Page 1

installation, start-up and

operating instructions

COMMERCIAL THERMOSTAT

(P/N TSTATBBPCM01-A)

Cancels: New II TSTAT-1

6/15/96

IMPORTANT: Read entire instructions before starting the

installation.

SAFETY CONSIDERATIONS

Read and follow manufacturer instructions carefully. Follow

all local electrical codes during installation. All wiring must

conform to local and national electrical codes. Improper wiring or installation may damage thermostat.

Recognize safety information. This is the safety alert symbol

. When the safety alert symbol is present on equipment

or in the instruction manual, be alert to the potential for personal injury.

Understand the signal words DANGER, WARNING, and CAUTION. These words are used with the safety alert symbol.

DANGER identifies the most serious hazards which will result in severe personal injury or death. WARNING signifies

a hazard which could result in personal injury or death. CAUTION is used to identify unsafe practices which would result

in minor personal injury or property damage.

GENERAL

Bryant’s 7-day, commercial, programmable thermostats are

wall-mounted, low-voltage thermostats which maintain room

temperature by controlling the operation of an HVAC (heating, cooling and ventilation) system. Separate heating and

cooling set points and auto-changeover capability allow occupied and unoccupied programming for energy savings.

All thermostats allow up to 4 time/temperature settings to

be programmed per 24-hr period. Each thermostat stores programs for 7 independent days. Batteries are not required. During power interruption the internal memory stores comfort

schedules for an unlimited time while the clock continues to

run for at least 72 hours.

The thermostat can be configured to accept several different

equipment configurations, from single-stage heating and cooling to 3 stages of heating and 2 stages of cooling. The thermostat comes factory configured for 1 stage of cooling and

1 stage of heating.

INSTALLATION

I. THERMOSTAT LOCATION

The thermostat should be mounted:

• approximately 5 ft from the floor

• close to or in a frequently used room, preferably on an in-

side partitioning wall

• on a section of wall without pipes or ductwork

The thermostat should not be mounted:

• close to a window, on an outside wall, or next to a door

leading to the outside

• where exposed to direct light and heat from a lamp, the

sun, a fireplace, or any other temperature-radiating object

which may cause a false reading

• close to or in direct airflow from supply registers or return

air grilles

• in areas with poor air circulation (such as behind a door or

in an alcove)

II. SET DIP SWITCHES

There are 4 small switches on the back of the circuit board

which must be configured by the installer. The ON position

is indicated by small letters on the switch. Ignore the numbers (1-4) on theswitch.Theswitchdesignation(A-D)isprinted

on a sticker next to the switch. To change a switch position,

use the corner of a small screwdriver to slide the switch

ON or OFF. Set the DIP switches before installing the

thermostat.

A. Air Conditioner or Heat Pump Selection (Switch A)

Use switchAto select between air conditioning and heat pump

applications.A heat pump application uses a reversing valve.

Set switch A to OFF for air conditioning applications (no reversing valve). Set switch A to ON for heat pump applications (O is used to energize the reversing valve). The factory

setting is OFF.

B. Compressor Stage Selection (Switch B)

Switch B is used to select between a single-stage and a 2-stage

compressor. Set switch B to OFF for a single-stage compressor.Set switch B to ON for a 2-stage compressor. The factory

setting is OFF.

C. Outdoor Air or Remote Room Sensor (Switch C)

Switch C is used to configure the thermostat to work with

either a outdoor air sensor or a remote room sensor. The sensor for the application must be connected to terminals S1 and

S2 of the thermostat. Set switch C to OFF for a outdoor air

sensor.Set switch C to ON for a remote room sensor.The factory setting is OFF.

D. Averaging of Sensors (Switch D)

Switch D isusedif a remote room sensor is being used (switch C

set to ON). The remote room sensor reading can be averaged

with the sensor reading of the thermostat. Set switch D to

OFF if averaging is not required. To average the readings of

the thermostat and remote room sensors, set switch D to ON.

The factory setting is OFF.

III. INSTALL THERMOSTAT

WARNING:

power to the unit. There may be more than one power

disconnect. Electrical shock can cause injury or death.

