Bryant EVOLUTION Zone Control SYSTXBBUIZ01-B Installation Instructions Manual

SYSTXBBUIZ01--B

EVOLUTIONt CONTROL

Installation Instructions

HOLD

E

VOLUTION™ SYSTEM

Fig. 1 -- Evolutiont Zone Control

HEAT

COOL

OFF

A04032

NOTE: Read the entire instruction manual before starting the

installation.

TABLE OF CONTENTS

PAGE

SAFETY CONSIDERATIONS 1.........................

INTRODUCTION 2...................................

INSTALLATION AND START--UP OVERVIEW 2..........

INSTALLATION 2....................................

INSTALLING EVOLUTION ZONE CONTROL 5...........

INITIAL POWER--UP 6................................

QUICK START 8.....................................

INSTALL / SERVICE MENUS 9.........................

EQUIPMENT SUMMARY MENU 9......................

INSTALL MENU 9....................................

SETUP MENU 9......................................

CHECKOUT MENUS 13...............................

SERVICE MENUS 14..................................

OPERATIONAL INFORMATION 16.....................

TROUBLESHOOTING 18..............................

SYSTEM MALFUNCTION SCREEN 19..................

SAFETY CONSIDERATIONS

Read and follow manufacturer instructions carefully. Follow all

local electrical codes during installation. All wiring must conform

to local and national electrical codes. Improper wiring or

installation may damage the Evolution Zone System. Recognize

safety information. This is the safety--alert symbol

see this symbol on the equipment and in the instruction manual, be

alert to the potential for personal injury. Understand the signal

words DANGER, WARNING, and CAUTION.

These words are used with the safety--alert symbol. DANGER

identifies the most serious hazards, which will result in severe

personal injury or death. WARNING signifies a hazard, which

could result in personal injury or death. CAUTION is used to

identify unsafe practices, which may result in minor personal

injury or product and property damage. NOTE is used to highlight

suggestions which will result in enhanced installation, reliability, or

operation.

. When you

INTRODUCTION

The Evolution Zone System consists of several intelligent

communicating components which includes the Evolution Zone

Control (or User Interface), Smart Sensors, Damper Control

Module, variable speed furnace or FE fan coil, 2--stage AC or HP

and Evolution Packaged Products, which continually communicate

with each other via a four--wire connection called the ABCD bus.

Commands, operating conditions, and other data are passed

continually between components over the ABCD bus. The result is

a new level of comfort, versatility, and simplicity.

All Evolution furnaces or fan coils are variable--speed and

multi--stage for maximum flexibility, efficiency, and comfort. They

support controlled ventilation, humidification, dehumidification,

and air quality control. Either an Evolution 2--stage

(communicating), or a standard 24VAC controlled outdoor unit

may be used.

When using conventional outdoor units, the Evolution furnace or

fan coil provides the 24 volt signals needed to control them. Also,

the Evolution Damper Control Module (P/N SYSTXBB4ZC01)

allows connection of a Bryant HRV or ERV without the need for a

separate wall control.

All system components are controlled through the wall mounted

BBUIZ01--B

Evolution Zone Control, which replaces the conventional

thermostat and provides the homeowner with a single wall control

for all features of the system.

Design Considerations

The Evolution Zone system is unique because a bypass damper

must not be used. This is possible due to the intelligence of the

system and variable speed motor technology. For trouble--free

applications, the following parameters should always be met:

1. Zones should be sized so that each zone can deliver at least

the minimum airflow for the system in both heating and

cooling modes.

2. Oversize duct work by 25% to avoid excess noise at minimum zone airflow.

3. Be aware that heating airflow may be higher than cooling

airflow depending on equipment combination.

INSTALLATION AND START--UP

OVERVIEW

This instruction covers installation of the Evolution Zone Control

only. Physical installation instructions for the indoor and outdoor

equipment, Damper Control Module, and accessories are provided

with each unit.

Setup, commissioning, operation, and troubleshooting of the

Evolution Zone System are covered in this installation instruction.

It is the guide to connecting the system components and

commissioning the system once all physical components are

installed. Special screen prompts and start--up capabilities are

provided in the Evolution System to simplify and automate the

initial commissioning of the system.

S Install Evolution Zone Control according to this instruc-

tion.

S Install indoor unit, outdoor unit, and accessories accord-

ing to their instructions.

S Wire complete system according to this instruction.

S Setup, commission, and operate system according to this

instruction to assure a smooth and trouble free start--up.

INSTALLATION

Check Equipment and Job Site

Inspect equipment. File claim with shipping company prior to

installation if shipment is damaged or incomplete.

Evolution Zone Control Location and Wiring

Considerations

!

WARNING

ELECTRICAL OPERATION HAZARD

Failure to follow this warning could result in personal injury

or death.

Disconnect power before routing control wiring.

All wiring must comply with national, local, and state codes.

