Bryant ERVXXSVB1100, HRVXXSVB1100, ERVXXSHB1100, HRVXXSHB1100, ERVXXLHB1200 Product Data

...

HRVXX

Heat Recovery Ventilators

ERVXX

Energy Recovery Ventilators

Product Data

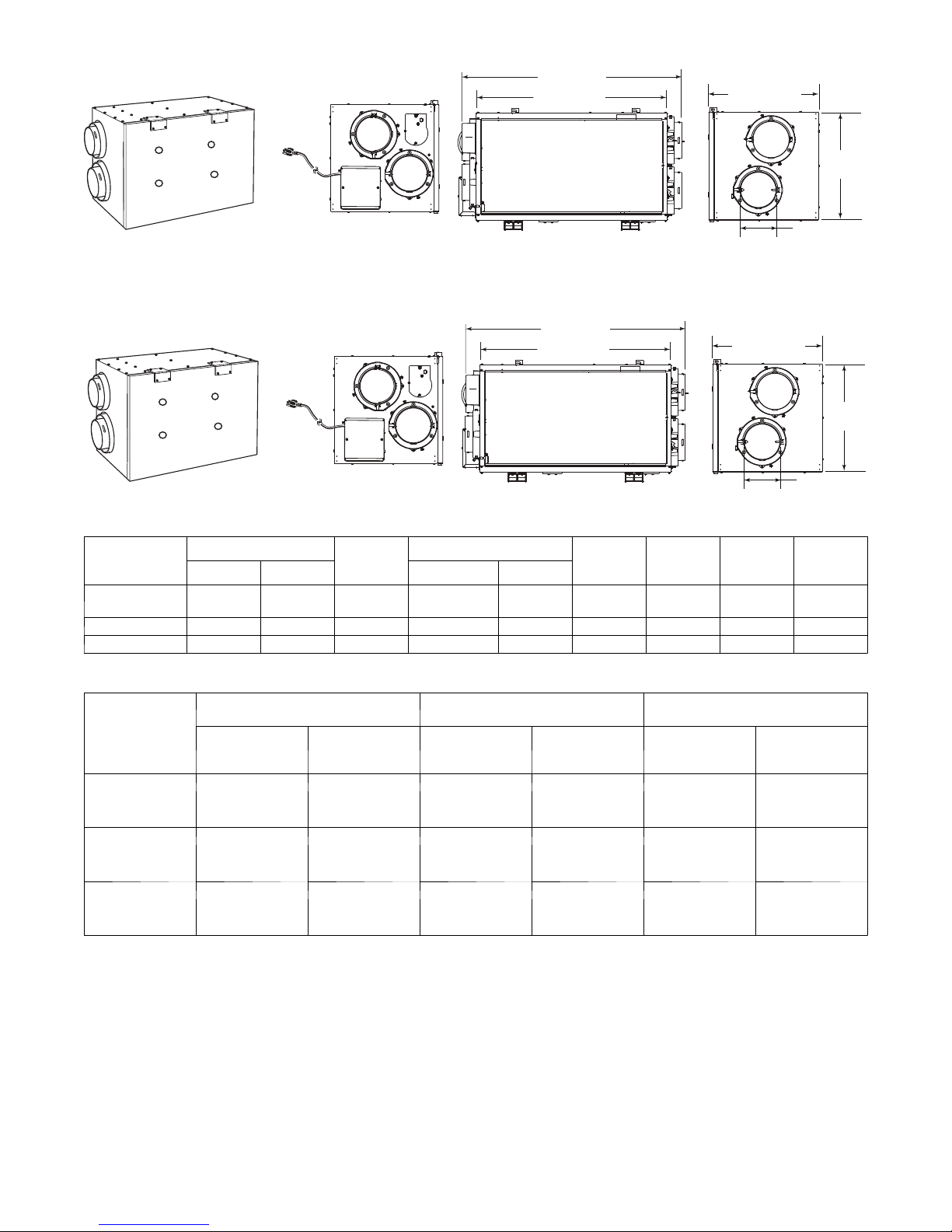

ERVXXSVB1100, HRVXXSVB1100

ERVXXSHB1100, HRVXXSHB1100

ERVXXLHB1200, HRVXXLHB1150, HRVXXLHB1250

HRVXXSVU11 5 7

A05229

A05330

A10299

A12338

The Heat Recovery Ventilation (HRV) and Energy Recovery

Ventilator (ERV) systems offered by Bryant are the finest on the

market today. These units provide efficient and cost effective heat

recovery during the heating season when needed most.

As temperatures drop below 23_F(--5_C), indoor air is recirculated

periodically through the heat exchanger core to prevent frost from

forming. Competitors’ methods of supplementary electric defrost

waste energy. Unlike rotary wheel heat exchangers which mix air

streams, these cross--flow or counterflow heat exchangers ensure

that there is no mixing of the stale air stream with the fresh outdoor

air stream.

A filter installed on the incoming outdoor air stream removes large

airborne particles from the intake air stream before they enter the

heat exchanger and reduces the maintenance required. The units’

acoustically engineered design make Bryant ventilators the quietest

on the market and ensures that comfort is felt, not heard.

Unlatching two (2) suitcase style latches allows easy removal of the

filters and core for cleaning on most units.

NOTE: The unit should not be installed in an attic or

unconditioned space unless provisions are made for drain line

freezing and condensation.

