BST Web Guiding System

ekrPro Com60

with analog sensors

BST International GmbH

Heidsieker Heide 53

33739 Bielefeld, Germany

Tel: +49 5206/999-0

Fax: +49 5206/999-999

e-mail: info@bst-international.com

ekrPro Com

with analog sensors Date: 23.11.2007

60

web guide controller EDV-No.: MD.191.01.05/1.6.x

Symbols used in this operating manual

Warning signs

Symbols are used in this operating manual in order to clearly

indicate particularly important places.

Attention!

!

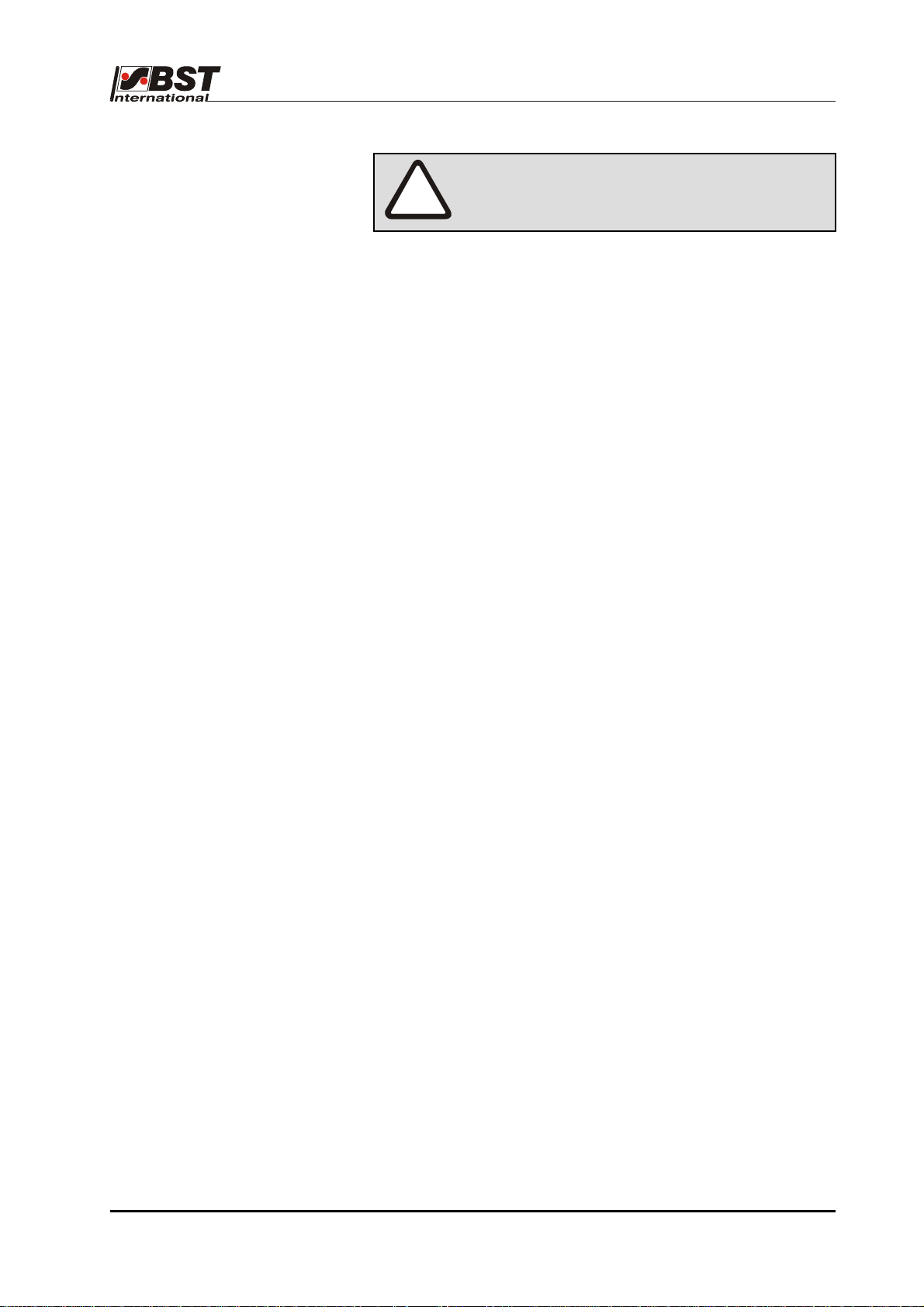

Using the keys

Using the keys is represented by the following symbols in this

manual:

You must obey this type of warning, in order to protect

yourself, as the operator, from bodily injuries arising

from mechanical movements.

Beware!

You must obey by this type of warning without fail, in

order to protect yourself, as the operator, from life

threatening injuries caused by electrical voltages.

Note

This symbol is used to point out additional useful tips,

which will help you to make optimum use of all of the

functions.

Press key.

LED operating status

indications

+

1) 2)

Some keys on the front panel of the ekrPro Com60 controller have

LED´s (light-emitting diodes) integrated in them. The different LED

operating states are represented as follows:

LED off

LED constantly lit = activated phase

LED flashing

Key combinations, keys have to be

pressed simultaneously.

Press keys in the specified order.

ekrPro Com

with analog sensors Date: 23.11.2007

60

web guide controller EDV No.: MD.191.01.05/1.6.x

Contents

Symbols used in this operating manual

Table of contents

Section A General information

Section B Commissioning

Section C Operation

Section D Appendix

ekrPro Com

with analog sensors Date: 23.11.2007

60

web guide controller EDV No.: MD.191.01.05/1.6.x

ekrPro Com60

with analog sensors

Section A

General information

A 1 Description

A 2 Specifications

A 3 Transport / Storage

A 4 Decommissioning

ekrPro Com

with analog sensors Date: 23.11.2007

60

web guide controller EDV No.: MD.191.01.05/1.6.x

Contents

Section A

General information

Symbols used in this manual

Table of contents

A 1 Description A1-1

A 1.1 General information A1-1

A 1.2 Utilisation A1-1

A 1.3 Housing versions A1-1

A 1.4 General definitions A1-2

A 1.4.1 Assignment of sensors to the guiding mode A1-2

selection keys

A 1.4.2 Inverting of the sensor signal A1-3

A 1.4.2 Size of oscillation amplitude related to sensor

scanning area A1-3

A 1.4.2 Oscillation types and curves A1-4

A 1.4.2 Allocation of FVGs for a FVGPro 2MK A1-4

A 1.5 Connectable components A1-4

A 1.6 Safety information A1-5

A 1.7 Emissions A1-5

A 2 Specifications A2-1

A 2.1 ekrPro Com

A 2.2 Optical edge sensor IR2001, IR2005 A2-3

A 2.3 Optical edge sensor IR2002 A2-3

A 2.4 IRS-U-2 A opto-electronic analog sensor A2-3

A 2.5 Ultrasonic edge sensor US2003, US2007, US2008 A2-4

A 2.6 Reflecting sensor TW 54 C 5 A2-4

A 2.7 Line sensor T 62 D 1 A2-5

A 2.8 Reflected light measuring light barrier R 42 D ... A2-5

A 2.9 Photoelectric fork sensor G 53 C2/5 A2-6

A 2.10 Switched power pack A2-7

A 3 Transport / Storage A3-1

A 4 Decommissioning A4-1

60

controller (version XT) A2-1

ekrPro Com

with analog sensors Date: 23.11.2007 Page: 1/1

60

web guide controller EDV No.: MD.191.01.05/1.6.x

Description A 1

The start-up, maintenance and installation

!

instructions described in this operating manual

must be strictly adhered to!

A 1 Description

The aim of the operating manual is to enable you to use the

guiding system rapidly by explaining the basic settings for initial

start-up (start-up menu) and the conventional functions for

operation. In addition, the complex functions will be described

using selected examples for setting certain parameters.

A 1.1 General information

This family of control systems includes:

• ekrPro Com

• ekrPro Key

Devices in the controller family can be interconnected at different

levels into a system network via a CAN-Bus.

A 1.2 Utilisation

The ekrPro Com

controller. Together with other BST components it may be used for:

• Web edge guiding (right or left)

60

: Controller with keyboard

60

: External control keyboard.

60

is a microprocessor controlled web guiding

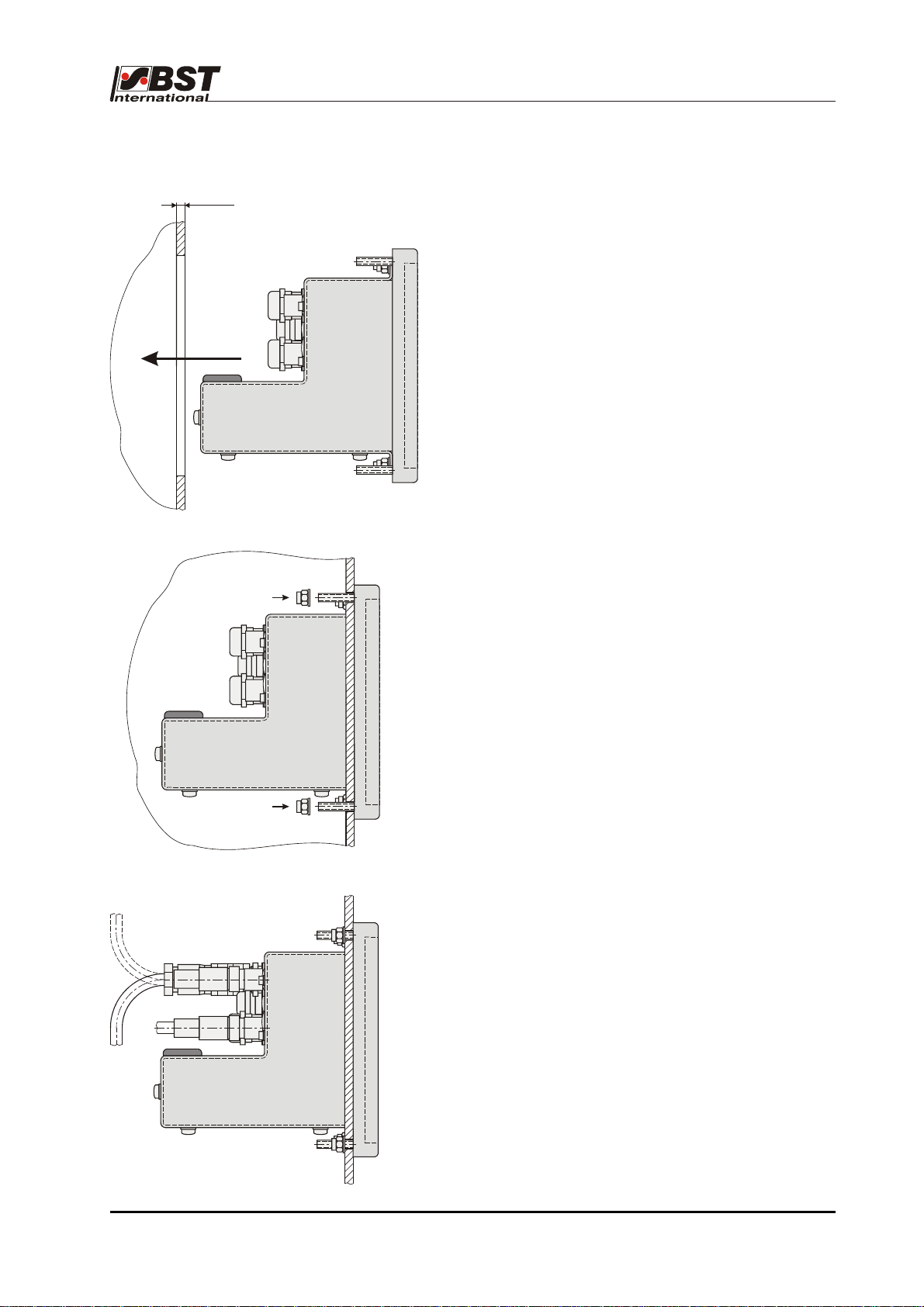

A 1.3 Housing Versions

• Web center guiding

• Guiding on continuous or interrupted printed lines

• Guiding on continuous or interrupted printed edges (still

being prepared)

• Web width measuring

The controller includes a separate control unit that can directly

control the sensor adjustment unit and it can be interconnected into

the system.

Any other utilisation must first be authorised by the manufacturer.

There are also standard PLC compatible inputs and outputs as well

as an OK-reporting system present.

The control unit ekrPro Com

60

is available in two different housing

versions:

• ekrPro Com60 XT: Mounting unit

(e.g. for wall mounting)

60

• ekrPro Key

Desk XT: Built-in unit

(e.g. for insertion in a

control console)

ekrPro Com

60

web guide controller

EDV No.: MD.191.01.05/1.6.x Chapter: A 1

with analog sensors Date: 23.11.2007 Page: 1/5

Description A 1

A 1.4 General

Settings

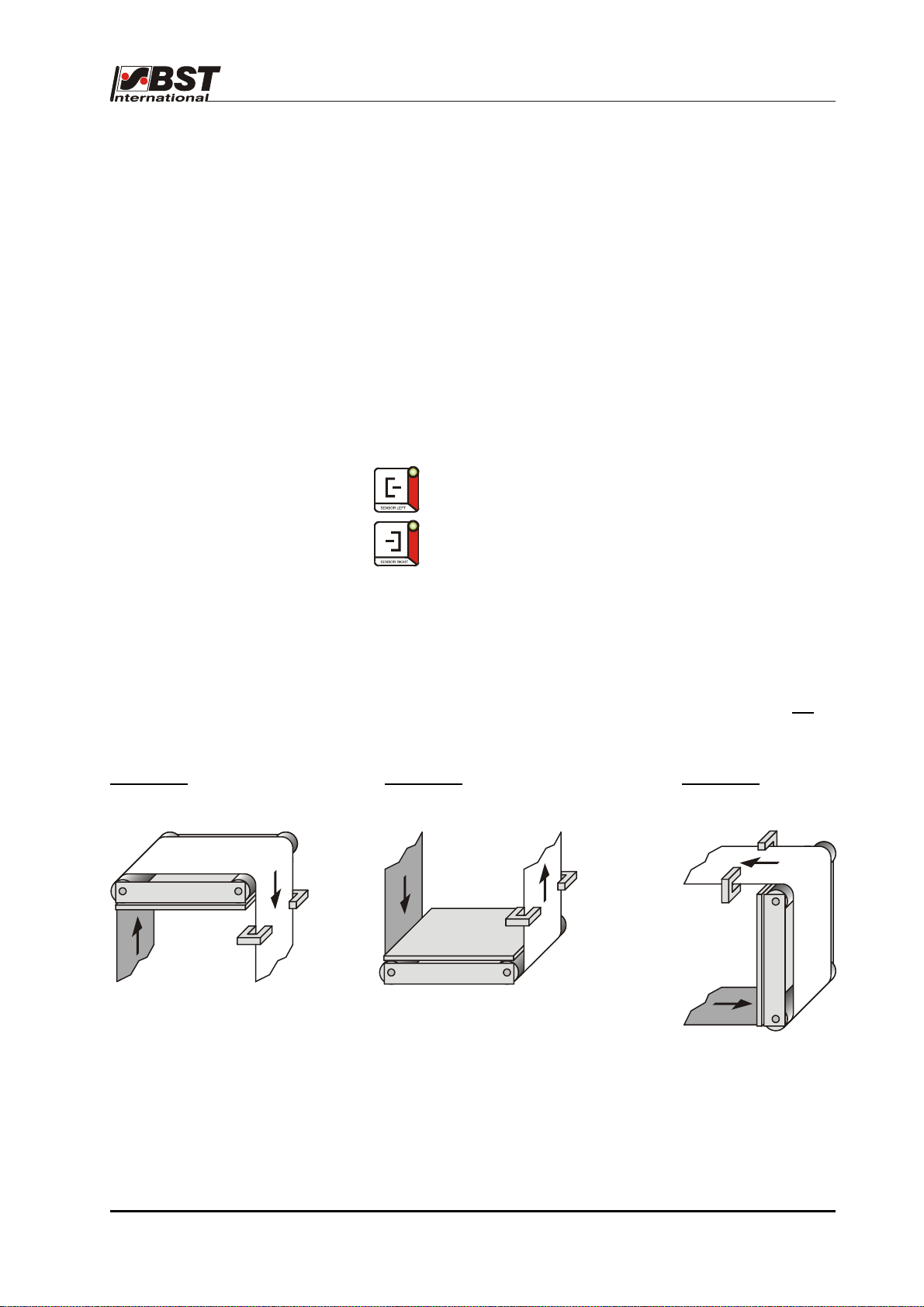

A 1.4.1 Assignment of sensors to the

to the scanning mode selection keys

In this operating manual, the edge sensors that are connected to

the controller are designated with “sensor 1” and “sensor 2”. On

the operating keyboard of the controller, the guiding mode

selection keys have the lettering „SENSOR LEFT“ and „SENSOR

RIGHT“ respectively.

