Page 1

WATER-TO-WATER

SYSTEM DESIGN GUIDE

50YEW, 50PSW, & GSW

WATER-TO-WATER SYSTEMS

WHATEVER IT TAKES.

Page 2

Water-to-Water System Design Guide Bryant Geothermal Heat Pump Systems

Table of Contents

Water-to-Water System Design Guide

Part 1: System Overview

Why Hydronics .............................................................................................1

Part II: Load Side Design

Heat Gain / Loss Calculations ..............................................................6

System Design & Selection .................................................................10

Piping Design ...............................................................................................22

Source & Load Pump Sizing ...............................................................24

Distribution Design ..................................................................................24

Radiant Floor Heating ............................................................................26

Baseboard Heating ...................................................................................27

Cast Iron Heating .....................................................................................28

Fan Coils ........................................................................................................29

Snow Melt Applications ........................................................................30

Part III: Source Side Design

System Selection ....................................................................................... 31

Open Loop Design ..................................................................................38

Closed Loop Design ............................................................................... 40

Closed Loop Instillation Guidelines ................................................42

Part IV: Controls

50YEW Controls ...................................................................................... 56

Wiring Diagrams .......................................................................................59

Revision Log...............................................................Inside Back Cover

Bryant works continually to improve its products. As a result, the design and specifi cations of each product at the time for order may be changed without notice and may

not be as described herein. Please contact Bryant’s Customer Service Department at 1-405-745-2920 for specifi c information on the current design and spec i fi ca tions, and

placing orders. Statements and other in for ma tion contained herein are not express warranties and do not form the basis of any bargain between the par ties, but are merely

Bryant’s opinion or com men da tion of its products.

Unit Information

50YEW Water-to-Water Series

Features .......................................................................................................... 70

Model Key .....................................................................................................72

Unit Performance ..................................................................................... 74

Physical Data ...............................................................................................75

Unit Dimensions .......................................................................................76

Electrical Data .............................................................................................77

Wiring Diagrams .......................................................................................78

Engineering Specifi cations .................................................................... 82

GSW Water-to-Water Series

Features .......................................................................................................... 86

Model Key .....................................................................................................88

Unit Performance ..................................................................................... 90

Physical Data ...............................................................................................97

Unit Dimensions .......................................................................................98

Electrical Data .......................................................................................... 100

Wiring Diagrams ....................................................................................101

Engineering Specifi cations ................................................................. 103

Page 3

Bryant Geothermal Heat Pump Systems

1

Water-to-Water System Design Guide

WHY HYDRONICS?

According to Webster’s Dictionary, hydronic heating is “a system of

heating or cooling that involves the transfer of heat by a circulating

fl uid (as water or vapor) in a closed system of pipes.” Because

water is the most effi cient way to move thermal energy, a hydronic

system requires much less transport energy in the process and

takes up far less space. For example, a 1” [25mm] diameter pipe

can carry as much heat as a 10” x 19” [254 x 483 mm] rectangular

duct carrying hot air at 130°F [54°C]. In addition, the mass of

the ground loop [geothermal piping] and/or radiant fl oor piping

provides thermal storage, allowing the system to virtually ignore

large changes in outdoor temperatures. There is no storage benefi t

in most HVAC systems.

Figure 1-1: Thermal Energy Comparison

Hydronics systems, especially systems using radiant fl oor heating,

provide lower operating costs than forced air systems. More Watts

are used to circulate air through ductwork than to circulate water

through piping. For example, a typical 80% effi cient natural gas

residential furnace with an output capacity of 80,000 Btuh [23.4

kW] uses an 850 Watt fan motor. For every Watt used to power

the fan, 94 Btuh [28 Watts] of heat is delivered via the forced air

ductwork. If a boiler or heat pump is used to generate heat, but

the heat is delivered through a radiant fl oor system, the pumping

power would typically be around 300-400 Watts, or 40% to 50%

of the air delivery system Watts, resulting in around 230 Btuh [67

Watts] of heat per Watt of pump power.

Radiant fl oor systems provide heat at occupant level. Hot air rises

to the ceiling (forced air systems), but heat always moves to cold

(radiant system). Therefore, a warm fl oor will heat objects in the

space, not the air directly, resulting in a space that feels warmer at

lower thermostat settings. Occupants will feel more comfor table,

and when the thermostat setting is lowered, the heat loss

decreases, resulting in better comfort at lower operating costs.

Hydronic heating systems can be combined with boilers or heat

pumps to generate hot water for radiant fl oor systems, baseboard

convectors, or radiators. Heat pumps are inherently more effi cient

than fossil fuel (natural gas, oil, or propane) heating systems, and

geothermal heat pumps are more effi cient than air-source heat

pumps, due to the mild heat source of the ground (as compared

to outdoor air temperatures). Water-to-air heat pumps heat the air,

and require a fan to circulate air through ductwork. Water-to-water

heat pumps heat water, allowing the design of a hydronic heating

system with the benefi ts of more effi cient energy distribution,

lower operating costs and better comfort.

Fossil fuel furnaces and boilers are always less than 100% effi cient.

Even the best systems are 95-96% effi cient. Geothermal heat

pumps typically deliver 4 to 6 Watts of heat for every Watt

of energy consumed to run the compressor and ground loop

pump(s). In other words, for each Watt of energy used, 3 to 5

Watts of free energy from the ground is added to provide 4 to

6 Watts of energy to heat the space. The use of a high effi ciency

water-to-water heat pump and a hydronic heating system is an

unbeatable combination.

Water-to-Water Heat Pumps

Bryant water-to-water heat pumps offer high effi ciencies, advanced

features, extremely quiet operation and application fl exibility. As

Bryant’s most adaptable products, water-to-water heat pumps may

be used for radiant fl oor heating, snow/ice melt, domestic hot water

heating, and many other hydronic heating applications.

Bryant’s exclusive double isolation compressor mounting system

provides the quietest water-to-water units on the market.

Compressors are mounted on rubber-grommets or vibration

isolation springs to a heavy gauge mounting plate, which is

then isolated from the cabinet base with rubber grommets for

maximized vibration/sound attenuation. A compressor discharge

muffl er and additional sound attenuation materials further enhance

the quiet operation (50YEW models).

Bryant water-to-water heat pumps are available as heating only

(50YEW series) or with reversible operation for heating and

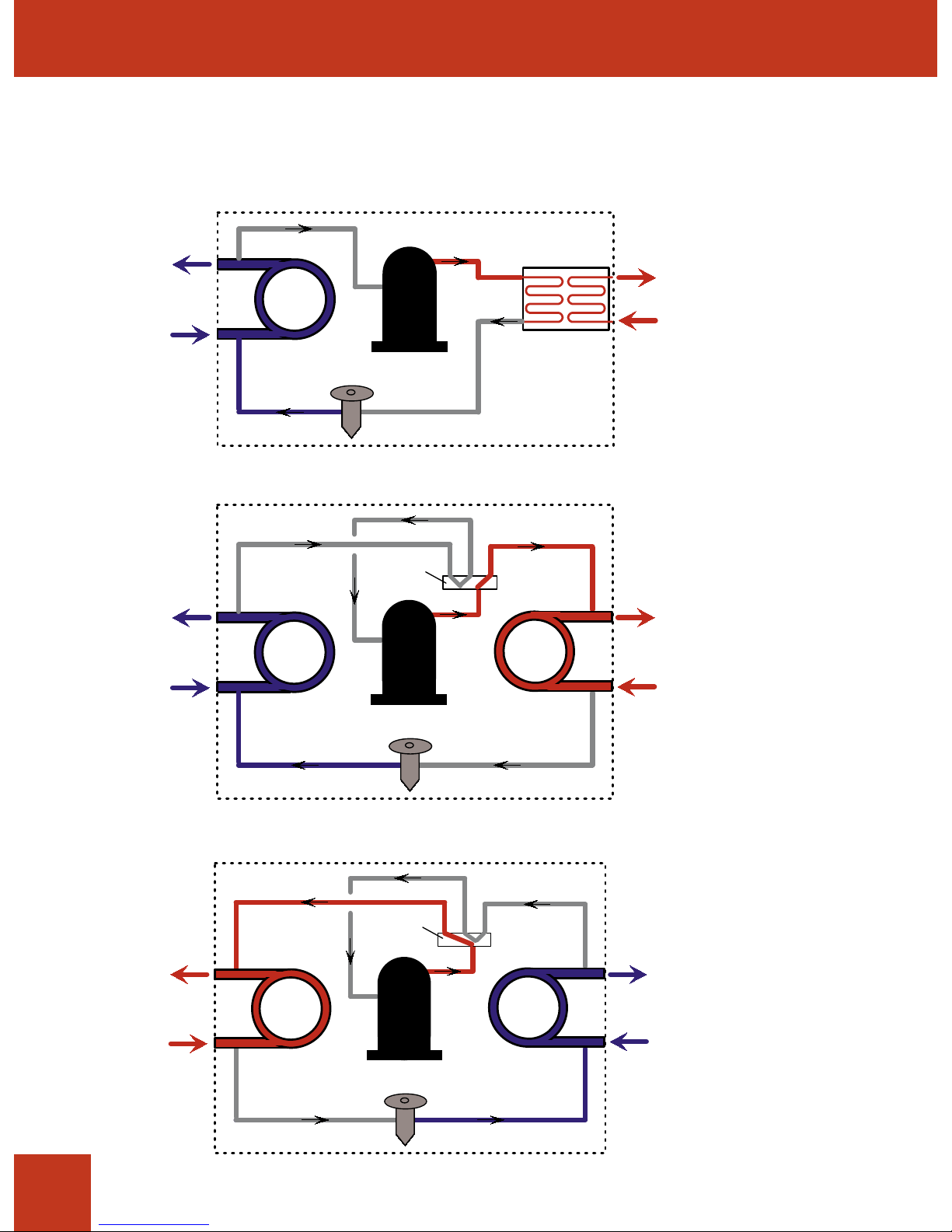

cooling (50PSW and GSW series). Figure 1-2 shows the simple

refrigerant circuit of the 50YEW series. With only four major

components, the refrigerant circuit is easy to understand and

troubleshoot if necessary.

The 50YEW series includes a special high temperature scroll

compressor coupled with heat exchangers designed specifi cally

for water heating, which provides unmatched effi ciencies and

performance. The evaporator is a coaxial (tube-in-tube) heat

exchanger that is capable of operation over a wide range

of temperatures, and is more rugged than other types of

evaporators, especially for open loop (well water) systems. The

condenser uses a close approach temperature brazed plate heat

exchanger that is designed for high temperature operation. This

combination of coaxial/brazed plate heat exchangers provides

the best combination of durability and effi ciency. Bryant always

recommends coaxial heat exchangers for evaporators. Brazed

plate heat exchangers may be used for condensers when the unit

is not reversible.

Part I: System Overview

Water Pipe

Air Duct

Page 4

2

Water-to-Water System Design Guide

Bryant: Whatever It Takes.

Figure 1-2: 50YEW Series Refrigerant Circuit

Figure 1-3: Reversible Water-to-Water Heat Pump, Heating Mode

Figure 1-4: Reversible Water-to-Water Heat Pump, Cooling Mode

To/From

Heating

Distribution

System

To/From

Ground

Loop

Compressor

TXV

Coaxial HX

(Evaporator)

Brazed Plate HX

(Condenser)

Source

Load

To/From

Heating

Distribution

System

To/From

Ground

Loop

Compressor

TXV

Reversing

Valve

Coaxial HX

(Evaporator)

Coaxial HX

(Condenser)

Source

Load

To/From

Chilled Water

Distribution

System

To/From

Ground

Loop

Compressor

TXV

Reversing

Valve

Coaxial HX

(Evaporator)

Coaxial HX

(Condenser)

Source

Load

Part I: System Overview

Page 5

Bryant Geothermal Heat Pump Systems

3

Water-to-Water System Design Guide

The 50YEW series compressors have a wide operating map, which

allows high temperature operation, up to 145°F [63°C] leaving

water temperature, even at 32°F [0°C] ground loop temperatures.

The ground loop heat exchanger [evaporator] is called the “Source”

heat exchanger in Bryant technical literature, and the heating

system heat exchanger is called the “Load” heat exchanger. The

terminology is not as important for heating only water-to-water

units, since the ground loop heat exchanger is always an evaporator,

but for reversible units, the evaporator and condenser change,

depending upon operating mode, heating or cooling.

Figure 1-3 shows a Bryant reversible water-to-water unit. With the

addition of a reversing valve, the Source and Load heat exchangers

can change functions, depending upon the desired mode of

operation. In the heating mode, the “Load” heat exchanger

functions as the condenser, and the “Source” heat exchanger

functions as the evaporator.

In fi gure 1-4, the reversible water-to-water heat pump now

provides chilled water on the load side instead of hot water. The

load heat exchanger becomes the evaporator, and the source heat

exchanger becomes the condenser. Because the evaporator is

susceptible to freezing under adverse operating conditions (e.g.

failed pump, controls problem, etc.), a coaxial heat exchanger is

used on the load side for reversible units.

