Bryant-Carrier FB4C, FY5B Installation Manual

FB4C

FY5B

FAN COIL UNITS

FOR PURONr REFRIGERANT

SIZES 018 TO 060

Installation Instructions

NOTE: Read the entire instruction manual before starting the

installation.

TABLE OF CONTENTS

PAGE

SAFETY CONSIDERATIONS 1........................

INTRODUCTION 1..................................

HEATER PACKAGES 2..............................

INSTALLATION 2...................................

Step 1 — Check Equipment 2.........................

Step 2 — Mount Unit 2..............................

Step3—AirDucts 4...............................

Step 4 — Electrical Connections 4.....................

Step 5 — Refrigerant Tubing Connection and Evacuation 7..

Step 6 — Refrigerant Flow--Control Device 7.............

Step 7 — Condensate Drains 8........................

Step 8 — Accessories 9..............................

Step 9 — Sequence of Operation 10....................

START--UP PROCEDURES 10.........................

CARE AND MAINTENANCE 10.......................

AIRFLOW PERFORMANCE TABLES 11................

SAFETY CONSIDERATIONS

Improper installation, adjustment, alteration, service, maintenance,

or use can cause explosion, fire, electrical shock, or other

conditions which may cause death, personal injury or property

damage. Consult a qualified installer, service agency, or your

distributor or branch for information or assistance. The qualified

installer or agency must use factory--authorized kits or accessories

when modifying this product. Refer to the individual instructions

packaged with kits or accessories when installing.

Follow all safety codes. Wear safety glasses, protective clothing

and work gloves. Have a fire extinguisher available. Read these

instructions thoroughly and follow all warnings or cautions

included in literature and attached to the unit. Consult local

building codes and the current editions of the National Electrical

Code (NEC) NFPA 70.

In Canada, refer to the current editions of the Canadian Electrical

Code CSA C22.1.

Recognize safety information. This is the safety--alert symbol

When you see this symbol on the unit and in instruction manuals,

be alert to the potential for personal injury.

Understand the signal words DANGER, WARNING,and

CAUTION. These words are used with the safety--alert symbol.

DANGER identifies the most serious hazards which will result in

severe personal injury or death. WARNING signifies hazards

.

which could result in personal injury or death. CAUTION is used

to identify unsafe practices which may result in minor personal

injury or product and property damage. NOTE is used to highlight

suggestions which will result in enhanced installation, reliability, or

operation.

!

WARNING

ELECTRICAL OPERATION HAZARD

Failure to follow this warning could result in personal injury

or death.

Before installing or servicing unit, always turn off all power to

unit. There may be more than 1 disconnect switch. Turn off

accessory heater power if applicable. Lock out and tag switch

with a suitable warning label.

!

CAUTION

CUT HAZARD

Failure to follow this caution may result in personal injury.

Sheet metal parts may have sharp edges or burrs. Use care and

wear appropriate protective clothing and gloves when

handling parts.

INTRODUCTION

Models FB4C and FY5B are Puron Fan Coils designed for

installation flexibility. These units are designed to meet the low air

leak requirements currently in effect.

FB4C uses a refrigerant piston metering device (018 thru 048) and

TXV (060) with an X13 integral electronically commutated motor

for efficiency. These units have be designed for upflow, downflow

(kit required), and horizontal orientations, including manufactured

and mobile home applications.

FY5B uses a refrigerant piston metering device (018 thru 048) with

2--speed PSC (permanent split capacitor) motors and TXV with

3--speed PSC motor for the 060 size, These units can be used for

upflow or downflow (kit required) orientations, including

manufactured and mobile homes applications.

These units require a field supplied air filter, and are designed

specifically for Puron refrigerant air conditioners and heat pumps

as shipped. These units are available for systems of 18,000 through

60,000 Btuh nominal cooling capacity. Factory--authorized, field -installed electric heater packages are available in sizes 5 through

30kW. See Product Data literature for all available accessory kits.

