Bryant-Carrier FFMA Installation Manual

FFMA

WALL MOUNT

FAN COIL UNIT

Installation Instructions

NOTE: Read the entire instruction manual before starting

installation.

TABLE OF CONTENTS

PAGE

SAFETY CONSIDERATIONS 1.........................

INTRODUCTION 1...................................

INSTALLATION 2....................................

Step 1 — Check Equipment 2...........................

Step 2 — Mount Fan Coil 2............................

Step 3 — Ductwork Specifications 4.....................

Step 4 — Condensate Drain 4...........................

Step 5 — Electrical Connections 4.......................

Step 6 — Select Proper Blower Speed 5...................

Step7—TXV 6....................................

START--UP 6.........................................

SEQUENCE OF OPERATION 6.........................

CARE AND MAINTENANCE 6.........................

AIRFLOW PERFORMANCE TABLES 7..................

SAFETY CONSIDERATIONS

Improper installation, adjustment, alteration, service, maintenance,

or use can cause explosion, fire, electrical shock, or other

conditions which may cause death, personal injury or property

damage. Consult a qualified installer, service agency, or your

distributor or branch for information or assistance. The qualified

installer or agency must use factory--authorized kits or accessories

when modifying this product. Refer to individual instructions

packaged with kits or accessories when installing.

Follow all safety codes. Wear safety glasses, protective clothing,

and work gloves. Use quenching cloth for brazing operations.

Have a fire extinguisher available. Read these instructions

thoroughly and follow all warning or cautions included in literature

and attached to the unit. Consult local building codes and the

current editions of the National Electrical Code (NEC) NFPA 70.

In Canada, refer to the current editions of Canadian Electrical Code

CSA C22.1.

Recognize safety information. This is the safety alert symbol

When you see this symbol on the unit and in instructions or

manuals, be alert to the potential for personal injury. Understand

the signal words DANGER, WARNING,andCAUTION.These

words are used with the safety alert symbol. DANGER identifies

the most serious hazards which will result in severe personal injury

or death. WARNING signifies hazards which could result in

personal injury or death. CAUTION is used to identify unsafe

practices, which may result in minor personal injury or product

and property damage. NOTE is used to highlight suggestions

which will result in enhanced installation, reliability, or operation.

INTRODUCTION

FFMA Fan Coils are designed with application flexibility in mind

and are suitable for closet and flush mount installations. The

FFMA is available with field--installed heat with circuit breaker.

Units are used indoors as the fan coil for split--system heat pumps

or air conditioners. The FFMA uses a refrigerant piston metering

device (018, 024, 030, and 036) and TXV (019, 025, 031, 037).

The FFMA also uses a 3 Speed PSC Motor (018, 024, 030, and

036) and a 5 speed multi--tap ECM motor for efficiency (019, 025,

031, 037). Units are available in 18,000 through 36,000 Btuh

nominal cooling capacities.

Field--installed heaters are available in 5, 7.5, and 10 kW sizes. The

coil is equipped with sweat--type connections and is vapor--charged

with dry nitrogen. The casing is fully insulated to meet applications

in conditioned space. Additional insulation is required if the unit is

installed in unconditioned space.

Units are designed for upflow applications only. Local codes may

limit this free--air--return type unit to installation in single--level

applications.

NOTE: Nuisance sweating may occur if the unit is installed in a

humid location with low airflow.

!

WARNING

ELECTRICAL OPERATION HAZARD

Failure to follow this warning could result in personal injury

or death.

Before installing or servicing unit, always turn off all power to

unit. There may be more than 1 disconnect switch. Turn off

accessory heater power if applicable. Lock out and tag switch

with a suitable warning label.

!

WARNING

EXPLOSION HAZARD

Failure to follow this warning could

result in death, serious personal injury,

and/or property damage.

Never use air or gases containing

.

!

CUT HAZARD

Failure to follow this caution may result in personal injury.

Sheet metal parts may have sharp edges or burrs. Use care and

wear appropriate protective clothing and gloves when handling

parts.

oxygen for leak testing or operating

refrigerant compressors. Pressurized

mixtures of air or gases containing

oxygen can lead to an explosion.

