Page 1

569J

60Hz AIR COOLED CONDENSING UNIT

PURONr (R--410A) REFRIGERANT

6 TO 20 NOMINAL TONS

Product Data

Bryant’s air-cooled air conditioning split systems:

S provide a logical solution for commercial needs

S have a rugged, dependable construction

S are available in single and circuit scroll compressor

capacity control

S have cooling capability up to 125_F(52_C) ambient

anddownto40_F(4_C) ambient standard

569J*07--14 shown

C09310

the environmentally sound refrigerant

FEATURES / BENEFITS

These dependable outdoor air cooled condensing units

match Bryant’s indoor-air handlers to meet a wide

selection of cooling solutions.

Constructed for long life

The 569J single circuit and 569J dual circuit, scroll

compressor models are designed and built to last. The

high efficient designed outdoor coil construction allows

for a more efficient design in a smaller cabinet size that

utilizes an overall reduction in refrigerant charge. Where

conditions require, special coil coating coil protection

option is available. Cabinets are constructed of prepainted

galvanized steel, delivering unparalleled protection from

the environment. Inside and outside surfaces are protected

to ensure long life, good looks, and reliable operation.

Safety controls are used for enhanced system protection

and reliability.

Each unit utilizes the Comfort Alert diagnostic and

troubleshoot control system. This protects the units

operation and provides valuable diagnostic information

when required.

Page 2

FEATURES AND BENEFITS (cont.)

Factory-installed options (FIOPs)

Certified and pre--engineered factory-installed options

(FIOPs) allow units to be installed in less time, thereby

reducing installed cost. FIOPs include:

S low ambient controls which provide cooling operation

down to --20_F(--29_C) ambient temperatures

S non-fused disconnect

S 115-v GFI (ground fault interrupter) convenience outlet,

powered and non--powered available

S special coil coating coil protection

S louvered hail guard

Efficient operation

These air cooled condensing units will provide EER’s up

569J

to 11.5 which meets ASHRAE 90.1 efficiency levels. The

569J dual compressor models provide two (2) stages of

cooling for remarkable partial load performance.

This high efficiency will help reduce overall operating

cost and energy consumption.

Controls for performance dependability

The 569J condensing units offer operating controls and

components designed for performance dependability. The

high efficiency hermetic scroll compressor is engineered

for long life and durability. The compressors include

vibration isolation for quiet operation. The high-pressure

switch protects the entire refrigeration system from

abnormally high operating pressures. A low-pressure

switch protects the system from loss of charge. These

units also include anti-short-cycling protection, which

helps to protect the units against compressor failure.

All units include a crankcase heater to eliminate liquid

slugging at start-up. Each unit comes standard with the

Comfort Alertt control system. This provides:

S System Go LED indicator

S Fault LED indicator

S Compressor fault LED indicator

S Phase loss protection

S Phase reversal protection

S Safety pressure indicator

S Anti--short cycle protection

The latest safety standards for 569J* units are assured

through UL, Canada approvals.

Innovative Bryant 524J packaged air

handlers are custom matched to 569J*condensing units

Information on matching 524J DX packaged air handler

follows for convenience. See separate product data for

more details. The 524J Series has excellent fan

performance, efficient direct-expansion (DX) coils, a

unique combination of indoor-air quality features, and is

easy to install. Its versatility and state-of-the-art features

help to ensure economical performance of the split system

both now and in the future.

Indoor--air quality (IAQ) features

The unique combination of IAQ features in the 524J

Series air handlers help to ensure that only clean, fresh,

conditioned air is delivered to the occupied space.

Direct-expansion (DX) 4 row cooling coils prevent the

build-up of humidity in the room, even during part-load

conditions.

Standard 2-in. (51mm) disposable filters remove dust and

airborne particles from the occupied space for cleaner air.

The pitched, non-corroding drain pan can be adjusted for

a right-hand or left-hand connection to suit many

applications and provide positive drainage and prevent

standing condensate.

The accessory economizer can provide ventilation air to

improve indoor-air quality by using demand control

ventilation. When used in conjunction with Bryant

Comfort System and CO

fresh outdoor air to replace stale, recirculated indoor air.

sensors, the economizer admits

2

Economy

The 524J Series packaged air handlers provide reduced

installation expense and energy-efficient performance.

Quick installation is ensured by the multipoise design.

Units can be installed in either the horizontal or vertical

configuration without modifications. Fan motors and

contactors are pre--wired and thermostatic expansion

valves (TXVs) are factory-installed on all 524J models.

High efficiency, precision-balanced fans minimize air

turbulence, surging, and unbalanced operation, cutting

operation expenses.

The economizer accessory precisely controls the blend of

outdoor air and room air to achieve comfort levels. When

the outside air enthalpy is suitable, outside air dampers

can fully open to provide “free” cooling without

energizing mechanical cooling.

Rugged dependability

The 524J series units are made to last. The die-formed

galvanized steel panels ensure structural integrity under

all operating conditions. Galvanized steel fan housings are

securely mounted to a die-formed galvanized steel fan

deck.

Rugged pillow-block bearings (524J14) are securely

fastened to the solid steel fan shaft with split collets and

clamp locking devices. Smaller unit sizes have spider-type

bearings.

2

Page 3

FEATURES AND BENEFITS (cont.)

Coil flexibility

Model 524J direct- expansion coils have galvanized steel

casings; inlet and outlet connections are on the same end.

The coils are designed for use with Puron (R--410A)

refrigerant and have

mechanically bonded to aluminum sine-wave fins. The

coils include matched, factory-installed thermostatic

expansion valves (TXVs) with matching distributor

nozzles and offers a removable power element and

extended connections.

3

/8-in. diameter copper tubes

Easier installation and service

The multipoise design and component layout ensures

quick unit installation and operation. Units can be

converted from horizontal to vertical operation by simply

repositioning the unit. Drain pan connections are

duplicated on both sides of the unit. The filters, motor,

drive, TXVs, and coil connections are all easily accessed

by removing a single side panel.

TABLE OF CONTENTS

PAGE

FEATURES / BENEFITS 1........................

MODEL NUMBER NOMENCLATURE 4............

AHRI CAPACITY RATINGS 5.....................

SOUND POWER LEVELS 5.......................

PHYSICAL DATA 6..............................

DIMENSIONS 8.................................

OPTIONS AND ACCESSORIES 11.................

SELECTION PROCEDURE 15.....................

TYPICAL WIRING SCHEMATIC 16................

PERFORMANCE DATA 18........................

ELECTRICAL DATA 43..........................

APPLICATION DATA 48.........................

TYPICAL PIPING AND WIRING 53................

GUIDE SPECIFICATIONS 57......................

569J

3

Page 4

569J

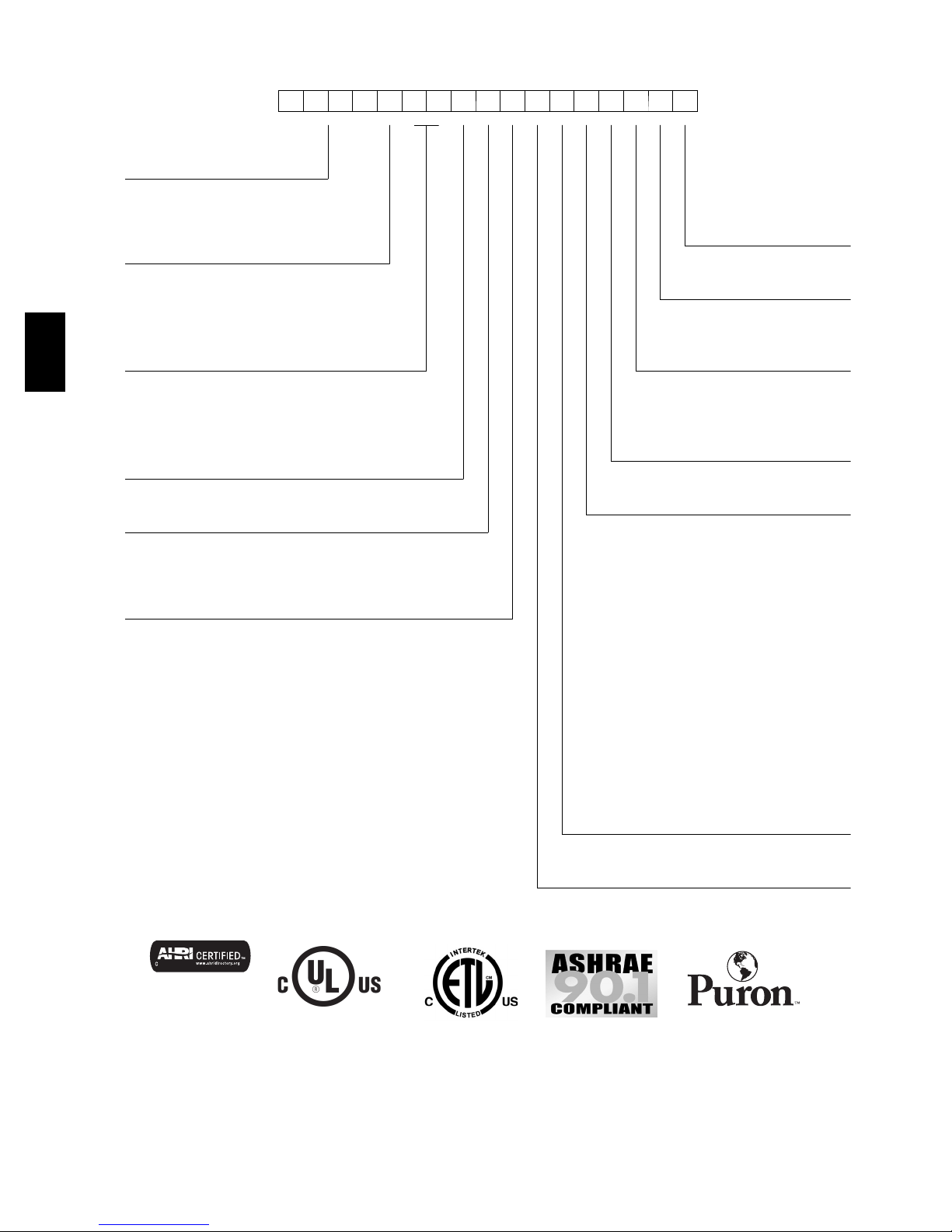

MODEL NUMBER NOMENCLATURE

1234567891011121314151617

5 6 9 J E 1 4 A 0 0 0 G 0 0 A 0 A

_____________

Model Type

569J = Bryant Condensing Unit

Puronr R--- 410A Refrigerant

Voltage Packaging

E = 460/3/60 A=Standard

P = 208/230/3/60 B=LTL

T = 575/3/60

Base Unit Controls

Nominal Tonnage 0=None

07 = 6 Tons 16 = 15 Tons

08 = 7.5 Tons 25 = 20 Tons Electrical Options

12 = 10 Tons A=None

14 = 12.5 Tons C = Non ---Fused Disconnect

Refrigerant Circuit Service Options

A = Single Circuit 0 = Electro--- Mechanical Controls

B = Single Circuit with Low Ambient Controller 1 = Unpowered Convenience Outlet

D=DualCircuit 2 = Powered Convenience Outlet

E = Dual Circuit with Low Ambient controller

Factory Assigned

Factory Assigned 0=Default

0=Default

Coil Options --- Condenser

With All Aluminum --- NOVATION Design

(07--- 16 sizes)

Factory Assigned G=Al/Al

0=Default K = E --- C o a t A l/ A l

T=Al/Alwithlouveredhailguard

W = E ---Coat Al/Al with louvered hail guard

Coil Options --- Condenser

With Round Tube/Plate Fin Design

A=Al/CuStandard

B = P r e --- C o a t e d A l/ C u

C --- E --- C o a t A l / C u

E= Cu/Cu

M=Al/CuStandardwithlouveredhailguard

N=Pre---CoatedAl/Cuwithlouveredhailguard

P = E ---Coat al/Cu with louvered hail guard

R = Cu/Cu --- Louvered hail guard

Use of the AHRI Certified

TM Mark indicates a

manufacturer’s

participation in the

program For verification

of certification for individual

products, go to

www.ahridirectory.org.

569J --- 6 to 12.5 Ton

Factory Assigned

0=Default

the environmentally sound refrigerant

569J --- 15 nd 20 Ton

Certified to ISO 9001

4

Page 5

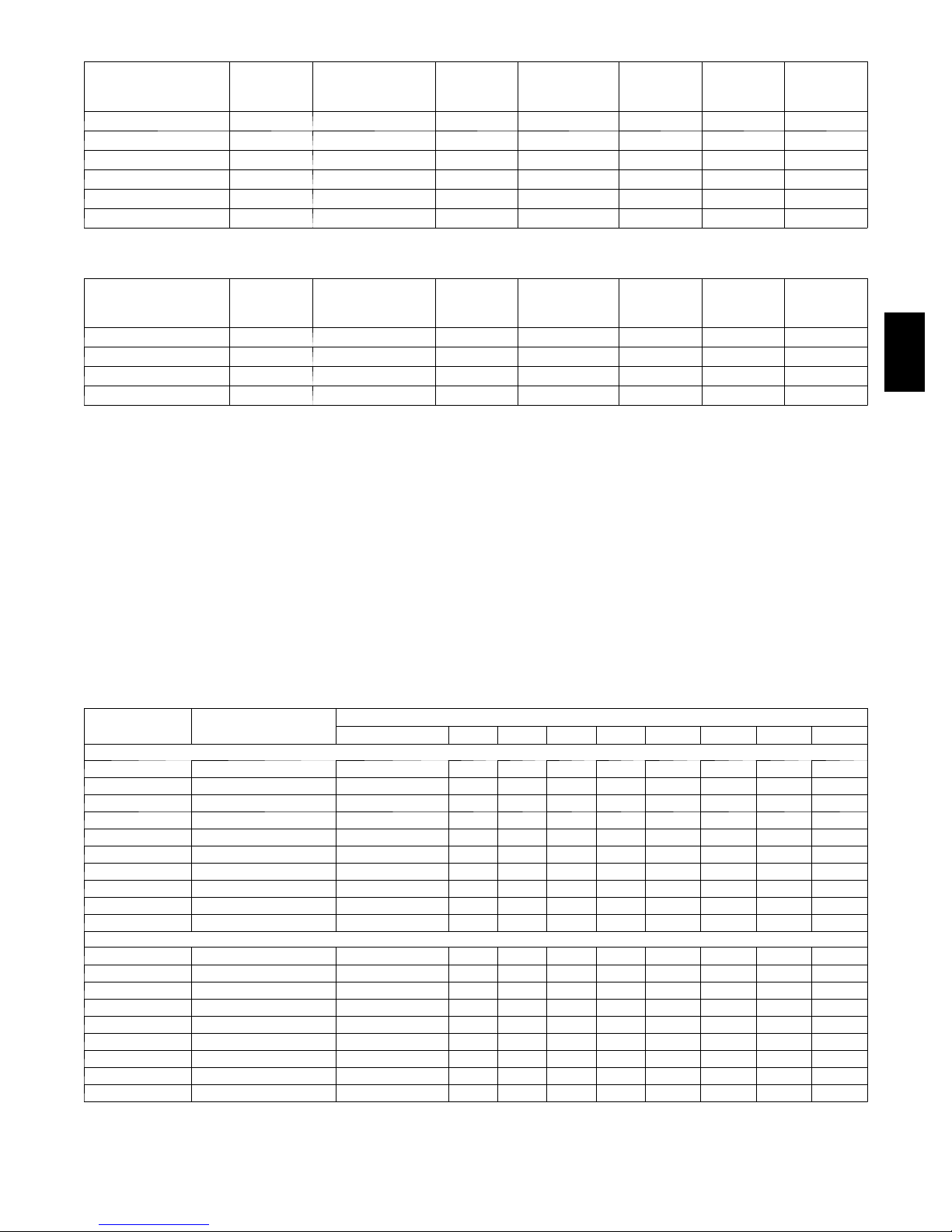

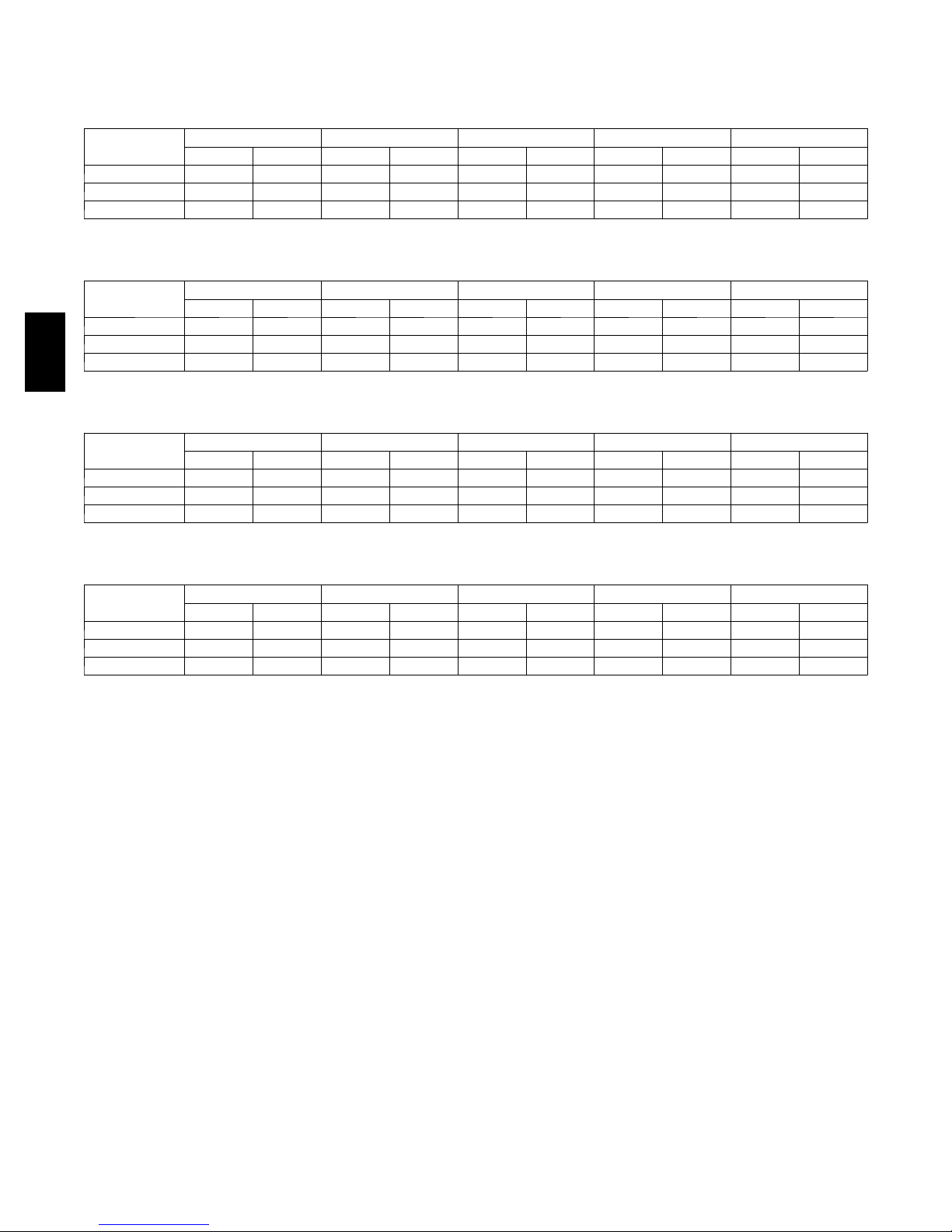

AHRI* CAPACITY RATINGS

UNIT

569J*07A/524J*07 1 1 6 71.0 6.2 11.5 12.2

569J*08A/524J*08 1 1 7.5 92.0 8.2 11.2 11.8

569J*12A/524J*12 1 1 10 117.0 10.4 11.2 12.0

569J*14A/524J*14 1 1 12.5 148.0 13.5 11.0 12.0

569J*16A/524J*16 1* 2 15 184.0 16.4 11.2 13.2

569J*25A/524J25 1* 2 20 240.0 21.8 11.0 11.2

* Single circuit with two (tandem) co mpressors. See application tip #38TIP ---10 ---03 for staging capabilities.

COOLING

CIRCUITS

COMPRESSORS

NOM.

CAPACITY

(TONS)

NET COOLING

CAPACITY

(MBH)

TOTAL

POWER

(kW)

EER IEER

UNIT

569J*12D/524J12 2 2 10 117.0 10.4 11.2 11.6

569J*14D/524J14 2 2 12.5 148.0 13.5 11.0 12.0

569J*16D/524J16 2 2 15 184.0 16.4 11.2 11.8

569J*25D/524J25 2 2 20 240.0 21.8 11.0 11.2

LEGEND

AHRI --- Air C o nditioning, Heating and Refrigeration

Institute

ASHRAE --- American Society of Heating, Refrigerating

and Air Conditioning, Inc.

