Page 1

installation and

MA1A

start-up instructions

10 SEER

RESIDENTIAL SELF-CONTAINED

AIR CONDITIONER/HEAT PUMP UNITS

NOTE: Read the entire instruction manual before starting the

installation.

SAFETY CONSIDERATIONS

Improper installation, adjustment, alteration, service, maintenance,

or use can cause explosion, fire, electrical shock, or other

conditions which may cause personal injury or property damage.

Consult a qualified installer, service agency, or your distributor or

branch for information or assistance. The qualified installer or

agency must use factory-authorized kits or accessories when

modifying this product. Refer to the individual instructions packaged with the kits or accessories when installing.

Follow all safety codes. Wear safety glasses and work gloves.

Read these instructions thoroughly and follow all warnings or

cautions attached to the unit. Consult local building codes and the

National Electrical Code (NEC) for special installation requirements.

Recognize safety information. This is the safety-alert symbol

When you see this symbol on the unit or in instructions and

manuals, be alert to the potential for personal injury.

Understand the signal words DANGER, WARNING, and CAUTION. These words are used with the safety-alert symbol. DANGER identifies the most serious hazards which willresultinsevere

personal injury or death. WARNING signifies hazards which

could result in personal injury or death. CAUTION is used to

identify unsafe practices which would result in minor personal

injury or product and property damage.

WARNING: Before installing or servicing system, always turn off main power to system. There may be more

than 1 disconnect switch. Turn off accessory heater

power if applicable. Electrical shock can cause personal

injury or death.

INTRODUCTION

The MA1A Air Conditioner and MH1A Heat Pump are UL Listed

per Standard UL 1995/UL 559 for use in manufactured homes.

These units are available in the cooling sizes shown in Table 1.

The MA1A and MH1A are single package units. All components

including outdoor coil, compressor, and refrigerant tubing are

located in 1 single package. The units are already piped, charged,

and wired.

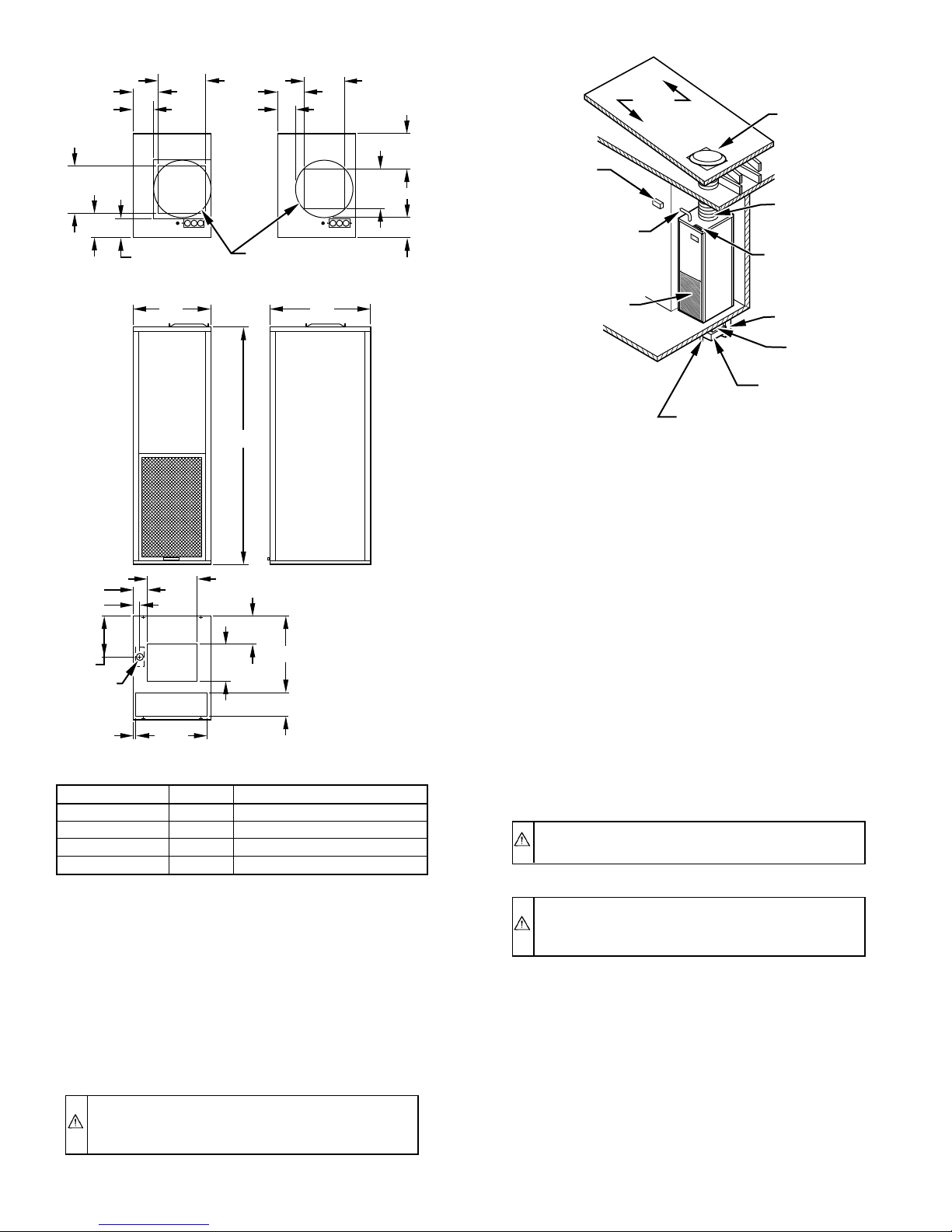

Refer to Fig. 2 for basic unit dimensions.

