Page 1

installation and

start-up instructions

PROGRAMMABLE DUAL FUEL THERMOSTAT

NOTE: Read the entire instruction manual before starting the

installation.

SAFETY CONSIDERATIONS

Read and follow manufacturer instructions carefully. Follow all

local electrical codes during installation. All wiring must conform

to local and national electrical codes. Improper wiring or installation may damage thermostat.

Recognize safety information. This is the safety-alert symbol

When you see this symbol on the equipment and in the instruction

manual, be alert to the potential for personal injury.

Understand the signal words DANGER, WARNING, and CAUTION. These words are used with the safety-alert symbol. DANGER identifies the most serious hazards which will result in severe

personal injury or death. WARNING signifies a hazard which

could result in personal injury or death. CAUTION is used to

identify unsafe practices which would result in minor personal

injury or product and property damage.

TSTAT

Cancels: New II TSTAT-0-6

6-95

®

.

A95221

Bryant’s 7-day programmable dual fuel thermostat is a wall-

INTRODUCTION

mounted, low-voltage thermostat which provides proper control of

a heat pump (HP) and furnace combination without using a

HP/furnace interface kit. Separate heating and cooling setpoints,

plus auto changeover allow setback programming for maximum

energy savings. Up to 4 time/temperature settings per 24 hour

period for 7 independent days may be programmed. Batteries are

not required; during a power interruption, the internal memory

stores programs for an unlimited time and the clock continues to

run for at least 72 hrs.

SYSTEM CONSIDERATIONS

The dual fuel thermostat is designed to be used only in HP/furnace

installations. It replaces a conventional 2-stage HP thermostat and

a HP/furnace interface kit. An outdoor temperature sensor, Part

No. TSTATBBSEN01 MUST be used with this thermostat. It is

not supplied with thermostat.

CAUTION: If HP is not already equipped with a highpressure switch, one must be added for dual fuel applications. It protects HP from overpressure which would

occur if a failure resulted in both HP and furnace

operating at same time. Kit No. KSAHI0201HPS includes required switch and instructions for its proper

installation.

A HP/furnace installation has several special requirements. Foremost is that furnace and HP must not be allowed to operate at same

time, except during HP defrost. A second is to have furnace

complete a heating cycle once it is turned on. A third is the need

to have HP not operate at all when outdoor temperatures are below

a certain value. Finally, HP and furnace must work together

properly to provide an efficient and comfortable defrost. These

requirements are addressed by the dual fuel thermostat itself and

an interface kit is NOT required.

Fig. 1—Bryant Programmable Thermostat

HEIGHT (IN.) WIDTH (IN.) DEPTH (IN.)

7-1/2 4-1/4 1-3/8

APPLICATION

The dual fuel thermostat is designedforthefollowing applications:

1-stage cool, 2-stage heat: 1-speed HP with 1-stage furnace

1-stage cool, 3-stage heat: 1-speed HP with 2-stage furnace

2-stage cool, 3-stage heat: 2-speed HP with 1-stage furnace

2-stage cool, 4-stage heat: 2-speed HP with 2-stage furnace*

*This combination must use furnace algorithm to control furnace

staging.

As outdoor temperature decreases, heat loss increases and HP

capacity decreases. There is a temperature below which HP will

not be able to "keep up" and furnace will be required to maintain

temperature. This is the thermal balance point.

There is also an economic balance point, determined by relative

costs of fuel and electricity, below which the furnace is the most

cost effective and above which the HP is the most cost effective.

Finally there may be a comfort balance point below which leaving

air temperature of HP is not comfortable, even if HP has sufficient

capacity to keep structure warm.

Any of these balance points may be the determining factor in the

selection of an outdoor temperature below which HP will be turned

off and only furnace allowed to operate. This balance point

temperature is entered into thermostat by installer. Outdoor temperatures from 15˚F to 55˚F may be selected. Instructions for

entering this selection is covered in the section: Balance

Point—Value Selection.

When outdoor temperature is below selected balance point temperature, furnace is used exclusively to supply heat.

When outdoor temperature is above both selected balance point

temperature and thermal balance point, HP will be used exclusively, because it will have sufficient capacity to satisfy load.

