Page 1

Zoning Design Guide

ZONE PERFECT PLUS

Cancels: AP17–2 AP17–5

8-00

NOTE: Read the entire instruction manual before starting the

installation.

TABLE OF CONTENTS

INTRODUCTION..........................................................................1

OVERVIEW OF ZONING............................................................1

WHAT IS ZONING?.....................................................................1

IS A ZONING SYSTEM RIGHT FOR THIS JOB?....................1

DESIGNING A ZONE PERFECT PLUS INSTALLATION......1

ASSIGNING ZONES...............................................................2

SIZING THE EQUIPMENT....................................................3

SIZING THE DUCT SYSTEM ...............................................3

REFERENCE FOR DUCT SIZING WORKSHEET:

STEP 6......................................................................................4

REFERENCE FOR DUCT SIZING WORKSHEET:

STEP 7......................................................................................5

APPENDIX ....................................................................................5

INTRODUCTION

Zone Perfect Plus is a zoning system capable of providing zone

control requirements for 2, 4, or 8 living or business areas. This

system allows the home or business owner to control the living

environment in an individualized way. The Zone Perfect Plus kit

includes the User Interface, Equipment Controller, Remote Sensors, an Outdoor Temperature Sensor, and Leaving Air Temperature (LAT) Sensor. See Fig. 1 for components which make up an

8–zone kit.

This guide provides information to help you design a Zone Perfect

Plus installation. It discusses general topics related to designing a

zoning control system.

Use this guide to help you design a zoning system that will:

• Meet or exceed the expectations regarding the system’s capabilities. This goal will result in improved customer perception

of your company, as well as repeat business and referrals.

• Protect the heating and cooling equipment used in the system.

This goal will result in improved system reliability, longer life

of heating and cooling equipment, and reduced warranty costs.

To design a zoning system to perform well under all conditions, it

is essential to viewthe systemas awhole atthe designstage, rather

than to begin selecting and installing individual components

without a careful assessment of how they will work together. Be

sure to perform all of the Tasks described in this guide before you

begin to install components.

OVERVIEW OF ZONING

Zoning systems bring the possibility of total comfort control to the

occupants by providing the right amount of heating or cooling to

each space. Comfort can be described as the absence of sensation.

Ideally, a zoning system should keep the occupants of the space

comfortable without them being aware of the system.

WHAT IS ZONING?

A zone is a conditioned space (one room or a group of rooms) that

is separately controlled by its own sensor. There are as many

sensors in a designed system as there are zones.

A zoning system is a heating and cooling control system that

maintains each zone at a predetermined temperature set point and

maintains the overall space at a predetermined humidity set point.

In addition to meeting these basic goals, Zone Perfect Plus is

designed to:

• Direct conditioned air proportionately based on the needs of

each zone, so that the zone(s) with the greatest demand receive

relatively more conditioned air.

• Keep the sound produced by the system low enough that

occupants will not find it objectionable.

• Conveniently interface with and protect the system’s heating

and cooling equipment.

• Maintain at least the minimum airflow necessary to keep

heating and cooling equipment running efficiently.

IS A ZONING SYSTEM RIGHT FOR THIS JOB?

When designing a zoning system, it is important to keep in mind

what a zoning system can and can not do. A zoning system is only

part of a complete heating and cooling system. A properly selected

heating and cooling system has a limited heating and cooling

capacity. A zoning systemmay ormay notincrease theeffective

capacity. This depends on whetherthe system isbeing designed

for comfort (no increase) or energy savings (some increase in

overall effective system capacity).

A zoning system reduces the effective size of the air distribution

system as dampers are adjusted and closed to meet the needs of the

zone. The primary challenge when designing a zoning system is to

make sure that the air distribution system cannot become so

effectively small that the reduction in airflow causes one of the

following problems:

• Air noise or draft becomes excessive.

• The heating or cooling equipment is shut down because

temperature limits are exceeded.

• The life of the equipment is reduced because of stresses related

to excess temperatures.

The addition of a zoning system will not correct undersized

duct problems. A zoning system will compensate for oversized

ducts, but might make a bad situation worse in the case of

undersized ducts. There are many ways to make a marginal duct

system perform better. Most of these approaches involve changing

ducts, registers, and/or heating or cooling equipment.

DESIGNING A ZONE PERFECT PLUS INSTALLATION

The main objective when designing a zoning system is to maintain

at least minimum airflow through the system when only one zone

requires conditioning, yet still provide sufficient airflow when all

zones require conditioning. The tasks described below provide

step-by-step instructions for designing an effective zoning system.

These tasks are grouped in the following phases:

Assigning Zones

Task 1–Assess the goals for comfort and energy savings.

Task 2–Conduct a site survey and make preliminary zone assign-

ments.

—1—

Page 2

Sizing the equipment

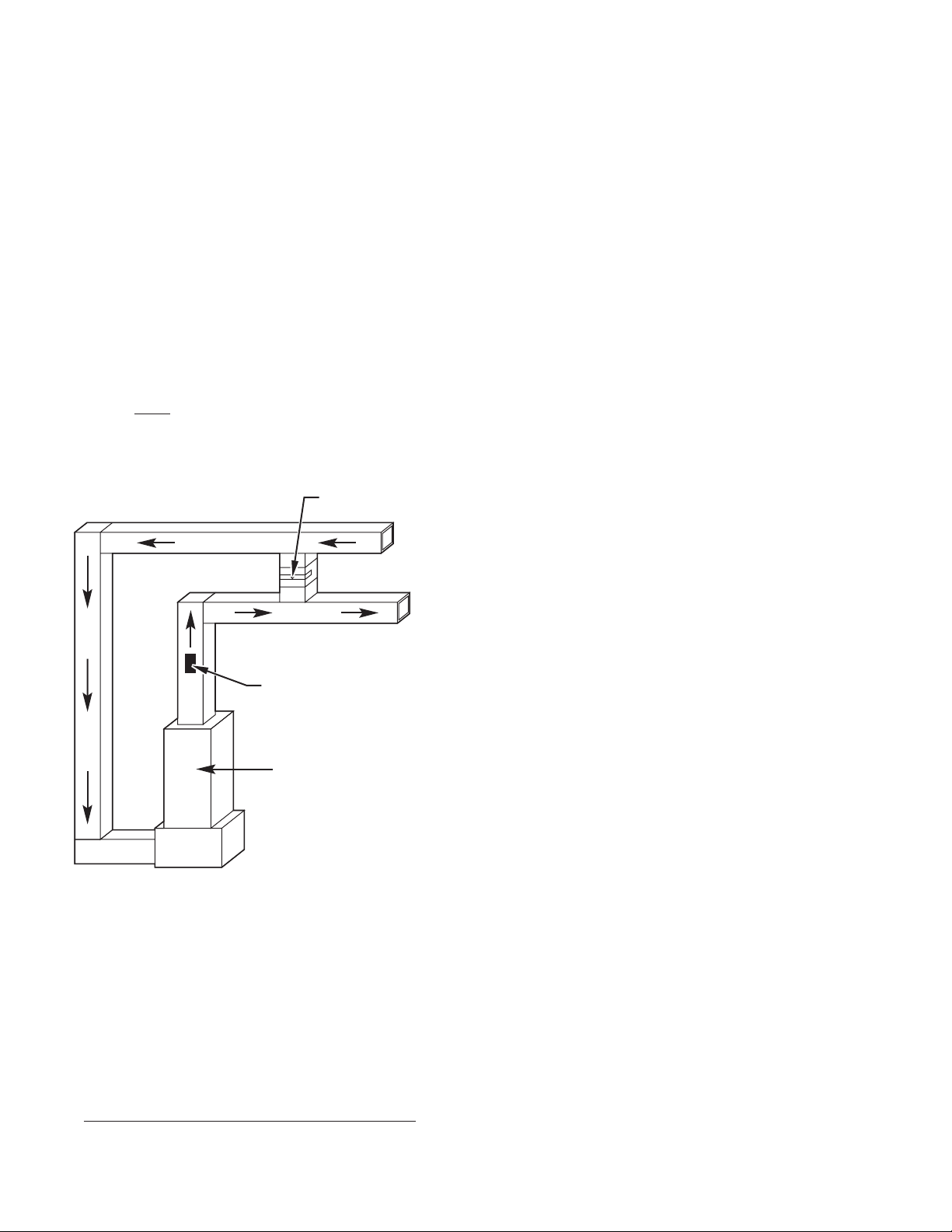

Fig. 1–Zone Perfect Plus 8 Zone Kit

Task 3–Calculate block load estimates and zone load estimates.

