Bryant Evolution Connex SYSTXBBECW01-A, Evolution Connex SYSTXBBECN01-A, Evolution Connex SYSTXBBECC01-A Installation Instructions Manual

SYSTXBBECW01--A, SYSTXBBECN01--A

& SYSTXBBECC01--A

Evolutionr Connext Control

Installation Instructions

A12479

NOTE: Read the entire instruction manual before starting the installation.

The features and functions outlined in the Installation Instructions reflect Version 11

software. See the Evolution Connex product page on the HVACPartner.com

website or the Downloads section of the www.MyEvolutionConnex.Bryant.com

website for the latest software release.

US Patents: Carrier U.S. Pat No. 7,243,004, Carrier U.S. Pat No. 7,775,452, pointSETt U.S.

Pat No. 7,415,102

TABLE OF CONTENTS

PAGE

1.Safety Considerations 1.............................................

2.Introduction 1.....................................................

3.Quick Start 2......................................................

3.1.Set Time and Date 2............................................

3.1.1. Manually Adjust Time and Date 3............................

3.1.2. Setup Time Zone 4........................................

3.1.3. Enable Time Synchronization 4..............................

3.2. Set Dealer Information 5........................................

4.Installation 6......................................................

4.1.Overview 6...................................................

4.2.Check Equipment 6............................................

4.3.Location 7....................................................

4.3.1. Wall Control 7...........................................

4.3.2. Remote Room Sensors 8...................................

4.3.2.1.Remote Room Sensor Averaging 8...........................

4.3.3. Smart Sensors (for zoning applications) 9......................

4.4.Wiring Considerations 9.........................................

4.4.1. Shielded Wire 12.........................................

4.4.2. Damper Control Module 13.................................

TABLE OF CONTENTS (cont.)

PAGE

4.5.Mounting 13..................................................

4.5.1. Decorative Backplate 14...................................

4.6.Humidifier Connections 15......................................

4.6.1. Bypass Humidifier 15......................................

4.6.2. Fan Powered Humidifiers 15................................

5.Commissioning 16.................................................

5.1.Searching for Indoor Unit 16.....................................

5.2.Searching for Outdoor Unit 17....................................

5.3.Indoor Evaporator Selection 18...................................

5.4.Electric Heater Selection 18......................................

5.4.1. Hydronic Heat Application 19...............................

5.5.Searching SAM Module (If Applicable) 20..........................

5.6.Searching for Zones (If Applicable) 20.............................

5.7. Filter Type Selection 21.........................................

5.8.Humidifier Installation 21........................................

5.9. Ultraviolet Lights Installation 21..................................

5.10.Equipment Summary 21........................................

5.11.Airflow Verification Check 22....................................

5.12.Duct Assessment (zoning applications only) 22......................

TABLE OF CONTENTS (cont.)

PAGE

6.Service Menu 24...................................................

6.1.Equipment Summary 25.........................................

6.2. Installation 25.................................................

6.3.Set up 26.....................................................

6.3.1. Thermostat 27............................................

6.3.1.1.Auto Mode set up 28......................................

6.3.1.2.Heat/Cool Deadband 28...................................

6.3.1.3.Offsets 28..............................................

6.3.1.4.Reset factory defaults 29...................................

6.3.1.5.Scheduling Enable 29.....................................

6.3.1.6.Smart Recovery Enable 29.................................

6.3.2. Fan Coil 29..............................................

6.3.2.1.Airflow 30..............................................

6.3.2.2.Altitude 31.............................................

6.3.2.3.Fan Coil Dehumidification 31...............................

6.3.2.4.Fan Coil G--Terminal 32...................................

6.3.2.5.Fan Coil G--Terminal Alert 32...............................

6.3.2.6.Fan Coil G--Terminal Label 33..............................

TABLE OF CONTENTS (cont.)

PAGE

6.3.3. Furnace 34..............................................

6.3.3.1.Furnace Airflow 35.......................................

6.3.3.2.AC/HP Air Flow 35.......................................

6.3.3.3.Furnace Staging 36.......................................

6.3.3.4.Furnace Airflow Limits (modulating furnace only) 36............

6.3.3.5.Furnace Off Delay 37.....................................

6.3.3.6.Altitude 37.............................................

6.3.3.7.Furnace Dehumidifier Drain 38.............................

6.3.3.8.Furnace G Terminal 38....................................

6.3.3.9.Furnace G Terminal Alert 39...............................

6.3.3.10.Furnace G Terminal Alert Label 39.........................

6.3.4. AC/Heat Pump 40........................................

6.3.4.1.Latching 40.............................................

6.3.4.2.Cooling Lockout 41......................................

6.3.4.3.Defrost Interval 42.......................................

6.3.4.4.Low Ambient Cooling 42..................................

6.3.4.5.Quiet Shift 42...........................................

6.3.4.6.AC/Heat Pump RPM Max 42...............................

6.3.4.7.Defrost Fan Delay 43.....................................

TABLE OF CONTENTS (cont.)

PAGE

6.3.4.8.Brownout Disable 43.....................................

6.3.4.9.Low Air Multiplier 43.....................................

