Page 1

SYSTXBBUIZ01--D

EVOLUTIONt CONTROL

Installation Instructions

A09484

Fig. 1 -- Evolutiont Zone Control

NOTE: Read the entire instruction manual before starting the

installation.

US Patents: Carrierr U.S. Pat No. 7,243,004, Carrierr U.S. Pat No. 7,775,452

TABLE OF CONTENTS

PAGE

SAFETY CONSIDERATIONS 1.........................

INTRODUCTION 1...................................

INSTALLATION AND START --UP OVERVIEW 2..........

INSTALLATION 2....................................

INSTALLING EVOLUTION ZONE CONTROL 3...........

INITIAL POWER--UP 5................................

QUICK START 7.....................................

INSTALL / SERVICE MENUS 8.........................

EQUIPMENT SUMMARY MENU 8......................

INSTALL MENU 8....................................

SETUP MENU 8......................................

CHECKOUT MENUS 13...............................

SERVICE MENUS 14..................................

OPERATIONAL INFORMATION 15.....................

TROUBLESHOOTING 18..............................

SYSTEM MALFUNCTION SCREEN 19..................

SAFETY CONSIDERA TIONS

Improper installation, adjustment, alteration, service, maintenance,

or use can cause explosion, fire, electrical shock, or other

conditions which may cause death, personal injury or property

damage. Consult a qualified installer, service agency or your

distributor or branch for information or assistance. The qualified

installer or agency must use factory--authorized kits or accessories

when modifying this product. Refer to the individual instructions

packaged with the kits or accessories when installing.

Follow all safety codes. Wear safety glasses, protective clothing,

and work gloves. Have a fire extinguisher available. Read these

instructions thoroughly and follow all warnings and cautions

included in literature and attached to the unit. Consult local

building codes and the current edition of the National Electrical

Code (NEC) NFPA 70.

In Canada, refer to the current editions of the Canadian Electrical

Code CSA C22.1.

Recognize safety information. When you see this symbol

the unit and in instructions or manuals, be alert to the potential for

personal injury. Understand the signal words DANGER,

WARNING,andCAUTION. These words are used with the

safety --alert symbol. DANGER identifies the most serious hazards,

which will result in severe personal injury or death. WARNING

signifies hazards, which could result in personal injury or death.

CAUTION is used to identify unsafe practices, which may result

in minor personal injury or product and property damage. NOTE

is used to highlight suggestions which will result in enhanced

installation, reliability, or operation.

on

INTRODUCTION

The Evolution Zone System consists of several intelligent

communicating components which includes the Evolution Zone

Control (or User Interface), Smart Sensors, Damper Control

Module, variable speed furnace or FE fan coil, 2--stage AC or HP

and Evolution Packaged Products, which continually communicate

with each other via a four--wire connection called the ABCD bus.

Commands, operating conditions, and other data are passed

continually between components over the ABCD bus. The result is

a new level of comfort, versatility, and simplicity.

All Evolution furnaces or fan coils are variable--speed and

multi--stage for maximum flexibility, efficiency, and comfort. They

support controlled ventilation, humidification, dehumidification,

and air quality control. Either an Evolution (communicating) or a

standard 24VAC controlled outdoor unit may be used.

When using conventional outdoor units, the Evolution furnace or

fan coil provides the 24 volt signals needed to control them. Also,

the Evolution Damper Control Module (P/N SYSTXBB4ZC01)

allows connection of a Bryant HRV or ERV without the need for a

separate wall control.

All system components are controlled through the wall mounted

Evolution Zone Control, which replaces the conventional

thermostat and provides the homeowner with a single wall control

for all features of the system.

Page 2

Design Considerations

The Evolution Zone system is unique because a bypass damper

must not be used. This is possible due to the intelligence of the

system and variable speed motor technology. For trouble--free

applications, the following parameters should always be met:

1. Zones should be sized so that each zone can deliver at least

the minimum airflow for the system in both heating and

cooling modes.

2. Oversize duct work by 25% to avoid excess noise at minimum zone airflow.

3. Be aware that heating airflow may be higher than cooling

airflow depending on equipment combination.

INSTALLATION, START--UP OVERVIEW

This instruction covers installation of the Evolution Zone Control

only. Physical installation instructions for the indoor and outdoor

equipment, Damper Control Module, and accessories are provided

with each unit.

Setup, commissioning, operation, and troubleshooting of the

Evolution Zone System are covered in this installation instruction.

It is the guide to connecting the system components and

UIZ01--D

commissioning the system once all physical components are

installed. Special screen prompts and start--up capabilities are

provided in the Evolution System to simplify and automate the

initial commissioning of the system.

S Install Evolution Zone Control according to this instruction.

S Install indoor unit, outdoor unit, and accessories according to

their instructions.

S Wire complete system according to this instruction.

S Setup, commission, and operate system according to this

instruction to assure a smooth and trouble free start--up.

INSTALLATION

Check Equipment and Job Site

Inspect equipment. File claim with shipping company prior to

installation if shipment is damaged or incomplete.

Evolution Zone Control Location and Wiring

Considerations

The Evolution Zone Control and Room Sensors should NOT be

mounted:

S Close to a window, on an outside wall, or next to a door leading

to the outside.

S Exposed to direct light or heat from a lamp, sun, fireplace, or

other temperature--radiating objects which could cause a false

reading.

S Close to or in direct airflow from supply registers.

S In areas with poor air circulation, such as behind a door or in an

alcove.

Remote Room Sensor Option

A Remote Room Sensor can be used with the Evolution Zone

Control to take the place of the User Interface internal temperature

sensor. This allows the Evolution Zone Control to be mounted in

areas with less than optimal airflow (such as near an exterior door,

window or in a closet). The remote sensor can be wired to the

terminal block connectors labeled S1 and S2 at the User Interface

backplate, or the ZS1 and ZS1C connection at the Damper Control

Module. In either case, the Evolution Zone Control will

automatically detect the Remote Room Sensor and ignore its

internal temperature sensor. It is also important to note the

humidity sensor cannot be remotely located, so do not locate the

Evolution Zone Control in an area where humidity sensing may

not be accurate.

In addition, the Remote Room Sensor is a temperature sensor only,

having no additional user inputs. This sensor is typically connected

to the Damper Control Module and used to sense and control

temperature in each zone.

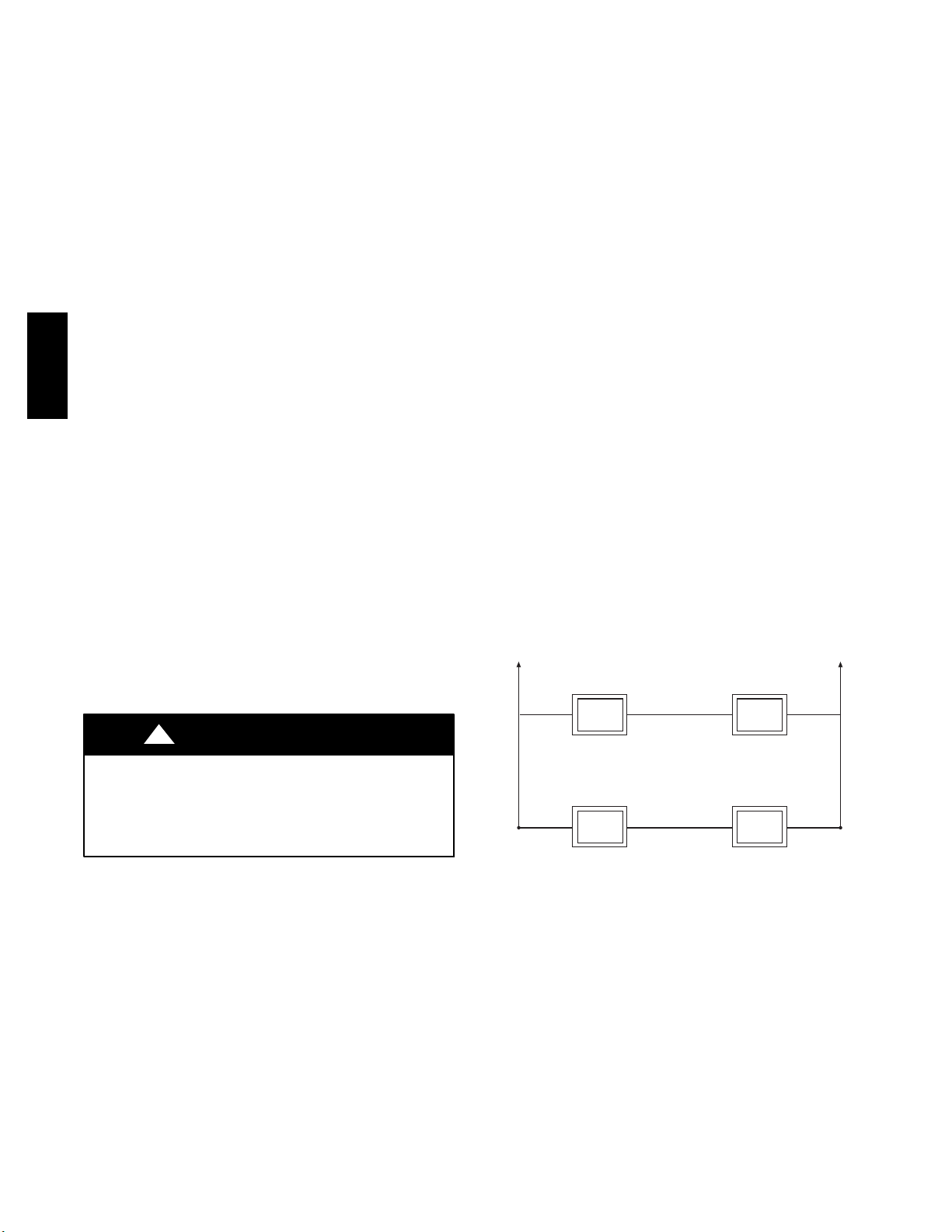

Remote Sensor Averaging

Typically, one Remote Room Sensor is used per zone, but multiple

sensors may be used and averaged in some applications. Averaging

requires a special series--parallel wiring method with a specific

number of sensors. See Fig. 2 in this manual for wiring diagram.

Damper Control

Module

ZS_

Damper Control

Module

ZS_C

!

WARNING

ELECTRICAL OPERATION HAZARD

Failure to follow this warning could result in personal injury

or death.

Disconnect power before routing control wiring.

All wiring must comply with national, local, and state codes.

Evolution Zone Control Location

The Evolution Zone Control User Interface is the command center

for the Evolution Zone System and is typically located in Zone 1 to

sense and control temperature in this zone. It should be located

where it is easily accessible and visible to the adult homeowner or

end user.

