Page 1

installation instructions

ZONE PERFECT™

TWO-ZONE

NOTE: Read the entire instruction manual before starting the

installation.

This symbol → indicates a change since the last issue.

TABLE OF CONTENTS

Safety Considerations.....................................................................1

Installation Considerations.............................................................1

Introduction ....................................................................................1

Installation...................................................................................1-4

Sequence Of Operation...............................................................4-7

Thermostat Wiring......................................................................6-8

Care And Maintenance ..................................................................8

Troubleshooting ........................................................................9-11

Wiring Diagrams.....................................................................12-16

Wiring Diagram Notes.................................................................16

SAFETY CONSIDERATIONS

Improper installation, adjustment, alteration, service, maintenance,

or use can cause fire, electrical shock, or other conditions which

may cause personal injury or property damage. Consult a qualified

installer, service agency, or your distributor or branch for information or assistance. The qualified installer or agency must use

factory-authorized kits or accessories when modifying this product. Refer to the individual instructions packaged with the kits or

accessories when installing.

Follow all safety codes and wear safety glasses. Have fire

extinguisher available. Read these instructions thoroughly and

follow all warnings or cautions attached to the unit. Consult local

and state building codes and Sheet Metal and Air Conditioning

National Association (SMACNA) for special installation requirements.

Recognize safety information. This is the safety-alert symbol

When you see this symbol on the unit or in instructions and

manuals, be alert to the potential for personal injury.

Understand the signal words DANGER, WARNING, or CAUTION. These words are used with the safety-alert symbol. DANGER identifies the most serious hazards which will result in severe

personal injury or death. WARNING signifies hazards which

could result in personal injury or death. CAUTION is used to

identify unsafe practices which would result in minor personal

injury or product and property damage.

INSTALLATION CONSIDERATIONS

→

1. Install in non-condensing area with ambients between 32°F

and 150°F.

2. Use vibration isolators (flex connectors) on zone dampers

and ductwork to minimize noise.

3. Place dampers away from areas that may be noise sensitive.

4. TXV is required in air conditioning and heat pump applications.

5. Use separate isolated transformer to supply power to Zone

Perfect Two-Zone Center. (40va minimum, class 2, transformer, field supplied)

PAGE

ZONEKIT

Cancels: II ZONEKIT-0-2 II ZONEKIT-0-6

6-97

®

T'stat

Y2

Y1

R

W1

W2

C

G

Y2

HP

→

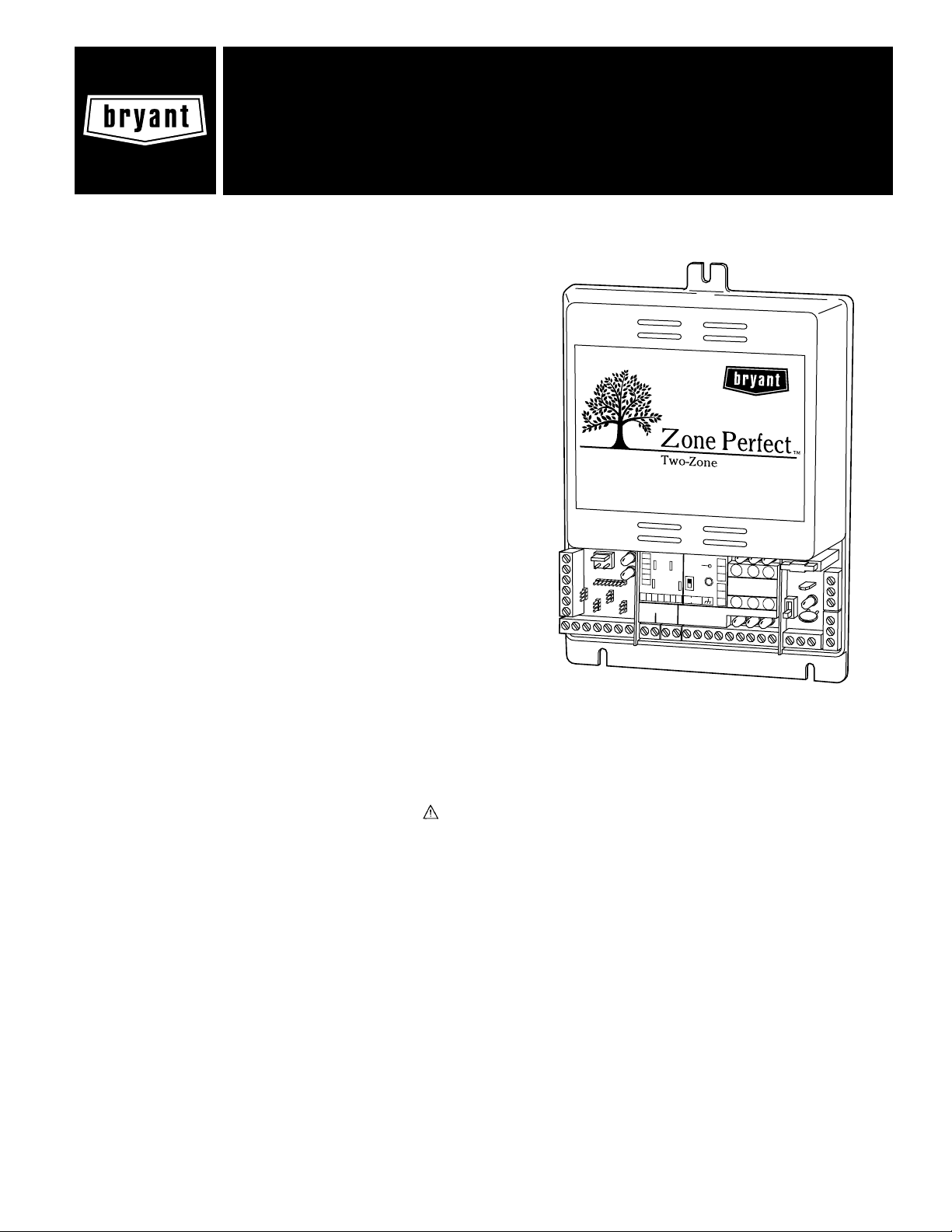

Fig. 1—Zone Perfect Two-Zone System

(Shown Without Cover)

6. Load calculations must be performed to determine equipment size. Equipment selection is matched to block load. It

is imperative equipment is not over sized.

7. Ductwork must be designed based off the sum of peak plus

.

25 percent oversize. It is imperative ductwork is not under

sized.

The Zone Perfect Two-Zone System allows the air conditioning

and heating equipment to control temperatures in 2 distinct spaces

or zones within a building. Each zone has independent temperature

settings controlled by a thermostat.

NOTE: Thermostats are purchased separately.

The comfort temperature settings can change automatically

through the use of schedules if programmable thermostats are

selected. This allows Zone Perfect Two-Zone to change the

temperature settings in zones to reflect occupancy or usage. The

Zone Perfect Two-Zone System uses motorized air volume control

dampers (also called zone dampers) to regulate the flow of

conditioned air into the zones.

