Page 1

SPLIT-SYSTEM

HEAT PUMP UNITS

697C (60 HZ)

Sizes 018 thru 060

FEATURES

ELECTRICAL RANGE —All units are single phase 208/230v.

COMPRESSOR —This unit features a scroll compressor,

which is significantly more efficient than conventional compressors. Its simple design offers improved reliability. Each

compressor is mounted on rubber isolators for additional

sound reduction. The scroll compressor starts under most

system loads, thus eliminating the need for start assistance

components. For improved serviceability, the 018 through

042 models are equipped with a compressor terminal plug.

Continuous operation is approved down to –30 ° F (–34.4 ° C)

in the heating mode and down to 55 ° F (12.8 ° C) in the cooling

mode. (See heating and cooling performance tables.) The

scroll compressor is covered with a standard 10-year limited

warranty.

BUILT-IN-RELIABLE COMPONENTS —All units include a suc-

tion tube accumulator that minimizes the amount of liquid refrigerant that reaches the compressor; a high-pressure

switch for high-pressure protection; and a low-pressure

switch for loss of charge protection.

DEFROST CONTROL BOARD —Incorporates a built-in 5-

minute compressor time-delay relay, defrost relay, defrost

timer, and low-voltage terminal board. The defrost control is a

time/temperature initiation/termination control, which includes

3 field-selectable time periods of 30, 50, and 90 minutes.

THERMOSTATIC EXPANSION VALVE (TXV) —This unit

must be installed with a TXV on the indoor coil. The FC4 and

FK4 indoor fan coils come factory equipped with a bi-flow

TXV. When installed in this application, no further change is

required. If any other indoor fan coil or furnace coil is used,

an accessory bi-flow TXV must be installed. See accessory

list in this publication for correct part no.

WEATHER-PROTECTIVE CABINET —Steel is galvanized and

coated with a layer of zinc phosphate. A coat of modified

polyester powder coating is then applied and baked-on, pro-

The

AeroQuiet System (AQS)

achieve ultra-low sound ratings.

Aerocoustic Design featuring the Aeromax opening and wire

dome top results in quieter and more efficient operation.

Energy-Efficient Fan and Fan Motor provide a slower fan oper-

ation, thus reducing noise and improving efficiency.

Sound Hood muffles noise from operation.

Discharge Muffler minimizes low frequency sound and pres-

sure pulsation generated by compressor discharge gas.

The 697C Outdoor Sections of Split-System Heat Pumps are

designed for quiet, reliable heating during the winter and

cooling during the summer. These heat pump systems provide economy of operation through energy conservation with

SEER up to 14.0 and HSPF up to 9.0. They recover heat for

indoor comfort from outdoor air during the heating season

and, by automatically reversing the refrigerant system, remove indoor heat and excess humidity during the cooling

season. All models are listed with UL, c-UL, ARI, and CEC.

consists of 4 design features to

viding each unit with a hard, smooth finish that will last for

many years.

All screws on cabinet exterior are coated for a long-lasting,

rust-resistant, quality appearance.

UNIT DESIGN —All units are equipped with totally enclosed

fan motors for greater reliability under rain and snow conditions. The large, wraparound coil uses copper tube and enhanced aluminum fin and is designed for optimum heat

transfer during heating and cooling. The vertical air discharge

carries the sound and air up and away from adjacent patio areas and foliage. Rows of composite coils can be cleaned with

a common garden hose.

EXTERNAL SERVICE VALVES —Both service valves are

brass, back seating type with sweat connections. Each valve

has a service port for ease of checking operating refrigerant

pressures. The suction service port provides for ease of

checking operating pressure in the heating mode.

LIMITED WARRANTY —Standard 1-year warranty on all

parts, with an additional 9-year warranty on compressor.

Form No. PDS 697C.18.3B

Page 2

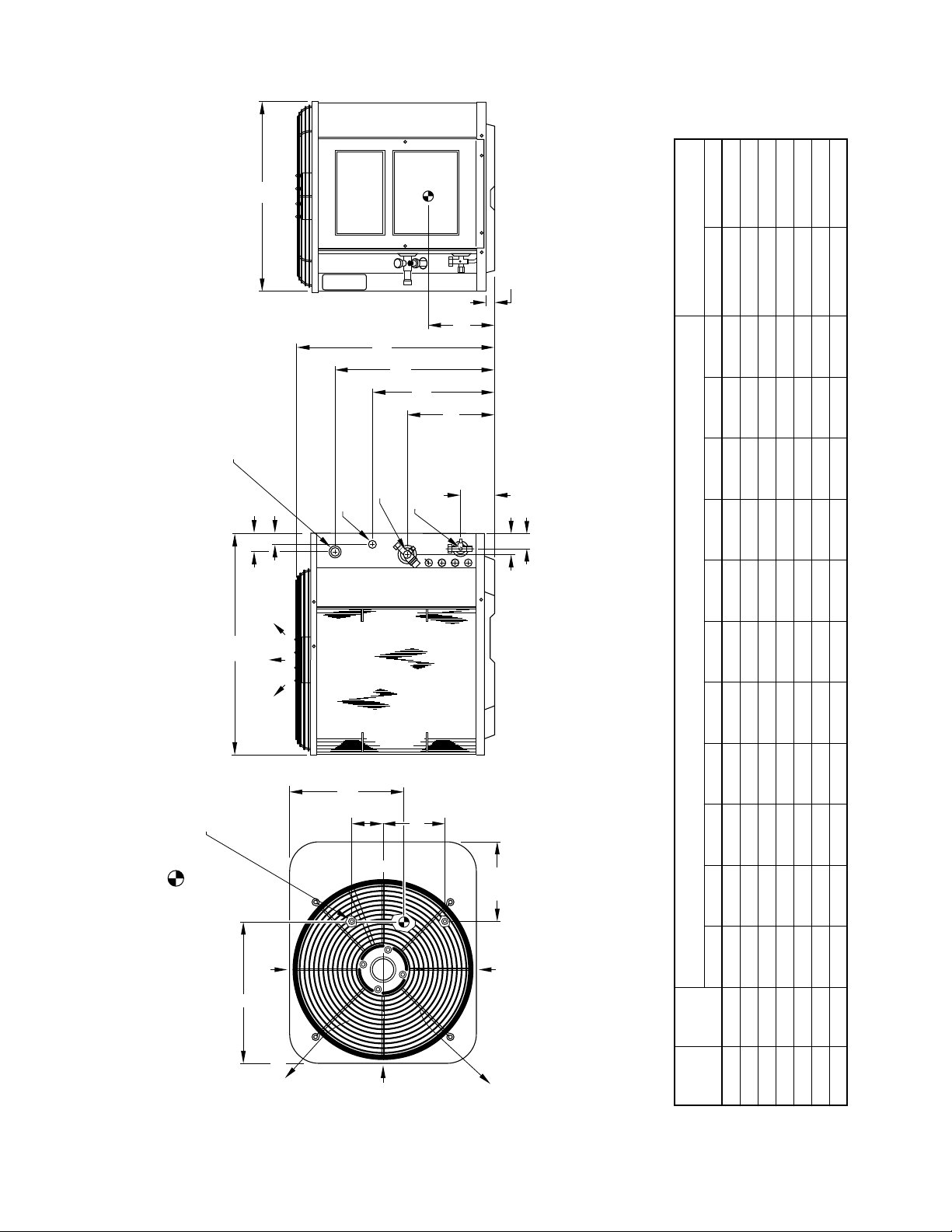

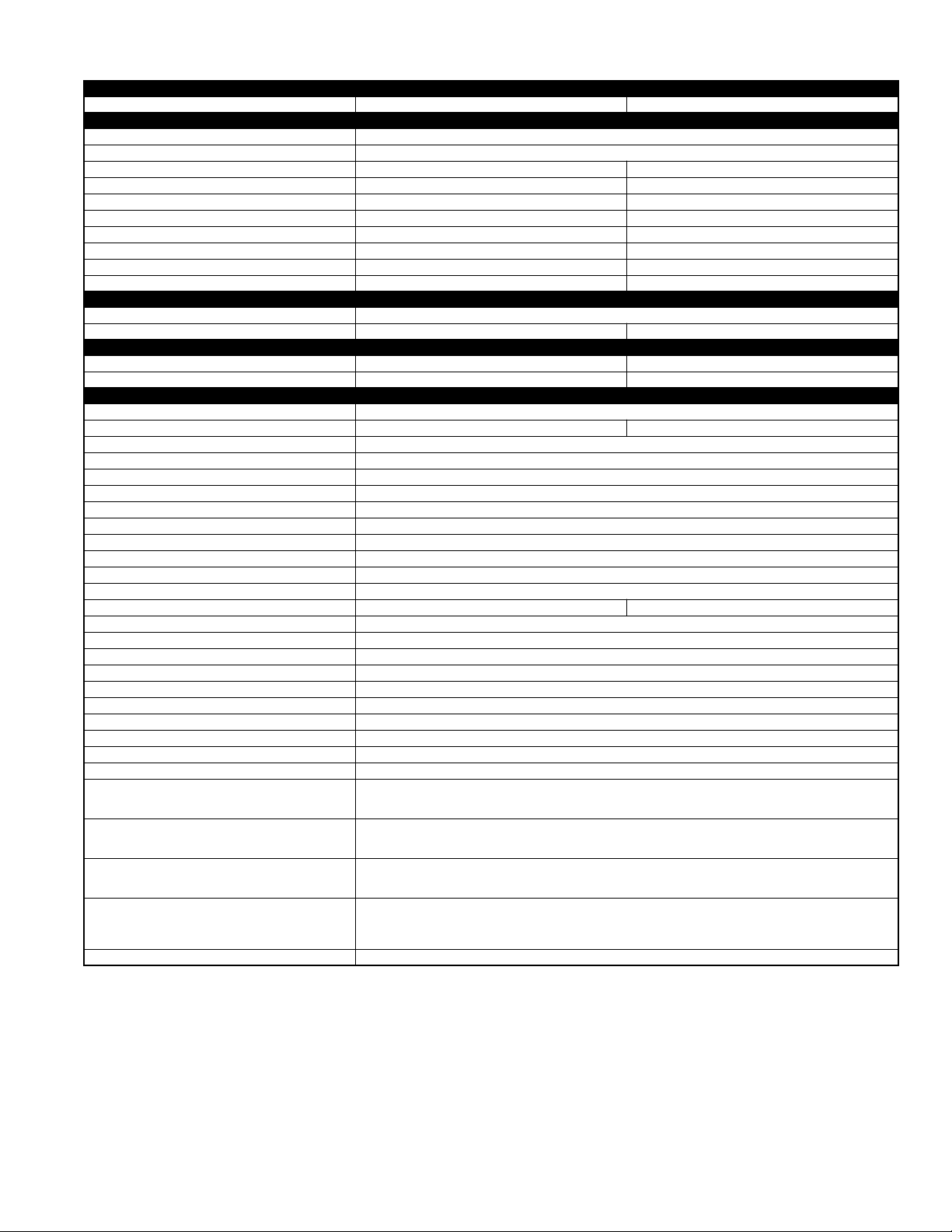

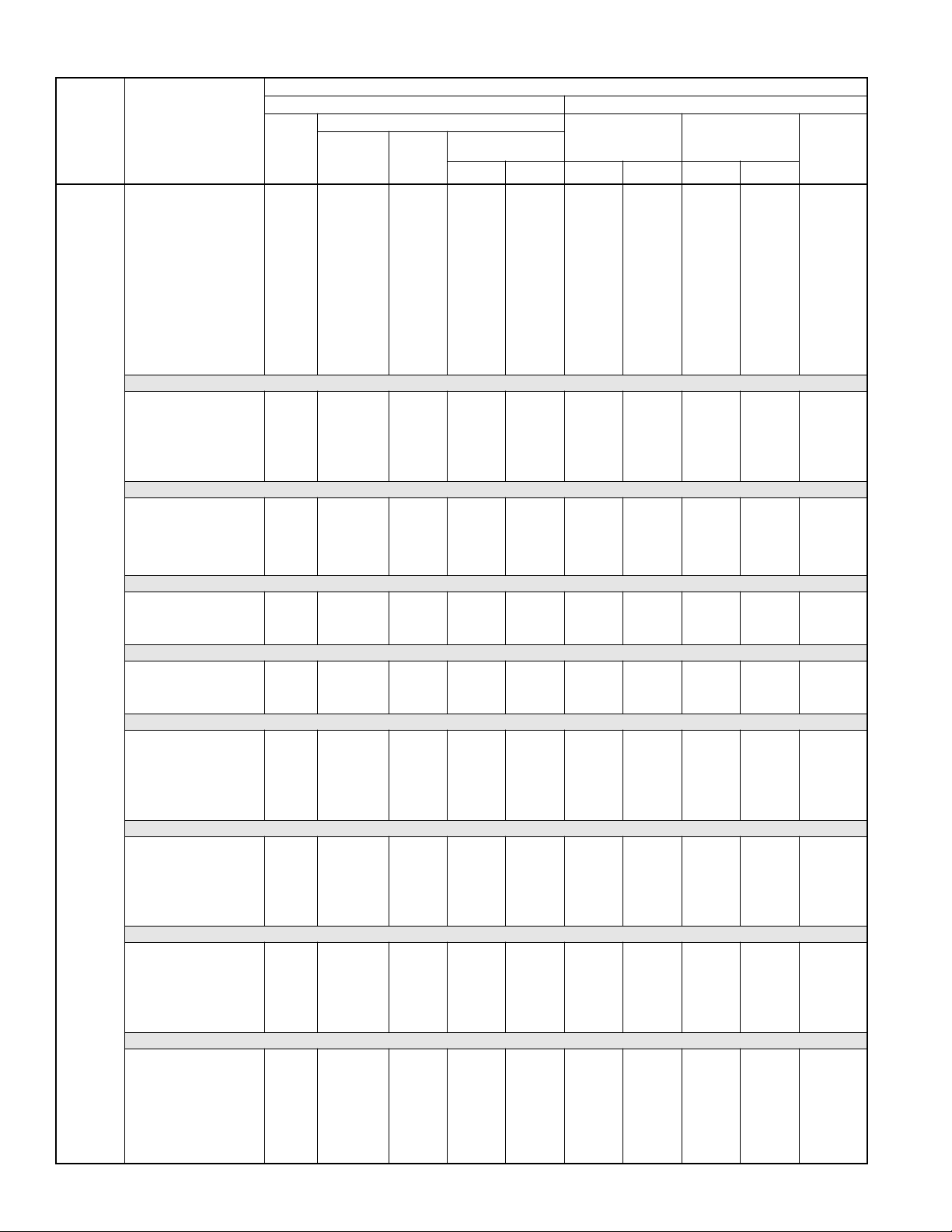

DIMENSIONS

A94148

B

ACCESS

DIA (22.22)

/8 IN.

7

DIA (34.92) KNOCKOUT

/8 IN.

1

DIA KNOCKOUT

/8 IN.

3

HOLE WITH 1

AND 1

FIELD POWER SUPPLY CONN

FIELD CONTROL

SUPPLY CONN

"

"

/16

/2

9

1

1

2

PANEL

A

DIA HOLE

DIA SUCTION

LINE CONN

H

/8 IN.

7

G

F

DIA LIQUID

/8 IN.

LINE CONN

3

"

/4

1

1

PAD DIMENSIONS

MINIMUM MOUNTING

M

"

/2

1

10

"

4

"

/4

3

1

N

C

AIR DISCHARGE

DIA (9.5) TIEDOWN KNOCKOUTS

/8 IN.

3

(2) PLACES IN BASEPAN

clearance to service end of unit, 48 in. above unit, 6 in. on one side, 12 in. on remaining side,

and 24 in. between units for proper airflow.

Minimum outdoor operating ambient in cooling mode is 55°F (unless low ambient control is used) max 125°F.2.

Maximum outdoor operating ambient in heating mode is 66°F.3.

Series designation is the 14th position of the unit model number.4.

1. Allow 30 in.

Center of gravity .5.

AIR IN

L

K

D

E

L

C

"

/16

3

8

AIR IN

NOTES:

DIMENSIONS (IN.)

