = Hx:

1x analog output, 1x analog input

00

10

1x digital output, 3x digital inputs

If field D = PA or FF:

1x Fieldbus output

1x digital output, 1x digital input

If field D = HA

5x analog outputs, 4x analog inputs

7x digital outputs, 4x digital inputs

7. Manufacturing number

BTG internal product identification number.

8. Frequency

The CPM operates at both 50 and 60 Hz.

9. Apparent power

Maximum power consumption (W).

10. Installation category

In accordance with CE-Directive. Fixed installation. Resistant to

transients.

11. Factory identification

12. Voltage

100-240 V AC to power supply.

13. Recycling

The CPM should be recycled in accordance with local regulations.

8 User Manual CPM PI2066en Rev.B © BTG 2019

Product Introduction

HA/Q0/C0/S/10/I230 A

DEFG HI

14. Type specification

The instrument variant is specified according to the code system

explained below:

D Communication Protocol

HA Analog 4-20 mA with HART

Hx

PA Profibus PA

FF Foundation Fieldbus

F0 Foundation Fieldbus supplied with FCI-1000

Q0 No module

Q1 Sensor control module SCM-8000

C0 No serial connector

C1 One serial connector

C2 Two serial connectors

S Standard housing with protecting cover

T Standard housing without protecting cover

L Large housing without protecting cover

10 10 m [32.8 ft]

20 20 m [65.6 ft]

30 30 m [98.4 ft]

40 40 m [131.2 ft]

55 55 m [180.4 ft]

I012 Interlock interface relay 12 V DC

I024 Interlock interface relay 24 V AC/DC

I048 Interlock interface relay 48 V DC

I060 Interlock interface relay 60 V DC

I120 Interlock interface relay 120 V AC/ 110 V DC

I230 Interlock interface relay 230 V AC/ 220 V DC

A Alarm relay max 230 V AC / 220 V DC

Analog 4-20 mA with HART

but can be set by customer from menu to: Passive output

E Sensor Control Module

F Communication Connector

G Housing

H Cable length

I Other options

Blank = no option

®

, Active output

®

, Standard is: Active output

15. Waste electricals

Do not place electrical items in the general waste, recycle in accordance

with local regulations.

16. QR code

QR code to scan for more information about the CPM on the site:

www.btg.com/mybtg/en/instruments/cpm.

© BTG 2019 User Manual CPM PI2066en Rev.B 9

Product Introduction

Declaration of Conformity

CE mark

COMMUNICATION PLATFORM

TYPE: CPM-1300

CPM-1400

CPM-1500

BTG INSTRUMENTS AB

P.O. Box 602

661 29 Säffle

Sweden

This declaration of conformity is issued under the sole responsibility of the manufacturer.

We declare that the above Communication Platform conforms to:

2014/35/EU Low Voltage Directive, LVD

2014/30/EU Electromagnetic Directive, EMC

2014/68/EU Pressure Equipment Directive, PED

The following harmonized standards have been practiced:

IEC/EN 61010-1:2010 Safety requirements for electrical equipment for measurement, control, and laboratory

use - Part 1: General requirements

EN ISO 12100:2010 Safety of machinery - General principles for design - Risk assessment and risk

reduction

EN 61326-1:2013 Electrical equipment for measurement, control and laboratory use - EMC requirements

Part 1: General requirements

Authorized Signature:………………………………… Date: 2018-03-01……………………

Name: Björn Fahlin…………………………………... Position: Director of Operations

1.5 CE-Declaration

When using the units in combinations other than those tested for, BTG can not

guarantee CE-directive conformity.

The units in combination with customer-installed external devices may conform

with EMC and safety requirements when properly installed and CE-marked

equipment is used.

The system operator is responsible for CE-directive conformity.

Conformity must be verified by inspection.

10 User Manual CPM PI2066en Rev.B © BTG 2019

Installation Instructions

2 Installation Instructions

2.1 Unpacking

The following is included in a CPM delivery:

1. 1 x CPM box with transmitter cable

2. 1 x Protection cover (not when pre-assambled on a base unit)

3. 1 x Quick reference guide card

© BTG 2019 User Manual CPM II2066en Rev.B 11

Installation Instructions

Quick Guide

Fig 5 Quick Reference

Guide

Slot for Quick

Reference Guide card

Quick Reference

Guide card

2.2 Assembly of Product Parts

The protection cover is equipped with a slot for the Quick Reference Guide

(QRG) card, which is enclosed with certain transmitters. If a QRG card of the

type shown in Fig 5 is enclosed with your transmitter, place it in the slot as

shown in Fig 5.

12 User Manual CPM II2066en Rev.B © BTG 2019

Installation Instructions

300

12"

200

8"

200

8"

Quick GuideQuick

Guide

200

8"

Fig 6 Recommended

clearances

2.3 Mounting Instructions

Tools required:

Screwdriver

Drilling machine

1. Mount the CPM in the selected location by fastening the protective cover

to a flat surface. Use four suitable screws.

• See Fig 6 for recommended clearances.

• The top of the protective cover can be used as a holder for a

HART-terminal.

© BTG 2019 User Manual CPM II2066en Rev.B 13

Installation Instructions

DANGER

Hazardous voltage

in the equipment

2.4 Cabling Instructions

NOTE!

BTG recommends that separate cables be used for analog and digital signals.

Multi conductor cables can be used.

NOTE!

Unused cable glands must be sealed in order to fulfill the IP 65 requirement.

2.5 Connection Instructions

All electrical connections are made inside the CPM.

To access the terminal blocks, loosen the two screws on the right side of the

front cover and open the CPM.

NOTE!

Secure all cables with cable ties to avoid short circuit.

14 User Manual CPM II2066en Rev.B © BTG 2019

Installation Instructions

DANGER

Hazardous voltage

in the equipment

++

--

100 240 V AC-

N

L

50W

+

+

--

NL

100 240 V AC-

PE N L

N

L

+ +

- -

AC

100-120/

200-240 V

AC

100-120/

200-240 V

+

+

--

NL

PENL

AC

100-120/

200-240 V

Fig 7 Connection of AC

cable

Fuse

Min. 4 A (200-240 V)

Min. 6 A (100-120 V)

Fuse

Min. 2 A

2.5.1 AC Connection to Power Supply Unit

A specific instruction manual for the power supply unit can be found inside the

CPM box.

