Page 1

FB4C

LEGACY LINE FAN COIL

SIZES 018 THRU 060

Product Data

AIR HANDLER TECHNOLOGY

The FB4C fan coil has the proven technology of Bryant fan coil

units with Puron refrigerant as well as vertical and horizontal

applications. The design features contoured condensate pans with

rugged drain connections, ensuring that little water is left in the

unit at the end of the cooling duty cycle. The lack of standing

condensate and corrosion free pans improves IAQ and product life,

features homeowners appreciate.

Standard features include grooved tubing and louvered fins. Coil

circuiting has also been updated to make the most of all Bryant

heat pumps and air conditioners. Units come with solid state fan

controls, 1--inch (25mm) thick insulation with R--value of 4.2,

multi--speed motors, and fully--wettable coils. Units can

accommodate factory-- and/or field--installed heaters from 3 to 30

kW.

It also should be noted that the unique cabinet design of these fan

coils meet stringent regulations for cabinet air leakage -- a

requirement of 2% cabinet leakage rate when tested at 1.0 inches of

static pressure.

The FB4C fan coil design is loaded with popular features. These

fan coils utilize the latest in electronic commutation motor (ECM)

technology through the use of high efficiency, multi--tap ECM

motors allowing reliable air delivery with increased static pressure.

It comes in a pre--painted (taupe metallic) galvanized steel casing

and a factory--supplied power plug for ease of installation. The

FB4C unit is shipped with a factory--installed Teflon--ring piston

A10083

FB4CNF(018--048) or a Puron refrigerant TXV FB4CNF060,

FB4CNP(018--060).

AT ITS FINEST

Page 2

STANDARD FEATURES

S Multi--tap ECM (electronic commutating motor) motors -- all sizes

S Integrated motor controls, with 90--sec off TDR function, have replaced integrated circuit board

S Five available speed tags to meet a wide range of applications

S Large, grooved tube, louvered fin coils

S Efficient, quiet, time--tested blower housings and diffusers

S Sturdy, drainable condensate pans

S Cabinet construction features innovations designed to prevent cabinet sweating

S Tested for condensate disposal in much tougher conditions than Air Conditioning and Refrigeration Institute requirements

S Super--thick R--4.2 insulation with vapor barrier

S Pre--painted galvanized steel cabinet (taupe metallic)

S Cabinet design meets stringent regulations for 2% cabinet leakage rate when tested at 1.0 inches static pressure

S Installation--flexible, multipoise units

S Horizontal hanging provisions on cabinet

S No tools required to access filter

S Newly improved filter rack area filter door insulation added for improved air seal

S Factory--installed heater packages available on select models (5-- through 15--kW)

S 3-- through 30--kW accessory heaters -- field installed

S Factory--supplied power plug

S Easy plug--in provisions for heater installation

S Entry options for high and low voltage wiring hook--up

S Leak--preventing sweat connections

S Puron refrigeration factory--installed Teflon--ring pistons on all FB4CNF (018--048) coils

S Thermostatic expansion valve, TXV, on all FB4CNP coils and FB4CNF060

S Designed for manufactured housing applications.

ADDITIONAL FEATURES

S Factory--installed heater packages available on select models

2

Page 3

MODEL NUMBER NOMENCLATURE

123456789101112

FB4CNF018000

Product Heating Size

F=FanCoil 00 = No Heat

05 = 5 kW

Typ e 75 = 7.5 kW

B = Base, Puron 08 = 8 kW

10 = 10 kW

Position 11 = 11 kW

4=Multipoise 15 = 15 kW

Coil Type

Series 0 = Copper

C T = T i n --- p l a t e

L = Aluminum

Electrical

N = 208/230v, 1 ph, 60 Hz Capacity

018 = 18,000

Cabinet Style 024 = 24,000

F = Single Piece with piston (TXV on FB4CNF060) 030 = 30,000

P=TXV 036 = 36,000

042 = 42,000

048 = 48,000

060 = 60,000

Use of the AHRI Certified

TM Mark indicates a

manufacturer’s

participation in the

program For verification

of certification for individual

products, go to

www.ahridirectory.org.

