Page 1

S E P / 1 0 / 2 0 0 8 / W E D 1 1 : 3 2

UTC TECH PUB

F A X N o , 3 1 7 2 4 0 5 6 6 2

348

Installation Instructions

G AS-FIRED HORIZONTAL FURN ACE

Series E

39348D6 Rev 1

7/15/68 ^

The Bjjant Model 348 gas “fired forced air

horizontal furnace is certified by the Ameri

can Gas Association for attic installation .

Install in accordance with the requirements

of the local utility or authority having juris

diction.

The installer is referred to the American

Standard "Installation of Gas Appliances and

Gas'Piping, ASA Z21,30-1964, as a sound

and practical guide. ' . _ __

INSPECTION

—ühe .furnace ..is- ■ shippeiLwith -GOnt-rol-s -fully-

assembled. Note that natural gas units are

equipped with a combination regulator and

main manual shut-Off. As assembled, the

valve handle is on the underneath side. When

,1 handle is parallel with direction of gas floWj

the valve is open; when handle is at right

angles to direction of gas flow, the valve is

closed.

GAS CONTROL OPTIONS

D4 - Natural Gas

Bryant Gas Control Valve

Bryant Automatic Pilot

Combination Regulator, Main and

“ ■

.......

Pii ot ' Ga s S upplyV'àlvé s

D5 - Natural Gas - 10G% Shut-off

.....

