Page 1

FFMA

Base Series Fan Coil

Sizes 018 thru 037

Product Data

The FFMA Series Fan Coil unit is primarily designed for

apartment applications as an upflow only indoor fan coil for

split--system heat pumps for use with Puron refrigerant.

Accessory field--installed electric heat kits are available in 5, 7.5 or

10 kW sizes. The 018, 024, 030, and 036 size units use a piston

refrigerant metering device. The 019, 025, 031 and 037 size units

come equipped with a TXV. All unit sizes are factory--configured

for Puron refrigerant. However, they can be used for R--22

applications with the addition of an accessory R--22 TXV kit.

This fan coil may be installed in a frame mount or wall hung

applications. The cabinet sizes allow units to fit between standard

stud spacings. No return--air ductwork is required if the application

provides for return air in the front of the cabinet through a louvered

closet door or optional louvered wall panel. This unit is field

convertible to bottom return without the need for an additional

accessory kit.

The cabinet exterior is made of galvanized sheet metal and is sealed

to limit cabinet air leakage to 2% when tested at 1.0 inches of static

pressure and 1.4% when tested at 0.5 inches of static pressure. The

cabinet is fully insulated to meet applications in conditioned space.

This unit is not approved for installation in unconditioned spaces.

The FFMA 018, 024, 030, and 036 sizes use a 3--speed PSC motor.

The FFMA 019, 025, 031, and 037 sizes use a 5--speed multi--tap

ECM motor for efficiency. Motors are suspended at three points

on rubber grommets for quieter operation. Coils are tin--plated

copper tube, aluminum fin.

Refrigerant lines and thermostat low voltage connections are made

through the top while the high voltage connections are made from

either the right, left or top side of the fan coil. Sweat--type

refrigerant connections on both liquid and vapor lines make for

swift, low--cost installation. All service access to the unit is

conveniently located in the front.

A13417

Primary and secondary drain connections exit from the bottom or

either side of the cabinet. Fresh air intake holes measuring 3.4” (35

mm) are located on each side of the unit cabinet and come capped

from the factory.

FEATURES

Page 2

MODEL NUMBER NOMENCLATURE

123456789101112

FFMANP018T00

Product

F=FanCoil Heating Size

0 0 = N o F a c t o r y --- I n s t a l l e d

Type Electric Heat

F = T h r u --- t h e --- Wa l l

Tube Ty p e

Position 0 = Copper

M=Upflow/Apartment T=TinPlate

Series

A

Electrical Capacity

N = 208/230v, 1ph--- 60 Hz 018, 019 = 18,000

024, 025 = 24,000

Refrigerant 030, 031 = 30,000

P=Puron (R---410A)

036, 037 = 36,000

the environmentally sound refrigerant

Use of the AHRI Certified

TM Mark indicates a

manufacturer’s

participation in the

program For verification

of certification for individual

products, go to

www.ahridirectory.org.