1. Turn off all power to unit.

2. If an existing thermostat is being replaced:

a. Remove existing thermostat from the wall.

b. Disconnect wires from existing thermostat. Do not

allow wires to fall back into the wall. As each wire

is disconnected, record wire color and terminal

connection.

c. Discard or recycle old thermostat.

NOTE: Mercury is a hazardous waste and must be disposed

of properly.

Before installing thermostat, turn off all

Page 2

3. Open thermostat rear door (mounting base) to expose

mounting holes.

4. Route thermostat wires through large hole in mounting base. Remove outer sheath from wires for added

flexibility.

5. Level mounting baseagainstwall and mark wall through

the 2 mounting holes in base.

3

6. Drill two

CAUTION:

⁄16-in. mounting holes in wall where marked.

Be careful not to drill into wiring in wall.

Electrical shock could result.

7. Secure mounting base to wall with 2 screws and anchors provided. Ensure all wires exit through hole in

mounting base.

8. Adjust wire length and routing to allow proper closure

of the thermostat. Strip each wire at the end no more

1

⁄4-in. to prevent adjacent wires from shorting to-

than

gether. Match and connect wires to terminals on the

thermostat. See Fig. 1-4.

CAUTION:

Improper wiring or installation maycause

damage to the thermostat. Check to ensure wiring is

correct before proceeding with installation of unit.

9. Push excess wiring into wall. Seal hole in wall to prevent drafts.

10. Close thermostat door.

11. Turn on power to unit. The thermostat will receive power

from the unit.

On power up the thermostat display shows the selected setup

mode (AC - single-stage air-conditioner,HP - single-stage heat

pump, A2 - 2-stage air conditioner, H2 - 2-stage heat pump)

for a few seconds, depending on DIP switch settings.

IV. SET THERMOSTAT CONFIGURATION

Configuration options, like DIP switch settings, are intended

to be selected at installation and are not normally modified

by the user. These options are not discussed in the owner’s

manual and must be done as part of the installation. A special procedure for the thermostat allows entry into the configuration mode. To enter configuration mode, press and hold

the fan button for approximately 10 seconds. The room temperature display will disappear and dashes (--) will be displayed on the thermostat screen. The thermostat will automatically exit configuration mode if no button is pressed for

10 seconds. Seven different configurations can be set in configuration mode.

A. Fahrenheit or Celsius Selection

The thermostat can be set to use a Celsius or Fahrenheit temperature display. Press the Change Day button in configuration mode to access the parameter. Use the Up and Down

buttons on the thermostat to change the setting between F

(Fahrenheit) and C (Celsius). The default value is F.

B. Fan ON or OFF When Heat is Energized Selection

The thermostat can be set to turn the fan (G output) on or off

when the heat input (terminal W) is energized. Press the Hold

button while in configuration mode to access the parameter.

Use the Up and Down buttons to toggle between OF (fan off

during heating) and ON (fan on during heating). The default

value is OF.

C. High Ambient Electric Heat Lockout Selection

If DIP switch Ais set to ON (heat pump application) and DIP

switch C is set to OFF (an outdoor temperature sensor is

present), electric heat can be locked out if the outdoor ambient temperature rises above the user-defined value. Temperatures of 15 to 55 F (in 5-degree increments) can be selected.

The lockout can also be disabled. The default is OF (disabled). Emergency heat mode disables this function. Press the

Copy Previous Day button in the configuration mode to access the parameter. Use the Up and Down buttons to increase or decrease the setting.

D. Clean Filter Timer Selection

The clean filter selection determines how many hours of blower

operation will pass before the Clean Filter message is displayed.A timer in the thermostat accumulates the total blower

operation hours. The range of values is 400 to 3600 hours (in

400-hour increments).

