User Manual for Short Wave Infrared Paint Curing Equipment

Infrared Model

IR-B02

2

Declaration of Conformity According to DIN EN 45014

Manufacturer:

Herewith, we declare that the machines and marketed models described in the following conform in

conception and in design to the relevant fundamental safety and health requirements of the applicable

EU directives.

All of our manufactured or assembled parts conform to the listed regulations.

If you change the machine without our explicit agreement, this declaration will be herewith invalidated.

Product type: Painting- and drying equipment (paint dryer)

Type designation: IR-B02

Serial-#: Construction year: 2015

Parameters:

Rated voltage:

Rated current:

Rated frequency:

Rated power input:

Protection class:

Degree of protection:

220 V

11 A

60 Hz

2000 W

I

IPX0

Tested according to:

EN 60335-1/A2:2006

EN 60335-2-30/A2:2007

EN 50366/A1:2006

This EC-Attestation of Conformity is issued on a voluntary basis according to the Low Voltage Directive

2006/95/EC relating to electrical equipment designed for use within certain voltage limits. It confirms

that the listed equipment complies with the principal protection requirements of the directive

Responsibility for technical documents: Hans-Joachim Bödrich, Michael Bellroth

Address: Refer to manufacturer’s address

Location/Date/Manufacturer’s signature

Function of the signer: Managing director

B-TEC GmbH

Zunftweg 6-8

D-31303 Burgdorf / Ehlershausen

.................................................................................

Hannover, 02.01.2015

3

Table of Contents

1. Important Information ............................................................................................................................. 4

2. Safety Regulations and Maintenance Advice ........................................................................................... 4

2.1 Work Area ........................................................................................................................................... 5

2.2 Use ...................................................................................................................................................... 5

2.3 Maintenance and Care ....................................................................................................................... 5

2.4 More Information ............................................................................................................................... 5

3. Technical Description of the Machine ...................................................................................................... 6

3.1 Technical Information ........................................................................................................................ 6

3.2 Wiring Diagram ................................................................................................................................... 6

3.3 Spare Parts .......................................................................................................................................... 7

4. Assembly / Installation ............................................................................................................................. 8

5. Operating Instructions .............................................................................................................................. 9

5.1 Curing Times ....................................................................................................................................... 9

6. Replacement of Emitter Lamp Tube ....................................................................................................... 10

7. Troubleshooting ..................................................................................................................................... 11

4

1. Important Information

Thank you for purchasing this B-Tec infrared paint curing unit IR-B02. Please note, the unit

has a rating plate attached which includes the model and serial number. Should you ever

need service or parts, please provide that information when calling B-Tec System, or your

distributor.

This short wave infrared paint dryer is specially made for baking automotive refinish coatings.

Its energy penetrates deep into the coating, ensuring not only a short baking time, but also

producing excellent through curing of the coating. Each bake cycle only costs a few cents,

making it highly efficient. The unit is built to last and its design offers the user great flexibility

to deal with all the various shapes and contours of the motor vehicle.

B-TEC equipment has been built to the highest quality standards to ensure reliability. In

order to get the best, safe use of this equipment, please read these instructions thoroughly

before commencing assembly or operation of the machine. Failure to do so could result in

damage or injury for which B-TEC will accept no responsibility or liability.

2. Safety Regulations and Maintenance Advice

B-TEC equipment is only allowed to be used for the purpose explicitly described below. Any

other use is in contrast with the regulations. The manufacturer cannot be held liable for

damages resulting from such non-regulatory use. Improper use can endanger the health of

the operator and of others and cause damage to the machine itself or to other materials and

assets.

There is no liability for damages or injuries resulting of the following situations:

Not complying with the instructions given in this manual

Changes of technical product specifications

Changes to or breaking the safety devices

5

2.1 Work Area

Do not use this equipment in an explosive or combustible environment; otherwise it may

lead to fire.

Use caution when moving the equipment over uneven floors to avoid tipping over or

damage to the emitters.

Keep the working area clean and free of any obstructions.

2.2 Use

To reduce the risk of explosion, DO NOT use in paint spray booths or within 10ft of

spraying operations, as per the requirement of UL 499.

This unit must be operated in a well-ventilated area.

