Page 1

SINGLE-PACKAGE

ELECTRIC HEATING

COOLING UNITS

HRVBBLHU

HRVBBLHU

HRVBBSVC

HRVBBLVU

Heat Recovery Ventilators

The Heat Recovery Ventilation (HRV) system off ered by Bryant

is the finest unit on the market today.

The HRVB provides efficient and cost-effective heat recovery

during the heating season when needed most.

As temperatures drop below 23°F (–5°C), indoor air is

recirculated periodically through the heat exchanger core to

prevent frost from forming. Competitors’ methods of

supplementary electric defrost waste energy. Unlike rotary

wheel heat exchangers which mix air streams, these cross flow

or counterflow heat exchangers ensure that there is no mixing

of the stale air stream with the fresh outdoor air stream.

A filter installed on the incoming outdoor air stream removes

large airborne particles from the intake air stream before they

enter the heat exchanger and reduces the maintenance

required.

The units’ acoustically engineered design makes them the

quietest on the market and ensures that comfort is felt, not

heard.

Unlatching 2 suitcase style latches allows easy removal of the

filters and core for cleaning.

HRVBBSVC

FEATURES

• Energy saving defrost cycle

• Cross flow, counterflow heat exchangers

• T w o filters on incoming outdoor air stream to protect the HRV

core

• Acoustical design

• No-tools maintenance

• Polypropylene heat exchanger core

HRVBBLVU

Form No. PDS HRV.71.1

Page 2

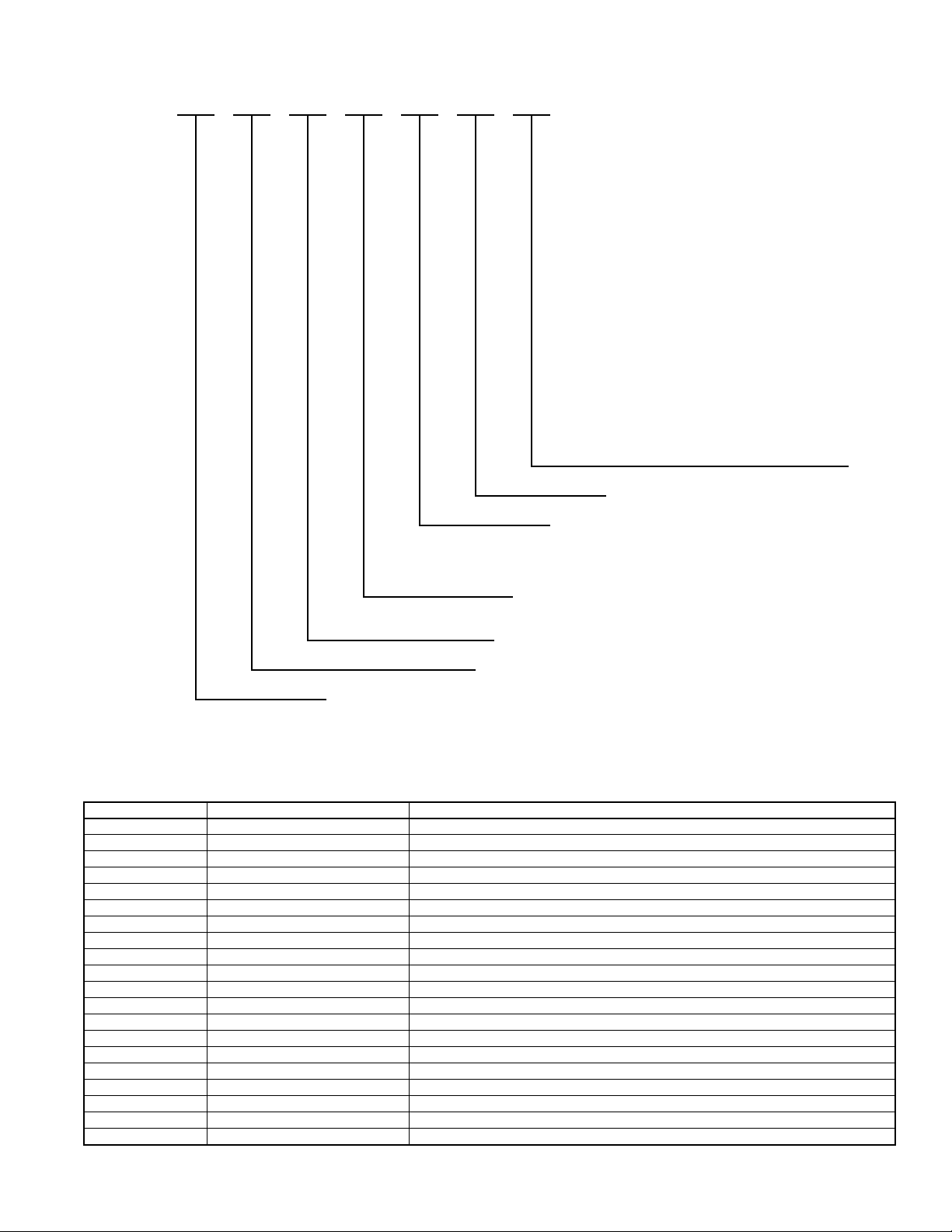

Model number nomenclature

HRV BB LHU 1 150

Electrical Supply:

1 — 115 volts

Descriptor:

LHU — Large Horizontal Unit

SVU — Small Vertical Unit

LVU — Large Vertical Unit

Brand:

Bryant

Equipment Type:

Heat Recovery

Ventilator

Maximum Capacity

(CFM)