UNIT DIMENSIONS

ABCDEFGHKLMSupport Feet Snow Stand

018 B 33-13/16 30 33 5-1/16 9-11/16 21-15/16 28-3/8 5/8 16-13/16 20-1/2 14 26 x 32 31 x 35

024 B 33-13/16 30 33 5-1/16 9-11/16 21-15/16 28-3/8 3/4 16-13/16 20-1/2 14 26 x 32 31 x 35

030 B 33-13/16 30 33 5-1/16 9-11/16 21-15/16 28-3/8 3/4 16-1/2 20-3/8 15 26 x 32 31 x 35

036 B 39-13/16 30 33 5-1/16 9-11/16 27-15/16 34-3/8 7/8 16-1/2 20-3/8 16 26 x 32 31 x 35

SIZE SERIES

UNIT

042 B 33-13/16 30 33 5-1/16 9-11/16 21-15/16 28-3/8 7/8 16-1/2 20-3/8 15 26 x 32 31 x 35

048 A 39-13/16 30 33 5-1/16 9-11/16 27-15/16 34-3/8 7/8 15-13/16 19-7/8 16 26 x 32 31 x 35

060 A 39-13/16 38-5/8 42-1/16 7-1/8 12-1/8 27-15/16 34-3/8 7/8 19-7/8 26 17-1/2 32 x 42 36 x 46

AIR DISCHARGE

AIR IN

AIR DISCHARGE

—2—

Page 3

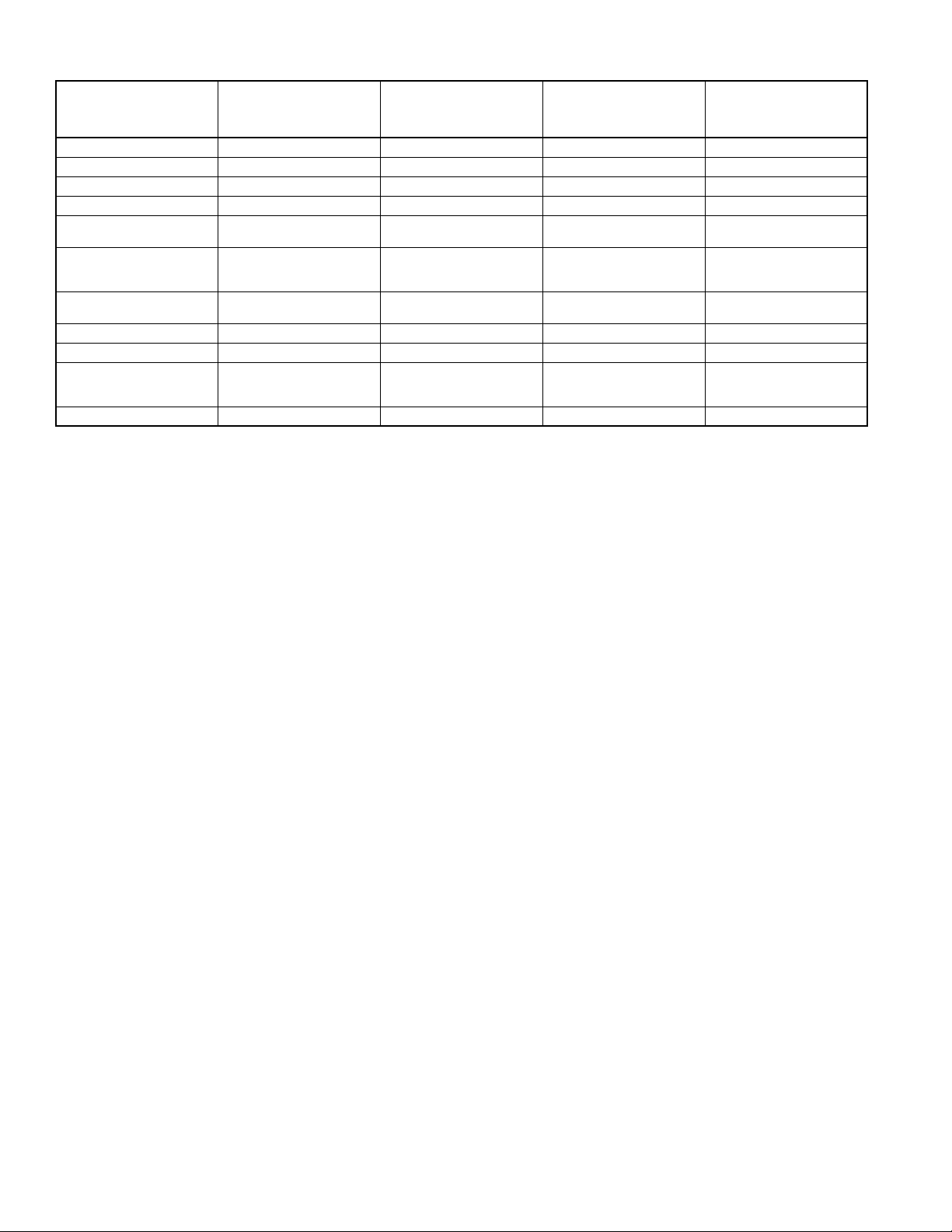

RECOMMENDED TUBE DIAMETERS

UNIT

SIZE

018

024, 030 3/4

036-048 7/8

060 1-1/8

* For tube set over 50 ft, consult Long-Line Application Guideline.

TUBE LENGTH

(Ft)*

0 to 50 3/8

LIQUID TUBE

DIAMETER (In.)

VAPOR TUBE

DIAMETER (In.)

5/8

METERING DEVICE

UNIT

SIZE SERIES

018 B 42 KHATX0901HSO

024 B 49 KHATX1001HSO

030 B 52 KHATX1101HSO

036 B 59 KHATX1201HSO

042 B 63 KHATX1201HSO

048 A 70 KHATX1301HSO

060 A 73 KHATX1401HSO

* TXV must be installed when indoor coil is not equipped with a TXV. TXV listed is for any approved

coil combination. All TXVs are bi-flow, hard shutoff.

OUTDOOR

PISTON

INDOOR

TXV*

T

O

D

E

A

I

R

F

I

I

T

A

R

S

E

C

R

E

R

U

T

C

N

A

U

F

U

N

A

M

A

R

C

O

M

H

P

E

A

Y

R

A

T

I

I

S

T

L

T

Y

P

I

U

N

M

G

P

W

I

T

H

®

E

T

Q

N

U

E

I

P

M

0

4

2

D

A

R

N

A

D

CERTIFICATION APPLIES ONLY WHEN THE

COMPLETE SYSTEM IS LISTED WITH ARI.

As an ENERGY STAR

Partner. Bryant has

determined that this

product meets the

ENERGY STAR guidelines

for energy efficiency.

SM

CERTIFICATION OF MANUFACTURING SITE.

—3—

Page 4

°

°

° F/ °

° F/ °

°

° F/ °

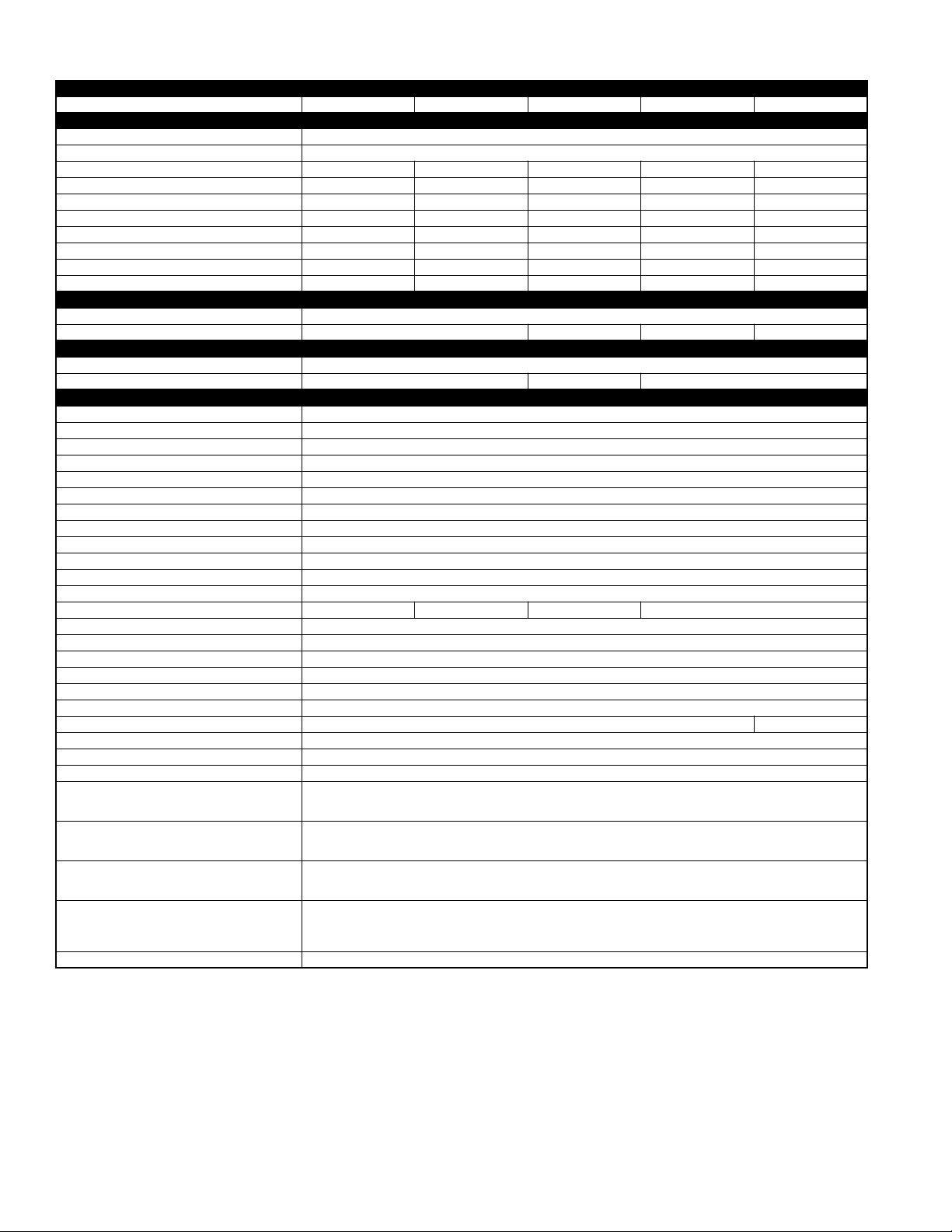

SPECIFICATIONS

UNIT SIZE-SERIES

Operating Weight (Lb) 198 198 221 211 231

ELECTRICAL

Unit Volts-Hertz-Phase 208/230-60-1

Operating Voltage Range 187—253

Unit Ampacity for Wire Sizing 16.1 17.5 18.7 21.0 32.0

Min Wire Size (60

Maximum Length (60

Max. Branch Circuit Fuse Size (Amps)‡ 25 25 30 30 50

Compressor Rated Load Amps 12.5 13.6 14.2 16.0 24.9

Locked Rotor Amps 47.0 61.0 72.5 88.0 104.0

Fan Motor HP and RPM 1/15 and 820 1/15 and 820 1/8 and 820 1/8 and 820 1/8 and 820

Full Load Amps 1.0 1.0 1.0 1.0 1.0

COMPRESSOR AND REFRIGERANT

Compressor Type Scroll

Refrigerant—Type and Amount (Lb)† R-22 and 5.63 R-22 and 8.88 R-22 and 7.13 R-22 and 10.88

OUTDOOR COIL AND FAN

Coil Face Area (Sq Ft) 15.15

Rated Airflow (CFM) 2500 2400 2900

OPTIONAL EQUIPMENT

Support Feet Kit—4 In. (4) KSASF0101AAA

Snow Stand—18 In. KHASS0206MPK

Time-Delay Relay KAATD0101TDR

Interface Control‡‡‡ KHAIC0101AAA

Service Alarm KHASA0101AAA††

Outdoor Thermostat KHAOT0301FST

Secondary Outdoor Thermostat KHAOT0201SEC

Cycle Protector Standard

Crankcase Heater KAACH1201AAA

Start Assist—PTC KAACS0201PTC

Start Capacitor and Relay KSAHS1501AAA

Sound Hood Standard

TXV Kits (Hard Shutoff) KHATX0901HSO KHATX1001HSO KHATX1101HSO KHATX1201HSO

TXV Kits (RPB) N/A

Low-Pressure Switch Standard

High-Pressure Switch Standard

Evaporator Freeze Thermostat KAAFT0101AAA‡‡

Isolation Relay KHAIR0101AAA‡‡

Liquid Solenoid Valve KHALS0101LLS

Filter Drier—Bi-flow P504-8083S (RCD) P504-8163S (RCD)

Low-Ambient Controller P251-0083(RCD)

MotorMaster® Control 32LT660004***

Ball Bearing Fan Motor HC38GE230 (RCD)

Thermostat, Auto Changeover,

Non-Programmable,

2-Stage Heat, 1-Stage Cool TSTATBHNHP01-A

Thermostat, Auto Changeover,

7-Day Programmable,

2-Stage Heat, 1-Stage Cool TSTATBHPHP01-A

Thermostat, Manual Changeover,

Non-Programmable,

2-Stage Heat, 1-Stage Cool HH07AT214

Thermostat, Auto Changeover,

Non-Programmable,

Dual Fuel Thermostat. Must be used with

Outdoor Sensor (TSTATBBSEN01) TSTATBHPDF01-A†††

Outdoor Sensor TSTATBBSEN01

See notes on page 5.

C/75 ° C Copper) (AWG)* 14/14 14/14 14/14 12/12 8/10

C/75 ° C) (Ft)** 46/44 44/42 41/39 60/57 97/59

C,

C,

F,

C,

018-B 024-B 030-B 036-B 042-B

—4—

Page 5

°

°

°

°

° F/ °

° F/ °

°

° F/ °

SPECIFICATIONS Continued

UNIT SIZE-SERIES

Operating Weight (Lb) 265 327

ELECTRICAL

Unit Volts-Hertz-Phase 208/230-60-1

Operating Voltage Range 187—253

Unit Ampacity for Wire Sizing 34.0 45.0

Min Wire Size (60

Maximum Length (60

Max. Branch Circuit Fuse Size (Amps)‡ 50 60

Compressor Rated Load Amps 26.5 34.9

Locked Rotor Amps 129.0 169.0

Fan Motor HP and RPM 1/8 and 820 1/5 and 820

Full Load Amps 1.0 1.4

COMPRESSOR AND REFRIGERANT

Compressor Scroll

Refrigerant—Type and Amount (Lb)† R-22 and 11.88 R-22 and 14.88

OUTDOOR COIL AND FAN

Coil Face Area (Sq Ft) 18.18 24.89

Rated Airflow (CFM) 2900 3600

OPTIONAL EQUIPMENT

Support Feet—4 In. (4) KSASF0101AAA

Snow Stand—18 In. KHASS0206MPK KHASS0306MPK

Time-Delay Relay KAATD0101TDR

Interface Control‡‡‡ KHAIC0101AAA

Service Alarm KHASA0101AAA††

Outdoor Thermostat KHAOT0301FST

Secondary Outdoor Thermostat KHAOT0201SEC

Cycle Protector Standard

Crankcase Heater Standard

Start Assist—PTC KAACS0201PTC

Start Capacitor and Relay KSAHS1601AAA

Sound Hood Standard

Bi-flow TXV Kits (Hard Shutoff) KHATX1301HSO KHATX1401HSO

Bi-flow TXV Kits (RPB) N/A

Low-Pressure Switch Standard

High-Pressure Switch Standard

Evaporator Freeze Thermostat KAAFT0101AAA‡‡

Isolation Relay KHAIR0101AAA‡‡

Liquid Solenoid Valve (LSV) KHALS0101LLS

Filter Drier—Bi-flow P504-8163S (RCD)

Low-Ambient Controller P251-0083 (RCD)

MotorMaster® Control 32LT660004***

Ball Bearing Fan Motor HC38GE230 (RCD)

Thermostat, Auto Changeover,

Non-Programmable,

2-Stage Heat, 1-Stage Cool TSTATBHNHP01-A

Thermostat, Auto Changeover,

7-Day Programmable,

2-Stage Heat, 1-Stage Cool TSTATBHPHP01-A

Thermostat, Manual Changeover,

Non-Programmable,

2-Stage Heat, 1-Stage Cool HH07AT214

Thermostat, Auto Changeover,

Non-Programmable,

Dual Fuel Thermostat. Must be used with

Outdoor Sensor (TSTATBBSEN01) TSTATBHPDF01-A†††

Outdoor Sensor TSTATBBSEN01

* If wire is applied at ambient greater than 30 ° C (86 ° F), consult Table 310-16 of the NEC (ANSI/NFPA 70). If other than uncoated (non-plated), 60 ° or 75 ° C

or 167 ° F) insulation, copper wire (solid wire for 10 A WG and smaller, stranded wire for larger than 10 AWG) is used, consult applicable tab les of the

(140

NEC (ANSI/NFPA 70). The ampacity of nonmetallic-sheathed cable (NM), trade name ROMEX, shall be that of 60

(ANSI/NFPA 70) Article 336-30.

† The factory refrigerant charge is for 15 ft of interconnecting tubing. For tubing lengths other than 15 ft, see Long-Line Application Guideline for additional

refrigerant requirements.

‡ Time-delay fuse or HACR breaker.

** Length shown is as measured 1 way along the wire path between the unit and the service panel for voltage drop not to exceed 2%.

†† For indicator light function, thermostat specified must be used and wired according to efficiency service alarm Installation Instructions.

‡‡ Used with low-ambient controller.

*** Fan motor with ball bearings required.

††† High-pressure switch must be added if not supplied with the system.

‡‡‡ Outdoor thermostat required.

