Page 1

FF1DNA,

FAN COIL UNITS

FF1D

FF1DNE

Sizes 018, 024, 030

FEATURES

The FF1DNA and FF1DNE Fan Coil units are designed as

upflow indoor air handlers for split-system heat pumps and air

conditioners. They are available with factory- or field-installed

electric heaters both of which include the disconnect. A fieldinstalled cooling control with disconnect is also available. A TDR

(Time Delay Relay) is included with either the electric heat or

the cooling control packages. The FF1DNE models are available with a factory installed TXV.

This fan coil may be installed free standing, wall hung or flush

mounted in the wall. The 22-in. wide cabinet size in all models

allows units to fit between standard stud spacings. No return air

ductwork is required if the application provides for return air in

the front of the cabinet through either a louvered closet door or

an optional accessory decorative grille panel.

The cabinet exterior is made of pre-painted galvanized sheet

metal. The cabinet is fully insulated to meet applications in conditioned space. Additional insulation is required if the unit is

installed in an unconditioned space. Unit is supplied with

replaceable filter.

Multispeed direct-drive PSC blower motors have been selected

to provide the proper air handling for both heating and cooling.

Motors are suspended at 3 points on rubber grommets for quieter operation.

All refrigerant lines, electrical power, and thermostat wiring

enter from the top of the cabinet. Sweat-type refrigerant connections on both liquid and suction lines make for swift, low-cost

installation. All service access to the unit is conveniently located

in the front.

®

The CHECK-FLO-RATER

dependable refrigerant metering, and eliminates potential service requirements of other metering devices. The CHECK-FLO-

®

RATER

maintenance or changeout.

In addition, units can be factory ordered with a hard shut-off

thermostatic expansion valve (TXV) metering device for performance improvement.

The drain pan is constructed of high-impact, sound-deadening,

corrosion-proof polyester resin. Primary and secondary drain

connections exit from the bottom or either side of the cabinet.

is located inside the unit, easily accessible for piston

piston ensures efficient and

Form No. PDS FF1D.18.2

Page 2

MODEL NUMBER NOMENCLATURE

F F 1 D N A 018 075

Electric Heater (kw)

000

005

075

011

Nominal Capacity (Btu)

018—18,000

024—24,000

030—30,000

A—Standard

E—TXV

N—208/230-1-60

D—Major Series

1—Upflow

F—Through-the-Wall

F—Fan Coil

T

O

D

E

A

I

R

F

I

I

T

A

R

S

E

C

R

E

R

U

T

C

A

F

U

N

A

M

A

R

C

O

A

M

I

R

C

P

O

Y

R

A

T

I

N

U

I

S

L

N

D

Y

I

T

I

N

I

O

G

N

I

N

W

G

I

T

E

T

H

T

Q

N

U

E

I

P

M

0

1

2

D

A

R

N

A

D

T

O

D

E

A

I

R

F

I

I

T

A

R

S

E

C

R

E

R

U

T

C

A

F

U

N

A

M

A

R

C

O

M

H

P

E

A

Y

R

A

T

I

N

U

I

S

L

T

Y

P

I

U

N

M

G

P

W

I

T

H

®

E

T

Q

N

U

E

I

P

M

0

4

2

D

T

A

R

N

A

D

• CERTIFICATION • LISTING

• TESTING • INSPECTION

CERTIFICATION APPLIES ONLY WHEN THE

COMPLETE SYSTEM IS LISTED WITH ARI.

PHYSICAL DATA

MODEL FF1DNA/FF1DNE 018 024 030

Fan

Rpm (2-Speed)

Motor HP (PSC)

Wheel (In.)

Filter (Permanent) (In.) 16 x 20 16 x 20 16 x 20

Connections (Sweat)

Suction OD

Liquid OD

Condensate (FPT)

Operating Weight

(In.)

(In.)

(In.)

(Lb) 76 79 82

(With Electric Heat)

NOTE: Rough-in dimensions are 38-1/4 x 22-1/4 inches.

810/750

1/12

10 x 6

5/8

3/8

3/4

980/780

1/5

10 x 6

3/4

3/8

3/4

®

1110/950

1/3

10 x 6

3/4

3/8

3/4

CLEARANCES

A minimum clearance of 21 in. is required in front of the access panels for servicing. Please note that this clearance is recommended

for servicing only. Installation clearances from combustible materials are: 0 in. from cabinet and supply-air duct (plenum included).