INSTALLATION

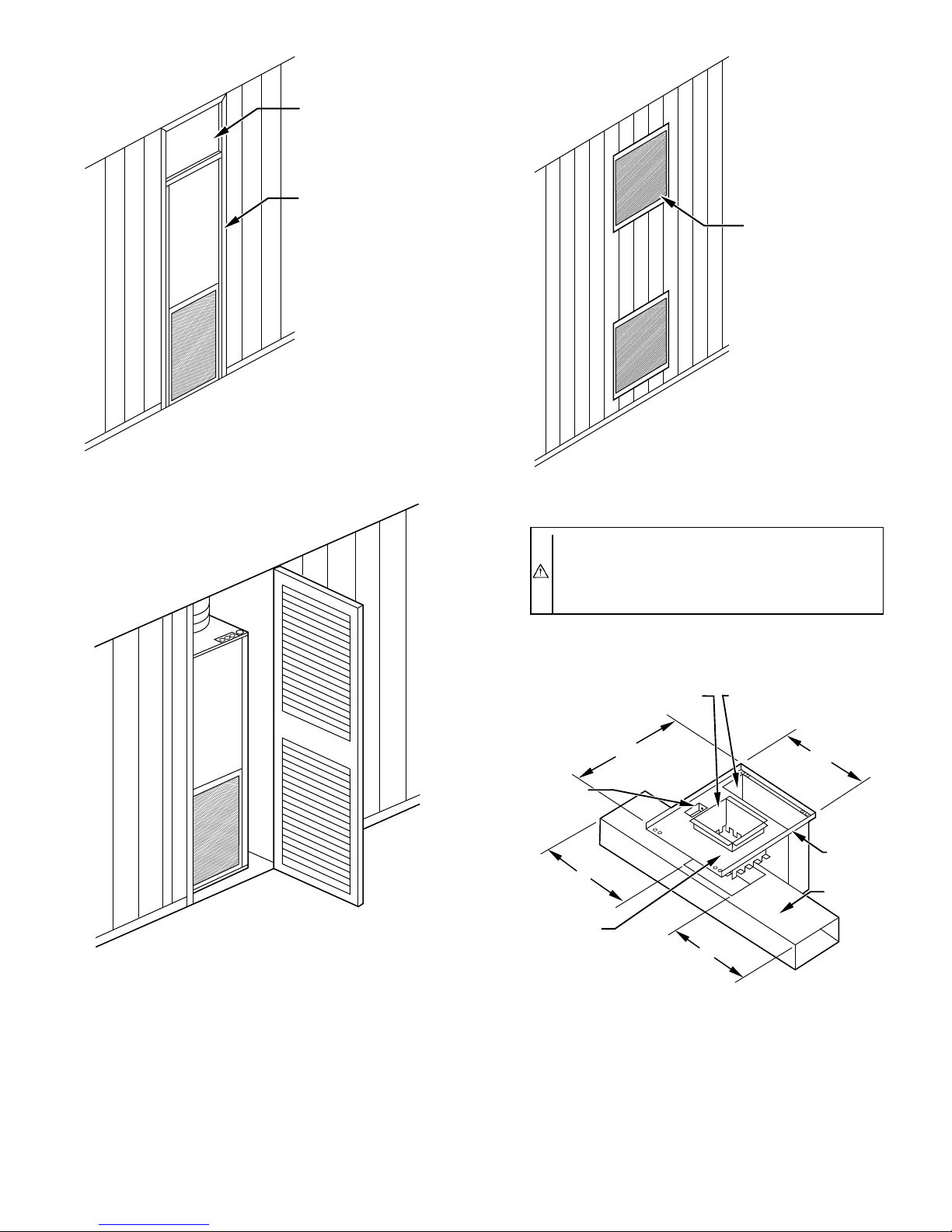

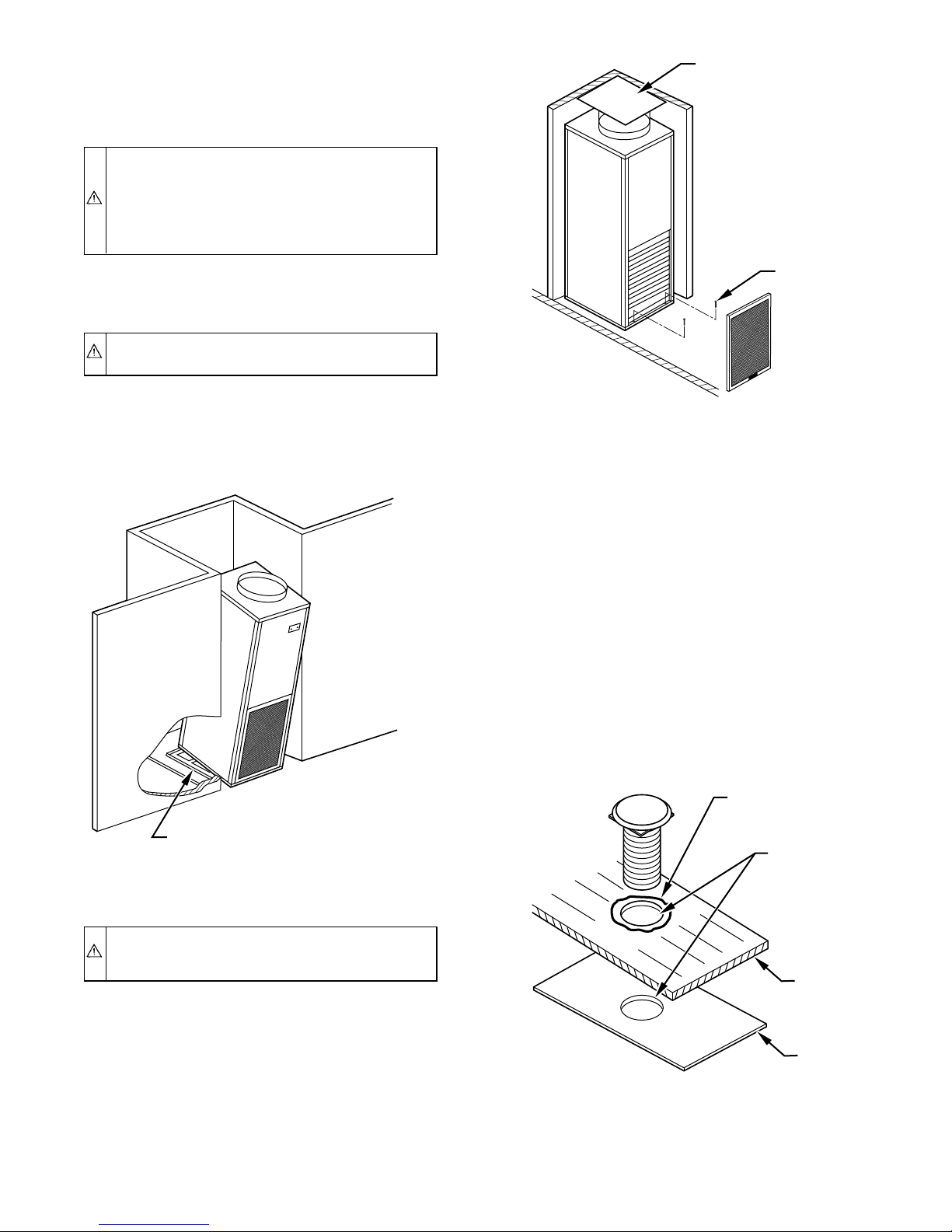

These units were designed for installation in manufactured homes,

but can be installed in a variety of other applications. These

instructions detail the method of installation for use in manufactured housing or other similar applications. Fig. 3 illustrates a

typical installation of this type. Study this drawing prior to starting

installation. It may be helpful to refer back to this drawing during

installation. Consult your distributor and the Application Guideline document for details regarding other installation applications.

MH1A

Cancels: New II MA1A-18-1

12-95

.

Fig. 1—Model MA1A/MH1A

TABLE 1—UNIT SIZES AND AVAILABLE

ELECTRIC HEAT

UNIT SIZE BTUH COOLING AVAILABLE KW

018 18,000 0—5—10

024 22,000 0—5—10

030 28,000 0—5—10—15

036 34,600 0—5—10—15—20

I. UNPACK UNIT AND INSPECT EQUIPMENT

Remove unit from carton and inspect for any shipping damage. Do

not install a damaged unit. Optional components used with unit

may include a thermostat, base and roof assembly kit, fresh air kit,

or return-air grille and air filter assembly.

Remove pallet by removing 4 bolts attaching pallet to base of unit.

CAUTION: The condensate drain outlet protrudes from

base of unit. To avoid damage to floors and floor

coverings, unit must be transported on an appliance dolly.

Do not slide unit on floor. Transport unit on appliance

dolly from side or rear only. Transporting unit from front

will damage air intake grille and lower coil. When setting

unit onto base template, unit may be carefully tilted from

front by a hand truck.

A95337

—1—

Page 2

7 7⁄16″

5 1⁄4″

10 11⁄16″

5 3⁄4″

11 9⁄16″ 10 3⁄8″

4 15⁄16″

BLOWER TOP

SCHEME NO. 1

20″ 25″

6 7⁄16″

4 5⁄8″

14-IN. ROUND

H

BLOWER TOP

SCHEME NO. 2

9 3⁄8″

8 9⁄16″

4 3⁄4″

ROOF

WALL

THERMOSTAT

THERMOSTAT WIRES

FROM THERMOSTAT

BLOCK

ROOM AIR INTAKE

AND FILTER

CONDENSATE DRAIN HOSE

(PIPE TO OUTSIDE OF STRUCTURE)

OUTDOOR-AIR

EXHAUST

14″ INSULATED

FLEX DUCT

PRIMARY

ELECTRICAL

SUPPLY

CONNECTIONS

OUTDOOR-AIR

PLENUM

INDOOR

PLENUM

INDOOR SUPPLY

DUCT

A95338

NOTE: If a door is used to enclose unit, refer to "Installation of

Unit Behind a Louvered Door or Enclosed in Closet" in Setup

section.

Fig. 3—Typical Installation

3 11⁄16″

1 13⁄16″

9 3⁄4″

DRAIN

1 1⁄32″

12 3⁄4″

18″

6 13⁄16″

9″

18 9⁄16″

5 1⁄2″

A95358

DIMENSIONS (IN.)

UNIT SIZE H BLOWER TOP SCHEME

018 57 Scheme No. 2

024 57 Scheme No. 2

030 67 Scheme No. 1

036 67 Scheme No. 1

Fig. 2—Unit Reference Drawing

II. ASSEMBLE SUPPLIES NEEDED FOR

INSTALLATION

The standard method of installation for units in manufactured

homes is with accessory base and roof assembly kit.

NOTE: If installing any other kit, Installation Instructions will be

furnished with kit.