• a ‘‘1’’ will be displayed for 400 hours of operation

• a ‘‘2’’ will be displayed for 800 hours of operation

• a ‘‘3’’ will be displayed for 1200 hours of operation

• a ‘‘4’’ will be displayed for 1600 hours of operation

• a ‘‘5’’ will be displayed for 2000 hours of operation

• a ‘‘6’’ will be displayed for 2400 hours of operation

• a ‘‘7’’ will be displayed for 2800 hours of operation

• a ‘‘8’’ will be displayed for 3200 hours of operation

• a ‘‘9’’ will be displayed for 3600 hours of operation

The selection can also be set to OF (disabled). Press the

Reset Filter button in the configuration mode to access the

parameter. Use the Up and Down buttons to change the setting. The default is 2 (800 hours).

NOTE: During the selection procedure, the Clean Filter message will be displayed, even if OF (disabled) is chosen.

E. Anticipator Adjustment Selection

The anticipator adjustment controls the sensitivity and cycle

rate of the thermostat. Higher numbers decrease the sensitivity and slow the cycle rate. Lower numbers increase sensitivity and speed up the cycle rate. A limiting feature of the

thermostat will not allow more than 4 equipment cycles per

hour, regardless of the anticipator setting. Values can range

from 1 to 9. The default is 3. The default selection will provide optimum performance in nearly all installations. Do not

change the setting unless there is a need to do so. Press the

Mode button during configuration mode to change the setting. Use the Up and Down buttons to increase or decrease

the value.

Unlike conventional thermostat anticipators, the setting is

not determined by current draw. There is no need to measure, know, or compensate for the current. There is no need

to ‘‘droop’’ with this thermostat, regardless of the anticipator

setting.

F. Keypad Lockout Selection

The thermostat has a lockout feature which will not acknowledge configuration buttons until the lockout code is entered.

After the lockout code has been entered, the keypad will remain unlocked until the user has stopped pressing keys for

2 minutes. The Lockout selection can be set to ON or OF (disabled). Press the Set Timekeyinconfigurationmodetochange

the setting. Use the Up or Down buttons to toggle between

off and on. The default is OF.

NOTE: If the lockout function is enabled, the user can only

disable the lockout by pressing the correct buttons, in order,

within a 10-second time period. The button sequence is: press

the Mode button; press the Copy Previous Day button; press

the Set Time button; and press the Hold button. The lockout

will then be disabled until the user stops pressing buttons

for 2 minutes.

