Page 1

installation and

operation instructions

MECHANICAL

AIR CLEANER

NOTE: Read the entire instruction manual before starting the

installation.

SAFETY CONSIDERATIONS

Installation and service of heating and air conditioning equipment

can be hazardous due to system pressure and gas and electrical

components. Only trained and qualified personnel should install,

repair, or service heating and air conditioning equipment.

Untrained personnel can perform basic maintenance functions

such as cleaning and replacingair filters. All other operations must

be performed by trained service personnel. When working on

heating and air conditioning equipment, observe precautions in the

literature, tags, and labels attached to or shipped with the unit and

other safety precautions that may apply.

Follow all safety codes. Wear safety glasses and work gloves. Use

quenching cloth for brazing operations. Have fire extinguisher

available. Read these instructions thoroughly and follow all

warning or cautions attached to the unit. Consult local building

codes and National Electrical Code (NEC) for special requirements.

It is important to recognize safety information. This is the

safety-alert symbol

in instructions or manuals, be alert to the potential for personal

injury.

Understand the signal words DANGER, WARNING, and CAUTION. These words are used with the safety-alert symbol. DANGER identifies the most serious hazards which will result in severe

personal injury or death. WARNING signifies hazards which

could result in personal injury or death. CAUTION is used to

identify unsafe practices which would result in minor personal

injury or product and property damage.

The Model MACA Efficient Mechanical Air Cleaner is designed

for installation in the return-air duct system of any forced-air

heating and/or cooling system. The model MACA Mechanical Air

Cleaners are available in three sizes, 1200, 1400, and 2000 CFM.

The Model MACA is a mechanical air cleaner incorporating

special pleated filter media designed to remove dirt, dust, pollen

and other microscopic particles from the air passing through it. The

pleats provide an exceptionally large filtering face area in a very

compact space which allows maximum dirt holding capacities with

minimum air flow resistance. (See Table 1.)

I. INSTALL AIR CLEANER CABINET IN RETURN-AIR

SYSTEM

CAUTION: Turn OFF the electrical supply to the fur-

nace or air handler before beginning installation.