NOTE!

Before installation, ensure that all power to the system has been turned off.

Cable connections must be made by authorized personnel.

NOTE!

Overcurrent protection is included in the power supply unit.

NOTE!

An external 2-pole switch close to the CPM is required as shown in Fig 7

(Not delivered from BTG).

The switch should be marked "Disconnecting device".

NOTE!

The connection cable must be able to withstand an ambient temperature of at

least 75 °C (167 °F).

1. Insert the power supply cable through the cable gland.

2. Connect the AC cable (100 - 240 V AC, 50-60 Hz) to the power supply unit

as shown in Fig 7.

© BTG 2019 User Manual CPM II2066en Rev.B 15

Installation Instructions

DANGER

Hazardous voltage

in the equipment

Fig 8 Analog Out 4-20 mA

Analog Out (DCS) 4-20 mA

0

814

250

35 (Max)

V

730

1200

W

24

A

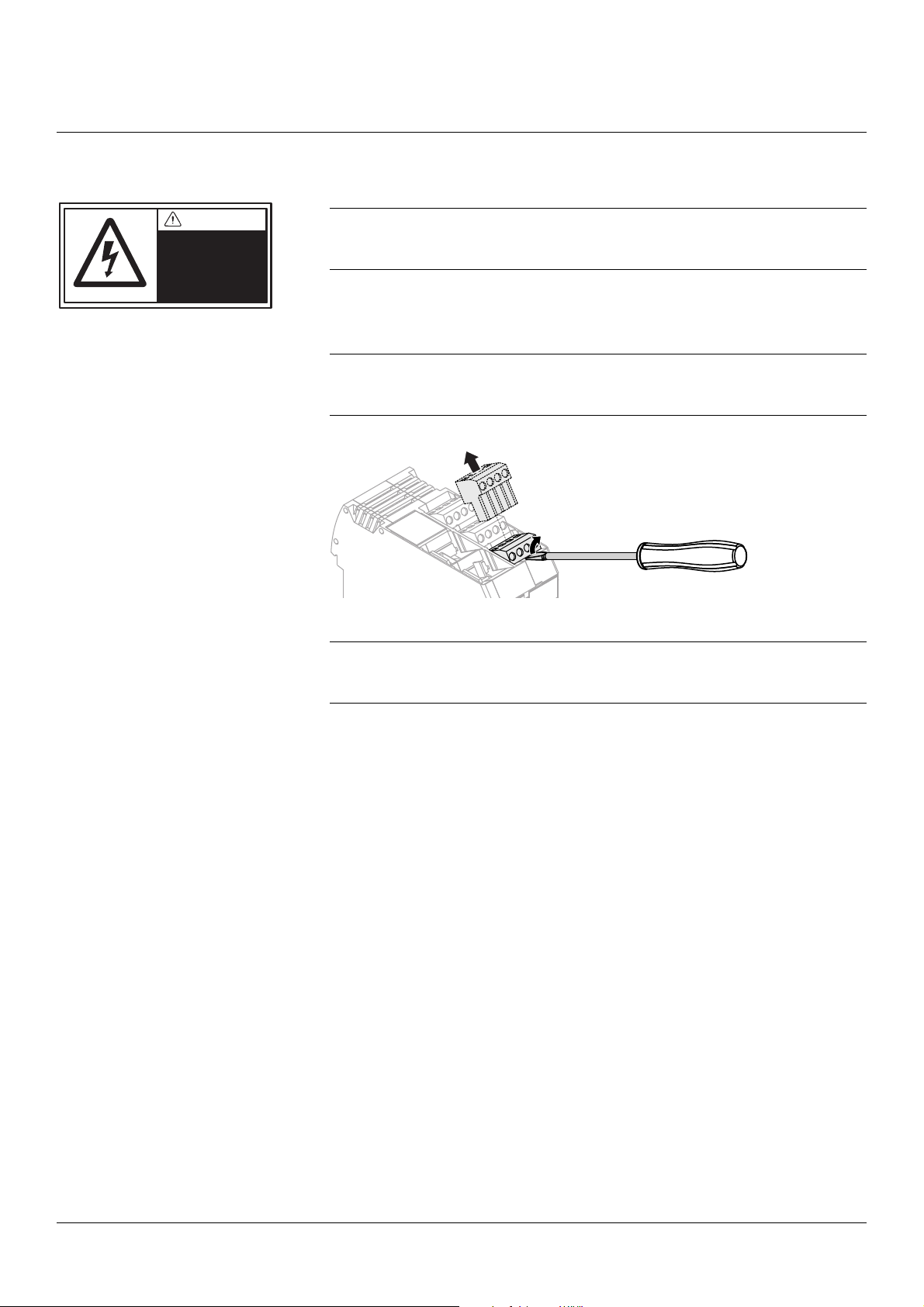

Fig 9 Releasing the

connection blocks

2.5.2 HCM-8000 / 8010 Connections

The Hart communication module (HCM-80xx) is using HART® protocol.

NOTE!

Before installation, ensure that all power to the system has been turned off.

Cable connections must be made by authorized personnel.

NOTE!

Fig 8 shows resistance as a function of supply voltage. The grey area is

accepted. The resistance is the sum of cable- and power source- resistance in

the current loop. The HART

250

®

communication requires a minimum resistance of

1. Insert the signal cable through the cable gland.

2. Connect the cable to the HCM-80xx as shown in Fig 11 or Fig 13.

NOTE!

The connection blocks can be released from the connection module for easier

access, as shown in Fig 9 below.

3. Connect the shield to the upper connection point on the shield filter module

(SFM-8000).

CAUTION!

The cable shield must always be connected to the upper connection point on

the shield filter module, and kept separated from the transmitter cable shield.