In addition to items included in base and roof assembly kit, the

following items are required to install unit. All sizes listed are

suggested.

• Adhesive duct tape, U.L. 181 aluminum or equivalent.

WARNING: Incorrect type of duct tape may be a fire

hazard. A failure to follow this warning could result in a

fire or explosion, and personal injury or death.

• 8 No. 10 X 1/2 rust-resistant, self-tapping sheet metal screws

(holding roof flashing).

• Permanent sealant such as "mastic."

• 4 wood screws (base template).

• 2 No. 8 X 3/4 wood screws (unit to floor). Do not overtighten

and compress seal.

• Silicone caulking (roof flashing)

• Thermostat cable (18 gage wire minimum).

NOTE: The number of conductors needed depends on type of

unit and thermostat being installed. Air conditioning units require

4- or 5-conductor wire depending on type of thermostat being

used. (Some thermostats require a C terminal connection for

proper operation.) Heat pump units require 6-conductor wire.

CAUTION: Do not use thermostat wire with less than

the recommended number of conductors.

CAUTION: Failure to adhere to indoor air, outdoor air,

and exhaust air requirements as listed in the following

sections will void unit warranty.

III. SETUP

A. Indoor-Air Duct Requirements

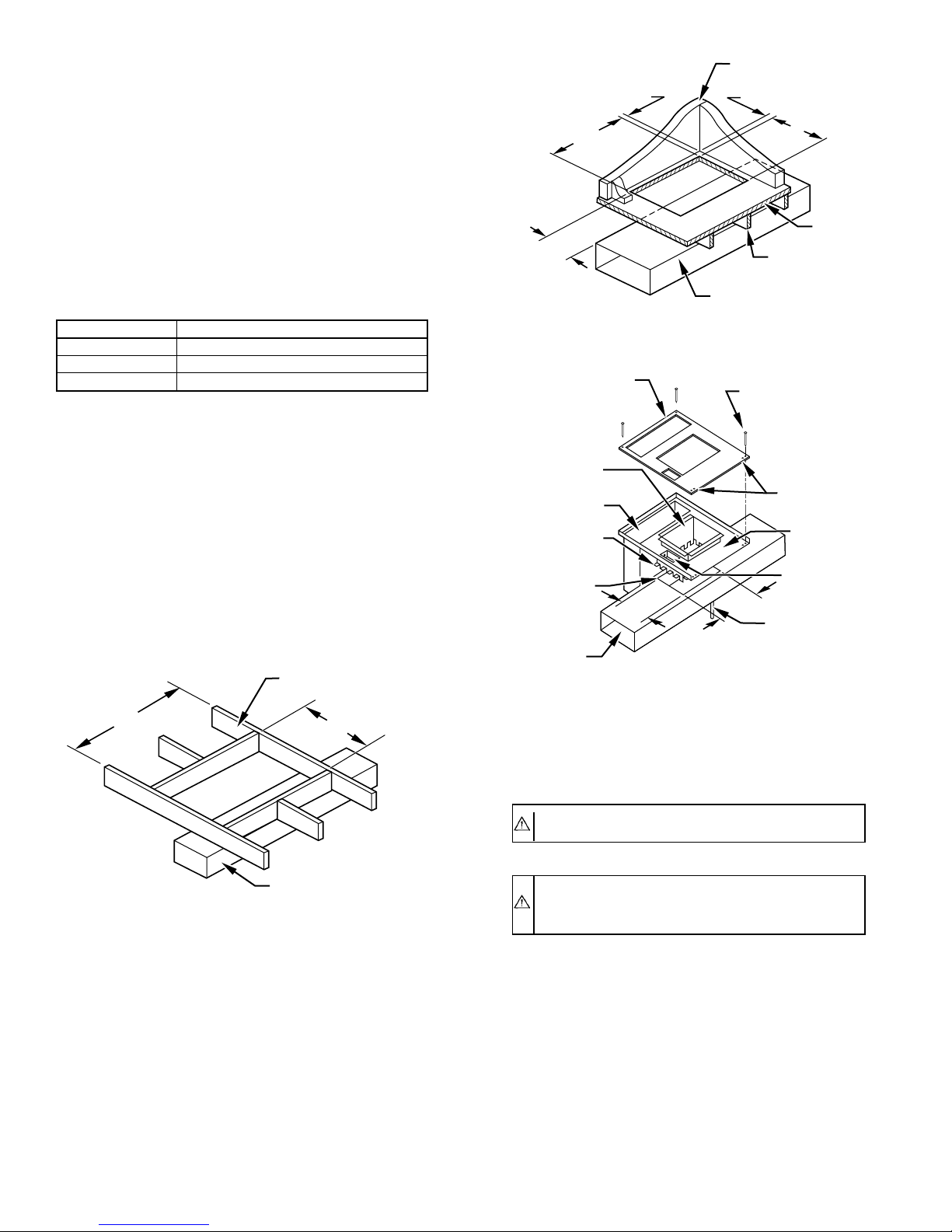

The MA1A and MH1A units are designed to be installed in 1 of

the following ways:

1. Installed flush with the wall. (See Fig. 4.)

2. Recessed behind a louvered door. (See Fig. 5.)

3. Installed in a closet with 1 or 2 return-air grilles. (See Fig.

6.) Refer to Installation of Unit Behind a Louvered Door or

Enclosed in Closet section for grille sizes.

—2—

Page 3

REMOVABLE WALL

INDOOR-AIR COLLAR

(12

11

⁄

16

″ X 8

15

⁄16″

X 9

1

⁄4″

DEEP)

OUTDOOR-AIR PLENUM

(5

7

⁄16″

X 17

15

⁄16″

X 19

1

⁄4″

DEEP)

203⁄

4

″

251⁄

4

″

24″

24″

BASE

TEMPLATE

FOAM

SEAL

DRAIN CUP

FRONT OF UNIT

METAL AIR

DUCT

NOTE: DO NOT OBSTRUCT OUTDOOR-AIR PLENUM OPENING.

PANEL FOR

UNIT'S SERVICE

REMOVABLE TRIM

FOR UNIT'S SERVICE

(DO NOT GLUE)

Fig. 4—Unit Installed with Front Exposed

OPTIONAL

LOCATION

NOTE: THE UNIT

MUST BE ACCESSIBLE

FOR SERVICE.

A95339

A95341

Fig. 6—Unit Installed in Closet with Return-Air Grille

CAUTION: The minimum installation clearance be-

tween both the indoor-air plenum and first 2 ft of metal

duct to any combustible material is 1 in. (See Fig. 7.) The

remainder of unit and duct work is approved for 0-in.

clearance.

Fig. 5—Unit Installed behind a Louvered Door

B. Indoor Supply Air Duct

The MA1A and MH1A units are designed to operate at a given

static pressure. The duct system, regardless of size, must not

exceed 0.3 in. static pressure. The design and construction of duct

system must also provide adequate air distribution to ensure

comfort levels throughout home.

If unit is being installed to replace another furnace or heating

system, a check of airflow rate (CFM) should be performed. If

airflow rate does not meetspecifications,duct alterations or repairs

must be made to correct airflow problem.

A95340

A95342

Fig. 7—Indoor-Air Plenum and Duct Clearances

C. Recommended Unit Clearances

For serviceability and elimination of compressor vibration transmission, it is recommended that the sides and back of unit be

installed with a minimum 1-in. clearance from walls. It is also

recommended that top of unit be installed with a clearance large

enough to allow removal of unit should it be necessary.

—3—

Page 4

D. Installation of Unit Behind a Louvered Door or

Enclosed in Closet

If unit is installed behind a louvered door and louvers are directly

in front of unit’s intake grille, a 2-in. clearance is recommended

between door and front of unit. If louvers are installed in upper part

of door so they are not directly in front of intake grill, a minimum

7-in. clearance is recommended between door and front of unit.

This also applies if a solid wall is used instead of a louvered door.

Should the louver be installed somewhere other than in front of

unit (for example, to the side of unit), consult your distributor

before proceeding to obtain recommended clearances. The recommended minimum return-air requirements to be used are shown in

Table 2.

APPROX.

8

″

181⁄2″

2″ TYP.

