Page 1

FAN UNIT

FH4B

Sizes 001 thru 004

PRACTICALITY & PERFORMANCE

Reliability, dependability, and great value are built into the FH4B

Fan Units. The unit is compact and easy to install, with capacities

ranging from 800 to 2000 CFM. The units are the right choice if

you need versatility and affordability in a fan unit.

These fan coil units offer an air handler for practical, no-nonsense application and outstanding performance. The multipoise

units allow greater flexibility to meet your upflow, downflow, or

horizontal installation requirements, and offer multiple electric

entry to permit quick, hassle-free hookup (003 and 004 when

coupled with coil are upflow/downflow only). All models come

fully equipped with solid-state cooling controls.

The FH4B, with its 3-speed motor and field-installed heater

package, provides the application versatility required for most

installations. Heater packages are available from 3- through 30kw, either fused or with a circuit breaker, or non-fused for 10-kw

and less.

Form No. PDS FH4B.01.3

Page 2

FEATURES

Prepainted galvanized sheet metal

•

•

Cooling controls with every unit

3-speed motor

•

•

Unique cabinet design to meet air leakages regulations

•

Factory-supplied cleanable filter

Easy access filter for cleaning—no tools required

•

•

Air sealed filter door

Field-installed heater packages 3- through 30-kw, fused, circuit breaker, non-fused (10-kw and down)

•

•

Factory-supplied power plug

Control board with replaceable 5-amp blade type auto fuse

•

•

Foil-faced high-density super thick R-4.2 insulation

Multiple electric entry

•

•

HUD approved for manufactured housing

•

40-va, 208/230-v transformer

All models listed with UL (U.S. and Canada) and ARI

•

MODEL NUMBER NOMENCLATURE

F H 4 B N F 001 015 AEAA

Electric Heater (kw)

003 015

005 020

008 024

009 030

010

001—1800 CFM

002—1200 CFM

003—1600 CFM

004—2000 CFM

F— Single Piece Cabinet with 1 in.

Super Thick Insulation

N—208/230-1-60

B—Series

4—Multipoise

H—Fan Unit

F—Fan Coil

A—Common Unit

E—Minor Engineering Change

A—Standard Unit

A—Standard Unit

T

O

D

E

A

I

R

F

I

I

T

A

R

S

E

C

R

E

R

U

T

C

A

F

U

N

A

M

A

R

C

O

M

H

P

E

A

Y

R

A

T

I

N

U

I

S

L

T

Y

P

I

U

N

M

G

P

W

I

T

H

®

E

T

Q

N

U

E

I

P

M

0

4

2

D

T

A

R

N

A

D

T

O

D

E

A

I

R

F

I

I

T

A

R

S

E

C

R

A

I

R

E

C

R

U

T

C

A

F

U

N

A

M

O

Y

N

R

D

A

I

T

T

I

N

U

E

T

Q

N

U

E

I

P

M

A

R

I

2

S

D

T

A

R

N

A

D

CERTIFICATION APPLIES ONLY WHEN THE

COMPLETE SYSTEM IS LISTED WITH ARI.

