Page 1

installation and

start-up instructions

THERMIDISTAT™ CONTROL

TSTAT

Cancels: II TSTAT-0-16 II TSTAT-0-20

5-98

NOTE: Read the entire instruction manual before starting the

installation.

This symbol → indicates a change since the last issue.

INDEX

Page

SAFETY CONSIDERATIONS.....................................................1

INTRODUCTION..........................................................................1

INSTALLATION CONSIDERATIONS.......................................1

INSTALLATION........................................................................1-7

Thermidistat Control Location..............................................1-2

Set DIP Switches......................................................................2

Install Thermidistat Control..................................................2-3

Set Thermidistat Control Configuration ...............................3-6

System Start-Up and Checkout.............................................6-7

Final Settings ............................................................................7

HUMIDITY CONTROL FEATURES.....................................7-10

Humidification.......................................................................7-8

Dehumidification ...................................................................8-9

Vacation...............................................................................9-10

OPERATIONAL INFORMATION........................................10-19

WIRING DIAGRAMS ...........................................................11-19

THERMIDISTAT CONTROL TROUBLESHOOTING............19

SAFETY CONSIDERATIONS

Read and follow manufacturer instructions carefully. Follow all

local electrical codes during installation. All wiring must conform

to local and national electrical codes. Improper wiring or installation may damage Thermidistat Control.

Recognize safety information. This is the safety-alert symbol

When you see this symbol on the equipment and in the instruction

manual, be alert to the potential for personal injury.

Understand the signal words DANGER, WARNING, and CAUTION. These words are used with the safety-alert symbol. DANGER identifies the most serious hazards which will result in severe

personal injury or death. WARNING signifies a hazard which

could result in personal injury or death. CAUTION is used to

identify unsafe practices which would result in minor personal

injury or product and property damage.

INSTALLATION CONSIDERATIONS

A. Power

Note that this control does not require batteries and is not "power

stealing." It does require 24vac (R and C terminals) of the

low-voltage transformer to be connected to it for proper operation.

It will not operate without these 2 connections.

B. Models

There is a single programmable/non-programmable model for all

applications. It can be configured for AC or HP, 1- or 2-speed

compressor, and for dual fuel installations, allowing it to be used

in place of all Bryant thermostats.

C. Humidify Equipment and Connections

The humidify output connects directly to 24vac operated humidifiers. No other connection or interlock is required. Any of several

installer-selectable operating modes are available.

D. Dehumidify Equipment and Connections

The dehumidify output connects to the dehumidify input on

variable-speed furnaces and fan coils. Additional dehumidification

is done by controlling the compressor. A variety of operating

modes are available.

E. Outdoor Temperature Sensor

→

Optimum performance is obtained when an outdoor temperature

sensor is used with the Thermidistat Control. Plan installation so

that 2 wires can be run from Thermidistat Control to an outdoor

location, preferably on the north side of the house or refer to

Installation Instructions included with the outdoor temperature

.

sensor for simplified connection. Sensor can be mounted to

outdoor unit and existing control wires may be used for its

connection. Details are provided in sensor instructions.

®

INTRODUCTION

Bryant’s 7-day programmable Thermidistat Control is a wallmounted, low-voltage control which combines temperature and

humidity control in a single attractive unit. An extension of

Bryant’s proven line of thermostats, it provides separate set points

for heating and cooling, and now adds humidification and dehumidification. Different heating and cooling set points and times are

programmable for 4 periods per day and 7 days per week. The

Thermidistat Control can also be field-configured as a nonprogrammable thermostat. When operating in the nonprogrammable configuration it will still have both temperature and

humidity control. Humidify and dehumidify outputs provide direct

control of humidity. Batteries are not used. During power loss an

internal memory stores programs and settings for unlimited time,

and the clock continues to run for at least 8 hr.

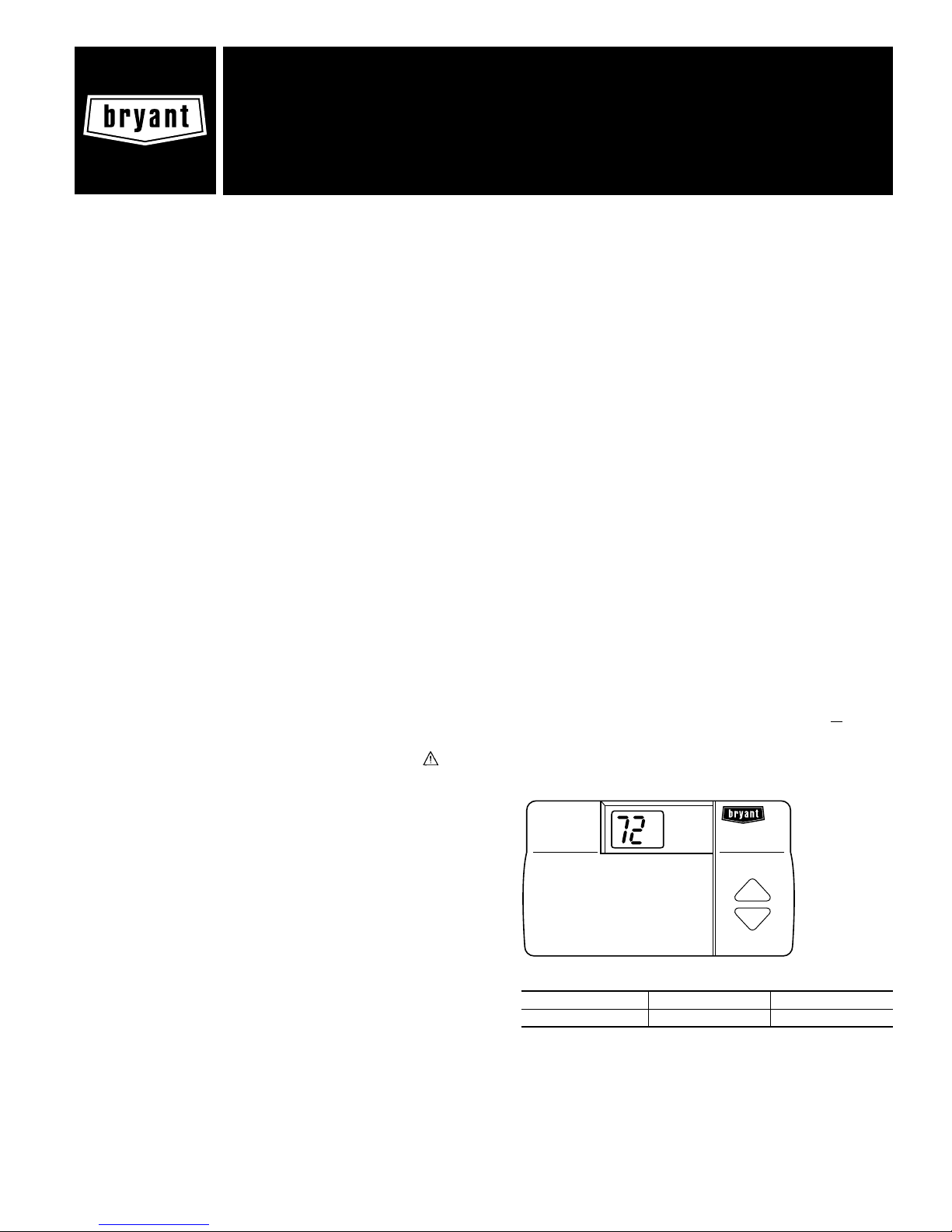

A96373

HEIGHT (IN.) WIDTH (IN.) DEPTH (IN.)

4-1/4 7-1/2 1-3/8

Fig. 1—Thermidistat Control

INSTALLATION

I. THERMIDISTAT CONTROL LOCATION

Thermidistat Control should be mounted:

• Approximately 5 ft (1.5m) from floor.

• Close to or in a frequently used room, preferably on an inside

partitioning wall.

—1—

Page 2

• On a section of wall without pipes or duct work.

Thermidistat Control should NOT be mounted:

• Closeto a window, on an outside wall, or next to a door leading

to the outside.

• Exposed to direct light and heat from a lamp, sun, fireplace, or

other temperature-radiating object which may cause a false

reading.

• Closeto or in direct airflow from supply registers and return-air

registers.

• In areas with poor air circulation, such as behind a door or in

an alcove.

II. SET DIP SWITCHES

There is a 4 section DIP switch within the Thermidistat Control

which must be properly set by the installer. It is easiest to set these

4 switches before the Thermidistat Control is mounted to the wall,

so STOP and complete the following steps:

1. Open hinged Thermidistat Control cover.

2. Remove cover completely by snapping it apart at hinge.

3. Open Thermidistat Control by pressing back half of the

right end of plastic case inward while, at the same time,

pulling front and back halves apart at the right end. The 2

halves will swing apart.

4. Snap hinge apart to completely separate the 2 halves.

5. Switches are located in upper right corner of circuit board.

To change switch position, use corner of a small screwdriver to slide switch to opposite position.

6. After switches have been set, do not reassemble the 2

halves. The rear plastic will be first mounted to wall.

A. Switch 1—AC/HP Select

Use this switch to select between air conditioner and heat pump

systems.

TO SET:

OFF—for air conditioner installations. This is factory default.

ON—for heat pump installations, using either a fan coil or furnace

(dual fuel).

B. Switch 2—1 Speed/2 Speed

This switch tells the system whether the compressor is 1 or 2

speed.

TO SET:

OFF—for single-speed compressor. This is factory default.

ON—for 2-speed compressors, whether AC or HP.