WALLS

2″

FRONT OF UNIT

FLOOR JOIST

FRAMING

191⁄2″

FLOOR

TABLE 2—MINIMUM RETURN-AIR REQUIREMENTS

UNIT SIZE NET FREE OPEN AREA (SQ IN.)

018 300

024 375

030, 036 450

IV. PREPARE FLOOR AND BASE

A. Install Installation Kit

Installing installation kit requires a hole through floor of home

approximately 18-1/2 in. wide by 19-1/2 in. deep to provide access

from unit to supply duct trunk and outside air.

NOTE: The diagrams show a typical installation. The actual

method of installation will be dictated by model and manufacturer

of the home. Installer will determine the best method to use.

1. Construct a boxed-in area of framework under unit location

slightly larger than the 18-1/2-in. by 19-1/2-in. hole to

provide adequate support for unit. (See Fig. 8.)

FLOOR JOIST

≈181⁄

″

2

≈191⁄

″

2

HOME DUCT TRUNK

A95344

Fig. 9—Dimensions of Hole

FOAM AIR SEAL

INDOOR AIR

COLLAR

OUTDOOR AIR

PLENUM

BEND

ALTERNATE

TABS

INDOOR AIR

CUTOUT

13″ x 91⁄8″

DUCT TRUNK

NOTE: THE DRAIN CUP, FOAM AIR SEAL, OUTDOOR-AIR

PLENUM, AND INDOOR-AIR COLLAR ARE PREASSEMBLED

AT FACTORY.

91⁄8″

FLAT-HEAD

WOOD SCREW

DO NOT USE

FRONT INSIDE

HOLES

BASE

TEMPLATE

DRAIN CUP

13″

DRAIN HOSE

(PIPE TO OUTSIDE

OF STRUCTURE)

A95345

Fig. 10—Installation of Base Template, Indoor-Air Collar,

and Outdoor-Air Plenum

SUPPLY-AIR DUCT

Fig. 8—Typical Framework Construction

2. Locate supply duct trunk so that it runs under front edge of

hole. Back edge of supply duct trunk should be approximately 8 in. from back of hole. (See Fig. 9.)

3. After floor section is complete; locate, mark, and cut a hole

through floor approximately 18-1/2 in. by 19-1/2 in. (See

Fig. 9.)

4. Place base template assembly over hole and mark indoor-air

plenum cutout in supply duct trunk measuring 13 in. by

9-1/8 in. (See Fig. 10.) Mark condensate drain hose and

outdoor-air plenum cutouts in insulation and vapor barrier

or drain to outside.

A95343

CAUTION: Be careful not to crimp drain hose attached

to condensate drain cup.

CAUTION: Failure to route drain hose where it will not

be kinked will cause drain trap to overflow, leaking water

onto floor.

5. Remove base template assembly. Reach through hole and

cut holes through vapor barrier and insulation for outdoorair plenum and condensate drain hose to extend through or

drain to outside. Also cut 13-in. by 9-1/8-in. hole in duct

trunk. (See Fig. 10.)

6. Bend every other tab up 90 degrees on indoor-air collar as

shown in Fig. 10.

7. Insert base template assembly into supply duct and secure it

with 4 flat-head screws, 1 in each corner. Bend remaining

tabs up 90 degrees locking indoor-air collar securely to

supply duct trunk. Use mastic or foil-type duct tape to seal

any openings. (See Fig. 10.)

—4—

Page 5

NOTE: Do not let indoor-air collar extend down into duct. It

MUST be flush with top of duct trunk. If collar does not fit

properly, minor adjustments may have to be made to collar.

8. Use Flex-Mend or equivalent RTV caulk to seal bottom

board to outdoor-air plenum.

WARNING: Non-foil-type tapes will not withstand the

temperature of heated air from unit and may be a fire

hazard. Failure to tape joint will allow heated or cooled

air to leak beneath home. A failure to follow this warning

could result in a fire or explosion, and personal injury or

death.

V. INSTALL UNIT

A. Setting Unit

CAUTION: Do not move unit on an unprotected floor.

Damage to floor will result.

TEMPORARILY COVER HOLE

WHILE THE 15-IN. CUTOUT IN

THE CEILING AND ROOF

ARE BEING MADE

WOOD SCREWS

1. If necessary, use an appliance dolly to position unit into

enclosure, being careful not to disturb foam seal on template. When unit’s front edge is in line with front edge of

base template, set unit upright onto base template. (See Fig.

11.)

BASE TEMPLATE

NOTE: TILT UNIT APPROXIMATELY 45° WHILE MOVING IT

INTO PLACE TO AVOID DISTORTION OF FOAM SEAL.

A95347

Fig. 11—Setting Unit on Base Template

NOTE: SCREW HOLES IN BOTTOM RAIL OF UNIT MUST

ALIGN WITH HOLES IN METAL BASE TEMPLATE.

A95348

Fig. 12—Securing Unit to Floor

4. Cover unit top as shown in Fig. 12. Cut a hole with a

diameter of approximately 15 in. through ceiling and roof

directly over outdoor-air exhaust. If hole in roof and ceiling

cannot be aligned directly over each other, a small bend in

the flexible duct may be required. Acceptable misalignment

of hole in ceiling and transition is a maximum of 2 in. per

each 12 in. of flex duct in elevation, up to a maximum of 6

in.

5. Seal any opening with mastic to prevent loss of conditioned

air into attic space.

B. Exhaust Air Venting

1. Apply a generous amount of mastic to roof surface and

around hole cut for outdoor-air duct to pass through. (See

Fig. 13.) Lower duct down through hole in roof and ceiling

and fasten flashing to roof with screws.

APPLY MASTIC TO

SEAL ROOF CAP

TO ROOF

15-IN. DIAMETER

HOLE

CAUTION: Only minor movement is allowed when

aligning holes in unit base with holes in template to

prevent damage to foam air seal.

2. Remove front grille of unit (if necessary) as shown in Fig.

12 and make minor adjustments in location of unit if

necessary to align screw holes in bottom rail of unit with

screw holes in base template.

3. The unit should be secured permanently to structure by

driving 2 wood screws through mating holes in bottom rail

of unit and base template into floor. Tighten screws flush to

foam seal. Overtightening screws will tip unit forward on

foam seal. Do NOT use any other procedure to permanently

secure unit to structure.

ROOF

CEILING

A95349

Fig. 13—Outdoor-Air Duct Installation

2. Apply additional mastic or sealant around flashing perimeter base to provide protection against rainwater leaking

under flashing.

—5—

Page 6

CAUTION: Failure to properly seal flashing to roof will

result in rainwater leaking into and damaging unit or

home. Proper sealing of roof vent is the responsibility of

installer.

3. Check fit where flexible duct passes through ceiling. Seal

any openings with foil-type duct tape or caulking to prevent

loss of conditioned air to attic or attic air leaking into home.

(See Fig. 14.)

ROOF CAP

ROOF

ROOF

FLASHING

TAPE APPLIED

TO SEAL HOLE

IN CEILING

CEILING

VI. MAKE ELECTRICAL CONNECTIONS

A. Electrical Requirements

WARNING: To prevent personal injury or equipment

damage, always disconnect main power before doing any

maintenance or wiring. A failure to follow this warning

could result in electrical shock, fire, or death.

NOTE: All electrical power supply conductors serving unit must

be copper.

The circuit breakers or fuses used for branch circuit protection

should be UL Recognized. If circuit breakers are used, the circuit

breaker for compressor circuit must have a UL HACR rating. If

fuses are used, the fuses for compressor circuit MUST be a time

delay.

All electrical wiring supplying unit must comply with the NEC

ANSI/NFPA 70, and all state and local codes.

Depending on auxiliary heater size, unit must be supplied with 1,

2, or 3 separate 240-v circuits from home’s circuit breaker panel or

fuse box. Refer to Table 3 and Table 4 for required circuits and

recommended wire size for each circuit.

The unit is equipped with circuit breakers enclosed in wiring

compartment. This compartment is located in top right-hand corner

of unit.

Ground wires for supply circuits must be attached to ground lug(s)

in circuit breaker box to provide required safety grounding of unit.

A95350

Fig. 14—Roof Cap Installation

4. Remove protective cover from top of unit and inspect fan

housing to make sure no debris is in fan housing.