STANDARD FEAT URES

HRV

S Energy saving defrost cycle

S Cross--flow, counterflow heat exchangers

S One filter on incoming air; one filter on outgoing air to

protect core

S Acoustical design

S Polypropylene heat exchanger core

ERV

S Integrated airflow balancing points

S Integrated furnace interlock

S High pressure blowers

S Onboard control for continuous high/low ventilator operation

S Energy saving defrost cycle

S Cross--flow, counterflow heat exchangers

S One filter on incoming air; one filter on outgoing air to

protect core

S No--tools maintenance

S Enthalpic heat exchanger core

HRVXXLVU1330

A12339

MODEL NUMBER NOMENCLATURE

ERV XX LHB 1 150

PRODUCT TYPE CFM

ERV --- Energy Recovery Ventilator

HRV --- Heat Recovery Ventilator VOLTAGE

1 --- 115/60/1

BRAND STYLE

XX --- Dual Branded LHB --- Large Horizontal, End Ports

Installer selects and applies logo badge HRV -- - 150, 250 cfm

E R V --- 2 0 0 c f m

SVB --- Small Horizontal, Top Vertical Ports

H R V & E R V --- 10 0 c f m

SHB --- Small Horizontal, End Ports

H R V & E R V --- 10 0 c f m

SVU --- Vertical, Top Ports

H R V --- 1 5 7 c f m

LVU --- Large Vertical, Top Ports

H R V --- 3 3 0 c f m

Energy Star Canada:

All units in this document meet Energy Star Tier 2

reguirements in Canada except HRVXXLVU1330reguirements in Canada except HRVXXLVU1

and ERVXXLHB1200

These products earned the

ENERGY STAR

energy efficiency guidelines set by

Natural Resources Canada and

the US EPA. They meet ENERGY

STAR requirements only when

used in Canada.

®

by meeting strict

Climate Map for Energy and Heat Recovery Ventilators

Helena

Salt Lake

City

Edmonton

Calgary

Denver

Regina

Winnipeg

Bismark

Minneapolis

Topeka

Green Bay

Madison

Des Moines

Springfield

Timmins

Milwaukee

Chicago

Indianapolis

Detroit

Ottawa

Harrisburg

Washington D.C.

Montreal

Syracuse

Hartford

Boston

Vancouver

Salem

Sacramento

Boise

Honolulu

HRV Recommended

ERV Recommended w/HRV or ERV Wall Control

ERV Recommended

Oklahoma City

Austin

2

Baton Rouge

Nashville

Atlanta

Raleigh

Columbia

Orlando

A00099

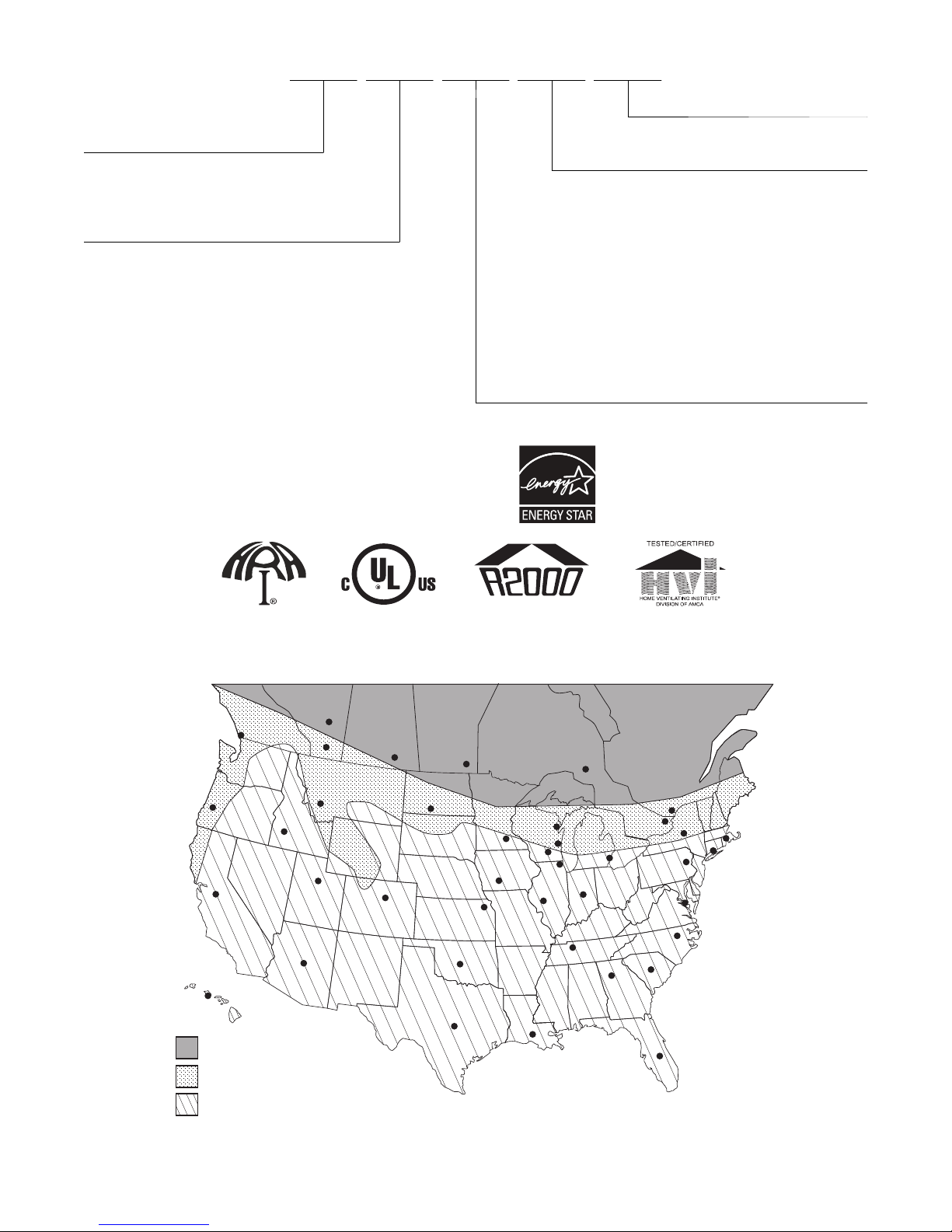

ERVXXSVB1100, HRVXXSVB1100

A

LL PORTS FIT

DIAMETER DUCTS

5”

4

4’’ (102 mm)

3

6’’ (152 mm)

(64 mm)

3

12 16”

(310 mm)

2½”

13

19 16”

(503 mm)

16¼”

(413 mm)

1

2

9

16

” (574 mm)

22

23¾” (603 mm)

1: F

RESH AIR TO BUILDING PORT

2: E

XHAUST AIR FROM BUILDING PORT

3: F

RESH AIR FROM OUTSIDE PORT

4: E

XHAUST AIR TO OUTSIDE PORT

PHYSICAL & ELECTRICAL DATA

MODEL

CAPACITY (LO--- HI)

CFM L/S TYPE AIR FLOW

PORT

LOC.