HEATER PACKAGES

This unit may or may not be equipped with an electric heater

package. For units not equipped with factory--installed heat, a

factory--approved, field--installed, UL listed heater package is

available from your equipment supplier. See unit rating plate for a

list of factory--approved heaters. Heaters that are not factory

approved could cause damage which would not be covered under

the equipment warranty. If fan coil contains a factory--installed

heater package, minimum circuit ampacity (MCA) and maximum

fuse/breaker may be different than units with a same size

field--installed accessory heater. The differences is not an error and

is due to calculation difference per UL guidelines.

INSTALLATION

Step 1 — Check Equipment

Unpack unit and move to final location. Remove carton taking care

not to damage unit. Inspect equipment for damage prior to

installation. File claim with shipping company if shipment is

damaged or incomplete.

Locate unit rating plate which contains proper installation

information. Check rating plate to be sure unit matches job

specifications.

FB4C / FY5B

Step 2 — Mount Unit

Unit can stand or lie on floor, or hang from ceiling or wall. Allow

space for wiring, piping, and servicing unit.

IMPORTANT: When unit is installed over a finished ceiling

and/or living area, building codes may require a field--supplied

secondary condensate pan to be installed under the entire unit.

Some localities may allow as an alternative, the running of a

separate, secondary condensate line. Consult local codes for

additional restrictions or precautions.