CAUTION

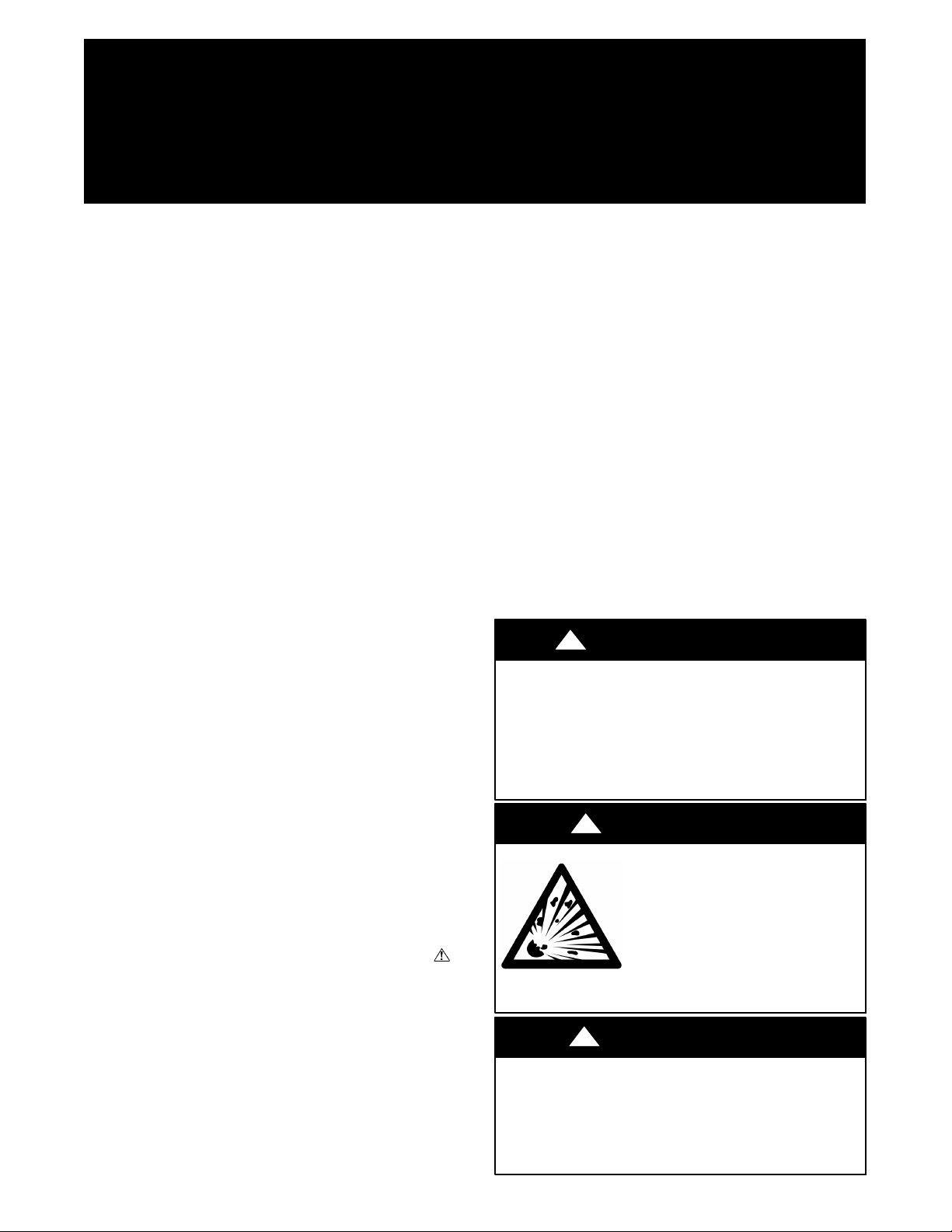

D

D1

W

W1

Low voltage

connection

Breaker switch

(comes with accessory

electric heater only)

Front return shown. Units

may also be installed as

bottom return. See the

applications section for

more detail.

Primary drain connection

3/4” (19 mm) female

pipe thread (fpt)

Auxiliary drain connection

3/4” (19 mm) female

pipe thread (fpt)

NOTE: Hand tighten only

Return air opening

All units are vertical upflow only.

Equipment shown with field-installed electric heat.

Liquid line connection

copper (sweat)

Vapor line connection

copper (sweat)

High voltage connection

7/8” (22 mm) dia

knock outs

(both sides of unit)

Some heater sizes may

require a conduit larger than

H

the 7/8” (22 mm) opening;

in this situation the high-voltage

connection opening should be

enlarged to fit conduit.

