Page 1

50ZHC

14 SEER Single P ackaged Heat Pump System

with Puronr (R---410A) Refrigerant

Single Phase

2 to 5 Nominal Tons (024 ---060)

Product Data

Single--Packaged Heat Pump Units with:

S Easy installation design

S Corrosion--proof unit base

S Class leading sound ratings

S Sloped drain for improved indoor air quality

S Scroll compressors

S Front and side service access

S Louvered panel coil protection

S Certified to leak 2% or less of nominal air conditioning CFM

delivered when pressurized to 1--in. W.C with all present air

inlets, air outlets, and condensate drain port(s) sealed.

This unit is a packaged heat pump for manufactured housing,

residential, and light commercial applications. Factory assembled

package is a compact, horizontal supply and return unit, combining

easy installation and maintenance with efficient performance.

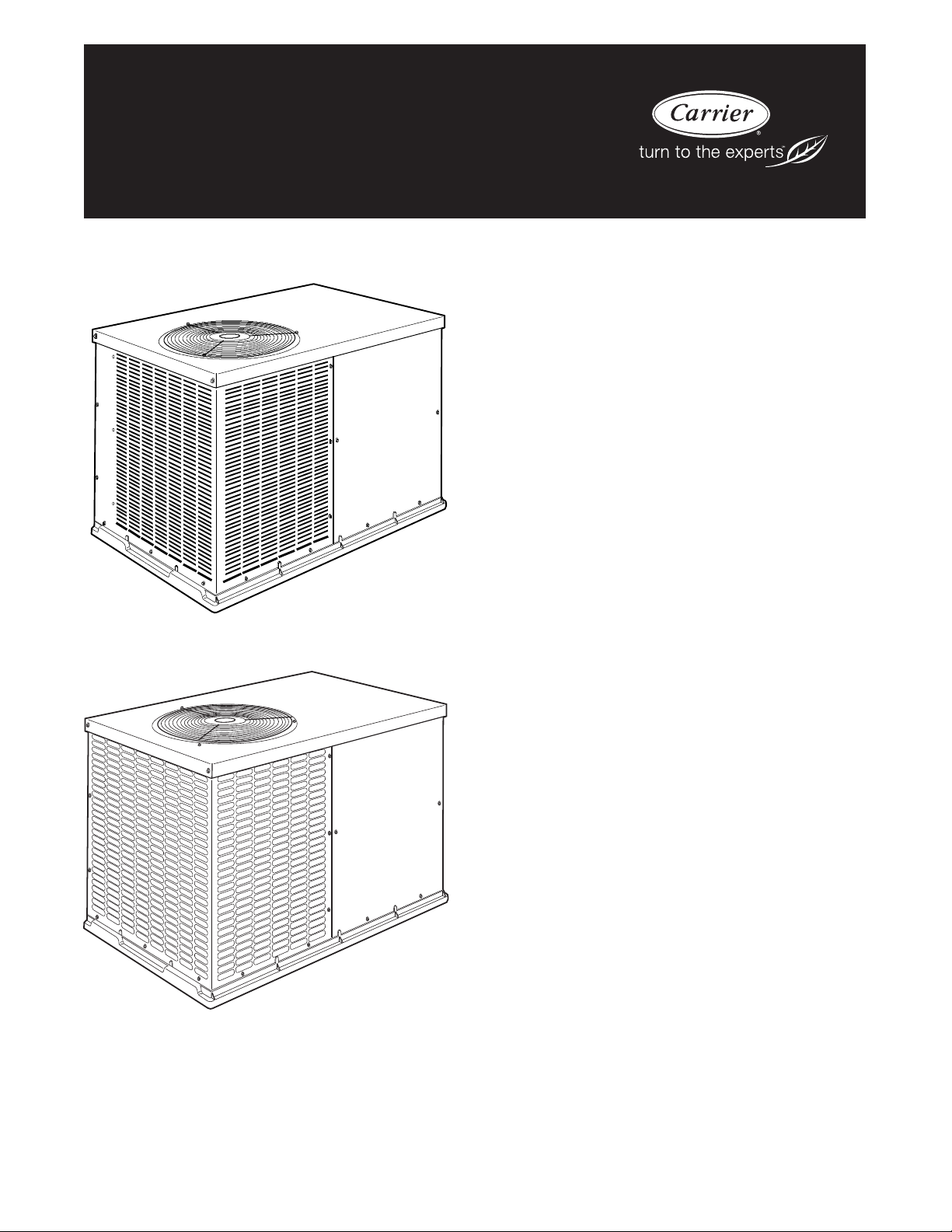

EASY TO INSTALL—The units are lightweight, compact single

A10165

024--048 Size

A150067

060 Size

Fig. 1 -- Unit 50ZHC

package units that are easy to handle. Every size unit has an

identical 32 by 51--in. (813 by 1295 mm) footprint to make job

site planning simple. The efficient design uses less sheet metal and

makes the 50ZHC units lighter than competitive units. The unit can

be easily positioned on the job site with the hand-- holds built into

the unit basepan.

AERODYNAMIC FAN BLADE DESIGN reduces overall sound

by up to 3dBA; low as 73dBA.

SERVICE ACCESS—The units are designed to be serviced from

both front and side. Routine maintenance tasks, such as coil

cleaning, are sped up with the multiple side panels design.

CORROSION PROOF UNIT BASE—The unit features a tough,

high--tech, single--piece composite material unit base with an

integrated drain. The composite material eliminates the potential

problem of rust and premature replacement which are common

with standard metal pans. Each unit base is sloped to eliminate

standing water. This feature minimizes the amount of standing

water inside the unit, which limits mold and mildew growth.

DURABLE STEEL CABINET—The watertight construction

and corrosion--resistant finish will keep it looking like new for

years. A specialized paint treatment process ensures quality

protection against the elements. A compact, low--profile design

utilizes a louvered coil enclosure for maximum protection against

hail damage and vandalism.

SCROLL COMPRESSORS—Each unit comes standard with a

scroll compressor. Each scroll compressor is hermetically sealed

against contamination to help promote longer life and dependable

operation. All scroll compressors have internal high--pressure and

overcurrent protection.

COIL EFFICIENCY—Indoor and outdoor coils are computer

designed for optimum heat transfer and cooling efficiency.

DEFROST SYSTEM—The system provides time/

temperature--based defrost cycles to maintain unit efficiency. This

1

FEATURES/BENEFITS

Page 2

highly reliable system monitors coil temperature and initiates a

defrost cycle only if it is required. The defrost cycle ends as soon as

defrosting is complete.

ACCESSORY ELECTRIC HEATERS —A variety of accessory

electric heaters are available for these units. These heaters are

comprised of a separate heater module mounted on the blower inlet

and remote mounted controls located in the unit control box.

Single point electrical connections are provided for powering both

the heater and the unit.

START COLLARS—Start collars are provided with each unit to

provide easy connection to the structure ductwork.

MODEL NUMBER NOMENCLATURE

DEPENDABLE COMPONENTS—Direct--drive, multi--speed

blower motor is standard on all models.

DIRECT--DRIVE, PSC OUTDOOR--FAN MOTORS are

designed to help reduce energy consumption and provide for

cooling operation down to 40F(4.4C). It’s high efficiency design

ensures high performance with most duct systems.

REFRIGERANT SYSTEM is designed to provide dependability.

Liquid refrigerant filter driers are used to promote clean,

unrestricted operation. Each unit leaves the factory with a full

refrigerant charge and is fully run tested. Refrigerant service

connections make checking operating pressure easier.

50ZHC

Typ e o f Un i t

50ZHC ---Single Packaged He at

50ZHC

Pump System

Nominal Cooling Capacity

024 --- 2.0 Tons

030 --- 2.5 Tons

036 --- 3.0 Tons

042 --- 3.5 Tons

048 --- 4.0 Tons

060 --- 5.0 Tons

N/A

024

--- --- ---

3

Electrical Supply

3 --- 208/230 --- 1 ---60

0

--- ---

Options

TP --- Base unit with tin plated indoor coi l hairpins

Only used if ordering an option

Series

TABLE OF CONTENTS

FEATURES/BENEFITS 1.........................................................................................

MODEL NUMBER NOMENCLATURE 2...........................................................................

AHRI CAPACITY RATINGS 3....................................................................................

PHYSICAL DATA 4.............................................................................................

ACCESSORIES 5...............................................................................................

DIMENSIONAL DRAWINGS 6...................................................................................

SELECTION PROCEDURE 9.....................................................................................

PERFORMANCE DATA 11.......................................................................................

TYPICAL WIRING SCHEMATICS 21..............................................................................

CONTROLS 23.................................................................................................

APPLICATION DAT A 23.........................................................................................

GUIDE SPECIFICATIONS 24.....................................................................................

PAGE

2

Page 3

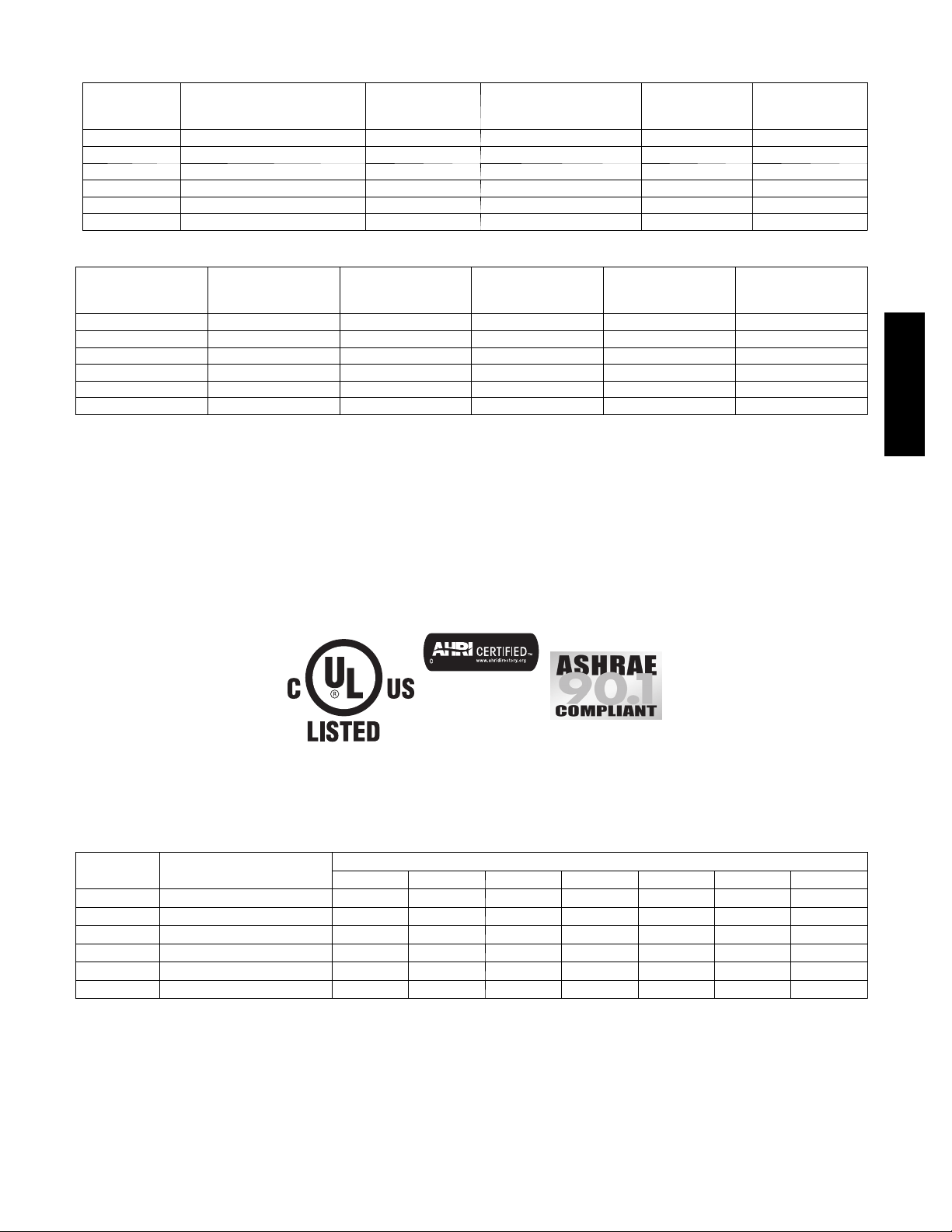

AHRI* CAPACITIES

Cooling Capacities and Efficiencies

UNIT SIZE NOMINAL TONS

024 2 800 24,000 11.50 14.50

030 2.5 1000 29,800 11.50 14.50

036 3 1200 36,000 11.50 14.50

042 3.5 1400 42,000 11.50 14.50

048 4 1600 46,500 11.50 14.00

060 5 1700 55,000 11.00 14.00

STANDARD

CFM

Heat Pump Heating Capacities and Efficiencies

NET HEATING

UNIT SIZE

024 23,400 3.7 13,400 2.4 8.0

030 28,600 3.7 15,600 2.4 8.0

036 34,400 3.5 20,200 2.4 8.0

042 40,000 3.5 23,400 2.4 8.0

048 45,000 3.5 26,600 2.3 8.0

060 56,000 3.5 34,000 2.4 8.0

LEGEND

dB---Sound Levels (decibels)

db—Dry Bulb

SEER—Seasonal Energy Efficiency Ratio

wb—Wet Bulb

COP---Coefficient of Performance

* Air Conditioning Heating & Refrigeration Institute

† At "A" conditions--80°F (26.7°C) indoor db/67°F (19.4°C) indoor wb & 95°F (35°C) outdoor db.