C

O

M

P

L

Y

I

N

I

O

G

N

I

N

W

G

I

T

H

0

1

REGISTERED

QUALITY

SYSTEM

—2—

Page 3

✓

✓

✓

✓

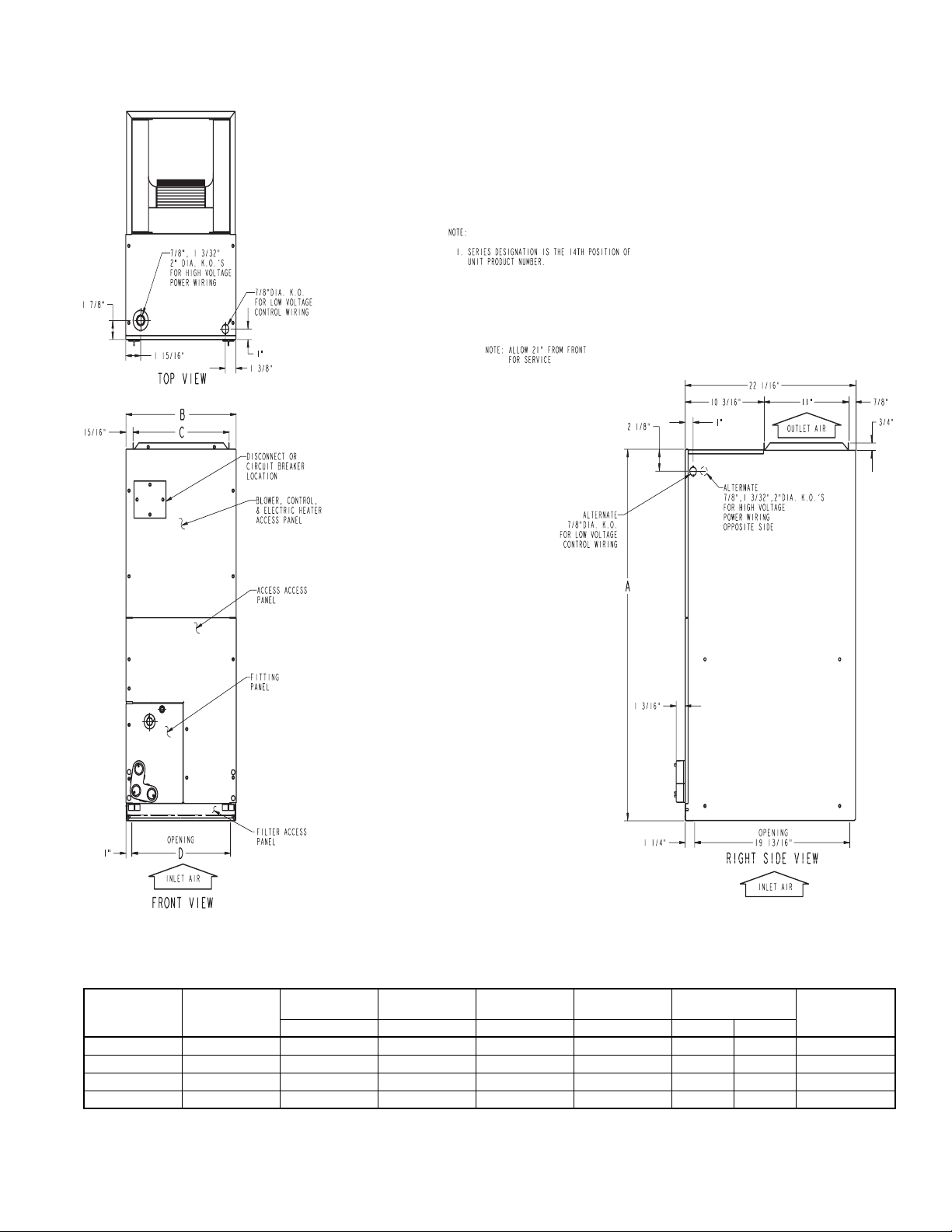

DIMENSIONS

ABCF

UNIT SERIES

FH4BNF001 E 42-11/16 14-5/16 12-7/16 12-5/16

FH4BNF002 E 49-5/8 17-5/8 15-3/4 15-5/8

FH4BNF003 E 49-5/8 21-1/8 19-1/4 19-1/8

FH4BNF004 E 53-7/16 21-1/8 19-1/4 19-1/8

—3—

ACCY. COIL

CONFIGURATION

A02300

OPERATING

WEIGHT (Lb)In. In. In. In. SLOPE “A”