According to the BST definition, the following link applies:

SENSOR LEFT = Sensor 1

SENSOR RIGHT = Sensor 2

The following is valid in respect of the sensor mounting positions:

The sensor, which is located to the left of the material in the

web movement direction (when looking from the material top

side), is sensor 1.

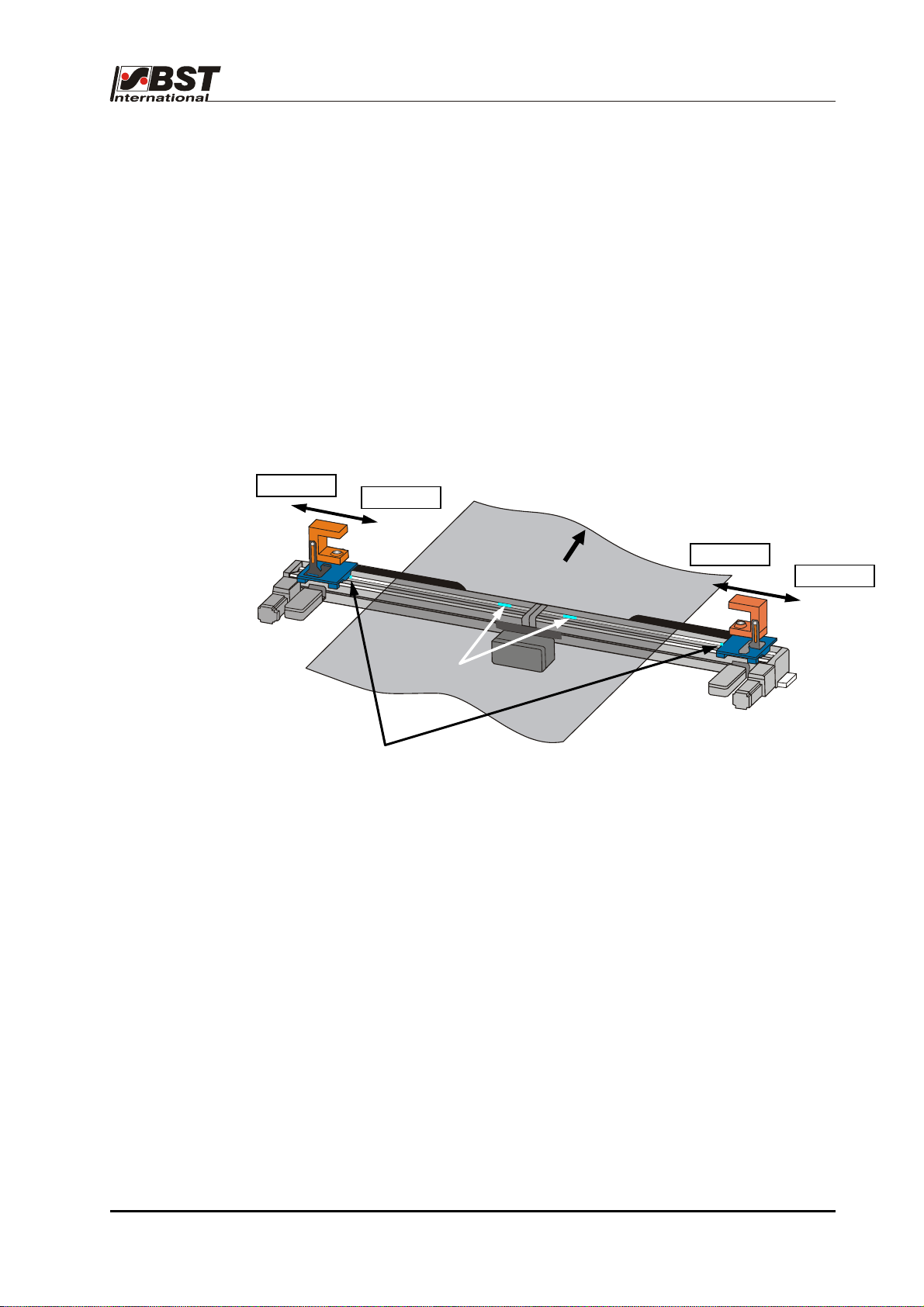

Example 1:

The material top side is the side of the material web which is not

direct contact with the deflection pulleys of the pivoting frame.

Example 2: Example 3:

Sensor right

(Sensor 2)

Sensor left

(Sensor 1)

Sensor left

(Sensor 1)

Sensor right

(Sensor 2)

Sensor left

(Sensor 1)

As standard, sensor 1 (Sensor left) must be connected to

connector X50 (terminal X1), while sensor 2 (Sensor right) must be

connected to connector X51 (terminal X2) of the terminal board.

Sensor right

(Sensor 2)

in

ekrPro Com

60

web guide controller

EDV No.: MD.191.01.05/1.6.x Chapter: A 1

with analog sensors Date: 23.11.2007 Page: 2/5

Description A 1

A 1.4.2 Inverting of the

sensor signal

If a BST edge sensor, of typical C-design, is mounted according to

the BST definition (see section A 1.4.1) as "Sensor left" (sensor 1),

then no inversion of the sensor signal is necessary.

If a BST edge sensor is mounted according to the BST definition

as "Sensor right" (sensor 2), then inversion should be activated via

the setup menu (see section B 3.4.4.3.1).

When the control units is delivered, inversion of the

sensor signal for sensor 2 is activated (factory setting).

Sensor left

Not permitted:

► Sensor:

Invert!

(Sensor looks to the left in the

direction of travel.)

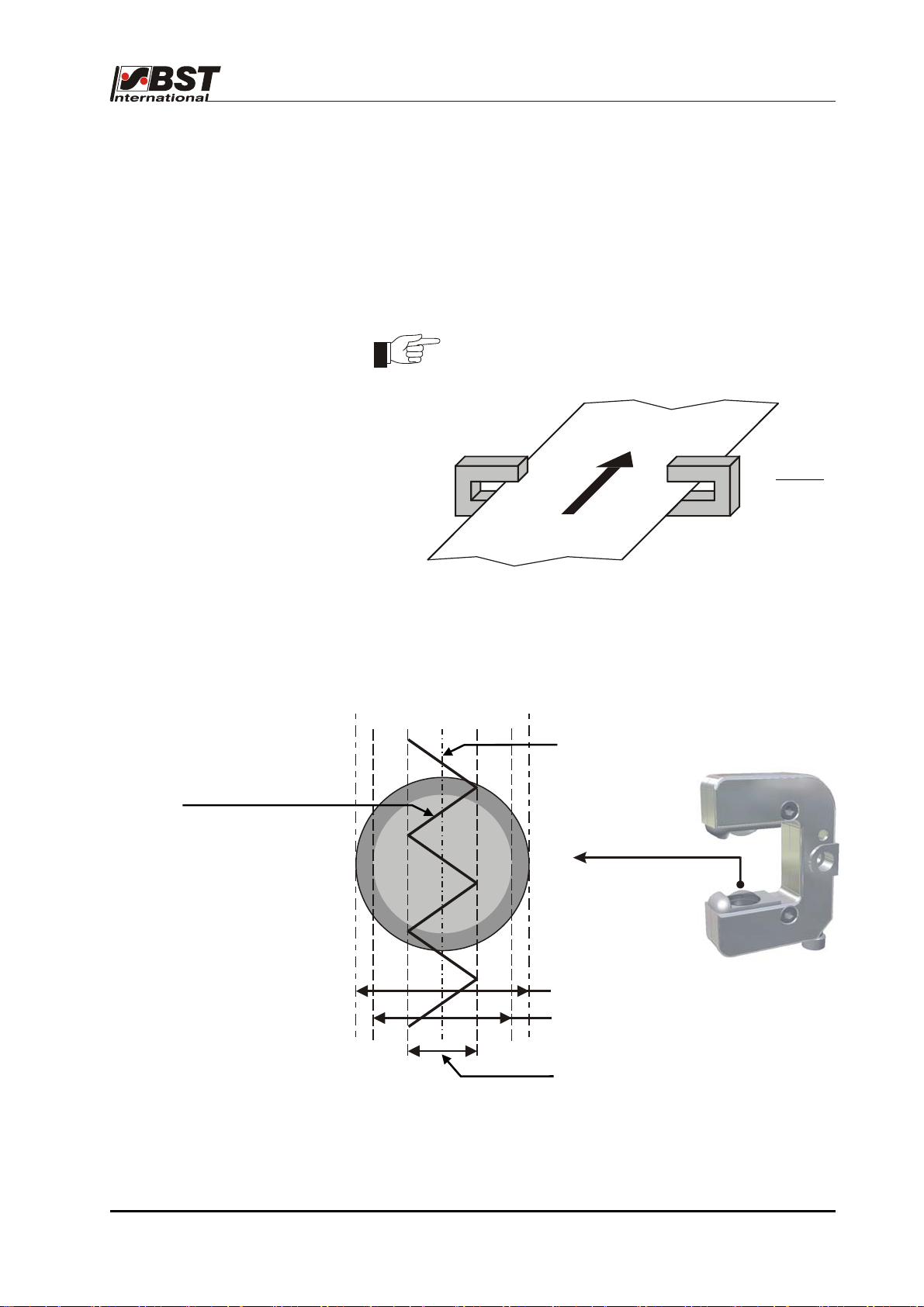

A 1.4.3 Size of oscillation amplitude

related to sensor scanning area

0 %

30 %

70 %

100 % Sensor coverage

Centre of sensor scanning area (visual range).

Oscillating web position

100 % of the sensor visual range

80 % of the sensor visual range =

maximum oscillation amplitude

40 % of the sensor visual range

The maximum possible oscillation amplitude is 80% of the sensor

visual range.

As an example, the oscillating web position is shown herewith an

attitude of 40% in "Sensor oscillation" mode.

ekrPro Com

60

web guide controller

EDV No.: MD.191.01.05/1.6.x Chapter: A 1

with analog sensors Date: 23.11.2007 Page: 3/5

Description A 1

A 1.4.4 Oscillation types and curves

An oscillation can be implemented either as a sensor oscillation or

an FVG oscillation.

In the case of the sensor oscillation, the curve described is a delta

function.

The FVG oscillation describes a curve in accordance with a sine

function.

Selections and settings are described under Point B 3.7.5.8.2.

A 1.4.5 Allocation of FVGs for a FVGPro 2MK

Traverse the FVG using the

appropriate key in the menu window

<<< >>>

FVG 1

>>> <<<

internal

limit switch

external

limit switch

Web travel direction

>>> <<<

<<< >>>

FVG 2

A 1.5 Connectable

components

The general plan (annex C2) shows the components that can be

connected to the ekrPro Com

60

controller.

60

ekrPro Com

with analog sensors Date: 23.11.2007 Page: 4/5

web guide controller

EDV No.: MD.191.01.05/1.6.x Chapter: A 1

Description A 1

A 1.6 Safety information

The safety relevant information in accordance with DIN EN 294,

DIN EN 349 and the industry specific safety regulations must be

taken into consideration when installing the BST equipment in the

production machine, these include:

• There must be a safe distance between the BST equipment and

the machinery already installed on-site, such as machine

panels, building structure, etc.

• The interconnecting lines between the control equipment and the

control components or edge sensors must be laid so that nobody

can trip over them, they are not taught and they are well

anchored.

• Ensure that there is sufficient free headroom.

If the free passage is restricted, the relevant building

components causing the restrictions must be padded and a

danger warning signs must be attached to them (yellow/black).

Only trained specialist personnel are permitted to

undertake the assembly, installation and

!

commissioning!

Before starting work, ensure the equipment is

electrically isolated. To this end always carry out the

following measures:

1. Switch off

2. Prevent switching back on.

3. Check the equipment is isolated.

4. Earth.

5. Cover or shield any adjacent parts that are still live.

The mains power must always be switched off before

the equipment is opened.

If it becomes necessary to work on the open equipment

with voltage applied, then only Protection class IP 20 is

provided.

There is always increased danger because of the mains

!

!

• Any transport safety devices that were used must be removed

prior to commissioning.

voltage!

Do not use the chassis or machine frame as a climbing

aid or a stepladder.

Do not remove any of the safety devices.

Positioning movements will be undertaken by the

actuator during functional testing away from the

production machine and/or during the commissioning!

The relevant safety arrangements must implemented

during performance checks!

Monitor the overall safety concept of the production

machine during commissioning!

A 1.7 Emissions

The A-rated equivalent continuous sound level of the equipment is

less than 70 dB(A).

