Page 1

PA13NA

PA13PA

13 SEER Split ---System Air Conditioner

With R ---410A Refrigerant

Single & Three Phase

1 --- 1 / 2 To 5 Ton s

Product Data

FEATURES AND BENEFITS

AVAILABLE SIZES:

Nominal sizes are available from 018 through 060 to meet the

needs of residential and light commercial applications.

CERTIFICATION:

All models are listed with UL, (U.S. and Canada), AHRI, and

CEC.

ELECTRICAL RANGE:

Units offered in single phase 208/230v are 018--060, three phase

208/230v in 036, 048 and 060, and three phase 460v in 060.

FAN MOTOR:

The totally enclosed fan motor provides greater reliability under

adverse conditions and dependable performance for many years.

The permanent split capacitor type motor was designed for

optimum efficiency. The motor was then qualified under extreme

conditions to help ensure a long, reliable life.

CABINET:

A weather protective cabinet of prepainted steel is protected

underneath by a galvanized coating and treated with a layer of zinc

phosphate for a finish that will last for many years. All screws on

cabinet exterior are coated for a long--lasting, rust--resistant, quality

appearance.

UNIT DESIGN:

The copper tube, enhanced sine wave, aluminum fin coil is

designed for optimum heat transfer. Vertical air discharge carries

sound and hot condenser air up and away from adjacent patio areas

and foliage. The base pan is designed for easy removal of water,

dirt, and leaves.

COMPRESSOR:

Each compressor is protected with internal temperature-- and

current--sensitive overloads. An internal pressure relief valve

provides high pressure protection to the refrigerant system. For

improved serviceability, all models are equipped with a compressor

terminal plug.

SERVICE VALVES:

Both service valves are brass, front seating type with sweat

connections. Valves are externally located so refrigerant tube

connections can be made quickly and easily. Each valve has a

service port for ease of checking operating refrigerant pressures.

SERVICEABILITY:

One access panel provides access to electrical controls. Removal of

top gives access to fan motor, compressor, and condenser coil.

Page 2

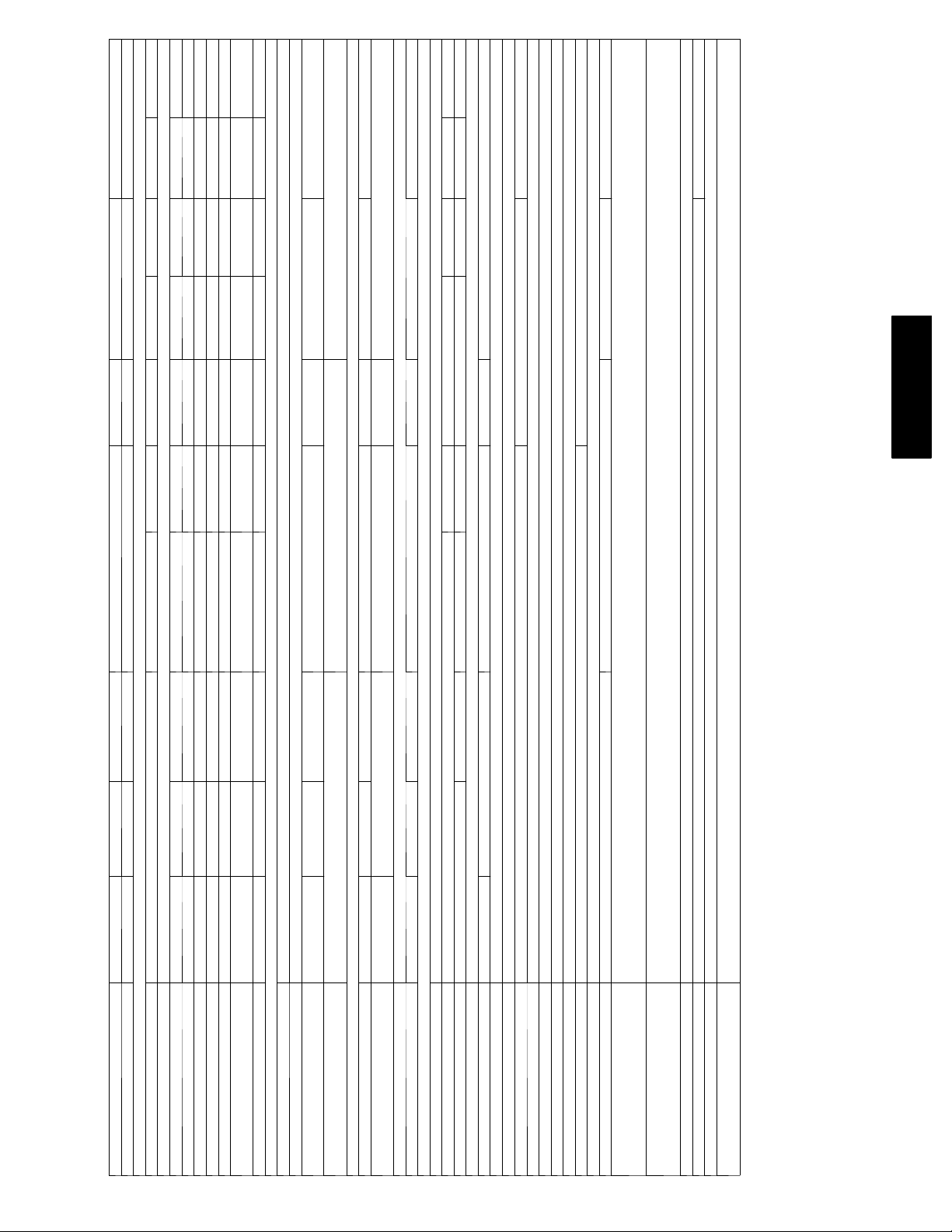

PRODUCT NUMBER NOMENCLATURE

13 SEER

Air Conditioner

with R --- 410A Refrigerant

PA1 3 N

A

018

000

B

A

Series

AA

Variatio ns

Electrical Supply

Variatio ns

N --- 208/230 --- 60 ---1

P --- 208/230 ---60 --- 3

Nominal Capacity

018 --- 1 --- 1 / 2 To n

024 --- 2 To n s

A --- R---410A

ISO 9001:2000

PA13NA / PA13PA

Use of the AHRI Certified

TM Mark indicates a

manufacturer’s

participation in the

program For verification

of certification for individual

products, go to

www.ahridirectory.org.

REGISTERED

®

030 --- 2 --- 1 / 2 To n s

036 --- 3 To n s

042 --- 3 --- 1 / 2 To n s

048 --- 4 To n

060 --- 5 To n

000 --- V a r i a t i o n s

This produ ct has been designed and man ufactur ed t o

meet Energy S tar® criteria for energy efficiency when

matched wi th appropriate coi l components. However,

proper refr igerant char ge an d proper air fl ow are crit ical

to achieve rated capacity and efficiency. Installation of

this product should f ollow all manufacturing refrigerant

charging and air flow instructions. Failure to confirm

proper charge and air flow may reduce energy

efficiency and shorten equ ipment l i fe.

2

Page 3

66 / 63

(20.1 / 19.2)

89 / 82

(27.1 / 25.0)

70 / 66

115 / 109

83 / 79

70 / 67

70 / 66

1/4 PSC and 1100

(21.3 / 20.1)

(35.1 / 33.2)

(25.3 / 24.1)

1100

1/5 PSC and

PA13NA / PA13PA

(21.3 / 20.4)

TSTATPPPAC01

TSTATPPBAC01

(21.3 / 20.1)

TSTATXXPBP01

74 / 70

(22.6 / 21.3)

70 / 66

(21.3 / 20.1)

66 / 62

(20.1 / 18.9)

Locked Rotor A mps 48.0 58.3 64.0 77.0 71.0 112.0 109.0 83.1 134.0 110.0

UNIT SIZE 018 024 030 036 042 048 060

SERIES B B B B B D B

ELECTRI CAL

Unit Volts—Hertz—Phase 208/230—60—1 208/230---60 ---1 208/230---60 ---3 208/230---60 ---1 208/230---60 ---1 208/230---60 ---3 208/230---60 --- 1 208/230---60 ---3

Operating Voltage Range* 187—253

Compresso r—Rated Load Amps 9.0 13.5 12.8 14.1 9.0 17.9 19.9 13.1 26.4 16.0

Condenser Fan Motor— Full Load Amps 0.5 0.8 0.8 1.4 1.4 1.1 1.4 1.4 1.4 1.4

Min Uni t Ampacity for Wire Sizing 11.7 17.6 16.8 19.0 12.7 23.5 26.2 17.8 34.4 21.4

Min Wire Size (60°/75° Copper) AWG** 14 12 12 12 14 10 8 12 8 12

Max Wire Length (60°/75°)ft(m)‡

Max Branch Circuit Fuse Size† 20 25 25 30 20 40 40 30 50 30

COMPRESSOR AND REFRIGERANT

SPECIFICATIONS

Typ e Scroll

3/4 and 3/8 7/8 and 3/8 1--- 1/8 and 3/8

3.15 (1.43) 3.15 (1.43) 3.63 (1.65) 4.67 (2.12) 6.07 (2.75) 7.00 (3.18) 8.00 (3.63)

AmountLb(kg)@15ft(4.6m)

Temperature and Current P rotectio n Internal Line Brea k

R--- 410A Refrigerant—

Refrigerant Tubes (In. OD)

}} Rated Vapor and Maximum Liquid

CONDENSER COIL AND FAN

Coil Face Area (Sq Ft) 8.4 8.4 9.8 12.60 17.3 19.29 15.14

Fan Motor—HP, Type, and RPM 1/12 PSC and 1100 1/ 10 PSC and 1100 1/4 PSC and 1100

Vol ts— Hertz—Ph ase 208/230—60—1

Condenser Airflow (CFM) 1700 2000 2000 2500 3000 3400 3400

OPTIONAL EQUIPMENT

Cycle Protector KSACY0101AAA

Start A ssist—PTC Type KAACS0201PTC N/A KAACS0201PTC N/A KAACS0201PTC N/A

Start Assist—Capacitor/Relay Type KSAHS1501AAA KSAHS1701AAA KSAHS1501AAA N/A KSAHS1501AAA N/A KSAHS1501AAA N/A

MotorMaster® Control KSALA0601AAA

Ball Bearing Fan Motor (RCD) HC32GE234 HC34GE239 HC40GR232 HC38GE219 HC40GE226

L o w --- P r e s s u r e S w i t c h KAALP0401PUR

H i g h --- P r e s s u r e S w i t c h KAAHI0501PUR

Compressor Sound Hood KSASH1801COP KSASH0601COP KSASH2101COP

T i m e --- D e l a y R e l a y KAATD0101TDR

Low--- Ambient Pressure Switch Kit KSALA0301410

Winter Start Control KAAWS0101AAA

Evaporator Freeze Thermostat KAAFT0101AAA

Compresso r Crankcase He ater KAACH1401AAA KAACH1201AAA

Liquid Line Solenoid Valve†† KAALS0201LLS

TXV (Hard Shutoff)†† KSATX0201PUR KSATX0301PUR KSATX0401PUR KSATX0501PUR

Standard Thermostat, Manual

Changeover, Non---Programmable, °F/°C,

1 --- St a g e H e a t , 1 --- St a g e C o o l

Thermostat, Auto C hangeover, 7 --- Day

Progra mmable , °F/°C , 1 --- S t a g e H e a t ,

1 --- St a g e C o o l

Outdoor Sensor TSTATXXSEN01---B

Liquid Line Fil ter Dri er KH43LG073 KH43LG074

Backplate for Standard Thermostat TSTATXXBBP01

Backplate for Programmable

Thermostat

N/A --- Not applicable in this application.

* Permissible limits of the voltage range at which unit will operate satisfactorily. Operation outside these limits may result in unit failure.

Article 336 --- 26.

{ Time---delay fuse or circuit breaker.

} Length shown is as measured 1 way along wire path between unit and service panel for voltage drop not to exceed 2%.

** If wire is applied at ambient greater than 30°C, consult Table 310 --- 16 of the NEC (NFPA 70). The ampacity of nonmetallic--- sheathed cable (NM), trade name ROMEX, shall be that of 60° C conductors, per the NEC (NFPA 70)

{{ Do not use hard shutoff TXV with liquid solenoid valve.

}} Units are rated with 25 ft (7.6 m) of lineset length. See Vapor Line Sizing and Cooling Capacity Loss table when using other sizes and lengths of lineset.