For accurate temperature measurement, the following guidelines

should be followed:

The Evolution Zone Control and Room Sensors should be

mounted:

S Approximately 5--ft (1.5 meters) from the floor.

S Close to or in a frequently used room, preferably on an inside

partitioning wall.

S On a section of wall without pipes or ductwork.

Sensor 1 Sensor 2

Sensor 3 Sensor 4

A03233

Fig. 2 -- Remote Room Sensor -- Parallel Wiring

Smart Sensor

Any zone may use a Smart Sensor. It provides a temperature

display and buttons to adjust the desired temperature in that zone

only. It also displays outdoor temperature and indoor humidity

sensed at the User Interface. Only one Smart Sensor may be used

per zone. They cannot be averaged like Remote Room Sensors. If a

Smart Sensor is used in a zone, a Remote Room Sensor may also

be used in the same zone. The Remote Room Sensor has priority

over the Smart Sensor. The Smart Sensor will display the Remote

Room Sensor temperature.

NOTE: Smart Sensors must be addressed to identify which zone it

will control. See Smart Sensor Installation Instructions for details.

2

Page 3

Wiring Considerations

Ordinary thermostat wire is recommended. Use 22 AWG or larger

for normal wiring applications. Continuous wire lengths over

100-- ft. (3 m) should use 20 AWG or larger.

NOTE: ABCD bus wiring only requires a four--wire connection;

however, it is good practice to run thermostat cable having more

than four wires in the event of a damaged or broken wire during

installation.

Each communicating device in the Evolution Zone System has a

four--pin connector labeled ABCD. It is recommended that the

following color code be used when wiring each device:

A — Green = Data A

B — Yellow = Data B

C — White = 24VAC (Com)

D — Red = 24VAC (Hot)

It is not mandatory that the above color code be used, but each

ABCD connector in the system MUST be wired consistently.

Shielded Wire

If the thermostat wiring will be located near or in parallel with high

voltage wiring, cable TV, Ethernet wiring, or radio frequency

equipment, then shielded thermostat wire can be used to reduce or

eliminate potential interference. The shield wire should be

connected to the C terminal, or ground, at the indoor unit. The

shield wire should NOT be connected to any terminal at the user

interface. Connecting the shield to ground at both ends can cause

current loops in the shield, reducing shield effectiveness.

Locating Damper Control Module

All wiring is run back to the Damper Control Module. Select a

location near the furnace or fan coil where wiring from the User

Interface, each Remote Room Sensor or Smart Sensor, each

damper actuator, and the equipment itself can come together easily.

The Damper Control Module is approved for indoor use only and

should never be installed with any of its components exposed to

the elements. The Damper Control Module (and zone dampers)

may be installed in any area where the temperature remains

between --4_F to 158_F(--20_Cto70_C), and there is no

condensation. The cover must be installed to prevent damage from

other sources. Do not locate where it will be accessible to children.

It may be mounted in either vertical or horizontal position.

Remember that wiring access is likely the most important

consideration.

!

CAUTION

ELECTRICAL OPERATION HAZARD

Failure to follow this caution may result in equipment damage

or improper operation.

To prevent possible damage to the Damper Control Module,

DO NOT mount on plenum, ductwork, or flush against

furnace or fan coil.

A

B

C

D

S1

S2

A09441

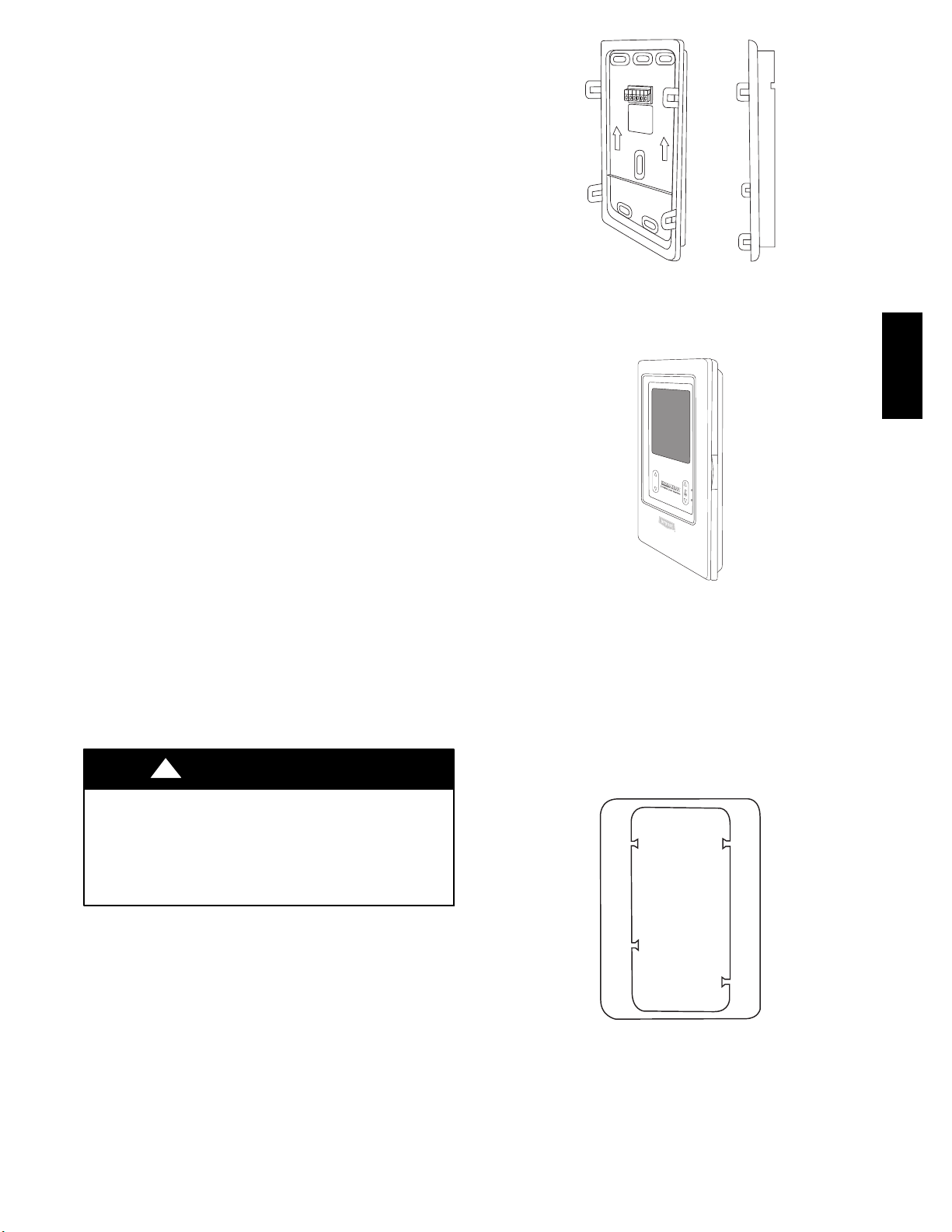

Fig. 3 -- Backplate

A backplate is supplied (See Fig. 4). Attach backplate to the wall

using only a small hole in the wall allowing a four wire connection

to pass through. Mount the assembly to the backplate.

A09486

Fig. 4 -- Evolutiont Zone Control

NOTE: Once Evolution Zone Control is secured to wall with the

backplate assembly (snapped together), care must be taken not to

bend or break the interlocking tabs when removing.

Decorative Backplate

Sold separately, a thin decorative backplate (see Fig. 5) is available

to hide any marks/screw holes left from the previous thermostat.

This decorative backplate (or beauty ring) is used by snapping it

onto the back of the mounting plate before securing the plate to the

wall.

UIZ01--D

Mounting Evolution Zone Control

First, become familiar with all plastic assembly pieces shown in

Figures 3 through 6. The User Interface will snap together with the

backplate.

A04017

Fig. 5 -- Decorative Backplate

3

Page 4

A

B

C

D

S1

S2

ZONING

®

User Interface

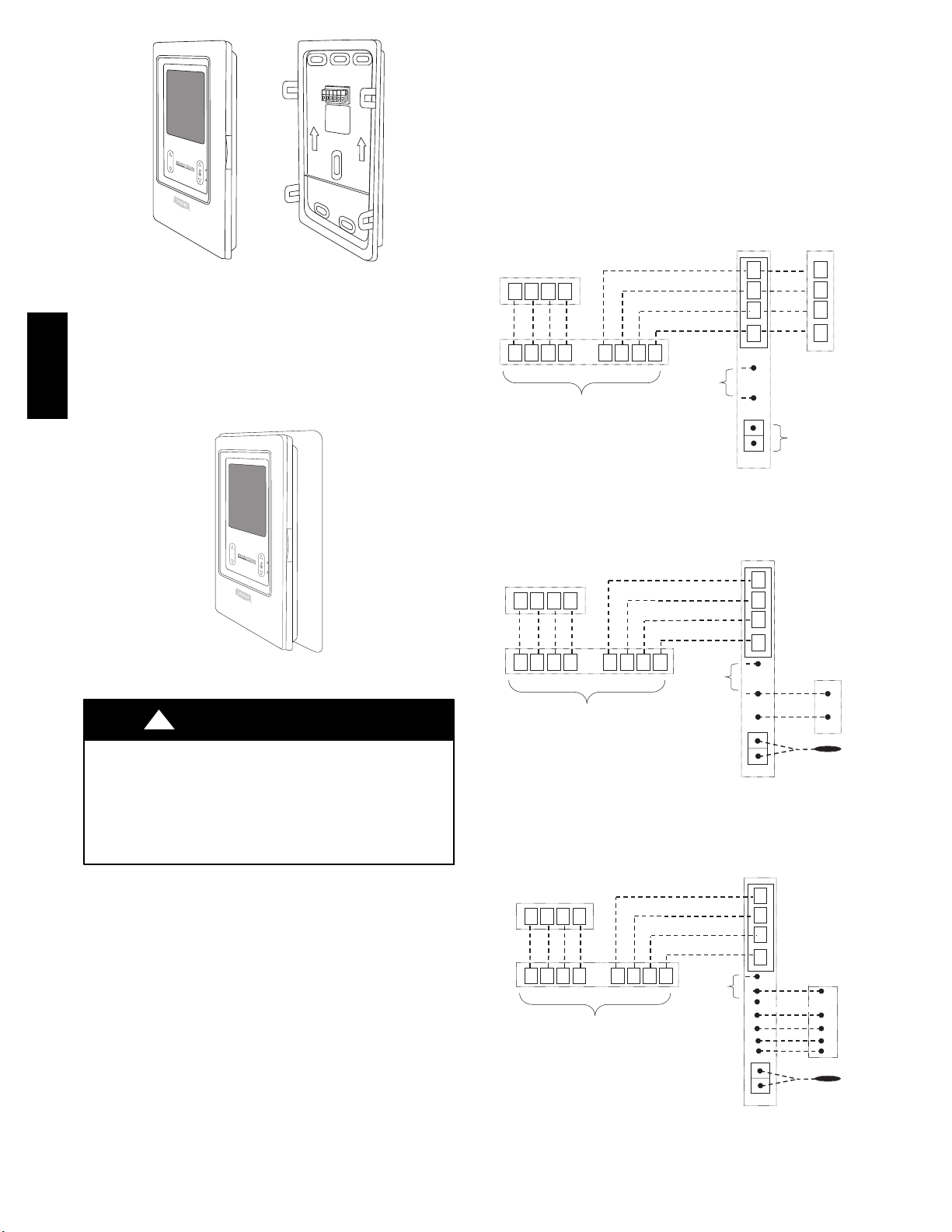

Fig. 6 -- Assembly

INSTALLING EVOLUTION ZONE

CONTROL

Removing Evolution Con trol

To remove the control from the base, insert a flat screw driver into

UIZ01--D

each of the four slots (two on each side) and pry towards yourself

to release the holding tabs. Refer to Fig. 7 to locate the slots.