I. CHECK EQUIPMENT AND JOBSITE

A. Inspect Equipment

File claim with shipping company, prior to installation, if shipment

is damaged or incomplete.

RC-RH

Equpimt

Jumper

Z

Fnc

Emergency

HP

24 VAC

RC

Equipment Term.

C1

o

Op

n

G

Heat

e

C

1

On

WARNING!

Z

C1

Off

o

under this label

Op

n

e

C

2

Rev

B

O

Y2

Y1

W1

DTO

Y1

Sensors

HP

Fnc

Fnc Ht

Off

w/oF

On

w/F

R

W1W2 C

Duct

INTRODUCTION

INSTALLATION

Y1

HOT parts

W1

W2

3

Y2

W2

G

RH

A97291

—1—

Page 2

II. WIRING

WARNING: To prevent personal injury or possible

equipment damage, disconnect the power supply before

routing wire.

All wiring must comply with local, state, and national codes.

NOTE: Use No. 18 AWG color-coded, insulated (35°C min)

wire. If thermostats are to be located more than 100 ft from the

Zone Perfect Two-Zone Center as measured along the control

voltage wires, use 16 AWG colored-coded wires to avoid excessive voltage drop. All wiring is run back to the Zone Perfect

Two-Zone Center.

III. INSTALL ZONE PERFECT TWO-ZONE

→

NOTE: Zone Perfect Two-Zone is approved for indoor use only

and should never be installed with any of its components exposed

to the elements. Do not mount Zone Perfect Two-Zone Center

where it will be accessible to children. Do not locate the center in

areas of the home that are noise sensitive since relays are energized

and de-energized during operation and may be an annoyance.

Install Zone Perfect Two-Zone in an area with a temperature range

between 32°F and 150°F.

Install Zone Perfect Two-Zone center in a vertical position. Locate

in an area that is easily accessible in case servicing should be

required.

CAUTION: To prevent possible damage to the Zone

Perfect Two-Zone Center, do not mount on plenum,

ductwork, or flush against furnace.

IV. INSTALL ZONE DAMPERS

IMPORTANT: If conditions exist for possible condensing, the

motor must be positioned for adequate draining. (See Fig. 2.)

NOTE: If a multi-damper enabler is used to link dampers

together, then add 5va per damper to the transformer power supply

rating. Reference multi-damper enabler Installation Instructions.

Zone dampers may be installed in any direction.

Install dampers so the actuator is visible for inspection and

accessible in the event it would ever need service. The black mark

on the end of the damper shaft represents the position of the

damper blade.

Before insulating the ductwork, check for proper damper operation. Apply 24vac between COM and OPN to open the damper and

COM and CLS to close the damper. (See Fig. 3.) The damper will

modulate counter-clockwise to open and clockwise to close.

MOUNTING

HUB

ACTUATOR

HOUSING

QUICK BLADE

RELEASE

BUTTON

(RED)

FIELD

INSTALLED

POWER WIRING

Fig. 3—Damper 24-vac Connections

AIRFLOW

AIRFLOW

90

45

0

CLS

COM

OPN

POSITION

INDICATOR

ANGULAR

ROTATION

STOPS

MOUNTING

BRACKET

A95096

If in an emergency it becomes necessary to force a damper open

manually, press in red quick blade release button with 1 hand and

turn mounting hub to reposition the damper shaft. Release button

to hold damper shaft in the new position.

To avoid noise and vibration, do not hard mount dampers to any

solid structure such as joists.

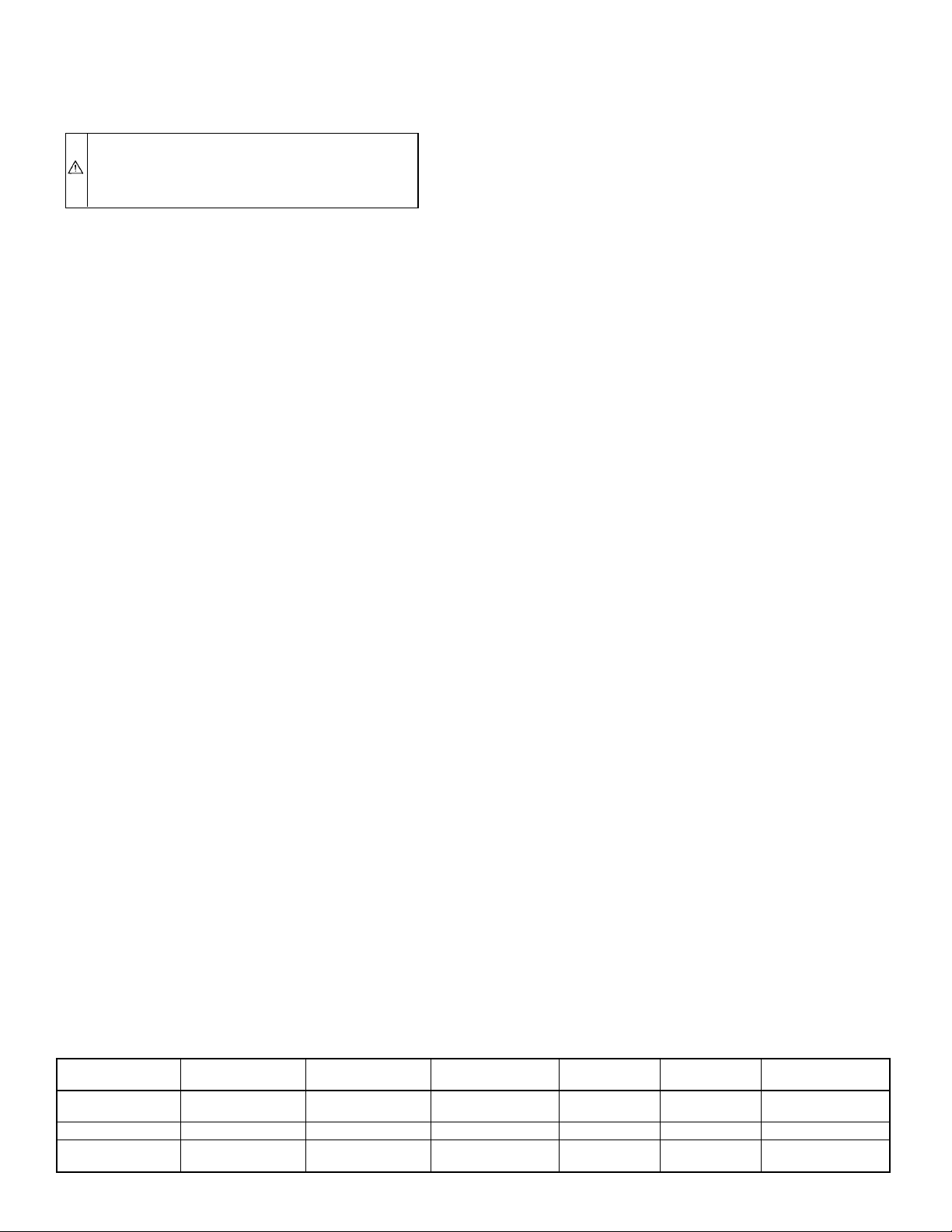

A. Round Metal Ductwork

IMPORTANT: If application exists with all metal ductwork

without insulation, flex connectors should be used on each end of

the zone dampers to avoid noise and vibration.