III. INSTALL THERMIDISTAT CONTROL

WARNING: Before installing Thermidistat Control,

turn off all power to equipment. There may be more than

1 power disconnect. Electrical shock can cause personal

injury or death.

1. Turn off all power to equipment.

2. If an existing thermostat is being replaced:

a. Remove existing thermostat from wall.

b. Disconnect wires from existing thermostat, 1 at a time.

c. As each wire is disconnected, record wire color and

terminal marking.

d. New or additional wire may be needed to accommodate

added humidity outputs.

e. Discard or recycle old thermostat.

NOTE: Mercury is a hazardous waste and MUST be disposed of

properly.

3. Select Thermidistat Control rear plastic. (If it is not separated from the remainder of the Thermidistat Control, refer

to Step 2 above.)

4. Route wires through large hole in rear plastic. Level rear

plastic against wall (for aesthetic value only—Thermidistat

Control need not be leveled for proper operation) and mark

wall through 2 mounting holes.

5. Drill two 3/16-in. mounting holes in wall where marked.

6. Secure rear plastic to wall with 2 screws and anchors

provided. Additional mounting holes are available for more

secure mounting if needed. Make sure all wires extend

through hole in mounting base.

7. Adjust length and routing of each wire to reach proper

connector block and terminal on rear plastic with 1/4-in.

extra length. Strip only 1/4 in. of insulation from each wire

to prevent adjacent wires from shorting together when

connected.

8. Match and connect equipment wires to proper terminals of

each connector block. (See Table 6 and Wiring Diagrams

Fig. 3 through 30.) Remember R and C must be connected

for proper operation.

CAUTION: Improper wiring or installation may damage

Thermidistat Control. Check to make sure wiring is

correct before proceeding with installation or turning on

power.

C. Switch 3—Smart/Conventional Recovery

Selects between conventional and smart recovery from setback.

Conventional recovery changes to new set point at programmed

time. Smart recovery, which is active in both heating and cooling,

starts 90 minutes earlier and smoothly adjusts set point so room

will arrive at programmed temperature at programmed time.

TO SET:

OFF—for smart recovery. This is factory default.

ON—for conventional recovery.

D. Switch 4—Installer Test OFF/ON

Selects a special installer test mode which assists with checkout

and troubleshooting. See Step 5.

TO SET:

OFF—for normal operation. This is factory default.

ON—for installer test mode.

9. Push any excess wire into wall and against rear plastic. Seal

hole in wall to prevent air leaks. Leaks can affect operation.

10. Reattach Thermidistat Control body to rear plastic by first

reattaching hinge.

11. Close Thermidistat Control assembly, making sure pins on

back of circuit board align with sockets in connector.

12. Turn on power to equipment.

On power up, all display segments will light for 5 sec. For the next

5 sec, a 2-digit code appears on large display which identifies

Thermidistat Control configuration:

1. AC—for 1-speed air conditioner

2. HP—for 1-speed heat pump

3. A2—for 2-speed air conditioner

4. H2—for 2-speed heat pump

—2—

Page 3

5. dF—for 1-speed dual fuel

6. d2—for 2-speed dual fuel

7. HS—for special 3-stage auxiliary heat with FK series Fan

Coil and 1-speed heat pump

When this identifier disappears, normal operation begins. The

MODE control should be set to OFF and FAN control to AUTO,

so equipment does not start until further configuration and checkout is completed.

IV. SET THERMIDISTAT CONTROL CONFIGURATION

Configuration options, like DIP switch settings, are intended to be

selected at installation and normally are not modified by the

homeowner. These options are not discussed in the homeowner’s

manual and therefore must be made as part of the installation. A

special procedure allows entry into the configuration mode. While

in configuration mode, up to 17 selections can be made. A

description of each selection and how to use the configuration

mode follows.

A. Configuration Options — Summary:

Option 1—Anticipator adjustment

Option 2—Clean filter timer adjustment

Option 3—English/Metric selection

Option 4—Fan (G) ON with W selection

Option 5—Variable-speed blower present selection

Option 6—Cooling lockout below 55° selection

Option 7—Variable speed super dehumidification selection (only

available when variable-speed blower is used)

Option 8—Auxiliary heat lockout temperature adjustment (only

available when heat pump is used)

Option 9—Three-stage auxiliary heat selection (only available

when single-speed heat pump is used)

Option 10—Dual fuel selection (only available when heat pump is

used)

Option 11—Dual fuel crossover temperature adjustment (only

available when dual fuel is selected)

Option 12—Defrost heat selection (only available when heat pump

is used)

Option 13—Room temperature offset adjustment

Option 14—Heat/cool dead band adjustment

Option 15—Enable auto mode

Option 16—Reserved for future use

Option 17—Non-Programmable selection

B. To Enter Configuration Mode:

Press and hold FAN button for approximately 10 sec until COOL

set point display indicates a flashing 01. The Thermidistat Control

is now in configuration mode. It will automatically exit this mode

if no button is pressed for 3 minutes. Pressing END button will exit

configuration mode immediately.

C. While in Configuration Mode:

The upper small (COOL set point) display indicates selected

option number and large display indicates selection made within

that option. One of these will be flashing. The up and down buttons

are used both to move between available options and to make

selection for each option. When option number (small display) is

flashing, up and down buttons adjust it, moving between available

option numbers. After desired option number has been selected,

press SET TIME/TEMP button once. The large display will now

flash, indicating that up and down buttons now control available

choices within that option. Each press of TIME/TEMP button

switches between available option (small display) and available

selections within each option (large display).

D. Configuration Options — Selection:

OPTION 1—ANTICIPATOR ADJUSTMENT

This adjustment controls sensitivity and cycle rate of Thermidistat

Control. Higher numbers decrease sensitivity and slow cycle rate.

Lower numbers increase sensitivity and cycle rate. However, a

limiting feature will not allow more than 4 cycles per hr, regardless

of setting. Anticipator values can range from 1 to 9. Factory

default is 3. This default selection provides optimum performance

in nearly all installations. Try it first. Do not change setting unless

there is evidence of need to do so.

Unlike conventional anticipators, this setting is not determined by

current draw. There is no need to measure, know, or compensate

for current draw. There is also no droop with this Thermidistat

Control. Regardless of setting and number of stages, both heating

and cooling will control to their respective set points.

TO ADJUST:

1. Enter configuration mode if not already there. See Step 4

"To Enter Configuration Mode." The upper small (COOL

set point) display will be flashing 01. If not, use up and

down buttons to move it to 01.

2. Press SET TIME/TEMP button once to flash current

selection of 1, 2, 3, 4, 5, 6, 7, 8, or 9 on large display.

Factory default is 3.

3. Use up and down buttons to move between available

choices.

4. Press SET TIME/TEMP button again to flash upper small

display for selection of another option, or press END to exit

configuration mode.

OPTION 2—CLEAN FILTER TIMER

Select hours of blower operation (heating, cooling, or fan) before

CLEAN FILTER icon is displayed. With OFF selected, icon will

never come on, disabling this feature. Time selection can range

from 400 to 3600 hr by selecting numbers 1 through 9. (Time is

400 X number selected.) Factory default is 2 (800 hr). Recommended selections are: disposable filter—400 to 800 hr, media

filter—1200 to 1600 hr, or electronic air cleaner—1600 to 2400 hr

of blower operation.

TO SELECT OR ADJUST:

1. Enter configuration mode if not already there. See Step 4

"To Enter Configuration Mode." Use up and down buttons

to make small (now flashing) display indicate 02.

2. Press SET TIME/TEMP button once to display current

selection of OF, 1, 2, 3, 4, 5, 6, 7, 8, or 9 on large display.

Factory default is 2.

3. Use up and down buttons to move between available

choices.

4. Press SET TIME/TEMP button again to flash upper small

display for selection of another option, or press END to exit

configuration mode.

OPTION 3—ENGLISH/METRIC

Select between Fahrenheit and Celsius operation. Factory default

is Fahrenheit.

TO SELECT OR ADJUST:

1. Enter configuration mode if not already there. See Step 4

"To Enter Configuration Mode." Use up and down buttons

to make small (now flashing) display indicate 03.

2. Press SET TIME/TEMP button once to flash current

selection of F or C. Factory default is F.

3. Use up and down buttons to move between F and C on large

display.

4. Press SET TIME/TEMP button again to flash upper small

display for selection of another option, or press END to exit

configuration mode.

—3—

Page 4

OPTION 4—FAN (G) ON WITH W

This selection determines whether fan (G) output is to be ON or

OFF when any W (furnace or strip heat) output is ON. Most

furnaces and fan coils manage their own blowers and do not

require separate G signal. For these applications, select OFF. Some

auxiliary heaters require separate G signal to turn on blower. In

this case, select ON. Factory default is OF (off).

TO SELECT:

1. Enter configuration mode if not already there. See Step 4

"To Enter Configuration Mode." Use up and down buttons

to make small (now flashing) display indicate 04.

2. Press SET TIME/TEMP button once to flash large display.

3. Use up or down buttons to alternate between OF and ON on

large display.

4. Press SET TIME/TEMP button again to flash upper small

display for selection of another option, or press END to exit

configuration mode.

OPTION 5—VARIABLE SPEED (ICM) BLOWER

If furnace or fan coil contains a variable-speed (ICM) blower, set

this option to ON. For normal (PSC) blowers, set to OF. This

selection enables system to use special features available only in

units with an ICM blower. Factory default is OF (off).

TO SELECT:

1. Enter configuration mode if not already there. See Step 4

"To Enter Configuration Mode." Use up and down buttons

to make small (now flashing) display indicate 05.

