Page 1

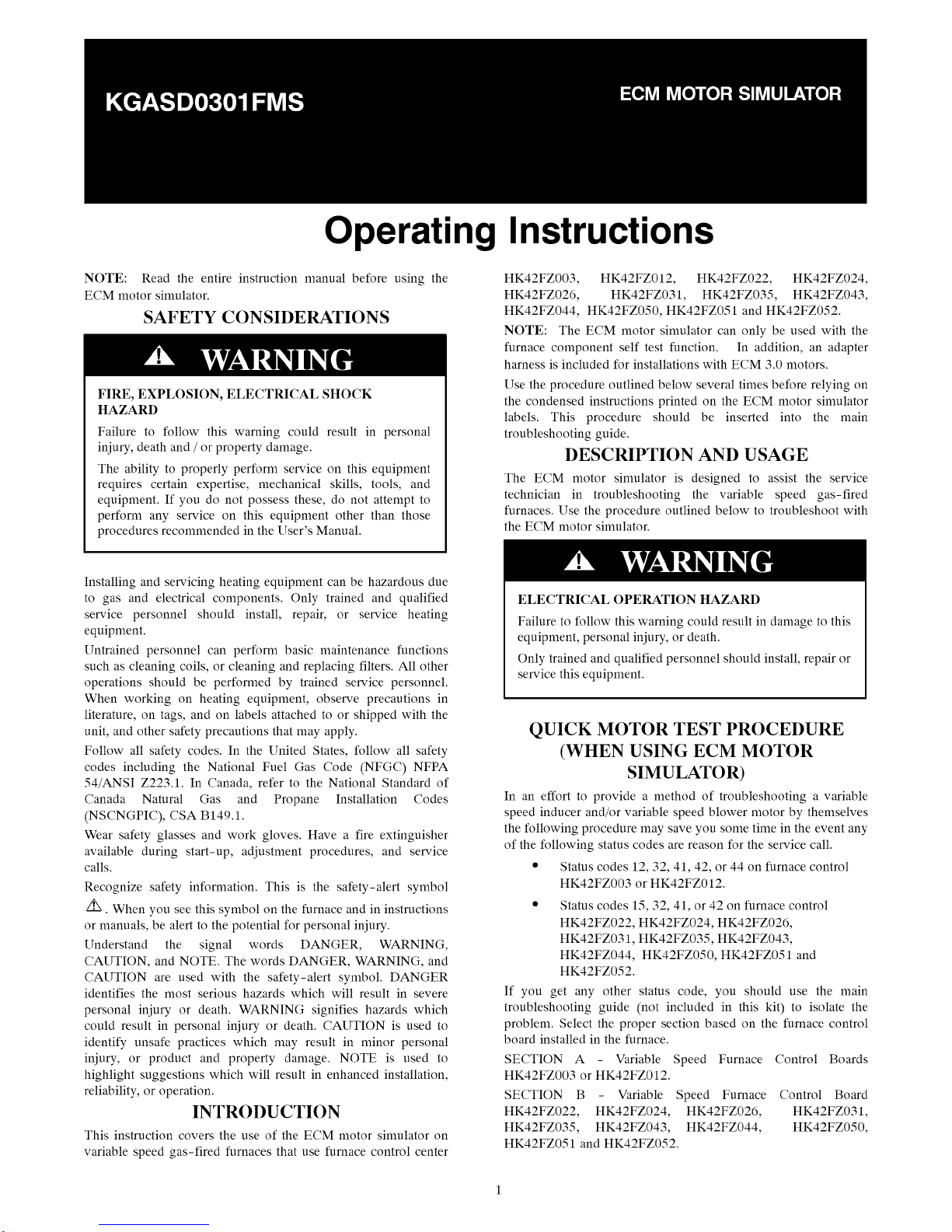

Operating Instructions

NOTE: Read the entire instruction manual before using the

ECM motor simulator.

SAFETY CONSIDERATIONS

FIRE, EXPLOSION, ELECTRICAL SHOCK

HAZARD

Failure to follow this warning could result in personal

injury, death and / or property damage.