When selecting equipment for systems that require cooling, all

aspects of the system design should be considered. In many cases,

a separate water-to-air unit for forced air cooling is more cost

effective than using a chilled water / fan coil application due to the

complication in controls and seasonal change-over. For ground

loop applications, the water-to-water and water-to-air units can

share one ground loop system.

Figure 1-5: COP vs TD

WATER-TO-WATER HEAT PUMP DESIGN

Design Temperatures

Various types of hydronic distribution systems have been used

successfully with geothermal heat pumps. Radiant fl oor systems

use relatively mild water temperatures, whereas baseboard

radiation and other types of heat distribution systems typically

use hotter water temperatures. When designing or retrofi tting

an existing hydronic heating system, it is especially impor tant to

consider maximum heat pump water temperatures as well as the

effect water temperatures have on system effi ciency.

Heat pumps using R-22 refrigerant are not designed to produce

water above 130°F [54°C]. Some heat pumps with R-410A and

R-407C refrigerant are capable of producing water up to 145°F

[63°C]. Regardless of the refrigerant, the effi ciency of the heat pump

decreases as the temperature difference (TD) between the heat

source (generally the earth loop) and the load water (the distribution

system) increases. Figure 1-5 illustrates the effect of source and load

temperatures on the system. The heating capacity of the heat pump

also decreases as the temperature difference increases.

As the temperature difference increases, the Coeffi cient of

Performance (COP) decreases. When the system produces

130°F [54°C] water from a 30° [-1°C] earth loop, the TD is

100°F [55°C], and the COP is approximately 2.5. If the system is

producing water at 90° F [32°C], the TD is 60°F [33°C] and the

COP rises to about 5.0, doubling the effi ciency.

If the water temperature of the earth loop is 90°F [32°C], and

the distribution system requires the same temperature, a heat

pump would not be needed. The system would operate at infi nite

effi ciency, other than the cost of pumping the water through the

Part I: System Overview

Page 6

4

Water-to-Water System Design Guide

Bryant: Whatever It Takes.

distribution system. When using the various types of hydronic

heat distribution systems, the temperature limits of the geothermal

system must be a major consideration. In new construction, the

distribution system can easily be designed with the temperature

limits in mind. In retrofi ts, care must be taken to address the

operating temperature limits of the existing distribution system.

System Components

The effi ciency, life expectancy and reliability of any hydronic heating

system depends upon how well the various components (heat pump,

distribution system, contols, etc.) work together. The heat pump must

be sized for the building loads; the earth loop must be sized to match

the building loads, ground conditions and climate; the circulating

pumps must be sized for the equipment, piping and ground loop. The

distribution system must be designed to heat and/or cool the building

comfortably. The components must then all be controlled effectively.

Building Heat Loss & Heat Gain

The design must begin with an accurate heating and/or cooling

load of the building. This is the most important step in the design

process. The sizing of the circulation pumps, the distribution

system and the earth loop are all derived directly from the sizing

of the equipment. Overestimating the heat loss or heat gain

means over sizing the system. The extra cost of the oversized

system is unnecessary. In fact, it may result in the selection of a

different type of system. If an oversized system is installed, it may

be ineffi cient and uncomfortable. If the system is undersized it will

not do an adequate job of heating and/or cooling the building.

Loop Design & Installation

Several factors determine the loop design for a specifi c installation.

The energy balance of the building determines how much heat is

taken from and rejected to the earth over the course of a year.

The climate determines the ambient earth temperatures and is a

major factor in the energy needs of the building. The ear th itself

(the conductivity of the soil or rock and the moisture content) are

major factors in calculating the size of the loop. The earth can only

take (heat rejected) or give up (heat extracted/absorbed) a fi xed

amount of Btu/hr [Watts] in a given area. The heat exchanger

must have suffi cient surface area.

The design of the loop itself (the size and type of pipe, the

velocity of the liquid circulating in the pipe and the spacing and

layout of the pipe) has a major effect on the heat absorption and

rejection capabilities of the loop. The depth (ver tical) or trench

length (horizontal) of the loop must be calculated using IGSHPA

(International Ground Source Heat Pump Association) methods

or approved software. In addition, the type and percentage of

antifreeze can have a signifi cant effect on loop performance.

The workmanship of the installation also plays a large role in the

effectiveness of the loop. All fusion joints must be done properly.

Vertical loops must be grouted properly for good contact with the

earth. Horizontal loops must be backfi lled with material that will

not cut the pipe, and the soil should be compacted around the

pipe for good contact. All closed loop piping systems should be

hydrostatically pressure tested before burial.

Many factors affect loop performance. Bryant offers training in

loop design and installation, and also provides residential and

commercial loop sizing software.

Controls

The control of a mechanical system determines how it functions. For

the building to work effi ciently and comfortably, the building owner

or manager must understand system functionality and controls.

As Figure 1-5 shows, the effi ciency of a heat pump is a factor

of the difference in temperature between the source and the

load. The heat loss or heat gain of a building varies with the

weather and the use of the building. As the outdoor temperature

decreases, the heat loss of the building increases. When the

ventilation system is operating, the heating or cooling loads

increase. As the occupancy increases, or more lighting is used, or

the solar gain increases, the cooling load increases. At times the

building may require virtually no heating or cooling.

The output of the hydronic heating distribution equipment,

whether it is baseboard radiation, fan coil units or radiant fl oor

heating equipment, is directly related to the temperature and

velocity of the water fl owing through it. Baseboard radiation puts

out approximately 50% less heat with 110°F [43°C] water than

with 130°F [54°C] water. The same is true with fan coil units and

radiant fl oor heating. For example, if a system is designed to meet

the maximum heat loss of a building with 130°F [54°C] water,

it follows that if the heat loss is 50% lower (when the outdoor

temperature is higher), the load can be met with 110°F [43°C]

water. The lower water temperature greatly increases the COP of

the heat pump. Outdoor temperature reset, discussed in part IV of

this manual, is a very cost-effective method of matching the heating

(load side) water temperature with the heat loss of the building.

Other considerations for controls include heating/cooling

switchover, pump control, backup heat (if equipped), distribution

system or zone controls, and priority assignments (e.g. determining

if radiant fl oor heating or domestic hot water will take priority).

The 50YEW series includes internal controls, which makes system

installation much easier. Other Bryant water-to-water heat pumps

must be controlled via external controls.

Part I: System Overview

Page 7

Bryant Geothermal Heat Pump Systems

5

Water-to-Water System Design Guide

SUMMARY

Hydronic geothermal systems can be used very effectively in new

installations, as well as in many retrofi t applications. Effi cient systems

can be designed for residential, commercial and industrial applications.

To make a system as effi cient as possible, it is important to follow

good design criteria. Some of the factors to consider are listed below:

• An accurate heat loss and heat gain must be calculated to

properly size the system.

• The system must meet the application requirements. In other

words, the design of the system must take into consideration

the type of distribution system and the needs of the customer.

For example, baseboard radiation designed for 180°F [82°C]

water should not be used with 130°F [54°C] water without

careful consideration and design analysis.

• The components of the system must be designed to work

together. The earth loop must be designed to work with the

heat pump; the pumping system must work effectively with the

earth loop and the heat distribution system; and the distribution

system must be chosen to work properly with the water

temperatures available from the heat pump.

• The system must be controlled to operate as effi ciently

as possible. It is important to operate the system to take

variations in the building loads into account. For example,

the heat loss of the building is reduced when the outdoor

temperature climbs, and the temperature of the water

circulated through the distribution system can be lowered,

allowing the heat pumps to operate more effi ciently. It is

possible to integrate the functions of the mechanical systems in

a building.

Part I: System Overview

Page 8

6

Water-to-Water System Design Guide

Bryant: Whatever It Takes.

HEAT LOSS / HEAT GAIN CALCULATIONS

Heat loss loss/gain calculations for any residential HVAC design

should be performed using standard industry practices. Br yant

accepted calculations include methods developed by ACCA (Air

Conditioning Contractors of America) used in Manual J, HRAI

(Heating, Refrigeration and Air Conditioning Institute of Canada)

and ASHRAE (American Society of Heating Refrigerating and Air

Conditioning Engineers). Light commercial load calculations should

be performed using ACCA Manual N or the ASHRAE method.

Other methods for load calculations outside of North America are

acceptable providing the methodology is recognized by the local

HVAC industry.

Heat Loss Calculations for Radiant Floor or Zoned

Baseboard Systems

A room-by-room calculation must be performed for all radiant

fl oor or zoned baseboard systems in order to determine the

design of the radiation system. Once the heat loss has been

calculated and the decision on fl ooring material has been made

for each room, the amount of radiant fl oor tubing, pipe spacing,

water temperature and layout can be determined, based upon the

Btuh/square foot [Watts/square meter] requirements. Similarly,

the amount of heat loss will allow the designer to determine the

length of baseboard convector required based upon the design

water temperature.

Outdoor design temperatures should be obtained from the

appropriate ACCA, ASHRAE or HRAI manual at the 99.6% condition

or local requirements, whichever is most severe. Indoor design

temperatures vary, based upon the type of system and customer

preference. Following are some minimum design guidelines:

*The nature of radiant fl oor heating tends to allow occupants

to feel the same comfort level with radiant fl oor heating at 65°F

[18°C] as with a forced air system at 70°F [21°C].

It is important to remember that a radiant fl oor system heats

objects, not the air. In turn, these objects radiate heat, which

heat people and furnishings to a comfortable temperature. Air

temperature remains near 65°F [18°C], and is approximately equal

from ceiling to fl oor. Forced air heating, by comparison, heats the

air, which heats the people and objects. Therefore, a higher air

temperature is required in order to bring people and objects up to

the same temperature as in a radiant heating system.

When calculating the heat loss of a structure, the nature of radiant

heating should be considered to allow for a more appropriately

sized system. As mentioned above, a thermostat setting of 65°F

[18°C] for a radiant fl oor system is comparable to a forced air

system with a thermostat setting of 70°F [21°C]. This principle

affects the heat loss in two ways:

1. The lower temperature difference [between indoor and

outdoor temperatures] causes the heat loss to be lower.

2. The lack of air movement lowers the infi ltration rate of

the structure.

Following is an example of the differences in load calculations for

radiant fl oor systems and forced air systems:

System A: Forced Air System

ACCA Manual J heat loss calculation

2,000 sq. ft. [186 sq. meter] residential structure

Outside design temperature = 0°F [-18°C]

Indoor design temperature = 70°F [21°C]

Temperature difference = 70°F [39°C]

Air changes per hour = 0.60 AC/H

Heat loss = 50,000 Btu/hr [14,654 Watts]

System B: Radiant Floor System

ACCA Manual J heat loss calculation

2,000 sq. ft. [186 sq. meter] residential structure

Outside design temperature = 0°F [-18°C]

Indoor design temperature = 65°F [18°C]

Temperature difference = 65°F [36°C]

Air changes per hour = 0.50 AC/H

Heat loss = 44,423 Btu/hr [13,020 Watts]

When the characteristics of a radiant fl oor system are considered,

equipment sizing can be signifi cantly impacted. In the example

above, the heat loss for the structure decreases by 5,577 Btu/hr

[1,635 Watts], or 11%. Industry estimates are as high as 20%.

However, Bryant encourages the use of load calculations at actual

temperature differences and infi ltration rates for equipment sizing,

rather than “rules of thumb.”

Heat Gain Calculations

Most space cooling is accomplished through the use of forced air.

Heat gain calculations must be performed on a room-by-room or

zoned basis. Although load calculations for single zone systems

may consider the whole house or building as one zone, a room-byroom calculation will facilitate air duct sizing.

Outdoor design temperatures should be obtained from the

appropriate ACCA, ASHRAE or HRAI manual at the 0.4%

condition or local requirements, whichever is most severe. Indoor

design temperatures for cooling typically range from 70-78°F [2125°C], with most designed at 75°F [24°C].

System Type

Indoor

Design Range

Minimum

Indoor Design

100% Radiant Floor* 65-70°F [18-21°C] 65°F [18°C]

Mixed Radiant/Forced Air 68-72°F [20-22°C] 68°F [20°C]

Baseboard 68-72°F [20-22°C] 68°F [20°C]

Part II: Load Side Design

Page 9

Bryant Geothermal Heat Pump Systems

7

Water-to-Water System Design Guide

SIZING WATER-TO-WATER EQUIPMENT /

BUFFER TANKS

Water-to-Water Equipment Sizing

Water-to-water equipment sizing is dependent upon the type of

hydronic system application (load side – indoor) and the type of

ground loop system (source side – outdoor). Since the capacity

and effi ciency of the water-to-water unit is directly related to the

entering source temperature, care must be taken to insure that

the unit will provide adequate capacity at design conditions. The

complexity of the ground loop sizing can be simplifi ed with the

use of software, like Bryant’s GeoDesigner. GeoDesigner allows

the user to enter the heat loss/heat gain, the water-to-water unit

size, and the ground loop parameters. An analysis based upon bin

weather data allows the user to size the equipment/ground loop

and obtain annual operating costs. Below is a typical screen shot.

