Page 1

Installation and Start-Up Instructions

EVOLUTION NETWORK INTERFACE MODULE

SYSTXBBNIM01

Network Interface Module

SYSTXBBNIM01

NOTE: Read the entire instruction manual before starting the

installation.

This symbol → indicates a change since the last issue.

TABLE OF CONTENTS

SAFETY CONSIDERATIONS.....................................................1

INTRODUCTION..........................................................................1

INSTALLATION...........................................................................1

Check Equipment and Job Site...........................................1

Component Location and Wiring Considerations..............1

Install Components..............................................................2

Ventilator (HRV/ERV) Wiring...........................................2

Dual Fuel with 1-Speed Heat Pump Wiring......................2

Var.-Spd. Indoor Units with 2-Spd. Outdoor Unit Wiring.2

SYSTEM START-UP....................................................................2

LED INDICATORS.......................................................................2

FUSE ..............................................................................................2

24 VAC POWER SOURCE..........................................................2

SAFETY CONSIDERATIONS

Read and follow manufacturer instructions carefully. Follow all

local electrical codes during installation. All wiring must conform

to local and national electrical codes. Improper wiring or installation may damage Evolution Control System. Recognize safety

information. This is the safety-alert symbol

symbol on the equipment and in the instruction manual, be alert to

the potential for personal injury. Understand the signal words

DANGER, WARNING, and CAUTION. These words are used

with the safety-alert symbol. DANGER identifies the most serious

hazards, which will result in severe personal injury or death.

WARNING signifies a hazard, which could result in personal

injury or death. CAUTION is used to identify unsafe practices,

which would result in minor personal injury or product and

property damage. NOTE is used to highlight suggestions which

will result in enhanced installation, reliability, or operation.

. When you see this

A03231

Cancels: NEW II NIM01-0-1

02-04

INTRODUCTION

The Network Interface Module (NIM) is used to interface the

following devices to the Evolution ABCD bus so they can be

controlled by the Evolution System. The following devices do not

have communication ability and the NIM is required to control:

• A Heat Recovery Ventilator / Energy Recovery Ventilator

(HRV/ERV) (when zoning is not applied).

• A non-communicating single-speed heat pump with a variablespeed furnace (dual fuel application only).

• A non-communicating two-speed outdoor unit (R-22 Series-A

unit).

INSTALLATION

I. CHECK EQUIPMENT AND JOB SITE

INSPECT EQUIPMENT — File claim with shipping company,

prior to installation, if shipment is damaged or incomplete.

II. COMPONENT LOCATION AND WIRING CONSIDERATIONS

WARNING: ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in personal

injury or possible equipment damage.

Disconnect power before beginning installation.

NOTE: All wiring must comply with national, local, and state

codes.

LOCATING NETWORK INTERFACE MODULE (NIM)

— Select a location near the variable-speed furnace or fan coil

where wiring from equipment can come together easily.

NOTE: Do not mount NIM in outdoor unit. The NIM is

approved for indoor use only and should never be installed with

any of its components exposed to the elements.

The NIM may be installed in any area where temperature remains

between 32° and 158° F, and there is no condensation. Remember

that wiring access is likely the most important consideration.

CAUTION: ELECTRICAL OPERATION HAZARD

Failure to follow this caution will result in equipment

damage or improper operation.

To prevent possible damage to NIM, do not mount on

plenum, duct work, or flush against furnace.

WIRING CONSIDERATIONS — Ordinary thermostat wire is

ideal when wiring the Evolution System (shielded cable is not

necessary). Use 18 - 22 AWG or larger for typical installations.

Lengths over 100 ft. should use 18 AWG or larger wire. Cut off or

fold back and tape any unneeded conductors. Plan the routing of

wiring early to avoid possible problems later.

NOTE: ABCD bus wiring only requires a four-wire connection;

however, it is good practice to run thermostat cable having more

than four wires in the event of a damaged or broken wire during

installation.

—1—

Page 2

The following color-code is recommended for each ABCD bus

connection:

A — Green = Data A

B — Yellow = Data B

C — White = 24VAC (Common)

D — Red = 24VAC (Hot)

It is not mandatory that the above color code be used, but each

ABCD connector in the system MUST be wired consistently.