—2—

Page 3

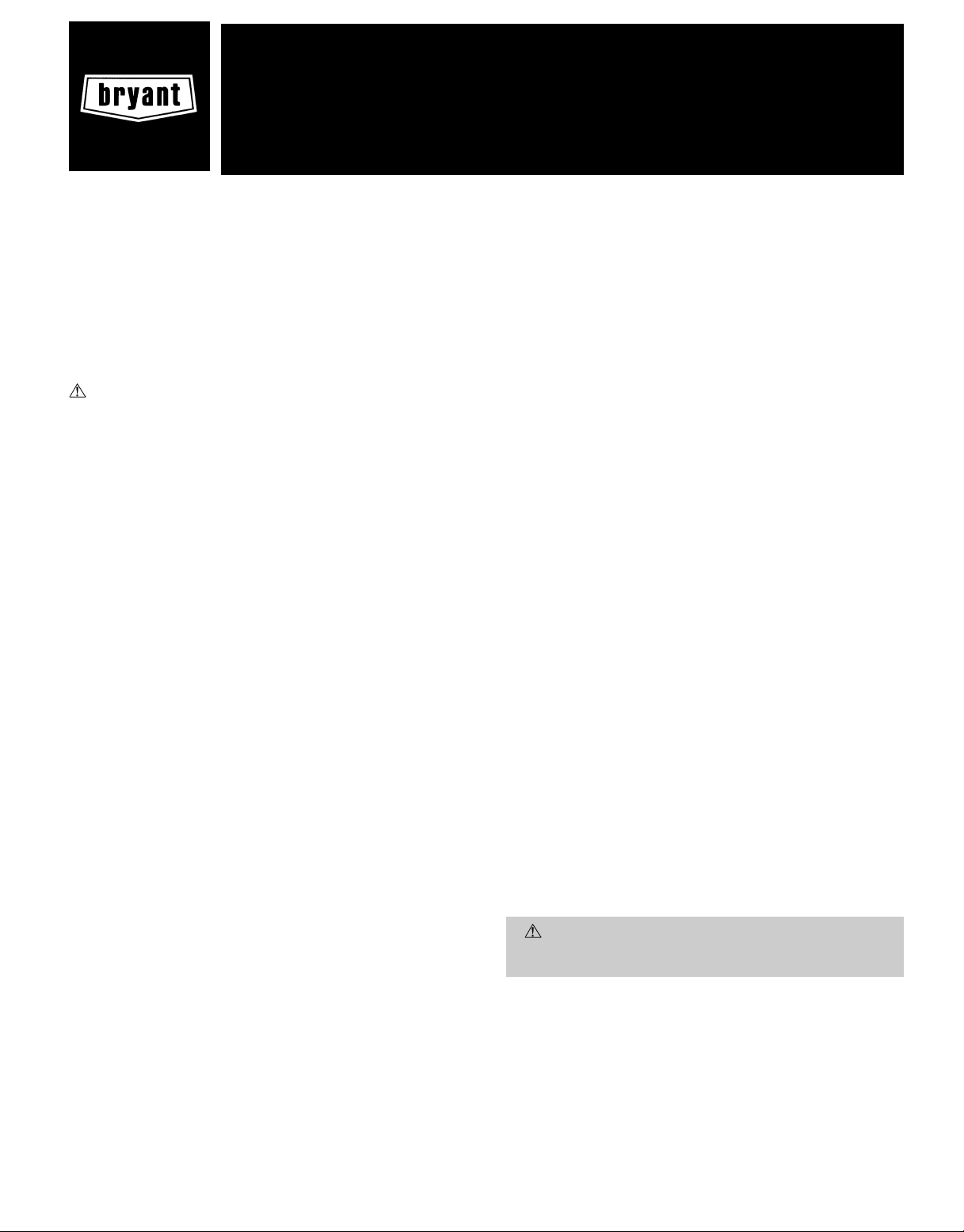

CONNECTION

BOARD

O/W2

Y1

R

G

Y/Y2

W/W1

C

B

548D036-120

549B036-120

551B036-150

558D036-150

580D036-150

581B036-150

DO NOT USE

S1

S2

COMMERCIAL

THERMOSTAT

L

*Does not apply to 558D and 580D036-150 units.

NOTES:

1. 558D and 580D036-072 units only have one stage of cooling, but

can have 2 stages of heat. In these applications set DIP switch B

to ON for 2-stage operation.

2. For 548D and 549B heat pump applications, set switch A to OFF

(air conditioning). The 548D and 549B units do not have an ‘‘O’’

terminal.

Fig. 1 — Thermostat Wiring (548D036-120; 549B036-120; 551B036-150;

558D036-150; 580D036-150; 581B036-150)