150 CFM

200 CFM

250 CFM

330 CFM

TESTED/CERTIFIED

HOME VENTILATING INSTITUTE

DIVISION OF AMCA

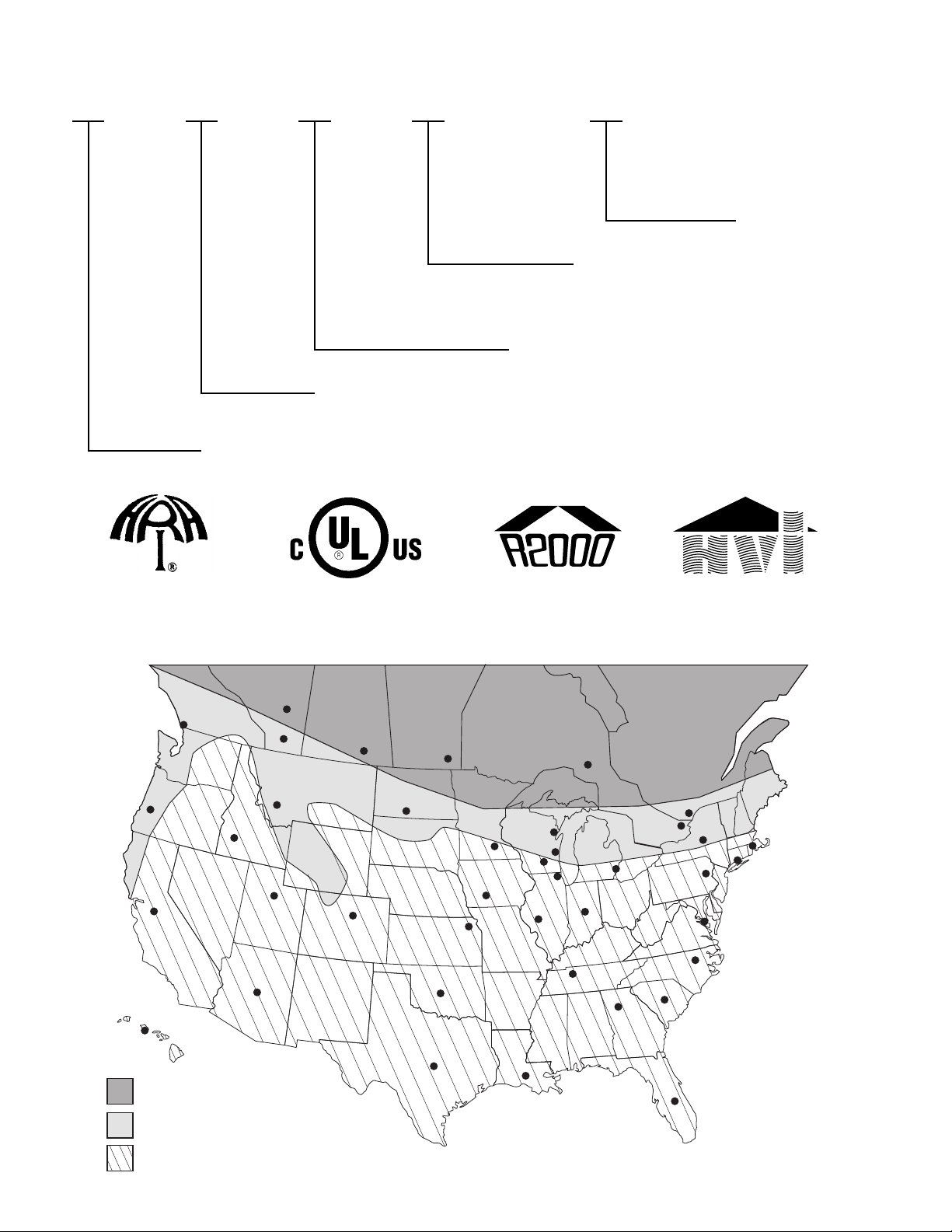

Climate Map for Energy and Heat Recovery Ventilators

Edmonton

Vancouver

Salem

Sacramento

Boise

Helena

Salt Lake

City

Calgary

Regina

Denver

Winnipeg

Bismark

Minneapolis

Topeka

Green Bay

Madison

Des Moines

Springfield

Timmins

Milwaukee

Chicago

Indianapolis

Detroit

Ottawa

Harrisburg

Washington D.C.

Montreal

Syracuse

Boston

Hartford

Honolulu

HRV Recommended

ERV Recommended w/HRV or ERV Wall Control

ERV Recommended

Oklahoma City

Austin

—2—

Baton Rouge

Nashville

Atlanta

Raleigh

Columbia

Orlando

A00099

Page 3

Controls and accessories part no. nomenclature

K V B CN 01 01 BAU

CONTROL DESCRIPTION

BAU — Bryant Automatic Control

BBS — Bryant Basic Control

BST — Bryant Standard Control

ACCESSORY DESCRIPTION

6FM — 6 in. Flowmeters (2)

7FM — 7 in. Flowmeters (2)

8FM — 8 in. Flowmeters (2)

EXH — Exhaust Hood

HOD — Intake Hood

KIT — Balancing Kit

FIR —Interlock Relay

TIMER DESCRIPTION

20C — 20-Minute Timer Kit Carrier

60M — 60 Minute Adjustable Timer Kit

FILTER DESCRIPTION

112 — 11-1/2 x 12-3/4

116 — 11-7/8 x 16-5/8

123 — 12-15/16 x 13-1/2

145 — 14-3/8 x 15-1/2

713 — 7-13/16 x 13-1/2

810 — 8-1/8 x 10-3/4

812 — 8-7/8 x 12-3/4

916 — 9 x 16-5/8

01 — Single Pack