2

Page 3

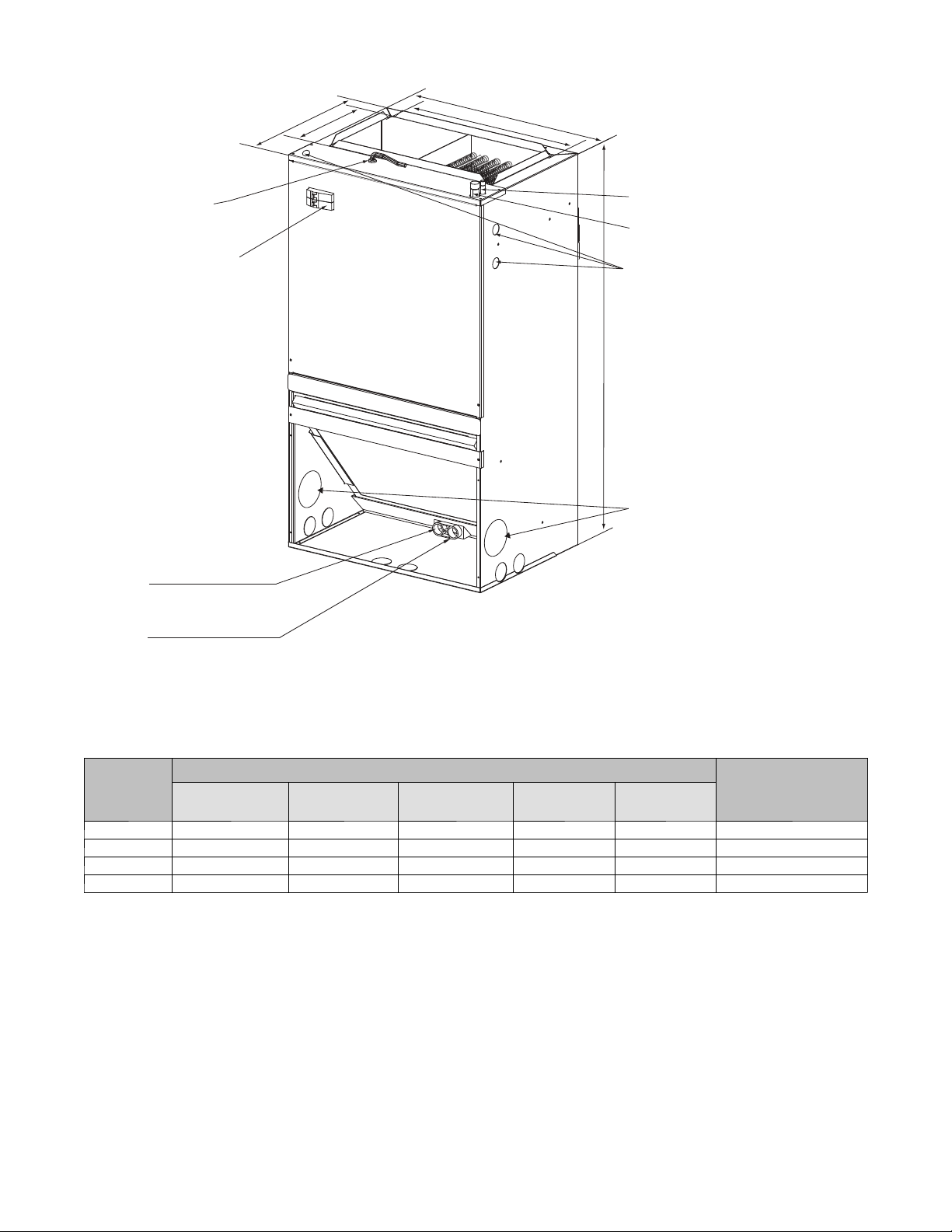

DIMENSIONS

Low voltage

connection

Breaker switch

(comes with accessory

electric heater only)

Front return shown. Units

may also be installed as

bottom return. See the

applications section for

more detail.

Primary drain connection

3/4” (19 mm) female

pipe thread (fpt)

D

D1

Return air opening

W

W1

Liquid line connection

copper (sweat)

Vapor line connection

copper (sweat)

High voltage connection

7/8” (22 mm) dia

knock outs

(both sides of unit)

Some heater sizes may

require a conduit larger than

H

the 7/8” (22 mm) opening;

in this situation the high-voltage

connection opening should be

enlarged to fit conduit.

Fresh air intakes,

3.4” (85.8 mm) dia

opening with

plastic cap

Auxiliary drain connection

3/4” (19 mm) female

pipe thread (fpt)

NOTE: Hand tighten only

All units are vertical upflow only.

Equipment shown with field-installed electric heat.

Fig. 1 -- Dimensional Drawing with Circuit Breaker

DIMENSIONAL DATA

Dimensions- In. (mm)

Model Size

18, 19 36-1/2 (928) 20-1/2 (521) 17-2/5 (452) 15 (381) 9-1/2 (242) 88 / 99 (40 / 45)

24, 25 36-1/2 (928) 20-1/2 (521) 17-2/5 (452) 15 (381) 9-1/2 (242) 88 / 99 (40 / 45)

30, 31 39-1/2 (1004) 22 (559) 18-4/5 (478) 19 (483) 9-1/2 (242) 110/ 121 (50 / 55)