ERVXXSVB1100 35 --- 105 17 --- 50 Top

transfer media

Enthalpic

CORE

WEIGHT

LBS. [KG]

VOLTAGE

Cross Flow 45 [20] 115/60/1 104 1.0

HRVXXSVB1100 35 --- 105 17 --- 50 Top Polypropylene Cross Flow 42 [19] 115/60/1 100 0.85

MAX

POWER

WATTS

MAX

AMPS

DEFROST OPERATION

OUTSIDE TEMPERATURE DEFROST CYCLE (MIN.)

MODEL

ERVXXSVB1100

HRVXXSVB1100

_C _F Defrosting

--- 5 t o --- 2 7 23 to --- 17 9 28

B e l o w --- 2 7 B e l o w --- 1 7 10 22

--- 5 t o --- 2 7 23 to --- 17 8 25

B e l o w --- 2 7 B e l o w --- 1 7 10 22

Operation Time Between

Each Defrost Cycle

A12327

HVI RATED ENERGY PERFORMANCE

MODEL MODE

ERVXXSVB1100

HRVXXSVB1100

SUPPLY

TEMP

_C _F L/S CFM

0 32 23 49 42 67 79 0.61

Heat

0 32 30 64 60 65 75 0.55

0 32 40 84 72 63 71 0.48

--- 2 5 --- 1 3 21 45 58 60 75 0.60

Cool 35 95 21 44 42 50

0 32 23 50 43 65 74 0.01

Heat

0 32 30 64 58 62 70 0.01

0 32 39 83 70 59 66 0.01

--- 2 5 --- 1 3 21 45 56 60 78 0.01

Cool 35 95

NET

AIR FLOW

VENTILATION PERFORMANCE

EXT. STATIC

MODEL

PRESSURE

Pa In w.g. L/S CFM L/S CFM L/S CFM

25 0.1 54 115 55 117 55 117

50 0.2 53 112 54 115 54 114

ERVXXSVB1100

100 0.4 49 105 50 106 50 106

200 0.8 42 89 43 92 42 88

250 1.0 38 81 39 82 38 81

25 0.1 53 111 53 112 57 120

50 0.2 51 107 51 108 54 114

HRVXXSVB1100

100 0.4 46 98 47 99 49 105

200 0.8 37 79 38 80 40 85

250 1.0 34 71 34 72 36 76

NOTE: For additional data points, refer to HVI Directory at www.hvi.org

NET SUPPLY AIR

FLOW

POWER

CONSUMED

(WATTS)