60

ekrPro Com

with analog sensors Date: 23.11.2007 Page: 5/5

web guide controller

EDV No.: MD.191.01.05/1.6.x Chapter: A 1

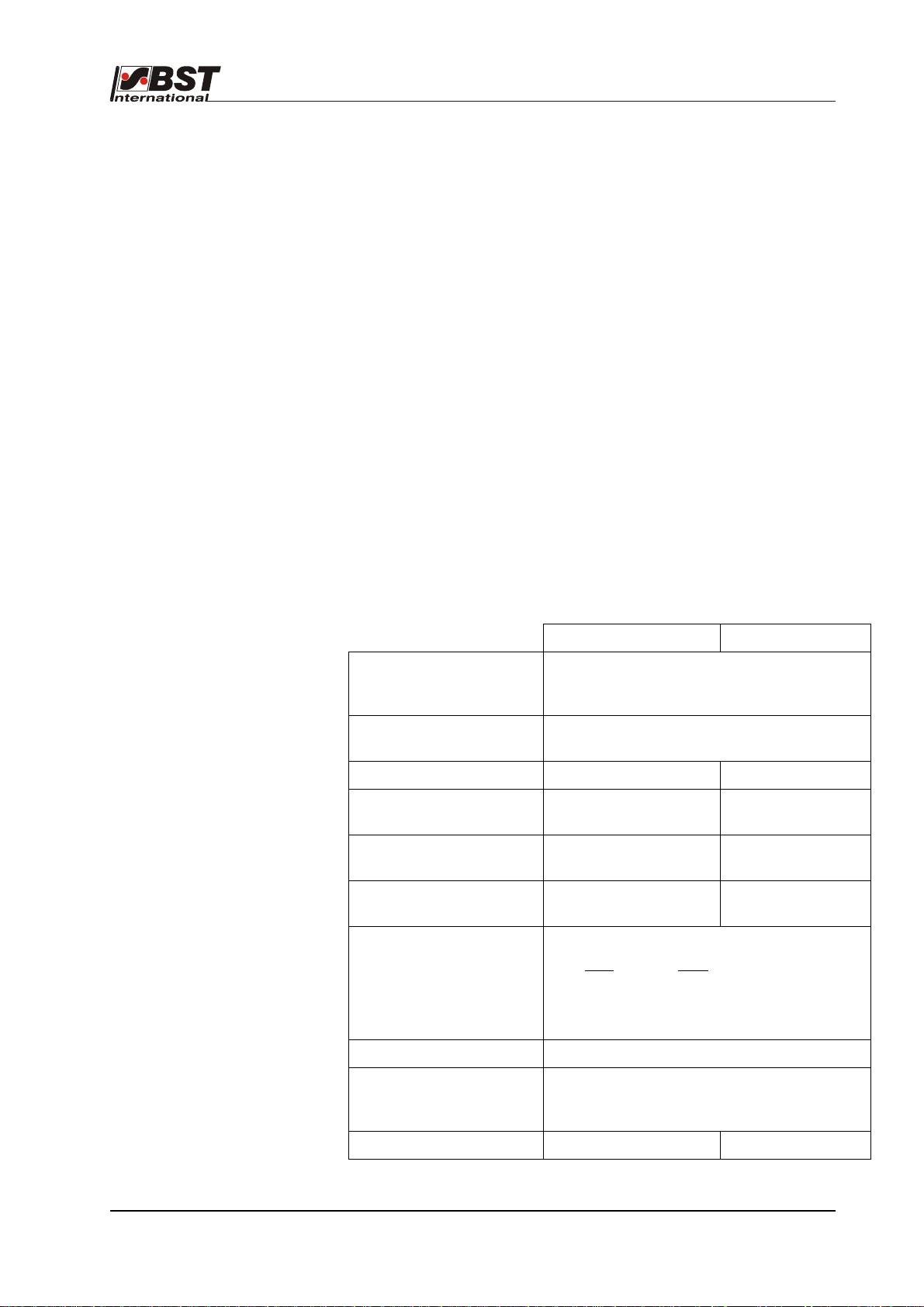

Specifications A 2

A 2 Specifications

A 2.1 ekrPro Com

Power supply 24V DC ± 5%

Power consumption 4W (without motor)

Input capacitance approx. 950µF

Controller inputs 2 x sensors, -9,75 V ...+9,75 V oder 0 V ...+9,75 V

FVG inputs 1x blocking, no

Digital inputs 12x digital inputs, no

Power supply outputs 2 x 24V (for CCD Pro camera)

60

controller (version XT)

12 bit selectable via software.

1 x sensor, -10,3 V to +10,3 V, 12 bit

1x EFE pot, -10,3 V to +10,3 V, 12 bit

1x pot return, -10,3 V to +10,3 V, 12 bit

1 x tacho, -9,0 V to + 9,0 V

1x blocking, input resistor 4.7 KΩ, operating points (<4 V (low)

and >8 V (high)), but can only be used against “+“ switched

sensors (pnp)

2x reference switch, no metallic separation

input resistor 4.7 KΩ,

operating points (<4 V (low) and >8 V (high)),

but can only be used against “+“ switched sensors (pnp),

supply 24V DC

input resistor 4.7 KΩ,

operating points (<4 V (low) and >8 V (high)),

but can only be used against “+“ switched sensors (pnp),

supply 24V DC

metallic separation

metallic separation,

Controller outputs Controller outputs -10.3V to -10 V, 12 bit 1x analog output

-10 V to +10 V, 2 mA

2x IR pulses

1x lamp supply 5 V, 1 A

Digital outputs 4 x digital outputs +24V, 1.0A per output, 1.5A

in total

No metallic separation.

Protected against feedback (positive voltage)

Controller output stage 1x DC motor 24V DC, max. 3 A, short circuit protected.

Select voltage, current or tachometer control (in preparation)

PWM 20 kHz

FVG output stage 1 x stepping motor, max. 1.5A; not

short circuit protected

CAN-bus 1x plug, 1x socket; no metallic separation

Screw connections /

plugs

Variable through exchangeable connection plate;

see Appendix D6

Protection class IP 54

60

ekrPro Com

web guide controller EDV No.: MD.191.01.05/1.6.x Chapter: A 2

with analog sensors Date: 23.11.2007 Page: 1/7

Specifications A 2

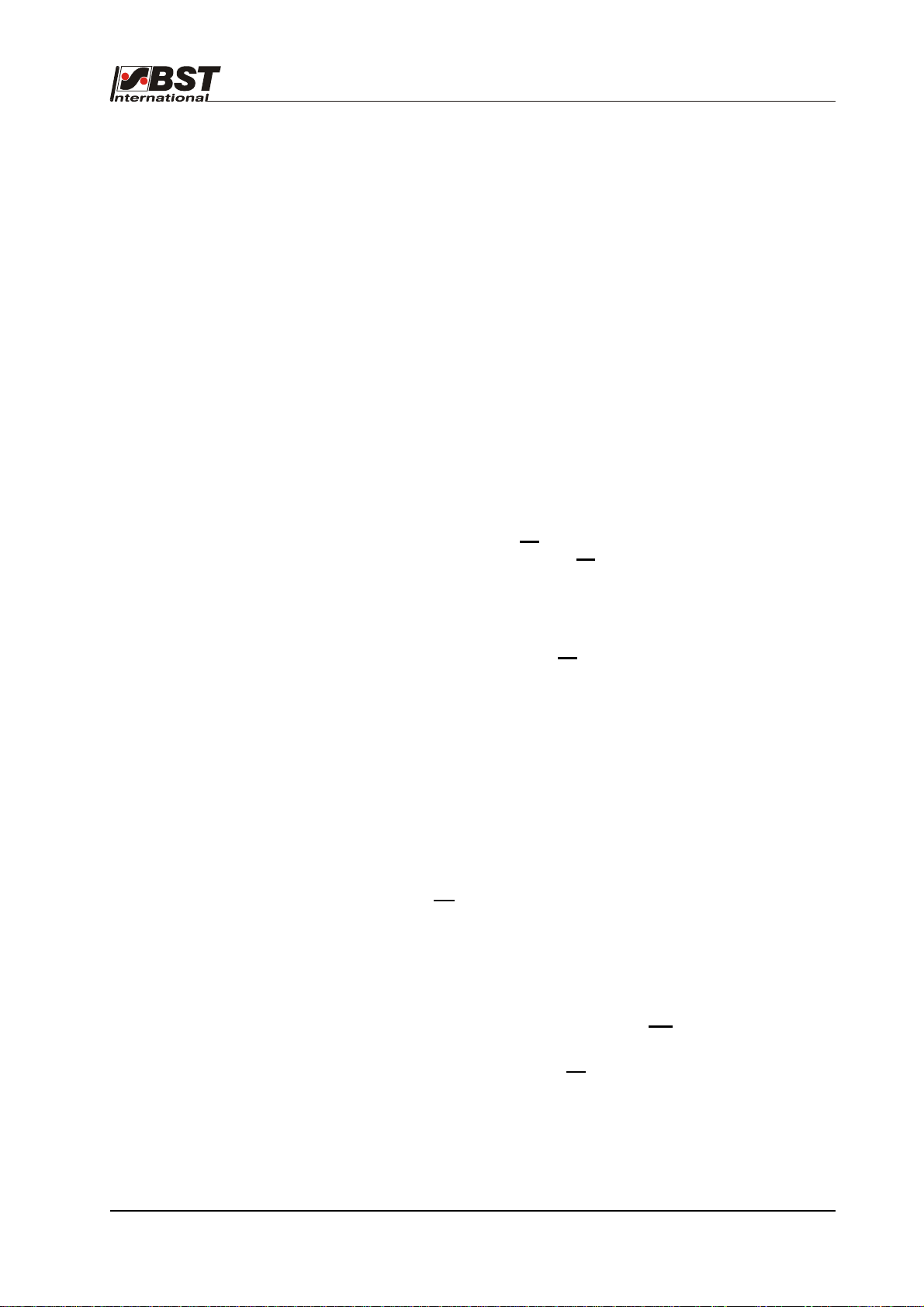

240

140

Display: LCD graphics module with 128 x 64 pixel and LED

background illumination

Ambient conditions: Temperature: 0° to 45°C max.

Humidity: 5% - 90%,

no condensation

Weight: ekrPro Com

ekrPro Com

60

: approx. 2.1 kg

60

Desk: approx. 2.3 kg

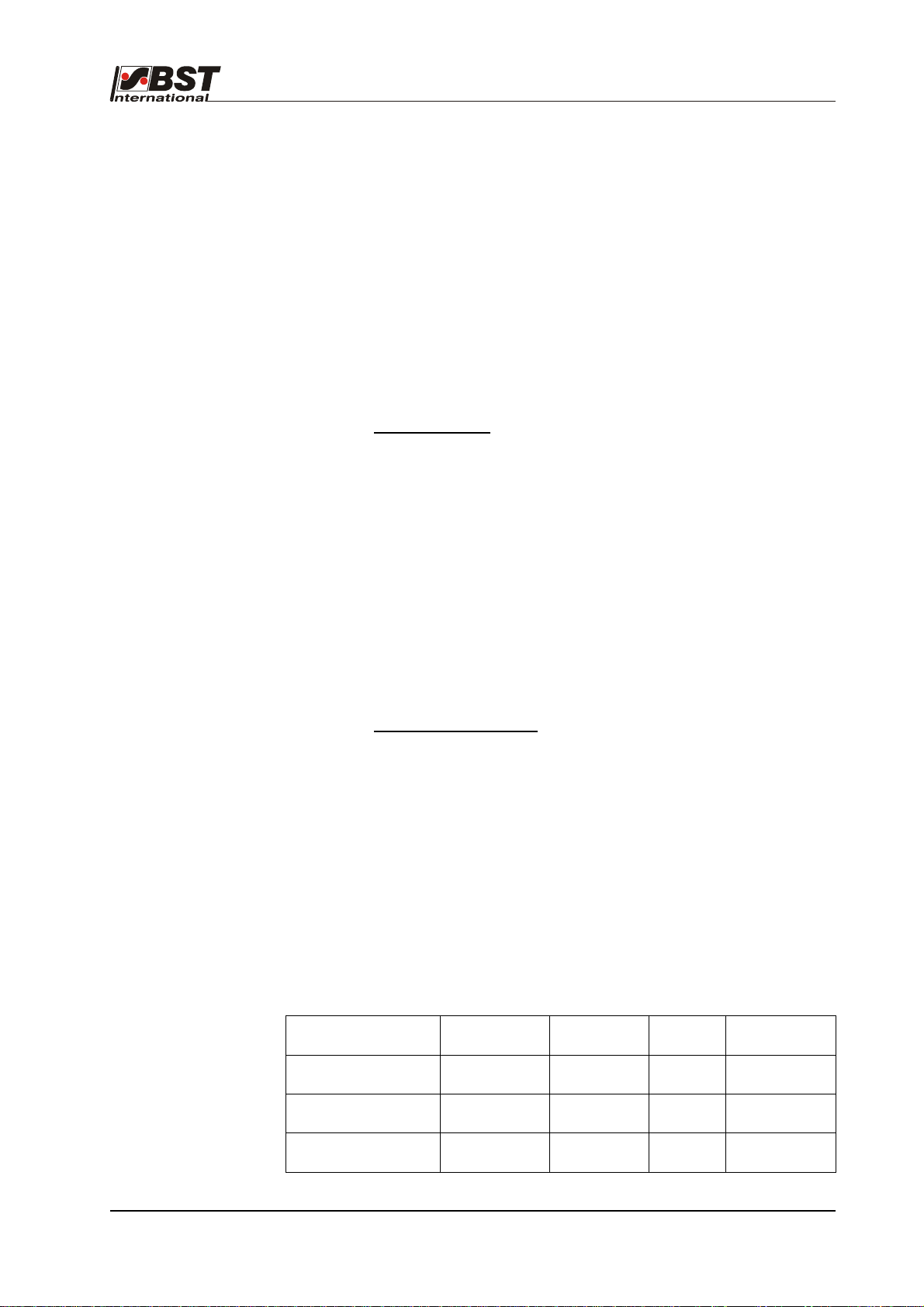

Case dimensions ekrPro Com

60

(Mounting unit):

140

160

240

70

Installation ekrPro Com

60

Desk (Built-in unit)

225

125

105

205

max. 10

15115

60

ekrPro Com

web guide controller EDV No.: MD.191.01.05/1.6.x Chapter: A 2

with analog sensors Date: 23.11.2007 Page: 2/7

Specifications A 2

A 2.2 A2.2 Optical edge sensor

IR 2001, IR 2005

Power supplies: from the controller

Measuring range, typical: 12 mm

Visual range, typical: 15 mm

Output: analog

Protection class: IP 54

Ambient conditions: Temperature: 0 to a max. 45 °C

Humidity: 5% - 90%, no condensation

Case dimensions:

(standard version)

A 2.3 Optical edge sensor

IR 2002

Power supplies: from the controller

Measuring range, typical: 8 mm

Visual range, typical: 13 mm

Output: analog

Protection class: IP 54

Ambient conditions: Temperature: 0° to 45°C max.