Task 4–Size the heating and cooling equipment.

Sizing the duct system

Task 5–Determine bypass needs/options.

Task 6–Explanation of the Duct Sizing Worksheet.

I. ASSIGNING ZONES

A. Task 1–Assess the goals for comfort and energy

savings

For a zoning system to be successful, it must meet the customer’s

goals for comfort and/or energy savings. Therefore, it is essential

to understand the goals before beginning to design the system. In

some situations, a customer’s expectations might not be realistic

and it would be impossible to design a system to meet those

expectations. By identifying this problem from the start, you can

help revise these expectations and avoid creating a dissatisfied

customer.

In addition to understanding the general goals for the zoning

system, you need to understand exactly how each space/zone will

be used. Use Owner Survey sheet provided. The appendix will

help you gather information from the owner/customer.

B. Task 2–Conduct a site survey and make preliminary

zone assignments

The purpose of conducting a site survey is to gather the information that you need to make zone assignments. Use the Floor Pan

Worksheet provided in the Appendix. Follow these guidelines:

8 Zone Kit

A99247

• Provide the rough dimensions of each area or room.

• Indicate the location and relative size of doors, windows, and

skylights. In particular, identify any large glass areas (exceeding 30 percent of the wall area).

• Indicate any equipment that may add a sensible/latent load

(Light Commercial: computers, copiers, and waiting rooms.

Residential: hot tubs, etc.).

• Indicate whether any trees or buildings cast shade on any of the

building’s exposures.

• Indicate the orientation of the home/building so you can

determine whether there are any rooms or areas facing south or

west where solar heat load may be a factor when making zone

assignments.

Considerations for a Retrofitting Installation

It is a far greater challenge to design a retrofitted zoning system

than it is to design a system for a new home or office. For a zoning

system to operate properly in a retrofitted installation, it usually is

necessary to use one or more of the following approaches to

compensate for an air distribution system that is too small for the

zoning system:

• Modify the existing ductwork and dampers tohandle additional

airflow.

• Set mechanical minimum damper positions in some zones.

• Improve the home/building’s insulation to reduce the demand

for heating and cooling (load) so that lower capacity equipment

can be used effectively in the installation.

—2—

Page 3

• Use multi-stage heating and cooling equipment so the equipment capacity can match the load when only a limited number

of zones require conditioning.

• Select an air handler that is designed to overcome the high

static pressure in the ductwork and force more air through the

system. ECM is a good choice.

When selecting the appropriate approach for a retrofitted system,

be sure to inform the owner of the trade-offs between cost and

comfort when comparing approaches.

Return-air Ductwork

The return-air system should be able to remove the same amount

of air from each zone as was supplied to it. If each zone does not

have its own return, then a cross-contamination of zone temperatures could occur. A good sizing method would be to size the

return at least as large as the main trunk of that particular zone.

Making Preliminary Zone Assignments

The owner’s/customer’s goals regarding comfort and energy

savings affect how many zones are appropriate for the system:

• In a system designed primarily for comfort, all zones usually

have comfort set points that remain relatively constant and that

have similar time schedules. Such a system may have a large

number of zones (5 to 8) of a relatively small size.

• In a system designed primarily for energy savings, zones must

be larger to guarantee proper airflow to the zones that need

conditioning (occupied), while the remaining zones will be

closed (unoccupied). Such a system generally must have a

smaller number of zones of a relatively larger size. In this case,

you must be careful not to “over zone” (i.e., assign too many

zones).

When making zone assignments, use the information that you

gathered when conducting the site survey. Group areas that:

• Are in use around the same time of day. For example, it often

makes sense to assign all bedrooms to a single zone because

they are occupied only during the night time when other rooms

in the home are not occupied.

• Have similar heating and cooling needs.

• Are physically separated from other areas.

• Are on the same level of the home. For example, the rooms on

the upstairs level often have a different heating and cooling

demand when compared to rooms downstairs. The differences

can be due to the tendency for heat to rise, different use or

occupancy, and the roof heat load.

• Have similar exposures to external heating gains and losses.

For example, it often makes sense to assign rooms with large

amounts of glass and western or southern exposure to the same

zone.

If possible, discuss these considerations with the owner. Get the

owner’s input before making initial zone assignments. Mark your

preliminary zone assignments on the Floor Plan Worksheet provided in the Appendix. At this point, consider your zone assignments to be preliminary.

II. SIZING THE EQUIPMENT

A. Task 3–Calculate block load estimates and zone

load estimates

Using the information that you gathered in Task 2, calculate both

heating and cooling load estimates (block load) for the entire

home/building.

The standard Btu load calculations used for non-zoned systems

apply equally well to zoned systems. Use a reliable method with

which you are comfortable. This information will be submitted in

Step 1 of the Duct Sizing Worksheet.

Next calculate individual “room-by-room” heating and cooling

load estimates (in Btu’s) for the home/building. This information

will be submitted in Step 2 of the Duct Sizing Worksheet. Then,

tentatively choose zone loads by adding rooms together and

writing them into Step 3 of the Duct Sizing Worksheet.

The zone load estimates are used to determine whether the zone

assignments you have make sense. They are also used to size the

zone dampers and ductwork.

B. Task 4–Size heating and cooling equipment

Zone Perfect Plus is designed for use with residential furnaces, fan

coils and light commercial products. Whenever possible, a thermostatic expansion valve (TXV)should beused. ZonePerfect Plus

is designed to operate with equipment in arange of 1.5 to 12.5 tons

in cooling mode.

How to determine the appropriate size of heating and cooling

equipment is a challenge that is subject to many debates. In a

zoning system, there is a very good possibility that a system will

use all zones on a given day. For that reason, we recommend that

you select the size of heating and air conditioning units based on

either the home’s/building’s block heating load or block cooling

load. Select the size of the air handling unit based on the load with

the largest required CFM (heating or cooling CFM, whichever is

larger). However, because the zoning system has the capability to

not condition some zones at any given time, and because it is

essential to maintain minimum airflow through the system at all

times, it is better to use slightly undersized equipment than slightly

oversized equipment in a zoning system.

Select heating and cooling equipment to meet the block heating

and cooling block load estimates that you have written into Step 1

of the Duct Sizing Worksheet. Use the Product Data for the

equipment that you are considering, determining whether the

equipment can meet the system’s needs. Verify that the selected

indoor air handler can meet the heating and cooling airflow

requirements. Write this information into Step 4 of the Duct Sizing

Worksheet.

