KLC 20

Technical Information

Wide Band Flame Detector KLC 20

for all kind of oil flames with intermittent burner operations

Short Description

The wide band flame detector KLC 20 is a compact flame detector, which is special designed for

blue burning combustion systems.

flicker frequencies of the flame.

flame signal into digital information to provide an output signal for burner control boxes. All flam

will be detected by an automatic sensitivity control.

maintenance are not necessary!

Due to international standards the flame detector KLC 20 will only detect signals caused by the

flicker of the flame and no signal

These fare signals caused by disturbing light sources, e.g. fluorescent tubes or background

radiation from hot refractories will be cut off, so that unwanted influences are not possible.

The f

lame detector is equipped with an optical interface to get online information about monitoring

of flame signal and serial number.

(formerly known as KLC 2002)

The patented evaluation of the flame signal is based on the

A RISC-

Processor enables the evaluation and conversion of the

Adjustments during commissioning and

from continuous radiation and all kinds of constant frequency.

TB_KLC_20_EN_REV1.DOCX

CE0085BP0001

es

- 2 -

TB_KLC_20_EN_REV1.DOCX

Safety Instruction

The KLC 20 is a safety component, so it is absolutely forbidden to open, to manipulate or to misuse this

flame detector! Replace the flame detector in case of any damage, fall, shock, moisture, wetness or

influences, which can destroy the flame detector, even though it is not recognizable! Repair works are

strictly prohibited!

Before working at the flame detector switch off the power supply. Before first commissioning or replacement

of the device check the wiring!

Technical Data

Input: AC 230/240 V (-15/+10%)

AC 115 V (optional)

Frequency 50 – 60 Hz

DC 24 V (optional)

Consumption typical 3 – 4 mA

Output: Switch-On Delay after energizing from safety relevant self check to final

operating condition typical 2 sec.

Switch-On delay after Flame On typical 0.5 sec.

Switch-Off time after Flame Off <0.5 sec.

max. switching current 15 mA,

max. switching power 0,3 W

max. switching voltage 280V AC / 400V DC

Optical Features: Spectral range 380 – 1150 nm, Peak wavelength 920 nm

Flicker frequencies 15 – 400 Hz

Switch on frequency: 52 Hz dominant flicker frequency

Switch off frequency: 15 Hz dominant flicker frequency

Acceptable loss of flame signal ca. 280 ms

Disturbing frequency cut off > 35Hz (optionally)

Operating Temperature: -20 to +60 °C

Humidity: max. 95%, no condensation permitted

Optional for higher temperatures

Operating position: any position

Kind of protection: IP 41

Protection Class: II

Protection against

electric shock: DIN EN 60730-2-5 (mounted)

weight: 0.029 kg

max. length of

connection cable: 1 m (optional for longer cables)

Certification: CE0085BP0001 *

* only versions with the function " Disturbing frequency cut off "