EER --- Energy Efficiency Ratio

IEER --- Integrated Energy Efficiency Ratio

COOLING

CIRCUITS

COMPRESSORS

NOM.

CAPACITY

(TONS)

NET COOLING

CAPACITY

(MBH)

NOTES

1. Rated in accordance with AHRI Standard 340/360, as

appropriate.

2. Ratings are based on:

Cooling Standard: 80_F(27_C) db, 67_F(19_C) wb

indoor air temp and 95_F(35_C) db outdoor air temp.

IEER Standard: 80_F(27_C) db, 67_F(19_C) wb indoor

air temp and 4 various outdoor temperatures.

3. All units comply wit h ASHRAE 90.1 Energy Standard for

minimum EER and IEER requirements.

TOTAL

POWER

(kW)

EER IEER

SOUND POWER LEVELS, dB

UNIT

569J*07A 1 82 86.4 86.0 79.2 80.2 77.6 72.0 67.9 62.3

569J*08A 1 82 86.8 85.7 80.3 80.3 77.7 72.3 70.2 65.4

569J*12A 1 82 82.8 81.5 79.2 79.4 76.2 72.3 69.4 64.2

569J*14A 1 82 82.9 78.5 77.0 77.0 75.6 75.9 72.3 70.9

569J*16A 1 80 90.3 81.8 78.0 76.7 75.2 70.5 66.4 61.9

569J*25A 1 85 91.0 85.0 80.0 86.0 79.0 73.0 68.0 63.0

569J*12D 2 82 85.2 84.0 81.0 79.5 76.6 72.4 69.3 69.5

569J*14D 2 82 84.7 79.8 78.8 77.6 77.0 72.5 70.3 67.3

569J*16D 2 80 90.3 81.8 78.0 76.7 75.2 70.5 66.4 61.9

569J*25D 2 85 91.0 85.0 80.0 86.0 79.0 73.0 68.0 63.0

569J*07A 1 85 89.3 85.0 82.0 82.7 80.2 75.2 71.0 66.0

569J*08A 1 85 89.3 85.0 82.0 82.7 80.2 75.2 71.0 66.0

569J*12A 1 83 86.6 81.9 85.7 80.0 77.1 74.6 69.2 65.8

569J*12D 2 84 86.3 85.8 81.4 81.9 79.5 75.1 71.9 68.9

569J*14D 2 83 81.7 80.9 82.2 80.4 78.2 73.6 69.7 65.4

569J*16A 2 83 86.7 81.2 78.9 80.4 78.0 74.2 70.2 65.0

569J*16D 2 83 86.7 81.2 78.9 80.4 78.0 74.2 70.2 65.0

569J*25A 2 85 91.0 85.0 80.0 86.0 79.0 73.0 68.0 63.0

569J*25D 2 85 91.0 85.0 80.0 86.0 79.0 73.0 68.0 63.0

LEGEND

dB = Decibel

NOTE: Outdoor sound data is measure in accordance with AHRI standard 270 --- 2008.

COOLING

CIRCUITS

A --- WE I GH T ED 63 125 250 500 1000 2000 4000 8000

N O V AT I O N --- A l l A l u m i n u m C o i l D e s i g n

RTPF --- Round Tube/Plate Fin Coil Design

OUTDOOR SOUND (dB)

569J

5

Page 6

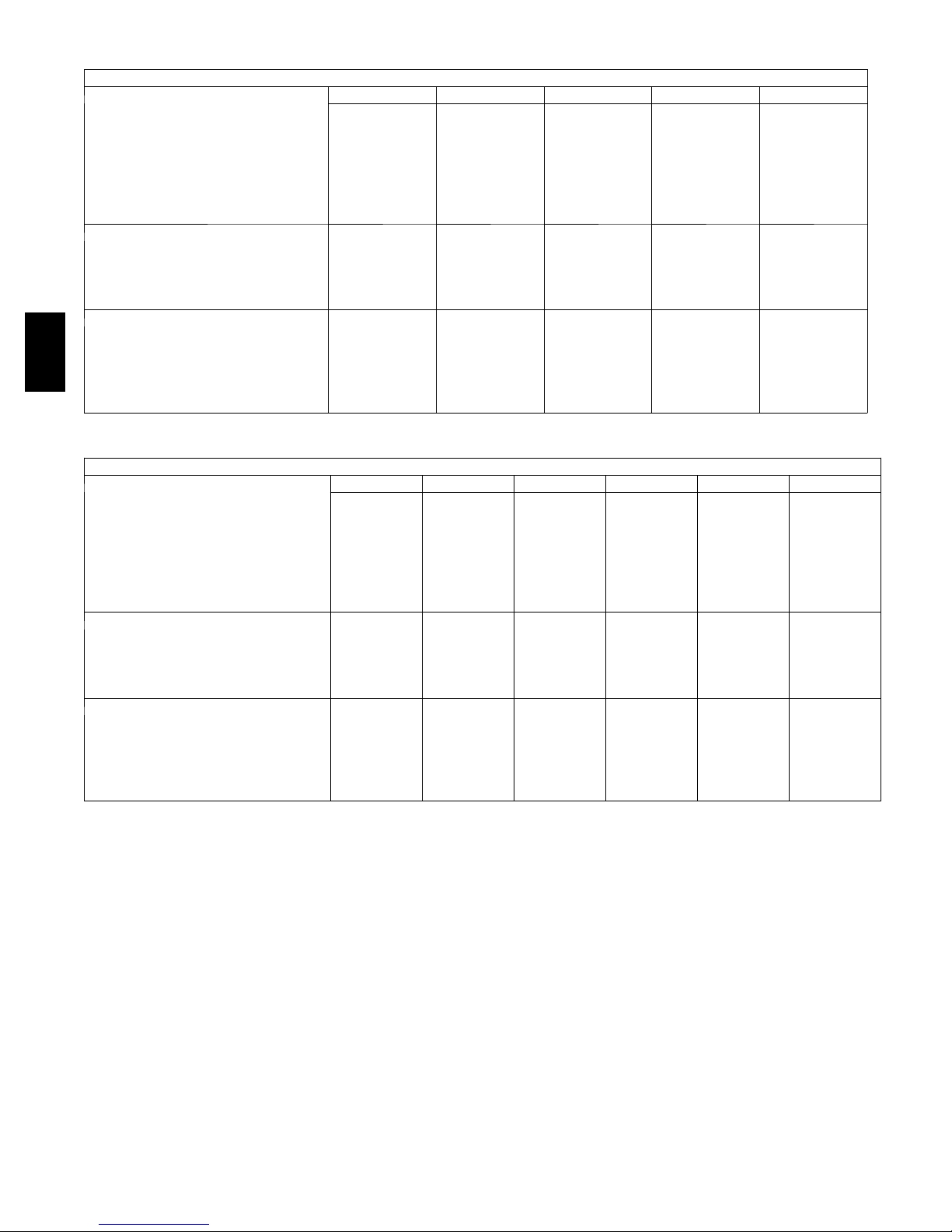

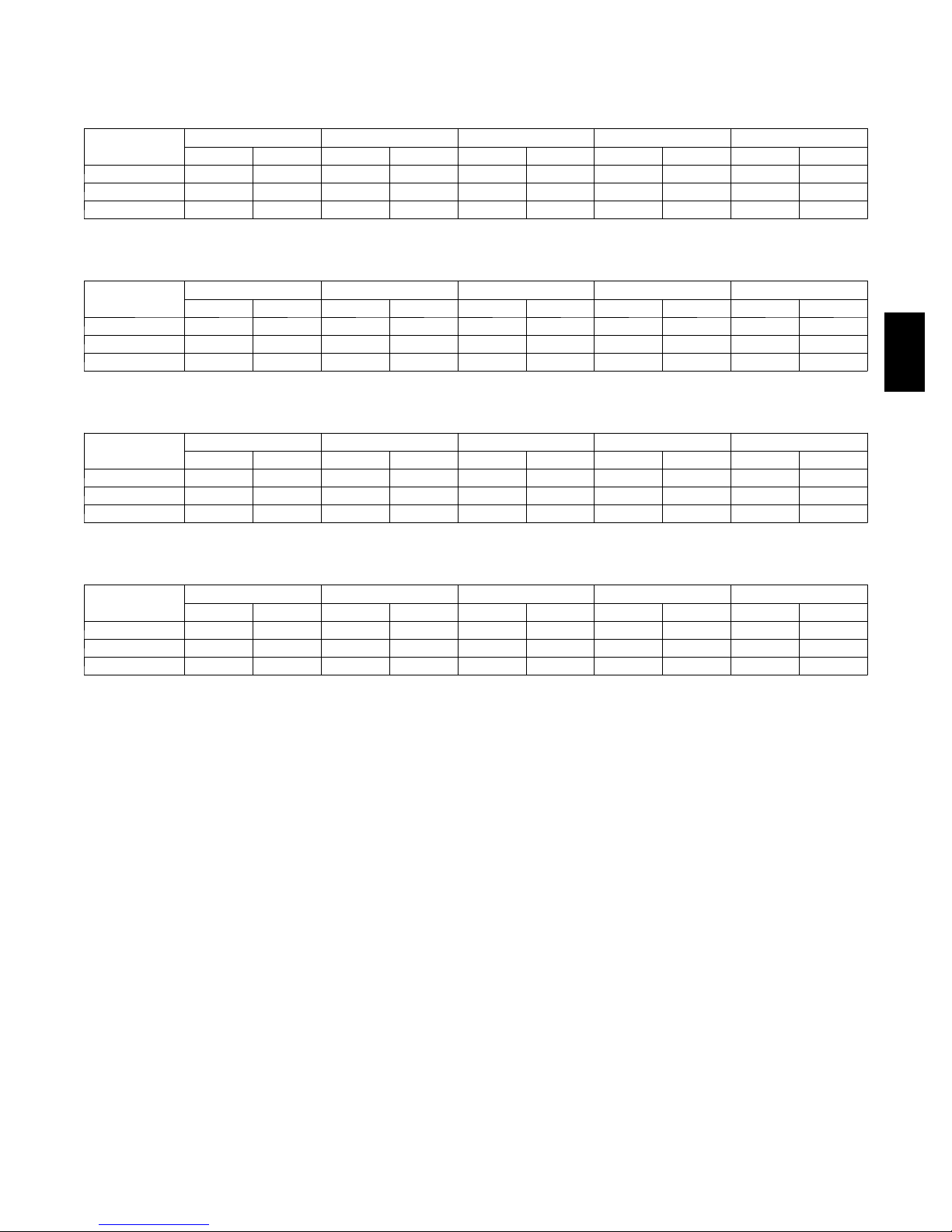

PHYSICAL DATA

Single Circuit Models with NOVATION --- All Aluminum Coil Design

569J*07A 569J*08A 569J*12A 569J*14A 569J*16A

Refrigeration System

# Circuits / # Comp. / Type 1/1/Scroll 1/1/Scroll 1/1/Scroll 1/1/Scroll 1/2/Scroll

R --- 410A charge A/B (lbs) 4.4 4.9 6.3 7.3 12.2

System charge w/ fan coil 8.4 10.2 13.8 18.0 24.6

Metering device TXV TXV TXV TXV TXV

High - -- press. Trip / Reset (psig) 630 / 505 630 / 505 630 / 505 630 / 505 630 / 505

Low ---press. Trip / Reset (psig) 54 / 117 54 / 117 54 / 117 54 / 117 54 / 117

Cond. Coil

Material (Fin/Tube) Al/Al Al/Al Al/Al Al/Al Al/Al

Coil type Novation Novation Novation Novation Novation

Rows / FPI 1/20.3 1/20.3 1/20.3 1/20.3 1/20.3

Tot a l fa ce a re a (f t2 ) 17.5 20.5 25.0 31.8 25.0 x 2

Cond. fan / motor

Qty / Motor drive type 2/direct 2/direct 2/direct 2/direct 3/direct

569J

Note: 569J*25 model is not available with NOVATION coil.

Refrigeration System

# Circuits / # Comp. / Type 1/1/Scroll 1/1/Scroll 1/1/Scroll 1/1/Scroll 1/2/Scroll 1/2/Scroll

R --- 410a charge A/B (lbs) 11.0 13.0 16.0 32.0 32.0 28.0

System charge w/ fan coil* 14.0 17.0 20.0 N/A 43.0 38.0

High - -- press. Trip / Reset (psig) 630 / 505 630 / 505 630 / 505 630 / 505 630 / 505 630 / 505

Low ---press. Trip / Reset (psig) 54 / 117 54 / 117 54 / 117 54 / 117 54 / 117 54 / 117

Cond. Coil

Cond. fan / motor

* Approximate system charge with about 25 ft piping of sizes indicated with matched 524J

Motor HP / RPM 1/4 / 1100 1/4 / 1100 1/4 / 1100 1/4 / 1100 1/4 / 1100

Fan diameter (in) 22 22 22 22 22

Nominal Airflow (cfm) 6,000 6,000 6,000 6,000 10,000

Watts (total) 610 610 610 610 970

Single Circuit Models with RTPF --- Round Tube/Plate Fin Coil Design

569J*07A 569J*08A 569J*12A 569J*14A 569J*16A 569J*25A

Metering device TXV TXV TXV TXV TXV TXV

Material (Fin/Tube) Al/Cu Al/Cu Al/Cu Al/Cu Al/Cu Al/Cu

Coil type RTPF RTPF RTPF RTPF RTPF RTPF

Rows / FPI 2/17 2/17 2/17 3/17 2/17 2/17

Tot a l fa ce a re a (f t2 ) 17.5 17.5 25.1 31.8 23.5 x 2 25.0 x 2

Qty / Motor drive type 2/direct 2/direct 2/direct 2/direct 3/direct 4/direct

Motor HP / RPM 1/4 / 1100 1/4 / 1100 1/4 / 1100 1/4 / 1100 1/4 / 1100 1/4 / 1100

Fan diameter (in) 22 22 22 22 22 22

Nominal Airflow (cfm) 6,000 6,000 6,000 6,000 9,000 12,000

Watts (total) 610 610 610 610 970 1150

6

Page 7

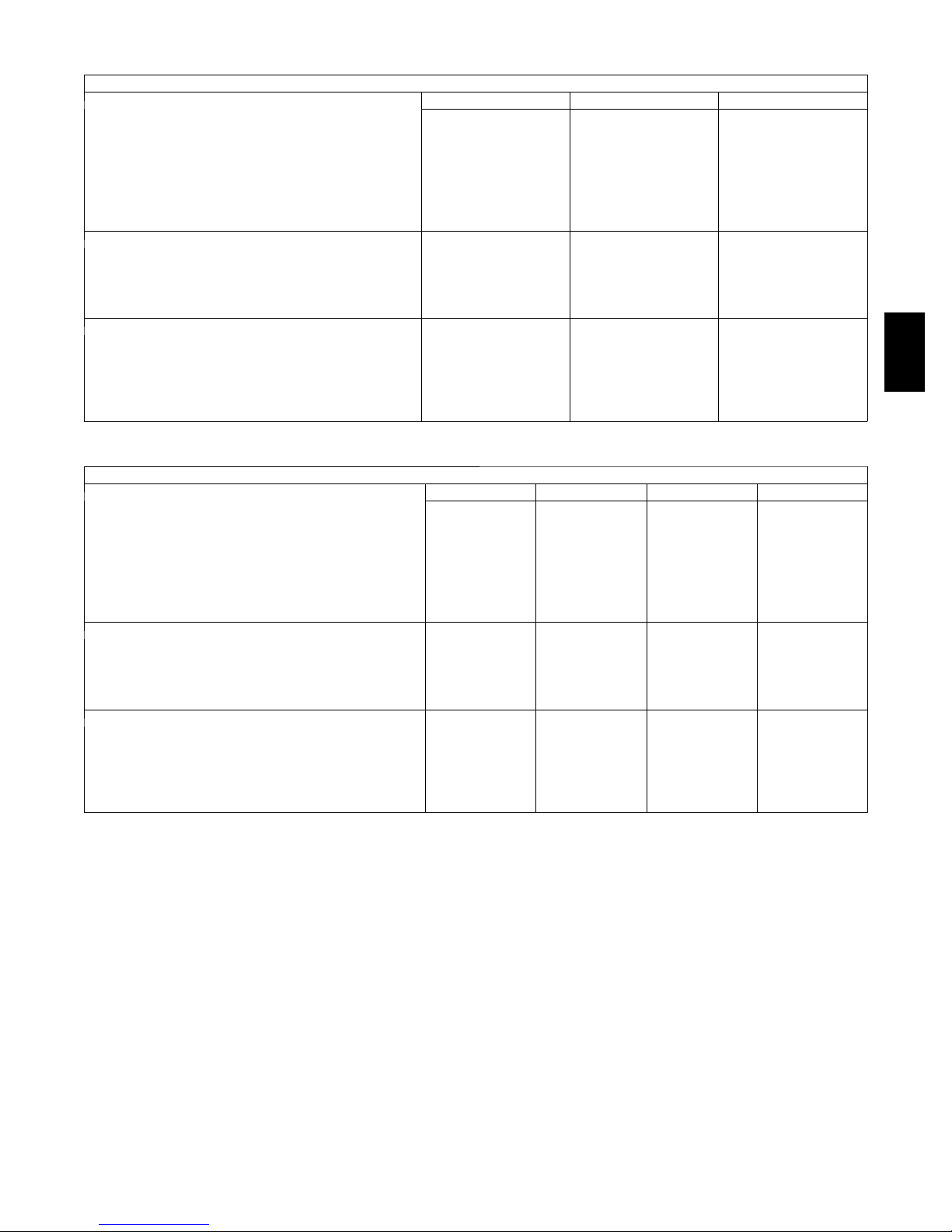

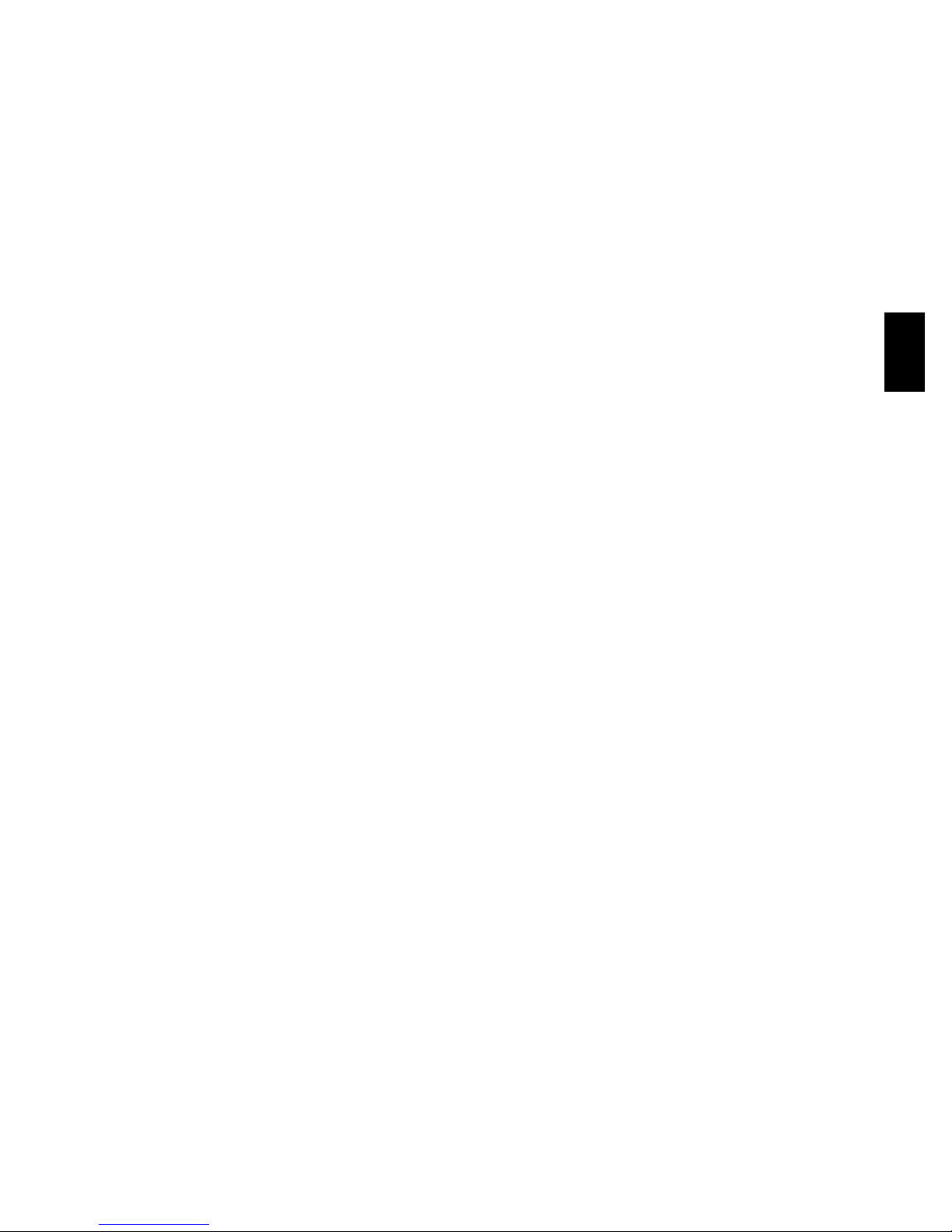

PHYSICAL DATA (CONT.)