** Rated in accordance with U.S. Government DOE Department of Energy) test procedures and/or AHRI Standards 210/240.

Notes:

1. Ratings are net values, reflecting the effects of circulating fan heat.

Ratings are based on:

Cooling Standard: 80°F (26.7°C) db, 67°F wb (19.4°C) indoor entering---air temperature and 95°F db (35°C) outdoor entering---air temperature.

2. Before purchasing this appliance, read important energy cost and efficiency information available from your retailer.

CAPACITY AT 47° F

(8.3° C) (Btuh)

COP @ 47° F

(8.3° C)

NET COOLING CAPA-

CITY AT 95° F (35° C)

(Btuh)

NET HEATING

CAPACITY AT 17° F

(-8.3° C) (Btuh)

EER† SEER**

COP @ 17° F

(-8.3° C)

HSPF**

50ZHC

Use of the AHRI Certified

TM Mark indicates a

manufacturer’s

participation in the

program For verification

of certification for individual

products, go to

www.ahridirectory.org.

A--Weighted Sound Power Level (dBA)

UNIT

SIZE

STANDARD RATING

(dBA)

24 73 54.4 54.9 58.8 67.5 53.7 48.5 39.4

30 75 55.4 63.9 62.8 59.0 54.7 45.5 37.9

36 74 60.4 58.9 62.8 63.0 58.7 52.5 45.4

42 79.5 59.9 64.4 69.3 68.0 65.2 63.0 60.4

48 75.6 59.9 64.4 64.8 65.0 59.7 55.5 48.9

60 79.0 67.6 65.7 68.6 70.5 65.3 59.8 50.0

TYPICAL OCTAVE BAND SPECTRUM (dBA without tone adjustment)

125 250 500 1000 2000 4000 8000

3

Page 4

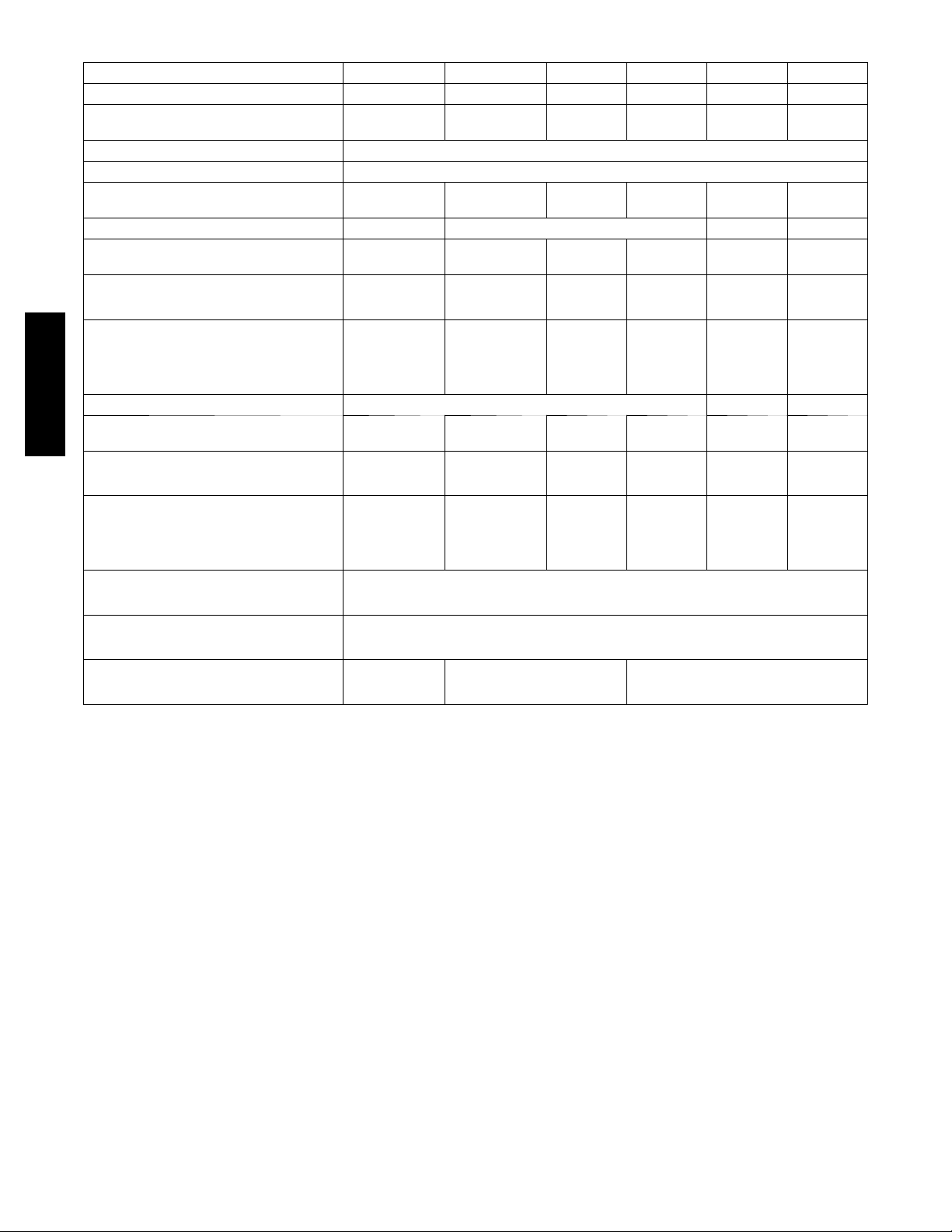

PHYSICAL DATA

UNIT SIZE 024 030 036 042 048 060

NOMINAL CAPACITY (ton) 2 2.5 3 3.5 4 5

SHIPPING WEIGHT (lb)

COMPRESSOR TYPE SCROLL

REFRIGERANT R-410A

REFRIGERANT QUANTITIY (lb)

OUTDOOR METERING DEVICE TXV Piston TXV Piston

ORIFICE ID (in.)

OUTDOOR COIL

ROWS...FINS/in.

FACE A REA ( sq . f t)

OUTDOOR FAN

NOMINAL AIRFLOW (cfm)

DIAMETER (in.)

DIAMETER (mm)

MOTOR HP (RPM)

50ZHC

*Required filter sizes shown are based on the AHRI (Air Conditionin g, Heating & Refrigeration Institute) rated airflow at a velocity of 300 ft/min (91 m) for throwaway type or 450 ft/min (137 m) for high capacity type. Recommended filters are 1 --- in. (25 mm) thick.

INDOOR METERING DEVICE Piston TXV TXV

ORIFICE ID (in.)

INDOOR COIL

ROWS...FINS/in.

FACE A REA ( sq . f t)

NOMINAL COOLING AIRFLOW (cfm)

INDOOR BLOWER

NOMINAL SIZE D x L (in.)

MOTOR (HP)

HIGH-PRESSURE SWITCH (psig)

LOW-PRESSURE SWITCH (psig)

CUTOUT

RESET (AUTO)

CUTOUT

RESET (AUTO)

RETURN-AIR FILTERS

THR OWAWAY (in.)

(kg)

QUANTITY (kg)

(mm)

(mm)

(mm)

(mm)

312

142

7.00

3.18

---

---

2...20

9.1

2000

20

508

1/8 (825)

0.059

1.499

3...12

4.3

800

10 x 8

254 x 203

1/3

20x20x1

508x508x25

333

151

7.20

3.27

0.049

1.245

2...20

10.2

2000

20

508

1/8 (825)

0.059

1.499

3...14

4.3

1000

11 x 9

279 x 229

1/3

610x762x25

24x30x1

334

152

6.30

2.86

0.057

1.448

2...20

10.2

2800

20

508

1/4 (1100)

0.067

1.702

3...12

4.9

1200

11 x 9

279 x 229

1/2

650 +/- 15

420 +/- 25

20 +/- 5

45 +/- 10

388

177

9.10

4.13

0.059

1.499

2...20

13.0

3100

20

508

1/4 (1100)

0.076

1.9304

3...14

4.9

1400

11 x 9

279 x 229

1/2

407

185

7.70

3.49

---

---

2...20

15.5

3100

20

508

1/4 (1100)

---

---

3...14

4.9

1600

11 x 9

279 x 229

3/4

24x36x1

610x914x25

475

215

11.5

5.22

0.070

1.778

2...20

15.5

3300

20

508

1/3 (1100)

---

---

3...14

4.9

1700

12 x 11

305 x 279

1

4

Page 5

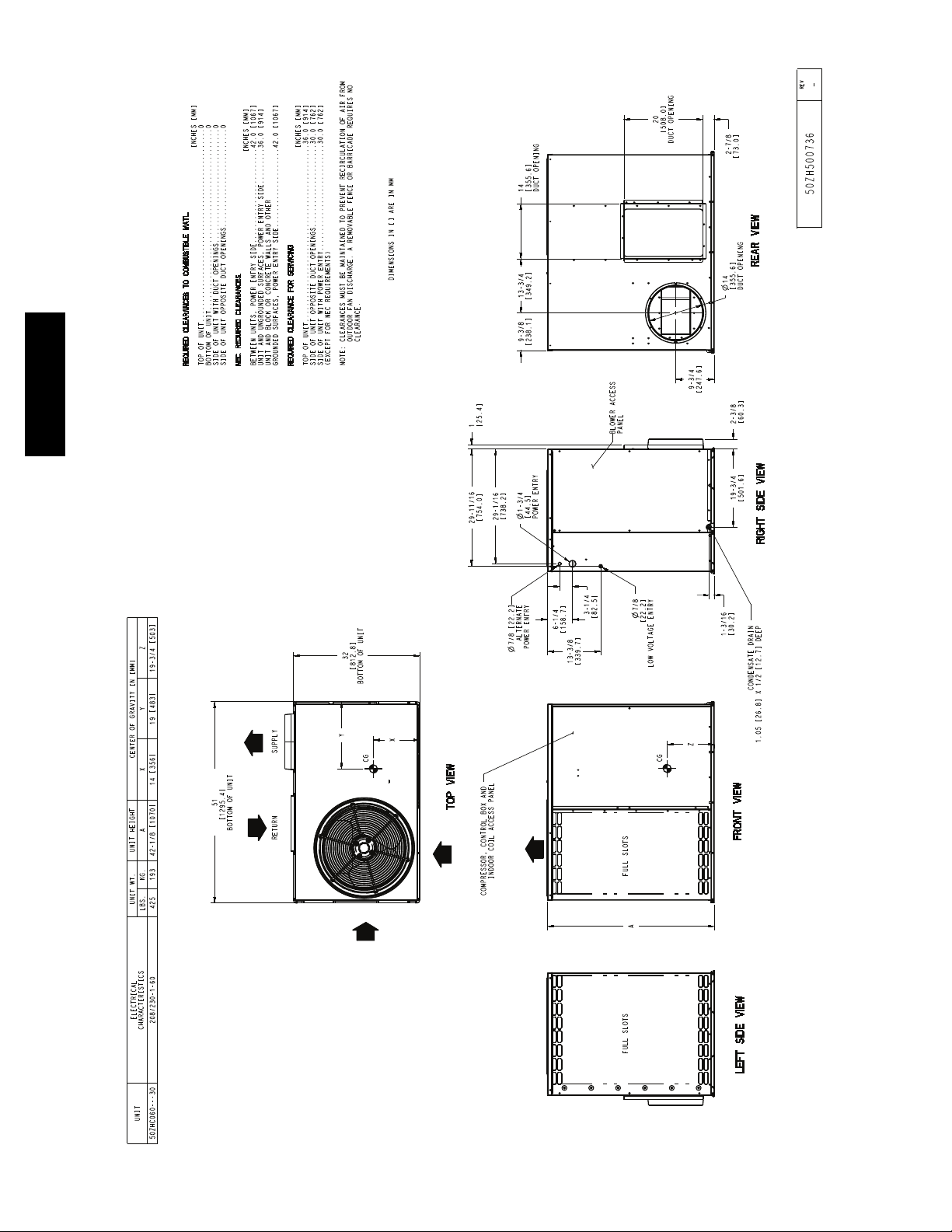

OPTIONS AND ACCESSORIES

FACTOR Y

ITEM DESCRIPTION

Coil Options Base u nit with tin plated indoor coil hairpins X

Compressor Start Kit

Corporate Thermostats

Crankcase Heater

Electric Heaters Electric Heat Supplement X

Low Ambient Kit

Time Guard II

Refer to Price Pages for available accessories.