In a zoning system, it is especially important to select heating and

cooling equipment that is not too large. Equipment that is larger

than necessary compounds the problem of keeping the airflow in

the system above the minimum required by the equipment when

few zones require conditioning. Because the zoning system shuts

down the equipment if the duct temperature falls outside the

minimum or maximum temperature limits, and limits the number

of times the equipment can restart to four times per hour, the actual

capacity provided by the system can be smaller with larger

equipment.

To help avoid such problems, size the equipment based on the

calculated block heating and cooling airflow (whichever is larger)

of the space. Do not add a fudge factor. Under even the heaviest

loads, the system has the capability to send its entire capacity to

less than the entire space. To redirect capacity where it is most

needed, the owner can easily set back some zones.

Protecting equipment with a Zoning System

Any time zoning is applied to heating and cooling equipment,

additional requirements must be performed. Variable-speed or

multi-speed residential equipment must have the logic removed,

which allows the zoning system to be in charge of staging.

Any cooling equipment that is going to run below its standard

minimum outdoor temperature must have low ambient kits and

wind baffles installed. Freeze-stats are required to protect the

equipment in the case the Leaving Air Temperature (LAT) sensor

cannot react quickly enough or has been disabled. For residential

equipment, consult the Application and Service manuals for the

required accessories. For Light Commercial (Tyler) products, see

the Product Data for the descriptions of the freeze-stats, wind

baffles, and MotorMaster options. When matched with zoning,

varying speed condensor motors are recommended over the less

expensive fan cycling controls.

III. SIZING THE DUCT SYSTEM

A. Task 5–Determine bypass needs

A way of bypassing air in the worst-case scenario (only one room

zone open while the other zones are closed) needs to be considered. Traditionally, a Barometric Bypass has been the only option.

—3—

Page 4

Direct bypassing only slows the inevitable, the bonnet/plenum

temperature will get too hot or cold and eventually shut down the

equipment. Barometric Bypassing to an open ceiling or open foyer

is another option. With this type of zoning system, there are some

other options to Barometric Bypassing.

“Controlled Leakage” is a way to divert air to otherwise closed

zones if the smallestzone isthe onlyone open.Each dampermotor

has a setscrew to allow a MIN setting. By not allowing the damper

to close all the way, we have created a controlled leakage. This

works great for retrofit application, when ductwork may not be

able to be oversized as much as needed.

“Out Zones” are another alternative to eliminating excess air. This

principle works from the duct temperature. If the bonnet/plenum

becomes too hot or cold, the system will open an “Out Zone”.

Bottom Line: If the smallest zone plus any controlled leakage can

not handle 60 percent of the nominal CFM, then some type of

“Bypassing Option” must be considered. It may not be used very

often, based on patented damper movement (the system tries to

achieve setpoints in all the zones at the same time). When

designing with comfortin mind, rarely will only one zone be open,

while the others are closed. Bypass Determination will be

completed in Step 5 of the Duct Sizing Worksheet.