Dual Circuit Models with NOVATION --- All Aluminum Coil Design

569J*12D 569J*14D 569J*16D

Refrigeration System

# Circuits / # Comp. / Type 2/2/Scroll 2/2/Scroll 2/2/Scroll

R --- 410A charge A/B (lbs) 3.0 /3.1 3.7/3.9 6.1/6.1

System charge w/ fan coil 7.4 / 7.4 10.8 / 10.8 12.0/12.0

Metering device TXV TXV TXV

High - -- press. Trip / Reset (psig) 630 / 505 630 / 505 630 / 505

Low ---press. Trip / Reset (psig) 54 / 117 54 / 117 54 / 117

Cond. Coil

Material (Fin/Tube)

Coil type Novation Novation Novation

Rows / FPI 1 / 20.3 1 / 20.3 1 / 20.3

Tot a l fa ce a re a (f t2 ) 25.0 31.8 25.0 x 2

Cond. fan / motor

Qty / Motor drive type 2/direct 2/direct 3/direct

Motor HP / RPM 1/4 / 1100 1/4 / 1100 1/4 / 1100

Fan diameter (in) 22 22 22

Nominal Airflow (cfm) 6,000 6,000 10,000

Watts (total) 610 610 970

Note: 569J*25D model is not available with NOVATION coil.

Dual Circuit Models with RTPF --- Round Tube/Plate Fin Coil Design

Refrigeration System

# Circuits / # Comp. / Type 2/2/Scroll 2/2/Scroll 2/2/Scroll 2/2/Scroll

R --- 410a charge A/B (lbs) 8.0 / 8.0 16.0 / 16.0 16.0 / 16.0 14.0 / 14.0

System charge w/ fan coil* 11.0 / 11.0 22.0 / 22.0 22.0 / 22.0 19.0 / 19.0

Metering device TXV TXV TXV TXV

High - -- press. Trip / Reset (psig) 630 / 505 630 / 505 630 / 505 630 / 505

Low ---press. Trip / Reset (psig) 54 / 117 54 / 117 54 / 117 54 / 117

Cond. Coil

Material (Fin/Tube) Al/Cu Al/Cu Al/Cu Al/Cu

Coil type RTPF RTPF RTPF RTPF

Rows / FPI 2/17 3/17 2/17 2/17

total face area (ft2) 25.1 31.8 23.5 x 2 25.0 x 2

Cond. fan / motor

Qty / Motor drive type 2/direct 2/direct 3/direct 4/direct

Motor HP / RPM 1/4 / 1100 1/4 / 1100 1/4 / 1100 1/4 / 1100

Fan diameter (in) 22 22 22 22

Nominal Airflow (cfm) 6,000 6,000 9,000 12,000

Watts (total) 610 610 970 1150

* Approximate system charge with about 25 ft piping of sizes indicated with matched 524J

Al/Al Al/Al Al/Al

569J*12D 569J*14D 569J*16D 569J*25D

569J

7

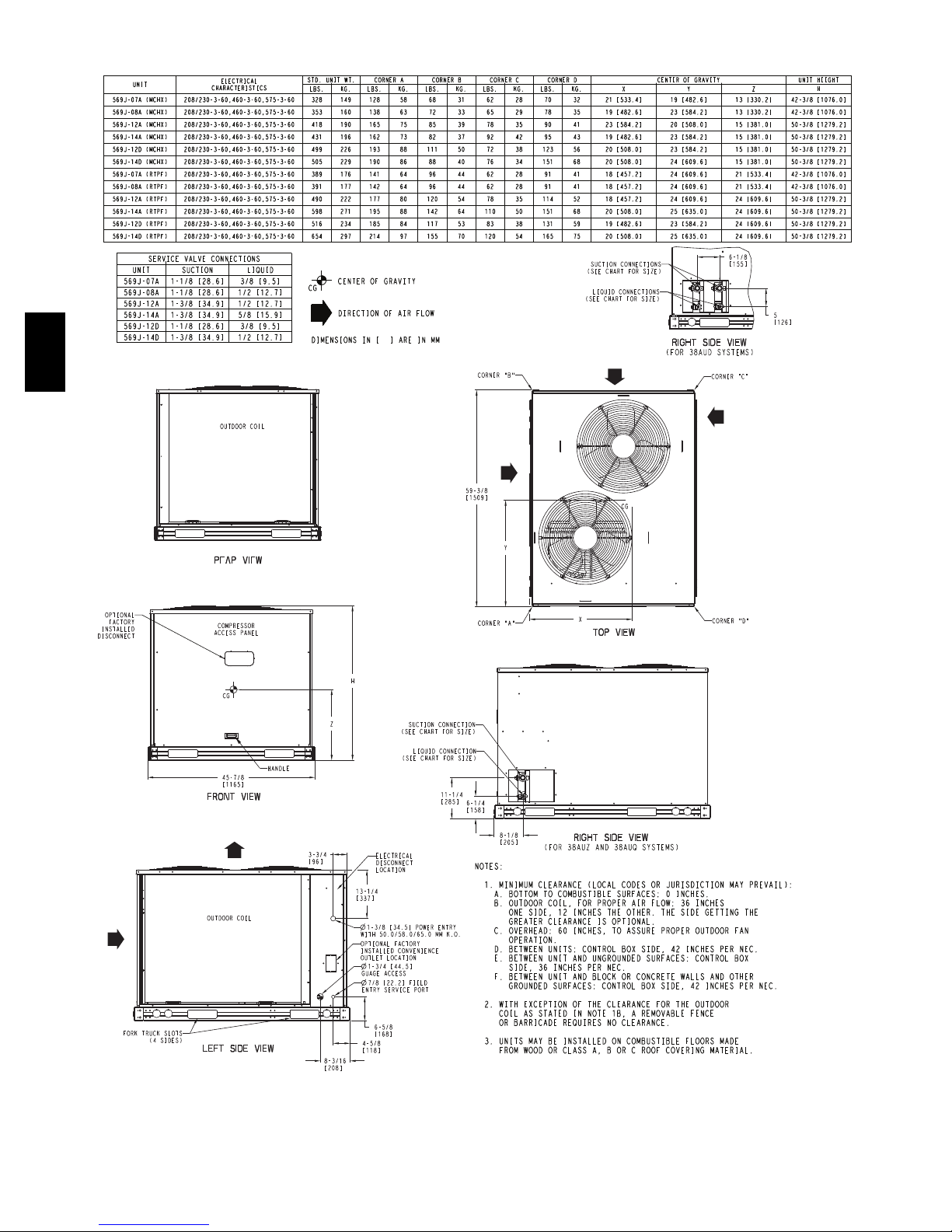

Page 8

569J

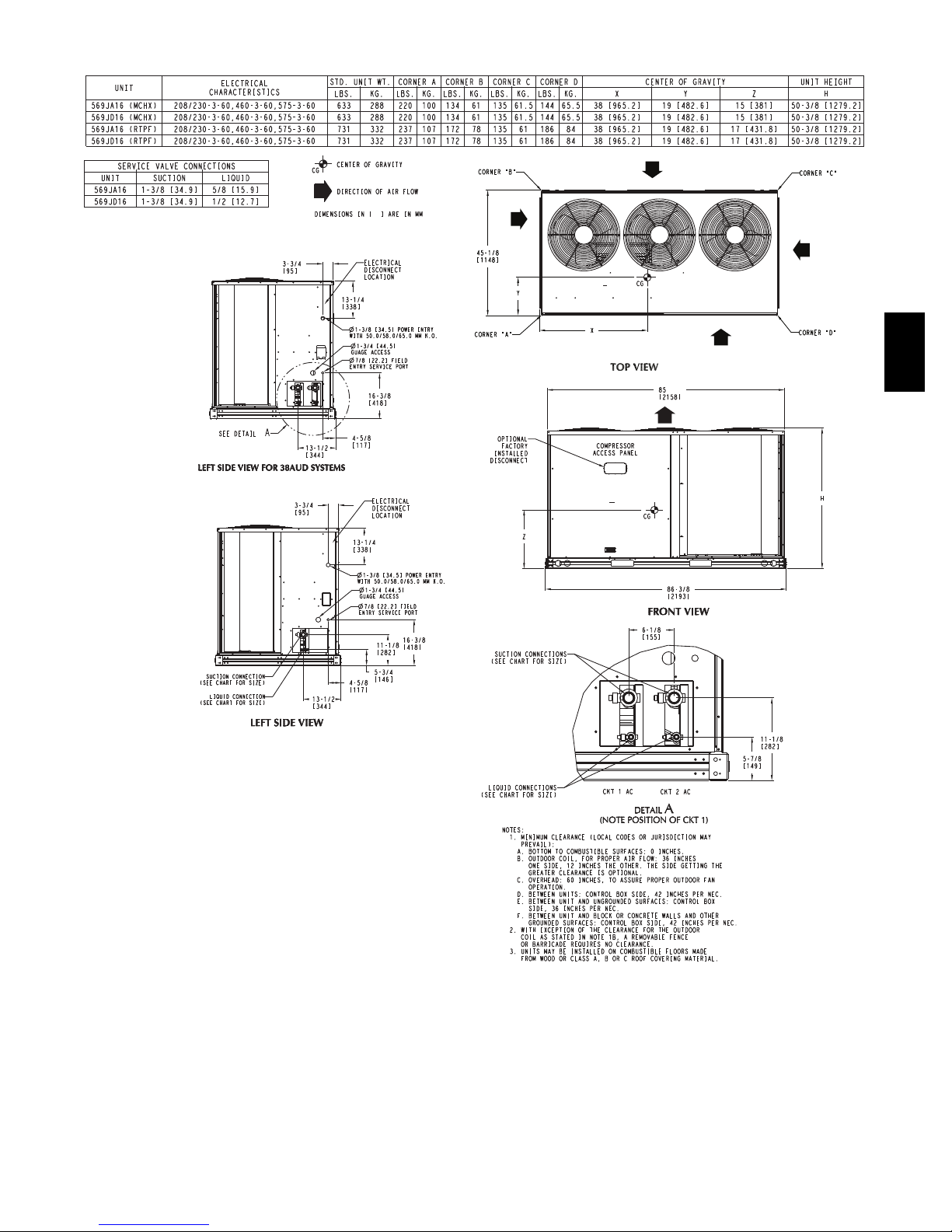

DIMENSIONS

C101212A

8

Page 9

DIMENSIONS (cont.)

569J

C101213

9

Page 10

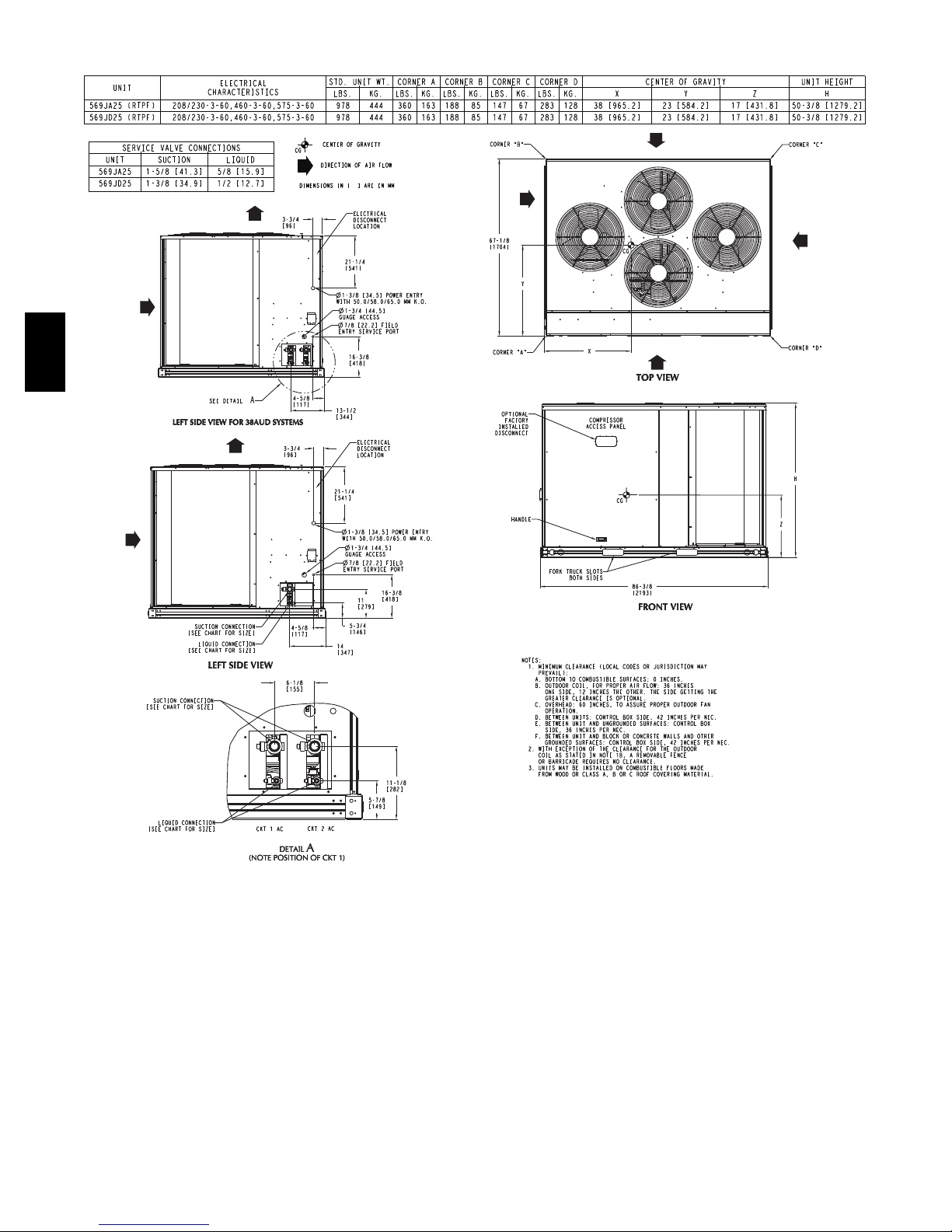

DIMENSIONS (cont.)

UNIT

569JA25 (RTPF) 208/230-3-60,460-3-60,575-3-60 978 444 360 163 188 85 147 67 283 128 38 [965.2] 23 [584.2] 17 [431.8] 50-3/8 [1279.2]

569JD25 (RTPF) 208/230-3-60,460-3-60,575-3-60 978 444 360 163 188 85 147 67 283 128 38 [965.2] 23 [584.2] 17 [431.8] 50-3/8 [1279.2]

SERVICE VALVE CONNECTIONS

UNIT SUCTION LIQUID

569JA25 1-5/8 [41.3] 5/8 [15.9]

569JD25 1-3/8 [34.9] 1/2 [12.7]

ELECTRICAL

CHARACTERISTICS

STD. UNIT WT. CORNER A CORNER B CORNER C CORNER D CENTER OF GRAVITY UNIT HEIGHT

LBS. KG. LBS. KG. LBS. KG. LBS. KG. LBS. KG. X Y Z H

CENTER OF GRAVITY

CG

DIRECTION OF AIR FLOW

DIMENSIONS IN [ ] ARE IN MM

569J

C101214

10

Page 11

OPTIONS AND ACCESSORIES

569J* OPTIONS AND ACCESSORIES

ITEM OPTION* ACCESSORY†

Disconnect Switch (non-fused)} X

Special--- coated Coil Protection X

Convenience Outlet (115-v)** X

Low Ambient Temperature

MotorMaster Ir Control

Wired Condenser Coil Grille (Novation 07 --- 14 models only) X

Louvered Hail Guard X X

Programmable Thermostats X

* Factory-installed option.

† Field-installed accessory.

} Non ---fused disconnect switch cannot be used when unit MOCP electrical rating exceeds 80 amps.

** Powered and non- -- powered versions available

569J* factory-installed options

X X

CONDENSER COIL OPTIONS

Coil Coating Application -- Novation Coils

Environment

Coil Description

Alum Fin / Alum Tube X

E --- C o a te d A l / Al X X X X X

NOTE: E ---Coat is only available and must b e used in any non---standard environment listed above.

Standard

N o n --- C o r r o s i v e

Mild Coastal

Moderate

Coastal

Severe

Coastal

Industrial

Industrial &

Coil Coating Application -- Round Tube/Plate Fin Coils

(07,08, 12, 16, 25 models)

Environment

E n v i r o --- S h i e l d ™ Description

Alum Fin / Cu Tube X

P r e --- C o a te d A l / Cu X

E --- C o a te d A l / Cu X X

Cu / Cu X X

NOTE: Refer to the Guide Specifications for further detail.

E-coated aluminum-fin coils have a flexible and durable

epoxy coating uniformly applied to all coil surfaces.

Unlike brittle phenolic dip and bake coatings, E-coating

provides superior protection with unmatched flexibility,

edge coverage, metal adhesion, thermal performance, and

most importantly, corrosion resistance.

E-coated coils provide this protection since all coil

surfaces are completely encapsulated from environmental

contamination. This coating is especially suitable in

industrial environments.

Pre--coated coils (RTPF coils only) provide protection in

mild coastal environments.

Standard

N o n --- C o r r o s i v e

Mild Coastal

Moderate

Coastal

Severe

Coastal

Industrial

Industrial &

–20_F (–29_C) low-ambient temperature kit option

(MotorMaster Ir) controls outdoor-fan motor operation

to maintain the correct head pressure at low outdoor

ambient temperatures.

Louvered hail guard package protects coils against

damage from flying debris and hail.

115-v convenience outlet is used to power electric drills,

lights, and refrigerant recovery machines. This means that

a separate 115-v power supply is no longer necessary.

Non-fused disconnect switch is used to remove power

locally at the condensing unit. This switch also includes a

power lockout capability to protect the service person.

This lockout switch saves the service person time and

effort because there is no need to access a distant

disconnect switch while servicing the unit.

569J

Coastal

Coastal

11

Page 12

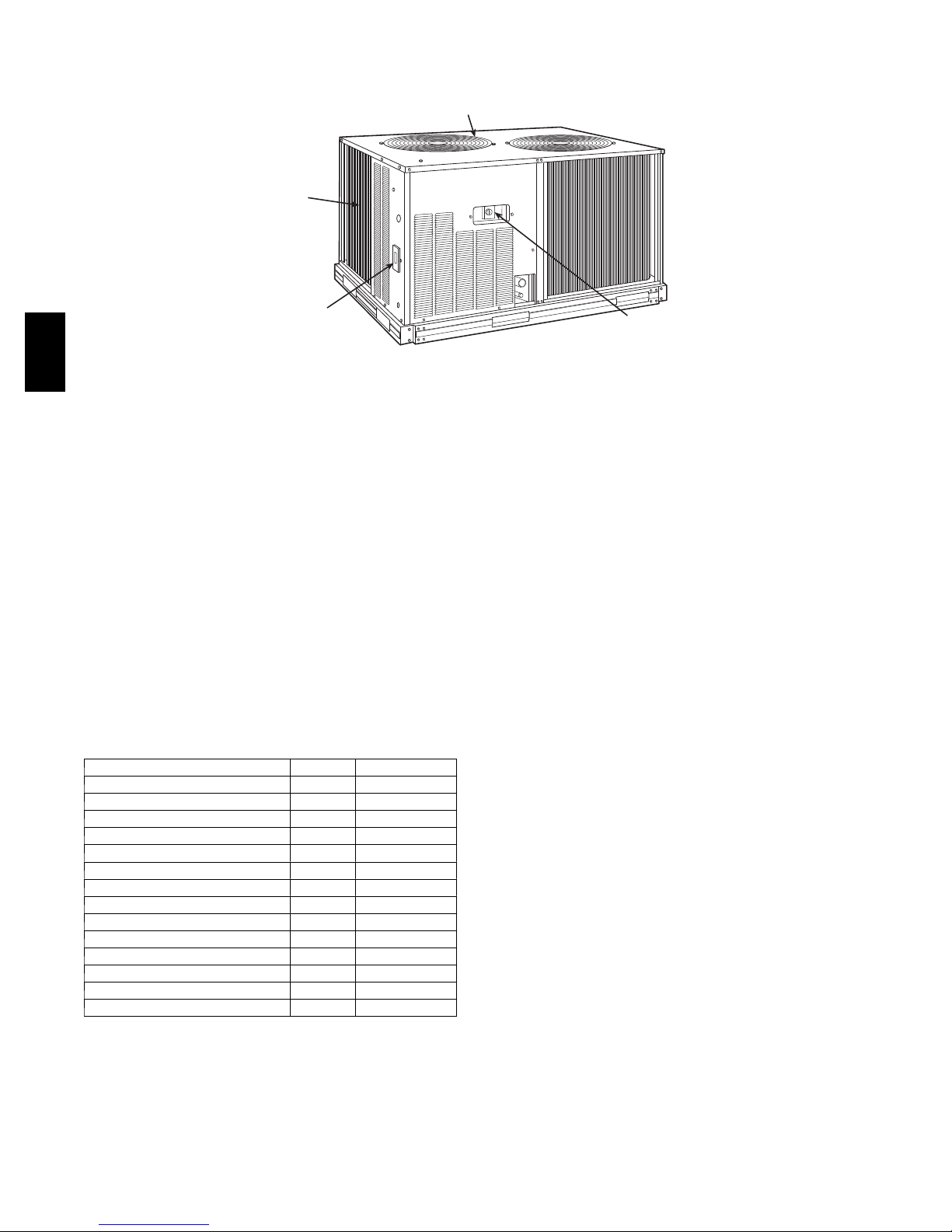

OPTIONS AND ACCESSORIES (cont.)