2. Press SET TIME/TEMP button once to flash large display.

3. Use up or down buttons to alternate between OF and ON on

large display. Factory default is OF.

4. Press SET TIME/TEMP button again to flash upper small

display for selection of another option, or press END to exit

configuration mode.

OPTION 6—COOLING LOCKOUT BELOW 55°F

This option disables cooling when outdoor temperature is below

55°F. It requires an outdoor temperature sensor. Set to OF to allow

cooling below 55°F. Set to ON to prevent cooling below 55°F.

Factory default is OF (off).

TO SELECT:

1. Enter configuration mode if not already there. See Step 4

"To Enter Configuration Mode." Use up and down buttons

to make small (now flashing) display indicate 06.

2. Press SET TIME/TEMP button once to flash large display.

3. Use up or down buttons to alternate between OF and ON on

large display. Factory default is OF.

4. Press SET TIME/TEMP button again to flash upper small

display for selection of another option, or press END to exit

configuration mode.

OPTION 7—VARIABLE SPEED SUPERDEHUMIDIFY

→

This option requires prior selection of variable-speed (ICM)

blower (Option 5). When selected, this option operates blower at

further reduced airflow from that of normal dehumidification when

there is a dehumidification demand without a cooling demand,

achieving maximum humidity removal with minimum cooling. It

is done by supplying blower with a Y signal and no G signal on a

call for cooling. Not all products with ICM blowers have this

feature. Check Installation Instructions for ICM air handler used.

Select OF for normal operation (Y and G supplied on a cooling

call). Select ON for super dehumidification (Y with no G on a

dehumidify only call). Factory default is OF (off).

TO SELECT:

1. Enter configuration mode if not already there. See Step 4

"To Enter Configuration Mode." Use up and down buttons

to make small (now flashing) display indicate 07.

2. Press SET TIME/TEMP button once to flash large display.

3. Use up or down buttons to alternate between OF and ON on

large display. Factory default is OF.

4. Press SET TIME/TEMP button again to flash upper small

display for selection of another option, or press END to exit

configuration mode.

OPTION 8—AUXILIARY HEAT LOCKOUT TEMPERATURE

This option requires prior selection of heat pump (DIP switch 1

ON). It allows selection of an outdoor temperature of OF, 5, 10,

15, 20, 25, 30, 35, 40, 45, 50, or 55°F. Outdoor temperature sensor

MUST be attached. If temperature is selected and outdoor temperature sensor is not attached, error message E3 will appear. See

"Error Codes." In heat pump systems, auxiliary heat is prevented

from operating for outdoor temperatures above selected temperature. In dual fuel systems, furnace is prevented from operating for

outdoor temperatures above selected temperature. However, heat

pump or furnace may be used during defrost. See Configuration

Option No. 12. If OF is selected, outdoor temperature does not

affect system operation. Factory default is OF (off).

TO SELECT:

1. Enter configuration mode if not already there. See Step 4

"To Enter Configuration Mode." Use up and down buttons

to make small (now flashing) display indicate 08.

2. Press SET TIME/TEMP button once to flash large display.

3. Use up or down buttons to move between OF, 5, 10, 15, 20,

25, 30, 35, 40, 45, 50, or 55 on large display. Factory

default is OF.

4. Press SET TIME/TEMP button again to flash upper small

display for selection of another option, or press END to exit

configuration mode.

OPTION 9—SPECIAL 3-STAGE ELECTRIC HEAT

This option requires prior selection of single-speed heat pump

(DIP switch 1—ON, DIP switch 2—OF). It provides 3 stages of

electric heat from W1 and W2 by sequencing W1 only, then W2

only, then both W1 and W2. See FK Series Fan Coil Installation

Instructions for further information. For 3-stage heat, select ON.

For normal 1- or 2-stage heat, select OF. Factory default is OF

(off).

TO SELECT:

1. Enter configuration mode if not already there. See Step 4

"To Enter Configuration Mode." Use up and down buttons

to make small (now flashing) display indicate 09.

2. Press SET TIME/TEMP button once to flash large display.

3. Use up or down buttons to alternate between OF and ON on

large display. Factory default is OF.

4. Press SET TIME/TEMP button again to flash upper small

display for selection of another option, or press END to exit

configuration mode.

OPTION 10—DUAL FUEL EQUIPMENT

CAUTION: All dual fuel installations must be equipped

with a high pressure switch to turn off compressor under

a high indoor coil pressure condition.

The high pressure switch protects compressor and indoor coil from

→

overpressure which would occur if a failure or wiring error

resulted in the heat pump and furnace operating at the same time.

—4—

Page 5

High Pressure Switch Kit includes required switch and instructions

for proper operation. For all dual fuel installations, outdoor

temperature sensor must be attached. If not, E3 error message will

appear. See "Error Codes."

This option requires prior selection of heat pump (DIP switch

1—ON), and must be selected in dual fuel installations. It prevents

simultaneous operation of both furnace and heat pump, and

prevents direct transition from heat pump to furnace operation.

When system is dual fuel (heat pump and furnace), set to ON.

When system contains fan coil, set to OF. Factory default is OF

(off).

TO SELECT:

1. Enter configuration mode if not already there. See Step 4

"To Enter Configuration Mode." Use up and down buttons

to make small (now flashing) display indicate 10.

2. Press SET TIME/TEMP button once to flash large display.

3. Use up or down buttons to alternate between OF and ON on

large display. Factory default is OF.

4. Press SET TIME/TEMP button again to flash upper small

display for selection of another option, or press END to exit

configuration mode.

OPTION 11—DUAL FUEL CROSSOVER TEMPERATURE

This option requires prior selection of heat pump (DIP switch

1—ON) and dual fuel equipment (Option 10—ON). It allows

selection of an outdoor temperature of OF, 5, 10, 15, 20, 25, 30,

35, 40, 45, 50, or 55°F. Outdoor temperature sensor must be

attached. If temperature is selected and outdoor temperature sensor

is not attached, error message E3 will appear. Heat pump is

prevented from operating for outdoor temperatures below selected

temperature. If OF is selected, outdoor temperature does not affect

system operation. Factory default is OF (off).

TO SELECT:

1. Enter configuration mode if not already there. See Step 4

"To Enter Configuration Mode." Use up and down buttons

to make small (now flashing) display indicate 11.

2. Press SET TIME/TEMP button once to flash large display.

3. Use up or down buttons to move between OF, 5, 10, 15, 20,

25, 30, 35, 40, 45, 50, or 55 on large display. Factory

default is OF.

4. Press SET TIME/TEMP button again to flash upper small

display for selection of another option, or press END to exit

configuration mode.

OPTION 12—DEFROST HEAT SELECT

This option allows installer to select the amount of heat provided

by Thermidistat Control during a heat pump defrost cycle. This can

be very helpful in maintaining a comfortable leaving air temperature during defrost. The Thermidistat Control senses when defrost

is in progress by monitoring voltage placed on the O line by the

heat pump while defrosting. It responds by turning on selected

combination of W1 and W2 during defrost. Note that this is very

different from the operation of an ordinary thermostat, which

cannot sense defrost in progress and only turns on its W outputs in

response to a temperature demand. Combinations of W1 and W2

are selected via the following:

The selection procedure is given below. If 0 is selected, operation

is like that of an ordinary thermostat, and a wire is required

between W2 of outdoor unit and a selected W on indoor unit.

When selection 1, 2, or 3 is made, no wire should be connected

from outdoor W2 because this connection may override selection

made. Obviously the heater must be in 2 sections, and fan coil

jumper must be removed between W1 and W2 for there to be a

difference between selections 1, 2, and 3. For most heaters, W1 is

lower wattage heater, and W2 is higher, although some have equal

elements for W1 and W2. Consult fan coil/heater combination for

the actual wattage connected to each of W1 and W2.

TABLE 1—W1 / W2 OUTPUTS

SELECTION DEFINITION

0

1 Only W1 is turned on.

2 Both W1 and W2 turned on.

3

Neither W1 or W2 is turned on.

This is factory default.

Only W2 turned on (available

only if 3-stage heat is selected).

In dual fuel applications, above selection choices apply and can be

used to select low or high heat if furnace is 2 stage. W1 will

produce low heat. W1 and W2 together produce high heat. This

option provides no value with single-stage furnaces because only

1 value of heat is available.

The selection choices guarantee selected outputs will be on during

defrost. If room temperature demand requires additional heat, it

will be supplied, resulting in additional outputs being turned on. If

room overheats, specified outputs will not turn off, guaranteeing a

sufficiently warm leaving air temperature during defrost. Temperature overshoot during defrost can occur, but is almost never

noticeable because of the short duration of the defrost cycle (4

minutes typical, 10 minutes maximum).

An additional feature of Thermidistat Control defrost is that it

always allows defrost cycle to run to completion. The Thermidistat

Control leaves the Y output on as long as outdoor unit holds

voltage on the O line, even if it is satisfied. This prevents

premature termination of defrost cycles, which occur with normal

thermostats.

TO SELECT:

1. Enter configuration mode if not already there. See Step 4

"To Enter Configuration Mode." Use up and down buttons

to make small (now flashing) display indicate 12.

2. Press SET TIME/TEMP button once to flash large display.

3. Use up or down buttons to move between 0, 1, 2, or 3 (if

available) on large display. See Table 1 for effect of these

choices. Factory default is 0.

4. Press SET TIME/TEMP button again to flash upper small

display for selection of another option, or press END to exit

configuration mode.