5. Push insulation up on lower end of flexible duct. Slip

flexible duct onto round adapter duct on top of unit and

secure duct to outdoor-air exhaust with mastic or U.L. 181

tape.

NOTE: An untaped or poorly taped joint will leak outside air into

home. All excess flex duct must be cut off and remaining duct

pulled tight.

6. Pull insulation down over taped joint and outdoor-air

exhaust. (See Fig. 15.) Fasten insulation in place with tape

and strap.

PULL INSULATION AND OUTER COVER SNUG TO TOP

OF UNIT AND FASTEN WITH STRAP-TYPE DUCT CLAMP.

SCREW

WARNING: The cabinet must have an uninterrupted or

unbroken ground according to National Electrical Code,

ANSI/NFPA 70 or local codes to minimize personal

injury if an electrical fault should occur. This may consist

of electrical wire or conduit approved for electrical

ground when installed in accordance with existing electrical codes. A failure to follow this warning could result

in an electrical shock, fire, or death.

WARNING: Failure to adhere to minimum wire sizes,

maximum over-current protection, disconnect, and

grounding requirements can cause personal injury, electrical shock, or a fire hazard. All wiring MUST comply

with requirements of the NEC, state, and local codes.

All low-voltage thermostat wires MUST be connected to lowvoltage terminal block mounted on left side of control box located

inside front panel of unit.

CAUTION: Power supply must be nominal 230-v, 1

phase. Do not exceed 253v or go below 197v.

B. Electrical Connections

IF POSSIBLE, INSERT A METAL SCREW W/FLAT

WASHER ABOVE WIRE FRAME OF FLEX DUCT TO

HELP HOLD IT ON ROUND ADAPTER.

Fig. 15—Securing Insulation

A95351

WARNING: To avoid personal injury or death, do not

supply power to unit with compressor terminal box cover

removed.

1. Remove front panel.

a. Remove 2 screws on bottom.

b. Remove 5 screws holding cover around breakers and

remove it to gain access to wiring compartment. (See

Fig. 16.)

—6—

Page 7

TABLE 3—COMPRESSOR ELECTRICAL DATA

UNIT

SIZE

018 10.2 1.2 1.2 15.2 12 100 15

024 12.5 2.2 2.2 20.0 12 74 20

030 15.0 3.1 2.2 24.0 10 98 30

036 19.0 3.1 3.1 30.0 8 163 40

* If wire is applied at ambient greater than 30°C (86°F), consult Table 310-16 of the NEC (ANSI/NFPA 70). The ampacity of nonmetallic-sheathed cable (NM), trade name

ROMEX, shall be that of 60°C (140°F) conductors, per the NEC (ANSI/NFPA 70) Article 336-30. If other than uncoated (non-plated), 60° or 75°C (140° or 167°F) insulation,

copper wire (solid wire for 10 AWG and smaller, stranded wire for larger than 10 AWG) is used, consult applicable tables of the NEC (ANSI/NFPA 70).

† Length shown is as measured 1 way along the wire path between the unit and the service panel for voltage drop not to exceed 2%.

‡ Time-delay fuse.

COMPRESSOR

AMPS

OUTDOOR FAN

AMPS

INDOOR FAN

AMPS

COMPRESSOR

CIRCUIT

AMPACITY

MINIMUM

WIRE

SIZE*

MAX WIRE

LENGTH

(FT)†

MAX FUSE‡

OR BREAKER

SIZE AMPS

TABLE 4—ELECTRIC HEAT ELECTRICAL DATA

ELECTRIC

HEATER

(KW)

5

10

15

20 036 44.8 56 6 60 111 44.8 56 6 60 111

* If wire is applied at ambient greater than 30°C (86°F), consult Table 310-16 of the NEC (ANSI/NFPA 70). The ampacity of nonmetallic-sheathed cable (NM), trade name

ROMEX, shall be that of 60°C (140°F) conductors, per the NEC (ANSI/NFPA 70) Article 336-30. If other than uncoated (non-plated), 60° or 75°C (140° or 167°F) insulation,

copper wire (solid wire for 10 AWG and smaller, stranded wire for larger than 10 AWG) is used, consult applicable tables of the NEC (ANSI/NFPA 70).

† Time-delay fuse.

‡ Length shown is as measured 1 way along the wire path between the unit and the service panel for voltage drop not to exceed 2%.

N/A—Not Applicable

USED ON 1ST CIRCUIT 2ND CIRCUIT

Unit

Size

018

024

030

036

018

024

030

036

030

036

Wire

Amps Ampacity

23.9 29.9 10 30 80 N/A N/A N/A N/A N/A

44.8 56 6 60 111 N/A N/A N/A N/A N/A

23.9 29.9 10 30 80 44.8 56 6 60 111

Size*

Max Fuse†

Size Amps

Max Wire

Length‡

(Ft)

Amps Ampacity

Wire

Size*

Max Fuse†

Size Amps

Max Wire

Length

(Ft)‡

CIRCUIT BREAKER BOX

CIRCUIT BREAKER

COVER

FRONT PANEL

Fig. 16—Gaining Access to Wiring Compartment

2. Connect electrical load and ground lead to unit as shown in

Fig. 17. Refer to previous section for electrical requirements. All low-voltage thermostat wires must be connected

to low-voltage terminal block mounted on side of control

box located inside unit.

A95352

VII. INSTALL WALL THERMOSTAT

A. General Information

Select a location for thermostat about 5 ft above floor in an area

where air circulation is good. Preferably an interior wall near unit’s

return-air grille is the ideal location.

Thermostat should not be mounted:

• Close to a window, or an outside wall, or next to a door leading

to the outside.

• Where it may be affected by drafts or dead air spots behind

doors or corners.

• Close to or in direct airflow from supply registers.

• Exposed to direct radiant heat from sun, lamps, appliances, or

other temperature-radiating objects which may cause a false

reading.

NOTE: Improper location of thermostat will cause poor operation

of unit.

B. Route Thermostat Cable

All wiring for thermostat circuit must be No. 18 AWG minimum,

color-coded thermostat cable and comply with NEC, state, and

local codes.

Refer to Table 5 for type of thermostat cable required for specific

installation applications.

NOTE: Heat pump can only be controlled witha6ormore

conductor, No. 18 AWG minimum thermostat cable and a heat

pump compatible thermostat. If heat pump is being installed to

replace another heating furnace or system, thermostat must be

replaced with 1 listed in Table 5 for heat pump use, and thermostat

cable must be replaced unless it is the proper type and size.

If an existing thermostat is being replaced:

1. Turn off all power to unit.

2. Remove existing thermostat from wall.

—7—

Page 8

SERVICE GROUND LUG

FOR NO. 10 AWG

AND NO. 8 AWG

NO. 6 AWG AUXILIARY

10KW HEATER NO. 2

LOAD LEADS

10KW

NO. 10 AWG AUXILIARY

5KW HEATER NO. 1

LOAD LEADS

NO. 8 AWG

COMPRESSOR LEADS

ON

ON

ON

COMPRESSOR

5KW

AUXILIARY

10KW HEATER NO. 2

LOAD LEADS

OFF

60 AMP

OFF

30 AMP

OFF

40 AMP

NO. 8 AWG

COMPRESSOR LEADS

AUXILIARY

5KW HEATER NO. 1

LOAD LEADS

A95353

NOTE: This diagram shows a typical wiring installation for an 036 unit with 15-kw heat. It may not reflect the wiring in unit. The actual wiring

installation to use depends on unit and electric heat requirements. (See Tables 3 and 4.) The installer must follow NEC, state, and local codes.

Fig. 17—Typical Wiring Installation

3. Disconnect wires from existing thermostat, 1 at a time. Be

careful not to allow wires to fall back into wall.

4. As each wire is disconnected, record wire color and

terminal marking.

5. Discard or recycle old thermostat.

NOTE: Mercury is a hazardous waste and MUST be disposed of

properly.

6. If existing thermostat cable is acceptable for application

(See Table 5), proceed to Mount Wall Thermostat and

Connect Thermostat Wires section.

If installing new thermostat cable, route as follows:

1. Drill hole for cable at location selected for thermostat.

2. Remove front panel of unit.

3. Route thermostat cable from unit’s compartment and pull

approximately 6-12 in. of cable through hole drilled in wall

for connection to thermostat terminals.