-^'BryanrGas Control“Wiye^^''^—--------------------------

Thermocouple Automatic ^Piìot

-

-----

Pilot Gas Valve . \

Gas Regulator

Main Gas Shut-off Valve -

D2 - Propane Gas - 100% Shut-off

Bryant Gas Control Valve

Thermocouple Automatic Pilot /

Pilot Gas Valve

Main Gas Shut-off Valve

..- -

----------

Page 2

S E P / 1 0 / 2 0 0 8 / W E D 1 1 : 3 3

UTC TECH PUB

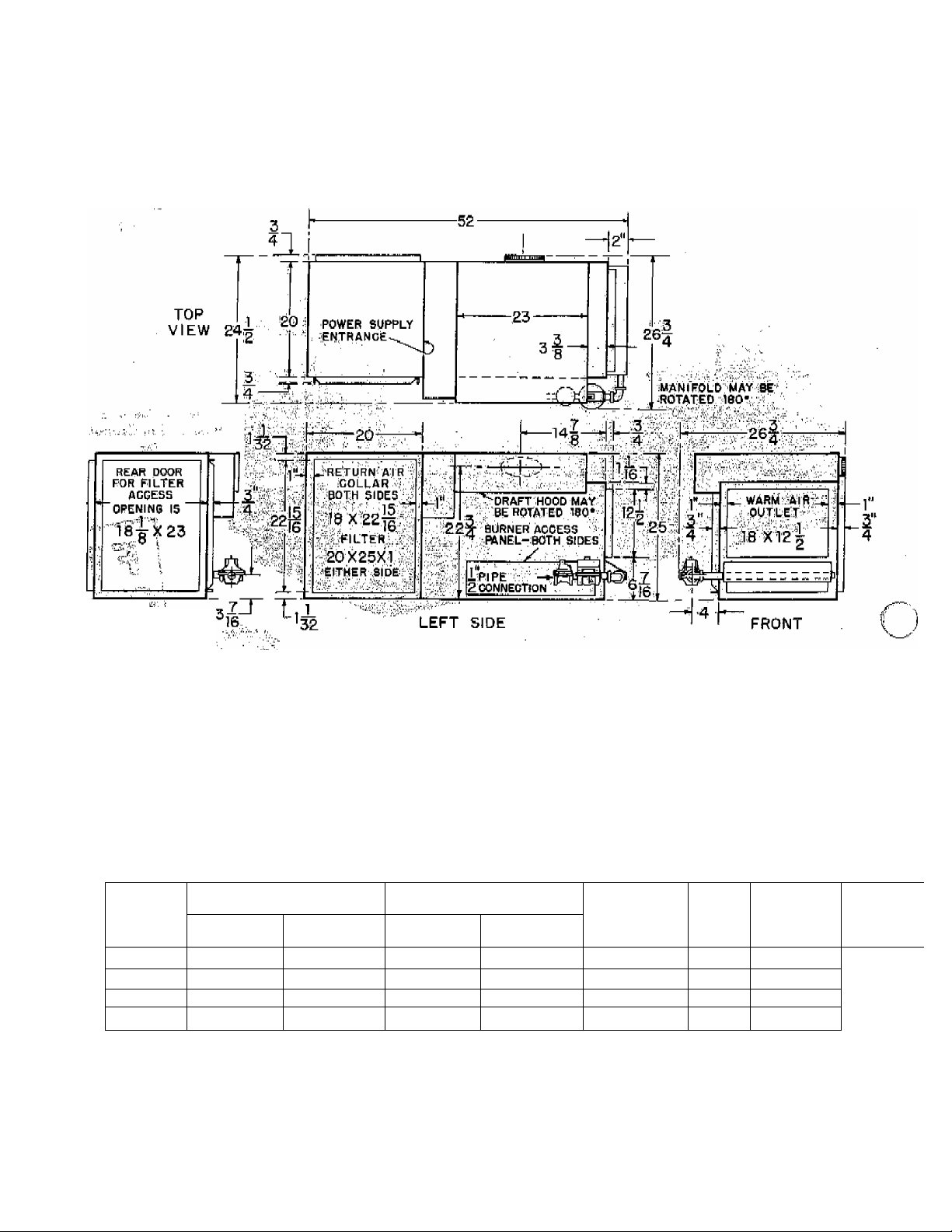

DIMENSIONS

3 1 7 2 4 0 5 6 6 2

..

w '-ilii. 'ii.' i:i

i-

REAR

■■ All-siK;es have the same dimensions.

:! ’iiOTvEii' Flue is 5" for sizes SO & ilDO; ■ ^ ■

;. v - Flue is 6" for size 125 & 145. ^ ■

R A TIN OS AN D CAPACIT | E 5

-l-f-l

-1-

pW,-, ,

AGA RATINGS* BTU/HR

MODEL

NO;

”8Ti:a^ “^^647000^

. 100-348 I0i);000 ' j

42S-348- _..435_000^-^

145^348

*Pot elevations Up to 20Q0 ft; fori higher altitudes, reduce mtingh 4% ier:e&ch;;.lGQD^ft. above sea level.

tOn size l45 permanent type filter is supplied as standard equipment. :‘See note cotidaming ait flow under

Table II, this iristfucUon. . /'■

INPUT OUTPUT' ,

. :80;000 ■ 1/2 1/2

■—iOOjDOO,-:-

145,000 , 116; 000 1/2

GAS CONNECTION SIZE :

NAT. PROP.

"■ 172 . -

------

iy_2—. .

■—^/2'

- ¡1/2 ¡.

BUilT-lN ^

FILTER

^2tT^':25jt;T^"

20 X 25 X 1

-20 3t 1-^ .i‘ .

^20 X 25 -x^il T:

FLUE

SIZE

■^■'5

5 175

.:■■■ 6

SHIPPING

---

.......

APPROX.

WT.

rers”

185 .—

185

■ 34S

- 2 -

Page 3

SE P / 10 /2 0 08 / WE D 11 : 33 AM UT C T E CH PU B

F AX N o . 3 1 7 2 40 56 6 2

P . 0 03 / 00 8

SPECIAL LOCATING INFORMATION

Also see the following section on mounting

the unit.

For special cases, refer to paragraphs 3 .4.2

and 3.4.3, American Standard "Installation of

Gas Appliances and Gas Piping, " ASA Z21,30

-1964.

1. Do not install unit in closet or alcove,

2. A,G.A, certified clearances from com

bustible material:

Attic Furnace

From Draft Diverter 6" *

From Casing Surface Line Contact Allowed

From Base > Ú"

*When the furnace is mstalled in ^space large

in comparison to the furnace, reduced clear

ances are permissible when combustibles in

question are adequately protected.. ^

3" clearance permitted when 28 gauge sheet

damper is in the full heat or full cool position

5 . The unit should be located centrally with

respect to the air distribution system .Choose

a location that will be as near the chimney as

possible.

6 . For flexibility in selecting location of unit,

the draft hood may be rotated 180 degrees.

The manifold may also be rotated 180 de

grees . The controls may then be on either

side of the furnace. They may also be in the

vertical plane “ leading up or down from the

manifold.

7. The wiring box is mounted externally

alongside the draft hood. The wiring box is

designed for field mounting on either side of

the unit without breaking wiring connections .

