Bryant Evolution SYSTXBB4ZC01 Installation And Start-up Instructions Manual

SYSTXBB4ZC01

Evolutionr Damper Control Module

Installation and Start--Up Instructions

A97038

NOTE: Read the entire instruction manual before starting the

installation.

SAFETY CONSIDERATIONS

Improper installation, adjustment, alteration, service, maintenance,

or use can cause explosion, fire, electrical shock, or other

conditions which may cause death, personal injury or property

damage. Consult a qualified installer, service agency or your

distributor or branch for information or assistance. The qualified

installer or agency must use factory--authorized kits or accessories

when modifying this product. Refer to the individual instructions

packaged with the kits or accessories when installing.

Follow all safety codes. Wear safety glasses, protective clothing,

and work gloves. Have a fire extinguisher available. Read these

instructions thoroughly and follow all warnings and cautions

included in literature and attached to the unit. Consult local

building codes and the current edition of the National Electrical

Code (NEC) NFPA 70. In Canada, refer to the current editions of

the Canadian Electrical Code CSA C22.1.

Recognize safety information. When you see this symbol

the unit and in instructions or manuals, be alert to the potential for

personal injury. Understand the signal words DANGER,

WARNING,andCAUTION. These words are used with the

safety--alert symbol. DANGER identifies the most serious hazards,

which will result in severe personal injury or death. WARNING

signifies hazards, which could result in personal injury or death.

CAUTION is used to identify unsafe practices, which may result

in minor personal injury or product and property damage. NOTE

is used to highlight suggestions which will result in enhanced

installation, reliability, or operation.

on

INSTALLATION CONSIDERATIONS

Before the actual installation of a zoning system can begin,

decisions need to be made to determine the number and location of

zones and sensors. This affects duct and damper selections.

See the Evolutionr System Zoning Design Guide for more

information on specifying and designing zoning systems.

This instruction covers the physical installation and start up of the

Evolutionr Damper Control. Use this instruction to guide the

actual installation process after all the air side decisions have been

made. One Damper Control is capable of handling up to four zones

of operation. When greater than four zones are required, a second

Damper Control Module is needed for zones 5 through 8 (8 zones

maximum).

S Install the Evolutionr Zone Control (Evolutionr Connext Wall

Control) and Remote Room Sensors in non--condensing areas

with ambient temperatures between 32 F and 120 F. In sta ll

dampers and the Evolutionr Damper Control in non --condensing

areas with ambient temperatures between --4 F to 158 F(--20 to

70 C).

S A TXV is required on the indoor coil when used with all

residential split system equipment.

S Proper equipment selection and duct sizing are important in a

zoned system.

S DO NOT USE a bypass damper with the Evolutionr Zoning

System. Additio n of a bypass will cause improper operation.

Airflow management will be performed by the Evolution r

Connext Wall Control algorithms. The Evolutionr Connext

Wall Control will monitor the system and will maintain proper

airflow through the heating / cooling equipment.

INTRODUCTION

The Evolutionr Zoning System allows air conditioning and

heating equipment to control temperatures and humidity in up to 8

distinct spaces, or zones, within a building. Each zone has

independent temperature settings. The comfort temperature

settings can change automatically through the use of schedules.

This allows the Evolutionr System to change temperature settings

in zones to reflect occupancy or usage. For example, the end user

can condition bedrooms in a home from 5:00 PM through 7:00

AM or the kitchen from 3:00 PM through 6:00 PM. The

Evolutionr System uses motorized air volume control dampers

(also called zone dampers) to regulate flow of conditioned air into

zones. In this manner, the system can selectively heat or cool

certain portions of a building depending upon space temperature

requirements.

Each zone requires a motorized zone damper to control the air

supplied to it and a zone sensor to sense temperature in each zone.

There are three types of zone sensors available and may be used in

combination:

S Evolutionr Connext Wall Control (p/n SYSTXCBBECC01,

SYSTXBBECW01, or SYSTXBBECN01) — Each installation

has only one Master wall/zoning control. This is the command

center for the entire system. It will typically be located in Zone 1

to sense and control the temperature in this zone. If desired, a

Remote Room Sensor or a Smart Sensor may be used to sense the

Zone 1 temperature. This can give the installer some flexibility in

locating the Master Evolutionr Connext wall control to another

area.