—1—

Page 2

If selection of balance point temperature is such that it is below

thermal balance point, all operation between these 2 temperatures

will be part HP and part furnace. A heating cycle will begin with

HP operation. Because HP has insufficient capacity, structure

temperature will slowly fall. After a time, thermostat will issue

next stage call, turning off HP and turning on furnace. Furnace will

operate until thermostat is completely satisfied at which time

furnace will turn off. The next heating cycle will begin with HP

and cycle will repeat.

This operating mode is acceptable as long as selected balance point

temperature is not too far below thermal balance point. This

thermostat has no "droop" between stages, and structure will not

cool significantly below setpoint before furnace comes on. However, there is a 15-minute timer which requires HP to operate for

15 minutes before furnace comes on. If balance point temperature

is set too far below thermal balance point, the temperature loss

during this 15 minute period could be uncomfortable.

For most installations balance point temperature setting should be

in the range of 25˚F to 45˚F. If set too high, HP will not be used

enough and its advantages not realized. If set too low, structure

temperature loss during HP operation will become uncomfortable.

In case of 2-speed heat pumps or 2-stage furnaces, thermostat will

start equipment at low capacity and if this is not sufficient, will

advance to higher capacity. If load demand is between low and

high capacities, it will cycle between these 2 stages, i.e. between

low and high heat pump speeds or between furnace low and high

fire. However, once operation proceeds from HP to furnace, it will

NOT cycle directly back to HP. Furnace will remain on until all

stages of thermostat are satisfied.

DESCRIPTION OF OPERATION

COOLING OPERATION—SINGLE SPEED

HP cooling:

O/W2 energizes reversing valve to select cooling operation.

G energizes furnace blower.

Y/Y2 energizes compressor and selects high blower speed at

furnace.

When cooling demand is satisfied, G and Y/Y2 are de-energized.

O/W2 will remain on to minimize cycling of reversing valve. It

will turn off only when a call for heat occurs.

COOLING OPERATION—TWO SPEED

Low-speed HP cooling:

O/W2 energizes reversing valve to select cooling operation.

G energizes furnace blower.

Y1/W2 energizes compressor at low speed and may determine

furnace blower speed.

High-speed HP cooling:

Y/Y2 is added to low-speed cooling call to operate compressor at

high speed and increase blower speed.

HEATING OPERATION—SINGLE-SPEED HP

HP heating:

O/W2 remains off to select heating operation.

G turns on furnace blower.

Y/Y2 energizes compressor and increases furnace blower speed.

HEATING OPERATION—TWO-SPEED HP

Low-Speed HP heating:

O/W2 remains off to select heating operation.

G turns on furnace blower.

Y1/W2 turns on compressor at low speed and may also adjust

blower speed for low-speed HP operation.

High-Speed HP heating:

Y/Y2 is added to low-speed HP heating call to operate compressor

at high speed and adjust blower for high-speed HP operation.

HEATING OPERATION—SINGLE-STAGE FURNACE

W/W1 causes furnace to operate. Furnace controls its own blower

at heating speed.

HEATING OPERATION—TWO-STAGE FURNACE—

THERMOSTAT CONTROL

Low fire:

W/W1 causes furnace to operate at low fire. Furnace controls its

own blower at low heating speed.

High fire: Y1/W2 is added to low-fire heating call to operate

furnace in high-fire mode. Furnace controls its own blower at high

heating speed.

HEATING OPERATION—TWO-STAGE FURNACE—

ALGORITHM CONTROL

W/W1 causes furnace to operate. Based on amount of time it is

required to be on, it determines when to operate at low fire and

when to operate at high fire. It controls its own blower at proper

speed.

DEFROST OPERATION

A unique feature of this thermostat is that a defrost cycle, once

started, will always be completed. This is true even if thermostat is

satisfied during defrost. The result is that a heating cycle never

begins with an uncompleted defrost and its associated "cold blow".

During operation of HP in heating mode, HP itself determines

when a defrost is necessary. It initiates defrost by energizing its O

and W wires. The signal on the O wire switches HP from heating

to cooling mode and W signal starts furnace. Thermostat monitors

this action by sensing the signal (which it did not create) on the O

line. It responds by turning on its W outputs (both if 2-stage

furnace) to hold furnace on high fire. At completion of defrost,

indicated by removal of signal from HP on O wire, thermostat does

1 of 2 things. If it is satisfied, it turns off all Y, G, and W outputs

which results in all equipment off. If not satisfied, it will turn off

Y and G, leaving W on until it becomes satisfied. In this way it

assures that furnace will be used to satisfy a heat demand existing

after a defrost cycle is completed.

