Page 1

PH4Z

14 SEER SINGLE---PACKAGED HEAT PUMP SYSTEM

Installation Instructions

IMPORTANT: Effective January 1, 2015, all split system and

packaged air conditioners must be installed pursuant to applicable

regional efficiency standards issued by the Department of Energy.

NOTE: Read the entire instruction manual before starting the

installation.

NOTE: Installer: Make sure the Owner’s Manual and Service

Instructions are left with the unit after installation.

TABLE OF CONTENTS

PAGE

SAFETY CONSIDERATIONS 2.........................

INTRODUCTION 2...................................

RECEIVING AND INSTALLATION 2--10.................

Check Equipment 2..................................

Identify Unit 2....................................

Inspect Shipment 2.................................

Provide Unit Support 2...............................

Slab Mount 2.....................................

Ground Mount 2..................................

Provide Clearances 2.................................

Place Unit 3........................................

Select and Install Ductwork 3...........................

Installing factory--supplied duct flanges 3...............

Configuring Units for Downflow (Vertical) Discharge 9....

Connect Condensate Drain 9...........................

Install Electrical Connections 9.........................

High--Voltage Connections 9.........................

Routing Power Leads Into Unit 9......................

Connecting Ground Lead to Unit Ground 10.............

Routing Control Power Wires 10.....................

Accessory Electric Heat Wiring 10.....................

PRE--START--UP 10...................................

START--UP 11--14.....................................

Check for Refrigerant Leaks 11.........................

Start--Up Cooling and Make Adjustments 11...............

Checking Cooling and Heating Control Operation 11......

Refrigerant Charge 11................................

No Charge 11.....................................

Low Charge Cooling 11.............................

Heating Mode Charge 12............................

Indoor Airflow and Airflow Adjustments 14...............

Sequence of Operation 14.............................

Fan Operation 14..................................

Cooling Operation 14...............................

Heating Operation 14...............................

Continuous Fan 14.................................

WITH R ---410A REFRIGERANT

SINGLE PHASE

2 --- 5 N O M I N A L T ON S ( S I Z E S 2 4 --- 6 0 )

A05165

PH4Z 024--048

A150067

PH4Z 060

Fig. 1 -- PH4Z

Certified to leak 2% or less of nominal air conditioning CFM

delivered when pressurized to 1--in. W.C. with all present air

inlets, air outlets, and condensate drain port(s) sealed.

Defrost 14.......................................

Electric Resistance Heating 14........................

MAINTENANCE 18--21................................

Air Filter 18........................................

Unit Top Removal 18.................................

Indoor Blower and Motor 19...........................

Outdoor Coil, Indoor Coil, and Condensate Drain Pan 19.....

Outdoor Fan Adjustment 19............................

Electrical Controls and Wiring 20.......................

Refrigerant Circuit 20.................................

Indoor Airflow 20...................................

1

Page 2

Metering Devices 20.................................

High Flow Valves 20.................................

High Pressure Switch 20..............................

Loss of Charge Switch 20.............................

R--410A Compressor 20...............................

Refrigerant 20......................................

Compressor Oil 21...................................

Servicing Systems on Roofs with Synthetic Materials 21......

Synthetic Roof Precautionary Procedure 21................

Liquid Line Filter Drier 21.............................

R--410A Refrigerant Charging 21.......................

TROUBLESHOOTING 21..............................

START--UP CHECKLIST 21............................

!

WARNING

PERSONAL INJURY AND ENVIRONMENTAL

HAZARD

Failure to relieve system pressure could result in personal

injury and/or death.

1. Relieve pressure and recover all refrigerant before

servicing existing equipment, and before final unit disposal.

Use all service ports and open all flow--control devices,

including solenoid valves.

2. Federal regulations require that you do not vent

refrigerant into the atmosphere. Recover during system

repair or final unit disposal.

SAFETY CONSIDERATIONS

Installation and servicing of this equipment can be hazardous due

to mechanical and electrical components. Only trained and

qualified personnel should install, repair, or service this equipment.

Untrained personnel can perform basic maintenance functions such

PH4Z

as cleaning and replacing air filters. All other operations must be

performed by trained service personnel. When working on this

equipment, observe precautions in the literature, on tags, and on

labels attached to or shipped with the unit and other safety

precautions that may apply.

Follow all safety codes. W ear safety glasses, protective clothing,

and work gloves. Use quenching cloth for brazing operations.

Have fire extinguisher available. Read these instructions

thoroughly and follow all warnings or cautions included in

literature and attached to the unit. Consult local building codes,

the current editions of the National Electrical Code (NEC) NFPA

70 and NFPA 90B--Installation Warm Air Heating and A/C

Systems (Residential). In Canada refer to the current editions of the

Canadian Electrical Code CSA C22.1.

Recognize safety information. This is the safety--alert symbol

When you see this symbol on the unit and in instructions or manuals, be alert to the potential for personal injury. Understand these

signal words: DANGER, WARNING, and CAUTION. These

words are used with the safety--alert symbol. DANGER identifies

the most serious hazards which will result in severe personal injury

or death. WARNING signifies hazards which could result in personal injury or death. CAUTION is used to identify unsafe practices which may result in minor personal injury or product and property damage. NOTE is used to highlight suggestions which will

result in enhanced installation, reliability, or operation.

!

WARNING

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in personal

injury or death.

Before installing or servicing system, always turn off main

power to system and install lockout tag. There may be

more than one disconnect switch. Turn off accessory heater

power switch if applicable.

!

CUT HAZARD

Failure to follow this caution may result in personal injury.

Sheet metal parts may have sharp edges or burrs. Use care

and wear appropriate protective clothing, safety glasses and

gloves when handling parts and servicing.

CAUTION

INTRODUCTION

This packaged heat pump is fully self-- contained and designed for

outdoor installation (See Fig. 1). Standard units are shipped in a

horizontal--discharge configuration for installation on a

ground--level slab or directly on the ground if local codes permit.

Standard units can be converted to downflow (vertical) discharge

configurations for rooftop applications with a field supplied

plenum.

RECEIVING AND INSTALLATION

Step 1 — Check Equipment

IDENTIFY UNIT

The unit model number and serial number are printed on the unit

informative plate. Check this information against shipping papers.

INSPECT SHIPMENT

Inspect for shipping damage while unit is still on shipping pallet. If

unit appears to be damaged or is torn loose from its anchorage,

have it examined by transportation inspectors before removal.

Forward claim papers directly to transportation company.

Manufacturer is not responsible for any damage incurred in transit.

.

Check all items against shipping list. Immediately notify the

nearest equipment distribution office if any item is missing. To

prevent loss or damage, leave all parts in original packages until

installation.

Step 2 — Provide Unit Support

For hurricane tie downs, contact distributor for details and PE

(Professional Engineering) Certificate, if required.

SLAB MOUNT

Place the unit on a solid, level concrete pad that is a minimum of 4

in. (102 mm) thick with 2 in. (51 mm) above grade. The slab

should extend approximately 2 in. (51 mm) beyond the casing on

all 4 sides of the unit. Do not secure the unit to the slab except

when required by local codes.

A 6--in. (152 mm) wide gravel apron should be used around the

flat surface to prevent airflow blockage by grass or shrubs. The

unit should be level within 1/4 in. (6 mm). This is necessary for the

unit drain to function properly.

GROUND MOUNT

The unit may be installed either on a slab or placed directly on the

ground if local codes permit. Place the unit on level ground

prepared with gravel for condensate discharge.