Isolate power supply before removing any covers.

Regular cleaning of tubes and reflectors should be done by using a piece of soft cloth or

cotton with IPA or mentholated spirits l (Note: cleaning must only be conducted after the

machine is disconnected from the power supply and has cooled down if necessary).

Allow 15 minutes for the solvent to dissipate before switching the unit back on.

The machine should be well grounded for safety. The grounding device should be

connected to the proper output port under correct direction. Unauthorized alteration or

change of output port is strictly prohibited. Use of any outlet converter is also disallowed.

If you are ever uncertain, please find a professional electrician to check whether the

grounding is correct. Please make sure the machine is well grounded to avoid electric

shock.

If the lamp / tube fails to work after starting, it may be caused by a loosened outlet plug.

In such a case, just switch off the machine and check that plug is secure in the socket in

the connection box.

Replace any chaffed or damaged cables / wires immediately to avoid the possibility of

electric shock.

Don’t misuse the electric cable. Do not drag the machine with the power cable or pull the

power plug. Keep the power cable away from hot, oily, or sharp objects.

Should the power cable become damaged, ask the manufacturer, service provider or a

professional to replace it to reduce the risk of injury / damage.

For replacement emitters / tube / bulb, only purchase from authorized distributors

2.3 Maintenance and Care

Regular cleaning of tubes and reflectors should be done by using a piece of soft cloth or

cotton with IPA, alcohol or mentholated spirits (Note: cleaning must only be conducted

after the machine is disconnected from the power supply and has cooled down if

necessary). Allow 15 minutes for the solvent to dissipate before switching the unit back

on.

The device should be protected by a 15-Amp slow fuse.

For replacement lamps / tubes, contact your distributor.

2.4 More Information

Always turn the unit off before moving, especially over rough surfaces.

Do not use the equipment in damp or wet locations.

6

3. Technical Description of the Machine

1. Each emitter is controlled by a separate switch.

2. Each cassette has angle adjustment

3. The height is adjustable.

4. Electronic timers are incorporated to regulate the bake cycles.

5. An ultrasonic distance measuring device is provided.

3.1 Technical Information

3.2 Wiring Diagram

Input current

11 A

Input voltage

220 V / 240 V - 60 Hz (1PH)

Short wave quartz halogen infrared

tube

2 x 1000 W

Max. power

2000 W

Range of timers

2 x 35 min

Baking area

24” x 32” inches

Baking time

1 - 35 min

Dimension: (W x H x L)

28” x 61” x 24”

Ultrasonic distance measurement

Control

Board

J

Diagram

ON

ON

OFF

OFF

S2

S3

D3D2

IR1 IR2

L

E

N

T1

Main Switch

S1

D1

R

ultrasonic

emitter

- B-Tec Systems reserves the right to make technical changes without notice -

7

3.3 Spare Parts

IR-B02 Parts List

S/N

Name of Parts

Item #

S/N

Name of Parts

Item #

1

Front Wheel

B01-1

11

Protective grill

B03-13

2

Rear Wheel

B01-2

12

Emitter Tube

B03-16

3

Pedestal

B01-3

13

Ultrasonic Distance

Sensor

B03-9

4

Square-Tube Column

B01-4

14

Small reflective

Panel

B03-21

5

Side Panel of Emitter

B03-19

15

Heat Dissipating

Plate

B03-20

6

Handle

B03-12

16

Ceramic Connector

B01-B-16

7

U-shaped Support bracket

B01-B-7

17

Large Reflective

Panel

B03-22

8

Control Box

B02-1

18

Transformer

220V/6W

B01-9

9

Locking Ring

B01-22

19

Relays 10A

B03-30

10

Bent Panel

B03-18

20

Lid Control Box

B01-11

Control box

20

1

3 4 2

Emitter

5

10

17

14

15

16 5 6

8

7

6

10

12

11

13

9

18

19

8

- B-Tec Systems reserves the right to make technical changes without notice -

Cassette Assembly

8

4. Assembly / Installation

1. Insert the upper section ③ of the vertical bar into the lower section ②.

2. Take out the pedestal ①, insert the vertical bar into the pedestal ① and fasten the

screws.

