Page 1

installation, start-up and

service instructions

TEMPSURE COMMERCIALTHERMOSTA T

(P/N TSTATBBP220-LA)

Cancels: New II TSTAT-8

11/1/98

CONTENTS

Page

SAFETY CONSIDERATIONS ...................... 1

GENERAL ..................................... 1

INSTALLATION ................................ 1-6

I. Select Thermostat Location ................ 1

II. Install Thermostat ........................ 2

III. Set Clock ................................ 3

IV. Heat Pump Configuration .................. 3

V. Configure Advanced Setup ................. 3

VI. Install Accessories ........................ 4

VII. Program Thermostat Schedules ............. 4

VIII. Calibrate Temperature Sensor .............. 6

IX. Light Sensor Adjustment .................. 6

X. Check Thermostat Operation ............... 6

XI. Final Checklist ........................... 6

OPERATION ................................... 7

I. Auto-Changeover ......................... 7

II. Light-Activated Operation .................. 7

III. Two-Stage Operation ...................... 7

IV. Clock Backup ............................ 7

V. Fan Operation ............................ 7

VI. Emergency Heat .......................... 7

VII. Electric Heat ............................. 7

VIII. Holiday Mode ............................. 7

IX. Keypad Lock ............................. 7

TROUBLESHOOTING ............................ 8

IMPORTANT: Read entire instructions before starting the

installation.

SAFETY CONSIDERATIONS

Read and follow manufacturer instructions carefully. Follow

all local electrical codes during installation. All wiring must

conform to local and national electrical codes. Improper wiring or installation may damage thermostat.

Recognize safety information. This is the safety alert sym-

. When the safety alert symbol is present on equip-

bol

ment or in the instruction manual, be alert to the potential

for personal injury.

Understand the signal wordsDANGER,WARNING, and CAUTION. These words are used with the safety alert symbol.

DANGER identifies the most serious hazards which will

result in severe personal injury or death. WARNING signifies a hazard which could result in personal injury or death.

CAUTION is used to identify unsafe practices which would

result in minor personal injury or property damage.

GENERAL

The 7-day, commercial, programmable thermostats are wallmounted, low-voltage thermostats which maintain room temperature by controlling the operation of an HVAC (heating,

ventilation, and air-conditioning) system. Separate heating

and cooling set points and auto-changeover capability allow

occupied and unoccupied programming for energy savings.

All thermostats allow up to 4 time/temperature settings to

be programmed per 24-hour period. Each thermostat stores

programs for 7 independent days. Batteries are not required.

During power interruption the internal NEVERLOST™

memory stores programmed schedules for an unlimited time

while the clock continues to run for at least 48 hours.

The thermostat can be configured to accept several different

equipment configurations, including heat pump operation.

NOTE: The thermostat is not factory-configured for use in

heat pump applications. The advanced setup must be performed to configure the thermostat for use with heat pump

units.

A light sensor is provided on the thermostat for light

activation. When the sensor detects light (the space is

occupied), the thermostat will enter Occupied 1 mode. If

the room is dark, the thermostat will follow its programmed

schedule.

INSTALLATION

I. SELECT THERMOSTAT LOCATION

The thermostat should be mounted:

• approximately 5 ft from the floor

• close to or in a frequently used room, preferably on an inside partitioning wall

• on a section of wall without pipes or ductwork

• where temperature operating limits are within 41 to 104 F

(5 to 40 C)

• where humidity operating range is within 0 to 95% relative humidity, non-condensing

The thermostat should NOT be mounted:

• close to a window, on an outside wall, or next to a door

leading to the outside

• where exposed to direct light and heat from a lamp, the

sun, a fireplace, or any other temperature-radiating object

which may cause a false reading

• close to or in direct airflow from supply registers or return

air grilles

• in areas with poor air circulation (such as behind a door or

in an alcove)

Page 2

II. INSTALL THERMOSTAT

WARNING:

Before installing thermostat, turn off all

power to the unit. There may be more than one power

disconnect. Electrical shock can cause injury or death.

1. Turn off all power to unit.

2. If an existing thermostat is being replaced:

a. Remove existing thermostat from the wall.

b. Disconnect wires from existing thermostat. Do not

allow wires to fall back into the wall. As each wire

is disconnected, record wire color and terminal

connection.

c. Discard or recycle old thermostat.

NOTE: Mercury is a hazardous waste and must be disposed

of properly.