The ability to properly perform service on this equipment

requires certain expertise, mechanical skills, tools, and

equipment. If you do not possess these, do not attempt to

perform any service on this equipment other than those

procedures recommended in the User's Manual.

Installing and servicing heating equipment can be hazardous due

to gas and electrical components. Only trained and qualified

service personnel should install, repair, or service heating

equipment.

Untrained personnel can perform basic maintenance functions

such as cleaning coils, or cleaning and replacing filters. All other

operations should be performed by trained service personnel.

When working on heating equipment, observe precautions in

literature, on tags, and on labels attached to or shipped with the

unit, and other safety precautions that may apply.

Follow all safety codes. In the United States, follow all safety

codes including the National Fuel Gas Code (NFGC) NFPA

54/ANSI Z223.1. In Canada, refer to the National Standard of

Canada Natural Gas and Propane Installation Codes

(NSCNGPIC), CSA B149.1.

Wear safety glasses and work gloves. Have a fire extinguisher

available during start-up, adjustment procedures, and service

calls.

Recognize safety information. This is the safety-alert symbol

AX. When you see this symbol on the furnace and in instructions

or manuals, be alert to the potential for personal injury.

Understand the signal words DANGER, WARNING,

CAUTION, and NOTE. The words DANGER, WARNING, and

CAUTION are used with the safety-alert symbol. DANGER

identifies the most serious hazards which will result in severe

personal injury or death. WARNING signifies hazards which

could result in personal injury or death. CAUTION is used to

identify unsafe practices which may result in minor personal

injury, or product and property damage. NOTE is used to

highlight suggestions which will result in enhanced installation,

reliability, or operation.

INTRODUCTION

This instruction covers the use of the ECM motor simulator on

variable speed gas-fired furnaces that use furnace control center

HK42FZ003, HK42FZ012, HK42FZ022, HK42FZ024,

HK42FZ026, HK42FZ031, HK42FZ035, HK42FZ043,

HK42FZ044, HK42FZ050, HK42FZ051 and HK42FZ052.

NOTE: The ECM motor simulator can only be used with the

furnace component self test function. In addition, an adapter

harness is included for installations with ECM 3.0 motors.

Use the procedure outlined below several times before relying on

the condensed instructions printed on the ECM motor simulator

labels. This procedure should be inserted into the main

troubleshooting guide.

DESCRIPTION AND USAGE

The ECM motor simulator is designed to assist the service

technician in troubleshooting the variable speed gas-fired

furnaces. Use the procedure outlined below to troubleshoot with

the ECM motor simulator.

ELECTRICAL OPERATION HAZARD

Failure to follow this warning could result in damage to this

equipment, personal injury, or death.

Only trained and qualified personnel should install, repair or

service this equipment.

QUICK MOTOR TEST PROCEDURE

(WHEN USING ECM MOTOR

SIMULATOR)

In an effort to provide a method of troubleshooting a variable

speed inducer and/or variable speed blower motor by themselves

the following procedure may save you some time in the event any

of the following status codes are reason for the service call.

• Status codes 12, 32, 41, 42, or 44 on furnace control

HK42FZ003 or HK42FZ012.

• Status codes 15, 32, 41, or 42 on furnace control

HK42FZ022, HK42FZ024, HK42FZ026,

HK42FZ031, HK42FZ035, HK42FZ043,

HK42FZ044, HK42FZ050, HK42FZ051 and

HK42FZ052.

If you get any other status code, you should use the main

troubleshooting guide (not included in this kit) to isolate the

problem. Select the proper section based on the furnace control

board installed in the furnace.

SECTION A Variable Speed Furnace Control Boards

HK42FZ003 or HK42FZ012.

SECTION B - Variable Speed Furnace Control Board

HK42FZ022, HK42FZ024, HK42FZ026, HK42FZ031,

HK42FZ035, HK42FZ043, HK42FZ044, HK42FZ050,

HK42FZ051 and HK42FZ052.