FACTORY-INSTALLED

COIL PROTECTION

OPTIONAL

FACTORY-INSTALLED

CONVENIENCE OUTLE

(powered and non-powered)

LOW AMBIENT CONTROL

(FACTORY-INSTALLED OR

FIELD-INSTALLED)

T

OPTIONAL

FACTORY-INSTALLED

DISCONNECT SWITCH

569J

569J* field-installed accessories

–20_F (–29_C) low-ambient temperature kit accessory

(MotorMaster Ir) controls outdoor-fan motor operation

to maintain the correct head pressure at low outdoor

ambient temperatures.

Louvered hail guard package protects coils against

damage from flying debris and hail.

Condenser coil grille package protects condensing unit

coil from impact by large objects and vandalism.

Bryant’s line of thermostats provide both programmable

and non-programmable capability with the new

Debonairr line of commercial programmable

thermostats. The Commercial Electronic thermostats

provide 7-day programmable capability for economical

applications.

524J OPTIONS AND ACCESSORIES

ITEM OPTION* ACCESSORY†

Alternate Fan Motors X

Alternate Drives X

CO2Sensors X

Condensate Drain Trap X

Discharge Plenum X

Economizer X

Electric Heat X

Hot Water Heating Coils X

Overhead Suspension Package X

Prepainted Units X

Return Air Grille X

Steam Heating Coil X

Subbase X

UV-C Germicidal Lamp** X

* Factory-installed option.

† Field-installed accessory.

** Contact application engineer.

C101216

524J factory-installed options

Alternate fan motors and drives are available to provide

the widest possible range of performance.

Units constructed of prepainted steel are available from

the factory for applications that require painted units. Unit

color is American Sterling Gray.

524J field-installed accessories

Two-row hot water coils have5/8-in. diameter copper

tubes mechanically bonded to aluminum plate fins. Coils

have non-ferrous headers.

One-row steam coil has 1-in. OD copper tube and

aluminum fins. The Inner Distributing Tube (IDT) design

provides uniform temperatures across the coil face. The

IDT steam coils are especially suited to applications

where sub-freezing air enters the unit.

Electric resistance heat coils have an open-wire design

and are mounted in a rigid frame. Safety cutouts for high

temperature conditions are standard.

Economizer (enthalpy controlled) provides ventilation

air and provides “free” cooling if the outside ambient

temperature and humidity are suitable. The economizer

can also be used in conjunction with Bryant Comfort

System thermostats and CO

air quality requirements. The economizer can be used in

both vertical and horizontal positions.

Discharge plenum directs the air discharge into the

occupied space; integral horizontal and vertical louvers

enable redirection of airflow. This accessory is available

unpainted or painted.

Return-air grille provides a protective barrier over the

return-air opening and gives a finished appearance to units

installed in the occupied space. This accessory is available

unpainted or painted.

sensors to help meet indoor

2

Subbase provides a stable, raised platform and room for

condensate drain connection for floor-mounted units. This

accessory is available unpainted or painted.

12

Page 13

OPTIONS AND ACCESSORIES (cont.)

Overhead suspension package includes necessary

brackets to support units in horizontal installations.

CO

sensors can be used in conjunction with the

2

economizer accessory to help meet indoor air quality

requirements. The sensor signals the economizer to open

when the CO

Bryant Comfort System programmable thermostat can

also be used to override the sensor if the outside-air

temperature is too high or too low.

level in the space exceeds the setpoint. A

2

Condensate drain trap includes an overflow shutoff

switch that can be wired to turn off the unit if the trap

becomes plugged. The kit also includes a wire harness

that can be connected to an alarm if desired. The

transparent trap is designed for easy service and

maintenance.

UV-C germicidal lamps kill mold and fungus that may

grow on evaporator coil and condensate pan surfaces. The

use of UV-C germicidal lamps eliminates the foul odors

that result from mold and fungus growth. These lamps

also provide a self-cleaning function for the evaporator

coil and drain pan. Contact application engineer for info.

569J

13

Page 14

OPTIONS AND ACCESSORIES (cont.)

569J

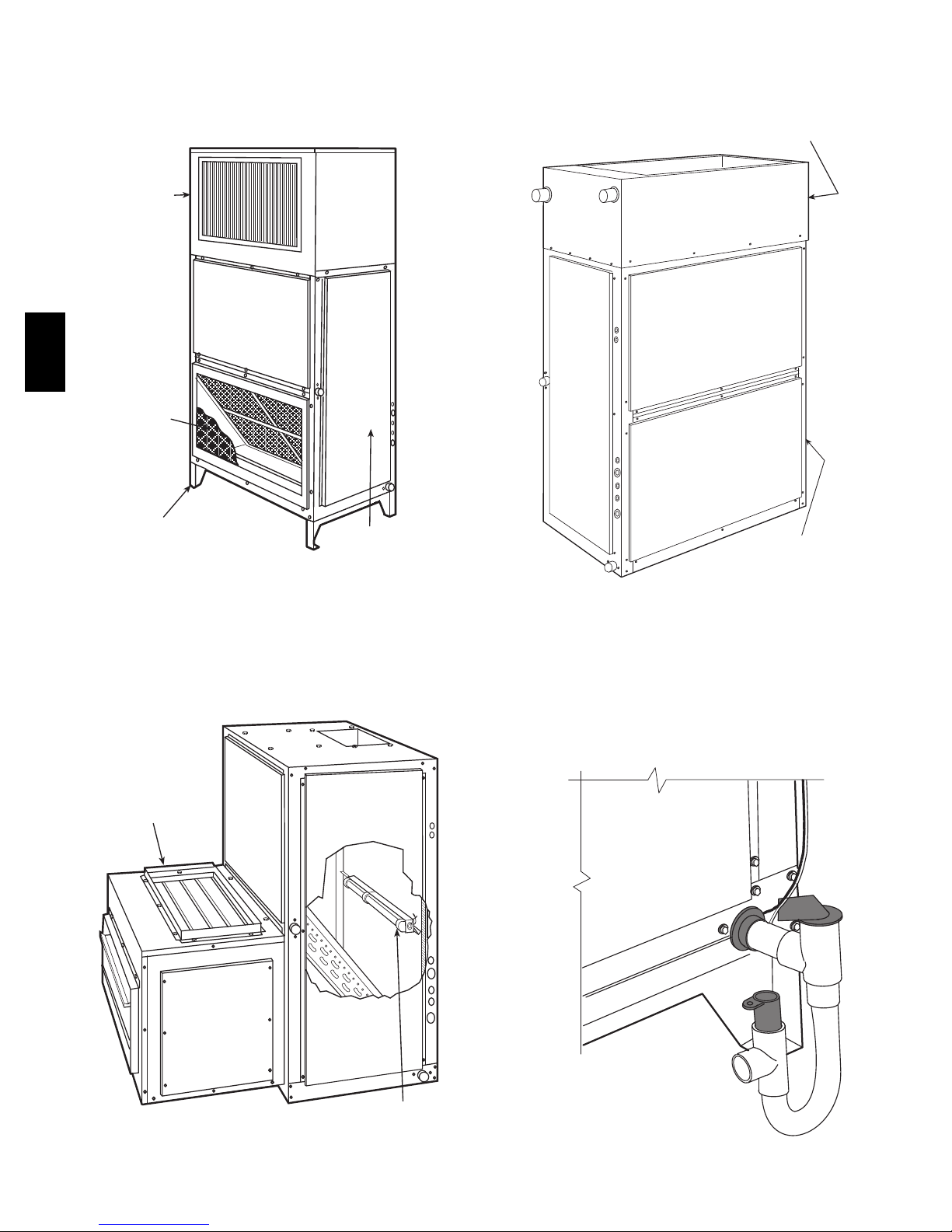

524J WITH DISCHARGE PLENUM

RETURN-AIR GRILLE AND SUBBASE

DISCHARGE

PLENUM

RETURN-AIR

GRILLE

SUBBASE

FAN

COIL

UNIT

524J WITH HOT WATER OR STEAM COIL

HOT WATER OR

STEAM COIL

FAN COIL

UNIT

524J WITH ECONOMIZER

AND UV-C GERMICIDAL LAMPS

ECONOMIZER

524J WITH CONDENSATE TRAP

UV-C GERMICIDAL LAMPS

C09259

14

Page 15

SELECTION PROCEDURE

Combination ratings for 569J* units matched with 524J

Series air handlers are in this book. If unit is used with an

air handler, use the Bryant Electronic Catalog AHU

(Air-Handling Unit) selection program to obtain combined

ratings.

I. Determine cooling load, evaporator-air

temperature, and quantity.

Given:

Total Cooling Capacity

Required (TC) 121,000 Btuh...................

Sensible Heat Capacity

Required (SHC) 95,000 Btuh...................

Compressor Type Scroll.........................

Temperature Air Entering

Condenser (Edb) 95_F.........................

Temperature Air Entering

Evaporator (db/wb) 80_F db, 67_Fwb............

Evaporator Air Quantity 4,000 cfm.................

External Static Pressure 0.4 in. wg.................

Length of Interconnecting

Refrigerant Piping 25 ft (Linear).................

Power Supply (V-Ph-Hz) 208/230-3-60.............

II. Select condensing unit air-handler combination.

For this example, select a 569J*12 matched with a

524J012 coil. This 569J*12/524J12 condensing unit

air-handler combination provides 122,000 Btuh of total

cooling capacity and 97,200 Btuh of sensible capacity at

the given conditions. If other temperatures or airflow

values are required, interpolate the values from the

combination ratings.

III. Determine sizes of liquid and suction lines.

Enter Refrigerant Piping Sizes table. The sizes shown

are based on an equivalent length of pipe. This

equivalent length is equal to the linear length of pipe

indicated at the top of each sizing column, plus a 50%

allowance for fitting losses. (For a more accurate

determination of actual equivalent length in place of

using the estimated 50% value, refer to Bryant System

Design Manual.) For this example, note in the linear

length column that the proper pipe size is

liquid line and 1

For extended line lengths over 100 feet, contact your

Bryant representative or application engineer.

3

/8in. for the suction line.

1

/2in. for the

IV. Determine fan rpm and bhp (brake horsepower).

Refer to the 524J Air Handler Catalog -- Fan

Performance table. Enter the Air Handler Fan

Performance table at 524J12 at 4000 cfm and move to

the External Static Pressure (ESP) column. Note that the

conditions require 803 rpm at 1.77 bhp.

V. Determine motor and drive.

Enter the Fan Motor Data tables and find the standard

motor for 524J12 unit rated at 2.4 Hp. Since the bhp

required is 1.77, a standard motor satisfies the

requirement and should be used.

Next, find the type of drive that satisfies the 803 rpm

requirement in the Drive Data tables. For the 524J012

unit, the Standard Drive table shows an rpm range of

666-863. Since the rpm required is 803, the standard

drive satisfies the requirement and should be used.

CONTROLS

Operating sequences

When the wall thermostat calls for cooling, terminals G

and Y1 are energized. As a result, the indoor fan contactor

(IFC) and the compressor contactor (C1) are energized,

causing the indoor fan motor (IFM), compressor #1, and

outdoor fans (OFM) to start. The field--supplied and

field--installed liquid line valve also opens, allowing the

system to function in Cooling mode.

If the unit has 2 stages of cooling, the wall thermostat will

additionally energize Y2. The Y2 signal will energize

compressor contactor #2 (C2), causing compressor #2 to

start.

Regardless of the number of stages, the field--supplied

liquid line valve shall opens and the outdoor fan

motors(OFM) runs continuously while unit is cooling.

When cooling demand decrease, the thermostat will

de--energize Y2. Y2 signal will de--energize compressor

contactor #2 (C2), causing compressor #2 to stop.

When cooling demand has been satisfied, the thermostat

will de--energize Y1, and G terminals. Y1 and G signal

will de--energize compressor contactor #1 (C1), causing

compressor #1 to stop. If the wall thermostat is set to

continuous (CONT), the indoor fan motor will continue

to operate. Otherwise, the indoor fan motor will stop.

The outdoor fan motors (OFM) will turn off and

field--supplied liquid line valve shall close , minimizing

the potential for refrigerant migration.

569J

15

Page 16

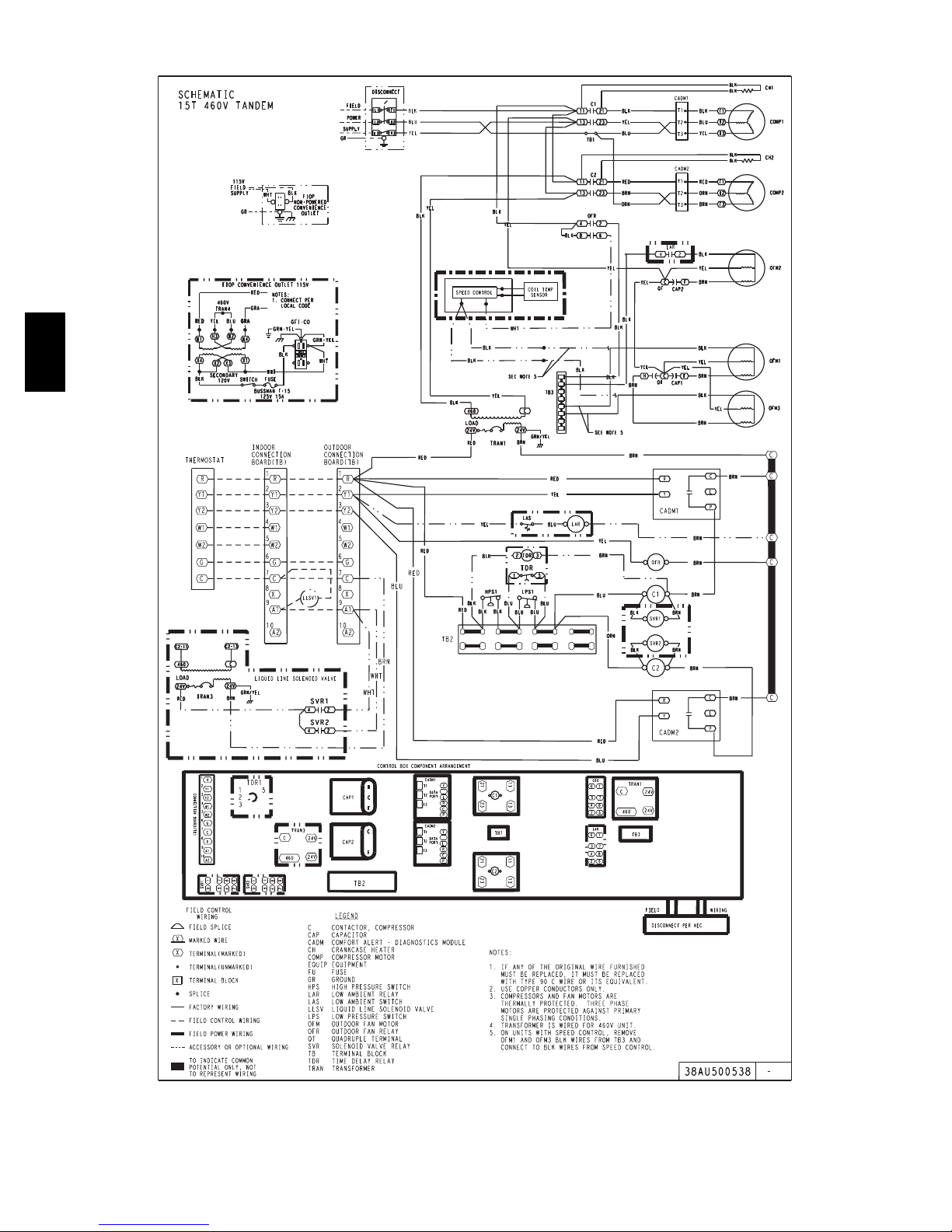

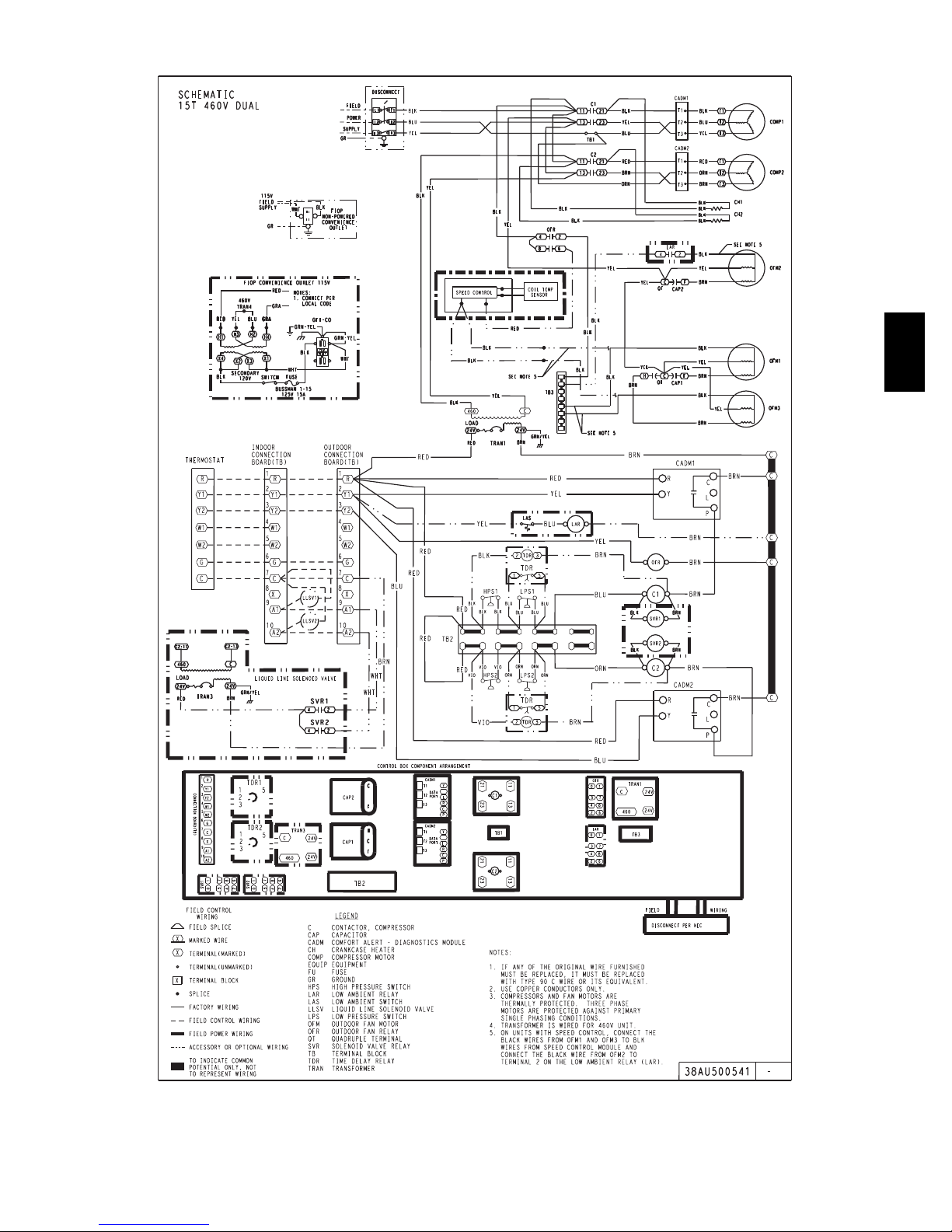

569J

TYPICAL WIRING SCHEMATIC

C09624

Typical 569J*16 Single Circuit

16

Page 17

TYPICAL WIRING SCHEMATIC (cont.)