01 — Part Number

AC — Accessory

CN — Control

FL — Filter Media

TM — Timer

A — Original Series

B — Second Series

V — Heat Recovery Ventilator (HRV)

K — Accessory Kit

ACCESSORIES

Kit Number Description Where Used

KVBCN0101CBS

KVBCN0101CST

KVBCN0101CAU Automatic HRV Control HRVBLSVU, HRVBBLVU

KVAAC0101FIR

KVATM010120C

KVATM010160M

KVAAC0101HOD Exterior Intake and Exhaust Hood 2 Required

KVAAC0101KIT

KVAAC01016FM

KVAAC01017FM

KVAAC01018FM

KVAFK0101150

KVAFK0201200

KVAFL0101713

KVAFL0101123

KVAFL0101123

KVAFL0101145

KVAFL0101810

KVAFL0101145

KVAFL0101810

Basic HRV Control Used with all HRVs

Standard HRV Control Used with all HRVs

Interlock Relay When combining an HRV with a Furnace or Fan Coil

20 Minute Push Button Timer Used with all HRVs when 20 minute manual operation is required

60 Minute Timer Used with all HRVs, time is adjustable between 10 and 60 minutes

Start up Balancing Kit Start up Balancing Kit, includes (2) 6 in. Flow Meter Collars & Magnehelic Gage

6 in. Flow Meter Collar At start up, when 6 in. duct work is connected to HRV

7 in. Flow Meter Collar At start up, when 7 in. duct work is connected to HRV

8 in. Flow Meter Collar At start up, when 8 in. duct work is connected to HRV

Internal Filter Used with HRVBBLHU 1150 Unit 11 3/4 x 12 7/8 x 3/4 (2)

Internal Filter Used with HRVBBLHU 1250 Unit 11 3/4 x 16 3/4 x 3/4 (2)