16 User Manual CPM II2066en Rev.B © BTG 2019

Installation Instructions

P1

P3

P2

Fig 10 HART Communication

Module HCM-8000

HCM-8000

P3

P2

P1

AO Analog Out( ) alternatives

Alternative 1: AO = Passive

Alternative 2: AO = Active

Transmitter

cable

Cable shield

SFM-8000

Digital In 3

Digital Out

DI3

P1

DO

+

-

LOAD

+24 V

+24 V

Digital In 2

Digital In 1

DI1

P2

DI2

+24 V

+24 V

Analog In 4-20 mA

Active Analog Out 4-20 mA

AO1

P3

AI1

+24 V

Analog In 4-20 mA

Passive 4-20 mAAnalog Out

Supplied with 14 - 35 V DC

AO1

P3

AI1

+24 V

+

-

LOAD

+24 V

Fig 11 Connection of HCM-

8000 cable

CAUTION

Always connect

the cable shield!

CAUTION!

The cable shield must always

be connected to the upper

connection point on the shield

filter module, and kept

separated from the transmitter

cable shield.

NOTE!

Note the polarity for

Passive or Active

Analog Out (AO).

If the analog output

signal (4-20 mA) is

passive, an external

source of current must

be used (14-35 V DC)

2.5.2.1 HCM-8000 Connections

NOTE!

The functions of the connections for each instrument type can be found in the

connection tables for HCM-8000 in section 5: Appendix

© BTG 2019 User Manual CPM II2066en Rev.B 17

Installation Instructions

P1

P3

P2

P4

P6

P5

P7

P9

P8

Fig 12 HART Communication

Module HCM-8010

P3

HCM-8010

P2

P1

P4

P5

P6

P7

P8

P9

Digital In 2

Digital In 1

Digital In 3

Digital Out

Analog In 4-20 mA

Active Analog Out 4-20 mA

Active Analog Out 2 (4-20 mA)

Active Analog Out 3 (4-20 mA)

Active Analog Out 4 (4-20 mA)

Active Analog Out 5 (4-20 mA)

Digital In 4

Digital Out 2

Solenoid Valve 4

Solenoid Valve 5

Transmitter

cable

Cable shield

SFM-8000

DI3

P1

DO

DI1

P2

DI2

AO1

P3

AI1

AO2

P4

AO3

AO4

P5

AO5

AI

P6

23 4

DI4

P7

DO2

SV4

P8

SV5

SV

P9

12 3

+

-

LOAD

+24 V

+24 V

+24 V

+24 V

+24 V

Analog In 2 (4-20 mA)

Analog In 3 (4-20 mA)

Analog In 4 (4-20 mA)

Common +24 V

+24 V

Solenoid Valve 1

Common +24 V

Solenoid Valve 2

Solenoid Valve 3

+

-

LOAD

+24 V

Fig 13 Connection of

HCM-8010 cables

CAUTION

Always connect

the cable shield!

CAUTION!

The cable shield must always

be connected to the upper

connection point on the shield

filter module, and kept

separated from the transmitter

cable shield.

NOTE!

For HCM-8010, only active

analog output is available.

2.5.2.2 HCM-8010 Connections

NOTE!

The functions of the connections for each instrument type can be found in the

connection tables for HCM-8010 in section 5: Appendix

18 User Manual CPM II2066en Rev.B © BTG 2019

Installation Instructions

DANGER

Hazardous voltage

in the equipment

Fig 14 Releasing the

connection blocks

2.5.3 FCM-8000 / 8010 Connections

NOTE!

Before installation, ensure that all power to the system has been turned off.

Cable connections must be made by authorized personnel.

1. Insert the signal cables through the cable glands.

2. Connect the cables to the FCM-80xx as shown in Fig 11 or Fig 13.

NOTE!

The connection blocks can be released from the connection module for easier

access, as shown in Fig 14 below.

3. Connect the shield to the upper connection point on the shield filter module.

CAUTION!

The cable shield must always be connected to the upper connection point on

the shield filter module, and kept separated from the transmitter cable shield.

© BTG 2019 User Manual CPM II2066en Rev.B 19

Installation Instructions

P1

P3

P2

Fig 15 Fieldbus Communication

Module FCM-8000

P3

FCM-8000

P2

P1

Transmitter

cable

Cable shield

SFM-8000

Shield

FF / PROFIBUS PA

Digital In 3

Digital Out

DI3

P1

DO

1

P2

2

P3

3

4

S

Software update

Fig 16 Connection of

FCM-8000 cables

CAUTION

Always connect

the cable shield!

CAUTION!

The cable shield must always

be connected to the upper

connection point on the shield

filter module, and kept

separated from the transmitter

cable shield.

2.5.3.1 FCM-8000 Connections

NOTE!