Deluxe

®

User Interface

Fig. 7 -- Decorative Backplate Assembly

!

WARNING

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in personal injury

or death.

Before installing Evolution Zone Control, turn off all power

to equipment. There may be more than one power source to

disconnect.

1. Turn off all power to equipment.

2. If an existing User Interface or control is being replaced:

a. Remove existing control from wall.

b. Disconnect wires from existing control.

c. Discard or recycle old control.

NOTE: Mercury is a hazardous waste, if existing control contains

any mercury, it MUST be disposed of properly. The User Interface

does not contain mercury.

3. Select Evolution Zone Control mounting plastic (recess

mount or surface mount and decorative backplate if desired).

4. Route wires through large hole in mounting plastic. Level

rear plastic against wall (for aesthetic value only -- Evolution Zone Control need not be level to operate properly) and

mark wall through two mounting holes.

A09488

A09434

5. Drill two 3/16--in. (4.8 mm) mounting holes in wall where

marked.

6. Secure mounting plastic to wall using two screws and anchors provided.

7. Adjust length and routing of each wire to reach each wire

entry on the connector backplate. Strip 1/4--in. (6.4 mm) of

insulation from each wire.

8. Match and connect thermostat wires to proper terminals on

User Interface backplate. See wiring diagram Fig. 8, 9, and

10.

Zone Control

User Interface &

Smart Sensor(s)

A B C D

A B C D A B C D

Damper

Control

module

Green

Yellow

White

Red

Humidifier

Connection

Indoor

Unit

HUM

COM

24V

OAT

A

B

C

D

Communicating

AC or HP

OAT

Sensor

(Optional)

Fig. 8 -- Communicating Indoor Unit w/2--Stage Puronr

Refrigerant Communicating Outdoor Unit

Indoor

Zone Control

User Interface &

Smart Sensor(s)

A B C D

A B C D A B C D

Damper

Control

module

Green

Yellow

White

Red

Humidifier

Connection

Unit

HUM

COM

24V

Y/Y2

OAT

A

B

C

D

1-Stage AC.

Fig. 9 -- Connection Diagram for Furnace or FE Fan Coil

with Non--Communicating 1--Stage AC

Green

Yellow

White

Red

Humidifier

Connection

Variable-Speed

Fan Coil

A

B

C

D

HUM

C

G

R

O

W

Y

OAT

1-Spd. HP

Zone Control

User Interface &

Smart Sensor(s)

A B C D

A B C D A B C D

Damper

Control

module

Fig. 10 -- Connection Diagram for FE Fan Coil with

Non-- Communicating 1--stage HP

A

B

C

D

C

Y

OAT

Sensor

C

R

O

W2

Y

OAT

Sensor

A04018

A04019

A07149

4

Page 5

A — Green = Data A

B — Yellow = Data B

C — White = 24VAC (Com)

D — Red = 24VAC (Hot)

NOTE: It is not mandatory that the above color code be used, but

each ABCD connection in the system MUST be wired consistently.

A separate ABCD Connector comes inside packaging and should

be used when connecting to furnace (or fan coil). Ensure connector

is inserted properly into circuit board. (See Fig. 11.)

ABCD

A03193

Fig. 11 -- Wire ABCD Connector

Bypass Humidifiers

A bypass humidifier should be wired directly to the furnace or fan

coil HUM and 24VAC COM terminals. The Evolution Zone

Control will automatically energize the HUM output during a call

for humidification.

Fan Powered Humidifiers

Most fan powered humidifiers produce internal 24VAC in order to

energize upon a switch or contact closure. For this application, a

24VAC N.O. Isolation Relay (DPST) MUST be used to prevent

mixing the internal humidifier power with the indoor equipment

transformer. Applying 24VAC isolation relay coil to furnace or fan

coil HUM and COM terminals will allow the Evolution Zone

Control to automatically energize the HUM output during a call for

humidification. The N.O. relay contacts will be used to energize the

humidifier. See fan powered humidifier installation instructions for

more details.

!

CAUTION

ELECTRICAL OPERATION HAZARD

Failure to follow this caution may result in equipment damage

or improper operation.

Improper wiring of the ABCD connector will cause the

Evolution Zone System to operate improperly. Check to make

sure all wiring is correct before proceeding with installation or

turning on power.

9. Push any excess wire into the wall. Seal hole in wall to prevent any air leaks. Leaks can affect operation.

10. Attach Evolution Zone Control to the mounting plastic by

lining up the plastic guides on the back of the control with

the opening on the mounting plastic and push on.

11. Perform installation of all other system equipment (i.e.

dampers, humidifier, ventilator, UV lights, etc.).

12. Turn on power to equipment.

See wiring diagrams Fig. 8, 9, and 10 for connecting the Evolution

Zone Control and Smart Sensors to the Damper Control Module.

More information regarding Damper Control set--up and wiring

can be found in Damper Control Module Installation Instructions.

See wiring diagram, Fig. 8, which includes an indoor

communicating furnace or FE fan coil, with a 2-- stage Puronr

refrigerant communicating outdoor unit. No additional OAT

(outdoor air temperature) sensor is required because the Evolution

Zone Control will use the temperature sensor inside the outdoor

unit.

In a hybrid heat installation with a non--communicating heat pump,

an OAT sensor must be installed or the heat pump will not run.

See wiring diagram, Fig. 9, for connecting an indoor

communicating furnace or FE fan coil with a 1--stage air

conditioning unit (non--communicating outdoor). An Outdoor Air

Temperature (OAT) sensor may be installed (but is not required) at

the indoor furnace or fan coil OAT terminals. When OAT sensor is

applied, the Evolution System will provide enhanced system

features and benefits.

See wiring diagram Fig. 10 for connecting an FE fan coil with a

1-- stage heat pump (non--communicating outdoor unit). When

OAT is applied, the Evolution System will provide enhanced

system features and benefits.

NOTE: For other applications not listed, refer to the Network

Interface Module (NIM) Installation Instructions.

Humidifier Connection

A 24VAC bypass or fan powered humidifier may be installed.

NOTE: Do Not Use a traditional humidistat to control humidifier

operation. If a humidifier is installed, let the Evolution Zone

Control operate humidifier.

!

CAUTION

EQUIPMENT HAZARD

Failure to follow this caution may result in equipment damage.

Do not apply 24VAC fan powered humidifier (with internal

power supply) direct to indoor unit HUM and COM terminals.

INITIAL POWER--UP

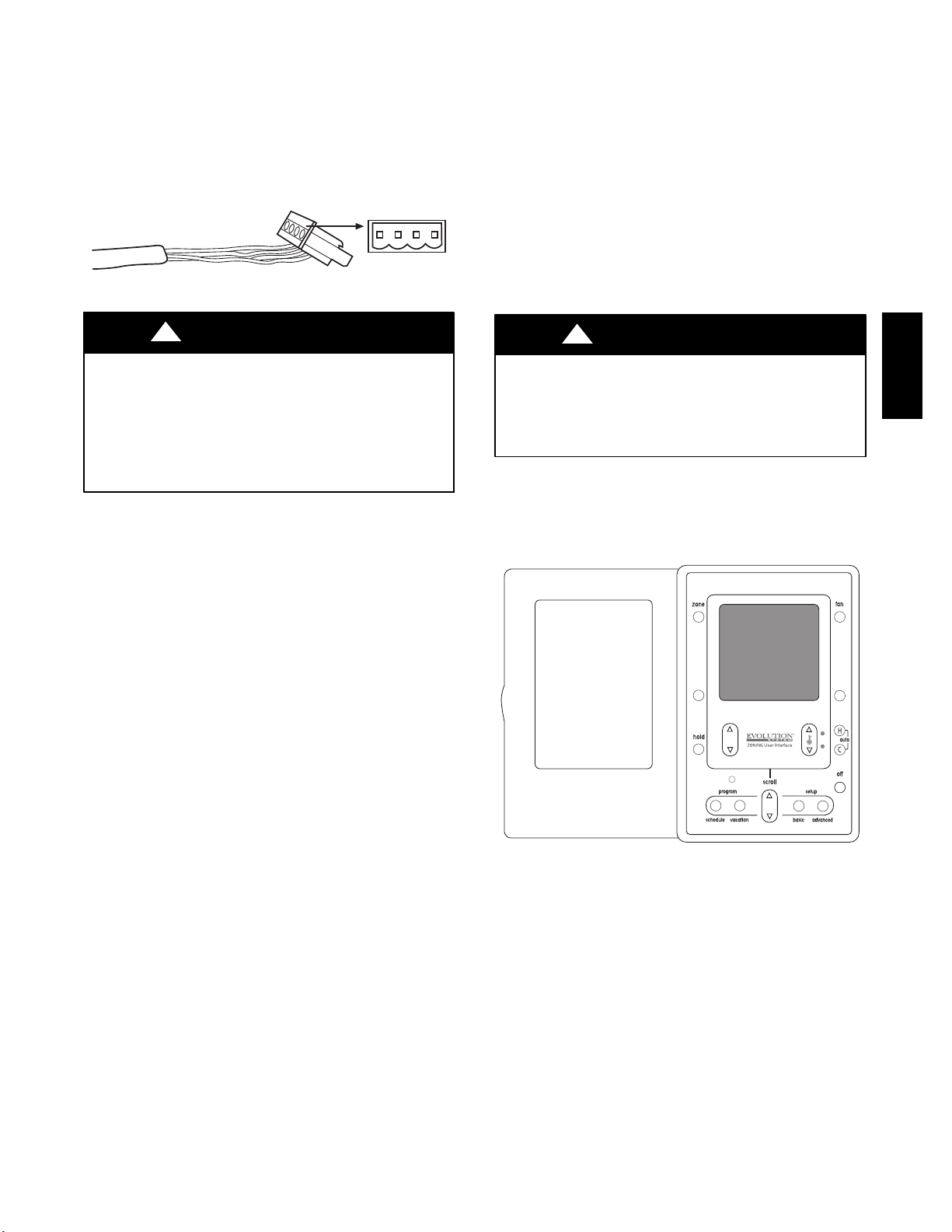

NOTE: Refer to Functional Overview (Fig. 12) to become

familiar with key function buttons such as “System On/Off”,

“Zone”, “Fan”, “Left--Side” and “Right--Side” buttons, etc. These

function buttons will be used frequently during setup.