Internal Filter Used with HRVBBSVU 1150 Unit 7 13/16 x 13 1/2 (2)

Internal Filter Used with HRVBBSVU 1200 Unit 12 15/16 x 13 1/2 (2)

Internal Filter Used with HRVBBLVU 1200 Unit 12 15/16 x 13 1/2 (2)

Internal Filter Used with HRVBBLVU 1200 Unit 14 3/8 x 15 1/2

Internal Filter Used with HRVBBLVU 1330 Unit 8 1/8 x 10 3/4 (1)

Internal Filter Used with HRVBBLVU 1330 Unit 14 3/8 x 15 1/2 (1)

Internal Filter Used with HRVBBLVU 1200 Unit 8 1/8 x 10 3/4 (1)

—3—

Page 4

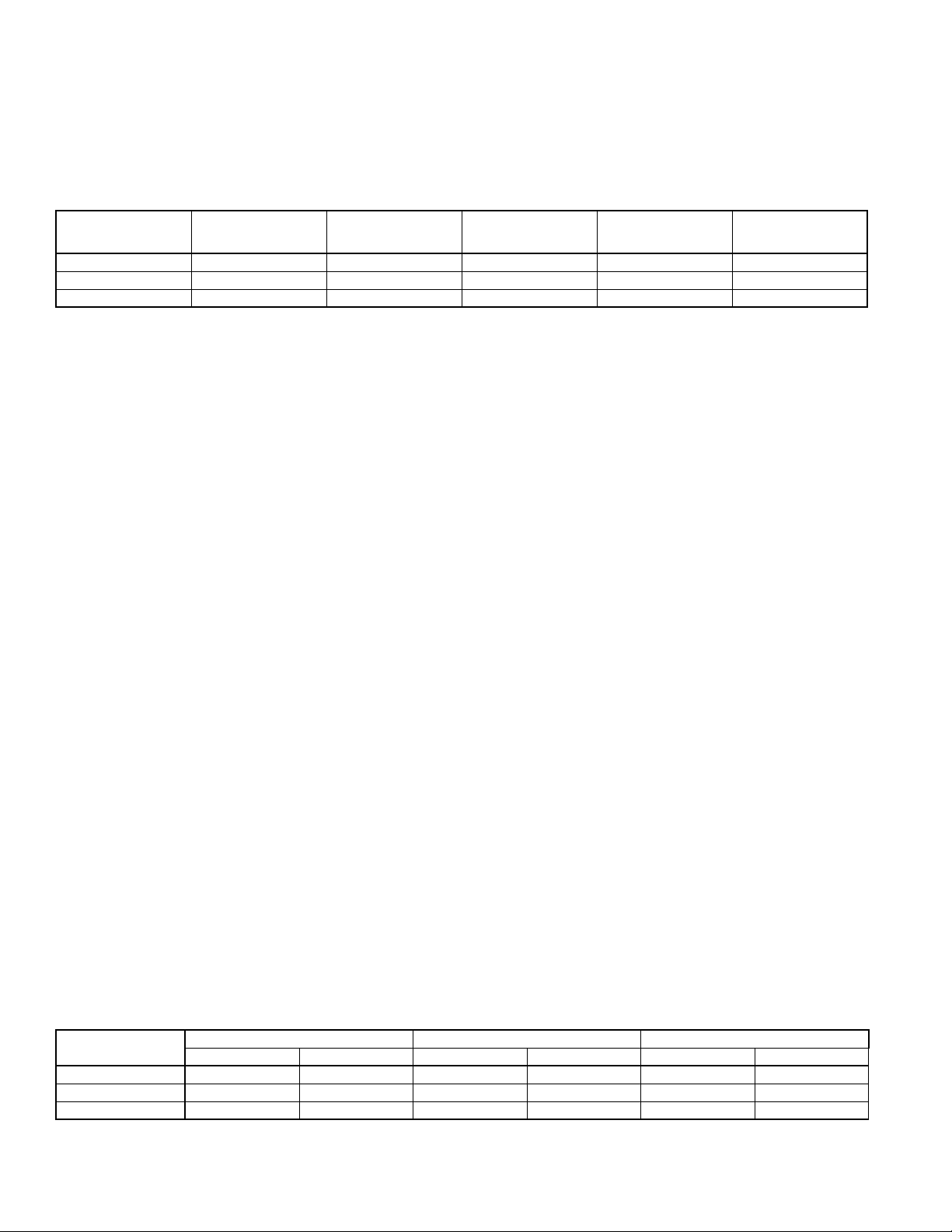

CONTROL FEATURES

Basic Control: Allows the user to manually set fan speed to low or high as required to maximize comfort.