The functions of the connections for each instrument type can be found in the

connection tables for FCM-8000 in section 5: Appendix

20 User Manual CPM II2066en Rev.B © BTG 2019

Installation Instructions

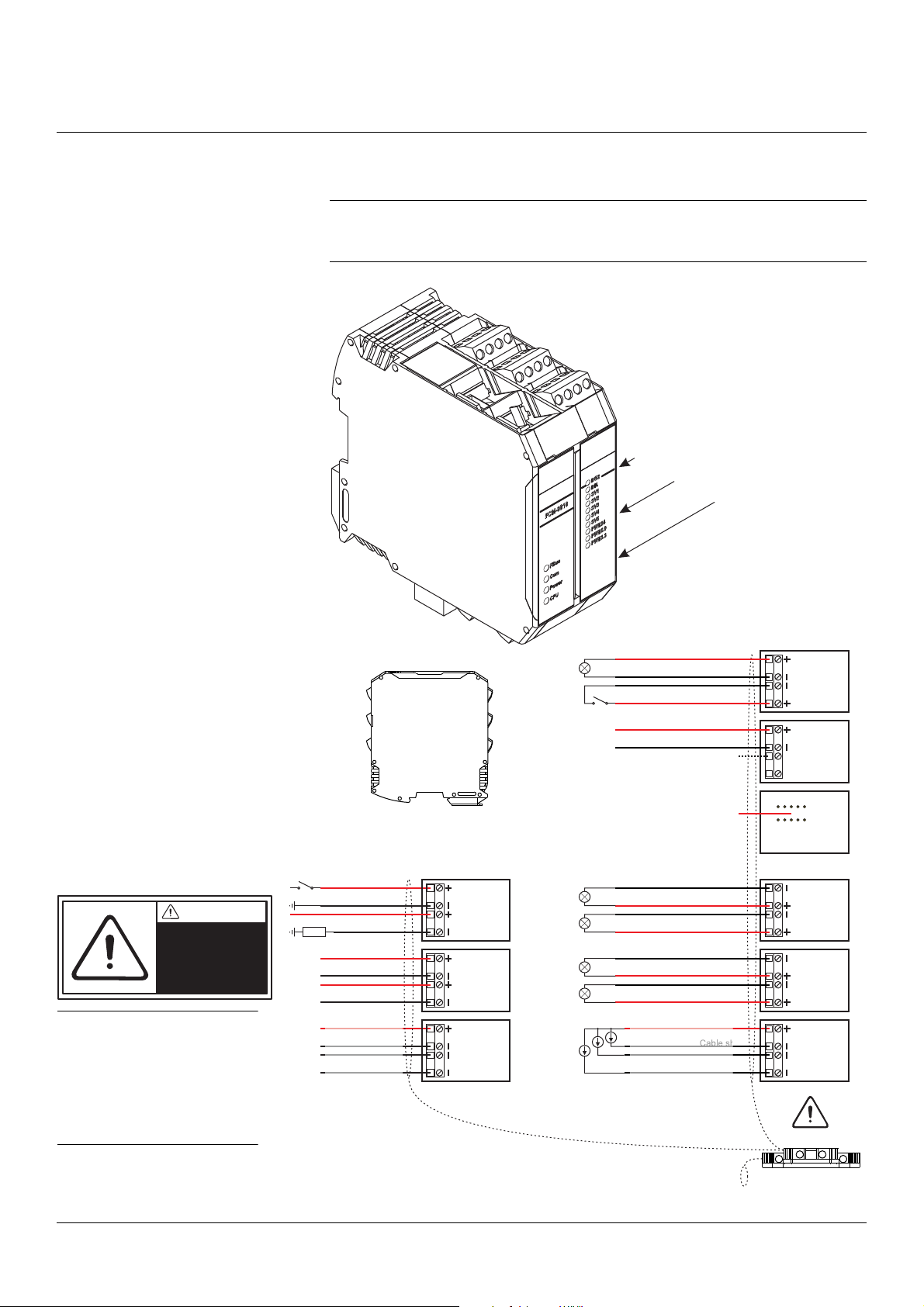

P1

P3

P2

P4

P6

P5

P7

P9

P8

Fig 17 Fieldbus Communication

Module FCM-8010

P3

FCM-8010

P2

P1

P4

P5

P6

P7

P8

P9

Transmitter

cable

Cable shield

SFM-8000

Cable shield

Shield

FF / PROFIBUS PA

Digital In 3

Digital Out

DI3

P1

DO

1

P2

2

P3

3

4

S

Software update

Active Analog Out 2 (4-20 mA)

Active Analog Out 3 (4-20 mA)

Active Analog Out 4 (4-20 mA)

Active Analog Out 5 (4-20 mA)

AO2

P4

AO3

AO4

P5

AO5

AI

P6

23 4

Analog In 2 (4-20 mA)

Analog In 3 (4-20 mA)

Analog In 4 (4-20 mA)

Common +24 V

Solenoid Valve 4

Solenoid Valve 5

SV4

P8

SV5

SV

P9

12 3

Solenoid Valve 1

Common +24 V

Solenoid Valve 2

Solenoid Valve 3

Digital In 4

Digital Out 2

DI4

P7

DO2

+24 V

+

-

LOAD

+24 V

Fig 18 Connection of

FCM-8010 cables

CAUTION

Always connect

the cable shield!

CAUTION!

The cable shield must always

be connected to the upper

connection point on the

shield filter module, and kept

separated from the

transmitter cable shield.

2.5.3.2 FCM-8010 Connections

NOTE!

The functions of the connections for each instrument type can be found in the

connection tables for FCM-8010 in section 5: Appendix

© BTG 2019 User Manual CPM II2066en Rev.B 21

Installation Instructions

DANGER

Hazardous voltage

in the equipment

HCM

8000

DI3

DO

+- +-

+- +-

+- +-

DI1 DI2

AO AI

P1

P2

P3

RS-485

red

black

blue

white

+- +-

+- +-

+- +-

P1

P2

P3

+- --

+- --

+- --

P6

P5

P4

SCM-8000

Common

Solenoid valve 2

Solenoid valve 3

Solenoid valve 5

Solenoid valve 6

Solenoid valve 7

Solenoid valve 4

Solenoid valve 9

Solenoid valve 8

Solenoid valve 1

-+-

P4

-

+

-

P6

-

+

-

P5

-

--

Sensor Cable

SCM-8000

-

+

-

+

P3

Sample button

Sampling indicatior +24 V

-

+

-

+

P2

-

+

-

+

P1

brown

black

white

blue

HCM-8000

P1

P2

P3

P4

P5

P6

SCM-8000

SCM

8000

Fig 19 Connection of

SCM-8000

2.5.4 Sensor Control Module SCM-8000

NOTE!

These connection instructions are only valid for DRT-5500. Other instruments

equipped with the SCM-8000 have all connections to the SCM unit pre-wired

at delivery.

NOTE!

Before installation, ensure that all power to the system has been turned off.

Cable connections must be made by authorized personnel.

22 User Manual CPM II2066en Rev.B © BTG 2019

Installation Instructions

DANGER

Hazardous voltage

in the equipment

+-+

-

White

Blue or Yellow

Brown

Black or Green

Cable shield

24 V DC

RS-485

1kΩ

SFM-8000

Fig 20 CPM-1300 cable to

transmitter

N

L

AC

100-120/

200-240 V

2

3

4S

SAB

On/Off

Red

Black

Blue

White

Fig 21 CPM-1400 cable to

transmitter

2.5.5 Connection to Transmitter

NOTE!

Before installation, ensure that all power to the system has been turned off.

Cable connections must be made by authorized personnel.

The pre-assembled cable is connected to the transmitter according to the

installation instruction for the transmitter.

Fig 20 shows the pre-assembled transmitter cable-connection inside the

CPM-1300.

© BTG 2019 User Manual CPM II2066en Rev.B 23

Fig 21 shows the transmitter cable-connection inside the CPM-1400

(for MEK-3000).