N/A—Not Applicable

C/75 ° C Copper) (AWG)* 8/10 6/8

C/75 ° C) (Ft)** 91/56 116/66

C,

C,

F,

C,

048-A 060-A

C (140 ° F) conductors, per the NEC

—5—

Page 6

°

°

°

°

°

°

°

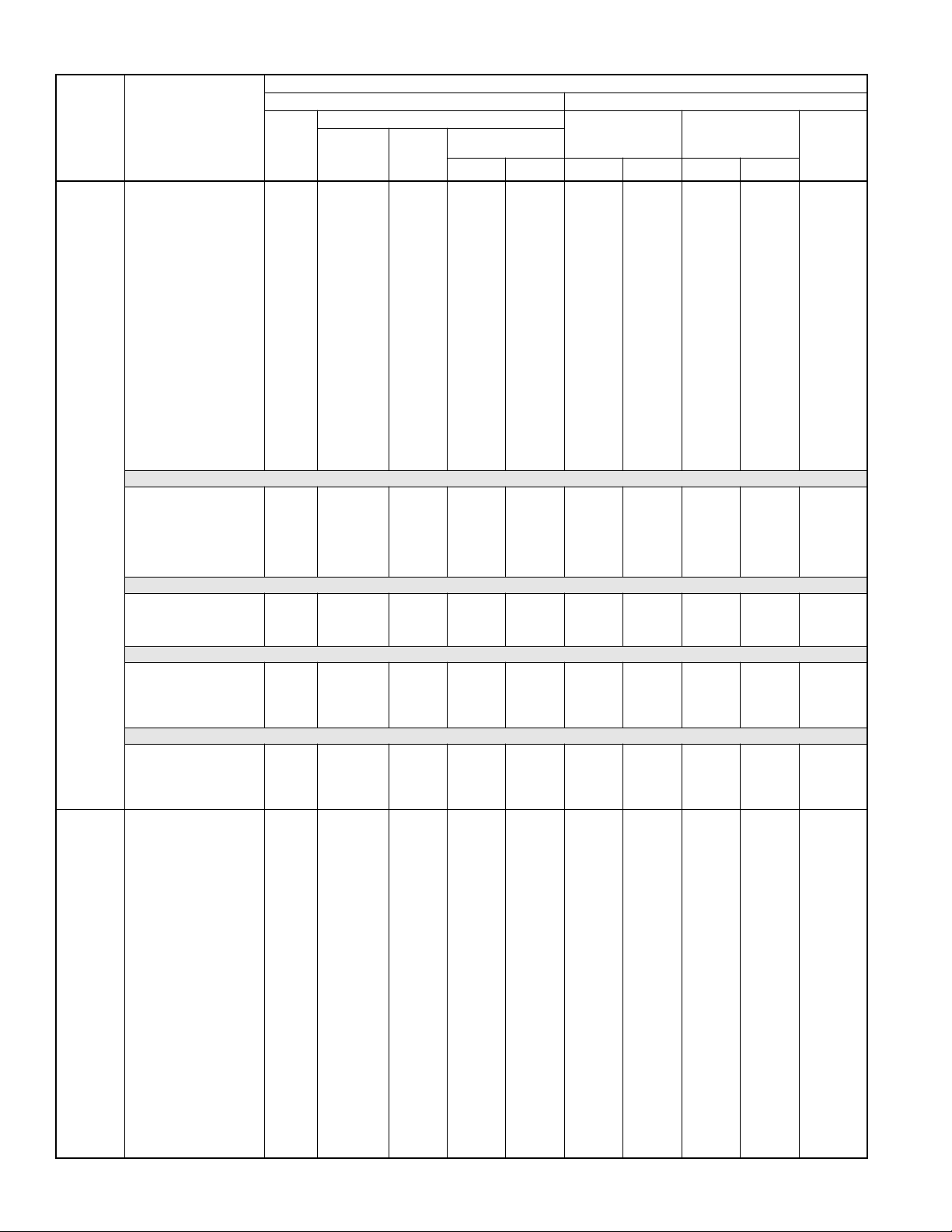

ACCESSORY USAGE GUIDELINE

REQUIRED FOR

LOW-AMBIENT

ACCESSORY

APPLICATIONS

(Below 55 ° F)

Crankcase Heater Yes Yes Yes No

Evaporator Freeze Thermostat Yes No No No

Winter Start Control Yes‡ No No No

Accumulator No No Yes No

Compressor Start Assist

Capacitor and Relay Yes Yes Yes No

Low Ambient Controller

MotorMaster® Control Yes No No No

or

Wind Baffle

See Low-Ambient

Instructions

Coastal Filter No No No Yes

Support Feet Recommended No No Recommended

Liquid-Line Solenoid Valve

or

Hard Shutoff TXV No

Ball Bearing Fan Motor Yes No No No

* For tubing line sets between 50 and 175 ft, refer to Residential’s Split System Long-Line Application Guidelines.

† For buried line applications, refer to Residential’s Split Systems Buried Line Application Guidelines.

‡ Only when low-pressure switch is used.

REQUIRED FOR

LONG-LINE

APPLICATIONS*

(Over 50 Ft)

REQUIRED FOR

BURIED LINE

APPLICATIONS†

(Over 3 Ft)

REQUIRED FOR

SEA COAST

APPLICATIONS

(Within 2 Miles)

No No No

See

Long-Line

Application Guideline Yes No

ACCESSORY DESCRIPTION AND USAGE (Listed Alphabetically)

1. Ball Bearing Fan Motor

A fan motor with ball bearings which permits speed reduction while maintaining bearing lubrication.

SUGGESTED USE: Required on all units where low-ambient controller (full modulation feature) or MotorMaster® Control has been added.

2. Compressor Start Assist-Capacitor/Relay Type

Start capacitor and start relay gives “hard” boost to compressor motor at each start-up.

SUGGESTED USE: Installations where interconnecting tube length exceeds 50 ft. Installations where outdoor design temperature exceeds 105

3. Compressor Start Assist-PTC Type

Solid-state electrical device which gives a “soft” boost to the compressor at each start-up.

SUGGESTED USE: Installations with marginal power supply.

4. Crankcase Heater

An electric resistance heater which mounts to the base of the compressor to keep the lubricant warm during off cycles. Improves compressor lubrication on

restart and minimizes chance of refrigerant slugging. May or may not include a thermostat control.

SUGGESTED USE: When interconnecting tube length exceeds 50 ft.

5. Evaporator Freeze Thermostat

An SPST temperature actuated switch which stops unit operation when evaporator reaches freeze-up conditions.

SUGGESTED USE: With low-ambient controller.

6. Filter Drier—Bi-flow

A device for removing contaminants from refrigerant circulating in a heat pump system; 2-direction flow for heat pumps.

SUGGESTED USE: Split-system heat pumps.

7. Interface Control

An electric control for controlling a heat pump and gas or oil furnace system for maximum energy savings. It allows heat pump to operate down to a predetermined economic balance point temperature, then switches to allow furnace operation only below that temperature. Requires outdoor thermostat (Item 12) to

be adjusted for economic balance point temperature.

SUGGESTED USE: For heat pump and gas- or oil-fired furnace combination systems.

8. Isolation Relay

An SPDT relay which switches the low-ambient controller out of the outdoor fan motor circuit when the heat pump switches to heating mode.

SUGGESTED USE: All heat pumps where low-ambient controller has been added.

9. Liquid Solenoid Valve (LSV)

An electrically operated shutoff valve to be installed at the outdoor unit and which stops and starts refrigerant liquid flow in response to compressor operation.

Maintains a column of refrigerant liquid ready for action at next compressor operation cycle.

SUGGESTED USE: In certain long-line applications. (Refer to Long-Line Application Guideline.)

10. Low-Ambient Controller

Head pressure controller is a cycle control device activated by a temperature sensor mounted on a header tube of the outdoor coil. It is designed to cycle the

outdoor fan motors in order to maintain condensing temperature within normal operating limits (approximately 130 to 110

will maintain working head pressure at low-ambient temperatures down to 0

SUGGESTED USE: Cooling operation at outdoor temperatures below 55

11. MotorMaster® Control

A fan speed control device activated by a temperature sensor. Designed to control condenser fan motor speed in response to the saturated, condensing temperature during operation in cooling mode only. For outdoor temperatures down to –20

SUGGESTED USE: Cooling operation at outdoor temperatures below 55

12. Outdoor Thermostat

An SPDT temperature actuated switch which turns on supplemental electric heaters when outdoor air temperature drops below set point.

SUGGESTED USE: Heat pump installations with multiple-stage supplemental heaters.

Replacement installations with hard shutoff expansion valve on indoor coil. Units installed with low-ambient controller. Units installed with liquid

solenoid valve.

Replacement installations with rapid pressure balance (RPB) expansion valve on indoor coil.

When unit will be operated below 55

All commercial installations.

F (12.8 ° C) outdoor air temperature. (Use with low-ambient controller.)

F high, 70 to 50 ° F low). The control

F when properly installed.

F (12.8 ° C).

F, it maintains condensing temperature at 100 ° F ± 10 ° F.

F.

F (40.6 ° C).

—6—

Page 7

ACCESSORY DESCRIPTION AND USAGE (Listed Alphabetically) Continued

13. Secondary Outdoor Thermostat

An SPDT temperature actuated switch which turns on a third stage of supplemental electric heaters when outdoor air temperature drops below the secondstage set point.

SUGGESTED USE: Heat pump installations where 3-stage operation of supplemental heaters is desired.

14. Service Alarm

A current-sensing lockout relay which provides immediate notification that compressor is not operating during a call for heating or cooling. Used with proper

room thermostat, the thermostat light is turned on signifying service is required. This can minimize electrical cost increase due to operation of supplemental

heaters only.

SUGGESTED USE: As a feature to notify owner immediately when the system is not operating most efficiently.

15. Snow Stand

Coated wire rack which supports unit 18 in. above mounting pad to allow for drainage from unit base.

SUGGESTED USE: Heat pump installations in heavy snowfall areas.

16. Sound Hood

Wraparound sound reducing cover for the compressor. Reduces unit sound level by about 2 dBA.

SUGGESTED USE: Unit installed closer than 15 ft to quiet areas—bedrooms, etc.

17. Support Feet

Four stick-on plastic feet which raise the unit 4 in. above the mounting pad. This allows sand, dirt, and other debris to be flushed from the unit base; minimizes

corrosion.

SUGGESTED USE: Coastal installations.

18. Thermostatic Expansion Valve (TXV)—Bi-flow

A modulating flow control valve which meters refrigerant liquid flow rate into the evaporator in response to the superheat of the refrigerant gas leaving the evaporator. Kit includes valve, adapter tubes, and external equalizer tube.

SUGGESTED USE: Required for improved system performance. (Refer to ARI Unitary Directory.)

19. Time-Delay Relay

An SPST delay relay which briefly continues operation of the indoor blower motor to provide additional cooling after the compressor cycles off.

SUGGESTED USE: For improved efficiency ratings for certain combinations of indoor and outdoor units. (Refer to ARI Unitary Directory.)

Heat pump installations in snowdrift locations.

Heat pump installations in areas of prolonged subfreezing temperatures.

All commercial installations.

Unit installed between 2 houses less than 10 ft apart.

Windy areas or where debris is normally circulating.

Rooftop installations.

Required for use on all zoning systems.

—7—

Page 8

UNIT SIZE-

SERIES

AND

SOUND

RATING

(dBA)

FC4BNF024† 18,000 TDR & TXV 12.20 — — 17,500 3.12 11,600 2.28 7.20/8.00

F(A,B)4AN(F,C)018 17,500 TDR — 11.70 — 17,000 2.84 11,400 2.16 6.80/7.20

F(A,B)4AN(F,C)024 18,000 TDR — 12.20 — 17,500 3.12 11,600 2.28 7.20/8.00

FD3ANA018 17,500 None — — 11.70 17,000 2.76 11,500 2.12 6.80/7.00

FD3ANA024 18,000 None — — 12.70 17,000 2.98 11,300 2.24 7.00/7.50

FF1BNA018 17,500 TDR — 12.50 — 17,000 2.92 11,200 2.22 7.00/7.50

FF1BNA024 18,500 TDR — 12.70 — 17,500 3.08 11,500 2.28 7.20/7.70

FG3AA024 18,000 None — — 12.20 17,000 2.92 11,400 2.20 7.00/7.50

FK4BNF001 19,000 TDR & TXV 14.00 — — 17,000 3.32 11,100 2.44 7.50/8.20

FK4BNF002 19,000 TDR & TXV 14.50 — — 17,000 3.52 11,100 2.54 8.00/8.50

FK4CNF001 19,000 TDR & TXV 14.50 — — 16,500 3.18 10,700 2.38 7.50/8.20

FK4CNF002 19,000 TDR & TXV 15.00 — — 16,600 3.30 10,700 2.42 7.80/8.50

CC5A/CD5A/CD5BA018 17,500 None — — 12.00 17,000 2.76 11,300 2.14 6.80/7.00

CC5A/CD5A/CD5BA024 18,000 None — — 12.50 17,500 2.94 11,400 2.22 7.00/7.50

CC5A/CD5A/CD5BW024 18,000 None — — 12.50 17,500 2.94 11,400 2.22 7.00/7.50

CD3(A,B)A018 17,500 None — — 12.00 17,000 2.76 11,300 2.14 6.80/7.00

CD3(A,B)A024 18,000 None — — 12.50 17,500 2.94 11,400 2.22 7.00/7.50

CE3AA024 18,000 None — — 12.50 17,500 2.98 11,500 2.24 7.00/7.50

CF5AA024 18,000 None — — 12.50 17,500 3.00 11,500 2.24 7.00/7.50

CJ5A/CK5A/CK5BA018 17,000 None — — 12.00 17,000 2.94 11,300 2.22 7.00

CJ5A/CK5A/CK5BA024 17,500 None — — 12.20 17,000 3.06 11,300 2.26 7.20

CJ5A/CK5A/CK5BW024 17,500 None — — 12.20 17,000 3.06 11,300 2.26 7.20

018-B

72

024-B

72

CK3BA024 17,500 None — — 12.20 17,000 3.06 11,300 2.26 7.20

CC5A/CD5A/CD5BA024 18,000 TDR — 14.00 — 17,000 2.98 10,900 2.28 7.00/7.70

CC5A/CD5A/CD5BW024 18,000 TDR — 14.00 — 17,000 2.98 10,900 2.28 7.00/7.70

CD3(A,B)A024 18,000 TDR — 14.00 — 17,000 2.98 10,900 2.28 7.00/7.70

CE3AA024 18,000 TDR — 13.50 — 17,000 2.96 11,000 2.26 7.00/7.70

CJ5A/CK5A/CK5BA018 17,500 TDR — 13.50 — 17,000 3.12 10,900 2.34 7.20

CJ5A/CK5A/CK5BA024 17,500 TDR — 14.00 — 17,000 3.24 10,900 2.40 7.50

CK3BA024 17,500 TDR — 14.00 — 17,000 3.24 10,900 2.40 7.50

CC5A/CD5A/CD5BA024 18,000 TDR — 14.00 — 17,000 2.98 10,800 2.28 7.00/7.70

CC5A/CD5A/CD5BW024 18,000 TDR — 14.00 — 17,000 2.98 10,800 2.28 7.00/7.70

CD3(A,B)A024 18,000 TDR — 14.00 — 17,000 2.98 10,800 2.28 7.00/7.70

CE3AA024 18,000 TDR — 13.50 — 17,000 2.98 11,000 2.26 7.00/7.70

CC5A/CD5A/CD5BA024 18,500 TDR — 14.00 — 17,000 3.08 11,000 2.32 7.20/8.00

CC5A/CD5A/CD5BW024 18,500 TDR — 14.00 — 17,000 3.08 11,000 2.32 7.20/8.00

CD3(A,B)A024 18,500 TDR — 14.00 — 17,000 3.08 11,000 2.32 7.20/8.00

CJ5A/CK5A/CK5BW024 18,000 TDR — 13.80 — 17,000 3.32 11,100 2.42 7.50

CK3BA024 18,000 TDR — 13.80 — 17,000 3.32 11,100 2.42 7.50

CC5A/CD5A/CD5BA024 18,500 TDR — 14.00 — 17,000 3.08 11,000 2.32 7.20/8.00

CC5A/CD5A/CD5BW024 18,500 TDR — 14.00 — 17,000 3.08 11,000 2.32 7.20/8.00

CD3(A,B)AS024 18,500 TDR — 14.00 — 17,000 3.08 11,000 2.32 7.20/8.00

CJ5A/CK5A/CK5BW024 18,000 TDR — 14.00 — 17,000 3.32 11,000 2.44 7.50

CK3BA024 18,000 TDR — 14.00 — 17,000 3.32 11,000 2.44 7.50

FC4BNF030† 24,000 TDR & TXV 12.00 — — 25,000 3.40 15,500 2.40 7.80/8.20

F(A,B)4AN(F,C)024 23,600 TDR — 11.70 — 25,000 3.34 15,600 2.36 7.70/8.00

F(A,B)4AN(F,C)030 24,000 TDR — 12.00 — 25,000 3.40 15,500 2.40 7.80/8.20

FC4BNF024 23,600 TDR & TXV 11.70 — — 25,000 3.34 15,600 2.36 7.70/8.00

FC4BNF033 24,600 TDR & TXV 12.00 — — 25,000 3.50 15,700 2.44 8.00/8.50

FD3ANA024 23,200 None — — 11.70 25,000 3.22 15,400 2.30 7.50/8.00

FD3ANA030 24,000 None — — 11.80 25,000 3.38 15,700 2.38 7.70/8.20

FF1(A,B)NA024 23,600 TDR — 11.70 — 25,000 3.36 15,600 2.36 7.70/8.20

FF1(A,B)NA030 24,000 TDR — 11.80 — 25,000 3.42 15,700 2.40 7.80/8.20

FG3AAA024 23,200 None — — 11.50 25,000 3.16 15,500 2.28 7.40/7.80

FK4BNF001 24,800 TDR & TXV 13.00 — — 25,000 3.62 15,200 2.54 8.20/8.50

FK4BNF002 25,000 TDR & TXV 13.20 — — 25,000 3.76 15,200 2.60 8.50/9.00

FK4BNF003 25,000 TDR & TXV 13.50 — — 24,400 3.68 15,000 2.58 8.50/9.00

FK4CNF001 24,400 TDR & TXV 13.00 — — 24,600 3.54 15,000 2.50 8.00/8.50

FK4CNF002 24,600 TDR & TXV 13.20 — — 24,800 3.68 15,100 2.56 8.20/8.80

FK4CNF003 24,800 TDR & TXV 13.50 — — 24,600 3.64 15,000 2.58 8.20/8.70

CC5A/CD5A/CD5BA024 23,400 None — — 11.50 25,000 3.20 15,500 2.28 7.50/8.00

CC5A/CD5A/CD5BA030 23,600 None — — 11.70 25,000 3.22 15,500 2.30 7.50/8.00

CC5A/CD5A/CD5BA036 24,400 None — — 12.00 25,000 3.46 15,600 2.42 8.00/8.20

CC5A/CD5A/CD5BW024 23,400 None — — 11.50 25,000 3.20 15,500 2.28 7.50/8.00

CC5A/CD5A/CD5BW030 23,600 None — — 11.70 25,000 3.22 15,500 2.30 7.50/8.00

CD5A/CD5BW036 24,400 None — — 12.00 25,000 3.46 15,600 2.42 8.00/8.20

CD3(A,B)A024 23,400 None — — 11.50 25,000 3.20 15,500 2.28 7.50/8.00

CD3(A,B)A030 23,600 None — — 11.70 25,000 3.22 15,500 2.30 7.50/8.00

CD3(A,B)A036 24,400 None — — 12.00 25,000 3.46 15,600 2.42 8.00/8.20

CE3AA024 23,400 None — — 11.50 25,000 3.18 15,500 2.30 7.50/8.00

CE3AA030 24,000 None — — 11.80 25,000 3.36 15,600 2.38 7.60/8.00

CF5AA024 23,600 None — — 11.70 25,000 3.26 15,600 2.32 7.50/8.00

See notes on page 15.