Step 3 — Provide Clearances

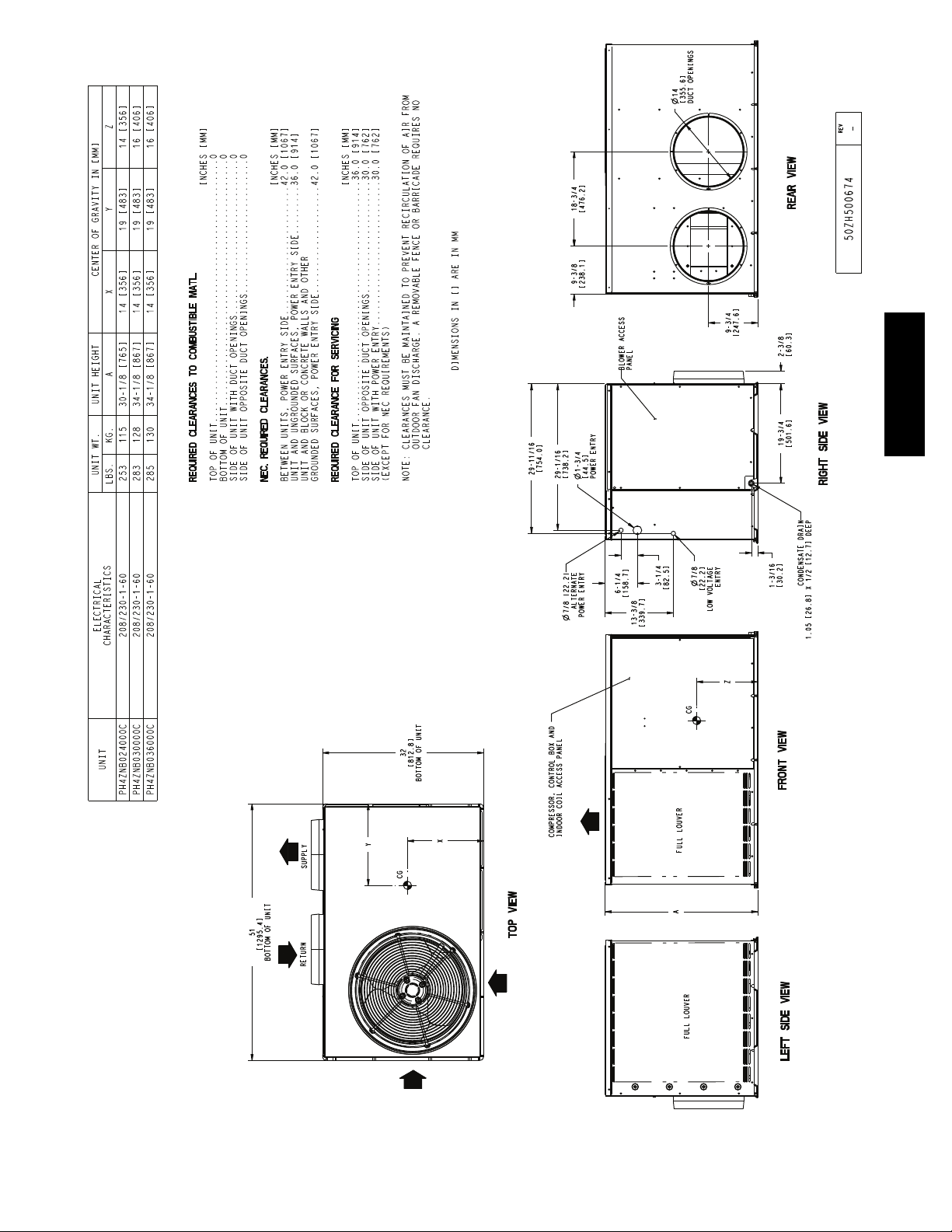

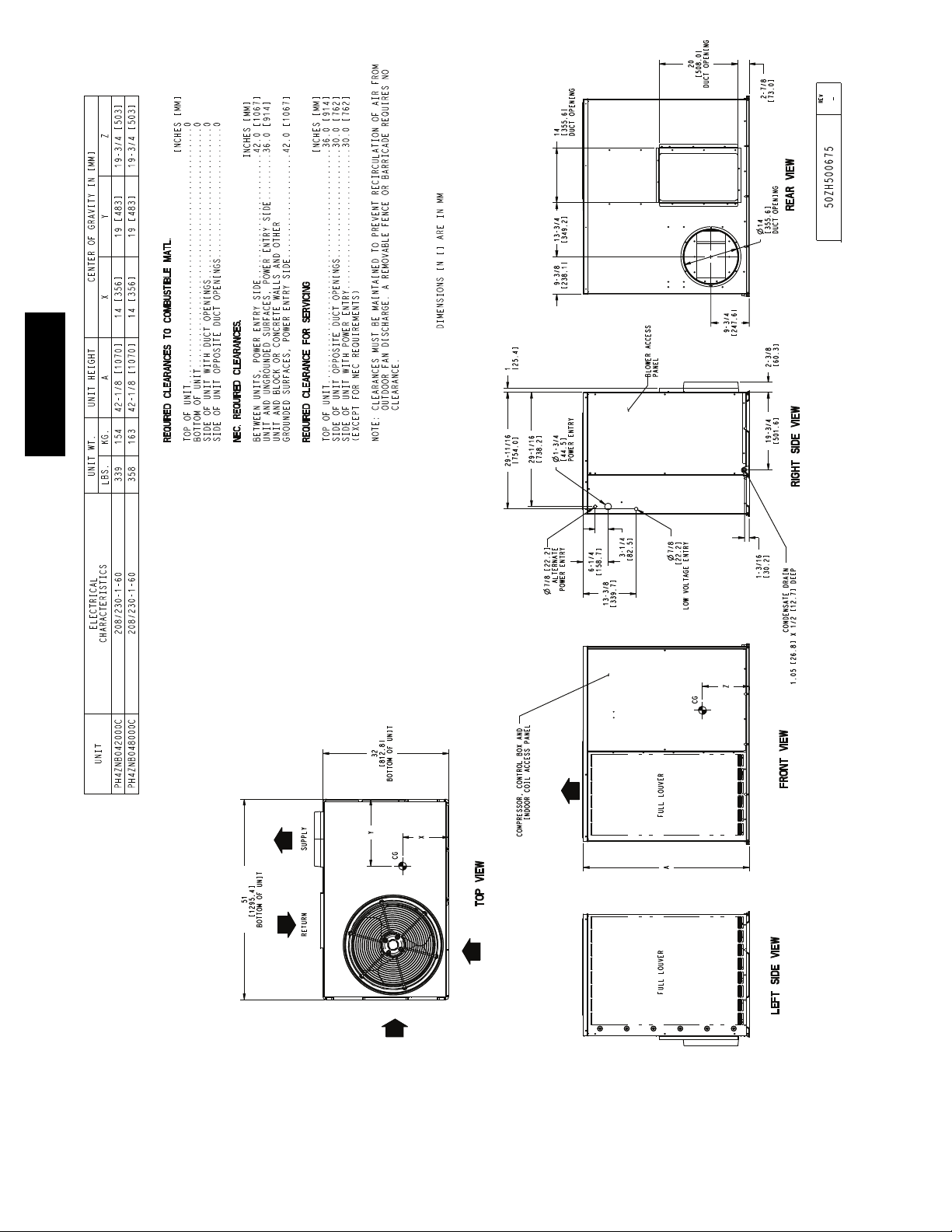

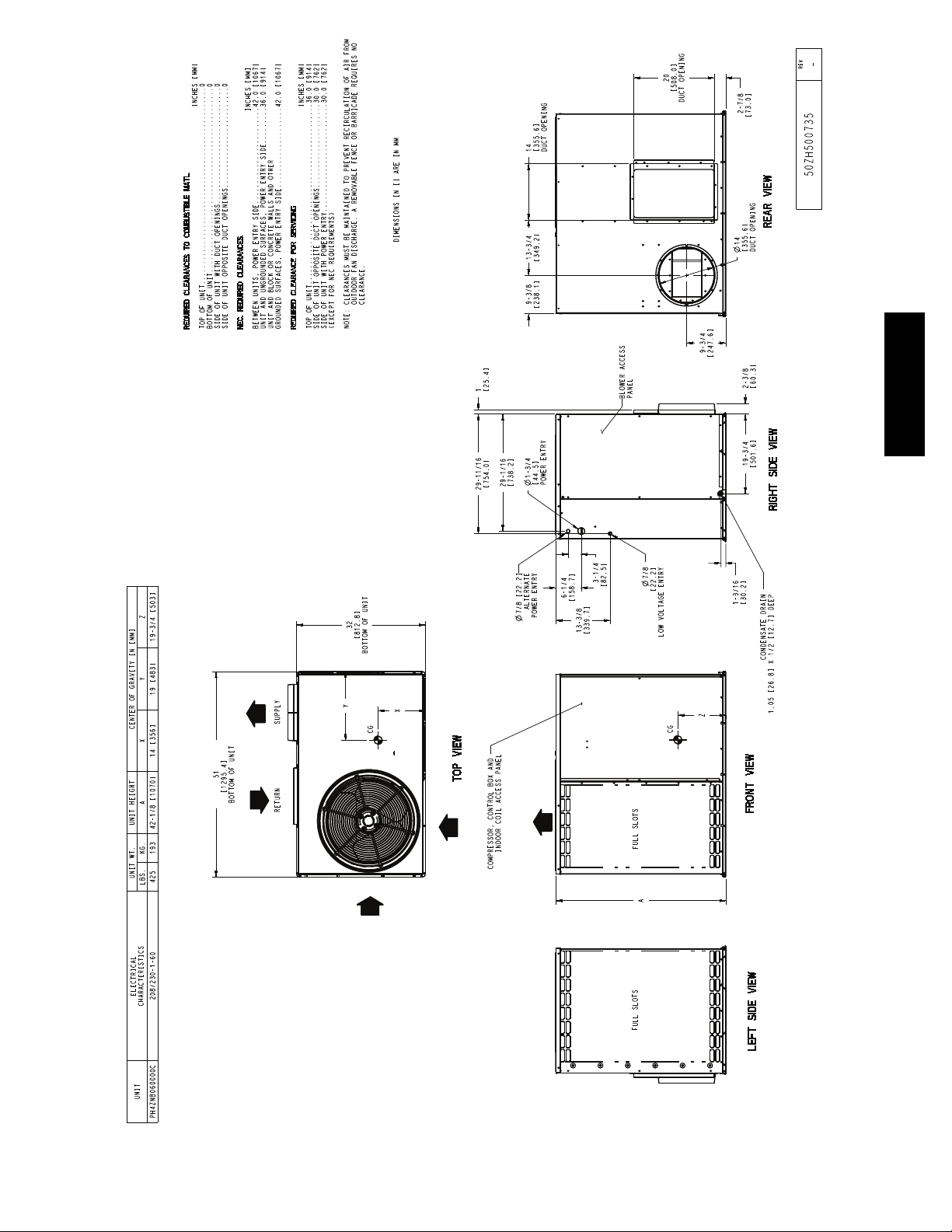

The required minimum service clearances are shown in Fig. 4--6.

Adequate ventilation and outdoor air must be provided.

The outdoor fan draws air through the outdoor coil and discharges

it through the top fan grille. Be sure that the fan discharge does not

recirculate to the outdoor coil. Do not locate the unit in either a

corner or under an overhead obstruction. The minimum clearance

under a partial overhang (such as a normal house overhang) is 48

2

Page 3

in. (1219 mm) above the unit top. The maximum horizontal

extension of a partial overhang must not exceed 48 in. (1219 mm).

IMPORTANT: Do not restrict outdoor airflow. An air restriction

at either the outdoor--air inlet or the fan discharge may be

detrimental to compressor life.

Do not place the unit where water, ice, or snow from an overhang

or roof will damage or flood the unit. Do not install the unit on

carpeting or other combustible materials. Slab--mounted units

should be at least 4 in. (102 mm) above the highest expected water

and runoff levels. Do not use unit if it has been under water.

Step 4 — Place Unit

Unit can be moved with the rigging holds provided in the unit

base. Refer to Table 1 for operating weights. Use extreme caution

to prevent damage when moving the unit. Unit must remain in an

upright position during all moving operations. The unit must be

level with in 1/4 in. (6 mm) for proper condensate drainage; the

ground--level pad must be level before setting the unit in place.

When a field-- fabricated support is used, be sure that the support is

level and that it properly supports the unit.

Step 5 — Select and Install Ductwork

The design and installation of the duct system must be in

accordance with the standards of the NFPA for installation of

non--residence type air conditioning and ventilating systems,

NFPA 90A or residence type, NFPA 90B and/or local codes and

ordinances.

Select and size ductwork, supply-- air registers, and return air grilles

according to ASHRAE (American Society of Heating,

Refrigeration, and Air Conditioning Engineers) recommendations.

Use the duct flanges provided on the supply-- and return-- air

openings on the side of the unit. See Fig. 4--6 for connectio n sizes

and locations. The 14--in. (356 mm) round or 14 x 20 in. (356 x

508 mm) rectangular duct collars are shipped inside the unit

attached to the base pan in the indoor blower compartment.

They are field--installed and must be removed from the indoor

blower compartment prior to start--up, even if they are not

used for installation. If a corrugated shipping block is used

under the blower housing, remove and discard the block and

label.