NOTE: Improper wiring of the ABCD connector will cause the

Evolution System to operate improperly. Check to make sure all

wiring is correct before proceeding with installation or turning on

power.

III. INSTALL COMPONENTS

INSTALL NETWORK INTERFACE MODULE — Plan wire

routing before mounting. The Evolution Network Interface Module is designed so that wires can enter it from the sides.

1. Remove top cover and mount NIM to wall using screws and

wall anchors provided.

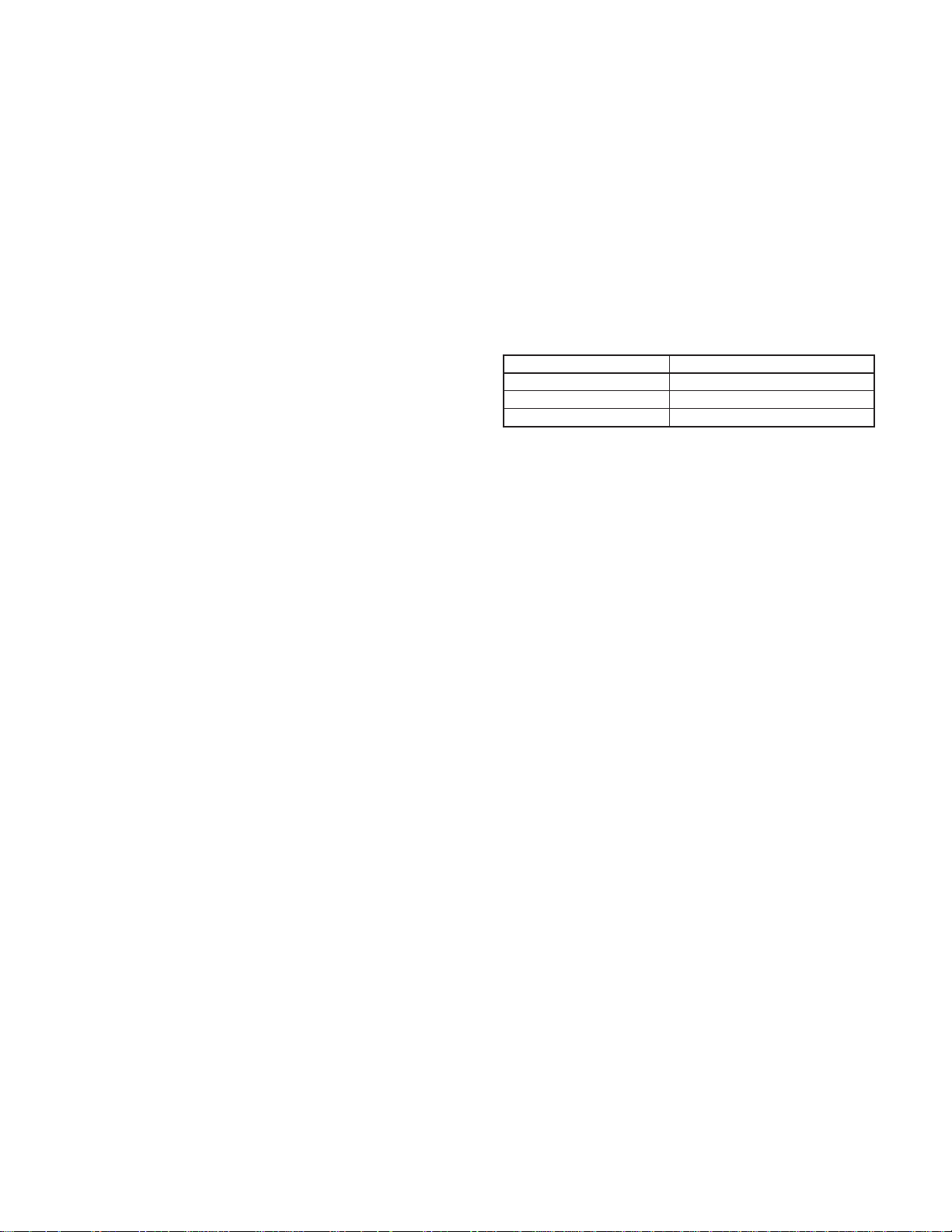

IV. VENTILATOR (HRV/ERV) WIRING

HRV / ERV INSTALLATION — The NIM can control a Bryant

Heat Recovery Ventilator / Energy Recovery Ventilator (HRV /

ERV). Connect four wires from ventilator control board (see

ventilator installation instructions for details) to connector labeled

(YRGB). This label identifies the color of the wire to match the

ventilator wire colors (Y=yellow, R=red, G=green, B=blue or

black). See Fig. 2 for ventilator (HRV / ERV) connection.