EMERGENCY HEAT

If EHEAT mode is selected at thermostat, all heating will be done

by furnace.

CONTINUOUS FAN

If FAN ON mode in selected, thermostat energizes G terminal,

which causes fan to operate when both heating and cooling are off.

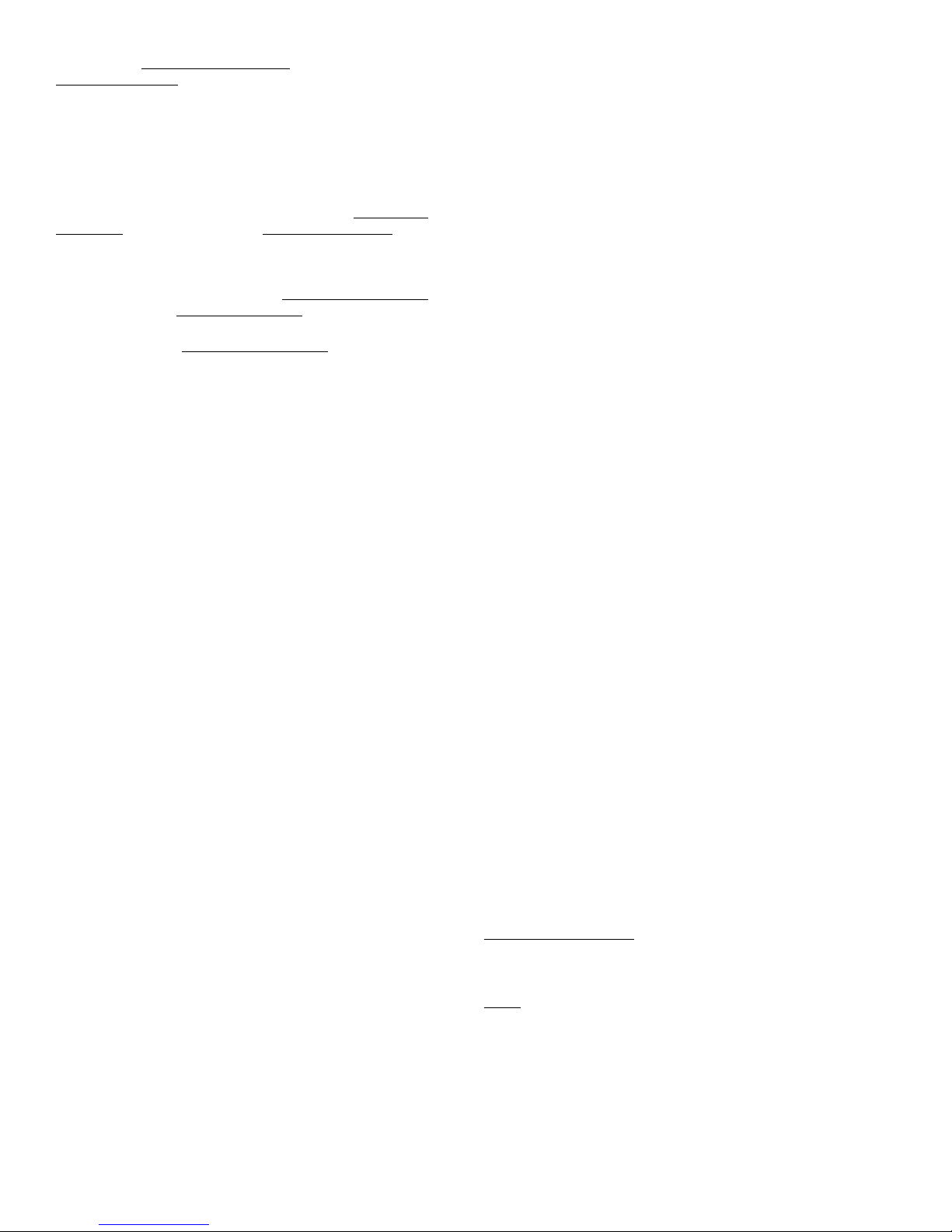

STAGING SEQUENCE—HEATING

Depending on whether HP is single or 2 speed and whether furnace

is single or 2 stage, the staging of thermostat outputs with

increasing demand varies. Table 1 shows the heating staging

sequence for all 4 possible combinations of single- and multi-stage

equipment. Note that thermostat itself has a maximum of 3 heating

stages. Note also that at outdoor temperatures below selected

balance point temperature no HP operation is allowed. As discussed earlier, once furnace is turned on, it remains on to satisfy all

demand.