When designing and installing ductwork, consider the following:

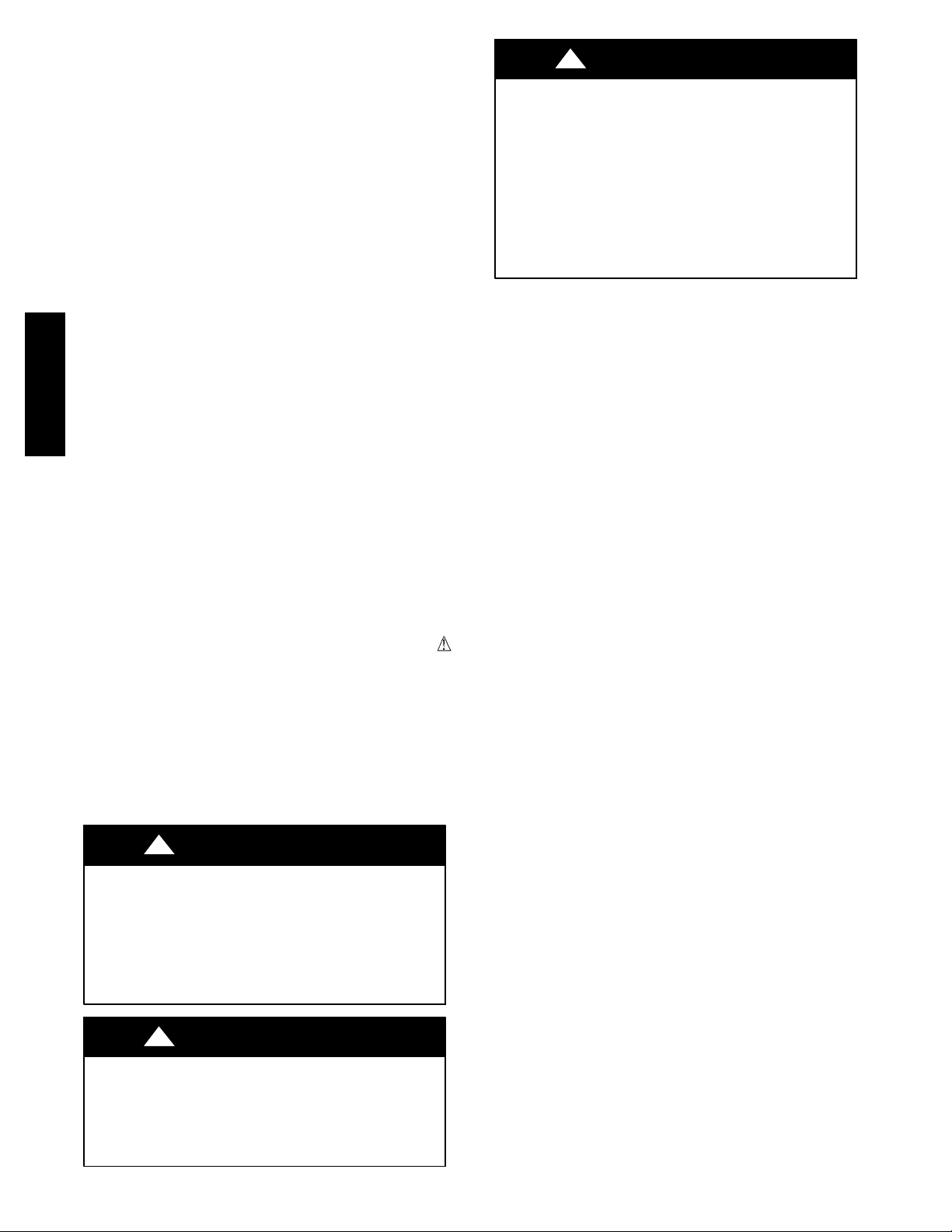

!

CAUTION

UNIT DAMAGE HAZARD

Failure to follow this caution may result in damage to unit

components.

When connecting ductwork to units, do not drill deeper

than 3/4 in. (19 mm) in shaded area shown in Fig. 2 or coil

may be damaged.

19.17 in.

(487 mm)

Fig. 2 -- Area Not to be Drilled More Than 3/4--in. (19 mm)

1. All units should have field--supplied filters or accessory

filter rack installed in the return--air side of the unit.

Recommended sizes for filters are shown in Table 1.

2. Avoid abrupt duct size increases and reductions. Abrupt

change in duct size adversely affects air performance.

IMPORTANT: Use flexible connectors between ductwork and

unit to prevent transmission of vibration. Use suitable gaskets to

ensure weather tight and airtight seal. When electric heat is

installed, use fireproof canvas (or similar heat resistant material)

connector between ductwork and unit discharge connection. If

flexible duct is used, insert a sheet metal sleeve inside duct. Heat

resistant duct connector (or sheet metal sleeve) must extend 24--in.

(610 mm) from electric heater element.

3. Size ductwork for cooling air quantity (cfm). The minimum

air quantity for proper electric heater operation is listed in

Table 2. Heater limit switches may trip at air quantities

below those recommended.

4. Seal, insulate, and weatherproof all external ductwork. Seal,

insulate and cover with a vapor barrier all ductwork passing

through conditioned spaces. Follow latest Sheet Metal and

Air Conditioning Contractors National Association

(SMACNA) and Air Conditioning Contractors Association

(ACCA) minimum installation standards for residential

heating and air conditioning systems.

5. Secure all ducts to building structure. Flash, weatherproof,

and vibration--isolate duct openings in wall or roof

according to good construction practices.

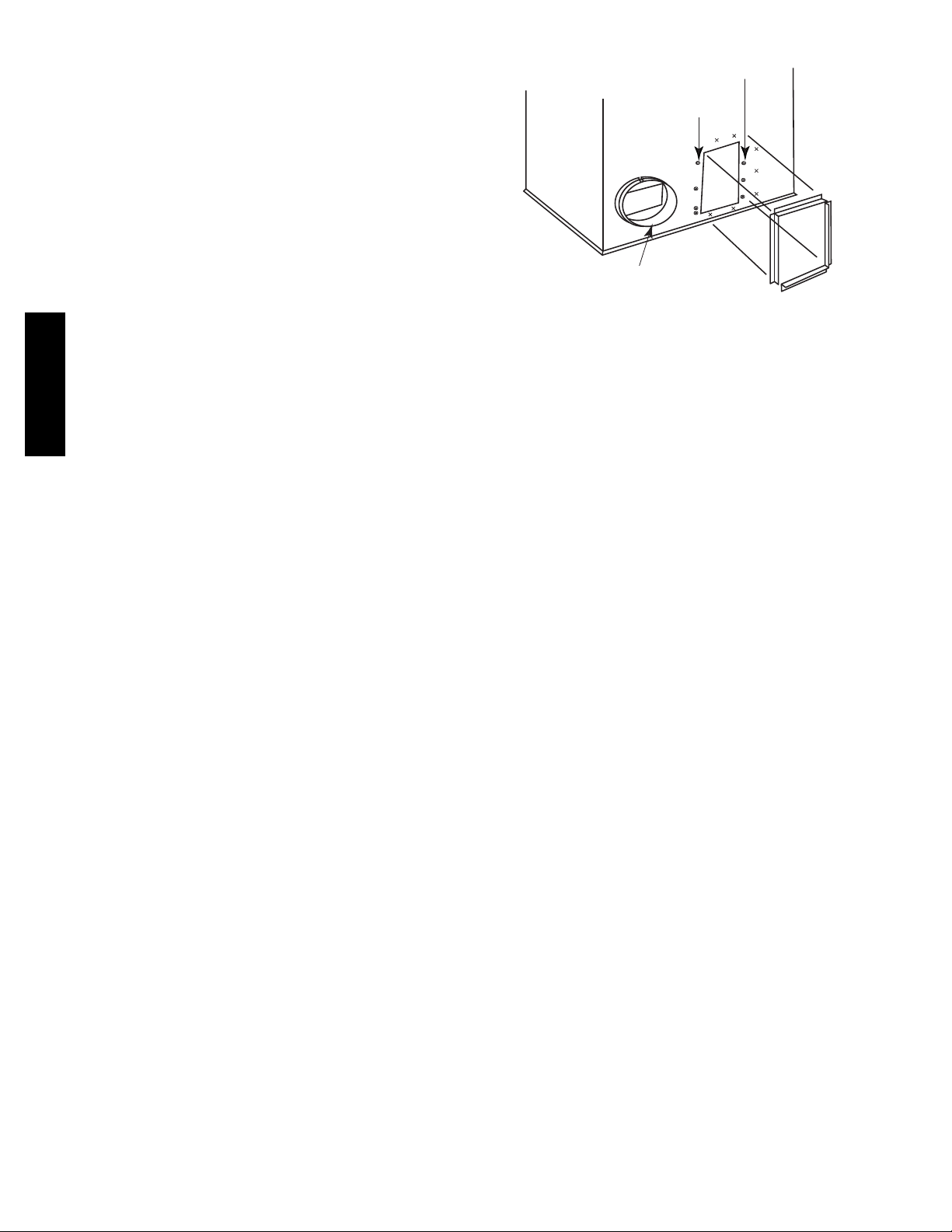

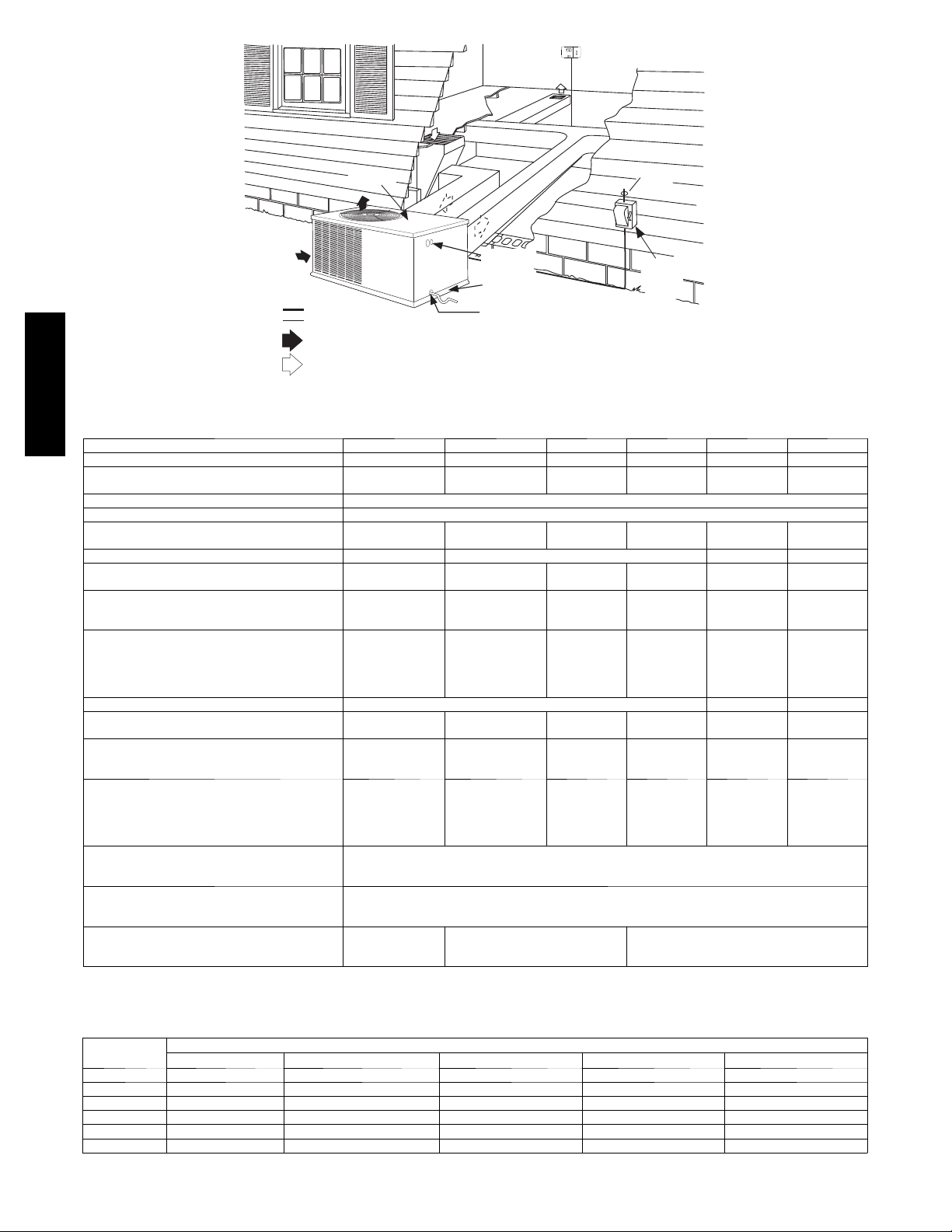

Fig. 7 shows a typical duct system with unit installed.