Leave adequate room for the condensate pan and refrigerant line connection.

NOTE: 22-3/4 to 24-in. on-center between-studs and 38-1/8 to 36-3/4-in. top-to-bottom inside-studs spacing.

—2—

Page 3

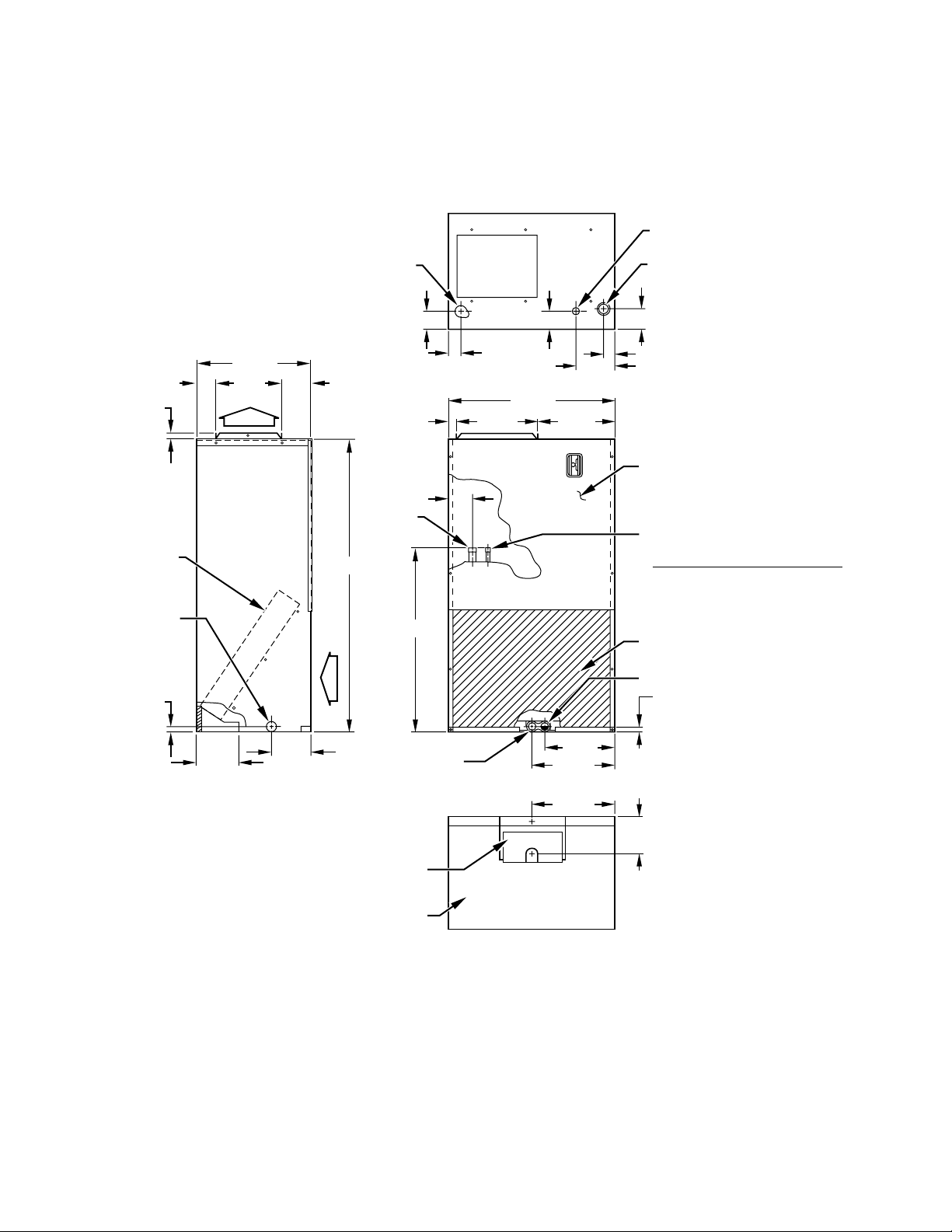

NOTE:

1. SERIES DESIGNATION IS

THE 14TH POSITION

OF UNIT MODEL NUMBER.

