Bryant CONDENSING GAS FURNACE 340MAV, CONDENSING GAS FURNACE 350MAV, CONDENSING GAS FURNACE 352MAV, CONDENSING GAS FURNACE 355MAV User's Information Manual

Page 1

USER’S INFORMATION MANUAL

MODEL 340MAV, 350MAV, 352MAV,

355MAV CONDENSING GAS

FURNACE

NOTE TO INSTALLER:

This manual must be left with the equipment user.

MODEL 350MAV (shown)

HIGH EFFICIENCY

GAS FURNACE

A97381

As an ENERGY STAR

Bryant Heating & Cooling

Systems has determined that

this product meets the ENERGY

STAR guidelines for energy

efficiency.

!

WARNING: If the information in this manual

SM

Partner,

is not followed exactly, a fire or explosion may

result causing property damage, personal injury or

loss of life.

— Do not store or use gasoline or other flammable

vapors and liquids in the vicinity of this or any

other appliance.

— WHAT TO DO IF YOU SMELL GAS:

— Do not try to light any appliance.

— Do not touch any electrical switch; do not use

any phone in your building.

• Immediately call your gas supplier from a

neighbor’s phone. Follow the gas supplier’s

instructions.

• If you cannot reach your gas supplier, call the

fire department.

— Installation and service must be performed by a

qualified installer, service agency or the gas

supplier.

Do not use this furnace if any part has been under water. Immediately call a qualified service technician

to inspect the furnace and to replace any part of the control system and gas control which has been

under water.

Page 2

†

WELCOME TO A NEW

GENERATION OF

COMFORT

Congratulations! In light of rising

energy costs, the Plus 90

Plus90

Gas-Fired, Condensing Furnaces are

among the soundest investments

today’s homeowner can make.

Your new furnace is truly a triumph

of technology in home heating. A

revolutionary design employs 2 heat

exchangers to “squeeze” out the maximum amount of heat from the fuel consumed. In fact, your new furnace is so

efficient, over 90 percent* of the heat

generated during combustion is captured and delivered inside your home.

That is more than a 33 percent* increase in heating efficiency over conventional furnaces.

These are among the most energy-efficient furnaces you can buy today. They

also are among the safest and most

dependable. We are proud of the technological advances incorporated into

the design of these furnaces. With only

minimal care, your new furnace will

deliver many years of money-saving

home comfort and enjoyment. Spend

just a few minutes with this manual to

learn the operation of your new furnace and the small amount of maintenance it takes to help keep it operating

at peak efficiency year after year.

* The output capacity and any representations of efficiency

™ and Plus 90i

for this furnace are based on standard Department of

Energy test procedures.

TM

, 340MAV,

TM

Multipoise,

MODELS 340MAV

(SHOWN) AND 350MAV

FIXED-CAPACITY

FURNACES

1

MODEL 355MAV

VARIABLE-CAPACITY

AND MODEL 352MAV

TWO-STAGE

FURNACES

2

INSTALLATION DATA

Date Installed

Dealer Name

Address

City

State Zip

Telephone

FURNACE

Product No.

Model No.

Serial No.

SPLIT-SYSTEM

OUTDOOR UNIT:

Product No.

Model No.

Serial No.

INDOOR COIL:

Product No.

Model No.

Serial No.