3

Page 4

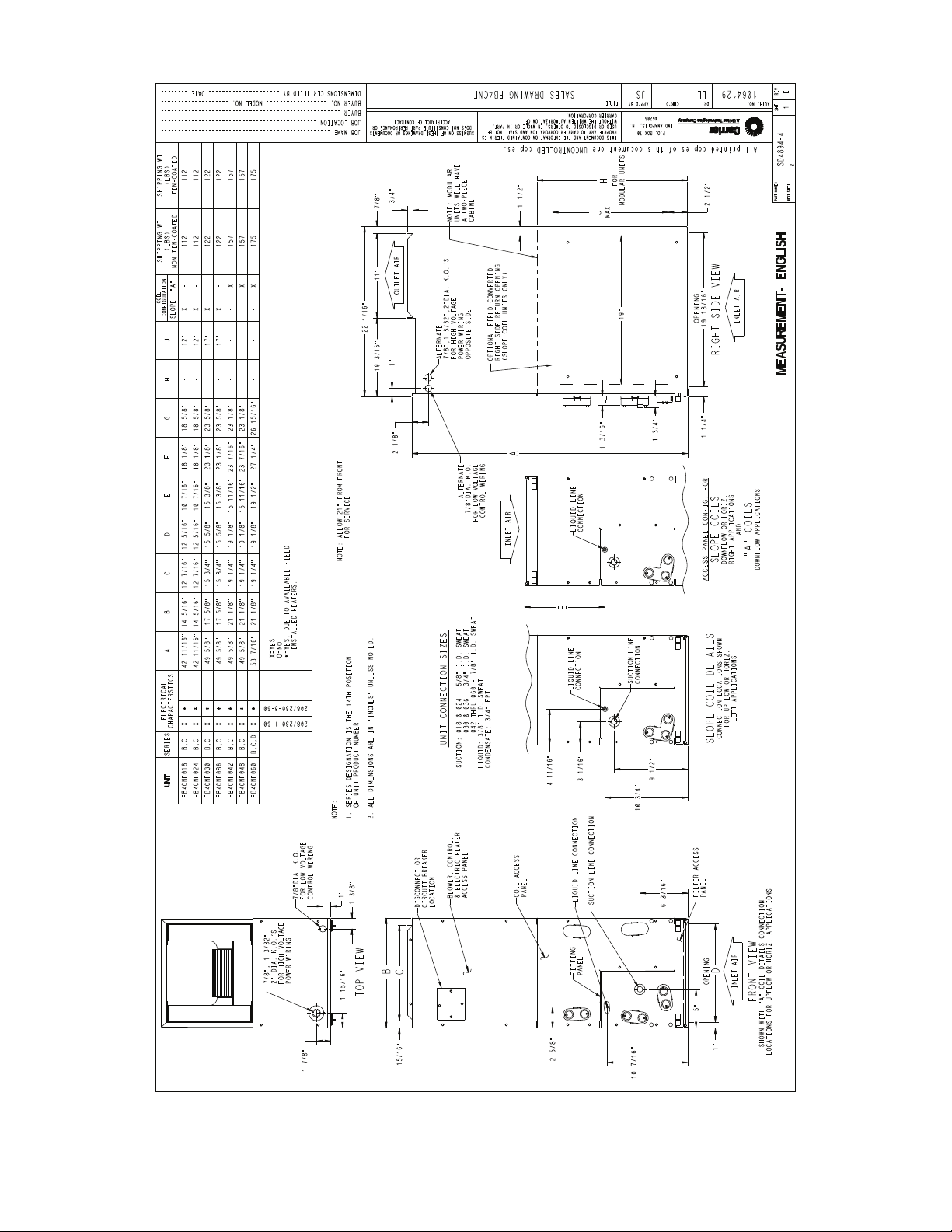

DIMENSIONS

Fig. 1 -- FB4CNF -- English

4

A12512

Page 5

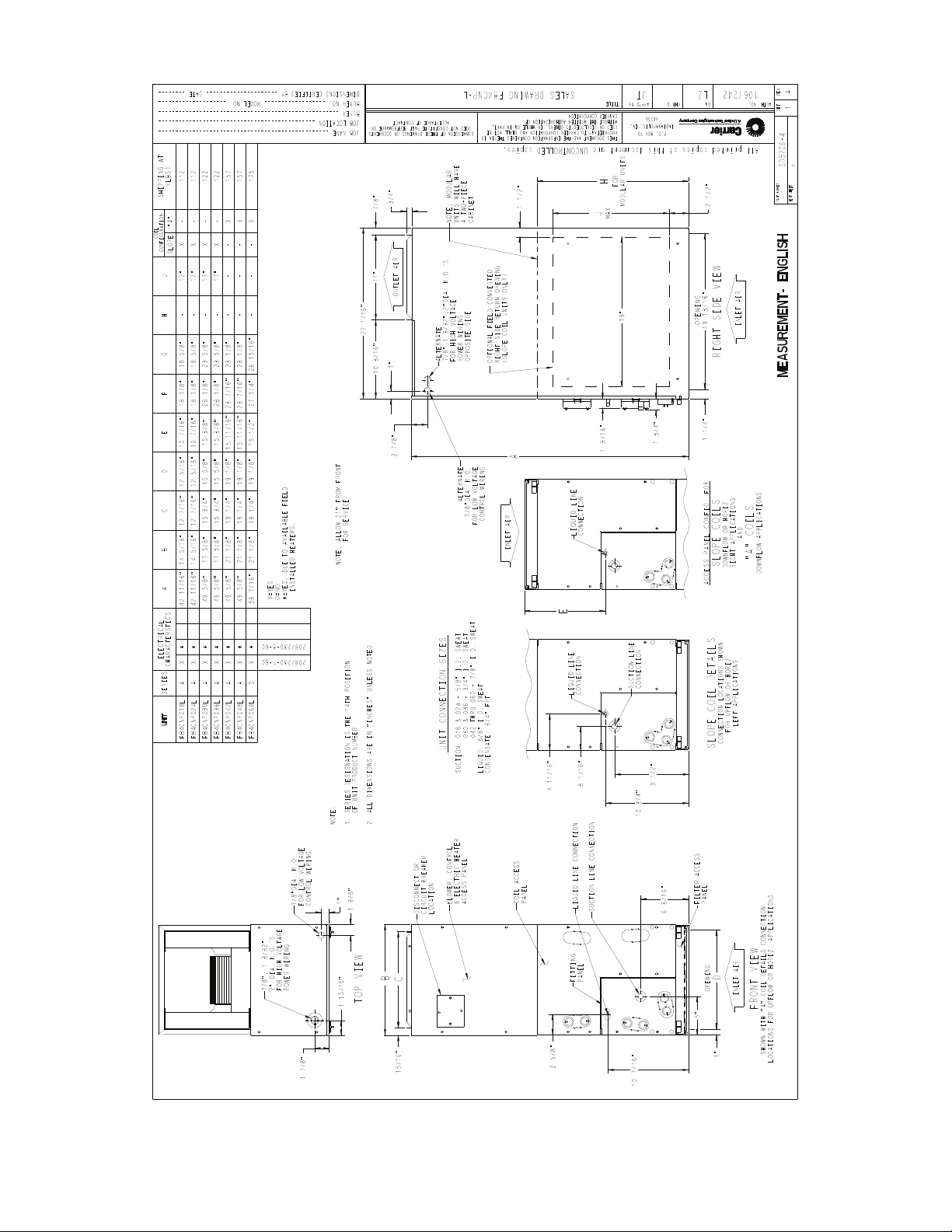

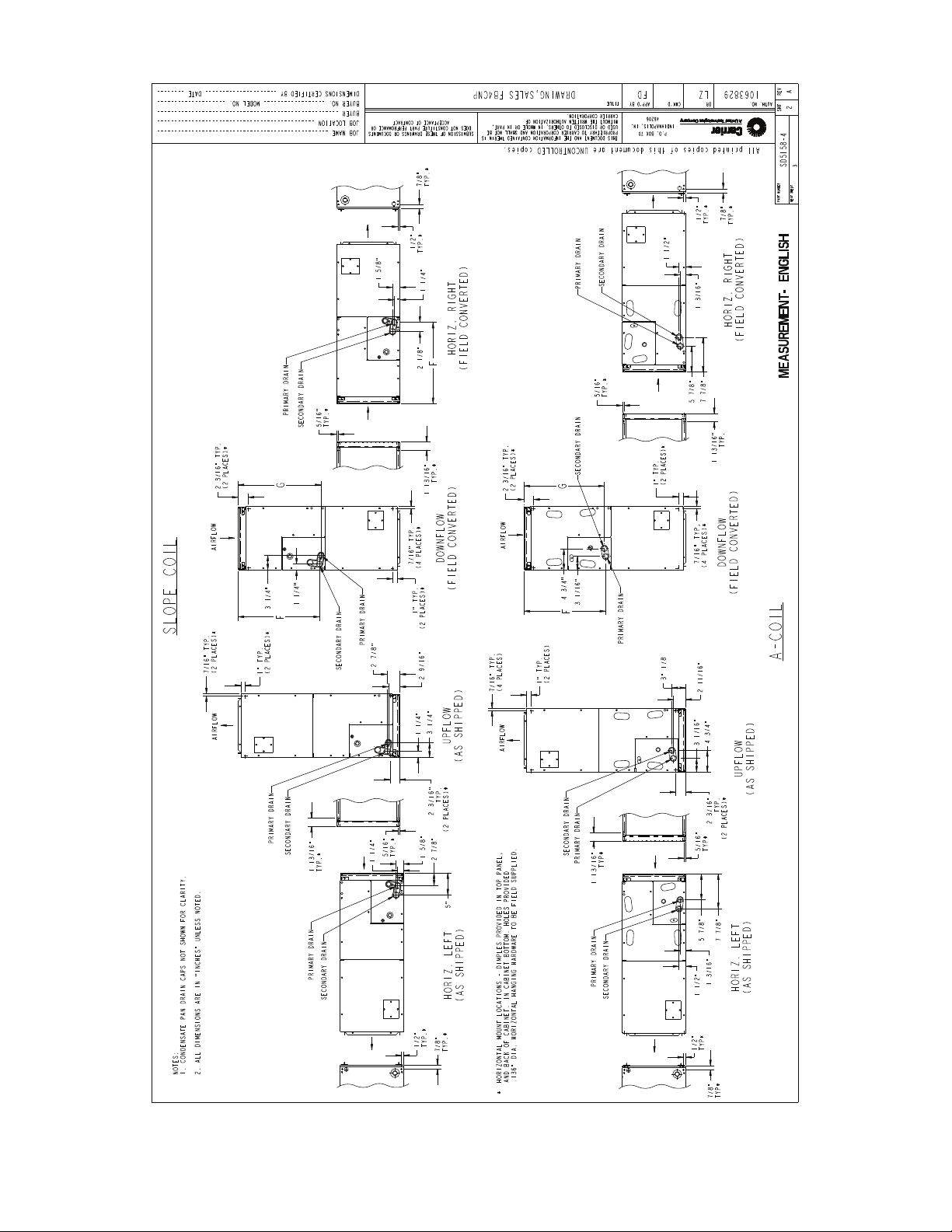

DIMENSIONS (cont.)

Fig. 2 -- FB4CNP -- English

5

A14026

Page 6

DIMENSIONS (cont.)

Fig. 3 -- FB4CNF and FB4CNP -- English

6

A12509

Page 7

DIMENSIONS (cont.)

Fig. 4 -- FB4CNF -- Metric

7

A12513

Page 8

DIMENSIONS (cont.)

Fig. 5 -- FB4CNP -- Metric

8

A14027

Page 9

DIMENSIONS (cont.)

Fig. 6 -- FB4CNF and FB4CNP -- Metric

9

A12511

Page 10

PHYSICAL DATA

ORDERING NO.

FB4CN(F,P)018(0,T,L) 18,000

FB4CN(F,P)024(0,T,L) 24,000

FB4CN(F,P)030(0,T,L) 30,000

FB4CN(F,P)036(0,T,L) 36,000

FB4CN(F,P)042(0,T,L) 42,000

FB4CN(F,P)048(0,T,L) 48,000

FB4CN(F,P)060(0,T,L) 60,000

NOMINAL COOLING

CAPACITY (Btuh)

Height Width Depth

42--- 11/16 in.

1084mm

42--- 11/16 in.

1084mm

49--- 5/8 in.

1260mm

49--- 5/8 in.

1260mm

49--- 5/8 in.

1260mm

49--- 5/8 in.

1260mm

53--- 7/16 in.

1357mm

DIMENSIONS

14--- 5/16 in.

363mm

14--- 5/16 in.

363mm

17--- 5/8 in.

447mm

17--- 5/8 in.

447mm

21--- 1/8 in.

536mm

21--- 1/8 in.

536mm

21--- 1/8 in.

536mm

22--- 1/16 in.

560mm

22--- 1/16 in.

560mm

22--- 1/16 in.

560mm

22--- 1/16 in.

560mm

22--- 1/16 in.

560mm

22--- 1/16 in.

560mm

22--- 1/16 in.

560mm

SHIPPING

WEIGHT

112 lb

51 kg

112 lb

51 kg

122 lb

55 kg

122 lb

55 kg

157 lb

71 kg

157 lb

71 kg

175 lb

79 kg

SPECIFICATIONS

FB4C 18 24 30 36 42 48 60

EVAPORATOR COIL

Face Area (sq. ft) 2.23 2.97 4.45 5.93

Configuration Slope A

FB4CNF

Metering Device

( Te f l o n --- r i n g pi s t o n )

Puron Refrigerant

FB4CNP

Metering Device

Puron Refrigerant

FILTER*

2 1 --- 1 / 2 --- i n

(546 mm) X

BLOWER ASSEMBLY

Motor Type (ECM) M u l t i --- t a p EC M

Motor HP 1/3 1/3 1/3 1/2 1/2 3/4 3/4

CFM 600 800 1000 1200 1400 1600 1750

*Filter must be field ---supplied for FB4C units.

EA52PT052 EA52PT057 EA52PT067 EA52PT070 EA52PT076 EA52PT080

TXV TXV TXV TXV TXV TXV

1 3 --- i n

(330 mm)

1 6 --- 3 / 8 --- i n

(417 mm)

1 9 --- 7 / 8 --- i n

(505 mm)

TXV

(Copper and

Tin models

only)

TXV

(Aluminum

models

only)

10

Page 11

PERFORMANCE DATA