Figure 2-1: GeoDesigner Heat Pump / Loop Sizing

Part II: Load Side Design / Equipment Sizing

Page 10

8

Water-to-Water System Design Guide

Bryant: Whatever It Takes.

Backup Heat

Just like water-to-air systems, which typically have some type

of backup heating capability, water-to-water systems can also

benefi t from the use of supplemental heating to help lower initial

installation costs. Design temperatures are usually chosen for

1%. In other words, 99% of the time, the outdoor temperature

is above the design temperature. If the heat pump is designed to

handle 100% of the load, it is larger than required 99% of the time.

GeoDesigner can determine an economical balance point that will

allow the water-to-water unit to be downsized when a backup

boiler or water heater is used for supplemental heat.

For example, suppose a home in Chicago has a heat loss the same as

the example above [44,423 Btuh, 13,019 Watts]. One 50YEW010

unit has a heating capacity of approximately 10kW [33,000 Btuh] at

32°F [0°C] entering source (ground loop) temperature. According

to GeoDesigner, the water-to-water unit could handle the heating

load 98% of the time. A backup electric boiler would consume

about 326 kWh annually for back up heat [$33 per year at $0.10/

kWh]. Two 50YEW010 units could handle the heating load no

matter what the outdoor temperature is (100% heating – no backup

required). However, this combination would only save about 239

kWh per year [$24 per year at $0.10/kWh], yet the additional

installation cost for a second unit and signifi cantly more ground loop

would never pay back in operating cost savings. In most cases, sizing

for 100% of the heating load is not cost effective.

Cooling

Cooling is not always desired with radiant heating systems. A

water-to-water heat pump system can provide chilled water to

ducted or non-ducted fan coil units. A reversible water-to-water

heat pump can provide chilled water to cool the building, as well

as hot water for the heating system. Buildings with fan coil units

can generally be retrofi tted for cooling quite easily. The diffi culty, as

mentioned in part I, is using existing fan coils for heating, especially

if they were originally sized for high water temperatures.

For optimal cooling and dehumidifi cation, Br yant recommends a

separate water-to-air heat pump for cooling. Controls are much

simpler when a water-to-water unit is used for space heating

and/or domestic water heating, and a water-to-air unit is used for

cooling. Since the water-to-water and water-to-air units can share

one ground loop, the installation cost of using a water-to-air unit

for cooling is simply the incremental cost of the unit. Generally, no

additional ground loop is required (in Northern climates), and the

cost of the water-to-air unit is usually less than the cost of chilled

water/fan coil units, especially if the cost of additional piping/

valving/controls and labor is considered. The cost of a water-toair unit is approximately the same as a ductless mini split, and is

much more effi cient. The advantages of geothermal heat pumps

for cooling (no outdoor unit, no refrigerant line sets, longevity, etc.)

should be considered when cooling is required.

Buffer Tank Sizing / Application

All water-to-water units used in heating applications require a

buffer tank to prevent equipment short cycling and to allow

different fl ow rates through the water-to-water unit than through

the hydronic heating delivery system. A buffer tank is also required

for chilled water cooling applications if the water-to-water unit(s)

is more than 20% larger than the cooling load and/or multiple fan

coil units will be used. Water-to-water units sized for the cooling

load in applications with only ONE fan coil unit may be able

to operate without a buffer tank, but this would be an unusual

situation, since the cooling load is normally much smaller than

the heating load. The best approach is to plan for a buffer tank in

every application.

The size of the buffer tank should be determined based upon

the predominant use of the water-to-water equipment (heating

or cooling). For heating, buffer tanks should be sized at one U.S.

gallon per 1,000 Btuh [13 Liters per kW] of heating capacity at

the maximum entering source water temperature (EST) and the

minimum entering load water temperature (ELT), the point at

which the water-to-water unit has the highest heating capacity,

usually 50-70°F [10-21°C] EST and 80-90°F [26-32°C] ELT. For

cooling, buffer tanks should be sized at one U.S. gallon per 1,000

Btuh [13 Liters per kW] of cooling capacity at the minimum EST

and the maximum ELT, the point at which the water-to-water unit

has the highest cooling capacity, usually 50-70°F [10-21°C] EST and

50-60°F [10-16°C] ELT. Select the size of the tank based upon the

larger of the calculations (heating or cooling). The minimum buffer

tank size is 40 U.S. gallons [150 Liters] for any system.

Electric water heaters typically make good buffer tanks because of

the availability and relatively low cost. However, the water heater

must be A.S.M.E. rated (rated for heating) in order to qualify as a

buffer tank. Attention should be paid to insulation values of the

tank, especially when a buffer tank is used to store chilled water

due to the potential for condensation. A minimum insulation value

of R-12 [2.11 K-m2/W] is recommended for storage tanks.

Part II: Load Side Design / Equipment Sizing

CAUTION:

Maximum leaving water temperature of the 50YEW series

equipment is 145°F [63°C]. For domestic hot water tank

temperatures or heating buffer tank temperatures above

130°F [54°C], pump and pipe sizing is critical to insure that

the fl ow rate through the heat pump is suffi cient to maintain

leaving water temperatures below the maximum temperature,

and to provide water fl ow rates within the ranges shown in

the performance section of this manual.

Page 11

Bryant Geothermal Heat Pump Systems

9

Water-to-Water System Design Guide

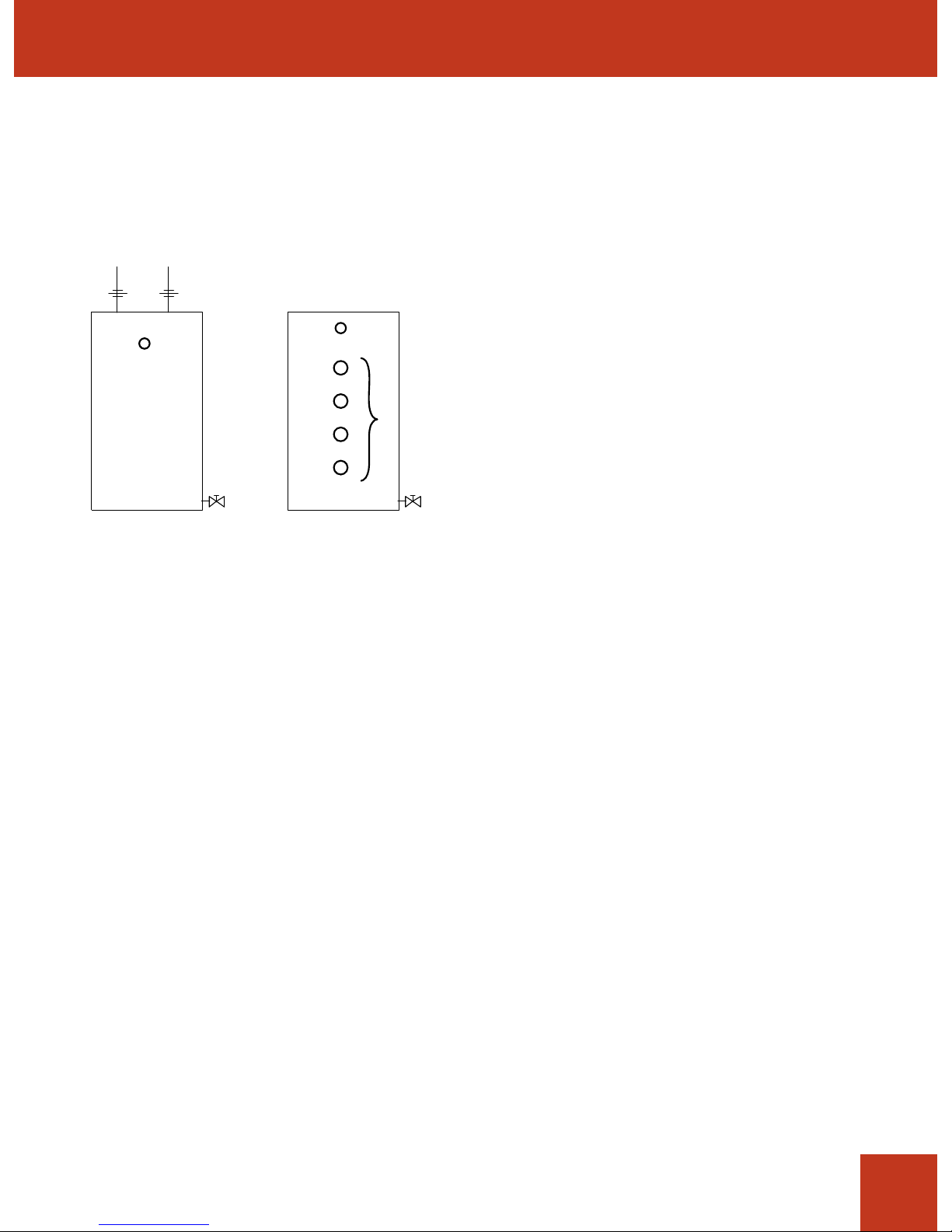

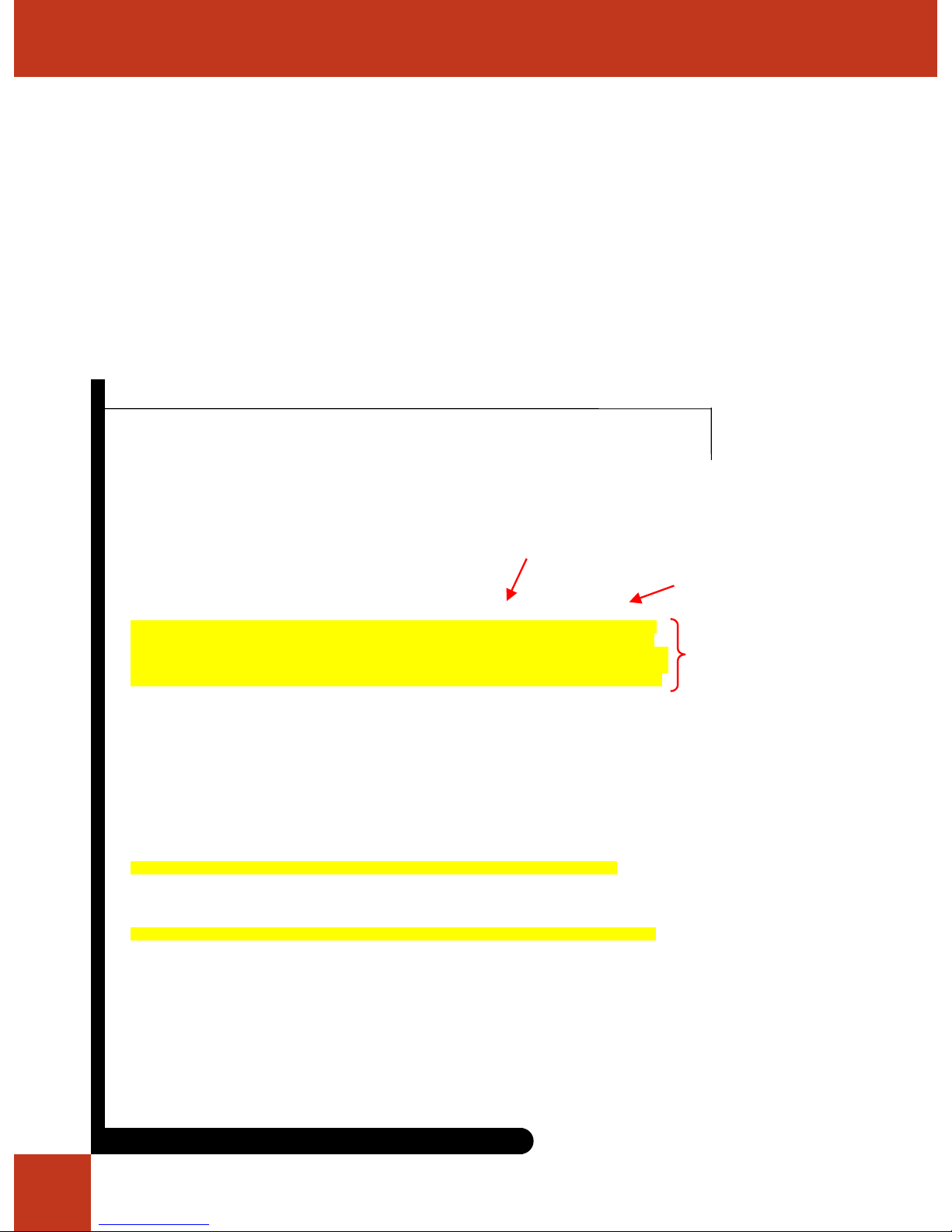

Figure 2-2: Connections – Electric Water Heater /

Buffer Tank

When using an electric water heat as a buffer tank, there are

fewer water connections. Alternate piping arrangements may be

required to make up for the lack of water connections. Schematics

are shown in the next section. Above is an illustration showing the

water connection differences between a buffer tank and an electric

water heater.

