Bryant ZONE PERFECT PLUS ZONEBB2KIT, ZONE PERFECT PLUS ZONEBB8KIT, ZONE PERFECT PLUS ZONEBB4KIT Zoning Design Manual

Page 1

zoning design guide

ZONE PERFECT PLUS

ZONEBB2KIT

ZONEBB4KIT

ZONEBB8KIT

Cancels: New AP17-2

4-98

TABLE OF CONTENTS

Page

INTRODUCTION........................................................................1

OVERVIEW OF ZONING.........................................................1

What is Zoning? .........................................................................1

Is a Zoning System Right for This Job? ...................................2

ZONE PERFECT PLUS FEATURES....................................2-3

Humidification Control...............................................................2

Dehumidification Control...........................................................2

Damper Control Scheme............................................................2

OUT Zones .................................................................................3

Bryant Access Home Zoning Software .....................................3

Eight-Zone Capacity...................................................................3

Ease of Installation and Installer Test .......................................3

ZONE PERFECT PLUS COMPONENTS............................3-4

User Interface..............................................................................3

Equipment Controller .................................................................4

Zone Sensors...............................................................................4

Remote Sensors.......................................................................4

Smart Sensors..........................................................................4

Equipment Sensors .....................................................................4

Zone Dampers.............................................................................4

DESIGNING A ZONE PERFECT PLUS

INSTALLATION ..................................................................4-10

Assigning Zones .........................................................................5

Task 1—Assess the homeowner’s goals

for comfort and energy savings...............................5

Task 2—Conduct a site survey and make

preliminary zone assignments..................................5

Conducting a Site Survey....................................................5

Making Preliminary Zone Assignments .............................5

Sizing the Equipment .................................................................6

Task 3—Calculate block load estimates

and zone load estimates...........................................6

Task 4—Size heating and cooling equipment .......................6

Task 5—Choose register and return locations.......................7

Determining the Number of Returns..................................7

Selecting Return Locations .................................................7

Selecting Register Locations...............................................7

Meeting Zoning Challenges in Two Story Homes ............7

Recording Return and Register Locations..........................7

Task 6—Determine Bypass Needs.........................................7

Task 7—Lay out supply ducts and locate dampers...............7

Task 8—Determine appropriate damper and duct sizes........8

Determining Duct Size Based on Damper Size.................8

Why Oversized Ducts are not a Problem

with Zone Perfect Plus........................................................8

Task 9—Choose locations for zone sensors..........................9

Considerations When Retrofitting an Installation .....................9

Installing the System..................................................................9

COMPONENTS REQUIRED FOR

SPECIFIC APPLICATIONS..................................................10

Thermostatic Expansion Valve ................................................10

Leaving Air Temperature Sensor.............................................10

Heat Pump Temperature Sensor ..............................................10

Outdoor Temperature Sensor ...................................................10

SPECIAL APPLICATIONS USING

ZONE PERFECT PLUS ....................................................10-12

Understanding the Requirements of Setback with Zoning .....10

Using Multi-Stage Equipment with Zoning.......................10-11

Using Variable-Speed Blowers with Zoning...........................11

Bypassing with Zoning .......................................................11-12

Bypassing to an Unconditioned Space.................................11

Bypassing to a Conditioned Space.......................................11

Bypassing Directly to the Air Return ..................................11

Bypassing Using OUT Zones...............................................12

GLOSSARY...........................................................................12-13

APPENDIX—WORKSHEETS............................................13-17

Zoning Design Checklist..........................................................14

Homeowner Survey.............................................................15-16

Floor Plan Worksheet...............................................................17

INTRODUCTION

This guide provides information to help you design a Zone Perfect

Plus installation. It discusses general topics related to designing a

residential zoning control system, as well as specific information

about Zone Perfect Plus.

Use this guide to help you design a zoning system that will:

• Meet or exceed the homeowner’s expectations regarding the

system’s capabilities. This goal will result in improved customer perception of your company, as well as repeat business

and referrals.

• Protect the heating and cooling equipment used in the system.

This goal will result in improved system reliability, longer life

of heating and cooling equipment, and reduced warranty costs.

To design a zoning system to perform well under all conditions, it

is essential to view the system as a whole at the design stage, rather

than to begin selecting and installing individual components

without a careful assessment of how they will work together. Be

sure to perform all of the tasks described in this guide before you

begin to install components.

This guide assumes that you have experience designing residential

heating and air conditioning systems. The information in this guide

is intended to supplement that experience. This guide does not

address commercial applications of Zone Perfect Plus.

OVERVIEW OF ZONING

Residential zoning systems bring the possibility of total comfort

control to the homeowner by providing exactly the right amount of

heating or cooling to each living space. Comfort can be described

as the absence of sensation. Ideally, a zoning system should keep

the occupants of the home comfortable without them being aware

of the system.

A. What is Zoning?

A zone is a conditioned space (one room or a group of rooms) that

is separately controlled by its own sensor. There are as many zones

in a home as there are sensors.

A zoning system is a heating and cooling control system that

maintains each zone of a home at a predetermined temperature and

that maintains the home at a predetermined humidity. In addition

to meeting these basic goals, Zone Perfect Plus is designed to:

—1—

Page 2

• Direct conditioned air proportionately based on the needs of

each zone, so that the zone(s) with the greatest demand receive

relatively more conditioned air.

• Keep the sound produced by the system low enough that

residents will not find it objectionable.

• Conveniently interface with and protect the home’s heating and

cooling equipment.

• Maintain at least the minimum airflow necessary to keep

heating and cooling equipment running efficiently.

B. Is a Zoning System Right for This Job?

When designing a zoning system, it is important to keep in mind

what a zoning system can and cannot do. A zoning system is only

part of a complete heating and cooling system for a residence. A

home’s heating and cooling system has a limited heating and

cooling capacity. A zoning system cannot increase that capac-

ity.

A zoning system reduces the effective size of the air distribution

system as dampers are adjusted and closed to meet the needs of

zones. The primary challenge when designing a zoning system is

to make sure that the air distribution system cannot become so

effectively small that the reduction in airflow causes one of the

following problems:

• Air noise becomes excessive.

• The heating or cooling equipment is shut down because

temperature limits are exceeded.

• The life of the equipment is reduced because of stresses related

to excess temperatures.

The addition of a zoning system will not correct existing duct

problems. A zoning system will compensate for oversized ducts,

but might make a bad situation worse in the case of undersized

ducts. There are many ways to make a marginal duct system

perform better. Most of these approaches involve changing ducts,

registers, and/or heating or cooling equipment.

PLUS

ZONE PERFECT

This section briefly describes features that are new in the Zone

Perfect Plus system and that distinguish this system from both

Zone Perfect and other residential zoning systems.

Zone Perfect Plus’s innovative features include:

• Humidification control

• Dehumidification control

• Sophisticated damper control scheme

• OUT zones

• Bryant Access Home Zoning Software

• Eight-zone capacity

• Improved ease of installation and installer testing.

A. Humidification Control

If a humidifier is included in the heating and cooling system, Zone

Perfect Plus can directly control it. A solid-state humidity sensor

is built into the User Interface to monitor and control humidity in

the home. The Equipment Controller’s HUM output controls any

humidifier with a 24-vac input.

The homeowner can set a humidify set point to any value between

10 percent and 45 percent relative humidity, or can turn off the

humidify feature. When the humidity drops 2 percent below the set

point in the heating mode, the system activates the HUM output to

turn on the humidifier. When the humidity rises 2 percent above

the set point in the heating mode, the system turns off the HUM

output. Humidification is provided only in the heating mode.

If the system includes an outdoor temperature (ODT) sensor, the

installer or homeowner can select an automatic humidity level

adjustment. This selection provides a 1 percent reduction in the

FEATURES

humidify set point for every 2°F reduction in outdoor temperature.

The homeowner can change the system’s humidify set point at any

time, and the system automatically adjusts the set point in response

to the outdoor temperature. This feature helps prevent sweating of

windows in very cold weather while allowing higher humidity

levels in warmer weather.

The system can be set to provide humidification only when there

is a humidify demand and any heat output (heat pump, furnace, or

auxiliary heat) is on. Alternatively, the system can be set to turn on

the HUM output and the blower when there is a humidify demand.

This selection allows humidification when there is no heat demand.

B. Dehumidification Control

The Equipment Controller’s dehumidify output can be used to

control any 24-vac device that decreases humidity when its control

signal is removed. Zone Perfect Plus includes an extensive set of

features for enhancing and controlling dehumidification, particularly when used with a variable-speed (ICM) blower.

The homeowner can set a dehumidify set point, separate from the

humidify set point, between 50 percent and 90 percent relative

humidity, or can turn off the dehumidify feature. When the

humidity rises 2 percent above the set point in the cooling mode,

the system turns off the dehumidify output. When the humidity

falls 2 percent below the set point in the cooling mode, the system

turns on the dehumidify output, supplying 24vac. Dehumidification is provided only in the cooling mode.

Zone Perfect Plus provides the following modes of humidification

control:

• Mode 1: When an ICM blower with a dehumidify input is used

with the system, the Equipment Controller’s dehumidify output

can be connected to it. This connection provides reduced

cooling airflow while dehumidification is needed, yielding

better moisture removal from cooling air.