Evolution Zone Control

The Evolution Zone Control User Interface is the command center

for the Evolution Zone System and is typically located in Zone 1 to

sense and control temperature in this zone. It should be located

where it is easily accessible and visible to the adult homeowner or

end user.

For accurate temperature measurement, the following guidelines

should be followed:

The Evolution Zone Control and Room Sensors should be

mounted:

S Approximately 5 feet (1.5 meters) from the floor.

S Close to or in a frequently used room, preferably on an

inside partitioning wall.

S On a section of wall without pipes or ductwork.

The Evolution Zone Control and Room Sensors should NOT be

mounted:

S Close to a window, on an outside wall, or next to a door

leading to the outside.

S Exposed to direct light or heat from a lamp, sun, fire-

place, or other temperature-- radiating objects which

could cause a false reading.

S Close to or in direct airflow from supply registers.

S In areas with poor air circulation, such as behind a door

or in an alcove.

Remote Room Sensor

A Remote Room Sensor can be used with the Evolution Zone

Control to take the place of the User Interface internal temperature

sensor. This allows the Evolution Zone Control to be mounted in

areas with less than optimal airflow (such as near an exterior door,

window or in a closet). The remote sensor can be wired to the

terminal block connectors labeled S1 and S2 at the User Interface

backplate, or the OS1 and OS1C connection at the Damper Control

Module. In either case, the Evolution Zone Control will

automatically detect the Remote Room Sensor and ignore its

internal temperature sensor. It is also important to note the

humidity sensor cannot be remotely located, so do not locate the

Evolution Zone Control in an area where humidity sensing may

not be accurate.

NOTE: S1 & S2 connection on User Interface backplate is now

used for Remote Room Sensor, NOT for OAT Sensor hookup.

In addition, the Remote Room Sensor is a temperature sensor only,

having no additional user inputs. This sensor is typically connected

to the Damper Control Module and used to sense and control

temperature in each zone.