569J

C09627

Typical 569J*16 Dual Circuit

17

Page 18

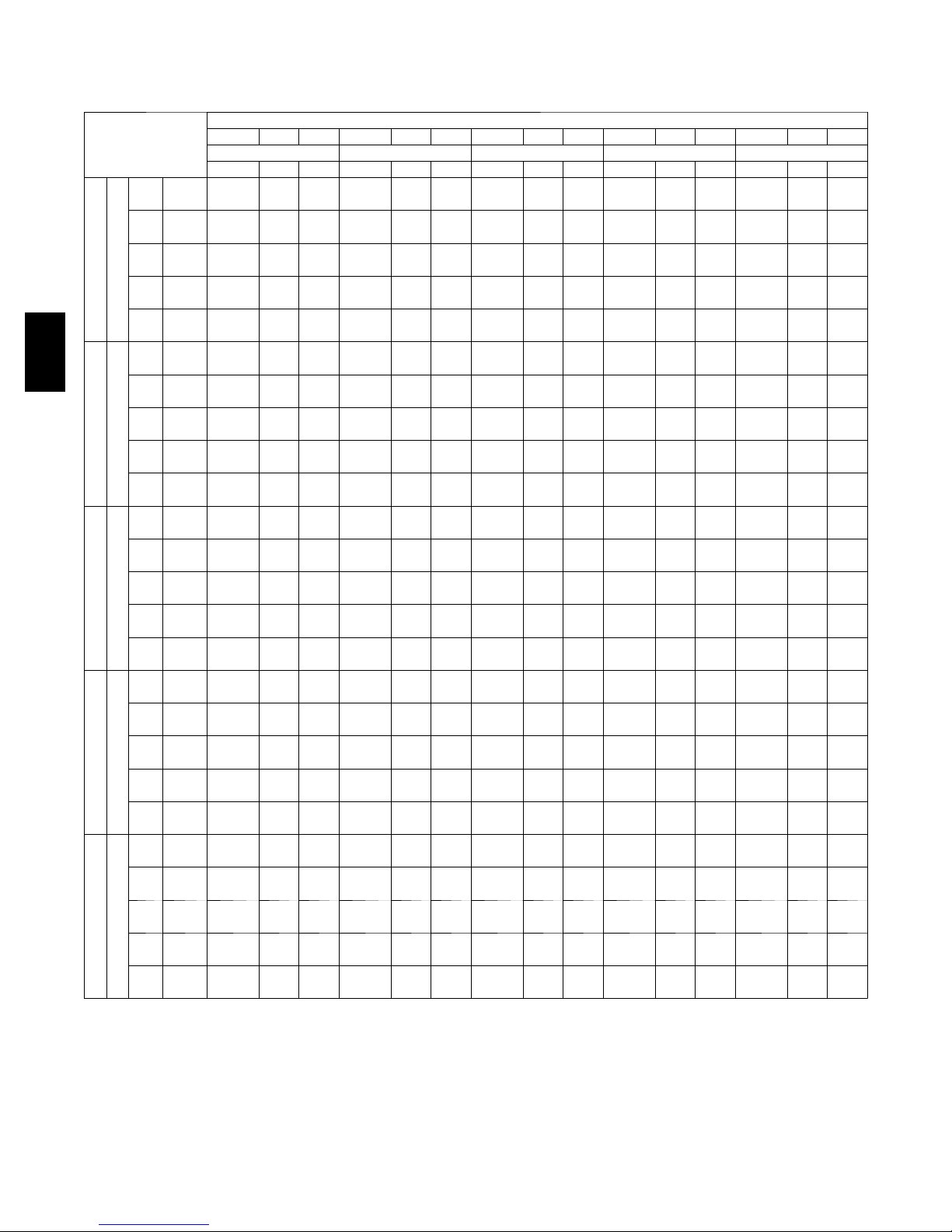

PERFORMANCE DATA

569J*07A CONDENSER ONLY RATINGS

SST (_F)

TC 46.7 45.1 41.7 39.8 37.9 33.9

20

25

30

35

569J

40

45

50

NOTE:

Condensing unit only ratings are at 45

kW 4.04 4.27 4.77 5.04 5.32 5.93

SDT 91.6 96.4 105.9 110.6 115.3 124.7

TC 51.8 50.2 46.5 44.6 42.6 38.4

kW 4.06 4.29 4.79 5.05 5.33 5.95

SDT 92.7 97.5 106.9 111.6 116.3 125.6

TC 57.0 55.2 51.4 49.4 47.3 42.9

kW 4.07 4.30 4.80 5.07 5.35 5.96

SDT 93.9 98.6 108.1 112.7 117.4 126.7

TC 62.7 60.8 56.8 54.6 52.4 47.8

kW 4.09 4.32 4.81 5.08 5.36 5.98

SDT 95.1 99.8 109.2 113.9 118.6 127.8

TC 68.7 66.7 62.5 60.2 57.9 53.0

kW 4.11 4.34 4.83 5.10 5.38 5.99

SDT 96.5 101.1 110.5 115.1 119.7 128.8

TC 75.2 73.1 68.5 66.2 63.7 58.6

kW 4.13 4.36 4.84 5.10 5.38 5.99

SDT 97.9 102.5 111.8 116.3 120.9 129.9

TC 82.2 79.9 75.1 72.5 69.9 64.4

kW 4.15 4.37 4.85 5.12 5.39 6.00

SDT 99.4 104.0 113.1 117.6 122.2 131.1

AIR TEMPERATURE ENTERING CONDENSER (_F)

80 85 95 100 105 115

_FSSTand95_F entering --- air temperature. EER = 13.1

569J*08A CONDENSER ONLY RATINGS

SST (_F)

TC 65.2 63.2 59.1 57.0 54.8 50.5

20

25

30

35

40

45

50

NOTE:

Condensing unit only ratings are at 45

LEGEND:

k W --- C om pr es so r Po we r

SDT --- Saturated Discharge Temperature at Compressor (

SST - -- Saturated Suction T emperature (

TC --- Gross Co o ling Capacity ( 1000 Btuh)

kW 5.04 5.33 5.98 6.34 6.73 7.60

SDT 95.3 100.2 109.8 114.7 119.5 129.2

TC 71.5 69.4 65.0 62.8 60.5 55.9

kW 5.12 5.42 6.07 6.42 6.81 7.66

SDT 96.4 101.2 110.8 115.6 120.4 129.9

TC 77.8 75.5 70.9 68.5 66.2 61.3

kW 5.22 5.51 6.16 6.51 6.89 7.74

SDT 97.6 102.4 111.9 116.6 121.3 130.7

TC 84.8 82.4 77.5 75.0 72.4 67.2

kW 5.32 5.61 6.26 6.61 6.99 7.83

SDT 98.8 103.5 112.9 117.6 122.3 131.6

TC 92.3 89.7 84.5 81.8 79.0 73.5

kW 5.44 5.73 6.37 6.72 7.10 7.94

SDT 100.1 104.8 114.2 118.8 123.5 132.7

TC 100.3 97.5 91.9 89.0 86.1 80.1

kW 5.57 5.86 6.50 6.85 7.23 8.07

SDT 101.6 106.2 115.5 120.2 124.8 133.9

TC 108.7 105.8 99.8 96.7 93.6 87.3

kW 5.71 6.00 6.64 7.00 7.38 8.21

SDT 103.1 107.8 117.0 121.6 126.2 135.3

80 85 95 100 105 115

_FSSTand95_F entering --- air temperature. EER = 13.0

_F)

AIR TEMPERATURE ENTERING CONDENSER (_F)

_F)

18

Page 19

PERFORMANCE DATA (cont.)

569J*12A CONDENSER ONLY RATINGS

SST (_F)

TC 78.0 75.4 70.1 67.3 64.6 58.9

20

25

30

35

40

45

50

NOTE:

Condensing unit only ratings are at 45

kW 6.03 6.44 7.31 7.76 8.23 9.21

SDT 94.0 98.7 108.2 113.0 117.7 127.2

TC 86.4 83.6 77.9 74.9 72.0 66.0

kW 6.11 6.53 7.41 7.87 8.36 9.36

SDT 95.2 100.0 109.4 114.2 118.9 128.2

TC 94.7 91.8 85.6 82.5 79.4 73.0

kW 6.20 6.62 7.51 7.98 8.47 9.49

SDT 96.6 101.3 110.7 115.4 120.0 129.2

TC 104.0 100.8 94.3 90.9 87.6 80.7

kW 6.30 6.71 7.61 8.09 8.58 9.62

SDT 98.1 102.7 112.0 116.6 121.2 130.4

TC 113.9 110.4 103.4 99.9 96.2 88.9

kW 6.39 6.81 7.71 8.20 8.70 9.75

SDT 99.5 104.2 113.4 117.9 122.5 131.6

TC 124.3 120.6 113.1 109.2 105.4 97.5

kW 6.49 6.92 7.83 8.32 8.82 9.89

SDT 101.1 105.7 114.8 119.4 123.9 132.9

TC 135.4 131.4 123.3 119.2 115.0 106.5

kW 6.61 7.04 7.96 8.45 8.96 10.03

SDT 102.8 107.3 116.4 120.9 125.4 134.3

AIR TEMPERATURE ENTERING CONDENSER (_F)

80 85 95 100 105 115

569J

_FSSTand95_F entering --- air temperature. EER = 13.5

569J*12D Dual Circuit CONDENSER ONLY RATINGS

SST (_F)

TC 75.29 69.95 67.18 64.32 58.42 55.21

20

25

30

35

40

45

50

NOTE:

Condensing unit only ratings are at 45

LEGEND:

k W --- C om pr es so r Po we r

SDT --- Saturated Discharge Temperature at Compressor (

SST - -- Saturated Suction T emperature (

TC --- Gross Co o ling Capacity ( 1000 Btuh)

kW 6.88 7.89 8.43 8.96 10.04 10.53

SDT 102.3 111.4 116.1 120.5 129.6 133.7

TC 83.12 77.31 74.32 71.28 64.99 61.76

kW 6.97 7.98 8.53 9.07 10.18 10.73

SDT 103.6 112.6 117.3 121.8 130.7 135.1

TC 91.41 85.21 81.99 78.76 72.08 68.58

kW 7.06 8.08 8.63 9.18 10.31 10.87

SDT 104.9 114.0 118.5 122.9 131.8 136.1

TC 100.35 93.69 90.26 86.76 85.11 75.65

kW 7.15 8.18 8.73 9.29 10.42 10.99

SDT 106.3 115.2 119.8 124.2 132.9 137.1

TC 109.90 102.58 98.84 95.06 87.13 83.07

kW 7.25 8.29 8.83 9.39 10.54 11.12

SDT 107.6 116.6 121.0 125.4 134.0 138.2

TC 119.86 111.84 107.74 103.56 95.02 90.54

kW 7.36 8.39 8.93 9.49 10.64 11.22

SDT 109.0 117.9 122.3 126.6 135.1 139.2

TC 130.20 121.39 116.90 112.33 103.07 98.17

kW 7.48 8.51 9.04 9.60 10.75 11.33

SDT 110.5 119.2 123.5 127.8 136.2 140.2

85 95 100 105 115 120

_FSSTand95_F entering --- air temperature. EER = 13.0

_F)

AIR TEMP ENT CONDENSER (_F)

_F)

19

Page 20

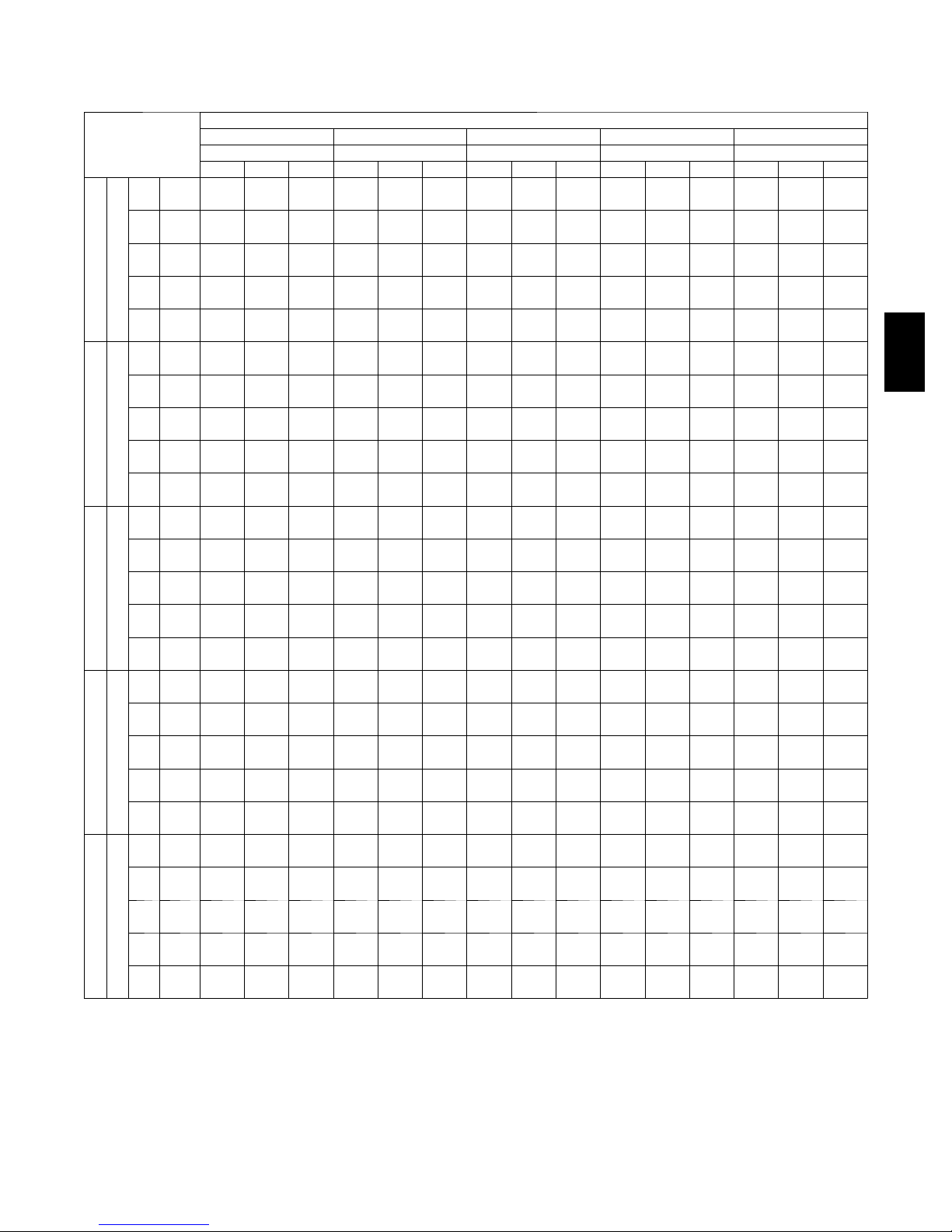

PERFORMANCE DATA (cont.)

569J*14A CONDENSER ONLY RATINGS

SST (_F)

TC 100.8 97.4 90.3 86.6 83.0 75.5

20

25

30

35

569J

40

45

50

NOTE:

Condensing unit only ratings are at 45

kW 8.48 8.97 10.00 10.53 11.07 12.19

SDT 98.0 102.6 111.8 116.4 120.9 130.0

TC 111.8 108.1 100.5 96.6 92.7 84.7

kW 8.66 9.15 10.20 10.75 11.31 12.47

SDT 99.6 104.1 113.2 117.7 122.3 131.3

TC 122.9 118.9 110.7 106.6 102.4 93.9

kW 8.84 9.35 10.41 10.97 11.55 12.75

SDT 101.3 105.8 114.8 119.3 123.8 132.7

TC 134.9 130.6 121.9 117.4 113.0 103.8

kW 9.05 9.55 10.64 11.21 11.80 13.03

SDT 103.1 107.6 116.5 120.9 125.4 134.2

TC 147.7 143.0 133.7 128.9 124.1 114.3

kW 9.27 9.78 10.88 11.47 12.07 13.32

SDT 105.1 109.5 118.3 122.8 127.1 135.8

TC 161.1 156.2 146.1 141.0 135.8 125.4

kW 9.51 10.03 11.15 11.73 12.34 13.61

SDT 107.2 111.6 120.3 124.7 129.0 137.5

TC 175.4 170.1 159.3 153.8 148.3 137.1

kW 9.78 10.30 11.42 12.02 12.63 13.92

SDT 109.5 113.8 122.4 126.7 130.9 139.4

AIR TEMPERATURE ENTERING CONDENSER (_F)

80 85 95 100 105 115

_FSSTand95_F entering --- air temperature. EER = 12.0

569J*14D Dual Circuit CONDENSER ONLY RATINGS

SST (_F)

TC 93.24 86.18 82.60 78.94 71.54 67.78

20

25

30

35

40

45

50

NOTE:

Condensing unit only ratings are at 45

LEGEND:

k W --- C om pr es so r Po we r

SDT --- Saturated Discharge Temperature at Compressor (

SST - -- Saturated Suction T emperature (

TC --- Gross Co o ling Capacity ( 1000 Btuh)

kW 9.22 10.36 10.96 11.56 12.76 13.37

SDT 104.4 113.3 117.8 122.2 130.9 135.2

TC 103.39 95.91 92.05 88.15 80.16 76.08

kW 9.42 10.60 11.21 11.83 13.10 13.73

SDT 106.1 114.9 119.3 123.7 132.3 136.6

TC 114.29 106.19 102.04 97.79 89.15 84.74

kW 9.63 10.84 11.46 12.10 13.41 14.07

SDT 107.8 116.6 120.9 125.3 133.8 138.0

TC 125.69 116.93 112.44 107.84 105.72 93.69

kW 9.84 11.07 11.71 12.36 13.70 14.38

SDT 109.5 118.2 122.6 126.8 135.2 139.4

TC 137.57 128.07 123.21 118.21 108.08 102.90

kW 10.05 11.30 11.95 12.61 13.98 14.68

SDT 111.3 119.9 124.2 128.4 136.7 140.8

TC 149.86 139.53 134.26 128.83 117.83 112.22

kW 10.27 11.53 12.18 12.85 14.24 14.95

SDT 113.1 121.6 125.8 130.0 138.1 142.1

TC 162.51 151.29 145.56 139.64 127.71 121.55

kW 10.50 11.76 12.42 13.09 14.48 15.20

SDT 114.9 123.3 127.5 131.6 139.6 143.5

85 95 100 105 115 120

_FSSTand95_F entering --- air temperature. EER = 13.0

_F)

AIR TEMP ENT CONDENSER (_F)

_F)

20

Page 21

PERFORMANCE DATA (cont.)

569J*16A CONDENSER ONLY RATINGS

SST (_F)

TC 125.5 121.8 114.2 106.6 99.7 79.7

20

25

30

35

40

45

50

NOTE:

Condensing unit only ratings are at 45

kW 10.5 11.2 12.6 14.2 16.0 17.5

SDT 98.6 103.4 113.0 122.7 134.9 136.0

TC 138.7 134.7 126.5 118.1 109.3 98.5

kW 10.7 11.4 12.8 14.3 16.0 17.9

SDT 100.0 104.7 114.2 123.6 132.9 140.5

TC 152.9 148.6 139.8 130.7 120.9 104.9

kW 10.9 11.6 13.0 14.6 16.2 17.8

SDT 101.4 106.2 115.5 125.0 133.6 139.4

TC 168.2 163.5 154.1 144.2 133.6 121.2

kW 11.2 11.8 13.2 14.8 16.5 18.1

SDT 102.9 107.5 117.0 126.2 134.8 142.1

TC 184.9 179.4 169.3 158.7 147.6 135.1

kW 11.5 12.0 13.5 15.1 16.8 18.5

SDT 105.2 108.9 118.5 127.7 136.7 144.5

TC 202.1 196.7 185.7 174.3 162.5 150.4

kW 11.7 12.4 13.9 15.6 17.5 19.6

SDT 106.4 111.2 120.9 130.7 140.4 150.2

TC 220.6 214.7 202.1 190.0 174.6 159.6

kW 11.9 12.6 13.9 15.4 16.9 18.5

SDT 107.2 111.7 120.4 129.4 136.9 144.9

80 85 95 105 115 125

_FSSTand95_F entering --- air temperature. EER = 12.7

AIR TEMPERATURE ENTERING CONDENSER (_F)

569J

569J*16D Dual Circuit CONDENSER ONLY RATINGS

SST (_F)

TC 127.6 123.7 116.0 108.1 99.7 90.2

20

25

30

35

40

45

50

NOTE:

Condensing unit only ratings are at 45

LEGEND:

k W --- C om pr es so r Po we r

SDT --- Saturated Discharge Temperature at Compressor (

SST - -- Saturated Suction T emperature (

TC --- Gross Co o ling Capacity ( 1000 Btuh)

kW 10.0 10.6 11.9 13.4 14.9 16.6

SDT 96.0 100.5 109.8 119.2 128.3 137.0

TC 140.9 136.7 128.3 119.5 110.4 101.2

kW 10.0 10.6 11.9 13.4 14.9 16.6

SDT 96.0 100.5 109.8 119.2 128.3 137.0

TC 155.0 150.5 141.3 132.0 122.3 111.4

kW 10.4 11.0 12.3 13.7 15.3 17.0

SDT 98.7 103.3 112.4 121.5 130.6 139.1

TC 170.1 165.3 155.4 145.2 134.4 123.3

kW 10.6 11.2 12.5 14.0 15.5 17.2

SDT 100.1 104.7 113.8 122.8 131.7 140.4

TC 186.3 181.0 170.3 159.0 147.3 134.9

kW 10.8 11.4 12.8 14.2 15.8 17.4

SDT 101.6 106.1 115.1 124.0 132.8 141.4

TC 203.4 197.6 185.7 173.5 160.6 147.2

kW 11.1 11.7 13.0 14.4 16.0 17.6

SDT 103.2 107.6 116.5 125.4 134.0 142.5

TC 221.4 214.9 202.0 188.6 174.5 159.7

kW 11.4 12.0 13.3 14.7 16.2 17.9

SDT 104.8 109.2 118.0 126.7 135.2 143.5

80 85 95 105 115 125

_FSSTand95_F entering --- air temperature. EER = 13.0

_F)

AIR TEMPERATURE ENTERING CONDENSER (_F)

_F)

21

Page 22

PERFORMANCE DATA (cont.)