A09482

Fig. 12 -- Functional Overview

Power Up Sequence

This section addresses initial power up (or commissioning) of a

new Evolution Zone Control. The User Interface will communicate

and identify all Evolution components in the system. The

following is a typical example for a communicating

Variable--Speed Furnace / Fan Coil with a 2--stage Air Conditioner

/ Heat Pump (including Hybrid Heat).

The User Interface display will light up and indicate that it is now

“ESTABLISHING COMMUNICATIONS WITH EQUIPMENT

PLEASE WAIT”. The User Interface will automatically continue

by “SEARCHING FOR EQUIPMENT”, followed by

“SEARCHING FOR OUTDOOR EQUIPMENT” (See Fig. 13).

Once the indoor and outdoor equipment has been found, the

Installer will be asked to select Accessories. Packaged Products

will be automatically identified and the Installer will be asked to

select Accessories. Proceed to Selecting Accessories.

UIZ01--D

5

Page 6

ESTABLISHING

COMMUNICATIONS

WITH EQUIPMENT

PLEASE WAIT

SOFTWARE

VERSION

INDOOR UNIT

SEARCHING FOR

INDOOR EQUIPMENT

WORKING

OUTDOOR UNIT

SEARCHING FOR

OUTDOOR EQUIPMENT

WORKING

Fig. 13 -- Power Up Sequence

NOTE: If the variable--speed indoor equipment (furnace or fan

coil) cannot be found, the User Interface will display “CANNOT

COMMUNICATE WITH INDOOR UNIT”. This MUST be

corrected before the initial power up sequence can continue. If

indoor unit is found, but outdoor unit is not found, “OUTDOOR

UNIT NOT IDENTIFIED” will appear. Proceed to the next section

for Outdoor Unit Identification.

Selecting Outdoor Unit

If there is no communicating outdoor unit, the screen, shown in

Fig. 14, will appear. Press either Left or Right Up/Down button to

select AC (air conditioner), HP (heat pump), or None (no unit

UIZ01--D

installed). Press right--side button to continue to next screen.

OUTDOOR UNIT

NOT IDENTIFIED

SELECT TYPE:

NONE, AC, HP

PRESS +/- TO MAKE

SELECTION

CONTINUE

NONE

OUTDOOR UNIT

ENTER HEAT PUMP

SIZE

18000 TO 60000 BTU

PRESS +/- TO MAKE

BACK CONTINUE

36000 BTU

SELECTION

OUTDOOR UNIT

HEAT PUMP

ENTER NUMBER OF

SPEEDS, 1 or 2:

PRESS +/- TO MAKE

SELECTION

BACK CONTINUE

Fig. 14 -- Selecting Outdoor Unit

If either AC or HP has been selected as the outdoor unit type, the

middle screen will appear (See Fig. 14). Press either Left or Right

Up/Down button to select appropriate Btu size of outdoor unit,

then press right side button to continue. If a NIM (Network

Interface Module) is applied for non --communicating two--stage

outdoor equipment, select 1 or 2 --stage compressor operation, and

press right--side button to continue.

NOTE: Range of outdoor unit Btu selection is limited by model

number of indoor unit installed. The Evolution Zone Control will

not allow an outdoor unit size that is not supported by the installed

indoor unit.

NOTE: On new system installations, the model and serial number

will be recognized and displayed. On any indoor/outdoor board

replacements, the equipment will be recognized but the exact

model/serial number will not be displayed.

Selecting Electric Heater

If the equipment is a fan coil, packaged heat pump, or packaged

AC and the electric heater is not self--identifying, “ELECTRIC

HEATER NOT IDENTIFIED” will appear (See Fig. 15). Press

either Left or Right Up/Down button to select appropriate size of

electric heater installed, then press right--side button to continue.

An asterisks (*) will appear next to electric heater sizes that may

cause excessive airflow.

ELECTRIC HEATER

NOT IDENTIFIED

ENTER SIZE:

NONE, 5,10,15 KW

PRESS +/- TO MAKE

SELECTION

BACK CONTINUE

Fig. 15 -- Selecting Electric Heater

5 KW

A03195

1

A03196

A03197

NOTE: Range of electric heaters available is limited by model

number of the equipment installed. The Evolution Zone Control

will not allow an electric heater size that is not supported by the

installed equipment.

Hydronic Heat Applications

The Evolution Zone Control supports Hydronic Heat applications

in the form of a hot water coil on FE fan coils only. If an FE fan

coil is installed, a Hydronic Heat kit should be installed in place of

the electric heater. See FE fan coil Product Data for accessory part

number. The system will identify that hydonic heat has been

installed during the initial commissioning process. The system will

treat the hot water coil as either auxiliary heat in a heat pump

application, or the sole heat source. Setup options for Hydronic

Heat applications are described in the Setup section of this

instruction.

Selecting Accessories

Once the indoor and outdoor equipment have been found or

entered, the following screens will appear allowing the Installer to

select the “AIR FILTER TYPE; HUMIDIFIER INSTALLED”;

and “UV LIGHTS INSTALLED” (See Fig. 16). Use either Left or

Right Up/Down button to make appropriate selections in the

highlighted area on the display screen. Press right--side button to

continue (or advance) to the next screen.

ACCESSORIES

AIR FILTER TYPE:

EAC

MEDIA

MEDIA + EAC

PRESS +/- TO MAKE

SELECTION

CONTINUE

AIR FILTER MEDIA TYPE HUMIDIFIER INSTALLED? U.V. LIGHTS INSTALLED?

EAC

ACCESSORIES

HUMIDIFIER

INSTALLED?

PRESS +/- TO MAKE

SELECTION

BACK CONTINUE

YES

ACCESSORIES

U.V. LIGHTS

INSTALLED?

PRESS +/- TO MAKE

SELECTION

BACK CONTINUE

YES

A03198

Fig. 16 -- Accessories —UV Lights

Air Filter Type

This accessory screen will appear first. The installer will need to

enter the type of filter (AIR FILTER, AIR CLEANER, or AIR

PURIFIER). See Table 1 and make a selection using Left or Right

Up/Down button, then press right--side button to continue.

Table 1 – Filter Selection

INSTALLED FILTER

1inchto4inchmedia AIR FILTER

High voltage EAC AIR CLEANER

Evolutiont Air Purifier AIR PURIFIER

MENU

SELECTION

Humidifier Installed

This will appear after the Air Filter Type screen. Select whether a

humidifier is installed on the system, YES or NO, then press

right--side button to continue.

UV Lights Installed

This screen will appear to select whether UV lights are installed on

the system, select YES or NO, then press right--side button to

continue.

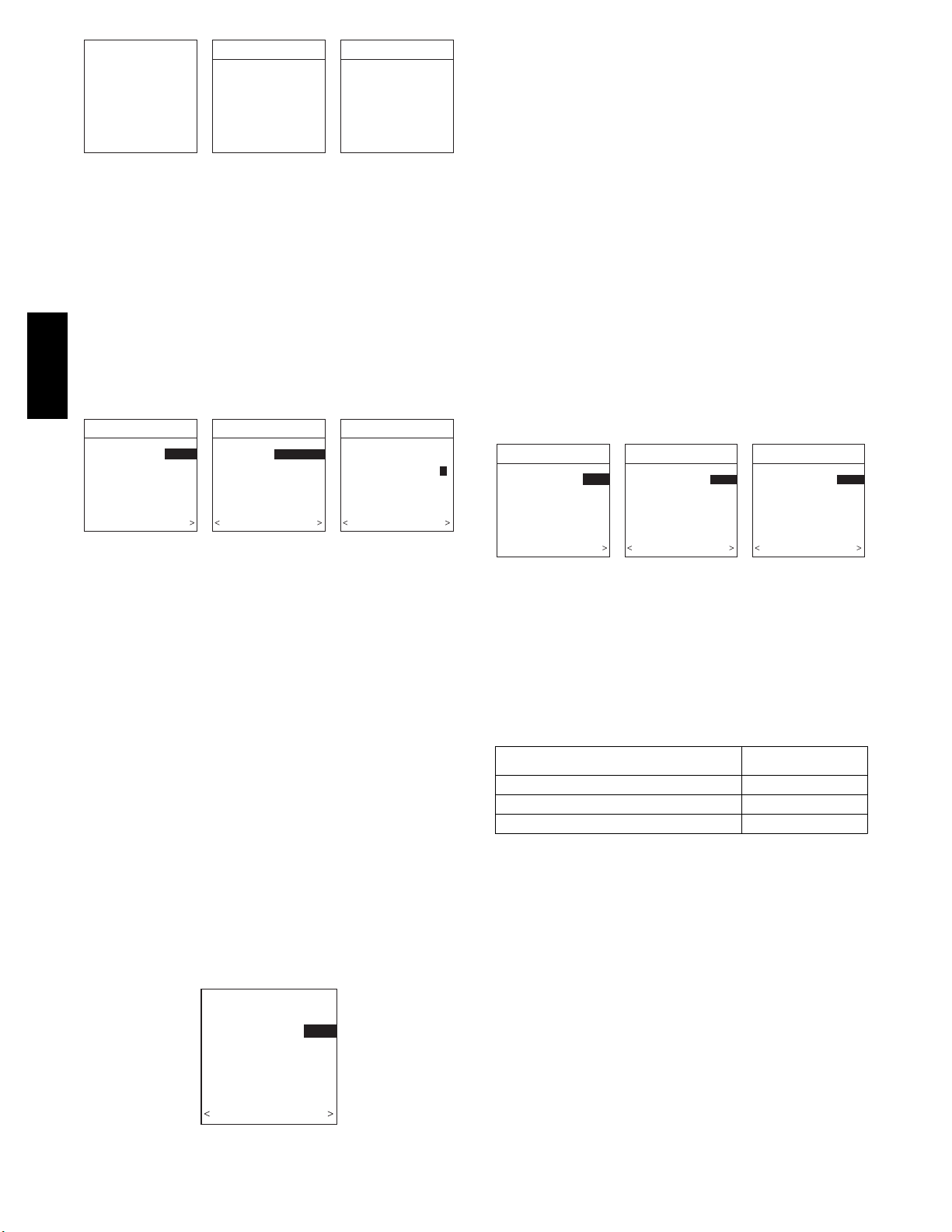

Zoning

“SEARCHING FOR ZONE EQUIPMENT” will appear on the

screen to identify the number of zones detected. This screen will

show Zone 1, Zone 2, etc. and indicate all zones having either a

Remote Room Sensor, or smart sensors associated with them. If the

system contains smart sensors, they must be assigned a zone

number before continuing. See Smart Sensor Installation

Instructions on how to assign Smart Sensors to their respective

zones. When finished, press right--side button to continue. See Fig.