• Mode 2: If the system has a 2-speed compressor and a PSC

blower, a dehumidify demand makes the compressor operate at

high speed only for any cooling demand. High-speed operation

provides better water removal than low-speed operation under

these circumstances.

• Mode 3: In a standard system with a PSC blower, Zone Perfect

Plus lowers the cooling set point up to 3°F in response to

dehumidify demand. This feature increases the equipment’s run

time and lowers the evaporator coil temperature.

• Mode 4: The vacation mode optional feature provides humidity

control by operating the cooling system when cooling is not

required. If the humidity rises above the dehumidify set point,

the system executes a special dehumidification routine. As long

as zone temperatures are not less than 70°F, a dehumidify

demand turns on the cooling equipment, limiting its ON time to

no more than 7 minutes at a time.

C. Damper Control Scheme

Up to 3 dampers can be wired in parallel and connected to 1 zone

output. A multi-damper enabler is not needed.

Using the set points and temperatures for each zone within the

system. Zone Perfect Plus determines whether active heating or

cooling is required, the zoning system:

1. Fully opens 1 or more dampers and positions others so that

all zones will be conditioned back to their set points at the

same time. Based on experience, the system learns the best

damper positions for meeting the home’s current demand

for heating and cooling and starts from these positions when

it determines that heating or cooling is required.

2. Turns on the necessary heating or cooling equipment.

3. While the equipment is on, once every 2 minutes makes

small adjustments in damper positions so that all zones

converge on their set points at the same time.

—2—

Page 3

4. Turns off the equipment when all zones reach their set

points.

5. Leaves dampers in their final positions while the equipment

is off.

6. If the equipment does not run for 2 hours, fully opens all

dampers.

Thus, the zoning system controls the damper(s) for each zone

based on the overall needs of the home and the relative need of the

zone. This scheme makes smooth and efficient use of the system’s

heating and cooling capacity.

When all zones require conditioning and all dampers are fully

open, there is some reduction in airflow velocity and the air

distribution system might not throw air as well as one might want.

The zoning system compensates for this reduction in airflow

velocity by partially closing dampers to zones that are improving

more quickly than others. This feature allows increased airflow

velocity in the remaining ducts, helping those zones become

conditioned more quickly than would otherwise be the case.

D. OUT Zones

Zone Perfect Plus has a new feature that lets the homeowner assign

OUT status to any zone with the touch of a button. By assigning

OUT status to a zone, the homeowner tells the system that the

selected zone is unoccupied and does not require conditioning. The

homeowner can set zones to OUT at any time, or OUT can be

programmed according to a schedule, like temperature set points

are programmed.

The system normally supplies no conditioning to an OUT zone. If

the temperature in an OUT zone exceeds 85°F or falls below 60°F,

the system supplies conditioning to maintain the zone within these

limits.

The system uses OUT zones to relieve the heating or cooling

equipment under equipment overload conditions. If the total

demand from all zones is such that the airflow is insufficient (or

bypassing is excessive), the leaving air temperature (LAT) sensor

or heat pump temperature (HPT) sensor detects this condition.

When temperatures begin to approach their limits, the system first

begins to open dampers in the OUT zones to relieve the overload

condition.

The system also monitors temperatures in the OUT zones and

never lets OUT zones become cooler than the coolest zone (in

cooling) or warmer than the warmest zone (in heating). This

feature prevents over conditioning of OUT zones while still using

them to relieve overload conditions.

Also, when a zone is set to OUT and the system is set up for

dehumidification, the OUT zone can be used to help remove

humidity by cooling it as much as possible. When there is a

dehumidify demand without a cooling demand, the system fully

opens the dampers in any zones set to OUT. The zones can be

cooled to as low as 70°F. If an OUT zone reaches 70°F, its damper

closes.

When all zones are set to OUT, the house is in vacation mode. The

cooling equipment comes on either to maintain the house below

85°F or to maintain the dehumidify set point by cooling the house

to as low as 70°F. This feature is extremely useful for unoccupied

homes in hot and damp climates.

E. Bryant Access Home Zoning Software

Bryant provides a software utility—Bryant Access Home Zoning

Software—that installers can use to assist them during a Zone

Perfect Plus installation. This software is provided free of charge

on the Zone Perfect Plus Introduction CD-ROM. It can be run

under Windows 3.1 or Windows’95 on a portable computer.

This software lets the installer:

• Monitor the zoning system during installation.

• Program the comfort schedule for the system.

• Perform additional setup tasks, if necessary.

F. Eight-Zone Capacity

Zone Perfect Plus is available in 2-zone, 4-zone, and 8-zone

models. Of course, not all zones have to be used in an installation

for the system to operate properly. For example, an 8-zone model

can be used for a system with 2 to 8 zones.

G. Ease of Installation and Installer Testing

Zone Perfect Plus has been designed to make it easy to install. For

example, connections on the Equipment Controller are color coded

to make them easy to identify.

Zone Perfect Plus provides an installer setup mode that makes it

easy to test the system during installation. By pressing buttons on

the User Interface, the installer can:

• Fully open a selected zone’s damper(s) and close all other

dampers.

• View the current temperature of any zone.

• Turn the blower on or off.

• Operate heating, cooling, or auxiliary heating for 2 minutes.

PLUS

ZONE PERFECT

COMPONENTS

The main components of a Zone Perfect Plus system are:

• A User Interface

• An Equipment Controller

• Zone sensors

• Equipment sensors

• Zone dampers

Each of these components is described in the following sections.

A. User Interface

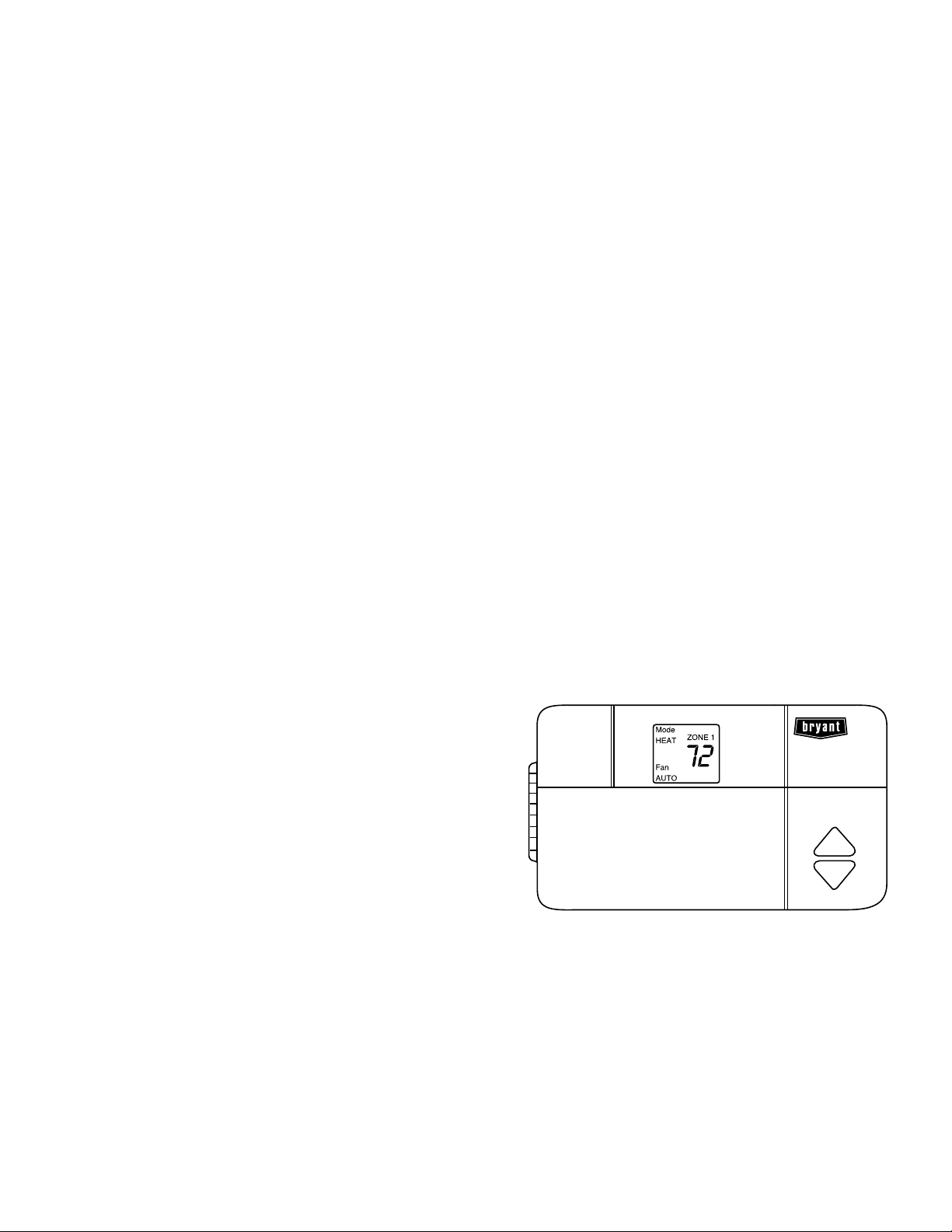

The User Interface, show in Fig. 1, is the command center or

"brains" for the entire zoning system. Through the User Interface,

the homeowner can program the temperature and schedule requirements for each zone, and can view the actual temperatures for each

zone. The User Interface usually is located in the main living area

for convenient access.