3.92 in.

(100 mm)

Deep

A10021

Installing factory--supplied duct flanges;

For 24, 30, and 36 sizes:

S Two round 14--in. (356 mm) duct collars are factory supplied.

S Line up the 6 holes in the duct collar with the pre--drilled holes

in the side panel.

S Fasten duct collar to side panel using field--supplied screws.

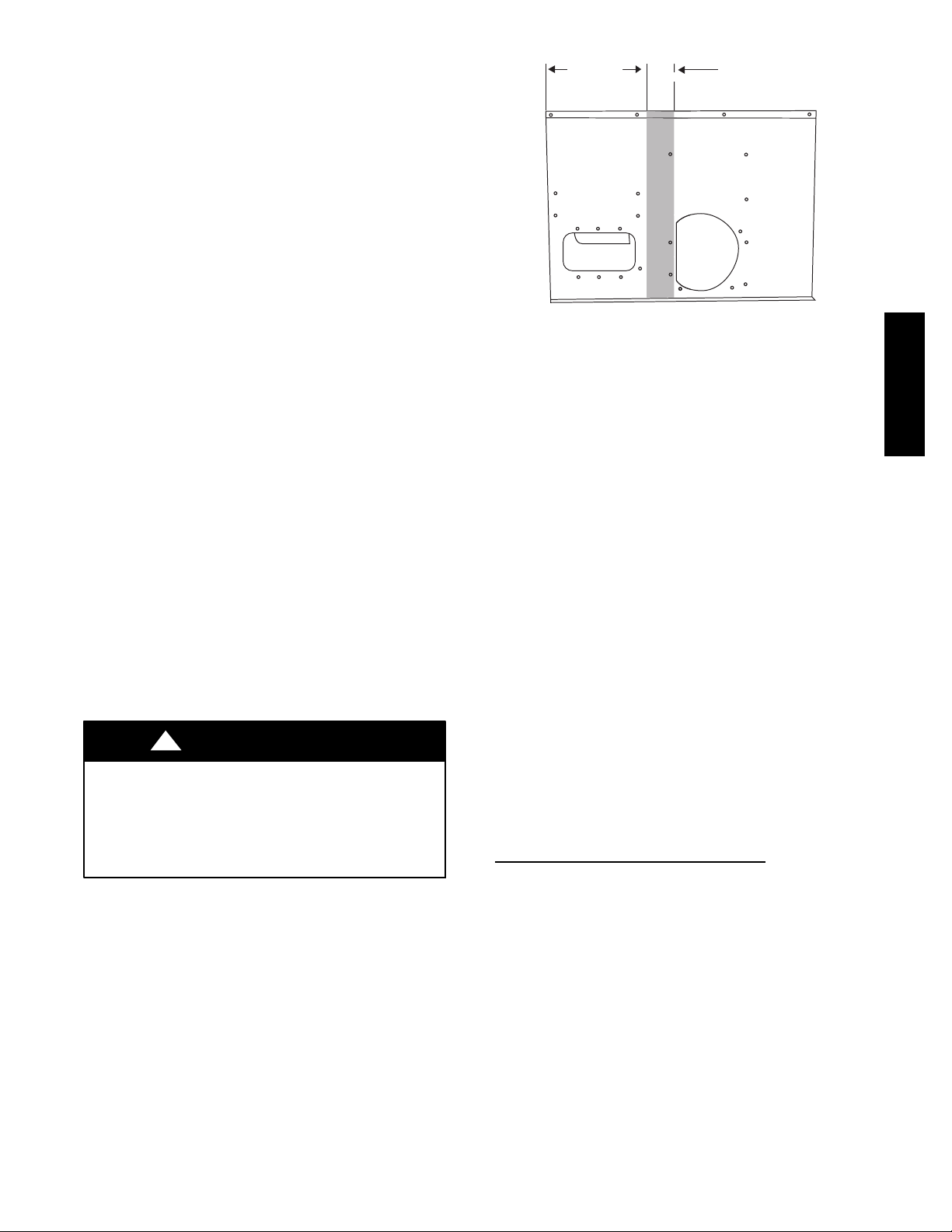

For 42, 48 and 60 sizes (See Fig. 3):

S One round 14--in. (356 mm) duct collar for the supply air

connections and two “L” brackets for the 14--in. x 20 --in. (356 x

508 mm) return air connection are factory--supplied.

S Line up the 6 holes in the supply duct collar with the pre--drilled

holes in the side panel. Fasten duct collar to side panel using

field--supplied screws.

S For the return, remove the 4 screws on the left side of the return

and install one of the “L” flanges on the left side by replacing

the 4 screws. Using the 2 dimples below the return, align the

PH4Z

3

Page 4

bottom of the “L” flange with the two dimples and attach using

filed--supplied thread--cutting screws.

For the second “L” flange, align flange with the three dimples to

the right of the return and the two dimples above the return and

attach using field--supplied thread--cutting screws.

NOTE: The factory--installed screws to the right of the return

should not be removed in this process.

PH4Z

3 Factory Installed Screws

(Must not be removed)

Remove 4 screws from left side

of duct opening and reuse to

install the left half of duct

flange.

Install supply duct flange

as shown into existing holes

with field-supplied screws.

X = Factory dimples for duct flange attachment.

Fig. 3 -- Installing Factory--Supplied Duct Flanges

A10081

4

Page 5

PH4Z

Fig. 4 -- Unit Base Dimensions, 024--036

5

A1456

Page 6

PH4Z

Fig. 5 -- Unit Base Dimensions, 042--048

6

A14557

Page 7

PH4Z

Fig. 6 -- Unit Base Dimensions, 060

7

A150072

Page 8

RETURN

AIR

INDOOR

THERMOSTAT

FROM

POWER

SOURCE

DISCONNECT

PER NEC

(UNIT AND

ELECTRIC

HEATER)

PH4Z

TOP COVER

Power Wiri ng

Control Wiring

Condenser Airflow

Evaporator Airflow

POWER AND

LOW-VOLTAGE

ENTRY

COMPOSITE

RUST-PROOF

BASEPAN

CONDENSATE

DRAIN

CONNECTION

Fig. 7 -- Typical Installation

Table 1 – Physical Data

UNIT SIZE 024 030 036 042 048 060

NOMINAL CAPACITY (ton) 2 2.5 3 3.5 4 5

SHIPPING WEIGHT (lb)

(kg)

COMPRESSOR TYPE SCROLL

REFRIGERANT R-410A

REFRIGERANT QUANTITIY (lb)

QUANTITY (kg)

OUTDOOR METERING DEVICE TXV Piston TXV Piston

ORIFICE OD (in.)

(mm)

OUTDOOR COIL

ROWS...FINS/in.

FACE A REA (sq. ft)

OUTDOOR FAN

NOMINAL AIRFLOW (cfm)

DIAMETER (in.)

DIAMETER (mm)

MOTOR HP (RPM)

INDOOR METERING DEVICE Piston TXV TXV

ORIFICE OD (in.)

(mm)

INDOOR COIL

ROWS...FINS/in.

FACE A REA (sq. ft)

INDOOR BLOWER

NOMINAL COOLING AIRFLOW (cfm)

NOMINAL SIZE D x L (in.)

(mm)

MOTOR (HP)

HIGH-PRESSURE SWITCH (psig)

CUTOUT

RESET (AUTO)

LOW-PRESSURE SWITCH (psig)

CUTOUT

RESET (AUTO)

RETURN-AIR FILTERS

THR OWAWAY (in.)

*Required filter sizes shown are based on the AHRI (Air Condition ing, Heating & Refrigeration Institute) rated airflow at a velocity of 300 ft/min (91 m) for throwaway type or 450 ft/ min (137 m) for high capacity type. Recommended filters are 1 ---in. (25 mm) thick.

(mm)

312

142

7.00

3.18

---

---

2...20

9.1

2000

20

508

1/8 (825)

0.059

1.499

3...12

4.3

800

10 x 8

254 x 203

1/3

20x20x1

508x508x25

333

151

7.20

3.27

0.049

1.245

2...20

10.2

2000

20

508

1/8 (825)

0.059

1.499

3...14

4.3

1000

11 x 9

279 x 229

1/3

610x762x25

24x30x1

334

152

6.30

2.86

0.057

1.448

2...20

10.2

2800

20

508

1/4 (1100)

0.067

1.702

3...12

4.9

1200

11 x 9

279 x 229

1/2

650 +/- 15

420 +/- 25

20 +/- 5

45 +/- 10

388

177

9.10

4.13

0.059

1.499

2...20

13.0

3100

20

508

1/4 (1100)

0.076

1.9304

3...14

4.9

1400

11 x 9

279 x 229

1/2

407

185

7.70

3.49

---

---

2...20

15.5

3100

20

508

1/4 (1100)

---

---

3...14

4.9

1600

11 x 9

279 x 229

3/4

24x36x1

610x914x25

A08207

475

215

11.5

5.22

0.070

1.778

2...20

15.5

3300

20

508

1/3 (1100)

---

---

3...14

4.9

1700

12 x 11

305 x 279

1

Table 2 – Minimum Airflow for Safe Electric Heater Operation

HP Unit

Size

5kW 7.5 kW 10 kW 15 kW 20 kW

24 750 800 800 X X

30 750 800 800 X X

36 750 800 800 1200 X

42 750 800 800 1200 X

48 750 800 800 1200 1800

60 750 800 800 1200 1800

X = NOT APPROVED COMBINATION

Minimum Airflow (CFM)

8

Page 9

CONFIGURING UNITS FOR DOWNFLOW (VERTICAL)

DISCHARGE

Units are dedicated side supply products. They are not convertible

to vertical air supply. A field-- supplied plenum must be used to

convert to vertical air discharge.

Step 6 — Connect Condensate Drain

NOTE: When installing condensate drain connection be sure to

comply with local codes and restrictions.