FB4C AIRFLOW PERFORMANCE (CFM)

MODEL & SIZE BLOWER SPEED 0.10 0.20 0.30 0.40 0.50 0.60

Tap 5 767 739 702 669 620 565

Tap 4 614 569 534 486 436 398

FB4C 018

FB4C 024

FB4C 030

FB4C 036

FB4C 042

FB4C 048

FB4C 060

--- A i r f l o w a b o v e 4 5 0 c f m / t o n .

NOTES:

1. Airflow based upon dry coil at 230v with factory ---approved filter and electric heater (2 element heater sizes 018 through 036, 3 element

heater sizes 042 through 060). For FB4C models, airflow at 208 volts is approximately the same as 230 volts because the multi ---tap ECM

motor is a constant torque motor. The torque doesn’t drop off at the speeds the motor operates.

2. To avoid potential for condensate blowing out of drain pan prior to making drain trap:

Return static pressure must be less than 0.40 in. wc.

Horizontal applications of 042 --- 060 sizes must have supply static greater than 0.20 in. wc.

3. Airflow above 400 cfm/ton on 048--- 060 size could result in condensate blowing off coil or splashing out of drain pan.

Tap 3 701 660 616 581 537 499

Tap 2 614 569 534 486 436 398

Tap 1 614 569 534 486 436 398

Tap 5 969 936 892 835 763 676

Tap 4 826 795 766 743 706 660

Tap 3 826 795 766 743 706 660

Tap 2 701 660 616 581 537 499

Tap 1 617 592 552 507 472 420

Tap 5 1108 1090 1065 1034 1009 974

Tap 4 1026 1000 969 938 899 865

Tap 3 1026 1000 969 938 899 865

Tap 2 909 873 842 799 762 724

Tap 1 825 795 757 722 674 634

Tap 5 1301 1276 1245 1218 1176 1121

Tap 4 1227 1191 1169 1143 1105 1074

Tap 3 1227 1191 1169 1143 1105 1074

Tap 2 1087 1062 1030 1001 966 930

Tap 1 1026 1000 969 938 899 865

Tap 5 1560 1544 1507 1464 1424 1358

Tap 4 1419 1397 1358 1320 1279 1239

Tap 3 1419 1397 1358 1320 1279 1239

Tap 2 1249 1220 1184 1142 1093 1052

Tap 1 1242 1205 1158 1110 1069 1026

Tap 5 1743 1712 1679 1642 1610 1574

Tap 4 1669 1634 1599 1564 1531 1499

Tap 3 1669 1634 1599 1564 1531 1499

Tap 2 1452 1413 1377 1339 1308 1271

Tap 1 1300 1256 1221 1182 1142 1101

Tap 5 1897 1867 1836 1808 1774 1736

Tap 4 1817 1785 1757 1724 1693 1655

Tap 3 1817 1785 1757 1724 1693 1655

Tap 2 1657 1621 1589 1557 1518 1474

Tap 1 1443 1412 1377 1332 1286 1243

11

Page 12

PERFORMANCE DATA (cont.)