3

Page 4

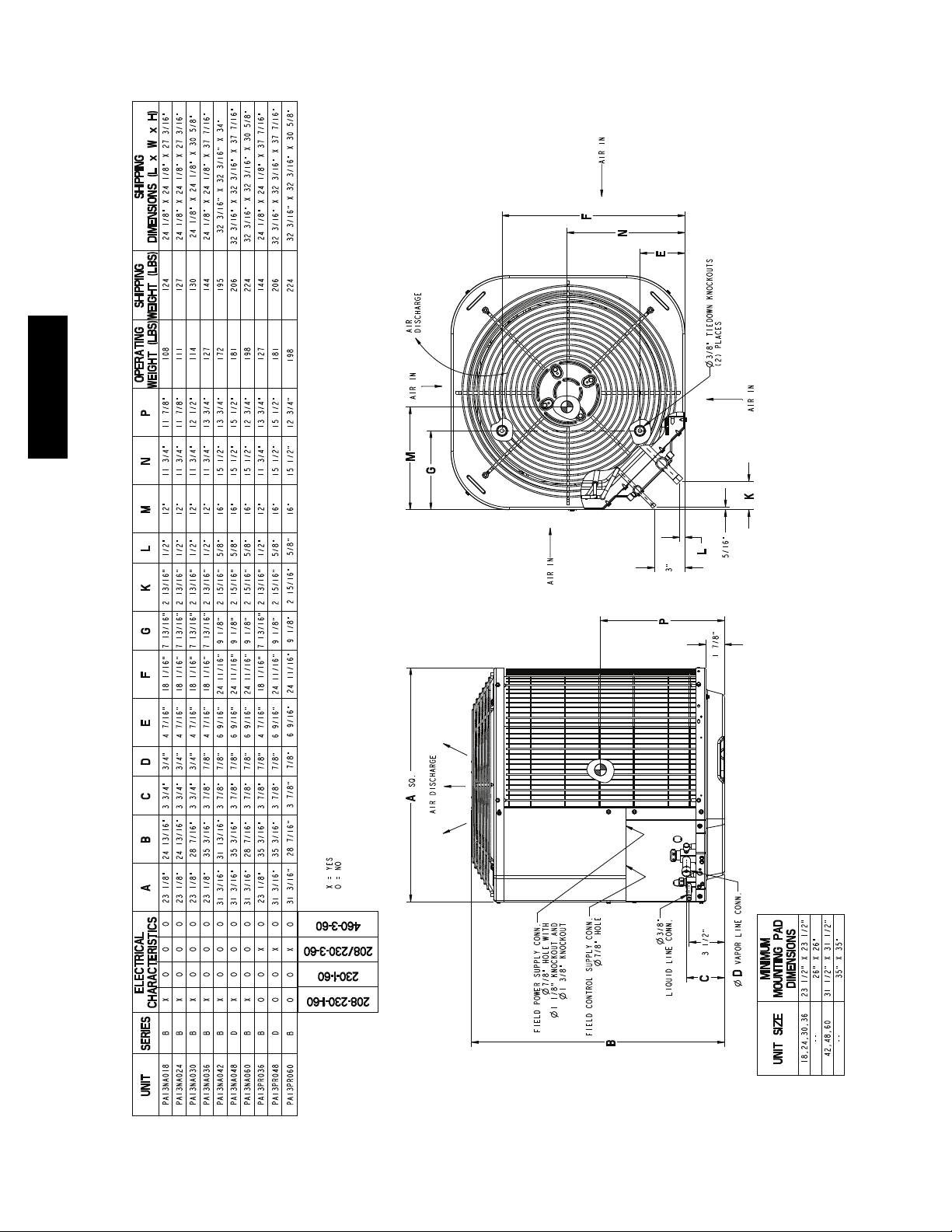

PA13NA / PA13PA

DIMENSIONS -- ENGLISH

4

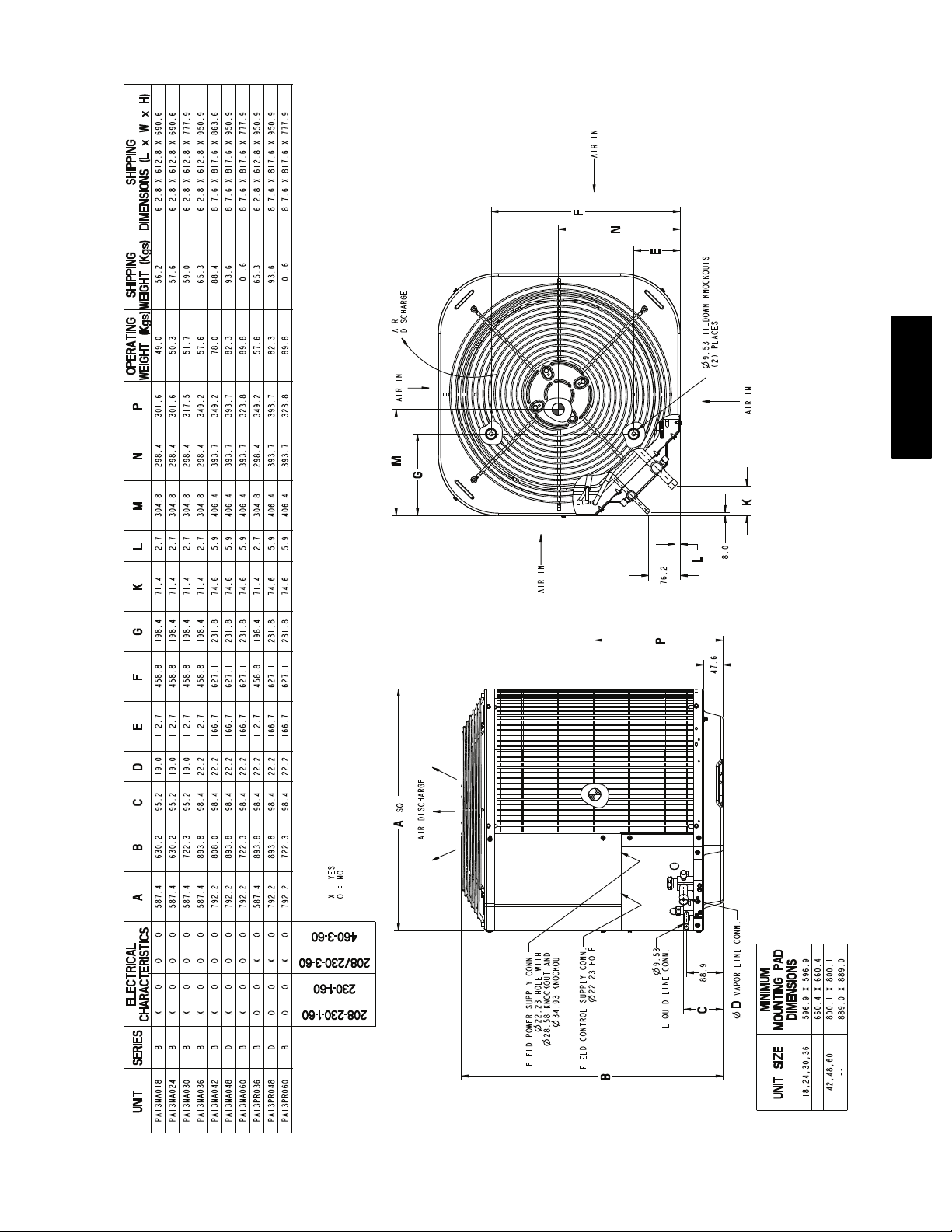

Page 5

PA13NA / PA13PA

DIMENSIONS -- SI

5

Page 6

Wall

6”

(152.4)

24”

(609.6)

Wall

PA13NA / PA13PA

Service

12”

(304.8)

12”

(304.8)

24”

(609.6)

Service

18”

(457.2)

24”

(609.6)

Service

18”

(457.2)

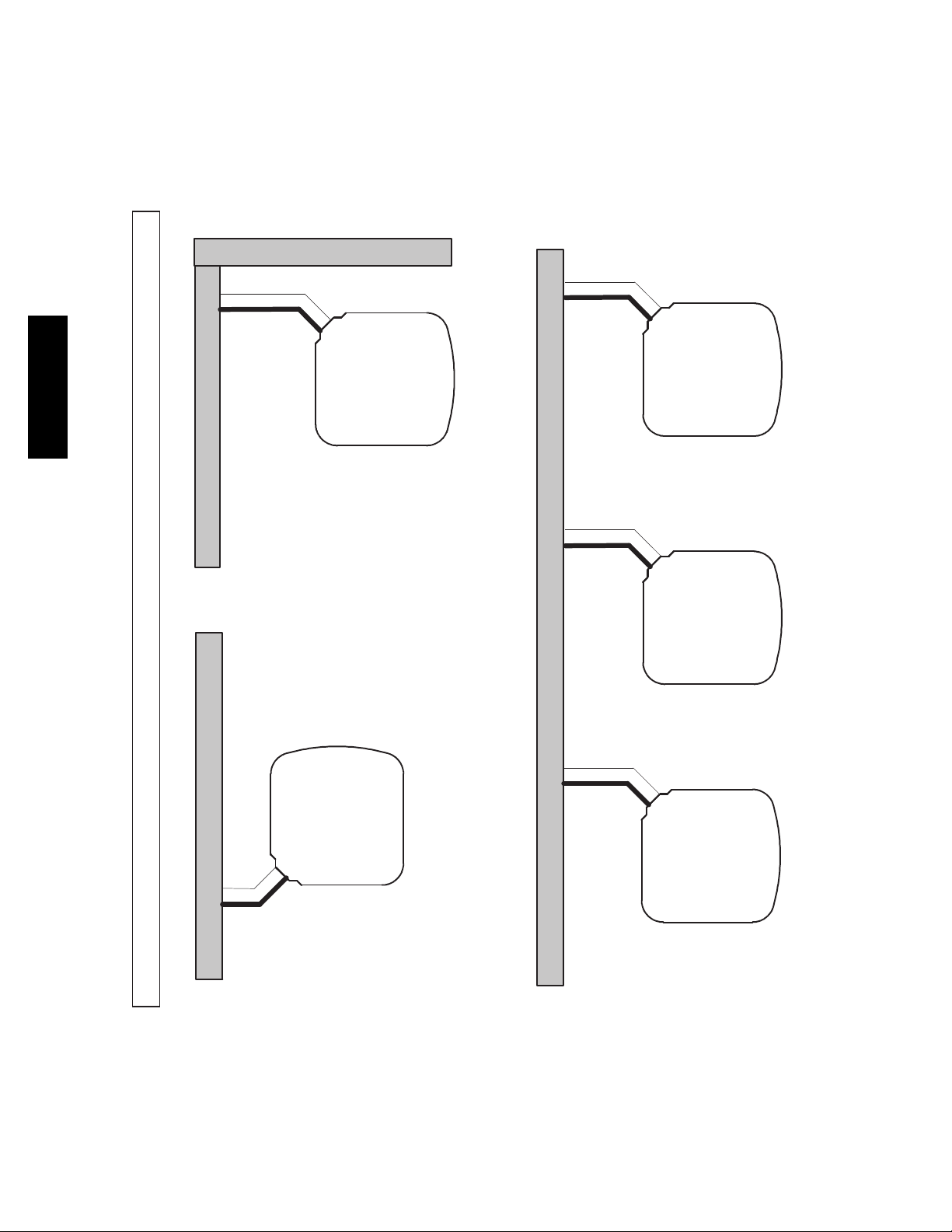

Clearances (various examples)

12”

(304.8)

6”

Wall

(152.4)

Wall

12”

(304.8)

CLEARANCES

24”

(609.6)

Service

24”

(609.6)

Service

18”

(457.2)

6

Note: Numbers in ( ) = mm

IMPORTANT: When installing multiple units in an alcove, roof well, or partially enclosed area, ensure there is adequate ventilation to prevent re--circulation of discharge air.

Page 7

REFRIGERANT CHARGE ADJUSTMENTS

Liquid Line Size R --- 410A Charge oz/ft

3/8

5/16 0.40

1/4 0.27

(Factory charge for lineset = 9 oz)

0.60

Units are factory charged for 15 ft (4.6 m) of 3/8” liquid line. The factory charge for 3/8” lineset 9 oz. When using other length or diameter

liquid lines, charge adjustments are required per the chart above.

Charging

Formula:

[(Lineset oz/ft x total length) – (factory charge for lineset)] = charge adjustment

Example 1: System has 15 ft of line set using existing 1/4“ liquid line. What charge adjustment is required?

Formula: (.27 oz/ft x 15ft) – (9 oz) = (-4.95) oz.

Net result is to remove 4.95 oz of refrigerant from the system

Example 2: System has 45 ft of existing 5/16” liquid line. What is the charge adjustment?

Formula: (.40 oz/ft. x 45ft) – (9 oz.) = 9 oz.

Net result is to add 9 oz of refrigerant to the system

LONG LINE APPLICATIONS

An application is considered Long Line, when the refrigerant level in the system requires the use of accessories to maintain acceptable

refrigerant management for systems reliability. See Accessory Usage Guideline table for required accessories. Defining a system as long line

depends on the liquid line diameter, actual length of the tubing, and vertical separation between the indoor and outdoor units.

For Air Conditioner systems, the chart below shows when an application is considered Long Line.

AC WITH R--410A REFRIGERANT LONG LINE DESCRIPTION ft (m)

Beyond these lengths, long line accessories are required

Liquid Line Size Units On Same Level Outdoor Below Indoor Outdoor Above Indoor

1/4

5/16 120 (36.6) 50 (15.2) 120 (36.6)

3/8 80 (24.4) 35 (10.7) 80 (24.4)

Note: SeeLongLineGuidelinefordetails

No accessories needed within allowed

lengths

No accessories needed within allowed

lengths

175 (53.3)

PA13NA / PA13PA

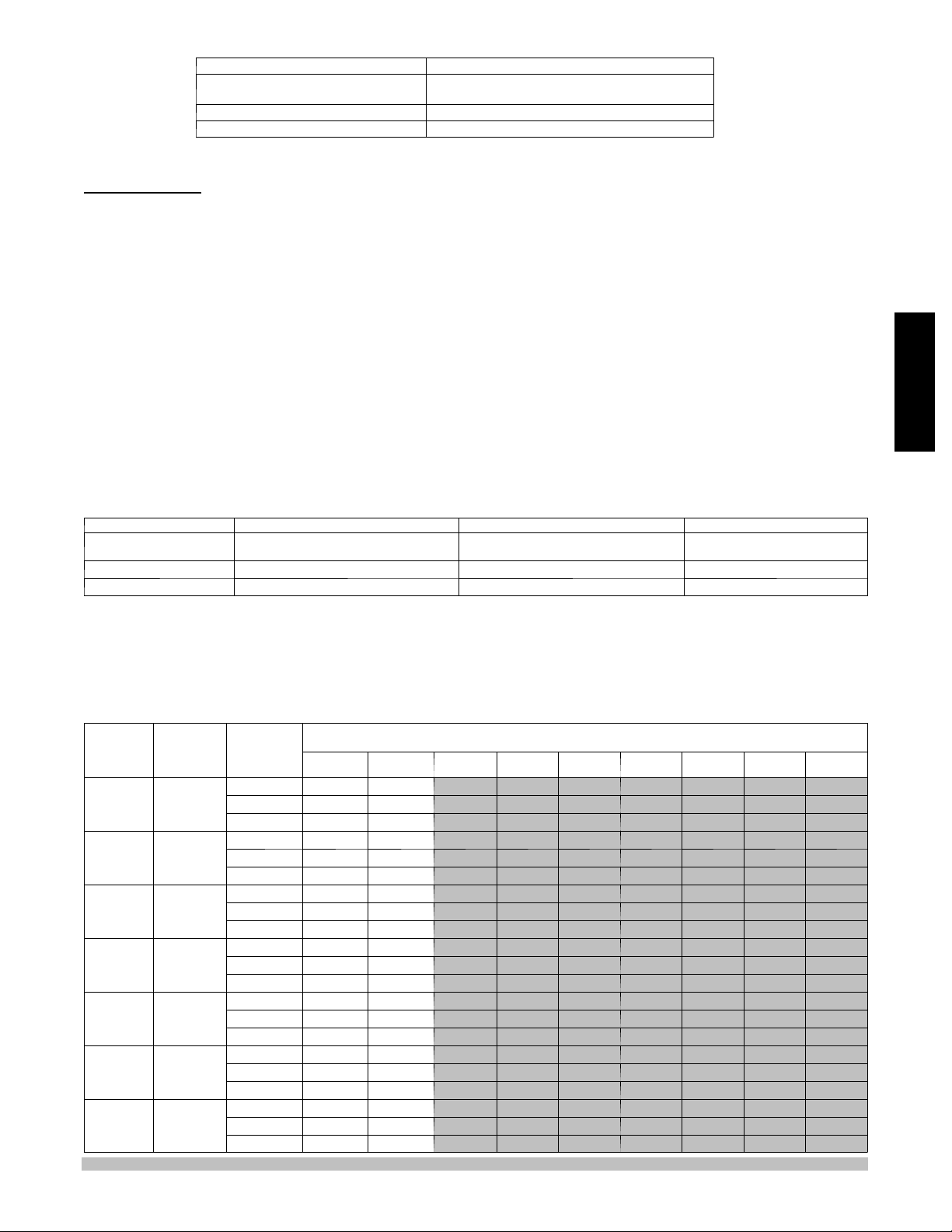

VAPOR LINE SIZING AND COOLING CAPACITY LOSS

Acceptable vapor line diameters provide adequate oil return to the compressor while avoiding excessive capacity loss. The suction line

diameters shown in the chart below are acceptable for AC systems with R--410A refrigerant:

Unit

Nominal

Size (Btuh)

18000

1Stage

AC with

R --- 410A

24000

1Stage

AC with

R --- 410A

30000

1Stage

AC with

R --- 410A

36000

1Stage

AC with

R --- 410A

42000

1Stage

AC with

R --- 410A

48000

1Stage

AC with

R --- 410A

60000

1Stage

AC with

R --- 410A

Applications in this area may be long line and may have height restrictions. See the Residential Piping and Long Line Guideline.