Unit removes condensate through a 1--3/64 in. (27 mm) ID hole

(using 3/4--in. (19 mm) ID piping or tubing) which is located at the

end of the unit. See Fig. 4--6 for location of condensate connection.

Condensate water can be drained directly onto the roof in rooftop

installations (where permitted) or onto a gravel apron in ground

level installations. Install a field --supplied condensate trap at end of

condensate connection to ensure proper drainage. Make sure that

the outlet of the trap is at least 1 in. (25 mm) lower than the drain

pan condensate connection to prevent the pan from overflowing

(See Fig. 8 and 9). When using a gravel apron, make sure it slopes

away from the unit.

If the installation requires draining the condensate water away from

the unit, install a 2--in. (51 mm) trap using a 3/4--in. (19 mm) ID

tubing or pipe. (See Fig. 8 and 9.) Make sure that the outlet of the

trap is at least 1 in. (25 mm) lower than the unit drain--pan

condensate connection to prevent the pan from overflowing. Prime

the trap with water. Connect a drain tube using a minimum of

3/4--in. (19 mm) PVC, 3/4 --in. (19 mm) CPVC, or 3/4--in. copper

pipe (all field supplied). Do not undersize the tube. Pitch the drain

tube downward at a slope of at least 1 in. (25 mm) for every 10 ft

(3 m) of horizontal run. Be sure to check the drain tube for leaks.

Prime trap at the beginning of the cooling season start--up.

Allowable glues for condensate trap connection are: Standard

ABS, CPVC, or PVC cement.

1” (25 mm) MIN

1" (25 mm) MIN

.

Fig. 8 -- Condensate Trap

TRAP

OUTLET

.

Fig. 9 -- PVC Condensate Trap

TRAP

OUTLET

2” (51 mm) MIN.

A08001

2" (51 mm) MIN

.

Step 7 — Install Electrical Connections

!

WARNING

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in personal

injury or death.

The unit cabinet must have an uninterrupted, unbroken

electrical ground to minimize the possibility of personal

injury if an electrical fault should occur. This ground may

consist of an electrical wire connected to the unit ground

screw in the control compartment, or conduit approved for

electrical ground when installed in accordance with NEC,

ANSI/NFPA 70 American National Standards Institute/

National Fire Protection Association (latest edition) (in

Canada, Canadian Electrical Code CSA C22.1) and local

electrical codes.

!

UNIT COMPONENT DAMAGE HAZARD

Failure to follow this caution may result in damage to the

unit being installed.

1. Make all electrical connections in accordance with NEC

ANSI/NFPA 70 (latest edition) and local electrical codes

governing such wiring. In Canada, all electrical

connections must be in accordance with CSA standard

C22.1 Canadian Electrical Code Part 1 and applicable

local codes. Refer to unit wiring diagram.

2. Use only copper conductor for connections between

field--supplied electrical disconnect switch and unit. DO

NOT USE ALUMINUM WIRE.

3. Be sure that high--voltage power to unit is within

operating voltage range indicated on unit rating plate. On

3--phase units, ensure phases are balanced within 2

percent. Consult local power company for correction of

improper voltage and/or phase imbalance.

4. Do not damage internal components when drilling

through any panel to mount electrical hardware, conduit,

etc.

HIGH--VOLTAGE CONNECTIONS

The unit must have a separate electrical service with a

field--supplied, waterproof disconnect switch mounted at, or within

sight from the unit. Refer to the unit rating plate, NEC and local

codes for maximum fuse/circuit breaker size and minimum circuit

amps (ampacity) for wire sizing.

The field--supplied disconnect may be mounted on the unit over

the high--voltage inlet hole when the standard power and

low--voltage entry points are used. See Fig. 10 and Fig. 11 for

acceptable location.

Operation of unit on improper line voltage constitutes abuse and

may cause unit damage that could affect warranty.

ROUTING POWER LEADS INTO UNIT

Use only copper wire between disconnect and unit. The

high--voltage leads should be in a conduit until they enter the unit;

conduit termination at the unit must be watertight. Run the

high--voltage leads through the hole on the control box side of the

unit (See Fig. 10). When the leads are inside the unit, run leads to

the control box (See Fig. 11). Connect leads to the black and

yellow wires (See Fig. 12).

CAUTION

PH4Z

9

Page 10

HIGH-VOLTAGEPOWER

WIRINGENTRYHOLE

LOW-VOLTAGEWIRING

ENTRYHOLE

(grommethole)

PH4Z

Fig. 10 -- Unit Electrical Connection

Electric Heat Control Box

(shown uninstalled)

Electric Heat wiring

interconnection (electric

heater controls removed

for clarity)

Fig. 11 -- Control Box Wiring

UNIT GROUND

GROUND

LEAD

SINGLE-PHASE

CONNECTIONS

TO DISCONNECT

PER NEC

L

L

Fig. 12 -- Line Power Connections

CONNECTING GROUND LEAD TO UNIT GROUND

Connect the ground lead to the chassis using the unit ground in the

control box (See Fig. 11 and Fig. 12).

ROUTING CONTROL POWER WIRES (24--V)

Form a drip-- loop with the thermostat leads before routing them

into the unit. Route the thermostat leads through grommeted hole

provided in unit into unit control box (See Fig. 10). Connect

thermostat leads and unit power leads as shown in Fig. 12, Fig. 13

and Fig. 14.

The unit transformer supplies 24--v power for complete system

including accessory electrical heater. Transformer is factory wired

for 230--v operation.

Unit main harness contains a 3 amp automotive style replaceable

fuse. If transformer secondary voltage is not available at red and

EQUIP GR

BLK

YEL

A08407

A10031

A10022

brown leads in unit low voltage box, check fuse in red lead near

transformer. Replace with Littelfuse brand, part number 257003.

Unit main harness also contains a 1k ohm, 3 watt load resistor

wired across low voltage leads “G” and “C”. Purpose of resistor is

to provide a small electrical load for the indoor thermostat fan

circuit to ensure reliable operation.

ACCESSORY ELECTRIC HEAT WIRING

Refer to accessory electric heat installation instructions for

information on installing accessory electric heat. Accessory electric

heat wiring is shown in Fig. 14 and Fig. 15.

NOTE: When installing an accessory electric heater, the high

voltage wire harness pass--through must be sealed with silicone or

equivalent at the partition in order to comply with the 2% or less

air leakage certification.

PRE--START--UP

!

WARNING

FIRE, EXPLOSION, ELECTRICAL SHOCK

HAZARD

Failure to follow this warning could result in personal

injury or death and/or property damage.

1. Follow recognized safety practices and wear protective

goggles when checking or servicing refrigerant system.

2. Relieve and recover all refrigerant from system before

touching or disturbing compressor plug if refrigerant

leak is suspected around compressor terminals.

3. Never attempt to repair soldered connection while

refrigerant system is under pressure.

4. Do not use torch to remove any component. System

contains oil and refrigerant under pressure.

5. To remove a component, wear protective goggles and

proceed as follows:

a. Shut off electrical power to unit and install

lockout tag.

b. Relieve and reclaim all refrigerant from system

using both high-- and low--pressure ports.

c. Cut component connecting tubing with tubing

cutter and remove component from unit.

d. Carefully unsweat remaining tubing stubs when

necessary. Oil can ignite when exposed to torch

flame.

Proceed as follows to inspect and prepare the unit for initial

start--up:

1. Remove all access panels.

2. Read and follow instructions on all DANGER, WARNING,

CAUTION, and INFORMATION labels attached to, or

shipped with unit.

!

WARNING

PERSONAL INJURY AND ENVIRONMENTAL

HAZARD

Failure to relieve system pressure could result in personal

injury and/or death.

Relieve pressure and recover all refrigerant before system

repair or final unit disposal.

Wear safety glasses and gloves when handling refrigerant.

Keep torches and other ignition sources away from

refrigerants and oils.

10

Page 11

Thermostat

G

Y

W2

R

RED

GREEN

O

ORANGE

C

BROWN

WHITE

and subbase

Fig. 13 -- Control Connections

3. Make the following inspections:

a. Inspect for shipping and handling damages, such as

broken lines, loose parts, disconnected wires, etc.

b. Inspect all field-- and factory--wiring connections. Be

sure that connections are completed and tight.

c. Ensure wires do not touch refrigerant tubing or sharp

sheet metal edges.

d. Inspect coil fins. If damaged during shipping and

handling, carefully straighten fins with a fin comb.

4. Verify the following conditions:

a. Make sure that outdoor--fan blade is correctly posi-

tioned in fan orifice. See Outdoor Fan Adjustment

section.

b. Make sure that air filter is in place.

c. Make sure that condensate drain pan and trap are filled

with water to ensure proper drainage.

d. Make sure that all tools and miscellaneous loose parts

have been removed.

Unit Control

Power

A10026

START--UP

Step 1 — Check for Refrigerant Leaks

Proceed as follows to locate and repair a refrigerant leak and to

charge the unit:

1. Locate leak and make sure that refrigerant system pressure

has been relieved and reclaimed from both high-- and

low--pressure ports.

2. Repair leak following accepted practices.

NOTE: Install a filter drier whenever the system has been opened

for repair.

3. Add a small charge of R--410A refrigerant vapor to system

and leak--test unit.

4. Recover refrigerant from system and evacuate to 500

microns if no additional leaks are found.

5. Charge unit with R--410A refrigerant, using an accurate

scale. Refer to unit rating plate for required charge.

Step 2 — Start--Up Cooling and Make Adjustments

Complete the required procedures given in the Pre--Start--Up

section before starting the unit. Do not jumper any safety devices

when operating the unit. Do not operate the unit in cooling mode

when the outdoor temperature is below 40F(4.4C) (unless

accessory low--ambient kit is installed). Do not rapid cycle the

compressor. Allow 5 min. between “on” cycles to prevent

compressor damage.

CHECKING COOLING AND HEATING CONTROL

OPERATION

Start and check the unit for proper cooling control operation as

follows:

1. Place room thermo stat SYSTEM switch in OFF position.

Observe that blower motor starts when FAN switch is

placed in ON position and shuts down within 60 sec. when

FAN switch is placed in AUTO position.

2. Place SYSTEM switch in COOL position and FAN switch

in AUTO position. Set control below room temperature.

Observe that compressor, outdoor fan, and indoor blower

motors start and that reversing valve shifts. Observe that

cooling cycle shuts down when control setting is satisfied.

Reversing valve (RV) remains energized.

3. Place system switch in HEAT position. Observe that

compressor, indoor fan and outdoor fan energize (Reversing

Valve is deenergized in heat pump heating mode). Set

control above room temperature. Observe that heating cycle

shuts down when control setting is satisfied.

4. When using an automatic changeover room thermostat,

place both SYSTEM and FAN switches in AUTO positions.

Observe that unit operates in Cooling mode when

temperature control is set to call for Cooling (below room

temperature), and unit operates in Heating mode when

temperature control is set to call for Heating (above room

temperature).