A98337

Fig. 1—User Interface

The main function of the User Interface is to monitor signals from

the temperature sensors, determine what actions need to be taken

to maintain each zone at the temperature programmed for it, and

send the appropriate control signals to the zone dampers and the

heating or cooling equipment.

The User Interface also includes a temperature sensor, which

usually is used to monitor the temperature in its zone (Zone 1), as

well as a humidity sensor. In some cases, the need to mount the

User Interface in a location convenient for the homeowner might

make its location unsuitable for accurately sensing the zone

temperature. In such cases, a Remote Sensor can be used for the

zone instead of the User Interface’s built-in sensor.

—3—

Page 4

B. Equipment Controller

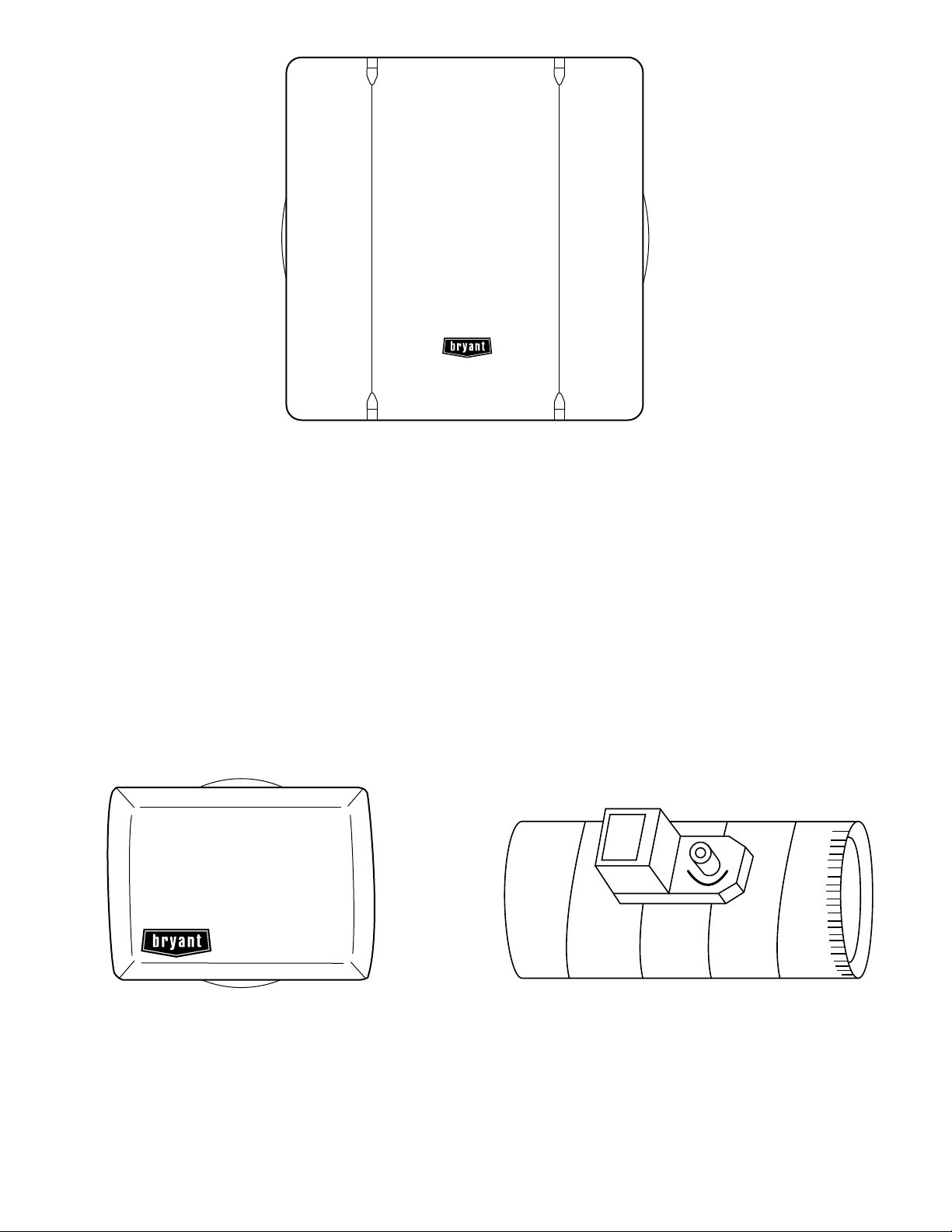

Fig. 2—Equipment Controller

The Equipment Controller, shown in Fig. 2, is essentially a

junction box for connecting all of the temperature sensor inputs,

and all of the outputs to the zone dampers and to the heating and

cooling equipment. It contains circuits and relays that provide

control of the zoning system, as well as control of the heating and

cooling equipment. The Equipment Controller operates under the

control of the User Interface.

C. Zone Sensors

Zone Perfect Plus kits include Remote Sensors. Optional Smart

Sensors also are available for use with the Zone Perfect Plus

system. Each of these types of sensors is described below.

REMOTE SENSORS

Remote Sensors, shown in Fig. 3, are used to measure the

temperature in each zone. A Remote Sensor does not provide a

means to view or adjust the zone temperature; the User Interface

provides a means to view and adjust temperatures for all zones.

A98338

• Zone Perfect Plus installations must include a LAT (leaving

air temperature) sensor.

• If the installation includes a heat pump, an HPT (heat pump

temperature) sensor also must be installed.

•AnODT (outdoor temperature) sensor is optional in most

applications.

For more information about equipment sensors, see the section

"Components Required for Specific Applications."

E. Zone Dampers

Each zone must have at least 1 zone damper, shown in Fig. 4. If

more than 1 duct serves a single zone, up to 3 dampers may be

wired in parallel to a single output on the Equipment Controller.

Each zone damper is operated by an electric motor actuator, which

receives signals from the Equipment Controller. Dampers have 15

positions, ranging from fully closed to fully open. The position

selected for each damper at any given time is based on the relative

conditioning needs of each zone in the current mode.

A98339

Fig. 3—Remote Sensor

SMART SENSORS

The Smart Sensor measures and displays the temperature in the

zone. It also provides a means to adjust the temperature in that

zone only.

D. Equipment Sensors

The following equipment sensors are used in Zone Perfect Plus

installations:

—4—

A98340

Fig. 4—Zone Damper

PLUS

DESIGNING A ZONE PERFECT

INSTALLATION

The main objective when designing a zoning system is to maintain

at least the minimum airflow through the system when only 1 zone

requires conditioning, yet still provide sufficient airflow when all

zones require conditioning. The tasks described below provide

step-by-step instructions for designing an effective zoning system.

These tasks are grouped into the following phases:

Page 5

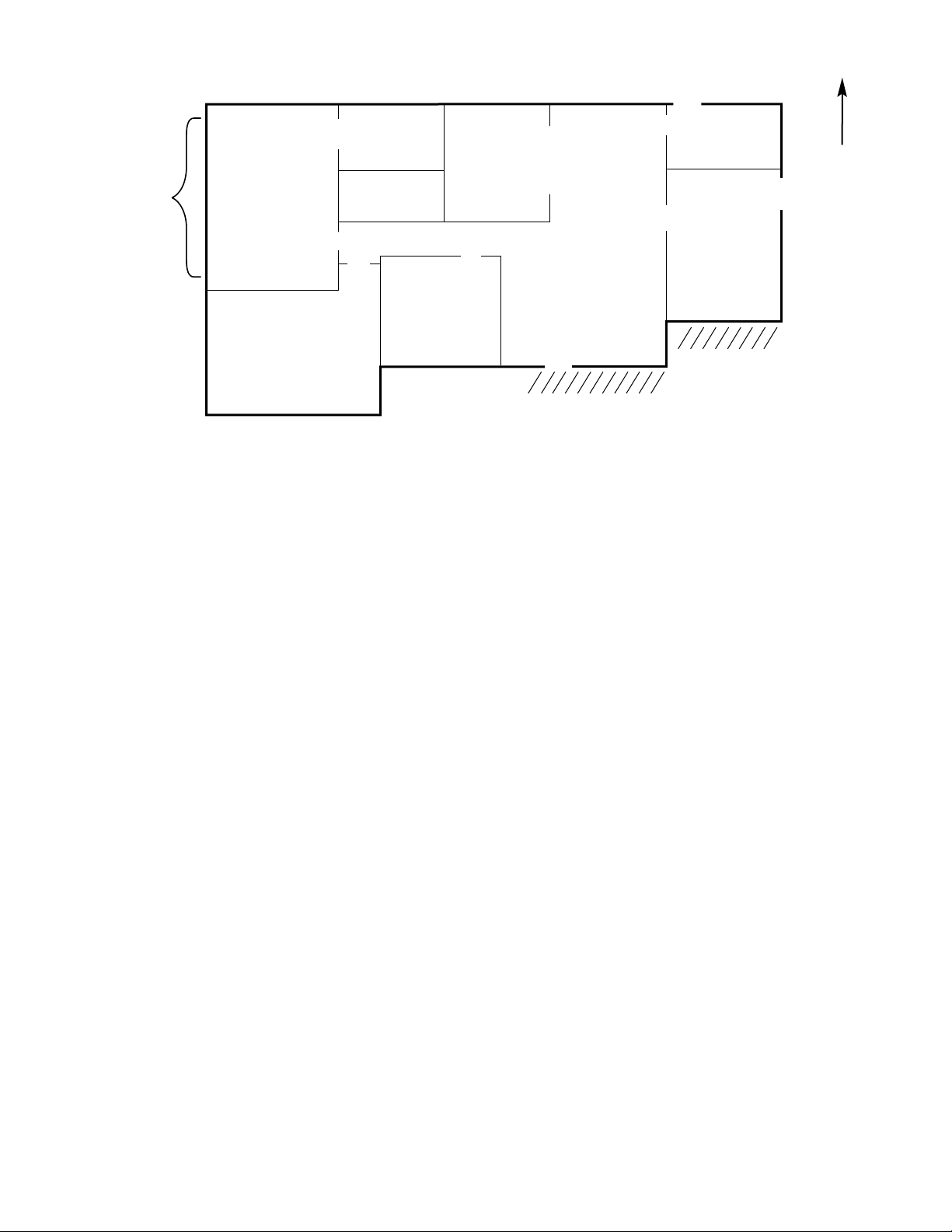

N

Bath

Bath

Bedroom

Large

WIndow

Master

Bedroom

Bedroom

Fig. 5—Example of a Floor Plan

• Assigning Zones

Task 1—Assess the homeowner’s goals for comfort and energy

savings.

Task 2—Conduct a site survey and make preliminary zone

assignments.

• Sizing the Equipment

Task 3—Calculate block load estimates and zone load estimates.

Task 4—Size the heating and cooling equipment.

• Laying Out and Sizing the Duct System

Task 5—Choose register and return locations.

Task 6—Determine bypass needs.

Task 7—Lay out supply ducts and locate dampers.

Task 8—Determine appropriate damper and duct sizes.

• Laying Out Zone Components

Task 9—Choose locations for zone sensors.

A. Assigning Zones

TASK 1—ASSESS THE HOMEOWNER’S GOALS FOR

COMFORT AND ENERGY SAVINGS

For a zoning system to be successful, it must meet the homeowner’s goals for comfort and/or energy savings. Therefore, it is

essential to understand the homeowner’s goals before beginning to

design the system. In some situations, a homeowner’s expectations

might not be realistic and it would be impossible to design a

system to meet those expectations. By identifying this problem

from the start, you can help the homeowner revise these expectations and avoid creating a dissatisfied customer.

In addition to understanding the homeowner’s general goals for the

zoning system, you need to understand exactly how the home’s

occupants will use each room or area in the home. Use the

Homeowner Survey provided in the Appendix to help you gather

information from the homeowner.

TASK 2—CONDUCT A SITE SURVEY AND MAKE

PRELIMINARY ZONE ASSIGNMENTS

Conducting a Site Survey

The purpose of conducting a site survey is to gather the information that you need to:

• Make zone assignments. Use the Floor Plan Worksheet

provided in the Appendix to draw a floor plan of the home.

Follow these guidelines:

Kitchen

Informal

Dining

Room

Living Room

Shaded

Family Room

Utility

Room

Shaded

— Provide the rough dimensions of each area or room.

— Indicate the location and relative size of doors, windows,

and skylights. In particular, identify any large glass areas

(exceeding 30 percent of the wall area).

— Indicate whether any trees or buildings cast shade on any of

the home’s exposures.

— Indicate the orientation of the home so you can determine

whether there are any rooms or areas facing south or west

where the solar heat load might be a factor when making zone

assignments.

Fig. 5 shows an example of a floor plan for a home, drawn as

part of a site survey.

• Calculate heating and cooling load estimates for the home

(Task 3). Gather the information required to use the method of

your choice for calculating these loads. If you have a worksheet

that you generally use to gather this information, feel free to

use it.

• Choose register and return locations (Task 5). Generally, the

Floor Plan Worksheet will provide sufficient information for

choosing register and return locations. In a retrofit installation,

indicate the location of existing duckwork, as well as heating

and cooling equipment.

• Lay out ducts and locate dampers (Task 6). Gather the

information about the home required to lay out ducts and locate

dampers using the method of your choice. If you have a

worksheet that you generally use to gather this information,

feel free to use it.

Making Preliminary Zone Assignments

The homeowner’s goals regarding comfort and energy savings

affect how many zones are appropriate for the system:

• In a system designed primarily for comfort, all zones usually

have comfort set points that remain relatively constant and that

have similar time schedules. Such a system may have a large

number of zones (5 to 8) of a relatively small size.

• In a system designed primarily for energy savings, there are

zones that are not used much of the time. Such a system must

have even larger ducts to guarantee proper airflow to the zones

that remain in use when some zones are unused. Such a system

generally must have a smaller number of zones of a relatively

larger size. In this case, you must be careful not to "over zone"

(assign too many zones).

When making zone assignments, use the information that you

gathered when conducting the site survey. Group areas that:

A98341

—5—

Page 6

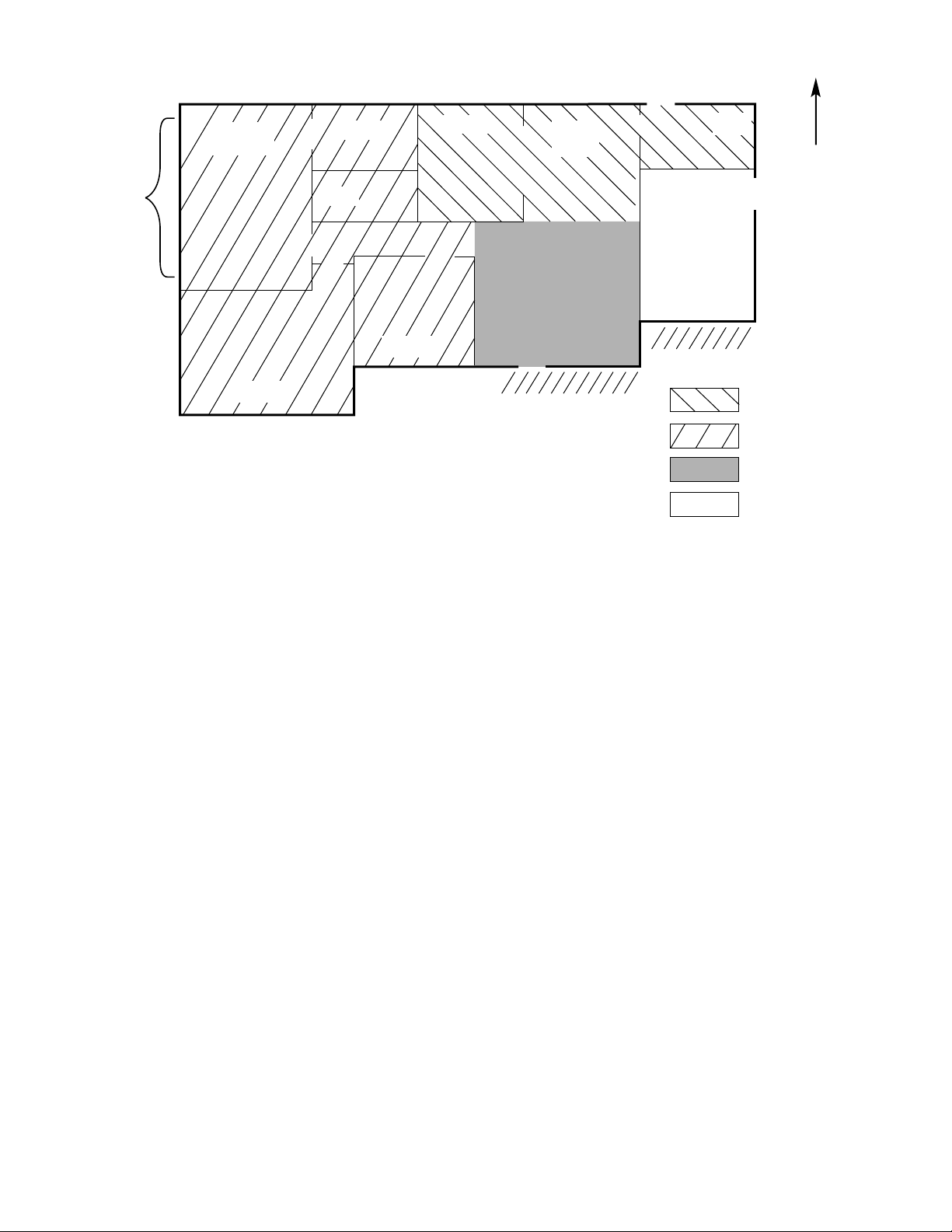

N

Bath

Bath

Bedroom

Large

WIndow

Master

Bedroom

Bedroom

Fig. 6—Example of Zoning Assignments

• Are in use around the same time of day. For example, it often

makes sense to assign all bedrooms to a single zone because

they are occupied only during the night time when other rooms

in the home are not occupied.

• Have similar heating and cooling needs.

• Are physically separated from other areas.

• Are on the same level of the home. For example, the rooms on

the upstairs level often have a different heating or cooling

demand when compared to rooms downstairs. The differences

can be due to the tendency for heat to rise, different use of

occupancy, and the roof heat load.