SENSIBLE

RECOVERY

EFFICIENCY

APPARENT

SENSIBLE

EFFECTIVE-

NESS

RECOVERY

MOISTURE

TRANSFER

GROSS AIR FLOW

SUPPLY EXHAUST

LATENT

TOTAL

RECOVERY

EFFICIENCY

3

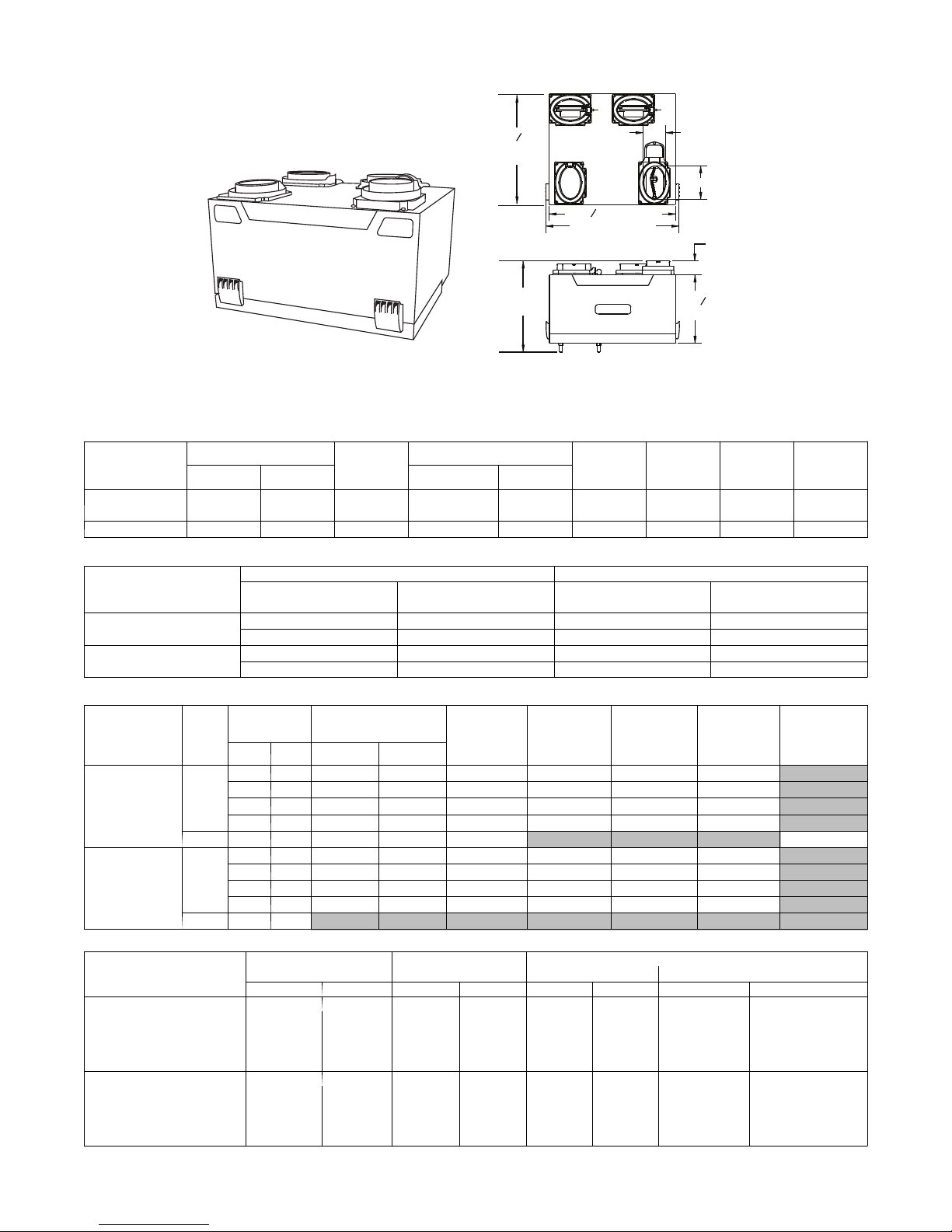

ALL PORTS FIT 5”

DIAMETER DUCTS

6”

(152 mm)

1

4” (102 mm)

ERVXXSHB1100, HRVXXSHB1100

1

27 /

16” (688 mm)

9

22 /16” (574 mm)

2

(349 mm)

13¾”

13

19 /16” (503 mm)

3

4

3

12 /16”

(310 mm)

1: FRESH AIR TO BUILDING PORT

2: EXHAUST AIR FROM BUILDING PORT

2” (51 mm)

3: FRESH AIR FROM OUTSIDE PORT

4: EXHAUST AIR TO OUTSIDE PORT

PHYSICAL & ELECTRICAL DATA

MODEL

CAPACITY (LO--- HI)

CFM L/S TYPE AIR FLOW

PORT

LOC.

ERVXXSHB1100 35 --- 105 17 --- 50 Ends

transfer media

Enthalpic

CORE

WEIGHT

LBS. [KG]

VOLTAGE

Cross Flow 45 [20] 115/60/1 104 1.0

HRVXXSHB1100 35 --- 105 17 --- 50 Ends Polypropylene Cross Flow 42 [19] 115/60/1 100 0.85

MAX

POWER

WATTS

MAX

AMPS

DEFROST OPERATION

OUTSIDE TEMPERATURE DEFROST CYCLE (MINUTES)

MODEL

ERVXXSHB1100

HRVXXSHB1100

_C _F Defrosting

--- 5 t o --- 2 7 23 to --- 17 9 28

B e l o w --- 2 7 B e l o w --- 1 7 10 22

--- 5 t o --- 2 7 23 to --- 17 8 25

B e l o w --- 2 7 B e l o w --- 1 7 10 22

Operation Time Between

Each Defrost Cycle

HVI RATED ENERGY PERFORMANCE

MODEL MODE

ERVXXCSHB1100

HRVXXSHB1100

SUPPLY

TEMP

NET AIR

FLOW

_C _F L/S CFM

POWER

CONSUMED

(WATTS)