Step 3 — Refrigerant Charge

Refrigerant Charge — The refrigerant system is fully charged with

R--410A refrigerant and is tested and factory sealed. Amount of

refrigerant charge is listed on unit nameplate and in Table 1. Unit

must operate a minimum of 15 minutes before checking charge.

NOTE: Adjustment of the refrigerant charge is not required unless

the unit is suspected of not having the proper R--410A charge.

NOTE: Unit sizes 024--042 have fixed orifice refrigerant metering

devices. There is a different charging procedure for both expansion

devices. Refer to the correct procedure for your unit.

NO CHARGE

Use standard evacuating techniques. After evacuating system,

weigh in the specified amount of refrigerant (refer to Table 1).

LOW CHARGE COOLING

024--042 Units, Fixed Metering Device:

1. Operate unit a minimum of 10 minutes before checking

charge.

2. Measure suction pressure by attaching an accurate gauge to

compressor suction side service port.

3. Measure suction side temperature by attaching an accurate

thermisitor type or electronic thermometer to suction line

about 10 in. from compressor.

4. Measure outdoor air dry--bulb temperature with thermometer.

5. Measure indoor air (return air) wet--bulb temperature with a

sling psychrometer or electronic equivalent.

6. Using Superheat Charging Table (Table 3) find outdoor

temperature and indoor air wet--bulb temperature. At this

intersection note superheat. Where a dash (----) appears on

PH4Z

11

Page 12

table do not attempt to charge unit under these conditions or

refrigerant slugging may occur. In this situation refrigerant

must be evacuated and weighed in. See rating plate for

charge quantity.

7. Refer to Required Suction Tube Temp. Table (Table 3).

Find superheat temperature located in Step 6 and suction

pressure. At this intersection note suction line temperature.

8. If unit has a higher suction line temperature than charted

temperature, add refrigerant until charted temperature is

reached.

9. If unit has a lower suction line temperature than charted

temperature, reclaim refrigerant until charted temperature is

reached.

10. If outdoor air temperature or pressure at suction port

changes, charge to new suction line temperature indicated

on chart.

048--060 Units, TXV

1. Measure Discharge line pressure by attaching a gauge to the

service port.

2. Measure the Liquid line temperature by attaching a tempera-

PH4Z

ture sensing device to it.

3. Insulate the temperature sensing device so that the Outdoor

Ambient doesn’t affect the reading.

4. Refer to the required Subcooling in Table 4 based on the

model size and the Outdoor Ambient temperature.

5. Interpolate if the Outdoor ambient temperature lies in between the table values.

6. Find the Pressure Value in the table corresponding to the

measured Pressure of the Compressor Discharge line.

7. Read across from the Pressure reading to obtain the Liquid

line temperature for a required Subcooling.

8. Add Charge if the measured temperature is higher than the

table value.

9. Remove charge if the measured temperature is lower than

the table value.

HEATING MODE CHARGE

Do not attempt to adjust charge by cooling methods while in heat

pump heating mode. Recover refrigerant and weigh in according to

unit data plate refrigerant data.

12

Page 13

Table 3 – Superheat Charging

PH4Z

Table 4 – Required Subcooling

A12098

13

A150075

Page 14

Step 4 — Indoor Airflow and Airflow Adjustments

!

WARNING

UNIT OPERATION HAZARD

Failure to follow this caution may result in equipment

damage or improper operation.

For cooling operation, the recommended airflow is 350 to

450 cfm for each 12,000 Btuh of rated cooling capacity.

Table 5 shows wet coil air delivery for horizontal discharge units.

NOTE: Be sure that all supply-- and return--air grilles are open,

free from obstructions, and adjusted properly.

!

WARNING

ELECTRICAL SHOCK HAZARD

PH4Z

Failure to follow this warning could result in personal

injury or death.

Disconnect electrical power to the unit and install lockout

tag before changing blower speed.

Blower speed tap can be changed by replacing the factory installed

blue low speed tap wire (cooling) with the unused black high speed

wire in unit control box. The red medium speed wire is factory

installed to operate with a call for supplemental electric heat. See

unit wiring diagram.

Be sure new airflow meets the range noted above and minimum

electric heat CFM, if equipped. Refer to Table 2 and 5.

All model sizes are factory wired or rated airflow operation.

Step 5 — Sequence of Operation

FAN O P E R ATION

The FAN switch on the thermostat controls indoor fan operation.

When the F AN switch is placed in the ON position, the indoor

(evaporator) fan motor (IFM) is energized through the G terminal

on the thermostat. The motor’s internal logic then provides power

to the indoor (evaporator) fan motor (IFM). The IFM will run

continuously when the FAN switch is set to ON.

When the FAN switch is set to AUTO, the thermostat deenergizes

the IFM (provided there is not a call for cooling). The contacts

open and the IFM is deenergized. The IFM will be energized only

when there is a call for cooling, in heat pump heating mode or if

the unit is equipped with accessory electric heat, the indoor--fan

motor will also run while the accessory electric heat is energized.

NOTE: Motors on this product are programmed for 60 second

time delay on tap 1 and 30 second time delay on tap 2. There is no

time delay on tap 3. The indoor fan will remain ON for the set time

delay after G or W2 is de--energized.

COOLING OPERATION

With a call for cooling (Y), the compressor, outdoor fan, and

indoor fan start immediately. When the cooling demand is met, Y

de--energizes, shutting the compressor, indoor fan and the outdoor

fan.

HEATING OPERATION

With a call for heating (Y), the compressor, outdoor fan, and

indoor fan start immediately. If Y cannot satisfy the heating

demand, the auxiliary or backup heat (W2) energizes. In case of

staged heating, W3 is energized if the demand is not met. When

heating demand is met, W3, W2 and Y sequentially de--energize

shutting the compressor, indoor fan and the outdoor fan.

CONTINUOUS FAN

With the continuous indoor fan option selected on the thermostat,

G is continuously energized. The continuous fan speed will be the

same as the cooling fan speed.

DEFROST

Defrost board (DB) is a time and temperature control, which

includes a field--selectable time period between checks for defrost

(30, 60, 90 and 120 minutes). The time period is factory--set at 60

minutes and should only be adjusted by a trained service person.

Electronic timer and defrost cycle start only when contactor is

energized and defrost thermostat (DFT) is closed.

Defrost mode is identical to Cooling mode. The outdoor fan motor

stops because of “OF1” and “OF2” contacts opening on the defrost

board, a bank of optional electric heat turns on to warm air

supplying the conditioned space.

ELECTRIC RESISTANCE HEATING

If accessory electric heaters are installed, on a call for “Emergency

Heat” the thermostat energizes W which energizes the heater relay

and in turn energizes the electric heaters. The IFM is energized

which starts the indoor--fan motor. If the heaters are staged, W2 is

energized when the second stage of heating is required. When the

need for heating is satisfied, the heater and IFM are de--energized.

14

Page 15

PH4Z

Fig. 14 -- Connection Electrical Diagram

15

A14563

Page 16

PH4Z

Fig. 13 Cont. -- Ladder Electrical Diagram

16

A14564

Page 17

Wires to be removed

A14444

Fig. 15 -- Accessory Electric Heater Wiring

Table 5 – Wet Coil Air Delivery*

(Deduct 10 percent for 208 Volt Operation)

230 VOLT HORIZONTAL DISCHARGE

UNIT

SIZE

024

030

036

042

048

060

*Air delivery values are based on operating voltage of 230v, wet coil, without filter or electric heater. Deduct filter and electric hea ter pressure drops to obtain

static pressure available for ducting.

NOTES:

1. Do not operate the unit at a cooling airflow that is less than 350 cfm for each 12,000 Btuh of rated cooling capacity. Evaporator coil frosting may occuratairflows below this point.

2. Standard Cubic Feet per Minute

SPEED TAP AIR DELIVERY

1 SCFM 933 799 758 707 675 608 549 497 435 394

2 SCFM 1016 921 882 854 809 761 711 668 599 552

3 SCFM 1079 1041 1003 970 944 909 866 810 764 724

1 SCFM 1052 1018 984 943 914 879 833 795 732 678

2 SCFM 1141 1107 1069 1036 1006 974 932 899 856 784

3 SCFM 1246 1213 1181 1144 1108 1078 1043 1015 973 931

1 SCFM 1311 1253 1195 1136 1083 1023 958 895 818 729

2 SCFM 1413 1364 1313 1256 1203 1148 1084 1022 969 882

3 SCFM 1571 1525 1473 1423 1364 1313 1261 1210 1156 1090

1 SCFM 1499 1434 1394 1349 1307 1273 1232 1169 1108 1038

2 SCFM 1568 1532 1497 1459 1407 1381 1346 1304 1252 1185

3 SCFM 1635 1593 1560 1523 1484 1439 1406 1369 1335 1264

1 SCFM 1657 1625 1590 1554 1517 1486 1448 1417 1381 1340

2 SCFM 1707 1673 1644 1614 1586 1549 1515 1479 1449 1407

3 SCFM 1931 1900 1870 1840 1809 1778 1749 1714 1683 1646

1 SCFM 1774 1746 1717 1678 1639 1590 1538 1492 1461 1418

2 SCFM 1857 1820 1784 1752 1720 1671 1625 1579 1532 1509

3 SCFM 2183 2144 2115 2079 2049 2018 1986 1933 1859 1733

2

0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1.0

EXTERNAL STATIC PRESSURE (IN. W.C.)

PH4Z

17

Page 18

Ta ble 6 – Filter Pressure Drop (IN. W.C.)

FILTER SIZE

in. (mm)

20X20X1

(508X508X25)

20X24X1

(508X610x25)

24X30X1

(610X762x25)

24X36X1

(610X914X25)

HEATER kW

5--20 0.033 0.037 0.042 0.047 0.052 0.060 0.067 0.075

500 600 700 800 900 1000 1100 1200 1300 1400 1500 1600 1700 1800 1900 2000 2100 2200

0.05 0.07 0.08 0.10 0.12 0.13 0.14 0.15 — — — — — — — — — —

— — — 0.08 0.09 0.10 0.11 0.13 0.14 0.15 0.16 — — — — — — —

— — — 0.04 0.05 0.06 0.07 0.07 0.08 0.09 0.10 — — — — — — —

— — — — — — — 0.06 0.07 0.07 0.08 0.09 0.09 0.10 0.11 0.12 0.13 0.14

Table 7 – Accessory Electric Heat Pressure Drop (IN. W.C.)

800 1000 1200 1400 1600 1800 2000 2200

CFM

CFM

MAINTENANCE

To ensure continuing high performance, and to minimize the

possibility of premature equipment failure, periodic maintenance

must be performed on this equipment. This cooling unit should be

inspected at least once each year by a qualified service person. To

PH4Z

troubleshoot unit, refer to Table 9, Troubleshooting Chart.