1. Crimp end of branch duct.

2. Slip end of flex connector over zone damper and use

self-tapping sheet metal screw to secure. (See Fig. 4.)

DAMPER MOUNTING

ACTUATOR

Fig. 2—Damper Motor Positioning

BRACKET

A95128

NOTE: Insulate damper using 1-1/2 in. insulation (check local

codes). In areas where excessive condensing may occur, carefully

insulate over the actuator assembly. Make sure insulation does not

interfere with operation of actuator.

—2—

SUPPLY

FLEX

CONNECTOR

ZONE DAMPER

Fig. 4—Round Metal Ductwork

A95129

3. Properly seal joint using duct tape, mastic, or other approved method. Do not allow mastic to come in contact

with actuator.

4. Insulate damper using 1-1/2-in. to 2-in. insulation. (Check

your local codes.) (See Fig. 5.)

NOTE: All zone dampers and ductwork must be properly supported according to local codes or SMACNA standards.

B. Rectangular Metal Ductwork

1. Make connections using S-lock and drives. (See Fig. 6.)

2. Properly seal joint using duct tape, mastic, or other approved method. Do not allow mastic to come in contact

with actuator.

Page 3

1

/ ″ STEEL STRAP

2

FLEXIBLE

DUCT

ZONE

DAMPER

Fig. 5—Insulated Round Metal Ductwork

S-LOCK

SUPPLY

AIR DUCT

DRIVE

Fig. 6—Rectangular Metal Ductwork

3. Insulate damper using 1-1/2-in. to 2-in. insulation. (Check

your local codes.) (See Fig. 7.)

1

2

1 / " TO 2"

INSULATION

A95130

ZONE

DAMPER

A92478

Fig 8—Round Flexible Ductwork

A95132

NOTE: All zone dampers and ductwork must be properly supported according to local codes or SMACNA standards.

1

2

/ ″ STEEL STRAP

A95133

Fig. 9—Insulated Round Flexible Ductwork

D. Rectangular Fibrous Glass Ductwork

1. Insert 1 end of zone damper into 1 end of fibrous glass

ductwork approximately 2 to 3 in. (See Fig. 10.)

FIBROUS

GLASS

DUCTWORK

FIELD

SUPPLIED

SCREWS

ZONE

DAMPER

A95131

Fig. 7—Insulated Rectangular Metal Ductwork

NOTE: All zone dampers and ductwork must be properly sup-

ported according to local codes or SMACNA standards.

NOTE: There should be a minimum of 4 ft between the zone

damper and the first branch duct if more than 1 branch duct is

downstream of the zone damper.

C. Round Flexible Ductwork

1. Slip 1 end of flexible ductwork over 1 end of zone damper.

(See Fig. 8.)

2. Secure the flexible duct to zone damper using SMACNA or

other approved method.

3. Properly seal joint using duct tape, mastic, or other approved method. Do not allow mastic to come in contact

with actuator.

4. Insulate damper using 1-1/2-in. to 2-in. insulation. (Check

your local codes.) (See Fig. 9.)

2″ TO 3″

A92480

Fig. 10—Rectangular Fibrous Glass Ductwork

2. Screw field-supplied screws and tabs into zone damper.

3. Properly seal joint using duct tape, mastic, or other approved method. Do not allow mastic to come in contact

with actuators

4. Insulate damper using 1-1/2-in. to 2-in. insulation. (Check

your local codes.) (See Fig. 11.)

1

2

1 / ″ TO 2″

INSULATION

A95134

Fig. 11—Insulated Rectangular Fibrous Glass Ductwork

V. INSTALL BAROMETRIC BYPASS DAMPER

NOTE: The barometric bypass damper is a critical part of the

Zone Perfect Two-Zone System for control of minimum airflow

and noise reduction. It is recommended that the bypass be

installed.

—3—

Page 4

The bypass should be installed according to local codes and

SMACNA standards. Be sure the bypass is properly supported.

For proper installation, refer to the Installation Instructions packaged with the barometric bypass.

CAUTION: Failure to properly install the bypass

damper can cause permanent damage to the HVAC

equipment. For single-speed furnace applications, the

bypass air must never exceed 25 percent.

VI. INSTALL LEAVING AIR TEMPERATURE DUCT SEN-

→

SOR

Locate duct temperature sensor in main supply trunk after heating

and cooling coil and before the bypass damper and before the first

branch. The duct sensor must be radiant shielded to prevent heat

from affecting the correct air temperature.

1. Drill 1/4-in. hole at location in supply trunk where sensor

will be installed.

2. Insert sensor in hole and use as template to mark 2

mounting holes.

3. Drill two 1/16-in. holes to accept No. 6 screws through

pre-drilled holes in duct temperature sensor back plate.

4. Use 2 No. 6 sheet metal screws to mount duct temperature

sensor to unit.

5. Connect sensor to 2-conductor wire using provided wire

nuts. (See Fig. 12 for connection to equipment controller.)

→

VII. INSTALL HEAT PUMP (HP) TEMPERATURE SENSOR

The HP temperature sensor is required in all heat pump/fan coil

installations. It is not used in dual fuel (heat pump/furnace

installation.) It measures the indoor coil temperature. The sensor is

to be installed downstream of the indoor coil, but before the

electric heaters. It can be installed through the wall of the fan coil

or may be located entirely inside the fan coil near the blower inlet.

Anchor firmly in place with cable ties so that it cannot interfere

with the blower wheel. To activate the HP temperature sensor,

remove factory supplied resistor from HP terminal block and

replace with sensor leads. When activated, the HP temperature

sensor has built in LAT set points of 50°F and 45°F in the cooling

mode, and 105°F and 110°F in the heating mode. This is

non-adjustable. (See Fig. 12 for connection to Zone Perfect

Two-Zone center.)

SEQUENCE OF OPERATION

I. SEQUENCE OF EVENTS FOR A NORMAL HEATING

OR COOLING CYCLE

The thermostats will determine if active heating or cooling is

required. If so, the Zone Perfect Two-Zone system will perform

the following:

• Make sure all zone dampers are fully open.

• Energize HVAC equipment fan.

• Energize heating or cooling equipment. The equipment may be

a compressor, furnace, strip heater, etc.

• Set zone damper to the open or closed position based upon

individual zone demand.

• Energize additional stages of heating or cooling if the thermostat

demand warrants.

• Turn off heating or cooling equipment when all zones are

satisfied.

• Open all zone dampers when equipment is turned off (after 90

sec delay).

This is the basic sequence of operation for the Zone Perfect

Two-Zone System. The actual control of the dampers, HVAC

equipment, and system fan will change with the configuration of

the system. Depending upon the configuration, Zone Perfect

Two-Zone can control heat pumps, furnaces, and dual fuel

applications, (dual fuel will require a third party relay interface).