MOUNTING THE UNIT

The unit may be placed directly on a combus-

.■tible;.;^ clearance requirements listed

should be observed.

O

to '.'the cpihbusLible "^materialxíánd ; coyjsrsíiail

cómbus tibie;, .Wi'thih-;J5

Lë''''îhatéri^D' '■■is''"'àpplied' ■tb'’"the

material::and:;;covers all surfaces within 6".

Other methods of protecting the combustible

,materiail'.a37e!:.':,ide ,in-.,T®ë''!^Ô,''Îlme

'èÿnl;Stanfe of Gas Appliances

and Gras P.i;ping, " AsA Z2i .30-1964*

3 . Service Access; Leave as much clearance

ad^posd'ible for service. The following is

considered mihimum:' ■

■■ '25 ■’':'at filter ■ end 'to replace.;filtdr

!' 6" at top for cleaning heat exchanger

4. Location with respect to codling equipment:

pf ,th,e cooling .unit to; avoid condensation in

d'^e; furnace, beating lelement.. -When ..installed

■^arallel.^yitb'.a poping,unit,^da.mpcrs or,other

meani^ used to control the flow of air mast be

adequate ^ tp. prevenf chilled air from entering

the. furnace . If the, dampers are manually

operated, they must be equipped with means

to prevent operation of either unit unless the

............... ■

...

.................

rsf'oteG'-'fhb^^^'^^^ 348'Hs A ;G.A. certified for

,painf,;d2r';iii:ie A^fth C'ombustible mater

ial' abdye : ei^pept "drait hood must

, ,be ;at .least anyvcombusti^^^ material.

.Mpreifha^ dr ; line contact is not ap

proved.- ;If >an installation Gonflicts with

A*.G.A< ^PP^^'oval, consult .local codes for

protective insulation requirements. See

Ameri,cap Ap“

plianc.ea ;and Gas Fiping, ASA^Z2^

The draft hood may be reversed, The mani

fold may be reversed . The control's may be

horizontal or vertical. See page 4.

If the unit is mounted so as to require shims

^(uneven, floor ox-craWl .space.).it must be .S;tip-_

porfed as shown in Figtire A. "When unit Is

suspended, the same kind of supjiort is re -

_quire.d.,_Riy^nt,.s.upplles..asj0pfipnaiivd.quipb\bnt_.

a suspension kit hs picturedthTi^rd B. The

_two __ chahhels, should' be plhce d 'Under the :iur_-

nace as ■ shown in The .¡Support for

the blower comparftheht "Is fastened the

channel and theh bent abound htid fastened to

the other end of the ciiaiiiiel shoWii in Fig

ure C . This in effect mabes a support erfending out under the blower, compartihenb. Note:

the hanging rods for ttie suspension bars musi

be supplied by the installer. See page 5.

- 3 ^

348

Page 4

S E P / 1 0 / 2 0 0 8 / W E D 1 1 : 3 4 A M

UTC TECH PUB

1 , 3 1 7 2 4 0 5 6 6 2

P , 0 0 4 / 0 0 8

All i^electrical opi}neptions,,ar,e: ■.№

'he vh,';pérhi'ahent.i'liÿe.l:',iusèd;'èlectric'Circuit.P,;;

.....'.in'âiiüal;''7.S.witch ShòuÌ'd'.'he 'proyided.for this''..■ ' -:.".'/‘■■. a■

circuit. ^Üdnhêci-' iurh^^ 1X5 volt, ' 613

^;CÙrr e.nt .-power- ■ ■

.!p.üpplÿ;..,:F;or-Xuihia'ce^'';With';'-3j^.4''№

r: 230'Volt poorer süpply iis rëcDhiihè^ ,

¿The héat anticipatói: du.:thë№ogtat should Switch:

:'^'set"at'0,'8":àmpâ. ..'■.. /,.■ ^ . '.../.î::' „ , , i-.

I/-''

■■■■ "-■■ V. .■..., ' ■■’■■■ Thermodisc Auxiliary-ifLimifSwltch -

^T’U ^ Vu ^ ^ ■ _i-L __l"i J /'-L

The room tliermostat should be located where;

..

-it ■■ will-be in,,the- imturalOirdulatin^ path

room air : : Avoid locatiop^^^^ :therriip- ; : ; : /Limit Coutrdl ^ -i This control functions to shut

i .,i-.