6.3.5. Heat Source Lockout 44....................................

6.3.6. Stages / Latch for Evolution V 44.............................

6.3.7. Zoning (If Applicable) 45...................................

6.3.7.1.Zoning Disable 45........................................

6.3.7.2.Zone Offsets 46..........................................

6.3.7.3.Zone Airflow Limits 46....................................

6.3.7.4.Duct Assessment Time 46..................................

6.3.8. Accessories 47...........................................

6.3.8.1.Filter 47................................................

6.3.8.2.Humidifier 48...........................................

6.3.8.3.Ultraviolet Lights 48......................................

6.3.8.4.Ventilator 48............................................

6.3.9. Utility Curtailment 49......................................

6.3.10. Hydronic Airflow 49......................................

6.4.Check out 50.................................................

6.4.1. Electric Heat 51..........................................

6.4.2. Furnace 51..............................................

TABLE OF CONTENTS (cont.)

PAGE

6.4.3. Hydronic 52.............................................

6.4.4. Air Conditioning 52.......................................

6.4.5. Heat Pump Heating 53.....................................

6.4.6. Heat Pump Cooling 54.....................................

6.4.7. Humidifier 54............................................

6.4.8. Ventilator 55.............................................

6.4.9. Zoning (If Applicable) 55...................................

6.4.9.1.Airflow Limits 55........................................

6.4.9.2.Damper/Sensor Check 55..................................

6.4.9.3.Zone Duct Assessment 56..................................

6.4.9.4.Sensor Type 56..........................................

6.5.Service Information 56..........................................

6.5.1. Advanced Diagnostics 57...................................

6.5.2. Fan Coil Status 57........................................

6.5.3. Furnace Status 58.........................................

6.5.4. AC Status 58.............................................

6.5.5. Heat Pump Status 59......................................

6.5.6. Zoning Status 59..........................................

6.5.7. Last 10 System Events 60...................................

TABLE OF CONTENTS (cont.)

PAGE

6.5.8. Run/Fault History 61......................................

6.5.9. Model/Serial Numbers 61...................................

6.5.10. Service Phone Number 62..................................

6.6.Refrigerant Charging (Evolution Extreme Only) 63....................

6.6.1. Charging 63.............................................

6.6.2. Pump down 64...........................................

6.6.3. Evacuation 64............................................

6.7.Refrigerant Charging Evolution V 65...............................

6.7.1. Charging 66.............................................

6.7.2. Pump down 67...........................................

6.7.3. Evacuation 67............................................

6.7.4. EXV Position 68..........................................

6.8.Dealer Logo 68................................................

6.9. Utility Event Setup 69..........................................

7.Wireless Setup 70..................................................

7.1.SYSTXBBECC01--A Model (only) 71..............................

7.2.SYSTXBBECW01--A Model (only) 74.............................

8.Appendix A -- Wiring Diagrams 79....................................

NOTE: See the Owner’s Manual for information regarding software upgrades.

1

1. Safety Considerations

Improper installation, adjustment, alteration, service, maintenance, or use can cause

explosion, fire, electrical shock, or other conditions which may cause death,

personal injury or property damage. Consult a qualified installer, service agency or

your distributor or branch for information or assistance. The qualified installer or

agency must use factory--authorized kits or accessories when modifying this HVAC

system. Refer to the individual instructions packaged with the kits or accessories

when installing.

Follow all safety codes. Wear safety glasses, protective clothing, and work gloves.

Have a fire extinguisher available. Read these instructions thoroughly and follow

all warnings and cautions included in literature and attached to the unit. Consult

local building codes and the current edition of the National Electrical Code (NEC)

NFPA 70. In Canada, refer to the current editions of the Canadian Electrical Code

CSA C22.1.

Recognize safety information. When you see this symbol

on the unit and in

instructions or manuals, be alert to the potential for personal injury. Understand the

signal words DANGER, WARNING,andCAUTION. These words are used with

the safety--alert symbol. DANGER identifies the most serious hazards, which will

result in severe personal injury or death. WARNING signifies hazards, which could

result in personal injury or death. CAUTION is used to identify unsafe practices,

which may result in minor personal injury or product and property damage. NOTE

is used to highlight suggestions which will result in enhanced installation,

reliability, or operation.

2. Introduction

The Evolutionr System consists of several intelligent communicating components

which include the Evolutionr Connext Control (or User Interface), variable speed

furnace or FE fan coil, and 2--stage AC or HP, which continually communicate with

each other via a four--wire connection called the ABCD bus. Commands, operating

2

conditions, and other data are passed continually between components over the

ABCD bus. The result is a new level of comfort, versatility, and simplicity.

All Evolutionr furnaces or fan coils are variable--speed and multi stage for

maximum flexibility, efficiency, and comfort. They support controlled ventilation,

humidification, dehumidification, and air quality control. Either an Evolutionr

(communicating), or a standard single--stage 24VAC controlled outdoor unit may be

used.

When using a Bryant HRV or ERV with a zoned system, the Evolutionr Zone

board allows connection of a Bryant HRV or ERV without the need for separate

wall control.

When using conventional single--stage outdoor units, the Evolution furnace or fan

coil provides the 24 volt signals needed to control them. Also, the Evolutionr

Network Interface Module (P/N SYSTXBBNIM01) allows connection of a Bryant

HRV or ERV without the need for separate wall control.