S Remote Room Sensor (p/n SYSTXBBRRS01) — Any zone may

use a Remote Room Sensor (including Zone 1). This is a

temperature sensor only, having no additional user inputs. In

applications where zone temperature averaging may be desired,

this may be done using 4 Remote Room Sensors in a series /

parallel wiring config u ratio n (S ee Fig . 11 for Remote Room

Sensor Averaging).

S Smart Sensor (p/n SYSTXBBSMS01) — Any zone may use a

Smart Sensor (including Zone 1). It provides a temperature

display and buttons to adjust the desired temperature in that zone

only. It also displays the outdoor temperature and indoor

humidity.

Be sure to select the desired sensor type for each zone. Zone sensors

other than the Evolutionr Connext wall control must be purchased

separately. Installation Instructions for these sensors are included

with them.

INSTALLATION

Step 1 — Check Equipment and Job Site

INSPECT EQUIPMENT—File claim with shipping company,

prior to installation, if shipment is damaged or incomplete.

Step 2 — Component Location and Wiring

Considerations

!

WARNING

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in personal injury

or death.

Before installing sensor, turn off all power to unit. There may

be more than one power disconnect.

NOTE: All wiring must comply with national, local, and state

codes.

LOCATING Evolutionr DAMPER CONTROL

All system wiring is run back to the Evolutionr Damper Control.

Select a location near the Evolutionr furnace or fan coil where

wiring from the Evolutionr Connext wall control, each Remote

Room Sensor or Smart Sensor, each damper actuator, and the

equipment itself can come together easily.

The Evolutionr Damper Control is approved for indoor use only

and should never be installed with any of its components exposed

to the elements. The Evolutionr Damper Control (and the zone

dampers) may be installed in any area where the temperature

remains between --4 F to 158 F(--20 Cto70 C), and where

there is no condensation. The cover must be installed to prevent

damage from other sources. Do not locate where it will be

accessible to children. It may be mounted in either vertical or

horizontal position. Remember that wiring access is likely the most

important consideration.

!

CAUTION

ELECTRICAL OPERATION HAZARD

Failure to follow this caution may result in equipment damage

or improper operation.

To prevent possible damage to the Evolutionr Damper

Control, do not mount on plenum, ductwork, or flush against

surface.

LOCATING MASTER ZONING WALL CONTROL

The Evolutionr Connext wall control is the command center for

the Evolutionr Zone System. It should be located where it is easily

accessible and visible to home or business owner. It is also

normally the Zone 1 sensor and as such needs to be located to

properly measure the temperature in Zone 1. If these two

requirements conflict, a separate Remote Room Sensor can be

added for Zone 1.

When a Remote Room Sensor is connected to Zone 1 terminals

(ZS1 and ZS1C) of the Evolutionr Damper Control, the system

automatically switches to using this sensor for Zone 1 and ignores

the sensor within the Evolutionr Connext wall control. This

arrangement allows the Evolutionr Connext wall control to be

located at any convenient place within the home or business. In this

arrangement, only the Zone 1 Remote Room Sensor must be

located in Zone 1.

NOTE: The Evolutionr Connext wall control also controls

humidity functions. If the wall control is not used to control Zone 1

temperature, it must still be located in a suitable area where

humidity control will not be affected.

LOCATING SENSORS

For proper operation, each sensor must accurately measure the

temperature within its zone. For accurate temperature

measurement, the following guidelines should be followed:

Sensor should be mounted:

S Approximately 5 ft. (1.5m) from floor.

S Close to the center of its zone, preferably on an inside wall.

S On a section of wall without pipes or duct work.

Sensor should NOT be mounted:

S Close to a window, on an outside wall, or next to a door leading to

the outside.

S Where it will be exposed to direct light and heat from a lamp, sun,

fireplace, or other temperature radiating object which may cause a

false reading.

S Close to or in direct airflow from supply registers.

S In areas with poor air circulation, such as behind a door or in an

alcove.

WIRING CONSIDERATIONS

Ordinary thermostat wire is ideal when wiring the Evolutionr

Zoning System (shielded cable is not necessary). Use 20 AWG or

larger for typical installations. Lengths over 100 ft. should use 18

AWG or larger wire. Remote Room Sensors require only two

conductors, but it is recommended that at least four conductors be

run. This will allow a Smart Sensor to replace the Remote Room

Sensor with no wiring changes at a later date. The Evolutionr

Connext wall control requires four conductors, each damper

actuator requires three conductors. Cut off or fold back and tape

any unneeded wires. Plan the routing of wiring early to avoid

possible problems later. Remember, all wires converge at the

Evolutionr Damper Control, so its location is important.