OPTION 13—ROOM TEMPERATURE OFFSET ADJUST

This option allows calibration (or deliberate miscalibration) of

room temperature sensor. There are various reasons why homeowners may want to have displayed temperature adjusted to a

higher or lower value. The selected number is number of degrees,

plus or minus, which will be added to actual temperature. The

numbers can range between -5 and +5. Factory default is 0. This

adjusted value will be used as actual temperature for both display

and control action. For example, if 2 is selected, 72°F actual will

read 74°F. If set point is 72°F, the room will control to an actual

temperature of 70°F which will be displayed and acted upon as if

it were 72°F. The effect is that a positive number selection will

make the room temperature lower and vice versa. The Thermidistat

Control is calibrated within an accuracy of plus or minus 1° when

shipped from the factory, so this adjustment will provide the best

accuracy when set to 0.

TO SELECT:

1. Enter configuration mode if not already there. See Step 4

"To Enter Configuration Mode." Use up and down buttons

to make small (now flashing) display indicate 13.

2. Press SET TIME/TEMP button once to flash large display.

3. Use up or down buttons to move between -5, -4, -3, -2, -1,

0, 1, 2, 3, 4, or 5 on large display. Factory default is 0.

4. Press SET TIME/TEMP button again to flash upper small

display for selection of another option, or press END to exit

configuration mode.

—5—

Page 6

OPTION 14—HEAT/COOL DEAD BAND ADJUSTMENT

This option selects the minimum difference between heat and cool

set points. A larger difference saves energy and a smaller difference decreases temperature difference between heating and cooling. Factory default is 2, which means cooling set point must be a

minimum of 2° above heating set point. An attempt to move them

closer will result in one "pushing" the other to maintain the

required difference.

Depending on set points, moving dead band closer than 2° may

result in regular cycling between heat and cool when AUTO mode

is selected. However, this cycling cannot occur more often than 1

transition every 20 minutes. The system has a built-in requirement

that it cannot switch between heat and cool without a 20 minute

"off" time between the 2 operations. Specifically, to switch from 1

mode to the other, there must be no demand for the old mode and

a demand for the new mode, and this must exist continually for 20

minutes before transition to the new mode will occur.

TO SELECT:

1. Enter configuration mode if not already there. See Step 4

"To enter Configuration Mode." Use up and down buttons

to make small (now flashing) display indicate 14.

2. Press SET TIME/TEMP button once to flash large display.

3. Use up or down buttons to move between 0, 1, 2, 3, 4, 5, or

6 on large display. Factory default is 2.

4. Press SET TIME/TEMP button again to flash upper small

display for selection of another option, or press END to exit

configuration mode.

OPTION 15—ENABLE AUTO MODE

This option allows the installer to enable or disable AUTO mode

(automatic changeover between heat and cool). When disabled,

AUTO icon does not appear when successive presses of MODE

button are used to move between OFF, HEAT, COOL, and

EHEAT (in heat pump systems). Factory default is ON (AUTO

enabled).

TO SELECT:

1. Enter configuration mode if not already there. See Step 4

"To Enter Configuration Mode." Use up and down buttons

to make small (now flashing) display indicate 15.

2. Press SET TIME/TEMP button once to flash large display.

3. Use up and down buttons to move between OF and ON on

large display. Factory default is ON (AUTO enabled).

4. Press SET TIME/TEMP button again to flash upper small

display for selection of another option, or press END to exit

configuration mode.

→

OPTION 16—RESERVED FOR FUTURE USE

→

OPTION 17—ENABLE NON-PROGRAMMABLE OPERATION

This option converts the programmable Thermidistat Control to a

non-programmable control for those users who do not want

programmability. The clock is retained, but the days of the week

and the daily schedules have been eliminated, making it operate as

if HOLD were permanently ON. Some of the buttons (used in

programming only and now not needed) are redefined to simplify

the non-programmable operation. To match these redefined buttons, a new keypad label, included with the Thermidistat, must be

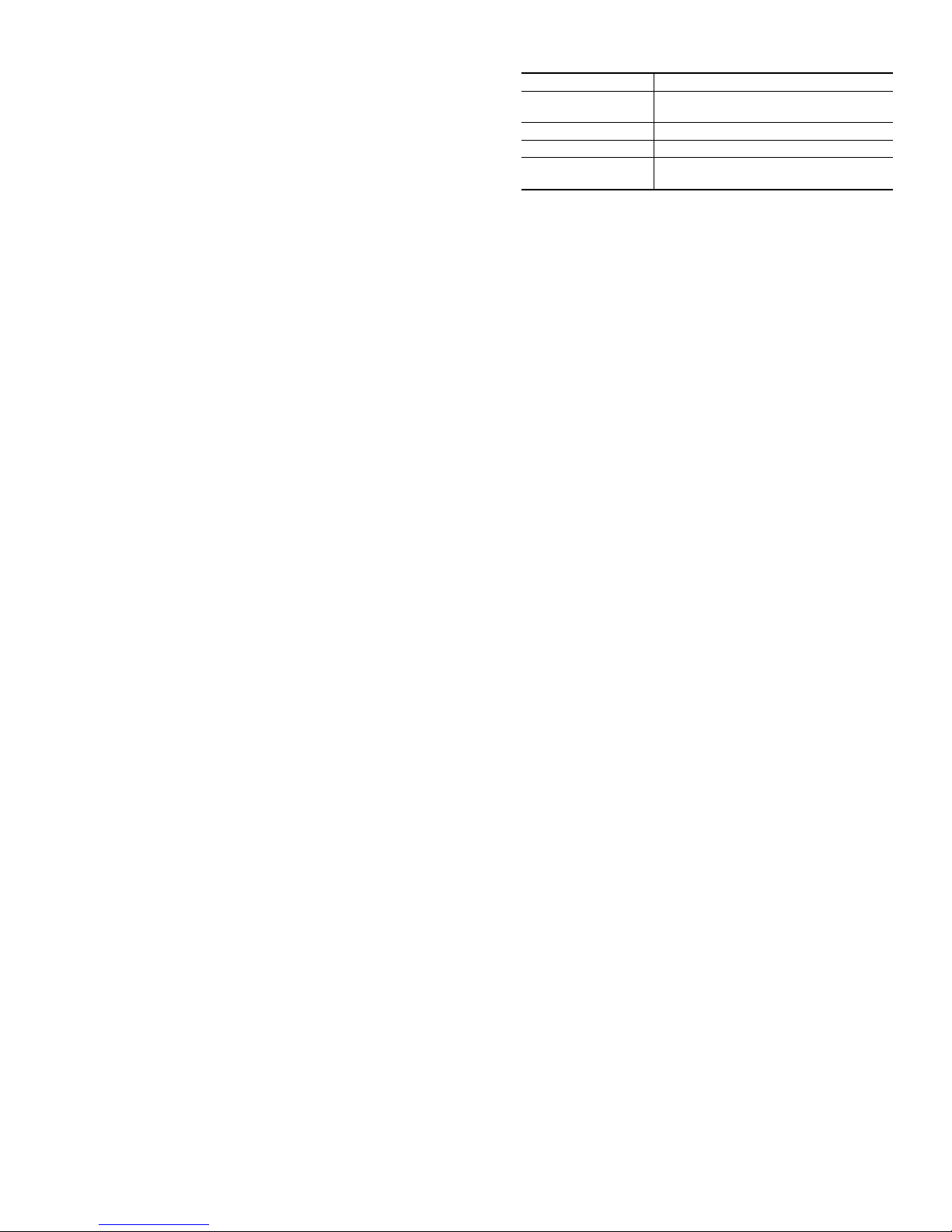

placed over the original keypad label. Fig. 2 shows both the

original keypad label and the non-programmable keypad label.

When this option is selected, the new keypad label must be applied

over (or in place of) the original. Because these adhesive-backed

keypad labels are not designed to be removed, this conversion

should be considered permanent. Once the change to nonprogrammable operation is done, a procedure is not provided to

easily change it back. Should this change be needed, it is best to

trade the Thermidistat for one which has not been converted.

Both programmable and non-programmable versions of the Homeowner’s Manual are available.

Once it has been determined that a particular installation is to be

made non-programmable, the only changes required are:

• Attach non-programmable keypad label over original programmable one.

• Set Configuration Option No. 17 to ON.

To attach the provided non-programmable keypad label, carefully

peel off its backing and apply it over the original keypad label.

PLEASE HEED: Once the new keypad label makes contact, it will

stick firmly in place and adjustments cannot be made. CAREFULLY locate an edge of the keypad label, making sure its

position and orientation are correct. Then, from the attached edge,

smooth the rest of the keypad label over the original. Make sure the

new keypad label does not interfere with the motion of the buttons

which it surrounds.

TO SELECT:

1. Enter configuration mode if not already there. See Step 4

"To Enter Configuration Mode." Use up and down buttons

to make small (now flashing) display indicate 17.

2. Press SET TIME/TEMP button once to flash large display.

3. Use up and down buttons to move between OF and ON on

large display. Factory default is OF.

4. Press SET TIME/TEMP button again to flash upper small

display for selection of another option, or press END to exit

configuration mode.

→

E. Redefinition of Buttons

Fig. 2 shows the original (programmable) button labels on the left

and the redefined (non-programmable) buttons on the right. In the

figure, the buttons are numbered for easy reference. They are not

numbered on the actual product. Six of the buttons (numbers 1

through 5 and 9) have been redefined.

Button 3 originally alternated between time, cool set point, and

heat set point with each press. Now, button 1 selects the cool set

point, button 2 selects the heat set point, and button 3 selects time,

now used only to set the clock. Note that the days of the week are

gone.