Installation Instructions

N

L

++

--

AC

100-120/

200-240 V

2

3

4S

SAB

On/Off

Fig 22 24 V On/Off switch

2.5.6 24 V On/Off Switch

Some CPM models are equipped with a fuse used as an On/Off switch for the

24 V supply to the CPM and the transmitter. Fig 22 shows the 24 V On/Off

switch in the CPM-1400 for MEK-3000.

24 User Manual CPM II2066en Rev.B © BTG 2019

Installation Instructions

SD

M

e

m

o

ry

C

a

rd

+-+

-

-

+

-

+

Communication

module

Fig 23 Location of SD card

reader

2.6 Backup Card

The HCM-8000 and FCM-8000 is equipped with a slot for a memory card of

the type Secure Digital (SD). A SD card is not included in a CPM delivery.

All transmitter settings, transmitter data, and calibration data can be stored on

a SD card. The SD card reader is located on the communication module card,

and can be accessed by opening the front cover of the CPM (see Fig 23).

© BTG 2019 User Manual CPM II2066en Rev.B 25

Installation Instructions

RS-485

Fig 24 RS-485 connections

1 Software update and

temporary

communication

2 Primary communication;

BTG Software (Only on

certain CPM models)

2

1

2.7 RS-485 Connection

26 User Manual CPM II2066en Rev.B © BTG 2019

Service Instructions

3 Service Instructions

3.1 Maintenance Routines

No regular maintenance is required for the CPM apart from keeping the unit

clean and free from pulp.

© BTG 2019 User Manual CPM SI2066en Rev.A 27

Service Instructions

28 User Manual CPM SI2066en Rev.A © BTG 2019

4 Parts List

+-+

-

NL

PE

POWER

SUPPLY

HCM-8000

HCM-8000

Com

Power

CPU

Pulptec

TM

1

5

2

6

4

3

7

Parts List

Most spare parts are delivered in kits. Each kit includes instructions.

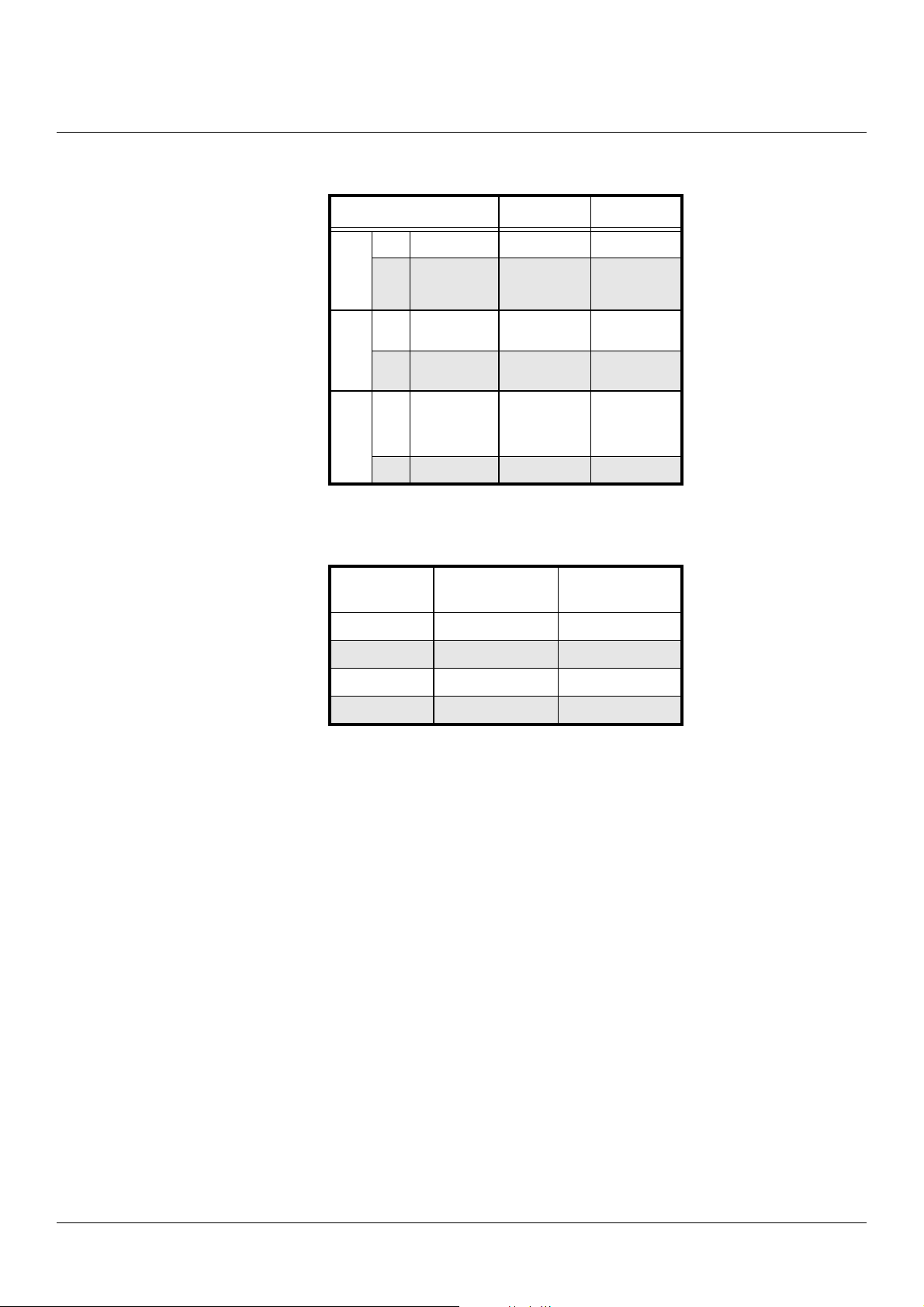

4.1 CPM Kits

Kit

No.