• Have similar exposures to external heating gains and losses.

For example, it often makes sense to assign rooms with large

amounts of glass and western or southern exposure to the same

zone.

• The homeowner intends to "set back" at the same time.

• Let you avoid extremely small zones that would cause the

airflow through the unit to become extremely low when only 1

zone requires conditioning.

If possible, discuss these considerations with the homeowner. Get

the homeowner’s input before making initial zone assignments.

Mark your preliminary zone assignments on the Floor Plan

Worksheet provided in the Appendix. Fig. 6 shows an example of

zoning assignments marked on a floor plan worksheet.

At this point, consider your zone assignments to be preliminary.

The next task helps you check whether the zone assignments are

feasible.

B. Sizing the Equipment

TASK 3—CALCULATE BLOCK LOAD ESTIMATES AND

ZONE LOAD ESTIMATES

Using the information that you gathered in Task 2, calculate both

heating and cooling load estimates for the entire home. These

estimates are used primarily for sizing the heating and cooling

equipment for the system.

Kitchen

Shaded

Utility

Room

Zone 1

Zone 2

Zone 3

Zone 4

A98342

Informal

Dining

Room

Living Room

Shaded

Family Room

The standard Btu load calculations used for non-zoned systems

apply equally well to zoned systems. Use a reliable method with

which you are comfortable.

After you have tentatively defined the zones for a home, calculate

individual peak heating and cooling load estimates (in Btu’s) for

each of the zones. Use a reliable method with which you are

comfortable to calculate the peak zone load estimates. Refer to the

information that you gathered in Task 2.

The peak zone load estimates are used to determine whether the

zone assignments you have made make sense. They also are used

to size the zone dampers and ductwork.

When a zone is recovering from being set back, the system must

supply additional capacity beyond the zone’s losses to change the

temperature. The farther the desired setback, the more capacity

must be added.

For zones that will be set back and that need reliable recovery,

multiply their calculated zone loss by a recovery factor of 1.25.

Use the larger zone load estimate when determining the size of the

damper and duct required for the zone.

TASK 4—SIZE HEATING AND COOLING EQUIPMENT

Zone Perfect Plus is designed for use with a furnace or fan coil in

conjunction with a condensing unit or heat pump with a thermostatic expansion valve (TXV). Zone Perfect Plus operates within

an airflow range of 1.5 to 6 tons in the cooling mode.

How to determine the appropriate size of heating and cooling

equipment is a challenge that is subject to much debate. In a

residential zoning system, there is a very good possibility that a

system will use all zones on a given day. For that reason, we

recommend that you select the size of heating and air conditioning

units based on either the home’s block heating load or block

cooling load (whichever is greatest). Select the size of the air

handling unit based on the unit with the largest required CFM.

However, because the system has the capability to not condition

some zones at any given time, and because it is essential to

—6—

Page 7

maintain minimum airflow through the system at all times, it is

better to use slightly undersized equipment than slightly oversized

equipment in a zoning system.

Select heating and cooling equipment to meet the peak heating and

cooling block load estimates that you calculated in Task 3. Use the

Product Data Sheets for the equipment that you are considering to

determine whether the equipment can meet the system’s needs.

Verify that the selected indoor air handler can meet the heating and

cooling airflow requirements, as well as the system’s external

static pressure requirements.

NOTE: When you design the air distribution system, you need the

Product Data for the indoor air handler’s performance characteristics.

In a zoning system, it is especially important to select heating and

cooling equipment that is not too large. Equipment that is larger

than necessary compounds the problem of keeping the airflow in

the system above the minimum required by the equipment when

few zones require conditioning. Because the system shuts down

the equipment if the duct temperature falls outside the minimum or

maximum temperature limits, and limits the number of times the

equipment can restart to 4 times per hour, the actual capacity

provided by the system can be smaller with larger equipment.

To help avoid such problems, size the equipment based on the

calculated peak heating or cooling airflow (whichever is larger) of

the home. Do not add a fudge factor. Under even the heaviest

loads, the system has the capability to send its entire capacity to

less than the entire home. To redirect capacity where it is most

needed, the homeowner can easily set back some zones.

For information about the different types of heating and cooling

equipment that can be used with zoning systems, see the section

"Special Applications Using Zone Perfect Plus."

TASK 5—CHOOSE REGISTER AND RETURN

LOCATIONS

Determining the Number of Returns

Each zone should have a separate return with sufficient capacity to

return all of the air that is delivered to that zone. If you cannot

provide a separate return for a zone, use one of the following

methods to maintain airflow to that zone:

• Leave space under doors.

• Install grilles into or above doors.

• Provide a connection from the zone to another area that has an

adequate return.

When the air leaving a zone must pass into another zone, cross

conditioning occurs and it becomes difficult to maintain different

temperatures in the 2 zones. For this reason, a zone that is

significantly "set back" at times needs its own return.

Selecting Return Locations

The location of the returns for a zone significantly affects the

capacity that can be delivered to that zone. A high return removes

warmer air from the ceiling and a low return removes cooler air

from the floor. For a 2-story home, it is best to have both high and

low returns.

The location of the returns for a zone also has a significant effect

on the comfort in that zone. Because our feet are generally on the

floor and our heads are never closer than about 2 ft from the

ceiling. It is more important to keep the floor at a comfortable

temperature. In both cooling and heating, floors can become

uncomfortably cool and a low return can help alleviate this

problem.

In homes where the air handler is located in the basement, a return

near the basement floor will help avoid overcooling of the

basement. A low return also helps with the removal of dampness

and radon from the basement. However, a low return in the

basement lowers the return temperature cooling, increasing the

size of ducts required for proper operation of the system.

For homes with cathedral ceilings or multi-story rooms, a return at

the highest point can enhance both efficiency and comfort,

particularly during heating.

Selecting Register Locations

The general issues related to selecting register locations are the

same in zoned systems as they are in non-zoned systems. The only

exception is that the velocity of air leaving a register is likely to be

higher in a zoned system. Locate the register to take advantage of

the greater mixing of air that can be provided by the higher air

velocity and to minimize the discomfort caused downwind from

the register. As always, select register and return locations to avoid

stratification of air in the room and to maximize the mixing that

occurs when air swirls through a room.

Meeting Zoning Challenges in 2-Story Homes

In a 2-story home where cooling is the primary challenge, keep in

mind the principle of buoyancy—the tendency for cool air to sink

and warm air to rise. The lower level might tend to be over

conditioned or the upper level might tend to be under conditioned.

To help avoid such problems, on the upper level you can:

• Use high registers to mix the cooled air with the warm air near

the ceiling.

• For registers, direct or deflect the air upward and maintain high

grille velocity.

• Install returns near the ceiling.

• Close doors to rooms and minimize space below doors when

possible, but only if each room has its own return.

• Install a ceiling fan in each room.

Recording Return and Register Locations

You can mark the locations for returns and registers on the Floor

Plan Worksheet for the home. Indicate the approximate height of

each return and register.

TASK 6—DETERMINE BYPASS NEEDS

Bypass dampers have become a standard component in many

zoning systems produced today. When multi-stage equipment with

an ICM blower motor is used in a properly sized duct system, a

bypass is not always necessary.

The use of a bypass to add load to a system is most common in

commercial applications. In residential applications, a direct bypass is most common. Without proper precautions, the use of a

direct bypass can lead to poor comfort and/or equipment failure.

A direct bypass recycles either the coldest or hottest air in the

system back into the return air inlet when it is needed the least. In

cooling, the direct bypass can cause the coil to freeze and the

equipment to shut down due to the low temperature limit. In

heating, the direct bypass can cause overheating and the equipment

to shut down due to the high temperature limit. Either of these

situations reduces the comfort that the system can provide.

A direct bypass with Zone Perfect Plus using the out zone feature

is an excellent option. The bypass reduces air noise under

minimum load and the out zone feature keeps the equipment from

shutting down.

TASK 7—LAY OUT SUPPLY DUCTS AND

LOCATE DAMPERS

The supply air duct system for a zoning system has a different

layout than one designed for a conventional single zone system.

Provide a separate zone duct to carry all of the air for each zone.

The zone damper for each zone is located in its zone duct. Branch

ducts connect to each zone duct, downstream from the zone

damper. They supply conditioned air to individual rooms or areas

in the zone.

In some systems, it might not be convenient to connect all of the

branch ducts for a zone to a single zone damper. In such a case,

multiple branch ducts can be fed through multiple (up to 3) zone

dampers. All of the zone dampers for the zone are wired in parallel

so that they open and close the same amount at the same time.

—7—

Page 8

N

Bath

Bath

Bedroom

Large

WIndow

Master

Bedroom

Bedroom

Zone Damper

Fig. 7—Example of Supply Duct Layout and Damper Locations

You can mark the supply duct layout and damper location on the

Floor Plan Worksheet for the home. Fig. 7 shows an example of

supply duct layout and damper locations marked on a floor plan

worksheet.