175

192

106

114.5

Page 4

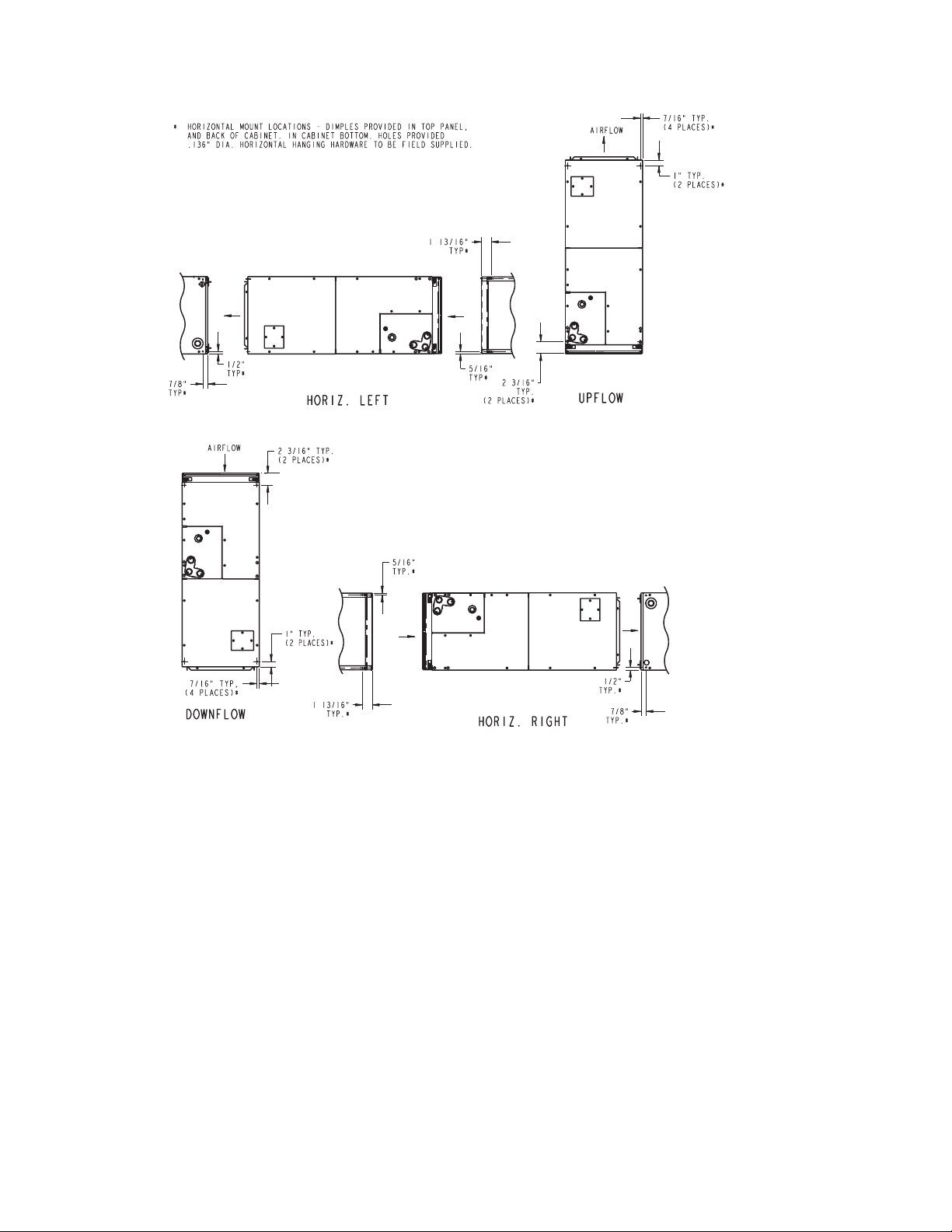

DIMENSIONS Continued

—4—

A02301

Page 5

DIMENSIONS Continued

POWER ENTRY

OPTIONS

24-IN. FRONT SERVICE

CLEARANCE

2 Ω

FIELD SUPPLIED

SUPPLY DUCT

LOW VOLT

ENTRY

OPTIONS

UNIT

FH4B001

FH4B002

1 Ω

″

19″

A

″

A

12 In.

17 In.

FIELD MODIFIED

SIDE RETURN

LOCATION FOR

SLOPE COIL

UNITS ONLY

FIELD SUPPLIED

RETURN PLENUM

*Side Return not compatible when used in conjunction with accessory cooling coil

Field-modified Side Return Location

For Slope Coils Only

A02294

—5—

Page 6

SPECIFICATIONS

UNIT SIZE 001 002 003 004

FAN

Air Discharge

CFM (Nominal)

Motor Hp (PSC)

FILTER 21-1/2 x 13 21-1/2 x 16-3/8 21-1/2 x 19-7/8

850

1/4

1300

1/3

1700

3/4

AIRFLOW PERFORMANCE* (CFM)

EXTERNAL STATIC PRESSURE (IN. WC)

SIZE

FH4B001

FH4B002

FH4B003

FH4B004

BLOWER

SPEED

HIGH 1173 1270 1135 1225 1090 1170 1045 1126 993 1058 925 981

MED 900 1025 875 991 847 963 810 922 768 869 695 802

LOW 579 687 560 663 537 639 505 610 451 554 384 467

HIGH 1630 1841 1605 1798 1567 1748 1525 1696 1480 1629 1415 1560

MED 1244 1438 1225 1407 1190 1383 1170 1342 1141 1308 1100 1265

LOW 1001 1172 985 1147 955 1116 930 1094 908 1062 850 1024

HIGH ————2118 — 2060 2202 1949 2106 1853 1989

MED 1757 2061 1745 2016 1734 1985 1716 1943 1686 1890 1624 1802

LOW 1290 1535 1286 1535 1281 1528 1277 1515 1263 1467 1245 1431

HIGH ————2257 — 2235 — 2188 — 2113 2336

MED ——1930 2215 1914 2196 1887 2163 1838 2106 1787 2047

LOW 1620 1881 1620 1870 1613 1864 1607 1853 1594 1836 1562 1802

* With factory approved filter, 10-kw elec heat 001 and 002 sizes, 15-kw elec heat 003 and 004 sizes 230-volt.