2

Page 3

8

10

5

16

9

6

11

5

4

18

2

17

3

12

7

1

14

15

13

19

8

10

5

15

14

13

16

9

11

5

2

17

3

4

12

18

6

20

1

7

19

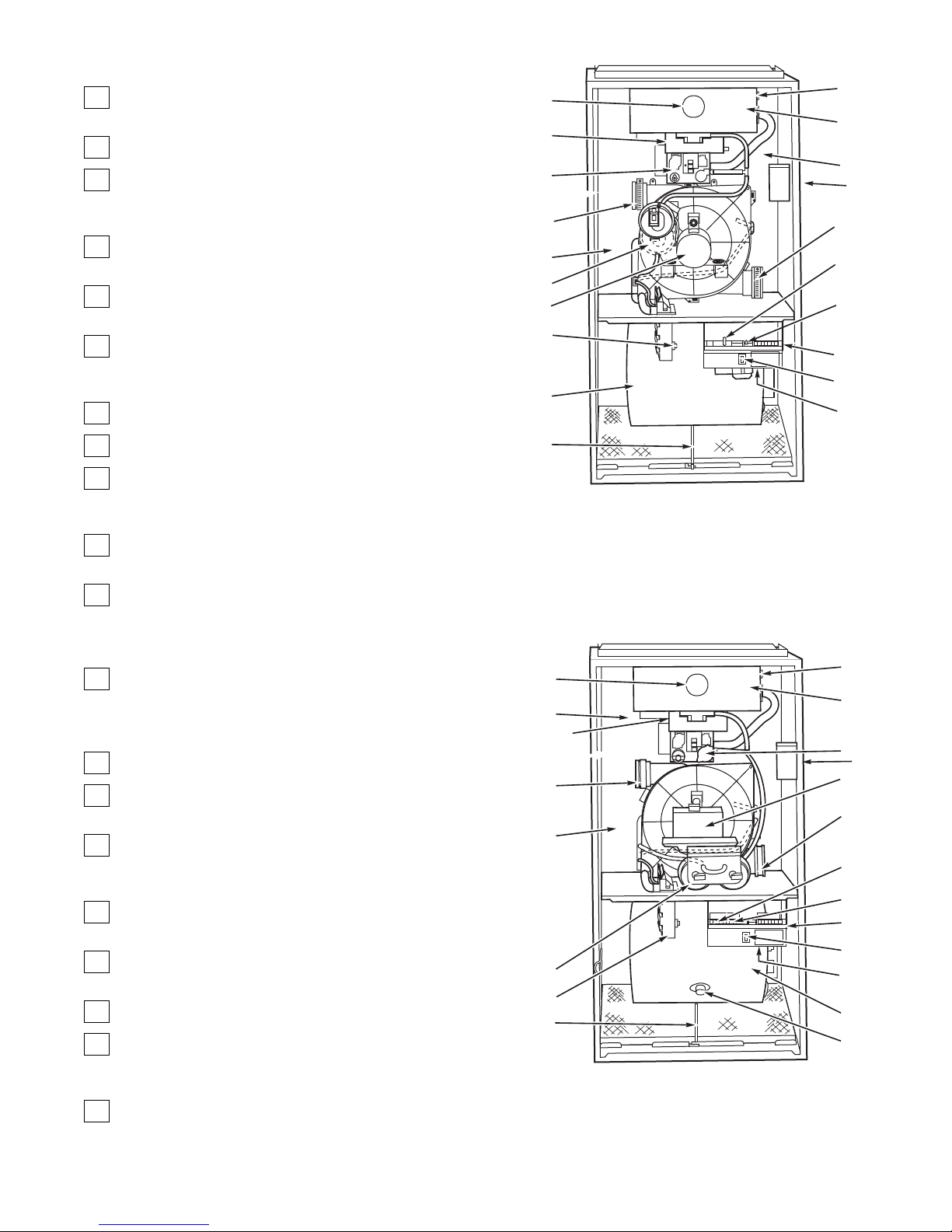

FURNACE COMPONENTS

1

Combustion-air intake connection to ensure

contaminant-free air (right or left side).

2

Burner sight glass for viewing burner flame.

3

Burner assembly (inside). Operates with energysaving inshot burners and hot surface ignitor for safe,

dependable heating.

4

Redundant gas valve. Safe, efficient. Features 1 gas

control with 2 internal shutoff valves.

5

Vent outlet. Uses PVC pipe to carry vent gases from

the furnace’s combustion system (right or left side).

6

Inducer motor. Pulls hot flue gases through the heat

exchangers, maintaining negative pressure for added

safety.

7

Blower access panel safety interlock switch.

8

Air filter and retainer.

9

Condensate drain connection. Collects moisture

condensed from burned gases for disposal into home

drain system.

10

Heavy-duty blower. Circulates air across the heat

exchangers to transfer heat into the home.

11

Secondary condensing heat exchanger (inside).

Wrings out more heat through condensation.

Constructed with Polypropylene-laminated steel to

ensure durability.

12

Primary serpentine heat exchanger (inside).

Stretches fuel dollars with the S-shaped heat-flow

design. Solid construction of corrosion-resistant

aluminized steel means reliability.

13

Control center.

14

3-amp fuse provides electrical and component

protection.

15

Light emitting diode (LED) on control center. Code

lights are for diagnosing furnace operation and

service requirements.

16

Pressure switch(es) ensure adequate flow of flue

products through furnace and out vent system.

17

Rollout switch (manual reset) to prevent

overtemperature.

18

Junction box for 115-v electrical power supply.

19

Transformer (24v) behind control center provides

low-voltage power to furnace control center and

thermostat.

20

Limit switch (manual reset) on 355MAV only.

MODELS 340MAV, 350MAV,

AND 352MAV FURNACES

(UPFLOW POSITION)

MODEL 355MAV

FURNACE (UPFLOW POSITION)