INDOOR

UNIT

TC

COMBINATION RATINGS*

ARI STANDARD RATINGS*

Cooling Heating

Seasonal Efficiency SEER

Factory-

Supplied

Enhance-

ment

COILS + 333(B,J)AV036060 VARIABLE-SPEED FURNACE

COILS + 333(B,J)AV048080 VARIABLE-SPEED FURNACE

COILS + 355MAV042060 VARIABLE-SPEED FURNACE

COILS + 355MAV042080 VARIABLE-SPEED FURNACE

Standard

Rating

Field-Supplied

Accessory‡

TXV

TXV&TDR**

High-Temp Low-Temp Seasonal

TC COP TC COP

—8—

Efficiency

HSPF/HSPF

with LSV

Page 9

UNIT SIZE-

SERIES

AND

SOUND

RATING

(dBA)

CJ5A/CK5A/CK5BA024 23,200 None — — 11.50 25,000 3.30 15,500 2.34 7.50

CJ5A/CK5A/CK5BA030 23,600 None — — 11.70 24,400 3.28 15,500 2.34 7.50

CJ5A/CK5A/CK5BW024 23,200 None — — 11.50 25,000 3.30 15,500 2.34 7.50

CJ5A/CK5A/CK5BW030 23,600 None — — 11.70 24,400 3.28 15,500 2.34 7.50

CK3BA024 23,200 None — — 11.50 25,000 3.30 15,500 2.34 7.50

CK3BA030 23,600 None — — 11.70 24,400 3.28 15,500 2.34 7.50

CC5A/CD5A/CD5BA030 23,800 TDR — 13.00 — 24,000 3.26 14,900 2.38 7.70/8.20

CC5A/CD5A/CD5BW030 23,800 TDR — 13.00 — 24,000 3.26 14,900 2.38 7.70/8.20

CD3(A,B)A030 23,800 TDR — 13.00 — 24,000 3.26 14,900 2.38 7.70/8.20

CE3AA030 24,000 TDR — 13.00 — 24,000 3.42 15,000 2.44 8.00/8.50

CJ5A/CK5A/CK5BA024 23,600 TDR — 12.50 — 24,000 3.46 15,000 2.46 8.00

CJ5A/CK5A/CK5BA030 24,000 TDR — 13.00 — 24,000 3.46 15,000 2.48 8.00

CJ5A/CK5A/CK5BW030 24,000 TDR — 13.00 — 24,000 3.46 15,000 2.48 8.00

CK3BA024 23,600 TDR — 12.50 — 24,000 3.46 15,000 2.46 8.00

CK3BA030 24,000 TDR — 13.00 — 24,000 3.46 15,000 2.48 8.00

CC5A/CD5A/CD5BA030 23,800 TDR — 13.00 — 24,000 3.28 14,900 2.38 7.70/8.20

CC5A/CD5A/CD5BW030 23,800 TDR — 13.00 — 24,000 3.28 14,900 2.38 7.70/8.20

CD3(A,B)A030 23,800 TDR — 13.00 — 24,000 3.28 14,900 2.38 7.70/8.20

CE3AA030 24,000 TDR — 13.00 — 24,000 3.42 15,000 2.44 8.00/8.50

CC5A/CD5A/CD5BA030 23,800 TDR — 13.00 — 24,000 3.30 14,900 2.40 7.70/8.20

CC5A/CD5A/CD5BW030 23,800 TDR — 13.00 — 24,000 3.30 14,900 2.40 7.70/8.20

CD3(A,B)A030 23,800 TDR — 13.00 — 24,000 3.30 14,900 2.40 7.70/8.20

CE3AA030 24,000 TDR — 13.00 — 24,000 3.46 14,900 2.46 8.00/8.50

024-B

72

030-B

72

CC5A/CD5A/CD5BA030 23,800 TDR — 13.00 — 24,000 3.28 14,900 2.38 7.70/8.20

CC5A/CD5A/CD5BW030 23,800 TDR — 13.00 — 24,000 3.28 14,900 2.38 7.70/8.20

CD3(A,B)A030 23,800 TDR — 13.00 — 24,000 3.28 14,900 2.38 7.70/8.20

CE3AA030 24,000 TDR — 13.00 — 24,000 3.44 15,000 2.46 8.00/8.50

CC5A/CD5A/CD5BA030 24,200 TDR — 13.00 — 24,000 3.38 15,100 2.42 7.80/8.40

CC5A/CD5A/CD5BW030 24,200 TDR — 13.00 — 24,000 3.38 15,100 2.42 7.80/8.40

CD3(A,B)A030 24,200 TDR — 13.00 — 24,000 3.38 15,100 2.42 7.80/8.40

CJ5A/CK5A/CK5BW030 24,400 TDR — 12.80 — 24,200 3.52 15,200 2.50 8.00

CK3BA024 23,800 TDR — 12.50 — 24,400 3.52 15,200 2.48 8.00

CK3BA030 24,400 TDR — 12.80 — 24,200 3.52 15,200 2.50 8.00

CC5A/CD5A/CD5BA030 24,200 TDR — 12.80 — 24,000 3.38 15,100 2.42 7.80/8.40

CC5A/CD5A/CD5BW030 24,200 TDR — 12.80 — 24,000 3.38 15,100 2.42 7.80/8.40

CD3(A,B)A030 24,200 TDR — 12.80 — 24,000 3.38 15,100 2.42 7.80/8.40

CJ5A/CK5A/CK5BW024 23,800 TDR — 12.50 — 24,400 3.52 15,200 2.48 8.00

CJ5A/CK5A/CK5BW030 24,400 TDR — 12.80 — 24,400 3.52 15,200 2.50 8.00

CK3BA024 23,800 TDR — 12.50 — 24,400 3.52 15,200 2.48 8.00

CK3BA030 24,400 TDR — 12.80 — 24,400 3.52 15,200 2.50 8.00

CC5A/CD5A/CD5BA030 24,200 TDR — 13.00 — 24,000 3.40 15,100 2.44 7.80/8.40

CC5A/CD5A/CD5BW030 24,200 TDR — 13.00 — 24,000 3.40 15,100 2.44 7.80/8.40

CD3(A,B)A030 24,200 TDR — 13.00 — 24,000 3.40 15,100 2.44 7.80/8.40

CJ5A/CK5A/CK5BW024 24,000 TDR — 12.80 — 24,200 3.56 15,100 2.52 8.00

CJ5A/CK5A/CK5BW030 24,400 TDR — 13.00 — 24,200 3.56 15,100 2.52 8.00

CK3BA024 24,000 TDR — 12.80 — 24,200 3.56 15,100 2.52 8.00

CK3BA030 24,400 TDR — 13.00 — 24,200 3.56 15,100 2.52 8.00

CC5A/CD5A/CD5BA030 24,200 TDR — 13.00 — 24,000 3.40 15,100 2.44 7.80/8.40

CC5A/CD5A/CD5BW030 24,200 TDR — 13.00 — 24,000 3.40 15,100 2.44 7.80/8.40

CD3(A,B)A030 24,200 TDR — 13.00 — 24,000 3.40 15,100 2.44 7.80/8.40

FC4BNF036† 28,400 TDR & TXV 12.10 — — 30,000 3.14 18,500 2.28 7.70/8.00

F(A,B)4ANF030 28,000 TDR — 12.30 — 30,000 3.12 18,300 2.28 7.70/8.00

F(A,B)4ANF036 28,400 TDR — 12.10 — 30,000 3.14 18,500 2.28 7.70/8.00

FC4BNF030 28,000 TDR & TXV 12.30 — — 30,000 3.12 18,300 2.28 7.70/8.00

FC4BNF033 28,800 TDR & TXV 12.50 — — 30,000 3.22 18,400 2.32 8.00/8.20

FD3ANA030 28,000 None — — 12.10 30,000 3.12 18,400 2.26 7.70/8.00

FF1(A,B)NA030 28,200 TDR — 12.20 — 30,000 3.16 18,400 2.28 7.70/8.00

FG3AAA036 28,200 None — — 12.20 30,000 3.12 18,300 2.28 7.70/8.00

FK4BNF001 29,000 TDR & TXV 13.00 — — 30,000 3.28 18,000 2.38 8.00/8.50

FK4BNF002 29,200 TDR & TXV 13.50 — — 30,000 3.42 18,100 2.42 8.20/8.70

FK4BNF003 29,600 TDR & TXV 14.00 — — 29,800 3.42 17,800 2.46 8.20/8.70

FK4BNF004 29,800 TDR & TXV 13.50 — — 30,000 3.56 18,100 2.50 8.50/9.00

FK4CNF001 28,600 TDR & TXV 13.50 — — 29,600 3.28 17,900 2.40 8.00/8.30

FK4CNF002 28,800 TDR & TXV 13.50 — — 29,800 3.38 18,000 2.44 8.20/8.50

FK4CNF003 29,200 TDR & TXV 14.00 — — 29,600 3.38 17,800 2.46 8.20/8.50

See notes on page 15.

INDOOR

UNIT

COMBINATION RATINGS* Continued

ARI STANDARD RATINGS*

Cooling Heating

Seasonal Efficiency SEER

Field-Supplied

Accessory‡

TXV

TC

Factory-

Supplied

Enhance-

ment

COILS + 333(B,J)AV036060 VARIABLE-SPEED FURNACE

COILS + 333(B,J)AV048080 VARIABLE-SPEED FURNACE

COILS + 333(B,J)AV060100 VARIABLE-SPEED FURNACE

COILS + 333(B,J)AV060120 VARIABLE-SPEED FURNACE

Standard

Rating

COILS + 355MAV042040 VARIABLE-SPEED FURNACE

COILS + 355MAV042060 VARIABLE-SPEED FURNACE

COILS + 355MAV042080 VARIABLE-SPEED FURNACE

COILS + 355MAV060100 VARIABLE-SPEED FURNACE

TXV&TDR**

High-Temp Low-Temp Seasonal

TC COP TC COP

Efficiency

HSPF/HSPF

with LSV

—9—

Page 10

UNIT SIZE-

SERIES

AND

SOUND

RATING

(dBA)

CC5A/CD5A/CD5BA030 27,800 None — — 12.00 30,000 3.00 18,300 2.22 7.50/7.70

CC5A/CD5A/CD5BW030 27,800 None — — 12.00 30,000 3.00 18,300 2.22 7.50/7.70

CC5A/CD5A/CD5BA036 28,600 None — — 12.50 30,000 3.18 18,400 2.30 7.70/8.00

CD5A/CD5BW036 28,600 None — — 12.50 30,000 3.18 18,400 2.30 7.70/8.00

CD3(A,B)A030 27,800 None — — 12.00 30,000 3.00 18,300 2.22 7.50/7.70

CD3(A,B)A036 28,600 None — — 12.50 30,000 3.18 18,400 2.30 7.70/8.00

CE3AA030 28,000 None — — 12.00 30,000 3.12 18,300 2.28 7.70/8.00

CE3AA036 28,400 None — — 12.50 30,000 3.12 18,300 2.28 7.70/8.00

CF5AA036 28,600 None — — 12.50 30,000 3.16 18,400 2.30 7.70/8.00

CJ5A/CK5A/CK5BA030 27,800 None — — 12.00 29,400 3.06 18,200 2.26 7.50

CJ5A/CK5A/CK5BA036 28,800 None — — 12.50 30,000 3.22 18,500 2.32 7.70

CJ5A/CK5A/CK5BW030 27,800 None — — 12.00 29,400 3.06 18,200 2.26 7.50

CJ5A/CK5A/CK5BW036 28,800 None — — 12.50 30,000 3.22 18,500 2.32 7.70

CK3BA030 27,800 None — — 12.00 29,400 3.06 18,200 2.26 7.50

CK3BA036 28,800 None — — 12.50 30,000 3.22 18,500 2.32 7.70

CC5A/CD5A/CD5BA036 28,800 TDR — 13.50 — 29,000 3.28 18,000 2.40 8.00/8.50

CD5A/CD5BW036 28,800 TDR — 13.50 — 29,000 3.28 18,000 2.40 8.00/8.50

CD3(A,B)A036 28,800 TDR — 13.50 — 29,000 3.28 18,000 2.40 8.00/8.50

CE3AA036 28,400 TDR — 13.20 — 29,000 3.20 17,900 2.36 7.80/8.20

CJ5A/CK5A/CK5BA030 28,200 TDR — 13.00 — 29,000 3.18 17,800 2.34 7.70

CJ5A/CK5A/CK5BW030 28,200 TDR — 13.00 — 29,000 3.18 17,800 2.34 7.70

CK3BA030 28,200 TDR — 13.00 — 29,000 3.18 17,800 2.34 7.70

CC5A/CD5A/CD5BA036 29,000 TDR — 13.70 — 29,000 3.30 17,800 2.42 8.00/8.50

CD5A/CD5BW036 29,000 TDR — 13.70 — 29,000 3.30 17,800 2.42 8.00/8.50

CD3(A,B)A036 29,000 TDR — 13.70 — 29,000 3.30 17,800 2.42 8.00/8.50

CE3AA036 28,600 TDR — 13.50 — 29,000 3.22 17,800 2.38 8.00/8.20

CJ5A/CK5A/CK5BW030 28,200 TDR — 13.20 — 29,000 3.20 17,700 2.36 7.70

CK3BA030 28,200 TDR — 13.20 — 29,000 3.20 17,700 2.36 7.70

CC5A/CD5A/CD5BA036 29,000 TDR — 14.00 — 29,000 3.32 17,800 2.44 8.00/8.50

CD5A/CD5BW036 29,000 TDR — 14.00 — 29,000 3.32 17,800 2.44 8.00/8.50

CD3(A,B)A036 29,000 TDR — 14.00 — 29,000 3.32 17,800 2.44 8.00/8.50

CE3AA036 28,600 TDR — 13.70 — 29,000 3.26 17,800 2.40 8.00/8.50

030-B

74

CC5A/CD5A/CD5BA036 28,800 TDR — 13.50 — 29,000 3.28 18,000 2.40 8.00/8.50

CD5A/CD5BW036 28,800 TDR — 13.50 — 29,000 3.28 18,000 2.40 8.00/8.50

CD3(A,B)A036 28,800 TDR — 13.50 — 29,000 3.28 18,000 2.40 8.00/8.50

CE3AA036 28,400 TDR — 13.20 — 29,000 3.20 17,900 2.36 7.80/8.20

CC5A/CD5A/CD5BA036 29,000 TDR — 13.30 — 30,000 3.30 18,200 2.40 8.00/—

CD5A/CD5BW036 29,000 TDR — 13.30 — 30,000 3.30 18,200 2.40 8.00/—

CD3(A,B)A036 29,000 TDR — 13.30 — 30,000 3.30 18,200 2.40 8.00/—

CJ5A/CK5A/CK5BW030 28,400 TDR — 12.70 — 29,400 3.18 18,100 2.34 7.70

CJ5A/CK5A/CK5BW036 29,000 TDR — 13.20 — 30,000 3.34 18,100 2.40 8.00

CK3BA030 28,400 TDR — 12.70 — 29,400 3.18 18,100 2.34 7.70

CK3BA036 29,000 TDR — 13.20 — 30,000 3.34 18,100 2.40 8.00

CC5A/CD5A/CD5BA036 29,000 TDR — 13.30 — 30,000 3.30 18,200 2.40 8.00/—

CD5A/CD5BW036 29,000 TDR — 13.30 — 30,000 3.30 18,200 2.40 8.00/—

CD3(A,B)A036 29,000 TDR — 13.30 — 30,000 3.30 18,200 2.40 8.00/—

CJ5A/CK5A/CK5BA036 29,000 TDR — 13.20 — 30,000 3.34 18,100 2.40 8.00

CJ5A/CK5A/CK5BW030 28,400 TDR — 12.70 — 29,400 3.18 18,100 2.34 7.70

CK3BA030 28,400 TDR — 12.70 — 29,400 3.18 18,100 2.34 7.70

CK3BA036 29,000 TDR — 13.20 — 30,000 3.34 18,100 2.40 8.00

CC5A/CD5A/CD5BA036 29,000 TDR — 13.50 — 30,000 3.34 18,100 2.42 8.00/—

CD5A/CD5BW036 29,000 TDR — 13.50 — 30,000 3.34 18,100 2.42 8.00/—

CD3(A,B)A036 29,000 TDR — 13.50 — 30,000 3.34 18,100 2.42 8.00/—

CJ5A/CK5A/CK5BW030 28,400 TDR — 13.00 — 29,000 3.20 18,100 2.34 7.70

CJ5A/CK5A/CK5BW036 29,000 TDR — 13.00 — 29,400 3.36 18,000 2.42 8.00

CK3BA030 28,400 TDR — 13.00 — 29,000 3.20 18,100 2.34 7.70

CK3BA036 29,000 TDR — 13.00 — 29,400 3.36 18,000 2.42 8.00

CC5A/CD5A/CD5BA036 29,000 TDR — 13.50 — 30,000 3.34 18,100 2.42 8.00/—

CD5A/CD5BW036 29,000 TDR — 13.50 — 30,000 3.34 18,100 2.42 8.00/—

CD3(A,B)A036 29,000 TDR — 13.50 — 30,000 3.34 18,100 2.42 8.00/—

CJ5A/CK5A/CK5BA030 28,600 TDR — 13.20 — 29,000 3.24 17,900 2.38 8.00

CJ5A/CK5A/CK5BA036 29,000 TDR — 13.50 — 29,400 3.40 17,900 2.44 8.00

CJ5A/CK5A/CK5BW030 28,600 TDR — 13.20 — 29,000 3.24 17,900 2.38 8.00

CJ5A/CK5A/CK5BW036 29,000 TDR — 13.50 — 29,400 3.40 17,900 2.44 8.00

CK3BA030 28,600 TDR — 13.20 — 29,000 3.24 17,900 2.38 8.00

CK3BA036 29,000 TDR — 13.50 — 29,400 3.40 17,900 2.44 8.00

See notes on page 15.