2

NOTE: Wiring of the ABCD bus only requires a four-- wire

connection; however, it is good practice to run thermostat cable

having more than four wires in the event of a damaged or broken

wire during installation.

The following color code is recommended for each ABCD bus

connection:

A — Green = Data A

B — Yellow = Data B

C — White = 24 VAC (Com)

D — Red = 24VAC (Hot)

It is not mandatory that the above color code be used, but each bus

connection in the system MUST be wired consistently.

Step 3 — Install Components

INSTALL Evolutionr DAMPER CONTROL

The Evolutionr Damper Control is designed so that wires can enter

it from behind, above, or below. Plan wire routing before mounting

Damper Control.

1. Remove cover to access mounting holes.

2. Mount back plate to wall using screws and wall anchors

provided.

3. Level back plate and tighten screws.

INSTALL MASTER ZONING WALL CONTROL

See the Evolutionr Connext wall control Installation Instructions

for details.

NOTE: Improper wiring of the ABCD connector will cause the

Evolutionr Zoning System to operate improperly. Check to make

sure all wiring is correct before proceeding with installation or

turning on power.

INSTALL REMOTE ROOM SENSORS

1. Separate the sensor cover and mounting back plate by

squeezing the top and bottom of the cover together firmly

by grasping the raised top and bottom ridges. This will release the cover. Mount to the wall using the screws and anchors provided.

2. Pull a 2 --conductor wire through hole on right--hand side.

3. Recommended connection is BLACK to either terminal,

WHITE to remaining terminal (sensor terminals are not

marked for polarity because polarity is not important).

Stranded or common bell wire may be used. Lengths up to

1000 ft. will contribute no noticeable error.

4. Push any extra wire into the wall and seal the hole to prevent air leaks. Align the sensor cover with the base plate,

then press firmly until the cover snaps into place.

INSTALL ZONING SMART SENSOR

See the Evolutionr Zoning Smart Sensor Installation Instructions

for details.

Step 4 — Install Zone Dampers

Proper selection and sizing of dampers is very important for proper

system operation. Be sure to consult the Damper Product Data

Sheet and Evolutionr Zoning Design Guide for assistance in

making these selections. Selection and sizing information is not

provided in this installation instruction. Zone dampers are available

in round, rectangular, and slip--in design, and may be installed in

any position. Install the damper so that the actuator is visible for

inspection and accessible in the event it would need to be serviced.