II. SELECTION OF A SYSTEM MODE

The first step in any heating or cooling cycle requires Zone Perfect

Two-Zone to receive an input from any thermostat located in a

zone. Zone Perfect Two-Zone will then prepare to operate the

heating or cooling equipment as requested by the thermostat. (See

Fig. 12.)

III. PRE-POSITIONING DAMPERS AND STARTING

SYSTEM FAN

In order to minimize noise and enhance system operation, Zone

Perfect Two-Zone maintains fully open zone dampers prior to

starting the system fan or the heating/cooling equipment. The

intent is to provide the HVAC equipment with unrestricted

ductwork and to reduce pressure surges. Zone Perfect Two-Zone

also fully opens the dampers whenever a heating or cooling cycle

is completed (this is done after a 90 sec delay). All zone dampers

will remain fully open until the next heating or cooling cycle.

The other reason for opening the dampers is to provide unrestricted

ductwork to other equipment which is not directly controlled by

Zone Perfect Two-Zone. One example may be a Heat Recovery

Ventilator. If Zone Perfect Two-Zone is not actively controlling

the HVAC system, then it must not impose any control influences

(such as closed zone dampers) on the system and prevent proper

operation of other devices.

Only the zone 1 thermostat controls continuous fan operation.

When the zone 1 thermostat has the fan selector switch in the

AUTO position, the fan will operate only when the heating and

cooling equipment is operating. When the zone 1 thermostat has

the fan selector switch in the ON position, the fan will operate

continuously. Zone 2 will not control this.

IV. HVAC EQUIPMENT CONNECTIONS

The Zone Perfect Two-Zone relay outputs are shown in Table 1.

The Y1 and Y2 contacts are used for the compressor contactor

only. Zone Perfect Two-Zone operates the heat pump by energizing the compressor contactor and controlling the reversing valve

through the O relay output. The W1 and W2 contacts are always

used for heat sources. These are heating only units such as

furnaces, strip heaters, etc. The relay outputs for Zone Perfect

Two-Zone are shown in Table 1.

In automatic changeover, the zoning system works on a first come

first serve basis. If 1 zone is calling for heating and the other for

cooling, the zone which sent its demand to the I/O center first will

operate the equipment in that mode until that zone is satisfied.

TABLE 1—AVAILABLE HEATING AND COOLING STAGES VERSUS SYSTEM TYPE

TYPE OF HVAC

EQUIPMENT USED

Single-Stage Heat

Pump

2-Stage Heat Pump Y1 Y2 Energized Y1/W1 W2 De-energized

Cooling Only, any

Heater Type

COOLING STAGE 1 COOLING STAGE 2

Y1 — Energized Y1/W1 W2 De-energized

Y1 Y2 — W1 W2 —

REVERSING VALVE

O

HEAT STAGE 1 HEAT STAGE 2

REVERSING VALVE

O

—4—

Page 5

V. DUCT TEMPERATURE OPTIMIZER (DTO)

→

FOR MONITORING LEAVING AIR TEMPERATURE

As Zone Perfect Two-Zone System operates through a heating or

cooling cycle, the zone demands will change. This changes the

actual load that is applied to the HVAC equipment. If the zone

airflow decreases, the cooling equipment will tend to lower

supply-air temperatures which could tend to exceed the LAT trip

limits. Conversely, the heating equipment will tend to raise

supply-air temperatures which could exceed high trip limits. In

cooling, when the LAT reaches the non-adjustable low temperature trip limit (50°F) the LAT algorithm begins operating, closed

dampers are initially opened 3 positions, then 1 position every 20

sec there after until full open. Zone Perfect Two-Zone will not shut

down second-stage cooling (if used); however, if temperature

continues to drop to 45°F, the zoning system will turn off both

stages of cooling. If the temperature improves, the system will stay

in the duct temperature optimizer mode until the LAT reaches

55°F or higher. At 55°F the LAT algorithm will reset and return

dampers to their original position. In the heating mode, Zone

Perfect Two-Zone will perform the same duct temperature optimization. The trip limits will be determined by the jumper setting.

(See Fig. 12.) This will continue until the LAT problem is

corrected.

This control helps Zone Perfect Two-Zone System cope with

installations where the air conditioning system may suffer from

poor ductwork, improperly sized heating or cooling equipment,

and/or improper settings of the barometric bypass damper. This

control is especially useful in retrofit applications where the size

and routing of the ductwork may not be entirely known or

satisfactory.

The duct temperature optimizer works by controlling how cold or

hot the air inside the supply-air duct gets by monitoring the

temperature of the air inside the supply-air system.

Whenever Zone Perfect Two-Zone is providing heating or cooling,

the zone within the home that is asking for conditioned air will

always have its damper fully open. The other zone in the system

may or may not have an open damper depending upon its

particular needs. If the ductwork is too small (or the air

conditioner/heater is too large), then the zone requiring conditioned air may not be able to take enough air to allow your

equipment to operate properly. Zone Perfect Two-Zone will detect

this, and open up the closed damper allowing the equipment to

continue to operate.

CAUTION: The duct temperature optimizer may be

disabled on the control center. A 10k resistor can be

installed in place of the duct sensor at the terminal block.

By disabling the duct temperature optimizer, the LAT

safety algorithm is removed from the system.

It is highly recommended that you use this control option. The

heating LAT is adjustable for the duct sensor. In this Installation

Instruction, you will find the section showing an adjustment for the

heating LAT. (See Fig. 12.) It is very important that this temperature is properly set. For gas or oil furnaces, the temperature limit

will be in the higher temperature range. For heat pumps the

temperature setting should always be in the lower temperature

range.

If you encounter a situation where 1 zone seems to have poor

ductwork, then the Zone Perfect Two-Zone system is capable of

reverting back to a fully open, constant-volume system. If this

condition persists, it should always be looked upon as an indication

of a HVAC problem, not a Zone Perfect Two-Zone problem.

VI. ELECTRONIC THERMOSTAT CONNECTION WITH

ZONE PERFECT TWO-ZONE CONTROL

Bryant electronic non-programmable and programmable thermostats can be connected to the Zone Perfect Two-Zone. See pre-sale

literature for thermostat part numbers.

NOTE: The zone control board is only capable of 2-stage heat

and 2-stage cool operation. Fig. 13 and 14 will reflect these

applications only. Review and understand the following items

before installing.

A. Thermostat Setup

1. Thermostat will not operate unless both R and C are

connected to zone module input.

2. If selected thermostat is a heat pump (HP) or 2-speed (2S)

model, convert thermostat to air conditioning operation.

This will assure that Y signals are generated for cooling,

and W signals are generated for heating from thermostat to

zone module input. The thermostat O/W2 output will now

be the second-stage heat call. If installation is a heat pump

system, the zone control board will provide proper output

signal to heat pump.

3. Select "Zoning" option on thermostat. This will disable the

Timeguard and 4-cycle per hr (cph) protection built into

thermostat. Let zone control board perform the Timeguard

and cycle protection. Refer to thermostat Installation Instruction under Zoning for more detail.