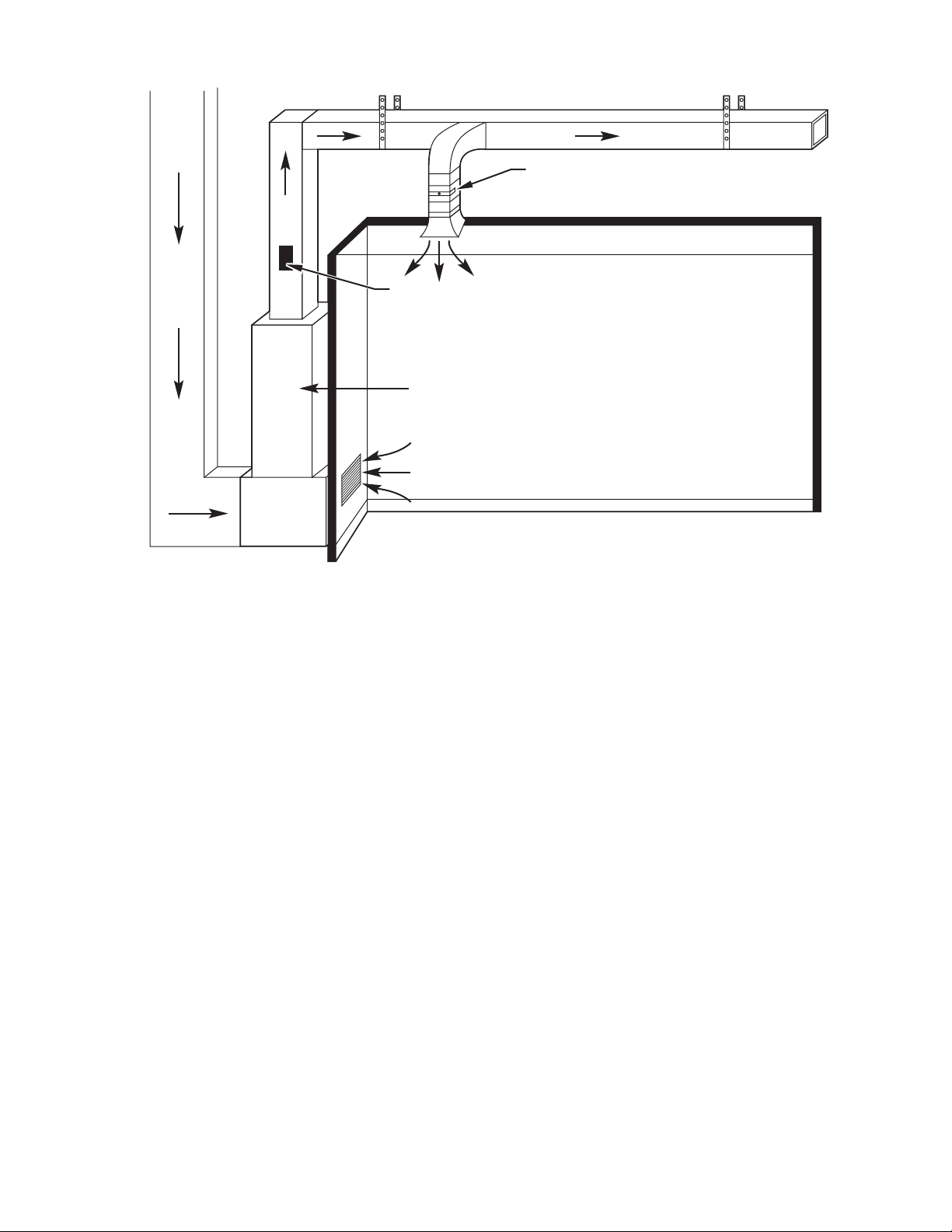

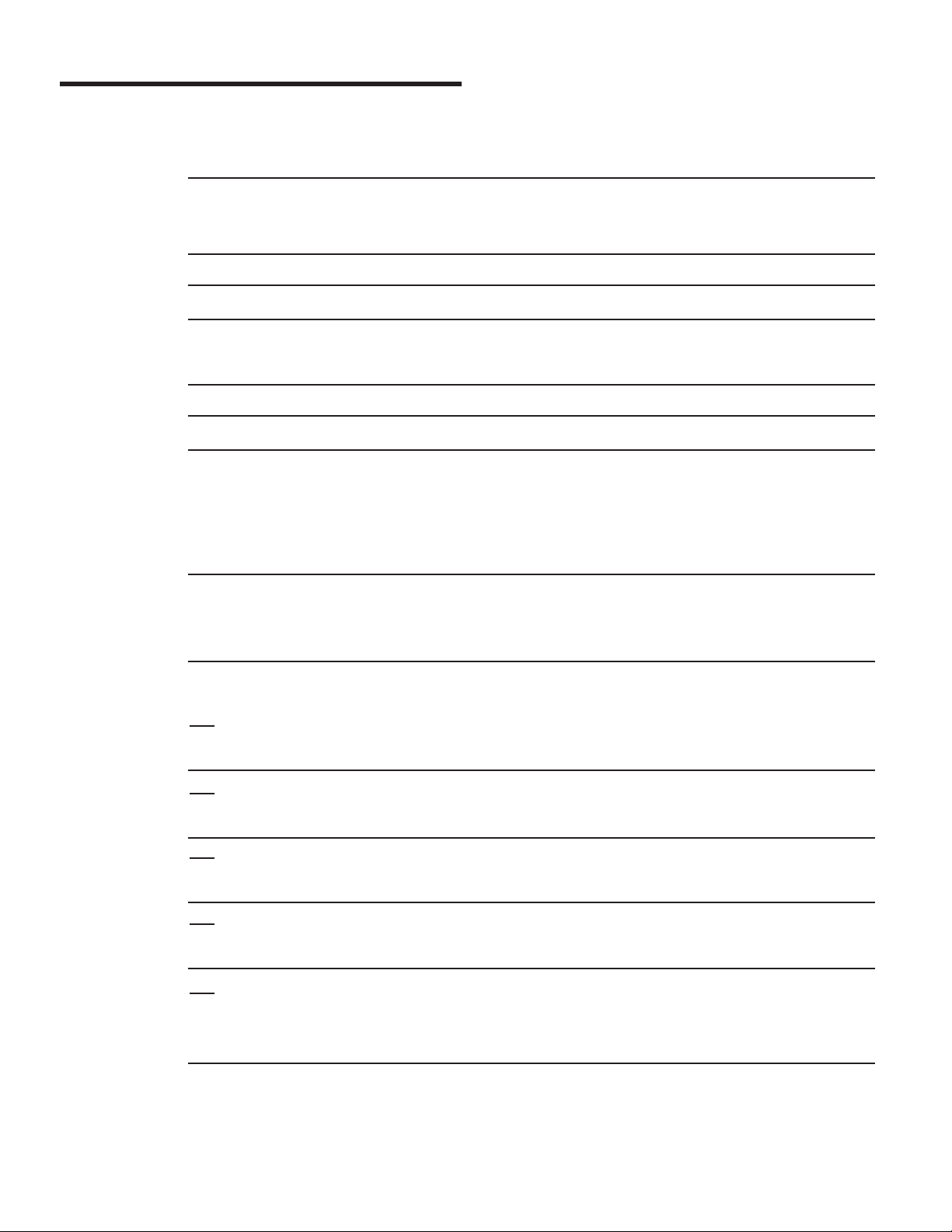

Installation of the Bypass Damper can either be a “Direct-Return”

or “Dump-Zone”. (See Fig. 2 and Fig. 3.)

Location of the Bypass Damperis very important.Listed beloware

a few guidelines for proper location.

BYPASS

RETURN AIR DUCTWORK

SUPPLY AIR DUCTWORK

LEAVING AIR

TEMPERATURE

SENSOR

INDOOR

UNIT

A00190

Fig. 2–Direct Return Installation

1. Location must be accessible for inspection and maintenance.

2. Location must be in an area that has allowed the airflow on

the supply side to become smooth and allows bypassed air

to mix with return-air, before entering the equipment.

3. The leaving air temperature (LAT) must be installed upstream (ahead of) from the bypass inlet.

4. Do not locate too closely to an open return. The bypassed

air could cause the return to become positively pressured.

5. Consult Bypass Damper Installation Instruction for more

information.

B. Task 6–Explanation of the Duct Sizing Worksheet

The Duct Sizing Worksheet will help size the supply ductwork for

a zoning system. Traditional methods, whether zoning was being

applied or not, have been to design duct work at .1 in. wc supply

and .08 in. wc return. But not everyone knew that this was based

on 100 ft of equivalent ductwork. Factoring in the equivalent

lengths of fittings could cause the Total Equivalent Length (TEL)

to go past 100 ft This could leave the ductwork undersized.

When zoning was to be applied to the system, we recommend 25

percent overissuing of the ductwork to handle the varying conditions of airflow in the system. Some distributors/dealers have a

built-in “safety-factor” by designing the system with 30 percent

oversizing. Other manufacturers of zoning products have recommended as much as 50–75 percent oversizing. In most cases, the

oversizing took care of any TEL’s over 100 ft.

The reason for this new Design Guide Worksheet is to help ease

the fear of designing a zoning system. The way the worksheet is

put together was to look at as many scenarios as possible, then

apply three design techniques to each example. Each scenario was

designed at:

1. 25 percent oversizing at .1 in. wc supply

2. 25 percent oversizing at .08 in. wc supply (to compensate

for TEL over 100’)

3. 30 percent oversizing at .1 in. wc supply (to compensate for

TEL over 100’)

In 99 percent of the applications, the ductwork sizes “crunched

out” to the same size.

So, if you have designed a zoning systemin the past, use this guide

to see if the sizes match. If this if your first zoning design, have

faith that the sizes are not too large. Our patented damper

movement will adjust the airflow to where it’s needed. If you are

applying zoning to an existing duct system, compare what you

have to what you need. Then make the necessary adjustments to

the ductwork.

You should have completed Tasks 1–5 of the Duct Sizing

Worksheet by following Tasks 1–5.

NOTE: The use of good take-offs and fittings are critical to the

TEL of any ductwork system. Take-off and fitting Total Equivalent Length (TEL) examples are further explained in the Residential Air System Design (Catalog #791–443).

IV. REFERENCE FOR DUCT SIZING WORKSHEET:

(SEE STEP 6 OF DUCT SIZING WORKSHEET, PAGE 9)

Using Table 1 determine the minimum Main Duct square inches

and the minimum Total Branch square inches by locating the

desired Zone CFM (from Task 3) along the left-verticle column. If

your desired Zone CFM falls between the listed CFM’s, use the

one closest to your calculated CFM. Follow the desired Zone CFM

across until you reach the Equipment Capacity, along the top,

required for your application. Write these values for each zone in

the area provided in Task 6.

NOTE: If two or more zones share a main duct (see Fig. 6) then

add the zone CFM’s together and use that CFM to size the Main

Duct. Then as each zone is “branched-off”, it becomes the zone

“Main Branch” and would be sized based on the individual zone

square inches.

The listed areas (square inches) will providea maximum zone duct

pressure drop of approximately 0.1 in. wc / 100 ft and a maximum

of 900 fpm for main ducts and 700 fpm for branch ducts for sheet

metal ductwork. For “Duct board”, multiply areas by 1.1, or for

“flex-duct” multiply areas by 1.25 to maintain same duct pressure

drop and fpm. If CFM in Step 3 is based on cooling and the design

is NOT based on 400 CFM/ton, divide that CFM by 400. Multiply

the areas by this number (Example: a system design of 350

CFM/ton of airflow, multiply areas by: 350/400 = .88).

NOTE: The “grey-shaded” boxes represent zone CFM’s of less

than 20 percent of the total CFM. The square inches were

increased approximately 10 percent to help deal with situations

where limited zones may be open.