Typical Electric

Water Heater

HC

Drain (3)

Connection for

Press Relief Valve

Hot/Cold Water

Connections

(1) (2)

Typical

Buffer Tank

Connection for

Press Relief Valve

Load & Source

Connections

(1)

(2)

(3)

(4)

Drain (5)

Part II: Load Side Design / Equipment Sizing

Page 12

10

Water-to-Water System Design Guide

Bryant: Whatever It Takes.

SYSTEM DESIGN

As mentioned in part I, hydronics applications offer a wide range

of application fl exibility, so much in fact, that it is necessary to

narrow down the choices in order to start designing the system.

As with any heating and cooling design, there is never a perfect

solution, but rather a compromise between installation costs,

operating costs, desired features and comfort. Once the system is

selected, design of the distribution system, pumps, piping and other

components can be considered.

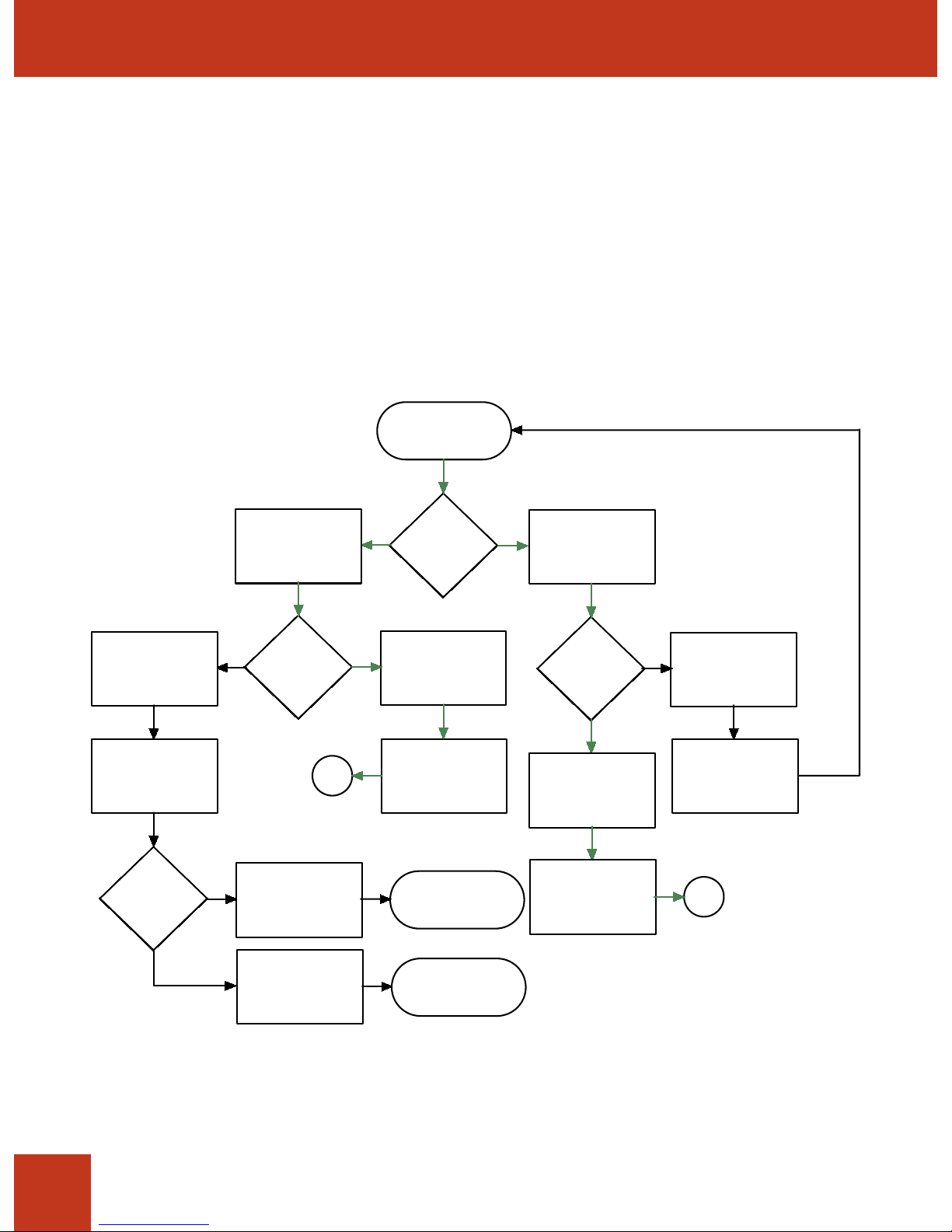

Figure 2-3a: System Selection Flow Chart (Part 1)

SYSTEM SELECTION

Figures 2-3a and 2-3b present system selection in fl ow chart

format for the load side of the water-to-water unit. There are

six piping schematics following the fl ow charts that illustrate each

of the possible choices. There are also two additional piping

schematics, one for alternate buffer tank piping, and one for using a

backup boiler for supplemental heat. To select the correct drawing,

begin in fi gure 2-3a, and fi nish the selection process in fi gure 2-3b.

Start

(Load Side Applications)

Heating

System?

Radiant Floor

Baseboard Convection

Radiator

Fan Coil

Cooling

System?

Cooling

System?

Chilled Water / Fan Coil

Chilled Radiant Floor

Chilled Water / Fan Coil

Chilled Radiant Floor

See drawing 2-5 (

50PSW

/

GSW + sep htg /clg buffer

tanks)

No Cooling or Separate

Cooling System

No Cooling or Separate

Cooling System

Use 50PSW or GSW series

Reversible Model

Buffer

Tanks?

Buffer tank for heating and

a separate buffer tank for

cooling

One buffer tank for both

heating and cooling

Use 50YEW (high temp) or

50PSW/GSW ( med temp)

series

Use 50YEW (high temp)

series

1

2

(required)

NOTE: Green arrows indicate Bryant

recommended applications.

High temp (

50YEW

) unit is

not reversible.

See drawing 2-6 (

50PSW

/

GSW +

one htg

/clg buffer

tank)

Part II: Load Side Design / System Design & Selection

Page 13

Bryant Geothermal Heat Pump Systems

11

Water-to-Water System Design Guide

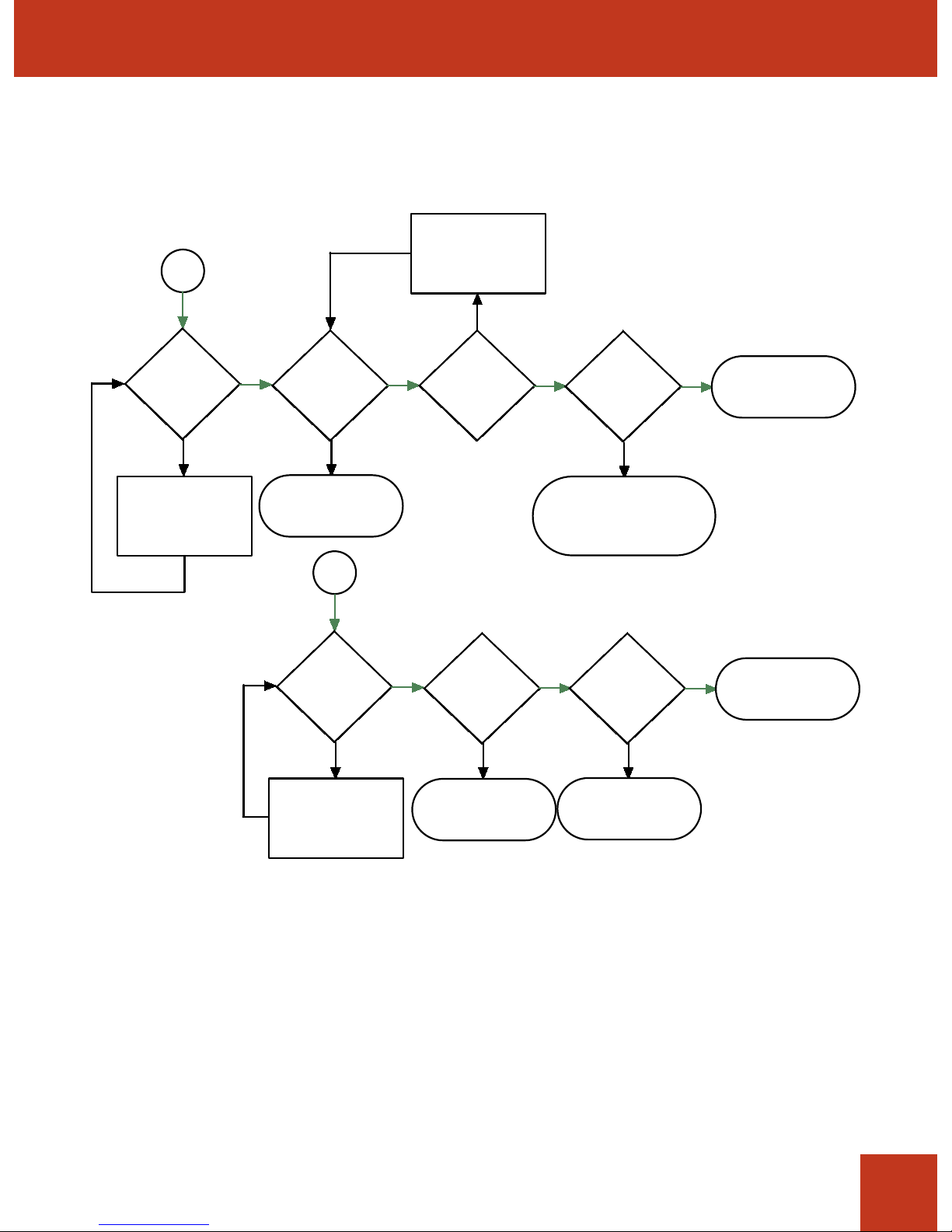

Figure 2-3b: System Selection Flow Chart (Part 2)

1

Buffer

Tank?

Buffer tank is required

No

Ye s

Domestic

Hot

Wat er ?

No

Ye s

50YEW?

Ye s

No

50YEW has integrated

controls. Choose 50YEW

(other choices are possible,

but not shown in

drawings).

Indirect

Water

Heater?

Ye s

No

NOTE: Green arrows indicate Bryant

recommended applications.

See drawing 2-1 (50YEW +

Indirect Water Heater)

Secondary Heat Exchanger / Pump

is required. See drawing 2-2 (50YEW

+HX + Pump + Water Heater)

2

Buffer

Tank?

No

Ye s

Domestic

Hot

Wat er ?

No

Ye s

Indirect

Wat er

Heater?

Ye s

No

See drawing 2-1 (50YEW +

Indirect Water Heater)

Secondary Heat Exchanger / Pump

is required. See drawing 2-2

(50YEW + HX + Pump +

Water Heat)

See drawing 2-3 (

50YEW

)

or drawing 2-4 (

50PSW

/

GSW

)

See drawing 2-3 (

50YEW

)

Buffer tank is required

Part II: Load Side Design / System Design & Selection

Page 14

12

Water-to-Water System Design Guide

Bryant: Whatever It Takes.