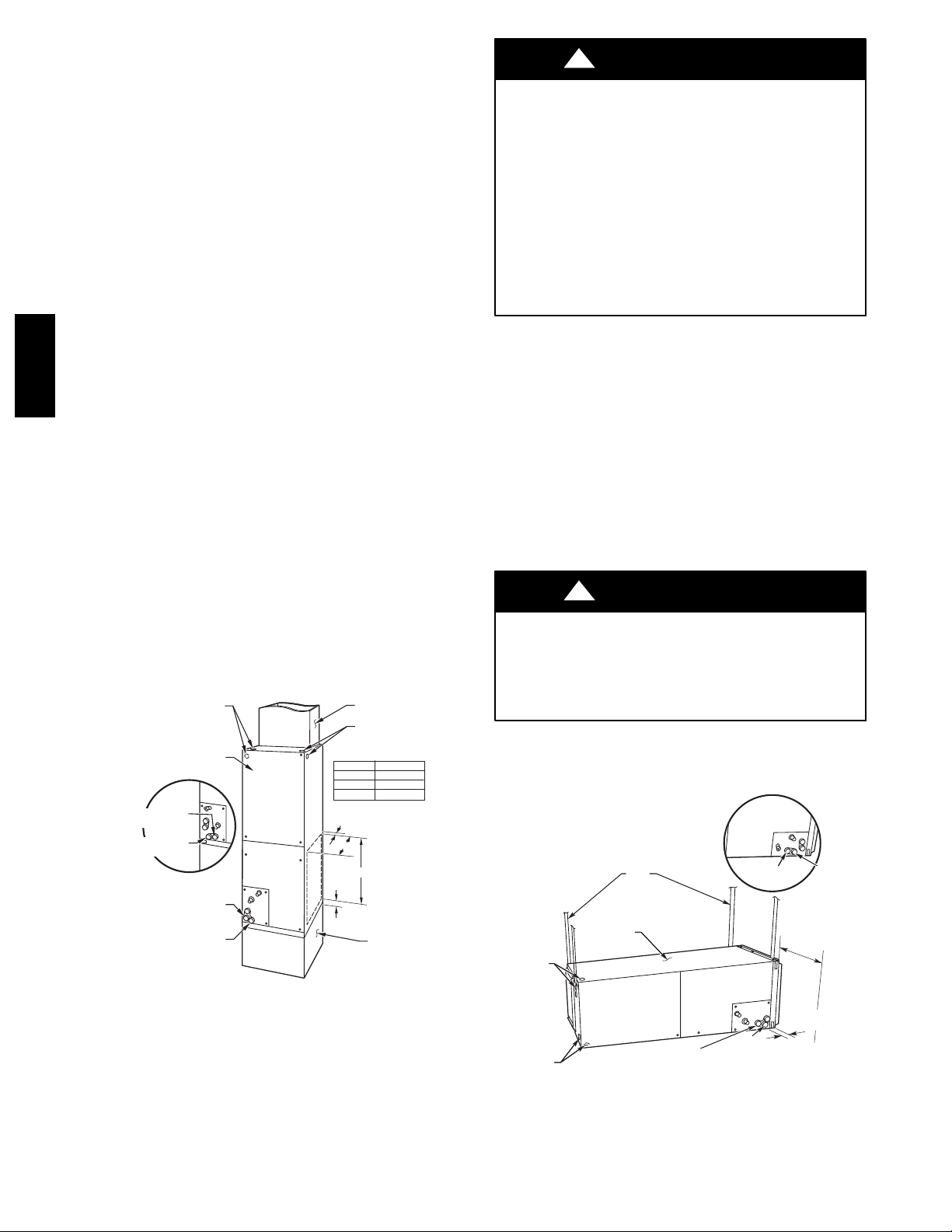

A. Upflow Installation

If return air is to be ducted through a floor, set unit on floor over

opening and use 1/8 to 1/4--in (3 to 6 mm) thick fireproof resilient

gasket between duct, unit, and floor.

Side return is a field option on slope coil models. Cut opening per

dimensions. (See Fig. 1.) A field--supplied bottom closure is

required.

018 - 048 21" (533 mm) FRONT SERVICE

060 - 060 24" (610mm) CLEARANCE

UPFLOW/DOWNFLOW

SECONDARY DRAIN

UPFLOW/DOWNFLOW

B. Downflow Installation

In this application, field conversion of the evaporator is required

using accessory downflow kit along with an accessory base kit.

Use fireproof resilient gasket, 1/8 to 1/4--in (3 to 6 mm) thick,

between duct, unit, and floor.

POWER ENTRY

OPTIONS

UNIT

018

A COIL

UNITS

PRIMARY DRAIN

UPFLOW/DOWNFLOW

SECONDARY DRAIN

UPFLOW/DOWNFLOW

PRIMARY DRAIN

024 - 030

036 19" (483 mm)

1.5" (38 mm)

19" (483 mm)

2.5"

(64 mm)

Fig. 1 -- Slope Coil Unit in Upflow Application

FIELD SUPPLIED

SUPPLY DUCT

LOW VOLT

ENTRY

OPTIONS

A

12" (305 mm)

17" (432 mm)

FIELD MODIFIED

SIDE RETURN

A

LOCATION FOR

SLOPE COIL

UNITS ONLY

FIELD SUPPLIED

RETURN PLENUM

A07565

!

CAUTION

UNIT OR PROPERTY DAMAGE HAZARD

Failure to follow this caution may result in product or property

damage.

The conversion of the fan coil to downflow requires special

procedures for the condensate drains on both A--coil and slope

units. The vertical drains have an overflow hole between the

primary and secondary drain holes. This hole is plugged for all

applications except downflow, but must be used for downflow.

During the conversion process, remove the plastic cap

covering the vertical drains only and discard. Remove the plug

from the overflow hole and discard. At completion of the

downflow installation, caulk around the vertical pan fitting to

door joint to retain the low air leak performance of the unit.

NOTE: To convert units for downflow applications, refer to

Installation Instructions supplied with kit for proper installation.

For slope fan coils, use kit Part No. KFADC0201SLP. For A--coils,

use kit Part No. KFADC0401ACL. Use fireproof resilient gasket,

1/8 to 1/4--in (3 to 6 mm) thick, between duct, unit, and floor.

NOTE: Gasket kit number KFAHD0101SLP is also required for

all downflow applications to maintain low air leak/low sweat

performance.

C. Horizontal Installation (FB4C only)

Units must not be installed with access panels facing up or down.

All other units are factory built for horizontal left installation. (See

Fig. 2 and 3.) When suspending unit from ceiling, dimples in

casing indicate suitable location of screws for mounting metal

support straps. (See Fig. 2.)

!

CAUTION

PROPERTY DAMAGE HAZARD

Failure to follow this caution may result in product or property

damage.

For optimum condensate drainage performance in horizontal

installations, unit should be leveled along its length and width.

For horizontal applications having high return static and humid

return air, the Water Management Kit, KFAHC0125AAA, may

need to be used to assist in water management.