SENSIBLE

RECOVERY

EFFICIENCY

APPARENT

SENSIBLE

EFFECTIVE-

NESS

0 32 23 49 42 67 79 0.61

Heat

0 32 30 64 60 65 75 0.55

0 32 40 84 72 63 71 0.48

--- 2 5 --- 1 3 21 45 58 60 75 0.60

Cool 35 95 21 44 42 50

0 32 23 50 43 65 74 0.01

Heat

0 32 30 64 58 62 70 0.01

0 32 39 83 70 59 66 0.01

--- 2 5 --- 1 3 21 45 56 60 78 0.01

Cool 35 95

LATENT

RECOVERY

MOISTURE

TRANSFER

TOTAL

RECOVERY

EFFICIENCY

VENTILATION PERFORMANCE

MODEL

EXT. STATIC

PRESSURE

NET SUPPLY AIR

FLOW

Pa In w.g. L/S CFM L/S CFM L/S CFM

25 0.1 54 115 55 117 55 117

50 0.2 53 112 54 115 54 114

ERVXXSHB1100

100 0.4 49 105 50 106 50 106

200 0.8 42 89 43 92 42 88

250 1.0 38 81 39 82 38 81

25 0.1 53 111 53 112 57 120

50 0.2 51 107 51 108 54 114

HRVXXSHB1100

100 0.4 46 98 47 99 49 105

200 0.8 37 79 38 80 40 85

250 1.0 34 71 34 72 36 76

NOTE: For additional data points, refer to HVI Directory at www.hvi.org

SUPPLY EXHAUST

GROSS AIR FLOW

A12328

4

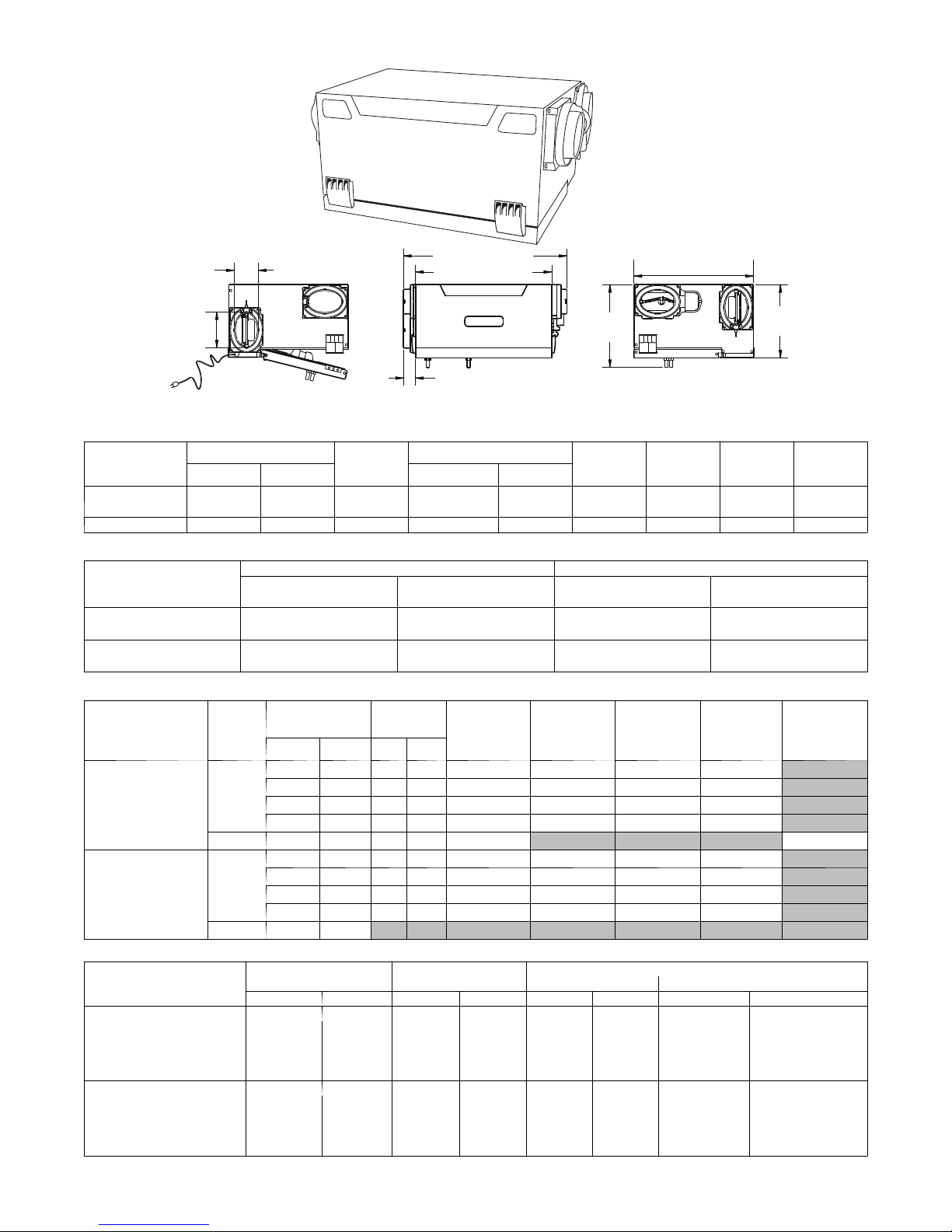

ERVXXLHB1200, HRVXXLHB1150, HRVXXLHB1250

39” (991 mm)

34” (864 mm)

3

ERV

4

1. Fresh air to house.

2. Exhaust air from house.

3. Fresh air from outside.

4. Exhaust air to outside.

35” (891 mm)

30¼” (768 mm)

3

HRV

4

PHYSICAL & ELECTRICAL DATA

MODEL

CFM L/S TYPE AIR FLOW

ERVXXLHB1200 80 --- 198 38 --- 93 Ends

CAPACITY (LO--- HI)

PORT

LOC.

transfer media

HRVXXLHB1150 66 --- 163 31 --- 77 Ends Polypropylene Cross flow 65 [30] 115/60/1 160 1.5

HRVXXLHB1250 82 --- 204 39 --- 96 Ends Polypropylene Cross flow 65 [30] 115/60/1 195 2.1

Enthalpic

CORE

WEIGHT

LBS. [KG]

VOLTAGE

Cross flow 76 [35] 115/60/1 200 2.1

17¼” (438 mm)

2

17¼” (438 mm)

2

MAX

POWER

WATTS

1

6”

(152 mm)

1

6”

(152 mm)

AMPS

17”

(432 mm)

17”

(432 mm)

A12341

MAX

DEFROST OPERATION

MODEL

ERVXXLHB1200

HRVXXLHB1150

HRVXXLHB1250

OUTSIDE TEMPERATURE DEFROST CYCLE (MIN.)

Operation Time

_C _F Defrosting

Between Each

Defrost Cycle

EXTENDED DEFROST CYCLES

(MIN.)

Operation Time

Defrosting

Between Each

Defrost Cycle

--- 5 23 10 60 10 30

--- 1 5 5 10 30 10 20

--- 2 7 --- 1 7 10 20 10 15

--- 5 23 7 50 10 30

--- 1 5 5 7 25 10 20

--- 2 7 --- 1 7 10 20 10 15

--- 5 23 6 50 10 30

--- 1 5 5 6 25 10 20

--- 2 7 --- 1 7 10 20 10 15

5

ERVXXLHB1200, HRVXXLHB1150, HRVXXLHB1250 (cont.)

HVI RATED ENERGY PERFORMANCE

SUPPLY

MODEL MODE

ERVXXLHB1200

HRVXXLHB1150

HRVXXLHB1250

Heat

Cool 35 95 39 82 81 52

Heat

Cool 35 95

Heat

Cool 35 95

TEMP

_C _F L/S CFM

0 32 39 80 84 60 72 0.60

0 32 54 114 113 58 69 0.53

0 32 79 167 169 56 66 0.45

--- 2 5 --- 1 3 31 65 116 41 86 0.47

0 32 31 66 67 67 79 0

0 32 40 86 74 65 75 0

0 32 54 115 90 61 70 0

--- 2 5 --- 1 3 38 81 87 60 76 0.02

0 32 39 82 71 65 75 0.01

0 32 61 130 129 60 69 0.01

--- 2 5 --- 1 3 40 84 114 60 76 0.03

VENTILATION PERFORMANCE

EXT. STATIC

MODEL

ERVXXLHB1200

HRVXXLHB1150

HRVXXLHB1250

NOTE: For additional data points, refer to HVI Directory at www.hvi.org

PRESSURE

Pa In w.g. L/S CFM L/S CFM L/S CFM

25 0.1 105 222 106 225 106 225

75 0.3 93 198 94 200 100 212

100 0.4 86 183 88 186 93 198

150 0.6 70 148 71 150 75 158

200 0.8 50 107 51 108 29 61

25 0.1 85 180 86 182 92 194

75 0.3 77 163 77 164 81 171

100 0.4 71 150 71 151 71 151

150 0.6 60 128 61 130 40 85

175 0.7 51 108 52 110 27 57

25 0.1 106 225 107 227 118 249

75 0.3 96 204 97 205 111 235

100 0.4 90 192 91 193 107 226

150 0.6 76 161 76 162 89 189

175 0.7 67 142 67 143 75 159

NET AIR

FLOW

NET SUPPLY AIR

FLOW

POWER

CONSUMED

(WATTS)