17.

6

Page 7

ZONING

SEARCHING FOR

ZONE EQUIPMENT

WORKING

ZONE 1 UI

ZONE 2 RS

ZONE 3 RS

ZONE 4 RS

UI=USER INTERFACE

RS=REMOTE SENSOR

SS=SMART SENSOR

BACK CONTINUE

ZONING

A04084

Fig. 17 -- Zoning

Equipment Summary

The “EQUIPMENT SUMMARY” screen will appear after

Accessories have been selected. This screen will give a summary of

all equipment automatically found or manually selected. If a wrong

selection was made, press left--side button (BACK selection) to go

back to that particular screen and make changes. When everything

is OK, press right--side button again to continue. (See Fig. 18.)

EQUIPMENT SUMMARY

FURNACE 58MVB0100-12

AC

FILTER EAC

HUMIDIFIER YES

UV LIGHTS YES

ZONES 12345678

NO YES

24ANA136A003

SETUP

COMPLETE!

SAVE

ALL SELECTIONS/

NO YES

A07024

Fig. 18 -- Equipment Summary

The “SETUP COMPLETE! SAVE ALL SELECTIONS?” screen

will appear after Equipment Summary. To Save All Selections

press (YES) right--side button. Pressing the left--side button (NO

selection) will return to the Equipment Summary screen where

changes can be performed to any of the equipment selection

screens. After selecting YES, the initial power up sequence of the

new Evolution Zone Control is complete.

Static Pressure Check

STATIC

PRESSURE

CHECK

PLEASE WAIT

Fig. 19 -- Static Pressure Check

This screen will appear after Setup is exited. The system will open

all dampers and perform a static pressure check. This process will

take about 1-- 1/2 minutes to complete. When completed, a screen

will appear displaying the static pressure (in inches) across the

equipment at the expected highest delivered airflow. If the blower

RPM is greater than 1200, then a warning will appear, but

equipment operation and the TrueSenset dirty filter detection

operation will not be affected.

NOTE: The static pressure check occurs only at initial installation,

or when INSTALL is run in the INSTALL/SERVICE menu.

EXTERNAL STATIC

PRESSURE

MEASURED:

0.72 INCHES

AT 1200 CFM

CONTINUE >

A05000

Duct Assessment

The following screen will appear after STATIC PRESSURE screen

is exited. Press right--side button to start Duct Assessment. Duct

Assessment will measure the relative size of the ductwork, up to

and through the dampers. These measurements are used to control

the correct amount of airflow in the zoned system. Status messages

will appear on the screen to indicate what the system is doing. The

process will take approximately one minute per zone. The duct

assessment will override a call for heat or cool.

A duct assessment will automatically occur each day at a user

selectable time. The factory default time is 1:00 p.m. but, may be

changed by entering the Zoning Setup menu. See Zoning Setup

section of this manual. The duct assessment will override a call for

heat or cool. The system will first open all zones and drive the

blower to 175 CFM/ton o f cooling (or the minimum indoor unit’s

airflow, whichever is greater). It will then take a static pressure

measurement. The system will then close all zones and open one

zone at a time, taking a static pressure measurement for each zone.

The system will then close all zones and take a pressure

measurement, getting a value for the duct leakage up to and

through the dampers. With these static pressure measurements, the

system will calculate the relative size of each zone as well as the

percent leakage through the dampers At the end of the process, the

display will show the relative size of each zone duct. See Fig. 20.

If the User Interface detects an error (damper not moving or

damper wired backwards), it will perform the duct assessment

again. If it still detects a damper problem, it will default the

measurements into equal sizes, with 10% leakage, and display the

zone number for the suspected zone damper.

DUCT ASSESSMENT

MEASURE DUCT

CAPACITY FOR EACH

ZONE.

4 MINUTES ARE REQUIRED

TO COMPLETE

PRESS START TO BEGIN

QUIT START

DUCT ASSESSMENT

ASSESSMENT ACTIVE

PLEASE WAIT

OPENING ALL ZONES

AIRFLOW STABILIZING

PROGRESS

STOP

DUCT ASSESSMENT

ZONE CAPACITY

ZONE1 25

ZONE 2 20

ZONE 3 25

ZONE 4 20

DAMPER LEAKAGE 10

QUIT START

A04085

Fig. 20 -- Duct Assessment

QUICK START

For first time installers, Quick Start will allow a quick start up of

the Evolution Zone System before learning all the details of system

operation. However, for the best possible comfort and operation

refer to the Evolution Zone Control Owner’s Manual.

Set Day, Time & Desired Humidity

1. Open the door of the Evolution Zone Control and press the

BASIC button.

2. Adjust the highlighted HOUR setting using the LEFT Up/

Down button.

3. Press SCROLL button (down) to highlight MINUTE.

4. Adjust the MINUTE setting using the LEFT Up/Down

button.

5. Press SCROLL button (down) to highlight DAY.

6. Adjust the current DAY setting using the LEFT Up/Down

button.

7. Press SCROLL button (down) to highlight HUMIDITY.

8. Press the red HEAT button to select heating humidity.

9. Adjust desired heating humidity level using either (+/--) button.

10. Press the blue COOL button to select cooling humidity.

11. Adjust the desired cooling humidity level using either(+/--)button.

12. To exit press BASIC button or close door.

13. If changes are made, you will be asked to “SAVE

CHANGES? YES/NO.”

UIZ01--D

7

Page 8

Override Heating Schedule

1. Press the red HEAT button. Heating mode is confirmed

when the red LED next to the red HEAT button is lit.

2. Use the RIGHT Up/Down button to select your desired

heating temperature.

3. The default time for temporarily overriding the temperature

schedule is 2:00 HRS as indicated by the text on the lower

left.

NOTE: Override time will not appear if programming has been

turned off.

4. You can change the temporary override time in 15--minute

increments by pressing the LEFT Up/Down button until

the desired override time is selected, or press the HOLD

button anytime to override the schedule indefinitely.

Quick Program Schedule For All Days

This section will give you a quick program schedule for ALL

DAYS of the week. For more information on how to create

customized schedules for every day, the entire week, or weekend,

refer to the Owner’s Manual.

UIZ01--D

1. Open the door of the control.

2. Press the SCHEDULE button, which allows you to create

one schedule for the entire home.

3. Press either the LEFT or RIGHT side button repeatedly (if

necessary) until “ALLDAYS” is displayed. The WA K E

time period will be highlighted.

4. Using the LEFT Up/Down button, set the start time for this

time period.

5. Press the red HEAT button. Heating temperature will begin

flashing.

6. Set the heating temperature using the RIGHT Up/Down

button.

7. Press the blue COOL button. Cooling temperature will begin flashing.

8. Set the cooling temperature using the RIGHT Up/Down

button.

9. Set the remaining periods by using the SCROLL button to

select “DAY”, “EVENING”, and “SLEEP”.

10. To copy a zone, use SCROLL button to select “COPY”.

Select YES and copy this zone schedule to other zones using NO or YES.

11. Exit the scheduling mode by either closing the door or

pressing the SCHEDULE button.

12. If changes are made, you will be asked to “SAVE

CHANGES YES/NO.”

INSTALL / SERVICE MENUS

The “INSTALL / SERVICE” menus contain a set of vital

information. This information enables the Installer or Service

person to view a summary of what has been installed, etc. This

information is not covered in the Owner’s Manual.

To ent er INSTALL / SERVICE menus, press and hold the

ADVANCED button for at least ten seconds. The following menu

will appear (See Fig. 21):

NOTE: The INSTALL / SERVICE menu will automatically exit

after 60 minutes of no push button activity.

EQUIPMENT SUMMARY: Shows all equipment recognized by

and attached to the system.

INSTALL: Used when adding, changing out, or un--installing

equipment.

SETUP: Used to view or modify equipment settings.

CHECKOUT: Allows testing of equipment operation

SERVICE: Used to view operation and fault history of equipment

and enter dealer name/phone number for display

EQUIPMENT SUMMARY MENU

EQUIPMENT SUMMARY

FURNACE 58MVB0100-12

AC

FILTER EAC

HUMIDIFIER YES

UV LIGHTS YES

ZONES 1234

BACK

24ANA136A003

A07117

Fig. 22 -- Equipment Summary

This screen shows indoor unit type and model number, outdoor

unit type (and model number if a 2--stage unit), filter type and any

accessories that are installed, and how many zones are recognized.

INST ALL MENU

INSTALL

TO ADD, UNINSTALL OR

RE-INSTALL EQUIPMENT,

PRESS RIGHT SIDE

BUTTON

BACK INSTALL

A03202

Fig. 23 -- Install Menu

This menu item will perform start--up process in order to learn all

equipment in system. Press right side button to initiate the process.

See Fig. 23.

SETUP MENU

SETUP

THERMOSTAT

FURNACE

HEAT PUMP

ZONING

ACCESSORIES

SYSTEM MAINTENANCE

BACK SELECT

A04089

Fig. 24 -- Setup Menu

INSTALL/SERVICE

EQUIPMENT SUMMARY

INSTALL

SETUP

CHECKOUT

SERVICE

SOFTWARE VERSION 1

EXIT SELECT

Fig. 21 -- Install / Service Menus

This menu has several layers, allowing modification of equipment

settings. No settings will need to be made at equipment (i.e. DIP

switches on a furnace). All configuration settings made effective

from this menu will override equipment configuration made by dip

switches. Fig. 24 shows all the information that can be found in the

SETUP menu.

A03200

8

Page 9

Setup -- Thermostat

Auto Mode Setup:

S Enable/Disable Auto Changeover mode (default = Enable).

S Auto Changeover Time may be adjusted 5 to 120 minutes,

(default = 30 minutes).

When Auto mode is enabled (factory default) a change from heat

to cool (or vice versa) will not occur until an opposite mode

demand has existed for 30 minutes. If the setpoint is changed, the

30 minute timer is deleted.

Heat/Cool Deadband:

S 0to6_F(0to3_C), (default = 2_F).

The minimum difference enforced between heating and cooling

desired temperatures. This can allow one setting to “push” the

other to maintain this difference.

Offsets:

This option allows calibration (or deliberate miscalibration) of the

temperature and humidity sensors. These offsets are added to the

actual temperature/humidity values (default = 0).