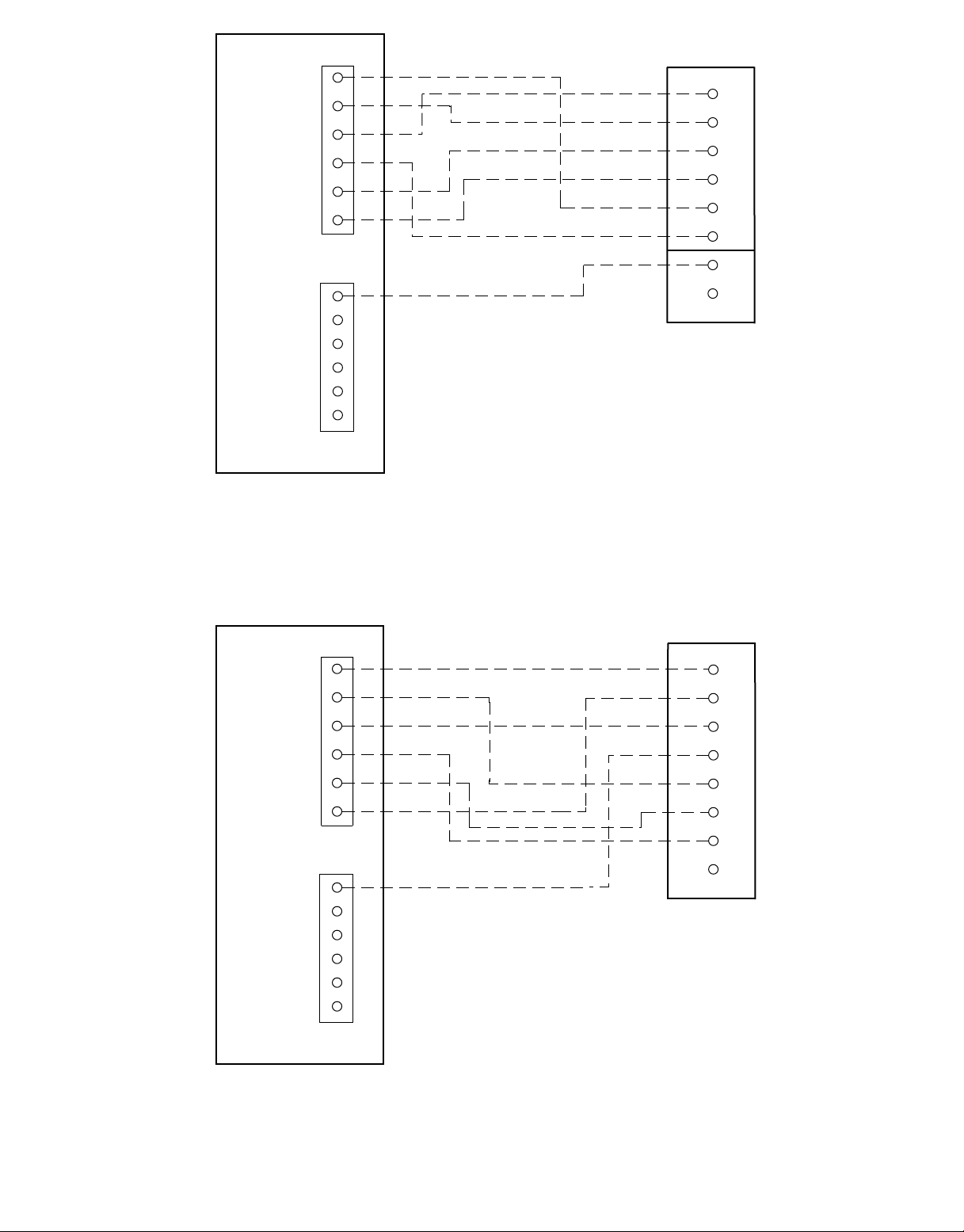

R

Y1

Y2

W1

W2

G

C

X

*

O/W2

Y1

Y/Y2

W/W1

DO NOT USE

S1

S2

COMMERCIAL

THERMOSTAT

TB2

W2

W1

R

G

C

B

L

R

C

Y1

Y2

G

X

551A155-240

559E180-240

559F180-300

579E180-240

579F180-300

581A155-240

Fig. 2 — Thermostat Wiring (551A155-240; 559E180-240; 559F180-300;

579E180-240; 579F180-300; 581A155-240)

—3—

Page 4

O/W2

Y1

Y/Y2

W/W1

DO NOT USE

S1

S2

COMMERCIAL

THERMOSTAT

TB2

RC

R

G

C

B

L

RH

W1

W2

Y1

Y2

G

C

X

11

2

4

C2

FIELD

RELAY

C1

FIELD RELAY

542J150 and 180

NOTES:

1. Field relay P/N HN61KK224.

2. Setswitch Ato OFF (air conditioning). The 542J units do not have an

‘‘O’’ terminal.

Fig. 3 — Thermostat Wiring (542J150 and 180)

O/W2

Y1

Y/Y2

W/W1

DO NOT USE

S1

S2

COMMERCIAL

THERMOSTAT

TB3

W2

W1

R

G

C

B

L

558G,H240-360

580G,H240-360

R

C

Y1

Y2

G

X

Fig. 4 — Thermostat Wiring (558G,H240-360 and 580G,H240-360)

—4—

Page 5

G. Low Ambient Cooling Lockout Selection

The Low Ambient Cooling Lockout feature will lock out cooling mode if the outdoor-air temperature is below the lockout

cooling temperature (user-configured).