All system components are controlled through the wall mounted Evolution Connex

Control, which replaces the conventional thermostat and provides the homeowner

with a single wall control for all features of the system.

3. Quick Start

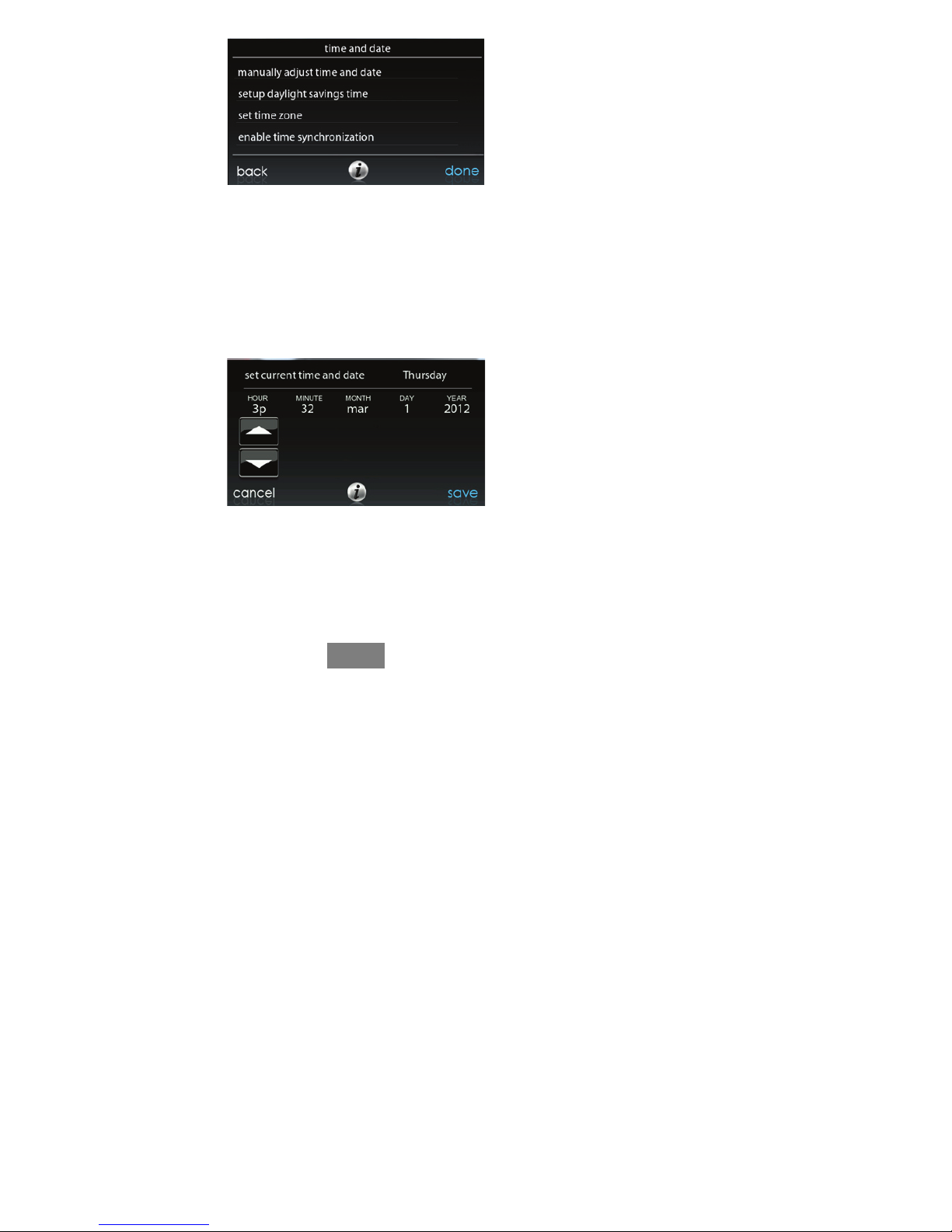

3.1. Set Time and Date

The time and date can either be set manually or can be synchronized with the web

server (only for Wi--Fi enabled units). From the main screen, touch MENU,onthe

bottom of the control. The TIME/DATE icon will bring up the time and date menu.

3

A14215

3.1.1. Manually Adjust Time and Date

d To s et th e HOUR, MINUTE, MONTH, DAY, or YEAR touch the feature

you wish to change.

d Use the Up (Y) and Down (B) buttons to make the appropriate changes.

d When you have completed all of the settings touch SAVE.

A14216

4

3.1.2. Setup Time Zone

The time zone can be selected by selecting the setup time zone from the menu.

Then select the time zone for the location. Time zones for both US and Canada are

included.

A14217

3.1.3. Enable Time Synchronization

After setting up the time zone, the time synchronization can then be done. Both

setting the time zone and enabling time synchronization must be done in order to

enable time synchronization.