Maximum

Liquid Line

Diameters

(In. OD)

3/8

3/8

3/8

3/8

3/8

3/8

3/8

Vapo r Line

Diameters

(In. OD)

1/2 1 2 3 5 6 7 8 9 11

5/8 0 1 1 1 2 2 2 3 3

3/4 0 0 0 0 1 1 1 1 1

5/8 0 1 2 2 3 3 4 5 5

3/4 0 0 1 1 1 1 1 2 2

7/8 0 0 0 0 0 1 1 1 1

5/8 1 2 3 3 4 5 6 7 8

3/4 0 0 1 1 1 2 2 2 3

7/8 0 0 0 0 1 1 1 1 1

5/8 1 2 4 5 6 8 9 10 12

3/4 0 1 1 2 2 3 3 4 4

7/8 0 0 0 1 1 1 1 2 2

3/4 0 1 2 2 3 4 4 5 6

7/8 0 0 1 1 1 2 2 2 3

11/8 0 0 0 0 0 0 0 0 0

3/4 0 1 2 3 4 5 5 6 7

7/8 0 0 1 1 2 2 2 3 3

11/8 0 0 0 0 0 0 0 1 1

3/4 1 2 4 5 6 7 9 10 11

7/8 0 1 2 2 3 4 4 5 5

11/8 0 0 0 1 1 1 1 1 1

26--- 50

(7.9--- 15.2)

51--- 80

(15.5--- 24.4)

81--- 100

(24.7--- 30.5)

Cooling Capacity Loss (%)

Total Equivalent Line Length ft. (m)

101--- 125

(30.8--- 38.1)

126--- 150

(38.4--- 45.7)

151--- 175

(46.0--- 53.3)

176--- 200

(53.6--- 61.0)

201--- 225

(61.3--- 68.6)

226--- 250

(68.9--- 76.2)

7

Page 8

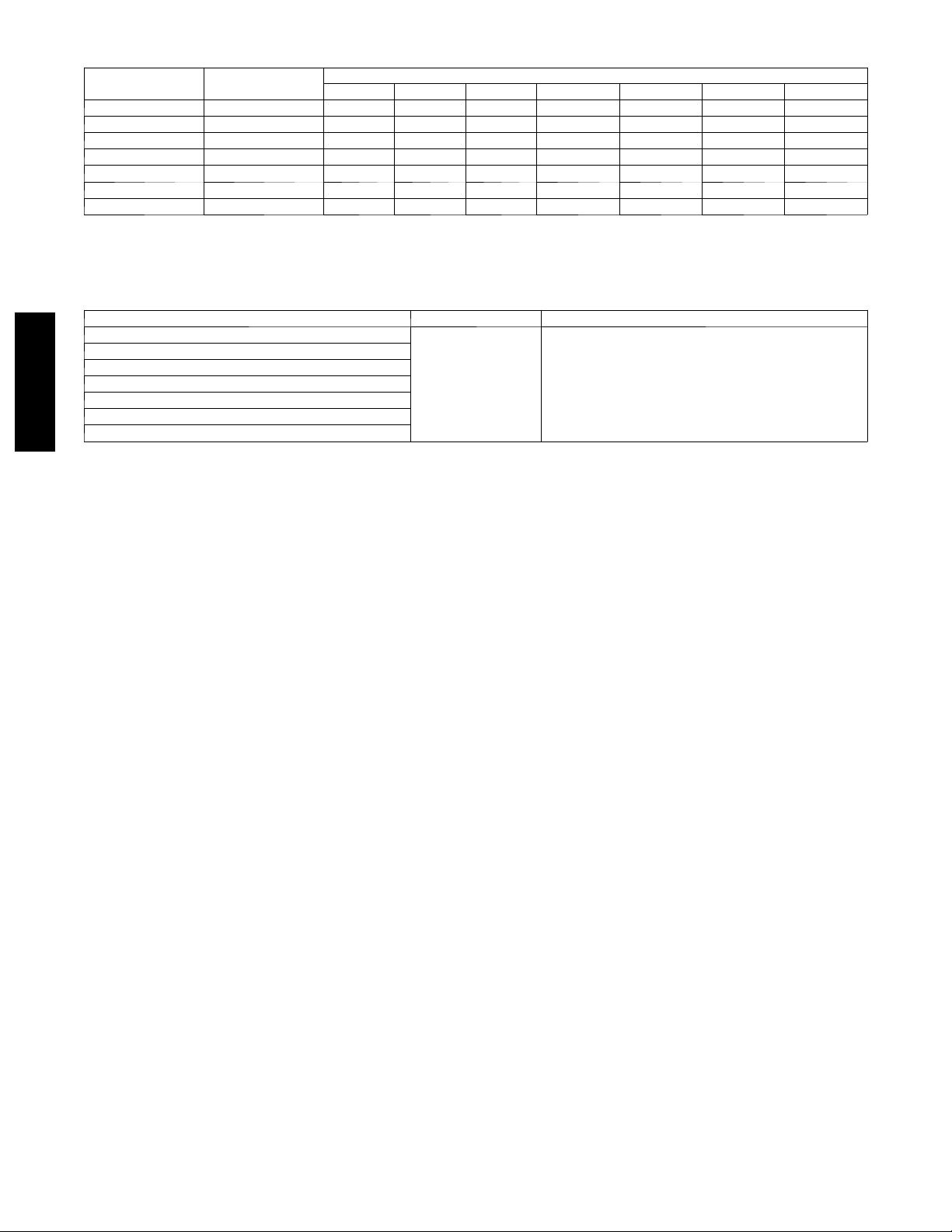

A--WEIGHTED SOUND POWER (dBA)

U N I T S I Z E ---

SERIES

018--- B 76 49.5 59.0 63.0 66.5 62.5 58.5 54.0

024--- B 76 50.5 61.0 67.0 68.0 65.0 60.0 55.5

030--- B 76 52.0 59.5 65.0 65.0 62.0 58.5 50.5

036--- B 77 61.5 63.5 68.5 72.0 68.5 63.0 56.5

042--- B 80 56.0 64.5 69.5 71.0 66.0 64.0 59.0

048--- D 80 57.5 65.5 70.5 72.0 68.5 67.0 61.5

060--- B 80 59.5 69.5 72.5 73.5 71.0 68.0 63.5

NOTE: T ested in accordance with AHRI Standard 270 ---95 (not listed in AHRI).

Standard

Rating (dBA)

125 250 500 1000 2000 4000 8000

TYPICAL OCTAVE BAND SPECTRUM (dBA without tone adjustment)

METERING DEVICE

UNIT SIZE--- SERIES INDOOOR REQUIRED SUBCOOLING _F(_C)

018 --- B

024 --- B

030 --- B

036 --- B

042 --- B

048 --- D

PA13NA / PA13PA

* TXV must be ordered separately when indoor coil is not equipped with a TXV. TXV must be hard ---shutoff type.

060 --- B

TXV* 10(5.6)

8

Page 9

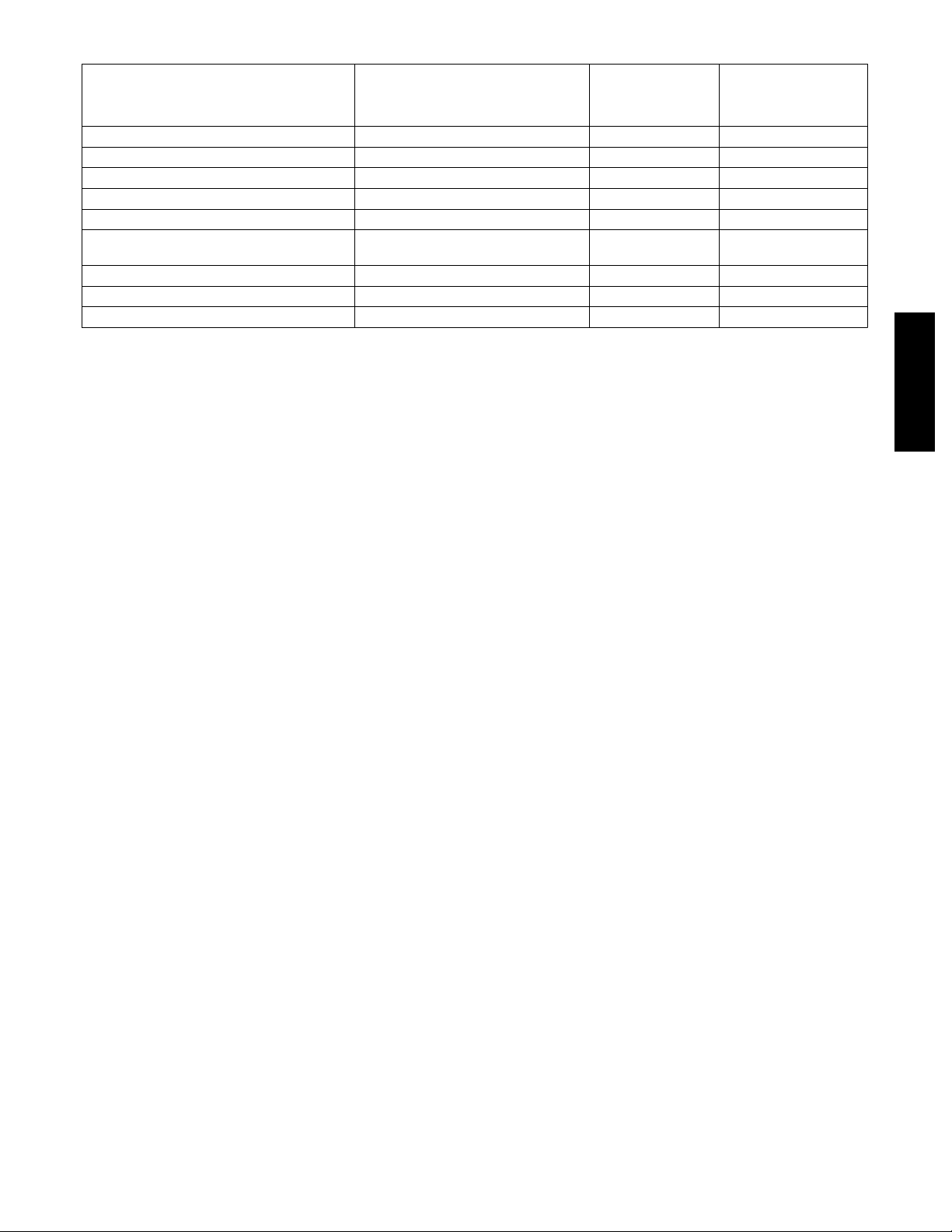

ACCESSORY USAGE GUIDELINE

REQUIRED FOR LOWMBIENT

ACCESSORY

Ball Bearing Fan Motor Yes{ No No

Compressor Start Assist Capacitor and Relay Yes Yes No

Crankcase Heater Yes Yes No

Evaporator Freeze Thermostat Ye s No No

H a r d S h u t --- O f f T X V Yes Yes Yes

Liquid Line Solenoid Valve No

Low Ambient Kit (Pressure Switch) Yes No No

Support Feet Recommended No Recommended

* For tubing line sets between 80 and 200 ft. (24.4 and 76.2 m) and/or 20 ft. (6.1 m) vertical differential, refer to Residential Split--- System Longline Application

Guideline.

{ Required for Low Ambient Controller (full modulation feature) and MotorMasterr Control only.

Winter Start Control Yes No No

COOLING APPLICATIONS

(Below 55°F / 22.8°C)

REQUIRED FOR

LONG LINE

APPLICATIONS*

(Over80Ft./24.4m)

S e e L o n g --- L i n e A p -

plication Guideline

Accessory Description and Usage (Listed Alphabetically)

1. Compressor Start Assist -- Capacitor and Relay

Start capacitor and relay gives a ”hard” boost to compressor motor

at each start up.

Usage Guideline:

Required for reciprocating compressors in the

following applications:

Long line

Low ambient cooling

Hard shut off expansion valve on indoor coil

Liquid line solenoid on indoor coil

Required for single--phase scroll compressors in the

following applications:

Long line

Low ambient cooling

Suggested for all compressors in areas with a history of

low voltage problems.

2. Compressor Start Assist — PTC Type

Solid state electrical device which gives a ”soft” boost to the

compressor at each start--up.

Usage Guideline:

Suggested in installations with marginal power supply.

3. Crankcase Heater

An electric resistance heater which mounts to the base of the

compressor to keep the lubricant warm during off cycles. Improves

compressor lubrication on restart and minimizes the chance of

liquid slugging.

Usage Guideline:

Required in low ambient cooling applications.

Required in long line applications.

4. Cycle Protector

The cycle protector is designed to prevent compressor short

cycling. This control provides an approximate 5--minute delay after

power to the compressor has been interrupted for any reason,

including power outage, protector control trip, thermostat jiggling,

or normal cycling.

Suggested in all commercial applications.

5. Evaporator Freeze Thermostat

An SPST temperature actuated switch that stops unit operation

when evaporator reaches freeze--up conditions.

Usage Guideline:

Required when low ambient kit has been added.

6. Low Ambient Pressure Switch Kit

A long life pressure switch which is mounted to outdoor unit

service valve. It is designed to cycle the outdoor fan motor in order

to maintain head pressure within normal operating limits

(approximately 100 psig to 225 psig). The control will maintain

working head pressure at low ambient temperatures down to

0_F/--17.8_C when properly installed.

Usage Guideline:

A Low Ambient Pressure Switch or MotorMasterr

Low Ambient Controller must be used when cooling

operation is used at outdoor temperatures below 55_F

(12.8_C).

Suggested for all commercial applications.

7. Support Feet

Four stick--on plastic feet that raise the unit 4 in. (101.6 mm) above

the mounting pad. This allows sand, dirt, and other debris to be

flushed from the unit base, minimizing corrosion.

Usage Guideline:

Suggested in the following applications:

Coastal installations.

Windy areas or where debris is normally circulating.

Rooftop installations.

For improved sound ratings.

8. Thermostatic Expansion Valve (TXV)

A modulating flow--control valve which meters refrigerant liquid

flow rate into the evaporator in response to the superheat of the

refrigerant gas leaving the evaporator.

Kit includes valve, adapter tubes, and external equalizer tube. Hard

shut off types are available.

NOTE: When using a hard shut off TXV with single phase

reciprocating compressors, a Compressor Start Assist Capacitor

and Relay is required.

Usage Guideline:

Required to achieve AHRI ratings in certain equipment

combinations. Refer to combination ratings.

Hard shut off TXV or LLS required in air conditioner

long line applications.

Required for use on all zoning systems.

9. Winter Start Control

This control is designed to alleviate nuisance opening of the

low--pressure switch by bypassing it for the first 3 minutes of

operation.

REQUIRED FOR

SEA COAST

APPLICATIONS

(Within2miles/3.2km)

No

PA13NA / PA13PA

9

Page 10

RATINGS AND PERFORMANCE

AHRI Ref. Number Model Number Indoor Coil Model N umber Furnace Model Number Cooling Capacity EER SEER