INDOOR

UNIT

COMBINATION RATINGS* Continued

ARI STANDARD RATINGS*

Cooling Heating

Seasonal Efficiency SEER

Field-Supplied

Accessory‡

TXV

TC

Factory-

Supplied

Enhance-

ment

COILS + 333(B,J)AV036060 VARIABLE-SPEED FURNACE

COILS + 333(B,J)AV048080 VARIABLE-SPEED FURNACE

COILS + 333(B,J)AV060100 VARIABLE-SPEED FURNACE

COILS + 333(B,J)AV060120 VARIABLE-SPEED FURNACE

COILS + 355MAV042040 VARIABLE-SPEED FURNACE

COILS + 355MAV042060 VARIABLE-SPEED FURNACE

COILS + 355MAV042080 VARIABLE-SPEED FURNACE

COILS + 355MAV060100 VARIABLE-SPEED FURNACE

Standard

Rating

—10—

TXV&TDR**

High-Temp Low-Temp Seasonal

TC COP TC COP

Efficiency

HSPF/HSPF

with LSV

Page 11

UNIT SIZE-

SERIES

AND

SOUND

RATING

(dBA)

030-B

74

036-B

74

CJ5A/CK5A/CK5BA030 28,600 TDR — 13.00 — 29,000 3.22 18,000 2.36 8.00

CJ5A/CK5A/CK5BW030 28,600 TDR — 13.00 — 29,000 3.22 18,000 2.36 8.00

CJ5A/CK5A/CK5BW036 29,000 TDR — 13.50 — 29,400 3.38 18,000 2.44 8.00

CK3BA030 28,600 TDR — 13.00 — 29,000 3.22 18,000 2.36 8.00

CK3BA036 29,000 TDR — 13.50 — 29,400 3.38 18,000 2.44 8.00

FC4BN(F,B)042† 34,200 TDR & TXV 12.00 — — 36,000 3.34 22,800 2.42 7.80/8.20

F(A,B)4ANF036 33,600 TDR — 11.50 — 36,000 3.24 22,800 2.36 7.60/8.00

F(A,B)4AN(F,B)042 34,200 TDR — 12.00 — 36,000 3.34 22,800 2.42 7.80/8.20

FC4BNF036 33,600 TDR & TXV 11.50 — — 36,000 3.24 22,800 2.36 7.60/8.00

FC4BNF033 34,200 TDR & TXV 11.70 — — 36,000 3.34 22,800 2.42 7.80/8.20

FG3AAA036 33,400 None — — 11.50 36,000 3.24 22,600 2.38 7.60/8.00

FK4BNF001 33,800 TDR & TXV 12.00 — — 36,000 3.34 22,400 2.42 7.80/8.20

FK4BNF002 33,800 TDR & TXV 12.00 — — 36,000 3.44 22,600 2.46 7.80/8.50

FK4BNF003 34,800 TDR & TXV 13.00 — — 35,600 3.50 22,000 2.52 8.00/8.50

FK4BNF004 34,600 TDR & TXV 12.50 — — 36,000 3.64 22,400 2.58 8.20/9.00

FK4CNF001 33,600 TDR & TXV 12.50 — — 35,400 3.32 22,000 2.46 7.80/8.20

FK4CNF002 33,600 TDR & TXV 12.50 — — 35,800 3.44 22,200 2.50 8.00/8.50

FK4CNF003 34,400 TDR & TXV 13.00 — — 35,200 3.46 21,800 2.54 8.00/8.50

CC5A/CD5A/CD5BA036 34,000 None — — 12.00 36,000 3.32 22,600 2.42 7.70/8.20

CD5A/CD5BW036 34,000 None — — 12.00 36,000 3.32 22,600 2.42 7.70/8.20

CC5A/CD5A/CD5BA042 34,000 None — — 12.00 36,000 3.32 22,600 2.42 7.70/8.20

CC5A/CD5A/CD5BW042 33,800 None — — 12.00 36,000 3.28 22,600 2.40 7.70/8.20

CC5A/CD5A/CD5BA043 34,000 None — — 12.00 36,000 3.32 22,600 2.42 7.70/8.20

CC5A/CD5A/CD5BW043 34,000 None — — 12.00 36,000 3.32 22,600 2.40 7.70/8.20

CD3(A,B)A036 34,000 None — — 12.00 36,000 3.32 22,600 2.42 7.70/8.20

CD3(A,B)A042 34,000 None — — 12.00 36,000 3.32 22,600 2.42 7.70/8.20

CE3AA036 33,600 None — — 11.70 36,000 3.26 22,600 2.38 7.60/8.20

CE3AA042 34,400 None — — 12.00 36,000 3.36 22,600 2.44 7.70/8.20

CF5AA036 34,000 None — — 12.00 36,000 3.30 22,600 2.40 7.70/8.20

CJ5A/CK5A/CK5BA036 33,600 None — — 12.00 36,000 3.32 22,400 2.42 7.70

CJ5A/CK5A/CK5BA042 34,200 None — — 12.00 36,000 3.36 22,800 2.44 7.80

CJ5A/CK5A/CK5BN042 33,600 None — — 12.00 36,000 3.32 22,400 2.42 7.70

CJ5A/CK5A/CK5BW036 34,200 None — — 12.00 36,000 3.32 22,400 2.42 7.70

CK3BA036 33,600 None — — 12.00 36,000 3.36 22,800 2.44 7.80

CK3BA042 34,200 None — — 12.00 36,000 3.36 22,800 2.44 7.80

CC5A/CD5A/CD5BA042 34,000 TDR — 12.70 — 35,400 3.36 22,000 2.46 7.80/8.20

CC5A/CD5A/CD5BW042 34,000 TDR — 12.70 — 35,400 3.36 22,000 2.46 7.80/8.20

CD3(A,B)A042 34,000 TDR — 12.70 — 35,400 3.36 22,000 2.46 7.80/8.20

CC5A/CD5A/CD5BC048 33,600 TDR — 12.70 — 35,200 3.26 22,000 2.44 7.70/8.00

CE3AA042 34,200 TDR — 12.70 — 35,600 3.40 22,200 2.48 7.80/8.50

CJ5A/CK5A/CK5BA036 34,000 TDR — 12.50 — 35,600 3.40 22,000 2.48 7.80

CK3BA036 34,000 TDR — 12.50 — 35,600 3.40 22,000 2.48 7.80

CC5A/CD5A/CD5BA042 34,200 TDR — 13.00 — 35,200 3.40 21,800 2.50 7.80/8.50

CC5A/CD5A/CD5BW042 34,200 TDR — 13.00 — 35,200 3.40 21,800 2.50 7.80/8.50

CD3(A,B)A042 34,200 TDR — 13.00 — 35,200 3.40 21,800 2.50 7.80/8.50

CC5A/CD5A/CD5BC048 33,600 TDR — 13.00 — 35,000 3.30 21,800 2.46 7.80/8.20

CE3AA042 34,400 TDR — 13.00 — 35,400 3.44 22,000 2.52 8.00/8.50

CJ5A/CK5A/CK5BA042 34,600 TDR — 12.50 — 36,000 3.48 22,200 2.52 8.00

CJ5A/CK5A/CK5BW036 34,200 TDR — 12.80 — 35,400 3.44 22,000 2.50 8.00

CK3BA036 34,200 TDR — 12.80 — 35,400 3.44 22,000 2.50 8.00

CK3BA042 34,600 TDR — 12.50 — 36,000 3.48 22,200 2.52 8.00

CC5A/CD5A/CD5BA042 34,200 TDR — 13.00 — 35,200 3.42 21,800 2.52 8.00/8.50

CC5A/CD5A/CD5BW042 34,200 TDR — 13.00 — 35,200 3.42 21,800 2.52 8.00/8.50

CD3(A,B)A042 34,200 TDR — 13.00 — 35,200 3.42 21,800 2.52 8.00/8.50

CC5A/CD5A/CD5BC048 33,800 TDR — 13.00 — 35,000 3.34 21,600 2.48 7.80/8.20

CE3AA042 34,400 TDR — 13.00 — 35,200 3.48 21,800 2.54 8.00/8.50

CJ5A/CK5A/CK5BA042 34,800 TDR — 13.00 — 35,800 3.54 22,000 2.56 8.00

CJ5A/CK5A/CK5BW036 34,400 TDR — 13.00 — 35,200 3.48 21,800 2.54 8.00

CK3BA036 34,400 TDR — 13.00 — 35,200 3.48 21,800 2.54 8.00

CK3BA042 34,800 TDR — 13.00 — 35,800 3.54 22,000 2.56 8.00

CC5A/CD5A/CD5BA042 34,200 TDR — 13.00 — 35,200 3.40 21,800 2.50 7.80/8.50

CC5A/CD5A/CD5BW042 34,200 TDR — 13.00 — 35,200 3.40 21,800 2.50 7.80/8.50

CD3(A,B)A042 34,200 TDR — 13.00 — 35,200 3.40 21,800 2.50 7.80/8.50

CC5A/CD5A/CD5BC048 33,600 TDR — 13.00 — 35,000 3.32 21,800 2.46 7.80/8.20

CE3AA042 34,400 TDR — 13.00 — 35,400 3.46 22,000 2.52 8.00/8.50

CJ5A/CK5A/CK5BA042 34,800 TDR — 13.00 — 35,800 3.54 22,000 2.56 8.00

CJ5A/CK5A/CK5BW036 34,400 TDR — 13.00 — 35,400 3.46 21,800 2.54 8.00

CK3BA036 34,400 TDR — 13.00 — 35,400 3.46 21,800 2.54 8.00

CK3BA042 34,800 TDR — 13.00 — 35,800 3.54 22,000 2.56 8.00

See notes on page 15.

INDOOR

UNIT

COMBINATION RATINGS* Continued

ARI STANDARD RATINGS*

Cooling Heating

Seasonal Efficiency SEER

Field-Supplied

Accessory‡

TXV

TC

Factory-

Supplied

Enhance-

ment

COILS + 333(B,J)AV036060 VARIABLE-SPEED FURNACE

COILS + 333(B,J)AV048080 VARIABLE-SPEED FURNACE

COILS + 333(B,J)AV060100 VARIABLE-SPEED FURNACE

COILS + 333(B,J)AV060120 VARIABLE-SPEED FURNACE

Standard

Rating

COILS + 355MAV060120 VARIABLE-SPEED FURNACE

TXV&TDR**

High-Temp Low-Temp Seasonal

TC COP TC COP

Efficiency

HSPF/HSPF

with LSV

—11—

Page 12

UNIT SIZE-

SERIES

AND

SOUND

RATING

(dBA)