5

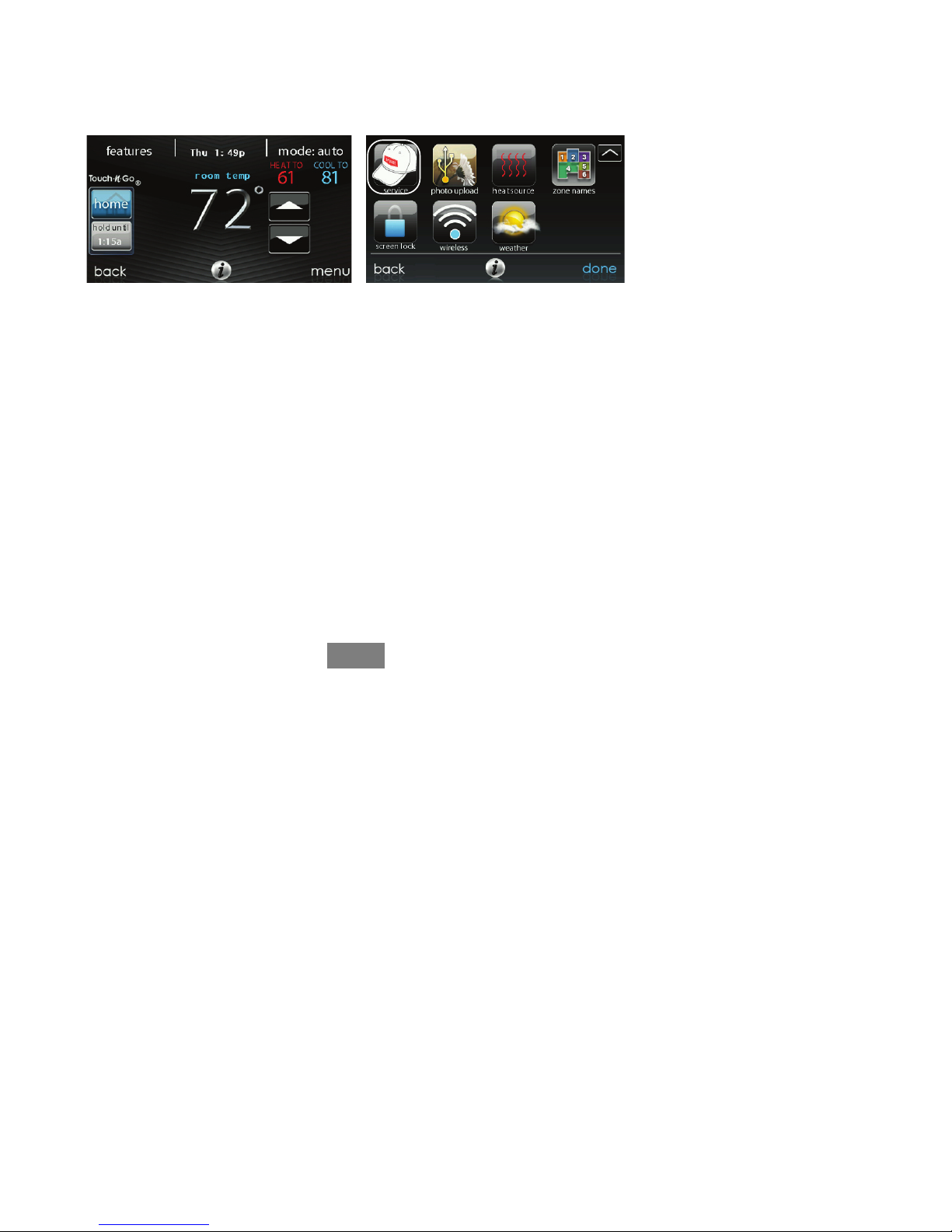

3.2. Set Dealer Information

From the main screen, touch MENU, on the bottom of the control. The SERVICE

icon allows you to upload your contact information into the Evolution Connex

Control.

A14274

S Format your contact information and logo (if applicable) using the PC/MAC

application, save it to a standard USB drive. See Section 6.7.

S Touch the SERVICE icon for about 10 seconds, then touch DEALER LOGO

UPLOAD.

S Place the USB drive into the USB port on the bottom of the Evolution Connex

Control and follow the on screen prompts.

S More detailed information can be found on HVACPartners.com under the

Product tab> Thermostats & Controls> SYSTXBBECW01> Documents &

Downloads> Marketing/Miscellaneous> Evolution Connex Control Dealer

Logo Application -- Instructions.

6

4. Installation

4.1. Overview

This instruction covers installation of the Evolutionr Connext Control and the

Evolutionr Wireless Access Point only. Physical installation instructions for the

indoor and outdoor equipment, and accessories are provided with each unit.

Setup, commissioning, operation, and troubleshooting of the Evolutionr System are

covered only in this installation instruction. It is the guide to connecting the system

components and commissioning the system once all physical components are

installed. Special screen prompts and start--up capabilities are provided in the

Evolution System to simplify and automate the initial commissioning of the system.

S Install the Evolution Connex Control according to this instruction.

S Install indoor unit, outdoor unit, and accessories according to their instructions.

S Wire complete system according to this instruction.

S Setup, commission, and operate system according to this instruction to assure a

smooth and trouble free start--up.

4.2. Check Equipment

Inspect equipment. File a claim with shipping company prior to installation if

shipment is damaged or incomplete.