—4—

Page 5

RETURN AIR

DUCT

SUPPLY AIR DUCT

BAROMETRIC

BYPASS

LEAVING AIR

TEMPERATURE

SENSOR

INDOOR UNIT

RETURN AIR

Fig. 3–Dump Zone Installation

V. REFERENCE FOR DUCT SIZING WORKSHEET: (SEE

STEP 7 AT DUCT SIZING WORKSHEET, PAGE 9)

Using Table 2A locate the Minimum Main Duct Area from Step

6 (duct sizing worksheet) to determine the Main Duct size. Select

a damper/duct size at least as large as the area required. Refer to

the Product Data for sizes of dampers. If the Main Duct is split or

runs in two directions, divide up the total zone CFM needed to

each main, locate the square inch areas to meet the required CFM

and then size the dampers.

Using Table 2B locate the Minimum Branch Area from Step 6 to

determine the Branch Duct size(s). Any combination can be used,

as long as the total of the Branch Duct area meets or exceeds the

required amount.

APPENDIX

The following appendix provides worksheets for you to copy and

use when designing a Zone Perfect Plus installation:

• Owner Survey

• Floor Plan Worksheet

A00191

• Duct Sizing Worksheet

• Examples

We will show three examples of the zoning design guide.

Example 1

Light Commercial — Doctor’s Office

Heating Load: 125,000 Btu

Cooling Load: 115,000 Btu

Equipment selected: 581B120125

Example 2

Residential Ranch

Heating Load: 90,000 Btu

Cooling Load: 52,000 Btu

Equipment Selected: 355MAV060100 and 598B060

Example 3

Taking Example 2 and substitute Duct-Board as main and FlexPipe as branch runs. We will begin at Step 6.

—5—

Page 6

Owner Survey

1. How many members are there in your household/building?

2. Describe the activities in your household on an unusual day. In particular, are

there activities that might require extra cooling or heating?

3. Describe the typical usage of the various areas of your home/office throughout the day.

4. What areas, if any, in your home/office that are used infrequently, such as a formal

dining/meeting room, or that are unoccupied for large periods of time during the

day or night?

5. Is there an area in your home/office that will be used for physical activity?

6. Describe the entertaining that you do in your home:

How often do you entertain in the summer? In the winter?

During what times of the day do you typically entertain?

How many people do you usually entertain?

What areas of your home do you use when you entertain?

Are there times when people go in and out of the house frequently (for example,

if you entertain outdoors)?

—6—

A00153

Page 7

7. What temperature do you normally want to maintain in your home/office during the day

in the summer? The nights in the summer? The days in the winter? The nights in the

winter?

8. Are there any times when you want significantly different temperatures in all or part of

your home? If so, in what areas or rooms? How quickly do you want the temperature

change to occur?

9. To what extent do you want to be able to control the temperature in your home?

10. What do you expect from your indoor comfort system?

Additional Questions for an Existing Home/Office Building

1. Are there any areas or rooms in your home/office that are too hot or cold in the winter?

In the summer?

2. Do you have a humidity problem in your home/office? Too much? Too little?

3. How long do you plan to live in your present home?

4. What do you like about your present heating and cooling system? What do you dislike?

A00154

—7—

Page 8

Floor Plan Worksheet

—8—

A98347

Page 9

DUCT SIZING WORKSHEET

Step 1:Calculate Block Load

Heating Load:_____________________ Btuh Cooling Load:____________________ Btuh

Step 2:Room by Room Load

Room Heating Load (Btuh) Cooling Load (Btuh) Airflow (CFM )* Zone Number

____________ ____________ ____________ ____________ _____________

____________ ____________ ____________ ____________ _____________

____________ ____________ ____________ ____________ _____________

____________ ____________ ____________ ____________ _____________

____________ ____________ ____________ ____________ _____________

____________ ____________ ____________ ____________ _____________

____________ ____________ ____________ ____________ _____________

____________ ____________ ____________ ____________ _____________

____________ ____________ ____________ ____________ _____________

____________ ____________ ____________ ____________ _____________

____________ ____________ ____________ ____________ _____________

____________ ____________ ____________ ____________ _____________

____________ ____________ ____________ ____________ _____________

____________ ____________ ____________ ____________ _____________

____________ ____________ ____________ ____________ _____________

____________ ____________ ____________ ____________ _____________

*Highest CFM determined from Heat/Cool Btuh

Step 3: Zone CFM totals

Zone 1 ____________ CFM Zone 5 _____________CFM

Zone 2 ____________ CFM Zone 6 _____________CFM

Zone 3 ____________ CFM Zone 7 _____________CFM

Zone 4 ____________ CFM Zone 8 _____________CFM

Step 4: Equipment Selection

Indoor Section ____________ Outdoor Section _____________

Heating Capacity/CFM ____________ _____________

Cooling Capacity/CFM ____________ _____________

Design CFM ____________

Step 5: Bypass Determination

System Design CFM * ____________ X 0.60 = ______________

* Design CFM can be: Step 1C from above OR if Two Speed/Variable Speed equipment is selected, select low speed CFM value.

Step 6: Zone Minimum Area (sq. in.)(from Table 1, page 21)

CFM Main Duct (sq. in.) Branch Area (sq. in.)

Zone 1 ____________ ____________ ____________

Zone 2 ____________ ____________ ____________

Zone 3 ____________ ____________ ____________

Zone 4 ____________ ____________ ____________

Zone 5 ____________ ____________ ____________

Zone 6 ____________ ____________ ____________

Zone 7 ____________ ____________ ____________

Zone 8 ____________ ____________ ____________

—9—

Page 10

Step 7:Main Trunk (Table 2A) and Branch Duct (Table 2B) Sizes

Zone 1

Main Duct (sq. in.):____________________ = Main Duct Size:____________

Branch (sq. in.):_______________________

Size:__ Qty:___ Area (from Table 2B) =________________+

Size:__ Qty:___ Area (from Table 2B) =________________+

=________________ Total Sq. In.

Zone 2

Main Duct (sq. in.):____________________ = Main Duct Size:____________

Branch (sq. in.):_______________________

Size:__ Qty:___ Area (from Table 2B) =_________________+

Size:__ Qty:___ Area (from Table 2B) =_________________+

=_________________ Total Sq. In.

Zone 3

Main Duct (sq. in.):____________________ = Main Duct Size:____________

Branch (sq. in.):_______________________

Size:__ Qty:___ Area (from Table 2B) =________________+

Size:__ Qty:___ Area (from Table 2B) =________________+

=________________ Total Sq. In.

Zone 4

Main Duct (sq. in.):____________________ = Main Duct Size:____________

Branch (sq. in.):_______________________

Size:__ Qty:___ Area (from Table 2B) =________________+

Size:__ Qty:___ Area (from Table 2B) =________________+

=________________ Total Sq. In.

Zone 5

Main Duct (sq. in.):____________________ = Main Duct Size:____________

Branch (sq. in.):_______________________

Size:__ Qty:___ Area (from Table 2B) =________________+

Size:__ Qty:___ Area (from Table 2B) =________________+

=________________ Total Sq. In.

Zone 6

Main Duct (sq. in.):____________________ = Main Duct Size:____________

Branch (sq. in.):_______________________

Size:__ Qty:___ Area (from Table 2B) =________________+

Size:__ Qty:___ Area (from Table 2B) =________________+

=________________ Total Sq. In.

Zone 7

Main Duct (sq. in.):____________________ = Main Duct Size:____________

Branch (sq. in.):_______________________

Size:__ Qty:___ Area (from Table 2B) =________________+

Size:__ Qty:___ Area (from Table 2B) =________________+

=________________ Total Sq. In.

Zone 8

Main Duct (sq. in.):____________________ = Main Duct Size:___________

Branch (sq. in.):_______________________

Size:__ Qty:___ Area (from Table 2B) =________________+

Size:__ Qty:___ Area (from Table 2B) =________________+

=________________ Total Sq. In.

