Bryant 925SA Series, 925SA030040, 925SA042060, 925SA048080, 925SA048100 Product Data

...

925SA

PREFERREDt SERIES SINGLE--STAGE

4--WAY MULTIPOISE

CONDENSING GAS FURNACE, SERIES A

Product Data

A11264

The 925SA Multipoise SEER Boost Condensing Gas Furnace

features the single--stage Preferred™ System. The multi--tap ECM

blower motor is at the heart of the electrical efficiency provided by

this furnace. With an Annual Fuel Utilization Efficiency (AFUE)

of 96.2%, the Preferred single--stage gas furnace provides added

savings over standard gas furnaces. This Preferred Gas Furnace

features 4--way multipoise installation flexibility, and is available in

five model sizes. The 925SA can be vented for direct

vent/two--pipe, ventilated combustion air, or single--pipe

applications. A Bryant Preferred Control and Preferred Air

Conditioner or Heat Pump, can be used to form a complete

Preferred Series System. All units meet California Air Quality

Management District emission requirements. All sizes are design

certified in Canada.

STANDARD FEATURES

S Quiet operation. Compare for yourself at HVACpartners.com

S Ideal height 35” (889 mm) cabinet: short enough for taller coils,

but still allows enough room for service

S Preferred Features—match with the Preferred Control for

Preferred System benefits

S Silicon Nitride Perfect Light™ Hot Surface Igniter

S SmartEvap™ technology helps control humidity levels in the

home when used with a compatible humidity control system

S FanOnPlus™ technology allows control ofcontinuous fan

speed from a compatible thermostat

S External Media Filter Cabinet included

S 4--way multipoise design for upflow, downflow or horizontal

installation, with unique vent elbow and optional through-the--cabinet downflow venting capability

S Multi--tap ECM blower motor, single--speed inducer motor, and

single--stage gas valve

S Self--diagnostics

S Adjustable blower speed for cooling, continuous fan, and

dehumidification

S Aluminized--steel primary heat exchanger

S Stainless--steel condensing secondary heat exchanger

S Propane convertible (See Accessory list)

S Factory--configured ready for upflow applications

S Fully--insulated casing including blower section

S Convenient Electronic Air Cleaner and Humidifier connections

S Direct--vent/sealed combustion, single--pipe venting or

ventilated combustion air

S Installation flexibility: sidewall or vertical vent

S Residential installations may be eligible for consumer financing

through the Retail Credit Program

LIMITED WARRANTY*

S 10 year parts and lifetime heat exchanger limited warranty to the

original purchaser upon timely registration.

S Limited warranty period is five years for parts and twenty years

for the heat exchanger if not registered within 90 days of

installation.{

* For owner occupied, residential applications.

{Jurisdictions where warranty benefits cannot be conditioned on registra-

tion will receive registered limited warr anty benefits.

CERTIFIED

Use of the AHRI Certified TM Mark indicates a

manufacturer’s participation in the program. For

verification of certification for individual products,

go to www.ahridirectory.org.

1

Always Ask For

SPECIFICATIONS

Heating Capacity and Efficiency 030040 042060 048080 048100 066120

Input High Heat (BTUH) 40,000 60,000 80,000 100,000 120,000

Output High Heat (BTUH) 39,000 58,000 78,000 98,000 117,000

Efficiency AFUE % (ICS) 96.2 96.2 96.2 96.2 96.2

Certified Temperature

Rise Range ºF (ºC)

Airflow Capacity and Blower Data 030040 042060 048080 048100 066120

Certified External Static

Pressure (in. w.c.)