4. The zone 1 thermostat is the only thermostat that can

control continuous fan operation with zoning. Connect G

between zone 1 thermostat and zone 1 input on zone control

module.

5. Follow all safety and installation considerations outlined in

the thermostat Installation Instructions.

B. Zone Control Board Setup

1. Configure zone control board jumper for Tstat (thermostat)

Fnc option only. Do not use Tstat HP option. When Tstat

Fnc is selected this will setup control inputs to recognize Y1

and Y2 for first- and second-stage cooling, W1 and W2 for

first- and second-stage heating.

2. Configure zone control board for either Equipmt (equipment), HP or Fnc. When a heat pump system is used,

Equipmt HP mode should be selected. The zone control

board will provide the proper output signal to the heat

pump. When a gas/electric furnace is used, Equipmt Fnc

mode should be selected for proper output signal.

3. Configure zone control board for either Fnc Ht, w/f (with

fan), or w/of (without fan). With Fan mode should be

selected when a heat pump is installed and fan is needed to

come on immediately with demand. Without Fan mode

should be selected when fan is controlled by gas/electric

furnace.

4. Configure zone control board for either DTO On or Off.

When DTO On is selected (Factory default) and if a LAT

trip occurs, closed dampers will begin opening to try and

keep equipment running by maintaining proper air temperatures. However, if LAT temperatures exceed their limits,

equipment will start staging down. When DTO Off is

selected, equipment will stage down. Closed dampers will

not open on initial trip, however if LAT temperatures

exceed their limits, control will lock out and damper will

open.

→

NOTE: An HP temperature sensor must be used with a heat pump

application using electric strip heat. This is necessary in case the

DTO is set to the Off position.

—5—

Page 6

Thermostat

Zone 2

Y2

Y1

R

W

W2

C

1

1

G

D

4

Y1

W1

Y2

R

Thermostat

Zone 1

W2

B

C

G

2

3

Duct

HP

Sensors

H

L

Rc

I

O

B

Y

Equipment

J

K

M

N

Y1

W2

W1

Rh

G

2

C

3

24

24 VAC

Power

E

v

A

F

CL

OP

C

CL

OP

C

Zone

1

Damper

Zone

2

Damper

A97293

I/O CENTER CONNECTIONS

GGY2Y2Y1Y1RRW1W1W2W2C

ZONE 1

††

*

C

THERMOSTAT/SUBBASE

CONNECTIONS

ONLY HOOKUP "C" WHEN SUPPLIED BY THERMOSTAT

*

†

HOOKUP WHEN USING APPLICABLE TWO-STAGE

THERMOSTATS WITH TWO-STAGE EQUIPMENT

→ Fig. 12—Zone Perfect Two-Zone Circuit Board with Standard Thermostat Wiring

I/O CENTER CONNECTIONS

Y2Y2Y1Y1RRW1W1W2W2C

ZONE 2

††

*

C

THERMOSTAT/SUBBASE

CONNECTIONS

ONLY HOOKUP "C" WHEN SUPPLIED BY THERMOSTAT

*

†

HOOKUP WHEN USING APPLICABLE TWO-STAGE

THERMOSTATS WITH TWO-STAGE EQUIPMENT

A93494 A93495

—6—

Page 7

NON-PROGRAMMABLE

ELECTRONIC

THERMOSTAT

MODEL AC

TWO-ZONE BOARD

THERMOSTAT

INPUT

NON-PROGRAMMABLE

ELECTRONIC

THERMOSTAT

MODEL HP

TWO-ZONE BOARD

THERMOSTAT

INPUT

R24 VAC HOT

24 VAC COMM

HEAT STAGE 1

COOL STAGE 1

FAN

SINGLE-STAGE HEAT,

SINGLE-STAGE COOL

SEE NOTES 1 AND 3

NON-PROGRAMMABLE

ELECTRONIC

THERMOSTAT

MODEL 2S

C

W

/W1

Y

/Y2

G

R

C

W1

Y1

*

G

W2

Y2

TWO-ZONE BOARD

THERMOSTAT

INPUT

24 VAC COMM

HEAT STAGE 1

COOL STAGE 1

FAN

HEAT STAGE 2

N/A

N/A

N/A

OUTDOOR

SENSOR

CONNECTION

R24 VAC HOT

C

W

/W1

Y

/Y2

G

O

/W2

Y1

B

L

S1

S2

R

C

W1

Y1

G

*

Y2

W2

TWO-STAGE HEAT,

SINGLE-STAGE COOL

SEE NOTES 1, 2, AND 3

R

C

W1

Y2

*

G

W2

Y1

TWO-STAGE HEAT,

TWO-STAGE COOL

SEE NOTES 1, 2, AND 3

WIRING DIAGRAM NOTES:

* Hook up G on zone 1 thermostat only.

1.

Cut R19 jumper on thermostat.

2.

Disable timeguard and cycle protection in thermostat by setting

3.

it to ZONE mode. Refer to thermostat Installation Instructions for

details on how to do this.

24 VAC COMM

HEAT STAGE 1

COOL STAGE 2

FAN

HEAT STAGE 2

COOL STAGE 1

N/A

TROUBLE

OUTDOOR

SENSOR

CONNECTION

R24 VAC HOT

C

W

/W1

Y

/Y2

G

O

/W2

Y1

B

L

S1

S2

→ Fig. 13—Electronic Non-Programmable Thermostat Wiring Diagrams

TIMEGUARD

The Zone Perfect Two-Zone provides equipment protection with

an internal 5-minute timeguard delay. This delay is present upon

initial power up. There is also a 5-minute timeguard delay for all

cooling (Y1) and heat pump modes. The time guard can be cleared

by using the comprotec override feature. Second-stage (Y2) and

(W2) will have a 5-minute delay between stages and also can be

cleared using the comprotec override feature.

A97294

—7—

Page 8

PROGRAMMABLE

ELECTRONIC

THERMOSTAT

MODEL AC

TWO-ZONE BOARD

THERMOSTAT

INPUT

PROGRAMMABLE

ELECTRONIC

THERMOSTAT

MODEL HP

TWO-ZONE BOARD

THERMOSTAT

INPUT

FAN

HEAT STAGE 1

COOL STAGE 1

N/A

N/A

24 VAC COMM

N/A

N/A

OUTDOOR

SENSOR

CONNECTION

PROGRAMMABLE

ELECTRONIC

THERMOSTAT

MODEL 2S

R24 VAC HOT

G

W

/W1

Y

/Y2

O

/W2

Y1

/W2

C

B

L

S1

S2

R

G

*

W1

Y1

W2

Y2

C

SINGLE-STAGE HEAT,

SINGLE-STAGE COOL

SEE NOTES 1 AND 3

TWO-ZONE BOARD

THERMOSTAT

INPUT

FAN

HEAT STAGE 1

COOL STAGE 1

HEAT STAGE 2

N/A

24 VAC COMM

N/A

N/A

OUTDOOR

SENSOR

CONNECTION

R24 VAC HOT

G

W

/W1

Y

/Y2

O

/W2

Y1

/W2

C

B

L

S1

S2

R

G

*

W1

Y1

W2

Y2

C

TWO-STAGE HEAT,

SINGLE-STAGE COOL

SEE NOTES 1, 2, AND 3

COOL STAGE 1

FAN

HEAT STAGE 1

COOL STAGE 2

HEAT STAGE 2

24 VAC HOT

24 VAC COMM

N/A

TROUBLE

OUTDOOR

SENSOR

CONNECTION

Y1

/W2

G

W

/W1

Y

/Y2

O

/W2

R

C

B

L

S1

S2

Y1

G

*

W1

Y2

W2

R

C

TWO-STAGE HEAT,

TWO-STAGE COOL

SEE NOTES 1, 2, AND 3

WIRING DIAGRAM NOTES:

* Hook up G on zone 1 thermostat only.