36, 37 39-1/2 (1004) 22 (559) 18-4/5 (478) 19 (483) 9-1/2 (242) 110/ 121 (50 / 55)

Unit He ight

H

Unit Width

W

Unit Width

W1

Unit Depth

D

Unit Depth

D1

Unit Weight /

Shipping Weight

Lbs. (kg)

A150161

3

Page 4

SPECIFICATIONS

Unit Size

FFMANP0 18 24 30 36

Nominal Cooling Capacity (BTUH) 18,000 24,000 30,000 36,000

COIL

Puron- Refrigerant metering Device * (Piston) 50 57 65 72

Fins Per In. 17 17 17 17

Face Area Ft

Coil Configuration Slope

BLOWER & MOTOR

Air Discharge Upflow

Blower Type Direct Drive

CFM (Nominal) 600 800 1000 1200

Motor Type PSC PSC PSC PSC

Motor HP 1/6 1/4 1/3 1/2

Rated RPM 1075 1075 1075 1075

Motor Speeds 3 3 3 3

FILTER

Field Installed

CONNECTIONS (Sweat)

Suction --- in. (mm) 3/4 In. (19 mm)

Liquid --- in. (mm) 3/8 In. (9.5 mm)

Condensate (FPT) In. (mm) 3/4 In. (19 mm)

ELECTRICAL DATA

Voltage 208/230 208/230 208/230 208/230

Hertz 60 60 60 60

Circuit Amps 0.8 1.0 1.28 1.8

Minimum Circuit Ampacity 1 1.3 1.6 2.3

Maximum Circuit Protector 15 (A) 15 (A) 15 (A) 15 (A)

2

2.1 2.1 3.0 3.0

16x20x1

(406x508x25)

16x20x1

(406x508x25)

20x20x1

(508x508x25)

20x20x1

(508x508x25)

* The piston included with the fan coil is unique to this product and CANNOT be replaced with the piston shipped with outdoor unit. Refer to the AHRI ratings

to check if your combination can use the piston shipped with the unit or requires an accessory TXV.

Unit Size

FFMANP0 19 25 31 37

Nominal Cooling Capacity (BTUH) 18,000 24,000 30,000 36,000

COIL

Puron- Refrigerant metering Device TXV

Fins Per In. 17 17 17 17

Face Area Ft

Coil Configuration Slope

BLOWER & MOTOR

Air Discharge Upflow

Blower Type Direct Drive

CFM (Nominal) 600 800 1000 1200

Motor Type ECM ECM ECM ECM

Motor HP 1/3 1/3 1/2 1/2

Rated RPM 1050 1050 1050 1050

Motor Speeds 5 5 5 5

FILTER

Field Installed

CONNECTIONS (Sweat)

Suction --- in. (mm) 3/4 In. (19 mm)

Liquid --- in. (mm) 3/8 In. (9.5 mm)

Condensate (FPT) In. (mm) 3/4 In. (19 mm)

ELECTRICAL DATA

Voltage 208/230 208/230 208/230 208/230

Hertz 60 60 60 60

Circuit Amps 1.9 1.9 2.7 2.7

Minimum Circuit Ampacity 2.4 2.4 3.4 3.4

Maximum Circuit Protector 15 (A) 15 (A) 15 (A) 15 (A)

2

2.1 2.1 3.0 3.0

16x20x1

(406x508x25)

16x20x1

(406x508x25)

20x20x1

(508x508x25)

20x20x1

(508x508x25)

4

Page 5

PERFORMANCE DATA

PSC-- AIRFLOW PERFORMANCE (STANDARD CFM)

MODEL

SIZE

18

24

30

36

--- Shaded boxes represent airflow ou tside the required 300-450 cfm/ton.