A-COIL

HORIZONTAL LEFT

PRIMARY

DRAIN

018-048 21" (533 mm)

060-060 24" (610 mm)

FRONT SERVICE

CLEARANCE

(FULL FACE

OF UNIT)

1.75" (44 mm)

FILTER ACCESS

CLEARANCE

A07566

LOW VOLT

ENTRY

OPTIONS

POWER

ENTRY OPTIONS

UNIT

FIELD

SUPPLIED

HANGING

STRAPS

SECONDARY

DRAIN

PRIMARY

DRAIN

SECONDARY

DRAIN

Fig. 2 -- Slope Coil Unit in Horizontal Left Application

(FB4C only)

2

DRAIN PAN

SUPPORT BRACKET

A

FACT ORY SHIPPED

HORIZONTAL LEFT

APPLICATION

B

C

HORIZONTAL

DRAIN PAN

AIR SEAL

ASSEMBLY

REFRIGERANT

CONNECTIONS

Fig. 3 -- A--Coil in Horizontal Left Application

(Factory Ready FB4C only)

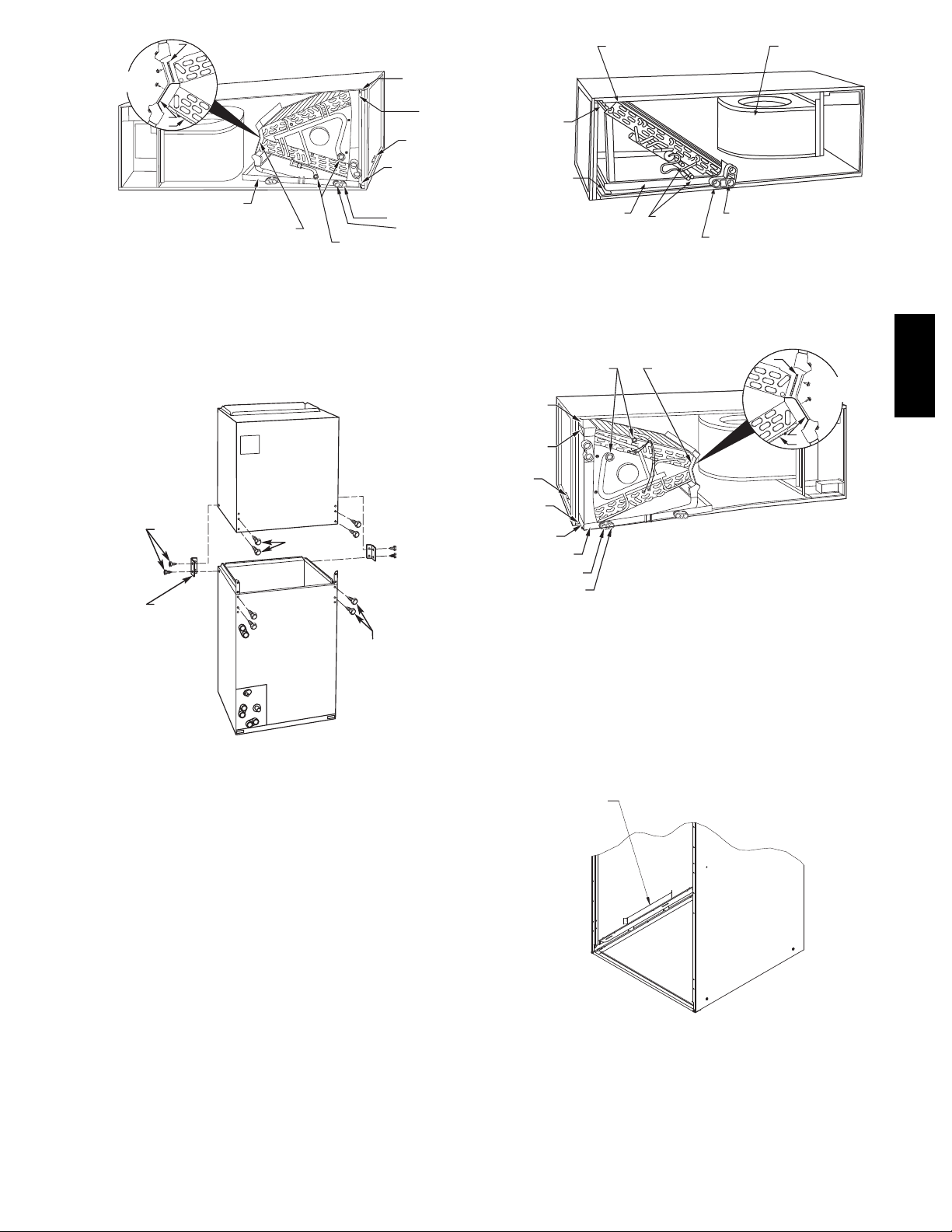

NOTE: Modular units can be disassembled and components

moved separately to installation area for reassembly. This process

accommodates small scuttle holes and limiting entrances to

installation sites. (See Fig. 4.)

BLOWER BOX

2 SCREWS

REAR CORNER

BRACKET

2 SCREWS

COIL BOX

2 SCREWS

Fig. 4 -- Removal of Brackets on Modular Units Horizontal

Right Conversion of Units With Slope Coils (FB4C only)

NOTE: Gasket kit number KFAHD0101SLP is required for

horizontal slope coil conversion to maintain low air leak/low sweat

performance.

1. Remove blower and coil access panel and fitting panel. (See

Fig. 5.)

2. Remove coil mounting screw securing coil assembly to

right side casing flange.

3. Remove coil assembly.

4. Lay fan coil unit on its right side and reinstall coil assembly

with condensate pan down. (See Fig. 5.)

5. Attach coil to casing flange using coil mounting screw previously removed.

6. Make sure the pan cap in the fitting door is properly seated

on the fitting door to retain the low air leak rating of the

unit.

7. Add gaskets from kit KFAHD per kit instructions.