4339971 PA13NA018****B †CAP**1814A**+TDR 17,200 10.9 13.0

4340066 PA13NA018****B CAP**1814A** PG8*EA024045 17,200 12.0 14.0

4739802 PA13NA018****B CAP**1814A** PG95XA*30040A*** 17,400 11.8 14.2

4340067 PA13NA018****B CAP**2414A** PG8*EA024045 17,200 12.0 14.5

4739803 PA13NA018****B CAP**2414A** PG95XA*30040A*** 17,800 12.0 14.5

4339972 PA13NA018****B CAP**2414A**+TDR 17,200 11.0 13.0

4739804 PA13NA018****B CAP**2417A** PG95XA*30040A*** 17,800 12.0 14.5

4339973 PA13NA018****B CAP**2417A**+TDR 17,200 10.9 13.0

4340064 PA13NA018****B CAP**3619A**+TDR 17,600 11.0 13.0

4340070 PA13NA018****B CNPH*2417A** PG8*EA024045 17,200 12.0 14.5

4739809 PA13NA018****B CNPH*2417A** PG95XA*30040A*** 17,700 11.8 14.2

4339977 PA13NA018****B CNPH*2417A**+TDR 17,200 11.0 13.0

4340068 PA13NA018****B CNPV*1814A** PG8*EA024045 17,200 12.0 14.0

4739805 PA13NA018****B CNPV*1814A** PG95XA*30040A*** 17,500 11.8 14.2

4339974 PA13NA018****B CNPV*1814A**+TDR 17,200 10.9 13.0

4739806 PA13NA018****B CNPV*1917A** PG95XA*30040A*** 17,900 12.0 14.5

4340051 PA13NA018****B CNPV*1917A**+TDR 18,000 11.0 13.0

4340069 PA13NA018****B CNPV*2414A** PG8*EA024045 17,200 12.0 14.5

4739807 PA13NA018****B CNPV*2414A** PG95XA*30040A*** 17,700 11.8 14.2

4339975 PA13NA018****B CNPV*2414A**+TDR 17,200 10.9 13.0

4739808 PA13NA018****B CNPV*2417A** PG95XA*30040A*** 17,700 11.8 14.2

4339976 PA13NA018****B CNPV*2417A**+TDR 17,200 11.0 13.0

4340071 PA13NA018****B CSPH*2412A** PG8*EA024045 17,200 12.0 14.5

4739810 PA13NA018****B CSPH*2412A** PG95XA*30040A*** 17,800 12.0 14.5

4339979 PA13NA018****B CSPH*2412A**+TDR 17,200 11.0 13.0

4340076 PA13NA018****B FF1ENP018 17,200 10.9 13.0

4340335 PA13NA018****B FF1ENP019 17,200 12.0 14.0

PA13NA / PA13PA

4340077 PA13NA018****B FF1ENP024 17,200 10.9 13.0

4340329 PA13NA018****B FF1ENP025 17,200 12.2 14.5

4340336 PA13NA018****B FF1ENP031 17,800 11.5 14.0

4340337 PA13NA018****B FF1ENP037 17,800 11.5 14.0

4340072 PA13NA018****B PF4MNA018 17,200 10.9 13.0

4340074 PA13NA018****B PF4MNA019 17,200 12.0 14.0

4340073 PA13NA018****B PF4MNA024 17,200 10.9 13.0

4340075 PA13NA018****B PF4MNA025 17,200 12.0 14.5

4340394 PA13NA018****B PF4MNB019 17,600 12.0 14.5

4340395 PA13NA018****B PF4MNB025 17,600 12.0 14.5

4340396 PA13NA018****B PF4MNB031 17,600 12.0 14.5

4339980 PA13NA024****B †CAP**2414A**+TDR 23,000 11.0 13.0

4340078 PA13NA024****B CAP**2414A** PG8*EA024045 23,000 12.0 14.0

4739811 PA13NA024****B CAP**2414A** PG95XA*30040A*** 22,600 11.2 13.5

4739812 PA13NA024****B CAP**2417A** PG95XA*30040A*** 22,800 11.2 13.5

4739813 PA13NA024****B CAP**2417A** PG95XA*42060B*** 22,600 12.0 14.5

4339981 PA13NA024****B CAP**2417A**+TDR 23,000 11.0 13.0

4340079 PA13NA024****B CAP**3014A** PG8*EA024045 23,000 12.0 14.0

4739814 PA13NA024****B CAP**3014A** PG95XA*30040A*** 22,800 11.2 13.5

4339982 PA13NA024****B CAP**3014A**+TDR 23,000 11.0 13.0

4739815 PA13NA024****B CAP**3017A** PG95XA*30040A*** 23,000 11.4 13.7

4739816 PA13NA024****B CAP**3017A** PG95XA*42060B*** 23,000 12.0 14.5

4339983 PA13NA024****B CAP**3017A**+TDR 23,000 11.0 13.0

4340065 PA13NA024****B CAP**3619A**+TDR 23,400 11.0 13.0

4340082 PA13NA024****B CNPH*2417A** PG8*EA024045 23,000 11.5 14.0

4739825 PA13NA024****B CNPH*2417A** PG95XA*30040A*** 22,600 11.2 13.5

4739826 PA13NA024****B CNPH*2417A** PG95XA*42060B*** 22,400 12.0 14.5

4339988 PA13NA024****B CNPH*2417A**+TDR 23,000 11.0 13.0

4340083 PA13NA024****B CNPH*3017A** PG8*EA024045 23,000 12.0 14.0

4739827 PA13NA024****B CNPH*3017A** PG95XA*30040A*** 23,000 11.4 13.7

4739828 PA13NA024****B CNPH*3017A** PG95XA*42060B*** 23,000 12.0 14.5

4339989 PA13NA024****B CNPH*3017A**+TDR 23,000 11.0 13.0

4340342 PA13NA024****B CNPH*3117A** PG8*EA024045 23,400 12.0 14.5

4739829 PA13NA024****B CNPH*3117A** PG95XA*30040A*** 23,400 11.4 13.7

4739830 PA13NA024****B CNPH*3117A** PG95XA*42060B*** 23,400 12.5 15.0

4340053 PA13NA024****B CNPH*3117A**+TDR 23,400 11.0 13.0

4340080 PA13NA024****B CNPV*2414A** PG8*EA024045 23,000 11.5 13.5

4739817 PA13NA024****B CNPV*2414A** PG95XA*30040A*** 22,600 11.2 13.5

4339984 PA13NA024****B CNPV*2414A**+TDR 23,000 11.0 13.0

4739818 PA13NA024****B CNPV*2417A** PG95XA*30040A*** 22,600 11.2 13.5

4739819 PA13NA024****B CNPV*2417A** PG95XA*42060B*** 22,400 12.0 14.5

4339985 PA13NA024****B CNPV*2417A**+TDR 23,000 11.0 13.0

4340081 PA13NA024****B CNPV*3014A** PG8*EA024045 23,000 12.0 14.0

4739820 PA13NA024****B CNPV*3014A** PG95XA*30040A*** 22,800 11.2 13.5

4339986 PA13NA024****B CNPV*3014A**+TDR 23,000 11.0 13.0

4739821 PA13NA024****B CNPV*3017A** PG95XA*30040A*** 23,000 11.4 13.7

4739822 PA13NA024****B CNPV*3017A** PG95XA*42060B*** 23,000 12.0 14.5

4339987 PA13NA024****B CNPV*3017A**+TDR 23,000 11.0 13.0

4739823 PA13NA024****B CNPV*3117A** PG95XA*30040A*** 23,400 11.4 13.7

4739824 PA13NA024****B CNPV*3117A** PG95XA*42060B*** 23,400 12.5 15.0

4340052 PA13NA024****B CNPV*3117A**+TDR 23,400 11.0 13.0

4340084 PA13NA024****B CSPH*2412A** PG8*EA024045 23,000 12.0 14.0

4739831 PA13NA024****B CSPH*2412A** PG95XA*30040A*** 22,800 11.2 13.5

See notes on page 17

10

Page 11

RATINGS AND PERFORMANCE CONTINUED

AHRI Ref. Number Model Number Indoor Coil Model N umber Furnace Model Number Cooling Capacity EER SEER

4739832 PA13NA024****B CSPH*2412A** PG95XA*42060B*** 22,600 12.0 14.5

4339991 PA13NA024****B CSPH*2412A**+TDR 23,000 11.0 13.0

4340085 PA13NA024****B CSPH*3012A** PG8*EA024045 23,000 12.0 14.0

4739833 PA13NA024****B CSPH*3012A** PG95XA*30040A*** 23,000 11.4 13.7

4739834 PA13NA024****B CSPH*3012A** PG95XA*42060B*** 22,800 12.0 14.5

4339992 PA13NA024****B CSPH*3012A**+TDR 23,000 11.0 13.0

4340090 PA13NA024****B FF1ENP024 23,000 10.9 13.0

4340330 PA13NA024****B FF1ENP025 23,000 11.7 14.0

4340091 PA13NA024****B FF1ENP030 23,000 10.9 13.0

4340331 PA13NA024****B FF1ENP031 23,000 11.7 14.0

4340338 PA13NA024****B FF1ENP037 23,600 11.5 14.0

4340086 PA13NA024****B PF4MNA024 23,000 11.0 13.0

4340088 PA13NA024****B PF4MNA025 23,000 11.5 13.5

4340087 PA13NA024****B PF4MNA030 23,000 11.0 13.0

4340089 PA13NA024****B PF4MNA031 23,000 12.0 14.0

4340397 PA13NA024****B PF4MNB025 23,400 12.0 14.5

4340398 PA13NA024****B PF4MNB031 23,600 11.5 14.0

4340399 PA13NA024****B PF4MNB037 23,800 12.0 14.5

4339993 PA13NA030****B †CAP**3014A**+TDR 27,200 10.8 13.0

4340092 PA13NA030****B CAP**3017A** PG8*EA048070 27,200 11.5 13.5

4739835 PA13NA030****B CAP**3017A** PG95XA*42060B*** 27,400 11.5 14.0

4739836 PA13NA030****B CAP**3017A** PG95XA*48080B*** 27,600 11.5 14.0

4339994 PA13NA030****B CAP**3017A**+TDR 27,200 10.8 13.0

4339995 PA13NA030****B CAP**3614A**+TDR 27,200 10.8 13.0

4340093 PA13NA030****B CAP**3617A** PG8*EA048070 27,200 11.5 13.5

4739837 PA13NA030****B CAP**3617A** PG95XA*42060B*** 27,600 11.5 14.0

4739838 PA13NA030****B CAP**3617A** PG95XA*48080B*** 27,800 11.8 14.2

4339996 PA13NA030****B CAP**3617A**+TDR 27,200 10.8 13.0

4739841 PA13NA030****B CAP**3619A** PG95XA*42060B*** 27,600 11.5 14.0

4739842 PA13NA030****B CAP**3619A** PG95XA*48080B*** 27,800 11.8 14.2

4340054 PA13NA030****B CAP**3619A**+TDR 27,400 10.8 13.0

4340094 PA13NA030****B CAP**3621A** PG8*EA048090 27,200 12.0 14.0

4739839 PA13NA030****B CAP**3621A** PG95XA*42060B*** 27,600 11.8 14.2

4739840 PA13NA030****B CAP**3621A** PG95XA*48080B*** 27,800 11.8 14.2

4339997 PA13NA030****B CAP**3621A**+TDR 27,200 10.8 13.0

4340098 PA13NA030****B CNPH*3017A** PG8*EA048070 27,200 11.5 13.5

4340099 PA13NA030****B CNPH*3017A** PG8*EA048090 27,200 11.5 13.5

4739853 PA13NA030****B CNPH*3017A** PG95XA*42060B*** 27,600 11.5 14.0

4739854 PA13NA030****B CNPH*3017A** PG95XA*48080B*** 27,600 11.5 14.0

4340002 PA13NA030****B CNPH*3017A**+TDR 27,200 10.8 13.0

4340355 PA13NA030****B CNPH*3117A** PG8*EA048070 27,600 11.5 14.0

4340356 PA13NA030****B CNPH*3117A** PG8*EA048090 27,600 12.0 14.5

4739855 PA13NA030****B CNPH*3117A** PG95XA*42060B*** 28,200 11.8 14.2

4739856 PA13NA030****B CNPH*3117A** PG95XA*48080B*** 28,400 11.8 14.2

4340056 PA13NA030****B CNPH*3117A**+TDR 27,600 11.0 13.0

4340100 PA13NA030****B CNPH*3617A** PG8*EA048070 27,200 11.5 13.5

4340101 PA13NA030****B CNPH*3617A** PG8*EA048090 27,200 11.5 14.0

4739857 PA13NA030****B CNPH*3617A** PG95XA*42060B*** 27,600 11.5 14.0

4739858 PA13NA030****B CNPH*3617A** PG95XA*48080B*** 27,600 11.5 14.0

4340003 PA13NA030****B CNPH*3617A**+TDR 27,200 10.8 13.0

4339998 PA13NA030****B CNPV*3014A**+TDR 27,200 10.8 13.0

4340095 PA13NA030****B CNPV*3017A** PG8*EA048070 27,200 11.5 13.5

4739843 PA13NA030****B CNPV*3017A** PG95XA*42060B*** 27,600 11.5 14.0

4739844 PA13NA030****B CNPV*3017A** PG95XA*48080B*** 27,600 11.5 14.0

4339999 PA13NA030****B CNPV*3017A**+TDR 27,200 10.8 13.0

4340351 PA13NA030****B CNPV*3117A** PG8*EA048070 27,600 11.5 14.0

4739845 PA13NA030****B CNPV*3117A** PG95XA*42060B*** 28,200 11.8 14.2

4739846 PA13NA030****B CNPV*3117A** PG95XA*48080B*** 28,400 11.8 14.2

4340055 PA13NA030****B CNPV*3117A**+TDR 27,600 11.0 13.0

4340096 PA13NA030****B CNPV*3617A** PG8*EA048070 27,200 11.5 13.5

4739847 PA13NA030****B CNPV*3617A** PG95XA*42060B*** 27,600 11.5 14.0

4739848 PA13NA030****B CNPV*3617A** PG95XA*48080B*** 27,600 11.5 14.0

4340000 PA13NA030****B CNPV*3617A**+TDR 27,200 10.8 13.0

4340097 PA13NA030****B CNPV*3621A** PG8*EA048090 27,200 11.5 14.0

4739849 PA13NA030****B CNPV*3621A** PG95XA*42060B*** 27,600 11.5 14.0

4739850 PA13NA030****B CNPV*3621A** PG95XA*48080B*** 27,800 11.5 14.0

4340001 PA13NA030****B CNPV*3621A**+TDR 27,200 10.8 13.0

4340364 PA13NA030****B CNPV*3717A** PG8*EA048070 27,800 12.0 14.5

4739851 PA13NA030****B CNPV*3717A** PG95XA*42060B*** 28,400 12.0 14.5

4739852 PA13NA030****B CNPV*3717A** PG95XA*48080B*** 28,600 12.0 14.5

4340057 PA13NA030****B CNPV*3717A**+TDR 27,800 11.0 13.0

4340102 PA13NA030****B CSPH*3012A** PG8*EA048070 27,200 11.5 13.5

4340103 PA13NA030****B CSPH*3012A** PG8*EA048090 27,200 11.5 13.5

4739859 PA13NA030****B CSPH*3012A** PG95XA*42060B*** 27,600 11.5 14.0

4739860 PA13NA030****B CSPH*3012A** PG95XA*48080B*** 27,800 11.5 14.0

4340005 PA13NA030****B CSPH*3012A**+TDR 27,200 10.8 13.0

4340104 PA13NA030****B CSPH*3612A** PG8*EA048070 27,200 11.5 13.5

4340105 PA13NA030****B CSPH*3612A** PG8*EA048090 27,200 12.0 14.0

4739861 PA13NA030****B CSPH*3612A** PG95XA*42060B*** 28,000 11.8 14.2

4739862 PA13NA030****B CSPH*3612A** PG95XA*48080B*** 28,200 11.8 14.2

See notes on page 17

PA13NA / PA13PA

11

Page 12

RATINGS AND PERFORMANCE CONTINUED

AHRI Ref. Number Model Number Indoor Coil Model N umber Furnace Model Number Cooling Capacity EER SEER