3

3

4

Page 4

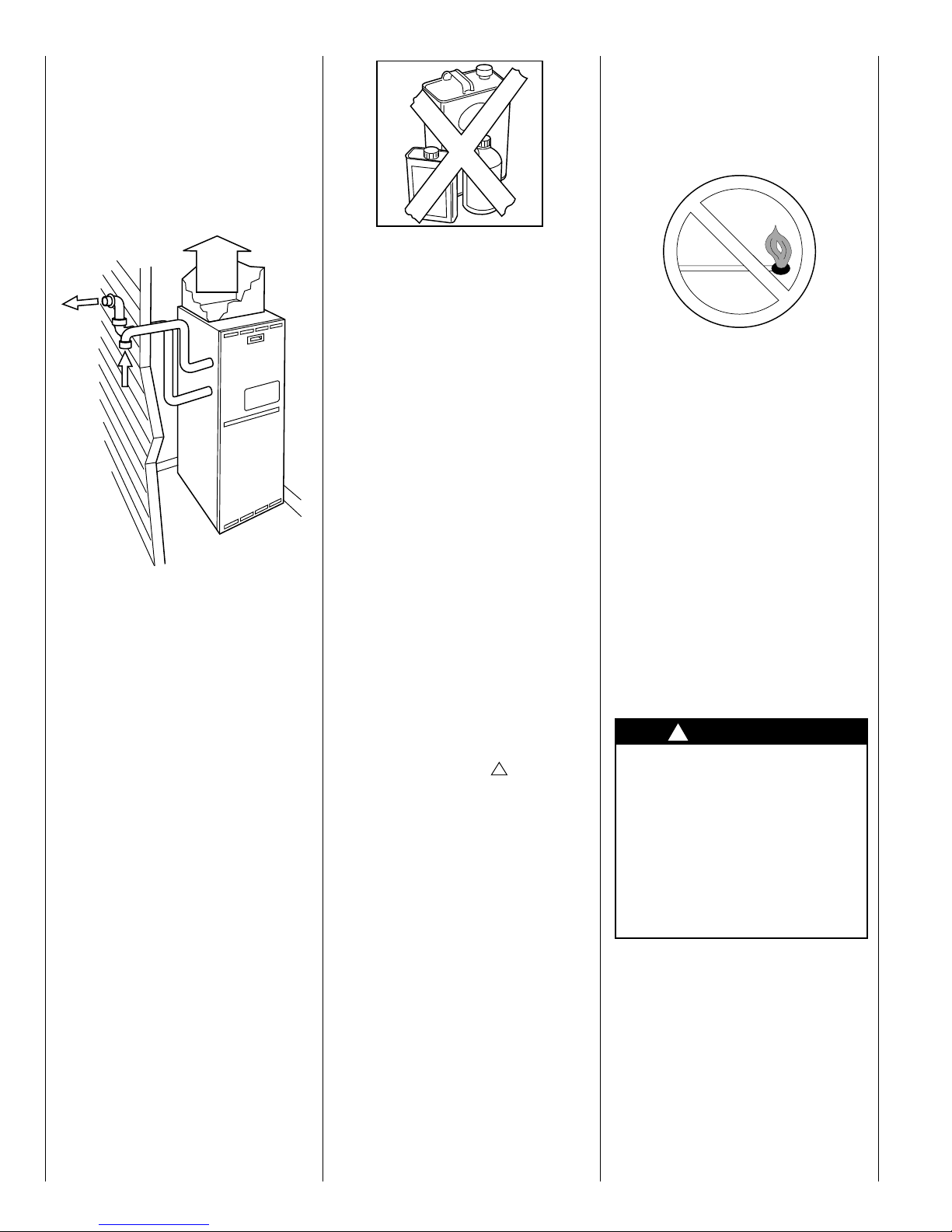

!

!

IMPORTANT FACTS

Your gas furnace uses air from

outside the home for combustion

and venting. It is not to be installed

using in-house air. Therefore, both

pipes must terminate outside the

structure and must not be obstructed

in any way.

To minimize the possibility of serious

personal injury, fire, damage to

your furnace, or improper operation,

carefully follow these safety rules:

• Keep the area around your furnace

free of combustible materials, gasoline, and other flammable liquids

and vapors.

• Do not cover the furnace, store trash

or debris near it, or in any way block

the flow of fresh air to the unit.

• A furnace installed in an attic or

other insulated space must be kept

free and clear of insulating material.

Examine the furnace area when installing the furnace or adding more insulation. Some insulation materials may be

combustible.

NOTE:

Do not use this furnace if any

part has been under water. Immediately call a qualified service technician

to inspect the furnace and to replace

any part of the control system and any

gas control which has been under

water.

NOTE:

agency must use only factoryauthorized replacement parts, kits,

and accessories when modifying this

product.

The qualified installer or

This furnace contains SAFETY

DEVICES which must be MANUALLY RESET. If the furnace is left unattended for an extended period of

time, have it checked periodically for

proper operation. This precaution will

prevent problems associated with no

heat, such as frozen water pipes, etc.

See “Before You Request a Service

Call” section in this manual.

SAFETY

CONSIDERATIONS

Installing and servicing of heating

equipment can be hazardous due to

gas and electrical components.

Only trained and qualified personnel

should install, repair, or service heating equipment.

5

Untrained personnel can perform basic

maintenance functions such as cleaning

and replacing air filters. All other operations must be performed by trained service personnel. Observe safety

precautions in this manual, on tags, and

on labels attached to the furnace and

other safety precautions that may apply.

Recognize safety information. This is

the safety-alert symbol . When you

see this symbol on the furnace and in

instructions or manuals, be alert to the

potential for personal injury.

Understand the signal words DANGER,

WARNING, and CAUTION. These

words are used with the safety-alert symbol. DANGER identifies the most serious

hazards which

sonal injury or death. WARNING signifies hazards which

personal injury or death. CAUTION is

used to identify unsafe practices which

would result in minor personal injury or

product and property damage.

NOTE is used to highlight suggestions

which

tion, reliability, or operation.

will result in severe per-

could result in

will result in enhanced installa-

STARTING YOUR

FURNACE

Instead of a continuously burning pilot

flame which wastes valuable energy,

your furnace uses an automatic, hot

surface ignition system to light the

burners each time the thermostat

starts your furnace.

important safeguards:

Follow these

6

• Never attempt to light the burners

manually with a match or other source

of flame.

• Read and follow the operating

instructions on the furnace, especially

the item that reads as follows:

Wait 5 minutes to clear out any gas.

Then smell for gas, including near

the floor. If you smell gas,

Follow “B” in the safety information

above on this furnace label. If you

don’t smell gas, go to the next step.