0.10 0.20 0.30 0.40 0.50 0.60

208 230 208 230 208 230 208 230 208 230 208 230

2000

3/4

AIRFLOW PERFORMANCE WITH ACCESSORY COIL (CFM)

MODEL

AND

SIZE

FH4B001 WITH

KFAEC0501024

FH4B002 WITH

KFAEC0601036

FH4B003 WITH

KFAEC0301048

FH4B004 WITH

KFAEC0401060

BLOWER

MOTOR

SPEED

HIGH

MED 835 900 795 855 745 800 690 740

LOW 605 695 575 665 530 625 485 580

HIGH

MED 1235

LOW 1035 1185 1010 1150 980 1115 940 1070

HIGH

MED 1740

LOW 1425 1605 1395 1555 1360 1495 1315 1430

HIGH

MED

LOW 1680 1895 1655 1855 1625 1810 1595 1765

0.10 0.20 0.30 0.40 0.50 0.60

208 230 208 230 208 230 208 230 208 230 208 230

945 975 900 930 840 870 780 805 695 725 560 595

1485 1550 1425 1490 1365 1420 1300 1350 1230 1275 1150 1190

1380 1200 1325 1160 1265 1110 1210 1055 1140 985 1070

1880 1935 1785 1830 1700 1735 1615 1645 1520 1555 1430 1460

1840 1660 1750 1585 1660 1510 1575 1435 1485 1350 1390

2145 2245 2085 2185 2030 2115 1965 2045 1905 1975 1830 1895

2025 2175 1970 2110 1915 2050 1860 1990 1805 1905 1740 1830

NOTES: 1. Airflow based upon dry coil at 230v with factory approved accessory filter and electric heater (10-kw electric heat, sizes 001 and 002;

15-kw electric heat, sizes 003 and 004).

2. To avoid potential for condensate blowing out of drain pan prior to making drain trap:

—Return static pressure must be less than 0.4 in. wc

—Horizontal applications of 048-070 sizes must have supply static greater than 0.20 in. wc

Airflow outside max ARI airflow of 450 cfm/ton on 018-154 sizes

Airflow above 400 cfm/ton on 060-070 sizes. Airflows in this region could result in condensate blowing off coil or splashing out of drain pan.

TOTAL EXTERNAL STATIC PRESSURE (IN. WC)

610 650 470 510

425 510 340 395

890 1010 825 935

1255 1360 1170 1270

1555 1705 1500 1645

FILTER STATIC PRESSURE DROP (IN. WC)

CFM

UNIT SIZE

001 — 0.044 0.075 0.110 —————

002 ———0.072 0.100 0.130 ———

003 —————0.092 0.120 0.152 —

004 ——————0.120 0.152 0.187

400 600 800 1000 1200 1400 1600 1800 2000

—6—

Page 7

FAN COIL ELECTRICAL DATA

(UNITS WITHOUT ELECTRICAL HEAT)

UNIT

SIZE

001 208/230 1.8 2.3 14 15

002 208/230 2.7 3.4 14 15

003 208/230 4.3 5.4 14 15

004 208/230 5.4 6.8 14 15

* Use copper wire only. 75°C must be used in this application. When using non-metallic (NM) sheathed cable, wire size required should be based on

that of 60°C conductors, instead of wire sizes shown in table above per NEC 1999 Article 336-26.

FLA — Full Load Amps

NOTE: If branch circuit wire length exceeds 100 ft., consult NEC 215-2 to determine maximum wire length. Use 2% voltage drop.

VOLTS

(1 PHASE) FLA

MIN

CKT

AMPS

BRANCH CIRCUIT

Min Wire

Size AWG* Fuse Amps

ELECTRIC HEATER INTERNAL PROTECTION*

HEATER KW PHASE

31 ——

51 — 1/60

81 — 1/60

10 1 — 1/60

15 1 2/30 – 2/60 2/60

20 1 4/60 2/60

24 3/1 6/60 —

30 3/1 6/60 —

9 1/3** ——

15 3 ——

18 3 ——

* 5-, 8-, 10-kw factory-installed heat has no internal protection. 15-kw factory-installed heat is internally protected with fuses.