4340006 PA13NA030****B CSPH*3612A**+TDR 27,200 10.8 13.0

4340110 PA13NA030****B FF1ENP030 27,200 10.8 13.0

4340332 PA13NA030****B FF1ENP031 27,200 11.5 13.5

4340111 PA13NA030****B FF1ENP036 27,200 11.0 13.0

4340333 PA13NA030****B FF1ENP037 27,200 11.5 13.5

4340106 PA13NA030****B PF4MNA030 27,200 10.8 13.0

4340108 PA13NA030****B PF4MNA031 27,200 11.5 13.5

4340107 PA13NA030****B PF4MNA036 27,200 10.8 13.0

4340109 PA13NA030****B PF4MNA037 27,200 11.0 13.5

4340400 PA13NA030****B PF4MNB031 27,600 11.5 14.0

4340401 PA13NA030****B PF4MNB037 27,800 12.0 14.5

4340402 PA13NA030****B PF4MNB043 27,800 11.0 13.5

4340007 PA13NA036****B †CAP**4821A**+TDR 34,000 11.0 13.0

4739863 PA13NA036****B CAP**3617A** PG95XA*42060B*** 33,000 11.4 13.7

4739864 PA13NA036****B CAP**3617A** PG95XA*48080B*** 33,000 11.4 13.7

4739869 PA13NA036****B CAP**3619A** PG95XA*42060B*** 33,000 11.4 13.7

4739870 PA13NA036****B CAP**3619A** PG95XA*48080B*** 33,000 11.4 13.7

4739865 PA13NA036****B CAP**3621A** PG95XA*42060B*** 33,200 11.4 13.7

4739866 PA13NA036****B CAP**3621A** PG95XA*48080B*** 33,200 11.5 14.0

4340112 PA13NA036****B CAP**4221A** PG8*EA048090 33,400 11.5 13.5

4340113 PA13NA036****B CAP**4221A** PG8*EA060110 33,400 11.5 13.5

4739867 PA13NA036****B CAP**4221A** PG95XA*42060B*** 33,400 11.4 13.7

4739868 PA13NA036****B CAP**4221A** PG95XA*48080B*** 33,400 11.5 14.0

4340114 PA13NA036****B CAP**4224A** PG8*EA060135 33,400 11.5 13.5

4340008 PA13NA036****B CAP**4817A**+TDR 34,000 11.0 13.0

4340115 PA13NA036****B CAP**4821A** PG8*EA048090 34,000 11.5 13.5

PA13NA / PA13PA

4340116 PA13NA036****B CAP**4821A** PG8*EA060110 34,000 12.0 14.0

4340117 PA13NA036****B CAP**4824A** PG8*EA060135 34,000 12.0 14.0

4340009 PA13NA036****B CAP**4824A**+TDR 34,000 11.0 13.0

4739881 PA13NA036****B CNPH*3617A** PG95XA*42060B*** 33,000 11.4 13.7

4739882 PA13NA036****B CNPH*3617A** PG95XA*48080B*** 33,000 11.4 13.7

4340123 PA13NA036****B CNPH*4221A** PG8*EA048090 33,400 11.5 13.5

4340124 PA13NA036****B CNPH*4221A** PG8*EA060110 33,400 11.5 13.5

4340125 PA13NA036****B CNPH*4221A** PG8*EA060135 33,400 11.5 13.5

4739883 PA13NA036****B CNPH*4221A** PG95XA*42060B*** 33,400 11.4 13.7

4739884 PA13NA036****B CNPH*4221A** PG95XA*48080B*** 33,400 11.5 14.0

4340016 PA13NA036****B CNPH*4221A**+TDR 33,000 11.0 13.0

4340375 PA13NA036****B CNPH*4321A** PG8*EA024045 34,400 11.0 13.5

4340376 PA13NA036****B CNPH*4321A** PG8*EA048070 34,400 11.5 14.0

4340377 PA13NA036****B CNPH*4321A** PG8*EA048090 34,400 12.0 14.5

4340378 PA13NA036****B CNPH*4321A** PG8*EA060110 34,400 12.0 14.5

4739885 PA13NA036****B CNPH*4321A** PG95XA*42060B*** 34,400 11.8 14.2

4739886 PA13NA036****B CNPH*4321A** PG95XA*48080B*** 34,200 11.8 14.2

4340060 PA13NA036****B CNPH*4321A**+TDR 34,400 11.0 13.0

4340126 PA13NA036****B CNPH*4821A** PG8*EA048090 34,000 11.5 13.5

4340127 PA13NA036****B CNPH*4821A** PG8*EA060110 34,000 12.0 14.0

4340128 PA13NA036****B CNPH*4821A** PG8*EA060135 34,000 12.0 14.0

4340012 PA13NA036****B CNPH*4821A**+TDR 34,000 11.0 13.0

4739871 PA13NA036****B CNPV*3617A** PG95XA*42060B*** 33,000 11.4 13.7

4739872 PA13NA036****B CNPV*3617A** PG95XA*48080B*** 33,000 11.4 13.7

4739873 PA13NA036****B CNPV*3621A** PG95XA*42060B*** 33,000 11.4 13.7

4739874 PA13NA036****B CNPV*3621A** PG95XA*48080B*** 33,000 11.4 13.7

4340370 PA13NA036****B CNPV*3717A** PG8*EA048070 34,200 11.5 14.0

4739875 PA13NA036****B CNPV*3717A** PG95XA*42060B*** 34,200 11.5 14.0

4739876 PA13NA036****B CNPV*3717A** PG95XA*48080B*** 34,200 11.8 14.2

4340058 PA13NA036****B CNPV*3717A**+TDR 34,200 11.0 13.0

4739877 PA13NA036****B CNPV*4217A** PG95XA*42060B*** 33,600 11.4 13.7

4739878 PA13NA036****B CNPV*4217A** PG95XA*48080B*** 33,600 11.5 14.0

4340049 PA13NA036****B CNPV*4217A**+TDR 33,000 11.0 13.0

4340118 PA13NA036****B CNPV*4221A** PG8*EA048090 33,400 11.5 13.5

4340119 PA13NA036****B CNPV*4221A** PG8*EA060110 33,400 11.5 13.5

4739879 PA13NA036****B CNPV*4221A** PG95XA*42060B*** 33,400 11.4 13.7

4739880 PA13NA036****B CNPV*4221A** PG95XA*48080B*** 33,400 11.5 14.0

4340015 PA13NA036****B CNPV*4221A**+TDR 33,000 11.0 13.0

4340059 PA13NA036****B CNPV*4324A**+TDR 34,400 11.0 13.0

4340120 PA13NA036****B CNPV*4821A** PG8*EA048090 34,000 11.5 14.0

4340121 PA13NA036****B CNPV*4821A** PG8*EA060110 34,000 12.0 14.0

4340010 PA13NA036****B CNPV*4821A**+TDR 34,000 11.0 13.0

4340122 PA13NA036****B CNPV*4824A** PG8*EA060135 34,000 12.0 14.0

4340011 PA13NA036****B CNPV*4824A**+TDR 34,000 11.0 13.0

4739887 PA13NA036****B CSPH*3612A** PG95XA*42060B*** 33,800 11.5 14.0

4739888 PA13NA036****B CSPH*3612A** PG95XA*48080B*** 33,800 11.8 14.2

4340129 PA13NA036****B CSPH*4212A** PG8*EA048090 33,400 11.5 14.0

4340130 PA13NA036****B CSPH*4212A** PG8*EA060110 33,400 12.0 14.0

4340131 PA13NA036****B CSPH*4212A** PG8*EA060135 33,400 11.5 13.5

4739889 PA13NA036****B CSPH*4212A** PG95XA*42060B*** 34,000 11.5 14.0

4739890 PA13NA036****B CSPH*4212A** PG95XA*48080B*** 34,000 11.8 14.2

4340017 PA13NA036****B CSPH*4212A**+TDR 33,000 11.0 13.0

4340132 PA13NA036****B CSPH*4812A** PG8*EA048090 34,000 12.0 14.0

4340133 PA13NA036****B CSPH*4812A** PG8*EA060110 34,000 12.0 14.0

See notes on page 17

12

Page 13

RATINGS AND PERFORMANCE CONTINUED

AHRI Ref. Number Model Number Indoor Coil Model N umber Furnace Model Number Cooling Capacity EER SEER

4340134 PA13NA036****B CSPH*4812A** PG8*EA060135 34,000 12.0 14.0

4340014 PA13NA036****B CSPH*4812A**+TDR 34,000 11.0 13.0

4340334 PA13NA036****B FF1ENP037 33,000 11.5 13.5

4806518 PA13NA036****B PF4MNA037 33,600 11.3 13.7

4340137 PA13NA036****B PF4MNA042 33,000 10.9 13.0

4340138 PA13NA036****B PF4MNA043 33,000 11.0 13.0

4340135 PA13NA036****B PF4MNA048 34,000 11.0 13.0

4340136 PA13NA036****B PF4MNA049 34,000 11.0 13.0

4340403 PA13NA036****B PF4MNB037 34,400 11.5 14.0

4340404 PA13NA036****B PF4MNB043 34,400 11.5 14.0

4340405 PA13NA036****B PF4MNB049 35,000 12.0 14.5

4341573 PA13PA036****B †CAP**4821A**+TDR 34,000 11.0 13.0

4341603 PA13PA036****B CAP**4221A** PG8*EA048090 33,400 11.5 13.5

4341604 PA13PA036****B CAP**4221A** PG8*EA060110 33,400 11.5 13.5

4341605 PA13PA036****B CAP**4224A** PG8*EA060135 33,400 11.5 13.5

4341574 PA13PA036****B CAP**4817A**+TDR 34,000 11.0 13.0

4341606 PA13PA036****B CAP**4821A** PG8*EA048090 34,000 11.5 13.5

4341607 PA13PA036****B CAP**4821A** PG8*EA060110 34,000 12.0 14.0

4341608 PA13PA036****B CAP**4824A** PG8*EA060135 34,000 12.0 14.0

4341575 PA13PA036****B CAP**4824A**+TDR 34,000 11.0 13.0

4341614 PA13PA036****B CNPH*4221A** PG8*EA048090 33,400 11.5 13.5

4341615 PA13PA036****B CNPH*4221A** PG8*EA060110 33,400 11.5 13.5

4341616 PA13PA036****B CNPH*4221A** PG8*EA060135 33,400 11.5 13.5

4341582 PA13PA036****B CNPH*4221A**+TDR 33,000 11.0 13.0

4341617 PA13PA036****B CNPH*4821A** PG8*EA048090 34,000 11.5 13.5

4341618 PA13PA036****B CNPH*4821A** PG8*EA060110 34,000 12.0 14.0

4341619 PA13PA036****B CNPH*4821A** PG8*EA060135 34,000 12.0 14.0

4341578 PA13PA036****B CNPH*4821A**+TDR 34,000 11.0 13.0

4341602 PA13PA036****B CNPV*4217A**+TDR 33,000 11.0 13.0

4341609 PA13PA036****B CNPV*4221A** PG8*EA048090 33,400 11.5 13.5

4341610 PA13PA036****B CNPV*4221A** PG8*EA060110 33,400 11.5 13.5

4341581 PA13PA036****B CNPV*4221A**+TDR 33,000 11.0 13.0

4341611 PA13PA036****B CNPV*4821A** PG8*EA048090 34,000 11.5 14.0

4341612 PA13PA036****B CNPV*4821A** PG8*EA060110 34,000 12.0 14.0

4341576 PA13PA036****B CNPV*4821A**+TDR 34,000 11.0 13.0

4341613 PA13PA036****B CNPV*4824A** PG8*EA060135 34,000 12.0 14.0

4341577 PA13PA036****B CNPV*4824A**+TDR 34,000 11.0 13.0

4341620 PA13PA036****B CSPH*4212A** PG8*EA048090 33,400 11.5 14.0

4341621 PA13PA036****B CSPH*4212A** PG8*EA060110 33,400 12.0 14.0

4341622 PA13PA036****B CSPH*4212A** PG8*EA060135 33,400 11.5 13.5

4341583 PA13PA036****B CSPH*4212A**+TDR 33,000 11.0 13.0

4341623 PA13PA036****B CSPH*4812A** PG8*EA048090 34,000 12.0 14.0

4341624 PA13PA036****B CSPH*4812A** PG8*EA060110 34,000 12.0 14.0

4341625 PA13PA036****B CSPH*4812A** PG8*EA060135 34,000 12.0 14.0

4341580 PA13PA036****B CSPH*4812A**+TDR 34,000 11.0 13.0

4341628 PA13PA036****B PF4MNA042 33,000 10.9 13.0

4341629 PA13PA036****B PF4MNA043 33,000 11.0 13.0

4341626 PA13PA036****B PF4MNA048 34,000 11.0 13.0

4341627 PA13PA036****B PF4MNA049 34,000 11.0 13.0

PA13NA / PA13PA

4340018 PA13NA042****B †CAP**4221A**+TDR 39,500 11.0 13.0

4340139 PA13NA042****B CAP**4221A** PG8*EA048090 39,500 11.5 13.5

4340140 PA13NA042****B CAP**4221A** PG8*EA060110 39,500 11.5 13.5

4739891 PA13NA042****B CAP**4221A** PG95XA*42060B*** 40,000 11.2 13.5

4739892 PA13NA042****B CAP**4221A** PG95XA*48080B*** 40,000 11.2 13.5

5099916 PA13NA042****B CAP**4221A** PG95XA*60080C*** 40,000 11.5 14.0

5099917 PA13NA042****B CAP**4221A** PG95XA*60100C*** 40,000 11.7 14.0

4340141 PA13NA042****B CAP**4224A** PG8*EA060135 39,500 11.5 13.5

5099918 PA13NA042****B CAP**4224A** PG95XA*60080C*** 40,000 11.5 13.7

5099919 PA13NA042****B CAP**4224A** PG95XA*60100C*** 40,000 11.7 14.0

4739895 PA13NA042****B CAP**4224A** PG95XA*66120D*** 40,500 11.5 14.0

4340019 PA13NA042****B CAP**4224A**+TDR 39,500 11.0 13.0

4739896 PA13NA042****B CAP**4817A** PG95XA*42060B*** 41,000 11.4 13.7

4739897 PA13NA042****B CAP**4817A** PG95XA*48080B*** 41,000 11.4 13.7

4340020 PA13NA042****B CAP**4817A**+TDR 40,000 11.0 13.0

4340142 PA13NA042****B CAP**4821A** PG8*EA048090 40,000 12.0 14.0

4340143 PA13NA042****B CAP**4821A** PG8*EA060110 40,000 12.0 14.0

4739898 PA13NA042****B CAP**4821A** PG95XA*42060B*** 40,500 11.4 13.7

4739899 PA13NA042****B CAP**4821A** PG95XA*48080B*** 40,500 11.4 13.7

5099920 PA13NA042****B CAP**4821A** PG95XA*60080C*** 41,000 11.7 14.0

5099921 PA13NA042****B CAP**4821A** PG95XA*60100C*** 40,500 11.7 14.0

4340021 PA13NA042****B CAP**4821A**+TDR 40,000 11.0 13.0

5099924 PA13NA042****B CAP**4823A** PG95XA*60080C*** 41,000 11.7 14.0

5099925 PA13NA042****B CAP**4823A** PG95XA*60100C*** 40,500 11.7 14.0

4739904 PA13NA042****B CAP**4823A** PG95XA*66120D*** 41,000 11.8 14.2

4340144 PA13NA042****B CAP**4824A** PG8*EA060135 40,000 12.0 14.0

5099922 PA13NA042****B CAP**4824A** PG95XA*60080C*** 41,000 11.7 14.0

5099923 PA13NA042****B CAP**4824A** PG95XA*60100C*** 40,500 11.7 14.0

4739902 PA13NA042****B CAP**4824A** PG95XA*66120D*** 41,000 11.8 14.2

4340022 PA13NA042****B CAP**4824A**+TDR 40,000 11.0 13.0

See notes on page 17

13

Page 14

RATINGS AND PERFORMANCE CONTINUED

AHRI Ref. Number Model Number Indoor Coil Model N umber Furnace Model Number Cooling Capacity EER SEER