S Zone1Offset:--5to+5_F(--3_Cto+3_C).

S Outside Temp Offset: --5 to +5_F(--3_Cto+3_C).

S Humidity Offset: --10 to +10%.

Elevation:

0 to 10000 feet. This value is used to correct the static pressure

readings the system performs.

Cycles Per Hour:

S Maximum cycles per hour = 4 (default) or 6.

Programming:

S ON (default)-- allows program schedule to be set by user.

S OFF -- system becomes non--programmable

S Periods Per Day = 2 or 4 (default = 4)

S Programmable Fan On/Off (default = Off). If ON is selected, fan

can be set to Auto, Low, Med, or High.

Smart Recovery:

S On or Off (default = On)

Applies to programmable operation only. Will start recovery 90

minutes prior to schedule change in both heating and cooling

mode. Refer to operational information for more detail.

English/Metric Display:

S_For_C (default = _F)

Reset Factory Defaults:

Program Schedule:

S Yes/No to reset back to Energy Star default Time and Temp

schedules.

User Settings:

S Yes/No to reset the user settings in the Advanced Setup to

factory default settings.

Install Settings:

S Yes/No to reset install settings in Install/Service menus to factory

default settings.

Last 10 System Events:

S Yes/No to reset last 10 system events under Service Info menu.

Setup -- Furnace

Upon a first time start --up of the Evolution Zone Control, the

furnace DIP switch settings will be copied to the furnace setup

menu. Any changes can then be made from the Evolution Zone

Control.

Furnace Airflow:

S COMFORT (default)

S EFFICIENCY

Selects the airflow of the furnace when heating. EFFICIENCY is

the airflow used to meet specified ratings, COMFORT is a

decreased airflow used to increase the output air temperature and

provide increased comfort.

Cooling Airflow:

S COMFORT (default) -- cooling airflow is varied depending on

humidity and temperature demands settings. This selection

enables the full dehumidify and comfort capabilities of the

system. When COMFORT is not selected, the unit will not run

reduced airflows for dehumidification.

S EFF 325 -- fixed airflow used to achieve specified ratings -- no

dehumidification airflow reduction. This is nominally 325

CFM/ton, but will vary if a 2--stage outdoor unit is used.

S EFF 350 -- fixed airflow used to achieve specified ratings -- no

dehumidification airflow reduction. This is nominally 350

CFM/ton, but will vary if a 2--stage outdoor unit is used.

S MAXIMUM -- 400 CFM/ton.

S QUIET-- minimum cooling airflow that the system can safely

run (typically 300 CFM/ton). Use this setting if duct noise is a

severe problem. Note that duct sweating in high humidity

environments could be an issue.

Heat Pump Heating:

S COMFORT (default) Heat Pump airflow is varied depending on

outdoor temperature to maximize comfort.

S EFF 325 -- fixed airflow used to achieve specified ratings -- no

dehumidification airflow reduction. This is nominally 325

CFM/ton, but will vary if a 2--stage outdoor unit is used.

S EFF 350 -- fixed airflow used to achieve specified ratings -- no

dehumidification airflow reduction. This is nominally 350

CFM/ton, but will vary if a 2--stage outdoor unit is used.

S MAXIMUM -- 400 CFM/ton.

Dehum Airflow:

S NORMAL (factory default) -- When equipment is running to

dehumidify, the airflow is allowed to adjust to a minimum to

satisfy the dehumidification call.

S HIGH -- Minimum airflow during the dehumidify mode is

increased to reduce duct and register sweating. Also increases

minimum airflow during normal cooling operation to reduce

duct sweating.

Low Heat Rise

S ON

S OFF (default)

Set to ON if the system contains a bypass humidifier. The ON

setting will increase the furnace low heat airflow.

Staging

S SYSTEM (default)

S LOW

S LOW--MED

S LOW--HIGH

S MED

S MED--HIGH

S HIGH

NOTE: Two--stage furnace has LOW and HIGH selections only.

UIZ01--D

9

Page 10

Controls the staging of the furnace. SYSTEM setting will allow

the Evolution Zone Control to determine furnace staging. LOW

will only run the low stage of furnace heat. LOW--MED will run

the low and medium stages (2 stages of heat). MED will only run

the medium stage of heat. MED-- HIGH will run the medium and

high stages (2 stages of heat). HIGH will only run the high stage

of furnace heat.

G Terminal

This setup option selects desired operation when the R--G circuit

changes state on the furnace control board depending on setup.

S DISABLED (Default)

S FAN -- turns on fan to selected fan speed when G terminal is

energized. See Fig. 25. This setting is used in conjunction with

fresh air supply products (e.g. fresh air/make-- up air dampers).

R

UIZ01--D

FE Fan Coil or

Variable Speed Furnace

G

Fig. 25 -- G Input Wiring for Blower Operation

S FAN SPEED -- select Low, Med, High for all zones when G

terminal is energized

S SHUTDOWN -- shuts off fan and equipment when initiated.

This function is not intended for emergency fire shutdown. It

may be activated by a dry contact from an external device such

as a float switch or a relay. User selects whether the contact is

NC -- normally closed (default) or NO -- normally open. User

Interface displays SYSTEM MALFUNCTION on screen and

registers G terminal shutdown event in Last 10 System Events.

See Fig. 26.

R

FE Fan Coil or

Variable Speed Furnace

G

Fig. 26 -- G Input Wiring for System Shutdown

with Evolutiont Control (Contact type selectable;

Normally Closed (default) or Normally Open)

High Stage Timer

Minimum amount of time low stage must operate before high stage

is activated. Ten to 60 minutes. 10 = default

A demand of 5_ or more will override the staging timer.

A07114

A07115

Furnace Airflow (Capacity) Limiting

The following settings allow the installer to restrict the furnace

within certain minimum and maximum airflows. These airflows

are converted to capacities. The Min and Max limits are

determined by the equipment size. These settings are not the same

as the zoning airflow limits.

Min CFM (only appears with modulating

furnaces)

Minimum CFM to run a modulating furnace. This will increase

the minimum operating capacity of the furnace. Default value is

the furnace air flow for the lowest heat capacity.

Maximum CFM (only appears with modulating

furnaces)

Maximum CFM to run a modulating furnace. This will reduce the

operating capacity of the furnace. Default value is the furnace air

flow for the highest heat capacity.

Off Delay

S 90 seconds

S 120 seconds (default)

S 150 seconds

S 180 seconds

Amount of time the blower will continue to run after heating has

shut off.

Dehum Drain

Turns off the continuous fan at the end of cooling for five minutes,

in order to drain the indoor coil of water. The fan will only be

turned off if a dehumidify demand existed at the start of or during

the cooling cycle. Default is enabled.

Altitude

S US 0 -- 2000 (default)

S US 2001 -- 3000

S CA 2001 -- 4500 (for Canada only)

S US 3001 -- 4000

S US 4001 -- 5000

S US 5001 -- 6000

S US 6001 -- 7000

S US 7001 -- 8000

S US 8001 -- 9000

S US 9001 -- 10000

This setting will adjust the furnace’s airflow to compensate for

altitude. Altitude adjustment is not available with older furnaces.

Please see furnace instructions for further details.

Setup -- Fan Coil

Heat Pump Heating:

S COMFORT (default) Heat Pump airflow is varied depending on

outdoor temperature to maximize comfort.

S EFF 325 -- fixed airflow used to achieve specified ratings -- no

dehumidification airflow reduction. This is nominally 325

CFM/ton, but will vary if a 2--stage outdoor unit is used.

S EFF 350 -- fixed airflow used to achieve specified ratings -- no

dehumidification airflow reduction. This is nominally 350

CFM/ton, but will vary if a 2--stage outdoor unit is used.

S MAXIMUM -- 400 CFM/ton.

Heat Pump Cooling Airflow:

S COMFORT (default) Cooling airflow is varied depending on

humidity and temperature demand settings. This selection

enables the full dehumidify and comfort capabilities of the

system. When COMFORT is not selected, the unit will not run

reduced airflows for dehumidification. Heat Pump airflow is

varied depending on outdoor temperature to maximize comfort.

S EFF 325 and EFF 350 -- fixed airflow used to achieve specified

10

Page 11

ratings -- no dehumidification airflow reduction. This is

nominally 350 CFM/ton, but will vary if a 2--stage outdoor unit

is used.

S MAXIMUM -- 400 CFM/ton. Dehumidify features are not active

when set to maximum.

S QUIET-- minimum cooling airflow that the system can safely

run (typically 300 CFM/ton). Use this setting if duct noise is a

severe problem. Note that duct sweating in high humidity

environments could be an issue.

Dehum Airflow:

S NORMAL (factory default) -- When equipment is running to

dehumidify, the airflow is allowed to adjust to a minimum to

satisfy the dehumidification call.

S HIGH -- Minimum airflow during the dehumidify mode is

increased to reduce duct and register sweating. Also increases

minimum airflow during normal cooling operation to reduce

duct sweating.

Heater Size:

S (choices dependent upon fan coil model)

This will show the heater size entered during the start--up process.

This value can be changed to another value (limited by the model

number of the fan coil). If the electric heater is self--identifying, this

value is not shown.

Elect Heat Lockout

S NONE (default)

S +5 to 55_F (--15 to 18_C)

Outside temperature above which the electric heat will not operate

except for defrost.

G Terminal

This setup option selects desired operation when the R--G circuit is

made on the fan coil control board.

S DISABLED (Default)

S FAN -- turns on fan to selected fan speed when G terminal is

energized. See Fig. 25.

This setting is used in conjunction with fresh air supply products

(e.g. fresh air/make--up air dampers).

S FAN SPEED -- select Low, Med, High for all zones when G

terminal is energized.

S SHUTDOWN -- shuts off fan and equipment when initiated.

This function is not intended for emergency fire shutdown. It

may be activated by a dry contact from an external device such

as a float switch or a relay. User selects whether the contact is

NC -- normally closed (default) or NO-- normally open. User

Interface displays SYSTEM MALFUNCTION on screen and

registers G terminal shutdown event in Last 10 System Events.

See Fig. 26.

Dehum Drain

Turns off the continuous fan at the end of cooling for five minutes,

in order to drain the indoor coil of water. The fan will only be

turned off if a dehumidify demand existed at the start of or during

the cooling cycle. Default is enabled.

Reheat Dehum

Enables electric heat to be used while Cool to Dehumidify is

running. This will allow the Cool to Dehumidify function to run

much longer, greatly improving humidity control in cooling mode.

Accumulated electrical energy used while reheating (in

kilowatt--hours) is shown on the Fan Coil Run Hours screen and

can be reset there. This is only available with fan coil systems.