4. Strip outer casing off area of cable pulled through wall for

greater flexibility.

TABLE 5—REQUIRED THERMOSTAT CABLE TYPE

NO. OF

APPLICATION THERMOSTAT

Robertshaw (TX400-42K) 4 G, R, Y, W Fig. 18

Air Conditioner

Heat Pump

TSTATPPNAC01-A 5 R, C, W/W1, Y/Y2, G Fig. 19

TSTATPPPAC01-A 5 R, C, W/W1, Y/Y2, G Fig. 20

Honeywell (T841A1548) 6 G, R, Y, B, W2, E Fig. 21

TSTATPPNHP01-A 8 R, C, W/W1, Y/Y2, G, B, S1, S2 Fig. 25

TSTATPPPHP01-A 8 R, G, W/W1, Y/Y2, C, B, S1, S2 Fig. 26

CONDUCTORS

REQUIRED

18 GAGE

REQUIRED

CONNECTIONS

WIRING

DIAGRAM

—8—

Page 9

C. Mount Wall Thermostat and Connect Thermostat

Wires

Determine the type of thermostat needed for unit application and

follow instructions in the appropriate section below.

ROBERTSHAW AIR CONDITIONING THERMOSTAT

1. Remove cover (friction fit) from thermostat body by gripping at top and bottom and lifting from subbase. Use

extreme care not to damage working parts.

2. Remove subbase from thermostat body by loosening captive screws.

3. Hold subbase level against wall in final thermostat location.

Mark wall with a pencil where screws will attach subbase to

wall. Use designated subbase mounting holes only.

4. Set subbase aside and drill mounting holes in wall with

3/32-in. drill bit.

5. Route thermostat wires from hole in wall through opening

in center of subbase.

6. Attach thermostat subbase to wall using mounting screws

and predrilled holes in wall.

NOTE: Make sure white wire on thermostat subbase is connected

to A2 terminal.

7. Strip approximately 1/2-in. of insulation off end of each

wire. Connect thermostat wires to appropriate thermostat

screw terminals on subbase. (See Fig. 18.)

CONTROL

VOLTAGE

THERMOSTAT

FAN

24VAC HOT

COOL

HEAT

G

R

Y

W

GREEN

RED

YELLOW

WHITE

TERMINAL

STRIP

G

R

Y

W

A95354

NOTE: Connect only terminals shown to thermostat.

Fig. 18—Air Conditioner Circuit Connections

(Robertshaw Thermostat)

8. Push excess wire back into wall. Seal hole in wall to prevent

drafts.

9. Mount thermostat body on subbase with captive screws.

10. Set heat anticipator indicator (located in upper left corner of

thermostat body) to appropriate value based on the heater

size for unit being installed. (See Table 6.)

TABLE 6—HEAT ANTICIPATOR VALUES FOR

AIR CONDITIONING UNITS

HEATER SIZE (KW) ANTICIPATOR SETTING

0 N/A

5 0.16

10 0.16

15 0.32

20 0.32

N/A—Not Applicable

11. Install thermostat cover. Carefully align "D" shaped dial

shaft with matching shaped hole in hub of setting dial, then

press cover carefully on thermostat body.

12. Set outdoor thermostat to 50°F.

NOTE: Refer to Installation Instructions packaged with thermostat for additional information.

ELECTRONIC AIR CONDITIONING THERMOSTATS

(PROGRAMMABLE AND NON-PROGRAMMABLE)

1. Open thermostat rear door (mounting base) to expose

mounting holes. The base can be removed to simplify

mounting. Snap apart carefully at hinge to separate mounting base from remainder of thermostat.

2. Route thermostat wires through large hole in mounting

base.

3. Level mounting base against wall and mark wall through 2

mounting holes.

4. Drill two 3/16-in. mounting holes in wall where marked.

5. Secure mounting base to wall with 2 screws and anchors

provided, making sure all wires extend through mounting

base.

6. Adjust wire length and routing to allow proper closure of

thermostat. Strip each wire end no more than 1/4-in. to

prevent adjacent wires from shorting together. Match and

connect equipment lead wire to correct terminals of the

thermostat connector. (See Fig. 19 and 20.)

NOTE: All TSTAT models have no batteries and are not "power

stealing." They do require 24 vac (R and C terminals) to be

connected for proper operation. Thermostat will not operate

without these 2 connections.

7. Push excess wiring into wall. Seal hole in wall to prevent

drafts.

8. Snap hinge back together.

9. Turn on power to unit.

10. Reconfigure thermostat to energize fan (G) terminal

with call for heat (W).

Since this is a self-contained unit, there is no furnace or fan

coil to energize the blower when electric heat is initiated.

The thermostat MUST be reconfigured to start blower when

electric heat is selected (G is energized whenever W is

energized).

a. Non-Programmable Model

(1.) Enter thermostat configuration mode by pressing

and holding FAN button for approximately 10 sec.

The room temperature disappears and display

should read "1-." Thermostat is now in configuration mode.

NOTE: If FAN button is pressed again or if no

button is pressed for 60 sec, thermostat will exit

configuration mode and return to normal operation.

To re-enter configuration mode, the FAN button

must be pressed and held for 10 sec again.

(2.) Use up and down buttons until thermostat display

reads "5-."

(3.) Press MODE button once to display current selec-

tion of ON or OFF. Factory default is OFF.

(4.) Use the up or down button to change from OFF to

ON.

(5.) Press FAN button to exit configuration mode.

NOTE: Refer to electronic thermostat Installation Instructions for

more information if needed.

—9—

Page 10

MODEL AC

PROGRAMMABLE

ELECTRONIC

THERMOSTAT

CONTROL

VOLTAGE

TERMINAL

STRIP

MODEL AC

NON-PROGRAMMABLE

ELECTRONIC

THERMOSTAT

24 VAC HOT

24 VAC COMM

HEAT STAGE 1

COOL STAGE 1

FAN

R

C

W/W1

Y/Y2

G

CONTROL

VOLTAGE

TERMINAL

STRIP

R

X

W

Y

G

A95413

NOTE: X terminal on control voltage terminal strip must be connected to C terminal on thermostat for proper thermostat operation.

Fig. 19—Air Conditioning Circuit Connections

(Non-Programmable Electronic Thermostat)

b. Programmable Model

(1.) Enter thermostat configuration mode by pressing

and holding FAN button for approximately 10 sec.

The room temperature disappears and display

should read "--." Thermostat is now in configuration mode.

NOTE: If no button is pressed for 10 sec, thermostat will exit configuration mode and resume normal

operation. To re-enter configuration mode, FAN

button must be pressed and held for 10 sec again.

(2.) Press HOLD button to display current selection of

OF (off) or ON (on). Factory default is OF for off.

(3.) Use the up or down button to change from OF (off)

to ON (on).

(4.) Wait 10 sec to exit configuration mode.

NOTE: Refer to the electronic thermostat Installation Instructions

for more information if needed.

11. With an electronic thermostat such as this one, it should not

be necessary to change the factory default anticipation

setting. Consult thermostat Installation Instructions if heat

anticipation must be adjusted.

HONEYWELL HEAT PUMP THERMOSTAT

1. Strip approximately 1/2-in. of insulation off end of each

wire routed through hole in wall.

2. Connect thermostat wires to thermostat by placing colored

wire under appropriate terminal screw on back of thermostat as indicated by label over low-voltage terminal block

located on left side of control box. (See Fig. 21.)

3. Push all but approximately 2 in. of thermostat cable back

into wall. Seal opening around cable to prevent drafts

through hole which could interfere with operation of unit.

24 VAC HOT

FAN

HEAT STAGE 1

COOL STAGE 1

N/A

N/A

24 VAC COMM.

N/A

N/A

OUTDOOR

SENSOR

CONNECTION

R

G

W/W1

Y/Y2

O/W2

Y1/W2

C

B

L

S1

S2

R

G

W

Y

X

A95414

NOTE: Terminals O/W2, Y1/W2, B, and L are not used on thermostat. X terminal on control voltage terminal strip must be connected to

C terminal on thermostat for proper thermostat operation. An optional

outdoor temperature sensor may be connected to S1 and S2 terminals

on thermostat.