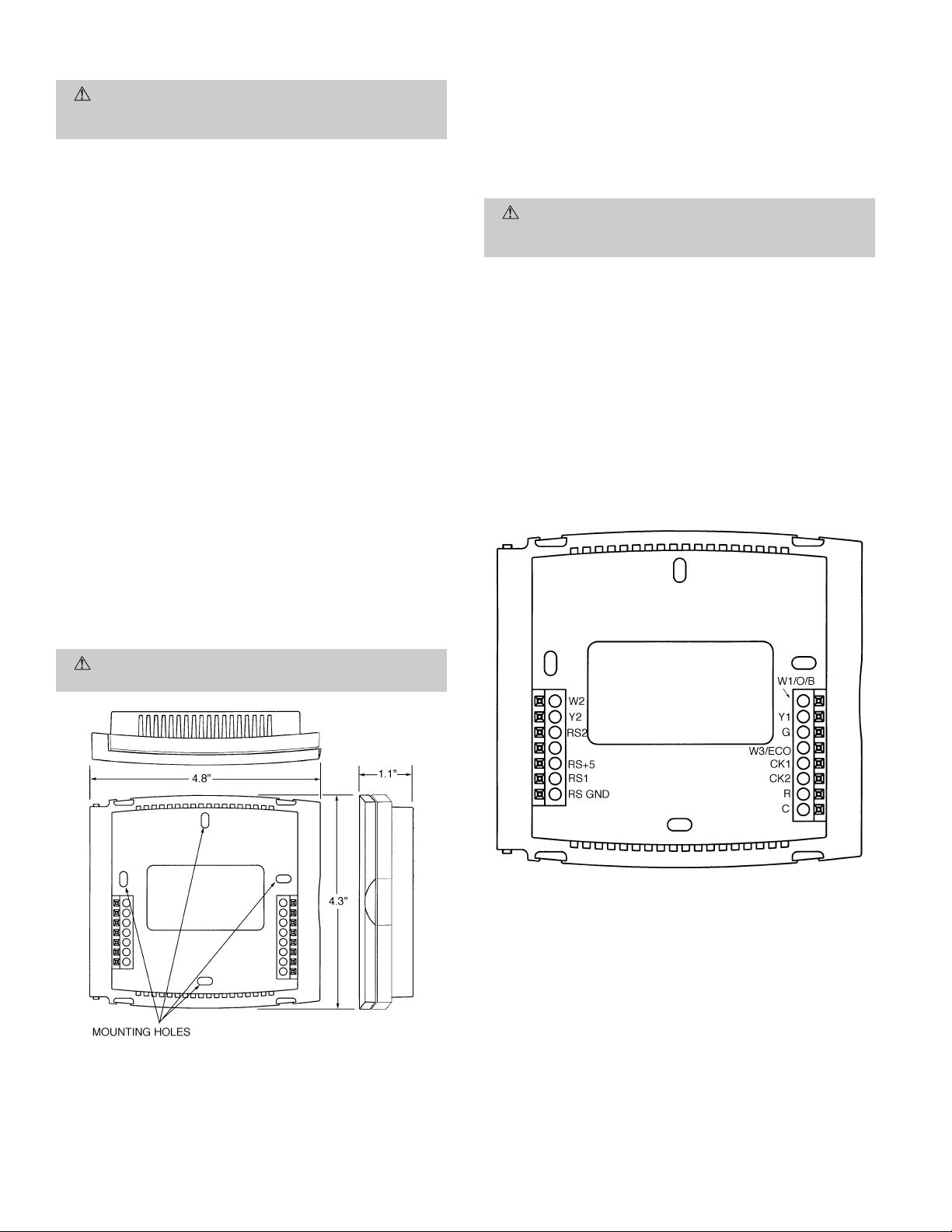

3. Remove the thermostat cover from wall plate (mounting base) to expose mounting holes. See Fig. 1. With

the thermostat facing forward, press the back plate on

the left hand side top corner to release the two prongs

holding on the cover.Pulloff the cover when the prongs

have been disengaged.

4. Route thermostat wires through large hole in mounting base. Remove outer sheath from wires for added

flexibility. Standard solid or multi-conductor thermostat wire should be used from the thermostat to the

unit. Size and length considerations are as fol-

lows: for a maximum distance from unit of 36 ft,

use 22AWG(American Wire Gage) wire; for a maximum distance from unit of 100 ft, use 18AWGwire.

5. Level mounting base against wall and mark wall through

the 2 mounting holes in base.

3

6. Drill two

⁄16-in. mounting holes in wall where marked.

7. Secure mounting base to wall with 2 screws and

anchors provided. Ensure all wires exit through hole

in mounting base.