Compressor Start K it assists compressor start ---up by providing

additional starting torque.

Thermostats provide control for the system heating and cooling

functions.

Crankcase Heater provides anti ---floodback protection for low --load coolin g applications.

Low Ambient Kit (Motormaster II Control) allows the use of mechanical cooling down to outdoor temperatures as low as 0°F

( --- 18° C) when properly installed.

Automatically prevents the compressor from restarting for at least

4 minutes and 45 seconds after shutdown of the compressor. Not

required when a corporate programmable thermostat is applied.

INSTALLED

OPTION

Accessory Electric Heater Usage

CATALOG

ORDERING NO.

NOMINAL

CAPACITY (kW)

CIRCUIT

BREAKER

(Yes/No)

STAGES

024 030 036 042 048 060

CPHEATER125A0* 3.8 / 5.0 No 1

CPHEATER126A0* 3.8 / 5.0 Yes 1

CPHEATER127A0* 5.6 / 7.5 No 2

CPHEATER128A0* 5.6 / 7.5 Yes 2

CPHEATER129A0* 7.5 / 10.0 No 2 NONE

CPHEATER130A0* 7.5 / 10.0 Ye s 2

CPHEATER131A0* 11.3 / 15.0 Yes 2

CPHEATER132A0* 15.0 / 20.0 Yes 2

Approved combination

USED WITH SIZES

FIELD

INSTALLED

ACCESSORY

X

X

X*

X

X

50ZHC

Multiplication Factors

HEATER kW RATING VOLTAGE DISTRIBUTION MULTIPLICATION FACTOR

200 .69

240

Example: 15.0 kW (at 240v) heater on 208v

=15.0(.75multfactor)

= 11.25 capacity at 208v

208 .75

230 .92

240 1.00

5

Page 6

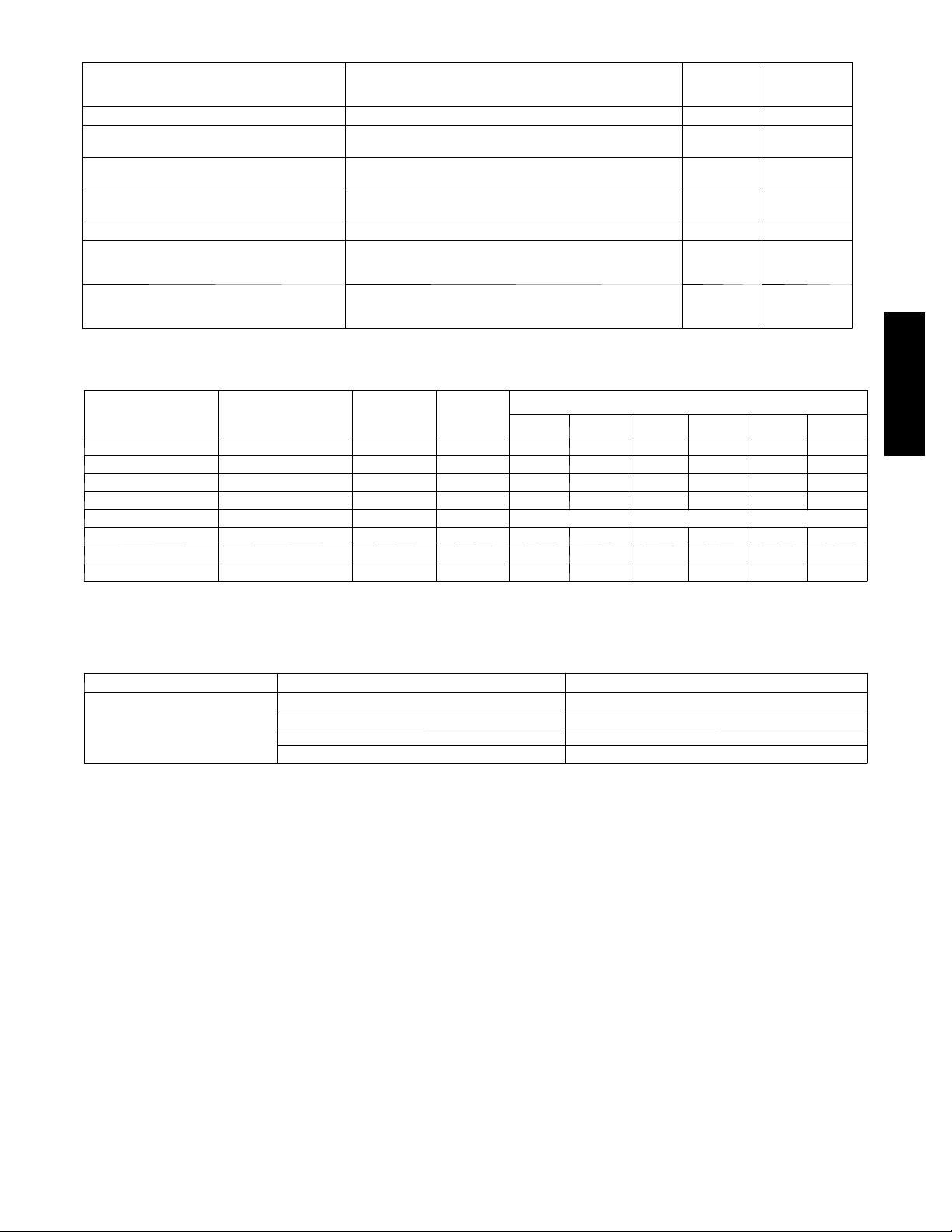

BASE UNIT DIMENSIONS—024--036

50ZHC

A14554

6

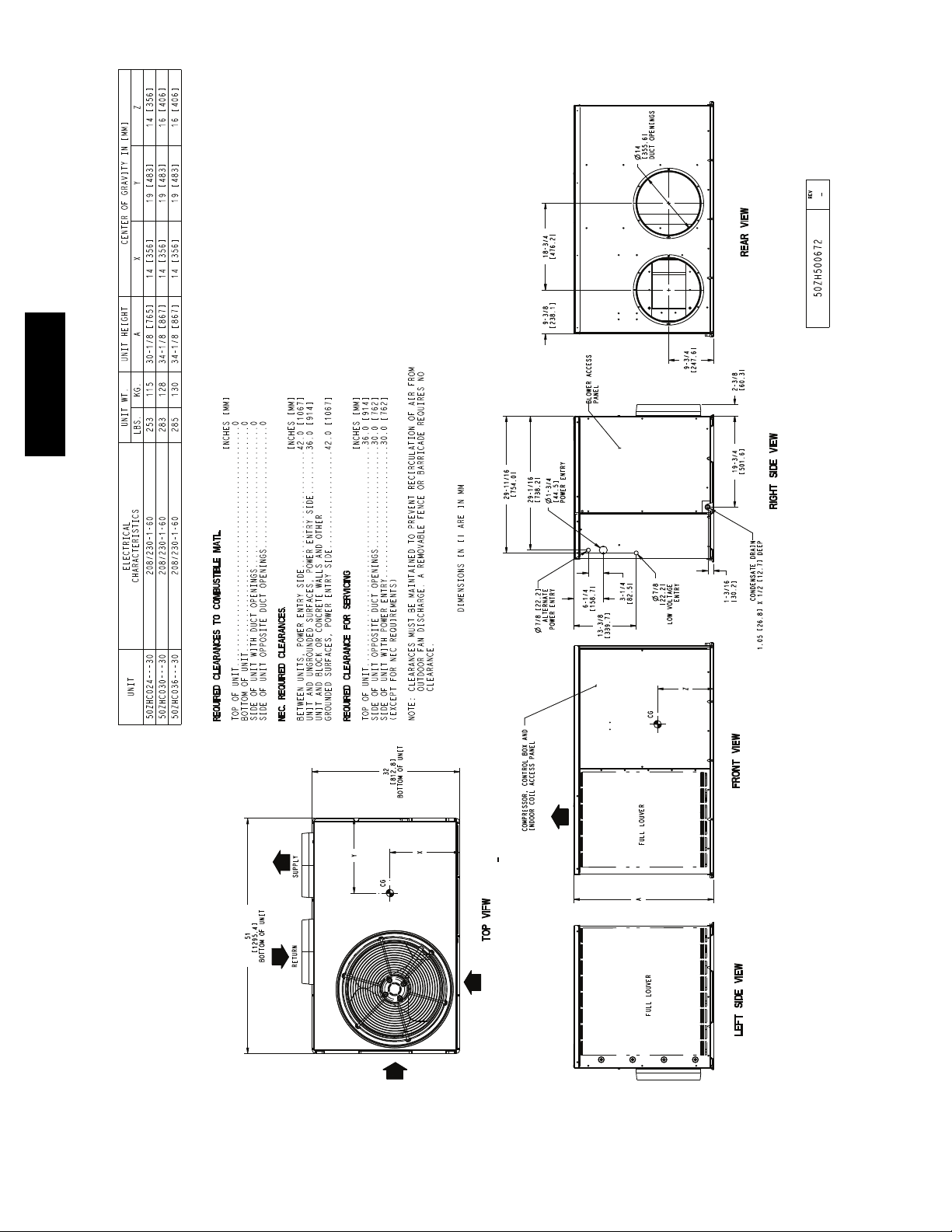

Page 7

BASE UNIT DIMENSIONS—042--048

50ZHC

A14555

7

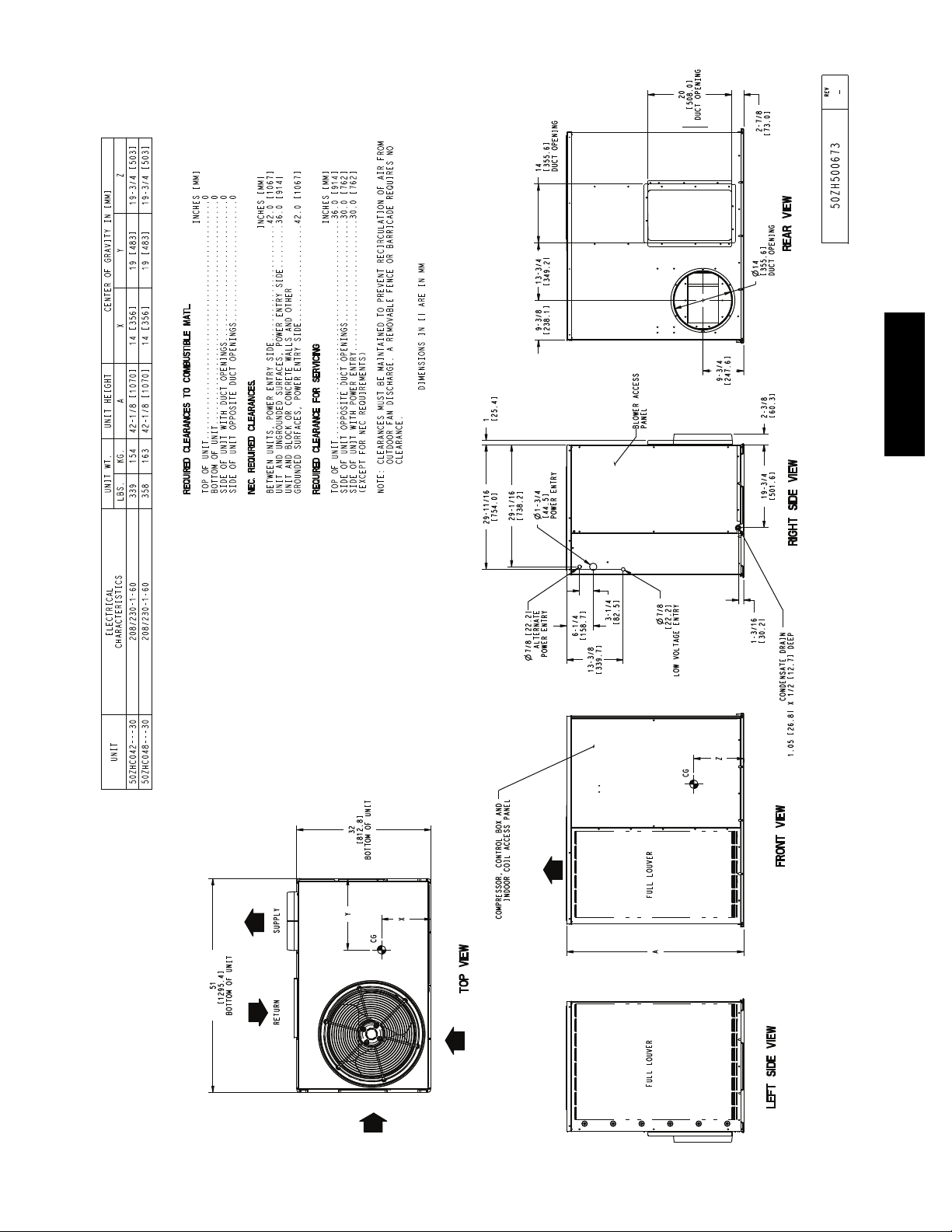

Page 8

BASE UNIT DIMENSIONS—060

50ZHC

A150071

8

Page 9

SELECTION PROCEDURE

I. DETERMINE COOLING AND HEATING

REQUIREMENTS AT DESIGN CONDITIONS

Given:

Required Cooling Capacity (TC 28,000 Btuh...........