Airflow Delivery

@RatedESP(CFM)

Cooling Cap acity (tons)

@ 400, 350 CFM/ton

Direct-Drive Motor Type Electronically Commutated Motor (ECM)

Direct-Drive Motor HP 1/2 3/4 3/4 1 1

Motor Full Load Amps 6.8 8.4 8.4 10.9 10.9

RPM Rang e 600 - 1200

Speed Selections 5

Blower Wheel Dia x Width in. 11x7 11x8 11x8 11x10 11 x 11

Air Filtration System

Filter Used for Certified Watt Data

Electrical Data 030040 042060 048080 048100 066120

Input Voltage Volts-Hertz-Phase 115-60-1

Operating Voltage Range Min-Max 104-127

Maximum Input Amps Amps 8.1 9.7 9.7 12.2 12.2

Unit Ampacity Amps 11.0 13.0 13.0 16.1 16.1

Minimum Wire Size AWG 14 14 14 12 12

Maximum Wire Length

@ Minimum Wire Size

Maximum Fuse/Ckt Bkr

(Time-Delay Type Recommended)

Transformer Capacity (24vac output) 40 VA

External Control Power

Available

Controls 030040 042060 048080 048100 066120

Gas Connection Size 1/2” - NPT

Burners (Monoport) 2 3 4 5 6

Gas Valve (Redundant)

Gas C onversion Kit - Natural to Propane KGANP50011SP

Gas Conversion Kit - Propane to Natural KGAPN42011SP

Manufactured (Mobile) Home Kit KGAMH0301KIT

Ignition Device Silicon Nitride

Limit Control 165 180 170 160 160

Heating Blower Control (Heating Off-Delay) Adjustable: 90, 120, 150, 180 seconds

Cooling Blower Control (Time Delay Relay) 90 seconds

Communication System none

Thermostat Connections Y1, DHUM, G C W, Y/Y2, R

Accessory Connections EAC (115vac); HUM (24vac); 1-stg AC (via Y/Y2)

High Heat

Heating 0.10 0.12 0.15 0.20 0.20

Cooling 0.5 0.5 0.5 0.5 0.5

High Heat 695 1000 1360 1730 2125

Cooling 925 1505 1610 1720 2055

400 CFM/ton 2 3.5 4 4 5

350 CFM/ton 2.5 4 4.5 5 6

Feet 33 28 28 35 35

(M) (10.1) (8.5) (8.5) (10.7) (10.7)

Amps 15 15 15 20 20

Heating 24.3 VA

Cooling 34.6 VA

Manufacturer White Rogers™

Minimum Inlet Gas

pressure (in. W.C.)

Maximum Inlet Gas

pressure (in. W.C.)

40 - 70

(21-38)

KGAWF1606UFR KGAWF1306UFR KGAWF1406UFR KGAWF1506UFR KGAWF1506UFR

40 - 70

(21-38)

Factory Supplied Media Cabinet

40 - 70

(21-38)

FieldSuppliedFilter

4.5

13.6

40 - 70

(21-38)

40 - 70

(21-38)