8. Adjust wire length and routing to allow proper closure

of the thermostat. Strip each wire at the end no more

1

⁄4-in. to prevent adjacent wires from shorting to-

than

gether. Match and connect wires to terminals on the

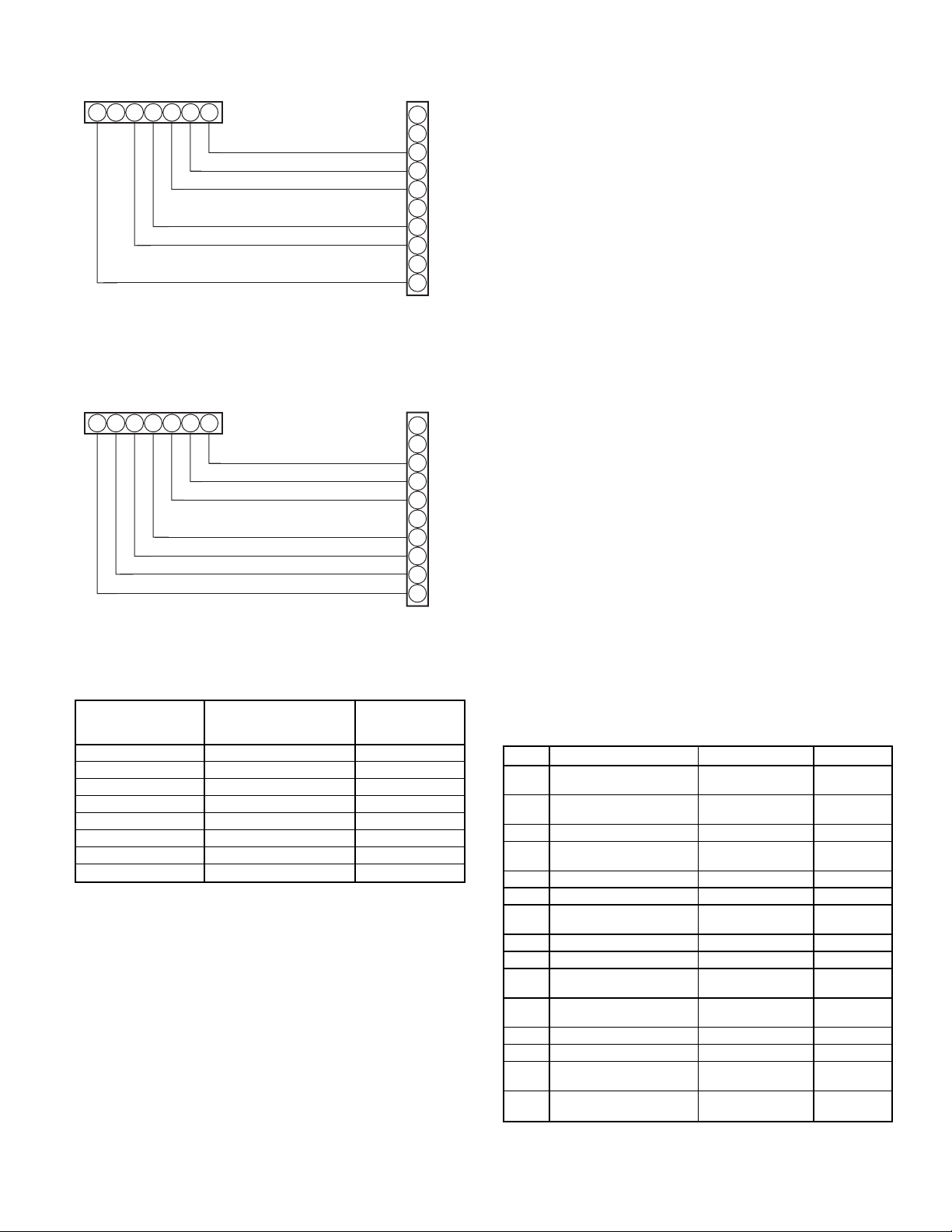

thermostat. See Fig. 2-4 and Table 1.

CAUTION:

Improper wiring or installation may cause

damage to the thermostat. Check to ensure wiring is

correct before proceeding with installation of unit.

9. Push excess wiring into wall. Seal hole in wall to prevent drafts.

10. Re-attach thermostat cover to back plate by aligning

the top two prongs of the back plate in the vertical groove

of the top cover and then snapping the cover onto the

back plate.

11. Turnon power to unit. The thermostat will receive power

from the unit. The thermostat will be powered by 24 v,

nominal (18 to 30 vac). Terminals R (+ 24 v), W1/O/B

(first stage heat or reversing valve), Y1 (first stage cooling), and G (fan relay) will always be connected. Some

applications will use C (common),Y2 (second stage cooling), or W2 (second stage heating).

WARNING:

Be careful not to drill into wiring in wall.

Electrical shock could result.

Fig. 1 — Thermostat Mounting

W2 — Second-Stage

Y2 — Second-Stage

RS2 — Not Used

RS+5 — Not Used

RS1 — Not Used

RS

GND

Heat

Compressor

— Not Used

Fig. 2 — Thermostat Wiring

LEGEND

W1/O/B — First-Stage Heat or

Y1 — First-Stage Compressor

G—Fan

W3/ECO — Third-Stage Heat or

CK1 — Not Used

CK2 — Not Used

R—24 vac Transformer

C—24 vac Transformer

Reversing Valve

Economizer (Not Used)

Common

—2—

Page 3

THERMOSTAT

W2Y2R

O

W1

B

G

C

Y1

24 VAC COMMON

FAN RELAY

COMPRESSOR RELAY

1st STAGE HEAT CIRCUIT

24 VAC RETURN

2nd STAGE HEAT CIRCUIT

TYPICAL

UNIT

L

E

C

G

Y1

O

W1

R

Y2

W2

Fig.3—Typical Wiring (Single-Stage Cooling Units)

THERMOSTAT

W2Y2R

B

O

W1

Y1

G

C

24 VAC COMMON

COMPRESSOR RELAY

1st STAGE HEAT CIRCUIT

24 VAC RETURN

2nd STAGE COMPRESSOR RELAY

2nd STAGE HEAT CIRCUIT

FAN RELAY

TYPICAL

UNIT

L

E

C

G

Y1

O

W1

R

Y2

W2

Fig.4—Typical Wiring (Two-Stage Cooling Units)

Table 1 — Thermostat Wiring Terminations

EXISTING

WIRE

DESIGNATION

GorF Fan G

Y1, Y, or C Cooling Y1

W1, W, or H Heating W1/O/B

Rh, R, M, Vr, or A Power (24 v) R

C Common C*

O/B Reversing Valve W1/O/B†

Y2 Second Stage Cooling Y2*

W2 Second Stage Heating W2*

*Terminals C, W2, and Y2 may not be used in all applications.

†Used on Heat Pump applications only.

FUNCTION

TERMINAL

CONNECTION

III. SET CLOCK

The Set Clock button allows the user to change the time and

day displayed on the thermostat. Press the Set Clock button.

The current time will blink on and off. Press the UPARROW

and DOWN ARROW buttons until the correct time is shown.

Hold down the buttons to quickly move through the time display. The AM and PM annunciators will automatically change.

Hold down the Fan button while pressing UP ARROW or

DOWN ARROW to change the time by hours instead of minutes. To ensure the schedules are properly followed, make sure

that AM or PM is correct for the time chosen. When the correct time is shown, press the Mode button to modify the day

of the week. The current day will blink on and off. Press the

UP ARROW and DOWN ARROW buttons until the correct

day is shown. Press the Set Clock button again to exit the

Set Time mode.

IV. HEAT PUMP CONFIGURATION

To configure the thermostat for heat pump operation, Advanced Setup Steps 3 (Heat Pump Operation) and 4 (Reversing Valve Polarity) must be configured correctly. See the

Configure Advanced Setup section for information on configuring these options.

NOTE: Some large commercial rooftop heat pump units (542J)

must be configured with Advanced Setup Step 3 (Heat Pump

Operation) set to OFF. Refer to the base unit instructions for

more information.

V. CONFIGURE ADVANCED SETUP

To enter into the advanced setup screens of the thermostat,

press the Mode and Program buttons at the same time. The

Advanced Setup Step number is shown in the top right

corner of the thermostat screen. Use the Mode button to

advance through the steps. There are 15Advanced Setup Steps.