Fresh air intakes,

3.4” (85.8 mm) dia

opening with

plastic cap

Fig. 1 -- Dimensional Drawing with Circuit Breaker

Table 1 – Dimensional Data

Dimensions- In. (mm)

Model Size

Unit H eight

H

Unit Width

W

Unit Width

W1

Unit Depth

D

Unit Depth

D1

18, 19 36-1/2 (928) 20-1/2 (521) 17-4/5 (452) 15 (381) 9-1/2 (242) 88 / 99 (40 / 45)

24, 25 36-1/2 (928) 20-1/2 (521) 17-4/5 (452) 15 (381) 9-1/2 (242) 88 / 99 (40 / 45)

30, 31 39-1/2 (1004) 22 (559) 18-4/5 (478) 19 (483) 9-1/2 (242) 110/ 121 (50 / 55)

36, 37 39-1/2 (1004) 22 (559) 18-4/5 (478) 19 (483) 9-1/2 (242) 110/ 121 (50 / 55)

INSTALLATION

Step 1 — Check Equipment

Unpack unit and move to final location. Remove carton, taking

care not to damage unit. Remove protective sheet metal from the

base of the unit, if equipped. Inspect equipment for damage prior to

Failure to do this will result in condensate leaking out from the

unit, potentially causing structural damage to the surrounding

support structures, drywall, carpet, etc. around the unit. Also, both

mounting structures require the ability to accommodate a minimum

of load of 150 pounds. Failure to do this will cause damage to the

support structure and potentially damage the unit.

Unit Weight /

Shipping Weight

Lbs. (kg)

installation. File claim with shipping company if shipment is

damaged or incomplete. Locate rating plate on unit. It contains

information needed to properly install unit. Check rating plate to be

sure unit matches job specifications. A front access panel is

provided, which permits access to blower assembly and electrical

controls for removal and servicing.

NOTE: Minimum clearance of 21” (533 mm) is required in front

of access panel for servicing only. Installation clearance from

combustible materials is 0” (0 mm) from cabinet and supply--air

duct (plenum included). Ensure there is adequate space on top of

unit for refrigerant line connections and on bottom of unit for

condensate trap. (See Fig. 1 and 2.)