£ ' ""qS, -the " gas :.ahd -cner^ze .the hlpwer motor if

¿drafta: frfapi; Windows, idpors.. or oth^r ippeh-:^ the fartiade hêchmhR teO.

; Xngs leading th

/Vhdrhónth,Xrom':^^i^rip ,prrègistars; or.

; to exposuró^y/hefè ih p',,,pa turai” òr

the air is cut off .such ,as behind doors, ahoyp

'br'helow mantels^ ;shelves/,btcr i ,'.:^,, , . ,,

The thermostat . should not bp exposed to heat

from , npapby . radiatb firèpïaces ; radios,

.¿kmps£.';:rays :.pf the :sh^ 'dier'“

miostat ;be . vm wail cbintainiiig pipes

0T. warm air ddhts,' 'or a fide or vënt which

__

____

_________

.'-'.V'. .^V. 'I ..'vr.o..Î. pvv. . .

còuld:, affèdtv its Ó,pe,ia4^^^^ It :fEom

'proï>ef |tSe' '-xOpm-' riempe rature .

Ànÿ.lioie in :^e'.plas^^^ which

thèritiûstat

:' COhITROLS;

N on -adjjuë table

' ^,e''¿.ecbhin;iende.d ^ of Checking the

-lini'it ' Vonthoi -isf .to '.^adda-iiy biôç;h“oÿ ■'the'-he-turh'':ai,r.,'aîtè,ï';^ 'lurna'cd'Ìia;s h'e.cn òpeXàtiiig

■for ..^n-pehipd'.of'àtTeastX 'rnihutéd .xAs''bqoÌi

a|; ‘the- ,Ximid;,ha'à.';proveh , 'the Tetdrh;'.aih

opening 'shòuld''hd uiiblochë'd 'to perdait normal

air circulation . Ëÿ dsiiig ibid hiethod tb-d^

the'"'iihiit control,''lt-';ca.n^ be bs'tdMdh'éd 'that

the limit is functioning properly and wall "fdil

safe" in case of motor failure .

_____

o

_

o

- 4 -

Page 5

S E P / 1 0 / 2 0 0 8 / W E D 1 1 : 3 4

UTC TECH PUB

1 , 3 1 7 2 4 0 5 6 6 2

P , 0 0 5 / 0 0 8

Controls L(contmuod) ‘ ' ■

t ^ \ . I'

The 348 Series E furnace is eqüípí|péd"^ án

adjustable fan'coiitrol switch/This confrdi^ i^

a single pole, single thrOw'íine voltage switch

actuated :by a heat motor.

The fan control adjusting lever is factory-set

at the center position and should give opti

mum . ,p^iformane^ ,íil, most,.,iiistallations..

dr' “^ere

:■ find'^vpiiige,, ■ as: cpnsid^

low báté¿l, output, it may be necessary to

increase " ol-tipap th^/.blower re -

maiptS Oh . Tor lOh^ operation, move

. adjh^iiig',le^

-■ ppsitip:^/;::^

switch'/^^^/^^ contact sooner pnd. ta^ea ^

ih^irhum time .to breaJk contact.;

“blower, operation, niov e: tlie lever .in Üié bp '

posite'■■direction.

Automatic Pilot r- Check the 'shut-off feature

of the automatic'pilot as follows; '

1. Spt the robin therimostat bn call for heat.

o

Bryant Qàs' 'Control Valve - if/not already

biiecked wjhéii lightitig the ^ ' checik;;

the' proper" operation of this Valve l^y moving

the room therinosm pointer abbye and

room temperature and- observe that the main

burners light on call foi heat and go off when

the pointer is moved below thé rooîn temper

ature.

'2. Close maiu manual gas shut-off valve and

the màhùàl pilot shut-off valve b ■

3 i pilot must break the eléctric circuit withiii

three ::m shut off. In the

case of tiië 100% shut-off contrcil, listen for

a click in the automatic shut-off valve. The

24rvolt circuit is not interrupted but the 100%'

shut-off valve should click within 3 minutés . \

- 5 -

348

Page 6

S E P / 1 0 / 2 0 0 8 / W E D 1 1 : 3 5 A M

UTC TECH PUB

Contrais (continued)

$lbwex'-ÁdjugFment - K blower speed is

not correct; the fan control switch may not

operate correctly. If an adjustable fan switch

is used with the unit, do not attempt to adjust

this switch iuntil the blower performance has

been checked ,;as described below,.