NOTE: If system is zoned (contains an Evolution Damper Control Module), the ventilator may be connected either directly to the

Damper Control module or to the NIM. In either case, the

Evolution Zone Control will properly discover the ventilator.

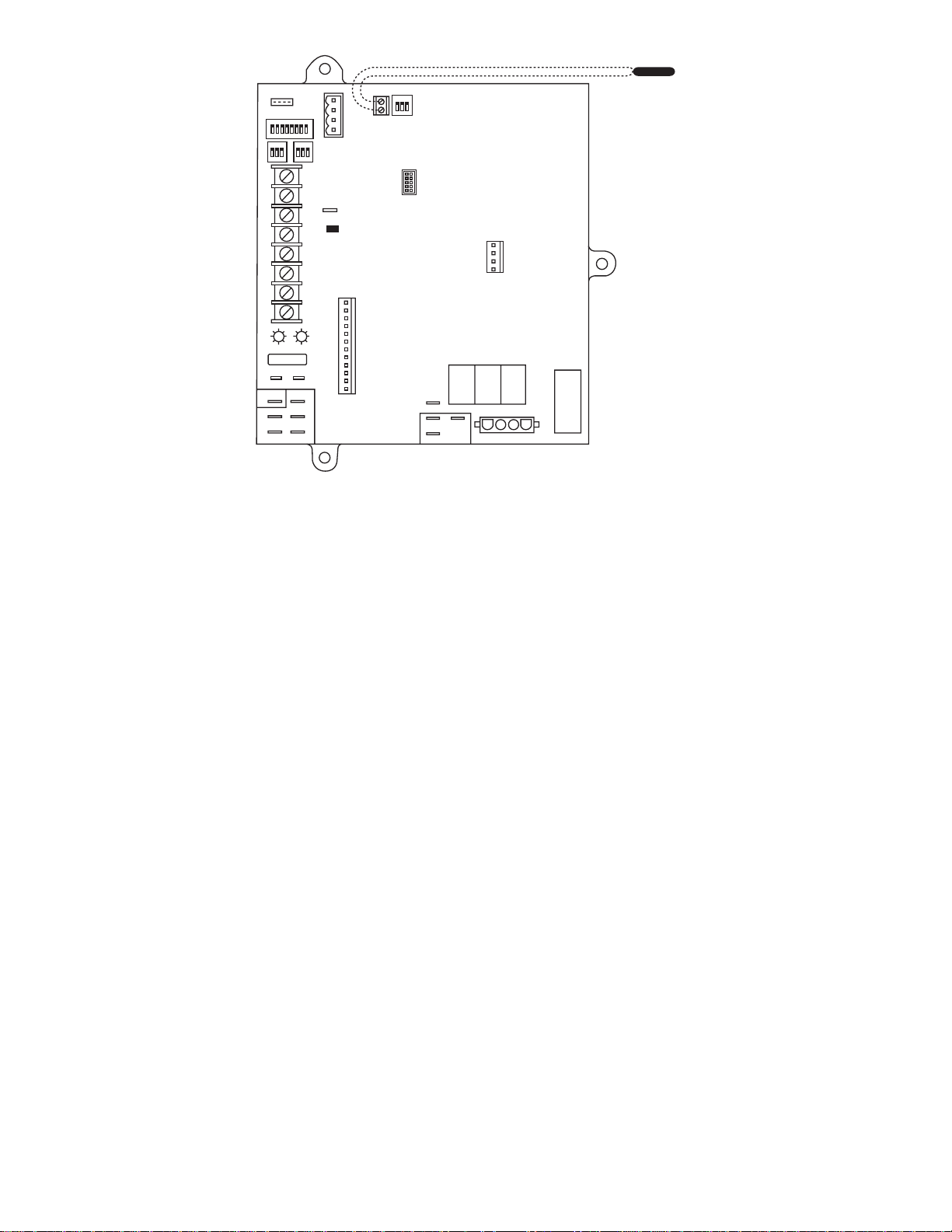

V. DUAL FUEL WITH 1-SPEED HEAT PUMP WIRING

DUAL FUEL INSTALLATION WITH 1-SPEED HEAT

PUMP — The NIM is needed when a variable-speed furnace is

applied with a Bryant single-speed (non-communicating) heat

pump. See Fig. 3 for wiring details. An outdoor air temperature

sensor MUST be connected to furnace control board for proper

operation (see Fig. 5 for details).