Sensible Heat Capacity (SHC) 20,500 Btuh............

Required Heating Capacity 28,550 Btuh...............

Outdoor Entering--Air Temperature 95F(35C)........

Outdoor-- Air Winter Design Temperature 20F(--6.7C)..

Indoor-- Air Winter Design Temperature ............70F

(21.1C)

Indoor Entering--Air Temperature . . . . . . . . . . . . . 80F (26.7C)

edb, 67F ewb (19.4C)

Indoor-- Air Quantity ........................1000 CFM

ExternalStaticPressure ...................0.20IN.W.C.

ElectricalCharacteristics(V--Ph--Hz)..........230--1--60

edb — entering dry bulb

ewb — entering wet bulb

The required heating capacity is 28,550 Btuh. Therefore, 11,810

Btuh (28,550 -- 16,740) additional electric heat is required.

Determine additional electric heat capacity in kW.

11,810 Btuh

3414 Btuh/kW

3.46 kW of heat required

=

Enter the Accessory Electric Heater Usage table on page 4 for

208/240v. single--phase, 030 unit. The 5--kW heater at 240v most

closely satisfies the heating required. To calculate kW at 230v,

multiply the heater kW by multiplication factor 0.92 found in the

Multiplication Factors table on page 4.

5 kW x 0.92 = 4.6 kW

4.6 x 3414 = 15,704 Btuh

To calculate kW at 208 v, see Multiplication Factors table on page

4.

Total unit heating capacity is 32,444 Btuh (16,740 +15,704).

II. SELECT UNIT BASED ON REQUIRED COOLING

CAPACITY

Enter Cooling Capacities table at condenser entering temperature

of 95F(35C), indoor air entering at 1000 cfm and 67F (19.4C)

ewb (entering wet bulb). The 030 unit will provide a total cooling

capacity of 28,800 Btuh and a sensible heat capacity of 21,600

Btuh.

For indoor--air temperature other than 80F edb (entering dry

bulb), calculate sensible heat capacity correction, as required, using

the formula found in Note 3 following the cooling capacities

tables.

NOTE: Unit ratings are net capacities.

III. SELECT ELECTRIC HEAT

Enter the 030 Heating Capacities table at 1000 CFM. At 70F

(21.1C) return indoor air and 20F(--6.7C) air entering outdoor

coil, the integrated heating capacity is 16,740 Btuh. (Select

integrated heating capacity value since deductions for outdoor--coil

frost and defrosting have already been made. No correction is

required.)

IV. DETERMINE FAN SPEED AND POWER

REQUIREMENTS AT DESIGN CONDITIONS

Before entering the air delivery tables, calculate the total static

pressure required. From the given, the Accessory Electric Heat

Pressure Drop table, and the Filter Pressure Drop table, find:

External static pressure 0.20 IN. W.C.

Filter 0.09 IN. W.C.

Electric heat 0.04

IN. W.C.

Total static pressure 0.33 IN. W.C.

Enter the table for Dry Coil Air Delivery — Horizontal Discharge

at 1000 CFM and 230v high speed. The blower will deliver 1036

CFM @ 0.40 IN W.C. static pressure. This will adequately handle

job requirements.

50ZHC

9

Page 10

kW

BASED ON INDOOR ENT. AIR

AT 70 ºF AND AT RATED CFM

0.0

8.8

24

48

14.6

42

23.4

50ZHC

20.5

60

17.6

36

11.7

30

5.9

2.9

BALANCE POINT WORKSHEET

80

70

60

50

40

30

OUTDOOR TEMPERATURE, ºF

-10 0 10 20 30 40 50 60 70

20

10

0

MBTUH

BUILDING HEAT LOSS, UNIT INTEGRATED HEATING CAPACITY,

A150088

10

Page 11

kW

Sys

kW

Sys

Total

MBtuh

Capacity

kW

Sys

Total

MBtuh

Capacity

Tot a l

MBtuh

Capacity

kW

Sys

Tot a l

MBtuh

Capacity

kW

Sys

Tot a l

50ZHC

MBtuh

kW

Sys

Total

MBtuh

Capacity

Capacity

kW

Sys

Tot a l

MBtuh

Capacity

kW

Sys

Total

MBtuh

Capacity

OUTDOOR COIL ENTERING AIR TEMPERATURES ° F (° C)

CONDENSER ENTERING AIR TEMPERATURES _F(°C)

kW

Sys

Total

MBtuh

Capacity

kW

Sys

Total

75 (24) 85 (29) 95 (35) 105 (41) 115 (46) 125 (52)

MBtuh

Capacity

Total Sens Total Sens Total Sens Total Sens Total Sens Total Sens

-10 (-23) 0 (-18) 10 (-12) 20 (-7) 30 (-1) 40 (4) 50 (10) 60 (16)

kW

Sys

Tot a l

MBtuh

Capacity

kW

Sys

Tot a l

MBtuh

Capacity

kW

Sys

Tot a l

MBtuh

Capacity

kW

Sys

Tot a l

MBtuh

Capacity

Tot a l Integ To t al Integ Tot al Integ To t a l Integ Total Integ Tot a l Integ Tot a l Integ To t a l Integ

PERFORMANCE DATA

EVAPORATOR

COOLING CAPACITY

024

57 (14) 24.13 24.13 1.40 22.67 22.67 1.71 21.20 21.20 2.06 19.18 19.18 2.47 17.23 17.23 2.96 15.34 15.34 3.54

62 (17) 24.96 21.58 1.40 23.28 20.60 1.71 21.59 19.65 2.06 19.26 19.17 2.47 17.27 17.27 2.96 15.37 15.37 3.54

67 (19) 27.16 18.15 1.41 25.39 17.31 1.71 23.57 16.44 2.07 21.73 15.60 2.50 19.32 14.52 2.99 16.69 13.34 3.56

72 (22) 29.39 14.74 1.41 27.59 14.01 1.72 25.69 13.23 2.08 23.72 12.42 2.51 21.74 11.67 3.02 19.42 10.81 3.59

57 (14) 25.10 25.10 1.41 23.59 23.59 1.72 22.07 22.07 2.08 20.33 20.33 2.50 18.25 18.25 2.99 16.19 16.19 3.57

62 (17) 25.55 23.03 1.41 23.84 22.03 1.72 22.15 21.95 2.08 20.37 20.37 2.50 18.29 18.29 2.99 16.22 16.22 3.57

67 (19) 27.67 19.15 1.42 25.86 18.33 1.73 24.00 17.45 2.09 22.11 16.59 2.51 19.85 15.73 3.00 17.17 14.46 3.59

72 (22) 29.86 15.30 1.42 28.03 14.57 1.73 26.11 13.76 2.09 24.08 12.98 2.53 22.06 12.21 3.04 19.80 11.48 3.62

57 (14) 25.89 25.89 1.43 24.34 24.34 1.74 22.76 22.76 2.10 21.17 21.17 2.52 19.11 19.11 3.02 16.95 16.95 3.60

62 (17) 26.06 24.33 1.43 24.36 24.36 1.74 22.78 22.78 2.10 21.19 21.19 2.52 19.15 19.15 3.02 16.99 16.99 3.60

67 (19) 28.05 20.05 1.43 26.22 19.25 1.74 24.32 18.35 2.10 22.40 17.50 2.53 20.23 16.79 3.03 17.60 15.54 3.62

AIR

CFM EWB

63* (17) 25.41 17.66 1.40 23.69 16.80 1.71 21.95 15.92 2.07 19.64 14.77 2.48 17.12 13.57 2.96 14.73 12.42 3.53

700

63* (17) 25.93 18.68 1.42 24.17 17.81 1.72 22.39 16.92 2.08 20.25 15.91 2.50 17.60 14.64 2.98 15.13 13.44 3.55

800

63* (17) 26.33 19.62 1.43 24.53 18.74 1.74 22.72 17.85 2.10 20.71 17.02 2.51 18.05 15.69 3.00 15.48 14.40 3.57

900

72 (22) 30.22 15.79 1.44 28.37 15.07 1.75 26.41 14.26 2.11 24.36 13.48 2.54 22.29 12.72 3.05 20.07 12.05 3.64

700 7.21 6.64 1.43 9.32 8.58 1.49 11.68 10.72 1.55 14.33 13.00 1.61 17.38 15.23 1.68 20.83 20.83 1.76 24.83 24.83 1.84 29.30 29.30 1.93

800 7.25 6.67 1.43 9.36 8.61 1.48 11.71 10.75 1.53 14.37 13.03 1.59 17.43 15.27 1.65 20.89 20.89 1.71 24.92 24.92 1.79 29.46 29.46 1.86

900 7.29 6.70 1.43 9.39 8.64 1.47 11.75 10.78 1.52 14.40 13.06 1.57 17.47 15.31 1.62 20.95 20.95 1.68 25.00 25.00 1.75 29.60 29.60 1.81

700 7.13 6.56 1.50 9.22 8.48 1.56 11.56 10.61 1.62 14.18 12.86 1.69 17.18 15.06 1.76 20.59 20.59 1.84 24.54 24.54 1.93 28.93 28.93 2.02

800 7.16 6.58 1.50 9.25 8.51 1.55 11.58 10.63 1.61 14.20 12.88 1.67 17.22 15.09 1.73 20.64 20.64 1.80 24.62 24.62 1.88 29.07 29.07 1.95

900 7.19 6.61 1.50 9.28 8.53 1.55 11.61 10.65 1.60 14.23 12.91 1.65 17.25 15.12 1.71 20.69 20.69 1.77 24.69 24.69 1.84 29.20 29.20 1.90

700 7.06 6.50 1.57 9.14 8.41 1.64 11.45 10.51 1.71 14.05 12.74 1.78 17.01 14.90 1.85 20.37 20.37 1.94 24.26 24.26 2.03 28.56 28.56 2.12

800 7.09 6.52 1.57 9.16 8.43 1.63 11.47 10.53 1.69 14.06 12.76 1.75 17.03 14.92 1.82 20.41 20.41 1.89 24.32 24.32 1.97 28.69 28.69 2.05

900 7.12 6.55 1.57 9.18 8.45 1.63 11.49 10.54 1.68 14.08 12.77 1.74 17.06 14.95 1.80 20.45 20.45 1.86 24.38 24.38 1.93 28.80 28.80 2.00

65

70

INDOOR AIR

Seepage17forcoolingnotes.