Standard Control: Offers automatic dehumidistat control and the option to select continuous or intermittent fan

operation. Setting the wall control to low will activate the continuous mode.

Automatic Control: In addition to the features found with standard control, this package offers a recirculation mode.

These controls may only be used to operate stand-alone units with the defrost option which enables the recirculation

feature.

CONTROL

DESCRIPTION

Basic

Standard

Automatic‡

* Air exchange with outside.

† No air exchange with outside.

‡ Use only on units with defrost.

FAN

SPEED

CONTROL

Yes No Yes No No

Yes Yes Yes Yes No

Yes Ye s Yes Yes Yes

DEHUMIDISTAT

CONTROL

CONTINUOUS

MODE*

INTERMITTENT

MODE*

CIRCULATION

MODE†

CONTROL DESCRIPTION AND USAGE

Fan Speed Control — Enables user to modulate fan speed from low to high air exchange with outside.

Dehumidistat Control — Allows the user to select the relative humidity le v el at which the unit would change f an speed

for dehumidification in the winter months.

Continuous Mode — If the relative humidity inside the building is lower than selected, air exchange occurs with the

outside at low speed. If the relative humidity inside the house is higher than selected, air exchange occurs with the

outside at high speed. Ensures continuous air exchange for constant air quality.

Intermittent Mode — If the relative humidity inside the building is low er than selected, no air exchange occurs and the

system turns off. If the relative humidity inside the house is higher than selected, air exchange occurs with the outside

at high speed. Ensures minimum air exchange level when the building is unoccupied to minimize operating costs.

Circulation Mode — If the relative humidity inside the building is low er than selected, the ambient air would be circulated

and filtered at high speed. If the relativ e humidity inside the house is higher than selected, air exchange would occur with

the outside at high speed. Ensures continuous movement and filtration of air for maximum comfort. Available with

automatic control only.

AUTOMATIC DEFROST CYCLE FEATURES

All models offer a non-electric defrost cycle feature which prevents frost and ice buildup within the heat recovery core.

When the outside air temperature falls below 23°F (–5°C) it is electronically sensed and the dampers close the outside

air ports. This allows warm indoor air to recirculate within the heat recovery core. The frequency of this cycle increases

as the outside air temperature decreases.

23°F TO 55°F (–5°C TO –15°C) 4°F TO –17°F (–15.6°C TO –27.3°C) BELOW –18°F (–27.8°C)

MODEL

HRVBBLHU

HRVBBSVU

HRVBBLVU

* All defrost times are in the standard mode (as shipped)

† Time between defrost when within specified temperature range

DEFROST* EXCHANGE† DEFROST* EXCHANGE† DEFROST* EXCHANGE†

6 Minutes 60 Minutes 6 Minutes 32 Minutes 6 Minutes 20 Minutes

6 Minutes 60 Minutes 6 Minutes 32 Minutes 6 Minutes 20 Minutes

6 Minutes 60 Minutes 6 Minutes 32 Minutes 6 Minutes 20 Minutes

—4—

Page 5

DIMENSIONS

A98002

" DIA

8

/

7

5

(149.2)

4 PLCS

15"

(381.0)

F

E

G

"

8

/

7

16

(460.4)

2

(428.6)

3

"

4

/

1

30

(768.3)

NOTES:

1.FRESH AIR FROM OUTSIDE

2.FRESH AIR FROM HRV TO HOUSE

3.STALE AIR FROM HOUSE TO HRV

4.STALE AIR FROM HR TO OUTSIDE

"

16

/

5

2

(58.7)

"

8

/

1

18

1

3

"

16

/

2

1"

(56.2)

4 PLCS

(25.4)

2 PLCS

"

4

/

3

(120.6)

4

4

20"

(508.0)

B

A

ABCDEFG

19 483 5-13/16 147.7 5-1/16 128.1 14-1/2 368.9 11-3/16 283.9 4-3/8 111.3 10-1/16 255.6

in. mm in. mm in. mm in. mm in. mm in. mm in. mm

15-1/8 384.2 4-1/16 104 5/58 143.3 14-1/2 368.9 10-3/8 288.9 4-3/8 111.3 7-3/4 196.9

C

D

MODEL NO.