2

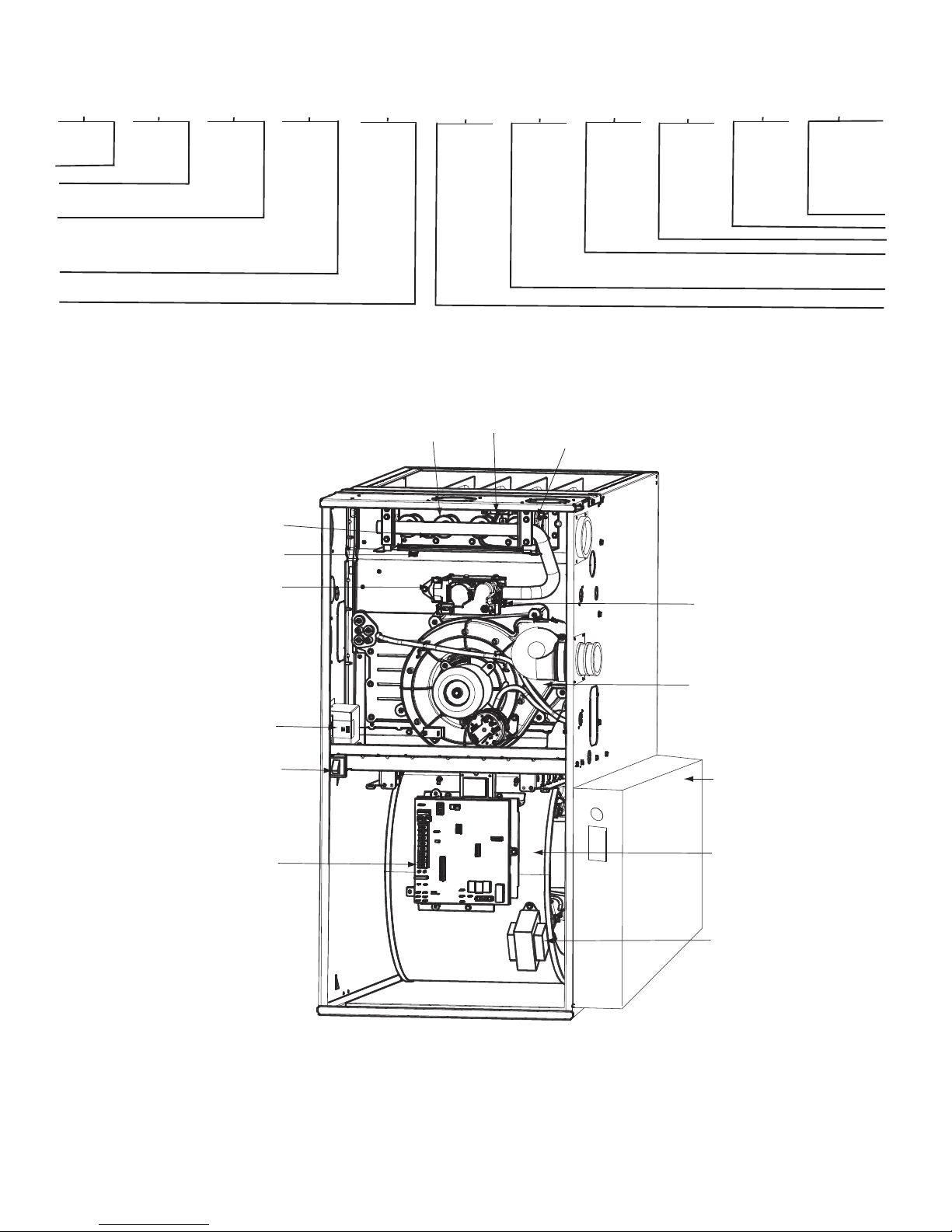

MODEL NUMBER NOMENCLATURE

1 - 2

Family/Tier

92

91 - Legacy

92 - Preferred

98 - Evolution

3

Base Eff.

5

0 --- 90 AFUE

3 --- 93 AFUE

5 --- 95 AFUE

6 --- 96 AFUE

7 --- 97 AFUE

Htg. Stages

S - Single Stage

T - Two Stage

M - Modulating

MANUAL RESET

ROLLOUT SWITCH

OPERATING INSTRUCTIONS

NOT SHOWN (LOCATED ON

MAIN FURNACE DOOR, SEE

OPERATING INSTRUCTIONS

INSIDE DOOR FIGURE).

ELECTRICAL JUNCTION

BOX (IF REQUIRED,

LOCATION MAY VARY)

4

S

FLAME

SENSOR

GAS VALVE

5

Major Series

A

Major Series

6 - 7

Clg. Cap.

30

24 - 800 CFM

30 - 1000 CFM

36 - 1200 CFM

42 - 1400 CFM

48 - 1600 CFM

54 - 1800 CFM

60 - 2000 CFM

66 - 2200 CFM

(@ 0.5” ESP)

Not all familes have these models.

8 - 10

Htg. Cap.

040

040=40,000 BTU

060=60,000 BTU

080=80,000 BTU

100=100,000 BTU

120=120,000 BTU

11

Motor

E

S - Standard

E - Energy Efficient

V - Variable Speed

FURNACE COMPONENTS

HOT SURFACE

GAS BURNER

IGNITER

MANUAL RESET

ROLLOUT SWITCH

12 - 13

Width

14

14 - 14.2”

17 - 17.5”

21 - 21.0”

24 - 24.5”

14

Voltage

A

Voltage

MAIN LIMIT SWITCH

(BEHIND GAS VALVE)

INDUCER MOTOR

ASSEMBLY

15

Features

--

L - Low NOx

16

Minor Series

A

A11165

BLOWER DOOR

SAFETY SWITCH

FURNACE

CONTROL

BOARD

RATING PLATE NOT SHOWN

(LOCATED ON BLOWER DOOR)

REPRESENTATIVE DRAWING ONLY, SOME MODELS MAY VARY IN APPEARANCE.