Button 5 used to alternate between humidify and dehumidify. Now

button 4 selects dehumidify and button 5 selects humidify.

Button 9 now loses the HOLD label, making it END only. This

button is only used to END the humidity screen and the configuration mode.

These changes both simplify operation for the homeowner and find

use for the buttons which are no longer needed when programmability is removed.

V. SYSTEM START-UP AND CHECKOUT

The Thermidistat Control is designed with a built-in installer test

capability. It allows easy operation of equipment without delays or

set point adjustments to force heating or cooling.

To enable installer test mode, move DIP switch No. 4 to ON

position. To access this switch, open case as described in Step 2.

Use the corner of a small screwdriver to slide switch No. 4 to ON

position.

While in installer setup mode, clock will display "InSt," FAN

button will control fan, and MODE button will control heating and

cooling.

A. To Test Fan:

F,an button switches FAN icon between AUTO and ON. While

ON is displayed, G output will be on, turning fan on. Allow up to

10 sec after button is pressed for fan to turn on and off. On some

fan coils, fan continues to operate for 90 sec after G signal is

removed.

—6—

Page 7

COPY PREVIOUS DAY PROGRAM MODE

SET COOL SET DHUM MODE

1

CHANGE DAY HUMIDITY FAN

47

258

SET TIME/TEMP VACATION HOLD/END

369

PROGRAMMABLE CONFIGURATION

(OPTION 17 OFF)

B. To Test Cooling and Dehumidification:

Press MODE button until COOL icon turns on. Cooling begins

within 10 sec and remains on for 4 minutes. If system is 2-speed,

low speed comes on for first 2 minutes, followed by high speed for

second 2 minutes. At the end of 4-minute run, cooling stops, and

MODE reverts back to OFF. At any time during 4-minute run time,

cooling may be turned off by pressing MODE button until OFF

appears. While cooling is on, successive presses of HUMIDITY

button turn dehumidify output on and off. While this output is

active, "dhu" appears in cool set point display. Equipment outputs

for different equipment types are listed in Table 2.

C. To Test Primary Heating and Humidification:

Press MODE button until HEAT icon turns on. Primary heating

begins within 10 sec and remains on for 4 minutes. This will be

furnace or electric heat in AC system and heat pump heating in

heat pump system. If system has 2 stages of primary heat, first

stage will be on for 2 minutes followed by second stage for 2

minutes. At the end of 4-minute run, heating stops, and MODE

reverts back to OFF. At any time during 4-minute run time, heating

may be turned off by pressing MODE button until OFF appears.

While heating is on, successive presses of HUMIDITY button turn

humidify output on and off. While this output is active, "hu"

appears in heat set point display. Equipment outputs for different

equipment types are listed in Table 2.

D. To Test Auxiliary Heating:

Auxiliary heating only exists in heat pump systems. To test, press

MODE button until EHEAT icon turns on. This will be electric

heat in standard heat pump systems and furnace in dual fuel

systems. Auxiliary heating begins within 10 sec and remains on for

4 minutes. If there are 2 stages of auxiliary heat, first stage comes

on for 2 minutes followed by second stage for 2 minutes. At the

end of 4-minute run, heating stops and MODE reverts back to

OFF. At any time during 4-minute run time, heating may be turned

off by pressing MODE button until OFF appears. Actual outputs

for different equipment types are listed in Table 2.

VI. FINAL SETTINGS

Be sure to return DIP switch No. 4 back to OFF position to exit

installer setup mode. Assuming system is to be left in operation

after installation is complete, use MODE button to select between

HEAT, COOL, or AUTO to provide desired operation of heating,

cooling, or both.

The default set points and programmed schedule conform to the

Energy Star® requirements of the U.S. Department of Energy for

both heating and cooling. These provide energy saving temperature settings. Refer to Table 3.

Reset

Filter

→ Fig. 2—Programmable/Non-Programmable Keypad Labels

1

SET HEAT SET HUM

47

FAN

258

SET TIME VACATION END

369

NON-PROGRAMMABLE CONFIGURATION

(OPTION 17 ON)

TABLE 3—ENERGY STAR DEFAULT SCHEDULE

SCHEDULE HEAT COOL

Wake 6:00 AM 68°F 78°F

Day 8:00 AM 60°F 85°F

Evening 5:00 PM 68°F 78°F

Sleep 10:00 PM 60°F 82°F

If programmed schedule is to be used, make sure HOLD icon is

off. This feature is turned on and off by HOLD button.

If fixed temperatures are desired, use HOLD button to turn on

HOLD icon. This will maintain set points, not allowing them to

change with programmed schedule.

The FAN button may be used to select between AUTO (fan on

only with equipment) and FAN (fan on continuously) fan modes.

For further information on temperature selection and programming, refer to Homeowner’s Guide.

HUMIDITY CONTROL FEATURES

The various humidity control features of the Thermidistat Control

are explained below. They are grouped into 2 sections: humidification and dehumidification. At the end of each section, instructions on how to select each feature are given.

A. Humidification

The Thermidistat Control directly connects to a standard 24-vac

humidifier to control humidification in the home. A humidify set

point between 10 and 45 percent relative humidity is selected by

the homeowner, or all humidification can be turned off. When

humidity in home drops below set point, humidifier will be turned

on to raise humidity level. Humidification can only occur in

heating mode (HEAT or AUTO/HEAT). Five different humidification selections are available and are described below.

1. Normal Humidify

In normal humidify, humidifier will be on if there is a

humidity demand and any heating equipment is on. This

will include furnace, heat pump, or auxiliary heat. In heat

pump applications, this is an improvement over using an

external humidistat, which only supplies humidity when

auxiliary heat is on.

2. Fan Humidify

This configuration allows a humidify demand to turn on fan

and humidifier together, even if there is no heat demand. It

is particularly useful when the furnace is oversized, resulting in short heating cycles. It allows the humidifier to run

longer, supplying more humidity to the home. Note that fan

hours will increase, using more electricity. Also, the humidifier delivers less moisture to cooler air than it does to

heated air.

Reset

Filter

A98286

—7—

Page 8

TABLE 2—EQUIPMENT OUTPUTS

1-SPEED AC 2-SPEED AC 1-SPEED HP 2-SPEED HP

Cool—0 to 2 minutes Y, G Y1, G Y, G, O Y1, G, O

Cool—2 to 4 minutes Y, G Y1, Y2, G Y, G, O Y1, Y2, G, O

Heat—0 to 2 minutes W1 W1 Y, G Y1, G

Heat—2 to 4 minutes W1, W2 W1, W2 Y, G Y1, Y2, G

Eheat—0 to 2 minutes --- --- W1 W1

Eheat—2 to 4 minutes --- --- W1, W2† W1*

* Two-stage heat not available

NOTE: For Y—use terminal Y/Y2, for Y1—use terminal Y1/W2, for W2—use terminal O/W2,

for O—use terminal O/W2, for W1—use terminal W/W1, for W2†, use terminal Y1/W2

3. Auto Humidify

This feature is designed to eliminate the problem of

sweating windows in very cold weather. When selected, the

set point is automatically reduced by 1 percent for every

drop of 2°F in outdoor temperature between 50°F and 0°F.

The set point may be changed at any time, and it will

continue to track outdoor temperature from the new set

point and current outdoor temperature. The adjusted set

point range is still limited to between 10 and 45 percent

relative humidity. To use this feature, an outdoor temperature sensor MUST be attached. If not, E3 error message will

be displayed.

4. Auto and Fan Humidify

The 2 choices of AUTO and FAN can be selected together.

This provides both functions simultaneously.

5. Humidify Off

The humidify function can be turned off completely. This

does not require changing existing set points.

TO SELECT HUMIDIFICATION (BETWEEN NORMAL,

FAN, AUTO, FAN AND AUTO, OR OFF) (SEE TABLE 4.)

Press HUMIDITY button to bring up humidity select screen. It is

indicated by "hu" or "dhu" in clock display. Successive presses

will change between "hu" and "dhu" in clock display. Select "hu"

for humidity functions. The large display shows actual humidity

level. The smaller display (in heat set point location) shows

humidity set point (HSP) or OF (off). When HSP value is

displayed, its value can be changed with up and down buttons.

Successive presses of MODE button will move between 5 choices

described above and each will be indicated as shown in Table 4.

To exit humidity select screen, press END button.

ADDITIONAL HUMIDIFY COMMENTS

The humidifier is actually turned on when humidity is 2 percent

below set point and turned off when it reaches 2 percent above set

point. This built-in hysteresis prevents humidify output from

toggling on and off when humidity level is near set point.

The vacation mode provides some additional humidification functions. These are specially designed to provide protection for an

unoccupied home while simultaneously minimizing energy use.

Refer to "Vacation" section for additional information.

B. Dehumidification

Dehumidification is done only during cooling. Depending on type

of equipment used, compressor speed, blower speed, set point

adjustment, and equipment cycling are modified to provide added

dehumidification. A dehumidification set point (separate from

humidification set point) is available to the homeowner. It can

range from 50 to 90 percent relative humidity. When actual

humidity is higher than set point, a dehumidification demand

exists. The Thermidistat Control responds by activating its dehumidify output. It may also control the compressor and blower,

depending on equipment type and dehumidify selection choice.

The 3 available selections are described below.

The amount of extra dehumidification available is very dependent

on the type of equipment in the home. Without a variable-speed

blower, the system’s ability to adjust dehumidification is very

limited.

1. Normal Dehumidify Operation

When normal dehumidify is selected, the compressor will

not turn on without a cooling demand. If dehumidify

demand exists while cooling, dehumidify output will also

be active (24vac removed). This output commands variablespeed blowers to reduce their airflow, which improves

water removal from the cooled air.