7

4.3. Location

ELECTRICAL OPERATION HAZARD

Failure to follow this warning could result in personal injury

or death.

Disconnect power before routing control wiring.

!

WARNING

All wiring must comply with national, local, and state codes.

4.3.1. Wall Control

The Evolution Connex Control is the command center for the Evolution System. It

should be located where it is easily accessible and visible to the adult homeowner

or end user. For accurate temperature measurement, the following guidelines should

be followed:

The Evolution Connex Control and Remote Room Sensors SHOULD be mounted:

S Approximately 5--ft (1.5 m) from the floor.

S Close to or in a frequently used room, preferably on an inside partitioning wall.

S On a section of wall without pipes or ductwork.

The Evolution Connex Control and Remote Room Sensors SHOULD NOT be

mounted:

S Close to a window, on an outside wall, or next to a door leading to the outside.

S Exposed to direct light or heat from a lamp, sun, fireplace, or other

temperature--radiating objects which could cause a false reading.

8

S Close to or in direct airflow from supply registers.

S In areas with poor air circulation, such as behind a door or in an alcove.

4.3.2. Remote Room Sensors

A Remote Room Sensor can be used with the Evolution Connex Control to take the

place of the control’s internal temperature sensor. This allows the Evolution Connex

Control to be mounted in areas with less than optimal airflow (such as near an

exterior door, window or in a closet). The remote sensor can be wired to the

terminal block connectors labeled S1 and S2 at the control’s backplate, or the ZS1

and ZS1C connection at the Damper Control Module. In either case, the Evolution

Connex Control will automatically detect the Remote Room Sensor and ignore its

internal temperature sensor.

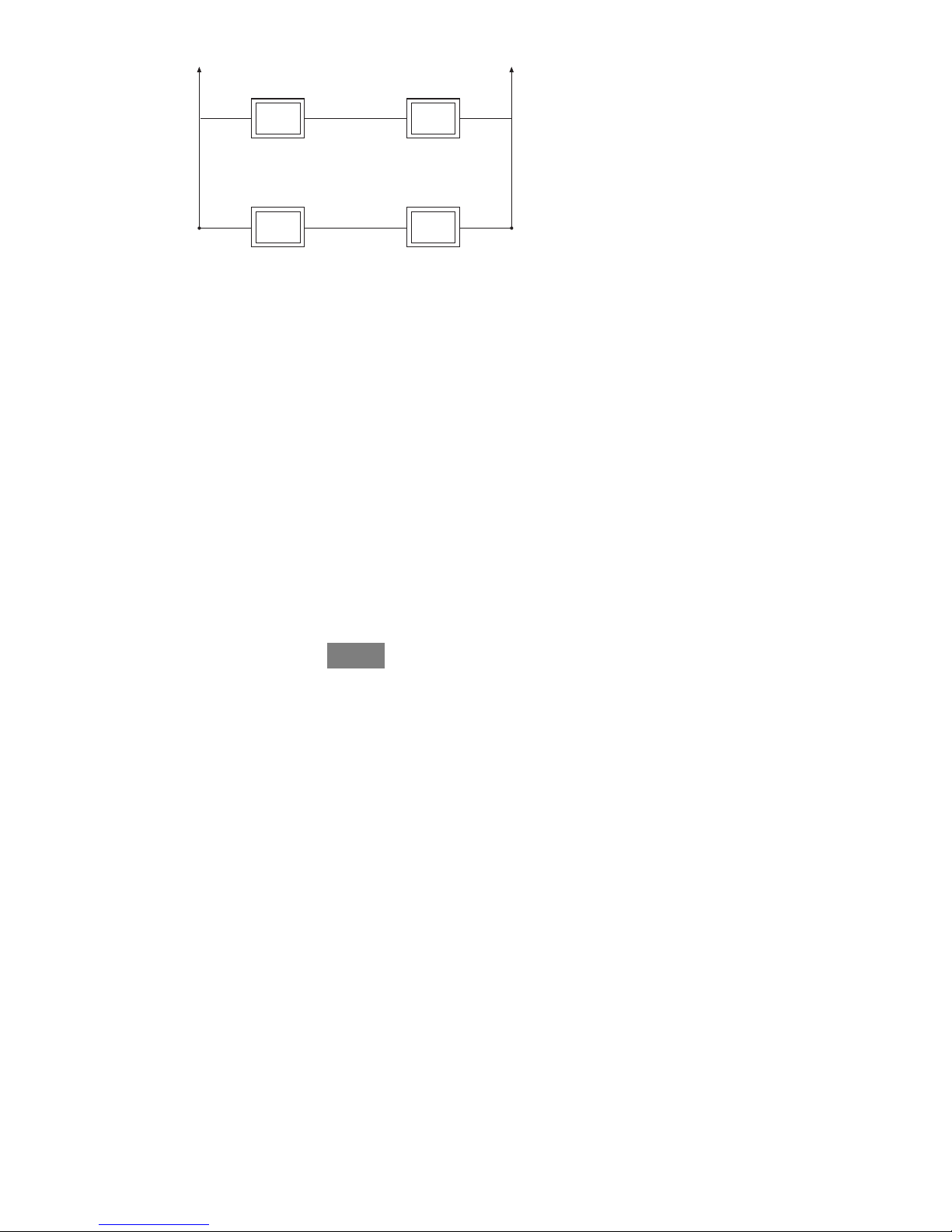

4.3.2.1. Remote Room Sensor Averaging

Typically, one remote sensor is used but, multiple sensors may be used and

averaged in some applications. Averaging requires a special series--parallel wiring

method with a specific number of sensors. See figure below. It is also important to

note the humidity sensor cannot be remotely located, so do not locate the Evolution

Control in an area where humidity sensing may not be accurate.

