Bryant FNCCAB series, FNCCAB-0014, FNCCAB-0017, FNCCAB-0021, FNCCAB-0024 Installation Instructions Manual

Page 1

Sizes:

014, 017, 021, 024

Installation Instructions

C04032

Fig. 1 -- FNCCAB High Efficiency Air Filtration System

NOTE: Read the entire instruction manual before starting the

installation.

SAFETY CONSIDERATIONS

Improper installation, adjustment, alteration, service, maintenance,

or use can cause explosion, fire, electrical shock, or other

conditions which may cause death, personal injury, or property

damage. Consult a qualified installer, service agency, or your

distributor or branch for information or assistance. The qualified

installer or agency must use factory--authorized kits or accessories

when modifying this product. Refer to the individual instructions

packaged with the kits or accessories when installing.

Follow all safety codes. Wear safety glasses, protective clothing,

and work gloves. Use quenching cloth for brazing operations.

Have fire extinguisher available. Read these instructions

thoroughly and follow all warnings or cautions included in

literature and attached to the unit.. Consult local building codes

and current editions of the National Electrical Code ( NEC ) NFPA

70. In Canada, refer to current editions of the Canadian electrical

code CSA 22.1.

Recognize safety information. This is the safety--alert symbol

When you see this symbol on the furnace and in instructions or

manuals, be alert to the potential for personal injury. Understand

the signal words DANGER, WARNING, CAUTION and NOTE.

The words DANGER, WARNING,andCAUTION are used with

the safety alert symbol. DANGER identifies the most serious

hazards which will result in severe personal injury or death.

WARNING signifies a hazard which could result in personal

injury or death. CAUTION is used to identify unsafe practices

FNCCAB

High Efficiency Filtration System

For Fan Coils

which may result in minor personal injury or product and property

damage. NOTE is used to highlight suggestions which will result

in enhanced installation, reliability, or operation.

INTRODUCTION

These instructions cover the installation, operation and

maintenance of FNCCAB High Efficiency Air Filtration System.