569J*25A CONDENSER ONLY RATINGS

SST (_F)

TC 159.2 154.5 144.5 133.9 122.5 110.2

20

25

30

35

569J

40

45

50

NOTE:

Condensing unit only ratings are at 45

kW 13.0 13.7 15.3 17.1 19.2 21.5

SDT 97.3 101.8 110.6 119.3 127.9 136.5

TC 176.1 171.0 160.2 148.8 136.5 123.2

kW 13.2 14.0 15.6 17.4 19.5 21.8

SDT 98.9 103.3 112.0 120.7 129.2 137.6

TC 194.2 188.6 176.9 164.5 151.3 136.9

kW 13.5 14.3 15.9 17.7 19.7 22.0

SDT 100.6 104.9 113.6 122.1 130.5 138.8

TC 213.5 207.4 194.7 181.2 166.8 151.2

kW 13.8 14.6 16.2 18.0 20.0 22.3

SDT 102.4 106.7 115.2 123.6 131.9 140.1

TC 234.1 227.4 213.5 198.8 183.1 166.1

kW 14.2 14.9 16.5 18.3 20.3 22.6

SDT 104.3 108.5 116.9 125.2 133.3 141.4

TC 255.9 248.6 233.3 217.3 200.1 181.7

kW 14.6 15.3 16.9 18.7 20.7 22.9

SDT 106.3 110.5 118.7 126.8 134.9 142.7

TC 279.0 270.9 254.2 236.7 218.1 197.8

kW 15.1 15.8 17.3 19.1 21.1 23.2

SDT 108.5 112.5 120.6 128.6 136.5 144.1

80 85 95 105 115 125

_FSSTand95_F entering --- air temperature. EER = 12.9

AIR TEMPERATURE ENTERING CONDENSER (_F)

569J*25D Dual Circuit CONDENSER ONLY RATINGS

SST (_F)

TC 160.3 155.5 145.3 134.3 122.5 109.6

20

25

30

35

40

45

50

NOTE:

Condensing unit only ratings are at 45

LEGEND:

k W --- C om pr es so r Po we r

SDT --- Saturated Discharge Temperature at Compressor (

SST - -- Saturated Suction T emperature (

TC --- Gross Co o ling Capacity ( 1000 Btuh)

kW 12.7 13.4 15.0 16.8 18.8 21.1

SDT 97.0 101.5 110.3 119.1 127.7 136.3

TC 177.2 171.9 160.8 149.0 136.3 122.3

kW 12.7 13.4 15.0 16.8 18.8 21.1

SDT 97.0 101.5 110.3 119.1 127.7 136.3

TC 195.1 189.4 177.4 164.5 150.7 135.6

kW 13.2 13.9 15.5 17.3 19.3 21.5

SDT 100.3 104.6 113.3 121.8 130.3 138.6

TC 214.3 208.0 194.9 180.9 165.9 149.5

kW 13.5 14.3 15.8 17.6 19.6 21.8

SDT 102.1 106.3 114.9 123.3 131.7 139.8

TC 234.6 227.7 213.4 198.2 181.7 163.9

kW 13.9 14.6 16.2 17.9 19.9 22.1

SDT 104.0 108.2 116.6 124.9 133.1 141.1

TC 256.3 258.7 242.3 224.9 206.2 186.1

kW 14.3 15.2 16.7 18.5 20.4 22.5

SDT 106.0 111.1 119.2 127.4 135.4 143.1

TC 279.1 272.0 254.7 236.3 216.6 195.4

kW 14.7 15.5 17.0 18.7 20.6 22.7

SDT 108.1 112.3 120.4 128.4 136.4 143.9

80 85 95 105 115 125

_FSSTand95_F entering --- air temperature. EER = 13.0

_F)

AIR TEMPERATURE ENTERING CONDENSER (_F)

_F)

22

Page 23

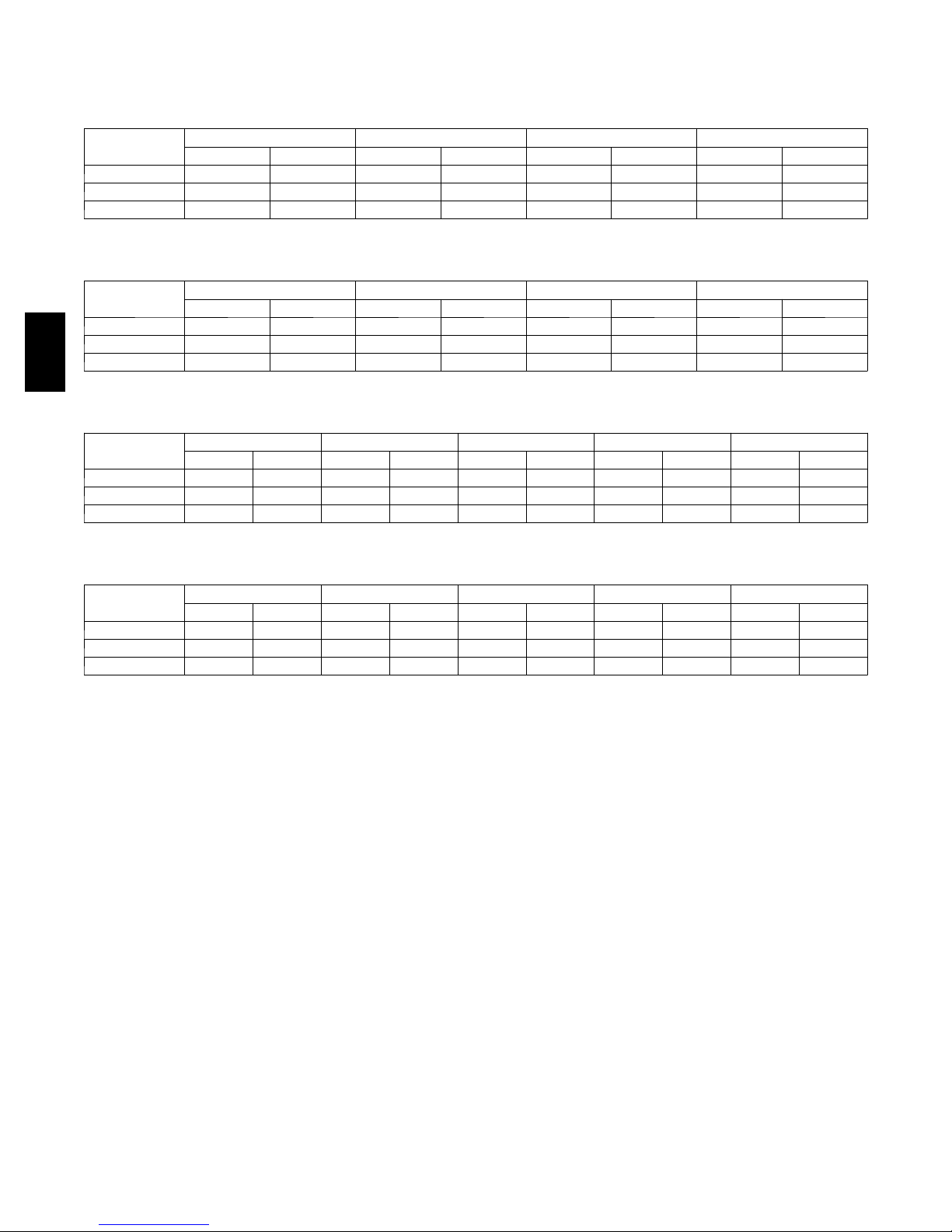

PERFORMANCE DATA (cont.)

569J*07A -- 524J*07 COMBINATION RATINGS

AMBIENT TEMPERATURE

85 95 105 115 125

EA (db) EA (db) EA (db) EA (db) EA (db)

75 80 85 75 80 85 75 80 85 75 80 85 75 80 85

THC 65.8 65.8 74.1 63.4 63.4 71.4 60.7 60.7 68.3 58.3 58.3 65.7 54.7 54.7 61.6

58

SHC 57.4 65.8 74.1 55.3 63.4 71.4 53.0 60.7 68.3 50.9 58.3 65.7 47.8 54.7 61.6

THC 68.1 68.1 70.7 65.2 65.2 69.2 62.0 62.0 67.6 58.1 58.1 65.7 54.6 54.6 55.4

62

SHC 51.9 61.3 70.7 50.4 59.8 69.2 48.9 58.3 67.6 47.1 56.4 65.7 36.3 45.9 55.4

THC 74.0 74.0 74.0 70.9 70.9 70.9 67.3 67.3 67.3 63.4 63.4 63.4 56.7 56.7 56.7

67

EA (wb)

1800 Cfm

EA (wb)

2100 Cfm

EA (wb)

2400 Cfm

EA (wb)

2700 Cfm

EA (wb)

3000 Cfm

--- Not operational

THC --- Total Cooling Capacity, Gross (1,000 Btuh)

SHC --- Sensible Cooling Capacity, Gross (1,000 Btuh)

SHC 42.3 51.8 61.3 41.0 50.5 59.9 39.5 49.0 58.4 37.9 47.3 56.8 35.3 44.9 54.4

THC 80.7 80.7 80.7 77.3 77.3 77.3 73.6 73.6 73.6 69.4 69.4 69.4 63.2 63.2 63.2

72

SHC 32.7 42.2 51.8 31.4 40.9 50.4 30.0 39.5 49.0 28.4 37.9 47.4 26.2 35.7 45.3

THC --- 86.2 86.2 --- 82.6 82.6 --- 78.6 78.6 --- 74.3 74.3 --- 70.7 70.7

76

SHC --- 34.5 44.3 --- 33.2 43.0 --- 31.8 41.6 --- 30.3 40.0 --- 29.0 38.7

THC 69.0 69.0 77.8 66.5 66.5 74.9 63.7 63.7 71.8 61.2 61.2 69.0 --- --- ---

58

SHC 60.3 69.0 77.8 58.0 66.5 74.9 55.6 63.7 71.8 53.5 61.2 69.0 --- --- ---

THC 70.2 70.2 77.1 67.2 67.2 75.5 64.0 64.0 73.6 60.4 60.4 70.7 --- --- ---

62

SHC 55.7 66.4 77.1 54.2 64.8 75.5 52.5 63.0 73.6 50.2 60.4 70.7 --- --- ---

THC 75.9 75.9 75.9 72.6 72.6 72.6 68.9 68.9 68.9 64.8 64.8 64.8 59.1 59.1 59.9

67

SHC 44.8 55.7 66.5 43.4 54.3 65.1 41.9 52.8 63.6 40.3 51.1 62.0 38.1 49.0 59.9

THC 82.5 82.5 82.5 79.0 79.0 79.0 75.2 75.2 75.2 70.9 70.9 70.9 63.9 63.9 63.9

72

SHC 33.7 44.6 55.5 32.4 43.3 54.2 31.0 41.8 52.7 29.4 40.3 51.1 26.9 37.9 48.8

THC --- 88.1 88.1 --- 84.3 84.3 --- 80.2 80.2 --- 75.5 75.5 --- 71.8 71.8

76

SHC --- 35.8 47.0 --- 34.5 45.6 --- 33.0 44.2 --- 31.4 42.5 --- 30.2 41.2

THC 71.7 71.7 80.8 69.0 69.0 77.8 66.1 66.1 74.5 62.6 62.6 70.6 58.9 58.9 66.3

58

SHC 62.6 71.7 80.8 60.3 69.0 77.8 57.7 66.1 74.5 54.7 62.6 70.6 51.4 58.9 66.3

THC 72.0 72.0 82.7 69.1 69.1 80.8 66.2 66.2 77.4 63.0 63.0 73.6 --- --- ---

62

SHC 59.0 70.9 82.7 57.4 69.1 80.8 55.0 66.2 77.4 52.3 63.0 73.6 --- --- ---

THC 77.3 77.3 77.3 74.0 74.0 74.0 70.2 70.2 70.2 66.1 66.1 66.9 62.5 62.5 65.0

67

SHC 47.1 59.3 71.5 45.7 57.9 70.1 44.2 56.4 68.6 42.6 54.7 66.9 41.0 53.0 65.0

THC 84.0 84.0 84.0 80.4 80.4 80.4 76.4 76.4 76.4 71.8 71.8 71.8 67.5 67.5 67.5

72

SHC 34.6 46.9 59.1 33.3 45.5 57.8 31.9 44.1 56.3 30.2 42.4 54.6 28.7 40.8 52.9

THC --- 89.5 89.5 --- 85.7 85.7 --- 81.4 81.4 --- 76.7 76.7 --- --- ---

76

SHC --- 36.9 49.4 --- 35.6 48.1 --- 34.2 46.6 --- 32.6 45.0 --- --- ---

THC 73.9 73.9 83.3 71.2 71.2 80.2 68.1 68.1 76.7 64.8 64.8 73.0 58.6 58.6 66.0

58

SHC 64.6 73.9 83.3 62.2 71.2 80.2 59.5 68.1 76.7 56.5 64.8 73.0 51.2 58.6 66.0

THC 74.0 74.0 86.5 71.3 71.3 83.3 68.2 68.2 79.7 64.8 64.8 75.8 --- --- ---

62

SHC 61.5 74.0 86.5 59.2 71.3 83.3 56.6 68.2 79.7 53.8 64.8 75.8 --- --- ---

THC 78.5 78.5 78.5 75.1 75.1 75.1 71.2 71.2 73.2 67.0 67.0 71.5 63.2 63.2 69.4

67

SHC 49.3 62.7 76.2 47.9 61.3 74.8 46.4 59.8 73.2 44.7 58.1 71.5 43.0 56.2 69.4

THC 85.1 85.1 85.1 81.4 81.4 81.4 77.3 77.3 77.3 72.6 72.6 72.6 65.3 65.3 65.3

72

SHC 35.5 49.0 62.5 34.2 47.6 61.1 32.7 46.1 59.6 31.1 44.5 57.9 28.6 42.2 55.7

THC --- 90.7 90.7 --- 86.7 86.7 --- 82.3 82.3 --- --- --- --- --- ---

76

SHC --- 38.1 51.8 --- 36.7 50.4 --- 35.3 48.9 --- --- --- --- --- ---

THC 75.9 75.9 85.5 73.0 73.0 82.3 69.8 69.8 78.7 66.3 66.3 74.7 62.4 62.4 70.4

58

SHC 66.3 75.9 85.5 63.8 73.0 82.3 61.0 69.8 78.7 57.9 66.3 74.7 54.5 62.4 70.4

THC 75.9 75.9 88.8 73.1 73.1 85.4 69.9 69.9 81.7 66.4 66.4 77.6 60.2 60.2 70.4

62

SHC 63.1 75.9 88.8 60.7 73.1 85.4 58.0 69.9 81.7 55.1 66.4 77.6 50.0 60.2 70.4

THC 79.5 79.5 80.7 76.0 76.0 79.3 72.1 72.1 77.6 67.9 67.9 75.7 63.7 63.7 73.5

67

SHC 51.4 66.0 80.7 49.9 64.6 79.3 48.4 63.0 77.6 46.7 61.2 75.7 44.8 59.2 73.5

THC 86.1 86.1 86.1 82.3 82.3 82.3 78.0 78.0 78.0 73.3 73.3 73.3 69.6 69.6 69.6

72

SHC 36.3 51.0 65.8 35.0 49.7 64.4 33.5 48.1 62.8 31.9 46.5 61.1 30.5 44.9 59.3

THC --- 91.6 91.6 --- 87.6 87.6 --- --- --- --- --- --- --- --- ---

76

SHC --- 39.1 54.0 --- 37.8 52.7 --- --- --- --- --- --- --- --- ---

569J

23

Page 24

PERFORMANCE DATA (cont.)

569J*07A -- 524J*08 COMBINATION RATINGS

AMBIENT TEMPERATURE

85 95 105 115 125

EA (db) EA (db) EA (db) EA (db) EA (db)

75 80 85 75 80 85 75 80 85 75 80 85 75 80 85

THC 71.6 71.6 80.7 69.1 69.1 77.9 66.2 66.2 74.6 63.2 63.2 72.2 --- --- ---

58

SHC 62.5 71.6 80.7 60.3 69.1 77.9 57.8 66.2 74.6 55.0 63.2 72.2 --- --- ---

THC 72.5 72.5 81.5 69.6 69.6 79.6 66.6 66.6 76.6 63.2 63.2 73.2 --- --- ---

62

SHC 58.5 70.0 81.5 56.9 68.2 79.6 54.6 65.6 76.6 52.1 62.7 73.2 --- --- ---

THC 78.1 78.1 78.1 74.8 74.8 74.8 71.2 71.2 71.2 67.0 67.0 67.7 60.9 60.9 64.5

67

EA (wb)

2250 Cfm

569J

EA (wb)

2600 Cfm

EA (wb)

3000 Cfm

EA (wb)

3400 Cfm

EA (wb)

3750 Cfm

--- Not operational

THC --- T otal Cooling Capacity, Gross (1,000 Btuh)

SHC --- Sensible Cooling Capacity, Gross (1,000 Btuh)