See Table2. Press the Program button at any time to exit the

Advanced Setup mode.

NOTE: Advanced Setup Steps 1 and 2 are configured with

the Set Clock button, and are not accessed through the

advanced setup screens.

A. Heat Pump Configuration (Steps 3 and 4)

T oset the thermostat for heat pump operation,Advanced Setup

Step 3 must be configured to ON. Use the UP and DOWN

ARROW buttons to configure the step. The default is OFF.

Press the Mode button to continue to Step 4. Step 4 is used to

set the reversing valve polarity for the heat pump. The variable can be set to either ‘‘B’’ or ‘‘O.’’ Set the reversing valve

polarity to the correct value depending on the application. The

default is ‘‘O.’’

NOTE: Step 4 will appear only if Step 3 is set to ON. Step 5

will appear only if Step 3 is set to OFF.

Table 2 — Advanced Setup Configuration

STEP DESCRIPTION RANGE DEFAULT

1* Time of Day

2* Day of the Week

3 Heat Pump Off/On Off

4

5 Electric Heat Off/On Off

6 Deadband 1 - 6 degrees 2

7

8 Cycles per Hour d, d1,2-6 6

9 Thermoglow™ Backlight Off/On On

10

11

12 Temperature Units F/C F

13 Security Level 0 - 3 0

14

15

*Accessed and configured through the Set Clock button.

Reversing Valve

Polarity

Forced Minimum

Temperature Difference

Reset Service

Filter Icon

Service Filter

Run Time

Maximum Allowable

Heat Set Point

Minimum Allowable

Cooling Set Point

12:00 AM -

11:59 PM

Sunday through

Saturday

O/B O

0 - 6 degrees 2

——

0-1950 hrs 500 hrs

35 - 99 F (1-37 C) 80 F (27 C)

35 - 99 F (1-37 C) 65 F (18 C)

12:00 AM

Monday

—3—

Page 4

B. Electric Heat Configuration (Step 5)

Step 5 is used to configure the thermostat for electric heat.

The variable can be configured ON or OFF. The default is

OFF.

NOTE: Step 5 will appear only if Step 3 is set to OFF.

C. Deadband (Step 6)

The deadband is the difference in temperature above the

cooling set point or below the heating set point that the thermostat will wait before turning on the first stage of heating or cooling. For example, if the cooling set point is 82 F

(28 C) and the deadband is 2 degrees, the first stage of cooling will not be energized until the temperature reaches 84 F

(30 C). The range of values is 1 to 6 degrees. The default is

2 degrees.

D. Set Point Minimum Difference (Step 7)

The minimum difference between heating and cooling set points

can be user-configured. The range is from 0 to 6 degrees. The

default is 2 degrees. The minimum difference is enforced during Auto-Changeover and Program On operation.

E. Cycles Per Hour Limit (Step 8)

The number of times that heating or cooling can be energized per hour can be configured. Set the variable to ‘‘d’’ for

no limit. Set the variable to ‘‘d1’’to disable the 5-minute compressor lockout. The variable can also be set from 2 to 6 cycles

per hour. The default is 6 cycles per hour.

CAUTION:

5-minute compressor lockout is disabled or compressor

is allowed unlimited cycles. Do not set thermostat

Advanced Setup Step 8 to ‘‘d’’ or ‘‘dl’’ unless specifically

recommended for the application.

F. Backlight Display (Step 9)

The display backlight can be set to ON (always on) or OFF

(turn off 8 seconds after usage). The default is ON.

G. Service Filter (Steps 10 and 11)

Step 10 allows the user to reset the Service Filter counter to

zero and remove the ‘‘SERVICE FILTER’’ icon (if displayed

on the thermostat screen). Press the FANbutton while in Setup

Step 10 and the counter is reset to zero. Press the Mode button to adjust the number of hours the blower will run before

the ‘‘SERVICE FILTER’’ icon is displayed. The range is 0 to

1950 hours. Set the variable to 0 to disable this function. The

default is 500 hours.

H. Fahrenheit/Celsius Operation (Step 12)

The thermostat can be set to operate in Fahrenheit or Celsius degrees. Set the variable to ‘‘F’’ for Fahrenheit operation. Set the variable to ‘‘C’’for Celsius operation. The default

is ‘‘F.’’

I. Security Level (Steps 13 to 15)

The Security Level limits the actions that the user can perform at the thermostat. There are 4 security levels. When the

security level is set to ‘‘0,’’no security will be in effect. When

the security level is set to ‘‘1,’’ the set point range is limited

by the settings of Steps 14 and 15. When the security level is

set to ‘‘2,’’ the set point range is limited by the settings of

Steps 14 and 15 and the Program On mode is always in effect. When the security level is set to ‘‘3,’’ the set point range

is limited by the settings of Steps 14 and 15, the Program On

mode is always in effect, and set point changes are prohibited. The default is 0.

Damage to compressor could result if

Security Maximum Heat Set Point (Step 14)

If the Security Level is not set to 0, the maximum heating

set point will be in effect. The user will not be allowed to set

the heating set point over the specified value. The range of

values is 35 to 99 F (1 to 37 C). The default is 80 F (27 C).

Security Minimum Cool Set Point (Step 15)

If the Security Level is not set to 0, the minimum cooling set

point will be in effect. The user will not be allowed to set the

cooling set point below the specified value. The range of values is 35 to 99 F (1 to 37 C). The default is 65 F (18 C).

VI. INSTALL ACCESSORIES

The following accessory can be used with this thermostat:

Add-a-Wire™ accessory (TSTATBBPACC-AW).

Refer to the accessory installation instructions for the accessory for more information.