4340150 PA13NA042****B CNPH*4221A** PG8*EA048090 39,000 11.5 13.5

4340151 PA13NA042****B CNPH*4221A** PG8*EA060110 39,000 11.5 13.5

4340152 PA13NA042****B CNPH*4221A** PG8*EA060135 39,000 11.5 13.5

4739917 PA13NA042****B CNPH*4221A** PG95XA*42060B*** 40,000 11.2 13.5

4739918 PA13NA042****B CNPH*4221A** PG95XA*48080B*** 40,000 11.2 13.5

5099934 PA13NA042****B CNPH*4221A** PG95XA*60080C*** 40,000 11.5 13.7

5099935 PA13NA042****B CNPH*4221A** PG95XA*60100C*** 40,000 11.5 13.7

4739920 PA13NA042****B CNPH*4221A** PG95XA*66120D*** 40,000 11.5 14.0

4340026 PA13NA042****B CNPH*4221A**+TDR 39,500 11.0 13.0

4739921 PA13NA042****B CNPH*4321A** PG95XA*42060B*** 41,000 11.4 13.7

4739922 PA13NA042****B CNPH*4321A** PG95XA*48080B*** 41,500 11.5 14.0

5099936 PA13NA042****B CNPH*4321A** PG95XA*60080C*** 41,500 11.7 14.0

5099937 PA13NA042****B CNPH*4321A** PG95XA*60100C*** 41,500 12.0 14.5

4739924 PA13NA042****B CNPH*4321A** PG95XA*66120D*** 41,500 11.8 14.2

4340153 PA13NA042****B CNPH*4821A** PG8*EA048090 40,000 12.0 14.0

4340154 PA13NA042****B CNPH*4821A** PG8*EA060110 40,000 12.0 14.5

4340155 PA13NA042****B CNPH*4821A** PG8*EA060135 40,000 12.0 14.0

4739925 PA13NA042****B CNPH*4821A** PG95XA*42060B*** 40,500 11.4 13.7

4739926 PA13NA042****B CNPH*4821A** PG95XA*48080B*** 41,000 11.4 13.7

5099938 PA13NA042****B CNPH*4821A** PG95XA*60080C*** 41,000 11.7 14.0

5099939 PA13NA042****B CNPH*4821A** PG95XA*60100C*** 41,000 12.0 14.0

4739928 PA13NA042****B CNPH*4821A** PG95XA*66120D*** 41,000 11.8 14.2

4340027 PA13NA042****B CNPH*4821A**+TDR 40,000 11.0 13.0

4739905 PA13NA042****B CNPV*4217A** PG95XA*42060B*** 40,000 11.2 13.5

4739906 PA13NA042****B CNPV*4217A** PG95XA*48080B*** 40,000 11.2 13.5

4340050 PA13NA042****B CNPV*4217A**+TDR 39,000 11.0 13.0

4340145 PA13NA042****B CNPV*4221A** PG8*EA048090 39,000 11.5 13.5

PA13NA / PA13PA

4340146 PA13NA042****B CNPV*4221A** PG8*EA060110 39,000 11.5 13.5

4739907 PA13NA042****B CNPV*4221A** PG95XA*42060B*** 40,000 11.2 13.5

4739908 PA13NA042****B CNPV*4221A** PG95XA*48080B*** 40,000 11.2 13.5

5099926 PA13NA042****B CNPV*4221A** PG95XA*60080C*** 40,000 11.5 13.7

5099927 PA13NA042****B CNPV*4221A** PG95XA*60100C*** 40,000 11.5 13.7

4340023 PA13NA042****B CNPV*4221A**+TDR 39,500 11.0 13.0

5099928 PA13NA042****B CNPV*4324A** PG95XA*60080C*** 41,500 12.0 14.5

5099929 PA13NA042****B CNPV*4324A** PG95XA*60100C*** 41,500 12.0 14.5

4739911 PA13NA042****B CNPV*4324A** PG95XA*66120D*** 42,000 12.0 14.5

4340147 PA13NA042****B CNPV*4821A** PG8*EA048090 40,000 12.0 14.0

4340148 PA13NA042****B CNPV*4821A** PG8*EA060110 40,000 12.0 14.5

4739912 PA13NA042****B CNPV*4821A** PG95XA*42060B*** 40,500 11.4 13.7

4739913 PA13NA042****B CNPV*4821A** PG95XA*48080B*** 41,000 11.4 13.7

5099930 PA13NA042****B CNPV*4821A** PG95XA*60080C*** 41,000 11.7 14.0

5099931 PA13NA042****B CNPV*4821A** PG95XA*60100C*** 41,000 12.0 14.0

4340024 PA13NA042****B CNPV*4821A**+TDR 40,000 11.0 13.0

4340149 PA13NA042****B CNPV*4824A** PG8*EA060135 40,000 12.0 14.0

5099932 PA13NA042****B CNPV*4824A** PG95XA*60080C*** 41,000 11.7 14.0

5099933 PA13NA042****B CNPV*4824A** PG95XA*60100C*** 41,000 11.7 14.0

4739916 PA13NA042****B CNPV*4824A** PG95XA*66120D*** 41,000 11.8 14.2

4340025 PA13NA042****B CNPV*4824A**+TDR 40,000 11.0 13.0

4340156 PA13NA042****B CSPH*4212A** PG8*EA048090 40,000 12.0 14.0

4340157 PA13NA042****B CSPH*4212A** PG8*EA060110 40,000 12.0 14.0

4340158 PA13NA042****B CSPH*4212A** PG8*EA060135 40,000 12.0 14.0

4739929 PA13NA042****B CSPH*4212A** PG95XA*42060B*** 40,500 11.4 13.7

4739930 PA13NA042****B CSPH*4212A** PG95XA*48080B*** 41,000 11.4 13.7

5099940 PA13NA042****B CSPH*4212A** PG95XA*60080C*** 41,000 11.7 14.0

5099941 PA13NA042****B CSPH*4212A** PG95XA*60100C*** 41,000 11.7 14.0

4739932 PA13NA042****B CSPH*4212A** PG95XA*66120D*** 41,000 11.8 14.2

4340029 PA13NA042****B CSPH*4212A**+TDR 40,000 11.0 13.0

4340159 PA13NA042****B CSPH*4812A** PG8*EA048090 40,000 12.0 14.0

4340160 PA13NA042****B CSPH*4812A** PG8*EA060110 40,000 12.0 14.5

4340161 PA13NA042****B CSPH*4812A** PG8*EA060135 40,000 12.0 14.0

4739933 PA13NA042****B CSPH*4812A** PG95XA*42060B*** 41,000 11.4 13.7

4739934 PA13NA042****B CSPH*4812A** PG95XA*48080B*** 41,000 11.4 13.7

5099942 PA13NA042****B CSPH*4812A** PG95XA*60080C*** 41,500 11.7 14.0

5099943 PA13NA042****B CSPH*4812A** PG95XA*60100C*** 41,000 12.0 14.0

4739936 PA13NA042****B CSPH*4812A** PG95XA*66120D*** 41,500 11.8 14.2

4340030 PA13NA042****B CSPH*4812A**+TDR 40,000 11.0 13.0

4340162 PA13NA042****B PF4MNA042 39,500 11.0 13.0

4340164 PA13NA042****B PF4MNA043 39,500 11.5 13.5

4340163 PA13NA042****B PF4MNA048 40,000 11.0 13.0

4340165 PA13NA042****B PF4MNA049 40,000 12.0 14.0

4340406 PA13NA042****B PF4MNB043 41,000 11.5 14.0

4340407 PA13NA042****B PF4MNB049 41,500 12.0 14.5

4340408 PA13NA042****B PF4MNB061 42,000 12.5 14.5

5091146 PA13NA048****D †CAP**4821A**+TDR 46,000 11.0 13.0

5091148 PA13NA048****D CAP**4817A** PG95XA*48080B*** 45,000 11.0 13.3

5091147 PA13NA048****D CAP**4817A**+TDR 46,000 11.0 13.0

5091150 PA13NA048****D CAP**4821A** PG8*EA048090 45,000 11.0 13.5

5091151 PA13NA048****D CAP**4821A** PG8*EA060110 45,000 11.5 14.0

5091233 PA13NA048****D CAP**4821A** PG95XA*60080C*** 45,000 11.3 13.7

5091234 PA13NA048****D CAP**4821A** PG95XA*60100C*** 45,000 11.5 13.7

See notes on page 17

14

Page 15

RATINGS AND PERFORMANCE CONTINUED

AHRI Ref. Number Model Number Indoor Coil Model N umber Furnace Model Number Cooling Capacity EER SEER

5091227 PA13NA048****D CAP**4823A** PG95XA*66120D*** 45,000 11.5 13.7

5091162 PA13NA048****D CAP**4823A**+TDR 46,000 11.0 13.0

5091154 PA13NA048****D CAP**4824A** PG8*EA060135 45,000 11.5 14.0

5091153 PA13NA048****D CAP**4824A** PG95XA*66120D*** 45,000 11.5 13.7

5091152 PA13NA048****D CAP**4824A**+TDR 46,000 11.0 13.0

5091157 PA13NA048****D CAP**6021A** PG8*EA048090 46,000 11.5 14.0

5091158 PA13NA048****D CAP**6021A** PG8*EA060110 46,000 12.0 14.0

5091235 PA13NA048****D CAP**6021A** PG95XA*60080C*** 46,000 11.7 14.0

5091236 PA13NA048****D CAP**6021A** PG95XA*60100C*** 46,000 11.7 14.0

5091155 PA13NA048****D CAP**6021A**+TDR 46,500 11.0 13.0

5091161 PA13NA048****D CAP**6024A** PG8*EA060135 46,000 11.5 14.0

5091160 PA13NA048****D CAP**6024A** PG95XA*66120D*** 46,000 11.5 14.0

5091159 PA13NA048****D CAP**6024A**+TDR 46,500 11.0 13.0

5091165 PA13NA048****D CAP**6025A** PG8*EA060135 46,000 11.5 14.0

5091164 PA13NA048****D CAP**6025A** PG95XA*66120D*** 46,000 11.5 14.0

5091163 PA13NA048****D CAP**6025A**+TDR 46,500 11.0 13.0

5091183 PA13NA048****D CNPH*4821A** PG8*EA048090 45,500 11.5 13.5

5091184 PA13NA048****D CNPH*4821A** PG8*EA060110 45,500 11.5 14.0

5091185 PA13NA048****D CNPH*4821A** PG8*EA060135 45,500 11.5 14.0

5091180 PA13NA048****D CNPH*4821A** PG95XA*48080B*** 45,000 11.0 13.0

5091239 PA13NA048****D CNPH*4821A** PG95XA*60080C*** 45,500 11.5 13.7

5091240 PA13NA048****D CNPH*4821A** PG95XA*60100C*** 45,500 11.5 13.7

5091182 PA13NA048****D CNPH*4821A** PG95XA*66120D*** 45,500 11.5 13.7

5091179 PA13NA048****D CNPH*4821A**+TDR 46,000 11.0 13.0

5091191 PA13NA048****D CNPH*6024A** PG8*EA048070 45,500 11.0 13.0

5091192 PA13NA048****D CNPH*6024A** PG8*EA048090 46,000 11.5 14.0

5091193 PA13NA048****D CNPH*6024A** PG8*EA060110 46,000 12.0 14.5

5091194 PA13NA048****D CNPH*6024A** PG8*EA060135 46,000 11.5 14.0

5091188 PA13NA048****D CNPH*6024A** PG95XA*48080B*** 45,500 11.0 13.5

5091190 PA13NA048****D CNPH*6024A** PG95XA*66120D*** 46,000 11.5 14.0

5091187 PA13NA048****D CNPH*6024A**+TDR 46,500 11.0 13.0

5091199 PA13NA048****D CNPH*6124A** PG8*EA048070 46,000 11.0 13.0

5091200 PA13NA048****D CNPH*6124A** PG8*EA048090 46,500 11.5 14.0

5091201 PA13NA048****D CNPH*6124A** PG8*EA060110 46,500 12.0 14.5

5091202 PA13NA048****D CNPH*6124A** PG8*EA060135 46,500 11.5 14.0

5091196 PA13NA048****D CNPH*6124A** PG95XA*48080B*** 46,000 11.3 13.5

5091198 PA13NA048****D CNPH*6124A** PG95XA*66120D*** 46,500 11.5 14.0

5091195 PA13NA048****D CNPH*6124A**+TDR 46,500 11.0 13.5

5091168 PA13NA048****D CNPV*4821A** PG8*EA048090 45,500 11.5 13.5

5091169 PA13NA048****D CNPV*4821A** PG8*EA060110 45,500 11.5 14.0

5091229 PA13NA048****D CNPV*4821A** PG95XA*48080B*** 45,000 11.0 13.0

5091237 PA13NA048****D CNPV*4821A** PG95XA*60080C*** 45,500 11.5 13.7

5091238 PA13NA048****D CNPV*4821A** PG95XA*60100C*** 45,500 11.5 13.7

5091166 PA13NA048****D CNPV*4821A**+TDR 46,000 11.0 13.0

5091172 PA13NA048****D CNPV*4824A** PG8*EA060135 45,500 11.5 14.0

5091171 PA13NA048****D CNPV*4824A** PG95XA*66120D*** 45,500 11.5 13.7

5091170 PA13NA048****D CNPV*4824A**+TDR 46,000 11.0 13.0

5091175 PA13NA048****D CNPV*6024A** PG8*EA060135 46,000 11.5 14.0

5091174 PA13NA048****D CNPV*6024A** PG95XA*66120D*** 46,000 11.5 14.0

5091173 PA13NA048****D CNPV*6024A**+TDR 46,500 11.0 13.0

5091178 PA13NA048****D CNPV*6124A** PG8*EA060135 47,000 12.0 14.5

5091177 PA13NA048****D CNPV*6124A** PG95XA*66120D*** 47,000 12.0 14.5

5091176 PA13NA048****D CNPV*6124A**+TDR 47,000 11.0 13.5

5091207 PA13NA048****D CSPH*4812A** PG8*EA048090 45,500 11.5 14.0

5091208 PA13NA048****D CSPH*4812A** PG8*EA060110 45,500 11.5 14.0

5091209 PA13NA048****D CSPH*4812A** PG8*EA060135 45,500 11.5 14.0

5091204 PA13NA048****D CSPH*4812A** PG95XA*48080B*** 45,000 11.2 13.2

5091241 PA13NA048****D CSPH*4812A** PG95XA*60080C*** 45,500 11.5 13.7

5091242 PA13NA048****D CSPH*4812A** PG95XA*60100C*** 45,500 11.5 13.7

5091206 PA13NA048****D CSPH*4812A** PG95XA*66120D*** 45,500 11.5 13.7

5091203 PA13NA048****D CSPH*4812A**+TDR 46,000 11.0 13.0

5091214 PA13NA048****D CSPH*6012A** PG8*EA048070 46,000 11.0 13.2

5091215 PA13NA048****D CSPH*6012A** PG8*EA048090 46,500 11.5 14.0

5091216 PA13NA048****D CSPH*6012A** PG8*EA060110 46,500 12.0 14.5

5091217 PA13NA048****D CSPH*6012A** PG8*EA060135 46,500 11.5 14.0

5091211 PA13NA048****D CSPH*6012A** PG95XA*48080B*** 46,000 11.2 13.5

5091243 PA13NA048****D CSPH*6012A** PG95XA*60080C*** 46,500 11.7 14.0

5091244 PA13NA048****D CSPH*6012A** PG95XA*60100C*** 46,500 11.7 14.0

5091213 PA13NA048****D CSPH*6012A** PG95XA*66120D*** 46,500 11.5 14.0

5091210 PA13NA048****D CSPH*6012A**+TDR 47,000 11.0 13.0

5091221 PA13NA048****D PF4MNA048 46,000 11.0 13.0

5091222 PA13NA048****D PF4MNA049 46,500 11.5 14.0

5091218 PA13NA048****D PF4MNA060 46,500 11.0 13.0

5091223 PA13NA048****D PF4MNA061 47,500 11.5 14.0

5091219 PA13NA048****D PF4MNB049 46,500 11.5 14.0

5091220 PA13NA048****D PF4MNB061 47,500 12.0 14.5

PA13NA / PA13PA

5091048 PA13PA048****D †CAP**4821A**+TDR 46,000 11.0 13.0

5091050 PA13PA048****D CAP**4817A** PG95XA*48080B*** 45,000 11.0 13.3

5091049 PA13PA048****D CAP**4817A** +TDR 46,000 11.0 13.0

5091052 PA13PA048****D CAP**4821A** PG8*EA048090 45,000 11.0 13.5

See notes on page 17

15

Page 16

RATINGS AND PERFORMANCE CONTINUED

AHRI Ref. Number Model Number Indoor Coil Model N umber Furnace Model Number Cooling Capacity EER SEER