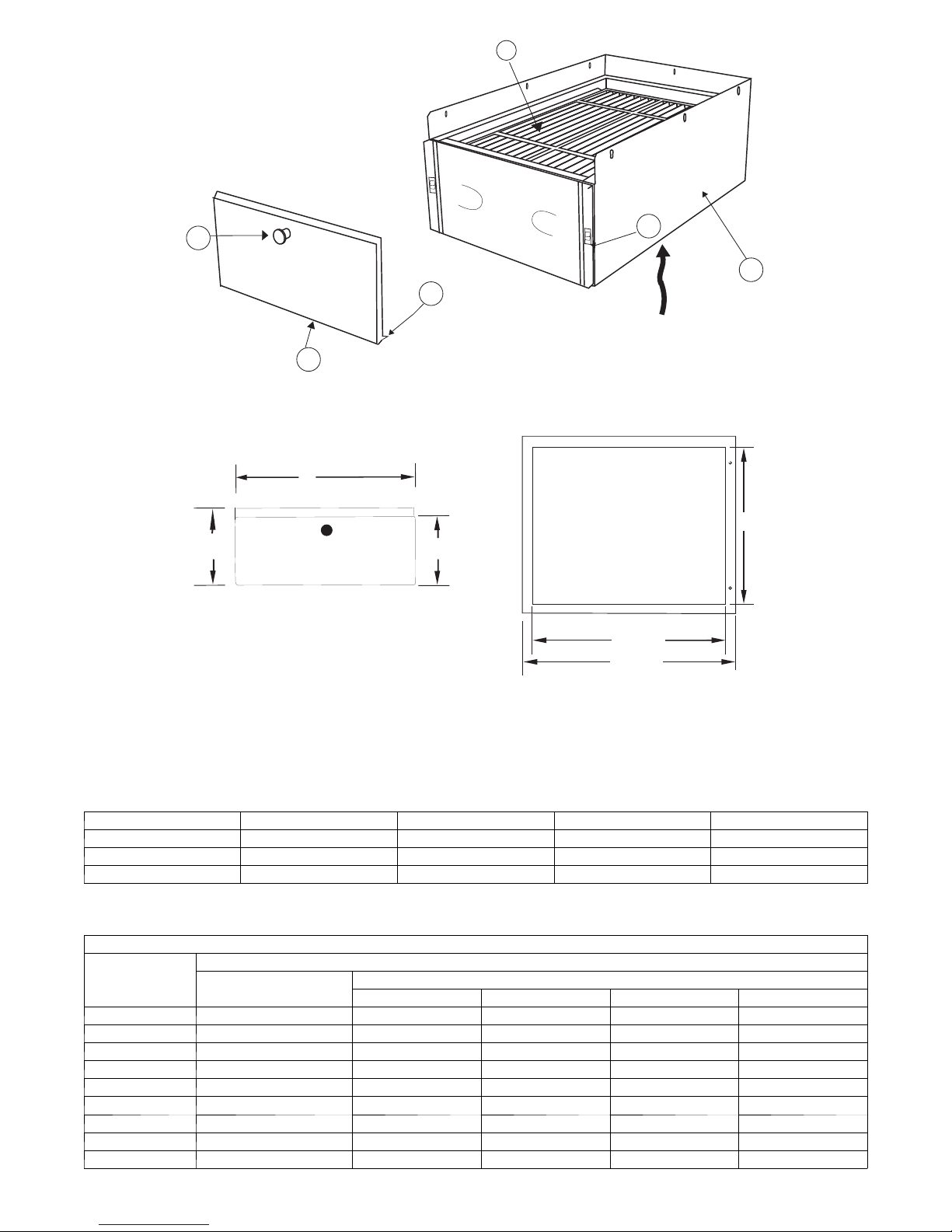

Become familiar with the components listed in Table 1. See Fig. 2.

Table 1 – FNCCAB Major Components

COMPONENT DESCRIPTION

1 Cabinet

2 Filter

3 Access Handle

4 Access Door

5 Door Latch Hardware

6 Door Alignment Table

DESCRIPTION AND USAGE

!

CAUTION

UNIT OPERATION AND SAFETY HAZARD

Failure to follow this caution may result in personal injury

and/or damage to the equipment.

Prior to installing this product, you should read these entire

instructions and follow all directions.

APPLICATION

This High Efficiency Air Filtration System must be used in a

forced air heating, cooling or ventilation system. This High

Efficiency Air Filtration System cleaner should be installed in the

system so that all the system air is circulated through this air

cleaner. The High Efficiency Air Filtration System will only

remove the airborne contaminants delivered to it. Maximum

performance is obtained when the system blower is set for

continuous operation.

.

INSTALLATION REQUIREMENTS

The location for the High Efficiency Air Filtration System is on the

return side of the fan coil next to the blower compartment. In this

location, both the blower motor and cooling coils will be kept

clean. Do not install the air cleaner in the discharge (supply) air

duct. The front of this unit must be readily accessible for periodic

inspection and replacement of filter to maintain maximum

efficiency and trouble--free operation.

Page 2

2

3

5

1

6

AIR FLOW

4

C04033

Fig. 2 -- FNCCAB Major Components

A

B

7 "8-7/8 "

19-1/2"

22-1/4"

Fig. 3 -- FNCCAB Dimensions

Table 2 – Dimensions and Airflow

MODELS FNCCAB---0014 FNCCAB---0017 FNCCAB---0021 FNCCAB---0024

Airflow (CFM) Range 600---900 600 --- 1350 600---2000 600--- 2200

A 14---5/16 --- in (36 cm) 1 7 --- 5 / 8 --- i n (4 5 cm ) 2 1 --- 1 / 8 --- i n (5 4 cm ) 2 4 --- 5 / 8 --- i n (6 3 cm )

B 1 1 --- i n ( 2 8 c m ) 14---11/32 --- in (36 cm) 1 7 --- 7 / 8 --- i n (4 5 cm ) 21--- 11/32- --in (54 cm)

Table 3 – Typical Pressure Drop

TYPICAL PRESSURE DROP

Airflow Range

(CFM)

600 .044 .125 .060 .040 .015

800 .075 .150 .090 .060 .030

1000 .072 .250 .125 .070 .040

1200 .100 --- .180 .090 .060

1400 .092 --- .250 .140 .090

1600 .120 --- --- .187 .125

1800 .152 --- --- .230 .150

2000 .187 --- --- .280 .190

2200 --- --- --- --- .250

Typical Factory--- supplied

Filter in Fan Coil Unit

FNCCAB --- 0014 FNCCAB --- 0017 FNCCAB --- 021 FNCCAB --- 0024

Resistance (in. w.c.)