Page 2

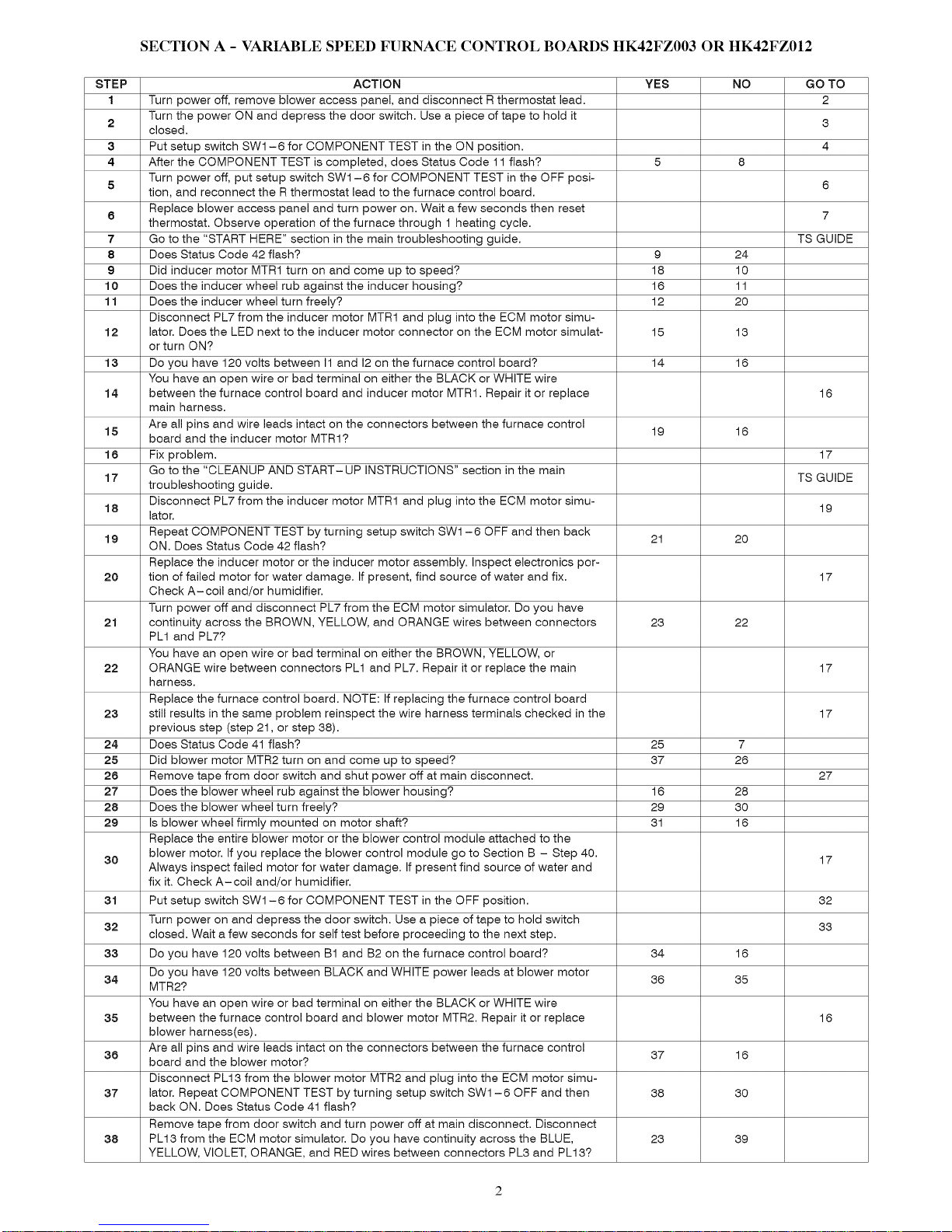

SECTIONA - VARIABLESPEEDFURNACECONTROLBOARDSHK42FZ003ORHK42FZ012

STEP ACTION YES NO GO TO

1 Turn power off, remove blower access panel, and disconnect R thermostat lead. 2

2 Turn the power ON and depress the door switch. Use a piece of tape to hold it 3

closed.