1. Remove and discard existing furnace or air handler filter(s).

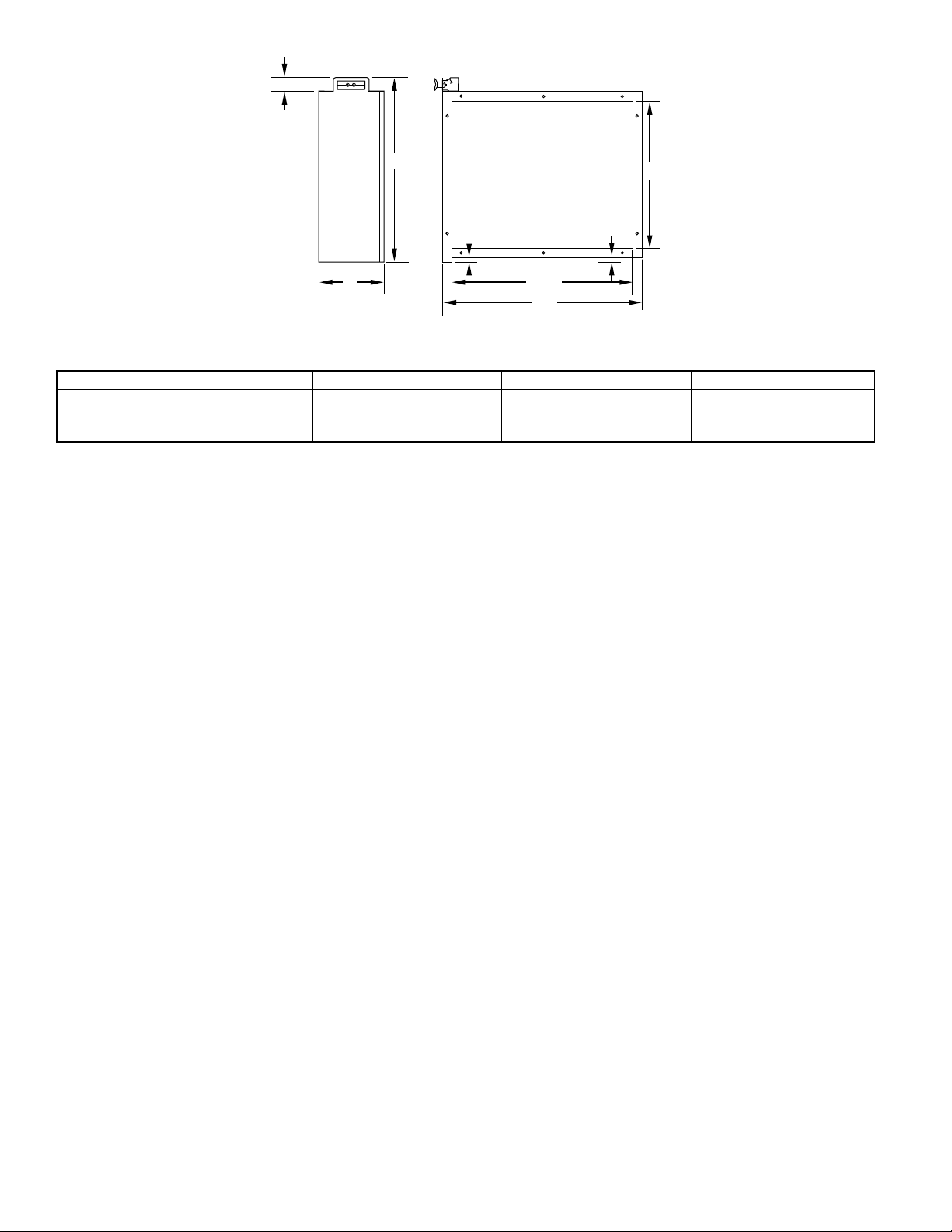

2. Referring to Fig. 2 and 3 for air cleaner dimensions and

typical installations, determine best installation location of

air cleaner.

. When you see this symbol on the unit and

INTRODUCTION

INSTALLATION

MACA

Cancels: New II MACA-12-1

3-98

A98152

Fig. 1—Model MACA Mechanical Air Cleaner

TABLE 1—AIR CLEANER PRESSURE DROP

SIZE 12 14 20

Airflow

(CFM)

600 0.055 0.045 0.04

800 0.08 0.06 0.05

1000 0.12 0.115 0.09

1200 0.16 0.16 0.115

1400 — 0.23 0.15

1600 — — 0.18

1800 — — 0.22

2000 — — 0.27

NOTE: A 26-in. clearance must be allowed for removal of the

media assembly from the air cleaner cabinet.

3. Using standard practices, remove a section of return-air

duct to allow installation of air cleaner cabinet.

4. Install air cleaner in duct opening. (Use a transition if

openings are different).

5. Mounting holes are provided for duct work attachment.

(See Fig. 2). If adjoining duct work is flanged, install

screws so that their heads are inside cabinet to prevent

damage to filter during removal and installation.

6. Remove media filter from plastic bag and place media filter

in cabinet. Directional arrows on filter cartridge must point

in direction of air flow.

7. After unit has been secured, seal seams air tight with duct

tape or caulking.

8. Reinstall cabinet front panel door assembly.

Resistance (In. wc)