Model Number

C04031

2

Page 3

FNCCAB Typical Horizontal Installation

Screws to be removed and reused when

Installing FNCCAB to Fan Coil (2-Left Side, 2-Right SIde)

FNCCAB Typical Vertical (Upflow or Downflow) Installation

Fig. 4 -- Typical Installation

C04029

CONNECTING FLANGE

MOUNTING HOLES

Fig. 5 -- Mounting Holes and Mounting Flange

SELECT LOCATION FOR THE AIR CLEANER

Select a location that is readily accessible for periodic inspection

and cleaning. Allow a minimum of 26--in. in front of the access

panel for filter removal and replacement. For complete unit

dimensions refer to Fig. 3.

IMPORTANT: Failure to replace filter can cause damage to the

system.

This High Efficiency Air cleaner can be mounted in several

positions. See Fig. 4 for proper air cleaner mounting with a variety

of installation styles.

!

CAUTION

MOUNTING HOLES

C04034

!

WARNING

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in personal injury

or death.

Only a trained, experienced service person should install this

air cleaner. A thorough checkout of the unit installation should

be completed before unit operation. Before performing

installation, service or maintenance operations on unit, turn off

all power to unit. TAG DISCONNECT SWITCH WITH

LOCKOUT TAG.

CUT HAZARD

Failure to follow this caution may result in personal injury.

Sheet metal parts may have sharp edges or burrs. Use care and

wear appropriate protective clothing and gloves when

handling these parts.

3

Page 4

INSTALLATION

1. Turn off power disconnect and install lockout tag.

2. Check the airflow rating given on this product to make sure

it is suitable for your application.

3. Remove the fan coil filter door and the factory supplied

1--in air filter. Discard filter and reinstall filter door.

NOTE: The air cleaner cannot remove existing dirt from the

blower and ducts.

NOTE: The following is a typical installation of this air cleaner on

an upflow furnace. You may have to alter the installation to fit your

specific application.

4. Remove screws from the fan coil edge (return side) and retain for use once FNCCAB is in place.

5. Slide FNCCAB installation connecting flange over fan coil

cabinet (return side) edge.

6. Mounting holes are provided for simple connection to unit

cabinet. See Fig. 5. The clearance slots/holes are sized for

#10 sheet metal screws or pop rivets. Reinstall the four

screws removed in item 4 above, then shoot screws into remaining four clearance slots/holes of FNCCAB. If the adjoining duct work is flanged, install the screws so that the

screw heads are inside the cabinet. This will prevent damage

to the filter during removal and installation.

7. After the cabinet has been secured, use caulk or tape to seal

connecting seams airtight to the bottom opening as required.

8. If not already installed, slide filter into mounted FNCCAB.

9. Install access door and ensure a tight seal. See Fig. 6.

OWNERS MANUAL SECTION

FNCCAB and FILFNC Maintenance

How to Maintain your air cleaner

The filter media in your cabinet MUST be replaced periodically.

The frequency of filter replacement is best determined by visual

examination.

On average, filters of this type should be replaced before each

heating and each cooling season under normal usage (or at least

yearly under minimum usage).

Steps for Replacing Filter

1. Turn off power to blower.

2. Open access door by pulling the handle. Remove door completely.

3. Pull used filter straight out of cabinet and discard.

4. Remove new filter from packaging.

5. Slide new filter into cabinet with Air--Flow arrow pointing

in the direction of air flow (toward fan coil cabinet).

6. Replace access door. See Fig. 6.

7. Turn on power to blower.

REPLACEMENT FILTERS

REPLACEMENT FILTERS FOR YOUR HIGH

EFFICIENCY AIR FILTRATION SYSTEM

Remember, periodic inspection and replacement of your filter will

ensure high efficiency air cleaning. Contact your HVAC dealer for

replacement filters. See Table 4.

2a

1a

2b

1b

FNCCAB Door Latching Procedure

Step 1-Fully Insert Door Alignment Tabs (1a) into Cabinet Slots (1b)

Step 2-Firmly Pivot Door upward to Capture Door Tabs (2a)

into Cabinet Latching Mechanism (2b)

Fig. 6 -- Door Assembly Detail View

Table 4 – Replacement Filter Order Number

MERV 8 FILXXFNC0014 FILXXFNC0017 FILXXFNC0021 FILXXFNC0024

MERV 11 FILXXFNC0114 FILXXFNC0117 FILXXFNC0121 FILXXFNC0124

Quantity per carton 2 2 2 2

C04035

Copyright 2012 CAC / BDP D 7310 W. Morris St. D Indianapolis, IN 46231 Edition Date: 12/12

Manufacturer reserves the right to change, at any time, specifications and designs without notice and without obligations.

C a t a l o g N o : I M --- F N C B --- 0 2

R e p l a c e s : I M --- F N C B --- 0 1

4

Loading...

Loading...