3 Put setup switch SW1-6 for COMPONENT TEST in the ON position. 4

4 After the COMPONENT TEST is completed, does Status Code 11 flash? 5 8

5 Turn power off, put setup switch SW1-6 for COMPONENT TEST in the OFF posi- 6

tion, and reconnect the Rthermostat lead to the furnace control board.

Replace blower access panel and turn power on. Wait a few seconds then reset

6 thermostat. Observe operation of the furnace through 1 heating cycle. 7

7 Go to the "START HERE" section in the main troubleshooting guide. TS GUIDE

8 Does Status Code 42 flash? 9 24

9 Did inducer motor MTR1 turn on and come up to speed? 18 10

10 Does the inducer wheel rub against the inducer housing? 16 11

11 Does the inducer wheel turn freely? 12 20

Disconnect PL7 from the inducer motor MTR1 and plug into the ECM motor simu-

12 lator. Does the LED next to the inducer motor connector on the ECM motor simulat- 15 13

or turn ON?

13 Do you have 120 volts between I1 and 12on the furnace control board? 14 16

You have an open wire or bad terminal on either the BLACK or WHITE wire

14 between the furnace control board and inducer motor MTR1. Repair it or replace 16

main harness.

15 Are all pins and wire leads intact on the connectors between the furnace control 19 16

board and the inducer motor MTRI?

16 Fix problem. 17

Go to the "CLEANUP AND START-UP INSTRUCTIONS" section in the main

17 TS GUIDE

troubleshooting guide.

18 Disconnect PL7 from the inducer motor MTR1 and plug into the ECM motor simu- 19

lator.

Repeat COMPONENT TEST by turning setup switch SW1-6 OFF and then back

19 ON. Does Status Code 42 flash? 21 20

Replace the inducer motor or the inducer motor assembly. Inspect electronics por-

20 tion of failed motor for water damage. If present, find source of water and fix. 17

Check A-coil and/or humidifier.

Turn power off and disconnect PL7 from the ECM motor simulator. Do you have

21 continuity across the BROWN, YELLOW, and ORANGE wires between connectors 23 22

PL1 and PL7?

You have an open wire or bad terminal on either the BROWN, YELLOW, or

22 ORANGE wire between connectors PL1 and PL7. Repair it or replace the main 17

harness.

Replace the furnace control board. NOTE: tf replacing the furnace control board

23 still results in the same problem reinspect the wire harness terminals checked in the 17

previous step (step 21, or step 38).

24 Does Status Code 41 flash? 25 7

25 Did blower motor MTR2 turn on and come up to speed? 37 26

26 Remove tape from door switch and shut power off at main disconnect. 27

27 Does the blower wheel rub against the blower housing? 16 28

28 Does the blower wheel turn freely? 29 30

29 Isblower wheel firmly mounted on motor shaft? 31 16

Replace the entire blower motor or the blower control module attached to the

30 blower motor. If you replace the blower control module go to Section B - Step 40. 17

Always inspect failed motor for water damage. If present find source of water and

fix it. Check A-coil and/or humidifier.

31 Put setup switch SW1-6 for COMPONENT TEST in the OFF position. 32

32 Turn power on and depress the door switch. Use a piece of tape to hold switch 33

closed. Wait a few seconds for self test before proceeding to the next step.

33 Do you have 120 volts between B1 and B2 on the furnace control board? 34 16

34 Do you have 120 volts between BLACK and WHITE power leads at blower motor 36 35

MTR2?

You have an open wire or bad terminal on either the BLACK or WHITE wire

35 between the furnace control board and blower motor MTR2. Repair it or replace 16

blower harness(es).

36 Are all pins and wire leads intact on the connectors between the furnace control 37 16

board and the blower motor?

Disconnect PL13 from the blower motor MTR2 and plug into the ECM motor simu-

37 lator. Repeat COMPONENT TEST by turning setup switch SW1-6 OFF and then 38 30

back ON. Does Status Code 41 flash?

Remove tape from door switch and turn power off at main disconnect. Disconnect

38 PL13 from the ECM motor simulator. Do you have continuity across the BLUE, 23 39

YELLOW, VIOLET, ORANGE, and RED wires between connectors PL3 and PL13?