9

Sensor 1 Sensor 2

Sensor 3 Sensor 4

Damper Control

Module

ZS_

Damper Control

Module

ZS_C

A03233

4.3.3. Smart Sensors (for zoning applications)

Any zone may use a Smart Sensor. It provides a temperature display and buttons to

adjust the desired temperature in that zone only. It also displays outdoor

temperature and indoor humidity sensed at the control. Only one Smart Sensor may

be used per zone. They cannot be averaged like Remote Room Sensors. If a Smart

Sensor is used in a zone, a Remote Room Sensor may also be used in the same

zone. The Remote Room Sensor has priority over the Smart Sensor. The Smart

Sensor will display the Remote Room Sensor temperature.

NOTE: Smart Sensors must be addressed to identify which zone it will control. See

Smart Sensor Installation Instructions for details.

4.4. Wiring Considerations

Ordinary thermostat wire is recommended. Use 22 AWG or larger for normal

wiring applications. Continuous wire lengths over 100 ft. should use 20 AWG or

larger.

10

NOTE: ABCD bus wiring only requires a four--wire connection; however, it is

good practice to run thermostat cable having more than four wires in the event of a

damaged or broken wire during installation.

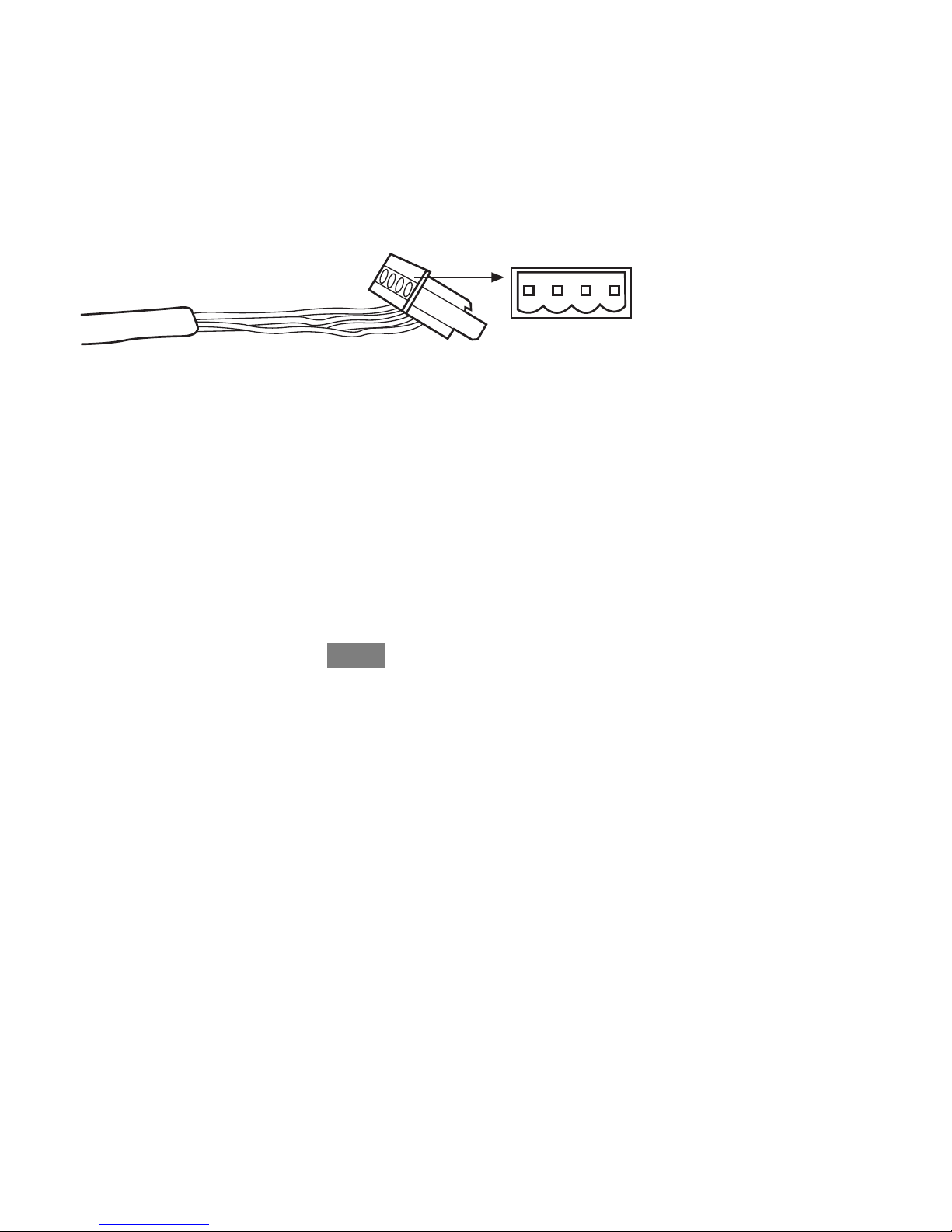

Each communicating device in the Evolutionr Zone System has a four--pin

connector labeled ABCD. It is recommended that the following color code be used

when wiring each device:

A — Green = Data A

B — Yellow = Data B

C — White = 24VAC (Com)

D — Red = 24VAC (Hot)

ABCD

A03193

It is not mandatory that the above color code be used, but each ABCD connector in

the system MUST be wired consistently.