NOTES:

1. Airflow based upon dry coil at 230V with no electric heat and fa ctory --- approved filter.

2. Airflow is equivalent for front or bottom return configurations.

BLOWER

SPEEDS

High 776 733 695 653 610 564 525 464

Med 661 624 585 546 502 454 415 354

Low 565 529 487 448 405 353 299 244

High 917 881 830 790 739 687 631 564

Med 819 785 745 703 654 604 544 480

Low 668 631 591 551 506 464 403 343

High 1236 1176 1115 1064 1000 936 861 793

Med 1113 1065 1014 962 908 842 772 701

Low 935 894 852 807 755 694 631 561

High 1350 1292 1228 1167 1108 1045 981 902

Med 1266 1198 1139 1088 1029 970 905 831

Low 1115 1066 1015 966 918 861 801 722

0 0.1 0.2 0.3 0.4 0.5 0.6 0.7

ECM AIRFLOW PERFORMANCE (STANDARD CFM)

MODEL SIZE BLOWER SPEEDS

Tap ( 5 ) 884 854 833 803 771 737 700 668 632

Tap ( 4 ) 796 767 737 709 675 645 612 579 538

19

25

31

37

--- Shaded boxes represent airflow ou tside the required 300-450 cfm/ton.

NOTES:

1. Airflow based upon dry coil at 230V with no electric heat and factory---approved filter. For 19, 25, 31 and 37 sizes, a irflow at 208V is approximately the same

as 230V because the multi--- tap ECM motor is a constant torque motor. The torque doesn’t drop off at the speeds in which the motor operates.

2. Airflow is equivalent for front or bottom return configurations.

Tap ( 3 ) 714 681 654 616 588 555 527 494 459

Tap ( 2 ) - Fa c t o r y 653 619 584 558 525 494 463 434 396

Tap ( 1 ) 581 545 511 472 440 407 374 344 329

Tap ( 5 ) 884 854 833 803 771 737 700 668 632

Tap ( 4 ) - Fa c t o r y 796 767 737 709 675 645 612 579 538

Tap ( 3 ) 714 681 654 616 588 555 527 494 459

Tap ( 2 ) 653 619 584 558 525 494 463 434 396

Tap ( 1 ) 581 545 511 472 440 407 374 344 329

Tap ( 5 ) 1309 1272 1236 1200 1164 1125 1088 1051 1010

Tap ( 4 ) 1122 1088 1056 1022 986 950 915 877 836

Tap ( 3 ) 1109 1073 1038 1003 973 937 901 867 828

Tap ( 2 ) - Fa c t o r y 1010 975 941 904 869 835 793 751 704

Tap ( 1 ) 936 899 862 833 793 755 710 664 619

Tap ( 5 ) 1309 1272 1236 1200 1164 1125 1088 1051 1010

Tap ( 4 ) - Fa c t o r y 1122 1088 1056 1022 986 950 915 877 836

Tap ( 3 ) 1109 1073 1038 1003 973 937 901 867 828

Tap ( 2 ) 1010 975 941 904 869 835 793 751 704

Tap ( 1 ) 936 899 862 833 793 755 710 664 619

0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8

EXTERNAL STATIC PRESSURE (In. W.C.)

EXTERNAL STATIC PRESSURE (IN WC.)

AIRFLOW PERFORMANCE (CFM)

Size Min Max

18 / 19 450 675

24 / 25 600 900

30 / 31 750 1125

36 / 37 900 1350

CFM

5

Page 6

PERFORMANCE DATA (CONT.)

GROSS COOLING CAPACITIES (mbh)

UNIT

SIZE

18 /

19

24 /

25

30 /

31

36 /

37

CFM --- C u b i c F t p e r M i n u t e EWB --- Entering Wet Bulb _F(_C) LWB --- L e a v in g W e t B u l b _F(_C) TC --- Gross Cooling Ca pacity 1000 Btuh

SHC --- Gross Sen sible Capacity 1000

Btuh

NOTES:

INDOOR

COIL AIR

CFM EWB TC SHC BF TC SHC BF TC SHC BF TC SHC BF TC SHC BF

72 (22) 38 18 0.00 35 17 0.00 31 15 0.00 27 14 0.00 22 12 0.00

67 (19) 32 19 0.00 28 18 0.00 25 16 0.00 20 14 0.00 15 12 0.00

525

62 (17) 26 20 0.00 22 18 0.00 19 17 0.01 15 15 0.07 13 13 0.21

72 (22) 42 20 0.00 38 18 0.00 34 17 0.00 30 15 0.00 24 13 0.00

67 (19) 34 21 0.00 31 19 0.00 26 17 0.00 22 16 0.00 17 14 0.01

600

62 (17) 28 22 0.01 24 20 0.01 20 19 0.01 17 17 0.08 14 14 0.22

72 (22) 45 21 0.00 41 20 0.00 37 18 0.00 32 16 0.00 26 14 0.00

67 (19) 37 23 0.01 33 21 0.01 29 19 0.01 24 17 0.01 18 15 0.01

675

62 (17) 30 24 0.01 26 22 0.01 22 20 0.01 19 19 0.10 16 16 0.24

72 (22) 46 22 0.00 43 20 0.00 38 19 0.00 33 17 0.00 27 15 0.00

67 (19) 38 24 0.01 35 22 0.01 30 20 0.01 25 18 0.01 19 16 0.01

700

62 (17) 31 25 0.01 27 24 0.01 23 22 0.02 20 20 0.11 17 17 0.24

72 (22) 50 24 0.00 46 22 0.00 41 20 0.01 36 18 0.01 30 16 0.01

67 (19) 41 26 0.01 37 24 0.01 32 22 0.01 27 20 0.01 21 18 0.02

800

62 (17) 34 28 0.01 30 26 0.01 25 25 0.03 22 22 0.14 19 19 0.26

72 (22) 53 25 0.01 48 24 0.01 44 22 0.01 38 20 0.01 32 17 0.01

67 (19) 44 28 0.01 39 26 0.01 34 24 0.01 29 22 0.02 22 19 0.02

900

62 (17) 36 30 0.02 32 28 0.02 27 27 0.05 24 24 0.16 21 21 0.28

72 (22) 67 33 0.00 61 30 0.00 54 27 0.00 46 23 0.00 37 20 0.00

67 (19) 55 34 0.01 49 31 0.01 41 28 0.01 33 24 0.01 23 20 0.01

875

62 (17) 44 35 0.01 38 32 0.01 30 28 0.01 24 24 0.07 20 20 0.23

72 (22) 74 37 0.00 67 33 0.00 59 30 0.00 50 26 0.00 40 22 0.01

67 (19) 61 38 0.01 54 34 0.01 46 31 0.01 37 27 0.01 25 22 0.01

1000

62 (17) 49 39 0.01 42 35 0.01 34 31 0.02 27 27 0.08 22 22 0.24

72 (22) 79 39 0.00 72 36 0.00 63 32 0.01 54 28 0.01 43 24 0.01

67 (19) 65 41 0.01 57 37 0.01 49 33 0.01 39 29 0.01 28 24 0.02

1100

62 (17) 52 42 0.02 45 38 0.02 36 34 0.02 29 29 0.09 24 24 0.25

72 (22) 73 36 0.00 67 33 0.00 59 29 0.01 51 26 0.01 41 22 0.01

67 (19) 60 38 0.01 54 34 0.01 46 31 0.01 37 27 0.01 27 23 0.02

1050

62 (17) 49 39 0.01 42 36 0.01 34 32 0.02 28 28 0.09 23 23 0.24

72 (22) 80 39 0.00 73 36 0.00 65 32 0.01 55 28 0.01 45 24 0.01

67 (19) 66 41 0.02 58 38 0.02 50 34 0.02 41 30 0.02 30 26 0.02

1200

62 (17) 53 43 0.02 46 40 0.02 38 36 0.02 32 32 0.11 26 26 0.25

72 (22) 85 42 0.00 78 39 0.01 69 35 0.01 59 31 0.02 48 27 0.02

67 (19) 71 45 0.02 63 41 0.02 54 37 0.02 44 33 0.02 32 28 0.03

1350

62 (17) 57 47 0.02 49 44 0.02 41 39 0.03 35 35 0.12 29 29 0.26

35 (2) 40 (4) 45 (7) 50 (10) 55 (13)

BF --- B y pa s s F a c to r MBH --- 1000 Btuh

1. Contact manufacturer for cooling capacities at conditions

other than shown in table.

2. Formulas:

Leaving db = entering db --sensible heat cap.