15 3⁄16″

1

8

2 3⁄4″

3

⁄4″

⁄4″ 4 3⁄16″

OUTLET AIR

DIMENSIONS — FF1DNA, FF1DNE

REFRIGERANT

LINES ENTRY

3

2

⁄8″

5

1

⁄8″

TOP VIEW

22 1⁄8″

7

⁄8″

11

3

⁄16″

2 7⁄16″

10

1

5

⁄16″

LOW VOLTAGE ENTRY

( 7⁄8″ DIA. HOLE)

POWER ENTRY

3

1

⁄8″ DIA. KNOCKOUT

7

⁄8″ DIA. HOLE

13

⁄16″

2

9

⁄16″

⁄16″

1

3

COIL

1

1

⁄8″ DIA.

KNOCKOUT

3

⁄4″

1

⁄4″

3

SUCTION

TUBE

38 1⁄16″

1

⁄16″

24

INLET AIR

11

5

⁄16″

5″

PRIMARY DRAIN

SIDE VIEW FRONT VIEW

PATCH PLATE

FAN COIL BASE

7

⁄16″

9

11 1⁄16″

11 1⁄16″

BLOWER, CONTROL AND

ELECTRIC HEATER

ACCESS PANEL

LIQUID TUBE

UNIT CONNECTION SIZES

SUCTION, 018, 024, 030 LIQUID,

CONDENSATE, 3⁄4″ NPT

3

⁄8″ I.D. SWEAT

FILTER MEDIA

SECONDARY DRAIN

13

⁄16″

5″

3

⁄4″ I.D. SWEAT

BOTTOM VIEW

—3—

A98336

Page 4

SPECIFICATIONS

UNITS WITHOUT ELECTRIC HEATERS OR CONTROLS

UNIT SIZE 0180 0240 0300

RATINGS & PERFORMANCES

Nominal Capacity (Btuh)* 18,000 24,000 30,000

Nominal Airflow (CFM) 650 870 1080

ELECTRICAL

Unit Volts-Phase (60 Hz) 208/230—1 208/230—1 208/230—1

Operating Voltage Range 187—253 187—253 187—253

Internal Circuit Protection None

Minimum Ampacity for Wire Sizing —

Minimum Wire Size† 14

Maximum Fuse Size (Amps or Ckt Bkr) 15

Control Transformer 24V (Va) —

INDOOR COIL

Rows & Fins Per In. 2 & 14 3 & 14

Height x Width (In.) 18 x 17.8 22 x 17.8

Face Area (Sq Ft) 2.23 2.72

R-22 Refrigerant Metering Device–FF1DNA Check-Flo-Rater

R-22 Refrigerant Metering Device–FF1DNE TXV

Piston Number‡ 55 63 70

Condensate Drain Connection (Pri-Sec) 3/4 FPT

INDOOR BLOWER & MOTOR

Wheel Diameter x Width (In.) 10 x 6

Filter Size—Cleanable (In.) 16 x 20 x 1

Blower Motor HP 1/12 1/5 1/3

Blower Motor Speeds & Type 2 & PSC 2 & PSC 2 & PSC

Full Load Amps 0.7 1.5 2.0

OPTIONAL EQUIPMENT

Cooling Control Relay-Transformer Package

(with TDR)

Louvered Wall Panel with Frame (6 Pack) KFBLG0106LGL

Electric Heat Package See ‘‘Optional Field-Installed Electric Heat Packages’’ Ta ble