System Descriptions

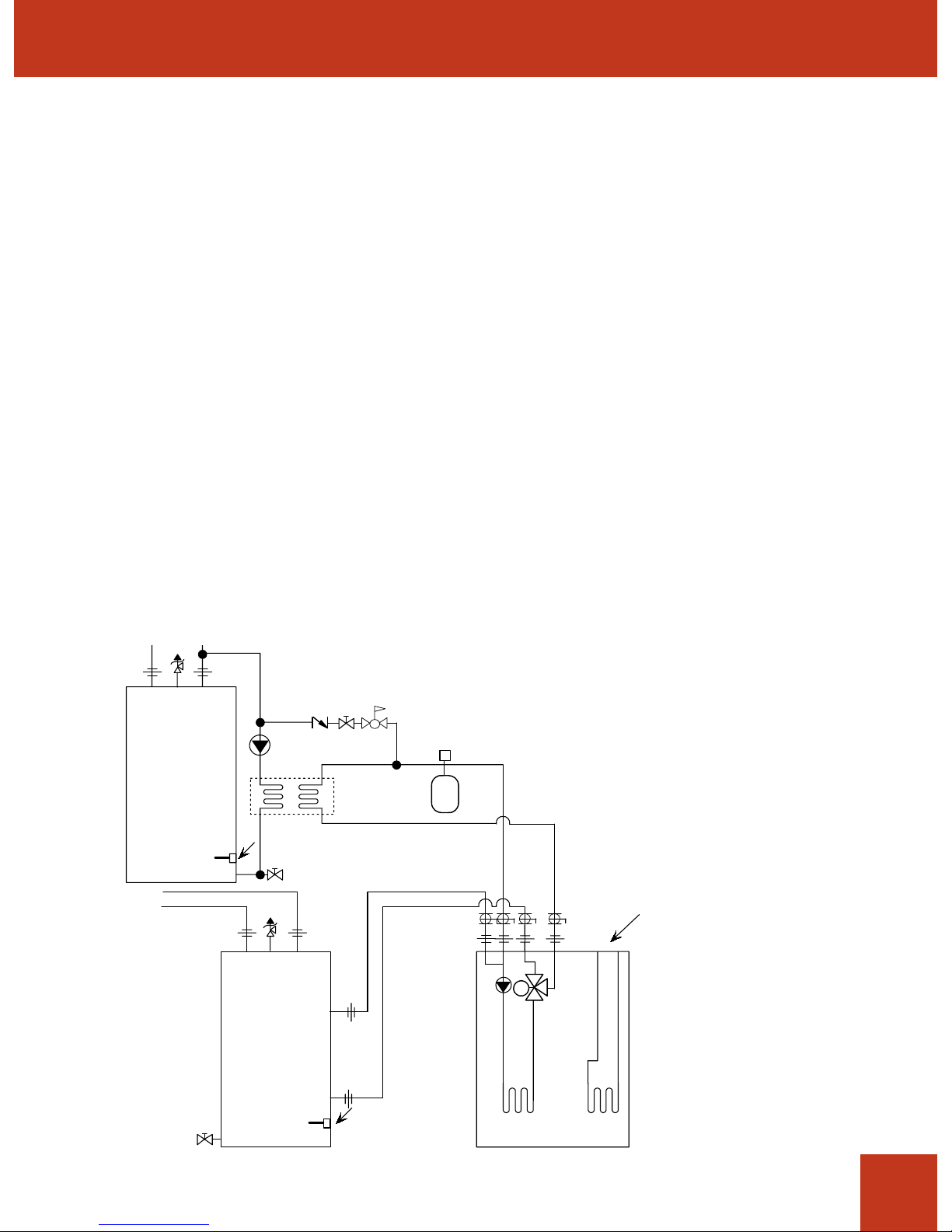

Figure 2-4: Component Legend for Drawings 2-1 to

2-9

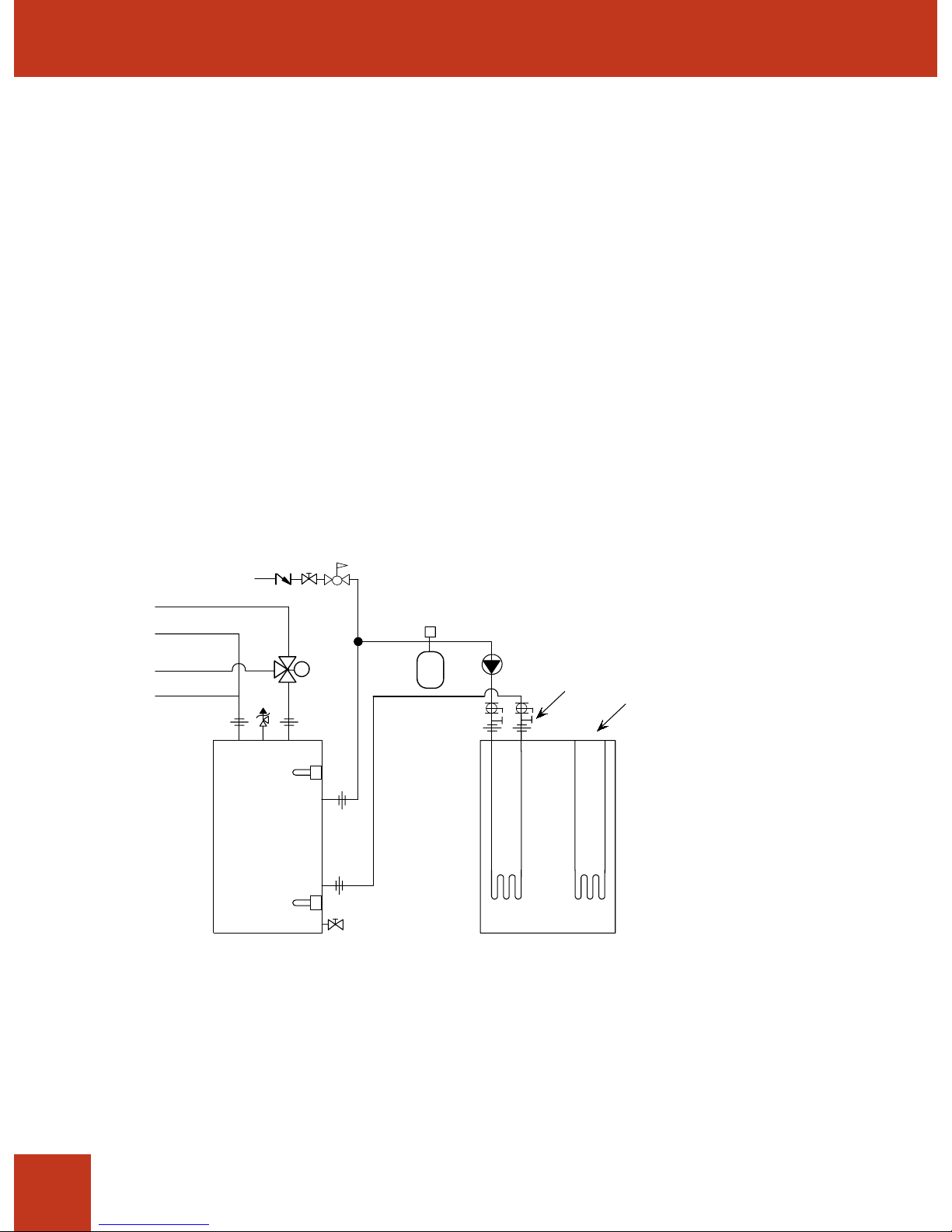

Drawing 2-1 – 50YEW Typical Load Piping Indirect Water Heater

/ No Cooling or Separate Cooling System: System #1 uses one

or more water-to-water units and a buffer tank for each unit.

Drawing 2-1 shows a typical piping arrangement for this system.

A thermistor mounted in an immersion well senses buffer tank

temperature, which allows the internal controls (50YEW units

only) to engage the water-to-water unit compressor, load pump

and source pump(s) when the tank temperature drops below

the set point, typically 120°F [49°C] or less. The radiant fl oor (or

baseboard, radiator, fan coil, etc.) system therefore is completely

isolated from the water-to-water unit. The controls for the

hydronic distribution system energize pumps and/or zone valves to

allow heated water in the buffer tank to fl ow through the heating

distribution system. Potable water is heated via an indirect water

heater, so that heating system water and potable water do not mix.

The 50YEW unit has an internal motorized valve, which allows

the load pump to send heated water to the buffer tank or the

indirect water heater. A thermistor mounted in an immersion well

senses DHW tank temperature, which allows the internal controls

(50YEW units only) to engage the water-to-water unit compressor,

load pump and source pump(s) when the DHW tank temperature

drops below the set point, typically 130°F [54°C]. If desired,

cooling is accomplished with a separate system.

Component Legend

3-Way Valve - Manually Operated

3-Way Valve - Motorized

Mixing Valve

Ball Valve

Gate Valve

Pressure Reducing Valve

Pressure Relief ("Pop-Off") Valve

Union

Pressure/Temperature (P/T) Port

Circulator Pump

Heat Exchanger

T

Check Valve

M

Indirect

Water Heater

Heating

Buffer Tank

NOTES:

1. Place air vent at the highest point in the system. If

internal expansion tanks are installed, only an air

vent is required.

2. Thermistors should be installed in an immersion well.

Locate thermistor in the bottom half of the tank.

3. If electric water heat is used instead of buffer tank, see

drawing 2-7.

4. P/T (pressure/temperature) ports are internal for

50YEW units on load and source connections.

5. Other components (additional ball valves, unions, etc.)

may be required for ease of service. This drawing

shows only minimum requirements. Your specific

installation will dictate final component selections.

6. Buffer tank must be approved as a heating vessel.

7. Local code supercedes any piping arrangements or

components shown on this drawing.

To/From

Radiant Floor,

Radiator,

Baseboard,

or Fan Coil

Heating System

HC

HC

Exp

Ta nk

Note 1

Air Vent

See drawings in section 3 for Source connections

03Oct07

Note 3

50YEW

Unit

Source HX

(coaxial)

Load HX

(brz plt)

INOUTIN OUTOUT

HTG DHW

M

DHW

IN

HTG

P. R. V .

Thermistor

Note 2

If heat exchanger

of indirect water

heater does not

have enough

mass, see

drawing 2-9

Thermistor

Note 2

Drawing 2-1: 50YEW Typical Load Piping Indirect Water Heater / No Cooling or Separate

Cooling System

Part II: Load Side Design / System Design & Selection

Page 15

Bryant Geothermal Heat Pump Systems

13

Water-to-Water System Design Guide

Drawing 2-2 – 50YEW Typical Load Piping Water Heater with

Secondary Heat Exchanger / No Cooling or Separate Cooling

System: System #2 uses one or more water-to-water units

and a buffer tank for each unit. Drawing 2-2 shows a typical

piping arrangement for this system. A thermistor mounted in

an immersion well senses tank temperature, which allows the

internal controls (50YEW units only) to engage the water-to-water

unit compressor, load pump and source pump(s) when the tank

temperature drops below the set point, typically 120°F [49°C]

or less. The radiant fl oor (or baseboard, radiator, fan coil, etc.)

system therefore is completely isolated from the water-to-water

unit. The controls for the hydronic distribution system energize

pumps and/or zone valves to allow heated water in the buffer

tank to fl ow through the heating distribution system. Potable

water is heated via a direct water heater (typically an electric

water heater) and a secondary heat exchanger (typically a brazed

plate heat exchanger), so that heating system water and potable

water do not mix. The 50YEW unit has an internal motorized

valve, which allows the load pump to send heated water to the

buffer tank or the secondary heat exchanger for heating potable

water. A thermistor mounted in an immersion well senses tank

temperature, which allows the internal controls (50YEW units

only) to engage the water-to-water unit compressor, load pump

and source pump(s) when the tank temperature drops below

the set point, typically 130°F [54°C]. The use of a direct water

heat and secondary heat exchanger requires a pump between

the secondary heat exchanger and the water heater. The addition

of a pump contactor near the water heater will be necessary to

energize the pump any time the 50YEW load pump is energized

for potable water heating. If desired, the 50YEW controls allow

emergency water heating via electric elements if the 50YEW unit

is locked out. This requires a contactor at the water heater to

energize the electric elements when the heat pump is locked out.

Cooling is accomplished with a separate system.

Secondary Heat Exchanger Sizing: Due to the

lower water temperatures associated with heat

pumps (as compared to 180-200°F [82-93°C] boiler

temperatures), heat exchanger sizing is critical.

Bryant recommends the use of sizing software

provided by the heat exchanger manufacturer. An

example is shown in fi gure 2-5. NOTE: Even though

the maximum leaving water temperature of the

50YEW series equipment is 145°F [63°C], some

room for piping changes, pump performance, and/

or pressure switch tolerance, should be considered

via slightly lower design temperatures (143°F [62°C]

is shown in fi gure 2-5 example). Refrigerant high

pressure switches typically have a tolerance of ± 15

psi [±1 Bar], potentially resulting in nuisance faults if

the switch tolerance is on the lower side of the range.

The compressor is rated for 145-149°F [63-65°C]

operation, but if the switch is marginal, a slightly

conservative design temperature will help avoid

nuisance faults.

Drawing 2-2: 50YEW Typical Load Piping Water Heater with Secondary Heat Exchanger /

No Cooling or Separate Cooling System

Thermistor

Note 2

Heating

Buffer Tank

NOTES:

1. Place air vent at the highest point in the system. If

internal expansion tanks are installed, only an air

vent is required.

2. Thermistors should be installed in an immersion well.

Locate thermistor in the bottom half of the tank.

3. If electric water heat is used instead of buffer tank, see

drawing 7.

4. P/T (pressure/temperature) ports are internal for

50YEW units on load and source connections.

5. Other components (additional ball valves, unions, etc.)

may be required for ease of service. This drawing

shows only minimum requirements. Your specific

installation will dictate final component selections.

6. Buffer tank must be approved as a heating vessel.

7. Local code supercedes any piping arrangements or

components shown on this drawing.

To/From

Radiant Floor,

Radiator,

Baseboard,

or Fan Coil

Heating System

HC

See drawings in section 3 for Source connections

03Oct07

Note 3

Direct

Water Heater

HC

Exp

Ta nk

Note 2

Air Vent

Plate Heat

Exchanger

Secondary

Pump

50YEW

Unit

Source HX

(coaxial)

Load HX

(brz plt)

INOUTIN OUTOUT

HTG DHW

M

DHW

IN

HTG

P. R. V .

Thermistor

Note 2

Part II: Load Side Design / System Design & Selection

Page 16

14

Water-to-Water System Design Guide

Bryant: Whatever It Takes.

CAUTION:

Maximum leaving water temperature of the 50YEW series

equipment is 145°F [63°C]. For domestic hot water tank

temperatures or heating buffer tank temperatures above 130°F

[54°C], pump and pipe sizing is critical to insure that the fl ow

rate through the heat pump is suffi cient to maintain leaving water

temperatures below the maximum temperature, and to provide

water fl ow rates within the ranges shown in the performance

section of this manual.

SWEP INTERNATIONAL

v.1.5.6 SWEP North America, Inc.