A "freeze protect" feature is built into the dual fuel thermostat. If

indoor temperature sensor fails, and thermostat is in HEAT or

AUTO mode, heat will be cycled when outdoor temperature is

below 50˚F. The amount of heat supplied will increase as outdoor

temperature decreases, keeping structure from freezing.

INSTALLATION

NOTE: All TSTAT models do not have batteries and are not

"power stealing". They do require 24VAC (R and C terminals) to

be connected for proper operation. Thermostat will not operate

without these 2 connections.

—2—

Page 3

WIRING

DIAGRAM

Fig. 2

Fig. 3

Fig. 4

Fig. 5

SYSTEM

TYPE

1-speed HP

1-stage furnace

1-speed HP

2-stage furnace

2-speed HP

1-stage furnace

2-speed HP

2-stage furnace

TABLE 1—HEATING STAGES

OUTDOOR TEMP/

BAL. PT. TEMP

Above HP Furnace —

Below Furnace — —

Above HP Furnace Lo Furnace Hi

Below Furnace Lo Furnace Hi —

Above HP Lo HP Hi Furnace

Below Furnace — —

Above HP Lo HP Hi Furnace Lo or Hi

Below Furnace Lo or Hi — —

STAGE 1 STAGE 2 STAGE 3

I. THERMOSTAT LOCATION

Thermostat should be mounted:

• Approximately 5 ft (1.5m) from floor.

• Close to or in a frequently used room, preferably on an inside

partitioning wall.

• On a section of wall without pipes or duct work.

• In a location where the outdoor temperature sensor wires can be

routed to thermostat location. It is acceptable to use 2 separate

wires in thermostat cable to connect outdoor sensor. These

wires may be connected at furnace to another pair continuing to

outdoor heat pump. The outdoor sensor may then be mounted

and connected in vicinity of heat pump, but be sure it is not

located in direct sunlight.

Thermostat should NOT be mounted:

• Close to a window, on an outside wall, or next to a door leading

to the outside.

• Exposed to direct light and heat from a lamp, sun, fireplace, or

other temperature-radiating object which may cause a false

reading.

• Close to or in direct airflow from supply registers and return-air

grilles.

• In areas with poor air circulation, such as behind a door or in

an alcove.

II. SET DIP SWITCHES

There are 4 small switches on the back of the circuit board which

must be set by the installer. The ON position is indicated by small

letters on the switch itself. Ignore numbers 1-4 on the switch. The

switch designation (A through D) is on the circuit board next to the

switch. To change a switch position use the corner of a small

screwdriver to slide it between on and off. Make these selections

BEFORE installing the thermostat--it is much easier.

SWITCH A—NOT USED IN DUAL FUEL THERMOSTATS

This switch must be in OFF position in all dual fuel applications.

DO NOT turn ON.

SWITCH B—SETBACK RECOVERY

Selects between normal and smart recovery from setback. Normal

recovery changes to the new setpoint at the programmed time.

Smart recovery, which is active in heating mode only, starts earlier

and adjusts the setpoint slowly so that room temperature will arrive

at the programmed temperature at the programmed time.

TO SET:

OFF—for smart recovery. This is the factory default.

ON—for normal recovery.

SWITCH C—DISABLE LOW-AMBIENT COOLING

Use to allow or prevent cooling operation below an outdoor

temperature of 55˚F. Prevention of cooling below 55˚F adds to

compressor reliability. If outdoor temperature sensor fails or is

disconnected, cooling is allowed regardless of switch setting.

TO SET:

OFF—cooling is allowed at outdoor temperatures below 55˚F.

ON—cooling is disabled at outdoor temperatures below 55˚F.