KFDCC0101DCC

UNITS WITH FACTORY-INSTALLED ELECTRIC HEATERS OR CONTROLS

SIZES 018005 018075 018011††

RATINGS & PERFORMANCES

Nominal Capacity (Btuh)* 18,000 18,000 18,000

Nominal Airflow (CFM) 650 650 650

Electric Heating Output (kw @240v) 5.0 7.5 11.0

Electric Heating Capacity (MBH @208/230v) 13.5/16.3 19.9/24.2 28.9/35.1

ELECTRICAL

Unit Volts-Phase (60 Hz) 208/230—1 208/230—1 208/230—1

Operating Voltage Range 187—253 187—253 187—253

Internal Circuit Protection None

Full Load Amps 18.1/20.0 27.1/30.0 39.8/44.0

Minimum Ampacity for Wire Sizing 23.5/25.9 34.8/38.4 50.6/55.9

Minimum Wire Size† 10/10 8/8 6/6

Maximum Wire Length (Ft)† 112/112 118/118 125/125

Maximum Fuse Size (Amps or Ckt Bkr) 25/30 35/40 60/60

Control Transformer 24V (VA) 40

INDOOR COIL

Rows & Fins Per In. 2 & 14

Height x Width (In.) 18 x 17.8

Face Area (Sq Ft) 2.23

R-22 Refrigerant Metering Device–FF1DNA Check-Flo-Rater

R-22 Refrigerant Metering Device–FF1DNE TXV

Piston Number‡ 55

Condensate Drain Connection (Pri-Sec) 3/4 FPT

INDOOR BLOWER & MOTOR

Wheel Diameter x Width (In.) 10 x 6

Filter Size—Cleanable (In.) 16 x 20 x 1

Blower Motor HP 1/12

Blower Motor Speeds & Type 2 (PSC)

Full Load Amps 0.7

OPTIONAL EQUIPMENT

Louvered Wall Panel with Frame (6 Pack) KFBLG0106LGL

Electric Heat Package See ‘‘Optional Field-Installed Electric Heat Packages’’ Ta ble

See notes on page 5.

—4—

Page 5

SPECIFICATIONS Continued

UNITS WITH FACTORY-INSTALLED ELECTRIC HEATERS OR CONTROLS

UNIT SIZE 024005 024075 024011 030005 030075 030011

RATINGS & PERFORMANCES

Nominal Capacity (Btuh)* 24,000 24,000 24,000 30,000 30,000 30,000

Nominal Airflow (CFM) 870 1080

Electric Heating Output (kw @240v) 5.0 7.5 11.0 5.0 7.5 11.0

Electric Heating Capacity (MBH @208/230v) 14.0/16.9 20.4/24.7 29.4/35.7 14.3/17.2 20.7/25.0 29.7/36.0

ELECTRICAL

Unit Volts-Phase (60 Hz) 208/230—1 208/230—1 208/230—1 208/230—1 208/230—1 208/230—1

Operating Voltage Range 187—253 187—253 187—253 187—253 187—253 187—253

Internal Circuit Protection None

Full Load Amps 18.1/20.0 27.1/30.0 39.8/44.0 18.1/20.0 27.1/30.0 39.8/44.0

Minimum Ampacity for Wire Sizing 24.5/26.9 35.8/39.4 51.6/56.9 25.2/27.5 36.4/40.0 52.3/57.5

Minimum Wire Size† 10/10 8/8 6/6 10/10 8/8 6/6

Maximum Wire Length (Ft)† 112/112 117/117 122/122 112/112 117/117 125/125

Maximum Fuse Size (Amps or Ckt Bkr) 25/30 40/40 60/60 30/30 40/40 60/60

Control Transformer 24V (Va) 40

INDOOR COIL

Rows & Fins Per In. 3 & 14

Height x Width (In.) 18 x 17.8 22 x 17.8

Face Area (Sq Ft) 2.23 2.73

R-22 Refrigerant Metering Device-FF1DNA Check-Flo-Rater

R-22 Refrigerant Metering Device-FF1DNE TXV

Piston Number‡ 63 70

Condensate Drain Connection (Pri-Sec) 3/4 FPT

INDOOR BLOWER & MOTOR

Wheel Diameter x Width (In.) 10 x 6

Filter Size—Cleanable (In.) 16 x 20 x 1

Blower Motor HP 1/5 1/3

Blower Motor Speeds & Type 2 (PSC)

Full Load Amps 1.5 2.0

OPTIONAL EQUIPMENT (P/N’s)

Louvered Wall Panel with Frame (6 Pack) KFBLG0106LGL

Electric Heat Package See ‘‘Optional Field-Installed Electric Heat Packages’’ Ta ble

* Rated in accordance with U.S. Government DOE test procedures and/or ARI Standard 210/240-94.