3483 Satellite Blvd., Suite 210

Duluth, GA 30096

SWEP SSP CBE

HEAT EXCHANGER: B10Tx30H/1P (1” fittings)

SINGLE PHASE - Rating

7002PES41:etaDelpmaxE:remotsuC

WHDrofXHyradnoces)zH06(010WE50Y:ecnerefeR

2EDIS1EDISSTNEMERIUQERYTUD

)%0.02(retaW-locylGenelyporP1ediSdiulF

retaW2ediSdiulF

]76.15[00.521]76.16[00.341:]C°[F°erutarepmettelnI

]40.65[78.231]22.75[00.531:]C°[F°erutarepmetteltuO

]34.54[00.21]34.54[00.21:]m/l[mpgSUetarwolF

:porderusserp.xaM

287.0597.0:UTNhtgnellamrehT

PHYSICAL PROPERTIES

]68.35[49.821]44.95[00.931:]C°[F°erutarepmetecnerefeR

415.0477.0:PcytisocsivcimanyD

694.0718.0:Pcllaw-ytisocsivcimanyD

75.1674.26:tfuc/blytisneD

1999.09969.0:F°,bl/utByticapactaehcificepS

4473.06503.0:F°,h,tf/utBytivitcudnoclamrehT

PLATE HEAT EXCHANGER

]27631[05664:]W[h/utBdaoltaeH

m[tfrqsaerarefsnarttaehlatoT

2

] : 9.34 [0.868]

5994:tfrqs/h/utBxulftaeH

Log mean temperature difference °F [°C] : 10.06 [5.59]

Overall H.T.C. (available/required) Btu/sqrft,h,°F : 950/496

]85.11[86.1]71.11[26.1:]aPk[isplatot-sporderusserP

]23.1[191.0]43.1[491.0:]aPk[ispstropni-

549.0549.0:niretemaidtroP

4151:slennahcforebmuN

03:setalpforebmuN

19:%gnicafrusrevO

100.0:utB/F°,h,tfrqsrotcafgniluoF

Note:

Disclaimer: Data used in this calculation is subject to change without notice. "SWEP may have patents, trademarks, copyrightsor otherintellectual property rights

covering subject matter in this document." "Except as expressly provided in any writtenlicense agreementfrom SWEP," "the furnishing of thisdocument does not give

you any license to these patents, trademarks, copyrights, or other intellectual property."

Sized to

deliver

130°F

[54°C]

at the

DHW

tank.

DHW tank

Heat Pump

DATE 14SEP07 PAGE 1 OF1

Part II: Load Side Design / System Design & Selection

Page 17

Bryant Geothermal Heat Pump Systems

15

Water-to-Water System Design Guide

Figure 2-5: Example Secondary Heat Exchanger Sizing

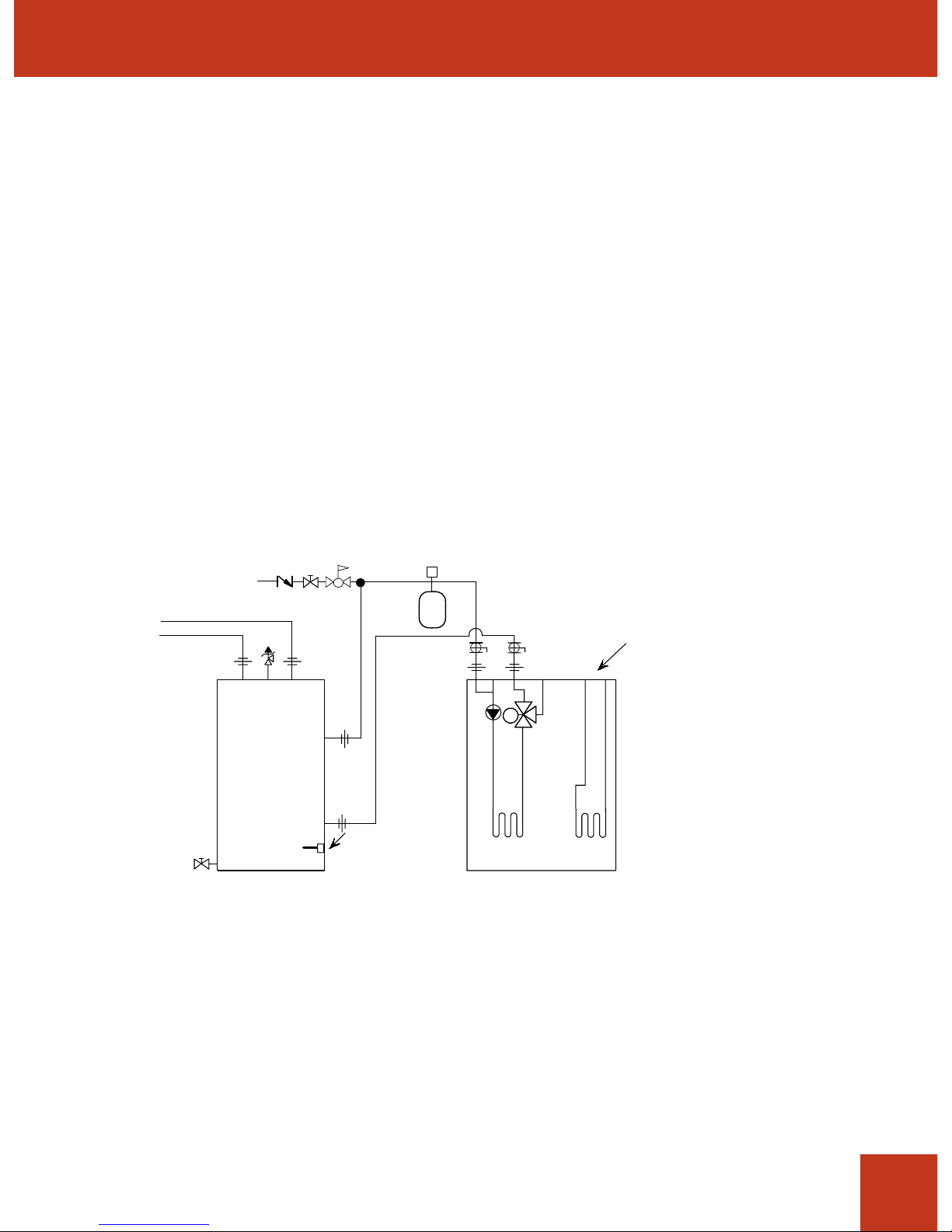

Drawing 2-3 – 50YEW Typical Load Piping / No DHW Heating

or Separate DHW System / No Cooling or Separate Cooling

System: System #3 uses one or more water-to-water units

and a buffer tank for each unit. Drawing 2-3 shows a typical

piping arrangement for this system. A thermistor mounted in

an immersion well senses tank temperature, which allows the

internal controls (50YEW units only) to engage the water-to-water

unit compressor, load pump and source pump(s) when the tank

temperature drops below the set point, typically 120°F [49°C] or

less. The radiant fl oor (or baseboard, radiator, fan coil, etc.) system

therefore is completely isolated from the water-to-water unit.

The controls for the hydronic distribution system energize pumps

and/or zone valves to allow heated water in the buffer tank to fl ow

through the heating distribution system. Potable water is heated

with a separate system. If desired, cooling is accomplished with a

separate system.

Heating

Buffer Tank

NOTES:

1. Place air vent at the highest point in the system. If

internal expansion tanks are installed, only an air

vent is required.

2. Thermistor should be installed in an immersion well.

Locate thermistor in the bottom half of the tank.

3. If DHW option is not used, DHW supply connection MUST

be plugged.

4. If electric water heat is used instead of buffer tank, see

drawing 2-7.

5. P/T (pressure/temperature) ports are internal for

50YEW units on load and source connections.

6. Other components (additional ball valves, unions, etc.)

may be required for ease of service. This drawing

shows only minimum requirements. Your specific

installation will dictate final component selections.

7. Buffer tank must be approved as a heating vessel.

8. Local code supercedes any piping arrangements or

components shown on this drawing.

To/From

Radiant Floor,

Radiator,

Baseboard,

or Fan Coil

Heating System

HC

See drawings in section 3 for Source connections

03Oct07

Note 4

50YEW

Unit

Source HX

(coaxial)

Load HX

(brz plt)

INOUT

OUT

OUT

HTG

DHW

M

IN

HTG

IN

DHW

Exp

Tank

Air Vent

Note 1

Note 3

P. R. V .

Cold Water Supply

Thermistor

Note 2

Drawing 2-3: 50YEW Typical Load Piping No DHW Heating or Separate DHW System / No

Cooling or Separate Cooling System

Part II: Load Side Design / System Design & Selection

Page 18

16

Water-to-Water System Design Guide

Bryant: Whatever It Takes.

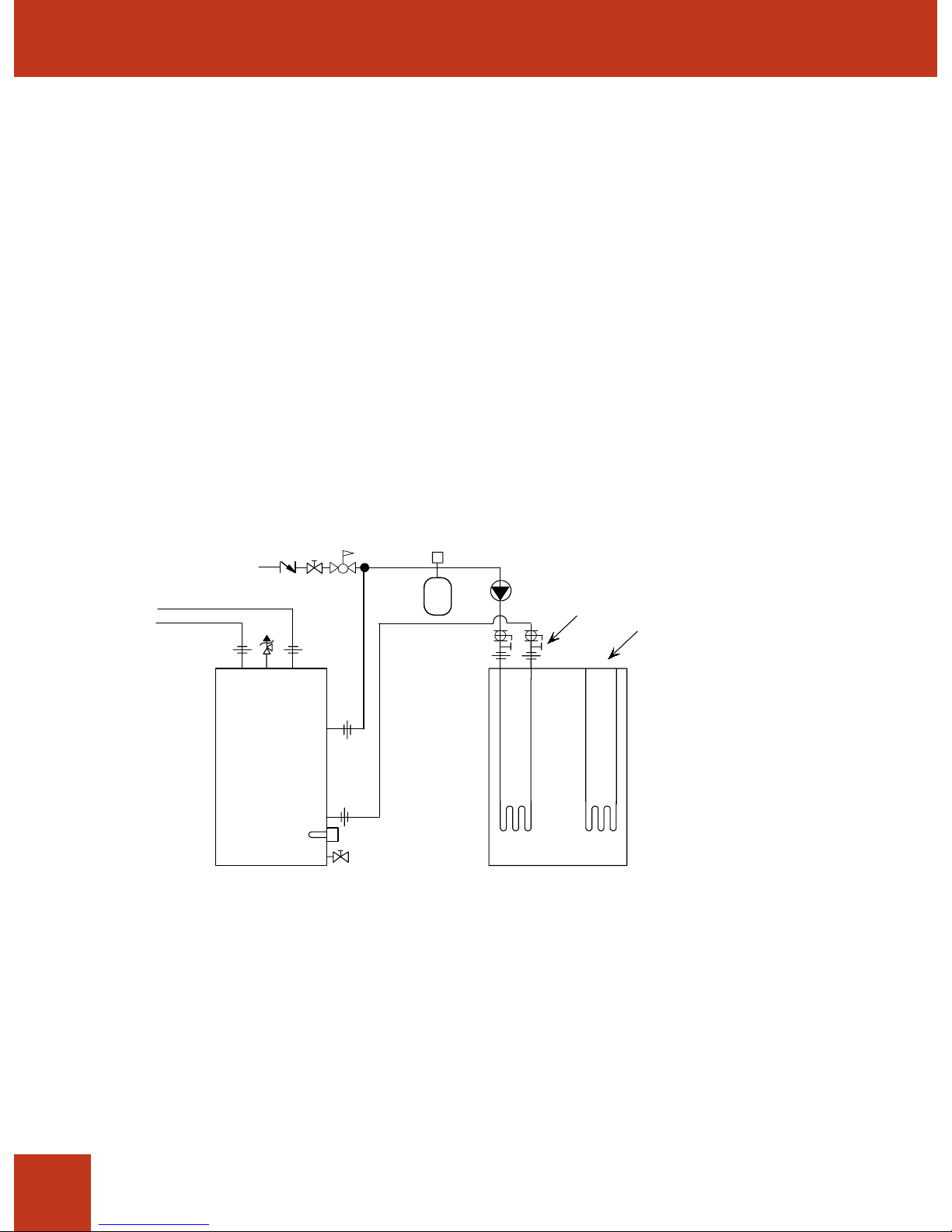

Drawing 2-4 – 50PSW/GSW Typical Load Piping / No DHW

Heating or Separate DHW System / No Cooling or Separate

Cooling System: System #4 uses one or more water-to-water

units and a buffer tank for each unit. Drawing 2-4 shows a typical

piping arrangement for this system. A thermistor mounted in an

immersion well senses tank temperature, which allows the waterto-water unit to engage the compressor, load pump and source

pump(s) when the tank temperature drops below the set point,

typically 120°F [49°C] or less. The radiant fl oor (or baseboard,

radiator, fan coil, etc.) system therefore is completely isolated from

the water-to-water unit. The controls for the hydronic distribution

system energize pumps and/or zone valves to allow heated water

in the buffer tank to fl ow through the heating distribution system.