• If a suspected malfunction occurs

with your gas control system, such as

the burners not lighting when they

should, refer to the shutdown procedures on the furnace, or in the “Shutting Down Your Furnace” section and

call your dealer as soon as possible.

WARNING

If overheating occurs or the

gas valve fails to shut off the

gas supply, turn off the external manual gas valve to the

furnace BEFORE turning off

the electrical supply. (See Fig.

9.) Failure to follow this warning could result in a fire or explosion, and personal injury

or death.

CHECK AIR FILTER: Before

attempting to start your furnace, be

sure the furnace air filter is clean and in

place. See “Performing Routine Maintenance” section in this manual.

Then proceed as follows:

STEPS FOR STARTING

YOUR FURNACE

1. Set your room thermostat to the

lowest temperature setting.

(See Fig. 8.)

7

STOP!

4

Page 5

®

(See Fig. 17.)

9. Open the external manual gas

furnace and wait 1 minute.

valve. (See Fig. 18.)

10. Set room thermostat to a temperature slightly above room tempera-

1

M

3

O

O

P

F

F

F

F

2

C

OR

N

O

OFF

ON

ture. This will automatically

signal the furnace to start.

11. When the furnace receives the

a

8

start signal, the hot surface ignitor at the main burners is auto-matically heated for 15 to 20 sec.

14

When the microprocessor control

C

L

O

S

E

verifies that there is sufficient

heat to ignite, the gas valve permits gas to flow to the main burners. After ignition and a time delay

of about 35 sec, the furnace blower

ON

will start. Variable-capacity furnaces start at low speed until the

control makes the necessary

adjustments to operate the blower

at either the low- or high-stage

speed.

9

NOTE:

If the burners fail to ignite after

15

4 attempts, the furnace control system

will lock out. If lockout occurs, main

burners fail to light, or blower does not

come on, shut down the furnace and

call your dealer for service.

10

2. Close the external manual gas

valve. (See Fig. 9.)

3. Turn off electrical supply to the

furnace. (See Fig. 10.)

4. Remove the main furnace door.

(See Fig. 11.)

5. Gas valve will have EITHER a control switch or control knob to turn

OFF or ON. Turn control switch or

knob on the gas valve to the OFF

position and wait 5 minutes. (See

Fig. 12 or 13.) Then smell for gas,

including near the floor. If you

smell gas,

furnace label. If you don’t smell

gas, go to next step.

6. After waiting 5 minutes, turn control switch or knob on the gas

valve to the ON position.

(See Fig. 14 or 15.)

7. Replace main furnace door.

(See Fig. 16.)

8. Turn on electrical supply to the

STOP! Follow “B” on

12. Set your thermostat to the temperature that satisfies your comfort

requirements.

11

SUGGESTION: Setting the thermostat back a few degrees and

compensating for the difference

with warmer clothing can make a

1

M

3

O

O

P

F

F

F

F

2

C

ON

OR

OFF

ON

big difference in your fuel consumption on extremely cold days.

The few degrees at the top of your

thermostat “comfort level” are the

most costly degrees to obtain.

When room temperature drops

below the temperature selected

on the thermostat, the furnace

will be switched on automatically.

12

When room temperature reaches

the degree selected on the thermostat, the furnace will be switched

off automatically.

Some thermostats have a FAN

mode with 2 selections, AUTO

F

O

F

and ON. When thermostat is set

to AUTO, the furnace blower

cycles on and off, controlled by

the thermostat. In ON mode, the

furnace blower runs continuously. This keeps the temperature

level in your home more evenly

balanced. It also continuously

13

filters the indoor air.

5

Page 6

O

!

P

E

N

16

17

The following procedures must be

followed:

1. Set your room thermostat to the

lowest temperature setting.

(See Fig. 19.)

2. Close the external manual gas

valve. (See Fig. 9.)

3. Turn off electrical supply to the

furnace. (See Fig. 20.)

4. Remove main furnace door.

(See Fig. 11.)

5. Turn control switch or knob on the

gas valve to OFF position.

(See Fig. 21 or 22.)

6. Replace main furnace door.

(See Fig. 16.)

7. If the furnace is being shut down

because of a malfunction, call

your dealer as soon as possible.

!

CAUTION

Furnace is not to be installed,

operated, and then turned off

and left turned off in an unoccupied structure during winter.

(See winterizing procedures in

maintenance section.)

20

PERFORMING

ROUTINE

MAINTENANCE

With proper maintenance and care, your

furnace will operate economically and

dependably. Instructions for basic maintenance are found on this and the following pages. However, before beginning

maintenance, follow these safety precautions:

WARNING

Turn off electrical power supply to your furnace before removing the main furnace door

to service or perform maintenance. Failure to follow this

warning could result in personal injury or death.

!

CAUTION

Although special care has

been taken to minimize sharp

edges, be extremely careful

when handling parts or reaching into the furnace.

FILTERING OUT

TROUBLE

A dirty air filter will cause a loss of airflow

in your duct system. When excessive loss

of airflow occurs, the furnace may cycle

on its safety controls. If this condition is

left unattended, the furnace will eventually lock out. It is recommended that the

furnace air filter be checked every 3 or 4

weeks and cleaned if necessary.

18

SHUTTING DOWN

YOUR FURNACE

Should you need to shut down your

furnace for service or maintenance,

you will need to turn the furnace off.