NOTE: Some outdoor units provide their own low--voltage power source and do

not require the “C” (24VAC common) and “D” (24VAC power) connections. See

the outdoor unit installation instructions for more information.

11

ELECTRICAL OPERATION HAZARD

Failure to follow this warning could result in personal injury

or death.

Before installing, modifying, or servicing system, the main

electrical disconnect switch must be in the OFF position. There

may be more than 1 disconnect switch. Lock out and tag

switch with a suitable warning label.

!

WARNING

S Turn off all power to equipment.

S If an existing Evolutionr Control or other control is being replaced:

d Remove existing control from wall.

d Disconnect wires from existing control.

d Discard or recycle old control.

S NOTE: Mercury is a hazardous waste, if existing control contains any

mercury, it MUST be disposed of properly. The Evolution Connex

Control does not contain mercury.

S Select Evolution Control mounting plastic (backplate and decorative backplate

if desired).

S Route wires through large hole in mounting plastic. Level rear plastic against

wall (for aesthetic value only; Evolution Connex Control need not be level to

operate properly) and mark wall through two mounting holes.

S Drill two 3/16--in (4.8 mm) mounting holes in wall where marked.

S Secure mounting plastic to wall using two screws and anchors provided.

12

S Adjust length and routing of each wire to reach each wire entry on the

connector backplate. Strip 1/4--in (6.4 mm) of insulation from each wire.

S Match and connect thermostat wires to proper terminals on control backplate.

d See wiring diagrams in Appendix A.

S Push any excess wire into the wall. Seal hole in wall to prevent any air leaks.

Leaks can affect operation.

S Attach Evolution Control to the mounting plastic by lining up the plastic guides

on the back of the control with the opening on the mounting plastic and push

on.

S Perform installation of all other system equipment (i.e. dampers, humidifier,

ventilator, UV lights, etc.).

S Turn on power to equipment.

4.4.1. Shielded Wire

If the thermostat wiring will be located near or in parallel with high voltage wiring,

radio, TV or Ethernet wiring, then four conductor, twisted--pair, shielded cable can

be used to reduce or eliminate potential interference. The shield wire should be

connected to the C terminal, or ground, at the indoor unit. The shield wire should

NOT be connected to any terminal at the user interface. Connecting the shield to

ground at both ends can cause current loops in the shield, reducing shield

effectiveness.

Connect one pair of the two--pair (minimum) cable to the A and B communication

terminals, and another pair to the C and D terminals at both ends of the cable. The

shield wire should ONLY be connected at the indoor equipment ground or C

terminal. Note that some outdoor units only require the A and B connections. See

the outdoor unit installation instructions for more information.

13

4.4.2. Damper Control Module (zoning systems only)

All zoning wiring is run back to the Damper Control Module. Select a location near

the furnace or fan coil where wiring from the control, each Remote Room Sensor or

Smart Sensor, each damper actuator, and the equipment itself can come together

easily. The Damper Control Module is approved for indoor use only and should

never be installed with any of its components exposed to the elements. The Damper

Control Module (and zone dampers) may be installed in any area where the

temperature remains between --4_F to 158_F(--20_Cto70_C), and there is no

condensation. The cover must be installed to prevent damage from other sources.

Do not locate where it will be accessible to children. It may be mounted in either

vertical or horizontal position. Remember that wiring access is likely the most

important consideration.

PERSONAL INJURY HAZARD

Failure to follow this caution may result in personal injury.

To prevent possible damage to the Damper Control Module,

DO NOT mount on plenum, ductwork, or flush against

furnace or fan coil.

CAUTION

!

4.5. Mounting

First become familiar with all plastic assembly pieces shown on the following page.

The Evolution Connex Control will snap together with the backplate. A backplate is

supplied. Attach backplate using only a small hole in the wall allowing a four wire

connection to pass through. Mount the assembly to the backplate.

14

A12214

A12215

NOTE: Once Evolution Control is secured to wall with the backplate assembly

(snapped together), care must be taken not to bend or break the interlocking tabs

when removing.

4.5.1. Decorative Backplate

Sold separately, a thin decorative backplate is available to hide any marks/screw

holes left from the previous thermostat. This decorative backplate (or beauty ring)

is used by snapping it onto the back of the mounting plate before securing the plate

to the wall.

15

A12213

NOTE: Once the Evolution Connex Control is secured to wall with the backplate

assembly (snapped together), care must be taken not to bend or break the

interlocking tabs when removing.

4.6. Humidifier Connections

A 24VAC bypass or fan powered humidifier may be installed.