Rec.

spare

Qty Part No. Spare Part Description

parts

1 1 PB0011007 Console kit

Without electronics Including:

Protective cover, Display holder, Front

tape, Attachments

Hart communication module Including:

2 1 PB0011015 HCM-8000 kit

PB0011023 Transmitter cable kit (CPM-1300)

31

P46033742 Transmitter cable (CPM-1400)

4 1 HB0011031 50 W power supply kit Including: Cable, Contact (2 pin)

5 1 PB0011049 Display card kit Including: Cable

Bottom socket, Contact for transmitter

(5 pin)

Standard 10 m

(other length on request)

MEK-3000 up to 20 m

(not shown in figure)

6 1 PB0011056 SFM-8000 kit Shield filter module kit

7 1 HB0011171 4-20 mA Active output kit

© BTG 2019 User Manual CPM PL2066en Rev.A 29

Parts List

N

L

++

--

AC

100-120/

200-240 V

2

3

4S

SAB

On/Off

SCM-8000

SCM-8000

Com1

Power

CPU

Pulptec

TM

Com2

SV6

SV5

SV4

SV3

SV2

SV1

HCM-8000

HCM-8010

HCM-8010

Pulptec

TM

HCM-8000

Com

Power

CPU

Pulptec

TM

DO2

DI4

SV1

SV3

POWER 5.0

POWER 24

POWER 3.3

SV2

DI51

DO3

HCM-8000

FCM-8000

Com

Power

CPU

Pulptec

TM

89 10 11 12 13

Kit

No.

Rec.

spare

parts

Qty Part No. Spare Part Description

Fieldbus communication module,

PB0011551 FCM-8000 kit

81

programmed for PROFIBUS (PA)

Including: Bottom socket, Contact for

transmitter (5 pin).

Fieldbus communication module,

PA0113415 FCM-8010 Unit

programmed for PROFIBUS (PA) for

extended in- and outputs

9 1

PB0021741 240 W Power Supply kit For CPM-1400 (MEK-3000)

P46036133 80 W Power Supply unit For CPM-1500 (SPK-5500)

10 1 P46033965 24 V Switch 24 V Switch

11 1 Terminal Block kit For CPM-1400 (MEK-3000)

Hart Communication Module with

12 1 PB0021774 HCM-8000/8010 kit

8010 card for extended in- and outputs

Including: Bottom sockets 5 pin x2

13 1 KB0021782 SCM-8000 kit

Sensor Control Module

Including: Bottom socket 5 pin

14 1 HA0111674 Communication cable RS-485 Serial (not in figure)

15 1 HA0112953 Communication cable RS-485 USB (not in figure)

16 1 PA0150151 RS485 service connector (not in figure)

17 * 1 P00X20418 SD card 512 MB Industrial

Memory card for back-up

(not in figure)

18 1 PA0174573 Alarm relay Kit (not in figure)

19 1 PA0119867 Interlock relay Kit (not in figure)

30 User Manual CPM PL2066en Rev.A © BTG 2019

5 Appendix

Appendix

5.1 HCM-8000 Connections

Connection Block ACT-2500 DRT-5500 MBT-2500 MBT-4500

DI3 Digital In 3 Sample Input

P1

DO Digital Out Alarm Output Data Ready Alarm Output Alarm Output

DI1 Digital In 1

P2

DI2 Digital In 2

AO Analog Out

P3

AI Analog In Not used Not used Not used

Calibration set

Input A

Calibration set

Input B

Consistency

output value

4 - 20 mA

Interlock

(1=Interlock)

Calibration set

Input A

Calibration set

Input B

Freeness

output value

4 - 20 mA

Sample Input Sample Input

Calibration set

Input A

Calibration set

Input B

Consistency

output value

4 - 20 mA

Calibration set

Input A

Calibration set

Input B

Viscosity

output value

4 - 20 mA

Temperature

or Flow input

4 - 20 mA

Connection Block MEK-2500 MEK-3000 OCT-25x1 TCR-25x1

DI3 Digital In 3 Sample Input

P1

DO Digital Out Alarm Output Alarm Output Alarm Output Alarm Output

DI1 Digital In 1

P2

DI2

Digital In 2

Calibration set

Input A

Calibration set

Input B

Sample Input

or Interlock

Calibration set

Input A

Calibration set

Input B

Sample Input Sample Input

Calibration set

Input A

Calibration set

Input B

Calibration set

Input A

Calibration set

Input B

AO Analog Out

P3

AI Analog In Not used Not used Not used Not used

Consistency

output value

4 - 20 mA

Consistency

output value

4 - 20 mA

Total

Consistency

output value

4 - 20 mA

Total

Consistency

output value

4 - 20 mA

© BTG 2019 User Manual CPM AX2066en Rev.B 31

Appendix

Connection Block TCS-2531 TCT-25x1

DI3 Digital In 3 Sample Input Sample Input

P1

DO Digital Out Alarm Output

DI1 Digital In 1

P2

DI2

Digital In 2

AO Analog Out

P3

AI Analog In Not used Not used

Calibration set

Input A

Calibration set

Input B

Total

Consistency

output value

4 - 20 mA

Calibration Set configuration

Calibration

Set

10 0

2 1 0

30 1

4 1 1

Input A

(Digital In 1)

Input B

(Digital In 2)

Alarm Output

or PCD-1000

control

Calibration set

Input A

Calibration set

Input B

Total

Consistency

output value

4 - 20 mA

32 User Manual CPM AX2066en Rev.B © BTG 2019

Appendix

5.2 HCM-8010 Connections

Connection Block

DI3 Digital In 3 Initiate lab sample Sample Input Sample Input Interlock

P1

DO Digital Out 1 Alarm Output Alarm Output

DI1 Digital In 1 Calibration set Input A Calibration set Input A Calibration set Input A Calibration set Input A

P2

DI2 Digital In 2 Calibration set Input B Calibration set Input B Calibration set Input B Calibration set Input B

AO Analog Out 1

P3

AI Analog In1

AO2 Analog Out 2

P4

AO3 Analog Out 3

AO4 Analog Out 4

P5

AO5 Analog Out 5

BT-5500

BLT-5500

Channel 1 output value

4 - 20 mA

Analog input signals

from external equipment

4 - 20 mA

Channel 2 output value

4 - 20 mA

Channel 3 output value

4 - 20 mA

Channel 4 output value

4 - 20 mA

Channel 5 output value

4 - 20 mA

DLT-5500 RET-25x2 RET-55xx

Alarm Output or PCD1000 control

Dissolved lignin

(Channel 1) output value

4 - 20 mA

Not used Not used Not used

Total consistency

(Channel 2) output value

4 - 20 mA

Not used Not used Not used

Not used Not used Not used

Total consistency

(Channel 1) output value

4 - 20 mA

Ash consistency

(Channel 2) output value

4 - 20 mA

Alarm Output

Total consistency

(Channel 1) output value

4 - 20 mA

Ash consistency

(Channel 2) output value

4 - 20 mA

(RET-55x3 only)