CC5A/CD5A/CD5BA042 34,400 TDR — 12.50 — 36,000 3.40 22,400 2.46 7.80/—

CD3(A,B)A042 34,400 TDR — 12.50 — 36,000 3.40 22,400 2.46 7.80/—

CJ5A/CK5A/CK5BA042 34,400 TDR — 12.50 — 36,000 3.44 22,400 2.48 8.00

CJ5A/CK5A/CK5BW036 34,400 TDR — 12.00 — 36,000 3.40 22,600 2.46 7.80

CK3BA036 34,400 TDR — 12.00 — 36,000 3.40 22,600 2.46 7.80

CK3BA042 34,400 TDR — 12.50 — 36,000 3.44 22,400 2.48 8.00

CC5A/CD5A/CD5BA042 34,400 TDR — 12.50 — 36,000 3.40 22,400 2.46 7.80/—

CD3(A,B)A042 34,400 TDR — 12.50 — 36,000 3.40 22,400 2.46 7.80/—

CJ5A/CK5A/CK5BA036 34,400 TDR — 12.00 — 36,000 3.40 22,400 2.46 7.80

CJ5A/CK5A/CK5BN042 34,400 TDR — 12.50 — 36,000 3.44 22,400 2.48 8.00

CK3BA036 34,400 TDR — 12.00 — 36,000 3.40 22,400 2.46 7.80

CK3BA042 34,400 TDR — 12.50 — 36,000 3.44 22,400 2.48 8.00

036-B

74

042-B

74

CC5A/CD5A/CD5BA042 34,600 TDR — 12.70 — 35,800 3.44 22,200 2.50 7.80/—

CD3(A,B)A042 34,600 TDR — 12.70 — 35,800 3.44 22,200 2.50 7.80/—

CJ5A/CK5A/CK5BA042 34,600 TDR — 12.50 — 36,000 3.46 22,200 2.50 8.00

CJ5A/CK5A/CK5BW036 34,400 TDR — 12.50 — 36,000 3.42 22,400 2.48 8.00

CK3BA036 34,400 TDR — 12.50 — 36,000 3.42 22,400 2.48 8.00

CK3BA042 34,600 TDR — 12.50 — 36,000 3.46 22,200 2.50 8.00

CC5A/CD5A/CD5BA042 34,600 TDR — 12.70 — 35,800 3.44 22,200 2.50 7.80/—

CD3(A,B)A042 34,600 TDR — 12.70 — 35,800 3.44 22,200 2.50 7.80/—

CJ5A/CK5A/CK5BA042 34,600 TDR — 12.80 — 35,800 3.50 22,200 2.54 8.00

CJ5A/CK5A/CK5BW036 34,600 TDR — 12.50 — 36,000 3.48 22,200 2.50 8.00

CK3BA036 34,600 TDR — 12.50 — 36,000 3.48 22,200 2.50 8.00

CK3BA042 34,600 TDR — 12.80 — 35,800 3.50 22,200 2.54 8.00

CJ5A/CK5A/CK5BA042 34,600 TDR — 12.80 — 35,800 3.50 22,200 2.54 8.00

CJ5A/CK5A/CK5BW036 34,600 TDR — 12.50 — 35,800 3.48 22,200 2.52 8.00

CK3BA036 34,600 TDR — 12.50 — 35,800 3.48 22,200 2.52 8.00

CK3BA042 34,600 TDR — 12.80 — 35,800 3.50 22,200 2.54 8.00

FK4CNF005† 41,000 TDR & TXV 14.00 — — 41,000 3.72 24,800 2.66 8.20/8.40

F(A,B)4AN(F,B)042 39,000 TDR — 12.00 — 41,000 3.32 25,600 2.40 7.50/7.70

F(A,B)4AN(F,B)048 39,500 TDR — 12.50 — 41,000 3.46 25,600 2.46 7.70/7.90

FC4BNF038 40,500 TDR & TXV 12.50 — — 41,000 3.56 25,800 2.50 7.80/8.00

FC4BN(F,B)042 39,000 TDR & TXV 12.00 — — 41,000 3.32 25,600 2.40 7.50/7.70

FC4BN(F,B)048 39,500 TDR & TXV 12.50 — — 41,000 3.46 25,600 2.46 7.70/7.90

FG3AAA048 39,000 None — — 12.00 41,000 3.38 25,400 2.44 7.50/7.70

FK4BNB005 41,500 TDR & TXV 13.50 — — 41,000 3.74 25,400 2.62 8.20/8.40

FK4BNF003 39,500 TDR & TXV 13.00 — — 41,000 3.44 250,00 2.50 7.80/8.00

FK4CNF003 39,500 TDR & TXV 13.50 — — 40,000 3.42 24,800 2.52 7.80/8.00

CC5A/CD5A/CD5BA042 39,000 None — — 12.00 41,000 3.32 25,400 2.40 7.50/7.70

CC5A/CD5A/CD5BW042 38,500 None — — 12.00 41,000 3.28 25,400 2.38 7.40/7.60

CC5A/CD5A/CD5BA043 39,000 None — — 12.00 41,000 3.32 25,400 2.40 7.50/7.70

CC5A/CD5A/CD5BW043 39,000 None — — 12.00 41,000 3.30 25,400 2.40 7.50/7.70

CD5A/CD5BA048 39,000 None — — 12.50 41,000 3.36 25,400 2.42 7.50/7.70

CC5A/CD5A/CD5BC048 38,500 None — — 12.50 41,000 3.22 25,400 2.38 7.30/7.50

CC5A/CD5A/CD5BW048 39,000 None — — 12.50 41,000 3.36 25,400 2.42 7.50/7.70

CD3(A,B)A042 39,000 None — — 12.00 41,000 3.32 25,400 2.40 7.40/7.60

CD3(A,B)A048 39,000 None — — 12.50 41,000 3.36 25,400 2.42 7.50/7.70

CE3AA042 39,500 None — — 12.00 41,000 3.36 25,400 2.42 7.50/7.70

CE3AA048 39,500 None — — 12.50 41,000 3.40 25,400 2.44 7.50/7.70

CF5AA048 39,500 None — — 12.50 41,000 3.34 25,400 2.42 7.50/7.50

CJ5A/CK5A/CK5BA042 40,000 None — — 12.00 41,000 3.34 25,600 2.42 7.50

CJ5A/CK5A/CK5BA048 40,000 None — — 12.00 41,000 3.40 25,600 2.44 7.50

CJ5A/CK5A/CK5BN042 40,000 None — — 12.00 41,000 3.34 25,600 2.42 7.50

CJ5A/CK5A/CK5BW048 40,000 None — — 12.00 41,000 3.40 25,600 2.44 7.50

CK3BA042 40,000 None — — 12.00 41,000 3.34 25,600 2.42 7.50

CK3BA048 40,000 None — — 12.00 41,000 3.40 25,600 2.44 7.50

CD5A/CD5BA048 39,000 TDR — 13.00 — 40,000 3.28 24,600 2.44 7.50/7.70

CC5A/CD5A/CD5BW048 39,000 TDR — 13.00 — 40,000 3.28 24,600 2.44 7.50/7.70

CD3(A,B)A048 39,000 TDR — 13.00 — 40,000 3.28 24,600 2.44 7.50/7.70

CC5A/CD5A/CD5BC048 38,500 TDR — 13.00 — 40,000 3.24 24,800 2.42 7.30/7.50

CE3AA048 39,500 TDR — 13.00 — 41,000 3.44 25,000 2.50 7.50/7.70

CD5A/CD5BA048 39,000 TDR — 13.00 — 40,000 3.28 24,600 2.44 7.50/7.70

CC5A/CD5A/CD5BW048 39,000 TDR — 13.00 — 40,000 3.28 24,600 2.44 7.50/7.70

CD3(A,B)A048 39,000 TDR — 13.00 — 40,000 3.28 24,600 2.44 7.50/7.70

CC5A/CD5A/CD5BC048 38,500 TDR — 13.00 — 40,000 3.26 24,800 2.42 7.30/7.50

CE3AA048 39,500 TDR — 13.50 — 41,000 3.44 25,000 2.52 7.50/7.70

CJ5A/CK5A/CK5BA042 40,000 TDR — 13.00 — 41,000 3.44 25,200 2.48 7.50

CJ5A/CK5A/CK5BA048 40,000 TDR — 13.20 — 41,000 3.50 25,200 2.52 7.70

See notes on page 15.

INDOOR

UNIT

COMBINATION RATINGS* Continued

ARI STANDARD RATINGS*

Cooling Heating

Seasonal Efficiency SEER

Field-Supplied

Accessory‡

TXV

TC

Factory-

Supplied

Enhance-

ment

COILS + 355MAV042040 VARIABLE-SPEED FURNACE

COILS + 355MAV042060 VARIABLE-SPEED FURNACE

COILS + 355MAV042080 VARIABLE-SPEED FURNACE

COILS + 355MAV060100 VARIABLE-SPEED FURNACE

COILS + 355MAV060120 VARIABLE-SPEED FURNACE

COILS + 333(B,J)AV036060 VARIABLE-SPEED FURNACE

COILS + 333(B,J)AV048080 VARIABLE-SPEED FURNACE

Standard

Rating

—12—

TXV&TDR**

High-Temp Low-Temp Seasonal

TC COP TC COP

Efficiency

HSPF/HSPF

with LSV

Page 13

UNIT SIZE-

SERIES

AND

SOUND

RATING

(dBA)

CK3BA042 40,000 TDR — 13.00 — 41,000 3.44 25,200 2.48 7.50

CK3BA048 40,000 TDR — 13.20 — 41,000 3.50 25,200 2.52 7.70

CD5A/CD5BA048 39,000 TDR — 13.50 — 40,000 3.32 24,400 2.48 7.50/7.70

CC5A/CD5A/CD5BW048 39,000 TDR — 13.50 — 40,000 3.32 24,400 2.48 7.50/7.70

CD3(A,B)A048 39,000 TDR — 13.50 — 40,000 3.32 24,400 2.48 7.50/7.70

CC5A/CD5A/CD5BC048 39,000 TDR — 13.50 — 40,000 3.30 24,600 2.46 7.50/7.70

CE3AA048 39,500 TDR — 13.50 — 41,000 3.50 24,800 2.54 7.80/8.00

CJ5A/CK5A/CK5BA042 40,000 TDR — 13.50 — 40,000 3.50 25,000 2.52 7.70

CJ5A/CK5A/CK5BW048 40,500 TDR — 13.75 — 41,000 3.56 25,000 2.56 8.00

CK3BA042 40,000 TDR — 13.50 — 40,000 3.50 25,000 2.52 7.70

CK3BA048 41,000 TDR — 13.50 — 41,000 3.56 25,000 2.56 8.00

CD5A/CD5BA048 39,000 TDR — 13.50 — 40,000 3.28 24,600 2.44 7.50/7.70

CC5A/CD5A/CD5BW048 39,000 TDR — 13.50 — 40,000 3.28 24,600 2.44 7.50/7.70

CD3(A,B)A048 39,000 TDR — 13.50 — 40,000 3.28 24,600 2.44 7.50/7.70

CC5A/CD5A/CD5BC048 39,000 TDR — 13.00 — 40,000 3.28 24,600 2.44 7.50/7.70

CE3AA048 39,500 TDR — 13.50 — 41,000 3.46 24,800 2.52 7.50/7.70

CJ5A/CK5A/CK5BA042 40,000 TDR — 13.50 — 41,000 3.48 25,000 2.52 7.70

CJ5A/CK5A/CK5BW048 40,500 TDR — 13.50 — 41,000 3.56 25,000 2.54 8.00

CK3BA042 40,000 TDR — 13.50 — 41,000 3.48 25,000 2.52 7.70

CK3BA048 40,500 TDR — 13.50 — 41,000 3.56 25,000 2.54 8.00

042-B

74

048-A

76

CD5A/CD5BA048 39,000 TDR — 12.50 — 41,000 3.26 25,400 2.38 7.30/—

CD3(A,B)A048 39,000 TDR — 12.50 — 41,000 3.26 25,400 2.38 7.30/—

CJ5A/CK5A/CK5BW048 40,000 TDR — 12.50 — 42,000 3.44 26,000 2.44 7.50

CK3BA048 40,000 TDR — 12.50 — 42,000 3.44 26,000 2.44 7.50

CD5A/CD5BA048 39,000 TDR — 12.50 — 41,000 3.26 25,400 2.40 7.30/—

CD3(A,B)A048 39,000 TDR — 12.50 — 41,000 3.26 25,400 2.40 7.30/—

CK3BA048 40,000 TDR — 12.50 — 42,000 3.46 25,800 2.46 7.50

CD5A/CD5BA048 39,000 TDR — 13.00 — 41,000 3.32 25,200 2.42 7.50/—

CD3(A,B)A048 39,000 TDR — 13.00 — 41,000 3.32 25,200 2.42 7.50/—

CJ5A/CK5A/CK5BA042 40,000 TDR — 12.50 — 42,000 3.40 25,800 2.44 7.50

CJ5A/CK5A/CK5BA048 40,500 TDR — 12.50 — 42,000 3.50 25,800 2.48 7.50

CK3BA042 40,000 TDR — 12.50 — 42,000 3.40 25,800 2.44 7.50

CK3BA048 40,500 TDR — 12.50 — 42,000 3.50 25,800 2.48 7.50

CD5A/CD5BA048 39,500 TDR — 13.00 — 41,000 3.34 25,000 2.44 7.50/—

CD3(A,B)A048 39,500 TDR — 13.00 — 41,000 3.34 25,000 2.44 7.50/—

CJ5A/CK5A/CK5BA042 40,000 TDR — 12.50 — 41,000 3.46 25,600 2.46 7.50

CJ5A/CK5A/CK5BA048 40,500 TDR — 13.00 — 41,000 3.54 25,600 2.52 7.70

CK3BA042 40,000 TDR — 12.50 — 41,000 3.46 25,600 2.46 7.50

CK3BA048 40,500 TDR — 13.00 — 41,000 3.54 25,600 2.52 7.70

CJ5A/CK5A/CK5BA042 40,000 TDR — 13.00 — 41,000 3.46 25,600 2.48 7.50

CJ5A/CK5A/CK5BW048 40,500 TDR — 13.00 — 41,000 3.54 25,600 2.52 7.70

CK3BA042 40,000 TDR — 13.00 — 41,000 3.46 25,600 2.48 7.50

CK3BA048 40,500 TDR — 13.00 — 41,000 3.54 25,600 2.52 7.70

FK4CNF005† 47,500 TDR & TXV 12.50 — — 48,500 3.38 30,200 2.50 7.80/8.00

F(A,B)4AN(F,B)048 45,500 TDR — 11.40 — 49,500 3.16 30,800 2.34 7.40/7.60

F(A,B)4AN(F,B)060 47,000 TDR — 11.50 — 50,000 3.24 31,000 2.36 7.50/7.70

FB4ANB070 47,500 TDR — 12.00 — 50,000 3.40 30,800 2.58 8.00/8.20

FC4BN(F,B)048 45,500 TDR & TXV 11.40 — — 49,500 3.16 30,800 2.34 7.40/7.60

FC4BNB054 48,000 TDR & TXV 12.10 — — 50,000 3.46 30,600 2.52 8.00/8.20

FC4BN(F,B)060 47,000 TDR & TXV 11.50 — — 50,000 3.24 31,000 2.36 7.50/7.70

FC4BNB070 47,500 TDR & TXV 12.00 — — 50,000 3.40 30,800 2.58 8.00/8.20

FG3AAA048 45,000 None — — 11.40 49,000 3.08 30,400 2.32 7.20/7.40

FG3AAA060 46,000 None — — 11.70 49,000 3.12 30,400 2.34 7.30/7.50

FK4BNB006 48,000 TDR & TXV 13.00 — — 49,000 3.56 30,200 2.56 8.10/8.30

FK4CNB006 48,000 TDR & TXV 13.00 — — 49,000 3.54 30,000 2.58 8.10/8.30

CD5A/CD5BA048 45,000 None — — 11.40 48,500 3.04 30,400 2.30 7.20/7.40

CC5A/CD5A/CD5BC048 44,500 None — — 11.30 48,000 2.88 30,200 2.22 6.90/7.10

CC5A/CD5A/CD5BW048 45,000 None — — 11.40 48,500 3.04 30,400 2.30 7.20/7.40

CC5A/CD5A/CD5BA060 45,000 None — — 11.50 48,500 3.00 30,400 2.28 7.10/7.30

CC5A/CD5A/CD5BW060 46,500 None — — 11.80 49,000 3.18 30,600 2.36 7.50/7.70

CD3(A,B)A048 45,000 None — — 11.40 48,500 3.04 30,400 2.30 7.20/7.40

CD3(A,B)A060 45,000 None — — 11.50 48,500 3.00 30,400 2.28 7.10/7.30

CE3AA048 45,500 None — — 11.60 49,000 3.08 30,400 2.32 7.30/7.50

CE3AA060 46,500 None — — 12.00 49,000 3.18 30,600 2.36 7.50/7.70

CF5AA048 45,500 None — — 11.60 48,500 3.02 30,400 2.28 7.10/7.30

CJ5A/CK5A/CK5BA048 45,000 None — — 11.50 48,500 3.10 30,400 2.32 7.20

CJ5A/CK5A/CK5BA060 46,000 None — — 11.50 49,000 3.12 30,400 2.34 7.20

CJ5A/CK5A/CK5BN060 46,000 None — — 11.50 49,000 3.12 30,400 2.34 7.20

See notes on page 15.

INDOOR

UNIT

COMBINATION RATINGS* Continued

ARI STANDARD RATINGS*

Cooling Heating

Seasonal Efficiency SEER

Field-Supplied

Accessory‡

TXV

TC

Factory-

Supplied

Enhance-

ment

COILS + 333(B,J)AV060100 VARIABLE-SPEED FURNACE

COILS + 333(B,J)AV060120 VARIABLE-SPEED FURNACE

Standard

Rating

COILS + 355MAV042040 VARIABLE-SPEED FURNACE

COILS + 355MAV042060 VARIABLE-SPEED FURNACE

COILS + 355MAV042080 VARIABLE-SPEED FURNACE

COILS + 355MAV060100 VARIABLE-SPEED FURNACE

COILS + 355MAV060120 VARIABLE-SPEED FURNACE

—13—

TXV&TDR**

High-Temp Low-Temp Seasonal

TC COP TC COP

Efficiency

HSPF/HSPF

with LSV

Page 14

UNIT SIZE-

SERIES

AND

SOUND

RATING

(dBA)