®

19

!

CAUTION

Never operate your furnace

1

M

3

O

O

P

F

F

F

F

2

C

ON

OR

OFF

ON

without the air filter in place.

Doing so may damage the furnace blower motor. An accumulation of dust and lint on

internal parts of your furnace

can cause a loss of efficiency.

21

The air filter is normally located in the

blower compartment (See Fig. 3 or 4)

or in the factory-supplied filter cabinet

attached to the side or bottom of the

blower cabinet. If air filter has been

F

O

F

installed in another location, contact

your dealer for instructions. To inspect,

clean, and/or replace the air filter(s),

follow these steps:

1. Turn off electrical supply to furnace. (See Fig. 20).

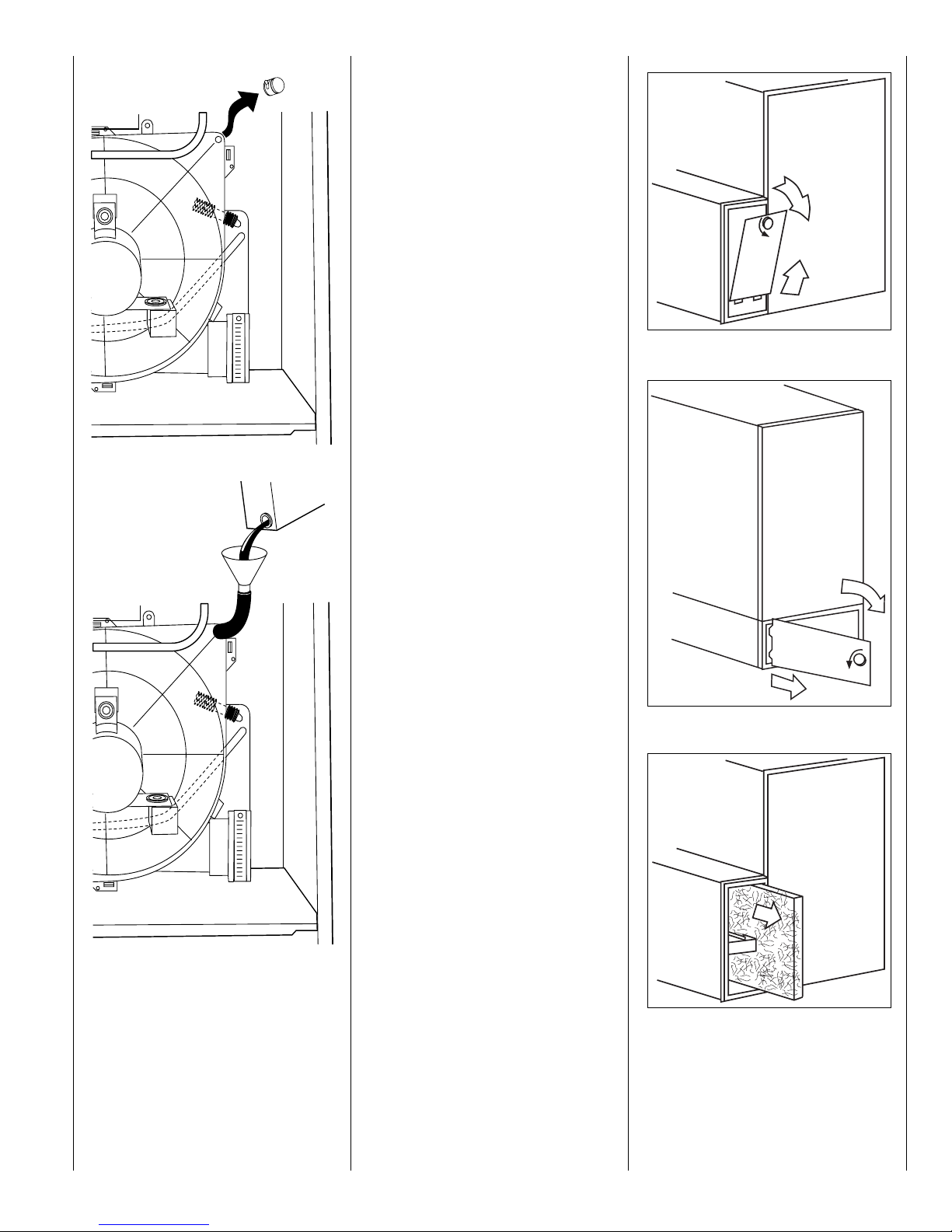

2. Remove door/access panel

22

• AIR FILTER(S) LOCATED IN

6

Page 7

BLOWER COMPARTMENT

a. Remove main furnace door.

(See Fig. 23)

b. Remove blower access panel.

(See Fig. 24)

NOTE: It will be necessary to

remove 2 screws

• AIR FILTER LOCATED IN FILTER CABINET

a. Remove filter cabinet door (See

Fig. 36 and 37)

NOTE: It will be necessary to

remove 1 thumbscrew

3. Remove air filter from furnace.

• AIR FILTER LOCATED IN

BLOWER COMPARTMENT

BOTTOM:

a. Slide filter retainer sideways

until it is free of latch. (See

Fig. 25)

b. Slide air filter out of furnace.