SENSIBLE

RECOVERY

EFFICIENCY

SUPPLY EXHAUST

APPARENT

SENSIBLE

EFFECTIVE-

NESS

GROSS AIR FLOW

RECOVERY

MOISTURE

TRANSFER

LATENT

TOTAL

RECOVERY

EFFICIENCY

6

24 9/16”

(624 mm)

(572 mm)

22 ½”

HRVXXSVU1157

P

OWER

CORD

3’

9

23

/16”

(599 mm)

16

2 ¹/

(53 mm)

”

13

3

/16”

(97 mm)

1

3

7

7

/16”

(189 mm)

4

1

14

/16”

(358 mm)

15

/16”

14

(380 mm)

18 ¼”

(464 mm)

2

NOTE: Every port fits 6” round duct.

1: E

XHAUST AIR TO OUTSIDE

2: F

RESH AIR FROM OUTSIDE

3: E

XHAUST AIR FROM BUILDING

4: F

RESH AIR TO BUILDING

PHYSICAL & ELECTRICAL DATA

MODEL

CAPACITY (LO--- HI)

CFM L/S TYPE AIR FLOW

PORT

LOC.

CORE

WEIGHT

LBS. [KG]

VOLTAGE

HRVXXSVU1157 67 --- 170 32 --- 80 Top Polypropylene Cross flow 56 [25] 115/60/1 125 1.0

MAX

POWER

WATTS

AMPS

DEFROST OPERATION

MODEL

HRVXXSVU1157

OUTSIDE TEMPERATURE DEFROST CYCLE (MINUTES

_C _F Defrosting Exchange

--- 5 t o --- 1 5 23 to 55 7 25

--- 1 6 t o --- 2 7 4 t o --- 1 7 7 25

B e l o w --- 2 7 B e l o w --- 1 7 10 22

HVI RATED ENERGY PERFORMANCE

MODEL MODE

HRVXXSVU1157 Heat

SUPPLY

TEMP

NET AIR

FLOW

_C _F L/S CFM

POWER

CONSUMED

(WATTS)

SENSIBLE

RECOVERY

EFFICIENCY

APPARENT

SENSIBLE

EFFECTIVE-

NESS

0 32 32 67 56 70 78 0.00

0 32 40 86 64 68 75 0.01

0 32 56 120 86 64 70 0.01

--- 2 5 --- 1 3 30 63 79 61 83 0.01

LATENT

RECOVERY

MOISTURE

TRANSFER

A12331

MAX

VENTILATION PERFORMANCE

MODEL

HRVXXSVU1157

EXT. STATIC PRESSURE NET SUPPLY AIR FLOW

Pa In w.g. L/S CFM L/S CFM L/S CFM

25 0.1 91 193 92 195 91 194

75 0.3 80 170 81 171 80 169

100 0.4 74 157 74 158 74 157

150 0.6 62 132 62 133 63 133

200 0.8 47 101 48 101 49 104

GROSS AIR FLOW

Supply Exhaust

7

HRVXXLVU1330

[

]

3

″

13/

16

5

″

[147.6]

1/

2

15

″

[393.7]

15/

6

″

16

[176.2]

″

2

2 PLCS

″

DRAIN

11/

″DIA.

16

[17.5]

2 PLCS

3/

″

16

NOTES:

1. FRESH AIR FROM OUTSIDE TO HRV

2. FRESH AIR FROM HRV TO HOUSE

3/

4

4

″

3. STALE AIR FROM HOUSE TO HRV

[120.6]

4. STALE AIR FROM HRV TO OUTSIDE

1

3/

″

16

[55.6]

3/

12

″

4

[323.9]

3/

22

″

8

[568.3]

1/

7

[181.0]

41″

[1041.4]

8

″

POWER

CORD

1/

1

[38.1]

2 PLCS

24

[611.2]

2

1/

8

″ DIA

8

[206.4]

2 PLCS

4

7/

8

5

″ DIA

[148.2]

1/

19

[484.2]

2 PLCS

43″

(1092.2)

″

16

3/

8

[208.0]

16

″

2

1/

″

16

9/

17

16

[446.9]

5/

16

18

[465.1]

1 ″ [25.4]

2 PLCS

15/

16

23

[608.0]

″

7

182.6

PHYSICAL & ELECTRICAL DATA

MODEL

CAPACITY (LO--- HI)

CFM L/S TYPE AIR FLOW

PORT

LOC.