SWITCH D—SELECT SINGLE-SPEED OR 2-SPEED HP

Use this switch to tell dual fuel thermostat whether it is controlling

a single- or 2-speed HP. It must be set properly.

TO SET:

OFF—for single-speed HP.

ON—for 2-speed HP.

III. INSTALL THERMOSTAT

WARNING: Before installing thermostat, turn off all

power to unit. There may be more than 1 power disconnect. Electrical shock can cause personal injury or death.

1. Turn OFF all power to unit.

2. If an existing thermostat is being replaced:

a. Remove existing thermostat from wall.

b. Disconnect wires from existing thermostat, 1 at a time.

Be careful not to allow wires to fall back into the wall.

c. As each wire is disconnected, record wire color and

terminal marking.

d. Discard or recycle old thermostat.

NOTE: Mercury is a hazardous waste and MUST be disposed of

properly.

3. Open thermostat rear door (mounting base) to expose

mounting holes. The base can be removed to simplify

mounting. Snap apart carefully at hinge to separate mounting base from remainder of thermostat.

4. Route thermostat wires through large hole in mounting

base. Allow an extra 10 to 12 in. of wire for connection to

terminals. Remove outer sheath over this entire length for

added flexibility.

5. Level mounting base against wall and mark wall through 2

mounting holes.

6. Drill two 3/16-in. mounting holes in wall where marked.

7. Secure mounting base to wall with 2 screws and anchors

provided, making sure all wires extend through mounting

base.

8. Adjust wire length and routing to allow proper closure of

thermostat. Strip each wire end no more than 1/4 in. to

prevent adjacent wires from shorting together. Match and

connect equipment lead wires to the correct terminals of the

thermostat connector. (See Fig. 2 through 5.) Both R and C

must be connected for proper thermostat operation.

CAUTION: Improper wiring or installation may damage

the thermostat. Check to make sure wiring is correct

before proceeding with installation or turning on unit.

—3—

Page 4

9. Push excess wiring into wall. Seal hole in wall to prevent

drafts.

10. Snap hinge back together.

11. Close thermostat door.

12. Turn ON power to unit.

On power up, display shows dF for a few seconds to indicate that

it is a dual fuel thermostat.

IV. SET THERMOSTAT CONFIGURATION

Configuration options, like DIP switch settings, are intended to be

selected at installation and normally are not modified by the

homeowner. These options are not discussed in the homeowner’s

manual and therefore must be made as part of the installation. A

special procedure allows entry into the configuration mode. The

thermostat will automatically exit this mode if no button is pressed

for 10 seconds. While in configuration mode, 4 option choices can

be made:

1. Fahrenheit or Celsius—Selection.

2. Balance point—Value Adjustment

3. Clean filter timer—Selection and Value Adjustment.

4. ’Anticipator’—Value Adjustment.

An explanation for each of these and how to enter the configuration mode follows.

TO ENTER THE CONFIGURATION MODE:

Press and hold FAN button for approximately 10 sec until room

temperature disappears and display reads "--". You are now in the

configuration mode.

NOTE: If no button is pressed for 10 sec, thermostat will exit

mode and resume normal operation. To re-enter configuration

mode, FAN button must be pressed and held again.

WHILE IN CONFIGURATION MODE, THESE SELECTIONS

ARE AVAILABLE:

FAHRENHEIT OR CELSIUS—SELECTION

Select between Fahrenheit or Celsius operation. Factory default is

Fahrenheit.

TO SELECT:

1. Enter configuration mode.

2. Press CHANGE DAY button to display F or C.

3. Use either up or down button to change between F and C.

BALANCE POINT—VALUE ADJUSTMENT

This adjustment allows installer to enter an outdoor temperature

below which HP will not be allowed to operate. Temperatures

between 15˚F and 55˚F can be selected in 5˚F steps. (Equivalent

values are used when Celsius operation is selected.) A discussion

of how to determine this temperature was provided earlier in the

APPLICATIONS section.

TO SELECT:

1. Enter configuration mode.

2. Press COPY PREVIOUS DAY button.

3. Use up or down buttons to move between 15, 20, 25, 30, 35,

40, 45, 50, and 55˚F (or equivalent values in ˚C).