—10—

Page 11

Waiting Room Room 1 Room 2 Room 3 Room 4

Bath

Office Office Lab

Bathrooms

Fig. 4–Light Commercial Application-Doctor’s Office (unzoned)

A00121

Waiting Room

Bathrooms

Room 1 Room 2 Room 3 Room 4

Office Office Lab

Zone 1

Zone 2

Zone 3

Zone 4

Zone 5

Zone 6

Fig. 5–Light Commercial Application-Doctor’s Office (zoned)

Bath

A00122

—11—

Page 12

DUCT SIZING WORKSHEET-EXAMPLE 1

Step 1:Calculate Block Load

Heating Load:______________125,000 Btuh Cooling Load:_____________115,000 Btuh

Step 2:Room by Room Load

Room Heating Load (Btuh) Cooling Load (Btuh) Airflow (CFM )* Zone Number

Waiting Room ___________ ____________ ____1,000___ _______6_____

Room 1_____ ___________ ____________ _____250____ _______1_____

Room 2_____ ___________ ____________ _____250____ _______1_____

Room 3_____ ___________ ____________ _____250____ _______2_____

Room 4_____ ___________ ____________ _____250____ _______2_____

Back Bathroom ___________ ____________ _____150____ _______4_____

Lab________ ___________ ____________ _____550____ _______4_____

Office_______ ___________ ____________ _____600____ _______3_____

Office/Restrooms ___________ ____________ _____700____ _______5_____

____________ ___________ ____________ ____________ _____________

____________ ___________ ____________ ____________ _____________

____________ ___________ ____________ ____________ _____________

____________ ___________ ____________ ____________ _____________

____________ ___________ ____________ ____________ _____________

____________ ___________ ____________ ____________ _____________

____________ ___________ ____________ ____________ _____________

*Highest CFM determined from Heat/Cool Btuh

Step 3: Zone CFM totals

Zone 1 _________500 CFM Zone 5 __________700 CFM

Zone 2 _________500 CFM Zone 6 ________1,000 CFM

Zone 3 _________600 CFM Zone 7 _____________ CFM

Zone 4 _________700 CFM Zone 8 _____________ CFM

Step 4: Equipment Selection

Indoor Section ____________ Outdoor Section ______581B120

Heating Capacity/CFM ______125,000 _________4,000

Cooling Capacity/CFM ______115,000 _________4,000

Design CFM ________4,000

Step 5: Bypass Determination

System Design CFM * 4,000________ X 0.60 = 2,400_________

(Value MUST be less than smallest zone CFM; otherwise Bypass Damper may be required)

* Design CFM can be: Step 1C from above OR if Two Speed/Variable Speed equipment is selected, select low speed CFM value.

—12—

Page 13

Step 6: Zone Minimum Area (Sq.In.) (From Table 1)

Zone 1 CFM__ 500____

Zone 2 CFM__ 500____

Zone 3 CFM__ 600____

Zone 4 CFM__ 700____

Zone 5 CFM__ 700____

Zone 6 CFM_1,000____

Zone 7 CFM _________

Zone 8 CFM _________

Main Duct __123___Sq.In.

Main Duct __123___Sq.In.

Main Duct __133___Sq.In.

Main Duct __154___Sq.In.

Main Duct __154___Sq.In.

Main Duct __189___Sq.In.

Main Duct ________Sq.In.

Main Duct ________Sq.In.

Branch Area__179___Sq.In.

Branch Area__179___Sq.In.

Branch Area__208___Sq.In.

Branch Area__246___Sq.In.

Branch Area__246___Sq.In.

Branch Area__330___Sq.In.

Branch Area________Sq.In.

Branch Area________Sq.In.

Table 1 Main Duct Area (sq.in.)

Zone CFM Equipment Capacity

2 2.5 3 3.5 4 5 6 7.5 8 8.5 10

200 Main 57 57 57 64 64 64

Branch 66 66 66 75 75 75

300 Main 79 79 79 79 79 87 87

Branch 99 99 99 99 99 110 110

400 Main 86 86 86 86 86 86 104 104 104

Branch 132 132 132 132 132 132 140 140 140

500 Main 113 113 113 113 113 113 113 123 123 123 123

Branch 165 165 165 165 165 165 165 179 179 179 179

600 Main 123 123 123 123 123 123 123 123 133 133 133

Branch 198 198 198 198 198 198 198 198 208 208 208

700 Main 143 143 143 143 143 143 143 143 154 154

Branch 231 231 231 231 231 231 231 231 246 246

Zone 1 & 2

Main Duct Square Inches __ 123 ____ = Main Duct Size___8x18____

Branch Square Inches_____179__

Size__10"___Qty___2___ Area (from Table 2B)=__180___+

Size_______ Qty_______ Area (from Table 2B)=________+

=__180___Total Sq.In.

A00132

Table 2A Main Duct Sizing

Equivalent Areas for Ducts (sq.in.)

Duct Height (in.) Round

Duct Width 8 10 Dia-Inch Sq.In.

86080 850

10 80 87 10 79

12 90 110 12 113

14 105 135 14 154

16 115 157 16 201

18 125 167

Zone 3

Main Duct Square Inches __ 133 ____ = Main Duct Size___10x14____

Branch Square Inches_____208__

Size__7"___Qty___2___ Area (from Table 2B)=__76___+

Size__8"___Qty___2___ Area (from Table 2B)=__135___+

=__211___Total Sq.In.

Table 2B Branch Duct Area (Sq.In.)

Duct Diameter - in.

Quantity 5 6 7 8 10

1 20283860 79

2 40 56 76 135 180

3 60 84 114 180 330

4 80 112 152 235 465

5 100 140 190 300 530

6 120 168 228 365 660

7 140 196 266 430 760

8 160 224 304 500 825

A00133

—13—

Page 14

Zone 4

Main Duct (sq. in.):_________________154 = Main Duct Size:_______10x16

Branch (sq. in.):____________________246

Size:8″ Qty:_3 Area (from Table 2B) =_____________180+

Size:10″ Qty:__1 Area (from Table 2B) =______________79+

=_____________259 Total Sq. In.

Zone 5

Main Duct (sq. in.):_________________154 = Main Duct Size:_______10x16

Branch (sq. in.):____________________246

Size:8″ Qty:__ 3 Area (from Table 2B) =_____________180+

Size:10″ Qty:__1 Area (from Table 2B) =______________79+

=_____________259 Total Sq. In.

Zone 6

Main Duct (sq. in.):_________________189 = Main Duct Size:_______10x20

Branch (sq. in.):____________________330

Size:10″ Qty:__3 Area (from Table 2B) =_____________330+

Size:__ Qty:___ Area (from Table 2B) =________________+

=_____________330 Total Sq. In.

Zone 7

Main Duct (sq. in.):____________________ = Main Duct Size:____________

Branch (sq. in.):_______________________

Size:__ Qty:___ Area (from Table 2B) =________________+

Size:__ Qty:___ Area (from Table 2B) =________________+

=________________ Total Sq. In.

Zone 8

Main Duct (sq. in.):____________________ = Main Duct Size:___________

Branch (sq. in.):_______________________

Size:__ Qty:___ Area (from Table 2B) =________________+

Size:__ Qty:___ Area (from Table 2B) =________________+

=________________+ Total Sq. In.

Zn 6

10x20

Main Duct “A” Main Duct “B”

Zn 5

10x16

Main Duct “A”= 1 + 5 + 6

Zns 1 + 5 + 6= 2200cfm

2200cfm = 346 sq.in.