HEATING CAPACITY

024

EDB CFM

(18)

(21)

75

(24)

11

Page 12

kW

Sys

kW

Sys

Total

MBtuh

Capacity

kW

Sys

Total

MBtuh

Capacity

Tot a l

MBtuh

Capacity

kW

Sys

Tot a l

MBtuh

Capacity

kW

Sys

Tot a l

50ZHC

MBtuh

kW

Sys

Total

MBtuh

Capacity

Capacity

kW

Sys

Tot a l

MBtuh

Capacity

kW

Sys

Total

MBtuh

Capacity

OUTDOOR COIL ENTERING AIR TEMPERATURES ° F (° C)

CONDENSER ENTERING AIR TEMPERATURES _F(°C)

kW

Sys

Total

MBtuh

Capacity

kW

Sys

Total

75 (24) 85 (29) 95 (35) 105 (41) 115 (46) 125 (52)

MBtuh

Capacity

kW

Sys

Tot a l

MBtuh

Capacity

kW

Sys

Tot a l

MBtuh

Capacity

kW

Sys

Tot a l

MBtuh

Capacity

kW

Sys

Tot a l

Total Sens Total Sens Total Sens Total Sens Total Sens Total Sens

-10 (-23) 0 (-18) 10 (-12) 20 (-7) 30 (-1) 40 (4) 50 (10) 60 (16)

MBtuh

Capacity

Tot a l Integ To ta l Integ To t a l Integ Tot a l Integ Tot a l Integ Tot a l Integ Tot a l Integ Tot a l Integ

875 7.47 6.87 1.56 10.12 9.31 1.65 13.30 12.21 1.75 16.77 15.21 1.86 20.50 17.96 1.97 24.97 24.97 2.10 30.32 30.32 2.25 36.79 36.79 2.43

875 7.19 6.61 1.64 9.84 9.05 1.73 12.91 11.85 1.83 16.57 15.03 1.96 20.24 17.73 2.07 24.62 24.62 2.20 29.87 29.87 2.35 36.22 36.22 2.53

1000 7.58 6.97 1.57 10.25 9.43 1.65 13.66 12.54 1.76 16.93 15.35 1.85 20.71 18.15 1.95 25.24 25.24 2.07 30.70 30.70 2.21 37.28 37.28 2.38

1125 7.67 7.06 1.57 10.37 9.54 1.65 13.77 12.64 1.75 17.06 15.47 1.84 20.88 18.30 1.94 25.47 25.47 2.05 30.98 30.98 2.18 37.61 37.61 2.36

875 6.90 6.35 1.71 9.54 8.78 1.81 12.58 11.55 1.92 16.37 14.85 2.05 20.00 17.53 2.17 24.29 24.29 2.30 29.43 29.43 2.46 35.66 35.66 2.65

1000 7.30 6.72 1.64 9.97 9.18 1.73 13.08 12.01 1.83 16.72 15.16 1.94 20.45 17.91 2.05 24.89 24.89 2.17 30.24 30.24 2.31 36.69 36.69 2.48

1125 7.40 6.81 1.65 10.09 9.29 1.73 13.24 12.16 1.82 16.86 15.29 1.93 20.61 18.06 2.03 25.11 25.11 2.15 30.52 30.52 2.28 37.03 37.03 2.46

1000 7.01 6.45 1.72 9.68 8.91 1.81 12.76 11.71 1.91 16.53 14.99 2.03 20.19 17.69 2.14 24.54 24.54 2.27 29.78 29.78 2.41 36.12 36.12 2.59

1125 7.11 6.55 1.72 9.80 9.02 1.81 12.90 11.84 1.91 16.65 15.10 2.03 20.34 17.83 2.13 24.76 24.76 2.25 30.07 30.07 2.39 36.45 36.45 2.56

57 (14) 29.24 29.24 1.83 27.70 27.70 2.15 26.11 26.11 2.52 24.49 24.49 2.96 22.75 22.75 3.50 20.93 20.93 4.14

62 (17) 30.19 27.55 1.83 28.33 26.42 2.15 26.44 25.27 2.52 24.56 24.41 2.96 22.80 22.80 3.50 20.97 20.97 4.14

63* (17) 30.79 22.41 1.84 28.86 21.37 2.16 26.91 20.34 2.53 24.89 19.29 2.97 22.79 18.22 3.50 20.56 17.11 4.12

67 (19) 33.31 23.34 1.87 31.27 22.30 2.18 29.18 21.25 2.56 27.03 20.20 3.00 24.77 19.12 3.54 22.46 18.03 4.18

72 (22) 36.86 19.05 1.91 34.65 18.09 2.23 32.38 17.13 2.61 30.03 16.15 3.06 27.59 15.16 3.61 25.07 14.15 4.25

57 (14) 30.61 30.61 1.86 28.97 28.97 2.18 27.29 27.29 2.56 25.55 25.55 3.01 23.72 23.72 3.55 21.82 21.82 4.19

62 (17) 31.02 29.70 1.86 29.13 28.47 2.18 27.33 27.33 2.56 25.59 25.59 3.01 23.75 23.75 3.55 21.84 21.84 4.19

63* (17) 31.52 23.91 1.87 29.53 22.85 2.19 27.49 21.77 2.56 25.40 20.69 3.00 23.23 19.57 3.54 20.97 18.43 4.16

67 (19) 34.09 24.95 1.90 31.97 23.88 2.21 29.80 22.80 2.59 27.56 21.70 3.04 25.24 20.58 3.58 22.85 19.44 4.22

72 (22) 37.71 20.07 1.94 35.41 19.09 2.26 33.04 18.10 2.65 30.61 17.10 3.10 28.09 16.07 3.65 25.47 15.04 4.30

57 (14) 31.77 31.77 1.89 30.04 30.04 2.22 28.28 28.28 2.60 26.44 26.44 3.05 24.52 24.52 3.59 22.52 22.52 4.24

62 (17) 31.81 31.81 1.90 30.08 30.08 2.22 28.32 28.32 2.60 26.48 26.48 3.05 24.55 24.55 3.60 22.55 22.55 4.24

63* (17) 32.11 25.37 1.90 30.05 24.27 2.21 27.96 23.16 2.59 25.81 22.03 3.04 23.58 20.87 3.57 21.30 19.67 4.21

67(19) 34.70 26.52 1.93 32.52 25.41 2.25 30.28 24.29 2.62 27.99 23.15 3.08 25.60 21.98 3.62 23.16 20.79 4.26

72 (22) 38.37 21.05 1.97 35.99 20.05 2.30 33.56 19.03 2.68 31.06 18.00 3.14 28.45 16.95 3.69 25.78 15.89 4.34

AIR

PERFORMANCE DATA (CONT)

COOLING CAPACITY

EVAPORATOR

030

CFM EWB

875

1000

1125

65

70

INDOOR AIR

Seepage17forcoolingnotes.

HEATING CAPACITY

030

EDB CFM

75

12

Page 13

kW

Sys

kW

Sys

To t a l

MBtuh

Capacity

kW

Sys

To t a l

MBtuh

Capacity

Tot a l

MBtuh

Capacity

kW

Sys

Tot a l

MBtuh

Capacity

kW

Sys

Tot a l

50ZHC

MBtuh

kW

Sys

To t a l

MBtuh

Capacity

Capacity

kW

Sys

Tot a l

MBtuh

Capacity

kW

Sys

To t a l

MBtuh

Capacity

OUTDOOR COIL ENTERING AIR TEMPERATURES _F(°C)

CONDENSER ENTERING AIR TEMPERATURES ° F (° C)

kW

Sys

To t a l

MBtuh

Capacity

kW

Sys

To t a l

75 (24) 85 (29) 95 (35) 105 (41) 115 (46) 125 (52)

MBtuh

Capacity

To t a l Sens Tot a l Sens To t a l Sens To t a l Sens To t a l Sens To t a l Sens

57 (14) 35.93 35.93 2.36 33.75 33.75 2.70 31.52 31.52 3.08 29.19 29.19 3.52 26.69 26.69 4.03 23.44 23.44 4.55

62 (17) 37.16 32.72 2.36 34.64 31.84 2.70 32.05 30.86 3.08 29.38 29.75 3.52 26.74 26.74 4.03 23.49 23.49 4.55

63* (17) 37.80 26.59 2.36 35.24 25.75 2.70 32.57 24.84 3.08 29.78 23.85 3.52 26.72 22.69 4.03 22.54 20.97 4.53

67 (19) 40.63 27.40 2.36 38.07 26.70 2.70 35.38 25.86 3.09 32.52 24.93 3.54 29.45 23.92 4.05 25.85 22.65 4.64

72 (22) 43.93 21.95 2.37 41.38 21.32 2.72 38.64 20.59 3.12 35.74 19.79 3.57 32.68 18.87 4.08 29.43 17.90 4.66

57 (14) 37.48 37.48 2.39 35.25 35.25 2.73 32.94 32.94 3.12 30.53 30.53 3.56 27.93 27.93 4.08 24.77 24.77 4.64

62 (17) 38.06 35.03 2.39 35.55 34.11 2.73 33.04 32.82 3.12 30.58 30.58 3.56 27.97 27.97 4.08 24.83 24.83 4.64

63* (17) 38.56 28.13 2.39 35.95 27.33 2.73 33.26 26.45 3.12 30.41 25.47 3.56 27.26 24.30 4.08 23.13 22.62 4.58

67 (19) 41.32 28.90 2.39 38.73 28.26 2.74 36.00 27.47 3.13 33.12 26.57 3.58 30.03 25.59 4.09 26.44 24.43 4.67

72 (22) 44.53 22.75 2.41 41.96 22.17 2.76 39.19 21.46 3.16 36.22 20.68 3.61 33.12 19.74 4.12 29.83 18.82 4.70

57 (14) 38.67 38.67 2.42 36.40 36.40 2.76 34.04 34.04 3.15 31.58 31.58 3.60 28.94 28.94 4.12 25.94 25.94 4.71

62 (17) 38.83 36.99 2.42 36.44 36.44 2.76 34.09 34.09 3.15 31.62 31.62 3.60 28.98 28.98 4.12 25.98 25.98 4.71

63* (17) 39.12 29.53 2.42 36.50 28.79 2.77 33.77 27.94 3.16 30.89 26.97 3.60 27.73 25.85 4.11 23.68 24.16 4.64

67(19) 41.83 30.27 2.43 39.21 29.67 2.77 36.45 28.95 3.17 33.55 28.08 3.62 30.48 27.11 4.13 26.96 26.05 4.71

72 (22) 44.95 23.44 2.44 42.38 22.92 2.80 39.58 22.24 3.20 36.58 21.46 3.65 33.42 20.55 4.16 30.10 19.65 4.75

AIR

-10 (-23) 0 (-18) 10 (-12) 20 (-7) 30 (-1) 40 (4) 50 (10) 60 (16)

kW

Sys

Tot a l

MBtuh

Capacity

kW

Sys

Tot a l

MBtuh

Capacity

kW

Sys

Tot a l

MBtuh

Capacity

kW

Sys

Tot a l

MBtuh

Capacity

Tot a l Integ Tot a l Integ Tot a l Integ Tot a l Integ To t a l Integ To t a l Integ To t a l Integ To tal Integ

1050 10.63 9.78 2.08 13.98 12.86 2.18 17.60 16.15 2.29 21.69 19.67 2.41 26.19 22.94 2.56 30.74 30.74 2.70 36.06 36.06 2.85 41.91 41.91 3.00

1200 10.83 9.96 2.09 14.19 13.05 2.19 17.87 16.40 2.30 22.40 20.31 2.42 26.47 23.19 2.54 31.10 31.10 2.66 36.49 36.49 2.79 42.00 42.00 2.93

1350 11.01 10.13 2.11 14.39 13.24 2.21 18.09 16.61 2.31 22.61 20.51 2.42 26.70 23.40 2.53 31.39 31.39 2.65 36.68 36.68 2.76 41.92 41.92 2.89

1050 10.08 9.27 2.15 13.46 12.38 2.26 17.08 15.67 2.38 21.12 19.15 2.51 25.84 22.64 2.67 30.33 30.33 2.82 35.56 35.56 2.99 41.41 41.41 3.14

1200 10.27 9.45 2.17 13.66 12.57 2.27 17.36 15.94 2.38 21.43 19.44 2.50 26.11 22.88 2.65 30.67 30.67 2.78 36.02 36.02 2.92 41.55 41.55 3.07

1350 10.45 9.61 2.19 13.86 12.75 2.29 17.59 16.14 2.39 21.70 19.68 2.50 26.35 23.09 2.64 30.96 30.96 2.77 36.27 36.27 2.89 41.52 41.52 3.02

1050 9.51 8.75 2.24 12.91 11.88 2.35 16.55 15.19 2.48 20.59 18.68 2.61 25.51 22.35 2.79 29.92 29.92 2.95 35.06 35.06 3.13 40.90 40.90 3.29

1200 9.70 8.92 2.26 13.14 12.09 2.37 16.82 15.44 2.48 20.89 18.95 2.60 25.78 22.59 2.76 30.26 30.26 2.91 35.52 35.52 3.06 41.07 41.07 3.21

1350 9.86 9.07 2.28 13.33 12.27 2.38 17.04 15.64 2.49 21.15 19.18 2.61 26.00 22.78 2.75 30.54 30.54 2.89 35.82 35.82 3.02 41.08 41.08 3.16

PERFORMANCE DATA (CONT)

COOLING CAPACITY

036

EVAPORATOR

65

70

CFM EWB

1050

1200

1350

Seepage17forcoolingnotes.