NOTE: This configuration is not available if DIP switch C (Remote Room Sensor) is set to ON or if the outdoor-air sensor is

in error.

The default is OF (disabled). The lockout temperature can be

set to OF (disabled) or 20 to 60 F in 5-degree increments (enabled). To configure the selection, press the Program button

in the configuration mode. Use the Up and Down buttons to

increase or decrease the setting.

V. CHECK THERMOSTAT OPERATION

Perform the following procedure to check thermostat

operation:

1. Press the Hold button. This will prevent the set point

from changing until the desired time and temperature

schedule is entered.

2. Press the Fan button to switch the fan annunciator from

AUTO to ON. The fan should run continuously. Check

fan operation. Press the fan button again to switch back

to AUTO.

3. Press the mode button repeatedly until HEAT is displayed in the mode annunciator. Press the Up button

until the set point reads 10 degrees above room temperature. The heating system should begin to operate

within 5 minutes.

4. Press the mode button repeatedly until COOL is displayed in the mode annunciator.Press the Down button

until the set point reads 10 degrees below room temperature. The cooling system should begin to operate

within 5 minutes.

VI. SELECT THERMOSTAT OPERATION SETTINGS

Thermostat operation should be configured. Set the Fan and

Mode configurations to their desired settings. Press the Up

and Down buttons to select the desired comfort temperature.

NOTE: Daily schedules can be programmed by the installer

or the user. A detailed explanation of the schedule programming is in the Owner’s Guide. If the daily schedules of the

thermostat are being configured, refer to the thermostat owner’s guide literature.

VII. FINAL CHECKLIST

1. Put away tools and instruments. Clean up debris and

packaging.

2. Review Owner’s Guide with occupant or owner.

3. Leave Owner’s Guide with occupant or owner.

OPERATION

I. HOLD, FAN, AND MODE BUTTON OPERATION

Pressing the Hold button disables the time and temperature

schedule and holds the current desired temperature set point.

When a Hold is active, the HOLD annunciator is displayed

on the thermostat screen. To release the Hold, press the Hold

button a second time.

The Fan button selects fan operation. When the fan is set to

ON, the fan willruncontinuously.When the fan is set to AUTO,

the fan will run during heating and cooling operation only.

The Mode button selects the operating mode of the thermostat. If OFF is selected, the thermostat will not enter heating

or cooling mode. If HEAT is selected, the thermostat will only

enter heating mode (if the room temperature is below the

heating set point). If COOL is selected, the thermostat will

only enter cooling mode (if the room temperature is above

the cooling set point). If AUTO is selected, the thermostat will

enter heating or cooling mode based on the room temperature and the heating and cooling set points. Heat pumps also

have an EHEATselection. If EHEATis selected, the heat pump

will use the second stage of heating to provide heat when

needed. The annuciator for each selection will be displayed

on the thermostat when selected.

II. FIVE-MINUTE COMPRESSOR SHORT-CYCLE

PROTECTION

The timer prevents the compressor from starting until it has

been offfor at least 5 minutes. The short-cycle protection function can be disabled (for one cycle only) by simultaneously

pressing the Fan button and the Up button.

III. FIFTEEN-MINUTE CYCLE TIMER

The cycle timer prevents the start of a heating or cooling cycle

until at least 15 minutes after the last start of the same cycle.

This function keeps the equipment from being cycled more

than 4 times in one hour. The cycle timer can be disabled (for

one cycle only) by either changing the temperature set point

or by simultaneously pressing the Fan button and the Up

button.

IV. FIFTEEN-MINUTE STAGING TIMER

When multi-stage heating or cooling is used, the staging timer

prevents any higher stage from energizing until at least

15 minutes has passed from the start of the previous stage.

The timer is disabled if the temperature demand is greater

than 5 degrees.

V. TWO-MINUTE MINIMUM ON TIME

In normal operation, when a stage is energized, it must remain on for at least 2 minutes.