TASK 8—DETERMINE APPROPRIATE DAMPER AND

DUCT SIZES

Airflow is the way that a zoning system moves heating or cooling

Btu’s to the load (the demand for heating or cooling in the home)

and back to the heating or cooling equipment. For the equipment

to perform properly, the system must maintain a minimum load on

the equipment. In a residential system, the necessary airflow

usually is measured in cubic feet per minute (CFM) exiting the

duct system. For most zoning systems, the system must maintain a

minimum of 300 CFM per ton exiting the duct system (not

recirculated).

A zoning system distributes air based on the differing load in each

zone. Most of the time, some of the dampers are partially closed;

some dampers may be completely closed. By using a larger duct

size for a zoning system that you would use in a non-zoned system,

you help assure that air flows at an appropriate velocity where it is

needed and that the sound level remains acceptable.

Because Zone Perfect Plus controls airflow based on the proportional needs of each zone, the logic used for selecting appropriate

damper and duct sizes is different than the logic you would use for

other zoning systems or a non-zoned system. It is not reasonable to

attempt to design an air distribution system that can handle 100

percent of the system’s airflow capacity through 1 zone. However,

it is reasonable to design the air distribution system to be able to

move the minimum airflow with one-third of the zones’ dampers

fully open.

NOTE: The use of multi-stage heating and/or cooling equipment

can significantly reduce the size of dampers and ducts required for

an installation. For more information, see the section "Using

Multi-Stage Equipment with Zoning."

Determining Duct Size Based on Damper Size

Kitchen

Informal

Dining

Room

Living Room

Shaded

Unit in

Basement

Family Room

Shaded

Utility

Room

Zone 1

Zone 2

Zone 3

Zone 4

A98343

The most logical way to determine the damper and duct size

requirements for a zoning system is to first determine the zone duct

size required for each zone. Select the damper size that will move

500 CFM per ton at the desired velocity as you normally would.

Do not undersize these dampers! Then, size ducts based on 500

CFM per ton of load to each zone. Zone ducts should always be as

large or larger than the selected damper.

NOTE: For zones that need quiet operation and fast setback

recovery, use 600 CFM per ton to size zone dampers and ducts.

Larger ducts are always better with an ICM blower system. With

a non-ICM blower in the system and excessively large ducts, one

or both of the following problems might occur:

• Humidity removal might suffer.

• Register "throw" might be reduced. Continuous fan use and

good register and return placement can solve this problem.

The combination of larger ducts and an ICM blower eliminates

many problems that can occur in a zoning installation.

It is wise to oversize the ducts for small zones so that the heating

and cooling equipment can continue to operate when only the

small zones need conditioning. The zoning system will maintain

proper temperature control even if the ducts are oversized.

When determining the duct size for a zoned system, keep in mind

that duct balancing, which is an important concept for designing

non-zoned systems, is not necessary in a zoned system. The zoning

system itself will balance the ducts.

Why Oversized Ducts Are Not a Problem

with Zone Perfect Plus

Example 1: When the air handling equipment is used on a system

with oversized ducts, it delivers less air through the ductwork. This

reduction in volume and velocity can cause conditioned air to

stratify and not reach the zone sensor in a zone. When this situation

occurs, the system assumes there is a greater demand in that zone

and opens the zone damper to increase airflow to that zone.

—8—

Page 9

User Interface

N

Large

WIndow

Master

Bedroom

Bedroom

Zone Damper

Fig. 8—Example of Zone Sensor Locations

Bath

Bath

X

Kitchen

X

Bedroom

= Zone Sensor Locations

X

Informal

Dining

Room

Living Room

Shaded

Basement

X

X

Unit in

Family Room

Shaded

Utility

Room

Zone 1

Zone 2

Zone 3

Zone 4

A98344

Example 2: In a 2-stage system the unit starts in low speed, the

system reacts the same as in Example 1 except, when more zones

demand conditioning and other zone dampers open, the system

switches the equipment to 2-stage mode, increasing the system

capacity and the airflow to the zones requiring conditioning.

TASK 9—CHOOSE LOCATIONS FOR ZONE SENSORS

One zone sensor is required for each zone. Generally, the User

Interface’s internal sensor serves as the zone sensor for its zone

(Zone 1). A Smart Sensor or Remote Sensor may be used in any

zone, except a Smart Sensor may not be used in Zone 1.

For proper operation of the Zone Perfect Plus system, each sensor

must accurately measure the temperature within its zone. Considerations for selecting a location for a sensor are essentially the

same as the considerations for selecting a location for any

thermostat.

When selecting a location for a sensor, follow these guidelines:

• Select a location close to the center of the sensor’s zone, on an

inside wall. In particular, avoid locations where the air from

another zone mixes with the air in the zone you are trying to

monitor. If the target temperatures for the 2 zones are different,

the system might not be able to determine the necessary amount

of conditioning to supply to each zone.

• Plan to mount the sensor approximately 5 ft (1.5 m) above the

floor.

• Select a section of wall without pipes or ductwork.

• If there are 2 or 3 bedrooms in a single zone, locate the sensor

in the hallway connecting the bedrooms, near the return grille

but not directly in the return airflow.

•Donot select a location:

— on an outside wall, close to a window, or next to a door

leading outside.

— exposed to direct light and heat from a lamp, the sun, a

fireplace, or any other heat-radiating object that might cause a

false reading.

— in direct airflow from supply registers and return grilles.

— in areas with poor circulation, such as behind a door or in an

alcove.

You can mark the locations for zone sensors on the Floor Plan

Worksheet for the home. Fig. 8 shows an example of zone sensor

locations marked on a floor plan worksheet.

C. Considerations When Retrofitting

an Installation

It is a far greater challenge to design a retrofitted zoning system

than it is to design a system for a new home. For a zoning system

to operate properly in a retrofitted installation, it usually is

necessary to use 1 or more of the following approaches to

compensate for an air distribution system that is too small for the

zoning system:

• Modify the existing ductwork and dampers to handle additional

airflow.

• Set mechanical minimum damper positions in some zones.

• Improve the home’s insulation to reduce the home’s demand

for heating and cooling (load) so that lower capacity equipment

can be used effectively in the installation.

• Use multi-stage heating and cooling equipment so the equipment capacity can match the load when only a limited number

of zones require conditioning.

• Select an air handler that is designed to overcome the high

static pressure in the ductwork and force more air through the

system. A unit with an ICM blower is a good choice.

When selecting the appropriate approach for a retrofitted system,

be sure to inform the homeowner of the tradeoffs between cost and

comfort when comparing approaches.

D. Installing the System

To install each component, follow the Zone Perfect Plus Installation Instructions provided with the Zone Perfect Plus kit and the

—9—

Page 10

Installation Instructions provided by Bryant with the selected

heating and cooling equipment. Thoroughly test the installation,

following the instructions provided, to ensure that it is installed

and set up properly.

COMPONENTS REQUIRED FOR SPECIFIC

APPLICATIONS

The following components are required in all Zone Perfect Plus

installations:

• a TXV (thermostatic expansion valve)

• a LAT (leaving air temperature) sensor, provided with all Zone

Perfect Plus kits

In a heat pump installation (not a dual fuel application), an HPT

(heat pump temperature) sensor is required.

In a dual fuel application, or any installation using the low

temperature lockout feature, the auxiliary heat lockout feature,

and/or the automatic humidity level adjustment feature, an ODT

(outdoor temperature) sensor is required. In other Zone Perfect

Plus applications, this sensor is optional.

Information about each of these components is provided in the

following sections.

A. Thermostatic Expansion Valve

A TXV is required in all Zone Perfect Plus installations. The

TXV replaces the fixed metering orifice, which regulates the

amount of liquid refrigerant entering the indoor evaporator. The

TXV assures that no liquid refrigerant leaves the evaporator,

possibly returning to the compressor and causing damage.

The likelihood of incomplete refrigerant evaporation is much

greater in a zoning system than in a non-zoned system because of

the reduced airflow when only a few zones require conditioning.

Thus, the TXV protects the compressor from possible damage

when airflow is very low.

NOTE: The purpose of the TXV is not to protect the coil from

freezing. The leaving air temperature (LAT) sensor performs this

function.

B. Leaving Air Temperature Sensor

A LAT sensor is required for all types of equipment. When

used with fossil fueled furnaces and air conditioned systems, locate

the LAT sensor in the air supply duct downstream of the furnace

and cooling coil. The LAT sensor must be upstream of the bypass

damper, if one is included in the system, or the first zone damper.

The LAT sensor monitors the leaving air temperature during both

heating and cooling. The User Interface is programmed with

temperature limits and prevents equipment operation if the leaving

air temperature exceeds the upper limit during heating or falls

below the lower limit during cooling.

When used with a heat pump, locate the LAT sensor downstream

of the accessory electric heaters. The LAT sensor monitors the air

temperature leaving the accessory electric heaters during heating,

as well as the temperature leaving the indoor coil during cooling.

C. Heat Pump Temperature Sensor

An HPT sensor is required in a heat pump installation, unless it is

a dual fuel application. Locate the HPT sensor in the air stream

between the indoor coil and the accessory heaters.

This sensor serves a similiar purpose to the LAT sensor, but does

not sense the temperature of the air leaving the electric heaters.

The HPT sensor monitors the air temperature leaving the indoor

coil during heating by the heat pump, and prevents the operation of

the heat pump if the leaving air temperature exceeds the fixed

temperature limit of 115°F.