(See Fig. 26)

• AIR FILTER(S) LOCATED IN

BLOWER COMPARTMENT

SIDE:

a. Remove filter retainer from

latch. (See Fig. 27.)

b. Gently remove air filter and

carefully turn the dirty side up

(if dirty) to avoid spilling dirt

from the filter. (see Fig. 28)

• AIR FILTER LOCATED IN FILTER CABINET:

a. Slide air filter out of furnace.

Keep dirty side up (if dirty) to

avoid spilling dirt. (See Fig. 38

and 39)

a. Factory specified disposable

media filter – Do not clean. If

dirty, replace only with media filter having the same part number

and size. Install with airflow

direction arrow pointing towards

blower.

b. Electronic air cleaner (EAC) –

Refer to EAC owner’s Manual

for maintenance information.

25

26

27

necessary. Spray water through fil-

ter in the opposite direction of airflow. Allow filter to dry.

6. Reinstall clean air filter

7. Reinstall filter retainer (for blower

compartment locations only)

8. Replace blower access panel and

main furnace door (See Fig. 29

and 30) or filter cabinet door (Fig.

40 and 41)

9. Turn on electrical supply to furnace.

If your furnace air filter needs to be

replaced, be sure to use the same size

and type of filter that was originally

supplied. Use the furnace filter table

and compare your furnace size with

the proper filter size.

UPFLOW FURNACE AIR

FILTER TABLE

AIR FILTER LOCATED IN BLOWER COMPARTMENT

FURNACE

CASING

WIDTH

(IN.)

17-1/2 (1) 16 x

21 (1) 16 x

24-1/2 (1 or 2) 16

AIR FILTER LOCATED IN FILTER CABINET:

FILTER

CABINET

HEIGHT

(IN)

16 (1) 16 x 25 x 1*

20 (1) 20 x 25 x 1*

24 (1) 24 x 25 x 1*

* Factory-provided with the furnace. Filters may be

field modified by cutting filter material and support

rods (3) in filters. Alternate sizes and additional fil-

ters may be ordered from your dealer.

FILTER SIZE

(IN.)

Side

Return

25 x 1*

25 x 1

x 25 x 1

FILTER SIZE

or (1) 16 x 25 x 4-5/16

or (1) 20 x 25 x 4-5/16

or (1) 24 x 25 x 4-5/16

Bottom

Return

(1) 16 x

25 x 1*

(1) 20 x

25 x 1*

(1) 24 x

25 x 1*

(IN.)

FILTER

TYPE

Cleanable

Cleanable

Cleanable

FILTER

TYPE

Cleanable

Disposable

Cleanable

Disposable

Cleanable

Disposable

23

24

4. Inspect the filter. If torn, replace it.

NOTE: If washable filter that was

shipped with the furnace has been

replaced by:

28

5. Wash filter (if dirty) in sink, bathtub, or outside with a garden hose.

Always use cold tap water. A mild

liquid detergent may be used if

7

!

CAUTION

Use care when cutting support

rods in filters to protect

against flying pieces and

sharp rod ends. Wear safety

glasses, gloves, and appropriate protective clothing. Failure

to follow this caution could result in personal injury.

Page 8

!

CAUTION

If dirt, rust, soot, or scale accumulations are found, call your

dealer. Do not operate your

furnace.

29

30

COMBUSTION AREA

AND VENT SYSTEM

Visually inspect the combustion area

and vent system before each heating

season. Make sure that all PVC pipes

leading into the combustion area and

vent are free from any cracks and sags.

Also check the combustion-air intake

and vent pipes on the outside of your

home for blockage.

When dirt, soot, scale, or rust is

allowed to build up, your furnace can

suffer a loss of efficiency and perform

improperly. Accumulations on the

main burners can result in firing out of

normal sequence. This delayed ignition creates an alarmingly loud sound.

!

CAUTION

If your furnace makes an especially loud noise when the

main burners light, shut down

your furnace and call your

dealer.

To inspect the combustion area and

vent system, you will need a flashlight.

Refer to Fig. 3 or 4, and proceed as

follows:

1. Turn off gas and electrical supplies

to the furnace and remove

the main furnace door. (See Fig. 9,

10, and 11.)

2. Remove burner enclosure front.

(See Fig. 31 or 32.)

Inspect the gas burners and ignitor

area for dirt, rust, soot, or scale.

3. Inspect the combustion-air and

vent pipes for sags, holes, cracks,

or disconnections.

!

DANGER

If holes are found in the pipes

or if any portion has become

disconnected, toxic fumes

can escape into your home.

DO NOT OPERATE YOUR

FURNACE. Call your dealer for

service.

4. Reinstall burner enclosure front.

5. If your furnace is free of the above

conditions, replace main furnace

door and turn on electrical and gas

supplies to your furnace.

(See Fig. 16, 17, and 18.)

6. Start the furnace and observe its

operation. Watch the burner flames

to see if they are clear blue, almost

transparent. (See Fig. 33.) If you

observe a suspected malfunction,

or the burner flames are not clear

blue, call your dealer.

31

32

33

HEADING SOUTH

FOR THE WINTER?

DON’T FORGET YOUR

FURNACE!

!

CAUTION

If the furnace is installed in an

unconditioned space where

the ambient temperatures may

be 32°F or lower, freeze protection measures must be taken.