5091053 PA13PA048****D CAP**4821A** PG8*EA060110 45,000 11.5 14.0

5091134 PA13PA048****D CAP**4821A** PG95XA*60080C*** 45,000 11.3 13.7

5091135 PA13PA048****D CAP**4821A** PG95XA*60100C*** 45,000 11.5 13.7

5091128 PA13PA048****D CAP**4823A** PG95XA*66120D*** 45,000 11.5 13.7

5091064 PA13PA048****D CAP**4823A** +TDR 46,000 11.0 13.0

5091056 PA13PA048****D CAP**4824A** PG8*EA060135 45,000 11.5 14.0

5091055 PA13PA048****D CAP**4824A** PG95XA*66120D*** 45,000 11.5 13.7

5091054 PA13PA048****D CAP**4824A** +TDR 46,000 11.0 13.0

5091059 PA13PA048****D CAP**6021A** PG8*EA048090 46,000 11.5 14.0

5091060 PA13PA048****D CAP**6021A** PG8*EA060110 46,000 12.0 14.0

5091136 PA13PA048****D CAP**6021A** PG95XA*60080C*** 46,000 11.7 14.0

5091137 PA13PA048****D CAP**6021A** PG95XA*60100C*** 46,000 11.7 14.0

5091057 PA13PA048****D CAP**6021A** +TDR 46,500 11.0 13.0

5091063 PA13PA048****D CAP**6024A** PG8*EA060135 46,000 11.5 14.0

5091062 PA13PA048****D CAP**6024A** PG95XA*66120D*** 46,000 11.5 14.0

5091061 PA13PA048****D CAP**6024A** +TDR 46,500 11.0 13.0

5091067 PA13PA048****D CAP**6025A** PG8*EA060135 46,000 11.5 14.0

5091066 PA13PA048****D CAP**6025A** PG95XA*66120D*** 46,000 11.5 14.0

5091065 PA13PA048****D CAP**6025A** +TDR 46,500 11.0 13.0

5091085 PA13PA048****D CNPH*4821A** PG8*EA048090 45,500 11.5 13.5

5091086 PA13PA048****D CNPH*4821A** PG8*EA060110 45,500 11.5 14.0

5091087 PA13PA048****D CNPH*4821A** PG8*EA060135 45,500 11.5 14.0

5091082 PA13PA048****D CNPH*4821A** PG95XA*48080B*** 45,000 11.0 13.0

5091140 PA13PA048****D CNPH*4821A** PG95XA*60080C*** 45,500 11.5 13.7

5091141 PA13PA048****D CNPH*4821A** PG95XA*60100C*** 45,500 11.5 13.7

5091084 PA13PA048****D CNPH*4821A** PG95XA*66120D*** 45,500 11.5 13.7

5091081 PA13PA048****D CNPH*4821A**+TDR 46,000 11.0 13.0

PA13NA / PA13PA

5091092 PA13PA048****D CNPH*6024A** PG8*EA048070 45,500 11.0 13.0

5091093 PA13PA048****D CNPH*6024A** PG8*EA048090 46,000 11.5 14.0

5091094 PA13PA048****D CNPH*6024A** PG8*EA060110 46,000 12.0 14.5

5091095 PA13PA048****D CNPH*6024A** PG8*EA060135 46,000 11.5 14.0

5091089 PA13PA048****D CNPH*6024A** PG95XA*48080B*** 45,500 11.0 13.5

5091091 PA13PA048****D CNPH*6024A** PG95XA*66120D*** 46,000 11.5 14.0

5091088 PA13PA048****D CNPH*6024A**+TDR 46,500 11.0 13.0

5091100 PA13PA048****D CNPH*6124A** PG8*EA048070 46,000 11.0 13.0

5091101 PA13PA048****D CNPH*6124A** PG8*EA048090 46,500 11.5 14.0

5091102 PA13PA048****D CNPH*6124A** PG8*EA060110 46,500 12.0 14.5

5091103 PA13PA048****D CNPH*6124A** PG8*EA060135 46,500 11.5 14.0

5091097 PA13PA048****D CNPH*6124A** PG95XA*48080B*** 46,000 11.3 13.5

5091099 PA13PA048****D CNPH*6124A** PG95XA*66120D*** 46,500 11.5 14.0

5091096 PA13PA048****D CNPH*6124A**+TDR 46,500 11.0 13.5

5091070 PA13PA048****D CNPV*4821A** PG8*EA048090 45,500 11.5 13.5

5091071 PA13PA048****D CNPV*4821A** PG8*EA060110 45,500 11.5 14.0

5091130 PA13PA048****D CNPV*4821A** PG95XA*48080B*** 45,000 11.0 13.0

5091138 PA13PA048****D CNPV*4821A** PG95XA*60080C*** 45,500 11.5 13.7

5091139 PA13PA048****D CNPV*4821A** PG95XA*60100C*** 45,500 11.5 13.7

5091068 PA13PA048****D CNPV*4821A**+TDR 46,000 11.0 13.0

5091074 PA13PA048****D CNPV*4824A** PG8*EA060135 45,500 11.5 14.0

5091073 PA13PA048****D CNPV*4824A** PG95XA*66120D*** 45,500 11.5 13.7

5091072 PA13PA048****D CNPV*4824A**+TDR 46,000 11.0 13.0

5091077 PA13PA048****D CNPV*6024A** PG8*EA060135 46,000 11.5 14.0

5091076 PA13PA048****D CNPV*6024A** PG95XA*66120D*** 46,000 11.5 14.0

5091075 PA13PA048****D CNPV*6024A**+TDR 46,500 11.0 13.0

5091080 PA13PA048****D CNPV*6124A** PG8*EA060135 47,000 12.0 14.5

5091079 PA13PA048****D CNPV*6124A** PG95XA*66120D*** 47,000 12.0 14.5

5091078 PA13PA048****D CNPV*6124A**+TDR 47,000 11.0 13.5

5091108 PA13PA048****D CSPH*4812A** PG8*EA048090 45,500 11.5 14.0

5091109 PA13PA048****D CSPH*4812A** PG8*EA060110 45,500 11.5 14.0

5091110 PA13PA048****D CSPH*4812A** PG8*EA060135 45,500 11.5 14.0

5091105 PA13PA048****D CSPH*4812A** PG95XA*48080B*** 45,000 11.2 13.2

5091142 PA13PA048****D CSPH*4812A** PG95XA*60080C*** 45,500 11.5 13.7

5091143 PA13PA048****D CSPH*4812A** PG95XA*60100C*** 45,500 11.5 13.7

5091107 PA13PA048****D CSPH*4812A** PG95XA*66120D*** 45,500 11.5 13.7

5091104 PA13PA048****D CSPH*4812A**+TDR 46,000 11.0 13.0

5091115 PA13PA048****D CSPH*6012A** PG8*EA048070 46,000 11.0 13.2

5091116 PA13PA048****D CSPH*6012A** PG8*EA048090 46,500 11.5 14.0

5091117 PA13PA048****D CSPH*6012A** PG8*EA060110 46,500 12.0 14.5

5091118 PA13PA048****D CSPH*6012A** PG8*EA060135 46,500 11.5 14.0

5091112 PA13PA048****D CSPH*6012A** PG95XA*48080B*** 46,000 11.2 13.5

5091144 PA13PA048****D CSPH*6012A** PG95XA*60080C*** 46,500 11.7 14.0

5091145 PA13PA048****D CSPH*6012A** PG95XA*60100C*** 46,500 11.7 14.0

5091114 PA13PA048****D CSPH*6012A** PG95XA*66120D*** 46,500 11.5 14.0

5091111 PA13PA048****D CSPH*6012A**+TDR 47,000 11.0 13.0

5091122 PA13PA048****D PF4MNA048 46,000 11.0 13.0

5091123 PA13PA048****D PF4MNA049 46,500 11.5 14.0

5091119 PA13PA048****D PF4MNA060 46,500 11.0 13.0

5091124 PA13PA048****D PF4MNA061 47,500 11.5 14.0

5091120 PA13PA048****D PF4MNB049 46,500 11.5 14.0

5091121 PA13PA048****D PF4MNB061 47,500 12.0 14.5

See notes on page 17

16

Page 17

RATINGS AND PERFORMANCE CONTINUED

AHRI Ref. Number Model Number Indoor Coil Model N umber Furnace Model Number Cooling Capacity EER SEER

4340044 PA13NA060****B †CAP**6024A**+TDR 57,000 11.0 13.0

4340192 PA13NA060****B CAP**6021A** PG8*EA060110 56,000 11.5 13.5

5099974 PA13NA060****B CAP**6021A** PG95XA*60080C*** 56,500 11.2 13.5

4340045 PA13NA060****B CAP**6021A**+TDR 56,000 11.0 13.0

4340193 PA13NA060****B CAP**6024A** PG8*EA060135 56,000 11.5 13.5

5099975 PA13NA060****B CAP**6024A** PG95XA*60080C*** 56,500 11.2 13.2

5099976 PA13NA060****B CAP**6024A** PG95XA*60100C*** 56,500 11.0 13.2

4739968 PA13NA060****B CAP**6024A** PG95XA*66120D*** 56,500 11.4 13.7

4340386 PA13NA060****B CAP**6025A** PG8*EA060135 56,500 11.0 13.2

5099977 PA13NA060****B CAP**6025A** PG95XA*60080C*** 56,500 11.2 13.2

5099978 PA13NA060****B CAP**6025A** PG95XA*60100C*** 56,500 11.0 13.2

4739969 PA13NA060****B CAP**6025A** PG95XA*66120D*** 56,500 11.4 13.7

4340061 PA13NA060****B CAP**6025A**+TDR 57,000 11.0 13.0

4340195 PA13NA060****B CNPH*6024A** PG8*EA060110 56,000 11.5 13.5

4340196 PA13NA060****B CNPH*6024A** PG8*EA060135 56,000 11.0 13.5

5099983 PA13NA060****B CNPH*6024A** PG95XA*60080C*** 56,000 11.2 13.5

5099984 PA13NA060****B CNPH*6024A** PG95XA*60100C*** 56,500 11.0 13.2

4739974 PA13NA060****B CNPH*6024A** PG95XA*66120D*** 56,500 11.4 13.7

4340047 PA13NA060****B CNPH*6024A**+TDR 57,000 11.0 13.0

4340389 PA13NA060****B CNPH*6124A** PG8*EA060110 56,500 11.0 13.5

4340390 PA13NA060****B CNPH*6124A** PG8*EA060135 56,500 11.0 13.2

5099985 PA13NA060****B CNPH*6124A** PG95XA*60080C*** 56,500 11.2 13.5

4739975 PA13NA060****B CNPH*6124A** PG95XA*66120D*** 56,500 11.4 13.7

4340063 PA13NA060****B CNPH*6124A**+TDR 57,000 11.0 13.0

4340194 PA13NA060****B CNPV*6024A** PG8*EA060135 56,000 11.0 13.5

5099979 PA13NA060****B CNPV*6024A** PG95XA*60080C*** 56,000 11.2 13.2

5099980 PA13NA060****B CNPV*6024A** PG95XA*60100C*** 56,500 11.0 13.2

4739970 PA13NA060****B CNPV*6024A** PG95XA*66120D*** 56,500 11.4 13.7

4340046 PA13NA060****B CNPV*6024A**+TDR 57,000 11.0 13.0

4340387 PA13NA060****B CNPV*6124A** PG8*EA060135 56,500 11.0 13.5

5099981 PA13NA060****B CNPV*6124A** PG95XA*60080C*** 57,000 11.3 13.5

5099982 PA13NA060****B CNPV*6124A** PG95XA*60100C*** 57,500 11.2 13.5

4739972 PA13NA060****B CNPV*6124A** PG95XA*66120D*** 57,000 11.4 13.7

4340062 PA13NA060****B CNPV*6124A**+TDR 57,000 11.0 13.0

4340197 PA13NA060****B CSPH*6012A** PG8*EA048090 56,000 11.0 13.5

4340198 PA13NA060****B CSPH*6012A** PG8*EA060110 56,000 11.5 13.5

4340199 PA13NA060****B CSPH*6012A** PG8*EA060135 56,000 11.5 13.5

5099986 PA13NA060****B CSPH*6012A** PG95XA*60080C*** 56,500 11.2 13.5

5099987 PA13NA060****B CSPH*6012A** PG95XA*60100C*** 57,000 11.2 13.5

4739977 PA13NA060****B CSPH*6012A** PG95XA*66120D*** 57,000 11.4 13.7

4340048 PA13NA060****B CSPH*6012A**+TDR 57,000 11.0 13.0

4340200 PA13NA060****B PF4MNA060 57,000 10.8 13.0

4340201 PA13NA060****B PF4MNA061 57,000 11.5 13.5

4340411 PA13NA060****B PF4MNB061 58,000 11.0 13.5

4341597 PA13PA060****B †CAP**6024A**+TDR 57,000 11.0 13.0

4341656 PA13PA060****B CAP**6021A** PG8*EA060110 56,000 11.5 13.5

5155532 PA13PA060****B CAP**6021A** PG95XA*60080C*** 56,500 11.2 13.5

4341598 PA13PA060****B CAP**6021A**+TDR 56,000 11.0 13.0

4341657 PA13PA060****B CAP**6024A** PG8*EA060135 56,000 11.5 13.5

5155533 PA13PA060****B CAP**6024A** PG95XA*60080C*** 56,500 11.2 13.2

5155534 PA13PA060****B CAP**6024A** PG95XA*60100C*** 56,500 11.0 13.2

5155535 PA13PA060****B CAP**6025A** PG95XA*60080C*** 56,500 11.2 13.2

5155536 PA13PA060****B CAP**6025A** PG95XA*60100C*** 56,500 11.0 13.2

4341659 PA13PA060****B CNPH*6024A** PG8*EA060110 56,000 11.5 13.5

4341660 PA13PA060****B CNPH*6024A** PG8*EA060135 56,000 11.0 13.5

5155541 PA13PA060****B CNPH*6024A** PG95XA*60080C*** 56,000 11.2 13.5

5155542 PA13PA060****B CNPH*6024A** PG95XA*60100C*** 56,500 11.0 13.2

4341600 PA13PA060****B CNPH*6024A**+TDR 57,000 11.0 13.0

5155543 PA13PA060****B CNPH*6124A** PG95XA*60080C*** 56,500 11.2 13.5

4341658 PA13PA060****B CNPV*6024A** PG8*EA060135 56,000 11.0 13.5

5155537 PA13PA060****B CNPV*6024A** PG95XA*60080C*** 56,000 11.2 13.2

5155538 PA13PA060****B CNPV*6024A** PG95XA*60100C*** 56,500 11.0 13.2

4341599 PA13PA060****B CNPV*6024A**+TDR 57,000 11.0 13.0

5155539 PA13PA060****B CNPV*6124A** PG95XA*60080C*** 57,000 11.3 13.5

5155540 PA13PA060****B CNPV*6124A** PG95XA*60100C*** 57,500 11.2 13.5

4341661 PA13PA060****B CSPH*6012A** PG8*EA048090 56,000 11.0 13.5

4341662 PA13PA060****B CSPH*6012A** PG8*EA060110 56,000 11.5 13.5

4341663 PA13PA060****B CSPH*6012A** PG8*EA060135 56,000 11.5 13.5

5155544 PA13PA060****B CSPH*6012A** PG95XA*60080C*** 56,500 11.2 13.5

5155545 PA13PA060****B CSPH*6012A** PG95XA*60100C*** 57,000 11.2 13.5

4341601 PA13PA060****B CSPH*6012A**+TDR 57,000 11.0 13.0

4341664 PA13PA060****B PF4MNA060 57,000 10.8 13.0

4341665 PA13PA060****B PF4MNA061 57,000 11.5 13.5

{ Tested combination

EER — Energy Efficiency Ratio

SEER — Sea sonal Energy Effi ciency Ratio

TDR — Time--- Delay Relay. In most cases, only 1 method should be used to achieve TDR function. Using more than 1 method in a system may cause degradation in performance.

NOTES:

1. R atings are net values reflecting the effe cts of circulating fan moto r heat. Suppl emental electric heat is not included.

2. Tested outdoor/indoo r combina tions ha ve been tested in accordance with DOE test procedures for central air conditioners. Ratings for other combinations are determined under DOE

3. De termine actual CFM va lues obtainable for your system by referring to fan performance data in fan coil or furnace coil literature.

4. Do not apply with capillary tube coils as performance and reliability are affected.

Use either the accessory Time---Delay Relay KAATD0101TDR or a furnace equipped with TDR. Most Payne furnaces are equipped with TDR.

computer simulation procedures.

PA13NA / PA13PA

17

Page 18

Tot a l S ys -

tem KW**

Capacity MBtuh

Tot a l S ys -

tem KW**

Capacity MBtuh

PA13NA / PA13PA

Tot a l S ys -

tem KW**

Capacity MBtuh

CONDENSER ENTER ING AIR TEMPERATURES ° F (°C )

Tot a l S ys -

tem KW**

PA13NA018(G)--- B Outdoor Section With CAPVP1814 Indoor Section

CAPACITY POWER FURNACE MODEL

COOLING INDOOR

MODEL

CSPH*2412A** 1.03 0.94 PG95XA*30040A***

CAP**2417A** 1.00 0.91 PG9MXA036060

CNPH*2417A** 1.00 0.91 PG9MXA036060

CNPV*1917A** 1.05 0.91 PG9MXA036060

CNPV*2417A** 1.00 0.91 PG9MXA036060

CAP**2417A** 1.03 0.94 PG9UAA042060

CSPH*2412A** 1.00 0.91 PG9MXA036060

CNPV*1917A** 1.05 0.95 PG9UAA042060

CNPV*2417A** 1.03 0.94 PG9UAA042060

See notes on pg. 27

Capacity MBtuh

Tot a l S ys -

tem KW**

75 (23.9) 85 (29.4) 95 (35) 105 (40.6) 115 (46.1)

Capacity Mbtuh

Tot a l Sens‡ Tot a l Sens‡ Tot a l Sens‡ Tot a l Sens‡ To tal Sens‡

CAPACITY POWER FURNACE MODEL

EWB

°F(°C)

72 (22.2) 20.35 10.09 1.18 19.43 9.75 1.35 18.46 9.40 1.54 17.51 9.07 1.75 16.49 8.72 1.98

67 (19.4) 18.72 12.43 1.19 17.86 12.08 1.37 16.95 11.72 1.55 16.04 11.37 1.77 15.07 11.00 2.00

62 (16.7) 17.21 14.74 1.21 16.41 14.38 1.38 15.59 14.00 1.57 14.75 13.61 1.78 13.92 13.92 2.02

57 (13.9) 16.70 16.70 1.22 16.05 16.05 1.38 15.37 15.37 1.57 14.67 14.67 1.78 13.92 13.92 2.02

72 (22.2) 20.73 10.59 1.20 19.69 10.22 1.37 18.69 9.87 1.56 17.72 9.54 1.77 16.67 9.18 2.00

67 (19.4) 19.03 13.21 1.22 18.14 12.86 1.39 17.20 12.50 1.58 16.27 12.15 1.79 15.27 11.77 2.02

62 (16.7) 17.59 15.82 1.23 16.78 15.44 1.40 15.95 15.95 1.59 15.23 15.23 1.80 14.44 14.44 2.04

57 (13.9) 17.38 17.38 1.24 16.69 16.69 1.40 15.97 15.97 1.59 15.23 15.23 1.80 14.44 14.44 2.04

72 (22.2) 21.01 11.06 1.22 19.88 10.67 1.39 18.85 10.32 1.58 17.86 9.98 1.80 16.79 9.62 2.03

67 (19.4) 19.25 13.95 1.24 18.34 13.61 1.41 17.38 13.24 1.60 16.43 12.88 1.81 15.41 12.50 2.05

62 (16.7) 17.94 17.79 1.26 17.20 17.20 1.43 16.44 16.44 1.61 15.67 15.67 1.82 14.84 14.84 2.06

57 (13.9) 17.92 17.92 1.26 17.20 17.20 1.43 16.44 16.44 1.61 15.67 15.67 1.82 14.84 14.84 2.06