SHC 46.9 58.7 70.5 45.6 57.4 69.1 44.1 55.9 67.6 42.4 54.2 66.0 40.1 52.0 63.8

THC 84.9 84.9 84.9 81.4 81.4 81.4 77.4 77.4 77.4 73.1 73.1 73.1 68.9 68.9 68.9

72

SHC 34.9 46.7 58.6 33.6 45.4 57.3 32.1 43.9 55.8 30.5 42.3 54.1 29.0 40.7 52.5

THC --- 90.6 90.6 --- 86.9 86.9 --- 82.5 82.5 --- 77.1 77.1 --- --- ---

76

SHC --- 37.1 49.1 --- 35.9 47.9 --- 33.5 43.4 --- 31.9 41.8 --- --- ---

THC 74.8 74.8 84.2 72.1 72.1 81.3 69.0 69.0 77.8 65.7 65.7 74.0 62.2 62.2 70.0

58

SHC 65.3 74.8 84.2 62.9 72.1 81.3 60.3 69.0 77.8 57.3 65.7 74.0 54.3 62.2 70.0

THC 74.9 74.9 87.2 72.1 72.1 84.3 69.1 69.1 80.8 65.7 65.7 76.8 61.7 61.7 72.1

62

SHC 62.0 74.6 87.2 60.0 72.1 84.3 57.4 69.1 80.8 54.6 65.7 76.8 51.2 61.7 72.1

THC 79.8 79.8 79.8 76.3 76.3 76.4 72.6 72.6 74.2 68.4 68.4 71.9 63.9 63.9 69.8

67

SHC 49.7 63.1 76.5 48.3 61.8 75.1 46.8 60.2 73.6 45.1 58.5 71.9 43.3 56.5 69.8

THC 86.5 86.5 86.5 82.9 82.9 82.9 78.8 78.8 78.8 74.3 74.3 74.3 69.5 69.5 69.5

72

SHC 36.0 49.4 62.9 34.7 48.1 61.6 33.2 46.6 60.1 31.6 45.0 58.4 29.9 43.3 56.7

THC --- 92.3 92.3 --- 87.7 87.7 --- --- --- --- --- --- --- --- ---

76

SHC --- 38.5 52.2 --- 36.5 49.2 --- --- --- --- --- --- --- --- ---

THC 77.6 77.6 87.4 74.8 74.8 84.2 71.5 71.5 80.6 67.9 67.9 76.5 64.9 64.9 73.1

58

SHC 67.7 77.6 87.4 65.3 74.8 84.2 62.5 71.5 80.6 59.3 67.9 76.5 56.7 64.9 73.1

THC 77.7 77.7 90.8 74.8 74.8 87.5 71.6 71.6 83.7 67.9 67.9 79.4 64.9 64.9 75.9

62

SHC 64.5 77.7 90.8 62.1 74.8 87.5 59.5 71.6 83.7 56.4 67.9 79.4 53.9 64.9 75.9

THC 81.2 81.2 83.0 77.7 77.7 81.6 73.9 73.9 80.0 69.6 69.6 78.0 65.3 65.3 74.4

67

SHC 52.7 67.8 83.0 51.3 66.4 81.6 49.8 64.9 80.0 48.0 63.0 78.0 44.5 59.4 74.4

THC 87.9 87.9 87.9 84.2 84.2 84.2 80.0 80.0 80.0 75.3 75.3 75.3 70.2 70.2 70.2

72

SHC 37.1 52.3 67.6 35.8 51.0 66.2 34.3 49.5 64.7 32.7 47.9 63.0 31.0 46.1 61.2

THC --- --- --- --- --- --- --- --- --- --- --- --- --- --- ---

76

SHC --- --- --- --- --- --- --- --- --- --- --- --- --- --- ---

THC 79.7 79.7 89.8 76.8 76.8 86.4 73.4 73.4 82.7 69.6 69.6 78.4 64.8 64.8 73.0

58

SHC 69.6 79.7 89.8 67.0 76.8 86.4 64.1 73.4 82.7 60.8 69.6 78.4 56.6 64.8 73.0

THC 79.8 79.8 93.3 76.8 76.8 89.8 73.5 73.5 85.9 69.7 69.7 81.4 65.6 65.6 76.8

62

SHC 66.3 79.8 93.3 63.8 76.8 89.8 61.0 73.5 85.9 57.8 69.7 81.4 54.5 65.6 76.8

THC 82.3 82.3 88.8 78.8 78.8 87.3 74.9 74.9 85.5 70.6 70.6 83.2 --- --- ---

67

SHC 55.4 72.1 88.8 53.9 70.6 87.3 52.4 68.9 85.5 50.5 66.8 83.2 --- --- ---

THC 88.9 88.9 88.9 85.1 85.1 85.1 80.8 80.8 80.8 76.1 76.1 76.1 --- --- ---

72

SHC 38.2 55.0 71.9 36.9 53.7 70.5 35.4 52.2 69.0 33.8 50.5 67.3 --- --- ---

THC --- --- --- --- --- --- --- --- --- --- --- --- --- --- ---

76

SHC --- --- --- --- --- --- --- --- --- --- --- --- --- --- ---

THC 81.5 81.5 91.9 78.5 78.5 88.4 75.0 75.0 84.5 71.1 71.1 80.1 64.7 64.7 72.9

58

SHC 71.2 81.5 91.9 68.5 78.5 88.4 65.5 75.0 84.5 62.1 71.1 80.1 56.5 64.7 72.9

THC 81.6 81.6 95.4 78.5 78.5 91.8 75.1 75.1 87.8 71.2 71.2 83.2 66.3 66.3 77.5

62

SHC 67.8 81.6 95.4 65.2 78.5 91.8 62.4 75.1 87.8 59.1 71.2 83.2 55.1 66.3 77.5

THC 83.2 83.2 93.9 79.7 79.7 92.2 75.8 75.8 90.3 71.5 71.5 87.7 --- --- ---

67

SHC 57.7 75.8 93.9 56.2 74.2 92.2 54.6 72.4 90.3 52.6 70.2 87.7 --- --- ---

THC 89.7 89.7 89.7 85.8 85.8 85.8 81.5 81.5 81.5 76.8 76.8 76.8 --- --- ---

72

SHC 39.1 57.4 75.7 37.8 56.0 74.3 36.3 54.5 72.7 34.7 52.8 71.0 --- --- ---

THC --- --- --- --- --- --- --- --- --- --- --- --- --- --- ---

76

SHC --- --- --- --- --- --- --- --- --- --- --- --- --- --- ---

24

Page 25

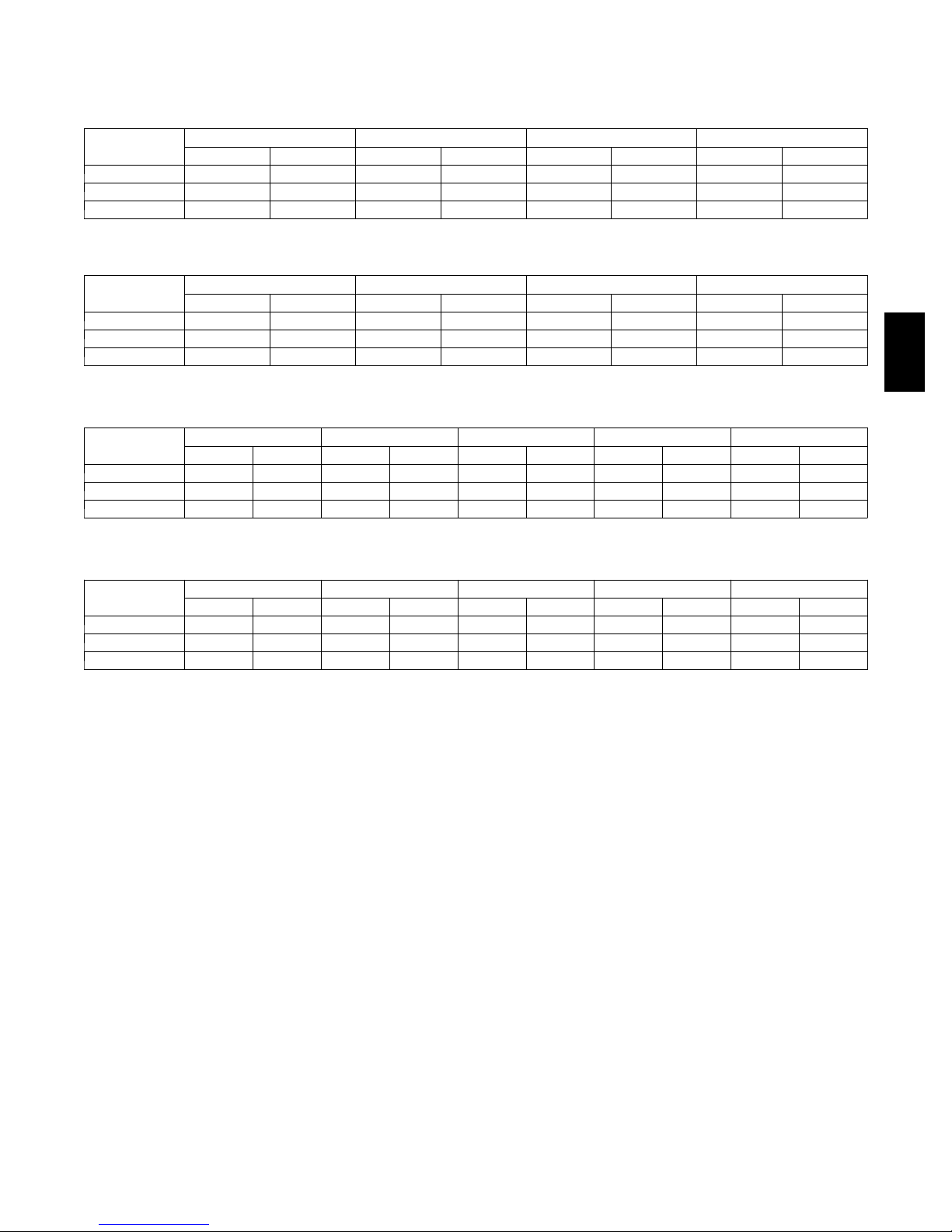

PERFORMANCE DATA (cont.)

569J*08A -- 524J*08 COMBINATION RATINGS

AMBIENT TEMPERATURE

85 95 105 115 125

EA (db) EA (db) EA (db) EA (db) EA (db)

75 80 85 75 80 85 75 80 85 75 80 85 75 80 85

THC 84.6 84.6 95.4 81.7 81.7 92.1 78.5 78.5 88.5 75.5 75.5 85.1 70.7 70.7 79.7

58

SHC 73.9 84.6 95.4 71.3 81.7 92.1 68.5 78.5 88.5 65.9 75.5 85.1 61.7 70.7 79.7

THC 88.2 88.2 89.4 84.6 84.6 87.6 80.7 80.7 85.6 76.9 76.9 83.6 73.2 73.2 81.3

62

SHC 66.1 77.7 89.4 64.3 75.9 87.6 62.4 74.0 85.6 60.5 72.0 83.6 58.5 69.9 81.3

THC 95.5 95.5 95.5 91.5 91.5 91.5 87.3 87.3 87.3 82.7 82.7 82.7 76.1 76.1 76.1

67

EA (wb)

2250 Cfm

EA (wb)

2625 Cfm

EA (wb)

3000 Cfm

EA (wb)

3375 Cfm

EA (wb)

3750 Cfm

--- Not operational

THC --- T otal Cooling Capacity, Gross (1,000 Btuh)

SHC --- Sensible Cooling Capacity, Gross (1,000 Btuh)

SHC 54.1 65.8 77.5 52.3 64.1 75.8 50.5 62.2 74.0 48.6 60.3 72.0 46.0 57.8 69.5

THC 103.4 103.4 103.4 99.2 99.2 99.2 94.6 94.6 94.6 89.6 89.6 89.6 82.3 82.3 82.3

72

SHC 41.8 53.7 65.5 40.2 52.0 63.8 38.4 50.2 62.0 36.6 48.3 60.1 33.8 45.6 57.4

THC --- 109.9 109.9 --- 105.4 105.4 --- 100.6 100.6 --- 95.3 95.3 --- 87.8 87.8

76

SHC --- 43.9 56.2 --- 42.3 54.7 --- 40.6 52.8 --- 38.7 50.9 --- 36.1 48.3

THC 88.7 88.7 99.9 85.6 85.6 96.4 82.1 82.1 92.5 78.7 78.7 88.7 75.4 75.4 85.0

58

SHC 77.4 88.7 99.9 74.7 85.6 96.4 71.7 82.1 92.5 68.8 78.7 88.7 65.8 75.4 85.0

THC 90.7 90.7 97.2 87.0 87.0 95.3 83.0 83.0 93.1 78.9 78.9 90.6 75.3 75.3 86.4

62

SHC 70.7 84.0 97.2 68.8 82.1 95.3 66.9 80.0 93.1 64.7 77.6 90.6 61.7 74.0 86.4

THC 97.8 97.8 97.8 93.7 93.7 93.7 89.2 89.2 89.2 84.4 84.4 84.4 76.7 76.7 76.7

67

SHC 57.0 70.4 83.8 55.3 68.7 82.1 53.4 66.8 80.2 51.5 64.8 78.2 48.6 62.0 75.5

THC 105.7 105.7 105.7 101.3 101.3 101.3 96.5 96.5 96.5 91.5 91.5 91.5 86.2 86.2 86.2

72

SHC 43.0 56.5 70.0 41.4 54.9 68.3 39.6 53.0 66.5 37.8 51.2 64.5 35.8 49.2 62.5

THC --- 112.2 112.2 --- 107.6 107.6 --- 102.5 102.5 --- 97.0 97.0 --- --- ---

76

SHC --- 45.4 59.5 --- 43.8 57.8 --- 42.0 55.9 --- 40.2 54.0 --- --- ---

THC 92.0 92.0 103.7 88.7 88.7 99.9 85.1 85.1 95.9 81.2 81.2 91.5 76.0 76.0 85.7

58

SHC 80.3 92.0 103.7 77.4 88.7 99.9 74.3 85.1 95.9 70.9 81.2 91.5 66.4 76.0 85.7

THC 92.9 92.9 104.3 89.2 89.2 102.0 85.1 85.1 99.5 81.4 81.4 95.1 --- --- ---

62

SHC 74.9 89.6 104.3 72.9 87.4 102.0 70.7 85.1 99.5 67.6 81.4 95.1 --- --- ---

THC 99.6 99.6 99.6 95.3 95.3 95.3 90.8 90.8 90.8 86.0 86.0 86.0 79.1 79.1 81.7

67

SHC 59.7 74.7 89.8 58.0 73.0 88.0 56.1 71.1 86.1 54.2 69.1 84.1 51.7 66.7 81.7

THC 107.5 107.5 107.5 103.0 103.0 103.0 98.0 98.0 98.0 92.9 92.9 92.9 88.0 88.0 88.0

72

SHC 44.1 59.2 74.3 42.5 57.5 72.6 40.7 55.7 70.7 38.8 53.8 68.7 37.0 51.8 66.7

THC --- 114.0 114.0 --- 109.1 109.1 --- 103.9 103.9 --- 98.3 98.3 --- --- ---

76

SHC --- 46.9 62.4 --- 45.2 60.7 --- 43.4 58.8 --- 41.5 56.8 --- --- ---

THC 94.8 94.8 106.8 91.3 91.3 102.9 87.5 87.5 98.6 83.4 83.4 94.0 77.9 77.9 87.8

58

SHC 82.8 94.8 106.8 79.7 91.3 102.9 76.4 87.5 98.6 72.9 83.4 94.0 68.0 77.9 87.8

THC 94.8 94.8 110.9 91.4 91.4 106.8 87.6 87.6 102.4 83.5 83.5 97.6 79.3 79.3 92.7

62

SHC 78.8 94.8 110.9 75.9 91.4 106.8 72.8 87.6 102.4 69.3 83.5 97.6 65.9 79.3 92.7

THC 101.0 101.0 101.0 96.6 96.6 96.6 92.0 92.0 92.0 87.0 87.0 89.6 82.8 82.8 87.3

67

SHC 62.3 78.9 95.4 60.6 77.1 93.7 58.7 75.2 91.7 56.7 73.2 89.6 54.8 71.0 87.3

THC 108.9 108.9 108.9 104.3 104.3 104.3 99.2 99.2 99.2 93.8 93.8 93.8 86.1 86.1 86.1

72

SHC 45.2 61.7 78.3 43.5 60.0 76.6 41.7 58.2 74.7 39.7 56.2 72.6 37.1 53.6 70.0

THC --- 115.4 115.4 --- 110.4 110.4 --- 105.1 105.1 --- 99.3 99.3 --- 92.2 92.2

76

SHC --- 48.2 65.2 --- 46.5 63.4 --- 44.7 61.6 --- 42.7 59.5 --- 40.4 57.1

THC 97.1 97.1 109.5 93.5 93.5 105.4 89.6 89.6 101.0 85.3 85.3 96.1 --- --- ---

58

SHC 84.8 97.1 109.5 81.7 93.5 105.4 78.2 89.6 101.0 74.5 85.3 96.1 --- --- ---

THC 97.2 97.2 113.7 93.6 93.6 109.5 89.7 89.7 104.8 85.5 85.5 100.0 78.2 78.2 91.4

62

SHC 80.8 97.2 113.7 77.8 93.6 109.5 74.5 89.7 104.8 71.1 85.5 100.0 64.9 78.2 91.4

THC 102.2 102.2 102.2 97.7 97.7 99.0 93.1 93.1 97.0 88.1 88.1 94.8 --- --- ---

67

SHC 64.8 82.8 100.8 63.0 81.0 99.0 61.1 79.1 97.0 59.1 77.0 94.8 --- --- ---

THC 110.1 110.1 110.1 105.3 105.3 105.3 100.2 100.2 100.2 94.7 94.7 94.7 90.0 90.0 90.0

72

SHC 46.1 64.2 82.2 44.4 62.4 80.4 42.6 60.5 78.4 40.7 58.5 76.4 38.9 56.6 74.2

THC --- 116.5 116.5 --- 111.5 111.5 --- 106.0 106.0 --- 100.1 100.1 --- 90.8 90.8

76

SHC --- 49.4 67.8 --- 47.7 66.0 --- 45.9 64.1 --- 43.9 62.0 --- 40.8 58.8

569J

25

Page 26

PERFORMANCE DATA (cont.)

569J*08A -- 524J*12 COMBINATION RATINGS

AMBIENT TEMPERATURE

85 95 105 115 125

EA (db) EA (db) EA (db) EA (db) EA (db)

75 80 85 75 80 85 75 80 85 75 80 85 75 80 85

THC 93.7 93.7 105.5 90.3 90.3 101.8 86.7 86.7 97.7 82.7 82.7 93.2 --- --- ---

58

SHC 81.8 93.7 105.5 78.9 90.3 101.8 75.7 86.7 97.7 72.2 82.7 93.2 --- --- ---

THC 94.5 94.5 106.5 90.8 90.8 104.2 86.8 86.8 101.5 83.0 83.0 97.0 78.0 78.0 91.2

62

SHC 76.4 91.4 106.5 74.4 89.3 104.2 72.1 86.8 101.5 68.9 83.0 97.0 64.8 78.0 91.2

THC 101.3 101.3 101.3 97.0 97.0 97.0 92.4 92.4 92.4 87.7 87.7 87.7 80.4 80.4 83.5

67

EA (wb)

3000 Cfm

569J

EA (wb)

3500 Cfm

EA (wb)

4000 Cfm

EA (wb)

4500 Cfm

EA (wb)

5000 Cfm

--- Not operational

THC --- T otal Cooling Capacity, Gross (1,000 Btuh)

SHC --- Sensible Cooling Capacity, Gross (1,000 Btuh)

SHC 60.9 76.3 91.7 59.2 74.5 89.9 57.3 72.7 88.0 55.4 70.7 86.0 52.7 68.1 83.5

THC 109.4 109.4 109.4 104.9 104.9 104.9 100.0 100.0 100.0 94.7 94.7 94.7 87.1 87.1 87.1

72

SHC 44.9 60.4 75.8 43.3 58.7 74.1 41.5 56.9 72.2 39.6 54.9 70.2 36.9 52.2 67.6

THC --- 116.1 116.1 --- 111.3 111.3 --- 106.1 106.1 --- 100.4 100.4 --- --- ---

76

SHC --- 47.7 63.5 --- 46.0 61.8 --- 44.3 60.0 --- 42.3 57.9 --- --- ---

THC 97.4 97.4 109.7 93.9 93.9 105.8 90.0 90.0 101.4 85.9 85.9 96.8 79.7 79.7 89.8

58

SHC 85.0 97.4 109.7 82.0 93.9 105.8 78.6 90.0 101.4 75.0 85.9 96.8 69.6 79.7 89.8

THC 97.5 97.5 114.0 93.9 93.9 109.9 90.1 90.1 105.4 86.0 86.0 100.5 82.6 82.6 96.6

62

SHC 81.0 97.5 114.0 78.0 93.9 109.9 74.8 90.1 105.4 71.4 86.0 100.5 68.6 82.6 96.6

THC 103.2 103.2 103.2 98.8 98.8 98.8 94.2 94.2 95.8 89.1 89.1 93.7 82.7 82.7 91.4

67

SHC 64.5 82.1 99.6 62.8 80.3 97.8 60.9 78.4 95.8 58.9 76.3 93.7 56.5 73.9 91.4

THC 111.2 111.2 111.2 106.6 106.6 106.6 101.6 101.6 101.6 96.2 96.2 96.2 88.8 88.8 88.8

72

SHC 46.3 63.9 81.4 44.7 62.2 79.7 42.9 60.3 77.8 40.9 58.3 75.8 38.4 55.8 73.2

THC --- 117.9 117.9 --- 113.0 113.0 --- 107.6 107.6 --- 101.8 101.8 --- --- ---

76

SHC --- 49.5 67.4 --- 47.8 65.6 --- 46.0 63.7 --- 44.0 61.6 --- --- ---

THC 100.4 100.4 113.1 96.7 96.7 109.0 92.7 92.7 104.5 88.4 88.4 99.6 82.0 82.0 92.4

58

SHC 87.7 100.4 113.1 84.4 96.7 109.0 80.9 92.7 104.5 77.2 88.4 99.6 71.6 82.0 92.4

THC 100.4 100.4 117.4 96.8 96.8 113.2 92.8 92.8 108.5 88.4 88.4 103.4 81.7 81.7 95.5

62

SHC 83.4 100.4 117.4 80.4 96.8 113.2 77.1 92.8 108.5 73.5 88.4 103.4 67.8 81.7 95.5

THC 104.7 104.7 107.0 100.3 100.3 105.1 95.5 95.5 103.1 90.4 90.4 100.8 82.8 82.8 94.5

67

SHC 67.9 87.5 107.0 66.1 85.6 105.1 64.2 83.6 103.1 62.2 81.5 100.8 54.7 74.6 94.5

THC 112.7 112.7 112.7 108.0 108.0 108.0 102.8 102.8 102.8 97.3 97.3 97.3 89.9 89.9 89.9

72

SHC 47.7 67.2 86.7 46.0 65.5 84.9 44.1 63.6 83.0 42.2 61.6 80.9 39.7 59.0 78.4

THC --- 119.4 119.4 --- 114.3 114.3 --- 108.7 108.7 --- 103.0 103.0 --- 94.3 94.3

76

SHC --- 51.2 71.0 --- 49.5 69.2 --- 47.6 67.2 --- 45.6 65.1 --- 42.8 62.0

THC 102.7 102.7 115.7 98.9 98.9 111.5 94.8 94.8 106.8 90.3 90.3 101.7 85.1 85.1 95.9

58

SHC 89.7 102.7 115.7 86.3 98.9 111.5 82.7 94.8 106.8 78.9 90.3 101.7 74.3 85.1 95.9

THC 102.8 102.8 120.2 99.0 99.0 115.7 94.8 94.8 110.9 90.3 90.3 105.6 83.6 83.6 97.8

62

SHC 85.4 102.8 120.2 82.2 99.0 115.7 78.8 94.8 110.9 75.1 90.3 105.6 69.5 83.6 97.8

THC 105.9 105.9 113.8 101.5 101.5 111.7 96.7 96.7 109.5 91.6 91.6 106.8 84.0 84.0 100.0

67

SHC 71.0 92.4 113.8 69.2 90.5 111.7 67.2 88.3 109.5 65.0 85.9 106.8 57.0 76.0 100.0

THC 113.8 113.8 113.8 109.0 109.0 109.0 103.7 103.7 103.7 98.1 98.1 98.1 89.5 89.5 89.5

72

SHC 48.9 70.3 91.7 47.2 68.6 89.9 45.3 66.6 87.9 43.4 64.6 85.7 40.6 61.8 83.1

THC --- 120.4 120.4 --- 115.3 115.3 --- 109.6 109.6 --- 103.9 103.9 --- --- ---

76

SHC --- 52.7 74.3 --- 51.0 72.4 --- 49.1 70.3 --- 47.1 68.1 --- --- ---

THC 105.0 105.0 118.3 101.0 101.0 113.9 96.8 96.8 109.0 92.1 92.1 103.8 88.1 88.1 99.3

58

SHC 91.7 105.0 118.3 88.2 101.0 113.9 84.5 96.8 109.0 80.5 92.1 103.8 76.9 88.1 99.3

THC 105.1 105.1 122.9 101.1 101.1 118.2 96.8 96.8 113.2 92.2 92.2 107.8 85.5 85.5 100.0

62

SHC 87.3 105.1 122.9 84.0 101.1 118.2 80.4 96.8 113.2 76.6 92.2 107.8 71.1 85.5 100.0

THC 107.1 107.1 120.5 102.6 102.6 118.3 97.8 97.8 115.8 92.7 92.7 112.8 --- --- ---

67

SHC 74.1 97.3 120.5 72.2 95.3 118.3 70.1 93.0 115.8 67.8 90.3 112.8 --- --- ---

THC 114.9 114.9 114.9 109.9 109.9 109.9 104.6 104.6 104.6 98.9 98.9 98.9 --- --- ---

72

SHC 50.1 73.4 96.7 48.4 71.6 94.8 46.5 69.6 92.7 44.6 67.5 90.5 --- --- ---

THC --- 121.4 121.4 --- 116.2 116.2 --- 110.4 110.4 --- 104.7 104.7 --- --- ---

76

SHC --- 54.2 77.5 --- 52.4 75.6 --- 50.5 73.4 --- 48.5 71.1 --- --- ---

26

Page 27

PERFORMANCE DATA (cont.)