Since the furnace uses a condensing

heat exchanger, some water will accumulate in the unit as a result of the heat

transfer process. Therefore, once it

has been operated, it cannot be turned

off and left off for an extended period

of time when temperatures will reach

32°F or lower unless winterized. Follow these procedures to winterize your

furnace:

1. Obtain propylene glycol (RV/

swimming pool antifreeze or

equivalent).

!

CAUTION

Do not use ethylene glycol

(Prestone II antifreeze coolant

or equivalent). Failure of plastic components will occur.

2. Turn off electrical supply to the

furnace. (See Fig. 20.)

3. Remove main furnace door.

(See Fig. 23.)

4. Remove upper inducer housing

drain connection cap.

(See Fig. 34.)

5. Connect field-supplied 1/2-in.

ID tube to upper inducer housing

drain connection.

6. Insert field-supplied funnel into

tube.

8

Page 9

7. Pour 1 quart of antifreeze into

funnel/tube. Antifreeze should

run through inducer housing,

overfill condensate trap, and flow

into open field drain.

(See Fig. 35.)

8. Remove funnel and tube from

inducer housing and replace drain

connection cap and clamp.

9. Replace main furnace door.

(See Fig. 30.)

34

35

A CHECK-UP

CHECKLIST

Your furnace represents an important

investment in your family’s comfort

and your home’s value. To keep it

performing properly and as a preventative to future problems, have a trained

service specialist give your furnace a

professional check-up annually. The

following checklist can be used as a

guideline to proper service:

• Inspect all flue gas passages, burners, heat exchangers, coupling

box(es), and inducer assembly.

• Inspect all combustion-air and vent

piping inside structure and pipe terminations outside the structure.

• Check gas pipes leading to and

inside of your furnace for leaks.

• Inspect and clean the blower motor

and wheel.

NOTE

: The inducer and blower motors

are pre-lubricated and require no additional lubrication. These motors can be

identified by the absence of oil ports on

each end of the motor.

• Inspect and change or clean air filter(s) if necessary.

• Inspect all supply- and return-air

ducts for obstructions, air leaks, and

insulation. Remedy any problem when

necessary.

• Inspect the return-air duct connection(s) at the furnace to ensure it is

physically sound, sealed to the furnace

casing, and terminates outside the

space containing the furnace.

• Inspect electrical wiring, connections, and components for loose

connections.

• Perform an operational checkout to

determine whether your furnace is

working properly and if it requires

adjustments.

• Inspect all condensate drain tubes

and condensate trap assembly for

leaks. The condensate removal system

should be cleaned annually by a qualified service agency. Refer to the Service and Maintenance Instructions for

further information.

• Examine the physical support of the

furnace. The support should be sound

with no cracks, sagging, gaps, etc.

around the base.

• Check furnace for any obvious signs

of deterioration.

36

37

38

9

Page 10

39

40

BEFORE YOU

REQUEST A

SERVICE CALL

If your furnace is not operating or not

performing properly, you may save

the expense of a service call by checking a few things yourself before calling

for service.

FOR INSUFFICIENT AIRFLOW:

• Check for dirty air filter(s).

• Check for blocked return-air or sup-

ply-air grilles throughout your home.

Ensure they are open and unobstructed.

If problem still exists, call your dealer

for service.

IF FURNACE FAILS TO OPERATE:

Follow this checklist step by step,

advancing to the next step only if furnace fails to start.

• Check thermostat for proper temperature. Is thermostat set above room

temperature?

• Is thermostat set to HEAT?

• Check fuses and circuit breakers. Is

electrical supply on?

• Is manual shutoff valve in gas supply

pipe in open position? (Follow start-up

procedures if you open gas valve.)

NOTE:

Turn off electrical supply

before continuing with checklist.

shut down the furnace and call for service. See “Shutting Down Your Furnace” section in this manual.

• Check for obstructions around the

vent termination outside the structure.

If your furnace still fails to operate, call

your service representative.

For your convenience, record the furnace product and serial numbers on

page 2. Should you ever require service, you will have ready access to the

information needed by your service

representative.

This furnace has an LED operation

and fault code display to aid the

installer, service technician, or homeowner while installing or servicing the

unit. The LED code can be seen by

removing the access door and viewing

LED(s) through the view port in the

blower access panel.

NOTE:

panel or turning off the 115-v electrical power supply will terminate LED

diagnostic code display and erase the

memory.

To decipher the meaning of the LED

code, and suggested action, the following cross-reference can be used.

Removing the blower access

41

• Is control switch or knob on gas

valve in ON position? (Follow start-up

procedures if you must reset switch or

knob to ON position.)

• Check manual reset flame rollout

switch located on the burner box in

combustion area. (See Fig. 3 or 4.) If

furnace has experienced high temperature conditions, this switch will shut

off the furnace. Reset it by pushing the

button on the switch. If it trips again,

10

Page 11

MODEL 340MAV AND 350MAV DIAGNOSTIC CHART

(See Fig. 3.)

FAULT

CODE FAULT CODE DESCRIPTION CHECKLIST

13 or 33 Limit Switch Lockout

14 or 34

24 Furnace Fuse Open Check for blown fuse and possible short in 24-v wiring.

31 Pressure Switch Not Closed

12, 21, 22,

or 23

No Fault

Code

Signaled

Ignition Lockout or

Ignition Proving Fault

Any Other Fault Code Call dealer for service.