** KFCEH1401N09 is single phase only.

† Circuit breakers are 2 pole.

FUSES

QTY/SIZE

CKT BKR

QTY/SIZE†

ELECTRIC HEATERS

HEATER

PART NO.

KFCEH0401N03 3 230/1 3 None 001 9,400

KFCEH0501N05 5 230/1 5 None 001, 002 15,700

KFCEH0801N08 8 230/1 8 None 001–004 25,100

KFCEH0901N10 10 230/1 10 None 001–004 31,400

KFCEH3201F20 20 230/1 5, 20 Fuse‡ 002–004 62,800

KFCEH1601315 15 230/3 5, 15 None 002–004 47,100

KFCEH2001318 18 230/3 6, 12, 18 None 003, 004 56,500

KFCEH3401F24 24 230/3* 8, 16, 24 Fuse 003, 004 75,300

KFCEH3501F30 30 230/3* 10, 20, 30 Fuse 003, 004 94,100

KFCEH2401C05 5 230/1 5 Circuit Breaker 001, 002 15,700

KFCEH2501C08 8 230/1 8 Circuit Breaker 001, 002 25,100

KFCEH2601C10 10 230/1 10 Circuit Breaker 001–004 31,400

KFCEH3301C20 20 230/1 5, 20 Circuit Breaker 002–004 62,800

KFCEH2901N09 9 230/1† 3, 9 None 002–004 28,200

KFCEH3001F15 15 230/1 5, 15 Fuse‡ 001–004 47,100

KFCEH3101C15 15 230/1 5, 15 Circuit Breaker 001–004 47,100

KW

@ 240V VOLTS/PHASE

STAGES (KW

OPERATING)

INTERNAL

CIRCUIT

PROTECTION

FAN COIL SIZE

USED WITH

HEATING CAP. **

@ 230V

—7—

Page 8

SMART HEAT

HEATER

PART NO.

KFCEH0101H10 10 230/1 3, 6, 9 None‡ 001, 002 31,400

KFCEH0201H15 15 230/1 3, 8, 11, 15 Fuse 001–003 47,100

KFCEH0301H20 20 230/1 5, 10, 15, 20 Fuse 002–004 62,800

* Field convertible to 1 phase.

† KFAEH2501N09 is field convertible to 3 phase.

‡ Single point wiring kit required for these heaters in Canada.

** Blower motor heat not included.

When using units with 20-, 24-, and 30-kw electric heaters, maintain a 1-in. clearance from combustible materials to discharge plenum and ductwork,

and maintain a distance of 36 in. from the unit. Use an accessory downflow base to maintain proper clearance on downflow installations.

Use flexible connectors between ductwork and unit to prevent transmission of vibration. When electric heater is installed, use heat resistant material

for flexible connector between ductwork and unit at discharge connection. Ductwork passing through unconditioned space must be insulated and

covered with vapor barrier.

KW

@ 240V VOLTS/PHASE

STAGES

(KW OPERATING)

INTERNAL

CIRCUIT

PROTECTION

FAN COIL SIZE

USED WITH

HEATING CAP. **

@ 230V

ESTIMATED SOUND POWER LEVEL (dBA)

CONDITIONS OCTAVE BAND CENTER FREQUENCY*

UNIT

SIZE

FH4-001 800 0.25 66.0 62.0 58.0 55.0 53.0 51.0 47.0

FH4-002 1200 0.25 67.8 63.8 59.8 56.8 54.8 52.8 48.8

FH4-003 1600 0.25 69.0 65.0 61.0 58.0 56.0 54.0 50.0

FH4-004 2000 0.25 70.0 66.0 62.0 59.0 57.0 55.0 51.0

* Estimated sound power levels have been derived using the method described in the 1987 ASHRAE HVAC Systems & Applications Handbook,

Chapter 52, p. 52.7

CFM

Ext Static

Pressure 63 125 250 500 1000 2000 4000

—8—

Page 9

Dual Circuit

208/230V (Ft)‡‡

Max Wire Length

Single

Circuit

Dual Circuit

208/230V

Max Fuse/Ckt Bkr Amps

Single

Circuit

Dual Circuit

208/230V

Min Gnd Wire Size

BRANCH CIRCUIT

Single

Circuit

Dual Circuit

208/230V††

Min Wire Size (AWG)

Single

Circuit

Dual Circuit

208/230V (Ft)‡‡

Max Wire Length

Single

Circuit

Dual Circuit

208/230V

Max Fuse/Ckt Brk Amps

Single

Circuit

Dual Circuit

208/230V

Min Gnd Wire Size

BRANCH CIRCUIT

Single

Circuit

Dual Circuit

208/230V††

Min Wire Size (AWG)