† Use copper wire only. Use 75°C in this application. When using non-metallic (NM) sheathed cable, wire size required should be based on that of 60°C con-

ductors, instead of wire sizes shown in table above per NEC 1996 Article 336-30. Length shown is as measured 1 way along wire path between unit and

service panel for voltage drop not to exceed 2%.

‡ Check outdoor unit for required piston size.

†† 018 Size with 11-kw heater not approved for use with heat pumps.

—5—

Page 6

BF

COOLING CAPACITIES (MBtuh)

EVAPORATOR

UNIT

SIZE

018

024

030

AIR

CFM and

BF

400 27 23 19 25 20 16 22 17 13 19 14 10 15 10 8

0.08

500

0.10

600 33 27 22 30 24 19 26 21 16 23 17 13 18 12 11

0.13

650 34 28 23 31 25 20 27 21 17 23 17 14 18 13 12

0.14

600 38 32 26 35 29 22 31 24 18 26 19 14 21 13 12

0.05

700 41 34 28 38 30 24 33 26 20 28 20 16 22 15 13

0.06

875 46 38 31 41 34 27 37 29 22 31 23 19 25 17 16

0.08

750 46 38 31 41 33 26 36 28 21 30 22 17 24 16 14

0.04

900 50 42 34 46 37 29 40 31 23 33 25 19 26 18 16

0.06

1075 54 45 37 49 40 32 43 34 26 37 27 22 29 19 18

0.07

* Saturated suction leaving evaporator coil.

Sensible Heat Capacity (1000 Btuh)

Gross Cooling Capacity (1000 Btuh)

—Bypass Factor

NOTES:

1. Net capacities shown include a deduction for evaporator fan motor heat.

2. Contact manufacturer for cooling capacities at conditions other than

shown in table.

3. Formulas:

Leaving db = entering db —

Leaving wb = wb corresponding to enthalpy of air leaving coil (h

h

= h

lwb

where h

total capacity (Btuh)

—

ewb

= enthalpy of air entering coil.

ewb

4.5 x CFM

35 40 45 50 55

72 67 62 72 67 62 72 67 62 72 67 62 72 67 62

13 14 15 12 13 13 10 11 12 9 10 10 8 8 8

30 25 21 28 22 18 24 19 15 21 15 12 16 11 10

14 16 17 13 14 16 12 13 14 10 11 12 9 10 10

15 17 19 14 16 18 13 14 16 11 13 13 10 11 11

16 18 20 14 17 18 13 15 16 12 13 14 10 11 12

18 20 21 16 18 19 15 16 17 13 14 14 11 11 12

19 21 23 18 19 21 16 18 19 14 15 16 12 13 13

21 24 27 20 22 24 18 20 22 16 18 19 14 15 16

21 23 25 19 21 22 17 19 20 15 16 17 12 13 14

23 26 28 21 23 25 19 21 22 17 18 19 14 15 16

25 28 31 23 26 28 21 23 25 18 21 22 16 17 18

sensible heat cap.

1.09 x CFM

)

lwb

COIL REFRIGERANT TEMPERATURE* (°F)

Evap Air—Entering Wet-Bulb Temp (°F)

4. Direct interpolation is permissible. Do not extrapolate.

5. SHC is based on 80°F db temperature of air entering coil. Below 80°F

subtract (corr factor x CFM) from SHC.

Above 80°F db, add (corr factor x CFM) to SHC.

SHC CORRECTION FACTOR

ENTERING AIR DRY-BULB TEMP (°F)

79 78 77 76 75 Under 75

BYPASS

FACTOR

0.10

0.20

0.30

Interpolation is permissible.

Correction Factor = 1.09 x (1 – BF) x (db – 80)

81 82 83 84 85 Over 85

Correction Factor

0.98

1.96

2.94

3.92

0.87

0.76

1.74

1.53

2.62

2.29

3.49

3.05

4.91

4.36

3.82

Use formula

shown below

OPTIONAL FIELD-INSTALLED ELECTRIC HEAT PACKAGES FOR FF1DNA AND FF1DNE

HEATER PART NUMBER

WITH TDR

SIZE

USED

WITH

KFDEH0801D05 All 5 208/230—1 14.3 17.2 7

KFDEH0901D75 All 7.5 208/230—1 20.7 25.0 7

KFDEH1001D11 All 11 208/230—1 29.7 36.0 7

* Heater capacities shown here are for the largest size fan coil unit, and they do include blower motor heat.