- 3 -

TB_KLC_20_EN_REV1.DOCX

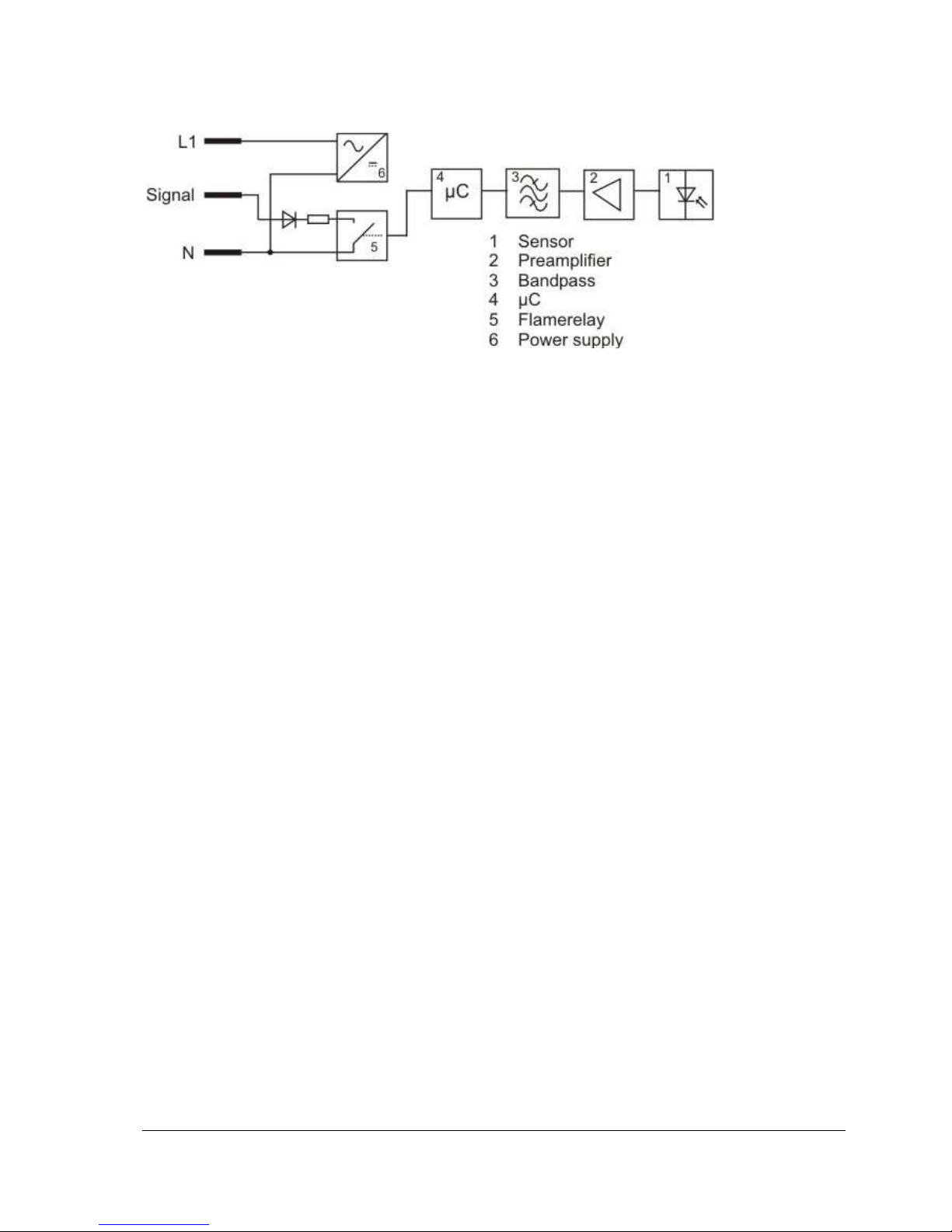

Block diagram

Mounting instructions

The KLC 20 should be mounted close to the flame with straight alignment. The compact flame detector

should be mounted with the mounting flange KLC or another suitable holder with Ø14 mm opening. The

radial adjustment to the flame is realised with the viewing angle adapter KLC and replaces the mounting

flange KLC. Fix the detector with the holder. The best flame signal will be achieved from strong flickering

parts of the flame radiation. The angle of view, especially with sight tubes, must be of appropriate

dimensions to avoid any reduction of flame radiation. Protect the sensor against other light sources.

To avoid any disturbance, do not align the detector direct to the ignition spark. Breakdowns during preventilation procedure may occur. The maximum length of the connection must be in accordance with the

technical data. Install the detector connection cable with most possible distance to the ignition cable.

Attention: For safety reasons and technical regulations a controlled burner shut down of at

least once per 24 hours must be guaranteed.

- 4 -

TB_KLC_20_EN_REV1.DOCX

Mounting flange KLC

The mounting flange KLC serves for to the

admission, attachment and adjustment of the flame detector. Two overall heights with 7 and 13mm are

available. By means of an O-ring the mounting flange KLC can be simply sealed to the burner housing.

Viewing Angel Adapter KLC for radial adjustment

With the optionally available viewing angle adapter by means of an

optimally formed out reflector surface the radial adjustment of the

KLC is accomplished 20 to the flame axle. The angle adapter

replaces the mounting flange KLC. Separate type of automatic

flame guard is not necessary therefore. With maintenance work the

reflector surface is to be controlled on possible contamination and

if necessary it is to clean with a clean, soft and lint free cloth.

Adapter ADP

The adapter ADP makes it possible to mount the flame guard series KLC with axial adjustment

directly to the combustion chamber. The integrated quartz glass is used as pressure barrier and prevents

the withdraw of heat gases from the burner. In case of higher temperature at the surface we offer a heat

insulating ADP.

- 5 -

TB_KLC_20_EN_REV1.DOCX

13,5

Dimensions

115

50 55

Viewing Angel Adapter KLC:

all dimensions in mm

Connector Diagram KLC 20

Control boxes Dungs / Satronic

Type of control box

MPA 22 TF 8..

DKO 9..

DKW 9..

DMO 9..

TMO 720-4

Blue terminal no.:

12 – 5 N 2 2 2

Black terminal no.:

12 – 3 Ion

1 1 1

Brown terminal no.:

6 – 17 L1

9 9 9

Ask for connector details of other burner control boxes.