Setup -- Heat Pump / AC

Cooling Lockout:

S NONE (default)

S 45_F(7_C)

S 50_F(10_C)

S 55_F(13_C)

Outside temperature below which cooling will not be provided.

Low Ambient Cooling:

S NO (default)

S YES

Selecting YES will enable the low ambient cooling operation in

the outdoor unit. This setting is only available with communicating

outdoor units and with Cooling Lockout set to NONE.Low

ambient kits are not needed with communicating outdoor units.

For detailed sequence of operation, see outdoor unit installation

instruction.

Entered Size:

S (dependent on indoor unit model)

Size of the outdoor unit entered during the start--up process. If the

outdoor unit is a communicating model, this value will not be

shown. This size can be changed here but is limited to sizes that the

indoor unit can handle.

Defrost Interval:

S 30 minutes

S 60 minutes

S 90 minutes

S 120 minutes (default)

S Auto--Defrost interval optimized by outdoor control (default for

communicating HP)

Time interval at which defrost cycles can occur on a heat pump.

Lockout Temp:

S Off (default)

S +5 to 55_F (--15 to 18_C)

Locks out the heat pump from operating below the selected outside

temperature. Appears with a fan coil only. Must be below any

electric lockout temperature in Fan Coil Setup.

Quiet Shift

S Off (default)

Turns on Quiet Shift function in 1--stage or 2-- stage

communicating heat pumps.

High Cool Latch:

S OFF (default)

S ON (high cool stage on at all times, unzoned only)

S 80 to 110_F (27 to 43_C) (unzoned only)

S DISABLE (disable use of high cool stage)

Outside temperature above which only the high speed (of a 2--stage

outdoor unit) will run when cooling. High Cool Latch setting of

On will not function in zoned systems.

High Heat Latch

S OFF (default)

S ON (high heat stage on at all times, unzoned only)

S 20 to 50_F(--7to10

2-- stage heat pump runs only high stage heating below a

selectable outdoor temperature. Selections from 20 to 50_F(--7

to 10_C) are available in 5_ increments. High Heat Latch setting

of On will not function in zoned systems.

S DISABLE (disable use of high heat stage)

_C)

UIZ01--D

11

Page 12

Defrost Fan Delay

HYBRID HEAT SETUP

FURNACE

LOCKOUT:

> 30 F

HEAT PUMP

LOCKOUT:

< 15 F

DEFROST W/FURNACE: YES

< BACK

HP TO FURNACE

STAGE TIME:

15 MIN

OUTSIDE LOCKOUT TEMPS

Turns on the outdoor unit fan at the end of a defrost cycle for

approximately 12 seconds. This helps to reduce any nuisance

refrigerant noise caused by the switching reversing valve. This

setup is only available on communicating heat pumps

Brownout Disable

Turns off the high voltage brownout detection function in the

outdoor unit control.

Lo Air Multiplier

Adjusts the low airflow speed on non--communicating two--stage

units. Choose 0.65 for units with a Bristol compressor, choose 0.80

(default) for units with a Copeland scroll compressor.

Setup -- Hybrid Heat

UIZ01--D

FURNACE LOCKOUT -- Temperature above which the furnace

will not operate, except for defrost.

S Default = NONE

S Available settings = NONE thru >55_F(13_C)

HEAT PUMP LOCKOUT -- Temperature below which the heat

pump will not operate.

S Default = NONE

S Available settings = NONE thru <55_F(13_C)

DEFROST W/FURNACE -- Choose whether furnace operates

during defrost cycle

S Default = YES

S Available settings = YES / NO

HP TO FURNACE STAGING TIME -- Adjust the minimum

amount of time high stage heat pump will run before furnace will

be allowed to run.

S Default = 15 MIN

S Available settings = 15--60 minutes

Setup -- Zoning

Disable Zoning:

S NO (default)

S YES

If YES is selected, zoning is disabled and all dampers open. The

system will run un-- zoned using the Zone 1 sensor.

Zone Offsets:

S Zone Temperature Offsets (default = 0) Range -- 5_Fto+5_F

(--3_Cto+3_C)

This option allows actual temperature offset for each zone,

allowing calibration (or deliberate miscalibration) of each sensor.

Humidifier interval is time only, not actual humidifier run time.

Airflow Limits:

Since bypass damper is prohibited in this system, this setting is

used to select the maximum allowable noise/airflow relationship

into each zone based on air noise and comfort requirements. For

setup guidelines, see Airflow Limits Checkout in the next section.

S Low -- 100% of maximum assessed airflow

S Med Low -- 138% of maximum assessed airflow

Fig. 27 -- Hybrid Heat Setup

A07030

S Medium -- 176% of maximum assessed airflow

S Med High -- 214% of maximum assessed airflow

S High -- 250% of maximum assessed airflow

S No Limit -- equipment does not stage down

CFM associated for each limit is shown on the screen. Compare

this value with the equipment’s low stage CFM value to ensure that

equipment will run for each zone. Assessed airflow is determined

as described in DUCT ASSESSMENT.

Duct Assessment Time

1 p.m. (default), adjustable in 1 hour increments from 1 p.m. to 12

a.m. (24 hours). Select which hour of the day the duct assessment

will be performed.

Setup -- Hydronic Heat

HYDRONIC HEAT SETUP

HOT WATER

LOCKOUT:

HEAT PUMP

LOCKOUT:

DEFROST W/WATER:

AIRFLOW:

BLOWER ON DELAY:

BLOWER OFF DELAY:

< BACK

> 30 F

< 45 F

YES

800 CFM

30 SEC

30 SEC

A07031

Fig. 28 -- Hydronic Heat Setup

HOT WATER LOCKOUT -- Outside temperature above which the

hot water will not operate except for defrost (if selected).

S Available settings -- NO, 5 to 55_F (-- 15 to 13_C) in 1 _

increments

HEAT PUMP LOCKOUT -- Outside temperature below which the

heat pump will not operate, 1_ resolution.

S Appears only with a heat pump outdoor unit.

S Available settings -- NO, 5 to 55_F (-- 15 to 13_C) in 1 _

increments

DEFROST W/WATER:

S Available settings: YES / NO (Default = YES)

S Appears only if heat pump is available. If no, hot water will not

run during a defrost.

AIRFLOW -- Selects desired airflow during Hydronic Heating

S Available range from OFF, 500 CFM(minimum) to 400

CFM/ton cooling maximum in 50 CFM increments.

S Default is the cooling airflow. (350 CFM/ton)

S OFF selection does not turn off airflow if heat pump is

defrosting.

BLOWER ON DELAY -- Time after hot water is requested that the

blower will turn on.

S Available settings -- 0 to 240 seconds in 30 second increments

S Default is 30

S Does not appear if a heat pump is present since heat pump and

hot water run simultaneously.

BLOWER OFF DELAY-- Time after hot water request terminates

before the blower will turn off.

S Available settings -- 0 to 240 seconds in 30 second increments

S Default is 0

Setup -- Accessories

Filter Type:

S Air Filter (i.e. TrueSenset)

S Electronic Air Cleaner

S Air Purifier (i.e. TrueSenset)

CLEAN INTERVAL: Never, 1 to 18 months. (Default = 90)

Enables a timer for the filter notification.

12

Page 13

Interval at which the Clean Filter notification will turn on.

PRESSURE MONITOR: ENABLE/DISABLE -- enables the static

pressure calculation for media--type filters.

Humidifier Installed:

S NO

S YES

If YES, indicates to the system whether a humidifier is installed

and enables humidification functions.

CHANGE PAD INTERVAL: 1 to 24 mo nths (default = 12

months)

Interval at which the Change Humidify Pad notification will be

displayed.

HUMIDIFY WITH FAN (Heating Mode Only):

S NO (default)

S YES

If YES, the humidifier will turn on if there is a humidify demand

present. The fan will turn on to Low speed if the fan setting is

Auto.

Ventilator:

NOTE: Only appears if ventilator is installed.

CLEAN INTERVAL:

S 60 to 180 days of actual operation (default = 90)

Interval at which the Clean Ventilator Pre--filter notification will

turn on.

UV Lights Installed

S NO

S YES

If YES, indicates to the system whether UV lights are installed.

CHANGE INTERVAL:

S 6 to 48 months operation time (default = 12 months)

Interval at which the Change UV Lights notification will be

displayed.

Setup -- System Maintenance

Remind Owner of Routine Maintenance Every:

This setup is used to adjust the timer interval in which the normal

System Maintenance notification is turned on for the homeowner.

Range =

S OFF

S 6 to 24 months, (default = 12 months) Pressing the right side

button will reset the timer. Pop--up confirmation will be shown.

SYSTEM MAINTENANCE

REMIND OWNER OF

MAINTENANCE EVERY:

12 MONTHS

% USED: 50%

< BACK

RESET >

A07033

Fig. 29 -- System Maintenance

Setup -- Utility Saver

Cooling/Heat Pump Heating (Hybrid Heat &Hydronic Heat

only):

S Turn off, Low Stage

Utility Saver is used to force the equipment to a lower stage (low

or off) when activated by the utility company, typically during

peak load times.

This setup is available only if the equipment has a utility saver

input (refer to outdoor equipment Installation Instructions). This

setup controls the response of the equipment when the utility saver

input is active.

The choices include:

S Turn Off , (equipment turns off)

S Low Stage (available if the AC/heat pump is a 2 --stage model,

runs low speed only)

CHECKOUT MENUS

CHECKOUT

FURNACE

HEAT PUMP HEATING

HEAT PUMP COOLING

HUMIDIFIER

VENTILATOR

BACK SELECT

A03204

Fig. 30 -- Checkout Menu

The Checkout menu will show the equipment installed in the

system. A sample checkout menu is shown in Fig. 30.

Checkout -- Furnace or Gas PAC

Make sure the furnace is properly installed before continuing.

S LOW HEAT RUNTIME: 5 min.

S HIGH HEAT RUNTIME: 5 min.

This menu item allows the furnace to be exercised. First, a low heat

runtime and high heat runtime are selected. Range = 5 -- 120 min.

If only the low heat is to be exercised:

The furnace will execute its ignition start-- up sequence. This

sequence will be displayed on the Evolution Zone Control screen.

After the gas valve and blower motor turn on, the screen will

automatically change to “FURNACE CHECK” and show the

current operating status of the furnace.

Checkout -- Electric Heat

S ELECTRIC HEAT RUNTIME: 5 min., Default time = 5 min.,

Range = 0 -- 120 min.

If you have a fan coil with electric heaters, this menu item will

allow the heaters to be exercised.

With self--identifying electric heaters, three stages of electric heat

are available to be exercised in any combination. Non--identifying

heaters will only provide one stage of heat.

Enter the run time (in minutes) of each stage of heat to be exercised

then press START (right--side button). The display will change to

show the fan coil’s operating status.