Page 3

SECTION A - VARIABLE SPEED FURNACE CONTROL BOARDS HK42FZ003 OR HK42FZ012 (CON'T)

STEP ACTION YES NO GO TO

You have an open wire or bad terminal on either the BLUE, YELLOW, VIOLET,

39 ORANGE, or RED wire between connectors PL3 and PL13. Repair it or replace 17

blower harness(es).

SECTION B - VARIABLE SPEED FURNACE CONTROL BOARDS HK42FZ022, HK42FZ024 HK42FZ026,

HK42FZ031, HK42FZ035, HK42FZ043, HK42FZ044, HK42FZ050, HK42FZ051, OR HK42FZ052

STEP ACTION YES NO GO TO

1 Turn power off, remove blower access panel, and disconnect User Interface ABCD 2

Connector (if used) or the Rthermostat lead (if used).

2 Turn the power on and depress the door switch. Use a piece of tape to hold it 3

closed.

3 Put setup switch SW1-6 for COMPONENT TEST in the ON position. 4

4 After the COMPONENT TEST is completed, does Status Code 11 flash? 5 8

Turn power off, put setup switch SW1-6 for COMPONENT TEST in the OFF posi-

5 tion, and reconnect the User Interface ABCD Connector (if used) or the R thermo- 6

star lead (if used) to the furnace control board.

Replace blower access panel and turn power on. Wait a few seconds then reset

6 thermostat. Observe operation of the furnace through 1 heating cycle. 7

7 Go to the "START HERE" section in the main troubleshooting guide. TS GUIDE

Does Status Code 42 flash?

8 Note: [f you get this status code on a furnace that does not have a variable speed 9 24

inducer motor then the model plug is incorrect. Reference the model plug chart on

the wiring schematic for the correct part number.

9 Did inducer motor [DM turn on and come up to speed? 18 10

10 Does the inducer wheel rub against the inducer housing? 16 11

11 Does the inducer wheel turn freely? 12 20

Disconnect PL11 from the inducer motor [DM and plug into the ECM motor simulat-

12 or. Does the LED next to the inducer motor connector on the ECM motor simulator 15 13

turn ON?

13 Do you have 120 volts between PL2-4 and L2 on the furnace control board? 14 16

You have an open wire or bad terminal on either the BLACK or WHITE wire

14 between the furnace control board and inducer motor [DM. Repair it or replace 16

main harness.

15 Are all pins and wire leads intact on the connectors between the furnace control 19 16

board and the inducer motor [DM?

16 Fix problem. 17

Go to the "CLEANUP AND START-UP INSTRUCTIONS" section in the main

17 TS GUIDE

troubleshooting guide.

18 Disconnect PL11 from the inducer motor [DM and plug into the ECM motor simulat- 19

or.

Repeat COMPONENT TEST by turning setup switch SW1-6 OFF and then back

19 ON. Does Status Code 42 flash? 21 20

Replace the inducer motor or the inducer motor assembly. Inspect electronics por-

20 tion of failed motor for water damage. [f present, find source of water and fix. 17

Check A-coil and/or humidifier.

Turn power off and disconnect PL11 from the ECM motor simulator. Do you have

21 continuity across the BROWN, YELLOW, and ORANGE wires between connectors 23 22

PL1 and PLll?

You have an open wire or bad terminal on either the BROWN,

22 YELLOW, or ORANGE wire between connectors PL1 and 17

PL11. Repair it or replace the main harness.

Replace the furnace control board. NOTE: If replacing the furnace control board

23 still results in the same problem, reinspect the wire harness terminals checked in 17

the previous step (step 21, or step 38).

24 Does Status Code 41 flash? 25 7

25 Did blower motor BLWM turn on and come up to speed? 37 26

26 Remove tape from door switch and shut power off at main disconnect. 27

27 Does the blower wheel rub against the blower housing? 16 28

28 Does the blower wheel turn freely? 29 30

29 [sblower wheel firmly mounted on motor shaft? 31 16

Replace the entire blower motor or the blower control module attached to the

blower motor. [f you replace the blower control module go to step 40. Always in-

30 spect failed motor for water damage. [f present find source of water and fix it. 17

Check A-coil and/or humidifier.