NOTE: Do NOT use a traditional humidistat to control humidifier operation. If a

humidifier is installed, let the Evolution Connex Control operate humidifier.

4.6.1. Bypass Humidifier

A bypass humidifier should be wired directly to the furnace or fan coil HUM and

24VAC COM terminals. The Evolution Control Connex will automatically energize

the HUM output during a call for humidification.

4.6.2. Fan Powered Humidifiers

Most fan powered humidifiers produce internal 24VAC in order to energize upon a

switch or contact closure. For this application, a 24VAC N.O. Isolation Relay

(DPST) MUST be used to prevent mixing the internal humidifier power with the

indoor equipment transformer. Applying 24VAC isolation relay coil to furnace or

fan coil HUM and COM terminals will allow the Evolution Connex Control to

16

automatically energize the HUM output during a call for humidification. The N.O.

relay contacts will be used to energize the humidifier. See fan powered humidifier

installation instructions for more details.

5. Commissioning

This section addresses initial power up (or commissioning) of a new Evolutionr

Connex Control. The control will communicate and identify all components in the

Evolutionr System. The following is a typical example for a communicating

variable--speed furnace / fan coil with a 2--stage air--conditioner / heat pump

(including Hybrid Heatr dual fuel system).

5.1. Searching for Indoor Unit

The Evolutionr Connex Control will light up and begin the commissioning process

by displaying “Searching for indoor unit”. This includes Evolutionr small

packaged products (SPP), with UI Version 8.0 software or later.

A12177

NOTE: If the Evolution--compatible indoor equipment (furnace or fan coil) cannot

be found, the control will display “Indoor unit not found”. This MUST be corrected

before the initial power up sequence can continue. Proceed to the next section,

Searching for outdoor unit. If it is not corrected, the Evolution Connex Control will

go into its DEMO operating mode.

17

A12178

5.2. Searching for Outdoor Unit

The Evolution Connex Control will then proceed to communicate with the outdoor

unit by displaying “Searching for outdoor unit”. This includes Evolutionr small

packaged products (SPP), with UI Version 8.0 software or later.

NOTE: If the outdoor unit cannot be found, the control will display “Outdoor unit

not found”.

S Select the appropriate unit installed; then, touch NEXT.

d AC1Stage – 1--stage air conditioner

d *AC2Stage – 2--stage air conditioner

d *HP1Stage – 1--stage heat pump

d *HP2Stage – 2--stage heat pump

d None – No outdoor unit installed

NOTE: For small packaged products (SPP), the selection screen is not needed and

will not appear.

S The installer will first be instructed to select the appropriate size of the outdoor

unit; then, touch SELECT.

*Network Interference Module (NIM) may be required for these selections to be displayed.

18

A13118

5.3. Indoor Evaporator Selection

If a furnace is installed with a variable capacity heat pump or an Evolution V heat

pump, a screen will appear to select the installed indoor evaporator coil. This

selection is used to adequately calculate the refrigerant charge required while in the

heat pump charging screens under the Heat Pump Checkout menu (See Pg. 54).

Select “other” for non--Bryant evaporators.

5.4. Electric Heater Selection

If the indoor equipment is a fan coil, the control will display “Searching for heater”

until one is found. If the electric heater is not self--identifying, the select heater

screen will appear. Touch the appropriate heater size; then, touch SELECT.

19

A13119

5.4.1. Hydronic Heat Application

The Evolution Connex Control supports 2 types of Hydronic Heat applications:

1. Hot water coil in combination with an FE fan coil and heat pump, or hot

water coil as sole heat source with an FE fan coil.

2. Non--zoned FE fan coil combined with radiant hot water heat.

In either application, a Hydronic Heat kit should be installed in place of an electric

heater. See FE fan coil Product Data for accessory part number. The system will

self--identify that hydronic heat has been installed during electric heater selection.

The system will treat the hot water coil as either auxiliary heat in a heat pump

application, or the sole heat source. Setup options for Hydronic Heat applications

are described in the setup section of this instruction.

20

A13117

5.5. Searching for SAM Module (If Applicable)

“Searching for SAM Module” will appear on the screen to determine if a System

Access Module, used for home automation only, is connected to the system.

The SYSTXBBSAM01 is not compatible with this control. The compatible modules

are SYSTXBBRCT01 and SYSTXBBRWF01. The SAM is used for home

automation purposes. The Evolution Connex control must have at least Version 8 or

newer to be compatible with the SAM.

NOTE: For more information regarding the SAM Module, reference the latest

version of the application specification entitled “Carrier Communicating HVAC

System” (Version 2 or later), available on HVACpartners.com, or the System

Access Module Installation Instructions.

5.6. Searching for Zones (If Applicable)

This function is not available with the 986T furnace.

“Zoning -- Searching” will appear on the screen to determine if any zones are

present. The screen will show Zone 1, Zone 2, etc. and indicate all zones having

either a Remote Room Sensor, or smart sensors associated with them. If the system

contains smart sensors, they must be assigned a zone number before continuing.

See the Smart Sensor Installation Instructions on how to assign Smart Sensors to

their respective zones. After each zone has been identified, touch NEXT.

Loading...

Loading...