D. Outdoor Temperature Sensor

An ODT sensor is required in all dual fuel applications. An ODT

sensor also is required to use the low temperature lockout feature,

the auxiliary heat lockout feature, and/or the automatic humidity

level adjustment feature in any installation.

For dual fuel systems, this sensor is used to control the switch from

electric to fossil fuel operation when the outdoor temperature

reaches the preset temperature. When used with the low temperature lockout feature, the ODT sensor is used to prevent equipment

operation during cooling when the outdoor temperature falls below

the preset lower limit.

When used with the auxiliary heat lockout feature, the ODT sensor

is used to prevent electric heat operation in a heat pump installation when the outdoor temperature rises above the preset limit.

When used with the automatic humidity level adjustment feature

during heating, the system automatically reduces the humidity set

point by 1 percent for every 2°F reduction in outdoor temperature.

In other Zone Perfect Plus applications, this sensor is optional.

SPECIAL APPLICATIONS USING ZONE PERFECT

This section discusses special Zone Perfect Plus applications that:

• Emphasize energy savings or "setback."

• Include multi-stage equipment.

• Include variable-speed blowers.

• Include a barometric bypass damper.

A. Understanding the Requirements of Setback with

Zoning

If you are designing a zoning system for energy savings, it is

important to understand the additional challenges that you face

before you begin to design the air distribution system. The energy

savings achieved by setting zone temperatures back (lower for

heating or higher for cooling) can be substantial. However,

"setback" brings additional requirements to the system.

The zones that are not set back might be surrounded by zones that

are. This situation results in the need to deliver additional capacity

to the zone that is not set back since the zone duct and damper need

to deliver the capacity required to meet the zone’s needs and to

compensate for the conditioning that spills over to the neighboring

zones that are set back.

Thus, the effective block load of any zone increases above the

value normally calculated for it when its neighboring zones are set

back. The amount of the increased load depends on the extent to

which the neighboring zones are set back. This need for additional

capacity increases the size of damper and duct required for the

zone.

When a zone has been set back, the system eventually must return

the zone to a more comfortable conditioning level. This need

increases the capacity that must be delivered to the zone. The

amount of additional capacity that is necessary is the capacity

required to match the zone’s load plus the capacity required to

implement recovery within a reasonable time period. The amount

of capacity required for recovery depends on the extent to which

the zone had been set back and the desired recovery time. Again,

this need for additional capacity increases the size of damper and

duct required for the zone.

The improved insulation found in today’s homes compounds the

demands imposed by setback. The better insulated the home, the

smaller the size of heating and cooling equipment required for the

home. However, the requirements of setback recovery are determined by the heat capacity of the zone, not by its losses, and heat

capacity is not changed by insulation. Improved insulation also

increases the challenge of maintaining different temperatures

between zones since the interior walls appear more transparent to

heat flow when the outer walls are better insulated. The opportunity for energy savings in addition to the savings already achieved

through better insulation is reduced in a well insulated home.

B. Using Multi-Stage Equipment with Zoning

When dampers are closed in some zones and the air distribution

system becomes effectively smaller in a system with single-stage

equipment, airflow may drop below the system’s minimum,

causing the equipment to shut down. In this situation, it is difficult

to maintain comfort in the home due to excessive equipment

cycling.

PLUS

—10—

Page 11

In contrast, multi-stage equipment shifts to low-stage operation

(typically 60 percent of total capacity) when the air distribution

system becomes effectively smaller. Because the equipment reduces its minimum airflow limit, it is able to continue to operate.

The reduced capacity generally is adequate to supply the necessary

conditioning since only 1 or 2 zones need conditioning under these

circumstances.

The following multi-stage equipment can be used with the zoning

system:

• Two-speed air conditioners.

• Two-speed heat pumps.

• Two-stage furnaces.

• Two-stage electric heat used without a heat pump.

NOTE: When using multi-stage heating or cooling equipment

with Zone Perfect Plus, the zoning system must be allowed to

control the equipment staging. Therefore, there must be separate

inputs for low-stage and high-stage operation, and the equipment

must be configured to operate from these inputs only. Outdoor

temperature switches, staging algorithms, and so forth should not

be used.

C. Using Variable-Speed Blowers with Zoning

PSC blowers are single-speed blowers. A PSC blower runs at a

fixed speed and cannot change speed as the dampers move. A PSC

blower usually can produce about 0.5 in. of static pressure.

In contrast, ICM blowers are variable-speed blowers. Air handlers

using ICM blowers are designed to supply a fixed quantity of air

into a duct system regardless of the external static pressure. The air

handler can "sense" the external static pressure and change the

motor speed to deliver the desired airflow. An ICM blower

typically can produce about 0.9 in. of static pressure.

In a properly-designed system, the use of an ICM blower can help

assure adequate airflow through the system regardless of damper

positions. Air handlers using ICM blowers typically are programmed to produce 325 CFM per ton (of equipment capability).

The use of such an air handler does not reduce the damper or duct

size requirements of a system, but does help the system run

properly and quietly without a bypass.

D. Bypassing with Zoning

When only 1 zone requires conditioning, airflow through the

ductwork can fall below the system’s minimum requirements. This

situation can cause problems for the system’s equipment and can

lead to discomfort for the home’s occupants.

There are 3 standard methods that have been developed to

maintain minimum airflow, reduce duct velocity, and reduce duct

noise:

• Bypass air to an unconditioned space.

• Bypass air to a conditioned space.

• Bypass air directly to the return.

The term "bypass" means to allow additional air through the

system that bypasses the zone dampers, the zones, or both. The 3

methods described above use a bypass damper, which receives air

from the supply plenum. A barometric damper, which opens when

the supply air pressure reaches a preset value, generally is used for

the bypass. Thus, the barometric bypass damper acts as a pressure

regulator, releasing enough air to reduce the supply plenum

pressure to an appropriate level.

In addition to the 3 standard bypass methods, Zone Perfect Plus

provides an additional bypassing method—OUT zones. OUT

zones can serve as an excellent bypassing method. You can think

of an OUT zone as a temporary dump zone. Ideally, an OUT zone

should be available in the system at all times.

Each of the conventional bypass methods, as well as bypassing

using OUT zones, is discussed in the sections below. As you

evaluate the usefulness of these methods for a particular installation, keep in mind that bypassing using OUT zones can work well

in conjunction with a barometric bypass.

NOTE: A bypass damper reduces air noise by reducing airflow

velocity in the ducts. A direct bypass to the return does not add

load to the system.

BYPASSING TO AN UNCONDITIONED SPACE

Conditioned air can be bypassed to an unconditioned space. This

type of bypass is considered an indirect bypass.

Although there is no limit on the amount of air that can be

bypassed using this method, this type of bypass wastes energy. In

addition, this method creates negative indoor pressure, which pulls

unconditioned air into the home. This method is rarely used in

zoning installations and we do not recommend it.

BYPASSING TO A CONDITIONED SPACE

Conditioned air also can be bypassed to a conditioned space, called

a dump zone. This type of bypass also is considered an indirect

bypass.

Although there is no limit on the amount of air that can be

bypassed using this method, this type of bypass reduces the

effectiveness of the zoning system. The dump zone tends to be

over conditioned and uncomfortable.

This method is acceptable if you have a zone that can function as

a dump zone, such as a large basement. However, there rarely is a

zone suitable for this use.

BYPASSING DIRECTLY TO THE AIR RETURN

There are advantages and disadvantages to bypassing directly to

the air return using a barometric damper. The advantages of a

direct barometric bypass include:

• A direct bypass serves as a pressure regulator, bypassing

enough air to hold the static pressure in the plenum to a safe

level. Thus, a direct bypass prevents excessive air velocities,

which can cause noise and drafts.

• Because a direct bypass returns conditioned air back into the air

handler, it makes the leaving air colder in cooling and warmer

in heating. A direct bypass increases the Btu content of the air

entering the duct system while airflow (CFM) remains at the

same level. The result is that more capacity can be forced into

the system without increasing the airflow.

• During cooling, the process of making the leaving air colder

removes more water from the air. When a system is bypassing

a large amount of air (only a small portion of the zones require

conditioning), there is relatively little total demand on the

system. During such periods of light load, humidity often can

be a problem. The direct bypass automatically increases the

removal of water when it is most needed.

The disadvantages of a direct barometric bypass include:

• It is very difficult, if not impossible, to determine how much air

is being bypassed under a given condition. Traditional calculation methods can assure that the bypass is large enough, but

do not prevent the bypass from becoming too large. The

amount of air that can be bypassed often is greater than the

amount that the equipment can tolerate.

NOTE: The dimensions and attachment points of the bypass

ductwork have more influence on the amount of air that is

bypassed than the ratings of the bypass damper.

• Airflow into the ductwork might be reduced excessively,

resulting in insufficient conditioning.

• Because too much air can be bypassed, entering and leaving air

temperatures can range outside safe values for the heating and

cooling equipment, possibly resulting in equipment failures or

shortened equipment life. A direct bypass, unlike an indirect

bypass, does not remove Btu’s from the equipment, although it

does allow more airflow through the equipment.