CLEAN FILTER TIMER—SELECTION AND ADJUSTMENT

Select hours of blower operation before CLEAN FILTER icon is

displayed. Timer accumulates total blower hours. Selection can

range from 400 to 3600 hours or can be turned off. Factory default

is 2 (800 hours). Recommended selections are: disposable

filter—400 to 800 hours, media filter—1200 to 1600 hours, or

electronic air cleaner—1600 to 2400 hours of blower operation.

TO SELECT:

1. Enter configuration mode.

2. Press RESET FILTER button to display OF (off) or digits

1 through 9.

3. Use up and down buttons to move between selections. Total

hours equals 400 times the displayed number. OF (off) turns

feature off.

4. During the selection process, the CLEAN FILTER icon will

remain on, even if OF (off) is chosen.

’ANTICIPATOR’—ADJUSTMENT

This adjustment controls the sensitivity and cycle rate of the

thermostat. Higher numbers decrease the sensitivity and slow the

cycle rate. Lower numbers increase sensitivity and increase cycle

rate. However, a limiting feature will not allow more than 4

equipment cycles per hour, regardless of setting. Values can range

from 1 to 9. Default is 3. This default selection will provide

optimum performance in nearly all installations. Try it first. Do not

change setting unless there is evidence of need to do so.

Unlike conventional anticipators, this setting is not to be determined by current draw. There is no need to measure, know, or

compensate for current. There is also no ’droop’ with this

thermostat, regardless of ’anticipator’ setting.

This adjustment controls only sensitivity and cycle rate—up to the

maximum of 4 cycles per hour.

TO ADJUST:

1. Enter configuration mode.

2. Press MODE button to display value between 1 and 9.

Factory default is 3.

3. Use up and down buttons to move between values.

V. HOLD, FAN, MODE BUTTON OPERATION

1. Pressing HOLD button disables the time/temperature

schedule and "holds" the current desired temperature. When

active, the HOLD annunciator is turned on. A second press

of the HOLD button releases the hold feature and turns off

the annunciator.

2. Pressing the FAN button alternately selects AUTO or ON

fan operation. Fan annunciator displays the current selection.

3. Pressing the MODE button will select OFF, HEAT, COOL,

AUTO, or EHEAT. Mode annunciator displays the current

selection.

4. Operation of other buttons is explained in the Homeowner’s

Guide.

VI. CHECK THERMOSTAT OPERATION

A. Select Hold

1. Press HOLD button to select "hold" feature. This will

prevent the setpoint from changing until the desired

time/temperature schedule is entered.

B. Fan Operation

1. Press FAN button, starting fan operation. Fan annunciator

switches from AUTO to ON.

2. Press FAN button, stopping fan operation. Fan annunciator

switches from ON to AUTO.

C. Heating Operation

1. Press MODE button until HEAT is displayed under the

mode annunciator.

2. Make sure outdoor temperature is above balance point

setting, so that HP will be enabled.

3. Press up button until display reads 10 degrees above room

temperature. HP should begin to operate within 5 minutes.

—4—

Page 5

4. Press MODE button until EHEAT is displayed. Furnace

Y/Y2

W/W1

R

24 VAC HOT

FAN

FURNACE

COMPRESSOR HI

RVS COOLING

COMPRESSOR LO

DUAL FUEL

THERMOSTAT

TWO-SPEED

HEAT PUMP

24 VAC COM

RVS HEATING

RVS SENSING

OUTDOOR

SENSOR

CONNECTION

S2

S1

L

B

G

R

R

W

Y2

Y

G

C

C

C

O/W2

Y1/W2

SINGLE-STAGE

FURNACE

W2

O

SEE NOTE 1

Y1

W3

OUTDOOR

TEMPERATURE

SENSOR

should begin to operate within 5 minutes.

D. Cooling Operation

1. Press MODE button until COOL is displayed under the

mode annunciator.

2. Press down button until display reads 10 degrees below

room temperature. Cooling system should begin to operate

within 5 minutes.

VII. SELECT DESIRED OPERATION

1. Press FAN button to select AUTO or ON position. Fan

annunciator displays current selection.

2. Press MODE button to select OFF, HEAT, COOL, or

EHEAT. If AUTO is selected, first select heating desired

temperature in HEAT mode and cooling desired temperature in COOL mode. Refer to homeowner’s guide. Mode

annunciator displays current selection.