2. Cool to Dehumidify

The cool to dehumidify selection tells the system to operate

the compressor, within limits, when there is a dehumidify

demand even if there is no cooling demand. The limits are

that the system may overcool up to 3°, but no more, while

attempting to satisfy a dehumidify demand. Within this 3°

range, there is an additional balance between overcooling

and humidity satisfaction. When overcooling must occur,

the dehumidify set point is adjusted upward by 2 percent per

degree of overcooling. For example, a cooling set point of

76°F and a dehumidify set point of 60 percent is equivalent

to a cooling set point of 75°F and a dehumidify set point of

62 percent. This dehumidify set point change is internal to

the Thermidistat Control and is not shown on the display.

During cool-to-dehumidify demand, the compressor runs a

maximum of 10 minutes on, followed by 10 minutes off.

When the compressor turns off, the fan (G output) is also

turned off immediately. The immediate fan shutoff prevents

re-evaporation of water on the coil, improving dehumidification. If fan is set to continuous, the G (fan on) signal is

removed for 5 minutes starting when compressor turns off.

In most furnaces and fan coils, the blower operates for 90

sec after both Y and G disappear. This 90-sec delay should

be removed, if possible, for maximum dehumidification

performance. Consult furnace or fan coil Installation Instructions to see if delay can be disabled.

TABLE 4—HUMIDIFICATION SELECTIONS

SELECTION MODE DISPLAY FAN DISPLAY

Normal Humidify Blank Blank HSP Value

Fan Humidify Blank FAN HSP Value

Auto Humidify AUTO Blank HSP Value

Auto and Fan AUTO FAN HSP Value

Humidify Off Blank Blank OF

HUMIDIFY SP

DISPLAY

—8—

Page 9

TABLE 5—DEHUMIDIFICATION SELECTIONS

SELECTION MODE DISPLAY FAN DISPLAY

Normal Dehumidify Blank Blank DSP Value

Cool to Dehumidify COOL Blank DSP Value

Dehumidify OFF Blank Blank OF

DEHUMIDIFY SP

DISPLAY

3. Dehumidify Off

Dehumidification can be turned off completely. This can be

done without changing existing set points.

TO SELECT DEHUMIDIFICATION (BETWEEN NORMAL,

COOL TO, AND OFF)

Press HUMIDITY button to bring up humidity selections. Successive presses will show "hu" or "dhu" in clock display. Select "dhu"

for dehumidify selections. The large display shows actual humidity

level. The smaller display (in cool set point location) shows

dehumidify set point (DSP) or OF (off). When DSP value is

displayed, its value can be changed with up and down buttons.

Successive presses of MODE button moves between 3 choices

above and each will be indicated as in Table 5.

SUPERDEHUMIDIFY (WITH COOL TO DEHUMIDIFY)

This selection only affects cool-to-dehumidify operation. It is part

of the installer setup (see Configuration Option No. 7) and must be

made by installer. The Homeowner’s Guide does not cover this

selection. A requirement is the use of a variable-speed indoor unit

with superdehumidify capability. During cool-to-dehumidify call,

it provides maximum dehumidification by reducing airflow to a

minimum. The actual superdehumidify command from Thermidistat Control to the indoor unit is a Y signal without a G signal in

addition to dehumidify signal. The indoor unit responds to this

combination by reducing the airflow to a minimum. All other

characteristics of cool to dehumidify are the same.

ADDITIONAL DEHUMIDIFY COMMENTS

Dehumidification can be enhanced (with some efficiency loss) by

turning blower off immediately at the end of each cooling cycle

(eliminating normal 90 sec blower off delay). Where maximum

humidity removal is desired, this should be done, if possible. Fan

coils have the capability of removing this off delay, furnaces do

not. On FK Fan Coils, set delay tap to 0/0. On standard fan coils,

a jumper can be cut to disable off delay. Refer to fan coil

Installation Instructions for details. If FAN is set for continuous

operation (fan ON icon displayed), G output is turned off for 5

minutes at the end of each cooling cycle as long as dehumidify

demand exists.

Like humidify, dehumidify actions are initiated when humidity is

2 percent above set point and are terminated when humidity drops

to 2 percent below set point. This prevents unnecessary toggling of

dehumidify actions when humidity is near set point.

The vacation mode contains additional dehumidify features designed to protect an unoccupied home. Refer to the "Vacation"

section for additional information.

With any dehumidify selection, if the system has a 2-speed

compressor (DIP switch No. 2 is ON) and does NOT have a

variable-speed blower (Configuration Option No. 5 set to OFF), all

cooling will be done at high speed while dehumidify demand

exists. This is because the combination of 2-speed compressor

without variable-speed blower generally has poor water removal

on low speed.

DEHUMIDIFY OUTPUT AND EQUIPMENT CONNECTIONS

When there is a dehumidify demand, dehumidify output is

activated, which means that a 24-vac signal is removed from the

DHUM output terminal. In other words, dehumidify output logic is

reversed — output is turned ON when no dehumidify demand

exists and is turned OFF when demand exists. This logic reversal

has come about from historical use of a standard humidistat to do

dehumidification. The humidistat contacts open on high humidity,

thus removing a 24-vac signal to initiate dehumidification. Equipment has been designed to operate in this manner, so the

Thermidistat Control must now accommodate the existing equipment.

→

Bryant FK Series Variable-Speed Fan Coils, all 333BAV and

333JAV 80% Variable-Speed Furnaces, and 355MAV 90%

Variable-Speed Furnaces with the DE connection have dehumidify

inputs which connect directly to Thermidistat Control DHUM

output. They are compatible with the reverse logic output and will

reduce their cooling CFM by approximately 20 percent when a

dehumidify demand is present.

The FK Series Fan Coil has a terminal marked DH which should

be connected to the Thermidistat Control DHUM output. Jumper

J1 on fan coil MUST be removed. It is located behind the DH

terminal. Additionally blower delay tap on fan coil should be set to

0/0 (no ON delay and no OFF delay) when using cool to

dehumidify. With this selection, the blower stops when G signal is

removed, preventing re-evaporation of water from the coil which

would occur during the normal 90 sec blower off delay. See Table

6 and Fig. 7 through 10.

On 333BAV and 333JAV Furnaces, a green wire marked DHUM

is connected to a spade lug which is connected to the G input

terminal. Unplug spade lug, cut off spade receptacle from wire

end, and splice a wire between green DEHUM wire and Thermidistat Control DHUM terminal. See Table 6 and Fig. 19 through

22.

→

Bryant 355MAV Furnaces also have a DEHUM input. The

DEHUM input acts differently depending on which style of

variable-speed furnace control you have. The older style variablespeed furnace control DOES NOT have a DE connection while the

newer style variable-speed furnace control has a DE connection.

Both of these variable-speed furnace controls function the same

except the DEHUM logic is reversed.

→

On the older style variable-speed furnace controls, a field-supplied

relay is required between the Thermidistat Control and furnace.

The relay coil is connected between DHUM output on the

Thermidistat Control and COM terminal on the furnace control. Its

normally closed contact is connected between R and DEHUM

terminals on the furnace control, where the DEHUM terminal is a

spade lug located next to the transformer secondary connections.

See Table 6 and Fig. 23 through 26. When a dehumidify demand

exists, relay is de-energized, and normally closed contacts supply

24vac to the furnace DEHUM terminal. As a result the furnace

control reduces the blower airflow by 15 percent.

→

On newer style variable-speed furnace controls, a field-supplied

relay IS NOT required. The DHUM output on the Thermidistat

Control is instead connected directly to the DEHUM terminal on

the furnace control, where the DEHUM terminal is a spade lug

located next to the transformer secondary connections. In addition

the DE jumper located next to the DEHUM terminal must be

removed to enable the DEHUM input. See Table 6 and Fig. 27

through 30. When a dehumidify demand exists the furnace control

reduces the blower airflow by 21 percent.

C. Vacation

A vacation selection is available specifically for times where the

home will not be occupied for an extended period. For convenience, 1 button selects vacation mode which is indicated by OUT

icon on display. Vacation mode also has an automatic hold,

—9—

Page 10

→ TABLE 6—WIRING DIAGRAM REFERENCE CHART

EQUIPMENT SELECTION

Typical Fan Coil Fig. 3 Fig. 4 Fig. 5 Fig. 6

FK4C Fan Coil Fig. 7 Fig. 8 Fig. 9 Fig. 10

1-Stage Furnace Fig. 11 Fig. 12 Fig. 13 Fig. 14

2-Stage Furnace Fig. 15 Fig. 16 Fig. 17 Fig. 18

Variable-Speed 2-Stage

Non-Condensing Furnace

Variable-Speed 2-Stage

Condensing Furnace

Without DE Connection

Variable-Speed 2-Stage

Condensing Furnace

With DE Connection

SINGLE-SPEED

AIR CONDITIONER

Fig. 19 Fig. 20 Fig. 21 Fig. 22

Fig. 23 Fig. 24 Fig. 25 Fig. 26

Fig. 27 Fig. 28 Fig. 29 Fig. 30

TWO-SPEED

AIR CONDITIONER

SINGLE-SPEED

HEAT PUMP

TWO-SPEED

HEAT PUMP

meaning that set points are not affected by the programmed

schedule. While in vacation mode, the system provides temperature and humidity protection for the home in all seasons, but not

comfort.