Case dimensions:

(standard version)

A 2.4 IRS-U-2 A opto-electronic analog sensor

See the manufacturer’s data-sheet

W = 40 mm

H = 95 mm

D = 107 mm

Humidity: 5% - 90%, no condensation

W = 25 mm

H = 57 mm

D = 85.5 mm

60

ekrPro Com

with analog sensors Date: 23.11.2007 Page: 3/7

web guide controller EDV No.: MD.191.01.05/1.6.x Chapter: A 2

Specifications A 2

A 2.5 Ultra-sonic sensor

US2003, US2007,

US2008

Power supplies: from the controller

Measuring range, typical: 15 mm (US 2008 = 4 mm)

Visual range, typical: 15 mm (US 2008 = 6 mm)

Output: analog

Protection class: IP 54

Ambient conditions: Temperature: 0 to a max. 45 °C

Humidity: 5% - 90%, no condensation

A 2.6 Reflection button

TW 54 C5

Case dimensions:

(standard version)

Power supplies: 8V – 15V; from the controller

Lamp voltage: 5V; 0.8A; from the controller for:

Measuring range: 5.0 mm at 6 mm sensing distance

Output signal: Negative with black areas

Protection class: IP 65

Ambient conditions: Temperature: 0 to a max. 50 °C

Weight: 240 g

Case dimensions: W = 26 mm

B= 25 mm

H = 76 mm

D = 113 mm

maximum of one sensor

2.5 mm at 13 mm sensing distance

Positive with white areas

Humidity: 5% - 90%, no condensation

H = 54.5 mm

D = 85.5 mm

60

ekrPro Com

with analog sensors Date: 23.11.2007 Page: 4/7

web guide controller EDV No.: MD.191.01.05/1.6.x Chapter: A 2

Specifications A 2

A 2.7 Line sensor T 62 D 1

Power supplies: from the controller

Lamp voltage: 5 V; 0.8 A

Sensing distance: 15 -30 mm

Measuring range: 3 -8 mm

Line widths: 0.5 -5 mm

Output voltage: 0 to ±10V

Protection class: IP 65

Ambient conditions: Temperature: 0 to a max. 50 °C

Humidity: 5% - 90%, no condensation

Weight: 1,100 g

Case dimensions: B= 67 mm

H = 105 mm

D = 128 mm

A 2.8 Reflected light

measuring light barrier R 42 D, etc.

R 42 D 12 R 42 D 16

Power supplies: +12V, 12 mA or

±12V, 15 mA or

±15V, 20 mA

Lamp voltage: 5V, 4W; from the controller for a maximum of

one sensor

Max. distance: 1 m 2 m

Measuring range

15 mm 40 mm

in front of front lens:

Diameter of light beam

25 mm 55 mm

in front of front lens:

Diameter of light beam

40 mm 55 mm

at half distance

Output voltage:

at: U

= +12 V

B

U

= ±12 V

B

U

= ±15 V

B

Corresponding to change in illumination:

dark

light

8.5V 2V

8.5V 0V

10.5V 0V

Protection class: IP 65

Ambient conditions: Temperature: 0° – 70°C

(temperature compensation

only up to 50°C

Weight: 1,000 g 1,200 g

60

ekrPro Com

web guide controller EDV No.: MD.191.01.05/1.6.x Chapter: A 2

with analog sensors Date: 23.11.2007 Page: 5/7

Specifications A 2

A 2.9 Fork light barrier

G 53 C2/5

Power supplies: from the controller

Lamp voltage: 5V

Fork width: 29 mm

Measuring range: ± 3.5 mm

Diameter of light beam: 11 mm

Protection class: IP 65

Ambient conditions: Temperature: -20 to a max. 60 °C

Humidity: 5% - 90%, no condensation

Weight: 400 g

Case dimensions: B= 21 mm

H = 85 mm

D = 87 mm

60

ekrPro Com

with analog sensors Date: 23.11.2007 Page: 6/7

web guide controller EDV No.: MD.191.01.05/1.6.x Chapter: A 2

Specifications A 2

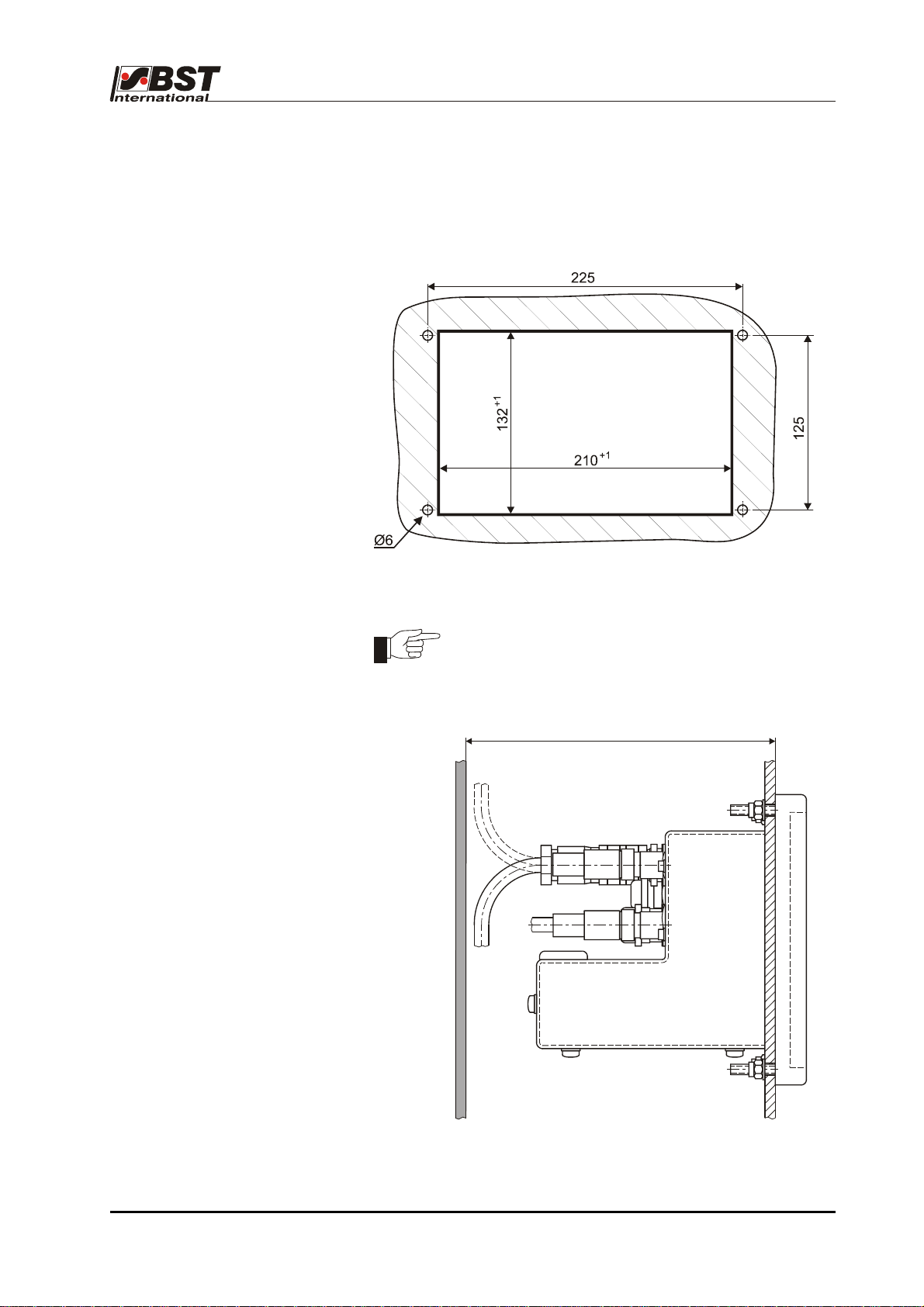

A 2.10 Switched power pack

Supply of the ekrPro Com

60

including the BST components takes

place over the switched power pack.

There are two supply possibilities:

1. over a central power pack in the machine

2. over a power pack allocated to the BST part

The following details are based on a control system comprising a

control unit ekrPro Com

60

, analogue sensors, sensor adjustment

unit and actuator (EMS1, EMS5, EMS10, EMS16, EMS17 or

EMS20)

1. Central supply

If supply takes place centrally from the machine the following

parameters are to be fulfilled:

• Output voltage: 24 V DC ± 5%

• Output current: 4.2 A DC

• Output power: 100 W

The power pack must be able to quickly charge (~ 5 sec) the input

capacitance (approx. 950µF) of the control amplifier after switching

on without recognizing this as a short circuit and so switching off

again.

The output should be permanently resistant to short-circuiting,

overloading and idle running.

2. Separate power pack

If a separate power pack is used for the BST components, we

recommend the use of units manufactured by PULS GmbH:

Input voltage: 85 - 264 V AC or 220 – 375 V DC

Output voltage: 24 V DC ± 5%

Output current: 4.2 A DC

Output power: 100 W

BST order number: 103 837

If a number of control systems are to be supplied from a single

switched power pack, then, dependent on the total required power,

the following power packs are also available:

Input voltage

85 – 264 V AC

220 -700 V DC

85 – 264 V AC

220 -700 V DC

340 – 479 V AC /3Ph.

450 -700 V DC

Output

voltage

24 V DC ± 5 % 10 A DC 240 W 118 661

24 V DC ± 5 % 20 A DC 480 W 109 365

24 V DC ± 5 % 20 A DC 480 W 116 679

Output

current

Output

power

BST order

number

60

ekrPro Com

web guide controller EDV No.: MD.191.01.05/1.6.x Chapter: A 2

with analog sensors Date: 23.11.2007 Page: 7/7

Transport A 3

A 3 Transport

The equipment will be shipped in accordance with the details

stipulated in the order:

• completely assembled and interconnected to the web guide

control system

• as component parts in standard cardboard boxes with cellular

lining material

If the unit will not be incorporated immediately, it should be stored

in a dry room until installation.

60

ekrPro Com

with analog sensors Date: 23.11.2007 Page: 1/1

web guide controller EDV No.: MD.191.01.05/1.6.x Chapter: A 3

Decommissioning A 4

A 4 Decommissioning

Decommissioning (scraping) the systems must be carried out in

together with the entire machine.

The necessary procedures must be prepared by the manufacturer

of the machine. You must take into consideration that the control

system is generally considered to be an electrical / electronic

device, which must be disposed of in accordance with the current

legal requirements.

You might also be able to return the system to BST International

GmbH, but the corresponding agreement must be made first.

ekrPro Com

60

web guide controller

EDV No.: MD.191.01.05/1.6.x Chapter: A 4

with analog sensors Date: 23.11.2007 Page: 1/1

ekrPro Com60

with analog sensors

Section B

Commissioning

B 1 Installation

B 2 Controls

B 3 Commissioning

B 4 Terminal assignments and service displays

ekrPro Com

with analog sensors Date: 23.11.2007

60

web guide controller EDV No.: MD.191.01.05/1.6.x

Contents

Section B

Commissioning

Symbols used in this manual

Table of contents

B 1 Installation B1-1

B 1.1 Installation site requirements B1-1

B 1.2 Installation ekrPro Com

B 1.2.1 Securing hole diagram B1-1

B 1.2.2 Installation B1-1

B 1.3 Installation ekrPro Com

B 1.3.1 Installation dimensions B1-2

B 1.3.2 Cabling B1-2

B 1.3.3 Installation B1-3

B 1.4 Installation instructions for EMC-wiring B1-4

B 1.5 Installation contrast/line sensor B1-5

B 1.5.1 Sensor arrangement B1-5

B 1.5.2 Installation line sensor T 62 D 1 B1-6

B 1.5.3 Installation reflection sensor TW 54 C 5 B1-7

B 2 Display and operating controls B2-1

B 2.1 Control panel B2-1

B 2.2 Navigating within the system B2-2

B 2.2.1 Function keys (F-keys) B2-2

B 2.2.2 Arrow keys B2-5

B 2.2.3 Buttons B2-6

B 3 Commissioning B3-1

B 3.1 General information B3-1

B 3.2 Electrical connections B3-2

B 3.3 Commissioning with a CAN bus B3-3

B 3.3.1 Check unit address or set up if necessary B3-3

B 3.3.2 Terminator activation B3-5

B 3.4 Adjust password B3-7

B 3.5 Commissioning standard system B3-9

B 3.5.1 Select standard system B3-9

B 3.5.2 Carry out master setup B3-10

B 3.5.3 Setting the actuator guiding direction B3-11

B 3.5.4 Setting the actuator path limits B3-11

B 3.5.5 Servo centre position and amplification for the B3-12

“SC” operating mode

B 3.5.6 Carry out material setup B3-13

B 3.5.6.1 Automatic material set-up B3-14

B 3.5.6.2 Manual material set-up B3-14

B 3.5.7 FVG - Sensor positioning device B3-15

B 3.5.8 Additional Functions B3-19

B 3.5.8.1 Tear Off Detection B3-19

B 3.5.8.1 Oscillation B3-23

B 3.6 Save settings B3-25

60

(Mounting unit) B1-1

60

Desk (Built-in unit) B1-2

ekrPro Com

60

web guide controller EDV No.: MD.191.01.05/1.6.x

with analog sensors Date: 23.11.2007 Page: 1/2

B 3.7 Set-up menu B3-26

B 3.7.1 Change User - User level selection B3-26

B 3.7.2 Material Setup - Sensor compensation B3-26

B 3.7.3 Sel. Std. System - Selection of a standard system B3-26

B 3.7.4 Save/Load settings- Load or save settings B3-26

B 3.7.5 General Set-up - System parameters B3-27

B 3.6.4.1 Setting the default values B3-27

B 3.6.4.2 Actuator –Actuator settings B3-28

B 3.6.4.3 Sensors/ EF E - Com m i s si o n i ng s e n so r s a n d EF E B3-35

B 3.6.4.4 Control Loop - Control loop settings B3-37

B 3.6.4.5 FVG - Sensor positioning device B3-38

B 3.6.4.6 Width Measure - Web width measurement B3-50

B 3.6.4.7 Edge Sources - Assignment of the sensors B3-54

to the guiding modes

B 3.6.4.8 Add. Functions - Special functions B3-56

B 3.6.4.9 Dig. IO Config. - Configuration of the digital B3-60

inputs and outputs

B 3.6.4.10 Special - Special device settings B3-69

B 3.6.5 Opt. Logic - Optional logic B3-72

B 3.6.6 Fieldbus - Field bus B3-72

B 3.6.7 Remote Device - Commissioning with a CAN bus B3-73

B 3.6.8 Test - Test program for service purposes B3-74

B 4 Terminal assignments and service displays B4-1

B 4.1 Board overview B4-1

B 4.2 Terminal diagrams B4-2

B 4.3 Service indicator displays B4-9

ekrPro Com

60

web guide controller EDV No.: MD.191.01.05/1.6.x

with analog sensors Date: 23.11.2007 Page: 2/2

Installation B 1

22

B 1 Installation

B 1.1 Installation site requirements

The ekrPro Com

free area.

Ambient conditions: Temperature: 0 to a max. 45°C

Humidity: 5 - 90%, no condensation

B 1.2 Installation ekrPro Com

60

(mounting unit)

B 1.2.1 Securing hole diagram

Ø

6

B 1.2.2 Installation

Attention! A free area of at least 300 mm in front of the housing

must be guaranteed so that it can be opened.