HRVBBLHU1150

HRVBBLHU1250

—5—

Page 6

POWER

CORD

WALL

CONTROL

WIRING

⁄8″ DIA

3

[9.5]

A98003

DIMENSIONS (continued)

⁄8″ DIA

7

5

3

[149.2]

⁄16″

9

4

[115.9)]

2 PLCS

F DIA

2 PLCS

1

3

⁄16″

3

2

[81.0]

C

NOTES:

1. FRESH AIR FROM OUTSIDE TO HRV

2. FRESH AIR FROM HRV TO HOUSE

3. STALE AIR FROM HOUSE TO HRV

4. STALE AIR FROM HRV TO OUTSIDE

⁄16″

3

2

[55.6]

4 PLCS

1″

[25.4]

2 PLCS

27″

[685.8]

/16″

1

[560.4]

22

A

⁄16″

15

[23.8]

1

⁄4″

3

19

[501.7]

D

B

⁄4″

3

5

4

[146.0]

DRAINS

⁄16″

11

[398.5]

15

⁄16″ DIA.

11

[17.5]

2 PLCS

E

G

—6—

ABCDEFG

in. mm in. mm in. mm in. mm in. mm in. mm in. mm

18-1/2 469.9 4-11/16 119.1 13-5/16 388.2 15-7/16 392.1 13-9/16 344.5 5-7/8 149.2 19-15/16 506.2

24-1/2 622.2 8-3/16 208.0 19-5/16 490.6 14-9/16 369.9 16-15/16 430.2 6-7/8 174.6 19-15/16 506.2

MODEL NO.

HRVBBSVU1150

HRVBBSVU1200

Page 7

⁄8″

1

7

POWER

[181.0]

CORD

41″

[1041.4]

WALL

CONTROL

WIRING

⁄8″ DIA

3

A98001

[9.5]

DIMENSIONS (continued)

NOTES:

1. FRESH AIR FROM OUTSIDE TO HRV

2. FRESH AIR FROM HRV TO HOUSE

3. STALE AIR FROM HOUSE TO HRV

4. STALE AIR FROM HRV TO OUTSIDE

⁄4″

3

9

⁄16″

17

⁄16″

13

5

[446.9]

3

4

[120.6]

[147.6]

1

⁄2″

15

[393.7]

1

⁄16″

15

6

2

⁄8″ DIA

1

[206.4]

2 PLCS

8

4

[176.2]

⁄16″

5

18

⁄8″ DIA

7

[148.2]

5

⁄16″

3

[55.6]

2

1 ″ [25.4]

[465.1]

2 PLCS

⁄2″

1

1

2 PLCS

2 PLCS

[38.1]

2 PLCS

43″

(1092.2)

3

⁄4″

12

[323.9]

15

⁄16″

23

1

⁄8″

3

22

[608.0]

⁄16″

[611.2]

24

[568.3]

⁄16″DIA.

DRAIN

11

[17.5]

2 PLCS

⁄16″

1

19

⁄16″

3

8

[208.0]

[484.2]

⁄16″

3

7

[182.6]

HRVBBLVU1200 or HRVBBLVU1330

—7—

Page 8

PHYSICAL DATA

MODEL DESCRIPTION CONVENTIONAL COMPACT HIGH EFFICIENCY

Model No.

Port Locations

Core Type

Weight — lb (kg)

Shipping Weight — lb (kg)

Shipping Dimensions (in.)

Height

Width

Depth

HRVBBVHU1150 HRVBBVHU1260 HRVBBSVC1150 HRVBBSVC1200 HRUBBLVU1150 HRUBBLVU1200 HRUBBLVU1330

Sides Sides Top Top Top Top Top

Polypropylene

Cross Flow

65 (29.5) 73 (33.2) 60 (27) 80 (36.3) 80 (36.3) 120 (54.5) 120 (54.5)

75 (34) 83 (37.6) 75 (34) 89 (40.4) 89 (40.4) 143 (64.9) 143 (64.9)

23 1/16

36 1/16

17 13/16

Polypropylene

Cross Flow

22 15/16

35 1/16

22 5/16

Polypropylene

Cross Flow

31.5

23.25

26.00

Polypropylene

Cross Flow

31.5

23.25

26.00

Polypropylene

Cross Flow

31.5

23.25

26.00

Polypropylene

Counterflow

47.5

26.0

26.0

Polypropylene

Counterflow

47.5

26.0

26.0

PERFORMANCE DATA

MODEL DESCRIPTION CONVENTIONAL COMPACT HIGH EFFICIENCY

Model No.