Location

Option

2

Remote Sensor A

veraging

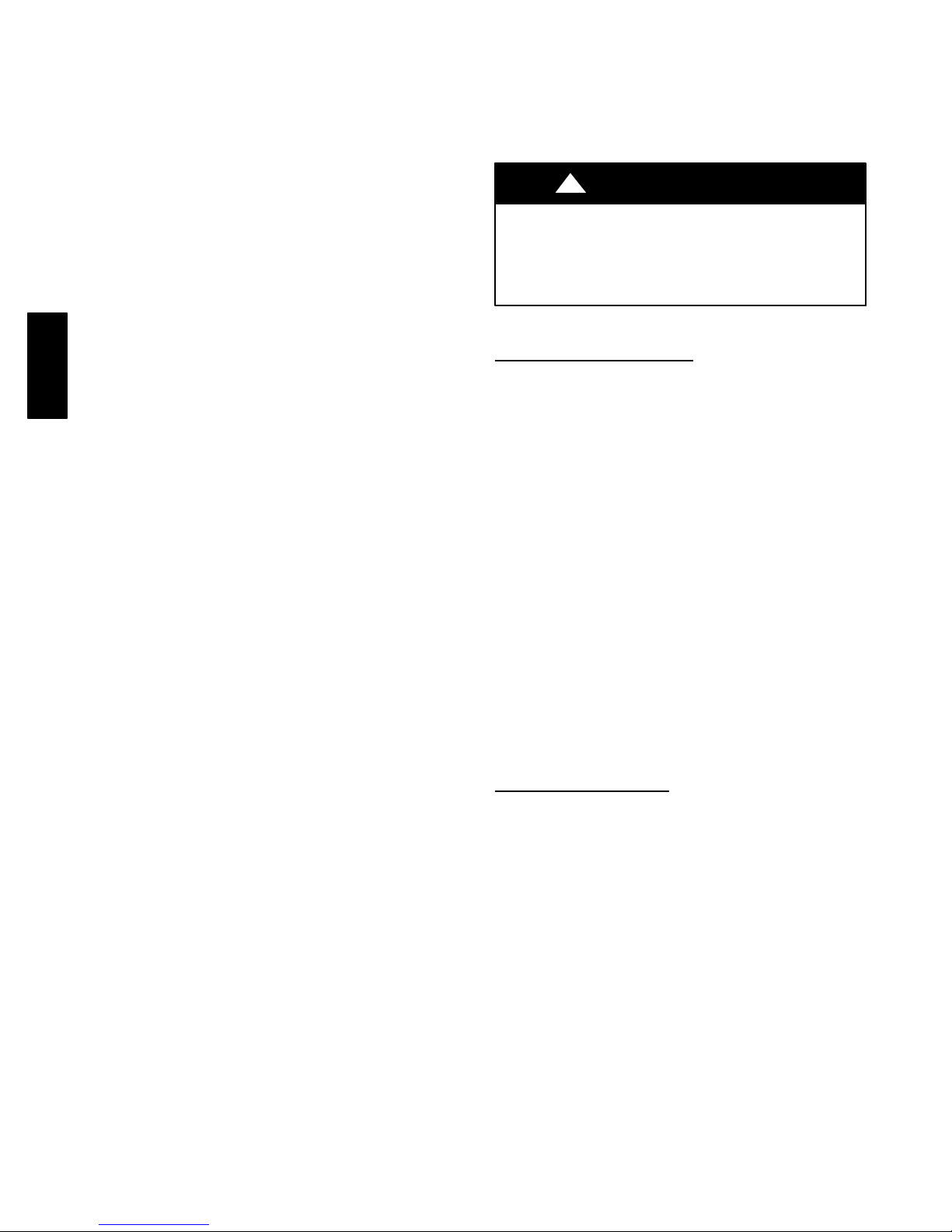

Typically, one Remote Room Sensor is used per zone, but multiple

sensors may be used and averaged in some applications. Averaging

requires a special series--parallel wiring method with a specific

number of sensors. See Fig. 2 in this manual for wiring diagram.

Damper Control

Module

ZS_

Sensor 1 Sensor 2

Sensor 3 Sensor 4

Damper Control

Module

ZS_C

A03233

Fig. 2 -- Remote Room Sensor -- Parallel Wiring

Sensor

Smart

Any zone may use a Smart Sensor. It provides a temperature

display and buttons to adjust the desired temperature in that zone

only. It also displays outdoor temperature and indoor humidity

sensed at the User Interface. Only one Smart Sensor may be used

per zone. They cannot be averaged like Remote Room Sensors. If a

Smart Sensor is used in a zone, a Remote Room Sensor may also

be used in the same zone. The Remote Room Sensor has priority

over the Smart Sensor. The Smart Sensor will display the Remote

Room Sensor temperature.

NOTE: Smart Sensors must be addressed to identify which zone it

will control. See Smart Sensor Installation Instructions for details.

Considerations

Wiring

Ordinary thermostat wire is recommended. Use 22 AWG or larger

for normal wiring applications. Continuous wire lengths over 100

ft. should use 20 AWG or larger.

NOTE: ABCD bus wiring only requires a four--wire connection;

however, it is good practice to run thermostat cable having more

than four wires in the event of a damaged or broken wire during

installation.

Each communicating device in the Evolution Zone System has a

four--pin connector labeled ABCD. It is recommended that the

following color code be used when wiring each device:

A — Green = Data A

B — Yellow = Data B

C — White = 24VAC (Com)

D — Red = 24VAC (Hot)

It is not mandatory that the above color code be used, but each

ABCD connector in the system MUST be wired consistently.

Locating Damper Control Module

All wiring is run back to the Damper Control Module. Select a

location near the furnace or fan coil where wiring from the User

Interface, each Remote Room Sensor or Smart Sensor, each

damper actuator, and the equipment itself can come together easily.

The Damper Control Module is approved for indoor use only and

should never be installed with any of its components exposed to

the elements. The Damper Control Module (and zone dampers)

may be installed in any area where the temperature remains

between --4_F to 158_F(--20_Cto70_C), and there is no

condensation. The cover must be installed to prevent damage from

other sources. Do not locate where it will be accessible to children.

It may be mounted in either vertical or horizontal position.

Remember that wiring access is likely the most important

consideration.

!

CAUTION

ELECTRICAL OPERATION HAZARD

Failure to follow this caution may result in equipment damage

or improper operation.

To prevent possible damage to the Damper Control Module,

DO NOT mount on plenum, ductwork, or flush against

furnace or fan coil.