VII. PROGRAM THERMOSTAT SCHEDULES

Before programming the thermostat, plan the thermostat daily

schedule. The schedule is divided into 7 days (Monday through

Sunday). Each day has from 2 to 4 time periods (Occupied 1,

Occupied 2, Occupied 3, Unoccupied) depending on the configuration of the thermostat. Each occupied time period has

a start time, stop time, heating set point, and cooling set point.

The unoccupied time period has a heating set point and a

cooling set point. The unoccupied time period is active when

ever an occupied time period is not active. Fill in Table 3 as

an aid to programming the daily schedules.

NOTE: When the sensor detects light (the space is occupied),

the thermostat will enter Occupied 1 mode. If the room is

dark, the thermostat will follow its programmed schedule.

The Occupied 1 schedule should be turned OFF to keep the

thermostat from entering Occupied 1 while the room is unoccupied. If the Occupied 1 schedule is turned ON, the thermostat will enter Occupied 1 per the schedule regardless of

light activation. The Occupied 1 set points are used as the

heating and cooling set points during light activation. The

Unoccupied set points should be used as non-work hour set

points (before 8:00 AM and after 5:00 PM) when using light

activation. For times when the building is unoccupied during

work hours (Monday through Friday, 8:00 AM to 5:00 PM),

the Occupied 2 schedule should be turned ON, and can be

used for moderate energy savings with set points of 80 F for

cooling and 65 F for heating.

A. Programming Mode

To program the daily schedules, perform the following

procedure:

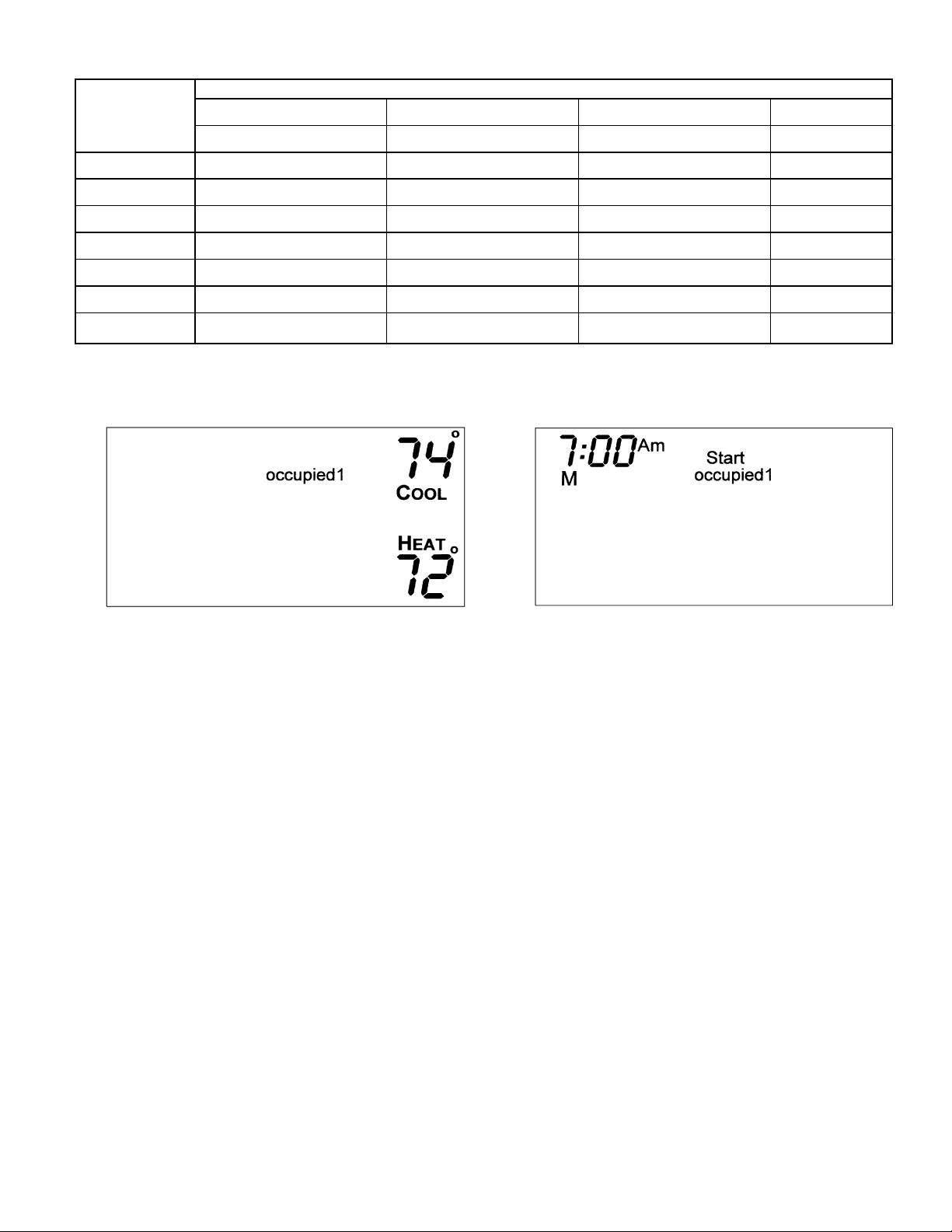

1. Enter programming mode by pressing the Program button. The Occupied 1 annunciator will appear on the thermostat display. Use the UP ARROW and DOWN

ARROW buttons to set the maximum number of

Occupied periods for each day. The thermostat can be

set to 1, 2, or 3. After the number of Occupied periods

has been selected, press the Mode button. See Fig. 5.

2. The cooling set point for Occupied 1 will be displayed.

Use the UP ARROW and DOWN ARROW buttons to

raise or lower the cooling set point until the desired

temperature is shown. The range of acceptable values

is 35 to 99 F (1 to 37 C). Press the Mode button to continue. See Fig. 5.