60

controller must be installed in a dry, vibration-

5

ekrPro Com

60

housing

5

2

1

1. Drill the securing holes as

shown in the mounting plan.

2. Use the four

screws to attach the

housing.

3. Wire in the electric cables (if

required) or plug in the

necessary cable

connections.

securing

60

ekrPro Com

web guide controller EDV No.: MD.191.01.05/1.6.x Chapter: B 1

with analog sensors Date: 23.11.2007 Page: 1/7

Installation B 1

B 1.3 Installation

ekrPro Com60 Desk

(built-in unit)

B 1.3.1 Installation dimensions

B 1.3.2 Cabling

Attention!

A space of at least 140 mm must be guaranteed for the

cabling in order to ensure that the cables are laid

correctly (see illustration).

Section

min. 140

60

ekrPro Com

with analog sensors Date: 23.11.2007 Page: 2/7

web guide controller EDV No.: MD.191.01.05/1.6.x Chapter: B 1

Installation B 1

B 1.3.3 Installation

max. 10

1. Cut out the insertion hole and drill four

mounting holes

(installation dimensions see chapter B 1.3.1).

2. Slide the ekrPro Com

60

Desk into the recess.

3. Use the four securing screws to secure the

controller ekrPro Com

60

Desk in place.

4. Wire in the electric cables or plug in the

necessary cable connections.

Attention!

A free area of at least 300 mm in front of the

housing must be guaranteed so that it can be

opened.

60

ekrPro Com

web guide controller EDV No.: MD.191.01.05/1.6.x Chapter: B 1

with analog sensors Date: 23.11.2007 Page: 3/7

Installation B 1

B 1.4 Installation instructions for EMC-wiring

housing wall

Union nut

Intermediate supports

Cable insert

1. Unscrew in the union nut for the cable

screw-in cable glands.

2. Pull out the clamping insert from the

intermediate supports.

Attention! Do not press down on the

cable insert.

3. Strip cable back by 8 mm so that the

screen braiding is uncovered

4. Pull the union nut onto the cable

5. Feed the cable into the cable clamp

and bend the screening back over the

cable clamp.

6. Push the clamping insert to the

intermediate support.

7. Fit the screws.

60

ekrPro Com

web guide controller EDV No.: MD.191.01.05/1.6.x Chapter: B 1

with analog sensors Date: 23.11.2007 Page: 4/7

Installation B 1

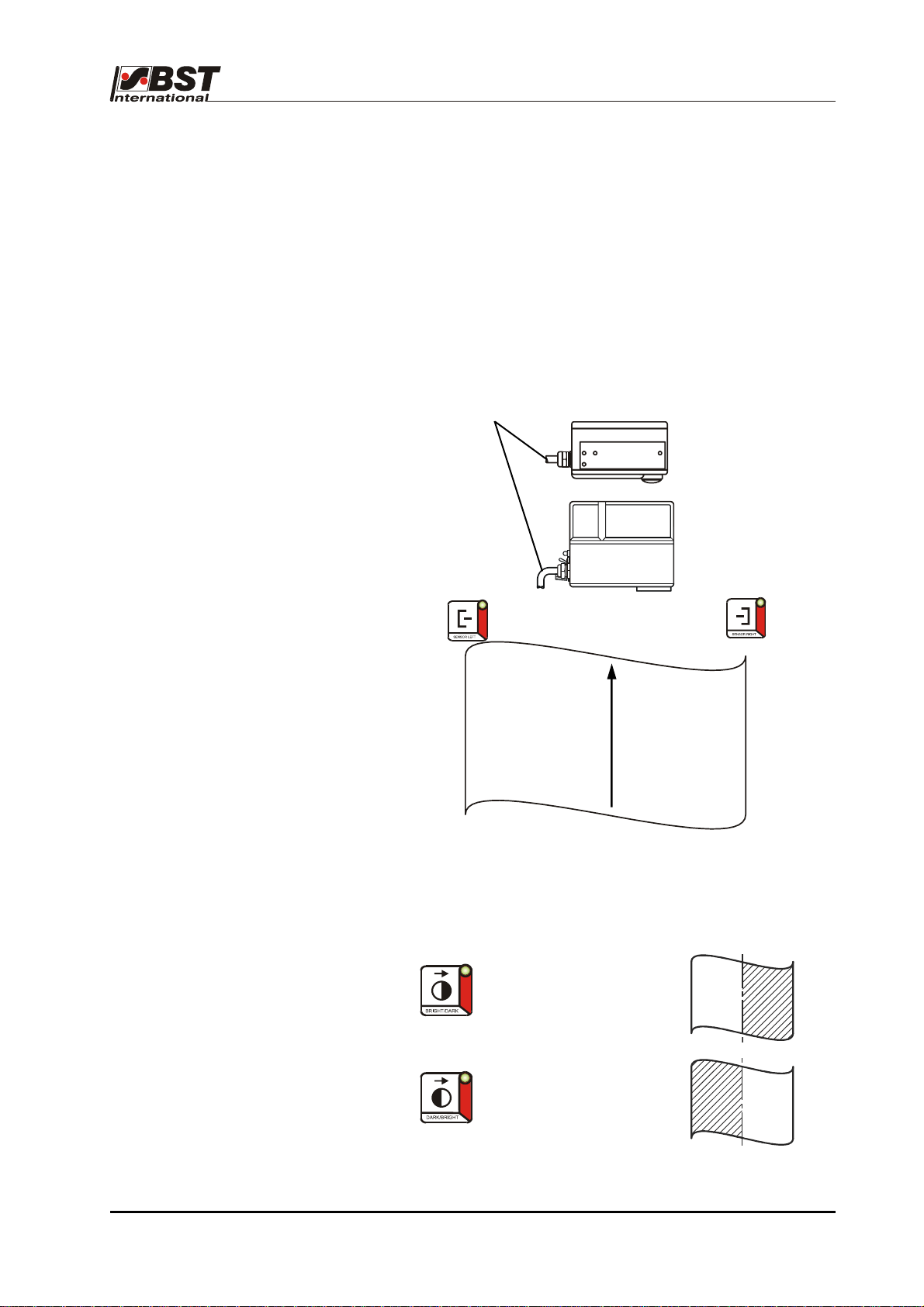

B 1.5 Installation

contrast / line sensor

B 1.5.1 Sensor arrangement

The sensors must be arranged as follows in order to ensure clear

allocation of the two keys on the front foil of the controller to the

corresponding contrast transitions:

• The sensor connection cable points in the direction of

sensor 1.

Sensor 1

This sensor arrangement results in the following key allocation:

Connection

cable

Material web

→

→

TW 54 C 5

T 62 D 1

Sensor 2

web running direction

Contrast transition

BRIGHT/DARK

Contrast transition

DARK/BRIGHT

60

ekrPro Com

with analog sensors Date: 23.11.2007 Page: 5/7

web guide controller EDV No.: MD.191.01.05/1.6.x Chapter: B 1

Installation B 1

°5°

°

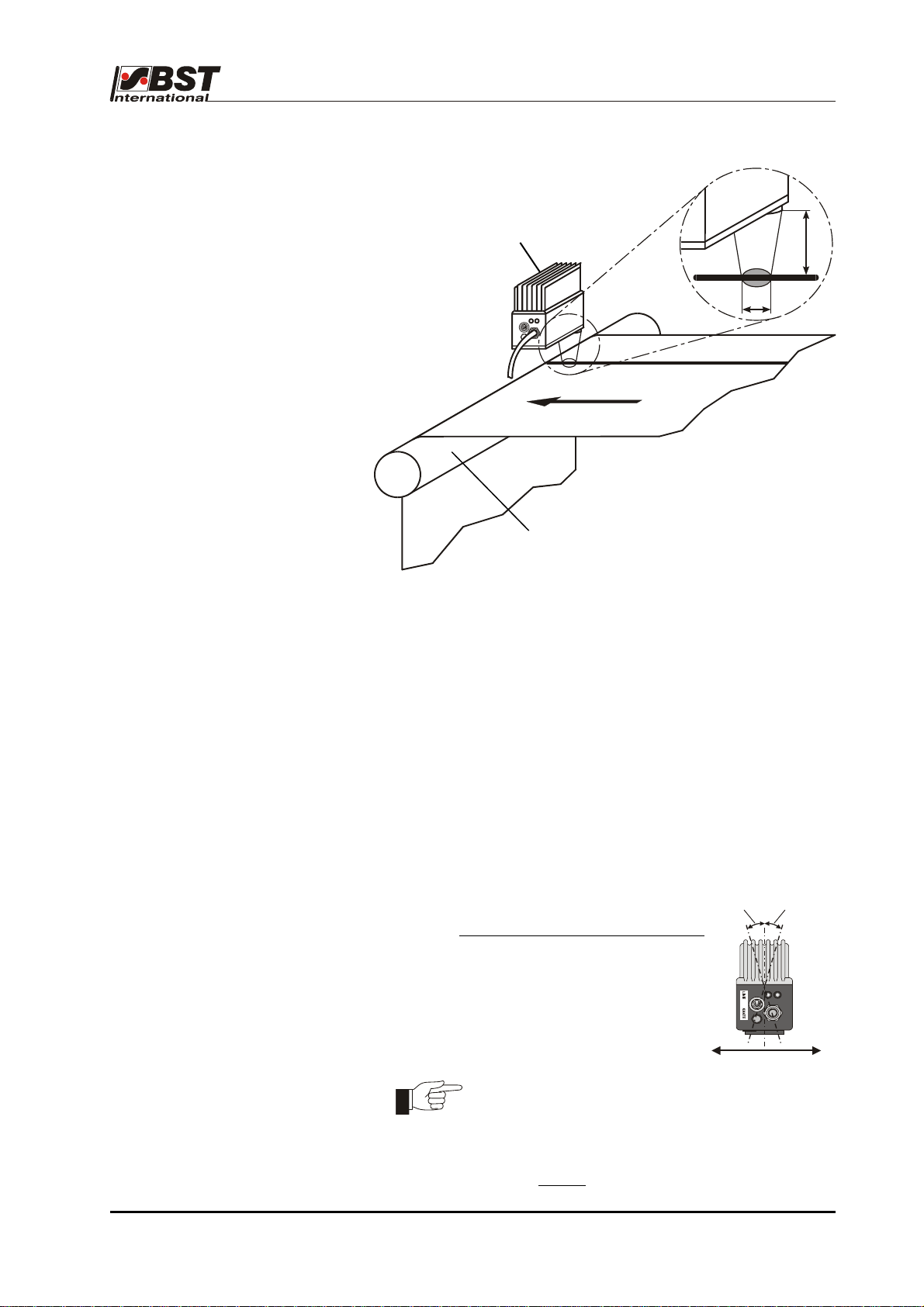

B 1.5.2 Installation

line sensor T 62 D 1

T 62 D 1

17

ø8

Deflection roller

Scanning arrangement T 62 D 1

The following points must be adhered to during installation of the

T 62 D 1 in order to realise optimum guiding results:

• The line sensor should be mounted on a torsionally rigid base.

• The line / contrast must be placed at right angles to the

longitudinal axis of the sensor (see drawing).

• The scanning should be carried out on a deflection roller.

This will ensure that any material web height fluctuations are

eliminated at the scanning point.

• The distance between the sensor scanning optics and the

material web must be set so that there is a light spot with a

diameter of approximately 8 mm (corresponding to a scanning

distance of approximately 17 mm) on the web.

• We recommend that the sensor angle is

reduced by 5° - 15° in the web running

direction when using very reflective materials

.

…15

5°…15

Web running direction

The light spot diameter can be reduced in size by

altering the distance from the web in order to

optimise the system when working with poor

contrast or narrow lines.

The scanning distance clearance must never

exceed 30 mm

.

60

ekrPro Com

web guide controller EDV No.: MD.191.01.05/1.6.x Chapter: B 1

with analog sensors Date: 23.11.2007 Page: 6/7

Installation B 1

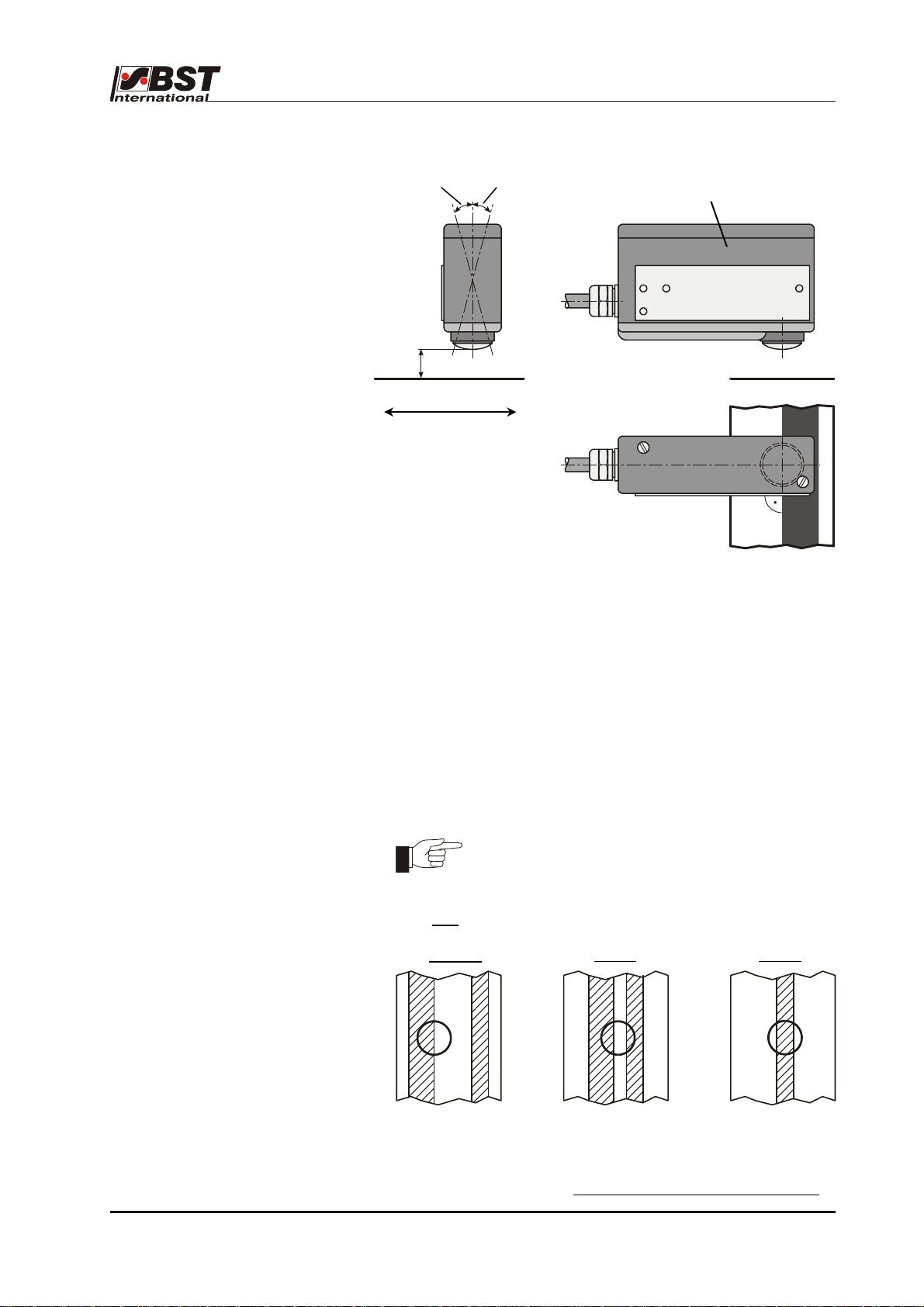

B 1.5.3 Installation

reflection sensor TW 54 C 5

5°…15°

5°…15°

TW 54 C 5

6…12

web running direction

You must abide by the following points when installing the

TW 54 C 5 reflection scanner in order to realise optimum guiding

results:

• The line sensor should be mounted on a torsionally rigid base.