HEATING CAPACITY

INDOOR AIR

036

(18)

EDB CFM

(21)

75

(24)

13

Page 14

kW

Sys

kW

Sys

To t a l

MBtuh

Capacity

kW

Sys

To t a l

MBtuh

Capacity

Tot a l

MBtuh

Capacity

kW

Sys

Tot a l

MBtuh

Capacity

kW

Sys

Tot a l

50ZHC

kW

Sys

To t a l

MBtuh

Capacity

MBtuh

Capacity

kW

Sys

Tot a l

MBtuh

Capacity

kW

Sys

To t a l

kW

Sys

Tot a l

MBtuh

Capacity

MBtuh

Capacity

OUTDOOR COIL ENTERING AIR TEMPERATURES _F(°C)

CONDENSER ENTERING AIR TEMPERATURES ° F (° C)

kW

Sys

Tot a l

MBtuh

Capacity

kW

Sys

Tot a l

MBtuh

Capacity

kW

Sys

Tot a l

75 (24) 85 (29) 95 (35) 105 (41) 115 (46) 125 (52)

kW

Sys

To t a l

MBtuh

Capacity

kW

Sys

To t a l

MBtuh

Capacity

To t a l Sens To t a l Sens To t a l Sens To t a l Sens To t a l Sens To t a l Sens

-10 (-23) 0 (-18) 10 (-12) 20 (-7) 30 (-1) 40 (4) 50 (10) 60 (16)

MBtuh

Capacity

Tot a l Integ Tot a l Integ To t a l Integ To t a l Integ To t a l Integ Tota l Integ Tot a l Integ Tot a l Integ

57 (14) 42.14 42.14 2.64 39.63 39.63 3.08 37.01 37.01 3.57 33.27 33.27 4.08 29.84 29.84 4.70 26.47 26.47 5.43

62 (17) 43.42 36.94 2.64 40.45 35.78 3.09 37.42 34.53 3.57 33.34 33.34 4.09 29.89 29.89 4.70 26.52 26.52 5.43

67 (19) 47.88 31.26 2.67 44.54 30.15 3.11 41.19 29.02 3.61 37.71 27.83 4.17 32.76 26.04 4.76 28.12 24.34 5.46

72 (22) 53.01 25.46 2.69 49.32 24.38 3.15 45.63 23.29 3.64 41.90 22.17 4.21 38.07 21.00 4.86 33.06 19.39 5.57

57 (14) 44.02 44.02 2.68 41.35 41.35 3.13 38.61 38.61 3.62 35.22 35.22 4.16 31.40 31.40 4.77 27.77 27.77 5.50

62 (17) 44.58 39.74 2.69 41.57 38.42 3.13 38.66 38.66 3.62 35.31 35.31 4.16 31.46 31.46 4.78 27.82 27.82 5.50

67 (19) 48.95 33.40 2.71 45.46 32.26 3.16 42.00 31.10 3.65 38.44 29.89 4.22 33.67 28.17 4.82 28.82 26.35 5.52

72 (22) 54.17 26.80 2.73 50.34 25.70 3.19 46.51 24.59 3.69 42.63 23.44 4.25 38.72 22.26 4.91 34.00 20.78 5.64

57 (14) 45.62 45.62 2.73 42.79 42.79 3.18 39.93 39.93 3.67 36.90 36.90 4.24 32.77 32.77 4.84 28.92 28.92 5.57

62 (17) 45.69 45.69 2.73 42.85 42.85 3.18 39.99 39.99 3.67 36.95 36.95 4.24 32.83 32.83 4.84 28.97 28.97 5.57

67 (19) 49.78 35.47 2.75 46.20 34.29 3.20 42.60 33.09 3.70 38.98 31.84 4.26 34.50 30.21 4.88 29.45 28.21 5.58

63* (17) 46.05 33.91 2.73 42.74 32.75 3.18 39.39 31.55 3.67 35.82 30.22 4.22 30.44 28.04 4.80 26.11 26.11 5.51

72 (22) 55.07 28.09 2.78 51.13 26.97 3.23 47.18 25.83 3.73 43.21 24.67 4.30 39.18 23.46 4.96 34.88 22.14 5.72

1225 12.34 11.36 2.53 15.76 14.50 2.57 19.85 18.22 2.65 25.09 22.75 2.79 29.92 26.22 2.93 35.54 35.54 3.11 42.06 42.06 3.32 49.79 49.79 3.56

1400 12.54 11.54 2.55 15.97 14.70 2.58 20.10 18.45 2.65 25.31 22.95 2.78 30.19 26.45 2.91 35.91 35.91 3.07 42.55 42.55 3.27 50.45 50.45 3.50

1575 12.71 11.69 2.57 16.16 14.87 2.59 20.31 18.64 2.65 25.49 23.12 2.78 30.42 26.65 2.89 36.21 36.21 3.04 42.96 42.96 3.23 50.96 50.96 3.46

1225 11.85 10.90 2.61 15.29 14.07 2.66 19.40 17.80 2.75 24.42 22.15 2.89 29.57 25.91 3.07 35.07 35.07 3.25 41.48 41.48 3.46 49.05 49.05 3.71

1400 12.06 11.09 2.63 15.53 14.29 2.67 19.67 18.05 2.75 25.02 22.69 2.90 29.86 26.16 3.04 35.46 35.46 3.21 41.97 41.97 3.41 49.70 49.70 3.64

1575 12.24 11.26 2.65 15.73 14.47 2.69 19.88 18.25 2.76 25.23 22.88 2.90 30.11 26.38 3.03 35.77 35.77 3.19 42.37 42.37 3.38 50.21 50.21 3.60

1225 11.26 10.36 2.68 14.75 13.57 2.75 18.88 17.33 2.86 23.67 21.47 3.00 29.23 25.61 3.20 34.61 34.61 3.39 40.89 40.89 3.61 48.32 48.32 3.87

1400 11.48 10.56 2.70 14.99 13.80 2.76 19.15 17.58 2.86 24.06 21.82 2.99 29.52 25.86 3.18 34.98 34.98 3.35 41.38 41.38 3.56 48.96 48.96 3.80

1575 11.67 10.74 2.73 15.21 13.99 2.78 19.39 17.80 2.87 24.38 22.11 2.99 29.75 26.06 3.16 35.30 35.30 3.33 41.78 41.78 3.52 49.46 49.46 3.76

AIR

63* (17) 44.22 29.99 2.65 41.17 28.91 3.09 38.00 27.77 3.58 33.40 26.01 4.08 29.10 24.34 4.69 24.87 22.66 5.40

63* (17) 45.24 31.99 2.69 42.05 30.87 3.13 38.79 29.71 3.62 34.39 28.04 4.14 29.80 26.25 4.74 25.51 24.46 5.45

PERFORMANCE DATA (CONT)

COOLING CAPACITY

042

EVAPORATOR

65

70

CFM EWB

1225

1400

1575

Seepage17forcoolingnotes.

HEATING CAPACITY

042

INDOOR AIR

(18)

EDB CFM

(21)

75

(24)

14

Page 15

kW

Sys

kW

Sys

To t a l

MBtuh

Capacity

kW

Sys

To t a l

MBtuh

Capacity

Tot a l

MBtuh

Capacity

kW

Sys

Tot a l

MBtuh

Capacity

kW

Sys

Tot a l

50ZHC

MBtuh

kW

Sys

To t a l

MBtuh

Capacity

Capacity

kW

Sys

Tot a l

MBtuh

Capacity

kW

Sys

To t a l

MBtuh

Capacity

OUTDOOR COIL ENTERING AIR TEMPERATURES _F(°C)

CONDENSER ENTERING AIR TEMPERATURES ° F (° C)

kW

Sys

To t a l

MBtuh

Capacity

kW

Sys

To t a l

75 (24) 85 (29) 95 (35) 105 (41) 115 (46) 125 (52)

MBtuh

Capacity

To t a l Sens Tot a l Sens Tot a l Sens To t a l Sens To t a l Sens To t a l Sens

57 (14) 46.42 46.42 3.18 44.08 44.08 3.54 41.54 41.54 3.95 38.75 38.75 4.42 35.66 35.66 4.95 32.25 32.25 5.57

62 (17) 47.91 40.50 3.18 45.08 39.17 3.55 42.09 37.68 3.96 38.91 38.54 4.42 35.70 35.70 4.95 32.29 32.29 5.57

67 (19) 52.27 34.25 3.20 49.14 32.98 3.58 45.78 31.63 3.99 42.12 30.16 4.45 38.13 28.58 4.98 33.83 26.88 5.59

72 (22) 57.10 27.89 3.22 53.65 26.66 3.61 49.95 25.33 4.02 45.93 23.91 4.49 41.59 22.37 5.01 36.91 20.74 5.61

57 (14) 48.26 48.26 3.23 45.74 45.74 3.60 43.02 43.02 4.01 40.04 40.04 4.48 36.76 36.76 5.02 33.12 33.12 5.63

62 (17) 49.02 43.31 3.23 46.11 41.79 3.61 43.09 43.09 4.01 40.09 40.09 4.48 36.80 36.80 5.02 33.15 33.15 5.63

67 (19) 53.29 36.42 3.25 50.03 35.11 3.63 46.50 33.70 4.04 42.68 32.18 4.50 38.56 30.53 5.03 34.15 28.73 5.64

72 (22) 58.19 29.22 3.27 54.58 27.94 3.66 50.71 26.58 4.08 46.53 25.11 4.54 42.02 23.54 5.07 37.21 21.88 5.66

57 (14) 49.79 49.79 3.28 47.12 47.12 3.66 44.25 44.25 4.07 41.10 41.10 4.54 37.62 37.62 5.07 33.80 33.80 5.68

62 (17) 50.03 49.53 3.28 47.17 47.17 3.66 44.30 44.30 4.07 41.15 41.15 4.54 37.65 37.65 5.07 33.83 33.83 5.69

67 (19) 54.07 38.50 3.30 50.68 37.14 3.68 47.02 35.68 4.10 43.10 34.10 4.56 38.87 32.36 5.08 34.38 30.42 5.69

63* (17) 48.68 33.02 3.18 45.78 31.78 3.55 42.67 30.46 3.96 39.29 29.02 4.42 35.60 27.47 4.95 31.60 25.78 5.57

63* (17) 49.67 35.05 3.24 46.64 33.77 3.61 43.39 32.40 4.02 39.87 30.91 4.48 36.05 29.29 5.01 31.96 27.51 5.62

63* (17) 50.44 37.00 3.29 47.28 35.67 3.66 43.93 34.25 4.07 40.31 32.70 4.53 36.41 30.99 5.06 32.23 29.06 5.67

72 (22) 59.02 30.47 3.32 55.27 29.16 3.71 51.27 27.76 4.13 46.95 26.26 4.59 42.32 24.66 5.12 37.39 22.97 5.71

AIR

-10 (-23) 0 (-18) 10 (-12) 20 (-7) 30 (-1) 40 (4) 50 (10) 60 (16)

kW

Sys

Tot a l

MBtuh

Capacity

kW

Sys

Tot a l

MBtuh

Capacity

kW

Sys

Tot a l

MBtuh

Capacity

kW

Sys

Tot a l

MBtuh

Capacity

Tot a l Integ To t a l Integ To ta l Integ To t a l Integ To tal Integ To t a l Integ To t al Integ Tot a l Integ

1400 15.18 13.97 2.94 19.00 17.48 3.05 23.31 21.40 3.17 28.19 25.57 3.30 33.88 29.68 3.43 40.24 40.24 3.57 47.39 47.39 3.71 55.53 55.53 3.84

1600 15.30 14.07 2.96 19.11 17.58 3.07 23.43 21.50 3.17 28.32 25.68 3.29 34.03 29.82 3.41 40.45 40.45 3.53 47.70 47.70 3.65 55.99 55.99 3.76

1800 15.41 14.18 2.99 19.23 17.69 3.09 23.55 21.62 3.19 28.46 25.81 3.29 34.20 29.96 3.40 40.66 40.66 3.51 47.98 47.98 3.62 56.39 56.39 3.71

1400 15.09 13.89 3.06 18.87 17.37 3.18 23.15 21.25 3.31 27.98 25.37 3.44 33.59 29.43 3.58 39.86 39.86 3.72 46.87 46.87 3.86 54.85 54.85 4.01

1600 15.19 13.97 3.08 18.96 17.45 3.19 23.24 21.33 3.31 28.08 25.47 3.42 33.73 29.55 3.55 40.06 40.06 3.68 47.18 47.18 3.80 55.31 55.31 3.93

1800 15.29 14.07 3.11 19.07 17.54 3.21 23.35 21.43 3.32 28.20 25.58 3.43 33.87 29.68 3.54 40.25 40.25 3.66 47.45 47.45 3.77 55.70 55.70 3.87

1400 15.08 13.88 3.20 18.82 17.32 3.32 23.04 21.15 3.45 27.80 25.21 3.59 33.33 29.20 3.74 39.48 39.48 3.89 46.35 46.35 4.03 54.16 54.16 4.18

1600 15.16 13.95 3.22 18.89 17.38 3.33 23.12 21.22 3.45 27.89 25.30 3.57 33.45 29.31 3.70 39.67 39.67 3.84 46.65 46.65 3.97 54.61 54.61 4.09

1800 15.25 14.03 3.24 18.98 17.46 3.35 23.21 21.30 3.46 28.00 25.39 3.57 33.58 29.42 3.69 39.85 39.85 3.82 46.91 46.91 3.93 55.01 55.01 4.04

PERFORMANCE DATA (CONT)

COOLING CAPACITY

048

EVAPORATOR

65

70

CFM EWB

1400

1600

1800

Seepage17forcoolingnotes.