—4—

Page 5

Table 3 — Daily Schedule Planner

DAY

OF THE

WEEK

Monday /// /// /// /

Tuesday /// /// /// /

Wednesday /// /// /// /

Thursday /// /// /// /

Friday /// /// /// /

Saturday /// /// /// /

Sunday /// /// /// /

NOTE: The cooling temperature set point must be higher than the heating temperature set point. (The

temperature difference may be changed in the advanced setup configuration.)

Occupied 1 Occupied 2 Occupied 3 Unoccupied

Start / Stop / Heat / Cool Start / Stop / Heat / Cool Start / Stop / Heat / Cool Heat / Cool

SCHEDULE

Fig. 5 — Setting Occupied 1 Set Points

3. The heating set point for Occupied 1 will be displayed.

Use the UP ARROW and DOWN ARROW buttons to

raise or lower the heating set point until the desired

temperature is shown. The range of acceptable values

is 35 to 99 F (1 to 37 C). Press the Mode button to continue. See Fig. 5.

4. The cooling set point for Unoccupied will be displayed.

Use the UP ARROW and DOWN ARROW buttons to

raise or lower the cooling set point until the desired

temperature is shown. The range of acceptable values

is 35 to 99 F (1 to 37 C) or ‘‘OF’’ (no unoccupied cooling). Press the Mode button to continue.

5. The heating set point for Unoccupied will be displayed. Use the UP ARROW and DOWN ARROW buttons to raise or lower the heating set point until the

desired temperature is shown. The range of acceptable

values is 35 to 99 F (1 to 37 C) or ‘‘OF’’(no unoccupied

heating). Press the Mode button to continue.

6. The day of the week will be shown. Use the UP

ARROW and DOWN ARROW buttons to change the

day of the week until the desired starting day is shown.

Possible choices are M (Monday) through S (Sunday).

Press the Mode button when the desired day is shown.

7. The Start Time for Occupied 1 will be displayed. Use

the UP ARROW and DOWN ARROW buttons to raise

or lower the time until the desired Start Time is shown.

Press the Mode button to continue. See Fig. 6.

Fig. 6 — Start Time Display

8. The Stop Time for Occupied 1 will be displayed. Use

the UP ARROW and DOWN ARROW buttons to raise

or lower the time until the desired Stop Time is shown.

Press the Mode button to continue.

9. The On/Off icon will be displayed. Use the UP

ARROW to turn the Occupied 1 period ON for this day.

Use the DOWN ARROW to turn the Occupied 1 period

OFF for this day.

10. Repeat Steps 2 through 9 to program the remaining

schedule for Occupied periods 2 and 3.

11. The Copy command can be used to copy the previous

day’s schedule if the schedules are the same. The copy

command becomes available after all the occupied

periods are programmed in a day. Use the UP ARROW

to change the copy command to YES. Use the DOWN

ARROW to change the copy command to NO. Press the

Mode button when the choice has been made. See

Fig. 7.

If NO was selected, the schedule will automatically

change to the next day and the user must enter the occupied and unoccupied schedules for that day.

NOTE: Occupied 1 schedule heating and cooling set points

are the same for each day. Occupied 2 and 3 set points

may be set to different values for each day of the week.

If YES was selected, the schedule will be copied to the

next day. The schedule copy may be repeated until Sunday is reached. The Sunday schedule cannot be copied

to Monday.