Step 2 — Mount Fan Coil

Fan coil Mounting Options

The fan coil comes standard with two different options for

mounting: wall mount or frame mount. Both mounting options

require the unit to be level from side to side and from front to back

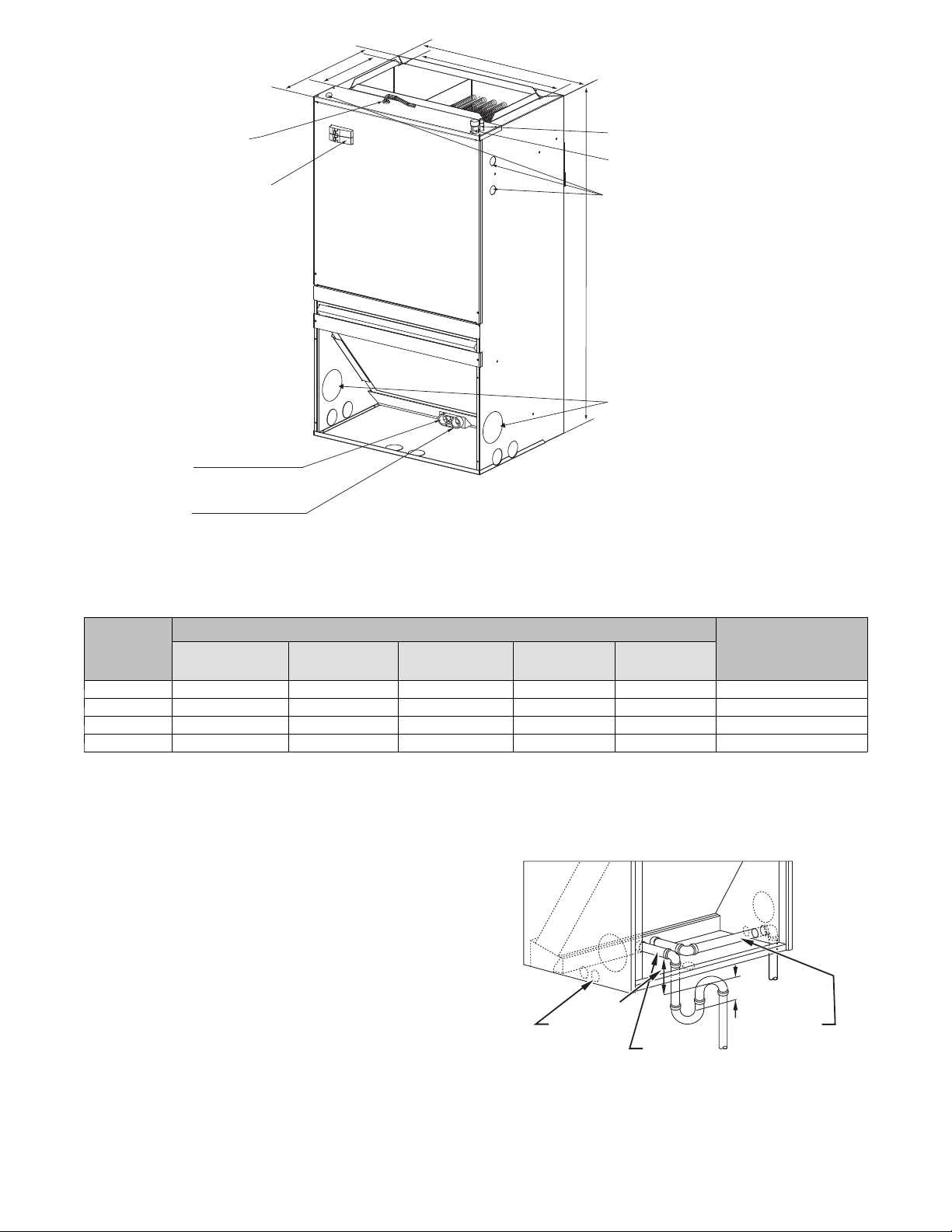

2" / 51mm

MIN

ALTERNATE

DRAIN EXITS ON

EITHER SIDE OF UNIT

Fig. 2 -- Condensate Drain

PRIMARY

DRAIN

NOTE: Use plastic pipe from

condensate pan to

exterior of fan coil.

2" / 51mm

MIN DRAIN

SECONDARY

(TRAP EXTERNAL

in order to allow condensate to properly drain from the unit.

A150162

DRAIN

TO UNIT)