HEATING CAPACITY

048

INDOOR AIR

(18)

EDB CFM

(21)

75

(24)

15

Page 16

kW

Sys

kW

Sys

Total

MBtuh

Capacity

kW

Sys

Total

Tot a l

MBtuh

Capacity

kW

Sys

Tot a l

MBtuh

Capacity

kW

Sys

Tot a l

50ZHC

CONDENSER ENTERING AIR TEMPERATURES _F(°C)

MBtuh

Capacity

kW

Sys

Total

MBtuh

Capacity

kW

Sys

Total

MBtuh

Capacity

MBtuh

Capacity

kW

Sys

Tot a l

MBtuh

Capacity

kW

Sys

Tot a l

MBtuh

Capacity

OUTDOOR COIL ENTERING AIR TEMPERATURES ° F (° C)

kW

Sys

Tot a l

MBtuh

Capacity

PERFORMANCE DATA (CONT)

COOLING CAPACITY

Total

75 (24) 85 (29) 95 (35) 105 (41) 115 (46)

Capacity

AIR

EVAPORATOR

060

Sys

MBtuh

CFM EWB

kW

Total Sens Total Sens Total Sens Total Sens Total Sens

57 (14) 53.70 53.70 3.72 50.79 50.79 4.25 47.77 47.77 4.87 44.64 44.64 5.59 41.30 41.30 6.44

62 (17) 56.51 46.21 3.74 53.06 45.28 4.27 49.52 44.21 4.89 45.86 42.96 5.61 42.02 41.46 6.45

63* (17) 57.26 37.98 3.75 53.73 37.03 4.28 50.11 35.97 4.90 46.36 34.78 5.62 42.40 33.40 6.46

1500

67 (19) 61.62 39.46 3.78 57.81 38.52 4.32 53.91 37.46 4.94 49.85 36.25 5.67 45.56 34.86 6.51

72 (22) 67.09 32.70 3.83 62.88 31.73 4.36 58.56 30.66 4.99 54.07 29.45 5.72 49.38 28.08 6.58

57 (14) 55.91 55.91 3.78 52.81 52.81 4.32 49.60 49.60 4.94 46.27 46.27 5.67 42.73 42.73 6.52

62 (17) 57.92 49.22 3.80 54.33 48.19 4.33 50.68 47.03 4.95 46.90 45.63 5.68 42.89 42.89 6.52

63* (17) 58.63 40.05 3.81 54.95 39.07 4.34 51.18 37.98 4.96 47.27 36.73 5.68 43.17 35.30 6.53

1700

67 (19) 63.05 41.68 3.84 59.07 40.70 4.38 55.00 39.60 5.00 50.76 38.34 5.73 46.33 36.90 6.58

72 (22) 68.57 34.07 3.88 64.19 33.07 4.42 59.69 31.95 5.05 55.01 30.69 5.79 50.18 29.28 6.64

57 (14) 57.35 57.35 3.83 54.11 54.11 4.37 50.79 50.79 4.99 47.33 47.33 5.72 43.64 43.64 6.57

62 (17) 58.83 51.31 3.84 55.15 50.22 4.38 51.43 48.93 5.00 47.52 47.52 5.72 43.70 43.70 6.58

67 (19) 63.92 43.28 3.88 59.83 42.27 4.42 55.65 41.14 5.04 51.31 39.85 5.78 46.77 38.38 6.63

63* (17) 59.48 41.54 3.85 55.69 40.53 4.38 51.83 39.41 5.00 47.83 38.14 5.73 43.62 36.67 6.57

1850

16

72 (22) 69.49 35.05 3.93 64.99 34.02 4.46 60.36 32.87 5.10 55.59 31.59 5.83 50.64 30.14 6.69

kW

Sys

Tot a l

MBtuh

Capacity

kW

Sys

Tot a l

-10 (-23) 0 (-18) 10 (-12) 20 (-7) 30 (-1) 40 (4) 50 (10) 60 (16)

MBtuh

Capacity

Tot a l Int eg To t a l Integ To t a l Integ To t a l Integ To t a l Integ To t al Integ To t al Integ To t a l Integ

1500 20.53 18.88 3.42 24.97 22.98 3.56 30.06 27.59 3.71 35.90 32.56 3.88 42.74 37.45 4.07 50.54 50.54 4.32 59.05 59.05 4.52 68.78 68.78 4.75

1700 20.57 18.92 3.41 24.98 22.99 3.54 30.04 27.57 3.67 35.85 32.51 3.82 42.65 37.37 3.99 50.44 50.44 4.21 58.95 58.95 4.38 68.71 68.71 4.56

1850 20.61 18.96 3.41 25.01 23.01 3.53 30.04 27.57 3.65 35.83 32.50 3.79 42.61 37.33 3.94 50.39 50.39 4.15 58.90 58.90 4.30 68.69 68.69 4.46701500 20.52 18.88 3.60 24.95 22.96 3.76 30.01 27.55 3.92 35.80 32.47 4.10 42.58 37.31 4.30 50.25 50.25 4.55 58.66 58.66 4.77 68.28 68.28 5.02

1700 20.57 18.92 3.59 24.97 22.98 3.73 29.99 27.53 3.87 35.75 32.42 4.03 42.49 37.23 4.21 50.15 50.15 4.43 58.55 58.55 4.61 68.19 68.19 4.81

1850 20.62 18.97 3.59 25.00 23.00 3.72 29.99 27.53 3.85 35.73 32.41 4.00 42.44 37.19 4.16 50.11 50.11 4.37 58.50 58.50 4.53 68.15 68.15 4.69751500 20.49 18.85 3.80 24.92 22.93 3.97 29.95 27.49 4.14 35.71 32.39 4.34 42.41 37.16 4.55 49.95 49.95 4.80 58.27 58.27 5.03 67.78 67.78 5.30

1700 20.55 18.91 3.78 24.94 22.95 3.94 29.94 27.48 4.09 35.66 32.34 4.26 42.32 37.08 4.45 49.85 49.85 4.67 58.15 58.15 4.86 67.67 67.67 5.08

1850 20.60 18.96 3.78 24.97 22.98 3.92 29.94 27.48 4.07 35.64 32.32 4.22 42.28 37.05 4.39 49.80 49.80 4.60 58.09 58.09 4.77 67.63 67.63 4.95

Seepage17forcoolingnotes.

HEATING CAPACITY

060

INDOOR AIR

EDB CFM

65

Page 17

50ZHC

ewb --

h

4.5xCFM

total capacity (Btuh)

lwb =

h

PERFORMANCE DATA (CONT)

LEGEND

lwb)

(Btuh)

1.10 x CFM

Sensible capacity

--

edb

t

ldb =

BF— Bypass Factor

d b --- D r y B u l b

edb— Entering Dry ---Bulb

Ewb — Entering Wet--- Bulb

kW — Total Unit Power Input

ldb— Leaving Dry ---Bulb

lwb— Leaving Wet---Bulb

SHC — Sensible Heat Capacity (1000 Btuh)

TC — Total Capacity (1000 Btuh) (net)

*At 75_F (23.9_C) entering dry bulb (Tennessee Valley Authority [TVA] rating conditions); all other at 80_F (26.75_C) entering dry bulb.

COOLING NOTE S:

1. Ratings are net; they account for the effects of the evaporator --- fan motor power and heat.

2. Direct interpolation is permissible. Do not extrapolate.

t

3. The following formulas may be used:

h

ewb = Enthalpy of air entering evaporator coil

Wet-- bulb temperature corresponding to enthalpy

air leaving evaporator coil (

h

lwb =

t

Where:

4. The SHC is based on 80_F (26.7_C) edb temperature of air entering evaporator coil. Below 80_F (26.7_C) edb, subtract (corr factor x CFM) from SHC.

Above 80_F (26.7_C) edb, add (corr factor x CFM) to SHC.

Correction Factor = 1.10 x (1 --- BF) x (e db --- 80).

17

Page 18

PERFORMANCE DATA (CONT)

Filter Pressure Drop (IN. W.C.)

FILTER SIZE

in. (mm)

20X20X1

(508X508X25)

20X24X1

(508X610x25)

24X30X1

(610X762x25)

24X36X1

(610X914X25)

500 600 700 800 900 1000 1100 1200 1300 1400 1500 1600 1700 1800 1900 2000 2100 2200

0.05 0.07 0.08 0.10 0.12 0.13 0.14 0.15 — — — — — — — — — —

— — — 0.08 0.09 0.10 0.11 0.13 0.14 0.15 0.16 — — — — — — —

— — — 0.04 0.05 0.06 0.07 0.07 0.08 0.09 0.10 — — — — — — —

— — — — — — — 0.06 0.07 0.07 0.08 0.09 0.09 0.10 0.11 0.12 0.13 0.14

Accessory Electric Heat Pressure Drop (IN. W .C.)

HEATER

kW

800 1000 1200 1400 1600 1800 2000 2200

5--20 0.033 0.037 0.042 0.047 0.052 0.060 0.067 0.075

Wet Coil Air Delivery*

(Deduct 10 percent for 208 Volt Operation)

230 VOLT HORIZONTAL DISCHARGE

50ZHC

UNIT

SIZE

024

030

036

042

048

060

*Air delivery values a r e based on operating voltage of 230v, wet coil, without filter or electric heater. Deduct filter and electric h ea ter pressure drops to obtain

static pressure available for ducting.

NOTES:

1. Do not operate the unit at a cooling airflow that is less than 350 cfm for each 12,000 Btuh of rated cooling capacity. Evaporator coil frosting may occuratairflows below this point.

2. Stan dard Cubic Feet per Minute

SPEED TAP AIR DELIVERY

1 SCFM 933 799 758 707 675 608 549 497 435 394

2 SCFM 1016 921 882 854 809 761 711 668 599 552

3 SCFM 1079 1041 1003 970 944 909 866 810 764 724

1 SCFM 1052 1018 984 943 914 879 833 795 732 678

2 SCFM 1141 1107 1069 1036 1006 974 932 899 856 784

3 SCFM 1246 1213 1181 1144 1108 1078 1043 1015 973 931

1 SCFM 1311 1253 1195 1136 1083 1023 958 895 818 729

2 SCFM 1413 1364 1313 1256 1203 1148 1084 1022 969 882

3 SCFM 1571 1525 1473 1423 1364 1313 1261 1210 1156 1090

1 SCFM 1499 1434 1394 1349 1307 1273 1232 1169 1108 1038

2 SCFM 1568 1532 1497 1459 1407 1381 1346 1304 1252 1185

3 SCFM 1635 1593 1560 1523 1484 1439 1406 1369 1335 1264

1 SCFM 1657 1625 1590 1554 1517 1486 1448 1417 1381 1340

2 SCFM 1707 1673 1644 1614 1586 1549 1515 1479 1449 1407

3 SCFM 1931 1900 1870 1840 1809 1778 1749 1714 1683 1646

1 SCFM 1774 1746 1717 1678 1639 1590 1538 1492 1461 1418

2 SCFM 1857 1820 1784 1752 1720 1671 1625 1579 1532 1509

3 SCFM 2183 2144 2115 2079 2049 2018 1986 1933 1859 1733

2

0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1.0

CFM

CFM

EXTERNAL STATIC PRESSURE (IN. W.C.)