346 sq.in. = 10x42

Fig. 6–Doctor’s Office Duct Work Layout

Zn 1

8x18

Zn 2

8x18

Zn 4

8x16

Zn 3

8x14

Main Duct “B”= 2 + 3 + 4

Zns 2 + 3 + 4= 1800cfm

1800cfm = 299 sq.in.

299 sq.in. = 10x36

A00134

—14—

Page 15

Living Room Dining Room Kitchen Family Room

Laundry

Master Bedroom

Bedroom 3Bedroom 2Bath

Master Bath

Fig. 7–Residential Application-House Floor Plan (unzoned)

A00186

Master Bedroom

Master Bath

Zone 1 Zone 2 Zone 3 Zone 4

Dining RoomLiving Room

Kitchen Family Room

Laundry

Bedroom 3Bedroom 2Bath

Bedroom 4

Fig. 8–Residential Application-House Floor Plan (zoned into four areas)

A00187

—15—

Page 16

DUCT SIZING WORKSHEET-EXAMPLE 2

Step 1:Calculate Block Load

Heating Load:__________90,000_____ Btuh Cooling Load:_________52,000_____ Btuh

Step 2:Room by Room Load

Room Heating Load (Btuh) Cooling Load (Btuh) Airflow (CFM)* Zone Number

Living Room_ ___________ ____________ ______150___ _______3_____

Dining Room/Foyer ___________ ____________ ______150___ _______3_____

Kitchen/Dinette ___________ ____________ ______200___ _______4_____

Family Room_ ___________ ____________ ______200___ _______4_____

Laundry Room ___________ ____________ ______300___ _______4_____

Master Bedroom/Bathroom ___________ ____________ ______400___ _______1_____

Bedrooms 2-4/Bathroom ___________ ____________ ______500___ _______2_____

____________ ___________ ____________ ____________ _____________

____________ ___________ ____________ ____________ _____________

____________ ___________ ____________ ____________ _____________

____________ ___________ ____________ ____________ _____________

____________ ___________ ____________ ____________ _____________

____________ ___________ ____________ ____________ _____________

____________ ___________ ____________ ____________ _____________

____________ ___________ ____________ ____________ _____________

____________ ___________ ____________ ____________ _____________

*Highest CFM determined from Heat/Cool Btuh

Step 3: Zone CFM totals

Zone 1 _____400____ CFM Zone 5 _____________CFM

Zone 2 _____500____ CFM Zone 6 _____________CFM

Zone 3 _____300____ CFM Zone 7 _____________CFM

Zone 4 _____700____ CFM Zone 8 _____________CFM

Step 4: Equipment Selection

Indoor Section ____355MAV06100__ Outdoor Section _________598B060__

Heating Capacity/CFM ____95,000/62,000__ __________1320/860__

Cooling Capacity/CFM ____53,000/34,000__ _______2,000/1,200__

Design CFM _____1,200 (low speed A/C)

Step 5: Bypass Determination

System Design CFM * ___1,200____ X 0.60 = _______720____

(Value MUST be less than smallest zone CFM; otherwise Bypass Damper may be required)

* Design CFM can be: Step 1C from above OR if Two Speed/Variable Speed equipment is selected, select low speed CFM value...used 2-speed A/C unit/low CFM=1200CFM

—16—

Page 17

Step 6: Zone Minimum Area (Sq.In.) (From Table 1)

Zone 1 CFM__ 400____

Zone 2 CFM__ 500____

Zone 3 CFM__ 300____

Zone 4 CFM__ 700____

Zone 5 CFM_________

Zone 6 CFM_________

Zone 7 CFM _________

Zone 8 CFM _________

Main Duct ___86___Sq.In.

Main Duct __113___Sq.In.

Main Duct ___87___Sq.In.

Main Duct __143___Sq.In.

Main Duct ________Sq.In.

Main Duct ________Sq.In.

Main Duct ________Sq.In.

Main Duct ________Sq.In.

Branch Area__132___Sq.In.

Branch Area__165___Sq.In.

Branch Area__110___Sq.In.

Branch Area__231___Sq.In.

Branch Area________Sq.In.

Branch Area________Sq.In.

Branch Area________Sq.In.

Branch Area________Sq.In.

Table 1 Main Duct Area (sq.in.)

Zone CFM Equipment Capacity

2 2.5 3 3.5 4 5 6 7.5 8

200 Main 57 57 57 64 64 64

Branch 66 66 66 75 75 75

300 Main 79 79 79 79 79 87 87

Branch 99 99 99 99 99 110 110

400 Main 86 86 86 86 86 86 104 104 104

Branch 132 132 132 132 132 132 140 140 140

500 Main 113 113 113 113 113 113 113 123 123

Branch 165 165 165 165 165 165 165 179 179

600 Main 123 123 123 123 123 123 123 123 133

Branch 198 198 198 198 198 198 198 198 208

700 Main 143 143 143 143 143 143 143 143

Branch 231 231 231 231 231 231 231 231

A00135

Step 7:Main Trunk (Table 2A) and Branch Duct (Table 2B) Sizes

Zone 1

Main Duct (sq. in.):__________________86 = Main Duct Size:________8x12

Branch (sq. in.):____________________132

Size:6″ Qty:__2 Area (from Table 2B) =_______________56+

Size:7″ Qty:__2 Area (from Table 2B) =_______________76+

=______________132 Total Sq. In.

Zone 2

Main Duct (sq. in.):_________________113 = Main Duct Size:________8x16

Branch (sq. in.):___________________165

Size:6″ Qty:__2 Area (from Table 2B) =_______________56+

Size:7″ Qty:__3 Area (from Table 2B) =______________114+

=______________165 Total Sq. In.

Zone 3

Main Duct (sq. in.):__________________87 = Main Duct Size:________8X12

Branch (sq. in.):____________________110

Size:7″ Qty:__3 Area (from Table 2B) =______________114+

Size:__ Qty:___ Area (from Table 2B) =_________________+

=______________114 Total Sq. In.

—17—

Page 18

Zone 4

Main Duct Square Inches__143____ = Main Duct Size __8x20_____

Table 2A Main Duct Sizing

Equivalent Areas for Ducts (sq.in.)

Duct Height (in.) Round

Duct Width 8 10 Dia-Inch Sq.In.

86080 850

10 80 87 10 79

12 90 110 12 113

14 105 135 14 154

16 115 157 16 201

18 125 167

20 145 190

22 155 210

24 165 215

Branch Square Inches_____231__

Size__6"___Qty___2___ Area (from Table 2B)=___56___+

Size__8"___Qty___3___ Area (from Table 2B)=__180___+

=__236___Total Sq.In.

Table 2B Branch Duct Area (Sq.In)

Duct Diameter - in.

Quantity 5 6 7 8 10

1 20283860 79

2 40 56 76 135 180

3 60 84 114 180 330

4 80 112 152 235 465

5 100 140 190 300 530

6 120 168 228 365 660

7 140 196 266 430 760

8 160 224 304 500 825

A00136

Zn 1

8x12

Zn 3

8x12

Fig. 9–Residential Duct Work Layout

Zn 4

8x20

Zn 2

8x16

A00137

—18—

Page 19

DUCT SIZING WORKSHEET-EXAMPLE 3

Starting from Step 6, we need to multiply the Main Duct Square Inches by 1.1 and the Branch Area

by 1.25.

Example: Zone 1 - Main Duct - 86x1.1 = 95 Sq.In.

Branch Area - 132x1.25 = 165 Sq.In.

Step 6: Zone Minimum Area (Sq.In.) (From Table 1)

Zone 1 CFM ___400____Main Duct ___95____Sq.In. Branch Area__165____Sq.In.