GROSS COOLING CAPACITIES (MBH) -- PURONR REFRIGERANT

SATURATED TEMPERATURE LEAVING EVAPORATOR (_F/C)

018

024

030

036

042

048

060

INDOOR COIL

AIR

CFM EWB TC SHC BF TC SHC BF TC SHC BF TC SHC BF TC SHC BF

72 / 22 41 20 0.00 37 17 0.00 32 15 0.00 27 13 0.02 21 11 0.03

67 / 19 33 20 0.03 29 18 0.03 24 16 0.03 19 13 0.03 13 11 0.04

525

62 / 17 26 20 0.03 22 18 0.03 18 16 0.04 14 14 0.10 11 11 0.26

72 / 22 45 22 0.00 40 19 0.00 35 17 0.01 30 15 0.03 23 12 0.04

67 / 19 37 22 0.04 32 20 0.04 27 17 0.04 21 15 0.04 15 12 0.05

600

62 / 17 29 22 0.04 24 20 0.04 19 18 0.05 15 15 0.12 13 13 0.28

72 / 22 49 24 0.00 44 21 0.00 38 19 0.03 32 16 0.04 25 13 0.05

67 / 19 40 24 0.05 35 22 0.05 29 19 0.05 23 16 0.05 16 14 0.06

675

62 / 17 32 25 0.05 27 22 0.05 21 19 0.06 17 17 0.14 14 14 0.29

72 / 22 43 22 0.00 38 20 0.00 33 17 0.03 28 15 0.04 22 12 0.05

67 / 19 35 23 0.05 30 20 0.05 25 18 0.05 20 15 0.05 14 13 0.06

700

62 / 17 28 23 0.06 23 21 0.06 18 18 0.06 15 15 0.14 12 12 0.29

72 / 22 47 24 0.00 42 22 0.01 36 19 0.04 31 17 0.06 24 14 0.06

67 / 19 38 25 0.06 33 22 0.06 28 20 0.07 22 17 0.07 15 14 0.08

800

62 / 17 30 26 0.07 25 23 0.07 20 20 0.08 16 16 0.17 13 13 0.31

72 / 22 51 26 0.00 45 24 0.03 40 21 0.06 33 18 0.07 26 15 0.07

67 / 19 41 27 0.07 36 25 0.08 30 22 0.08 24 19 0.08 17 16 0.09

900

62 / 17 33 28 0.08 28 25 0.08 22 22 0.09 18 18 0.19 15 15 0.33

72 / 22 62 31 0.00 56 28 0.00 49 24 0.02 41 21 0.04 32 17 0.04

67 / 19 51 32 0.04 44 28 0.05 37 25 0.05 29 21 0.05 21 18 0.05

875

62 / 17 40 32 0.05 34 29 0.05 27 25 0.06 21 21 0.13 18 18 0.28

72 / 22 68 34 0.00 61 31 0.00 53 27 0.04 45 23 0.05 35 19 0.06

67 / 19 56 35 0.06 49 31 0.06 41 28 0.06 32 24 0.06 22 20 0.07

1000

62 / 17 44 36 0.06 37 32 0.06 29 28 0.07 24 24 0.16 20 20 0.30

72 / 22 74 37 0.00 66 33 0.02 58 29 0.05 48 25 0.06 38 21 0.07

67 / 19 60 38 0.07 53 34 0.07 44 30 0.07 35 26 0.07 24 22 0.08

1125

62 / 17 48 39 0.07 40 35 0.07 32 31 0.09 26 26 0.18 21 21 0.32

72 / 22 68 34 0.00 61 31 0.00 53 27 0.04 45 23 0.05 35 20 0.06

67 / 19 56 36 0.06 49 32 0.06 41 28 0.06 32 24 0.07 22 20 0.07

1050

62 / 17 44 36 0.07 37 33 0.07 30 29 0.08 24 24 0.17 20 20 0.31

72 / 22 75 38 0.00 67 34 0.03 58 30 0.06 49 26 0.07 38 22 0.07

67 / 19 61 39 0.07 53 35 0.08 45 31 0.08 35 27 0.08 25 22 0.09

1200

62 / 17 49 40 0.08 41 36 0.08 32 32 0.09 26 26 0.19 22 22 0.33

72 / 22 81 41 0.00 72 37 0.05 63 32 0.07 53 28 0.08 41 23 0.09

67 / 19 66 43 0.08 58 38 0.09 48 34 0.09 38 29 0.09 27 25 0.10

1350

62 / 17 53 44 0.09 44 40 0.09 35 35 0.11 29 29 0.22 24 24 0.35

72 / 22 89 44 0.00 80 40 0.00 70 35 0.02 58 30 0.03 46 25 0.04

67 / 19 73 45 0.04 63 41 0.04 53 36 0.04 42 31 0.04 29 25 0.05

1225

62 / 17 58 46 0.04 48 41 0.04 38 36 0.05 30 30 0.12 25 25 0.28

72 / 22 98 49 0.00 88 44 0.00 77 39 0.03 64 33 0.04 50 28 0.05

67 / 19 80 50 0.05 70 45 0.05 58 39 0.05 46 34 0.05 32 28 0.06

1400

62 / 17 64 51 0.06 53 46 0.06 42 40 0.06 34 34 0.14 28 28 0.29

72 / 22 106 53 0.00 95 48 0.00 83 42 0.04 69 36 0.05 54 30 0.06

67 / 19 87 55 0.06 76 49 0.06 63 43 0.06 50 37 0.07 35 31 0.07

1575

62 / 17 69 56 0.07 58 50 0.07 46 44 0.08 37 37 0.17 31 31 0.31

72 / 22 88 46 0.00 79 42 0.00 69 37 0.03 58 31 0.04 45 26 0.05

67 / 19 72 48 0.05 63 43 0.05 52 37 0.05 41 32 0.05 29 27 0.06

1400

62 / 17 57 49 0.06 48 43 0.06 38 38 0.06 30 30 0.14 25 25 0.29

72 / 22 97 51 0.00 87 46 0.01 75 40 0.04 63 35 0.06 49 29 0.06

67 / 19 79 52 0.06 69 47 0.06 57 41 0.07 45 36 0.07 32 30 0.08

1600

62 / 17 63 54 0.07 53 48 0.07 42 42 0.08 34 34 0.17 28 28 0.31

72 / 22 105 55 0.00 94 50 0.03 82 44 0.06 68 38 0.07 54 31 0.07

67 / 19 86 57 0.07 75 51 0.08 62 45 0.08 49 39 0.08 34 33 0.09

1800

62 / 17 68 59 0.08 57 53 0.08 45 47 0.09 37 37 0.19 30 30 0.33

72 / 22 106 54 0.00 95 49 0.00 82 43 0.01 69 37 0.03 54 31 0.04

67 / 19 86 56 0.04 75 50 0.04 63 44 0.04 49 37 0.04 35 31 0.05

1600

62 / 17 68 56 0.04 57 50 0.04 45 44 0.05 36 36 0.12 29 29 0.28

72 / 22 113 58 0.00 101 52 0.00 88 46 0.02 74 39 0.04 58 33 0.04

67 / 19 92 59 0.04 80 53 0.05 67 47 0.05 53 40 0.05 37 33 0.05

1750

62 / 17 73 61 0.05 61 54 0.05 49 48 0.06 39 39 0.13 32 32 0.28

72 / 22 124 64 0.00 111 57 0.00 97 50 0.04 81 43 0.05 63 36 0.06