Potable water is heated with a separate system. If desired, cooling

is accomplished with a separate system.

Heating

Buffer Tank

NOTES:

1. Place air vent at the highest point in the system.

2. Aqua-stat should be installed in an immersion well.

Locate aqua-stat in the bottom half of the tank.

3. If electric water heat is used instead of buffer tank, see

drawing 2-7.

4. Other components (additional ball valves, unions, etc.)

may be required for ease of service. This drawing

shows only minimum requirements. Your specific

installation will dictate final component selections.

5. Buffer tank must be approved as a heating vessel.

6. Local code supercedes any piping arrangements or

components shown on this drawing.

To/From

Radiant Floor

HC

See drawings in section 3 for Source connections

03Oct07

Notes 2,3

50PSW

or GSW

Unit

Source HX

(coaxial)

Load HX

(coaxial)

INOUTOUTIN

Exp

Tank

Air Vent

Note 1

P. R. V .

Cold Water Supply

P/T port (50PSW / GSW units only)

Aqua-stat

Drawing 2-4: 50PSW / GSW Typical Load Piping No DHW Heating or Separate DHW System / No

Cooling or Separate Cooling System

Part II: Load Side Design / System Design & Selection

Page 19

Bryant Geothermal Heat Pump Systems

17

Water-to-Water System Design Guide

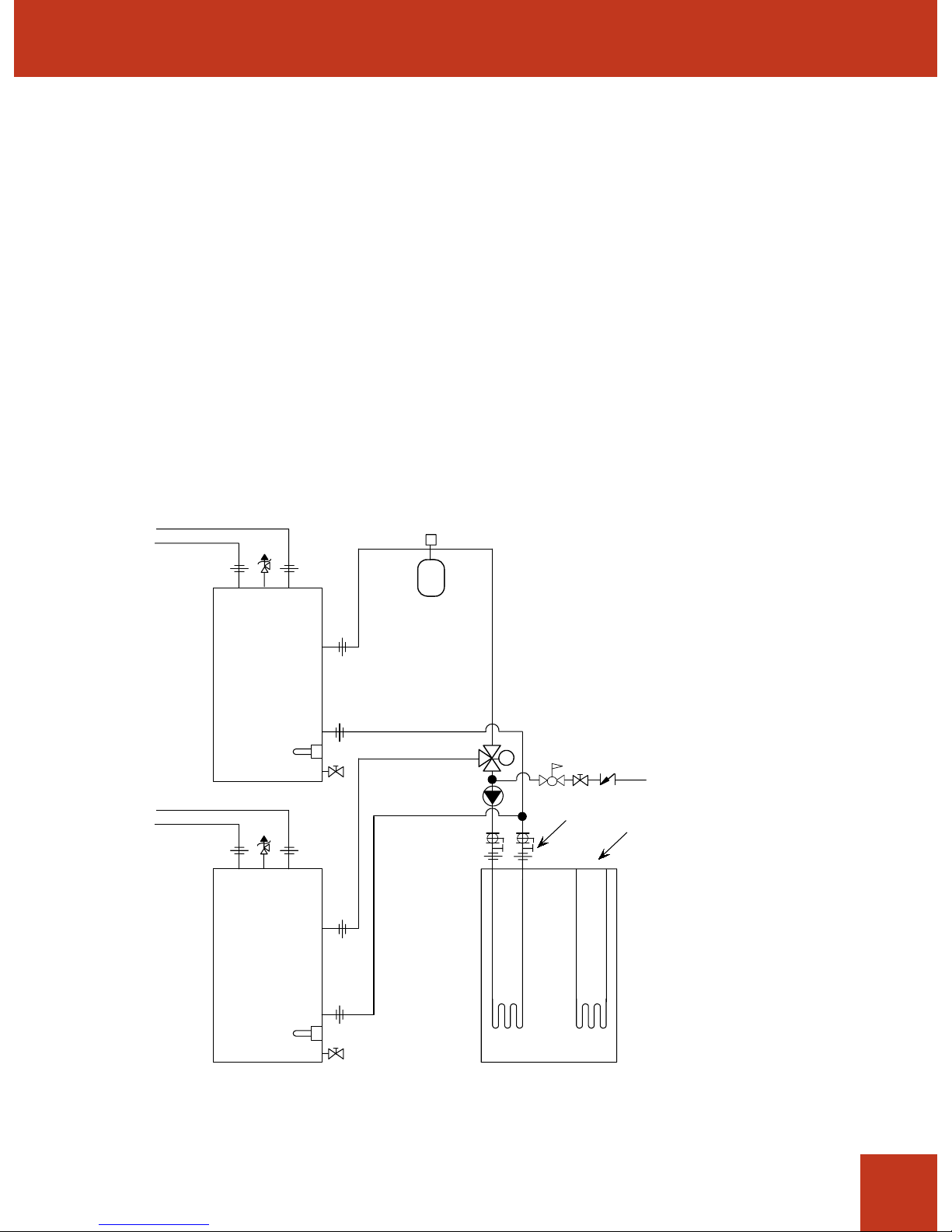

Drawing 2-5 – 50PSW/GSW Typical Load Piping - Chilled Water

Cooling System / Separate Heating & Cooling Buffer Tanks / No

DHW Heating or Separate DHW System: System #5 uses one

or more water-to-water units and two buffer tanks, one for heated

water, and one for chilled water. Drawing 2-5 shows a typical

piping arrangement for this system. An aqua-stat (well-mounted if

possible) in each tank senses tank temperature, which allows the

water-to-water unit to engage the compressor, load pump and

source pump(s) when the heating tank temperature drops below

the set point [typically 120°F [49°C] or less], or when the chilled

water tank temperature rises above the set point (typically 4550°F [7-10°C]). The radiant fl oor (or baseboard, radiator, fan coil,

etc.) heating system and the chilled water cooling system (typically

Drawing 2-5: 50PSW / GSW Typical Load Piping Chilled Water Cooling System / Separate Heating

and Cooling Buffer Tanks - No DHW Heating or

Separate DHW System

Chilled Water

Buffer Tank

NOTES:

1. Place air vent at the highest point in the system.

2. Aqua-stat should be installed in an immersion well.

Locate aqua-stat in the bottom half of the tank.

3. If electric water heat is used instead of buffer tank, see

drawing 2-7.

4. Motorized valve to be activated by unit RV solenoid

coil (24VAC).

5. Chilled water tank must be insulated to avoid condensation.

6. Other components (additional ball valves, unions, etc.)

may be required for ease of service. This drawing

shows only minimum requirements. Your specific

installation will dictate final component selections.

7. Buffer tank must be approved as a heating vessel.

8. Local code supercedes any piping arrangements or

components shown on this drawing.

To/From

Radiant Floor

HC

See drawings in section 3 for Source connections

03Oct07

50PSW

or GSW

Unit

Source HX

(coaxial)

Load HX

(coaxial)

INOUTOUTIN

Exp

Ta nk

Air Vent

Note 1

Heating

Buffer Tank

HC

To/From

Fan Coil Units

M

Notes 2,3

Note 4

Notes 2,3,5

Cold Water Supply

P. R. V .

P/T port (50PSW / GSW units only)

Aqua-stat

Aqua-stat

Note 2

Note 2

fan coil units) therefore are completely isolated from the waterto-water unit. The controls for the hydronic distribution system

energize pumps and/or zone valves to allow heated/chilled water

in the buffer tanks to fl ow through the heating/cooling distribution

systems. The motorized valve is used to switch between the

two tanks based upon heating or cooling season. Due to the

complexity of the controls, a manual seasonal changeover switch is

the best way to determine heated or chilled water operation. The

switch (typically a light switch) switches the unit reversing valve and

motorized valve. A reversible unit is required for this application

(50YEW is heating only – 50PSW/GSW units are reversible).

Potable water is heated with a separate system.

Part II: Load Side Design / System Design & Selection

Page 20

18

Water-to-Water System Design Guide

Bryant: Whatever It Takes.

Drawing 2-6 – 50PSW/GSW Typical Load Piping - Chilled Water

Cooling / Single Buffer Tank / No DHW Heating or Separate

DHW System: System #6 uses one or more water-to-water

units and a buffer tank for each unit. Drawing 2-6 shows a

typical piping arrangement for this system. Two aqua-stats (wellmounted if possible) sense tank temperature, one for heating and

one for cooling, which allows the water-to-water unit to engage

the compressor, load pump and source pump(s) when the tank

temperature drops below the set point (typically 120°F [49°C]

or less] in the heating mode, or when the tank temperature rises

above the set point [typically 45-50°F [7-10°C]) in the cooling

mode. The radiant fl oor (or baseboard, radiator, fan coil, etc.)

heating system and the chilled water cooling system (typically

fan coil units) therefore are completely isolated from the waterto-water unit. The controls for the hydronic distribution system

energize pumps and/or zone valves to allow heated/chilled water

in the buffer tank to fl ow through the heating/cooling distribution

systems. The motorized valves are used to switch between the

two distribution systems (and aqua-stats) based upon heating or

cooling season. Due to the complexity of the controls, a manual

seasonal changeover switch is the best way to determine heated

or chilled water operation. The switch (typically a light switch)

switches the unit reversing valve, motorized valves, and aqua-stats

(additional relays are required for determining heating/cooling

logic). A reversible unit is required for this application (50YEW

is heating only – 50PSW/GSW units are reversible). When using

one tank for both heated and chilled water, a buffer tank (not an

electric water heater) is recommended, since water heaters do not

have enough connections to facilitate all of the water connections

and the two well-mounted aqua-stats. Potable water is heated

with a separate system.

NOTES:

1. Motorized valves to be activated by unit RV solenoid

coil (24VAC).

2. Aqua-stat should be installed in an immersion well.

Locate heating aqua-stat in the bottom half of the tank.

Locate cooling aqua-stat in the top half of the tank.

3. Chilled water tank must be insulated to avoid condensation.

4. Place air vent at the highest point in the system.

5. Other components (additional ball valves, unions, etc.)

may be required for ease of service. This drawing

shows only minimum requirements. Your specific

installation will dictate final component selections.

6. Buffer tank must be approved as a heating vessel.

7. Local code supercedes any piping arrangements or

components shown on this drawing.

Heating / Chilling

Buffer Tank

To/ Fro m

Radiant Floor

HC

See drawings in section 3 for Source connections

03Oct07

Notes 2,3

50PSW

or GSW

Unit

Source HX

(coaxial)

Load HX

(coaxial)

INOUTOUTIN

Exp

Tank

Air Vent

Note 4

M

Note 1

To/ Fro m

Fan Coil Units

P. R. V .

Cold Water Supply

P/T port (50PSW / GSW only)

Aqua-stat

Aqua-stat

Cooling

Heating

Drawing 2-6: 50PSW / GSW Typical Load Piping Chilled Water Cooling System / Single Buffer Tank

- No DHW Heating or Separate DHW System

Part II: Load Side Design / System Design & Selection

Page 21

Bryant Geothermal Heat Pump Systems

19

Water-to-Water System Design Guide

Drawing 2-7 – Alternate Buffer Tank (Electric Water Heater)

Typical Piping: A “true” buffer tank is the best approach for control

of a hydronic system using a heat pump. Tanks are usually well

insulated, and there are typically a number of water connections

(6 or more in many cases), so that plumbing is easier and water

fl ows are not restricted. However, due to the cost of buffer tanks,

some installers use an electric water heater for the buffer tank. An

electric water heater is much less expensive, but may not have

enough water connections, and may require external installation.

Drawing 2-7 may be used as an alternate piping schematic for

drawings 2-1 through 2-5 when an electric water heater is used.

Drawing 2-6 requires a buffer tank due to the need for two aquastats. If a water heater is used, it must be approved as a heating

vessel (A.S.M.E. approval in the U.S.).

Drawing 2-7: Alternate Buffer Tank (Electric

Water Heater) Typical Piping

Part II: Load Side Design / System Design & Selection

Electric

Water Heater

NOTES:

1. Not all components shown (expansion tank, air vent, etc.).

Drawing is for buffer tank connections only.

2. Pump not needed for 50YEW unit with internal load pump option.

3. Thermistor or aqua-stat should be installed in an immersion

well. If water heater does not have well, one of the

heating elements should be removed, and a well adapter

4. Other components (additional ball valves, unions, etc.)

may be required for ease of service. This drawing

shows only minimum requirements. Your specific

installation will dictate final component selections.

5. Buffer tank must be approved as a heating vessel.

6. Local code supercedes any piping arrangements or

components shown on this drawing.

HC

Thermistor or Aqua-stat

Note 3

03Oct07

Note 3

Radiant

Floor

System

From Water-to-Water Unit

Note 1

Notes 1,2

To Water-to-Water Unit

(ASME Approved)

should be installed. Locate thermistor/aqua-stat in the

bottom half of the tank.

Page 22

20

Water-to-Water System Design Guide

Bryant: Whatever It Takes.

Drawing 2-8 – Piping for Backup Boiler (2nd Stage Heating):

Drawing 2-8 may be used for two different types of applications.