VI. VARIABLE-SPEED INDOOR UNIT WITH 2-SPEED

OUTDOOR UNIT WIRING

2-SPEED NON-COMMUNICATING OUTDOOR UNIT —

The NIM can control a 2-speed non-communicating air conditioner or heat pump (R-22 Series-A unit) with a variable-speed

indoor unit. See Fig. 4 for wiring details.

SYSTEM START-UP

Follow the system start-up process outlined in the Evolution Zone

Control or Evolution Control installation instructions.

LED INDICATORS

Under normal operation, the Yellow and Green LEDs will be on

continuously (solid). If the NIM does not successfully communicate with the Evolution Control, the Green LED will not be on. If

there are faults present, the Yellow LED indicator will blink a

two-digit status code. The first digit will blink at a fast rate, the

second at a slow rate.

STATUS CODE DESCRIPTION

16 = Communication Failure

45 = Board Failure

46 = Low Input Voltage

FUSE

A 3-amp automotive type fuse is used to protect the NIM from

overloading the outdoor unit R output. If this fuse fails, there is

likely a short in the wiring to the device being controlled by the

NIM. After short in wiring is fixed, fuse should be replaced with

an identical 3 amp automotive fuse.

24 VAC POWER SOURCE

The NIM receives its 24 VAC power from the indoor unit C and

D terminals (via ABCD connector bus). In most applications, there

is sufficient power (VA capacity) available from the indoor unit

transformer to accommodate a ventilator and / or outdoor unit

connection. No additional transformer is required.

—2—

Page 3

B

G

R

Y

Ventilator

Connection

B

G

R

Y

Yellow

Green

C

W

O

Y1

Y2

R

FUSE

A

B

C

D

Indoor

A

B

C

D

A

B

C

D

User

Interface

Unit

B

G

R

Y

Ventilator

(if used)

C

W2

O

Y

R

1 Spd. Heat Pump

Fig. 3 — Variable-Speed Furnace with 1-Spd. Heat Pump (Dual Fuel)

B

G

R

Y

V entilator

(if used)

C

W2

O

Y1

Y2

R

Outdoor 2-Spd.

AC or HP

(R-22 Series-A unit)

Fig. 4 — 2-Spd Non-Communicating AC or HP (R-22 Series-A Unit)

Fig. 2 — Ventilator (HRV / ERV) Connection

B

G

R

Y

YellowGreen

A

B

C

W

O

Y1

Y2

FUSE

R

B

G

R

Y

Yellow

Green

C

W

O

Y1

Y2

FUSE

R

C

D

A

B

C

D

with Variable-Speed Indoor Unit

A

B

C

D

Furnace

Indoor

Unit

A

B

C

D

A03143

A

B

C

D

User

Interface

A03144

User

Interface

A03145

A

B

C

D

—3—

Page 4

PL4

1

1

ABCD

HUM

OAT

PL9

1

PL7

1

PL8

OAT

Sensor

GDHUMY1W2

24Y

RY/Y2W/W1COM

STATUS

CODE

FUSE 3-AMP

SEC-2 SEC-1

FAC-2

LEDS

ACRDJ

COMM

PL1

CARRIER PN

NEUTRAL-L2

1

1-AMPS 115VAC

EAC-1

L1

PL3

1

PL2

VS HSI HI LO

Fig. 5 — HK42FZ022 Furnace Board with

Outdoor Air Temperature Connection

1

A03230

© 2004 Bryant Heating & Cooling Systems 7310 W. Morris St. Indianapolis, IN 46231

—4—

Printed in U.S.A. iinim01-0-1 Catalog No. 809-60014

Loading...

Loading...