3

MEDIA CABINET

BLOWER AND

MOTOR

CAPACITOR/

POWER CHOKE

(IF USED)

A11408

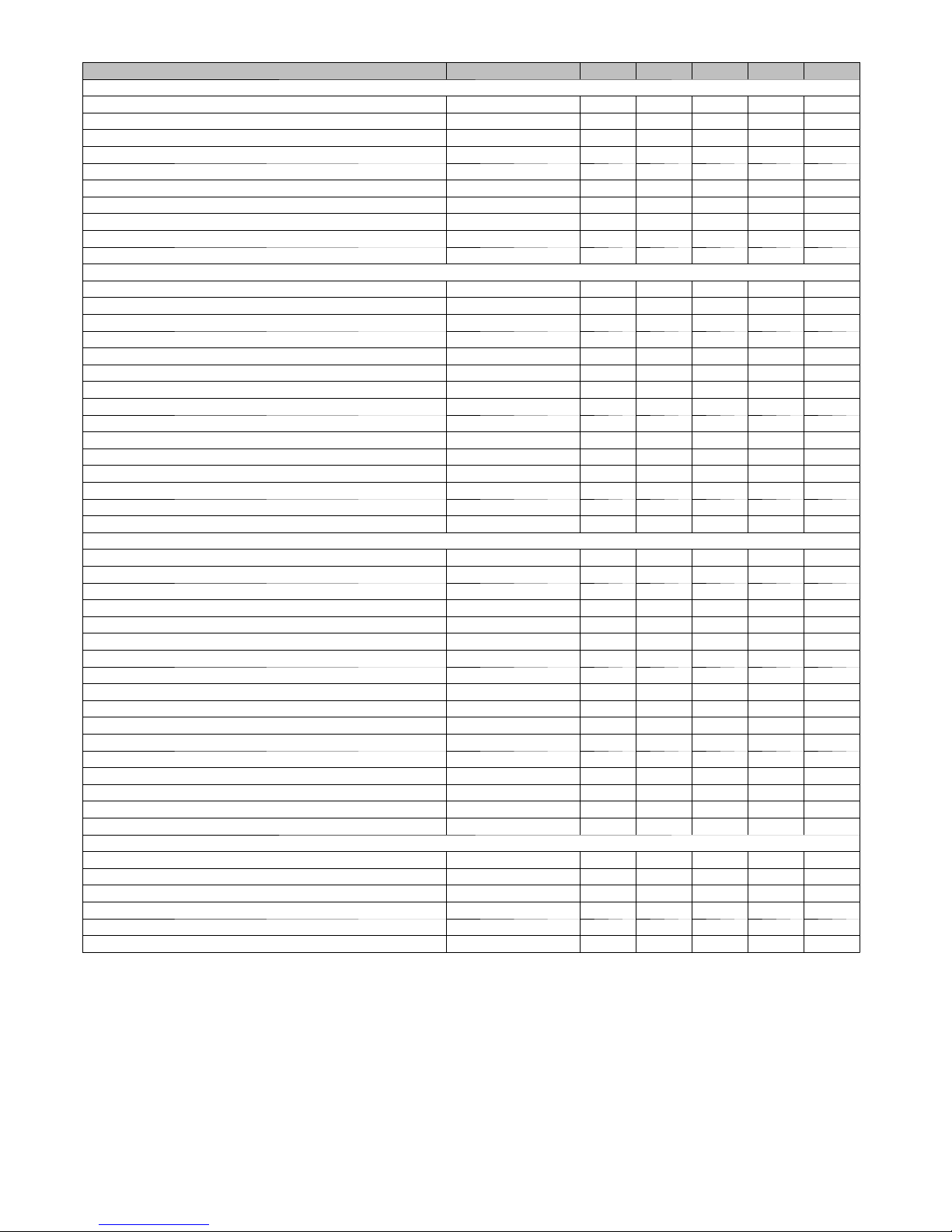

ACCESSORIES

DESCRIPTION PAR T NUM BER 030040 042060 048080 048100 066120

Venting, Drainage and Installation

Vent Kit - Through the Cabinet KGADC0101BVC X X X X X

Vent Terminal - Concentric - 2” (51 mm) KGAVT0701CVT X X X X N/A

Vent Terminal - Concentric - 3” (76 mm) KGAVT0801CVT N/A X X X X

Vent Terminal Bracket - 2” (51 mm) KGAVT0101BRA X X X X N/A

Vent Terminal Bracket - 3” (76 mm) KGAVT0201BRA N/A X X X X

CPVC to PVC Drain Adapters - 1/2” CPVC to 3/4” PVC KGAAD0110PVC X X X X X

Horizontal Trap Grommet - Direct Vent KGACK0101HCK X X X X X

Freeze Protect Kit - Heat Patch for Drain Trap KGAHT0201CFP X X X X X

Freeze Protect Kit - Heat Tape KGAHT0101CFP X X X X X

Furnace Base Kit for Combustible Floors KGASB0201ALL X X X X X

Gas Conversion

Mfg Home Kit - Single-stage KGAMH0601KIT X X X X X

GasCnvKit-NattoLP;Single-stage KGANP50011SP X X X X X

Gas Cnv Kit - LP to Nat; Single-stage KGAPN42011SP X X X X X

GasOrificeKit-#42(NatGas) KGAHA0150N42 X X X X X

GasOrificeKit-#43(NatGas) KGAHA0250N43 X X X X X

GasOrificeKit-#44(NatGas) KGAHA0350N44 X X X X X

GasOrificeKit-#45(NatGas) KGAHA0450N45 X X X X X