The temperature rise across the furnace

should be between 70F and 1Û0F . The blowers

are set .at, the factory to give approximately

85F temperature rise. Check this setting by

insertipg^. one thermometer in the return air

duct at the unit and another thermometer in

the plenum. Be sure the thermometer does

not ';see'^ the heat exchanger. The effect of

ráchaut heat will giv-e false readings. Allo^

:the unit to .Operate until the readipg^ on both :

di^rmòipetè have stabüii^çd. If the terobor.^fure ipise is too little or too greatf aidju^

blowerias described under section on blowers.

tdhder hp should the tempe'ra-^

'■ ture rise be allowed to exceed l'QQF'^.;.i:^j;;:i3::;c/^^^^

■ FI-LTEfîS

■ Qhe':x."'e 1 ■;-lithr0W'"a^ayi.l^p,^;iisu ^'■■ii

witii sizehhnd..125 permanent

f'iiter'/is-hu^^lie -the

F A X N0, 3 1 7 2 4 0 5 6 6 2

Color Code for .Speed

Common (white) ....

Hi Speed (black) ....

Med Speed (blue) ....

Med Lo Speed (yellow) - .

Lo Speed (red) .....

Important: It should be noted that air delivery

rate will vary with applied voltage at the

blower motor. If there ie any doubt about the

value of fluctuation of the supply voltage,

consult your local electric utility.

Belt Ptive

■The >125 and l4S'V3izes bel-t ,;drive units are

e^uii^ed'.w^ motors, wired at

the.factory for a 220rVOit power :Supply,. They

may be re-wif%dAih the

field for 115-volt

operation. See .wiping *

;.;. Tde;/id^ .at the factory

;is ;2^i>^2 ;:thr:h;s will provide

4pproximately:;i2i6p a

" ES:th;tic: ';p2:ess,ur^ .At thls setting

:the;^ , heat ex -

■■,cha:ngex-;ih.;''7,3,:7degrees{'F 1,25 and

. 85 idegrees F for/f^^

#C tap

#1 tap

#2 tap

#3 tap

#4 tap

Adjüstrn ',QÏ,'Biôwe r ,'Sp ëéjd^'” .7

To change "motor a pe e d: ;fap s > ' Tem òvè'the ■ mo ^ "

, ■, tor tap úleád, 'and relocate,; it,;¡Oñ;^;^ :¿,,

/ terminal' on ttie plugTn terminal block/speed

selector located in the.blower compártmeñt.'

■■ .See table '■ '''' ' '

■ ^ Cauiion: , When iádjusúiig 'iEi“"blowëiFTupeed'

'{ make ceÍTáin thoTeippera ri^e,acrpes the

ÿ heat /exchun^èr ;doés not {éxcoed'^ât .sp-^ified

:■ / On -the'■ratiiig^late.'""''^'''’'™■■■■

.Hêqt'ing type '*w* ■

Conpçc.t niotor Teod:

Size HP /;;■ '{//. ,.

80

1/8 y,eUow tap'3' ■■

80 ;

1/4:

100

1ÒÓ ■

125 i

145', 1/3

348

bláclcTáp 1

■1/8,1

„, f,., -Ï—fi——~—^—i”

i/3,

1/3^

■ M ëH'tJ irg/.C5 51 i rïg tTP

. iCóhn&ct m^tor lead; '

Heatjng

red 'tap 4 ' 'black'f’ap 1

,:"E. "

"'yellow tap 3 ' black tap 1

yelloiv tai¿) '3 black tap 1

biuie t^p 2 '

Cooling

Ì'. ■

■■ ■■■ '■

black tap 1

.If it; ^0 lehaiige /the' air delivery

rate:;,', .islihplyvdodseh'.:..!^ .iS.crew with an

' Alien ''Wi)^ehcH'i /the/''adjustable haK of

th.e-:Thi^l®WT to doge and counterc/io cJbivis e' /t9.; ;o;peh .■ ■ (/Jnc e ,pp sitione d, , .tighten

;::iihe'■ sc'reW''Oh'the'■ Tlat ; ■;a;,,

i l V U (M5TALL1HG :

The.furnace is factory agsembled. The order

_ .to hd: idUdwc.d in .setting ;thp. unit_iri plac.e^^^

making all hecessaa^ e onnedH (gas, elec trie,/VentihgA/ductwork, ^,e ie left to the