1.

Set thermostat dip switch A to ON.

2.

Set thermostat dip switch C to ON. This will disable

3.

timeguard and cycle protection in thermostat by setting

it to ZONE mode. Refer to thermostat Installation Instructions

for details on how to do this.

→ Fig. 14—Electronic Programmable Thermostat Wiring Diagrams

MAXIMUM CYCLE RATE

The Zone Perfect Two-Zone will allow a maximum of 4 equipment cycles per hr or 1 every 15 minutes when a heating or cooling

mode is activated. When a demand exists, and internal timer will

start counting down 15, 14, 13...0 minutes. Once the timer expires

the control will allow a new mode to restart the equipment. The

internal time, as well as the cooling 5-minute timeguard can be

cleared by using the comprotec override feature.

A97295

CARE AND MAINTENANCE

For continuing optimum performance and to minimize possible

equipment failure, it is essential that periodic maintenance be

performed on this equipment. Consult your servicing contractor for

the proper frequency of maintenance. Frequency may vary depending upon geographic areas.

—8—

Page 9

TROUBLESHOOTING

This section contains information to assist you in troubleshooting

problems and errors associated with the Zone Perfect Two-Zone

system. See Table 2.

I. SYSTEM DIAGRAM, JUMPERS, AND SWITCHES

→

NOTE: For correct control board operation, it must have either a

sensor attached or a 10k resistor in place at the duct and HP inputs.

High Heating Temperature Trip Limit Setting —

When DTO is On, temperature is sensed by duct

B

temperature sensor. When the duct temperature

reaches this temperature setting, the duct temperature

optimizer is enabled.

If the LAT is exceeded then heating will turn off.

NOTE: HP temperature sensor is recommended for

all heat pump applications.

1

Tstat

2

Equipmt

3

Fnc Ht

Fnc—Gas/electric thermostat is installed in

each zone.

Must be in this position to function properly.

HP—DO NOT USE.

Fnc—Air conditioning equipment installed

is a cooling only unit.

HP—Air conditioning equipment installed

is a heat pump.

W/O FAN—When demand for heating exists, fan is controlled by gas/electric furnace.

W/FAN—When demand for heating exists,

fan comes on immediately (heat pump

only).

NORMAL HEAT

PUMP SETTING

155°F

147°F

138°F

130°F

122°F

113°F

105°F

Emergency Heat Switch—This switch should remain

in the OFF position for both furnace and heat pump

C

operation. It should be switched to the ON position

only upon heat pump compressor failure to provide

emergency heat.

NORMAL GAS/

ELECTRICAL

SETTING

155°F

147°F

138°F

130°F

122°F

113°F

105°F

ON OFF

TEMPERATURE

EQUIPMENT

SHUTOFF

175°F

164°F

153°F

143°F

132°F

121°F

110°F

DTO

DTO Off—When supply-air temperatures

4

Damper Fuse—Protects damper from electrical dam-

A

age (3 Amp).

approach a trip limit, HVAC equipment

will turn off. Dampers do not open until

equipment is locked out by control.

DTO On—When supply-air temperatures

approach a trip limit, closed dampers open

to maintain proper air temperatures.

Comprotec Override—Momentarily short

pins together for temporary equipment time

D

delay override.

J6 jumper—Connects Rc and Rh inter-

E

nally.

Emergency heat LED—Will turn on when

F

emergency heat is on.

Red LED—Used for diagnostic errors.

G

Green LED—Flashes once every second

H

for normal operation, alternates with red

LED for diagnostic errors.

—9—

Page 10

Red LED—Displays ON when fan is energized.

I

Red LED—Displays ON when first-stage heat is

energized.

M

Red LED—Displays ON when first-stage cooling is

energized.

J

Red LED—Displays ON when second-stage cooling is

energized.

K

Red LED—Displays ON when reversing valve is ener-

L

gized.

LED CODES ERROR DESCRIPTION ACTION REQUIRED

Green flashes 1 time every sec and no

other LEDs are flashing.

Green flashes 1 time and Red flashes 1

time

Green flashes 1 time and Red flashes 2

times

Green flashes 1 time and Red flashes 3

times

Green flashes 1 time and Red flashes 4

times

Green flashes 1 time and Red flashes 5

times

Green flashes 2 times and Red flashes 1

time

Green flashes 2 times and Red flashes 2

times

Green flashes 2 times and Red flashes 3

times

Green flashes 2 times and Red flashes 4

times

Green flashes 2 times and Red flashes 5

times

Green flashes 3 times and Red flashes 1

time

Green flashes 3 times and Red flashes 2

times

Green flashes 3 times and Red flashes 3

times

Green flashes 3 times and Red flashes 4

times

Red LED—Displays ON when second-stage heat

is energized.

N

J2 (Not Shown)—Cut for 50 hz operation. Located under plastic housing approximately 1 in.

O

above comprotec override.

→ TABLE 2—TROUBLESHOOTING

Normal operation. None.

Wait until duct temperature cools below

Duct temperature sensor. First-stage heat

limit exceeded; heat will be locked out.

Duct temperature sensor. Second-stage

heat limit exceeded.

Duct temperature sensor. First-stage cool

limit exceeded; cool will be locked out.

Duct temperature sensor. Second-stage

cool limit exceeded.

HP temperature sensor. First-stage heat

limit exceeded; heat will be locked out.

HP temperature sensor error. Secondstage heat limit exceeded.

HP temperature sensor. First-stage cool

limit exceeded; cool will be locked out.

HP temperature sensor. Second-stage cool

limit exceeded.

1. Duct temperature sensor.

2. Temperature sensor is shorted.

1. Duct temperature sensor.

2. Temperature sensor is open.

1. HP temperature sensor.

2. Temperature sensor is shorted.

1. HP temperature sensor.

2. Temperature sensor is open.

Damper fuse blown.

Fatal control center circuit board failure. Replace control center.

exceeded temperature trip. (Heat leaving

air temperature trip limits set at LAT limits

POT on central control circuit board; range

is 110° to 175°F.)

Wait until duct temperature cools below

exceeded temperature trip. Range is 105°

to 155°F.

Wait until duct temperature raises above

exceeded temperature trip (45°F).

Wait until duct temperature raises above

exceeded temperature trip (50°F).