3. Install the support bracket ④ onto the vertical bar. Attach the cassette assembly to

the support bracket facing forward as in diagram below and fasten the handle.

4. Attach the power wire.

5. Important: Remove the stickers from the protection covers.

6. Important: Take out the red foam cubes behind the tubes.

Notes:

Power supply: 1 PH 220V/ 240V - 60Hz

When adjusting the height of the cassette, use your left hand to support the bracket

and your right hand to loosen the handle on the locking bracket two turns, and then

move the bracket with two hands supporting the two ends of the lamp bracket. Do not

do this operation using only one hand, to avoid any damage to the emitter / tube,

should it fall from your grasp.

9

5. Operating Instructions

Notes:

Power supply: 1PH 230V 50/60HZ

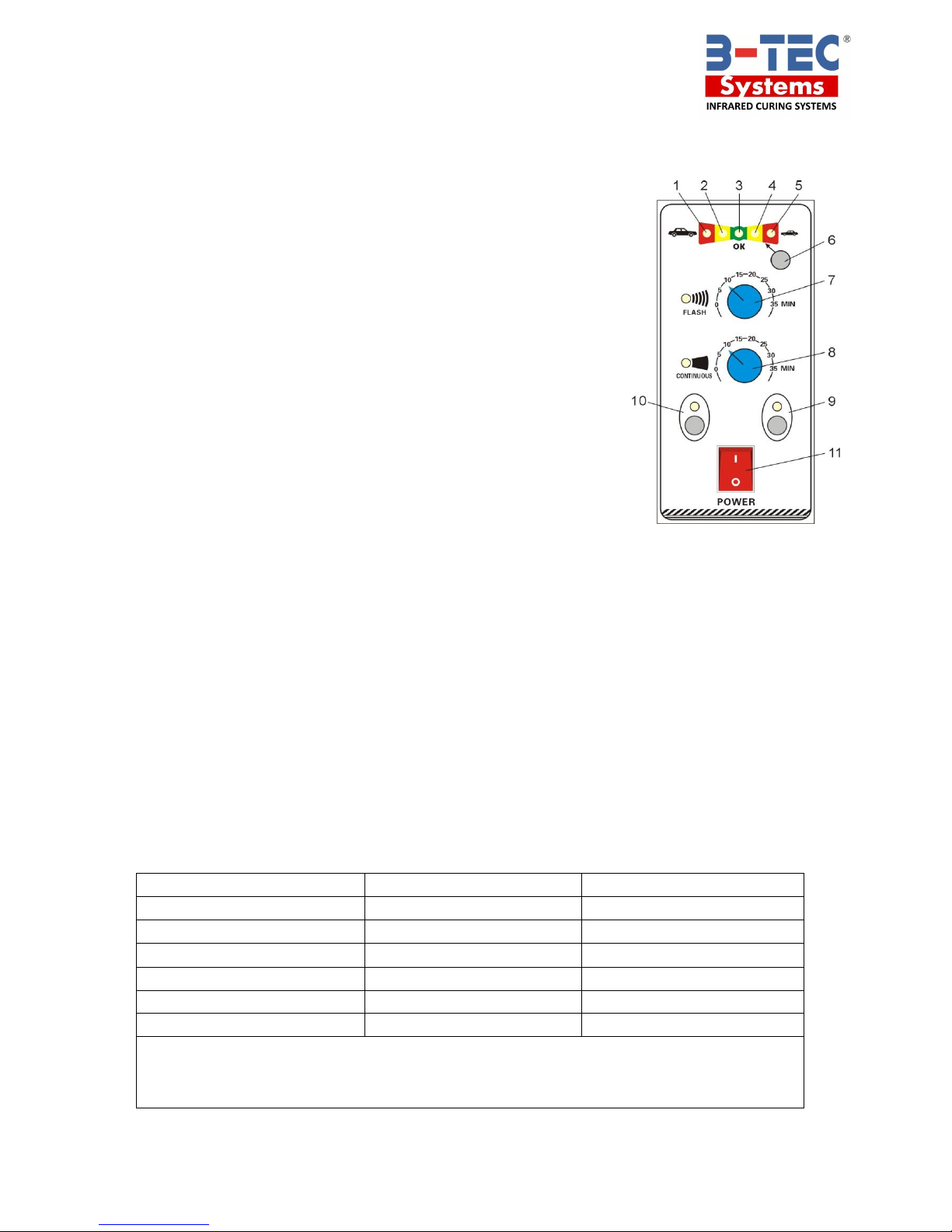

1. Adjust the direction of the emitters. They should be aligned

parallel to the car body.