Furnace Fails to Operate and No

Fault is Signaled

NOTES:

1. Light on continuously means control has power and working properly.

2. The fault code is a 2-digit number. The first digit is determined by the number of short flashes of the light and the second digit is determined by number of long flashes

of the light.

Check for dirty air filter.

Check for blocked return-air or supply-air grilles.

Check to be sure manual shutoff valve in gas supply pipe is in the open position. (Follow

start-up procedure if you open gas line.)

NOTE: Turn off the electrical supply and remove access doors before continuing with this

checklist.

Check to be sure control switch or knob on gas valve is in ON position. (Follow start-up procedures if you must reset switch or knob to ON position.)

Check for disconnected ground wire.

Check to make sure that all PVC pipes leading into the combustion-air intake and vent/

exhaust are free from any cracks and sags. Also check the combustion-air intake and vent/

exhaust pipes on the outside of your home for blockage.

Check for low propane gas pressure.

Check thermostat for proper temperature setting.

Check for blown fuses and circuit breakers.

Check to be sure blower access panel is properly in place.

MODEL 352MAV DIAGNOSTIC CHART

(See Fig. 3.)

FAULT

CODE FAULT CODE DESCRIPTION CHECKLIST

13 or 33 Limit Switch Lockout

14 or 34

24 Furnace Fuse Open Check for blown fuse and possible short in 24-v wiring.

31, 32, 43 Pressure Switch Fault

12, 21, 22,

23 or 45

No Fault

Code

Signaled

Ignition Lockout or

Ignition Proving Fault

Any Other Fault Code Call dealer for service.

Furnace Fails to Operate and No

Fault is Signaled

NOTES:

1. Light on continuously means control has power and working properly.

2. The fault code is a 2-digit number. The first digit is determined by the number of short flashes of the light and the second digit is determined by number of long flashes

of the light.

Check for dirty air filter.

Check for blocked return-air or supply-air grilles.

Check to be sure manual shutoff valve in gas supply pipe is in the open position. (Follow

start-up procedure if you open gas line.)

NOTE: Turn off the electrical supply and remove access doors before continuing with this

checklist.

Check to be sure control switch on gas valve is in ON position. (Follow start-up procedures if

you must reset switch to ON position.)

Check for disconnected ground wire.

Check to make sure that all PVC pipes leading into the combustion-air intake and vent/

exhaust are free from any cracks and sags. Also check the combustion-air intake and vent/

exhaust pipes on the outside of your home for blockage.

Check for low propane gas pressure.

Check thermostat for proper temperature setting.

Check for blown fuses and circuit breakers.

Check to be sure blower access panel is properly in place.

11

Page 12

MODEL 355MAV DIAGNOSTIC CHART

(See Fig. 4.)

FAULT

CODE FAULT CODE DESCRIPTION CHECKLIST

12 Blower Calibration Lockout Check for dirty air filter.

13 or 33 Limit Switch Lockout

14 or 34

24 Furnace Fuse Open Check for blown fuse and possible short in 24-v wiring.

31, 32, or 43 Pressure Switch Fault Check to make sure that all PVC pipes leading into the combustion-air intake and vent/

42

44 Blower Calibration Fault

21, 22, 23,

or 41

No Fault

Code

Signaled

Ignition Lockout or

Ignition Proving Fault

Inducer Outside Valid

Speed Range

Any Other Fault Code or Either of the

Red Lights On Continuously

Furnace Fails to Operate and No

Fault is Signaled

NOTES:

1. Red light 1 on continuously means furnace is operating in emergency heat.

2. Red light 2 on continuously means the microprocessor board has malfunctioned.

3. Yellow light on continuously means furnace is operating in high heat.

4. Green light on continuously means furnace is operating in low heat.

5. The fault code is a 2-digit number. The first digit is determined by the number of flashes of the yellow light and the second digit is determined by number

of flashes of the green light.

Check for blocked return-air or supply-air grilles.

Turn electrical supply off, then back on. Set the thermostat to call for heat.

Check to be sure manual shutoff valve in gas supply pipe is in open position. (Follow startup procedure if you open gas line.)

NOTE: Turn off the electrical supply and remove access doors before continuing with this

checklist.

Check to be sure control switch or knob on gas valve is in ON position. (Follow start-up

procedures if you must reset switch or knob to ON position).

Check for disconnected ground wire.

exhaust are free from any cracks and sags. Also check the combustion-air intake and

vent/exhaust pipes on the outside of your home for blockage.

Check for low propane gas pressure.

Check for dirty air filter(s).

Check for blocked return- or supply-air grilles.

NOTE: In zoned applications, fault 44 may flash during operation when a single zone is

calling for heat. When other zones call for heat, or the unit cycles, the fault should clear

itself. Call for service if fault 12 develops.

Call dealer for service.

Check thermostat for proper temperature setting.

Be sure thermostat is set to HEAT.

Check for blown fuses and circuit breakers.

Check to be sure blower access panel is properly in place.

© 2001 Bryant Heating & Cooling Systems, 7310 W. Morris St., Indpls., IN 46231

12 Printed in U.S.A. Catalog No. 5335-202 3-01

Cancels: OM05-30 OM05-32

Loading...

Loading...