NOMINAL

KW @

240V

HEATER

VOLTS—PHASE

(60 Hz)

—6—

HEATER

CAPACITY

(MBH)*

APPROX

SHIP.

WEIGHT

(lbs)208V 230V

Page 7

AIR DELIVERY (CFM) AT INDICATED EXTERNAL

STATIC PRESSURE AND VOLTAGE

EXTERNAL STATIC PRESSURE—IN. WC

UNIT

SIZE

018

024

030

NOTE: Data reflects a dry coil, filter, and 11-kw electric heater installed.

BLOWER MOTOR

SPEED

High 610 720 580 665 540 610 475 540 380 415

Low 480 580 450 545 415 500 375 430 320 340

High 895 985 860 955 825 915 785 865 730 805

Low 650 740 620 710 585 680 550 640 510 600

High 1160 1190 1105 1135 1050 1080 990 1020 935 960

Low 885 1025 870 985 835 940 810 890 770 840

0.1 0.2 0.3 0.4 0.5

208V 230V 208V 230V 208V 230V 208V 230V 208V 230V

AIR DELIVERY PERFORMANCE CORRECTION

COMPONENT PRESSURE DROP (IN. WC) AT INDICATED AIRFLOW

AIR DELIVERY (CFM) 400 500 600 700 800 900 1000 1100

1-Element

Electric

Heaters

Dry-toWet

Coil

Subtract the above pressure drop corrections from unit airflow data when that component or condition is used. The remaining external static pressure will be

available for the duct system.

5 kw

2-Element

7.5 & 11 kw

018 — 0.019 0.029 0.036 0.043 ———

024 ——0.030 0.039 0.051 0.062 0.076 —

030 ————0.058 0.070 0.082 0.091

0.007 0.010 0.015 0.025 0.035 0.055 0.070 0.080

0.010 0.012 0.018 0.028 0.050 0.075 0.100 0.130

ESTIMATED SOUND POWER LEVEL (dBA)

CONDITIONS OCTAVE BAND CENTER FREQUENCY*

UNIT

SIZE

FF1-018 600 0.25 64.7 60.7 56.7 53.7 51.7 49.7 45.7

FF1-024 800 0.25 66.0 62.0 58.0 55.0 53.0 51.0 47.0

FF1-030 1000 0.25 67.0 63.0 59.0 56.0 54.0 52.0 48.0

* Estimated sound power levels have been derived using the method described in the 1987 ASHRAE HVAC Systems & Applications Handbook,

Chapter 52, p. 52.7.

CFM

Ext Static

Pressure 63 125 250 500 1000 2000 4000

OTHER ACCESSORIES

KIT NUMBER DESCRIPTION USED ON SIZES

KFDCC0101DCC Cooling Control Package All

KFBLG0106LGL* Louvered Wall Panel with Frame All

* 6 pack

—7—

Page 8

SERVICE TRAINING

Packaged Service Training programs are an excellent way to increase your

knowledge of the equipment discussed in this manual, including:

• Unit Familiarization • Maintenance

• Installation Overview • Operating Sequence

A large selection of product, theory, and skills programs is available, using popular

video-based formats and materials. All include video and/or slides, plus companion

book.

Classroom Service Training plus "hands-on" the products in our labs can mean

increased confidence that really pays dividends in faster troubleshooting, fewer

callbacks. Course descriptions and schedules are in our catalog.

CALL FOR FREE CATALOG 1-800-644-5544

[ ] Packaged Service Training [ ] Classroom Service Training

A94328

SPECIFICATIONS SUBJECT TO CHANGE WITHOUT NOTICE

UNIT MUST BE INSTALLED IN ACCORDANCE

WITH INSTALLATION INSTRUCTIONS

Cancels: PDS FF1D.18.1

Form PDS FF1D.18.2

© 2003 Bryant Heating & Cooling Systems, 7310 W. Morris St. Indpls, IN 46231 PRINTED IN U.S.A. Catalog No. 12FF-1D1 1-03

—8—

Loading...

Loading...