Single

Circuit

208/230V (FT)‡‡

MAX WIRE LENGTH

208/230V

MAX FUSE/CKT BKR AMPS

208/230V

MIN GND

WIRE SIZE

208/230V††

MIN WIRE SIZE (AWG)

Dual Circuit

208/230V**

Min Ampacity

Single

Circuit

ELECTRIC HEATER ELECTRICAL DATA

Dual Circuit

208/230V

HEATER AMPS

Single

Circuit

CIRCUIT

INTERNAL

PROTECTION

PHASE

KW

HEATER

PART NO.

5 3.8 1 None 18.1/20.0 ——26.0/28.4 ——10/10 ——10/10 ——30/30 ——66/66 ——

5 3.8 1 None 18.1/20.0 ——31.2/33.5 ——8/8 ——10/10 ——35/35 ——85/88 ——

240v 208v L1,L2 L3,L4 L1,L2 L3,L4 L1,L2 L3,L4 L1,L2 L3,L4 L1,L2 L3,L4 L1,L2 L3,L4

5 3.8 1 Ckt Bkr 18.1/20.0 ——26.0/28.4 ——10/10 ——10/10 ——30/30 ——66/66 ——

1

2

1

KFCEH0401N03 3 2.3 1 None 10.9/12.0 ——15.9/17.3 ——12/12 ——12/12 ——20/20 ——67/68 ——

KFCEH2401C05

KFCEH0501N05

KFCEH0501N05

5 3.8 1 Ckt Bkr 18.1/20.0 ——31.2/33.5 ——8/8 ——10/10 ——35/35 ——85/88 ——

2

— 9 6.8 3 None 18.8/20.8 ——32.0/34.5 ——8/8 ——10/10 ——35/35 ——83/85 ——

KFCEH0801N08 8 6.0 1 None 28.9/32.0 ——44.7/48.5 ——8/8 ——10/10 ——45/50 ——59/60 ——

KFCEH2501C08 8 6.0 1 Ckt Bkr 28.9/32.0 ——44.7/48.5 ——8/8 ——10/10 ——45/50 ——59/60 ——

KFCEH2401C05

KFCEH0901N10 10 7.5 1 None 36.2/40.0 ——53.8/58.5 ——6/6 ——10/10 ——60/60 ——78/80 ——

KFCEH2901N09*** 9 6.8 1 None 32.8/36.0 ——49.5/53.5 ——8/6 ——10/10 ——50/60 ——54/87 ——

KFCEH1601315 15 11.3 3 None 31.3/34.6 ——47.7/51.8 ——8/6 ——10/10 ——50/60 ——56/90 ——

KFCEH3001F15*** 15 11.3 1 Fuse 54.2/59.9 36.2/40.0 18.1/20.0 76.3/83.4 53.8/58.5 22.7/25.0 4/4 6/6 10/10 8/8 10/10 10/10 80/90 60/60 25/25 88/89 78/80 75/76

KFCEH3101C15*** 15 11.3 1 Ckt Bkr — 36.2/40.0 18.1/20.0 — 53.8/58.5 22.7/25.0 — 6/6 10/10 — 10/10 10/10 — 60/60 25/25 — 78/80 75/76

KFCEH2001318 18 13.5 3 None 37.6/41.5 ——55.5/60.4 ——6/6 ——10/8 ——60/70 ——76/77 ——

KFCEH3201F20*** 20 15.0 1 Fuse 72.3/79.9 36.2/40.0 36.2/40.0 98.9/108.4 53.8/58.5 45.3/50.0 3/2 6/6 8/8 8/6 10/10 10/10 100/110 60/60 50/50 85/109 78/80 59/59

KFCEH2601C10 10 7.5 1 Ckt Bkr 36.2/40.0 ——53.8/58.5 ——6/6 ——10/10 ——60/60 ——78/80 ——

KFCEH3301C20*** 20 15.0 1 Ckt Bkr — 36.2/40.0 36.2/40.0 — 53.8/58.5 45.3/50.0 — 6/6 8/8 — 10/10 10/10 — 60/60 50/50 — 78/80 59/59