CJ5A/CK5A/CK5BW048 45,000 None — — 11.50 48,500 3.10 30,400 2.32 7.20

CJ5A/CK5A/CK5BX060 47,000 None — — 12.00 49,000 3.24 30,400 2.40 7.50

CK3BA048 45,000 None — — 11.50 48,500 3.10 30,400 2.32 7.20

CK3BA060 46,000 None — — 11.50 49,000 3.12 30,400 2.34 7.20

CC5A/CD5A/CD5BA060 45,000 TDR — 11.80 — 48,000 2.98 30,000 2.32 7.00/7.20

CD3(A,B)A060 45,000 TDR — 11.80 — 48,000 2.98 30,000 2.32 7.00/7.20

CC5A/CD5A/CD5BW060 46,500 TDR — 12.00 — 48,500 3.20 30,200 2.42 7.50/7.70

CE3AA060 46,500 TDR — 12.00 — 48,500 3.20 30,200 2.40 7.50/7.70

CJ5A/CK5A/CK5BA048 45,500 TDR — 11.80 — 48,500 3.12 30,200 2.36 7.20

CK3BA048 45,500 TDR — 11.80 — 48,500 3.12 30,200 2.36 7.20

CK3BA060 46,000 TDR — 12.00 — 48,500 3.16 30,000 2.38 7.20

CC5A/CD5A/CD5BA060 45,500 TDR — 12.00 — 47,500 3.04 29,800 2.34 7.00/7.20

CD3(A,B)A060 45,500 TDR — 12.00 — 47,500 3.04 29,800 2.34 7.00/7.20

CC5A/CD5A/CD5BW060 46,500 TDR — 12.50 — 48,000 3.26 29,800 2.44 7.50/7.70

CE3AA060 47,000 TDR — 12.50 — 48,000 3.24 30,000 2.44 7.50/7.70

CJ5A/CK5A/CK5BA060 46,500 TDR — 12.50 — 48,000 3.24 29,600 2.44 7.50

CJ5A/CK5A/CK5BW048 46,000 TDR — 12.20 — 48,000 3.20 29,600 2.42 7.50

CJ5A/CK5A/CK5BX060 47,500 TDR — 12.80 — 48,500 3.38 29,800 2.50 7.50

CK3BA048 46,000 TDR — 12.20 — 48,000 3.20 29,600 2.42 7.50

CK3BA060 46,500 TDR — 12.50 — 48,000 3.24 29,600 2.44 7.50

CC5A/CD5A/CD5BA060 45,500 TDR — 12.00 — 47,500 3.02 29,800 2.34 7.00/7.20

CD3(A,B)A060 45,500 TDR — 12.00 — 47,500 3.02 29,800 2.34 7.00/7.20

CC5A/CD5A/CD5BW060 46,500 TDR — 12.50 — 48,500 3.22 30,000 2.44 7.50/7.70

CE3AA060 46,500 TDR — 12.50 — 48,500 3.22 30,000 2.42 7.50/7.70

048-A

76

060-A

76

CJ5A/CK5A/CK5BA060 46,500 TDR — 12.50 — 48,000 3.22 29,800 2.42 7.50

CJ5A/CK5A/CK5BW048 46,000 TDR — 12.20 — 48,000 3.18 29,800 2.40 7.20

CJ5A/CK5A/CK5BX060 47,500 TDR — 12.50 — 48,500 3.36 29,800 2.48 7.50

CK3BA048 46,000 TDR — 12.20 — 48,000 3.18 29,800 2.40 7.20

CK3BA060 46,500 TDR — 12.50 — 48,000 3.22 29,800 2.42 7.50

CC5A/CD5A/CD5BA060 45,000 TDR — 11.50 — 48,500 2.94 30,400 2.26 7.00/7.20

CD3(A,B)A060 45,000 TDR — 11.50 — 48,500 2.94 30,400 2.26 7.00/7.20

CC5A/CD5A/CD5BW060 46,000 TDR — 11.80 — 49,000 3.16 30,400 2.36 7.30/7.50

CC5A/CD5A/CD5BA060 45,000 TDR — 11.50 — 48,500 2.96 30,400 2.28 7.00/7.20

CD3(A,B)A060 45,000 TDR — 11.50 — 48,500 2.96 30,400 2.28 7.00/7.20

CC5A/CD5A/CD5BW060 46,000 TDR — 11.80 — 49,000 3.16 30,400 2.38 7.30/7.50

CC5A/CD5A/CD5BA060 45,000 TDR — 11.80 — 48,500 2.98 30,200 2.30 7.00/7.20

CD3(A,B)A060 45,000 TDR — 11.80 — 48,500 2.98 30,200 2.30 7.00/7.20

CC5A/CD5A/CD5BW060 46,000 TDR — 12.00 — 49,000 3.18 30,200 2.40 7.50/7.70

CC5A/CD5A/CD5BA060 45,000 TDR — 11.80 — 48,500 2.98 30,000 2.32 7.00/7.20

CD3(A,B)A060 45,000 TDR — 11.80 — 48,500 2.98 30,000 2.32 7.00/7.20

CC5A/CD5A/CD5BW060 46,500 TDR — 12.20 — 49,000 3.20 30,200 2.42 7.50/7.70

CJ5A/CK5A/CK5BA060 47,000 TDR — 11.50 — 49,000 3.20 30,600 2.38 7.50

CJ5A/CK5A/CK5BN060 47,000 TDR — 11.50 — 49,000 3.20 30,600 2.38 7.50

CJ5A/CK5A/CK5BX060 48,000 TDR — 13.00 — 49,000 3.48 30,000 2.56 8.00

CK3BA060 47,000 TDR — 11.50 — 49,000 3.20 30,600 2.38 7.50

CJ5A/CK5A/CK5BA060 47,000 TDR — 11.80 — 49,000 3.22 30,600 2.40 7.50

CJ5A/CK5A/CK5BW048 46,000 TDR — 11.50 — 49,000 3.18 30,600 2.36 7.20

CJ5A/CK5A/CK5BX060 47,500 TDR — 12.00 — 49,000 3.34 30,600 2.46 7.50

CK3BA048 46,000 TDR — 11.50 — 49,000 3.18 30,600 2.36 7.20

CK3BA060 47,000 TDR — 11.80 — 49,000 3.22 30,600 2.40 7.50

FK4CNB006† 59,000 TDR & TXV 12.50 — — 61,000 3.32 39,000 2.58 8.30/8.50

F(A,B)4AN(F,B)060 57,500 TDR — 11.50 — 61,000 3.06 39,500 2.40 7.80/8.20

FB4ANB070 58,500 TDR — 12.00 — 61,000 3.22 39,500 2.48 8.00/8.20

FC4BN(F,B)060 57,500 TDR & TXV 11.50 — — 61,000 3.06 39,500 2.40 7.80/8.00

FC4BNB070 58,500 TDR & TXV 12.00 — — 61,000 3.22 39,500 2.48 8.00/8.20

FG3AAA060 56,500 None — — 11.50 61,000 2.94 39,000 2.36 7.50/7.70

FK4BNB006 59,000 TDR & TXV 12.50 — — 61,000 3.30 39,000 2.54 8.30/8.50

CC5A/CD5A/CD5BA060 55,500 None — — 11.50 61,000 2.82 38,500 2.30 7.30/7.50

CC5A/CD5A/CD5BW060 56,500 None — — 11.50 61,000 3.00 39,000 2.40 7.70/7.90

CD3(A,B)A060 55,500 None — — 11.50 61,000 2.82 38,500 2.30 7.30/7.50

CE3AA060 57,500 None — — 12.00 61,000 3.00 39,000 2.40 7.70/7.90

CJ5A/CK5A/CK5BA060 57,500 None — — 11.50 61,000 2.94 39,000 2.38 7.50

CJ5A/CK5A/CK5BX060 58,000 None — — 12.00 61,000 3.08 39,000 2.44 7.80

CK3BA060 57,500 None — — 11.50 61,000 2.94 39,000 2.38 7.50

See notes on page 15.

INDOOR

UNIT

COMBINATION RATINGS* Continued

ARI STANDARD RATINGS*

Cooling Heating

Seasonal Efficiency SEER

Field-Supplied

Accessory‡

TXV

TC

Factory-

Supplied

Enhance-

ment

COILS + 333(B,J)AV048080 VARIABLE-SPEED FURNACE

COILS + 333(B,J)AV060100 VARIABLE-SPEED FURNACE

COILS + 333(B,J)AV060120 VARIABLE-SPEED FURNACE

COILS + 355MAV042040 VARIABLE-SPEED FURNACE

COILS + 355MAV042060 VARIABLE-SPEED FURNACE

COILS + 355MAV042080 VARIABLE-SPEED FURNACE

COILS + 355MAV060100 VARIABLE-SPEED FURNACE

COILS + 355MAV060120 VARIABLE-SPEED FURNACE

Standard

Rating

TXV&TDR**

High-Temp Low-Temp Seasonal

TC COP TC COP

Efficiency

HSPF/HSPF

with LSV

—14—

Page 15

COMBINATION RATINGS* Continued

ARI STANDARD RATINGS*

UNIT SIZE-

SERIES

AND

SOUND

RATING

(dBA)

060-A

76

* Ratings are net values reflecting the effects of circulating fan heat. Supplemental electric heat is not included. Ratings are based on:

Cooling Standard: 80°F (27°C) db 67°F (19°C) wb indoor entering air temperature and 95°F (35°C) db air entering outdoor unit.

High-Temp Heating Standard: 70°F (21°C) db indoor entering air temperature and 47°F (8°C) db 43°F (6°C) wb air entering outdoor unit.

Low-Temp Heating Standard: 70°F (21°C) db indoor entering air temperature and 17°F (–9°C) db 15°F (–10°C) wb air entering outdoor unit.

† Outdoor section/indoor section combination tested in accordance with DOE test procedures for heat pumps. Ratings for other combinations are determined

under DOE computer simulation procedures.

‡ Requires hard shutoff TXV; based on computer simulation.

** TDR is on all furnaces, except 394HAD.

SEER —Seasonal Energy Efficiency Ratio LSV — Liquid Solenoid Valve

COP — Coefficient of Performance TDR — Time-Delay Relay

HSPF — Heating Seasonal Performance Factor TXV — Thermostatic Expansion Valve

TC — Total Capacity (Btuh)

INDOOR

UNIT

CC5A/CD5A/CD5BA060 55,500 TDR — 11.50 — 61,000 2.84 38,500 2.32 7.20/7.40

CD3(A,B)A060 55,500 TDR — 11.50 — 61,000 2.84 38,500 2.32 7.20/7.40

CC5A/CD5A/CD5BW060 57,000 TDR — 12.00 — 61,000 3.04 39,000 2.44 7.80/8.00

CE3AA060 57,500 TDR — 12.00 — 61,000 3.02 39,000 2.42 7.80/8.00

CJ5A/CK5A/CK5BA060 57,500 TDR — 12.00 — 61,000 2.94 38,500 2.40 7.50

CJ5A/CK5A/CK5BX060 58,500 TDR — 12.20 — 61,000 3.12 38,500 2.48 7.80

CK3BA060 57,500 TDR — 12.00 — 61,000 2.94 38,500 2.40 7.50

CC5A/CD5A/CD5BA060 55,000 TDR — 11.50 — 61,000 2.80 39,000 2.30 7.20/7.40

CD3(A,B)A060 55,000 TDR — 11.50 — 61,000 2.80 39,000 2.30 7.20/7.40

CC5A/CD5A/CD5BW060 56,500 TDR — 12.00 — 61,000 3.02 39,000 2.42 7.50/7.70

CE3AA060 57,500 TDR — 12.00 — 61,000 3.00 39,000 2.42 7.50/7.70

CJ5A/CK5A/CK5BA060 57,500 TDR — 11.80 — 61,000 2.96 38,500 2.38 7.50

CJ5A/CK5A/CK5BX060 58,000 TDR — 12.00 — 61,000 3.10 38,500 2.46 7.80

CK3BA060 57,500 TDR — 11.80 — 61,000 2.96 38,500 2.38 7.50

CC5A/CD5A/CD5BA060 55,000 TDR — 11.20 — 61,000 2.80 39,500 2.30 7.20/7.40

CD3(A,B)A060 55,000 TDR — 11.20 — 61,000 2.80 39,500 2.30 7.20/7.40

CC5A/CD5A/CD5BW060 56,500 TDR — 11.50 — 61,000 3.00 39,500 2.40 7.50/7.70

TC

Factory-

Supplied

Enhance-

ment

COILS + 333(B,J)AV060100 VARIABLE-SPEED FURNACE

COILS + 333(B,J)AV060120 VARIABLE-SPEED FURNACE

Cooling Heating

Seasonal Efficiency SEER

Field-Supplied

Standard

Rating

COILS + 355MAV060100 VARIABLE-SPEED FURNACE

Accessory‡

TXV

TXV&TDR**

High-Temp Low-Temp Seasonal

TC COP TC COP

Efficiency

HSPF/HSPF

with LSV

—15—

Page 16

Printed in U.S.A. 11-95 838-756

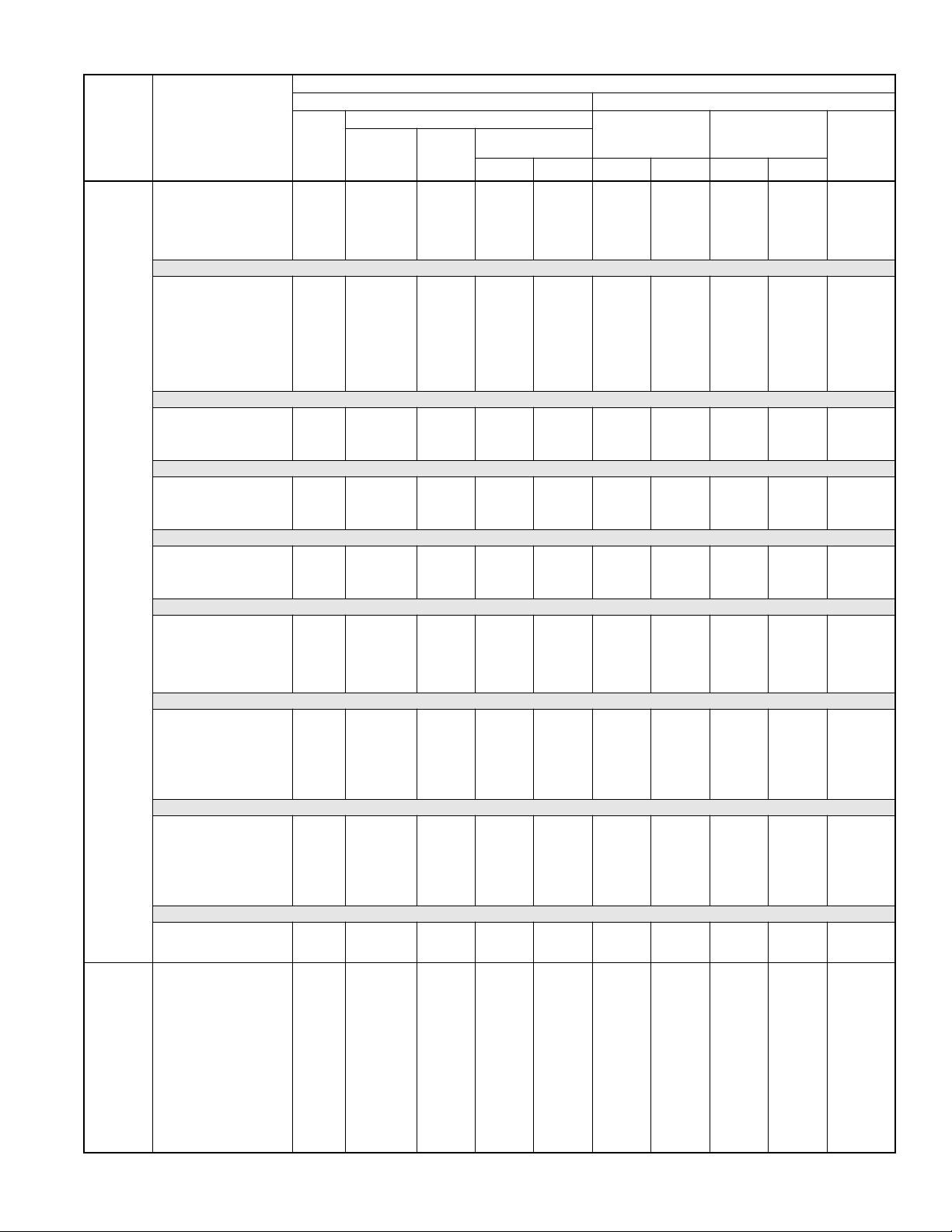

BUILDING HEAT LOSS, 1000 BTU/HR

UNIT INTEGRATED HEATING CAPACITY, 1000 BTU/HR

40

-10

0

10

10

20

30

OUTDOOR TEMPERATURE, °F

20

30

50

60

70

80

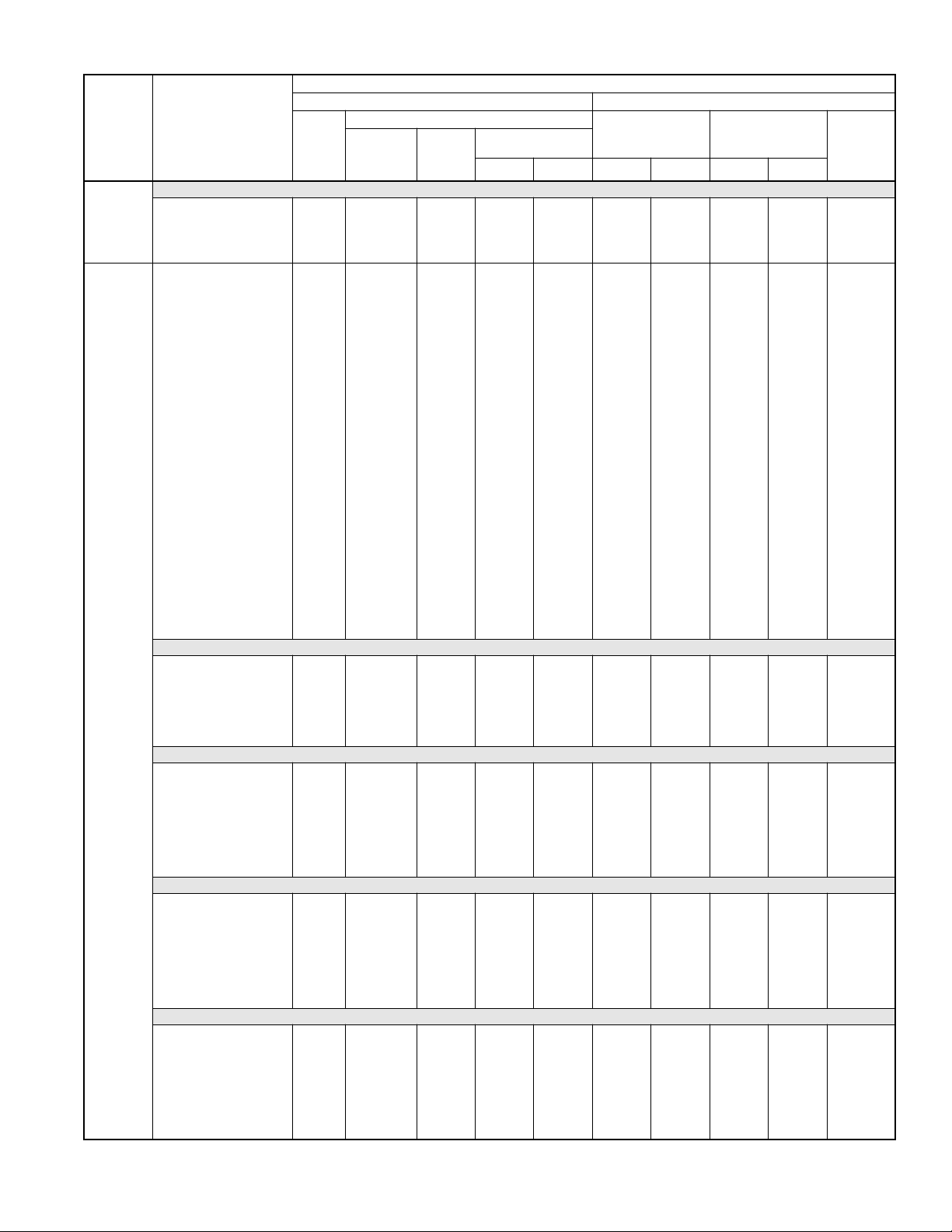

697C BALANCE POINT WORKSHEET

A95490

40

50

60 70

80

BASED ON INDOOR ENT. AIR AT

70°F AND AT RATED CFM

697CN018-B

FC4BNF024

2.9

5.9

697CN024-A/B

FC4BNF030

FC4BNF036

8.8

697CN036-A/B

FC4BN(F,B)042

697CN030-A/B

11.7

697CN042-A/B

FK4CNF005

14.7

697CN048-A

FK4CNF005

17.6

697CN060-A

FK4CNB006

20.5

23.4

KW

—16—

Page 17

DETAILED COOLING CAPACITIES*

EVAPORATOR

AIR

CFM EWB

75 85 95 105 115 125

Capacity

MBtuh†

Total

Kw**

Sys.