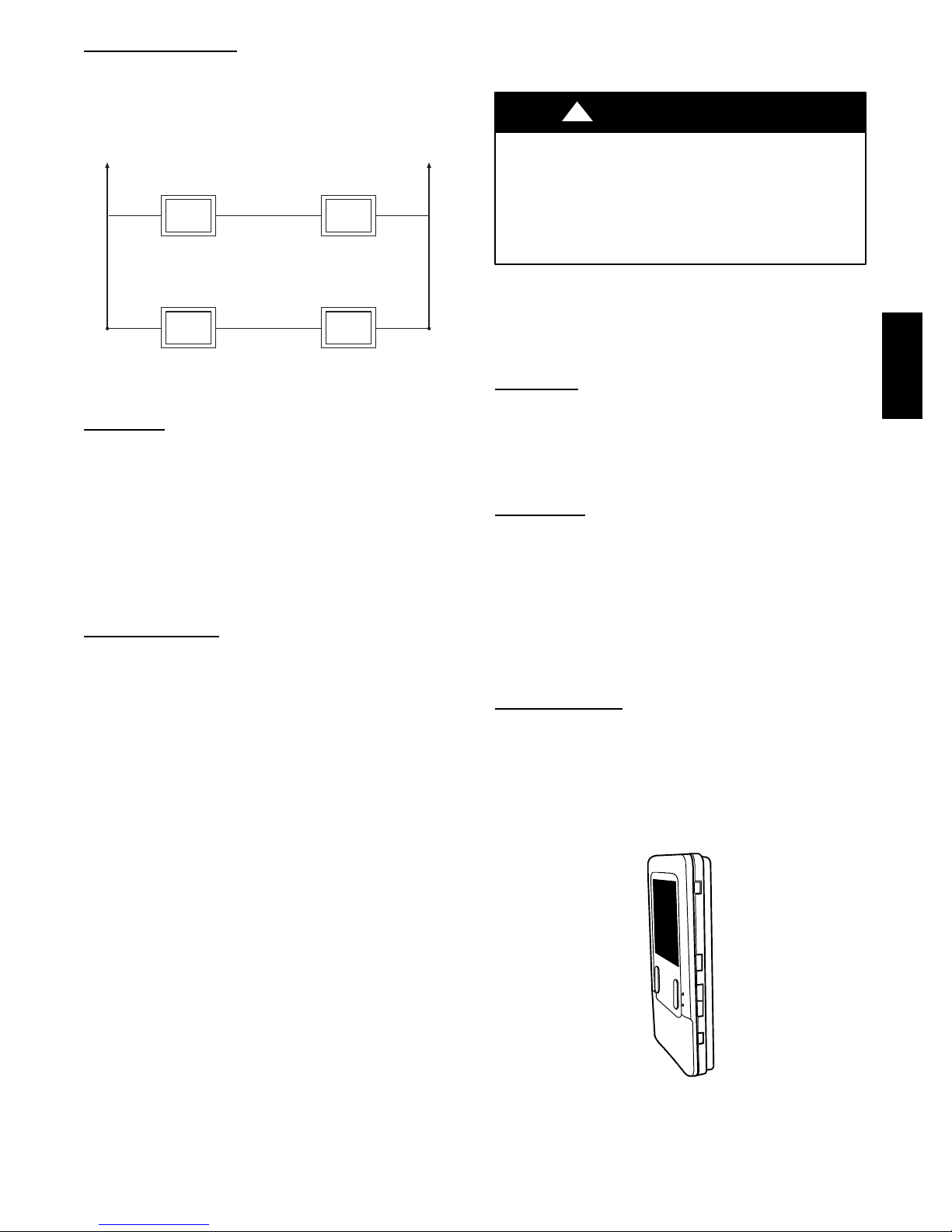

Mounting Evolution Zone Control

There are two options for mounting the Evolution Zone Control to

the wall. First, become familiar with all plastic assembly pieces

shown in Fig. 3 through 10. The User Interface will snap together

with either the Recess Mount or the Surface Mount backplate.

Mount

Recess

This provides the thinnest mounting configuration (See Fig. 4).

The backplate containing the recessed terminal block can be

mounted directly to the wall by cutting a hole 1 1/2” (38.1 mm)

wide by 2 1/8” (54 mm) high. Mark location and cut hole in wall.

NOTE: Always ensure the Evolution Zone Control location is

acceptable before cutting any holes in wall.

Surface

This provides surface mounting configuration, which allows use of

a small hole in the wall. A surface mount backplate is supplied (See

Fig. 5). Attach backplate as shown in Fig. 8, and the assembly will

mount directly to the wall requiring only a small hole in the wall

allowing a four wire connection to pass through.

NOTE: Once Evolution Zone Control is secured to wall with the

backplate assembly (snapped together), care must be taken not to

bend or break the interlocking tabs when removing. Gently remove

Evolution Zone Control by rocking up/down until interlocking

tabs release.

Decorative Backplate

Supplied is a thin decorative backplate (see Fig. 6) to hide any

marks/screw holes left from the previous thermostat. This

decorative backplate (or beauty ring) can be used in either the

recess or surface mount installation by snapping it onto back of

recessed mount backplate or surface mount backplate before

securing to wall. See Fig. 9 and 10 for a larger decorative backplate

P/N SYSTXXOLBP01 (5.75” / 146 mm wide x 6” / 15 2 mm

high), which can be ordered separately.

Mount

A03185

Fig. 3 -- Evolutiont Zone Control

BBUIZ01--B

3

Surface Mount

Backplate to wall

Interlocking Tabs (4)

Fig. 4 -- Recessed Mount Backplate

A03186

Fig. 8 -- Surface Mount Assembly

A03191

BBUIZ01--B

A03188

A03187

Fig. 5 -- Surface Mount Backplate

Fig. 9 -- Large Decorative Backplate

Fig. 6 -- Thin Decorative Backplate

Recessed terminal

block in wall 1

wide by 2

Recessed Mount

Interlocking Tabs (4)

Fig. 7 -- Recessed Mount Assembly

1

" (38.1 mm)

/

2

1

/8" (54 mm) high

A04017

A07150

A03192

Fig. 10 -- Decorative Backplate Assembly

4

INSTALLING EVOLUTION ZONE

CONTROL

!