• The line / contrast must be placed at right angles to the

longitudinal axis of the sensor (see drawing).

• The scanning should be carried out on a deflection roller.

This will ensure that any material web height fluctuations are

eliminated at the scanning point.

• The distance between the sensor scanning optics and the

material web has to be 6 - 12 mm, depending on the required

measuring range (diameter of the light spot).

The measuring range (light spot diameter)

depends on the distance between the contrast

transitions.

Only one

contrast transition may be located within the light spot.

correct

wrong wrong

Distance scanning optics D material web: 6 - 12 mm

Light spot diameter: 7.5 – 4 mm

• We recommend that the sensor angle is reduced by 5° - 15° in

the web running direction when using very reflective materials

60

ekrPro Com

web guide controller EDV No.: MD.191.01.05/1.6.x Chapter: B 1

with analog sensors Date: 23.11.2007 Page: 7/7

.

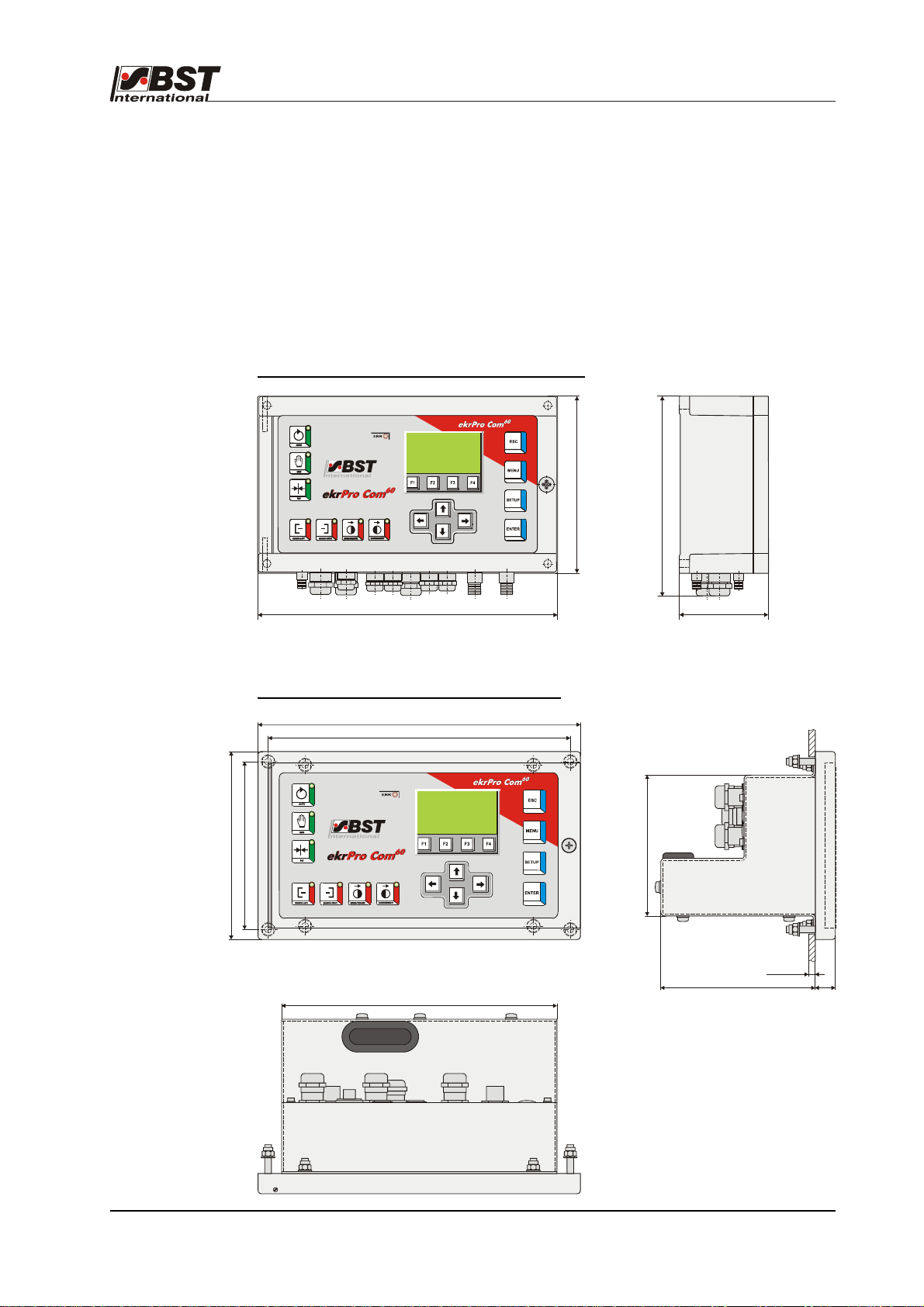

Controls B 2

B 2 Display and operating controls

B 2.1 Control panel

Graphics display

A contrast-rich LCD display with LED background illumination.

Display has 6 lines, each of 28 characters.

The graphics display is used for displaying the operating hours,

parameters and the set-up menus.

Keypad

The controller can be configured for operation using this keypad.

Key Function

+

Automatic guiding

Manual positioning

Centring the guiding device (servo-center)

Left web edge guide

Right web edge guide

Web center guiding

Edge / contrast control:

Contrast transition: light / dark

Edge / contrast control:

Contrast transition: dark / light

ekrPro Com

with analog sensors Date: 23.11.2007 Page: 1/6

60

web guide controller EDV No.: MD.191.01.05/1.6.x Chapter: B 2

’Automatic’ operating mode:

• Moves the setting to the left/right

’Manual’ operating mode:

• Manual left/right positioning of the

guiding device

• Change between the operating status

displays

Controls B 2

Key Function

B 2.2 Navigating within the system

Use the arrow keys and the F1 – F4 function keys to navigate

within the system.

The different functions are explained in the following.

If incorrect entries are made, or if functions are active which, for

example, prevent entering of parameters (e.g. keyboard lock) the

appropriate message windows are shown on the display for

5 seconds

This gives the user information about which error is present in the

current case. The message can be deleted using the "OK" key.

Menu navigation:

In editing box:

Jump back by one level

Cancels the last entry

Select controller settings or controller gain

for change the settings

Saves the settings at the end of the set-up

functions

Activates special functions

(e.g. oscillation)

(not used at the present moment)

Menu selection

ekrPro Com

60

web guide controller EDV No.: MD.191.01.05/1.6.x Chapter: B 2

with analog sensors Date: 23.11.2007 Page: 2/6

Controls B 2

B 2.2.1 Function keys (F-keys)

The F-keys functions are assigned in different dialog windows. The

associated abbreviated names are displayed at the bottom edge of

the screen.

Press the relevant F-key several times to select the required

numerical value. The time interval in between pressing the button

twice must never exceed 0.5 seconds.

Shortcut functions

The function keys are assigned numbers in the equipment menu.

Therefore a menu option can be selected by using the arrow keys

to navigate to the required menu sub-option or it can be selected

directly by using the shortcut number instead.

For example:

Selecting the actuator

The associated menu sub-option is 611

(see navigation overview as well).

1. Press key . This will display the set-up menu.

1

Current position

in device menu

Assignment of allocated

function keys

To enter the shortcut number:

2. Press F2 key 3x = 6.

51

The "General setup" menu including the first "Actuator"

submenu is called up.

3. Press the F1-key once = 1

Materia l Setup

Actuator

Sel. Std. System

Save/Load Settings

General Setup

opt. Logic

123 45 6 789 0

Type (EMS&Hydr.)

Sensors/EFE

Hydraulics Add-on

Control Loop

Direction

FVG

SC-Transducer

511

The required dialog will be displayed and you can now use the

arrow keys to select the parameter that has to be modified.

ekrPro Com

60

web guide controller EDV No.: MD.191.01.05/1.6.x Chapter: B 2

with analog sensors Date: 23.11.2007 Page: 3/6

Controls B 2

Entries in the editing box

The parameter values are entered directly in the editing box. This

can also be realised using the F-keys.

1. Open the required sub-menu and then press the ENTER key

to activate the editing box.

2. Use the horizontal arrow keys to mark the initial

position for the settting.

Width Measure Offset

current width:

enter ref.width

123 456

3. Enter the number. For example: press F4 x 1 = 0.

The actual position will jump automatically by 1 place to the

right after 0.5 seconds without an entry being made.

4. Now enter the next number in the same way as described

above in Section 3.

5. Press the ENTER button to import the modified value.

6. Press the ESC button to cancel the value.

Editing box

The arrow keys can also be used to enter a value in the editing box

in addition to using the F-keys.

Width Measure Offset

current width:

enter ref.width

123 456

Use the horizontal arrow keys to position the cursor on

the number to be modified.

Now use the vertical arrow keys to increase or decrease

the number.

Press ENTER to import the entered value.

Press the ESC button to cancel the value if you do not want to

save it.

789 0

mm

78.5

0

mm

78.5

0

789 0

Opened

editing box

Selected

digit

Opened

editing box

ekrPro Com

with analog sensors Date: 23.11.2007 Page: 4/6

60

web guide controller EDV No.: MD.191.01.05/1.6.x Chapter: B 2

Controls B 2

Entering negative numbers

Use the horizontal arrow keys to mark the initial

position for the setting.

Now use the vertical arrow keys so that the minus sign

is entered or removed.

After this, enter the digit sequence as described above.

B 2.2.2 Arrow keys

Various entries can be made and options can be selected from the

menu mode dialog windows.

The procedure for the various controls and lists is as follows:

Control elements

Use the arrow keys to mark the required control if there are several

control elements displayed in the same dialog window.

For example:

sens.mode W XP

0

0

0

0

5.00

5.00

5.00

5.00

Use the ’right’ arrow key to scroll forward and

use the ’left’ arrow key to scroll backwards.

The vertical arrow keys do not have a function here.

Option lists

An entry from a default list can be selected from an option list. This

is realised by pressing the ENTER button to open the selected

option list.

Example:

Select an actuator type

EMS 17

Select an actuator type

EMS 10

EMS 16

EMS 17

123 456 789 0

The “▼“ or “▲“ symbols displayed on the right of the option list

indicate that there are more entries in list than are displayed on the

screen.

Use the vertical arrow keys to mark the position in the

list.

Confirm the selection by pressing ENTER.

ekrPro Com

60

web guide controller EDV No.: MD.191.01.05/1.6.x Chapter: B 2

with analog sensors Date: 23.11.2007 Page: 5/6

Controls B 2

Checkbox

Use the vertical arrow keys

Arrow keys option using the checkbox control element.

Example:

(de)activate speed control

active

X

X = Option active

= Option inactive

Read-only Checkbox

Read-only checkboxes only have a display function.

These give the operator reports about the current status of the

components (e.g. stop switch statuses).

Example:

= activated

= not activated

B 2.2.3 Buttons

Button control elements are present in certain dialog windows

Select a sensor type

sensor1

<<<

dark

-2048 abs. 1775

auto

IR 2005

7%

dark

Inv.

bright

2047

bri.

If a button is marked and the ENTER button is pressed afterwards,

an action will be executed (e.g. traversing the actuator).

The button will be displayed as being pressed down and the action

will continue to be executed all the time that the ENTER button is

kept pressed down.

=

ekrPro Com

60

web guide controller EDV No.: MD.191.01.05/1.6.x Chapter: B 2

with analog sensors Date: 23.11.2007 Page: 6/6

Commissioning B 3

B 3 Commissioning

B 3.1 General information

The controller ekrPro Com

the control system (connected sensors, actuator, sensor adjustment

unit, ...) using the system parameters in the individual setup menus.

The required parameters have already been entered if the control

system is an integral part of a projected BST system. You do not

have to reset anything with regard to this.

A new system configuration is required if components or the

controller have been exchanged on-site.

The range of the settings and therefore the set-up menus that have

to be taken into consideration depend on the system being used.

To simplify commissioning, the commissioning staff can select his

system from a list of the most common standard systems (see

chapter B.3.5).

Following the selection, all of the basic settings are automatically

entered in the setup menu.

Finally the commissioning staff has only to check a few applicationrelated settings and if necessary adjust them accordingly.

The procedures to be used with the separate menus are described

in section B 3.7.5 General set-up.

Danger from mains voltage!

Never open the controller before switching off the

mains!

60

is matched to the actual configuration of

ekrPro Com

60

web guide controller EDV No.: MD.191.01.05/1.6.x Chapter: B 3

with analog sensors Date: 23.11.2007 Page: 1/73

Commissioning B 3

B 3.2 Electrical connections

The system must be wired according to the accompanying

connection diagram or plugged into the appropriate cable sockets.

Standard wiring sleeves with collars (DIN 46228/Part 4) must be

used with all cable connections up to 0.75 mm².

Wiring sleeves must not be used with cables from 0.75 mm² up to a

maximum of 1.5 mm².

Using wiring sleeves:

The spring-loaded terminals have been optimised for square

crimping. This can be realised using, for example, ‘WAGO’ variocrimp pliers.

This type of crimping also enables the connection to be connected

and disconnected without any problems.

The crimping is also gas-tight, i.e. there is no space inbetween the

conductor and the wiring sleeve.

Using cable without wiring sleeves:

For fine and multi-core cable and for fine-wired cable, whose kink

resistance is not sufficient due to its small diameter, in order to

overcome the contact force of the clamping springs, the clamp must

be correctly opened using a screwdriver.

Check that all the cables are fitted tightly after the connections have

been made (in both cases).

The ekrPro Com

connection.

If the supply voltage was inversely connected to terminals 42

and 43 of the controller, this inverse polarity would also be

connected to the 24 V output socket.

This could lead to damage to components connected to this

socket.

Attention! Applications with a sensor adjustment unit!

60

controller is protected against incorrect

The stepping motor output stages are not

protected against

short circuits.