Leaving wb = wb corresponding to enthalpy of air leaving

coil (h

h

)

lwb

lwb=hewb

--total capacity (Btuh)

4.5xCFM

where h

= enthalpy of air entering coil. Direct interpola-

ewb

tion is permissible. Do not extrapolate.

3. SHC is based on 80_F(27_C) db temperature of air enter-

ing coil. Below 80_F(27_C) db, subtract (Correction Fact-

or x CFM) from SHC. Above 80_F(27_C) db, add (Cor-

rectionFactorxCFM)toSHC.

4. Bypass Factor = 0 indicates no psychometric solution. Use

bypass factor of next lower EWB for approximation.

SATURATED TEMPERATURE LEAVING EVAPORATOR _F(_C)

SHC CORRECTION FACTOR

ENTERING AIR DRY -- BULB TEMPERATURE (_F)

79 78 77 76 75 Under 75

81 82 83 84 85 Over 85

ENTERING AIR DRY -- BULB TEMPERATURE (_C)

26 25 25 24 24 Under 75

27 28 28 29 29 Over 85

1.09 x CFM

BYPASS

FACTOR

0.10 .098 1.96 2.94 3.92 4.91

0.20 0.87 1.74 2.62 3.49 4.36

0.30 0.76 1.53 2.29 3.05 3.82

Interpolation is permissible.

Correction Factor = 1.09 x (1 --- BF) x (db --- 80)

Correction Factor

Use

formula

shown

below

6

Page 7

PERFORMANCE DATA (CONT.)

ESTIMATED SOUND POWER LEVEL (dBA)

CONDITIONS OCTAVE BAND CENTER FREQUENCY

UNIT SIZE

18, 19 600 0.25 46 52.1 48.9 51.8 52.5 51.7 49.7

24, 25 800 0.25 54.1 57.1 58.6 59 61.5 59.8 57

30, 31 1000 0.25 51.6 52.6 52.6 53.3 56.1 52.8 59.7

36, 37 1200 0.25 52.6 52.3 54.6 54.3 57.2 53.8 50.4

* Estimated sound power levelshave been derived using the method described in the 1987 ASHRAE HVAC Systems & Applications Handbook,Chapter 52,p. 52.7.

ELECTRICAL DATA FOR FFMANP(018,024,030,036) PSC MOTOR UNITS WITH ELECTRIC HEAT

Heat

Kit

Model

EHK2-05B

EHK2-08B 7.5 22.2 25.6 34.9 40.1 50 50 8 8 10 10 76 77

EHK2-10B 10 24.6 32.8 46.2 53.1 60 60 6 6 10 10 92 92

EHK2-05B

EHK2-08B 7.5 22.2 25.6 35.2 40.4 50 50 8 8 10 10 76 76

EHK2-10B 10 24.6 32.8 46.4 53.4 60 60 6 6 10 10 91 92

EHK2-05B

EHK2-08B 7.5 22.2 25.6 35.5 40.7 50 50 8 8 10 10 75 76

EHK2-10B 10 24.6 32.8 46.8 53.7 60 60 6 6 10 10 91 91

EHK2-05B

EHK2-08B 7.5 22.2 25.6 36.2 41.4 50 50 8 8 10 10 74 74

EHK2-10B 10 24.6 32.8 47.4 54.4 60 60 6 6 10 10 90 90

* †† Copper wire must be used. If other than uncoated (non ---plated), 75_C ambient, copper wire (solid wire for 10 AWG and smaller, stranded wire for larger

than 10 AWG) is used, consult applicable tables of the National electric Code (ANSI/NGPA 70).

* ‡‡ Length shown is as measured 1 way along wire path between unit and service panel for a voltage drop not to exceed 2%.