NOTE TO EQUIPMENT OWNER: Consult your local dealer

about the availability of a maintenance contract.

!

WARNING

PERSONAL INJ URY AND UNIT DAMAGE

HAZARD

Failure to follow this warning could result in personal

injury or death and possible unit component damage.

The ability to properly perform maintenance on this

equipment requires certain expertise, mechanical skills,

tools and equipment. If you do not possess these, do not

attempt to perform any maintenance on this equipment,

other than those procedures recommended in the Owner’s

Manual.

!

WARNING

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in personal

injury or death.

1. Turn off electrical power to the unit and install lockout

tag before performing any maintenance or service on this

unit.

2. Use extreme caution when removing panels and parts.

3. Never place anything combustible either on or in contact

with the unit.

1. Inspect air filter(s) each month. Clean or replace when

necessary.

2. Inspect indoor coil, drain pan, and condensate drain each

cooling season for cleanliness. Clean when necessary.

3. Inspect blower motor and wheel for cleanliness each

cooling season. Clean when necessary.

4. Check electrical connections for tightness and controls for

proper operation each cooling season. Service when

necessary.

5. Ensure electric wires are not in contact with refrigerant

tubing or sharp metal edges.

Air Filter

IMPORTANT: Never operate the unit without a suitable air filter

in the return --air duct system. Always replace the filter with the

same dimensional size and type as originally installed. See Table 1

for recommended filter sizes.

Inspect air filter(s) at least once each month and replace

(throwaway--type) or clean (cleanable--type) at least twice during

each cooling season and twice during the heating season if electric

heat is installed, or whenever the filter becomes clogged with dust

and lint.

Unit Top Removal

NOTE: When performing maintenance or service procedures that

require removal of the unit top, be sure to perform all of the routine

maintenance procedures that require top removal, including coil

inspection and cleaning, and condensate drain pan inspection and

cleaning.

!

WARNING

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in personal

injury or death.

Disconnect electrical power, and install lockout tag to the

unit before removing top.

!

UNIT OPERATION HAZARD

Failure to follow this caution may result in equipment

damage or improper operation.

Errors made when reconnecting wires may cause improper

and dangerous operation. Label all wires prior to

disconnecting when servicing.

The minimum maintenance requirements for this equipment are as

follows:

CAUTION

Only qualified service personnel should perform maintenance and

service procedures that require unit top removal.

Refer to the following top removal procedures:

1. Unplug all three wires from the outdoor fan motor.

2. Remove screws on unit top cover flange. (Save all screws.)

3. Lift top from unit carefully. Set top on edge and make sure

that top is supported by unit side that is opposite duct (or

plenum) side.

4. Carefully replace and secure unit top to unit, using screws

removed in Steps 1 and 2, when maintenance and/or service

procedures are completed.

18

Page 19

Indoor Blower and Motor

NOTE: All motors are pre--lubricated. Do not attempt to lubricate

these motors.

For longer life, operating economy, and continuing efficiency,

clean accumulated dirt and grease from the blower wheel and

motor annually.

!

WARNING

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in personal

injury or death.

Disconnect electrical power, and install lockout tag to the

unit before cleaning and lubricating the blower motor and

wheel.

To clean the blower wheel:

1. Remove the blower housing:

a. Remove the screws on the external side of the duct

panel that fasten the housing to the duct panel assembly.

b. Remove the side access panel and unscrew the

mounting bracket that fastens the blower housing to the

internal partition panel of the control box assembly.

c. Make sure that the blower housing is supported by hand

before completely removing the mounting bracket.

d. Slide the blower housing from the rails of the duct panel

and place it outside the unit.

2. Remove the blower wheel from the housing:

a. Loosen the set screw which secures the wheel to the

motor shaft.

b. Loosen the three mounting legs of the motor by

removing the bolts that fasten the mounting legs to the

housing.

c. Slide out the motor assembly (motor, belly band and the

3 mounting legs) from the hub of the wheel.

d. Remove the filler panel at the discharge end of the

blower housing by removing the two screws that fasten

it to the housing.

e. Ensure proper reassembly by marking wheel orientation.

Remove the wheel from the housing.

3. Remove the caked on dirt from the wheel and the motor

using a brush.

4. Remove lint and dirt accumulations from the wheel and

housing with a vacuum cleaner, using a soft brush

attachment.

5. Remove grease and oil with a mild solvent.

6. Reassemble

a. Slip the wheel back in the housing with the hub set

screw parented in the correct direction.

b. Install the filler panel.

c. Reinsert the motor assembly in the wheel hub and align

the mounting legs with the housing mounting hold

locations.

d. Tighten the mounting bolts to fasten the motor assembly

with the housing.

e. Center the wheel in the housing by sliding it, align the

flat end of the shaft with the set screw and tighten the

set screw.

f. Slide back the blower housing into the mounting rails in

the duct panel and install the mounting bracket back in

its position.

g. Install the screws on the external side of the duct panel

to fasten duct panel with the housing.

h. Replace the side access panel.

Outdoor Coil, Indoor Coil, and Condensate Drain Pan

Inspect the condenser coil, evaporator coil, and condensate drain

pan at least once each year.

The coils are easily cleaned when dry; therefore, inspect and clean

the coils either before or after each cooling season. Remove all

obstructions, including weeds and shrubs, that interfere with the

airflow through the condenser coil.

Straighten bent fins with a fin comb. If coated with dirt or lint,

clean the coils with a vacuum cleaner, using the soft brush

attachment. Be careful not to bend the fins. If coated with oil or

grease, clean the coils with a mild detergent and water solution.

Rinse coils with clear water, using a garden hose. Be careful not to

splash water on motors, insulation, wiring, or air filter(s). For best

results, spray condenser coil fins from inside to outside the unit. On

units with an outer and inner condenser coil, be sure to clean

between the coils. Be sure to flush all dirt and debris from the unit

base.

Inspect the drain pan and condensate drain line when inspecting

the coils. Clean the drain pan and condensate drain by removing all

foreign matter from the pan. Flush the pan and drain trough with

clear water. Do not splash water on the insulation, motor, wiring, or

air filter(s). If the drain trough is restricted, clear it with a

“plumbers snake” or similar probe device.

Outdoor Fan Adjustment

!

UNIT OPERATION HAZARD

Failure to follow this caution may result in damage to unit

components.

Keep the condenser fan free from all obstructions to ensure

proper cooling operation. Never place articles on top of

unit.

1. Shut off unit power supply and install lockout tag.

2. Remove outdoor--fan assembly (grille, motor, motor cover,

and fan) by removing screws and flipping assembly onto

unit top cover.

3. Inspect the fan blades for cracks or bends.

4. If fan needs to be removed, loosen the setscrew and slide the

fan off the motor shaft.

5. When replacing fan blade, position blade as shown in Fig.

16. Tighten setscrews.

Fig. 16 -- Outdoor Fan Adjustment

CAUTION

FAN

HUB

MOTOR

SHAFT

HP UNIT

SIZE

024

030

036

A

042

048

060

A

in. (mm)

13/16 (20.6)

13/16 (20.6)

0

0

1/2 (12.7)

1/2 (12.7)

A150076

PH4Z

19

Page 20

Electrical Controls and Wiring

Inspect and check the electrical controls and wiring annually. Be

sure to turn off the electrical power to the unit.

Remove access panel to locate all the electrical controls and wiring.

Check all electrical connections for tightness. Tighten all screw

connections. If any smoky or burned connections are noticed,

disassemble the connection, clean all the parts, re--strip the wire

end and reassemble the connection properly and securely.

Check to ensure no wires are touching refrigerant tubing or sharp

sheet metal edges. Move and secure wires to isolate from tubing

and sheet metal edges.

After inspecting the electrical controls and wiring, replace all the

panels. Start the unit, and observe at least one complete cooling

cycle to ensure proper operation. If discrepancies are observed in

operating cycle, or if a suspected malfunction has occurred, check

each electrical component with the proper electrical

instrumentation. Refer to the unit wiring label when making these

checks. (See Fig. 14)

Refrigerant Circuit

Inspect all refrigerant tubing connections and the unit base for oil

accumulation annually. Detecting oil generally indicates a

PH4Z

refrigerant leak.

!

WARNING

EXPLOSION, SAFETY AND ENVIRONMENTAL

HAZARD

Failure to follow this warning could result in personal

injury, death or equipment damage.

This system uses R--410A refrigerant which has higher

operating pressures than R--22 and other refrigerant. No

other refrigerant may be used in this system. Gauge set,

hoses, and recovery system must be designed to handle

R--410A. If you are unsure, consult the equipment

manufacturer.

If oil is detected or if low cooling performance is suspected, leak

test all refrigerant tubing using an electronic leak detector, halide

torch or liquid-- soap solution. If a refrigerant leak is detected, refer

to Check for Refrigerant Leaks section.

If no refrigerant leaks are found and low cooling performance is

suspected, refer to Checking and Adjusting Refrigerant Charge

section.

Indoor Airflow

The airflow does not require checking unless improper

performance is suspected. If a problem exists, be sure that all

supply-- and return--air grilles are open and free from obstructions,

and that the air filter is clean.

Metering Devices

Refrigerant cooling metering device is a piston located upstream of

the indoor coil distributor assembly. Refrigerant heating mode

metering device is a piston located upstream of the outdoor coil

distributor assembly.

High Flow Valves

High flow valves are located on the compressor hot gas and suction

tubes. Large black plastic caps distinguish these valves with

O--rings located inside the caps. Ensure the plastic caps are in place

and tight or the possibility of refrigerant leakage could occur. To

replace valve core body without removing charge, service tool p/n

SCFT20A is required.

High Pressure Switch

The high--pressure switch is located in the discharge line and

protects against excessive condenser coil pressure. It opens at 650

psig (4482 kPA). High pressure may be caused by a dirty

condenser coil, failed fan motor, or condenser air recirculation.

To check switch:

1. Turn off all power to unit.

2. Disconnect leads on switch.

3. Apply ohmmeter leads across switch. You should have

continuity on a good switch.

Loss of Charge Switch

The loss of charge switch is located in the liquid line and will

protect the compressor against a loss of charge condition. It opens

at 20 psig (138 kPa). If switch is open check system pressures. If

pressures are normal, check continuity and wiring of switch. Repair

or replace as required.

R--410A Compressor

The compressor used in this product is specifically designed to

operate with R--410A refrigerant and cannot be interchanged.

The compressor is an electrical (as well as mechanical) device.

Exercise extreme caution when working near compressors. Power

should be shut off, if possible, for most troubleshooting techniques.

Refrigerants present additional safety hazards.

!

WARNING

EXPLOSION HAZARD

Failure to follow this warning could result in personal

injury or death and/or property damage.

Wear safety glasses and gloves when handling refrigerants.

Keep torches and other ignition sources away from

refrigerants and oils.

Compressors vary in type by unit size. See Table 8 below for

compressor type by size.

Table 8 – Compressor Type

UNIT

All compressors in these units have internal overload protection.