AI2 Analog In 2

P6

AI4 Analog In 4

DI4 Digital In 4

P7

DO2 Digital Out 2

SV4 Sol. valve 4

P8

SV5 Sol. valve 5

SV1 Sol. valve 1

P9

SV2 Sol. valve 2

SV3 Sol. valve 3

(a) For more information about internally pre-wired connections, see the installation drawing for the transmitter

Analog input signals

from external equipment

4 - 20 mA

Not used Not used Not used

Nut used Not used Not used

Not used Not used Not used

Not used Not used Not usedAI3 Analog In 3

Internally pre-wired

Internally pre-wired

Internally pre-wired

(a)

(a)

(a)

© BTG 2019 User Manual CPM AX2066en Rev.B 33

Appendix

Connection Block RT-5500 SPC-5500 SPM-5500 SPK-5500 TCR-25x2

DI3 Digital In 3 Sample Input Interlock Interlock Remote stop Sample Input

P1

Digital Out 1

Floating DC

DO

switch max 30 V,

100 mA

DI1 Digital In 1

Alarm Output Alarm Output Alarm output Alarm Output Alarm Output

Calibration set

Input A

P2

DI2 Digital In 2

AO Analog Out 1

Calibration set

Input B

Residual (Channel

1) output value

4 - 20 mA

P3

Analog input

AI Analog In1

AO2 Analog Out 2

signals from

external equipment

4 - 20 mA

Conductivity

(Channel 2) output

value

4 - 20 mA

P4

Media temp.

AO3 Analog Out 3

(Channel 3) output

value

4 - 20 mA

AO4 Analog Out 4

P5

Not used

AO5 Analog Out 5 Not used

Not used Not used Calibration set Input A

Not used Not used Calibration set Input B

Filtrate charge

(Channel 1) output

value

4 - 20 mA

Configurable

(Channel 1) output

value

4 - 20 mA

Kappa

LRV - URV

output value

4 - 20 mA

Calibration set

Input A

Calibration set

Input B

Total consistency

(Channel 1) output

value

4 - 20 mA

Not used Not used Not used Not used

White water charge

(Channel 2) output

value

4 - 20 mA

Start streaming

potential for filtrate

(Channel 1)

Start streaming

potential for white

water (Channel 2)

Configurable

(Channel 2) output

value

4 - 20 mA

Configurable

(Channel 3) output

value

4 - 20 mA

Internally pre-

(a)

wired

RMS 0-0.0015 V

output value

4 - 20 mA

CwZ 0-1.65 V

output value

4 - 20 mA

CwT 0-0.165 V

output value

4 - 20 mA

Mean Kappa

LRV - URV

output value

4 - 20 mA

(b)

Ash consistency

(Channel 2) output

value

4 - 20 mA

Not used

Not used

Analog input

AI2 Analog In 2

P6

AI3 Analog In 3

signals from

external equipment

4 - 20 mA

Not used

Internally pre-

(a)

wired

Internally

pre-wired

Not used

AI4 Analog In 4 Not used

DI4 Digital In 4

P7

DO2

SV4 Sol. valve 4

P8

SV5 Sol. valve 5

SV1 Sol. valve 1

P9

SV2 Sol. valve 2

Digital Out 2

Floating DC

switch max 30 V,

100 mA

Not used

Not used

Data ready

Channel 1

Not used Not used

Data ready

Channel 2

Not used

Not used

Internally pre-

(a)

wired

Sample Input

Not used Data Ready

Internally pre-

(a)

wired

Internally pre-wired

Not used

Internally pre-

(a)

wired

Internally pre-wired

SV3 Sol. valve 3

(a) For more information about internally pre-wired connections, see the installation drawing for the transmitter

(b) Average since last start. Normally only used for batch applications

(a)

Not used

Not used

(a)

Not used

(a)

Not used

34 User Manual CPM AX2066en Rev.B © BTG 2019

Appendix

5.3 FCM-8000 Connections

ACT-2500

BLT-5500

BTT-5500

Connection Block

DLT-5500

MBT-2500

MBT-4500

MEK-2500

RT-5500

TCR-25xx

DRT-5500 MEK-3000

TCT-25x1

RET-25x2

DO Digital Out Alarm Output Data Ready Alarm Output

P1

DI3 Digital In 3 Sample Input

P2 FF / PROFIBUS PA

See separate table below for data between Profibus and

Transmitter

Interlock

(1 = interlock)

Data Between Profibus and transmitter

Profibus

AI1 AO

AI2

AI3 AO3 Not used

Trans

mitter

AO2 Not used

ACT-2500

MBT-2500

MEK-2500

MEK-3000

Consistency

output

BT-5500

BLT-5500

Channel 1

output

Channel 2

output

Channel 3

output

DLT-5500 DRT-5500 MBT-4500

Dissolved

lignin

(Channel 1)

output

Total

consistency

(Channel 2)

output

Not used Not used Not used

Alarm Output

or PCD-1000

control

Sample Input

or Interlock

Freeness

output

Not used Not used

Sample Input

Viscosity

output

AI4

AI5 AO5 Not used

AI6 AO6 Not used

AO1 AI Not used

DI DO

DO1 DI1

DO2 DI2

DO3 DI3

AO4 Not used

Alarm Out

Calibration

set Input A

Calibration

set Input B

Sample

(a)

Input

(a) Also available on hardware. See connection table above.