8. Align holes with tubing connections and condensate pan

connections, and reinstall access panels and fitting panel.

Make sure liquid and suction tube grommets are in place to prevent

air leaks and cabinet sweating. Install after brazing.

COIL

BRACKET

COI L

SUPPORT

RAIL

DRAIN PAN

SUPPORT

BRACKET

COIL

BRACKET

PRIMARY DRAIN

HORIZONTAL LEFT

SECONDARY DRAIN

HORIZONTAL LEFT

A00072

A95293

COIL

SUPPORT

RAIL

SLOPE COIL

COIL MOUNTING

SCREW

SKI

DRAINPAN

REFRIGERANT

CONNECTIONS

PRIMARY DRAIN

SECONDARY DRAIN

BLOWER

ASSEMBLY

Fig. 5 -- Conversion for Horizontal Right Applications

Using a Slope Coil (FB4C only)

Horizontal Right Conversion of Units With A--Coils

1. Remove blower and coil access panels. (See Fig. 6.)

A

B

C

COIL

SUPPORT

RAIL

COIL

BRACKET

DRAIN PAN

SUPPORT

BRACKET

COIL

SUPPORT

RAIL

BRACKET

HORIZONTAL

PRIMARY DRAIN

HORIZONTAL RIGHT

SECONDARY DRAIN

HORIZONTAL RIGHT

REFRIGERANT

CONNECTIONS

COIL

DRAIN PAN

AIR SEAL

ASSEMBLY

Fig. 6 -- Conversion for Horizontal Right Applications

Using A--Coil (FB4C only)

2. Remove metal clip securing fitting panel to condensate pan.

Remove fitting panel.

3. Remove 2 snap--in clips securing A--coil in unit.

4. Slide coil and pan assembly out of unit.

5. Remove horizontal drain pan support bracket from coil support rail on left side of unit and reinstall on coil support rail

on right side of unit. (See Fig. 7.)

DRAIN PAN

SUPPORT BRACKET

Fig. 7 -- Drain Pan Support Bracket

6. Convert air--seal assembly for horizontal right.

a. Remove air--seal assembly from coil by removing 4

screws.(SeeFig.6.)

b. Remove air splitter (B) from coil seal assembly by re-

moving 3 screws. (See Fig. 3--factory shipped inset.)

A03001

HORIZONTAL

RIGHT

APPLICATION

A00071

A07571

FB4C / FY5B

3

Loading...

Loading...