This protection will interrupt motor current under fault conditions

such as running current overload. The Copeland Scroll

compressors also have internal pressure relief that will relieve from

the high side to the low side if the differential is between 550 and

625 psig.

COMPRESSOR

TYPE

024 Copeland Scroll 3MAF Polyolester Oil (POE)

030 Copeland Scroll 3MAF Polyolester Oil (POE)

036 LG Scroll RB32G Polyolester Oil (POE)

042 LG Scroll RB32G Polyolester Oil (POE)

048 LG Scroll RB32G Polyolester Oil (POE)

060 Copeland Scroll 3MAF Polyolester Oil (POE)

MANUFACTURER SUGGESTED

OIL TYPE

Refrigerant

!

EXPLOSION, ENVIRONMENTAL SAFETY

HAZARD

Failure to follow this warning could result in personal

injury, death or equipment damage.

This system uses R--410A refrigerant which has higher

operating pressures than R--22 and other refrigerants. No

other refrigerant may be used in this system. Gauge set,

hoses, and recovery system must be designed to handle

R--410A. If you are unsure, consult the equipment

manufacturer.

WARNING

20

Page 21

This system uses R --410A refrigerant which has higher operating

pressures than R--22 and other refrigerants. No other refrigerant

may be used in this system. Gauge set, hoses, and recovery system

must be designed to handle R--410A. If you are unsure, consult the

equipment manufacturer. Failure to use R--410A compatible

servicing equipment or replacement components may result in

property damage or injury.

Compressor Oil

Use only manufacturer suggested compressor oil, see Table 8 for

correct oil.

NOTE: Alternate manufacturer approved compressor oil for

Copeland Scroll compressor: Uniqema RL32--3MAF, Copeland

Ultra 32 CC, Mobil Arctic EAL22 CC, ICI Emkarate RL22 or ICI

Emkarate 32CF.

This oil is extremely hygroscopic, meaning it absorbs water

readily. POE/PVE oils can absorb 15 times as much water as other

oils designed for HCFC and CFC refrigerants. Take all necessary

precautions to avoid exposure of the oil to the atmosphere.

Servicing Systems on Roofs with Synthetic Materials

POE/PVE (polyolester) compressor lubricants are known to cause

long term damage to some synthetic roofing materials. Exposure,

even if immediately cleaned up, may cause embrittlement (leading

to cracking) to occur in one year or more. When performing any

service that may risk exposure of compressor oil to the roof, take

appropriate precautions to protect roofing. Procedures which risk

oil leakage include, but are not limited to, compressor replacement,

repairing refrigerant leaks, replacing refrigerant components such

as filter drier, pressure switch, metering device, coil, accumulator,

or reversing valve.

Synthetic Roof Precautionary Procedure

1. Cover extended roof working area with an impermeable

polyethylene (plastic) drip cloth or tarp. Cover an

approximate10x10ft (3x3m)area.

2. Cover area in front of the unit service panel with a terry

cloth shop towel to absorb lubricant spills, prevent run--offs,

and protect drop cloth from tears caused by tools or

components.

3. Place terry cloth shop towel inside unit immediately under

component(s) to be serviced and prevent lubricant run--offs

through the louvered openings in the unit base.

4. Perform required service.

5. Remove and dispose of any oil contaminated material per

local codes.

Liquid Line Filter Drier

The filter drier is specifically designed to operate with R--410A.

Use only factory--authorized components. Filter drier must be

replaced whenever the refrigerant system is opened. When

removing a filter drier, use a tubing cutter to cut the drier from the

system. Do not unsweat a filter drier from the system. Heat from

unsweating will release moisture and contaminants from drier into

system.

R--410A Refrigerant Charging

Refer to unit informatio n plate and charging chart. Some R --410A

refrigerant cylinders contain a dip tube to allow liquid refrigerant to

flow from cylinder in upright position. For cylinders equipped

with a dip tube, charge R--410A units with cylinder in upright

position and a commercial metering device in manifold hose.

Charge refrigerant into suction--line.

TROUBLESHOOTING

Refer to the Troubleshooting Chart (Table 9) for troubleshooting

information.

START--UP CHECKLIST

Use the Start-- Up Checklist at the back of this manual.

PH4Z

21

Page 22

AIR CONDITIONER WITH R--410A QUICK REFERENCE GUIDE

R--410A refrigerant operates at 50--70 percent higher pressures than R--22. Be sure that servicing equipment and replacement components

are designed to operate with R --410A. R--410A refrigerant cylinders are rose colored.

S R--410A refrigerant cylinders manufactured prior to March 1, 1999, have a dip tube that allows liquid to flow out of cylinder in upright

position.

Cylinders manufactured March 1, 1999 and later DO NOT have a dip tube and MUST be positioned upside down to allow liquid to flow.

S Recovery cylinder service pressure rating must be 400 psig. DOT 4BA400 or DOT BW400.

S R--410A systems should be charged with liquid refrigerant. Use a commercial type metering device in the manifold hose.

S Manifold sets should be minimum 700 psig high--side and 180 psig low-- side with 550 psig low--side retard.

S Use hoses with minimum 700 psig service pressure rating.

S Leak detectors should be designed to detect HFC refrigerant.

S R--410A, as with other HFCs, is only compatible with POE/PVE oils.

S Vacuum pumps will not remove moisture from oil.

S Only use factory specified liquid--line filter driers with rated working pressures no less than 600 psig.

S Do not install a suction--line filter drier in liquid line.

S POE/PVE oils absorb moisture rapidly. Do not expose oil to atmosphere.

S POE/PVE oils may cause damage to certain plastics and roofing materials.

S Wrap all filter driers and service valves with wet cloth when brazing.

PH4Z

S A R--410A liquid--line filter drier is required on every unit.

S Do not use an R--22 TXV.

S Never open system to atmosphere while it is under a vacuum.

S When system must be opened for service, break vacuum with dry nitrogen and replace filter driers.

S Always replace filter drier after opening system for service.

S Do not vent R--410A into the atmosphere.

S Observe all warnings, cautions, and bold text.

S Do not leave R--410A suction line driers in place for more than 72 hrs.

22

Page 23

Table 9 – Troubleshooting Chart

SYMPTOM CAUSE REMEDY

Power failure Call power company

Fuse blown or circuit breaker tripped Replace fuse or reset circuit breaker

Compressor and outdoor fan

will not start

Compressor will not start but condenser fan

runs

Compressor cycles (other than normally satisfying) cooling/heating calls

Compressor operates continuously

Excessive head pressure

Head pressure too low

Excessive suction pressure

Suction pressure too low

Defective contactor, transformer, control relay, or

high--pressure, loss-of--charge or low--pressure switch

Insufficient line voltage Determine cause and correct

Incorrect or faulty wiring Check wiring diagram and rewire correctly

Thermostat setting too low/too high Reset Thermostat setting

Faulty wiring or circuit

Loose connections in compressor

Compressor motor burned out, seized, or Determine cause

internal overload open Replace compressor

Defective run capacitor, overload, or PTC (positive

temperature coefficient) thermistor

Low input voltage Determine cause and correct

Refrigerant overcharge or undercharge

Defective compressor Replace and determine cause

Insufficient line voltage Determine cause and correct

Blocked outdoor coil Determine cause and correct

Defective run/start capacitor, overload or start relay Determine cause and replace

Faulty outdoor fan motor or capacitor Replace

Restriction in refrigerant system Locate restriction and remove

Dirty air filter Replace filter

Unit undersized for load Decrease load or increase unit size

Thermostat temperature set too low Reset Thermostat setting

Low refrigerant charge Locate leak, repair, and recharge

Air in system

Outdoor coil dirty or restricted Clean c oil or remove restriction

Dirty air filter Replace filter

Dirty indoor or outdoor coil Clean coil

Refrigerant overcharged Recover excess refrigerant

Air in system

Indoor or outdoor air restricted or air short-- cycling Determine cause and correct

Low refrigerant charge Check for leaks, repair and recharge

Restriction in liquid tube Remove restriction

High Heat load Check for source and eliminate

Reversing valve hung up or leaking internally Replace valve

Refrigerant overcharged Recover excess refrigerant

Dirty air filter Replace filter

Low refrigerant charge Check for leaks, repair and recharge

Metering device or low side restricted Remove source of restriction

Insufficient coil airflow Check filter–replace if necessary

Temperature too low in conditioned area Reset Thermostat setting

Outdoor ambient below 55F(13C) Install low--ambient kit

Filter drier restric ted Replace

Replace component

Check wiring and repair or replace

Determine cause and replace

Recover refrigerant, evacuate system, and recharge to capacities shown on rating plate

Recover refrigerant, evacuate system, and recharge

Recover refrigerant, evacuate system, and recharge

PH4Z

23

Page 24

START--UP CHECKLIST

(REMOVE AND STORE IN JOB FILE)

I. PRELIMINARY INFORMATION

Model No ............................................................................................................................................................

Serial No .............................................................................................................................................................

Date .....................................................................................................................................................................

Technician ..........................................................................................................................................................

Customer Information(Name/Address) .....................................................................................................................

II. PRE--START--UP

____ Verify that all packing materials have been removed from unit.

____ Verify that condensate connection is installed per installation instructions.

____ Check all electrical connections and terminals for tightness.

____ Check wire proximity to refrigerant tubes and sheet metal edges.

____ Check that indoor (indoor) air filter is clean and in place.

____ Verify that unit installation is level.

____ Check fan wheel propeller for location in housing and setscrew tightness.

III. START--UP

Supply Voltage: L1--L2 __________

Compressor Amps: L1(C) __________ L2(S) __________ L3(R) __________

Indoor Fan Amps: __________ Outdoor Fan Amps: __________

PH4Z

TEMPERATURE--Cooling Mode

Outdoor Air Temperature: __________ DB ____________WB

Return--Air Temperature: __________ DB __________ WB

Cooling Supply Air: __________DB___________WB

PRESSURES--Cooling Mode

Refrigerant Suction __________ psig

Suction Line Temp* ___________

Refrigerant Discharge __________ psig

Discharge Temp {__________

TEMPERATURE--Heating Mode

Outdoor Air Temperature: __________ DB ____________WB

Return--Air Temperature: __________ DB __________ WB

Supply Air: __________DB___________WB

PRESSURES--Heating Mode

Refrigerant Suction __________ psig

Suction Line Temp* ___________

Refrigerant Discharge __________ psig

Discharge Temp {__________

*Measured at suction inlet to compressor

{Measured at liquid line leaving outdoor coil

Copyright 2016 CAC / BDP D 7310 W. Morris St. D Indianapolis, IN 46231 Edition Date: 5/16

Manufacturer reserves the right to change, at any ti me, specifications and designs without notice and without obligations.

24

C a t a l o g N o : I M --- P H 4 Z --- 0 4

R e p l a c es : I M --- P H 4 Z --- 0 3

Loading...

Loading...