Capacity — CFM @ 0.5–

0.3ESP (in. wc)

Efficiency (Sensible) —

percent

32°F (0°C)

–13°F (–25°C)

Efficiency (Latent) —

percent

@ all temperatures

Heat Core Exchange Area

— cu ft (cu m)

HRVBBLHU1150 HRVBBLHU1250 HRVBBSVC1150 HRVBBSVC1200 HRVBBLVU1150 HRVBBLVU1200 HRVBBLVU1330

130–168 191–210 106–150 177–211 123–141 189–209 300–334

65

65

0000000

120

3.4

65

60

166

4.7

69

60

90

8.4

77

67

144

13.3

81

69

144

13.3

84

72

210

19.5

ELECTRICAL DATA

80

74

210

19.5

Model

Voltage

Max Power — watts

Max Amps

CONVENTIONAL COMPACT HIGH EFFICIENCY

HRVBBLHU1150 HRVBBLHU1250 HRVBBSVC1150 HRVBBSVC1200 HRVBBLVU1150 HRVBBLVU1200 HRVBBLVU1330

120 120 120 120 120 120 120

150 218 115 195 115 250 500

1.4 1.9 1.2 1.8 1.2 2.2 5.4

—8—

Page 9

METHODS TO SIZE HRV’S

METHOD 1

1. Calculate cu ft of occupied space.

2. Multiply by recommended air changes per hr (AC/h).

3. Divide by 60 minutes per hr to convert to CFM.

EXAMPLE: 2000 sq ft with 8 ft ceiling

0.35 air changes per hr (AC/h)

(2000 sq ft x 8 ft ceiling x 0.35 AC/h) / 60 min/h = 93.3 CFM

METHOD 2

1. Multiply number of people times 15 CFM/person.

2. Multiply number of bath rooms 20 CFM/each.

3. Add 25 CFM for kitchen.

EXAMPLE: 2 people

2 baths

1 kitchen

(2 x 15) + (2 x 20) + 25 = 95 CFM

–5

0

5

10

15

20

25

30

35

40

ADDITIONAL HEATING AND COOLING LOAD CHARTS

Although the ventilators process the outside air before it enters the home , additional heating and cooling loads need to

be considered.

HEATING LOAD BTU

Outside

Temp °F

–25

–20

–15

–10

HRVBBLHU1150 HRVBBSVC1250 HRVBBSVC1150 HRVBBSVC1200 HRVBBLVU1150 HRVBBLVU1200 HRVBBLVU1330

4,688 8,165 6,970 7,690 5,500 6,650 9,990

4,466 7,744 6,470 7,090 5,030 6,070 9,310

4,598 8,008 5,990 6,520 4,590 5,510 8,650

4,334 7,547 5,520 5,970 4,160 4,970 8,000

4,069 7,087 5,070 5,440 3,750 4,470 7,380

3,805 6,627 4,550 4,840 3,300 3,910 6,640

3,541 6,167 4,130 4,360 2,940 3,470 6,060

3,502 6,100 3,730 3,900 2,600 3,050 5,500

3,220 5,608 3,290 3,400 2,240 2,600 4,870

2,938 5,116 2,930 3,000 1,940 2,240 4,350

2,950 5,138 2,580 2,610 1,670 1,910 3,850

2,636 4,591 2,240 2,250 1,410 1,600 3,370

2,322 4,045 1,900 1,880 1,160 1,300 2,870

2,009 3,498 1,600 1,560 1,940 1,040 2,430

The heating load chart shows the heating loads in Btuh for a range of winter design temperatures for each model of

ventilator.

Heat Load (Btuh) @ Inside Design Temp 72°F

EXAMPLE: The heating design temperature for Milwaukee, WI is –4°F. At –5°F, the additional heating load of the

HRVBBLHU1250 is 8417 Btuh. This additional load should be taken into consideration when sizing the

heating equipment.