WARNING

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in personal injury

or death.

Before installing Evolution Zone Control, turn off all power

to equipment. There may be more than one power source to

disconnect.

1. Turn off all power to equipment.

2. If an existing User Interface or control is being replaced:

a. Remove existing control from wall.

b. Disconnect wires from existing control.

c. Discard or recycle old control.

NOTE: Mercury is a hazardous waste, if existing control contains

any mercury, it MUST be disposed of properly. The User Interface

does not contain mercury.

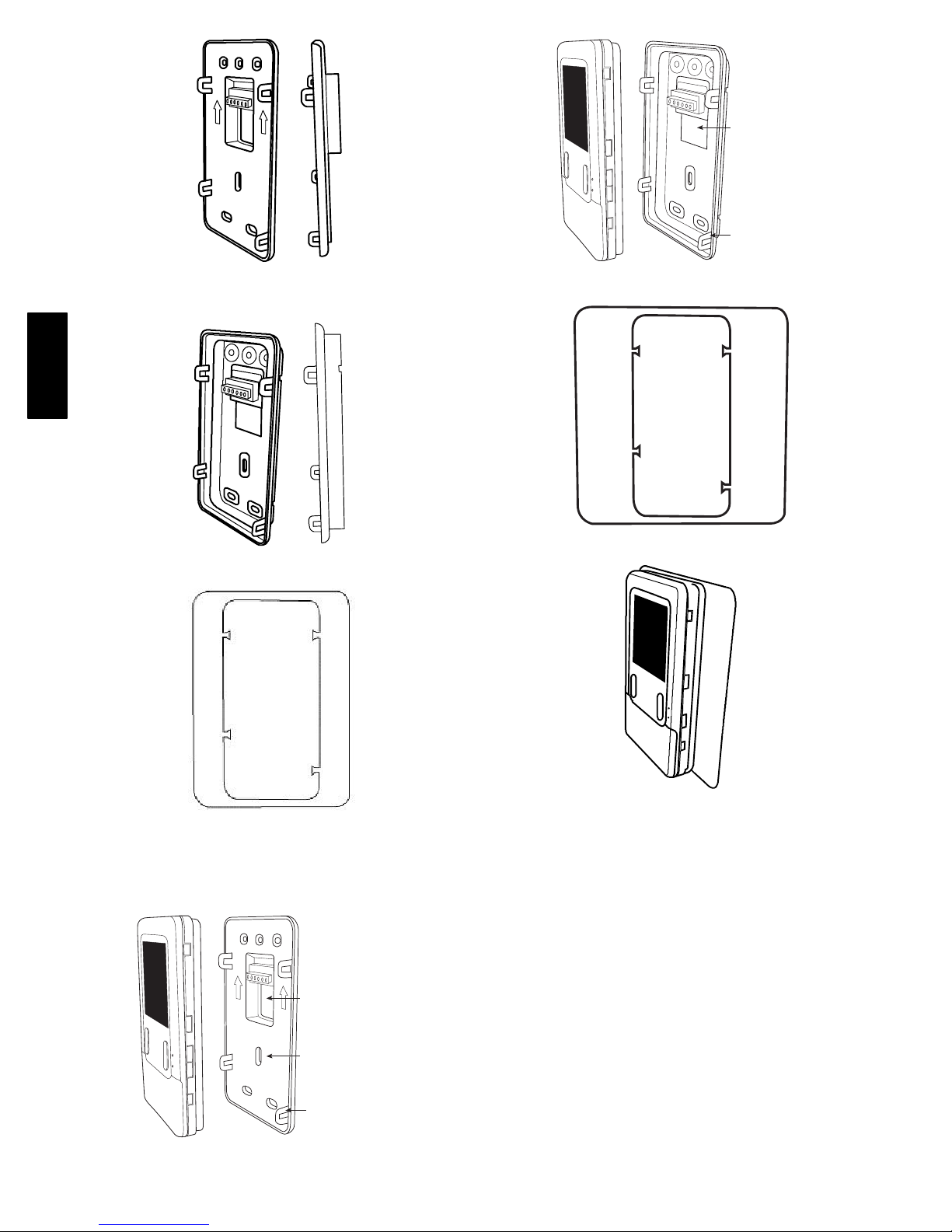

3. Select Evolution Zone Control mounting plastic (recess

mount or surface mount and decorative backplate if desired).

4. Route wires through large hole in mounting plastic. Level

rear plastic against wall (for aesthetic value only -- Evolution Zone Control need not be level to operate properly) and

mark wall through two mounting holes.

5. Drill two 3/16” (4.8 mm) mounting holes in wall where

marked.