CFM Ext Static Pressure 63 125 250 500 1000 2000 4000

MAX. Fuse

or Breaker

H e a t --- K i t

Ampacity

(HACR)

Min Wire

Size

(AWG) ††

Min Ground

Wire Size

Max Wire

Length (Ft)

‡‡

Used

on

Size

018

024

030

036

Nominal

Heat

Capacity

@ 240V

KW lbs. (kg) 208 240 208 240 208 240 208 240 208 240 208 240

5

5

5

5

Ship-

ping

Weight

5.1 (2.3)

5.1 (2.3)

5.1 (2.3)

5.1 (2.3)

Heater

Capacity

(MBH)

12.3 16.4 23.6 27.1 30 30 10 10 10 10 73 74

12.3 16.4 23.9 27.3 30 30 10 10 10 10 73 73

12.3 16.4 24.2 27.7 30 30 10 10 10 10 72 72

12.3 16.4 24.9 28.3 30 30 10 10 10 10 70 71

Minimum

Circuit

Ampacity

(MCA)

ELECTRICAL DATA FOR FFMANP(019,025,031,037) ECM MOTOR UNITS WITH ELECTRIC HEAT

Nominal

Heat

Kit

Model

EHK2-05B

EHK2-08B 7.5 22.2 25.6 36.3 41.5 50 50 8 8 10 10 73 74

EHK2-10B 10 24.6 32.8 47.6 54.5 60 60 6 6 10 10 89 90

EHK2-05B

EHK2-08B 7.5 22.2 25.6 36.3 41.5 50 50 8 8 10 10 73 74

EHK2-10B 10 24.6 32.8 47.6 54.5 60 60 6 6 10 10 89 90

EHK2-05B

EHK2-08B 7.5 22.2 25.6 37.3 42.5 50 50 8 8 10 10 71 72

EHK2-10B 10 24.6 32.8 48.6 55.5 60 60 6 6 10 10 87 88

EHK2-05B

EHK2-08B 7.5 22.2 25.6 37.3 42.5 50 50 8 8 10 10 71 72

EHK2-10B 10 24.6 32.8 48.6 55.5 60 60 6 6 10 10 87 88

* †† Copper wire must be used. If other than uncoated (non ---plated), 75_C ambient, copper wire (solid wire for 10 AWG and smaller, stranded wire for larger

than 10 AWG) is used, consult applicable tables of the National electric Code (ANSI/NGPA 70).

* ‡‡ Length shown is as measured 1 way along wire path between unit and service panel for a voltage drop not to exceed 2%.

Used

on

Size

019

025

031

037

Heat

Capacity

@ 240V

KW lbs. (kg) 208 240 208 240 208 240 208 240 208 240 208 240

5

5

5

5

Ship-

ping

Weight

5.1 (2.3)

5.1 (2.3)

5.1 (2.3)

5.1 (2.3)

Heater

Capacity

(MBH)

12.3 16.4 25 28.5 30 30 10 10 10 10 69 70

12.3 16.4 25 28.5 30 30 10 10 10 10 69 70

12.3 16.4 26 29.5 30 30 10 10 10 10 67 68

12.3 16.4 26 29.5 30 30 10 10 10 10 67 68

Minimum

Circuit

Ampacity

(MCA)

MAX. Fuse

or Breaker

H e a t --- K i t

Ampacity

(HACR)

Min Wire

Size

(AWG) ††

Min Ground

Wire Size

Max Wire

Length (Ft)

‡‡

7

Page 8

OTHER ACCESSORIES

Kit Number Description Used on sizes

KFBLG0106LGL Louvered Wall Panel with Frame (6 pack) 18, 19, 24, 25

KFBLG0206LGL Louvered Wall Panel with Frame (6 pack) 30, 31, 36, 37

KSATX0601HSO TXV Kit R-22 All

KSATX201PUR TXV Kit Puron (R-410A) 18, 19, 24, 25, 30, 31

KSATX301PUR TXV Kit Puron (R-401A) 36, 37

KFAET0150ETK PVC Condensate Trap Kit (50 pack) All

KFARA0110LGL Return Air Opening Grille (10 pack) 18, 19, 24, 25

KFARA0210LGL Return Air Opening Grille (10 pack) 30, 31, 36, 37

Copyright 2016 Carrier Corp. D 7310 W. Morris St. D Indianapolis, IN 46231 Edition Date: 01/16

Manufacturer reserves the right to change, at any time, specifications and designs without notice and without obligations.

8

Catalog No:FFMA--- 05PD

Replaces: FFMA ---04PD

Loading...

Loading...