Fig. 20—Air Conditioning Circuit Connections

(Programmable Electronic Thermostat)

CONTROL

VOLTAGE

THERMOSTAT

FAN

24 VAC HOT

COOL/HEAT

STAGE 1

RVS HEATING

HEAT

STAGE 2

EMERGENCY

HEAT

NOT USED

NOT USED

NOT USED

G

R

Y

B

W

2

EE

GREEN

RED

YELLOW

BLUE

WHITE

BROWN

OX

L

W

3

TERMINAL

STRIP

G

R

Y

B

W

2

A95355

NOTE: Terminals O, L, and W3 are not used on thermostat.

Fig. 21—Heat Pump Circuit Connections

(Honeywell Thermostat)

—10—

Page 11

4. Remove thermostat cover and place base against wall in a

near level position. Fasten to wall by driving 2 of the screws

provided with thermostat through slots in center of base and

into wall. (See Fig. 22.)

HEAT ANTICIPATOR INDICATOR

MOUNTING HOLE

MOUNTING HOLE

A95373

Fig. 22—Thermostat Mounting Screw Location

5. Remove and discard foam shipping pad from inside ther-

mostat.

CAUTION: Failure to remove foam shipping pad will

damage thermostat.

6. Level thermostat with a level. (See Fig. 23.) Tighten 2

mounting screws then drive 2 remaining screws through

holes in upper corners of base and into wall. (See Fig. 23.)

NOTE: Thermostat must be level for proper unit operation.

80

80

70

70

60

60

50

50

ONAUTO

COOLOFFHEATEM HEAT

FAN

A95356

Fig. 23—Leveling Thermostat

7. Set thermostat heat anticipator to appropriate value based

on the heater size for unit being installed. (See Fig. 24 and

Table 7.)

8. Replace thermostat cover by hooking tabs on top lip of

cover into slots in top retaining post and swinging cover

down until it snaps over lower retaining post.

9. Set outdoor thermostat to 50°F.

NOTE: Refer to Installation Instructions packaged with thermostat for additional information.

ELECTRONIC HEAT PUMP THERMOSTATS

(PROGRAMMABLE AND NON-PROGRAMMABLE)

1. Install Outdoor Temperature Sensor. Follow Installation

Instructions included with sensor and route wires through

hole in wall along with thermostat cable.

2. Open thermostat rear door (mounting base) to expose

mounting holes. The base can be removed to simplify

mounting. Snap apart carefully at hinge to separate mounting base from remainder of thermostat.

3. Route thermostat wires through large hole in mounting

base.

.10

.12

LONGER

.15

1.2

.8

.6

.4

.2

.3

COOLCOOLHEATEM HEAT

A95357

Fig. 24—Setting Heat Anticipator

TABLE 7—HEAT ANTICIPATOR VALUES FOR

HEAT PUMP UNITS

HEATER SIZE (KW) ANTICIPATOR SETTING

0 N/A

5 0.35

10 0.35

15 0.70

20 0.70

N/A—Not Applicable

4. Level mounting base against wall and mark wall through 2

mounting holes.

5. Drill two 3/16-in. mounting holes in wall where marked.

6. Secure mounting base to wall with 2 screws and anchors

provided, making sure all wires extend through mounting

base.

7. Adjust wire length and routing to allow proper closure of

thermostat. Strip each wire end no more than 1/4-in. to

prevent adjacent wires from shorting together. Match and

connect equipment lead wire to correct terminals of the

thermostat connector. (See Fig. 25 and 26.)

NOTE: All TSTAT models have no batteries and are not "power

stealing." They do require 24 vac (R and C terminals) to be

connected for proper operation. Thermostat will not operate

without these 2 connections.

8. Push excess wiring into wall. Seal hole in wall to prevent

drafts.

9. Snap hinge back together.

10. Turn on power to unit.

11. Reconfigure thermostat to allow thermostat and outdoor

temperature sensor to control electric heat lockout.

This configuration allows lockout of any W (Electric Heat)

when outdoor temperature is above a selected value. Temperatures of 15° to 55°F (or equivalent values in °C) can be

selected. Feature can be enabled or disabled. EMERGENCY HEAT mode disables this feature. Factory default

is OFF (disabled.)

To enable feature and set temperature value proceed as

follows:

a. Non-Programmable Model

(1.) Enter thermostat configuration mode by pressing

and holding FAN button for approximately 10 sec.

The room temperature disappears and display

should read "1-." Thermostat is now in configuration mode.

—11—

Page 12

MODEL HP

NON-PROGRAMMABLE

ELECTRONIC

THERMOSTAT

24 VAC HOT

24 VAC COMM

HEAT STAGE 2

COOL/ HEAT

STAGE 1

FAN

R

C

W/W1

Y/Y2

G

CONTROL

VOLTAGE

TERMINAL

STRIP

R

X

W2

Y

G

E

MODEL HP

PROGRAMMABLE

ELECTRONIC

THERMOSTAT

24 VAC HOT

FAN

HEAT STAGE 2

COOL/HEAT

STAGE 1

RVS COOLING

N/A

R

G

W/W1

Y/Y2

O/W2

Y1/W2

CONTROL

VOLTAGE

TERMINAL

STRIP

R

G

W2

Y

E

RVS COOLING

N/A

RVS HEATING

TROUBLE OR

CLEAN FILTER

OUTDOOR

SENSOR

CONNECTION

O/W2

Y1

B

L

S1

S2

B

OUTDOOR

TEMPERATURE

SENSOR

A95415

NOTE: Terminals O/W2, Y1, and L are not used on thermostat. An

outdoor temperature sensor must be connected to thermostat terminals

S1 and S2. X terminal on control voltage terminal strip must be

connected to C terminal on thermostat for proper thermostat operation. Terminals W2 and E must be jumpered on unit terminal block.

Fig. 25—Heat Pump Circuit Connections

(Non-Programmable Electronic Thermostat)

NOTE: If FAN button is pressed again or if no

button is pressed for 60 sec, thermostat will exit

configuration mode and return to normal operation.

To re-enter configuration mode, the FAN button

must be pressed and held for 10 sec again.

(2.) Use up and down buttons until thermostat display

reads "6-."

(3.) Press MODE button once to display current selec-

tion of OF, 15, 20, 25, 30, 35, 40, 45, 50, or 55.

Value should be OF for feature disabled.

(4.) Use up and down buttons to change from OF to 1 of

the available temperature choices. Value will depend on ambient temperature at which heat pump

can no longer handle heating load.

(5.) Press FAN button to exit configuration mode.

b. Programmable Model

(1.) Enter thermostat configuration mode by pressing

and holding FAN button for approximately 10 sec.

The room temperature disappears and display

should read "--." Thermostat is now in configuration mode.

NOTE: If no button is pressed for 10 sec, thermostat will exit configuration mode and resume normal

operation. To re-enter configuration mode, FAN

button must be pressed and held for 10 sec again.

(2.) Press COPY PREVIOUS DAY button to display

current selection of OF, 15, 20, 25, 30, 35, 40, 45,

50, or 55. Value should be OF for feature disabled.

24 VAC COMM.

RVS HEATING

TROUBLE

OUTDOOR

SENSOR

CONNECTION

S1

S2

C

B

L

X

B

OUTDOOR

TEMPERATURE

SENSOR

A95416

NOTE: Terminals O/W2, Y1/W2, and L are not used on thermostat.

An outdoor temperature sensor must be connected to thermostat

terminals S1 and S2. X terminal on control voltage terminal strip must

be connected to C terminal on thermostat for proper thermostat

operation. Terminals W2 and E must be jumpered on unit terminal

block.

Fig. 26—Heat Pump Circuit Connections

(Programmable Electronic Thermostat)

(3.) Use the up and down buttons to change from OF to

1 of the available temperature choices. Value will

depend on ambient temperature at which heat pump

can no longer handle heating load.

(4.) Wait 10 sec to exit configuration mode.

12. Jumper terminals W2 and E on unit terminal strip. This

allows electric heat to be activated when EMERGENCY

HEAT option is selected at thermostat.

13. With an electronic thermostat such as this one, it should not

be necessary to change the factory default heat anticipation

setting. Consult thermostat Installation Instructions if heat

anticipation must be adjusted.

NOTE: Refer to Installation Instructions packaged with thermostat for additional information.