SMART HEAT ELECTRICAL DATA

30 22.5 1 Fuse 109.0/120.0 ——144.8/158.5 ——0/00 ——6/6 ——150/175 ——117/150 ——

24 18.0 3 Fuse 50.1/55.4 ——71.2/77.8 ——4/4 ——8/8 ——80/80 ——94/95 ——

24 18.0 1 Fuse 86.7/95.5 ——116.9/127.9 ——1/1 ——6/6 ——125/150 ——115/116 ——

30 22.5 3 Fuse 62.6/69.2 ——86.8/95.0 ——3/3 ——8/8 ——90/100 ——97/98 ——

KFCEH3401F24†***

KFCEH3501F30†***

—9—

Dual Circuit

208/230V**

Min Ampacity

Single

Circuit

Dual Circuit

208/230V

HEATER AMPS

Single

Circuit

CIRCUIT

INTERNAL

PROTECTION

PHASE

KW

240v 208v L1,L2 L3,L4 L1,L2 L3,L4 L1,L2 L3,L4 L1,L2 L3,L4 L1,L2 L3,L4 L1,L2 L3,L4

HEATER

PART NO.

FIELD MULTIPOINT WIRING OF 24-AND 30-KW SINGLE PHASE

KFCEH0101H10 10 7.5 1 None 32.5/35.9 ——44.0/48.3 ——8/8 ——10/10 ——45/50 ——60/61 ——

KFCEH0201H15 15 11.3 1 Fuse 54.2/59.9 39.7/43.9 14.4/16.0 73.2/80.3 49.7/54.9 23.4/25.4 4/4 8/6 10/10 8/8 10/10 10/10 80/90 50/60 25/30 92/92 53/85 73/74

KFCEH0301H20 20 15.0 1 Fuse 72.3/79.9 36.2/40.0 36.2/40.0 97.2/106.7 52.0/56.8 45.3/50.0 3/2 6/6 8/8 8/6 10/10 10/10 100/110 60/60 50/50 87/111 81/82 93/93

208/230V**

MIN AMPACITY

208/230V

HEATER AMPS

PHASE

KW

240V 208V L1,L2 L3,L4 L5,L6 L1,L2 L3,L4 L5,L6 L1,L2 L3,L4 L5,L6 L1,L2 L3,L4 L5,L6 L1,L2 L3,L4 L5,L6

KFCEH3401F24† 24 18.0 1 28.9/32.0 28.9/32.0 28.9/32.0 44.7/48.5 36.2/40.0 36.2/40.0 8/8 8/8 8/8 10/10 45/50 40/40 40/40 59/60 73/73 73/73

KFCEH3501F30† 30 22.5 1 36.2/40.0 36.2/40.0 36.2/40.0 53.8/58.5 45.3/50.0 45.3/50.0 6/6 8/8 8/8 10/10 60/60 50/50 50/50 78/80 59/59 59/59

HEATER PART NO.

1. For fan coil sizes 018-036.

2. For fan coil sizes 042-060 and all FK4D, FV4B sizes.

3. Single circuit application of F15 and F20 heaters requires single-point wiring kit accessory

† Field convertible to 1 phase, single or multiple supply circuit.

(ANSI/NFPA 70).

‡ Field convertible to 3 phase.

** Includes blower motor amps of largest fan coil used with heater.

†† Copper wire must be used. If other than uncoated (non-plated), 75°C ambient, copper wire (solid wire for 10 AWG and smaller, stranded wire for larger than 10 AWG) is used, consult applicable tables of the National Electric Code

‡‡ Length shown is as measured 1 way along wire path between unit and service panel for a voltage drop not to exceed 2%.

NOTES:

*** Heaters are Intelligent Heat capable when used with the FK, FV fan coils and corporate 2-speed programmable thermostat (TSTATBBP2S01-A), or Thermidistat™ Control (TSTATBBPRH01-B).

Page 10

ELECTRIC HEATER STATIC PRESSURE DROP

The airflow performance data was developed using fan coils with 10-kw electric heaters (2 elements) in the 001 and 002 size units and

15-kw heaters (3 elements) in the 003 and 004 size units.

001, 002 003, 004

HEATER

ELEMENTS KW

0 0 +0.02 0 0 +0.04

1 3, 5 +0.01 2 8, 10 +0.02

2 8, 10 0 3 9, 15 0

3 9, 15 –0.02 4 20 –0.02

420–0.04 6 18, 24, 30 –0.10

The airflow performance data was developed using fan coils with 10-kw electric heaters (2 elements) in the 001 and 002 units and 15-kw heaters

(3 elements) in the 003 and 004 units. For fan coils with heaters of a different number of elements, the available external static at a given CFM from the

curve may be corrected by adding or subtracting available external static pressure as indicated above.