You must check, without fail, using a suitable test unit

(ohmmeter) that no short circuits or cross-connections

between the two windings exist before starting the

commissioning.

ekrPro Com

60

web guide controller EDV No.: MD.191.01.05/1.6.x Chapter: B 3

with analog sensors Date: 23.11.2007 Page: 2/73

Commissioning B 3

B 3.3 Commissioning

with a CAN Bus

B 3.3.1 Checking the unit address

and setting up if necessary

If the ekrPro Com

setting of the CAN device address must be checked.

The CAN device address setting up is carried out via the S1 BCD

switch on the processor board:

The ekrPro Com

state).

• Set the S1 BCD switch to "1" if the ekrPro Com

device connected to the CAN bus.

60

controller is operated via a CAN bus, then the

BCD switch S1

60

address is preset to "1" in the factory (delivery

60

is the only

• If you want to run several

ekrPro... family devices on one CAN bus

system, then different device addresses (1 – 8) must be set for

the devices.

One of the devices must be set to device address "1" without

fail! Device addresses 0 and 9 are reserved.

Each device address can only be used once per guiding

system!

Procedure:

1. Switch-off the power to the controller.

2. Open controller’s front cover.

3. Set S1 BCD switch to the required device address (1 – 8).

4. Close the controller’s front cover.

5. Restore the power.

ekrPro Com

60

web guide controller EDV No.: MD.191.01.05/1.6.x Chapter: B 3

with analog sensors Date: 23.11.2007 Page: 3/73

Commissioning B 3

ekrPro Key

60

(if fitted) :ekrPro Key60:

There are several plugs on the rear side of the

ekrPro Key

60

.

The BCD switch S1 for setting the address (node

number) is behind these plugs.

Procedure:

S1 BCD switch

1. Switch-off the power to the controller.

2. Remove the plug.

3. Check setting of BCD switch S1. If necessary, set

device address to S1 = 1.

4. Refit the plug.

5. Restore the power.

FVGPro Module (if fitted

) :FVGPro Module”

The device address setting up is also crried out via the

S1 BCD switch mounted on the board:

Procedure:

1. Switch off the power to the FVG Pro module.

2. Open housing’s front cover.

3. Check the setting of the BCD switch S1. If

necessary, set device address to S1 = 1.

4. Close the controller’s front cover.

5. Restore the power.

S1 BCD switch

The device address modification will be effective after the

power has been restored

.

ekrPro Com

60

web guide controller EDV No.: MD.191.01.05/1.6.x Chapter: B 3

with analog sensors Date: 23.11.2007 Page: 4/73

Commissioning B 3

B 3.3.2 Terminator activation

The terminator must be activated on each of the physical first

and

last CAN bus participants. The possible settings are described

below.

In the ekrPro Com

60

, the activation is carried out using switch S3 on

B 3.3.2.1 ekrPro Com

60

the processor circuit board. Set the switch to "ON“.

Terminator S3

Procedure:

B 3.3.2.2 ekrPro Key

60

(if fitted)

1. Switch-off the power to the controller.

2. Open controller’s front cover.

3. Activate terminator S3 (switch position ON)

4. Close the controller’s front cover.

5. Restore the power.

In the ekrPro Key

60

activation

is carried out via switch S3.

Remove plug on the

back side.

Set the switch to "ON“.

Switch S3

ekrPro Com

60

web guide controller EDV No.: MD.191.01.05/1.6.x Chapter: B 3

with analog sensors Date: 23.11.2007 Page: 5/73

Commissioning B 3

B 3.3.2.3 BST ProLogic

(if fitted)

In the BST ProLogic activation takes place using the DIP switch

segment 1 (S1 = ON) for the CAN 1.

CAN 2

B 3.3.2.4 FVGPro Module

(if fitted)

In the FVGPro Module activation is carried out via switch S3 on the

processor circuit board. Set the switch to "ON“.

Switch S3

Procedure:

1. Switch-off the power to the module.

2. Open module’s front cover.

3. Activate terminator S3 (switch position ON)

4. Close the module’s front cover.

5. Restore the power.

ekrPro Com

60

web guide controller EDV No.: MD.191.01.05/1.6.x Chapter: B 3

with analog sensors Date: 23.11.2007 Page: 6/73

Commissioning B 3

B 3.4 Adjust password

User administration in the ekrPro Com

60

differentiates between four

different user levels with different user rights.

The individual user levels are each protected by a password.

Dependent on the selected user level, more or fewer paths are

activated in the setup menu. Non-activated entries are greyed out in

the menus and cannot be selected.

The user levels with the corresponding user rights are shown in the

following table.

User level Rights Default Password

Operator

(Operator)

Mainten.

Maintenance

personnel

Admin.

Administrator

BST Support

(BST-Service

• No rights to make changes in the setup menus.

• Unlimited changing rights in the menu

“Material Setup”.

• Unlimited rights to make changes in the setup menus.

• As for “Admin.” (only for BST servicing purposes)

The unit is supplied with the user level Admin set.

The indicated default password should only be used for the first

access to the setup menu and then an application-appropriate

password entered. This is also true for the Mainten. user level. This

protects the system against unauthorized access.

Make sure these new passwords are only known to the authorized

personnel!

BST International GmbH is not liable for damage arising from the

incorrect use of the password(s).

An automatic logout time can be set for all user levels (timeout time).

If no key is pressed for the set time, the user is automatically logged

out and the controller changes to the user level Operator.

Changes to passwords and the timeout time is undertaken from the

menu General Setup > Special > Change Pwd

All passwords can be reset to the default passwords up to 20

seconds after switching on of the controller by pressing the key

combination F4” + “ESC.

When the controller is switched-off, the last active user level is

stored and automatically activated after a reboot.

The procedure for selecting the user level is described in the

following pages.

0

1

2

ekrPro Com

60

web guide controller EDV No.: MD.191.01.05/1.6.x Chapter: B 3

with analog sensors Date: 23.11.2007 Page: 7/73

Commissioning B 3

Selection of user level is undertaken from the Change User menu.

1. Select Change User menu and press ENTER.

Enter user level & password

User level

Password 0

Current

user level: Admin.

logout

Operator

login

2. The user level selection window appears.

In the lower part of the window the active user level is

displayed (Admin. in the example).

Enter user level & password

User level Operator

Password

Current

user level BST Support

123 456 789 0

Mainten.

Admin.

Press the ENTER button and the user level option list will then

be opened.

Select the desired user level with the up and down arrow

keys.

Confirm the selection by pressing ENTER.

Enter user level & password

User level Mainten.

Password

Current

user level: Admin

123 456 789 0

00000

3. Use the right and left arrow keys to select the Password

editing box and press ENTER.

Enter user level & password

User level Mainten.

Password

Current

user level: Admin

logout

1

login

Enter the password and confirm the entry with ENTER.

4. Press the F3-key (login).

The controller changes to the selected user level.

The Setup menu selection window appears.

Entries, for which there are no user rights in the selected user

level are shown greyed out.

ekrPro Com

60

web guide controller EDV No.: MD.191.01.05/1.6.x Chapter: B 3

with analog sensors Date: 23.11.2007 Page: 8/73

Commissioning B 3

B 3.5 Commissioning standard system

To simplify commissioning, the commissioning staff can select his

own system from a list of the most common standard systems listed

under the menu Sel. Std. System.

B 3.5.1 Select standard system

F1 for fa ct. def aults

Choose standard system …

select a standard config.

… & press F2 to acti vate

Set.Def.

F1 for fa ct. def aults

Choo se st andar d sys tem …

sele ct a sta ndard conf ig.

… & pr ess F2 to activate

Set.Def.

Following the selection, all of the basic settings are automatically

entered in the setup menu and the system is switched to the

operating mode MAN.

1. Press the MENU button.

The setup menu of the controller appears in the display.

2. Select menu "Sel. Std. System“ and press ENTER.

3. The selection window for the standard system will appear.

4. Press the ENTER button.

The option list opens with the most common standard

systems. Individual entries each contain the following

information:

Type of connected

sensor(s)

Type of connected

actuator

Type of the

sensor positioning device

(if fitted)

5. Use the vertical arrow keys to select the system that matches

the present system.

Confirm the selection with the ENTER key.

The selected system is displayed.

6. To import the standard system configuration, press

function key F2 (set.).

The selection is confirmed by the message window Standard

System Set.

The base settings in the setup menu are automatically

entered by the system.

After this, the selection window is displayed again.

7. Press the ESC button to exit the window.

Attention!

After selecting the standard system, adjustment for a

particular application (e.g. material properties) must

take place.

Accordingly, the following steps should be carried out:

ekrPro Com

60

web guide controller EDV No.: MD.191.01.05/1.6.x Chapter: B 3

with analog sensors Date: 23.11.2007 Page: 9/73

Commissioning B 3

B 3.5.2 Carry out master setup

The sensor type will already have been set when the standard

system was set.

The procedure is described for Sensor 1.

The master set-up for Sensors 2 and 3 is the same.

1. Select Sensors/EFE in General set-up and then select the

Sensor 1 sub-directory afterwards. Confirm the respective

selection by pressing ENTER.

2. Select the type of sensor that is connected to the system from

the option list displayed in the new window that has opened

up and then enter it.

Attention!

If the mounting position of the selected sensor differs from the

BST setting (see chapter A 1.4) or if the sensor outputs an

inverted signal (e.g. another manufacturer’s sensor is being

used), then the checkbox Inv. must be checked.

A master set-up will be carried out afterwards.

Master set-up can be run automatically or manually.

dark

Inv.

bright

2047

bri.

3. Automatic master set-up:

► Press the F1 button and then cover the sensor’s scanning

window with an opaque material for two seconds

afterwards.

Select a sensor type

sensor1

<<<

dark

-2048 abs. 1775

auto

IR 2005

7%

► Remove the material from the scanning window and press

the F2 button two seconds later.

► This completes the master set-up for this sensor.

4. Manual master set-up:

► Cover the sensor’s scanning window with an opaque

material and then press the F3 button.

► Remove the material so that the window is completely

uncovered and press the F4 button.

5. Run the master set-ups for Sensors 2 and 3.

ekrPro Com

60

web guide controller EDV No.: MD.191.01.05/1.6.x Chapter: B 3

with analog sensors Date: 23.11.2007 Page: 10/73

Commissioning B 3

B 3.5.3 Setting the actuator

guiding direction

For standard systems, the EMS17 is registered as the actuator.

The direction has to be set for it.

1. Select the sub-directory Direction from the menu Actuator.

Confirm the selection by pressing ENTER.

If necessary, the actuator guiding direction for manual mode

can be reversed by activating the checkbox Mot. Dir. Inverted.

The rotational direction can be checked on the spot.

Drive the actuator using the F2 or F3 key.

If key F2 is pressed, the actuator must move the material web

Toggle Man Dir. until

F2 moves to sensor 1

Mot. Dir. Inverted

in the direction of sensor 1, if F3 is pressed it must move it

towards sensor 2!

Pressing F2 or F3 automatically changes the controller to

“manual” operating mode.

The sensor allocation can be checked on the spot. Press the

MENU button. The operating display is shown.

Cover one sensor. The change to the coverage range shows

the allocation.

After this, press the MENU key to ENTER to the settings

menu.

2. Press the ESC button to exit the window.

B 3.5.4 Setting the actuator

path limits

From here it is possible to limit the adjustment travel of the

actuator.

Change User

Actuator

Material Setup

Sel. Std. System

General Setup

opt. Logic

123 456 789 0

Type (EMS&Hydr.)

Sensors/EFE

Control Loop

FVG

Type & Dir.

Hydraulics Add-on

Pos. Limit

Directions

SC W & XP

SC-Transducer

1. Select Actuator in General Setup, then the sub-directory

SC-Component and finally Pos. Limit.

Confirm the respective selection by pressing ENTER.

2. Use the vertical arrow keys to deactivate the checkbox active.

This deactivates the function of both limit switches.

The settings can only be entered in the deactivated state.

3. Use the F2 key to drive the actuator until it reaches the

required left limit switch position.

The actual position of the actuator supplied by the position

feedback is shown in the middle above the F2 and F3 keys.

4. Confirm this position by pressing the F1 key.

The limit switch position is stored.

The corresponding position value is shown below the

checkbox.

ekrPro Com

60

web guide controller EDV No.: MD.191.01.05/1.6.x Chapter: B 3

with analog sensors Date: 23.11.2007 Page: 11/73

Commissioning B 3

5. Use the F3 key to traverse the actuator until it reaches the

required right limit switch position.

6. Confirm this position by pressing the F4 key.

7. Reactivate both limit switches.

Select (x) checkbox active to do this.

The description is given in section 2.

Import of the limit switch position is indicated by a black circle

in the read-only checkbox above the F1 and/or F4 key.

Confirm the selection by pressing ENTER.

8. Press the ESC button to exit the inputting menu.

B 3.5.5 Setting centre position

and gain for “SC” operating mode

From here the centre position and the amplification for operating

mode SC are set.

1. Select Actuator in General Setup, then the sub-directory

SC-Component and finally SC W & XP.

2. Press ENTER to open the inputting menu and enter the

parameters.

3. The current actuator position will be displayed in the field

mot.pos..

4. Use the F2 and F3 keys in MAN operating mode to traverse

the actuator into the required position.

5. Press the F4 key if you want to save the current position as

the setpoint value for the centring position.

The setting from mot.pos. will be imported into set-point W.

6. The setpoint value setpoint W and the gain gain XP can also

be entered directly in the relevant window.

7. The settings can be checked on the spot by switching over to

the SC operating mode.

8. Press the ESC button to exit the window.

ekrPro Com

60

web guide controller EDV No.: MD.191.01.05/1.6.x Chapter: B 3

with analog sensors Date: 23.11.2007 Page: 12/73

Commissioning B 3

B 3.5.6 Carry out material setup

Automatic adjustment of the controller to match the characteristics of

the material to be scanned is carried out during material set-up

(e.g. different material transparency at the optical sensors or

different sound absorption in the case of ultrasonic sensors).

The material set-up is the same for all three sensors.

The procedure for sensor 1 is used as the example here:

1. Press the MENU button to open the set-up menu.

2. Select Material set-up and confirm by pressing ENTER.

3. Select Sensor 1 and confirm by pressing ENTER.

This will open the Sensor 1 material set-up window.

Material Setup - Sensor 1

<<<

dark

-2048 abs. 1775

auto

7%

dark

bright

2047

bri.

Material set-up can now be carried out either automatically or

manually.

The manual procedure should always be used if the contrast that

has to be scanned is critical.

ekrPro Com

60

web guide controller EDV No.: MD.191.01.05/1.6.x Chapter: B 3

with analog sensors Date: 23.11.2007 Page: 13/73

Commissioning B 3

B 3.5.6.1 Automatic material set-up

1. Press the F1-key.

2. Completely cover the sensor’s scanning window with the

material to be scanned for approx. 2 seconds.

3. Completely remove the material from the sensor scanning

window (no material over the sensor).

4. Press the F2-key.

This completes the material set-up for this sensor. Material set-up is

finished when the same procedure has been carried out for any

other sensors connected to the controller.

B 3.5.6.2 Manual material set-up

1. Completely cover the sensor’s scanning window with the

material to be scanned.