67 / 19 101 66 0.06 88 59 0.06 74 52 0.06 58 44 0.06 41 37 0.07

2000

62 / 17 80 67 0.06 67 60 0.06 53 53 0.07 43 43 0.16 35 35 0.30

35 / 2 40 / 4 45 / 7 50 / 10 55 / 13

UNIT

SIZE

FB4C

FB4C

FB4C

FB4C

FB4C

FB4C

FB4C

CFM --- C u b i c F t p e r M i n u t e EWB --- Entering Wet Bulb _F(_C) LWB --- Le a v i n g W e t B u l b _F(_C) TC --- Gross Cooling Capacity 1000 Btuh

SHC --- Gross Sensible Capacity 1000 Btuh BF --- By p a s s Fa c t o r MBH --- 1000 Btuh

12

Page 13

PERFORMANCE DATA (cont.)

NOTES:

1. Contact manufacturer for cooling capacities at conditions

other than shown in table.

2. Formulas:

Leaving db = entering db --sensible heat cap.

1.09 x CFM

Leaving wb = wb corresponding to enthalpy of air leaving

coil (h

h

)

lwb

lwb=hewb

--total capacity (Btuh)

4.5xCFM

where h

= enthalpy of air entering coil. Direct interpola-

ewb

tion is permissible. Do not extrapolate.

3. SHC is based on 80_F(27_C) db temperature of air enter-

ing coil. Below 80_F(27_C) db, subtract (Correction Factor

x CFM) from SHC. Above 80_F(27_C) db, add (Correc-

BYPASS

FACTOR

0.10 .098 1.96 2.94 3.92 4.91

0.20 0.87 1.74 2.62 3.49 4.36

0.30 0.76 1.53 2.29 3.05 3.82

Interpolation is permissible.

Correction Factor = 1.09 x (1 --- BF) x (db --- 80)

SHC CORRECTION FACTOR

ENTERING AIR DRY-- BULB TEMPERATURE (_F)

79 78 77 76 75 Under 75

81 82 83 84 85 Over 85

ENTERING AIR DRY-- BULB TEMPERATURE (_C)

26 25 25 24 24 Under 75

27 28 28 29 29 Over 85

Correction Factor

Use

formula

shown

below

tionFactorxCFM)toSHC.

4. Bypass Factor = 0 indicates no psychometric solution. Use

bypass factor of next lower EWB for approximation.

FB4C AIR DELIVERY PERFORMANCE CORRECTION COMPONENT PRESSURE DROP (in wc) AT

INDICATED AIRFLOW (DRY TO WET COIL)

UNIT SIZE

018 0.034 0.049 0.063 --- --- --- --- --- --- --- --- --- --- --- --- --- --- --- --- --- --- --- --- --- --- --- --- --- --024 0.034 0.049 0.063 0.076 0.089 --- --- --- --- --- --- --- --- --- --- --- --- --- --- --- --- --- --- --- --- --- --030 --- --- --- --- --- --- 0.049 0.059 0.070 0.080 --- --- --- --- --- --- --- --- --- --- --- --- --- --- --- --- --- --036 --- --- --- --- --- --- --- --- --- --- 0.070 0.080 0.090 0.099 --- --- --- --- --- --- --- --- --- --- --- --- --- --042 --- --- --- --- --- --- --- --- --- --- --- --- --- --- 0.049 0.056 0.063 0.070 --- --- --- --- --- --- --- --- --- --048 --- --- --- --- --- --- --- --- --- --- --- --- --- --- --- --- --- --- 0.063 0.070 0.076 0.083 0.090 --- --- --- --060 --- --- --- --- --- --- --- --- --- --- --- --- --- --- --- --- --- --- --- --- --- --- 0.049 0.054 0.059 0.065 0.070

500 600 700 800 900 1000 1100 1200 1300 1400 1500 1600 1700 1800 1900 2000

CFM

ELECTRIC HEATER STATIC PRESSURE DROP (in wc)

FB4C

018 --- 036

HEATER

ELEMENTS

0 0 +.02 0 0 +.04

1 3, 5 +.01 2 8, 10 +.02

2 8, 10 0 3 9, 15 0

3 9, 15 –.02 4 20 –.02

4 20 –.04 6 18, 24, 30 –.10

The airflow performance data was developed using fan coils with 10--- kW electric heaters (2 elements) in the 018 through 036 size units and

15---kW heaters (3 elements) in the 042 through 060 size units. For fan coils with heaters of a different number of elements, the external available static at a given CFM from the curve may be corrected by adding or subtracting available external static pressure as indicated above.

kW

EXTERNAL STATIC

PRESSURE

CORRECTION

HEATER

ELEMENTS

FB4C

042 --- 060

kW

EXTERNAL STATIC

PRESSURE

CORRECTION

MINIMUM CFM AND MOTOR SPEED SELECTION

FB4C

018 525 525 525 — 600 — — — — —

024 700 700 700 — 700 775 — — — —

030 — 875 875 — 875 875 — 1060 — —

036 — 1050 970 970 970 920 — 1040 — —

042 — — 1225 1225 1225 1225 1225 1225 — —

048 — — 1400 1400 1400 1400 1400 1400 1400 1400

060 — — 1750 1750 1750 1750 1750 1750 1750 1750

Speed Tap 4 (white wire) is used for electric heat only. White wire must remain on tap 4.

3 5 8 9 10 15 18 20 24 30

HEATER kW

13

Page 14

PERFORMANCE DATA (cont.)

FIELD--INSTALLED FILTER STATIC PRESSURE DROP (in wc)

FB4C

018 0.02 0.044 0.075 — — — — — —

024, 030 — 0.022 0.048 0.072 0.100 — — — —

036, 042, 048 — — — 0.051 0.070 0.092 0.120 0.152 —

060 — — — — — — 0.086 0.105 0.130

400 600 800 1000 1200 1400 1600 1800 2000

ACCESSORY ELECTRIC HEATERS

HEATER

PAR T NO.