MODEL

CAP**2414A** 1.00 0.99

CAP**2417A** 1.00 1.00

CAP**3619A** 1.02 1.01

CNPF*2418A** 1.00 0.99

CNPV*1814A** 1.00 1.00

CNPV*1917A** 1.05 1.04

EVAPORATOR AIR

CFM

525

600

675

COOLING INDOOR

*CAP**1814A** 1.00 1.00

CNPH*2417A** 1.00 0.99

FF1ENP018 1.00 1.00

FF1ENP019 1.00 0.91

FF1ENP024 1.00 1.00

FF1ENP025 1.00 0.89

FF1ENP031 1.03 0.98

FF1ENP037 1.03 0.98

PF4MNA018 1.00 1.00

PF4MNA019 1.00 0.91

PF4MNA024 1.00 1.00

PF4MNA025 1.00 0.91

PF4MNB019 1.02 0.93

PF4MNB025 1.02 0.93

PF4MNB031 1.02 0.93

CAP**1814A** 1.00 0.91 PG8*EA024045

CNPV*2414A** 1.00 1.00

CNPV*2417A** 1.00 0.99

CSPH*2412A** 1.00 0.99

CAP**2414A** 1.00 0.91 PG8*EA024045

CNPH*2417A** 1.00 0.91 PG8*EA024045

CNPV*1814A** 1.00 0.91 PG8*EA024045

CNPV*2414A** 1.00 0.91 PG8*EA024045

CAP**1814A** 1.01 0.94 PG95XA*30040A***

CSPH*2412A** 1.00 0.91 PG8*EA024045

CAP**2414A** 1.03 0.94 PG95XA*30040A***

CAP**2417A** 1.03 0.94 PG95XA*30040A***

CNPV*1814A** 1.02 0.94 PG95XA*30040A***

CNPV*1917A** 1.04 0.95 PG95XA*30040A***

CNPV*2414A** 1.03 0.95 PG95XA*30040A***

CNPH*2417A** 1.03 0.95 PG95XA*30040A***

CNPV*2417A** 1.03 0.95 PG95XA*30040A***

DETAILED COOLING CAPACITIES#

18

Page 19

Tot a l S ys -

Capacity MBtuh

tem KW**

Tot a l S ys -

Capacity MBtuh

tem KW**

CAPACITY POWER FURNACE MODEL

COOLING INDOOR

MODEL

CNPH*3017A** 1.00 0.92 PG9MXA036080

CNPH*3117A** 1.02 0.90 PG9MXA036080

CNPV*2417A** 1.00 0.96 PG9MXA036080

CNPV*3017A** 1.00 0.92 PG9MXA036080

CNPV*3117A** 1.02 0.90 PG9MXA036080

CSPH*2412A** 1.00 0.96 PG9MXA036080

CAP**2417A** 1.01 0.92 PG9UAA042060

CSPH*3012A** 1.00 0.92 PG9MXA036080

CAP**3017A** 1.02 0.93 PG9UAA042060

CNPV*2417A** 1.01 0.92 PG9UAA042060

CNPV*3017A** 1.02 0.93 PG9UAA042060

CNPV*3117A** 1.02 0.93 PG9UAA042060

See notes on pg. 27

PA13NA / PA13PA

Tot a l S ys -

tem KW**

Capacity MBtuh

CONDENSER ENTER ING AIR TEMPERATURES ° F (°C )

Tot a l S ys -

tem KW**

CAPACITY POWER FURNACE MODEL

MODEL

CAP**2414A** 0.98 0.97 PG95XA*30040A***

CAP**2417A** 0.99 0.97 PG95XA*30040A***

CAP**3014A** 0.99 0.97 PG95XA*30040A***

COOLING INDOOR

CAPACITY POWER FURNACE MODEL

57 (13.9) 23.92 23.92 1.71 23.04 23.04 1.91 22.08 22.08 2.13 21.10 21.10 2.37 20.02 20.02 2.64

MODEL

COOLING INDOOR

CAP**3017A** 1.00 0.96 PG95XA*30040A***

CAP**2417A** 1.00 1.00

CAP**3014A** 1.00 1.00

CAP**3017A** 1.00 1.00

*CAP**2414A** 1.00 1.00

CNPV*2414A** 0.98 0.97 PG95XA*30040A***

CNPV*2417A** 0.98 0.97 PG95XA*30040A***

CNPV*3014A** 0.99 0.97 PG95XA*30040A***

CNPH*2417A** 0.98 0.97 PG95XA*30040A***

CNPH*3017A** 1.00 0.96 PG95XA*30040A***

CNPH*3117A** 1.02 0.98 PG95XA*30040A***

CAP**3619A** 1.02 1.02

CNPF*2418A** 1.00 1.00

CNPH*2417A** 1.00 1.00

CNPV*3017A** 1.00 0.96 PG95XA*30040A***

CNPV*2414A** 1.00 1.00

CNPV*2417A** 1.00 1.00

CNPH*3017A** 1.00 1.00

CNPH*3117A** 1.02 1.02

CAP**2417A** 0.98 0.90 PG95XA*42060B***

CNPV*3117A** 1.02 0.98 PG95XA*30040A***

CNPV*3014A** 1.00 1.00

CAP**3017A** 1.00 0.92 PG95XA*42060B***

CSPH*2412A** 0.99 0.97 PG95XA*30040A***

CSPH*3012A** 1.00 0.96 PG95XA*30040A***

CNPV*3017A** 1.00 1.00

CNPV*3117A** 1.02 1.02

CSPH*2412A** 1.00 1.00

CSPH*3012A** 1.00 1.00

CNPV*2417A** 0.97 0.89 PG95XA*42060B***

CNPH*2417A** 0.97 0.89 PG95XA*42060B***

FF1ENP024 1.00 1.01

CNPV*3017A** 1.00 0.92 PG95XA*42060B***

CNPH*3017A** 1.00 0.92 PG95XA*42060B***

CNPH*3117A** 1.02 0.90 PG95XA*42060B***

FF1ENP025 1.00 0.94

FF1ENP030 1.00 1.01

FF1ENP031 1.00 0.94

FF1ENP037 1.03 0.98

CAP**2417A** 1.00 0.92 PG9MXA036060

CNPV*3117A** 1.02 0.90 PG95XA*42060B***

PF4MNA024 1.00 1.00

CAP**3017A** 1.00 0.92 PG9MXA036060

CSPH*2412A** 0.98 0.90 PG95XA*42060B***

CSPH*3012A** 0.99 0.91 PG95XA*42060B***

PF4MNA025 1.00 0.96

PF4MNA030 1.00 1.00

PF4MNA031 1.00 0.92

PF4MNB025 1.02 0.93

CNPH*2417A** 1.00 0.96 PG9MXA036060

CNPH*3017A** 1.00 0.92 PG9MXA036060

PF4MNB031 1.03 0.98

PF4MNB037 1.03 0.95

CNPV*2417A** 1.00 0.96 PG9MXA036060

CNPH*3117A** 1.02 0.90 PG9MXA036060

CAP**2414A** 1.00 0.92 PG8*EA024045

CAP**3014A** 1.00 0.92 PG8*EA024045

CNPV*3017A** 1.00 0.92 PG9MXA036060

CNPH*2417A** 1.00 0.96 PG8*EA024045

CNPV*3117A** 1.02 0.90 PG9MXA036060

CSPH*2412A** 1.00 0.96 PG9MXA036060

CNPH*3017A** 1.00 0.92 PG8*EA024045

CNPH*3117A** 1.02 0.93 PG8*EA024045

CAP**2417A** 1.00 0.92 PG9MXA036080

CSPH*3012A** 1.00 0.92 PG9MXA036060

CNPV*2414A** 1.00 0.96 PG8*EA024045

CNPV*3014A** 1.00 0.92 PG8*EA024045

CAP**3017A** 1.00 0.92 PG9MXA036080

CNPH*2417A** 1.00 0.96 PG9MXA036080

CSPH*2412A** 1.00 0.92 PG8*EA024045

CSPH*3012A** 1.00 0.92 PG8*EA024045

75 (23.9) 85 (29.4) 95 (35) 105 (40.6) 115 (46.1)

EVAPORATOR AIR

Capacity MBtuh

Tot a l S ys -

Capacity Mbtuh

EWB

CFM

PA13NA024(G)--- B Outdoor Section With CAPVP2414 Indoor Section

tem KW**

Tot a l Sens‡ Tot a l Sens‡ Tot a l Sens‡ Tot a l Sens‡ To tal Sens‡

°F(°C)

72 (22.2) 27.06 13.28 1.64 25.82 12.84 1.84 24.64 12.43 2.06 23.44 12.02 2.30 22.11 11.56 2.57

67 (19.4) 24.87 16.41 1.64 23.82 16.00 1.84 22.70 15.57 2.05 21.55 15.13 2.30 20.29 14.66 2.57

62 (16.7) 22.98 19.55 1.63 22.00 19.12 1.83 20.97 18.66 2.05 19.91 18.18 2.30 18.87 18.87 2.57

57 (13.9) 22.41 22.41 1.63 21.61 21.61 1.83 20.75 20.75 2.05 19.85 19.85 2.30 18.87 18.87 2.57

72 (22.2) 27.49 13.93 1.68 26.14 13.46 1.88 24.93 13.05 2.10 23.69 12.64 2.34 22.33 12.18 2.60

67 (19.4) 25.24 17.44 1.68 24.15 17.03 1.87 23.00 16.60 2.09 21.83 16.16 2.33 20.54 15.69 2.60

62 (16.7) 23.44 20.97 1.67 22.46 20.51 1.87 21.49 21.49 2.09 20.55 20.55 2.33 19.52 19.52 2.60

57 (13.9) 23.25 23.25 1.67 22.40 22.40 1.87 21.49 21.49 2.09 20.55 20.55 2.33 19.52 19.52 2.60

72 (22.2) 27.76 14.53 1.72 26.38 14.07 1.91 25.12 13.65 2.13 23.86 13.23 2.38 22.46 12.77 2.64

67 (19.4) 25.50 18.44 1.71 24.39 18.03 1.91 23.21 17.59 2.13 22.02 17.15 2.37 20.70 16.66 2.64

62 (16.7) 23.92 23.92 1.71 23.03 23.03 1.91 22.08 22.08 2.13 21.10 21.10 2.37 20.02 20.02 2.64

700

800

900

DETAILED COOLING CAPACITIES# (CONT.)

19

Page 20

Tot a l S ys -

Capacity MBtuh†

tem KW**

Tot a l S ys -

Capacity MBtuh†

tem KW**

CAPACITY POWER FURNACE MODEL

COOLING INDOOR

MODEL

CAP**3017A** 1.01 0.95 PG95XA*48080B***

CAP**3617A** 1.02 0.94 PG95XA*48080B***

CAP**3619A** 1.02 0.94 PG95XA*48080B***

CSPH*3612A** 1.03 0.94 PG95XA*42060B***

CAP**3621A** 1.02 0.94 PG95XA*48080B***

CNPV*3017A** 1.01 0.95 PG95XA*48080B***

CNPV*3117A** 1.04 0.96 PG95XA*48080B***

CNPV*3617A** 1.01 0.95 PG95XA*48080B***

CNPH*3017A** 1.01 0.95 PG95XA*48080B***

CNPH*3117A** 1.04 0.96 PG95XA*48080B***

CNPH*3617A** 1.01 0.95 PG95XA*48080B***

CNPV*3621A** 1.02 0.96 PG95XA*48080B***

CAP**3017A** 1.00 0.94 PG9MXA036060

CNPV*3717A** 1.05 0.95 PG95XA*48080B***

CAP**3617A** 1.00 0.90 PG9MXA036060

CSPH*3012A** 1.02 0.96 PG95XA*48080B***

CSPH*3612A** 1.04 0.95 PG95XA*48080B***

CNPH*3017A** 1.00 0.94 PG9MXA036060

CNPH*3117A** 1.01 0.91 PG9MXA036060

CNPV*3017A** 1.00 0.94 PG9MXA036060

CNPH*3617A** 1.00 0.94 PG9MXA036060

CNPV*3117A** 1.01 0.91 PG9MXA036060

CNPV*3617A** 1.00 0.94 PG9MXA036060

CNPV*3717A** 1.02 0.92 PG9MXA036060

CSPH*3012A** 1.00 0.94 PG9MXA036060

CAP**3017A** 1.00 0.94 PG9MXA036080

CSPH*3612A** 1.00 0.90 PG9MXA036060

CAP**3617A** 1.00 0.90 PG9MXA036080

CNPH*3017A** 1.00 0.90 PG9MXA036080

CNPH*3117A** 1.01 0.91 PG9MXA036080

CNPH*3617A** 1.00 0.90 PG9MXA036080

CNPV*3017A** 1.00 0.90 PG9MXA036080

CNPV*3117A** 1.01 0.91 PG9MXA036080

CNPV*3617A** 1.00 0.90 PG9MXA036080

CNPV*3717A** 1.02 0.92 PG9MXA036080

CSPH*3012A** 1.00 0.94 PG9MXA036080

CSPH*3612A** 1.00 0.90 PG9MXA036080

PA13NA / PA13PA

Tot a l S ys -

tem KW**

Capacity MBtuh†

CONDENSER ENTER ING AIR TEMPERATURES ° F (° C)

Tot a l S ys -

tem KW**

CAPACITY POWER FURNACE MODEL

MODEL

COOLING INDOOR

CAPACITY POWER FURNACE MODEL

57 (13.9) 28.55 28.55 2.06 27.50 27.50 2.30 26.37 26.37 2.56 25.19 25.19 2.86 23.89 23.89 3.18

MODEL

COOLING INDOOR

CNPV*3717A** 1.02 0.92 PG8*EA048070

CSPH*3012A** 1.00 0.94 PG8*EA048070

CAP**3017A** 1.00 1.00

*CAP**3014A** 1.00 1.00

CAP**3621A** 1.00 0.90 PG8*EA048090

CSPH*3612A** 1.00 0.94 PG8*EA048070

CAP**3614A** 1.00 1.00

CAP**3617A** 1.00 1.00

CNPH*3017A** 1.00 0.94 PG8*EA048090

CNPH*3117A** 1.01 0.91 PG8*EA048090

CAP**3619A** 1.01 1.01

CAP**3621A** 1.00 1.00

CNPV*3621A** 1.00 0.94 PG8*EA048090

CNPH*3617A** 1.00 0.94 PG8*EA048090

CNPF*3618A** 1.00 1.00

CNPH*3017A** 1.00 1.00

CSPH*3012A** 1.00 0.94 PG8*EA048090

CSPH*3612A** 1.00 0.90 PG8*EA048090

CNPH*3117A** 1.01 1.00

CNPH*3617A** 1.00 1.00

CAP**3014A** 0.99 1.05 PG95XA*30040A***

CAP**3017A** 1.00 1.05 PG95XA*30040A***

CAP**3614A** 1.00 1.05 PG95XA*30040A***

CAP**3617A** 1.00 1.05 PG95XA*30040A***

CNPV*3014A** 1.00 1.00

CNPV*3017A** 1.00 1.00

CNPV*3117A** 1.01 1.00

CNPV*3617A** 1.00 1.00

CNPV*3014A** 0.99 1.04 PG95XA*30040A***

CNPV*3017A** 1.00 1.05 PG95XA*30040A***

CNPV*3117A** 1.02 1.05 PG95XA*30040A***

CNPH*3017A** 1.00 1.05 PG95XA*30040A***

CNPH*3117A** 1.02 1.06 PG95XA*30040A***

CNPH*3617A** 1.00 1.05 PG95XA*30040A***

CNPV*3621A** 1.00 1.00

CNPV*3717A** 1.02 1.00

CSPH*3012A** 1.00 1.00

CNPV*3617A** 1.00 1.05 PG95XA*30040A***

FF1ENP030 1.00 1.00

FF1ENP031 1.00 0.94

FF1ENP036 1.00 0.98

CSPH*3612A** 1.00 1.00

CAP**3017A** 1.01 0.95 PG95XA*42060B***

CAP**3617A** 1.01 0.95 PG95XA*42060B***

CAP**3619A** 1.01 0.95 PG95XA*42060B***

CNPV*3717A** 1.03 1.05 PG95XA*30040A***

CSPH*3012A** 1.00 1.04 PG95XA*30040A***

CSPH*3612A** 1.02 1.06 PG95XA*30040A***

FF1ENP037 1.00 0.94

PF4MNA030 1.00 1.00

PF4MNA031 1.00 0.94

CAP**3621A** 1.01 0.93 PG95XA*42060B***

PF4MNA036 1.00 1.00

PF4MNA037 1.00 0.98

PF4MNB031 1.01 0.95

PF4MNB037 1.02 0.92