Wait until HP temperature cools below exceeded temperature trip. Fixed at 110°F.

Wait until HP temperature cools below exceeded temperature trip. Fixed at 105°F.

Wait until duct temperature raises above

exceeded temperature trip (45°F).

Wait until duct temperature raises above

exceeded temperature trip (50°F).

1. Verify that duct temperature sensor or

10k ohm resistor is attached to control center at duct temperature connectors.

2. Replace duct temperature sensor.

1. Verify that duct temperature sensor or

10k ohm resistor is attached to control center at duct temperature connectors.

2. Replace duct temperature sensor.

1. Verify that HP temperature sensor or

10k ohm resistor is attached to control center at HP temperature connectors.

2. Replace HP temperature sensor.

1. Verify that HP temperature sensor or

10k ohm resistor is attached to control center at HP temperature connectors.

2. Replace HP temperature sensor.

1. Check for short circuits on damper wire

connections at the dampers and control

center.

2. Replace damper fuse.

3. Check damper operation, may need to

be replaced.

—10—

Page 11

Table 3 shows a temperature/ohm/voltage relationship to help aid in troubleshooting the Zone Perfect Two-Zone System. This table will evaluate

→

both the Duct/HP temperature sensor operation. Use a digital multimeter to perform the following:

To verify a sensor is good, disconnect both leads from the I/O board and measure the resistance through the sensor. Match ohm reading to table

and compare temperature reading on table to ambient temperature surrounding sensor (Accuracy should be ± 5-10 percent). Example: if 10.92k

ohms are measured, this equals approximately 73°F.

To verify if I/O board is normal, reattach sensor to I/O board, set meter to 5vdc, and measure voltage across terminal connections. Match voltage

reading to temperature reading in chart. The ambient temperature surrounding sensor should be ± 5-10 percent. Example: 2.61vdc is approximately

73°F.