KFCEH0401N03 3 230/1 3 None 018–024 9,400

KFCEH0501N05 5 230/1 5 None 018–060 15,700

KFCEH0801N08 8 230/1 8 None 018–060 25,100

KFCEH0901N10 10 230/1 10 None 018–060 31,400

KFCEH3201F20 20 230/1 5, 20 Fuse} 030–060 62,800

KFCEH1601315 15 230/3 5, 15 None 036–060 47,100

KFCEH2001318 18 230/3 6, 12, 18 None 042–060 56,500

KFCEH3401F24 24 230/3* 8, 16, 24 Fuse 048, 060 78,300

KFCEH3501F30 30 230/3* 10, 20, 30 Fuse 048, 060 94,100

KFCEH2401C05 5 230/1 5 Circuit Breaker 018–060 15,700

KFCEH2501C08 8 230/1 8 Circuit Breaker 018–060 25,100

KFCEH2601C10 10 230/1 10 Circuit Breaker 018–060 31,400

KFCEH3301C20 20 230/1 5, 20 Circuit Breaker 030–060 62,800

KFCEH2901N09 9 230/1{ 3, 9 None 036–060 28,200

KFCEH3001F15 15 230/1 5, 15 Fuse} 024–060 47,100

KFCEH3101C15 15 230/1 5, 15 Circuit Breaker 024–060 47,100

*Field convertible to 1 phase.

{Field convertible to 3 phase.

}Single point wiring kit required for these heaters in Canada.

**Blower Motor heat not included.

kW @

240V

VOLTS/

PH

STAGES (kW

OPERATING)

CFM

INTERNAL

CIRCUIT

PROTECTION

FAN COIL SIZE

USED WITH

HEATING CAP.**

@ 230V

ESTIMATED SOUND POWER LEVEL (dBA)

CONDITIONS OCTAVE BAND CENTER FREQUENCY*

FB4C

018 600 0.25 64.7 60.7 56.7 53.7 51.7 49.7 45.7

024 800 0.25 66.0 62.0 58.0 55.0 53.0 51.0 47.0

030 1000 0.25 67.0 63.0 59.0 56.0 54.0 52.0 48.0

036 1200 0.25 67.8 63.8 59.8 56.8 54.8 52.8 48.8

042 1400 0.25 68.4 64.4 60.4 57.4 55.4 53.4 49.4

048 1600 0.25 69.0 65.0 61.0 58.0 56.0 54.0 50.0

060 2000 0.25 70.0 66.0 62.0 59.0 57.0 55.0 51.0

*Estimated sound power levels have been derived using the method described in the 1987 ASHRAE HVAC Systems & Applications Handbook, C hapter 52, p.

52.7.

CFM

Ext Static

Pressure

63 125 250 500 1000 2000 4000

14

Page 15

PERFORMANCE DATA (cont.)

ELECTRICAL DATA FOR UNITS WITH FACTORY--INSTALLED HEAT

SINGLE CIRCUIT DUAL CIRCUIT

FB4CNF

018(0,T,L)05 1/3 2.8 208/230/1/60 MKFCEH0501N05 18.1/20.0 26.1/28.5 30/30 N/A N/A N/A N/A N/A N/A

018(0,T,L)08 1/3 2.8 208/230/1/60 MKFCEH0801N08 28.9/32.0 39.6/43.5 40/45 N/A N/A N/A N/A N/A N/A

024(0,T,L)05 1/3 4.1 208/230/1/60 MKFCEH0501N05 18.1/20.0 27.8/30.0 30/30 N/A N/A N/A N/A N/A N/A

024(T,L)10 1/3 4.1 208/230/1/60 MKFCEH0901N10 36.2/40.0 50.4/55.1 60/60 N/A N/A N/A N/A N/A N/A

030(0,T,L)08 1/3 2.8 208/230/1/60 MKFCEH0801N08 28.9/32.0 39.6/43.5 40/45 N/A N/A N/A N/A N/A N/A

030(0,T,L)10 1/3 2.8 208/230/1/60 MKFCEH0901N10 36.2/40.0 48.8/53.5 50/60 N/A N/A N/A N/A N/A N/A

036(T,L)10 1/2 4.1 208/230/1/60 MKFCEH0901N10 36.2/40.0 50.4/55.1 60/60 N/A N/A N/A N/A N/A N/A

042(T,L)10 1/2 4.1 208/230/1/60 MKFCEH0901N10 36.2/40.0 50.4/55.1 60/60 N/A N/A N/A N/A N/A N/A

042(T,L)15 1/2 4.1 208/230/1/60 MKFCEH1501F15 54.2/59.9 72.9/80.0 80/80 36.2/40.0 50.4/55.2 50/60 18.1/20.0 22.6/25.0 25/25

048(T,L)10 3/4 6.0 208/230/1/60 MKFCEH0901N10 36.2/40.0 52.8/57.5 60/60 N/A N/A N/A N/A N/A N/A

048(T,L)15 3/4 6.0 208/230/1/60 MKFCEH1501F15 54.2/59.9 75.3/82.4 80/90 36.2/40.0 52.8/57.5 60/60 18.1/20.0 22.6/25.0 25/25

MTRHPMTR

VOLTS / PH/HZHEAT PACK

FLA

INSTALLED

HEATER

AMPS

MCA MOCP

HTR.

AMPS

L1/L2 L1/L2 L1/L2 L3/L4 L3/L4 L3/L4

MCA MOCP

ELECTRICAL DATA FOR UNITS WITHOUT ELECTRICAL HEAT

SINGLE CIRCUIT

MODEL NO.

MTR

HP

FB4CN(F,P)018(0,T,L)00 1/3 2.8 208/230/1/60 3.5 15 14

FB4CN(F,P)024(0,T,L)00 1/3 4.1 208/230/1/60 5.1 15 14

FB4CN(F,P)030(0,T,L)00 1/3 2.8 208/230/1/60 3.5 15 14

FB4CN(F,P)036(0,T,L)00 1/2 4.1 208/230/1/60 5.1 15 14

FB4CN(F,P)042(0,T,L)00 1/2 4.1 208/230/1/60 5.1 15 14

FB4CN(F,P)048(0,T,L)00 3/4 6.0 208/230/1/60 7.5 15 14

FB4CN(F,P)060(0,T,L)00 3/4 6.0 208/230/1/60 7.5 15 14

MTR

FLA

VOLTS/PH/HZ

MCA

MAXIMUM

OVERCURRENT

PROTECTION

HTR.

AMPS

MCA MOCP

BRANCH CIRCUIT

MIN WIRE SIZE*

AWG

*Usecopperwireonly.Use75_C only in this application. When using non --- metallic (NM) sheathed cable, wire size required should be based on that of 60_C

conductors, instead of wire sizes shown in table above per NEC Article 336--- 26.