18

Page 19

ELECTRICAL DATA

Units

Nominal

V-PH-HZ

Voltage

Range

MIN MAX FLA FLA kW* 208 240 208 230

24 208/230-1-60 197 253 10.3 61.6 0.9 2.8

30 208/230-1-60 197 253 13.5 72.5 0.9 2.8

36 208/230-1-60 197 253 14.7 75.0 1.7 4.1

42 208/230-1-60 197 253 16.3 112.3 1.7 4.1

48 208/230-1-60 197 253 18.3 108.0 1.7 6.0

60 208/230-1-60 197 253 26.2 144.2 1.9 7.6

*kW @ 208/240

** HACR Type Circuit Breaker

LEGEND

F L A --- F u l l L o a d Am p s

LRA --- Locked Rotor Amps

MCA --- Minimum Circuit Amps

MOCP --- Maximum Overcurrent Protection

RLA --- Rated Load Amps

NOTES:

1. In compliance with NEC (National El ectrical Code) requirements for multimotor and combination load equipment (refer to NEC Articles 430 and 440), the

overcurrent protective device for the unit shall be Power Supply fuse or circuit breaker.

2. Minimum wire size is based on 60_Ccopperwire.Ifotherthan60_C wire is used, or if length exceeds wire len gth in tabl e, determine size from NEC.

*Heater capacity (kW) based on heater vol tage of 208v & 240v. If power distribution voltage to unit varies from rated heater voltage, heater kW will vary accordingly.

Compressor Electrical Heat Power Supply

RLA LRA

OFM IFM Nominal FLA MCA

-/- - - 16.6 16.6 25

3.8/5 18 20.8 39.1 42.6 40/45

5.6/7.2 27 31.3 50.3 55.7 60/60

7.5/10 36.1 41.7 61.7 68.7 70/70

-/- - - 20.6 20.6 30

3.8/5 18 20.8 43.1 46.6 45/50

5.6/7.2 27 31.3 54.3 59.7 60/60

7.5/10 36.1 41.7 65.7 72.7 70/80

-/- - - 24.2 24.2 35

3.8/5 18 20.8 46.7 50.2 50/60

5.6/7.2 27 31.3 57.9 63.3 60/70

7.5/10 36.1 41.7 69.3 76.3 70/80

11.3/15 54.1 62.5 91.8 102.3 100/110

-/- - - 26.1 26.1 40

3.8/5 18 20.8 48.7 52.5 50/60

5.6/7.2 27 31.3 59.9 65.3 60/70

7.5/10 36.1 41.7 71.3 78.3 80/80

11.3/15 54.1 62.5 93.8 104.3 100/110

-/- - - 30.6 30.6 45

3.8/5 18 20.8 53.1 56.6 60/60

5.6/7.2 27 31.3 64.3 69.7 70/70

7.5/10 36.1 41.7 75.7 82.7 80/90

11.3/15 54.1 62.5 98.2 108.7 100/110

15.0/20.0 72.1 83.3 120.7 134 125/150

-/- - - 42.3 42.3 60

3.8/5 18 20.8 64.8 68.3 70/70

5.6/7.2 27 31.3 76.0 81.4 80/90

7.5/10 36.1 41.7 87.4 94.4 90/100

11.3/15 54.1 62.5 109.9 120.4 110/125

15.0/20.0 72.1 83.3 132.4 146.4 150/150

MOCP**

50ZHC

19

Page 20

TYPICAL INSTALLATION

RETURN

AIR

INDOOR

THERMOSTAT

TOP COVER

FROM

POWER

SOURCE

50ZHC

Power Wir ing

Control Wiring

Condenser Airflow

Evaporator Airflow

LOW VOLTAGE

ENTRY

POWER

ENTRY

COMPOSITE

RUST-PROOF

BASEPAN

CONDENSATE

DRAIN

CONNECTION

DISCONNECT

PER NEC

(UNIT AND

ELECTRIC

HEATER)

A10135

20

Page 21

TYPICAL CONNECTION WIRING SCHEMATIC—208/230--1--60

50ZHC

21

A14563

Page 22

TYPICAL LADDER WIRING SCHEMATIC—208/230--1--60

50ZHC

22

A14564

Page 23

TYPICAL WIRING SCHEMATIC (CONT)

Wires to be removed

50ZHC

Accessory Electric Heater Wiring

CONTROLS

Sequence of operation

When power is supplied to unit, the transformer (TRAN) is

energized.

Cooling Operation — With a call for cooling (O,Y,G), the

reversing valve, contactor, and indoor fan are energized. When the

cooling demand is met, Y and G are de--energized, shutting off the

contactor (compressor, outdoor fan). The indoor fan stops after a

60 second delay.

Heating Operation — With a call for heating (Y,G), the contactor

and indoor fan are energized. When the heating demand is met, Y

and G are de--energized, shutting off the contactor (compressor,

outdoor fan). The indoor fan stops after a 60 second delay.

Continuous Fan — With the continuous indoor fan option

selected on the thermostat, G is continuously energized keeping the

indoor fan running at all times.

Defrost — The defrost control is a time/temperature control which

includes a field--selectable time period between defrost cycles of

30, 60, and 90 minutes. Electronic timer and defrost cycle start

only when contactor is energized and defrost thermostat (DFT) is

closed.

Defrost mode is identical to cooling mode, except outdoor fan

motor stops and a bank of optional electric heat turns on to warm

air supplying the conditioned space.

A14444

APPLICATION DATA

Condensate trap — A 2 --in. (51 mm) condensate trap must be field

supplied.

1” (25 mm) MIN

Maximum cooling airflow — To minimize the possibility of

condensate blow--off from the evaporator, airflow through the units

should not exceed 450 CFM/ton.

Minimum cooling airflow — The minimum cooling airflow is

350 cfm/ton.

Minimum cooling operating outdoor air temperature —All

standard units have a minimum ambient operating temperature of

40F(4.4C). With accessory low ambient temperature kit, units

can operate at temperatures down to 0F (--17.8C).

Maximum operating outdoor air temperature —Maximum

outdoor operating air temperature for cooling is 125F (51.7C).

.

TRAP

OUTLET

2” (51 mm) MIN.

23

Page 24

GUIDE SPECIFICATIONS

SMALL PACKAGED PRODUCT AIR--TO--AIR

HEAT PUMP CONSTANT VOLUME APPLICATION

HVAC GUIDE SPECIFICATIONS

SIZE RANGE: 2 TO 5 TONS, NOMINAL (COOLING)

PART I -- GENERAL

SYSTEM DESCRIPTION

Outdoor packaged, electrically controlled, air--to--air heat

pump utilizing a scroll compressor for heating and cooling

duty. Unit shall discharge supply air horizontally as shown on

contract drawings.

QUALITY ASSURANCE

A. Unit shall be rated in accordance with AHRI Standards

210/240, and 270. Designed in accordance with UL

Standard 1995.

B. Unit shall be designed to conform to ASHRAE 15 .

C. Unit shall be UL listed as a total package for safety

requirements.

D. Insulation and adhesive shall meet NFPA 90A

50ZHC

requirements for flame spread and smoke generation.

DELIVERY, STORAGE, AND HANDLING

Unit shall be stored and handled per manufacturer’s

recommendations.

PART 2-- PRODUCTS

EQUIPMENT

A. General:

Factory--assembled, single piece, air-- to--air heat pump.

Contained within the unit enclosure shall be all factory wiring,

piping, controls, and refrigerant charge (R--410A).

B. Unit Cabinet:

1. Unit cabinet shall be constructed of phosphated,

bonderized, zinc--coated, prepainted steel.

2. Basepan shall be made of a single--piece non--corrosive,

composite material.

3. Indoor fan compartment cabinet surfaces shall be insulated

with a minimum 1/2 in. (12.7 mm) thick, flexible

insulation, coated on the air side, with aluminum foil--faced

insulation.

4. Cabinet panels shall be easily removable for servicing.

5. Unit shall have a factory-- installed, sloped, noncorrosive,

condensate drain.

6. Unit insulation conforms to ASHRAE 62P.

C. Fans:

1. Indoor Blower (Indoor Fan):

a. Fan shall be multispeed, direct drive as shown on the

equipment drawings.

b. Fan wheel shall be made from steel, be double--inlet

type. It shall have forward--curved blades with a

corrosion--resistant finish and shall be dynamically

balanced.

2. Outdoor fan shall be of the direct--driven propeller type

with aluminum blades, riveted to corrosion--resistant steel

spiders. It shall be dynamically balanced, and shall

discharge air upwards.

D. Compressor:

Fully--hermetic scroll type with external vibration isolation.

E. Coils:

1. Indoor and outdoor coils shall have aluminum--plate fins

mechanically bonded to seamless copper tubes with all

joints brazed.

2. Tube sheet openings shall be bellied to prevent tube wear.

3. Outdoor coil shall be protected by metal louvered panels.

F. Refrigerant Components:

1. TXV and AccuRater feed system.

2. Service gauge connections on suction and discharge lines.

3. Equipped with liquid line filter drier.

4. Equipped with accumulators on all sizes.

G. Controls and Safeties:

1. Unit Controls:

a. Unit shall be complete with self--contained low voltage

control circuit.

b. Unit shall incorporate an outdoor coil defrost system to

prevent excessive frost accumulation during heating

cycle and shall be controlled as follows:

(1.) Defrost shall be initiated on the basis of time and

coil temperature.

(2.) A 30/60/90-- minute timer shall activate defrost

cycle only if coil temperature is low enough to

indicate a heavy frost condition.

(3.) Defrost cycle shall terminate when defrost

thermostat is satisfied or shall have a positive

termination time of 10 minutes.

2. Safeties:

a. High Pressure Switch

b. Loss of Charge Switch

H. Operating Characteristics:

1. Unit shall be capable of starting and running at 125F

(51.7C) ambient outdoor temperature (60 size max ambient is 115F [46.1C]).

2. Compressor with standard controls shall be capable of

operation down to 40F(4.4C) ambient outdoor

temperature in cooling duty.

3. Compressor shall be capable of operation in heating cycle

down to --20F (--28.9C) ambient outdoor--air temperature.

4. Unit shall be capable of simultaneous heating duty and

defrost cycle operation when using electric heaters indicated

in Section L, Special Features.

I. Electrical Requirements:

All unit power wiring shall enter unit cabinet at a single

location.

J. Motors:

1. Compressor motors shall be of the refrigerant--cooled type

with line break thermal and current overload protection.

2. All fan motors shall have permanently lubricated bearings

and inherent automatic--reset thermal overload protection.

3. Outdoor-- fan motor shall be totally enclosed.

24

Page 25

GUIDE SPECIFICATIONS (CONT)

K. Grille

1. Louvered Grille:

Louvered grille shall be standard on all units.

L. Special Features Available

1. Coil Options:

Shall include factory--installed optional tin--plated indoor

coil.

2. Thermostat:

To provide for two-- stage heating and one--stage cooling in

addition to manual or automatic changeover and indoor fan

control.

3. Low--Ambient Package:

Shall consist of a solid-- state control and outdoor coil

temperature sensor for controlling outdoor fan motor

operation, which shall allow unit to operate down to 0F

(--17.8C) outdoor ambient temperature in cooling.

4. Crankcase Heater:

Shall provide anti--floodback protection for low--load

cooling applications.

5. Electric heaters:

a. Electric heater shall be available as a field--installed

option.

b. Heater elements shall be open wire type, adequately

supported and insulated with ceramic bushings.

c. Electric heater packages must provide single point

power connection capability.

6. Compressor Start Kit:

Shall be available to give a boost to the compressor motor

at each start--up.

7. Outdoor Thermostat Kit:

Thermostat allows for staging of electric heaters based on

outdoor air temperature.

50ZHC

25

Page 26

50ZHC

Copyright 2015 Carrier Corp. D 7310 W. Morris St. D Indianapolis, IN 46231 Edition Date: 04/15

Manufacturer reserves the right to change, at any time, specifications and designs without notice and without obligations.

26

Catalog No: 50ZHC--- 02PD

Replaces: 50ZHC ---01PD

Loading...

Loading...