6. Secure mounting plastic to wall using two screws and anchors provided.

7. Adjust length and routing of each wire to reach each wire

entry on the connector backplate. Strip 1/4” (6.4 mm) of insulation from each wire.

8. Match and connect thermostat wires to proper terminals on

User Interface backplate. See wiring diagram Fig. 12, 13,

and 14.

A — Green = Data A

B — Yellow = Data B

C — White = 24VAC (Com)

D — Red = 24VAC (Hot)

NOTE: It is not mandatory that the above color code be used, but

each ABCD connection in the system MUST be wired consistently.

A separate ABCD Connector comes inside packaging and should

be used when connecting to furnace (or fan coil). Ensure connector

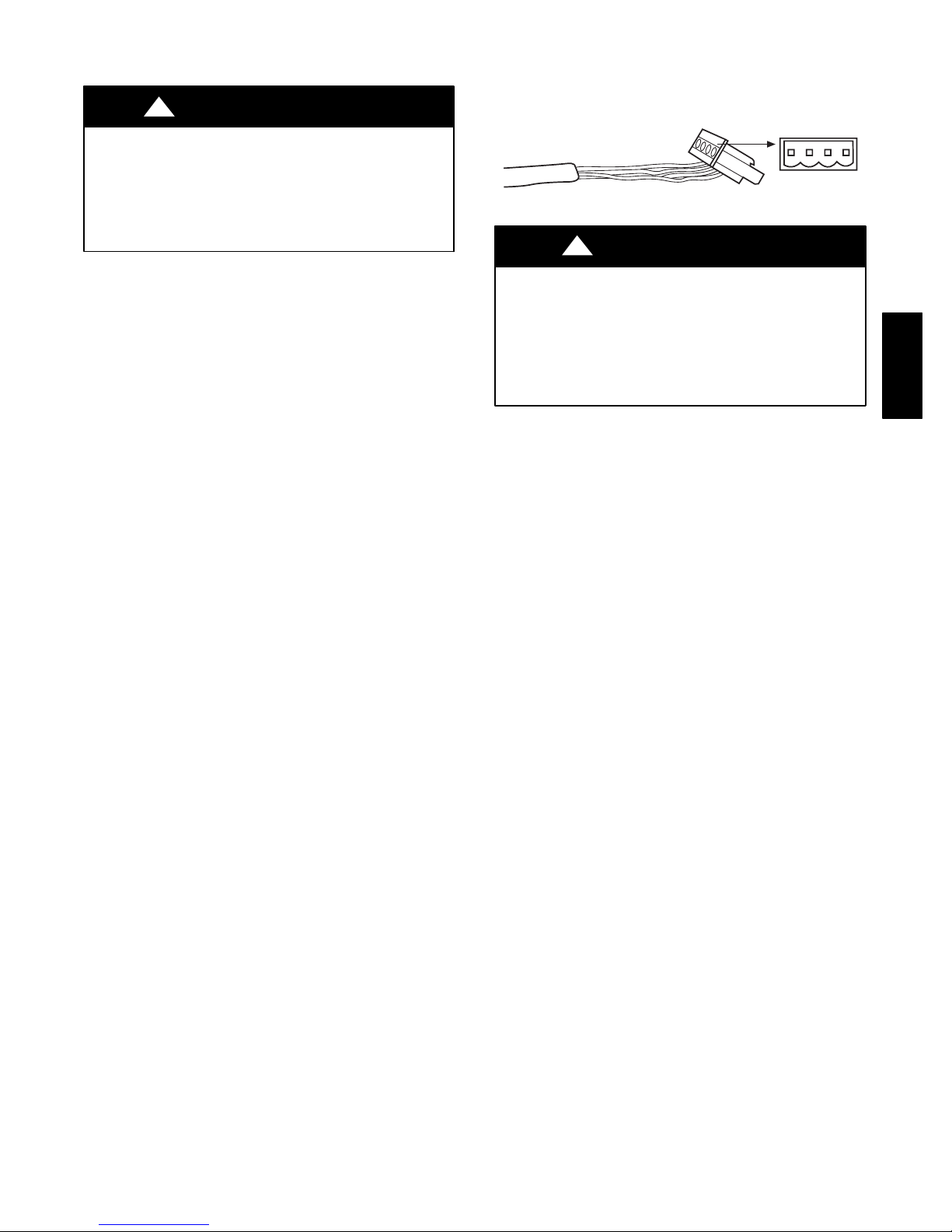

is inserted properly into circuit board. (See Fig. 11.)

ABCD

A03193

Fig. 11 -- Wire ABCD Connector

!

CAUTION

ELECTRICAL OPERATION HAZARD

Failure to follow this caution may result in equipment damage

or improper operation.

Improper wiring of the ABCD connector will cause the

Evolution Zone System to operate improperly. Check to make

sure all wiring is correct before proceeding with installation or

turning on power.