A boiler backup may be required because the water-to-water

unit lacks suffi cient capacity at design conditions, or because the

hydronic heating distribution system requires hotter water than the

water-to-water unit can produce.

• Water-to-Water Unit Lacks Capacity: This type of system would

be used when the water-to-water unit has been sized to handle

less than 100% of the heating load. It is common practice to size

geothermal heat pump systems to handle 80-90% of the load

in order to lower equipment and ground loop requirements,

especially when the cooling load is less than the heating

load. In this case, the boiler control should be set at the same

temperature as the buffer tank (or the boiler can be controlled

by outdoor temperature). When the buffer tank begins to drop

in temperature (i.e. the heat pump can no longer maintain tank

temperature), the boiler comes on to make up the difference.

This type of system is excellent for retrofi t installations, where an

existing boiler is in good operating condition.

Heating

Buffer Tank

NOTES:

1. Not all components shown (expansion tank, air vent, etc.).

Drawing is for buffer tank connections only.

2. Pump not needed for 50YEW unit with internal load pump option.

3. Mixing valve and appropriate piping required on non-condensing

boilers (consult boiler manufacturer literature).

4. Thermistor or aqua-stat should be installed in an immersion

well. If water heater does not have well, one of the heating

elements should be removed, and a well adapter should be

5. Other components (additional ball valves, unions, etc.)

may be required for ease of service. This drawing

shows only minimum requirements. Your specific

installation will dictate final component selections.

6. Buffer tank must be approved as a heating vessel.

7. Local code supercedes any piping arrangements or

components shown on this drawing.

HC

Thermistor or Aqua-stat

Note 4

03Oct07

Note 6

Radiant

Floor

System

From Water-to-Water Unit

Note 1

Notes 1,2

To Water-to-Water Unit

IN

OUT

Condensing

Boiler

Note 3

installed. Locate thermistor/aqua-stat in the bottom half

of the tank.

• Distribution System Requires Hotter Water: This type of system

would be used when baseboard convectors, cast iron radiators or

fan coil units are already installed in a retrofi t application. Since the

50PSW/GSW water-to-water units are only capable of producing

up to 130°F [54°C] leaving water temperature (50YEW waterto-water units can produce up to 145°F [63°C] leaving water

temperature), and the existing distribution system may require up

to 180°F [82°C] at design conditions, the water-to-water system

should be sized to handle the heating load up to the point where

hotter water is required (i.e. at the outdoor temperature balance

point). Typically, a properly sized water-to-water unit can handle

the load until the outdoor temperature drops to 20 to 30°F [-7

to -1°C]. At that point, the water-to-water unit compressor must

be disengaged (through the use of an outdoor thermostat or

other control means), and the boiler should be started. The water

delivered to the hydronic system now increases in temperature to

help satisfy the increased load.

Drawing 2-8: Piping for Backup Condensing Boiler

(2nd Stage Heating)

Part II: Load Side Design / System Design & Selection

Page 23

Bryant Geothermal Heat Pump Systems

21

Water-to-Water System Design Guide

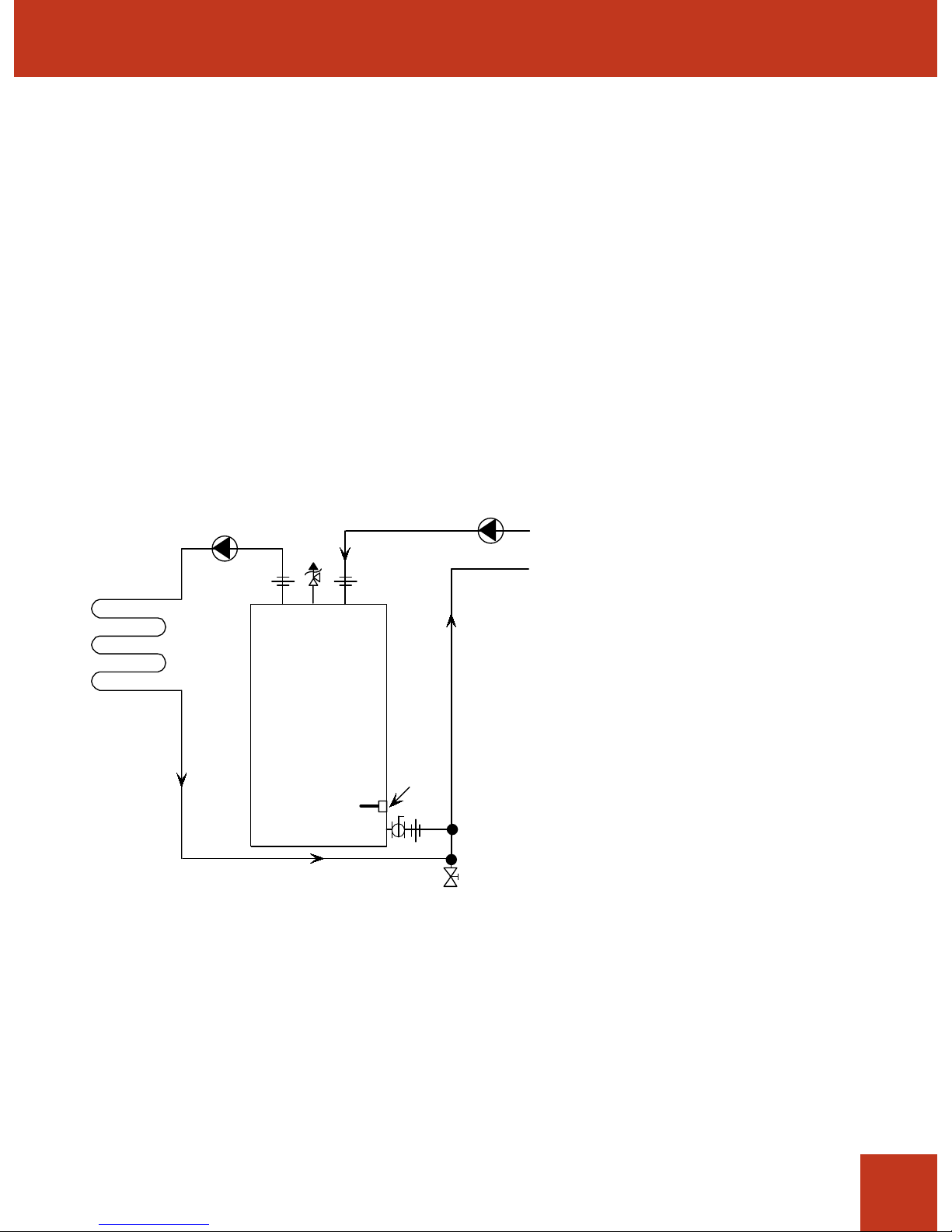

Drawing 2-9 – Piping for Indirect Water Heaters with Insuffi cient

Heat Exchanger Mass: Drawing 2-9 may be used for indirect

water heaters that lack a heat exchanger of suffi cient mass (see

fi gure 2-9 later in this section). Most indirect water heaters are

designed for 180°F [82°C] or hotter water. Using lower water

temperatures could cause the heat pump to short cycle and the

tank temperatures to remain below set point. When the piping

is arranged as shown in drawing 2-9, the mass is increased. The

disadvantages of this arrangement are higher installation costs,

more mechanical room space, and an additional pump (plus the

additional Watts associated with the pump). It is always best to use

an indirect water heater with more heat exchanger mass that is

designed for operation with lower water temperatures.

Drawing 2-9: Alternate DHW Piping - Indirect

Water Heater with Low Mass Heat Exchanger

Indirect

Water Heater

Direct

Water Heater

NOTES:

3. Place air vent at the highest point in the system. If internal

expansion tanks are installed, only an air vent is required.

2. Thermistor/aqua-stat should be installed in an immersion well.

Locate thermistor/aqua-stat in the bottom half of the tank.

4. If optional 50YEW pump is used, this pump is not necessary.

5. Other components (additional ball valves, unions, etc.)

may be required for ease of service. This drawing

shows only minimum requirements. Your specific

installation will dictate final component selections.

6. Local code supercedes any piping arrangements or

components shown on this drawing.

HC

HC

Exp

Tank

Note 3

Air Vent

Aqua-stat

Notes 1,2

03Oct07

(optional backup

electric elements)

P. R. V .

Thermistor or aqua-stat

Note 2

Note 4

1. Aqua-stat controls secondary pump.

To Water-to-Water Heat Pump

From Water-to-Water Heat Pump

Secondary Pump

Note 1

Cold

Water

Supply

Domestic

Hot

Water

Part II: Load Side Design / System Design & Selection

Page 24

22

Water-to-Water System Design Guide

Bryant: Whatever It Takes.

PIPING SYSTEM DESIGN

As with any heating and cooling application, proper design of the

delivery system is crucial to system performance, reliability and life

expectancy. Table 2-1 gives specifi cations for 3/4” [19 mm] and 1”

[25 mm] copper piping. Bryant recommends only type “L” straight

length copper tubing for connection between the water-to-water

unit and the buffer tank. In addition, all piping must be rated for

760 psi at 200°F [5.24 Pa at 93.3°C]. All piping must be insulated.

The smaller 3/4” [19 mm] tubing requires 1” [25 mm] diameter

insulation with a minimum 1/2” [13 mm] wall thickness. The larger

1” [25 mm] tubing requires 1-3/8” [35 mm] diameter insulation

with a minimum 1/2” [13 mm] wall thickness. The smaller 3/4”

[19 mm] tubing may be used on water-to-water units up to the

50YEW008 /50PSW008 / GSW036 with a maximum of 25 ft. [7.6

m] one-way and 8 elbows. The larger 1” [25 mm] tubing may be

used on water-to-water units up to the 50YEW012 / 50PSW012

/ GSW060 with a maximum of 25 ft. [7.6 m] one-way and 8

elbows. Refer to ASTM 388 for detailed information. Local codes

supersede any recommendations in this manual.

Table 2-1: Copper Type “L” Piping Specifi cations

melting point of approximately 361-421°F [183-216°C], and is

typically applied using a propane torch. Proper fl ux is required.

An acetylene torch may be used, but care must be taken not to

overheat the piping, which can cause the material to become

brittle. Solder type 95/5 1/8” [3.2 mm] diameter solder has

melting point of approximately 452-464°F [233-240°C], and is

typically applied using a map gas torch (propane will work). Proper

fl ux is required. An acetylene torch may be used, but care must be

taken not to overheat the piping, which can cause the material to

become brittle.

When preparing copper joints for soldering, tubing should be

cut square, and all burrs must be removed. Do not use dented

or pitted copper. Clean the inside of the tubing with a brush;

clean the outside with emery cloth approximately 1/2” [13 mm]

from the end of the fi tting. Debris in the system could cause

pump failure or corrosion. Do not put the fi tting in a bind before

soldering. Flux should be applied as a thin fi lm. Excess fl ux will

end up in the circulating fl uid. Rotate fi tting while soldering to

spread fl ux over the entire fi tting.

Pipe size* Flow rate**

Pressure

Drop***

Volume**** Pipe size* Flow rate**

Pressure

Drop***

Volume****

3/4” [19.1 mm]

2 [7.6] 1.5 [0.5]

2.7 [10.1]

1” [25.4 mm]

10 [37.9] 7.0 [2.1]

4.1 [15.3]

4 [15.1] 5.0 [1.5] 12 [45.4] 9.0 [2.7]

6 [22.7] 10.0 [3.0] 14 [53.0] 13.0 [3.9]

8 [30.3] 17.0 [5.1] 16 [60.6] 16.0 [4.8]

10 [37.9] 25.0 [7.5]

*Nominal inside diameter water pipe -- e.g. 3/4” type L has an inside diameter of 0.811” [206 mm] & an outside diameter of 0.875” [222 mm]

**U.S. gallons per minute [liters per minute]

***Foot of head per 100 ft. of pipe [meters of head per 30m of pipe]

****U.S. gallons per 100 ft. of pipe [liters per 30m of pipe]

PIPING SYSTEM INSTALLATION

Once the piping system has been designed, proper installation

techniques must be used to insure a problem-free system. When

piping is hung, 1-1/4” [32 mm] and smaller tubing must be

supported every 6 ft. [1.8 m]; 1-1/2” [38 mm] and larger tubing

must be supported every 10 ft. [3 m]. Always support the pipe

where a transition from horizontal to vertical is made. Plastic

coated or copper hangers should be used, allowing enough space

for the pipe insulation. Standoff type suppor ts are good for rigid

support, wall runs or shor t runs less than 10 ft. [3 m]. Clevis

hangers (held by threaded rod) are good for piping at different

heights. Finally, rail type hangers are good for different types of

pipe (e.g. water, conduit, etc.). Polyethylene clips are best for small

pipes. Always run piping at 90 or 45 degree angles. Local codes

supersede any recommendations in this manual.

Two types of soldering material may be used for hydronic

installations, 50/50 [50% tin, 50% lead] and 95/5 (95% tin, 5%

antimony). However, 50/50 may not be used for domestic water

piping. Solder type 50/50 1/8” [3.2 mm] diameter solder has a