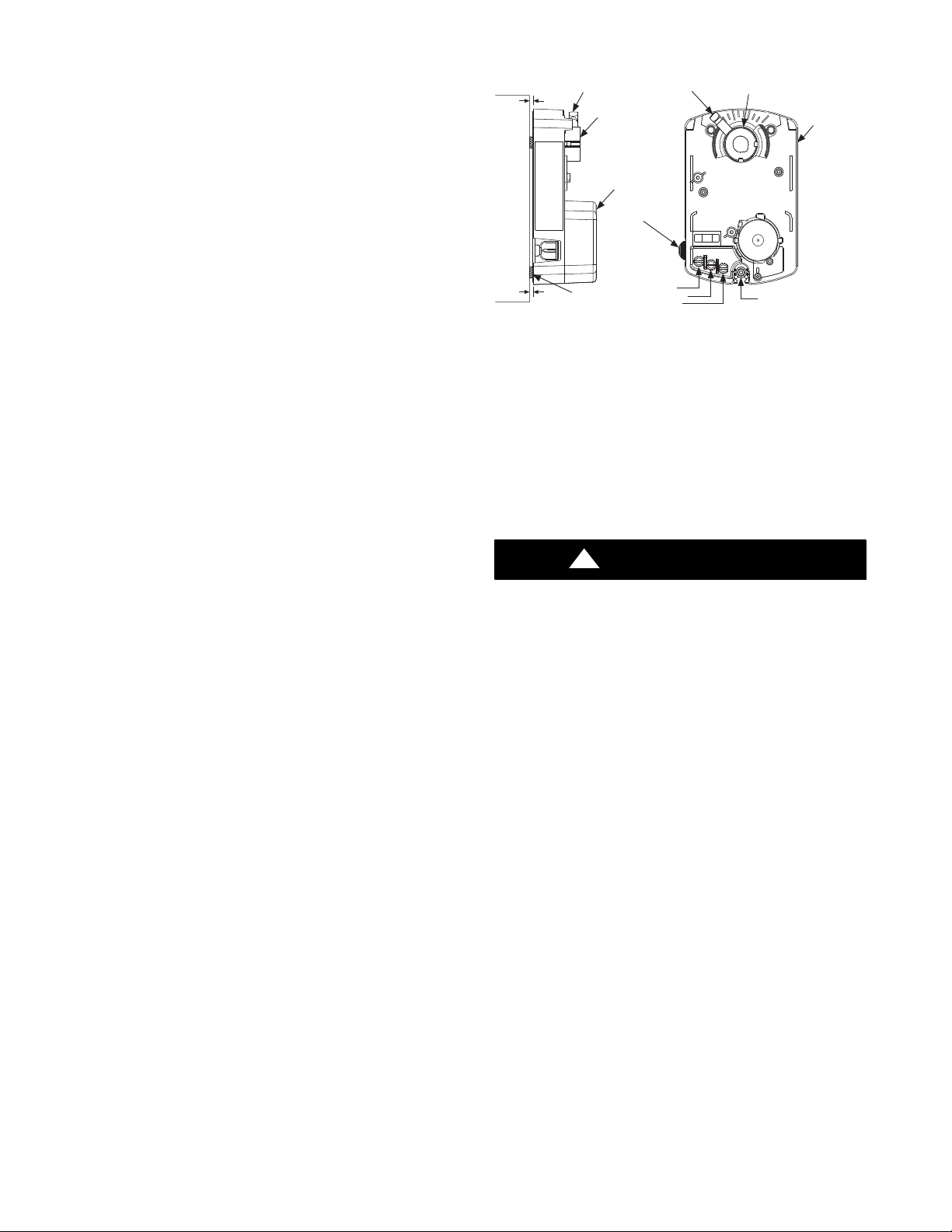

The black mark on the end of the damper shaft represents the

position of the damper blade. To wire the damper, locate the

terminals labeled: OPN (open); COM (common); CLS (closed; and

wire appropriately (see Fig. 1 for Damper 24 VAC connection).

3/16"

GAP

DAMPER

3/16"

GAP

SET SCREW

MOUNTING HUB

ANTI-ROTATION

MOUNTING SCREW

PLASTIC COVER

QUICK BLADE

RELEASE

(CLS) CLOSED

(COM) COMMON

(OPN) OPEN

SET SCREW

CLS

CLS

MOUNTING HUB

ACTUATOR

HOUSING

OPN

COM

COM

OPN

ANTI-ROTATION

MOUNTING SCREW (5/16")

Fig. 1 -- Damper 24VAC Connections

C03024

If the duct system requires multiple dampers for a single zone, up

to five dampers (maximum) may be wired in parallel. For all

applications, including retrofit, it is recommended to use only

current dampers with direct--drive style actuators. DO NOT use

older damper with crank-- arm style actuators.

If an actuator is removed from a damper for any reason, it must be

properly aligned when it is reinstalled. This can be done by

rotating the actuator and the blade to their closed positions and

then tightening the actuator (set screw) to the shaft. This assures

alignment at the closed position. (Pressing the quick blade release

button allows the actuator to be manually turned.)

!

CAUTION

ELECTRICAL OPERATION HAZARD

Failure to follow this caution may result in equipment damage

or improper operation.

Condensation can damage the actuator. When dampers are

located in an unconditioned space, condensation is likely to

occur in cooling. To prevent condensation and losses, all

dampers and ductwork in unconditioned space must be

insulated or otherwise protected.

Whenever condensation might occur, it is recommended that a

plastic actuator cover (p/n, DAMPACTXXCOV) be used over the

actuator. This cover can help prevent condensation on the actuator

by helping to keep out ambient humidity. Insulation may be

applied over the cover to minimize heat transfer.

To install, place the cover over the actuator and seal it in place over

the surrounding insulation with duct tape on all four sides. Sealing

need not be perfect because there will be positive pressure inside

the cover. Do not mount the dampers with their actuators hanging

directly beneath the ductwork. It is best to mount the actuator

facing in either the three or nine o’clock position.

For specific duct types, follow the instructions below:

NOTE: All zone dampers and ductwork must be properly

supported according to local codes or SMACNA standards.

3

Loading...

Loading...