—5—

Page 6

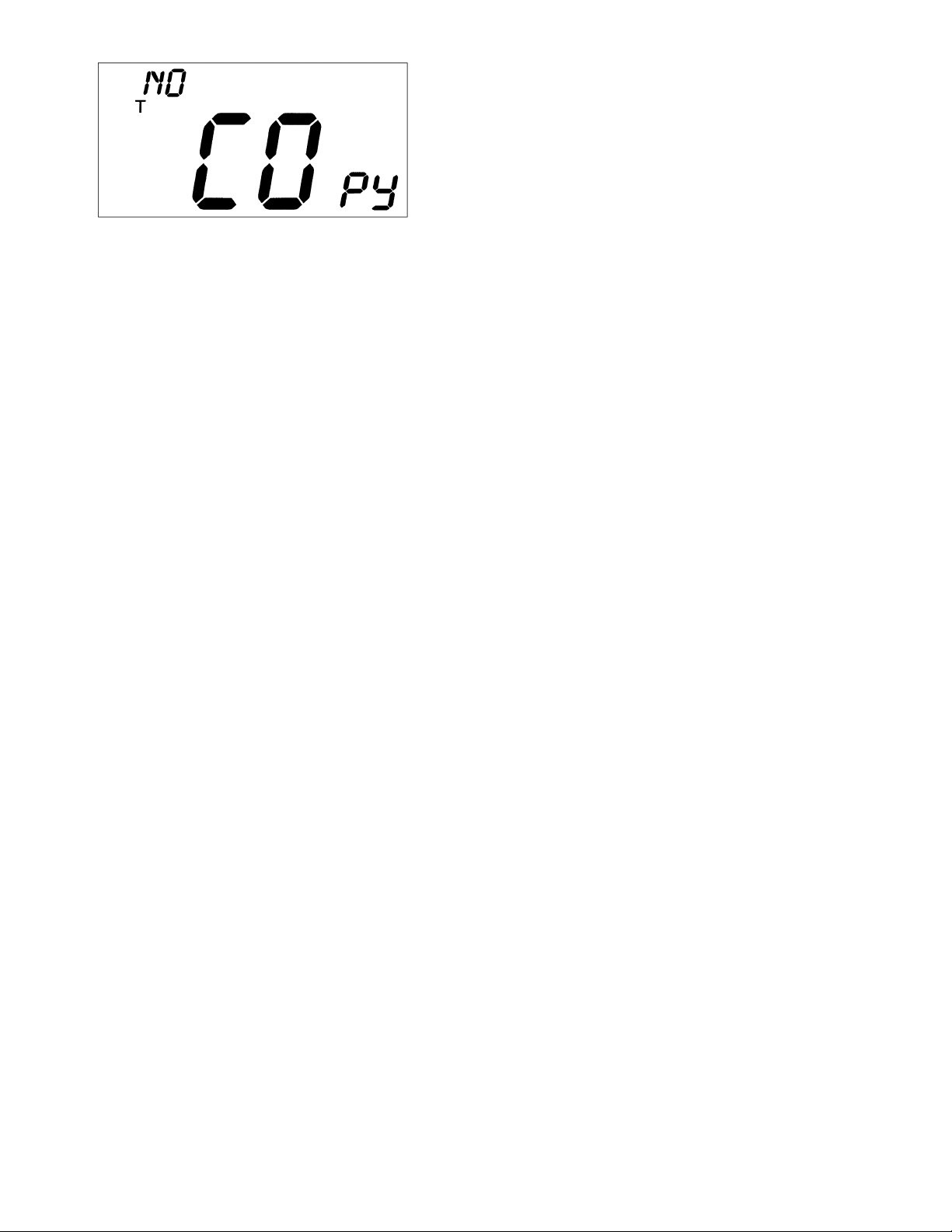

Fig. 7 — Copy Command Display

12. After all the times and set points for each day have

been entered, press the Program button to exit programming mode.

NOTE: The thermostat will continue to follow the schedule

until a new one is entered.

If only one occupied schedule is selected, the Occupied 2 and

3 schedules are skipped. If the start time is set later in the

day than the stop time, the program will run from midnight

of that day to the stop time and then from the start time to

midnight. If the same start and stop times are programmed

for an occupancy schedule, the thermostat will be in Occupied mode for 24 hours. If one occupied period starts or stops

within another occupied period, the lower numbered schedule has priority. For example, if schedule Occupied 3 is running for 24 hours and Occupied 2 schedule comes on from

1 to 3 PM, the set points from Occupied 2 are in effect from

1to3PM.

B. Overriding the Schedule

The schedule can be overridden by pressing the UP or DOWN

ARROW buttons to change the desired temperature. The thermostat will use the new set point until the next scheduled

time period starts.

VIII. CALIBRATE TEMPERATURE SENSOR

Every thermostat is factory calibrated. Under normal circumstances there will never be a need to re-calibrate the thermostat. If re-calibration must be done, perform the following

procedure:

1. Hold down the Mode and Fan buttons for 5 seconds. All

of the icons on the display screen will appear. Release

the buttons. Press the UP and DOWN ARROW buttons

simultaneously.

2. Press the UP and DOWN ARROW buttons simul-

taneously again. The current temperature will be

displayed.

3. Use an accurate thermometer to measure room tem-

perature. Press the UP or DOWN ARROW buttons until the number equals room temperature.

4. Press the Mode button to return to normal operation.

IX. LIGHT SENSOR ADJUSTMENT

The light sensor is used for light-activated operation. The sensor can be adjusted for a variable degree of sensitivity. The

sensitivity adjustment screw is located on the inner cover of

the thermostat, near the DOWNARROW button. Turning the

screw clockwise increases the sensitivity of the sensor to light.

Turningthe screw counterclockwise decreases the sensitivity

of the sensor to light.

To check for correct sensitivity, place the thermostat in Program On mode. The thermostat should be in Occupied 1 when

the lights are on. If the sensor does not enter Occupied 1 while

the lights are on, turn the screw clockwise until the Occupied 1 icon appears on the display. The thermostat should

enter Unoccupied mode when the lights are off. If the sensor

does not enter Unoccupied when the lights are turned off, turn

the screw counterclockwise until the Unoccupied icon

appears on the display.

IMPORTANT: An external device should not be used with the

dry contact switch with light activated operation. The light

sensor is wired to the dry contact switch. Another device will

cause conflicting signals to the thermostat. The RED wire of

the sensor is wired to CK1. The BLACK wire of the sensor is

wired to CK2.

X. CHECK THERMOSTAT OPERATION

To check thermostat operation, perform the following

procedure:

1. Press the Mode button repeatedly until the Heat icon

appears on the display. The thermostat is now in Heating mode.

2. Press the Fan button. The Fan Auto icon will appear on

the display screen. Press the UP ARROW button until

the heating set point is 10 F (6 C) higher than the current room temperature. Heating and fan should be

energized.

3. Press the Mode button repeatedly until the Cool icon

appears on the display. The thermostat is now in Cooling mode.

4. Press the DOWN ARROW button until the cooling set

point is 10 F lower than the current room temperature.

Cooling and fan should be energized.

5. Press the Mode button repeatedly until the Off icon

appears. Press the Fan button until the display reads

Fan On. The fan should energize.

6. If heating, cooling, or fan operation do not work, check

wiring and consult Table 4.

XI. FINAL CHECKLIST

1. Put away tools and instruments. Clean up debris and

packaging.

2. Review Owner’s Guide with occupant or owner.

3. Leave the manuals with owner.

—6—

Page 7

OPERATION

The Mode button selects the operating mode of the thermostat. If OFF is selected, the thermostat will not enter Heating or Cooling mode. If HEAT is selected, the thermostat will

only enter Heating mode (if the room temperature is below

the heating set point). If COOL is selected, the thermostat

will only enter Cooling mode (if the room temperature is above

the cooling set point). IfAUTO is selected, the thermostat will

enter Heating or Cooling mode based on the room temperature and the heating and cooling set points. If PROGRAM

ON is selected, the stored schedule is enabled and the thermostat will follow the Occupied and Unoccupied schedules

stored in its memory.