CORE

WEIGHT

LBS. [KG]

VOLTAGE

HRVXXLVU1330 300 --- 334 142 --- 158 Top Polypropylene Cross flow 145 [66] 115/60/1 500 5.4

MAX

POWER

WATTS

AMPS

DEFROST OPERATION

MODEL

HRVXXLVU1330

OUTSIDE TEMPERATURE DEFROST CYCLE (MINUTES

_C _F Defrosting Exchange

--- 5 t o --- 1 5 23 to 55 6 60

--- 1 6 t o --- 2 7 4 t o --- 1 7 6 32

B e l o w --- 2 7 B e l o w --- 1 7 6 20

WALL

CONTROL

WIRING

3/

8

″ DIA

[9.5]

A12332

MAX

HVI RATED ENERGY PERFORMANCE

MODEL MODE

_C _F L/S CFM

HRVXXLVU1330 Heat

--- 2 5 --- 1 3 115 117 264 74 89 0.07

VENTILATION PERFORMANCE

MODEL

HRVXXLVU1330

EXT. STATIC PRESSURE NET SUPPLY AIR FLOW

Pa In w.g. L/S CFM L/S CFM L/S CFM

25 0.1 168 357 172 364 148 314

75 0.3 158 334 160 340 132 279

100 0.4 151 321 155 328 126 266

150 0.6 136 288 139 294 109 232

200 0.8 126 246 118 251 93 198

SUPPLY

TEMP

NET AIR FLOW

POWER

CONSUMED

(WATTS)

SENSIBLE

RECOVERY

EFFICIENCY

APPARENT

SENSIBLE

EFFECTIVE-

NESS

LATENT

RECOVERY

MOISTURE

TRANSFER

0 32 55 117 219 80 94 --- 0.07

0 32 86 183 290 74 86 0.02

0 32 117 249 436 70 83 --- 0.01

GROSS AIR FLOW

Supply Exhaust

8

METHOD TO SIZE ERVs and HRVs

Ventilator Sizing

Tables 1 and 2 should be used to determine the required airflow for a home. These guidelines are taken from ASHRAE 62.2--2007.

Table 1 – Ventilation Air Requirements, cfm

FLOOR

AREA (ft

1501--- 3000 45 60 75 90 105

3001--- 4500 60 75 90 105 120

4501--- 6000 75 90 105 120 135

6001--- 7500 90 105 120 135 150

2

)

0 --- 1 2 --- 3 4 --- 5 6 --- 7 >7

<1500 30 45 60 75 90

>7500 105 120 135 150 165

BEDROOMS

AREA (m

139.1--- 279 21 28 35 42 50

279.1--- 418 28 35 42 50 57

418.1--- 557 35 42 50 57 64

557.1--- 697 42 50 57 64 71

Table 2 – Ventilation Air Requirements, L/s

FLOOR

2

)

0 --- 1 2 --- 3 4 --- 5 6 --- 7 >7

<139 14 21 28 35 42

>697 50 57 64 71 78

BEDROOMS

HEATING AND COOLING LOAD CHARTS

Although the ventilators process the outside air before it enters the home, additional heating and cooling loads need to be considered.

HEATING LOAD BTUH (APPROXIMATE)

OUTSIDE

TEMPERATURE

Deg. C Deg. F SVB1100 SHB1100 SVU1157 LHB1150 LHB1250 LVU1330 SVB1100 SHB1100 LHB1200

--- 3 2 --- 2 5 4778 4778 7690 6636 10603 9990 4071 4071 8143

--- 2 9 --- 2 0 4531 4531 7090 6294 10057 9310 3861 3861 7723

--- 2 6 --- 1 5 4285 4285 6520 5952 9510 8650 3983 3983 7967

--- 2 3 --- 1 0 4039 4039 5970 5610 8964 8000 3759 3759 7509

--- 2 1 --- 5 3800 3800 5440 5268 8417 7380 3525 3525 7051

--- 1 8 0 3410 3410 4840 4925 7871 6640 3297 3297 6594

--- 1 5 5 3095 3095 4360 4583 7324 6060 3323 3323 6647

--- 1 2 10 2795 2795 3900 4241 6777 5500 3215 3215 6430

--- 9 15 2465 2465 3400 3899 6231 4870 3107 3107 6214

--- 7 20 2195 2195 3000 3557 5684 4350 2834 2834 5669

--- 4 25 1935 1935 2610 3215 5138 3850 2562 2562 5124

--- 1 30 1680 1680 2250 2873 4591 3370 2289 2289 4579

2 35 1425 1425 1880 2531 4045 2870 2017 2017 4034

4 40 1200 1200 1560 2189 3498 2430 1744 1744 3489

HEATING LOAD (BTUH) @ INSIDE DESIGN TEMPERATURE 72° F(21°C)

HRV ERV

COOLING LOAD BTUH (APPROXIMATE)

Outside

Enthalpy

Btu/lb SVB1100 SHB1100 SVU1157 LHB1150 LHB1250 LVU1330 SVB1100 SHB1100 LHB1200

30 482 482 990 670 1071 1390 320 320 640

31 785 785 1650 1090 1741 2310 520 520 1040

32 1086 1086 2310 1509 2411 3240 720 720 1441

33 1388 1388 2970 1928 3080 4170 920 920 1841

34 1690 1690 3630 2347 3750 5090 1120 1120 2241

35 1992 1992 4290 2766 4419 6020 1320 1320 2641

36 2293 2293 4950 3185 5089 6940 1520 1520 3041

37 2595 2595 5610 3604 5759 7870 1720 1720 3441

38 2897 2897 6270 4023 6428 8790 1921 1921 3842

39 3198 3198 6930 4442 7098 9720 2121 2121 4242

40 3478 3478 7590 4831 7767 10650 2321 2321 4642

41 3802 3802 8250 5280 8437 11570 2521 2521 5042

42 4103 4103 8910 5699 9107 12500 2721 2721 5442

HEATING LOAD BTUH

The heating load chart shows the heating loads in Btuh for a range

of winter design temperatures for each model of ventilator.

Cooling Load (btuh) @ Inside Design Temperature

72°F(21°C) and 50% Relative Humidity

HRV ERV

COOLING LOAD BTUH

The cooling load chart shows loads in Btuh as well. To use the

cooling load chart, first find the design enthalpy from a

psychrometric chart using the design dry bulb and wet bulb

temperatures. The cooling load can then be found for a range of

enthalpies for each ventilator.