3. Press up or down buttons to select desired temperature.

4. If daily cycles are to be programmed now, refer to Homeowner’s Guide for programming instructions.

5. If thermostat has not been programmed, press HOLD button

to retain desired temperature setting.

NOTE: If HOLD button is not left ON, temperature setting will

be lost until time/temperature program is entered.

VIII. CHECKLIST

1. Put away tools and instruments, and clean up debris.

2. Review Homeowner’s Guide with owner.

3. Leave literature packet with owner.

R

G

C

B

L

S1

S2

TWO-STAGE OR

VARIABLE SPEED

FURNACE

R

G

W/W1

Y/Y2

O

W2

Y1

C

SEE NOTES 1 AND 2

OUTDOOR

TEMPERATURE

SENSOR

SINGLE-SPEED

HEAT PUMP

R

W2

Y

O

C

DUAL FUEL

THERMOSTAT

24 VAC HOT

FAN

FURNACE LO

COMPRESSOR

RVS COOLING

FURNACE HI

24 VAC COM

RVS HEATING

RVS SENSING

OUTDOOR

SENSOR

CONNECTION

W/W1

Y/Y2

O/W2

Y1/W2

A95216

Fig. 3—Two-Stage or Variable-Speed Furnace with

Single-Speed Heat Pump

DUAL FUEL

THERMOSTAT

24 VAC HOT

FAN

FURNACE

COMPRESSOR

RVS COOLING

N/A

24 VAC COM

RVS HEATING

RVS SENSING

OUTDOOR

SENSOR

CONNECTION

R

G

W/W1

Y/Y2

O/W2

Y1/W2

C

B

L

S1

S2

Fig. 2—Single-Stage Furnace with

Single-Speed Heat Pump

SINGLE-STAGE

FURNACE

SINGLE-SPEED

R

G

W

Y

C

SEE NOTE 1

OUTDOOR

TEMPERATURE

SENSOR

HEAT PUMP

W2

R

Y

O

C

A95217

Fig. 4—Single-Stage Furnace with

A95215

2-Speed Heat Pump

—5—

Page 6

DUAL FUEL

THERMOSTAT

24 VAC HOT

FAN

R

G

TWO-STAGE OR

VARIABLE SPEED

FURNACE

R

G

TWO-SPEED

HEAT PUMP

R

FURNACE

COMPRESSOR

HI

RVS COOLING

COMPRESSOR

LO

24 VAC COM

RVS HEATING

RVS SENSING

OUTDOOR

SENSOR

CONNECTION

W/W1

Y/Y2

O/W2

Y1/W2

C

B

L

S1

S2

W/W1

Y/Y2

O

Y1

W2

C

SEE NOTES 1 AND 2

OUTDOOR

TEMPERATURE

SENSOR

W2

Y2

O

Y1

W3

C

A95218

Fig. 5—Two-Stage or Variable-Speed Furnace with

2-Speed Heat Pump

WIRING DIAGRAM NOTES:

1. Underlined letter on dual terminal indicates its usage.

For Example: O/W2 means O, O/W2 means W2.

Outdoor Temperature Sensor must be attached in all dual

fuel installations.

Jumper wire between O/W2 and L thermostat terminals

MUST be present.

2. Y1 and O connections to 2-stage furnaces MAY NOT

EXIST, or may be only a wire rather than a screw terminal.

—6—

Page 7

OPERATIONAL INFORMATION

FIVE-MINUTE COMPRESSOR TIMEGUARD

This timer prevents the compressor from starting unless it has been off for at least 5 minutes. It can be defeated for 1 cycle by simultaneously

pressing the FAN mode button and the INCREASE TEMPERATURE button.

FIFTEEN-MINUTE CYCLE TIMER

This timer prevents the start of a heating or cooling cycle until at least 15 minutes after the last start of the same cycle. Its function is to assure

that equipment is not cycled more than 4 times per hour. This timer is defeated for 1 cycle when the desired temperature is manually changed.

It can also be defeated for 1 cycle by simultaneously pressing the FAN mode button and the INCREASE TEMPERATURE button.

FIFTEEN-MINUTE STAGING TIMER

In multistage heating or cooling, this timer prevents any higher stage from turning on until the preceeding stage has been on for 15 minutes. This

timer is defeated if the temperature error is greater than 5 degrees (usually due to a large change in desired temperature).