EXTERNAL STATIC

PRESSURE

CORRECTION

HEATER

ELEMENTS KW

EXTERNAL STATIC

PRESSURE

CORRECTION

ACCESSORIES

ITEM ACCESSORY PART NO.* FAN COIL SIZE USED WITH

Disconnect Kit KFADK0101DSC Cooling Controls and Heaters 3-kw through 10-kw

Downflow Base Kit KFACB0101CFB 001

KFACB0201CFB 002

KFACB0301CFB 003, 004

Downflow Conversion Kit KFADC0201SLP Slope Coil Units — 001, 002

KFADC0401ACL A-Coil Units — 003, 004

Single-Point Wiring Kit KFASP0101SPK Only with 15- and 20-kw Fused Heaters

Filter Kit (12 pack) KFAFK0112SML 001

KFAFK0212MED 002

KFAFK0312LRG 003, 004

Evaporator Coil KFAEC0501024 001

KFAEC0601036 002

KFAEC0301048 003

KFAEC0401060 004

Downflow/Horizontal Conversion Gasket Kit KFAHD0101SLP All

* Factory authorized and listed, field-installed.

Accessory Kits Description

Suggested and Required Use

1. Disconnect Kit

The kit is used to disconnect electrical power to the fan coil so service or maintenance may be performed safely.

SUGGESTED USE: FH4 units for 3-kw through 10-kw electric resistance heaters and cooling controls.

2. Downflow Base Kit

This kit is designed to provide a 1-in. minimum clearance between unit discharge plenum, ductwork, and combustible materials. It also provides a gap

free seal with the floor.

REQUIRED USE: This kit must be used whenever FH4 fan coils are used in downflow applications.

3. Downflow Conversion Kit

Fan coils are shipped from the factory for upflow or horizontal-left applications. Downflow conversion kits provide proper condensate water drainage

and support for the coil when used in downflow applications. Separate kits are available for slope coils and A-coils.

REQUIRED USE: This kit must be used whenever FH4A fan coils are used in downflow applications.

4. Single Point Wiring Kit

The single point wiring kit acts as a jumper between L1 and L3 lugs, and between the L2 and L4 lugs. This allows the installer to run 2 heavy-gage,

high-voltage wires into the fan coil rather than 4 light-gage, high-voltage wires.

SUGGESTED USE: FH4 fan coils with 15-kw and 20-kw fused heaters only.

5. Fan Coil Filter

The kit consists of 12 fan coil framed filters. These filters collect large dust particles from the return air entering the fan coil and prevent them from

collecting on the coil. This process helps to keep the coil clean, which increases heat transfer and in turn the efficiency of the system.

SUGGESTED USE: To replace filters in FH4 fan coils.

6. Evaporator Coil Kit

The kit contains a heating/cooling coil and drain pan.

SUGGESTED USE: Accessory coil used with FH4 fan unit.

7. Downflow/Horizontal Conversion Gasket Kit

This kit provides the proper gasketing of units when applied in either a Downflow or Horizontal application.

REQUIRED USE: FH4 fan coils.

—10—

Page 11

HEAT PUMP

MATCHED SYSTEM

VENTILATOR PLUS

ZONE PERFECT

EQUIPMENT CONTROLLER

PLUS

™

HUMIDIFIER

FAN COIL

ELECTRONIC

AIR CLEANER

A02295

—11—

Page 12

SERVICE TRAINING

Packaged Service Training programs are an excellent way to increase your

knowledge of the equipment discussed in this manual, including:

• Unit Familiarization • Maintenance

• Installation Overview • Operating Sequence

A large selection of product, theory, and skills programs is available, using popular

video-based formats and materials. All include video and/or slides, plus companion

book.

Classroom Service Training plus "hands-on" the products in our labs can mean

increased confidence that really pays dividends in faster troubleshooting, fewer

callbacks. Course descriptions and schedules are in our catalog.

CALL FOR FREE CATALOG 1-800-644-5544

[ ] Packaged Service Training [ ] Classroom Service Training

A94328

SPECIFICATIONS SUBJECT TO CHANGE WITHOUT NOTICE

UNIT MUST BE INSTALLED IN ACCORDANCE

WITH INSTALLATION INSTRUCTIONS

Cancels: PDS FH4B.01.2

Form PDS FH4B.01.3

© 2003 Bryant Heating & Cooling Systems, 7310 W. Morris St. Indpls, IN 46231 PRINTED IN U.S.A. Catalog No. 12FH-4B2 9-03

—12—

Loading...

Loading...