9

Ventilator installed with forced air system

Ventilator installed with independent air distribution

A99297

A99298

10

Control

Nam e

One-Touch Ec ono (Basic) Standard (HRV)

Standard Latent

(ERV)

Auto 60 min. Crank Timer 20 min. Push Button

Bryant Part #

KVBCN0101BLT KVBCN0101BBS KVBCN0101BST KVACN0101BLC KVBCN0101BAU KVATM010160M KVATM010120B

Main features

OFF-min-max-

intermittent- lighted

button

OFF-min-max

OFF-min-intermittent-

dehumidistat

OFF-min-intermittent-

dehumidistat

OFF-recirc-max-

intermittent-

dehumidistat

Allows up to 60 min

of high speed

20-min high speed

lighted push-button

Off, Off, Off, Off, O ff, Overrides main Overrides main

Intermittent (20 min. Low continuous, Low continuous, Low continuous, Low continuous, wall c ontrol. Vent. wall control. Vent.

low, 40 min. off), High continuous. Intermittent, Intermittent, 20 min. on / will operate in high will operate in high

Low continuous, No humidis tat. High speeed when High speeed when 40 min. off. for selected for 20 minutes

Modes High continuous humidity is humidity is Recirculation. number of minutes. unless button is

above

setpoint

below

setpoint Dehumidistat turns Up to 5 secondary pressed before

unit on high if controls may be 20 m inutes expires,

humidity levels rise connec ted to a then turns unit off.

above set level. single ventilator. Up to 5 secondary

No humidistat controls may be

connected to a

single ventilator.

ERVXXSHB1100

ERVXXSVB1100

●●●●

HRVXXSHB 1100

HRVXXSV B1100

●● ●●

HRVXXSVU1157

●●● ●●

ERVXXLHB1200

●●●●

HRVXXLHB1150

●●● ●●●

HRVXXLHB1250

●●● ●●●

HRVXXLVU1330

●●● ●●●

Main Controls

Auxiliary Controls

A12366

BRYANT VENTILATOR CONTROLS COMPATIBILITY MATRIX

11

ACCESSORIES

VENTILATOR ACCESSORY NUMBER NOMENCLATURE

123456789101112

KVBCN0101BBS

Product Control Description

BAU -- Bryant Automatic Control

KV -- Ventilator Accessory Kit BBS -- Bryant Basic Control

BLC -- Bryant Latent Control

BLT -- Bryant OneTouch Control

Series BST -- Bryant Standard Control

A -- Original Series

B -- Second Series Accessory Description

HOD -- Intake Hood

Type KIT -- Airflow Measuring Kit

AC01 -- Accessory 6FM -- Flow Collar 6-- in.

CN01 -- Control 7FM -- Flow Collar 7-- in.

TM01 -- Timer 8FM -- Flow Collar 8-- in.

AC01 -- Accessory

Timer Description

Package Quantity 120B -- 20 Minute Timer Kit

01 -- Single Pack 160M -- 60 Minute Timer Kit

KIT NUMBER DESCRIPTION WHERE USED

KVBCN0101BAU Automatic Wall Control Used with HRVs

KVBCN0101BBS Basic Wall Control Used with HRVs

KVBCN0101BLC Latent Wall Control Used with ERVs

KVBCN0101BLT Bryant OneTouch Control UsedwithERVsandHRVsasamainwallcontrol

KVBCN0101BST Standard HRV Control Used with HRVs

KVAAC0101HOD Exterior Intake and Exhaust Hood Used with ERVs and HRVs, 2 Required

KVBAC0101KIT Airflow Measuring Kit Start up B alancing Kit, includes (2) 6 in. Flow Meter Collars & Magnehelic Gauge

KVATM010120C 20 Minute Push Button Timer Used with ERVs and HRVs when 20 minute manual operation is required

KVATM010160M 60 Minute Timer Used with ERVs and HRVs, time is adjustable between 10 and 60 minutes

KVAAC01016FM 6 in. Flow Meter Collar Used with ERVs and HRVs, at start up, when 6 in. duct work is connected to HRV

KVAAC01017FM 7 in. Flow Meter Collar Used with ERVs and HRVs, at start up, when 7 in. duct work is connected to HRV

KVAAC01018FM 8 in. Flow Meter Collar Used with ERVs and HRVs, at start up, when 8 in. duct work is connected to HRV

12

PSYCHOMETRIC CHART

.35

Pounds of moisture

per pound of dry air

180

.025

170

.024

.40

.023

160

.022

150

105

Grains of moisture

per pound of dry air

100

95

90

85

Enthalpy at saturation, Btu per pound of dry air

49

48

47

46

45

80

44

43

42

.001

0

14.5 cu ft per pound of dry air

.45

.021

.020

.50

.019

.018

.55

.017

.016

.015

.70

.013

.014

.012

.011

heat

factor

Sensible

.010

.009

.008

.007

.006

.005

.004

.003

.002

.95

.85

.90

.80

.75

.65

.60

110

140

130

120

110

80

90

100

pound of dry air -0.3 Btu

Btu per

70

60

Enthalpy deviation

40

50

20

30

0

10

105

100

-.02 BTU

14.0 cu ft

95

90

-.01 BTU

10%

20%

85

30%

40%

50%

60%

70%

75

41

40

39

38

37

36

35

80%

90% Relative Humidity

70

34

33

32

31

-.08 Btu

-.06 Btu

-.04 Btu

65

-.02 Btu

30

29

60

28

27

55

80

13.5 cu ft

75

70

65

60

13.0 cu ft

55

50

26

25

24

23

22

21

20

45

19

40

+0.3 Btu

+0.2 Btu

+0.1 Btu

18

17

16

15

35

14

13

30

12

80%

60%

40%

25

12

11

10

9

8

7

Wet Bulb,

Dewpoint or

Saturation

Temperature F

+0.5 Btu

+0.4 Btu

20%

50

45

12.5 cu ft

30 35 40

25

Below 32ûF, properties and enthalpy deviation lines are for ice.

20

Dry Bulb

Temperature F

A98394

13

E2012 Bryant Heating & Cooling Systems D 7310 W. Mo rris St. D Indianapolis, IN 46231 Edition Date: 07/12

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

14

Catalog No. PDSERVHRV--- 0 2

Replaces: NEW

Loading...

Loading...