Channel 4

output

Channel 5

output

Channel 6

output

Input signal

from external

equipment

(a)

Alarm Out

Calibration

set Input A

Calibration

set Input B

Initiate lab

sample

Not used Not used Not used

Not used Not used Not used

Not used Not used Not used

(a)

Temperature

or Flow Input

(a)

Calibration

set Input A

Calibration

set Input B

Sample

(a)

Input

Not used Not used

(a)

Alarm Out

Calibration

set Input A

Calibration

set Input B

(a)

Sample

Input

(a)

Data Ready(aAlarm Out

Calibration

set Input A

Calibration

set Input B

(a)

Interlock

© BTG 2019 User Manual CPM AX2066en Rev.B 35

Appendix

Profibus

AI1 AO

AI2 AO2 Not used

Trans

mitter

TCT-25x1 RET-25x2 TCR-25x1 TCR-25x2

Total

Consistency

output value

Total

consistency

(Channel 1)

output value

Ash

consistency

(Channel 2)

output value

Total

Consistency

output value

Not used

Total

consistency

(Channel 1)

output value

Ash

consistency

(Channel 2)

output value

AI3 AO3 Not used Not used Not used Not used

AI4 AO4 Not used Not used Not used Not used

AI5 AO5 Not used Not used Not used Not used

AI6 AO6 Not used Not used Not used Not used

AO1 AI Not used Not used Not used Not used

DI DO

DO1 DI1

DO2 DI2

DO3 DI3

Alarm Out or

PCD-1000

(a)

control

Calibration

set Input A

Calibration

set Input B

Sample In

(a)

Alarm Out or

PCD-1000

(a)

control

Calibration

set Input A

Calibration

set Input B

Sample In

(a)

Alarm Out

Calibration

set Input A

Calibration

set Input B

Sample In

(a)

(a)

Alarm Out

Calibration

set Input A

Calibration

set Input B

Sample In

(a)

(a)

(a) Also available on hardware. See connection table above.

36 User Manual CPM AX2066en Rev.B © BTG 2019

Appendix

5.4 FCM-8010 Connections

Connection Block RET-55xx RT-5500 SPC-5500 SPM-5500 SPK-5500

DO Digital Out 1 Alarm Output Alarm Output Alarm Output Alarm Output Alarm Output

P1

DI3 Digital In 3 Interlock Sample Input Interlock Interlock Remote stop

P2 FF / PROFIBUS PA See separate table below for data between Profibus and Transmitter

Ash

AO2 Analog Out 2

P4

Consistency

(Channel 2)

output value

4-20 mA

(RET-55x3

only)

Conductivity

(Channel 2)

output value

4 - 20 mA

White water

charge

(Channel 2)

output value

4 - 20 mA

Configurable

(Channel 2)

output value

4 - 20 mA

RMS

output value

4 - 20 mA

Start

streaming

potential for

filtrate

(Channel 1)

Start

streaming

potential for

white water

(Channel 2)

AO3 Analog Out 3

AO4 Analog Out 4

P5

Internally

pre-wired

(a)

Media temp.

(Channel 3)

output value

4 - 20 mA

Not used Not used

AO5 Analog Out 5 Not used

Analog input

signals from

AI2 Analog In 2

P6

Not used

external

equipment

4 - 20 mA

Not used

AI3 Analog In 3

Not used

AI4 Analog In 4 Not used

DI4 Not used

P7

DO2 Digital Out 2

SV4 Sol. valve 4

P8

Internally

pre-wired

Internally

pre-wired

Not used

(a)

Not used Not used

(a)

Not used

Data ready

Channel 1

SV5 Sol. valve 5 Not used

Configurable

(Channel 3)

output value

4 - 20 mA

CwZ

output value

4 - 20 mA

CwT

output value

Internally pre-

(a)

wired

4 - 20 mA

Mean Kappa

output value

4 - 20 mA

Internally pre-

(a)

wired

Internally pre-

(a)

wired

Internally

pre-wired

(a)

Sample Input

Not used Data Ready

Internally prewired

(a)

Internally pre-

(a)

wired

SV1 Sol. valve 1

P9

SV2 Sol. valve 2

Internally

pre-wired

Not used

(a)

Data ready

Channel 2

Not used

Internally pre-

(a)

wired

Internally

pre-wired

(a)

SV3 Sol. valve 3

(a) For more information about internally pre-wired connections, see the installation drawing for the transmit-

ter

© BTG 2019 User Manual CPM AX2066en Rev.B 37

Appendix

Data Between Profibus and transmitter

Profibus

AI1 AO

AI2 AO2

AI3 AO3 Not used

AI4 AO4 Not used Not used

AI5 AO5 Not used Not used Not used

Trans

mitter

RET-55xx RT-5500 SPC-5500 SPM-5500 SPK-5500

(a)

(a)

Kappa

(Channel 1)

output

RMS

(a)

output

CwZ

(a)

output

CwT

(a)

output

Mean Kappa

(a)

output

Total

consistency

(Channel 1)

output

Ash

consistency

(Chanel 2)

(a)

output

(RET-55x3

only)

Residual

(Channel 1)

output

Conductivity

(Channel 2)

(a)

output

Media temp.

(Channel 3)

(a)

output

Filtrate

charge

(Channel 1)

output

White water

charge

(Channel 2)

(a)

output

Start

streaming

potential for

(a)

filtrate

(Channel 1)

Start

streaming

potential for

white water

(Channel 2)

Configurable

(Channel 1)

output

Configurable

(Channel 2)

output

Configurable

(Channel 3)

output

Stockline

dilution

(a)

actuator

Sensor

dilution

actuator

(a)

(a)

AI6 AO6 Not used Not used Not used Not used Not used

Input signal

AO1 AI Not used

DI DO

Alarm Out

from external

equipment

(a)

Alarm Out

Not used Not used Not used

(a)

Alarm Out

(a)

Alarm Out

(a)

Alarm Out

(a)

DO1 DI1

DO2 DI2

DO3 DI3

Calibration

set Input A

Calibration

set Input B

Interlock

(a)

Calibration

set Input A

Calibration

set Input B

Sample

(a)

Input

Not used Not used

Not used Not used

Interlock

(a) Also available on hardware. See connection table above.

Calibration

set Input A

Calibration

set Input B

(a)

Interlock

Remote

(a)

stop

(a)

38 User Manual CPM AX2066en Rev.B © BTG 2019

BTG Instruments AB

P.O. Box 602

SE-661 29 Säffle

Sweden

Phone: +46 533 426 00

www.btg.com

Loading...

Loading...