A13011

2

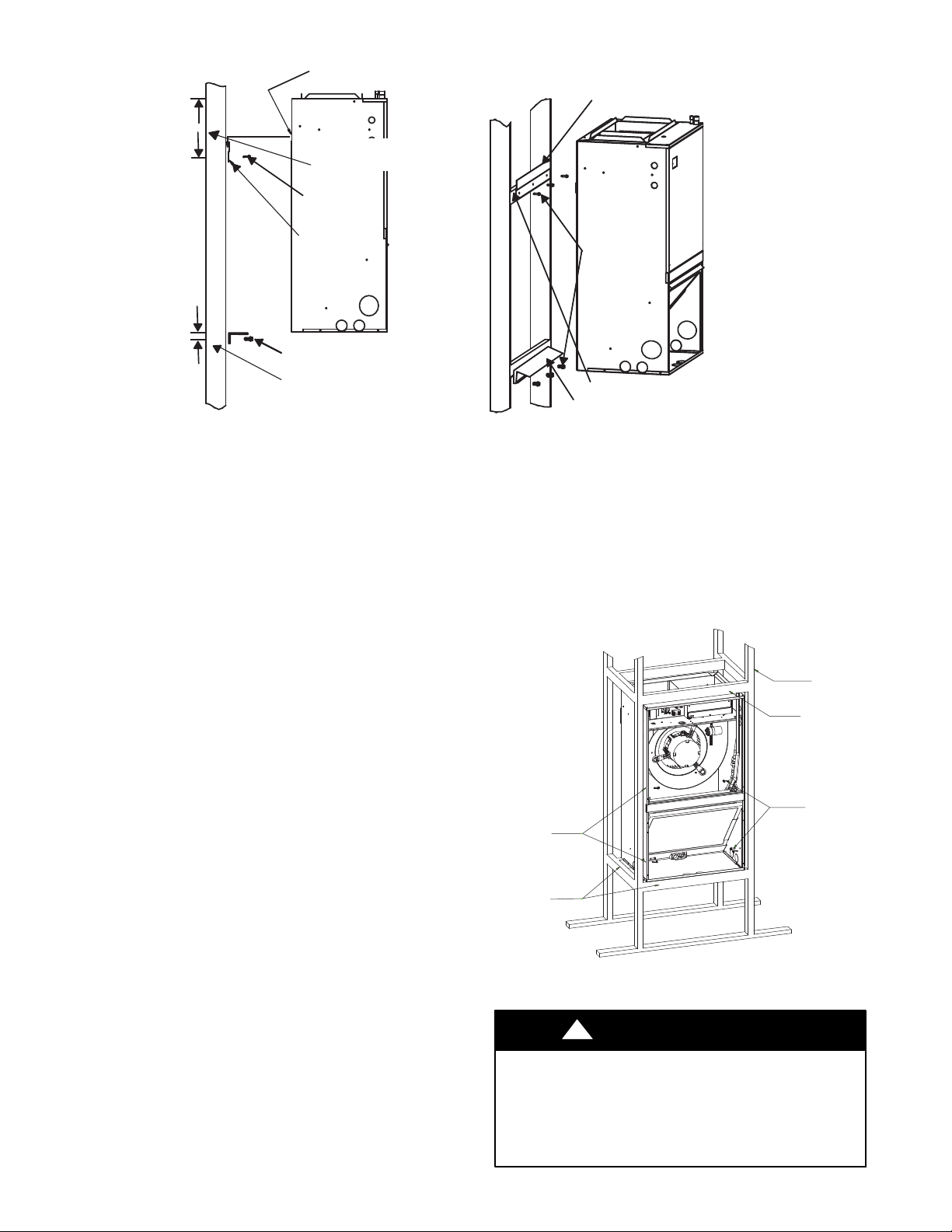

PROVIDED FANïCOIL

MOUNT

BRACKET

WALL BRACKET SCREW HOLES

ARE

LOCATED 9” (229 MM) FROM

TOP OF THE UNIT

THE

WOOD

SCREWS

PROVIDED

MOUNT

WALL

BRACKET

WOOD

SCREWS

WALL BRACKET SCREW HOLES

ARE

LOCATED 1” (25 MM) BELOW

BOTTOM OF THE UNIT

THE

NOTE: Mounting wall and supporting structure must be able to support a minimum of 150 lbs (68 kg).

Fig. 3 -- Wall Mount Installation

Wall Mount

The fan coil comes standard with a wall mounting bracket and fan

coil mounting bracket. Reference Fig. 3 for more detail.

1. Remove the wall mounting bracket from the back of the

unit by removing one screw which attaches the bracket to

the fan coil.

NOTE: Discard the screw after you have removed the wall

mounting bracket.

2. Install bracket on the wall by using three wood screws (not

provided) per wall--mount bracket. Make sure the bracket is

level in order to provide proper drainage from the unit.

NOTE: Do not attach the wall mounting bracket into unsupported

drywall. Make sure that the wood screws are going into a structure

that can support a minimum load of 150 pounds.

3. Lift the fan coil above the wall mounting bracket and attach

the unit to the installed bracket. Reference Fig. 3.

Frame Mount

The fan coil comes with eight clearance holes, four on each side.

These holes are used to mount the fan coil inside a frame structure

(see Fig. 4). When mounting in this fashion, make sure that the

wood screws are mounted from within the fan coil and not outside

of the unit. Installing the screws from outside of the unit may

damage the coil.

After moving unit into place, install refrigerant tubing as

follows:

1. Route tubing to connection points, taking care not to block

service access.

2. Remove plugs from liquid and vapor lines.

3. Braze connections using either silver bearing or non--silver

bearing brazing material. Do not use soft solder (materials

which melt below 800_F / 427_C). Consult local code

requirements. Always flow nitrogen through the system

refrigerant lines while brazing.

4. Pressurize system and leak--test. Repeat procedure until

leak--free.

NOTE: Model sizes 018, 024, 030 and 036 are shipped with a

piston metering device designed for the most common outdoor unit

PROVIDED WALL

MOUNT BRACKET

WOOD

SCREWS

SUPPORTING

(51

X

WALL MOUNT BRACKET FOR USE

WITH 30 AND 36 SIZE MODELS,

PROVIDED ON THOSE SIZES.

2” X

102 MM) STRUCTURE

4”

L14S011

matches. The piston included with the fan coil is unique to this

product and cannot be replaced with the piston shipped with the

outdoor unit. Refer to AHRI ratings to check if your combination

can use the piston shipped with the unit or requires an accessory

TXV. Model sizes 019, 025, 031 and 037 are provided with a

factory installed TXV.

WALL

STRUCTURE

SUPPORTING

X 4”

2”

X 102 MM)

(51

STRUCTURE

STUD

ATTACHMENT

HOLES

SUPPORTING

X 4”

2”

X 102 MM)

(51

STRUCTURE

WOOD

SCREWS

A13008

Fig. 4 -- Frame Mount Installation

!

CAUTION

ENVIRONMENTAL HAZARD

Failure to follow this caution may result in environmental

damage.

Do not vent refrigerant to atmosphere. Recover during system

repair or final unit disposal.

3

Loading...

Loading...