31 Put setup switch SW1-6 for COMPONENT TEST in the OFF position. 32

Page 4

SECTION B - VARIABLE SPEED FURNACE CONTROL BOARDS HK42FZ022, HK42FZ024 HK42FZ026,

HK42FZ031, HK42FZ035, HK42FZ043, HK42FZ044, HK42FZ050, HK42FZ051, OR HK42FZ052 (CON'T)

STEP ACTION YES NO GO TO

Turn power on and depress the door switch. Use a piece of tape to hold switch

32

closed. Put setup switch SW1-6 for COMPONENT TEST inthe OFF position. Wait 33

a few seconds for self test before proceeding to the next step.

33 Do you have 120 volts between L1 and L2 on the furnace control board? 34 16

34 Do you have 120 volts between BLACK and WHITE power leads at blower motor 36 35

BLWM?

You have an open wire or bad terminal on either the BLACK or WHITE wire

35 between the furnace control board and blower motor BLWM. Repair it or replace 16

blower harness(es).

36 Are all pins and wire leads intact on the connectors between the furnace control 37 16

board and the blower motor?

Disconnect PL13 from the blower motor BLWM and plug into the ECM motor simu-

37 lator. Use the adapter harness for installations with ECM 3.0 blower motors. Repeat 38 30

COMPONENT TEST by turning setup switch SW1-6 OFF and then back ON. Does

Status Code 41 flash?

Remove tape from door switch and turn power off at main dis-

38 connect. Disconnect PL13 from the ECM motor simulator or adapter harness (if 23 39

used). Do you have continuity across the BLUE, YELLOW, GREEN, and RED wires

between connectors PL3 and PL13?

You have an open wire or bad terminal on either the BLUE,

39 YELLOW, GREEN, or RED wire between connectors PL3 and 17

PL13. Repair it or replace blower harness.

ELECTRICAL OPERATION HAZARD

Failure to follow this warning could result in personal

injury or death.

Wait at least five minutes after disconnecting line voltage

from equipment before opening blower motor to prevent

electric shock.

STEP GO TO

40 41

Remove tape from door switch and turn power off at main disconnect.

ACTION

YES NO

Disconnect both multi-pin connectors from blower control module attached to the

41 42

blower motor. Be sure to depress release latches on connectors or they may get

damaged.

42 43

Remove control box assembly from blower shelf and position out of the way.

43 44

Remove blower assembly from furnace.

Remove two ¼-in. hex head bolts from blower control module attached to blower

44 45

motor.

Carefully lift blower control module off blower motor. Depress latch on internal con-

45 46

nector to disconnect blower control module from motor portion of blower motor.

DO NOT PULL ON WIRES. GRIP PLUG ONLY.

When blower control module is completely detached from blower motor, verify with

standard ohmmeter that the resistance from each motor lead in motor plug to un-

painted motor end plate is greater than lOOk ohms. Then verify motor windings are

46

not shorted or open by measuring resistance between each combination of pins in

47

motor plug (there are three different combinations, pin 1-2, pin 2-3, and pin

1-3). Resistance should be approximately equal across each combination of pins.

47

Did the motor pass the resistance check?

48

Does blower wheel turn freely with blower control module removed?

Replace blower control module. Inspect failed blower control module for water

49 17

damage. If present, find source of water and fix. Check A-coil and/or humidifier.

48 50

49 50

Replace entire blower motor including blower control module. Inspect blower con-

50 17

trol module for water damage. If present, find source of water and fix. Check A-

coil and/or humidifier.

Copyright 2012 CAC / BDP • 7310 W. Morris St. • Indianapolis, IN 46231 Printed in U.S.A. Edition Date: 02/12 Catalo_l No: IIKKGASD0301FMSO03

Manufacturer reserve8 the right to change, at any time, specification8 and design8 without notice and without obligations. Replaces: IIKKGASD030IFMS002

i

4

Loading...

Loading...