—9—

Page 10

COOLING LOAD BTU

31

32

33

34

35

36

37

38

39

40

Outside

Enthalpy

Btu/lb

30

41 5,280 8,437 6,510 8,250 6,430 8,250 11,570

42 5,699 9,107 7,030 8,910 6,940 8,910 12,500

HRVBBLHU1150 HRVBBLHU1250 HRVBBSVC1150 HRVBBSVC1200 HRVBBLVU1150 HRVBBLVU1200 HRVBBLVU1330

670 1,071 780 990 770 990 1,390

1,090 1,741 1,300 1,650 1,290 1,650 2,310

1,509 2,411 1,820 2,310 1,800 2,310 3,240

1,928 3,080 2,340 2,970 2,310 2,970 4,170

2,347 3,750 2,860 3,630 2,830 3,630 5,090

2,766 4,419 3,380 4,290 3,340 4,290 6,020

3,185 5,089 3,910 4,950 3,860 4,950 6,940

3,604 5,759 4,430 5,610 4,370 5,610 7,870

4,023 6,428 4,950 6,270 4,890 6,270 8,790

4,442 7,098 5,470 6,930 5,400 6,930 9,720

4,861 7,767 5,990 7,590 5,910 7,590 10,650

Cooling Load (Btuh) @ Inside Design Temp 75°F and 50% Relative Humidity

The cooling load chart shows loads in Btuh as well. To use the cooling load chart, first find the design enthalpy from a

psychrometric chart using the design dry bulb and wet bulb temperatures. (See psychrometric chart on p. 11.) The

cooling load can then be found for a range of enthalpies for each ventilator.

EXAMPLE: The cooling design dry bulb temperature for Milwaukee, WI is 87°F and the average wet bulb at that

temperature is 73°F. On the psychrometric chart the enthalpy is about 37.7 Btu/lb of dry air which will round

up to 38 Btu/lb of dry air. In the left column, at 38 Btu/lb the HRVBBLHU1250 would have an additional

cooling load of 6428 Btuh. This additional load should be taken into account when sizing the air cooling

equipment.

—10—

Page 11

.35

Pounds of moisture

per pound of dry air

180

105

Grains of moisture

per pound of dry air

.025

170

.024

.001

14.5 cu ft per pound of dry air

A98394

0

.40

.023

.022

.45

.021

.020

.50

.019

.018

.95

.85

.90

.017

.65

.60

.016

.55

.015

.80

.70

.75

.014

.013

.012

.011

heat

factor

Sensible

.010

.009

.008

.007

.006

.005

.004

.003

.002

110

0

10

160

150

140

130

120

110

100

90

80

pound of dry air -0.3 Btu

Btu per

60

70

50

40

Enthalpy deviation

20

30

105

100

-.02 BTU

95

90

100

14.0 cu ft

95

90

-.01 BTU

85

20%

10%

85

30%

Enthalpy at saturation, Btu per pound of dry air

49

48

47

46

45

80

50%

60%

70%

75

44

43

42

41

40

39

38

37

36

35

80%

90% Relative Humidity

70

34

33

32

31

65

30

29

28

27

PSYCHROMETRIC CHART

60

-.04 Btu

-.02 Btu

40%

-.06 Btu

55

-.08 Btu

80

13.5 cu ft

75

70

65

60

13.0 cu ft

55

—11—

50

26

25

24

23

22

21

20

45

19

40

+0.3 Btu

+0.2 Btu

+0.1 Btu

18

17

16

15

35

14

13

30

12

80%

60%

40%

25

12

11

10

9

8

7

Wet Bulb,

Dewpoint or

Saturation

Temperature F

+0.5 Btu

+0.4 Btu

20%

50

45

30 35 40

25

20

Dry Bulb

Temperature F

12.5 cu ft

Below 32˚F, properties and enthalpy deviation lines are for ice.

Page 12

HRV INSTALLED WITH FORCED AIR SYSTEM

A99297

HRV INSTALLED WITH INDEPENDENT AIR DISTRIBUTION

A99298

SPECIFICATIONS SUBJECT TO CHANGE WITHOUT NOTICE

UNIT MUST BE INSTALLED IN ACCORDANCE

WITH INSTALLATION INSTRUCTIONS

Cancels: New

FORM PDS HRV.71.1

© 2000 Bryant Heating & Cooling Systems, 7310 W. Morris St., Indpls., IN 46231 PRINTED IN U.S.A. Catalog No. 12HR-VBO 3-00

—12—

Loading...

Loading...