Capacity

MBtuh†

697C018-B Outdoor Section With FC4BNF024 Indoor Section

72 21.3 10.8 1.30 20.4 10.5 1.46 19.5 10.1 1.63 18.6 9.81 1.8 17.7 9.51 2.05 16.7 9.14 2.27

67 19.4 13.8 1.30 18.7 13.5 1.47 17.8 13.2 1.64 17.0 12.8 1.8 16.2 12.5 2.05 15.2 12.1 2.27

600

650

700

F(A,B)4AN(F,C) 018 0.97 1.00 CC5A/CD5A/CD5BW 024 1.00 0.90

CC5A/CD5A/CD5BA 018 0.97 1.00 CC5A/CD5A/CD5BA 024 1.03 0.91

CC5A/CD5A/CD5BW 024 1.00 0.99 CD3(A,B)A 024 1.03 0.91

CD3(A,B)A 018 0.97 1.00 CJ5A/CK5A/CK5BW 024 1.00 0.91

CJ5A/CK5A/CK5BA 018 0.94 0.97 CC5A/CD5A/CD5BW 024 1.03 0.91

CJ5A/CK5A/CK5BW 024 0.97 0.97 CJ5A/CK5A/CK5BW 024 1.00 0.90

CC5A/CD5A/CD5BA 024 1.00 0.90

See notes on page 26.

63†† 18.1 13.4 1.31 17.4 13.1 1.47 16.6 12.7 1.64 15.8 12.4 1.8 14.9 12.0 2.04 14.1 11.7 2.27

62 17.9 16.7 1.31 17.2 16.4 1.48 16.4 16.0 1.64 15.7 15.6 1.8 15.0 15.0 2.04 14.2 14.2 2.27

57 17.5 17.5 1.32 16.9 16.9 1.47 16.3 16.3 1.65 15.7 15.7 1.8 15.0 15.0 2.05 14.3 14.3 2.28

72 21.5 11.1 1.31 20.6 10.8 1.48 19.7 10.4 1.65 18.8 10.1 1.8 17.8 9.81 2.07 16.8 9.45 2.29

67 19.6 14.3 1.32 18.9 14.0 1.49 18.0 13.7 1.66 17.2 13.3 1.8 16.2 13.0 2.06 15.3 12.6 2.29

63†† 18.3 13.9 1.33 17.5 13.6 1.49 16.8 13.2 1.67 15.9 12.9 1.8 15.1 12.5 2.07 14.2 12.1 2.29

62 18.1 17.4 1.33 17.4 17.0 1.49 16.7 16.6 1.67 16.0 16.0 1.8 15.3 15.3 2.07 14.5 14.5 2.29

57 17.9 17.9 1.33 17.3 17.3 1.49 16.7 16.7 1.67 16.0 16.0 1.8 15.3 15.3 2.07 14.5 14.5 2.29

72 21.6 11.4 1.33 20.8 11.1 1.50 19.8 10.7 1.67 18.9 10.4 1.8 17.9 10.1 2.08 16.9 9.74 2.32

67 19.8 14.8 1.34 19.0 14.5 1.51 18.1 14.2 1.68 17.3 13.9 1.8 16.3 13.5 2.08 15.4 13.1 2.31

63†† 18.5 14.4 1.35 17.7 14.0 1.50 16.9 13.7 1.68 16.0 13.3 1.8 15.2 13.0 2.08 14.3 12.6 2.31

62 18.4 18.0 1.35 17.6 17.6 1.51 16.9 16.9 1.68 16.3 16.3 1.8 15.5 15.5 2.08 14.8 14.8 2.31

57 18.2 18.2 1.35 17.6 17.6 1.51 16.9 16.9 1.68 16.3 16.3 1.8 15.5 15.5 2.08 14.8 14.8 2.31

Multipliers for Determining the Performance With Other Indoor Sections

Indoor

Section Size

FC4BNF 024 1.00 1.00 CK3BA 024 0.97 0.89

024 1.00 1.00 CD3(A,B)A 024 1.00 0.90

FD3ANA 018 0.97 1.02 CE3AA 024 1.00 0.92

024 1.00 0.98 CJ5A/CK5A/CK5BA 018 0.97 0.90

FF1BNA 018 0.97 0.96 024 0.97 0.89

024 1.03 0.99

FG3AA 024 1.00 1.00 CC5A/CD5A/CD5BA 024 1.00 0.89

FK4BNF 001 1.06 0.90 CC5A/CD5A/CD5BW 024 1.00 0.89

002 1.06 0.89 CD3(A,B)A 024 1.00 0.89

FK4CNF 001 1.06 0.88 CE3AA 024 1.00 0.92

002 1.06 0.88

024 1.00 0.99 CC5A/CD5A/CD5BW 024 1.03 0.91

024 1.00 0.99 CK3BA 024 1.00 0.91

CE3AA 024 1.00 0.99

CF5AA 024 1.00 0.99 CC5A/CD5A/CD5BA 024 1.03 0.91

024 0.97 0.97 CD3(A,B)A 024 1.03 0.91

CK3BA 024 0.97 0.97 CK3BA 024 1.00 0.90

COILS + 333(B,J)AV036060 VARIABLE-SPEED FURNACE —— —

Capacity Power Capacity Power

Cooling

CONDENSER ENTERING AIR TEMPERATURES °F

Total

Sys.

Kw**

Capacity

MBtuh†

Total

Sys.

Kw**

Capacity

MBtuh†

Indoor

Section Size

COILS + 333(B,J)AV048080 VARIABLE-SPEED FURNACE

COILS + 355MAV042060 VARIABLE-SPEED FURNACE

COILS + 355MAV042080 VARIABLE-SPEED FURNACE

Total

Sys.

Kw**

Capacity

MBtuh†

Total

Sys.

Kw**

Capacity

Cooling

MBtuh†

Total

Sys.

Kw**Total Sens‡ Total Sens‡ Total Sens‡ Total Sens‡ Total Sens‡ Total Sens‡

—17—

Page 18

DETAILED COOLING CAPACITIES* Continued

EVAPORATOR

AIR

CFM EWB

75 85 95 105 115 125

Capacity

MBtuh†

Total

Sys.

Kw**

Capacity

MBtuh†

697C024-B Outdoor Section With FC4BNF030 Indoor Section

72 28.3 13.9 1.83 27.1 13.5 2.05 25.8 13.0 2.27 24.5 12.5 2.5 23.0 12.0 2.80 21.7 11.6 3.10

67 25.9 17.6 1.81 24.9 17.1 2.02 23.7 16.7 2.25 22.4 16.1 2.5 21.3 15.7 2.79 20.1 15.2 3.09

700

800

900

F(A,B)4AN(F,C) 024 0.98 1.01 CD3(A,B)A 030 0.99 0.92

FF1(A,B)NA 024 0.98 1.01 CC5A/CD5A/CD5BW 030 0.99 0.91

CC5A/CD5A/CD5BA 024 0.98 1.01 CC5A/CD5A/CD5BA 030 1.01 0.94

CC5A/CD5A/CD5BW 024 0.98 1.01 CJ5A/CK5A/CK5BA 024 0.99 0.95

CD5A/CD5BW 036 1.02 1.01 CJ5A/CK5A/CK5BW 024 0.99 0.95

CD3(A,B)A 024 0.98 1.01 030 1.02 0.95

CJ5A/CK5A/CK5BA 024 0.97 0.99 CD3(A,B)A 030 1.01 0.94

CJ5A/CK5A/CK5BW 024 0.97 0.99 030 1.02 0.95

CC5A/CD5A/CD5BA 030 0.99 0.93 CC5A/CD5A/CD5BW 030 1.01 0.94

CC5A/CD5A/CD5BW 030 0.99 0.93 CD3(A,B)A 030 1.01 0.94

CD3(A,B)A 030 0.99 0.93 CJ5A/CK5A/CK5BW 024 1.00 0.94

CJ5A/CK5A/CK5BA 024 0.98 0.93 CK3BA 024 1.00 0.94

CJ5A/CK5A/CK5BW 030 1.00 0.93

See notes on page 26.

63†† 24.2 17.1 1.79 23.2 16.7 2.00 22.3 16.3 2.25 21.1 15.8 2.5 19.9 15.2 2.78 18.7 14.7 3.07

62 23.8 21.1 1.78 22.9 20.7 2.00 21.8 20.2 2.24 20.7 19.6 2.4 19.7 19.1 2.77 18.6 18.5 3.07

57 22.9 22.9 1.78 22.1 22.1 2.00 21.3 21.3 2.23 20.4 20.4 2.4 19.5 19.5 2.78 18.6 18.6 3.07

72 28.7 14.5 1.87 27.5 14.1 2.08 26.1 13.6 2.31 24.7 13.1 2.5 23.2 12.6 2.83 21.9 12.1 3.13

67 26.5 18.7 1.85 25.3 18.2 2.06 24.0 17.7 2.29 22.7 17.2 2.5 21.5 16.7 2.82 20.3 16.2 3.12

63†† 24.7 18.2 1.83 23.6 17.7 2.04 22.6 17.2 2.28 21.4 16.7 2.5 20.1 16.2 2.81 18.9 15.7 3.10

62 24.4 22.6 1.83 23.3 22.1 2.04 22.2 21.5 2.27 21.2 20.9 2.5 20.2 20.2 2.82 19.1 19.1 3.11

57 23.7 23.7 1.82 22.9 22.9 2.04 22.0 22.0 2.27 21.0 21.0 2.5 20.1 20.1 2.81 19.1 19.1 3.11

72 29.0 15.1 1.91 27.8 14.7 2.12 26.4 14.2 2.35 24.9 13.7 2.6 23.5 13.2 2.88 22.0 12.7 3.16

67 26.8 19.7 1.89 25.5 19.2 2.09 24.2 18.7 2.32 23.1 18.2 2.5 21.7 17.7 2.86 20.4 17.2 3.15

63†† 25.0 19.1 1.87 23.9 18.6 2.08 22.8 18.1 2.32 21.6 17.6 2.5 20.4 17.1 2.86 19.0 16.5 3.14

62 24.8 23.9 1.86 23.7 23.3 2.07 22.6 22.5 2.31 21.6 21.6 2.5 20.7 20.7 2.86 19.5 19.5 3.15

57 24.5 24.5 1.87 23.6 23.6 2.07 22.6 22.6 2.31 21.7 21.7 2.5 20.6 20.6 2.85 19.6 19.6 3.15

Multipliers for Determining the Performance With Other Indoor Sections

Indoor

Section Size

FC4BNF 024 0.98 1.01

030 1.00 1.00 CC5A/CD5A/CD5BA 030 0.99 0.92

033 1.02 1.01 CC5A/CD5A/CD5BW 030 0.99 0.92

030 1.00 1.00 CE3AA 030 1.00 0.93

FD3ANA 024 0.97 0.99

030 1.00 1.02 CC5A/CD5A/CD5BA 030 0.99 0.91

030 1.00 1.02 CD3(A,B)A 030 0.99 0.91

FG3AAA 024 0.97 1.01 CE3AA 030 1.00 0.92

FK4BNF 001 1.03 0.94

002 1.04 0.94 CC5A/CD5A/CD5BA 030 0.99 0.92

003 1.04 0.92 CC5A/CD5A/CD5BW 030 0.99 0.92

FK4CNF 001 1.02 0.93 CD3(A,B)A 030 0.99 0.92

002 1.02 0.93 CE3AA 030 1.00 0.92

003 1.03 0.91

030 0.98 1.01 CC5A/CD5A/CD5BW 030 1.01 0.94

036 1.02 1.01 CD3(A,B)A 030 1.01 0.94

030 0.98 1.01 030 1.02 0.95

030 0.98 1.01 CK3BA 024 0.99 0.95

036 1.02 1.01 030 1.02 0.95

CE3AA 024 0.98 1.01

030 1.00 1.01 CC5A/CD5A/CD5BA 030 1.01 0.94

CF5AA 024 0.98 1.01 CC5A/CD5A/CD5BW 030 1.01 0.94

030 0.98 0.99 CJ5A/CK5A/CK5BW 024 0.99 0.95

030 0.98 0.99 CK3BA 024 0.99 0.95

CK3BA 024 0.97 0.99 030 1.02 0.95

030 0.98 0.99

COILS + 333(B,J)AV036060 VARIABLE-SPEED FURNACE

CE3AA 030 1.00 0.93 030 1.02 0.94

030 1.00 0.93 030 1.02 0.94

CK3BA 024 0.98 0.93 CC5A/CD5A/CD5BA 030 1.01 0.94

030 1.00 0.93 CC5A/CD5A/CD5BW 030 1.01 0.94

— — — CD3(A,B)A 030 1.01 0.94

Capacity Power Capacity Power

Cooling

CONDENSER ENTERING AIR TEMPERATURES °F

Total

Sys.

Kw**

Capacity

MBtuh†

Total

CC5A/CD5A/CD5BA 030 1.01 0.94

Capacity

Sys.

Kw**

MBtuh†

Indoor

Section Size

COILS + 333(B,J)AV048080 VARIABLE-SPEED FURNACE

COILS + 333(B,J)AV060100 VARIABLE-SPEED FURNACE

COILS + 333(B,J)AV060120 VARIABLE-SPEED FURNACE

COILS + 355MAV042040 VARIABLE-SPEED FURNACE

COILS + 355MAV042060 VARIABLE-SPEED FURNACE

COILS + 355MAV042080 VARIABLE-SPEED FURNACE

COILS + 355MAV060100 VARIABLE-SPEED FURNACE

—18—

Total

Sys.

Kw**

Capacity

MBtuh†

Total

Sys.

Kw**

Capacity

Cooling

MBtuh†

Total

Sys.

Kw**Total Sens‡ Total Sens‡ Total Sens‡ Total Sens‡ Total Sens‡ Total Sens‡

Page 19

DETAILED COOLING CAPACITIES* Continued

EVAPORATOR

AIR

CFM EWB

85 95 105 115

Capacity

MBtuh†

Total

System

Kw**

697C030-B Outdoor Section With FC4BNF036 Indoor Section

72 32.1 16.0 2.43 30.7 15.5 2.65 29.3 14.9 2.89 27.8 14.4 3.16

67 29.3 20.3 2.41 28.0 19.8 2.62 26.8 19.3 2.86 25.5 18.8 3.13

850

950

1050

FC4BNF 030 0.99 0.98 CD5A/CD5BW 036 1.02 0.91

F(A,B)4ANF 030 0.99 0.98 CJ5A/CK5A/CK5BW 030 0.99 0.92

FD3ANA 030 0.99 0.99

FF1(A,B)NA 030 0.99 0.99 CC5A/CD5A/CD5BA 036 1.02 0.90

FG3AAA 036 0.99 0.98 CD5A/CD5BW 036 1.02 0.90

FK4BNF 001 1.02 0.94 CD3(A,B)A 036 1.02 0.90

FK4CNF 001 1.01 0.92 CD5A/CD5BW 036 1.01 0.92

CC5A/CD5A/CD5BA 030 0.98 0.98

CC5A/CD5A/CD5BW 030 0.98 0.98 CD5A/CD5BW 036 1.02 0.95

CD5A/CD5BW 036 1.01 0.99 CD3(A,B)A 036 1.02 0.95

CD3(A,B)A 030 0.98 0.98 CJ5A/CK5A/CK5BW 030 1.00 0.96

CJ5A/CK5A/CK5BA 030 0.98 0.97 CC5A/CD5A/CD5BA 036 1.02 0.95

CJ5A/CK5A/CK5BW 030 0.98 0.97 CD3(A,B)A 036 1.02 0.95

CC5A/CD5A/CD5BA 036 1.01 0.92

CD5A/CD5BW 036 1.01 0.92 CC5A/CD5A/CD5BA 036 1.02 0.94

CD3(A,B)A 036 1.01 0.92 CD5A/CD5BW 036 1.02 0.94

CJ5A/CK5A/CK5BA 030 0.99 0.93 CJ5A/CK5A/CK5BW 030 1.00 0.95

CJ5A/CK5A/CK5BW 030 0.99 0.93 036 1.02 0.94

CC5A/CD5A/CD5BA 036 1.02 0.91 — — —

See notes on page 26.

63†† 27.3 19.7 2.39 26.1 19.2 2.60 24.8 18.7 2.84 23.4 18.1 3.10

62 26.8 24.5 2.38 25.8 24.0 2.60 24.5 23.4 2.84 23.2 22.7 3.10

57 26.0 26.0 2.38 25.1 25.1 2.59 24.2 24.2 2.83 23.1 23.1 3.10

72 32.4 16.5 2.47 31.0 16.0 2.69 29.6 15.5 2.94 28.0 15.0 3.20

67 29.8 21.4 2.45 28.4 20.8 2.67 27.1 20.3 2.91 25.6 19.7 3.17

63†† 27.7 20.7 2.43 26.4 20.2 2.65 25.2 19.7 2.89 23.8 19.1 3.15

62 27.3 25.9 2.43 26.2 25.3 2.64 25.1 24.7 2.89 23.8 23.8 3.15

57 26.8 26.8 2.43 25.9 25.9 2.64 24.9 24.9 2.89 23.8 23.8 3.15

72 32.9 17.2 2.52 31.5 16.7 2.74 30.0 16.1 2.98 28.1 15.5 3.25

67 30.0 22.4 2.49 28.7 21.8 2.71 27.4 21.3 2.95 25.9 20.7 3.22