VI. HEATING/COOLING SET POINT MINIMUM

DIFFERENCE

A minimum difference of 3 degrees is enforced between the

heating and cooling set points. The thermostat will not allow

the set points to be set within 3 degrees of each other.

VII. AUTO-CHANGEOVER TIMER

When the auto-changeover mode is selected, the thermostat

will not change from heating to cooling or cooling to heating

until an opposite demand has existed for a minimum of

10 minutes. The timer is disabled if the heating or cooling

set point is changed.

VIII. POWER-ON THERMOSTAT CHECK

When power is applied to the thermostat, all possible display

annunciators are turned on for a few seconds. The thermostat then indicates the current mode and configuration information with a 2-digit code. The following codes can be displayed: AC — single-speed air conditioner, HP — singlespeed heat pump, A2 — two-speed air conditioner, and H2 —

two-speed heat pump.

IX. ERROR CODES

The thermostat will display the following error codes if errors are detected:

E1 — If the thermostat cannot properly read room temperature, the thermostat will display an E1 and all outputs (except the fan if on), will be deenergized.

E2 — If the AC line voltage drops below the minimum level,

all outputs are deenergized and the thermostat will display

an E2. The E2 error will remain until proper line voltage has

—5—

Page 6

been restored (plus 15 seconds). If the line voltage is completely interrupted, the thermostat display will immediately

go blank.

X. SMART RECOVERY (Heating Mode Only)

unoccupied). The Smart Recovery function begins 1.5 hours

before the scheduled occupiedmodeand gradually adjusts room

temperature so the temperature is at the occupied mode set

point when the occupied time period begins.

The thermostat has 2 programmed schedule modes, normal

occupied mode and setback mode (a time when the space is

TROUBLESHOOTING

PROBLEM SOLUTION

LCD display on thermostat not illuminated Check for 24 vac between R and C at terminal connections. Both R and

‘‘E2’’ displayed on thermostat Brownout condition or voltage is too low to thermostat. Check wiring and

‘‘E1’’ displayed on thermostat Temperature sensor reading is out of range. Check the sensor for dam-

‘‘Clean Filter’’ is displayed on thermostat After the configured number of blower operating hours, the Clean Filter

‘‘--’’ displayed on thermostat If the outdoor thermostat is in error, not connected, or shorted, ‘‘--’’ will be

Cooling will not energize Select COOL mode. Decrease cooling set point to 10 degrees below

Heating will not energize Select HEAT mode. Increase heating set point to 10 degrees above room

C must be connected for proper thermostat operation.

check for 24 vac at R and C. The E2 error will clear 15 seconds after

acceptable power levels are restored.

age. Check sensor wiring. Cycle power to thermostat. If display is not

cleared, replace thermostat .

message will be displayed. This reminds the owner to replace the filter.

Press the Reset Filter button to reset the blower operation timer to

0 hours.

displayed. Check outdoor thermostat wiring and replace if necessary.

room temperature. Simultaneously press Fan and Up buttons to disable

timers. Check for 24 vac at Y/Y2 terminal. If present, thermostat is operating correctly and problem is with wiring or equipment. If 24 vac is not

present, replace the thermostat.

temperature. Simultaneously press Fan and Up buttons to disable timers.

Check for 24 vac at Y/Y2 terminal (for heat pump) or W/W1 terminal (for

gas/electric heat unit). If present, thermostat is operating correctly and

problem is with wiring or equipment. If 24 vac is not present, replace the

thermostat.

—6—

Page 7

Page 8

PACKAGED SERVICE TRAINING

Our packaged service training programs provide an excellent way to increase your knowledge of the

equipment discussed in this manual. Product programs cover:

• Unit Familiarization

• Installation Overview

• Maintenance

• Operating Sequence

A large selection of product, theory, and skills programs is available. All programs include a video

cassette and/or slides and a companion booklet. Use these for self teaching or to conduct full training

sessions.

For a free Service Training Material Catalog (STM), call 1-800-962-9212. Ordering instructions are

included.

Copyright 1996 Carrier Corporation CATALOG NO. BDP-809-641

Loading...

Loading...