NOTE: If branch circuit wire length exceeds 100 ft (30 m), consult NEC 215 ---2 to determine maximum wire length. Use 2% voltage drop.

FLA --- Fu l l L o a d A m p s

15

Page 16

Dual Circ uit

208/230V (Ft)‡

Max Wire Length

Single

Circuit

Dual Circ uit

208/230V

Single

Max Fuse/Ckt Bkr Amps

Circuit

208/230V (FT)‡

MAX WIRE L ENGTH

AMPS

208/230V

MAX FUSE/CKT BKR

Dual Circ uit

208/230V

Min Gnd Wire Size

Single

Min Wire Size (AWG)

Min Ampacity

208/230V

Circuit

Dual Circui t

208/230V†

Single

Circuit

Dual Circ uit

208/230V*

Single

Circuit

Dual Circui t

Single

Circuit

BRANCH CIRCUIT

HEATER AMPS

MIN WIRE SIZE (AWG)

MIN AMPACITY

HEATER AMPS

MIN GND

WIRE SI ZE

208/230V†

208/230V*

208/230V

208/230V

ACCESSORY ELECTRIC HEATER ELECTRICAL DATA

INTERNAL

PHA

kW

FIELD MULTIPOINT WIRING OF 24--AND 30--kW SINGLE PHASE

PHASE

kW

NO.

HEATER PART

240V 208V L1,L2 L3,L4 L5,L6 L1,L2 L3,L4 L5,L6 L1,L2 L3,L4 L5,L6 L1,L2 L3,L4 L5,L6 L1,L2 L3,L4 L5,L6

KFCEH3401F24†† 24 18.0 1 28.9/32.0 28.9/32.0 28.9/32.0 44.7/48.5 36.2/40.0 36.2/40.0 8/8 8/8 8/8 10/10 45/50 40/40 40/40 59/60 73/73 73/73

KFCEH3501F30†† 30 22.5 1 36.2/40.0 36.2/40.0 36.2/40.0 53.8/58.5 45.3/50.0 45.3/50.0 6/6 8/8 8/8 10/10 60/60 50/50 50/50 78/80 59/59 59/59

*Includes blower motor amps of largest fan coil used with heater.

{Copper wire must be used. If other than uncoated (non--- plated), 75_C ambient, copper wire (solid wire for 10 AWG and smaller, stranded wire for larger than 10 AWG) is used, consult applicable tables of the National Electric Code

(ANSI/NFPA 70).

}Length shown is as measured 1 way along wire path between unit and service panel for a voltage drop n ot to exceed 2%.

**Field convertible to 3 phase.

{{Field convertible to 1 phase, single or multiple suppl y circuit.

NOTES:

1. For fan coil sizes 018---036.

2. For fan coil sizes 042---060.

3. Single circuit application of F15 and F20 heaters requires single ---point wiring kit accessory.

CIRCUIT

PROTECTION

E

S

5 3.8 1 None 18.1/20.0 — — 26.0/28.4 — — 10/10 — — 10/10 — — 30/30 — — 66/66 — —

5 3.8 1 None 18.1/20.0 — — 31.2/33.5 — — 8/8 — — 10/10 — — 35/35 — — 85/88 — —

5 3.8 1 Ckt Bkr 18.1/20.0 — — 26.0/28.4 — — 10/10 — — 10/ 10 — — 30/30 — — 66/66 — —

240v 208v L1,l2 L3,L4 L1,L2 L3,L4 L1, L2 L3, L4 L1, L2 L3,L4 L1,L2 L3,L4 L1,L2 L3,L4

1

HEATER

PAR T N O.

KFCEH0401N03 3 2.3 1 None 10.9/12.0 — — 15.9/17.3 — — 12/12 — — 12/12 — — 20/20 — — 67/68 — —

KFCEH0501N05

5 3.8 1 Ckt Bkr 18.1/20.0 — — 31.2/33.5 — — 8/8 — — 10/10 — — 35/35 — — 85/88 — —

2

1

2

KFCEH0501N05

KFCEH2401C05

KFCEH2401C05

KFCEH0801N08 8 6.0 1 None 28.9/32.0 — — 44.7/48.5 — — 8/8 — — 10/10 — — 45/50 — — 59/60 — —

KFCEH2501C08 8 6.0 1 Ckt Bkr 28.9/32.0 — — 44.7/48.5 — — 8/8 — — 10/10 — — 45/50 — — 59/60 — —

KFCEH2901N09 9 6.8 1 None 32.8/36.0 — — 49.5/53.5 — — 8/6 — — 10/10 — — 50/60 — — 54/87 — —

KFCEH2901N09* * 9 6.8 3 None 18.8/20.8 — — 32.0/34.5 — — 8/8 — — 10/10 — — 35/35 — — 83/85 — —

KFCEH0901N10 10 7.5 1 None 36.2/40.0 — — 53.8/58.5 — — 6/6 — — 10/10 — — 60/60 — — 78/80 — —

KFCEH2601C10 10 7.5 1 Ckt Bkr 36.2/40.0 — — 53.8/58.5 — — 6/6 — — 10/10 — — 60/60 — — 78/80 — —

KFCEH3001F15 15 11.3 1 Fuse 54.2/59.9 36.2/40.0 18.1/20.0 76.3/83.4 53.8/58.5 22.7/25.0 4/4 6/6 10/10 8/8 10/10 10/10 80/90 60/60 25/25 88/89 78/ 80 75/76

KFCEH3101C15 15 11.3 1 Ckt Bkr — 36.2/40.0 18.1/20.0 — 53.8/58.5 22.7/25.0 — 6/6 10/10 — 10/10 10/10 — 60/60 25/25 — 78/80 75/76

KFCEH1601315 15 11.3 3 None 31.3/34.6 — — 47.7/51.8 — — 8/6 — — 10/10 — — 50/60 — — 56/90 — —

KFCEH2001318 18 13.5 3 None 37.6/41.5 — — 55.5/60.4 — — 6/6 — — 10/8 — — 60/70 — — 76/77 — —

24 18.0 3 Fuse 50.1/55.4 — — 71.2/77.8 — — 4/4 — — 8/8 — — 80/ 80 — — 94/95 — —

24 18.0 1 Fuse 86.7/95.5 — — 116.9/127.9 — — 1/ 1 — — 6/6 — — 125/150 — — 115/116 — —

30 22.5 3 Fuse 62.6/69.2 — — 86.8/95.0 — — 3/3 — — 8/8 — — 90/100 — — 97/98 — —

30 22.5 1 Fuse 109.0/120.0 — — 144.8/158.5 — — 0/00 — — 6/6 — — 150/175 — — 117/ 150 — —

KFCEH3201F20 20 15.0 1 Fuse 72.3/79.9 36.2/40.0 36.2/40.0 98.9/108.4 53.8/58.5 45.3/50.0 3/2 6/6 8/8 8/6 10/10 10/10 100/110 60/60 50/50 85/109 78/80 59/59

KFCEH3301C20 20 15.0 1 Ckt Bkr — 36.2/40.0 36.2/40.0 — 53.8/58.5 45.3/50.0 — 6/6 8/8 — 10/10 10/10 — 60/60 50/50 — 78/80 59/59

KFCEH3401F24††

KFCEH3501F30††

16

Page 17

HEATER ELECTRICAL DATA

ELECTRIC HEATER INTERNAL PROTECTION

HEATER kW PHASE

5 1 — 1/60

8 1 — 1/60

9 1/3 — —

10 1 — 1/60

15 1 2/30–2/60 2/60

15 3 — —

18 3 — —

20 1 4/60 2/60

24 1/3 6/60 —

30 1/3 6/60 —

*All circuit breakers are 2 pole.