→ TABLE 3—TEMPERATURE/OHM/VOLTAGE RELATIONSHIP

TEMP °F OHMS VOLTS TEMP °F OHMS VOLTS TEMP °F OHMS VOLTS TEMP °F OHMS VOLTS

30 34,367 3.873 73 10,921 2.610 117 4042 1.439 160 1693 0.724

32 32,654 3.828 75 10,449 2.555 118 3889 1.400 162 1637 0.703

34 31,030 3.781 77 10,000 2.500 120 3743 1.362 163 1582 0.683

36 29,498 3.734 79 9571 2.445 122 3603 1.324 165 1530 0.663

37 28,052 3.686 81 9164 2.391 124 3469 1.288 167 1480 0.645

39 26,686 3.637 82 8776 2.337 126 3340 1.252 169 1431 0.626

41 25,396 3.587 84 8407 2.284 127 3217 1.217 171 1385 0.608

43 24,171 3.537 86 8056 2.231 129 3099 1.183 172 1340 0.591

45 23,013 3.485 88 7720 2.178 131 2986 1.150 174 1297 0.574

46 21,918 3.433 90 7401 2.127 133 2878 1.117 176 1255 0.558

48 20,883 3.381 91 7096 2.075 135 2774 1.086 178 1215 0.542

50 19,903 3.328 93 6806 2.025 136 2675 1.055 180 1177 0.527

52 18,972 3.274 95 6530 1.975 138 2579 1.025 181 1140 0.512

54 18,090 3.220 97 6266 1.926 140 2488 0.996 183 1104 0.497

55 17,255 3.165 99 6014 1.878 142 2400 0.968 185 1010 0.483

57 16,464 3.111 100 5774 1.830 144 2315 0.940 187 1037 0.470

59 15,714 3.056 102 5546 1.784 145 2235 0.913 189 1005 0.457

61 15,000 3.000 104 5327 1.738 147 2157 0.887 190 974 0.444

63 14,323 2.944 106 5117 1.692 149 2083 0.862 — ——

64 13,681 2.889 108 4918 1.648 151 2011 0.837 — ——

66 13,071 2.833 109 4727 1.605 153 1943 0.813 — ——

68 12,493 2.777 111 4544 1.562 154 1876 0.790 — ——

70 11,942 2.721 113 4370 1.521 156 1813 0.767 — ——

72 11,418 2.666 115 4203 1.480 158 1752 0.745 — ——

WIRING DIAGRAMS

→ TABLE 4—WIRING DIAGRAM REFERENCE

OUTDOOR

UNIT

Single-Stage Furnace Fig. 15 Fig. 19 Fig. 23 Fig. 27

Two-Stage Furnace Fig. 16 Fig. 20 Fig. 24 Fig. 28

Typical Fan Coil Fig. 17 Fig. 21 Fig. 25 Fig. 29

FK4C Fan Coil Fig. 18 Fig. 22 Fig. 26 Fig. 30

SINGLE-SPEED

AIR CONDITIONER

TWO-SPEED

AIR CONDITIONER

SINGLE-SPEED

HEAT PUMP

TWO-SPEED

HEAT PUMP

—11—

Page 12

TWO-ZONE SYSTEM

RH

G

W2

W1

Y1

Y2

O

B

RC

→ Fig. 15—Single-Stage Furnace

With Single-Speed Air Conditioner

SINGLE-STAGE

FURNACE

R

AIR CONDITIONER

G

W

Y

C

SINGLE-SPEED

Y

C

A97296

2-STAGE OR

TWO-ZONE SYSTEM

RH

G

VARIABLE-SPEED

FURNACE

R

G

SINGLE-SPEED

AIR CONDITIONER

W2

W2

W/W1

W1

Y1

Y/Y2

C

Y2

O

B

RC

→ Fig. 16—Two-Stage or Variable-Speed Furnace

With Single-Speed Air Conditioner

Y

C

A97297

TWO-ZONE SYSTEM

RH

G

W2

W1

Y1

Y2

O

B

RC

See notes 1 and 3

→ Fig. 17—Typical Fan Coil

With Single-Speed Air Conditioner

TYPICAL

FAN COIL

C

R

G

W2

W3

Y/Y2

O

L

E

Y1

SINGLE-SPEED

AIR CONDITIONER

C

Y

*

*

**

*

**

A97298

TWO-ZONE SYSTEM

RH

G

W2

W1

Y1

Y2

O

B

RC

With Single-Speed Air Conditioner

FK4C

AIR CONDITIONER

FAN COIL

DH

R

C

G

W1

W2

Y/Y2

Y1

O

See note 1

→ Fig. 18—FK4C Fan Coil

SINGLE-SPEED

J1 JUMPER

C

Y

REMOVE J2 JUMPER

FOR HEAT STAGING AND

CONNECT W2 TO W2

A97299

—12—

Page 13

TWO-ZONE SYSTEM

RH

G

W2

W1

Y1

Y2

O

B

RC

→ Fig. 19—Single-Stage Furnace

With 2-Speed Air Conditioner

SINGLE-STAGE

FURNACE

R

G

W

C

Y

See note 2

2-SPEED

AIR CONDITIONER

R

C

Y2

Y1

A97300

2-SPEED

AIR CONDITIONER

2-STAGE OR

TWO-ZONE SYSTEM

RH

G

VARIABLE-SPEED

FURNACE

R

G

W2

W2

W/W1

W1

Y1

Y2

Y/Y2

C

Y

*

Y2

Y1

O

B

See notes 2 and 3

RC

→ Fig. 20—Two-Stage or Variable-Speed Furnace

With 2-Speed Air Conditioner

R

C

A97301

TWO-ZONE SYSTEM

RH

G

W2

W1

Y1

Y2

O

B

RC

→ Fig. 21—Typical Fan Coil

With 2-Speed Air Conditioner

TYPICAL

FAN COIL

R

C

G

W2

Y/Y2

E

W3

L

O

Y1

See notes 1, 2, and 3

2-SPEED

AIR CONDITIONER

R

C

*

Y2

*

*

*

*

Y1

TWO-ZONE SYSTEM

A97302

RH

W2

W1

Y1

Y2

RC

2-SPEED

AIR CONDITIONER

FK4C

FAN COIL

DH

R

G

O

C

G

W1

W2

Y1

Y/Y2

O

J1 JUMPER

R

C

REMOVE J2 JUMPER

FOR HEAT STAGING AND

CONNECT W2 TO W2

Y1

Y2

L

B

See note 1

A97303

→ Fig. 22—FK4C Fan Coil

With 2-Speed Air Conditioner

—13—

Page 14

TWO-ZONE SYSTEM

INTERFACE

CONTROL

(KHAIC0101AAA)

SINGLE-STAGE

FURNACE

SINGLE-SPEED

HEAT PUMP

RH

G

W2

W1

Y1

Y2

O

B

RC

R

GT

GF

RF

WF

E

HP

O

HP

OT

Y

HP

YT

E

C

T

1

2

3

OUTDOOR

THERMOSTAT

(KHAOT0301FST)

C

G

R

W

Y

See notes 4, 5, 6, and 7

→ Fig. 23—Single-Stage Furnace With Single-Speed Heat Pump

2-STAGE OR

VARIABLE-SPEED

FURNACE

TWO-ZONE SYSTEM

INTERFACE

CONTROL

(KHAIC0101AAA)

R

W2

O

Y

C

A97304

SINGLE-SPEED

HEAT PUMP

RH

G

W2

W1

Y1

Y2

O

B

RC

R

GT

GF

RF

WF

E

HP

O

HP

OT

Y

HP

YT

E

C

T

1

2

3

OUTDOOR

THERMOSTAT

(KHAOT0301FST)

W2

C

G

R

W/W1

Y/Y2

R

W2

O

Y

C

See notes 4, 5, 6, 7, and 8

→ Fig. 24—Two-Stage or Variable-Speed Furnace With Single-Speed Heat Pump

A97305

—14—

Page 15

C

R

G

W2

W3

O

Y1

*

*

*

L

*

E

*

SINGLE-SPEED

HEAT PUMP

C

R

W2

Y

O

A97306

TWO-ZONE SYSTEM

RH

G

W2

W1

Y1

Y2

O

B

RC

See notes 1 and 3

TYPICAL

FAN COIL

Y/Y2

→ Fig. 25—Typical Fan Coil With Single-Speed Heat Pump

TWO-ZONE SYSTEM

RH

G

W2

W1

Y1

Y2

O

B

RC

See note 1

→ Fig. 26—FK4C Fan Coil

With Single-Speed Heat Pump

FK4C

FAN COIL

C

DH

R

G

W1

W2

Y/Y2

O

Y1

SINGLE-SPEED

HEAT PUMP

C

J1 JUMPER

R

J2 JUMPER

W2

Y

O

A97307

TWO-ZONE SYSTEM

RH

G

W2

W1

Y1

Y2

O

B

RC

See notes 2, 5, 6, 7, 9, 10, and 11

→ Fig. 27—Single-Stage Furnace

SINGLE-STAGE

FURNACE

R

C

G

W

Y

With 2-Speed Heat Pump

2-SPEED

HEAT PUMP

R

C

W2

Y2

Y1

O

W3

A97308

2-SPEED

HEAT PUMP

2-STAGE OR

TWO-ZONE SYSTEM

RH

G

VARIABLE-SPEED

FURNACE

R

G

W2

W2

W/W1

W1

Y1

Y2

O

Y/Y2

C

Y1

O

*

*

B

RC

See notes 2, 3, 5, 6, 7, 8, 9, 10, and 11

→ Fig. 28—Two-Stage or Variable-Speed Furnace

With 2-Speed Heat Pump

R

W2

Y2

C

Y1

O

W3

A97309

—15—

Page 16

TWO-ZONE SYSTEM

RH

G

W2

W1

Y1

Y2

O

B

RC

See notes 1, 2, 3, 9, and 11

TYPICAL

FAN COIL

R

C

G

W2

*

Y/Y2

*

O

W3

*

L

*

E

*

Y1

2-SPEED

HEAT PUMP

R

C

W2

Y2

O

W3

Y1

TWO-ZONE SYSTEM

RH

G

W2

W1

Y1

Y2

O

B

RC

See notes 1, 2, 9, and 11

FK4C

FAN COIL

C

DH

R

G

W1

W2

Y1

Y/Y2

O

2-SPEED

HEAT PUMP

C

J1 JUMPER

R

J2 JUMPER

W2

Y1

Y2

O

W3

A97310

→ Fig. 29—Typical Fan Coil With 2-Speed Heat Pump

→ Fig. 30—FK4C Fan Coil With 2-Speed Heat Pump

A97311

→ WIRING DIAGRAM NOTES

1. Refer to fan coil Installation Instructions for proper wiring.

2. Refer to outdoor unit Installation Instructions for latent kit requirements.

3. Terminals marked with * may not be present on equipment.

4. Interface control transformer must be in phase with furnace transformer to get high-speed fan during heat pump operation.

5. Heat pump MUST have a high-pressure switch for dual-fuel applications.

6. Two-Zone Control does not know that dual fuel is applied. Do not use thermostat AUTO CHANGEOVER mode with dual-fuel applications,

keep both thermostats in same mode (heating or cooling).

7. Configure Two-Zone Control board (jumpers) for:

(J1) T-stat = Fnc

(J3) Equipmt = HP

(J4) Fnc Ht = w/fan

(J5) LAT = Set LAT jumper high enough to allow furnace to come on during defrost and second-stage operation.

(J7) DTO = On

8. Furnace must control its own second-stage heat operation, via the furnace control algorithm.

9. Refer to outdoor equipment Installation Instructions for proper set up.

10. Select Furnace Interface option, Balance Point, and Defrost Time on 2-speed heat pump control board.

11. DO NOT select "ZONE" position on 2-speed heat pump control board. In heating mode, heat pump outdoor temperature sensor will control

the compressor low- and high-speed change.

© 1997 Bryant Heating & Cooling Systems 7310 W. Morris St. Indianapolis, IN 46231

—16—

Printed in U.S.A. zkit06 Catalog No. 809-661

Loading...

Loading...