Although it is commonly believed that the equipment is

protected as long as proper airflow is maintained, this belief is

true for an indirect bypass but not for a direct bypass. A direct

—11—

Page 12

bypass provides no protection for the equipment even though it

increases the airflow through it. Particularly for furnaces, a

direct bypass can harm rather than help by overheating internal

components. Therefore, the amount of air bypassed during

heating with a direct bypass must be limited.

• If bypassing results in excessive temperature in the supply duct

and a limit is tripped, the equipment shuts down. To protect the

equipment, the zoning system does not allow the equipment to

be turned on more than 4 times per hour. If the limit is tripped

repeatedly, the amount of heating or cooling delivered to the

zones might decrease dramatically. Thus, a direct bypass might

initially help the performance of a system during a period of

limited demand, but it might eventually result in an abrupt loss

of conditioning.

NOTE: A leaving air temperature (LAT) sensor is required in

every Zone Perfect Plus system. If the system is programmed

properly, this sensor ensures that the equipment turns off when the

leaving air temperature exceeds a safe range. Although it might be

tempting to omit the LAT sensor to increase the system’s performance, you risk eventual equipment failure. The equipment’s

internal limits are not intended to be tripped repeatedly.

Similarly, if the LAT range is not programmed properly, you can

cause the equipment’s internal limits to trip repeatedly. Again, you

risk eventual equipment failure.

BYPASSING USING OUT ZONES

Although the OUT zone feature can be used to provide energy

savings to the homeowner, its primary use is to give the system a

place to direct excess airflow to avoid tripping limits that protect

the heating or cooling equipment when the airflow falls below the

minimum required to operate safely. By closing an OUT zone’s

damper(s) if the zone becomes cooler than the coolest zone (in

cooling) or warmer than the warmest zone (in heating), the system

avoids over conditioning the OUT zone. Thus, using OUT zones

for bypassing provides the advantages of bypassing to a dump

zone, but avoids the disadvantages.

The following scenario illustrates bypassing in a system that has

both a direct barometric bypass damper and several OUT zones.

This example illustrates the operation of the system in the cooling

mode. Keep in mind that the system would operate similarly in the

heating mode.

Imagine a zoning system is running in cooling mode and less than

1/3 of the zones have a cooling demand. The air pressure in the

ducts starts to build and the barometric bypass damper starts to

open. As the air recirculates to the return of the air handler and into

the evaporator coil, the leaving air temperature drops.

When the leaving air temperature, as measured by the leaving air

temperature (LAT) sensor, falls to 46°F, the system opens all OUT

zone dampers 3 positions. This action relieves the duct pressure

and may allow the bypass to close. If the temperature drops

another degree, the OUT zone dampers open another 3 positions.

The system continues to progressively open the OUT zone

dampers as the temperature falls until 1 of the following events

occurs:

• The leaving air temperature stabilizes and the OUT zone

dampers maintain position. (This result is the most common.)

• The demand is met for all zones and the system shuts down.

• The OUT zone dampers are fully open (position 15).

• The OUT zones become colder than the lowest cooling system

set point and their dampers close.

• In extreme cases, the leaving air temperature can fall to 40°F.

Usually this situation is caused by factors outside the heating

and cooling system, such as doors and windows left open when

the rest of the home is satisfied. In this extreme case, the limit

for the system is reached and the system shuts down the cooling

equipment.

GLOSSARY

Barometric Bypass Damper

Device used to control noise and maintain airflow in a heating or

cooling system during minimum airflow. When the supply airflow

reaches a preset value, the barometric bypass damper opens.

Block Load

Heating or cooling load of the home as 1 space.

Btu

British thermal unit. A standard unit of heat—the amount of heat

required to raise the temperature of 1 lb of water 1°F.

Bypass

Configuration that allows additional air through the system that

bypasses the zone dampers, the zones, or both.

Cooling Demand

The difference between the current temperature in a zone and the

zone’s cooling set point (when the temperature is higher than the

cooling set point).

Condition

Process of ventilating, heating, or cooling (and sometimes humidifying or dehumidifying) an area.

Dump Zone

Conditioned zone to which air is bypassed.

Equipment Controller

Device that interfaces with the home’s heating and cooling

equipment so Zone Perfect Plus can control that equipment.

External Static Pressure

Measured static in inches wc from the inlet to the outlet of the air

handling unit.

Heat Pump Temperature (HPT) Sensor

Device that measures the temperature of air leaving the indoor coil.

Zone Perfect Plus uses this temperature under certain circumstances to adjust the operation of the heating or cooling system.

Heating Demand

The difference between the current temperature in a zone and the

heating set point (when the temperature is lower than the heating

set point.)

ICM (Integral Control Motor) Blower

Variable-speed blower. Air handlers using ICM blowers are

designed to supply a fixed quantity of air into a duct system

regardless of the external static pressure.

Leaving Air Temperature (LAT) Sensor

Device that measures the temperature of air leaving the air handler

in heating or cooling. Zone Perfect Plus uses this temperature

under certain circumstances to adjust the operation of the heating

or cooling system.

Multi-Stage Equipment

Heating or cooling equipment that can adjust the capacity in

response to the demand of the zoning system.

OUT Zones

Zones (usually unoccupied) that have been selected to receive no

conditioning for a period of time unless the temperature exceeds

85°F or falls below 60°F. Zone Perfect Plus also uses OUT zones

to relieve the heating or cooling equipment under overload

conditions.

Outdoor Temperature (ODT) Sensor

Device that measures the temperature of the air outside. Zone

Perfect Plus uses this temperature under certain circumstances to

adjust the operation of the heating or cooling system.

PSC (Permanent Split Capacitor) Blower

Single-speed blower. A PSC blower runs at a fixed speed and

cannot change speed as the dampers move.

—12—

Page 13

Remote Sensor

Device that measures the temperature in a zone, but does not

provide a means to view or adjust the temperature.

Set Points

Temperatures selected to determine the acceptable temperature

range for each zone. The zone’s higher set point determines when

the zone needs to be cooled. The zone’s lower set point determines

when the zone needs to be heated.

Set Back

Process of significantly reducing the set point of a zone during

heating or increasing the set point of a zone during cooling to

reduce the amount of conditioning required in the zone.

Smart Sensor

Device that measures the temperature in a zone, and that provides

a means to view and adjust the temperature in that zone.

Thermostatic Expansion Valve (TXV)

Device that senses both the pressure and temperature at the outlet

of the evaporator, and adjusts the refrigerant flow into the

evaporator. The TXV ensures that no liquid refrigerant leaves the

evaporator, possibly returning to the compressor and causing

damage.

Ton

Measurement of heating or cooling equipment capacity equivalent

to 12,000 Btu’s per hour.

User Interface

Command center of Zone Perfect Plus. Includes displays and

buttons that let the homeowner select features and see information

about the system.

Zone

Distinct area within a building where the airflow is controlled by

a zone damper.

Zone Damper

Motorized air volume control damper, which regulates the flow of

conditioned air into the zone.

Zone Duct

The main air supply duct to a zone, which carries all of the air and

contains the Zone Damper for the zone.

Zone Load

Heating or cooling load of a single zone.

Zoning System

Equipment that allows cooling and/or heating equipment to regulate the temperature independently in different areas of a home.

APPENDIX—WORKSHEETS

This appendix provides the following worksheets for you to copy

and use when designing a Zone Perfect Plus installation:

• Zoning Design Checklist

• Homeowner Survey

• Floor Plan Worksheet

—13—

Page 14

A. Zoning Design Checklist

Use this checklist to make sure that you have completed each necessary task when designing a Zone Perfect Plus installation.

Assigning Zones

[] Task 1—Assess the homeowner’s goals for comfort and energy savings.

[] Task 2—Conduct a site survey and make preliminary zone assignments.

Sizing the Equipment

[] Task 3—Calculate block load estimates and zone load estimates.

[] Task 4—Size the heating and cooling equipment.

Laying Out and Sizing the Duct System

[] Task 5—Determine bypass needs.

[] Task 6—Choose register and return locations.

[] Task 7—Lay out supply ducts and locate dampers.

[] Task 8—Determine appropriate damper and duct sizes.

Laying Out Zone Components

[] Task 9—Choose locations for zone sensors.

—14—

Page 15

Homeowner Survey

1. How many members are there in your household?

2. Describe the activities in your household on an unusual day. In particular, are

there activities that might require extra cooling or heating?

3. Describe the typical usage of the various areas of your home throughout the day.

4. What areas, if any, in your home that are used infrequently, such as a formal dining

room, or that are unoccupied for large periods of time during the day or night?

5. What areas, if any, in your home that are closed off from the rest of the house

(for example, a room where you always keep the door closed?)

6. Is there an area in your home that will be used for exercise?

7. Describe the entertaining that you do in your home:

How often do you entertain in the summer? In the winter?

During what times of the day do you typically entertain?

How many people do you usually entertain?

What areas of your home do you use when you entertain?

Are there times when people go in and out of the house frequently (for example,

if you entertain outdoors)?

—15—

A98345

Page 16

8. What temperature do you normally want to maintain in your home during the day

in the summer? The night in the summer? The day in the winter? The night in the

winter?

9. Are there any times when you want significantly different temperatures in all or

part of your home? If so, in what areas or rooms? How quickly do you want the

temperature change to occur?

10. To what extent do you want to be able to control the temperature in your home?

11. What do you expect from your indoor comfort system?

Additional Questions for an Existing Home