FUSE

QTY/SIZE

When using units with 20--, 24--, and 30--kW electric heaters, maintain a 1--in. (25mm) clearance from combustible materials to discharge

plenum and ductwork and maintain a distance of 36--in. (914mm) from the unit. Use an accessory downflow base to maintain proper

clearance on downflow installations. Use flexible connectors between ductwork and unit to prevent transmission of vibration. When electric

heater is installed, use heat resistant material for flexible connector between ductwork and unit at discharge connection. Ductwork passing

through unconditioned space must be insulated and covered with vapor barrier

CKT BKR*

QTY/SIZE

ACCESSORIES

ITEM ACCESSORY PART NO.* FAN COIL SIZE USED WITH

1. Disconnect Kit KFADK0201DSC Cooling controls and heaters 3--- through 10 --- kW

KFACB0101CFB 018, 024

2. Downflow Base Kit

3. Downflow Conversion Kit

4. Downflow/Horizontal Conversion Gasket Kit KFAHD0101SLP All

5. Horizontal Water Management Kit (25 pack)

6. Single - -- Point Wiring Kit KFASP0101SPK O n l y wi t h 1 5 --- a n d 20 --- k W Fu s e d He a t e r s

7. Filter Kit (12 Pack)

8.

9. PVC Cond ensate Trap Kit (50 pack) KFAET0150ETK All

10. Air Cleaner 240 --- volt Conversion Kit KEAVC0201240 All

11. Standard Filter Rack Kit

12. TXV Kit Puron R--- 410A

13. T X V K i t R --- 2 2

* Factory authorized and listed, field---installed.

{ KFAHD0101SLP must al so be purchased f or downflow a pplications.

} KFAHD0101SLP must al so be purchased for downflow or horizontal applications.

Fan Coil Filter Cabinet

(Fan Coil Filter Media)

{

}

KFACB0201CFB 030, 036

KFACB0301CFB 042, 048, 060

KFADC0201SLP Slope Coil Units—018, 024, 030, 036

KFADC0401ACL A --- Coil Units—042, 048, 060

KFAHC0125AAA All

KFAFK0112SML 018, 024

KFAFK0212MED 030, 036

KFAFK0312LRG 042, 048, 060

FNCCABCC0014

(FILXXFNC0014)

FNCCABCC0017

(FILXXFNC0017)

FNCCABCC0021

(FILXXFNC0021)

KFAFR0101FRM 018, 024

KFAFR0201FRM 030, 036

KFAFR0301FRM 042, 048, 060

KFAFR0401FRM NA

KSATX0201PUR 018, 024, 030

KSATX0301PUR 036, 042

KSATX0401PUR 048

KSATX0601HSO 018, 024, 030, 036, 042

KSATX0701HSO 048

KSATX1001HSO 060

018, 024

030, 036

042, 048, 060

17

Page 18

ACCESSORIES (cont.)

Accessory Kits Description Suggested and Required Use

1. Disconnect Kit

The kit is used to disconnect electrical power to the fan coil so service or maintenance may be performed safely.

SUGGESTED USE: Units for 3-- through 10--kW electric resistance heaters and cooling controls.

2. Downflow Base Kit

This kit is designed to provide a 1--in. (25mm) minimum clearancebetween unit discharge plenum, ductwork, and combustible materials. It also provides a gap--free seal with the floor.

REQUIRED USE: This kit must be used whenever fan coils are used in downflow applications.

3. Downflow Conversion Kit

Fan coils are shipped from the factory for upflow or horizontal--left applications. Downflow conversion kits provide proper condensate

water drainage and support for the coil when used in downflow applications. Separate kits are available for slope coils and A--coils.

REQUIRED USE: This kit must be used whenever fan coils are used in downflow applications.

4. Downflow/Horizontal Conversion Gasket Kit

This kit provides the proper gasketing of units when applied in either a downflow or horizontal application.

REQUIRED USE: Fan coils in either downflow or horizontal applications.

5. Horizontal Applications -- Water Management Kit

This kit provides proper installation of fan coils under conditions of high static pressure and high relative humidity.

SUGGESTED USE: All fan coils.

6. Single Point Wiring Kit

The single point wiring kit acts as a jumper between L1 and L3 lugs, and between the L2 and L4 lugs. This allows the installer to run

two heavy--gauge, high--voltage wires into the fan coil rather than 4 light--gauge, high--voltage wires.

SUGGESTED USE: Fan coils with 15-- and 20--kW fused heaters only.

7. Filter Kit (12 pack)

The kit consists of 12 fan coil framed filters. These filters collect large dust particles from the return air entering the fan coil and

prevents them from collecting on the coil. This process helps to keep the coil clean, which increases heat transfer and, in turn, the

efficiency of the system.

SUGGESTED USE: To replace filters in fan coils.

REQUIRED USE: All units unless a filter grille is used.

8. Fan Coil Filter Cabinet

This cabinet is mounted to the fan coil on the return air end and designed to slip over the outer fan coil casing. The cabinets are

insulated using the same insulation as production fan coils. They are designed for the removal of particulates from indoor air using

FILXXFNC00(14, 17, 21, 24) media filter cartridges. These fan coil media filter cartridge kits are designed for the removal of particles

from indoor air. The cartridge is installed in the return air duct next to the air handler or further upstream.

SUGGESTED USE: All fan coils.

9. Condensate Drain Trap Kit

This kit consists of 50 PVC condensate traps. Each trap is pre--formed and ready for field installation. This deep trap helps the system

make and hold proper condensate flow even during blower initiation.

SUGGESTED USE: All fan coils.

10. Air Cleaner 240--volt Conversion Kit

The AIRA electronic air cleaner comes ready for 115--v operation.

REQUIRED USE: This kit is required when running 240--volt circuit to air cleaner.

11. Standard Filter Rack Kit

This kit mounts in fan coil filter rack area and modifies the existing filter rack to support standard 1--in. filter sizes.

SUGGESTED USE: Fan coils using standard filter sizes.

E2014 Bryant Heating & Cooling Systems D 7310 W. Mo rris St. D Indianapolis, IN 46231 Edition Date: 02/14 U.S. Export Classification: EAR99.

Manufacturer reserves the right to dis continue, or change at any time, specifications or designs without notice and without incurring obligations.

18

Catalog No. PDSFB4CNF--- 08

Replaces: PDSFB4CNF---07

Loading...

Loading...