—1—

Page 2

1″

A

C

TABLE 2—DIMENSIONS

MODEL A B C

MACAXCBBX012 18-1/8 13-3/4 5-1/4

MACAXCBBX014 18-1/8 13-3/4 7-1/4

MACAXCBBX020 22-1/8 17-3/4 7-1/4

Fig. 2—Dimensional Drawing

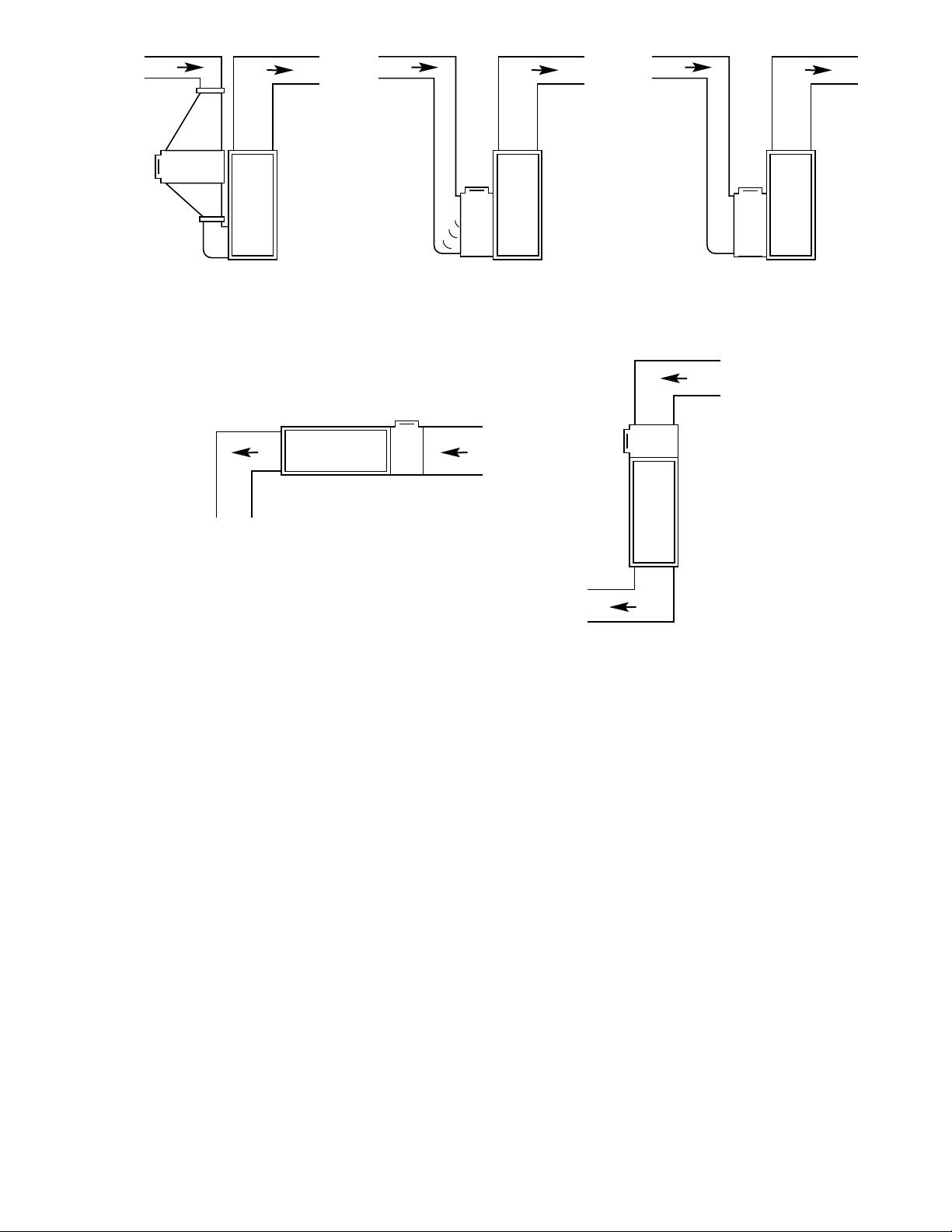

NOTE: The air cleaner is set up for left to right air flow, when

facing the access door. For right to left air flow, remove filter

cartridge, turn it around and replace in cabinet. Directional arrows

on filter cartridge must point in direction of air flow. (See Fig. 3

for typical installations.)

II. MAINTENANCE

1. The filter in your mechanical air cleaner must be replaced

periodically. The frequency of filter replacement is best

determined by visual examination.

B

5

⁄8″

225⁄8″

25″

3

⁄16″

Periodic inspection and annual replacement of your filter

will insure high efficiency air cleaning.

III. REPLACING FILTER MEDIA IN AIR CLEANER CABINET

1. Turn off power to furnace or air handler before removing

door.

1. Open access door by pulling handle. Remove door completely.

2. Pull used filter straight out of cabinet.

3. Slide new filter cartridge into cabinet with "AIR-FLOW"

arrow pointing in direction of air flow.

4. Replace door.

5. Turn power on.

A98178

—2—

Page 3

AIR FLOW

AIR FLOW AIR FLOW

UPFLOW FURNACE

WITH TRANSITION

HORIZONTAL

UPFLOW FURNACE

WITH TURNING VANES

AIR FLOW

Fig. 3—Typical Installations

UPFLOW FURNACE

NO TRANSITION

AIR FLOW

DOWNFLOW

A98179

—3—

Page 4

SERVICE TRAINING

Packaged Service Training programs are an excellent way to increase your

knowledge of the equipment discussed in this manual, including:

• Unit Familiarization • Maintenance

• Installation Overview • Operating Sequence

A large selection of product, theory, and skills programs is available, using popular

video-based formats and materials. All include video and/or slides, plus companion

book.

Classroom Service Training plus "hands-on" the products in our labs can mean

increased confidence that really pays dividends in faster troubleshooting, fewer

callbacks. Course descriptions and schedules are in our catalog.

CALL FOR FREE CATALOG 1-800-962-9212

[ ] Packaged Service Training [ ] Classroom Service Training

A94328

© 1998 Bryant Heating & Cooling Systems 7310 W. Morris St. Indianapolis, IN 46231

—4—

Printed in U.S.A. iimaca121 Catalog No. 13MA-CA0

Loading...

Loading...