VACATION SET POINTS

A special set of temperature and humidity set points exists which

are active in vacation mode. They are adjustable by the homeowner, are exclusively for vacation mode, and are remembered

from 1 vacation selection to the next. These set points will be

higher for cool and dehumidify and lower for heat and humidify

than those of occupied mode.

VACATION HUMIDIFICATION

Normal humidify is available, using vacation set points. Humidification by fan only is not available as vacation selection. Auto

humidification is available, adjusting its set point with outdoor

temperature the same as when occupied. The maximum humidity

set point can be adjusted separately from the occupied value, but

it must always be less than occupied value. This allows humidification to track outdoor temperature identically, whether occupied

or vacation, but allows maximum humidification to be less when

unoccupied. Vacation humidification can be turned off independently of occupied humidification.

VACATION DEHUMIDIFICATION

Normal Dehumidify, Cool to Dehumidify, and Dehumidify OFF,

are all available in vacation mode, and selection of 1 of these can

be different from that of occupied. Vacation dehumidification

selection and set points are remembered the next time vacation is

used.

Cool to dehumidify operates slightly differently, allowing the

home to be cooled to as low as 70°F when trying to achieve

dehumidify set point. The balance between dehumidify and

temperature set point adjustments is 1 percent set point increase

per degree of overcooling for temperatures below 76°F. For

example, at 74°F dehumidify set point is raised 2 percent, and at

72°F dehumidify set point is raised 4 percent. At temperatures

above 76°F, dehumidify set point is not changed.

Under no conditions will the house be cooled below 70°F,

regardless of dehumidify demand.

OPERATIONAL INFORMATION

A. Five-Minute Compressor Timeguard

This timer prevents compressor from starting unless it has been off

for at least 5 minutes. It can be defeated for 1 cycle by

simultaneously pressing FAN mode button and INCREASE TEMPERATURE button.

B. Fifteen-Minute Cycle Timer

This timer prevents the start of a heating or cooling cycle until at

least 15 minutes after the last start of the same cycle. Its function

is to assure that equipment is not cycled more than 4 times per hr.

This timer is defeated for 1 cycle when desired temperature is

manually changed. It can also be defeated for 1 cycle by

simultaneously pressing FAN mode button and INCREASE TEMPERATURE button.

C. Fifteen-Minute Staging Timer

In multistage heating or cooling, this timer prevents any higher

stage from turning on until preceding stage has been on for 15

minutes. This timer is defeated if temperature error is greater than

5°F (usually due to a large change in desired temperature).

D. Three-Minute Minimum On Time

→

In normal operation, when a stage turns on, it will not turn off for

a minimum of 3 minutes. If the set point is changed, this timer is

automatically canceled, allowing the equipment to turn off immediately when the demand is removed.

E. Heat/Cool Set points (Desired Temperature)

A minimum difference of 2° is enforced between heating and

cooling desired temperatures. This is done by allowing 1 setting to

"push" the other, to maintain this difference. This difference is

adjustable via Configuration Option 14.

F. Equipment ON Indicators

When cooling equipment is on, a COOL icon preceded by a small

triangle is displayed below cool set point. While cooling equipment turn on is delayed by a staging or cycle timer, triangle will

flash. The same is true for HEAT icon and its preceding triangle

located under heat set point. These 2 arrows are also used to

indicate state of humidify and dehumidify outputs. See next

section.

→

G. Humidify and Dehumidify Indicators

The humidity screen (selected by pressing the HUMIDITY button)

uses the same triangles referenced in the above paragraph to

indicate the state of the HUM and DHUM outputs. When

humidification or dehumidification is active, the triangle under its

set point is turned on.

H. Humidify/Dehumidify Output ON Indicators

Within humidity select screen (selected by Humidity button and

indicated by "hu" or "dhu" on clock display), triangle under

humidity set point will be on while humidify output is on. Triangle

under dehumidify set point will be on while dehumidify output is

active (turned off, because this output is reverse logic).

I. Auto Changeover

When auto changeover mode is selected, a change from heat to

cool (or vice versa) will not occur until an opposite mode demand

has existed for 20 minutes. If set point is changed, 20-minute

requirement is deleted.

J. Emergency Heat Mode

When Thermidistat Control is configured as a heat pump and

emergency heat is selected, all Y signals are locked out, and W

becomes energized upon a call for heat.

—10—

Page 11

THERMIDISTAT

HEAT STAGE 2

N/A

HEAT STAGE 1

COOL STAGE 1

FAN

24 VAC HOT

O/W2

Y1/W2

W/W1

Y/Y2

G

R

TYPICAL

FAN COIL

E

W3

W2

Y

G

R

1-SPEED

AIR CONDITIONER

Y

THERMIDISTAT

COOL STAGE 1

HEAT STAGE 2

HEAT STAGE 1

COOL STAGE 2

FAN

24 VAC HOT

Y1/W2

O/W2

W/W1

Y/Y2

G

R

TYPICAL

FAN COIL

E

W3

W2

Y

G

R

2-SPEED

AIR CONDITIONER

Y1

Y2

R

24 VAC COMM

N/A

HUMIDIFY

N/A

OUTDOOR

SENSOR

CONNECTION

THERMIDISTAT

RVS COOLING

HEAT STAGE 3

HEAT STAGE 2

HEAT/COOL

STAGE 1

FAN

24 VAC HOT

C

HUMIDIFIER

(24 VAC)

OUTDOOR

SENSOR

See notes 1, 6, 13, and 15

DHUM

C

HUM

B

S1

S2

Fig. 3—Typical Fan Coil With

1-Speed Air Conditioner

TYPICAL

FAN COIL

O/W2

Y1/W2

W/W1

Y/Y2

G

R

E

W3

W2

Y

G

R

1-SPEED

HEAT PUMP

O

W2

Y

R

C

A97382

24 VAC COMM

HUMIDIFY

OUTDOOR

SENSOR

CONNECTION

Fig. 4—Typical Fan Coil With

N/A

N/A

DHUM

HUM

C

B

S1

S2

C

HUMIDIFIER

(24 VAC)

OUTDOOR

SENSOR

See notes 1, 6, 13, and 16

C

A97383

2-Speed Air Conditioner

THERMIDISTAT

RVS COOLING

HEAT/COOL

STAGE 1

HEAT STAGE 3

HEAT/COOL

STAGE 2

FAN

24 VAC HOT

O/W2

Y1/W2

W/W1

Y/Y2

G

R

TYPICAL

FAN COIL

E

W3

W2

Y

G

R

2-SPEED

HEAT PUMP

O

Y1

W2

Y2

W3

R

24 VAC COMM

N/A

HUMIDIFY

RVS HEATING

OUTDOOR

SENSOR

CONNECTION

C

DHUM

HUM

B

S1

S2

See notes 1, 7, 14, and 15

C

HUMIDIFIER

(24 VAC)

OUTDOOR

SENSOR

Fig. 5—Typical Fan Coil With

1-Speed Heat Pump

C

A97384

24 VAC COMM

HUMIDIFY

RVS HEAT

OUTDOOR

SENSOR

CONNECTION

N/A

DHUM

C

HUM

B

S1

S2

C

HUMIDIFIER

(24 VAC)

OUTDOOR

SENSOR

See notes 1, 4, 5, 14, and 16

C

A97385

Fig. 6—Typical Fan Coil With

2-Speed Heat Pump

—11—

Page 12

THERMIDISTAT

HEAT STAGE 2

N/A

HEAT STAGE 1

COOL STAGE 1

FAN

24 VAC HOT

DEHUMIDIFY

24 VAC COMM

HUMIDIFY

N/A

OUTDOOR

SENSOR

CONNECTION

O/W2

Y1/W2

W/W1

Y/Y2

G

R

DHUM

C

HUM

B

S1

S2

FK SERIES

FAN COIL

W2

Y1

W1

Y/Y2

G

R

O

DH

C

HUMIDIFIER

(24 VAC)

OUTDOOR

SENSOR

See notes 1, 2, 6, 13, and 15

1-SPEED

AIR CONDITIONER

REMOVE J2 JUMPER

FOR HEAT STAGING

REMOVE

J1 JUMPER

FOR

DEHUMIDIFY

MODES

→ Fig. 7—FK Series Fan Coil With

1-Speed Air Conditioner

FK SERIES

THERMIDISTAT

HEAT STAGE 2

HEAT STAGE 1

Y

C

A98278

COOL STAGE 1

COOL STAGE 2

24 VAC HOT

DEHUMIDIFY

24 VAC COMM

HUMIDIFY

OUTDOOR

SENSOR

CONNECTION

FAN

N/A

O/W2

W/W1

Y1/W2

Y/Y2

G

R

DHUM

C

HUM

B

S1

S2

FAN COIL

W2

W1

Y1

Y/Y2

G

R

O

DH

C

HUMIDIFIER

(24 VAC)

OUTDOOR

SENSOR

See notes 1, 2, 6, 13, and 16

2-SPEED

AIR CONDITIONER

REMOVE J2 JUMPER

FOR HEAT STAGING

Y1

Y2

REMOVE

J1 JUMPER

FOR

DEHUMIDIFY

MODES

R

C

A98279

→ Fig. 8—FK Series Fan Coil With

2-Speed Air Conditioner

THERMIDISTAT

RVS COOLING

HEAT STAGE 3

HEAT STAGE 2

HEAT/COOL

STAGE 1

FAN

24 VAC HOT

DEHUMIDIFY

24 VAC COMM

HUMIDIFY

RVS HEATING

OUTDOOR

SENSOR

CONNECTION

O/W2

Y1/W2

W/W1

Y/Y2

G

R

DHUM

C

HUM

B

S1

S2

FK SERIES

FAN COIL

O

W2

W1

Y/Y2

G

R

Y1

DH

C

HUMIDIFIER

(24 VAC)