I. AUTO-CHANGEOVER

When the thermostat mode is set to AUTO, the thermostat will provide automatic changeover from Heating to Cooling mode and Cooling to Heating mode when required. The

thermostat will automatically switch to maintain the desired

temperature setting. The thermostat does not need to be manually changed from heating to cooling or cooling to heating

operation.

II. LIGHT-ACTIVATED OPERATION

A light sensor is provided on the thermostat for light activation. The thermostat must be in Program On mode for light

activation to be initiated. When the sensor detects light

(the space is occupied), the thermostat will enter Occupied 1

mode and heat or cool according to the Occupied 1 set points.

If the room is dark, the thermostat will follow its programmed schedule.

NOTE: Light activation does not work in Holiday mode.

III. TWO-STAGE OPERATION

The second stage of heat or cool is turned on when the first

stage has been on for a minimum of 2 minutes and the temperature differential from the set point is equal to or greater

than the set point plus the deadband plus 2 degrees.

IV. CLOCK BACKUP

In the event of a power loss, the thermostat will keep

time for a minimum of 48 hours without external power or

batteries.

V. FAN OPERATION

If Fan On is selected, the fan will run continuously during

occupied schedule (except when Mode is switched to OFF).

The fan will be off during unoccupied schedule except during

heating or cooling operation.

If Fan On is not selected, the fan will only operate during

heating or cooling operation.

VI. EMERGENCY HEAT

Emergency heat is available for heat pump applications. To

turn on emergency heat, press and hold the Fan button. While

holding the Fan button, press the UP button for 2 seconds.

An ‘‘EH’’ will be displayed. During emergency heat, the fan

will operate and the second stage of heat will be energized

(locking out the first stage compressor). To exit emergency

heat, press and hold the Fan button. While holding the Fan

button, press the UP button for 2 seconds. During emergency

heat, only OFF and HEAT modes are available.

VII. ELECTRIC HEAT

When the Electric Heat option in the advanced set up is set

to ON (configured by installer), the thermostat will turn on

the fan immediately any time there is a heat demand. This

feature should only be used on electric heating applications.

Do not use with gas heat.

VIII. HOLIDAY MODE

When the thermostat is in Holiday mode, the thermostat will

operate under Unoccupied set points. To configure and activate the Holiday mode, press the Holiday button. The ‘‘HOL’’

icon will be displayed along with the remaining days of Holiday mode operation. Press the UP or DOWN ARROWS to select the number of days that the holiday schedule will be in

effect. A value of 0 disables Holiday mode. The duration can

be set from 1 to 99 days. The thermostat will enter Holiday

mode on midnight of the next day after the mode has been

activated. Holiday mode will remain in effect until midnight

of the last configured day.

If the Holiday mode is in effect, the number of days remaining will blink on and off and the ‘‘Unoccupied’’ icon will be

displayed. The Override button will be active during Holiday

mode.

To turn off the Holiday mode before the remaining configured days have passed, press the Holiday button to enter into

the configuration mode. Press the DOWN ARROW to set the

number of days to zero. Holiday mode will be disabled.

IX. KEYPAD LOCK

To prevent unauthorized use of the thermostat, the front panel

buttons can be disabled. To disable or lock the keypad, press

and hold the Mode button. While holding down the Mode button, press the UP and DOWN ARROW buttons simultaneously. The ‘‘Locked’’ icon will appear on the display.

The thermostat is unlocked by performing the same procedure. Press and hold the Mode button. While holding down

the Mode button, press the UP and DOWN ARROW buttons

simultaneously. The ‘‘Locked’’ icon will be removed from the

display.

—7—

Page 8

TROUBLESHOOTING

Table 4 — Thermostat Troubleshooting

PROBLEM SOLUTION

Display on thermostat not illuminated. Check for 24 vac at the R terminal connection. Terminal R must

‘‘Service Filter’’ is displayed on thermostat. After the configured number of blower operating hours, the Service

Cooling will not energize. Select COOL mode. Decrease cooling set point to 10 degrees

Heating will not energize. Select HEATmode. Increase heating set point to 10 degrees above

When using 4 wires (R,G,W,Y), the cooling equipment tries repeatedly to turn on, but cannot. At

times the display dims or disappears.

When using 4 wires (R,G,W,Y), the heating equipment tries repeatedly to turn on, but cannot. At

times the display dims or disappears.

When controlling a heat pump, heat comes on

during cooling cycle.

When calling for cooling, both heating and cooling are energized.

When controlling a commercial heat pump unit,

unit runs in reverse or heating is always on.

be connected for proper thermostat operation.

Filter message will be displayed. This reminds the owner to re-

place the filter. Reset the Service Filter feature to reset the blower

operation timer to 0 hours.

below room temperature. Check for 24 vac at Y1 terminal. If present,

thermostat is operating correctly and problem is with wiring or equipment. If 24 vac is not present, replace the thermostat. Check for

Compressor Cycle per Hour Limit. Cooling may be locked out.

room temperature. Check for 24 vac at W1/O/B terminal. If present,

thermostat is operating correctly and problem is with wiring or equipment. If 24 vac is not present, replace the thermostat.

There is not enough power available. Connect a 270 ohm, 10 watt

power resistor at the air-conditioning equipment between terminals

W and C (non-heat pump applications only).

There is not enough power available. Connect a 270 ohm, 10 watt

power resistor at the air-conditioning equipment between terminals

Y and C (non-heat pump applications only).

Configure thermostat for heat pump operation (Table 2, Step 3).

The thermostat is configured for a heat pump. Configure the

thermostat for non-heat pump operation (Table 2, Step 3).

Commercial heat pumps require that Heat Pump Option on

thermostat is turned OFF.

Copyright 1998 Bryant Heating & Cooling Systems CATALOG NO. 809-683

Loading...

Loading...