D. Make Low-Voltage Connections at Unit

Attach thermostat wires to low-voltage terminal block on left side

of control box in locations indicated on label adjacent to terminal

block or appropriate thermostat wiring diagram in these instructions.

NOTE: Any unused conductors of thermostat cable not required

should be left unattached.

CAUTION: Recheck wiring color code schedule to be

certain proper terminals are connected before applying

power. Improper wiring or installation may damage

thermostat.

—12—

Page 13

VIII. ENSURE ADEQUATE OUTDOOR-AIR SUPPLY

Outdoor air is pulled from underneath the home, passed across the

outdoor-air coil, then pushed out through the roof cap exhaust.

Since the outdoor-air is pulled from beneath the home, it is very

important that the amount of ventilation panels or vents is

adequate. The underpinning vent panels or foundation vents are

rated for the amount of air that passes through them in sq in. of net

free area. Ensure that you have the correct amount of ventilation

needed for unit being installed. (See Table 8.)

TABLE 8—VENTILATION REQUIREMENTS

UNIT SIZE MINIMUM NET FREE OPEN AREA (SQ. IN.)

018 400

024 450

030 675

036 700

IX. CONSTRUCT OUTDOOR-AIR TUNNEL (IF REQUIRED)

NOTE: This is an OPTIONAL installation procedure to alleviate

problems that may occur with your air conditioner or heat pump

unit and various other appliances or ambient conditions.

A. Determine if an Outdoor-Air Tunnel is Required

We recommend that this procedure be used for any one or a

combination of the following conditions:

1. A fireplace is installed and gets its fresh air from underneath

structure.

Indication to use: When conditioner or heat pump turns on,

smoke from fireplace backdrafts and enters structure.

2. A gas water heater is installed that uses fresh air from

underneath structure.

Indication to use: When your air conditioner or heat pump

turns on, the pilot light for the water heater is blown out.

3. In extremely cold regions where water pipes may freeze.

Indication to use: In winter, pipes freeze.

B. Build Outdoor-Air Tunnel

NOTE: The equipment and materials to install this duct work are

NOT factory supplied, nor is manufacturer responsible for determining if this procedure should be utilized.

If it is determined that an outdoor-air tunnel is required, locate unit

air intake which comes through bottom board of home and build

outdoor-air tunnel as follows:

1. Using pressure-treated 2 X 2’s or similar material, frame a

tunnel from skirting or foundation wall to entrance of

outdoor-air plenum. (See Fig. 27 for a typical air tunnel.)

2. The condensate drain must not be allowed to drain inside air

tunnel. Pipe to outside of home. (See. Fig. 28.)

CAUTION: The tunnel and grille or screen must meet

the minimum requirements listed in Table 8 to get the

proper airflow to the unit intake. Failure to adhere to this

caution will affect the unit’s capacity and efficiency

ratings. A larger net free area may be used.

3. Attach 1-in. duct board to frame built in item 1.

4. Seal all joints thoroughly with caulking and/or duct tape.

5. Set base of walls about 2 in. in ground and backfill around

to provide a good air seal. (See Fig. 28.)

6. Install a louver or a screen over opening of air tunnel where

it penetrates skirting or foundation of home.

X. REFRIGERANT

The unit is pre-charged at the factory to the correct operating

charge and should not require adjustment. However, should an

adjustment be required or if the unit requires service, adhere to the

following precautions.

WARNING: Gage ports are equipped with Schrader

valves. To prevent personal injury, wear safety glasses

and gloves when handling refrigerant.

CAUTION: Compressor damage may occur if system is

overcharged.

WARNING: Do not vent refrigerant to atmosphere.

Recover all refrigerant before system repair or final unit

disposal to avoid personal injury or death. Use all service

ports and open all flow-control devices, including solenoid valves.

CARE AND MAINTENANCE

For continuing high performance, and to minimize equipment

failure, it is essential that periodic maintenance be performed on

this equipment. Consult your servicing contractor or User’s

Manual for the proper frequency of maintenance. Frequency of

maintenance may vary depending on geographic areas, such as

coastal application.

Leave User’s Manual with homeowner.

Explain system operation and maintenance procedures outlined in

User’s Manual.

—13—

Page 14

THERMOSTAT WIRES

MAIN POWER

CONNECTIONS

RETURN-AIR GRILLE

(AIR FILTER BEHIND

RETURN-AIR GRILLE)

BOTTOM

BOARD

CONDENSATE

DRAIN PIPE

HOME

SKIRTING OR

FOUNDATION

WALL

Fig. 27—Typical Outdoor-Air Tunnel

GROUND

GRILLE OR

SCREEN

OUTDOOR

AIR INTAKE

1" DUCTBOARD1" DUCTBOARD

2" X 2"

TREATED

LUMBER

A95383

BOTTOM

BOARD

SEAL W/DUCT

TAPE AND/OR

CAULK

DRAIN PIPE

TO OUTSIDE

(CONNECT TO

OUTSIDE)

GROUND

BACKFILL WITH DIRT

FOR GOOD AIR SEAL

NET FREE AREA (SEE VENTILATION

REQUIREMENTS TABLE)

SIZES MAY VARY AS LONG AS THE

MINIMUM NET FREE OPEN AREA

(INCLUDING GRILLE) MEETS THE

REQUIREMENTS LISTED IN

VENTILATION REQUIREMENTS TABLE.

OUTDOOR AIR PLENUM

SEAL W/DUCT

TAPE AND/OR

CAULK

1"

DUCTBOARD

2"X2"

TREATED

LUMBER

A95384

Fig. 28—Drain Pipe Routing

—14—

Page 15

DO'S AND DON'TS

18-IN. OFFSET

ALLOWABLE MISALIGNMENT

ROOFCAP

FLASHING FLASHING

ATTIC AREA

FLEX DUCT FLEX DUCT

NOTE: THE FLEX DUCT SHOULD

BE A STRAIGHT RUN FROM UNIT

TO ROOFCAP.

TYPICAL FRONT VIEW TYPICAL SIDE VIEW

ROOFCAP

DO'S

ATTIC AREA

TYPICAL FRONT VIEW TYPICAL SIDE VIEW

DON'TS

A95359

Fig. 29—Typical Installations

—15—

Page 16

FINAL CHECKLIST

1. Make sure circuit breakers inside unit are in ON position.

2. Check to see if hole in ceiling around 14-in. flex duct is

sealed or taped for a tight fit.

3. Unit is secured to floor with 2 wood screws in groove under

filter frame.

4. Condensate drain hose is below bottom board or piped to

exterior of home.

5. Outdoor-air intake is below bottom board and taped to

bottom board so insulation or vapor barrier cannot be

sucked into outdoor-air intake.

6. Roof flashing caulked and secured to roof.

7. Thermostat is level, packing pad removed (if applicable),

and heat anticipator indicator is set to recommended value

listed in Table 6 or 7 (unless electronic thermostat is used).

8. Test run in heating, cooling, and emergency heat (if

applicable) mode as follows:

a. Set fan control to ON. If fan runs, return control to

AUTO setting. This verifies fan is working properly.

b. Set system control from OFF to COOL. Lower tempera-

ture selector to 50° or lower. The compressor should

energize and cool air should blow through registers.

Once cooling test is complete, return system control to

OFF setting. Wait 5 minutes.

c. Set system control to HEAT and raise temperature

selector to 80° or higher. On air conditioner models,

electric heat should energize. On heat pump models,

compressor should energize. Hot air should blow

through registers.

d. On heat pump models, set system control to EM HEAT

(Emergency Heat). Compressor should turn off and heat

should continue to flow from registers.

NOTE: Temperature of this emergency heat will be

about the same temperature as any other electric furnace.

9. Make sure no noise is in upper fan housing. If you hear

knocking or flapping noise, turn unit off at thermostat and

flip main circuit breakers to OFF position. Disconnect

14-in. flex duct on top of unit and make sure no sheet rock,

plywood, lumber, nails, or trash is in fan housing.

10. Homeowner package included with home.

11. Thanks for doing a PROFESSIONAL job.

12. To ensure maximum performance, this unit requires 72 hr

of run time.

© 1995 BDP Co. • P.O. Box 70 • Indianapolis, IN 46206 Printed in U.S.A.

—16—

ma1a181 Catalog No. 92-33MA-1A5B

Loading...

Loading...