Checkout -- Heat Pump Heating

S HIGH HEAT RUNTIME: 5 min.

S LOW HEAT RUNTIME: 5 min.

S DEFROST: NO

The heat pump heating mode can be exercised with this menu

option. With a 2--stage heat pump, a low heat runtime and a high

heat runtime are independently selectable to exercise. A defrost

cycle is also selectable. Default time = Fixed 5 min. minimum,

range = 5 -- 120 min.

NOTE: Airflows during Checkout modes are fixed to the

Efficiency setting and are independent of other airflow settings. To

view airflows for normal heat pump heating mode, exit the

Checkout screen and apply a heating or cooling demand to the

system.

UIZ01--D

13

Page 14

Checkout -- Heat Pump Cooling or AC Cooling

S HIGH COOL RUNTIME: 5 min.

S LOW COOL RUNTIME: 5 min.

The heat pump cooling mode (or AC cooling mode) can be

exercised with this menu option. With a 2--stage heat pump or AC

unit, a low cool runtime and a high cool runtime are independently

selectable to exercise. The display will change to show the heat

pump or AC operating status.

Default time = Fixed 5 min. minimum, range = 5 -- 120 min.

NOTE: Airflows during Checkout modes are fixed to the

Efficiency setting and are independent of other airflow settings. To

view airflows for normal heat pump (or AC) cooling mode, exit the

Checkout screen and apply a heating demand to the system.

Checkout -- Humidifier

S OFF

S ON

The humidifier can be exercised On and Off with this menu option.

Checkout -- Ventilator

UIZ01--D

Speed:

S OFF

S LOW

S HIGH

The ventilator can be exercised through all of its operating speeds

with this menu option.

Checkout -- Zoning

Duct Assessment

This is the same Duct Assessment that runs on first start-- up.

Measures duct capacity for each zone. The Duct Assessment will

perform an airflow measurement on each zone and determine the

relative size of each zone along with damper leakage. This

assessment will require approximately 1 minute for each zone in

the system.

NOTE: A Duct Assessment will automatically occur every 24

hours at selected time to check system static and calibrate dampers.

Sensor / Damper Check:

The Sensor/Damper Check allows the installer to check each zone

damper for operation, as well as insure the zone sensor corresponds

to that particular zone.

When first initiated, the Zone 1 damper will fully open, and all

other zones will close. Using the scroll button, the installer can

select each zone and verify the damper is fully open while all other

dampers remain closed.

After proper damper operation has been verified, the installer can

now check and verify that each Remote Room Sensor corresponds

to the proper zone damper in the same zone. Start from the top and

highlight zone 1 to open damper. Temporarily disconnect any other

zone Remote Room Sensor (at sensor location). That zone damper

will now open, while the Zone 1 damper will close.

EXAMPLE: If the Zone 2 Remote Room Sensor is disconnected,

the Zone 2 damper will now open as indicated on the User

Interface display. The word “FAIL” will also be displayed instead

of the actual temperature for Zone 2. Reconnect Zone 2 sensor and

try all remaining sensors one at a time in the system. Smart Sensors

may also be checked, see Smart Sensor Installation Instructions for

procedure.

Airflow Limits:

S LOW

S MED LOW

S MED

S MED HIGH

S HIGH (default)

S NO LIMIT

Because there is no bypass damper, the Zone Airflow Limit check

will allow the installer to assess the airflow noise generated by the

system providing the maximum amount of airflow to each zone.

Select ZONE, then select AIRFLOW LIMIT: When Start is

pressed (right side button), the selected zone’s damper will fully

open, all others will close, and the indoor unit will provide the

maximum airflow for that zone (as selected in SETUP —

ZONING, Airflow Limits). If the airflow noise is objectionable, the

installer can select a lower airflow noise limit. If the noise is not

objectionable, the installer should leave HIGH selected, or even

NO LIMIT.

NOTE: Selecting a lower airflow noise limit may decrease the

homeowner’s comfort in that zone.

Sensor Types:

Shows list of all zones with corresponding sensor types.

UI = User Interface

SS = Smart Sensor

RS = Remote Sensor

Checkout -- System Access Module (SAM)

See System Access Module Installation Instructions for full details.

SERVICE MENUS

The Service Info menu will only show the equipment installed in

the system. Below is a sample using a furnace and a heat pump

(Hybrid Heat). A sample service menu is shown in Fig. 31.

SERVICE INFO

FURNACE STATUS

HEAT PUMP STATUS

LAST 10 SYSTEM FAULTS

RUN/FAULT HISTORY

TODAY’S DATE

MODEL/SERIAL NUMBER

SERVICE PHONE NUMBER

BACK SELECT

A03205

Fig. 31 -- Service Menu

Service -- Furnace Status or Gas PAC Status

The Status screens will show all of the current operating parameters

of each installed piece of equipment.

NOTE: To view a less detailed Equipment Status screen, press the

right side button. This will display equipment stage, fan status,

actual and target humidify settings.

Heat Stage:

S OFF, LOW, HIGH

Displays stage of heat that the furnace is currently delivering.

Airflow CFM:

S (furnace model dependent)

Cubic Feet per Minute of air the User Interface is currently

requesting.

Inducer RPM (90% furnaces only):

S Actual inducer motor RPM value.

Blower RPM:

S Actual blower motor RPM value.

Static Press:

S Inches of water. Displays calculated static pressure that the

furnace is currently experiencing.

S If static pressure cannot be accurately calculated, the display will

read UNKNOWN. When this is seen, the system is adjusting to

high static pressure by cutting back blower RPM.

Lockout Timer:

S Seconds

14

Page 15

If a lockout timer is active, this will show the current time value.

LAST 10 EVENTS

LOW PRESSURE

3/2/05

2:35 PM

< BACK MORE >

HP

3 EVENTS:

225 EVENTS _

ACTIVE

FN 2/28/05 6:10 PM

41-BLOWER MOTOR FAULT

F

SWITCH OPEN

F=FAULT

See furnace manual for details on lockout timers.

Service -- Fan Coil Status

Electric Heat:

S OFF, LOW, MED, HIGH

Displays stages of electric heat that the fan coil is currently

delivering.

Airflow CFM:

S (fan coil model number dependent)

Cubic Feet per Minute of air the User Interface is currently

requesting.

Blower RPM:

S Actual blower motor RPM value

Static Press:

S Inches of water. Displays the calculated static pressure the fan

coil is currently experiencing.

S If static pressure cannot be accurately calculated, the display will

read UNKNOWN. When this is seen, the system is adjusting to

high static pressure by cutting back blower RPM.

Service -- Heat Pump / AC Status

Stage: (Heat / Cool)

S OFF, LOW, HIGH

Displays stage of heating or cooling that the Heat Pump/AC is

delivering.

Defrost:

S NO, YES

Displays status of defrost mode if heat pump.

Airflow CFM:

S Airflow User Interface is requesting from blower.

Outdoor Coil Temp:

S_For_C (default = _F)

Temperature of the outdoor unit coil (only available on

communicating outdoor units).

Blower RPM:

S Actual RPM feedback from indoor blower motor.

Static Press:

S Calculated static pressure of indoor unit.

S If static pressure cannot be accurately calculated, the display will

read UNKNOWN. When this is seen, the system is adjusting to

high static pressure by cutting back blower RPM.

Service -- Zoning Status

Zone Status:

This screen will show each zone in the system with the

corresponding damper position (POS), and CFM being delivered

to each zone. Damper position range is from 0 to 15 (0 = closed, 15

= open).

Service -- Last 10 System Events

Fig. 32 -- Last 10 System Events

A07032

This screen will show last 10 events that occurred throughout the

system. Each entry has the time and date incident recorded. Service

technician should enter current date in “TODAY’S DATE”menu

section BEFORE checking and logging the last 10 system events.

These events are stored in the memory of the User Interface and are

resettable in the Thermostat Setup screen under the Reset Factory

Default selection.

Each entry has a two--letter acronym preceding the event name to

identify which piece of equipment generated the event. This event

history can be cleared under Thermostat Setup, Reset Factory

Defaults.

HP = Heat Pump

AC = Air Conditioner

FN = Furnace

FC = Fan Coil

ZN1=ZoneBoard1

ZN2=ZoneBoard2

SPP = Packaged product

SAM = System Access Module

Service -- Run / Fault History

This information is stored in the equipment circuit boards (if

communicating) and displayed on the User Interface. The indoor

unit and outdoor unit (if communicating) have the following

histories:

NOTE: For Critical Fault Screens, see Troubleshooting section in

this document.

Resettable Faults:

S Fault counters for each piece of equipment that can be reset.

Cycle Counters:

S Number of heat/cool/power cycles the unit has performed.

Run Times:

S Lifetime hours of operation in heating, cooling, and how long

the unit has been powered.

S Kilowatt hours used of electric reheat for dehumidification.

Service -- Today’s Date

This menu item allows the installer to enter the current date. It is

used for time/date stamping of system faults. This should be

verified every time prior to viewing “LAST 10 SYSTEM

EVENTS” section.

Service -- Model / Serial Numbers

This menu item allows the installer to view the model number and

serial number (if available) of all communicating pieces of

equipment in the system. This information resides in the original

circuit board from the factory. If a circuit board has been replaced,

the model and serial number will no longer be displayed.

Service -- Service Phone Number

This menu item allows the installer to enter a name and phone

number that the homeowner can call for future service of the

system. This name and phone number will appear to the

homeowner whenever a service reminder pop--up message is

displayed (i.e. Change Filter, etc.).

To edit:

S Use Right Up/Down button button to move cursor left and right.

S Use Left Up/Down button button to select numbers and letters.

S Use Scroll button to move up and down between NAME and

NUMBER.

OPERATIONAL INFORMATION

Zone Selection

S Press top left ZONE button to select zones.

15

UIZ01--D

Page 16

Continuous Fan Operation

Pressing FAN button will scroll through the following:

S AUTO = No fan operation except during equipment operation.

S LOW = Approximately 50% of High Speed operation.

S MED = Half way between High and Low speed operation.

S HIGH = Highest of either High Heating or High Cooling CFM.

Continuous fan operation is programmable. The programming

option must be enabled in the Thermostat Setup. See the

Homeowner’s Manual for detailed instructions on programming

the fan.

Five--Minute Compressor Timeguard

This timer prevents compressor from starting unless it has been off

for at least 5 minutes. It can be defeated by simultaneously pressing

the Fan and Temp + buttons.

Emergency Heat (for heat pump applications)

To activate Emergency Heat, you must press and hold the HEAT

button for 3 seconds to activate. Repeat to deactivate.

Heat Source Selection (Hybrid or Hydronic Heat)

UIZ01--D

If user wishes to override normal operation in Hybrid Heat or

Hydronic Heat applications, press and hold the heat button for 3

seconds to select desired heat source.