2. Turn on the switch for ultrasonic distance measuring device (6) The optimal distance

is reached, when the green indicator light illuminates (3). As required, you can also

shut down and ignore this function. The optimal distance is approximately 24”

3. Adjust the timer button (7) to set Pre-heating baking time.

4. Adjust the timer button (8) to set full baking time.

5. Turn on the power switch (11).

6. Turn on the switch for ultrasonic distance measuring device (6) and set the optimal

distance. The optimal distance is reached, when the green indicator lights on (3). As

required, you can also shut down and ignore this function.

7. Select one or both emitters (9 & 10).

8. The machine stops automatically after the cycle is completed. If you want to continue using

the unit, restart the machine after 5 minutes.

Curing Times (The following times are provided as an approximate guide only)

(1) Red light: Distance is too close

(2) Yellow light: Distance is rather close

(3) Green light: Distance is suitable

(4) Yellow light: Distance is rather far

(5) Red light: Distance is too far

(6) Button for ultrasonic distance measuring

(7) Timer for half power / flash time

(8) Timer for full bake / continuous time

(9 & 10) On / off buttons for each cassette

(11) Power switch

Paint type

Flash off

Full bake (Minutes)

Filler/Stopper

---

5-7

Primer

---

6-8

Hi-build

---

10-12

Solid-color

---

11

Clear coat

---

12

Waterborne primer

---

8-10

Note: We suggest that 5 minutes half power / flash time is added when curing high build primers and

dark colors. When possible consult a B-TEC paint curing data sheet.

10

6. Replacement of Emitter Lamp Tube

Un-plug the power supply, before replacing the infrared emitter / tube.

1. Remove the side panel.

2. Release the radiating panel / reflector.

3. Disconnect the two leads to the emitter /lamp.

4. Remove the protective grill on the front of the cassette.

5. Take out the defective emitter and fit the new emitter after checking that the part you

purchased is correct. Ensure that you attach the wires correctly.

6. Install the protective grill, radiating panel and the side panel.

Use a piece of soft cloth or cotton to clean the reflector panel and the emitter with alcohol.

Cleaning must be conducted after the machine is disconnected from the power source and

cooled down if necessary. Do not restart the equipment until all solvent / cleaning fluid

residue has evaporated. 15 minutes advised as the evaporation time.

Disconnect

the wires of the emitter

1 2 3

4

5

6

11

7. Troubleshooting

PROBLEM

POSSIBLE CAUSE

POSSIBLE SOLUTION

SOLVENT

POPPING

Unit too close to panel

Move unit further away

Insufficient flash off time

Increase flash off time

Paint system has a fast reducer

Use a standard or slow reducer

UNDER CURE

OR SOFTNESS

OF THE PAINT

FILM

Unit too far away

Move unit closer

Insufficient bake time

Increase full bake time

Excessive film weight

Apply lighter coats

SOFTNESS ON

EDGES OF

REPAIR

Repair too large for I.R. unit

Split area into two, move unit for

2nd application. If flash off is

used, it will not be necessary on

second application

DIFFICULTY IN

POLISHING

OUT DIRT NIBS

Too long on bake cycle

Reduce cure time

Unit too close to panel

Move unit further away

UNEVEN CURE

IR cassettes not shaped to

contours of repair

Adjust IR cassettes for even heat

distribution

For optimal baking performance, we recommend that users should obtain either B-TEC paint

curing data, or consult the paint companies’ recommendations. A general guide is supplied

on page 9.

IF IN ANY DOUBT ABOUT ASSEMBLY OR OPERATION OF THE

UNIT PLEASE DO NOT HESITATE TO CONTACT YOUR

DISTRIBUTOR OR THE B-TEC SERVICE DEPARTMENT AT (480)

621-5304.

Above specifications and diagrams are subject to revision. B-TEC reserves the right to make any

changes without notification.

Loading...

Loading...