Zone 2 CFM ___500____Main Duct __124____Sq.In. Branch Area__206____Sq.In.

Zone 3 CFM ___300____Main Duct ___96____Sq.In. Branch Area__138____Sq.In.

Zone 4 CFM ___700____Main Duct __157____Sq.In. Branch Area__289____Sq.In.

Zone 5 CFM __________Main Duct _________Sq.In. Branch Area_________Sq.In.

Zone 6 CFM __________Main Duct _________Sq.In. Branch Area_________Sq.In.

Zone 7 CFM __________Main Duct _________Sq.In. Branch Area_________Sq.In.

Zone 8 CFM __________Main Duct _________Sq.In. Branch Area_________Sq.In.

Step 7: Main Trunk (Table 2A) and Branch Duct Size (Table 2B) Sizes

Zone 1

Main Duct Square Inches ___95____ Main Duct Size___8x14____

Table 2A Main Duct Sizing

Equivalent Areas for Ducts (sq.in.)

Duct Height (in.) Round

Duct Width 8 10 Dia-Inch Sq.In.

86080 850

10 80 87 10 79

12 90 110 12 113

14 105 135 14 154

16 115 157 16 201

18 125 167

A00138

—19—

Page 20

Branch Square Inches_____165__

Table 2B Branch Duct Area (Sq.In)

Duct Diameter - in.

Quantity 5 6 7 8 10

1 20283860 79

2 40 56 76 135 180

3 60 84 114 180 330

4 80 112 152 235 465

5 100 140 190 300 530

6 120 168 228 365 660

7 140 196 266 430 760

8 160 224 304 500 825

Size_______Qty_______ Area (from Table 2B)=________+

Size__8"___Qty___3___ Area (from Table 2B)=__180___+

=__180___Total Sq.In.

Zone 2

Main Duct Square Inches___124____ =Main Duct Size ___8x18___

Branch Square Inches ___206____

Size_______Qty_______ Area (from Table 2B)=________+

Size__8"___Qty___4___ Area (from Table 2B)=__235___+

=__235___Total Sq.In.

Zone 3

Main Duct Square Inches___96____ =Main Duct Size ___8x14___

Branch Square Inches ___138____

Size_______Qty_______ Area (from Table 2B)=________+

Size__7"___Qty___4___ Area (from Table 2B)=__152___+

=__152___Total Sq.In.

Zone 4

Main Duct Square Inches___157____ =Main Duct Size ___8x24___

Branch Square Inches ___289____

Size__8"___Qty___5___ Area (from Table 2B)=__300___+

Size_______Qty_______ Area (from Table 2B)=________+

=__300___Total Sq.In.

A00139

—20—

Page 21

TABLE 1–ZONE CFM

MAIN & BRANCH DUCT AREA (SQ. IN.)

Equipment Capacity

2 2.5 3 3.5 4 5 6 7.5 8 8.5 10 12.5

200

300

400

500

600

700

800

900

1000

1100

1200

1300

1400

1500

1600

1700

1800

1900

2000

2100

2200

2300

2400

2500

Shaded areas represent less than 20 percent of total CFM, increased by one size.

*Main Duct sq in. aredetermined by multiplying CFM by 1.3 (200x1.3=260). Then size duct based on square inches of round pipe. Example: 260CFM.1 in. wc = 8.5” round

pipe=57sqin.

**Branch duct sq in. are based on 6” pipe delivering 100 CFM .1 in. wc X 1.3 = 130 CFM. Take 130 CFM .1 in. wc =6.5”pipe = 33 sq in. Example: 33 sq in. /100 CFM X

2=66CFM

Main 57** 57 57 64 64 64

Branch 66*** 66 66 75 75 75

Main 79 79 79 79 79 87 87

Branch 99 99 99 99 99 110 110

Main 86 86 86 86 86 86 104 104 104

Branch 132 132 132 132 132 132 140 140 140

Main 113 113 113 113 113 113 113 123 123 123 123

Branch 165 165 165 165 165 165 165 179 179 179 179

Main 123 123 123 123 123 123 123 123 133 133 133 133

Branch 198 198 198 198 198 198 198 198 208 208 208 208

Main 143 143 143 143 143 143 143 143 154 154 154

Branch 231 231 231 231 231 231 231 231 246 246 246

Main 154 154 154 154 154 154 154 154 154 154 165

Branch 264 264 264 264 264 264 264 264 264 264 273

Main 165 165 165 165 165 165 165 165 165 177

Branch 297 297 297 297 297 297 297 297 297 311

Main 189 189 189 189 189 189 189 189 189 201

Branch 330 330 330 330 330 330 330 330 330 330

Main 201 201 201 201 201 201 201 201 201

Branch 363 363 363 363 363 363 363 363 363

Main 214 214 214 214 214 214 214 214 214

Branch 396 396 396 396 396 396 396 396 396

Main 227 227 227 227 227 227 227 227

Branch 429 429 429 429 429 429 429 429

Main 241 241 241 241 241 241 241 241

Branch 462 462 462 462 462 462 462 462

Main 254 254 254 254 254 254 254

Branch 495 495 495 495 495 495 495

Main 269 269 269 269 269 269 269

Branch 528 528 528 528 528 528 528

Main 284 284 284 284 284 284

Branch 561 561 561 561 561 561

Main 299 299 299 299 299 299

Branch 594 594 594 594 594 594

Main 314 314 314 314 314

Branch 627 627 627 627 627

Main 314 314 314 314 314

Branch 660 660 660 660 660

Main 330 330 330 330

Branch 693 693 693 693

Main 346 346 346 346

Branch 726 726 726 726

Main 363 363

Branch 759 759

Main 363 363

Branch 792 792

Main 380 380

Branch 825 825

—21—

Page 22

TABLE 2A-MAIN DUCT SIZING

EQUIVALENT AREAS FOR DUCTS (SQ. IN.)

Duct Height Round

Duct Width 8(in.) 10(in.) Dia-in. Sq-in.

8 60 80 8 50

10 80 87 10 79

12 90 110 12 113

14 105 135 14 154

16 115 157 16 201

18 125 167 18 269

20 145 190 20 314

22 155 210 22 380

24 165 215

26 227

28 241

30 254

32 269

34 284

36 299

38 314

40 330

42 346

44 363

TABLE 2B-BRANCH DUCT AREA (SQ. IN.)

DUCT DIAMETER - IN.

Quantity 5 6 7 8 10121416

1 20 28 38 50 79 113 154 201

2 40 56 76 135* 180 365 565 760

3 60 84 114 180 330 530 795 825

4 80 112 152 235 465 730 825

5 100 140 190 300 530 825

6 120 168 228 365 660

7 140 196 266 430 760

8 160 224 304 500 825

9 180 252 342 565

10 200 280 380 630

11 220 308 418 660

12 240 336 456 726

13 260 364 494 795

14 280 392 532

15 300 420 570

Two 8” pipes have approximately the same volume of five 6” pipes. To keep static approximately .1 in. wc, the numbers were adjusted to handle same CFM .1 in. wc.

Example:

6”pipe=100CFM.1in.wcX5=500CFM

8”pipe=240CFM.1in.wcX2=480CFM.

Square inches adjusted to match sizes with Table 1 — Branch values.

—22—

Page 23

—23—

Page 24

© 2000 Bryant Heating & Cooling Systems 7310 W. Morris St. Indianapolis, IN 46231

—24—

Printed in U.S.A. ap17–5 Catalog No. 809–651

Loading...

Loading...