569J*12A -- 524J*12 COMBINATION RATINGS

AMBIENT TEMPERATURE

85 95 105 115 125

EA (db) EA (db) EA (db) EA (db) EA (db)

75 80 85 75 80 85 75 80 85 75 80 85 75 80 85

THC 110.5 110.5 121.5 106.2 106.2 117.1 101.6 101.6 112.4 96.9 96.9 107.5 92.5 92.5 102.9

58

SHC 99.4 110.5 121.5 95.3 106.2 117.1 90.9 101.6 112.4 86.3 96.9 107.5 82.0 92.5 102.9

THC 114.0 114.0 114.0 108.8 108.8 111.4 103.3 103.3 108.7 97.6 97.6 105.6 91.2 91.2 101.6

62

SHC 92.3 103.2 114.0 89.9 100.6 111.4 87.3 98.0 108.7 84.5 95.1 105.6 80.8 91.2 101.6

THC 123.2 123.2 123.2 117.4 117.4 117.4 111.5 111.5 111.5 105.1 105.1 105.1 --- --- ---

67

SHC 76.4 86.8 97.2 74.1 84.4 94.7 71.7 81.9 92.1 69.1 79.3 89.4 --- --- ---

EA (wb)

3000 Cfm

3500 Cfm

4000 Cfm

4500 Cfm

5000 Cfm

--- Not operational

THC --- T otal Cooling Capacity, Gross (1,000 Btuh)

SHC --- Sensible Cooling Capacity, Gross (1,000 Btuh)

THC 133.0 133.0 133.0 126.8 126.8 126.8 120.4 120.4 120.4 113.5 113.5 113.5 106.0 106.0 106.0

72

SHC 60.2 70.1 79.9 57.9 67.7 77.5 55.6 65.3 74.9 53.2 62.7 72.3 50.5 60.0 69.4

THC --- 140.7 140.7 --- 134.2 134.2 --- 127.6 127.6 --- 120.2 120.2 --- 112.3 112.3

76

SHC --- 56.4 65.8 --- 54.1 63.4 --- 51.8 61.0 --- 49.3 58.4 --- 46.6 55.6

THC 115.8 115.8 128.4 111.2 111.2 123.6 106.3 106.3 118.6 101.1 101.1 113.2 94.3 94.3 106.2

58

SHC 103.3 115.8 128.4 98.8 111.2 123.6 94.1 106.3 118.6 89.0 101.1 113.2 82.5 94.3 106.2

THC 117.4 117.4 124.5 112.0 112.0 121.6 106.6 106.6 118.3 101.1 101.1 113.2 93.0 93.0 104.8

62

SHC 99.5 112.0 124.5 96.9 109.2 121.6 93.8 106.0 118.3 89.0 101.1 113.2 81.2 93.0 104.8

THC 126.1 126.1 126.1 120.0 120.0 120.0 113.8 113.8 113.8 107.2 107.2 107.2 101.0 101.0 101.0

67

SHC 81.5 93.4 105.4 79.1 91.0 102.8 76.7 88.4 100.2 74.1 85.8 97.4 71.6 83.2 94.7

EA (wb)

THC 135.6 135.6 135.6 129.2 129.2 129.2 122.6 122.6 122.6 115.5 115.5 115.5 108.0 108.0 108.0

72

SHC 62.8 74.1 85.4 60.5 71.7 82.9 58.2 69.3 80.4 55.7 66.7 77.7 53.2 64.0 74.9

THC --- 143.2 143.2 --- 136.5 136.5 --- 129.7 129.7 --- 122.1 122.1 --- --- ---

76

SHC --- 58.4 69.2 --- 56.1 66.8 --- 53.8 64.4 --- 51.3 61.8 --- --- --THC 120.2 120.2 134.3 115.3 115.3 129.2 110.1 110.1 123.8 104.5 104.5 118.0 97.1 97.1 110.4

58

SHC 106.1 120.2 134.3 101.4 115.3 129.2 96.4 110.1 123.8 91.0 104.5 118.0 83.9 97.1 110.4

THC 120.5 120.5 133.7 115.3 115.3 129.2 110.2 110.2 123.9 104.6 104.6 118.1 97.0 97.0 110.3

62

SHC 105.6 119.7 133.7 101.4 115.3 129.2 96.5 110.2 123.9 91.1 104.6 118.1 83.8 97.0 110.3

THC 128.2 128.2 128.2 122.0 122.0 122.0 115.6 115.6 115.6 108.8 108.8 108.8 101.3 101.3 102.0

67

SHC 86.2 99.7 113.2 83.9 97.2 110.6 81.4 94.7 108.0 78.8 92.0 105.1 76.0 89.0 102.0

EA (wb)

THC 137.6 137.6 137.6 131.0 131.0 131.0 124.2 124.2 124.2 116.9 116.9 116.9 109.3 109.3 109.3

72

SHC 65.2 78.0 90.7 62.9 75.6 88.2 60.6 73.1 85.7 58.1 70.6 83.0 55.6 67.8 80.1

THC --- 145.0 145.0 --- 138.2 138.2 --- 131.2 131.2 --- --- --- --- --- ---

76

SHC --- 60.3 72.5 --- 58.1 70.1 --- 55.8 67.7 --- --- --- --- --- --THC 123.8 123.8 139.3 118.6 118.6 134.0 113.2 113.2 128.4 107.3 107.3 122.2 102.3 102.3 117.1

58

SHC 108.2 123.8 139.3 103.2 118.6 134.0 98.0 113.2 128.4 92.4 107.3 122.2 87.6 102.3 117.1

THC 123.9 123.9 139.4 118.7 118.7 134.1 113.3 113.3 128.4 107.4 107.4 122.3 101.8 101.8 116.5

62

SHC 108.3 123.9 139.4 103.3 118.7 134.1 98.1 113.3 128.4 92.5 107.4 122.3 87.1 101.8 116.5

THC 130.0 130.0 130.0 123.6 123.6 123.6 117.1 117.1 117.1 110.2 110.2 112.5 102.8 102.8 109.3

67

SHC 90.8 105.8 120.9 88.3 103.2 118.2 85.8 100.6 115.4 83.2 97.8 112.5 80.3 94.8 109.3

EA (wb)

THC 139.1 139.1 139.1 132.4 132.4 132.4 125.5 125.5 125.5 118.1 118.1 118.1 110.3 110.3 110.3

72

SHC 67.4 81.7 95.9 65.2 79.3 93.3 62.9 76.8 90.8 60.4 74.2 88.1 57.8 71.5 85.2

THC --- 146.4 146.4 --- 139.6 139.6 --- --- --- --- --- --- --- --- ---

76

SHC --- 62.2 75.7 --- 59.9 73.3 --- --- --- --- --- --- --- --- --THC 126.8 126.8 143.8 121.4 121.4 138.2 115.8 115.8 132.3 109.8 109.8 126.1 103.0 103.0 119.1

58

SHC 109.8 126.8 143.8 104.5 121.4 138.2 99.2 115.8 132.3 93.4 109.8 126.1 86.9 103.0 119.1

THC 126.9 126.9 143.9 121.4 121.4 138.2 115.9 115.9 132.4 109.8 109.8 126.2 103.1 103.1 119.2

62

SHC 109.8 126.9 143.9 104.6 121.4 138.2 99.3 115.9 132.4 93.5 109.8 126.2 87.0 103.1 119.2

THC 131.4 131.4 131.4 125.0 125.0 125.5 118.4 118.4 122.7 111.5 111.5 119.6 104.1 104.1 116.1

67

SHC 95.1 111.7 128.2 92.6 109.1 125.5 90.1 106.4 122.7 87.3 103.4 119.6 84.2 100.1 116.1

EA (wb)

THC 140.3 140.3 140.3 133.5 133.5 133.5 126.6 126.6 126.6 119.0 119.0 119.0 111.1 111.1 111.1

72

SHC 69.6 85.3 100.9 67.4 82.9 98.4 65.1 80.5 95.9 62.6 77.9 93.2 60.0 75.1 90.3

THC --- 147.6 147.6 --- --- --- --- --- --- --- --- --- --- --- ---

76

SHC --- 64.0 78.8 --- --- --- --- --- --- --- --- --- --- --- ---

569J

27

Page 28

PERFORMANCE DATA (cont.)

569J*12 A-- 524J*14 COMBINATION RATINGS

AMBIENT TEMPERATURE

85 95 105 115 125

EA (db) EA (db) EA (db) EA (db) EA (db)

75 80 85 75 80 85 75 80 85 75 80 85 75 80 85

THC 119.7 119.7 132.9 115.2 115.2 128.3 110.5 110.5 123.4 105.3 105.3 118.0 97.9 97.9 110.4

58

SHC 106.5 119.7 132.9 102.2 115.2 128.3 97.6 110.5 123.4 92.6 105.3 118.0 85.5 97.9 110.4

THC 121.2 121.2 130.3 116.0 116.0 127.0 110.8 110.8 122.9 105.4 105.4 118.1 98.7 98.7 111.1

62

SHC 104.0 117.2 130.3 101.0 114.0 127.0 97.2 110.1 122.9 92.7 105.4 118.1 86.2 98.7 111.1

THC 130.0 130.0 130.0 124.4 124.4 124.4 118.5 118.5 118.5 112.0 112.0 112.0 104.9 104.9 104.9

67

EA (wb)

3750 Cfm

569J

EA (wb)

4300 Cfm

EA (wb)

5000 Cfm

EA (wb)

5700 Cfm

EA (wb)

6250 Cfm

--- Not operational

THC --- T otal Cooling Capacity, Gross (1,000 Btuh)

SHC --- Sensible Cooling Capacity, Gross (1,000 Btuh)

SHC 85.3 97.8 110.3 83.1 95.5 108.0 80.8 93.1 105.5 78.3 90.5 102.7 75.6 87.7 99.8

THC 139.4 139.4 139.4 133.7 133.7 133.7 127.7 127.7 127.7 120.9 120.9 120.9 113.5 113.5 113.5

72

SHC 65.3 77.1 88.8 63.3 75.0 86.7 61.2 72.8 84.4 58.9 70.4 81.8 56.3 67.7 79.0

THC --- --- --- --- --- --- --- --- --- --- --- --- --- --- ---

76

SHC --- --- --- --- --- --- --- --- --- --- --- --- --- --- ---

THC 124.1 124.1 138.8 119.4 119.4 134.1 114.5 114.5 128.9 109.0 109.0 123.2 100.5 100.5 114.4

58

SHC 109.2 124.1 138.8 104.8 119.4 134.1 100.0 114.5 128.9 94.8 109.0 123.2 86.6 100.5 114.4

THC 124.5 124.5 138.3 119.5 119.5 134.1 114.5 114.5 128.9 109.1 109.1 123.3 101.0 101.0 114.9

62

SHC 108.7 123.5 138.3 104.9 119.5 134.1 100.1 114.5 128.9 94.9 109.1 123.3 87.1 101.0 114.9

THC 132.1 132.1 132.1 126.4 126.4 126.4 120.4 120.4 121.1 113.8 113.8 115.6 106.5 106.5 109.5

67

SHC 90.7 104.9 119.0 88.5 102.5 116.6 86.1 100.1 114.1 83.6 97.4 111.2 80.7 94.5 108.1

THC 141.3 141.3 141.3 135.5 135.5 135.5 129.5 129.5 129.5 122.6 122.6 122.6 114.3 114.3 114.3

72

SHC 68.1 81.4 94.7 66.1 79.3 92.6 64.0 77.1 90.3 61.7 74.7 87.7 57.6 69.7 81.7

THC --- --- --- --- --- --- --- --- --- --- --- --- --- --- ---

76

SHC --- --- --- --- --- --- --- --- --- --- --- --- --- --- ---

THC 128.9 128.9 145.7 124.1 124.1 140.7 118.9 118.9 135.3 113.2 113.2 129.3 106.8 106.8 122.7

58

SHC 112.1 128.9 145.7 107.5 124.1 140.7 102.5 118.9 135.3 97.0 113.2 129.3 90.9 106.8 122.7

THC 129.0 129.0 145.8 124.2 124.2 140.7 119.0 119.0 135.3 113.3 113.3 129.4 106.8 106.8 122.7

62

SHC 112.2 129.0 145.8 107.6 124.2 140.7 102.6 119.0 135.3 97.1 113.3 129.4 91.0 106.8 122.7

THC 134.4 134.4 134.4 128.6 128.6 128.6 122.5 122.5 124.7 115.8 115.8 121.8 108.4 108.4 118.5

67

SHC 97.3 113.6 129.8 95.1 111.2 127.4 92.7 108.7 124.7 90.1 105.9 121.8 87.0 102.8 118.5

THC 143.4 143.4 143.4 137.5 137.5 137.5 131.3 131.3 131.3 124.3 124.3 124.3 --- --- ---

72

SHC 71.6 86.8 102.0 69.6 84.7 99.9 67.5 82.6 97.6 65.2 80.1 95.0 --- --- ---

THC --- --- --- --- --- --- --- --- --- --- --- --- --- --- ---

76

SHC --- --- --- --- --- --- --- --- --- --- --- --- --- --- ---

THC 132.3 132.3 151.0 127.3 127.3 145.8 122.0 122.0 140.3 116.1 116.1 134.1 109.5 109.5 127.2

58

SHC 113.6 132.3 151.0 108.8 127.3 145.8 103.7 122.0 140.3 98.1 116.1 134.1 91.8 109.5 127.2

THC 132.4 132.4 151.1 127.4 127.4 145.9 122.1 122.1 140.3 116.2 116.2 134.2 109.5 109.5 127.3

62

SHC 113.7 132.4 151.1 108.9 127.4 145.9 103.8 122.1 140.3 98.1 116.2 134.2 91.8 109.5 127.3

THC 136.0 136.0 141.8 130.2 130.2 137.7 124.1 124.1 134.2 117.4 117.4 130.6 110.3 110.3 125.5

67

SHC 103.2 121.5 139.8 100.8 119.0 137.2 98.1 116.1 134.2 94.9 112.7 130.6 90.2 107.8 125.5

THC 144.7 144.7 144.7 138.8 138.8 138.8 132.0 132.0 140.6 126.0 126.0 133.0 --- --- ---

72

SHC 74.8 92.0 109.1 72.8 89.9 107.0 71.4 88.0 81.8 68.7 85.2 101.8 --- --- ---

THC --- --- --- --- --- --- --- --- --- --- --- --- --- --- ---

76

SHC --- --- --- --- --- --- --- --- --- --- --- --- --- --- ---

THC 134.9 134.9 155.1 129.8 129.8 149.8 124.4 124.4 144.2 118.3 118.3 137.8 111.6 111.6 130.8

58

SHC 114.7 134.9 155.1 109.9 129.8 149.8 104.7 124.4 144.2 98.9 118.3 137.8 92.5 111.6 130.8

THC 135.0 135.0 155.2 129.9 129.9 149.9 124.5 124.5 144.2 118.4 118.4 137.9 111.7 111.7 130.9

62

SHC 114.8 135.0 155.2 109.9 129.9 149.9 104.7 124.5 144.2 98.9 118.4 137.9 92.5 111.7 130.9

THC 137.2 137.2 147.6 131.4 131.4 144.9 125.3 125.3 141.6 118.7 118.7 137.5 111.8 111.8 131.0

67

SHC 107.8 127.7 147.6 105.3 125.1 144.9 102.4 122.0 141.6 98.6 118.1 137.5 92.7 111.8 131.0

THC 145.7 145.7 145.7 139.9 139.9 139.9 --- --- --- --- --- --- --- --- ---

72

SHC 77.3 96.0 114.7 75.4 94.0 112.6 --- --- --- --- --- --- --- --- ---

THC --- --- --- --- --- --- --- --- --- --- --- --- --- --- ---

76

SHC --- --- --- --- --- --- --- --- --- --- --- --- --- --- ---

28

Page 29

PERFORMANCE DATA (cont.)

569J*12D -- 524J*12 COMBINATION RATINGS

AMBIENT TEMPERATURE

85 95 105 115 125

EA (db) EA (db) EA (db) EA (db) EA (db)

75 80 85 75 80 85 75 80 85 75 80 85 75 80 85

THC 111.6 111.6 125.3 107.3 107.3 120.5 102.6 102.6 115.2 97.3 97.3 109.4 91.7 91.7 103.0

58

SHC 97.9 111.6 125.3 94.1 107.3 120.5 89.9 102.6 115.2 85.3 97.3 109.4 80.3 91.7 103.0

THC 115.9 115.9 119.8 110.5 110.5 117.1 104.8 104.8 114.2 98.3 98.3 110.7 92.4 92.4 106.2

62

SHC 88.6 104.2 119.8 86.0 101.5 117.1 83.2 98.7 114.2 79.9 95.3 110.7 76.2 91.2 106.2

THC 125.6 125.6 125.6 119.9 119.9 119.9 113.7 113.7 113.7 107.1 107.1 107.1 99.6 99.6 99.6

67

SHC 71.9 87.6 103.3 69.4 85.1 100.8 66.8 82.5 98.1 63.9 79.6 95.3 60.8 76.5 92.2

EA (wb)

3000 Cfm

3500 Cfm

4000 Cfm

4500 Cfm

5000 Cfm

--- Not operational

THC --- T otal Cooling Capacity, Gross (1,000 Btuh)

SHC --- Sensible Cooling Capacity, Gross (1,000 Btuh)

THC 135.6 135.6 135.6 129.6 129.6 129.6 123.1 123.1 123.1 116.1 116.1 116.1 108.4 108.4 108.4

72

SHC 55.0 70.8 86.6 52.6 68.4 84.2 50.1 65.9 81.7 47.4 63.2 79.0 44.5 60.3 76.1

THC --- 143.6 143.6 --- 137.4 137.4 --- 130.7 130.7 --- 123.3 123.3 --- 115.2 115.2

76

SHC --- 57.3 73.6 --- 55.1 71.4 --- 52.7 68.9 --- 50.1 66.2 --- 47.4 63.4

THC 117.1 117.1 131.6 112.5 112.5 126.4 107.5 107.5 120.8 102.0 102.0 114.7 95.7 95.7 107.7

58

SHC 102.6 117.1 131.6 98.6 112.5 126.4 94.2 107.5 120.8 89.4 102.0 114.7 83.8 95.7 107.7

THC 119.3 119.3 130.8 113.8 113.8 127.8 108.1 108.1 123.7 102.1 102.1 119.1 95.7 95.7 111.7

62

SHC 95.1 112.9 130.8 92.3 110.0 127.8 88.9 106.3 123.7 85.1 102.1 119.1 79.7 95.7 111.7