OUTDOOR

SENSOR

See notes 1, 2, 7, 14, and 15

1-SPEED

HEAT PUMP

REMOVE J2 JUMPER

FOR HEAT STAGING

REMOVE

J1 JUMPER

FOR

DEHUMIDIFY

MODES

→ Fig. 9—FK Series Fan Coil With

1-Speed Heat Pump

O

W2

R

FK SERIES

THERMIDISTAT

FAN

O/W2

Y1/ W2

W/W1

Y/Y2

G

R

DHUM

C

HUM

B

S1

S2

RVS COOLING

HEAT/COOL

STAGE 1

HEAT STAGE 3

Y

C

A98280

HEAT/COOL

STAGE 2

24 VAC HOT

DEHUMIDIFY

24 VAC COMM

HUMIDIFY

RVS HEATING

OUTDOOR

SENSOR

CONNECTION

FAN COIL

O

Y1

W1

W2

Y/Y2

G

R

DH

C

HUMIDIFIER

(24 VAC)

OUTDOOR

SENSOR

See notes 1, 2, 4, 5, 14, and 16

2-SPEED

HEAT PUMP

O

Y1

W2

J2 JUMPER

FOR HEAT STAGING

Y2

REMOVE J1

JUMPER

FOR

DEHUMIDIFY

MODES

R

W3

C

A98281

→ Fig. 10—FK Series Fan Coil With

2-Speed Heat Pump

—12—

Page 13

THERMIDISTAT

N/A

N/A

HEAT STAGE 1

COOL STAGE 1

FAN

24 VAC HOT

O/W2

Y1/ W2

W/W1

Y/Y2

G

R

1-STAGE

FURNACE

W

Y

G

R

1-SPEED

AIR CONDITIONER

Y

THERMIDISTAT

N/A

COOL STAGE 1

HEAT STAGE 1

COOL STAGE 2

FAN

24 VAC HOT

O/W2

Y1/W2

W/W1

Y/Y2

G

R

1-STAGE

FURNACE

W

Y

G

R

2-SPEED

AIR CONDITIONER

Y1

Y2

R

N/A

HUMIDIFY

N/A

OUTDOOR

SENSOR

CONNECTION

THERMIDISTAT

RVS COOLING

N/A

HEAT STAGE 2

(FURNACE)

HEAT/COOL

STAGE 1

(COMPRESSOR)

FAN

24 VAC HOT

C

DHUM

HUM

B

S1

S2

C

HUMIDIFIER

(24 VAC)

OUTDOOR

SENSOR

See notes 13 and 15

Fig. 11—Single-Stage Furnace With

1-Speed Air Conditioner

O/W2

Y1/W2

W/W1

Y/Y2

G

R

1-STAGE

FURNACE

W

Y

G

R

1-SPEED

HEAT PUMP

W2

C

A97391

24 VAC COMM

HUMIDIFY

OUTDOOR

SENSOR

CONNECTION

N/A

N/A

C

DHUM

HUM

B

S1

S2

C

HUMIDIFIER

(24 VAC)

OUTDOOR

SENSOR

See notes 13 and 16

C

A97392

Fig. 12—Single-Stage Furnace With

2-Speed Air Conditioner

1-STAGE

THERMIDISTAT

FAN

O/W2

Y1/W2

W/W1

Y/Y2

G

R

O

Y

R

RVS COOLING

HEAT/COOL

STAGE 1

(COMPRESSOR LO)

HEAT STAGE 3

(FURNACE)

HEAT/COOL

STAGE 2

(COMPRESSOR HI)

24 VAC HOT

FURNACE

W

Y

G

R

2-SPEED

HEAT PUMP

O

Y1

W2

Y2

W3

R

24 VAC COMM

N/A

HUMIDIFY

N/A

OUTDOOR

SENSOR

CONNECTION

C

DHUM

HUM

B

S1

S2

C

HUMIDIFIER

(24 VAC)

OUTDOOR

SENSOR

See notes 3, 9, 14, 15, and 17

Fig. 13—Single-Stage Furnace With

1-Speed Heat Pump (Dual Fuel)

C

A97393

24 VAC COMM

HUMIDIFY

OUTDOOR

SENSOR

CONNECTION

N/A

N/A

C

DHUM

HUM

B

S1

S2

C

HUMIDIFIER

(24 VAC)

OUTDOOR

SENSOR

See notes 3, 4, 5, 9, 14, 16, and 17

C

A97394

Fig. 14—Single-Stage Furnace With

2-Speed Heat Pump (Dual Fuel)

—13—

Page 14

THERMIDISTAT

HEAT STAGE 2

N/A

HEAT STAGE 1

COOL STAGE 1

FAN

24 VAC HOT

O/W2

Y1/ W2

W/W1

Y/Y2

G

R

2-STAGE

FURNACE

W2

W/W1

Y/Y2

G

R

1-SPEED

AIR CONDITIONER

Y

THERMIDISTAT

HEAT STAGE 2

COOL STAGE 1

HEAT STAGE 1

COOL STAGE 2

FAN

24 VAC HOT

2-STAGE

O/W2

Y1/W2

W/W1

Y/Y2

G

R

FURNACE

W2

W/W1

Y/Y2

G

R

2-SPEED

AIR CONDITIONER

Y1

Y2

R

24 VAC COMM

N/A

HUMIDIFY

N/A

OUTDOOR

SENSOR

CONNECTION

THERMIDISTAT

RVS COOLING

HEAT STAGE 3

(FURNACE HI)

HEAT STAGE 2

(FURNACE LO)

HEAT/COOL

STAGE 1

(COMPRESSOR)

FAN

24 VAC HOT

C

DHUM

HUM

B

S1

S2

C

HUMIDIFIER

(24 VAC)

OUTDOOR

SENSOR

See notes 6, 13, and 15

Fig. 15—Two-Stage Furnace With

1-Speed Air Conditioner

2-STAGE

O/W2

Y1/W2

W/W1

Y/Y2

G

R

FURNACE

W2

W/W1

Y/Y2

G

R

1-SPEED

HEAT PUMP

W2

C

A97395

24 VAC COMM

N/A

HUMIDIFY

N/A

OUTDOOR

SENSOR

CONNECTION

C

DHUM

HUM

B

S1

S2

C

HUMIDIFIER

(24 VAC)

OUTDOOR

SENSOR

See notes 6, 13, and 16

C

A97396

Fig. 16—Two-Stage Furnace With

2-Speed Air Conditioner

2-STAGE

THERMIDISTAT

FAN

Y1/W2

W/W1

O/W2

Y/Y2

G

R

O

Y

R

RVS COOLING

HEAT/COOL

STAGE 1

(COMPRESSOR LO)

HEAT STAGE 3

(FURNACE)

HEAT/COOL

STAGE 2

(COMPRESSOR HI)

24 VAC HOT

FURNACE

W2

W/W1

Y/Y2

G

R

2-SPEED

HEAT PUMP

O

Y1

W2

Y2

W3

R

24 VAC COMM

HUMIDIFY

OUTDOOR

SENSOR

CONNECTION

N/A

N/A

C

DHUM

HUM

B

S1

S2

C

HUMIDIFIER

(24 VAC)

OUTDOOR

SENSOR

See notes 3, 7, 9, 10, 14, 15, and 17

Fig. 17—Two-Stage Furnace With

1-Speed Heat Pump (Dual Fuel)

C

A97397

24 VAC COMM

N/A

HUMIDIFY

N/A

OUTDOOR

SENSOR

CONNECTION

C

DHUM

HUM

B

S1

S2

See notes 3, 4, 5, 8, 9, 10, 14, 16, and 17

C

HUMIDIFIER

OUTDOOR

SENSOR

C

A97398

Fig. 18—Two-Stage Furnace With

2-Speed Heat Pump (Dual Fuel)

—14—

Page 15

VARIABLE SPEED 80% NON-CONDENSING FURNACE

O

Y1

THERMIDISTAT

HEAT STAGE 2

N/A

HEAT STAGE 1

COOL STAGE 1

FAN

24 VAC HOT

O/W2

Y1/W2

W/W1

Y/Y2

G

R

FURNACE

BOARD

W2

W/W1

Y/Y2

G

R

AFS

BOARD

1-SPEED

AIR CONDITIONER

Y

VARIABLE SPEED 80% NON-CONDENSING FURNACE

O

THERMIDISTAT

COOL STAGE 1

HEAT STAGE 2

HEAT STAGE 1

COOL STAGE 2

FAN

24 VAC HOT

Y1/W2

O/W2

W/W1

Y/Y2

G

R

Y1

FURNACE

BOARD

W2

W/W1

Y/Y2

G

R

AFS

BOARD

2-SPEED

AIR CONDITIONER

Y1

Y2

R

24 VAC COM

DEHUMIDIFY

HUMIDIFY

N/A

OUTDOOR

SENSOR

CONNECTIONS

C

DHUM

HUM

B

S1

S2

COM

HUM

DEHUM

PL9-10

HUMIDIFIER

(24 VAC)

OUTDOOR

SENSOR

See notes 6, 10, 12, 13, and 15

C

A97434

Fig. 19—Variable-Speed 2-Stage Non-Condensing Furnace

With 1-Speed Air Conditioner

VARIABLE SPEED 80% NON-CONDENSING FURNACE

O

THERMIDISTAT

RVS COOLING

HEAT STAGE 3

HEAT STAGE 2

HEAT/COOL

STAGE 1

FAN