TWO-MINUTE MINIMUM ON TIME

In normal operation, when a stage turns on, it will not turn off for a minimum of 2 minutes.

HEAT/COOL SETPOINTS (DESIRED TEMPERATURES)

A minimum difference of 3 degrees is enforced between heating and cooling desired temperatures. This is done by allowing one setting to "push"

the other, to maintain this difference.

AUTO CHANGEOVER

When the auto changeover mode is selected, a change from heat to cool (or vice versa) will not occur until an opposite mode demand has existed

for 20 minutes. If the setpoint is changed, the 20 minute requirement is deleted.

POWER ON CHECK

When AC power is first applied, all segments of display are turned on for a few seconds. Following this, the temperature display reads dF for a

few seconds to indicate that it is a dual fuel thermostat.

ERROR CODES

E1 - If thermostat cannot properly read room temperature, the room temperature display will indicate E1 and thermostat will enter FREEZE

PROTECT mode. When outdoor temperature is below 50˚F furnace will operate for sufficient time every half hour to keep home from

freezing. The ON time is given by the formula: Minutes ON equals 15 minus (outdoor temperature in ˚F divided by 4).

E2 - If the AC line voltage drops below a minimum (brownout) level, all outputs are turned off and the display indicates E2. This condition will

remain for 15 seconds after proper line voltage is restored. If the AC line voltage disappears completely, the display will immediately go

blank.

E3 - If thermostat cannot properly read outdoor temperature E3 will be displayed in place of room temperature. The thermostat will continue to

operate, but will only use furnace in HEAT mode.

AUXILIARY HEAT ICON

This icon is displayed when the furnace is operating.

SMART RECOVERY

With Smart Recovery selected, the transition out of a heating setback begins a fixed time period before the selected recovery time and gradually

adjusts room temperature so that the desired temperature will be achieved at the selected recovery time. The fixed time period is 1 hr for furnaces

and 1.5 hrs for heat pumps.

THERMOSTAT TROUBLESHOOTING

SYMPTOM WHAT TO CHECK

No LCD on temperature display

″Trouble″ on temperature display

″E2″ on temperature display

″E1″ on temperature display

″Clean Filter″ on temperature display

Cooling will not come on

Heating will not come on

Check for 24 VAC between R and C at terminal connections. Both R and C must be connected for proper operation.

Outdoor temperature sensor reading out of range. An attempt to read outdoor temperature results in ″--″ on display. Check for shorted, open, or failed outdoor temperature sensor.

Brownout condition or too low of voltage to thermostat. Double check wiring and check for 24 VAC between R and

C. E2 will clear 15 seconds after proper voltage is restored.

Temperature sensor reading out of range. Check sensor for damage. If recycling power does not clear display,

thermostat should be replaced.

After the selected number of hours of blower operation ″clean filter″ will display on LCD. This is to remind the homeowner to ″check″ filter. Press ″reset filter″ button to clear display and reset timer to 0.

Select COOL mode. Decrease cooling setpoint to 10 degrees below room temperature. Simultaneously press FAN

and INCREASE TEMPERATURE buttons to defeat timers. Check for 24 VAC at Y/Y2 terminal. If present, thermostat is OK and problem is with equipment or wiring. If not present, replace thermostat.

Select HEAT mode. Increase heating setpoint to 2 or 3 degrees (not more) above room temperature. Simultaneously press FAN and INCREASE TEMPERATURE buttons to defeat timers for 1 cycle. Check for 24 VAC at

Y/Y2 terminal (single-speed HP) or Y1/W2 terminal (2-speed HP) within 10 seconds. Increase heating setpoint to

7 or 8 degrees above room temperature. Check for 24VAC at W/W1 terminal (single-speed HP) or Y/Y2 terminal

(2-speed HP) within 2 minutes. After 2 minutes check for 24VAC at Y1/W2 terminal (single-speed HP) or W/W1

terminal (2-speed HP).

—7—

Page 8

© 1995 BDP Co. • P.O. Box 70 • Indianapolis, IN 46206 Printed in U.S.A.

—8—

tstat06 Catalog No. 92-33TS-TA28B

Loading...

Loading...