19

7 69 48

26

35

4,5

7,5

30

22

Operating Indicator LED

Via the built-

in LED the flame detector KLC 20 is indicating the following operating conditions:

LED is OFF:

KLC is not active

LED is blinking:

KLC is active, safety test finishe

LED is ON:

KLC is active, safety test finished, flame detected

Function Disturbing frequency cut off

The KLC 20 is optionally available with the

detects only real flames, which are

and every constant frequency e.g. from fluorescent tube or other electrical lamp,

to a permanent flame detection

. In this case the KLC 20 will switch the output a first but after a period of

about 9 seconds the KLC 20 will switch the output off again. During revision it has to be kept in mind that

this propert

y is intended and no malfunction.

Commissioning and Maintenance

The installation and commissioning has to be done by qualified personnel only. Before energizing check the

cabling and wiring in accordance to the diagram. To maintain the detector just k

using a dry cloth. Do not use any kind of cleaning sprays or liquids.

plug in the flame detector to the mounting flange. A simple test of the switch on and off function is to use a

normal

AC light source. The standard version will switch the flame relay and the red LED shines

permanently. With the optional version “disturbing cut off function” the relay will be interrupted after about 9

seconds

and the red LED blinks.

necessary at any time.

Important note:

By the safety function of the

by means of a simple art source of light. If a flame simulation, e.g. du

without a real flame, is needed, a source of light with a modulating frequency between

per second

or the flame simulation device TG10

Diagnostic with KLC com

With the data int

erface KLC com, consisting of optical adapter

with cable, interface (USB

) and software, the following

information can be read from the KLC 20:

- Impulses

- Serial Number

- Version / Edition

-

present flicker frequency

For connection place the optical adapter to the opening at the

LED. Via the connection cable and the interface the a.m.

information will be transferred to a Laptop or PC by using the

special software. Further information

KLC com.

- 6 -

d, no flame detected

function disturbing frequency cut off. With this option the KLC 20

characterized by unsteady changing flicker frequencies. Constant light

are cut off and won’t lead

eep the sight glass clean by

Use only the ribbed area to pull out or

The detector KLC 20 is a self-

checking device, further tests are not

disturbing frequency cut off,

a flame simulation is not possible

ring the final inspection of the burner

is to be used.

is available in the manual

TB_KLC_20_EN_REV1.DOCX

60 and 150 cycles

- 7 -

TB_KLC_20_EN_REV1.DOCX

Overview of articles

Article Version Part-No.

Flame detector KLC 20/230 Axial, with disturbing

frequency cut off

611120110105

Flame detector KLC 20/230 Axial, with disturbing

frequency cut off and optical

IR – Filter

611120112105

Flame detector KLC 20/230 Axial, without disturbing

frequency cut off*

611120210105

Flame detector KLC 20/120 Axial, with disturbing

frequency cut off

611220110105

Flame detector KLC 20/120 Axial, without disturbing

frequency cut off

611220210105

Flame detector KLC 20/24 Axial, with disturbing

frequency cut off

611320110105

Flame detector KLC 20/24 Axial, with disturbing

frequency cut off and optical

IR – Filter

611320112105

Flame detector KLC 20/24 Axial, without disturbing

frequency cut off

611320210105

Mounting flange KLC

overall height 7 mm 665001010000

Mounting flange KLC

overall height 13 mm 665002010000

Viewing angle adapter KLC

Accessories for radial

mounting applications

615001020000

ADP 11 - UV

Adapter for direct mounting

applications

575010512210

ADP 21 - UV

Adapter for direct mounting

applications, heat insulating

575010512230

Connecting cable KLC length 300mm 661030040100

Connecting cable KLC length 350mm 661035040100

Connecting cable KLC length 600mm 661060040100

Connecting cable KLC length 1000mm 661100040100

Connecting cable KLC length 2000mm 661200040100

Connecting cable KLC On request

Data interface KLC-Com, USB

optical adapter, USB-

interface, Software

731000080980

Flame simulation device TG 10 730061010900

* Versions without disturbing frequency cut off are not permissible for gas applications

Disposal information

The flame detector is equipped with electrical and electronic components and

must be disposed separate from household waste. Follow the local and actual

regulations for waste disposal.

- 8 -

TB_KLC_20_EN_REV1.DOCX

DIN EN ISO 9001:2000

Zertifikat: 09 100 5438

UK Authorised Distributor:

HeatSol Technology Limited

9,Buckholt Business Centre

Buckholt Drive

Warndon

Worcester WR4 9ND

Telephone: 01905 457557 Fax: 01905 759515

Email for sales: sales@heatsol.co.uk

Email for technical advice: info@heatsol.co.uk

BST Solutions GmbH

Eggerscheidter Straße 57

D - 40883 Ratingen

Telefon: +49 (02102) 1005959

Telefax: +49 (02102) 1005979

Email: info@bst-solutions.de

http://www.bst-solutions.de

© BST Solutions 2015 technical modification reserved Revision 1

Loading...

Loading...