_h.ie Cretion /of the installeri. Recommendations

listed: on/ of this instruction

'SilpUld. he followed.. Connection to .gas{main________

supply ik"made,wi^ .supplied 1^ in

staller:..,. Wiring; .shpuld he . acc omplished ip

accordance with the applicable wiring dia

gram.. ' ■ .. '

„■■/"/ /.; t 1

B-cmember to check for correct wiring, on fhp

multi “tapped motors... in making up the low

voltage circuit on 100% shut-off controls, the

thermocouple pilot and automatic shut-off

- 6 -

Page 7

S E P / 1 0 / 2 0 0 8 / W E D 1 1 : 3 5

UTC TECH PUB

F A X N o , 3 1 7 2 4 0 5 6 6 2

valve are independent of the 24-volt circuit.

The ehippitig bolt should be removed from the

belt drive blower in accordance with label in

structions on the blower.

Remove the burner shipping wire after the

furnace has been set in place. It is recom

mended that flexible fireproof connections be

made from the unit to ductwork. Insulate all

ducts in attics and other cold areas .

CLEANING THE FURNACE

Burner shipping wire should have been re

moved when furnace was first installed.

1. Shut off all electric and gas supply to the

furnace.

2. Remove burner access panel (2 screws).

There is a panel on each side; either or both

may be used ,

3. The burner with pilot is located on either

the left or right end of the manifold.

After removing either or both..side access

panels* the burners may be removed in any

order with the burner with pilot being re

moved first or last.

a. Burners that dp not have the pilot at^

tached;

a-1. Lift upward out of back holding

slot-

a ^2. Piish burner to rear to disengage

/■ X\7f ^ ■

' ' ";a-3'.''Withdm through access

................. '^'opening.

b . Burners that have, the pilot attached:

_7A.A7b.-T < Цíacdhh.¿cf:

. ■ ; by removing wire nuts, Tbis ap-

' A fplies only fo Biyaht pilot. -.

—; "'-bT:2'i DiscohneC,t“^ilot■^gas■-^:Supply--m^

7' /y'aT,the .pilot valve

' ' . ,w,

.........

AA5_'

b“3. Straighten all tubing disconnected

in (2) above so that it sticks

strai^t out towards the manifold

end of furnace,

b-4. Lift burner upwards out of hold

ing slot* disengage from mani

fold spud, and then rotate the

burner with attached pilot and tub“

ing So that the pilot is on the top

side.

b“5. Remove entire assembly through

the access opening.

4. Disconnect vent pipe at draft hood.

5. Remove draft hood assembly.

6. Remove flue baffles from heat exchanger.

7. Use a flexible handled steel cleaning brush

to loosen scale and soot. Remove these

scrapings from bottom of combustion cbam-

ber.

8. ,Re-assemble furnace.

CARE AND MAINTENANCE

Care of Blowers: Motors on the belt drive

blowers are provided with oil wells, and

should be oiled at least twice a year with a

good grade of SAE 30 oil, The motors on the

direct drive blowers are sealed units and do

not require the addition of oil.

Blower. beaH semiApeirmhnentiylufei^^ :

cated'. ;;A^^ is normally good for

3 to .S .years-.--'-TOien necessary to add lubri

cant, use ''Culf Plastic E".

Filters should he examined f re -

■“qU!^ntly“^pr^,elpgging-^due to dirt-.---The dispo;^ —

able filters' ¡should'be replaced when they become ;dji:ty;,i;.pem type filters may be

-eleaned-using"-oiea'r-'Water-;-eoat-"the^-^^^

Water 3 olublf;; 6 il afte r cleaning. '

—■ Biscohhkit-pilotvbiee

■ 'Biyant valve.

. ■

......

On ip0%5 ilw-obf Apote

- disconnect thermocouple at auto

matic shut-off valve.

Cleaning"^: T^e heat should be ex

amined periodically to see if. th^3;e has been

an laccumuiatldn of rust, soot* etc . Clean as

required.

- 7 -

348

Page 8

S E P / 1 0 / 2 0 0 8 / W E D 1 1 : 3 6

UTC TECH PUB

F A X N o , 3 1 7 2 4 0 6 6 6 2

HEATING ONLY with ON-OFF FAN - Model 885 Thermostat P/N 34427D33 OR Thermostat P/N 34427D35 with

Sub-base P/N 34427D36*

Loading...

Loading...