9. Push any excess wire into the wall. Seal hole in wall to prevent any air leaks. Leaks can affect operation.

10. Attach Evolution Zone Control to the mounting plastic by

lining up the plastic guides on the back of the control with

the opening on the mounting plastic and push on.

11. Perform installation of all other system equipment (i.e.

dampers, humidifier, ventilator, UV lights, etc.)

12. Turn on power to equipment.

See wiring diagrams Fig. 12, 13, and 14 for connecting the

Evolution Zone Control and Smart Sensors to the Damper Control

Module. More information regarding Damper Control set--up and

wiring can be found in Damper Control Module Installation

Instructions.

See wiring diagram, Fig. 12, which includes an indoor

communicating furnace or FE fan coil, with a 2--stage Puronr

refrigerant communicating outdoor unit. No additional OAT

(outdoor air temperature) sensor is required because the Evolution

Zone Control will use the temperature sensor inside the outdoor

unit.

See wiring diagram, Fig. 13, for connecting an indoor

communicating furnace or FE fan coil with a 1--stage air

conditioning unit (non--communicating outdoor). An Outdoor Air

Temperature (OAT) sensor may be installed (but is not required) at

the indoor furnace or fan coil OAT terminals. When OAT sensor is

applied, the Evolution System will provide enhanced system

features and benefits.

See wiring diagram Fig. 14 for connecting an FE fan coil with a

1-- stage heat pump (non--communicating outdoor unit). When

OAT is applied, the Evolution System will provide enhanced

system features and benefits.

NOTE: For other applications not listed, refer to the Network

Interface Module (NIM) Installation Instructions.

BBUIZ01--B

5

Zone Control

User Interface &

Smart Sensor(s)

A B C D

Indoor

Green

Yellow

White

Red

Unit

A

B

C

D

Communicating

A B C D A B C D

HUM

COM

24V

OAT

(Optional)

Damper

Control

module

Humidifier

Connection

Fig. 12 -- Communicating Indoor Unit w/2--Stage Puronr

Refrigerant Communicating Outdoor Unit

Indoor

Zone Control

User Interface &

Smart Sensor(s)

BBUIZ01--B

A B C D

A B C D A B C D

Damper

Control

Green

Yellow

White

Red

Humidifier

Connection

Unit

HUM

COM

24V

Y/Y2

A

B

C

D

module

OAT

Fig. 13 -- Connection Diagram for Furnace or FE Fan Coil

with Non--Communicating 1--Stage AC

Green

Yellow

White

Red

Humidifier

Connection

Variable-Speed

Fan Coil

A

B

C

D

HUM

C

G

R

O

W

Y

OAT

Zone Control

User Interface &

Smart Sensor(s)

A B C D

A B C D A B C D

Damper

Control

module

Fig. 14 -- Connection Diagram for FE Fan Coil with

Non-- Communicating 1--stage HP

Humidifier Connection

A 24VAC bypass or fan powered humidifier may be installed.

NOTE: Do Not Use a traditional humidistat to control humidifier

operation. If a humidifier is installed, let the Evolution Zone

Control operate humidifier.

AC or HP

A

B

C

D

OAT

Sensor

1-Stage AC.

1-Spd. HP

A04018

C

Y

OAT

Sensor

A04019

Sensor

A07149

OAT

Bypass

Humidifiers

A bypass humidifier should be wired directly to the furnace or fan

coil HUM and 24VAC COM terminals. The Evolution Zone

Control will automatically energize the HUM output during a call

for humidification.

Fan Powered

Humidifiers

Most fan powered humidifiers produce internal 24VAC in order to

energize upon a switch or contact closure. For this application, a

24VAC N.O. Isolation Relay (DPST) MUST be used to prevent

mixing the internal humidifier power with the indoor equipment

transformer. Applying 24VAC isolation relay coil to furnace or fan

coil HUM and COM terminals will allow the Evolution Zone

Control to automatically energize the HUM output during a call for

humidification. The N.O. relay contacts will be used to energize the

humidifier. See fan powered humidifier installation instructions for

more details.

!

CAUTION

EQUIPMENT HAZARD

Failure to follow this caution may result in equipment damage.

Do not apply 24VAC fan powered humidifier (with internal

power supply) direct to indoor unit HUM and COM terminals.