2. Press the F3-key.

3. Completely remove the material from the sensor scanning

window (no material over the sensor).

4. Press the F4-key

The sequence is arbitrary, i.e. the dark setting (steps 1 and 2) or the

bright setting (steps 3 and 4) can be made first.

For sensors TW54 and T62, you must use the special

Material-Setup – Sensor 3 (see Point C 2.3.4).

ekrPro Com

60

web guide controller EDV No.: MD.191.01.05/1.6.x Chapter: B 3

with analog sensors Date: 23.11.2007 Page: 14/73

Commissioning B 3

B 3.5.7 FVG - Sensor positioning device

The stepping motor output stages are not

protected against

short circuits.

You must check, without fail, using a suitable test unit

(ohmmeter) that no short circuits or cross-connections

between the two windings exist before starting the

commissioning.

The connection cable from the ekrPro Com

60

control unit to the

sensor adjustment unit must not exceed the maximum cable

length of 20 m.

Power is continuously applied to the stepping motor output

stage, even when stopped. Therefore any work undertaken on

the interconnections must only be carried out with the power

switched off.

B 3.5.7.1 Default values set

Depending on the configuration selected under Select Standard

System, various default settings are carried out in the FVG

submenu.

B 3.5.7.1.1 Configuration-dependent default values

1. Selection IR2005:EMS 17 or US2007:EMS 17

For this selection, the sensor positioning device connection

entitled "not connected" is selected and entered. No additional

entries have to be carried out.

2. Selection IR2005:EMS17:1MK60 or IR2005 EMS17:1MK75

resp. US2007:EMS17:1MK60 or US2007:EMS17:1MK75

If one of these configurations is selected, the FVG 1MK Op. sensor

positioning device connection is selected and entered.

The following settings-dependent parameters are selected and

entered:

- Homing Direction – retraction direction and limit switch assignment

• at the first setting after switching on: not reversed

- Offset 1:

• at the first setting after switching on:

Offset = 0

Inverted = no

- Offset 2:

• at the first setting after switching on:

Offset = 2000

Inverted = yes

ekrPro Com

60

web guide controller EDV No.: MD.191.01.05/1.6.x Chapter: B 3

with analog sensors Date: 23.11.2007 Page: 15/73

Commissioning B 3

- Range – Traversing range limits

• at the first setting after switching on:

min = 0.0

max = 5000.0

- Feed – Feed for stepping motor / gearing combination

This setting is treated as the feed per motor revolution for the

stepping motor / gearing combination.

The respective value is automatically entered when the FVG type

is selected:

for FVG 1MK60 = 20088

for FVG 1MK75 = 61666.

The manufacturer has entered this default setting and you are

only permitted to modify it (if necessary) after having obtained the

manufacturer’s agreement.

The relevant procedure then has to be agreed.

All warranty claims will be invalidated in any other case.

3. Selection IR2005:EMS17:2MK60 or IR2005 EMS17:2MK75

resp. US2007:EMS17:2MK60 or US2007:EMS17:2MK75

If one of these configurations is selected, the "FVG 2MK Op.“

sensor positioning device connection is selected and entered.

The following settings-dependent parameters are selected and

entered for the FVG 1 (Slide 1)and the FVG 2 (Slide 2):

Slide 1

- Homing Direction – retraction direction and limit switch

assignment

• at the first setting after switching on: not

reversed

- Offset - positional offset to FVG position

• at the first setting after switching on: Offset = 2000

Inverted = no

- Range – Traversing range limits

• at the first setting after switching on:

min = 0.0

max = 5000.0

- Feed – Feed for stepping motor / gearing combination

This setting is treated as the feed per motor revolution for the

stepping motor / gearing combination.

The respective value is automatically entered when the FVG type

is selected:

for FVG 2MK60 = 20088

for FVG 2MK75 = 61666.

The manufacturer has entered this default setting and you are

only permitted to modify it (if necessary) after having obtained the

manufacturer’s agreement.

The relevant procedure then has to be agreed.

All warranty claims will be invalidated in any other case.

ekrPro Com

60

web guide controller EDV No.: MD.191.01.05/1.6.x Chapter: B 3

with analog sensors Date: 23.11.2007 Page: 16/73

Commissioning B 3

Slide 2

- Homing Direction – retraction direction and end switch

assignment

• at the first setting after switching on: not

reversed

- Offset - positional offset to FVG position

• at the first setting after switching on: Offset = 2000

Inverted = yes

- Range – Traversing range limits

• at the first setting after switching on:

- Feed – Feed for stepping motor / gearing combination

This setting is treated as the feed per motor revolution for the

stepping motor / gearing combination.

The respective value is automatically entered when the FVG type

is selected:

for FVG 2MK60 = 20088

for FVG 2MK75 = 61666.

The manufacturer has entered this default setting and you are

only permitted to modify it (if necessary) after having obtained the

manufacturer’s agreement.

The relevant procedure then has to be agreed.

All warranty claims will be invalidated in any other case.

B 3.5.7.1.2 Configuration-independent default value

The following values are general settings, which can be selected

and entered as default values independently of the FVG selected.

- Retract Mode – free-running mode

min = 0.0

max = 5000.0

• at the first setting after switching on: SC & Man

- Norming Mode – Standardization Mode

Setting of the standardization mode is dependent on the type of

sensor being used.

Infrared sensors: The mode is always set to "bright/dark“.

Ultrasonic sensors: The mode is always set to "no norming“.

- Width Adjust – FVG operating mode for center line guiding

• at the first setting after switching on: Level Outer

ekrPro Com

60

web guide controller EDV No.: MD.191.01.05/1.6.x Chapter: B 3

with analog sensors Date: 23.11.2007 Page: 17/73

Commissioning B 3

- Repositioning – repositioning of the material after certain

events

The current position of the material web is saved once an event

takes place (e.g. web tear). Once the event has been rectified, the

material is repositioned to this position. This functionality is only

effective once pre-positioning has been activated.

- Velocities – adjustment of positioning speeds

• at the first setting after switching on:

Retract velocity: 60 mm / s

Edge push velocity: 5 mm / s

Slow manual velocity: 1 mm / s

Fast manual velocity: 60 mm / s

Norming velocity: 60 mm / s

- Special – Special settings for driving the FVG slides

• at the first setting after switching on:

Mode after error: Man

Carry out setting according to point B 3.7.5.5, if the settings listed

above, for the sensor adjustment unit, do not corresponding to the

operating requirements.

ekrPro Com

60

web guide controller EDV No.: MD.191.01.05/1.6.x Chapter: B 3

with analog sensors Date: 23.11.2007 Page: 18/73

Commissioning B 3

B 3.5.8 Add. Functions – Special functions

Useful additional functions can be realised using the ekrPro Com

60

These functions can be accessed quickly under this menu point.

These functions deal with the Tear Off Detection and Oscillation.

B 3.5.8.1 Tear-Off Det. – Tear-off detection

Tear-off detection enables, dependent on the selected sensing

type (edge / contrast guiding) the following functions:

1. With web edge guiding:

Detection of torn off sections on the web edge using edge

sensors IR2001/2005, US2007, …

This function is activated during web edge guiding, if during

operation of the web guiding system errors arise from the web

edge that is being scanned.

The function detects both tears into the material web (inward

tear) as well as projecting material (outward tear).

2. With contrast guiding:

Guiding on interrupted printed or contrast edges with contrast

sensors T62D1 or TW54C5.

Interrupted printed

or contrast edge

Light spot of the

contrast sensor

Tear-off

inwards

Tear-off

outwards

Tear-off detection can be implemented using the same sensors that

are used for web guiding.

Alternatively a second sensor can be used.

.

ekrPro Com

60

web guide controller EDV No.: MD.191.01.05/1.6.x Chapter: B 3

with analog sensors Date: 23.11.2007 Page: 19/73

Commissioning B 3

Criteria for detecting a tear:

To detect a tear, at least one of the two following criteria must be

fulfilled:

1. Exceeding / undershooting of the preset threshold value

If the sensor signal exceeds or falls below the set threshold value

(threshold), then this is recognised as a tear.

After a preset delay time (delay) has elapsed, the web guiding

system is automatically blocked.

Blocking of the guidance system is lifted, as soon as the sensor

signal again lies above/below the set threshold value and the set

run-on time (hold time) has elapsed.

2. Exceeding of the preset maximum rate of change of the sensor

signal.

The system continuously checks the rate of change speed of the

sensor signal in both positive and negative directions. If the

preset maximum permissible rate of change (sig. chg. lim.) is

exceeded, then this is recognized as a tear.

After a preset delay time (delay) has elapsed, the web guiding

system is automatically blocked.

If the set rate of change is undershot, then blocking of the guiding

system is not

lifted.

Lifting of the blocking is only implemented if the preset threshold

value (threshold) is again undershot (see point 1).

Conditions for guiding on interrupted printed or contrast edges

For trouble-free operation of the control unit, the following conditions

must be fulfilled:

1. Minimum mark length

The printed or contrast edge to be sampled must not fall below

the minimum mark length L

depends on the maximum web speed, v

. The minimum mark length

min

, the sampling cycle, t,

max

and the diameter, d, of the light spot of the contrast sensor used.

It can be calculated using the following formula.

Light spot

dL

L

min

V

[m/min]

[m] = * 3 * t [s] +

max

60 s/min

d [mm]

1000 mm/m

= minimum mark length [m]

L

min

v

= max. web speed [m/min]

max

t = sampling cycle [s] = 0.004 s

d = light spot diameter [mm]

ekrPro Com

60

web guide controller EDV No.: MD.191.01.05/1.6.x Chapter: B 3

with analog sensors Date: 23.11.2007 Page: 20/73

Commissioning B 3

Example calculation:

At a maximum web speed v

diameter d = 8 mm the resultant minimum mark length L

= 300 m/min and a light spot

max

min

,

equals:

L

300 m/min

= ¹ 3 ¹ 0,004 s ¬

min

60 s/min

8 mm

1000 mm/m

L

= 0,068 m = 68 mm

min

2. Alignment of the contrast sensor:

When scanning an interrupted line

, correct alignment

of the contrast sensor must be observed:

• The contrast sensor must be aligned so that the

edge

of the line is located in the sensor light spot.

• Only one

edge may be located within the light

spot.

correct

wrong wrong

3. Operating mode setting for the contrast sensor T 62 D 1

The operating mode selection switch on the sensor must be set

to the position Kante (edge).

Operating mode

selection switch

ekrPro Com

60

web guide controller EDV No.: MD.191.01.05/1.6.x Chapter: B 3

with analog sensors Date: 23.11.2007 Page: 21/73

Commissioning B 3

Parameter settings

Setting of the parameters for the function tear-off detection is made

separately for each guiding mode. If necessary, a different sensor

can be allocated as the tear-off detection sensor for each guiding

mode. It is also possible to allocate two different guiding modes with

different parameters to a single sensor.

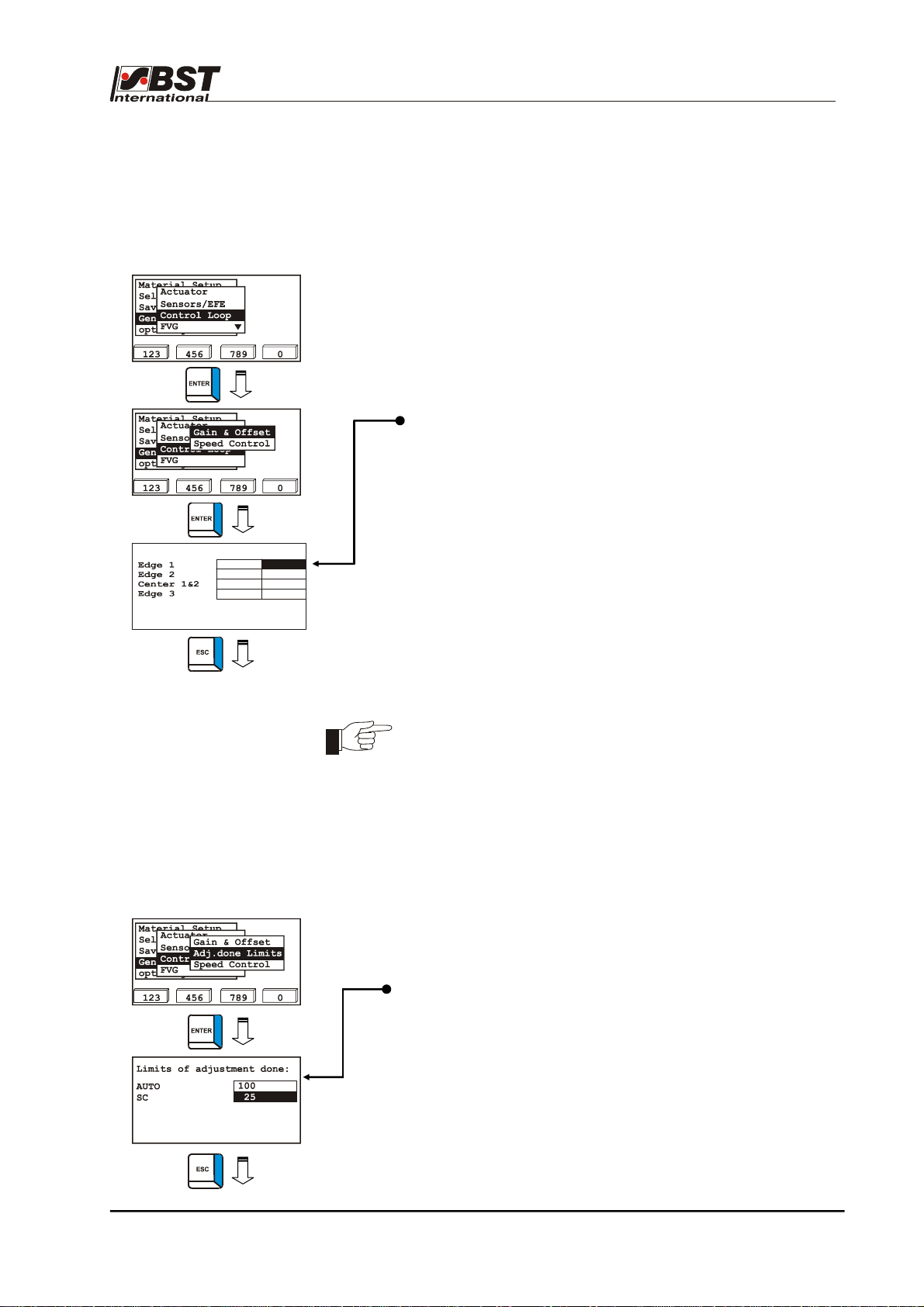

1. Select Add. Functions in General Setup and then select the

Tear Off Det. sub-directory afterwards.

Confirm the respective selection by pressing ENTER.

2. Select the desired guiding mode (Edge 1, Edge 2, Edge 3,

Center 1&2) from the option list.

Confirm the selection by pressing ENTER.