INITIAL POWER--UP

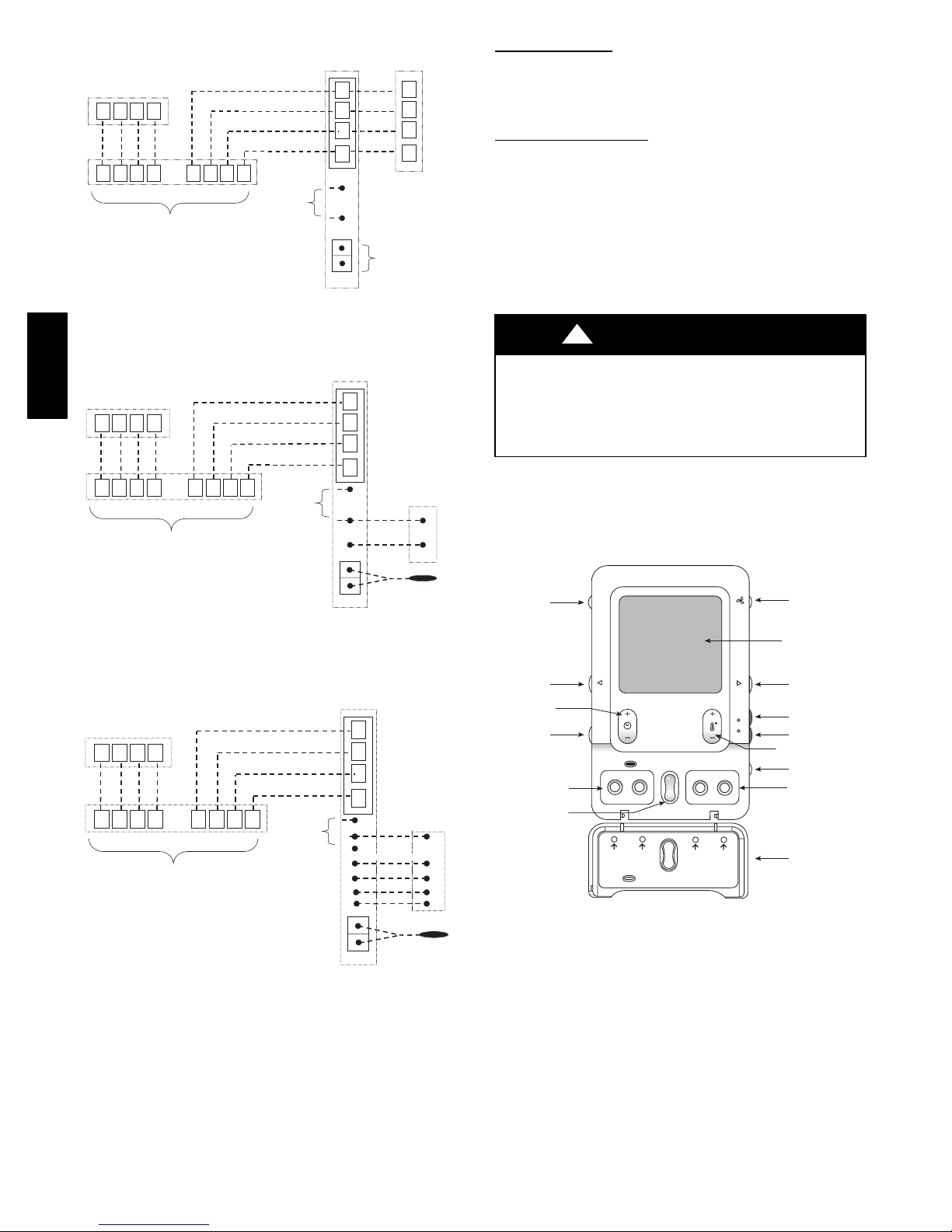

NOTE: Refer to Functional Overview (Fig. 15) to become

familiar with key function buttons such as “System On/Off”,

“Zone”, “Fan”, “Left--Side” and “Right--Side” buttons, etc. These

function buttons will be used frequently during setup.

Zone

Button

Left-Side

Button

Time (+/-)

Button

Hold

Button

Schedule & Vacation

Program Buttons

Up/Down

C

R

O

W2

Y

Scroll Buttons

ZONE

HOLD

SCHEDULE VACATION

PROGRAM

Schedule

to program

temperature

schedule

Vacation

to start/end

vacation

SCROLL

Scroll

up & down

BASIC

Basic

to set time,

humidity

SETUPS

ADVANCED

Advanced

for all other

settings

HEAT

COOL

Fig. 15 -- Functional Overview

Power Up Sequence

This section addresses initial power up (or commissioning) of a

new Evolution Zone Control. The User Interface will communicate

and identify all Evolution components in the system. The

following is a typical example for a communicating

Variable--Speed Furnace / Fan Coil with a 2 --stage Air Conditioner

/ Heat Pump (including Hybrid Heat).

The User Interface display will light up and indicate that it is now

“ESTABLISHING COMMUNICATIONS WITH EQUIPMENT

PLEASE WAIT”. The User Interface will automatically continue

by “SEARCHING FOR EQUIPMENT”, followed by

“SEARCHING FOR OUTDOOR EQUIPMENT” (See Fig. 16).

Fan Button

Display Screen

(LCD)

Right-Side

Button

Heat Button

Cool Button

Temperature

(+/-) Button

System

On/Off Button

Basic & Advanced

Setup Buttons

Flip Down

Door

A04038

6

Loading...

Loading...