GasOrificeKit-#46(NatGas) KGAHA0550N46 X X X X X

GasOrificeKit-#47(NatGas) KGAHA1550N47 X X X X X

GasOrificeKit-#48(NatGas) KGAHA1650N48 X X X X X

Gas Orifice Kit - #54 (LP) KGAHA0650P54 X X X X X

Gas Orifice Kit - #55 (LP) KGAHA0750P55 X X X X X

Gas Orifice Kit - #56 (LP) KGAHA0850P56 X X X X X

Gas Orifice Kit - 1.25mm (LP) KGAHA5750125 X X X X X

Gas Orifice Kit - 1.30mm (LP) KGAHA5750130 X X X X X

Indoor Air Quality

Bryant Perfect Air Purifier - 16x25 (406x635mm) GAPAAXBB1625-A08 X X X X X

Bryant Perfect Air Purifier - 20x25 (508x635mm) GAPAAXBB2025-A08 X X X X X

Bryant Perfect Air Purifier Repl. Filter- 16x25 (406x635mm) GAPABBCAR1625-A05 X X X X X

Bryant Perfect Air Purifier Repl. Filter- 20x25 (508x635mm) GAPABBCAR1625-A05 X X X X X

EZ Flex Cabinet 16” (406 mm) EZXCABCC1016-A20 X X X X X

EZ Flex Cabinet 20” (508 mm) EZXCABCC1020-A20 X X X X X

Cartridge Media Filter - 16” (406 mm) FILXXCAR0016 X X X X X

Cartridge Media Filter - 20” (508 mm) FILXXCAR0020 X X X X X

Cartridge Media Filter - 24” (610 mm) FILXXCAR0024 N/A X X X X

EZ-Flex Filter - 16” (406 mm) EXPXXFIL0016 X X X X X

EZ-Flex Filter - 20” (508 mm) EXPXXFIL0020 X X X X X

EZ-Flex Filter - 24” (610 mm) EXPXXFIL0024 N/A X X X X

EZ-Flex Filter with End Caps - 16” (406 mm) EXPXXUNV0016 X X X X X

EZ-Flex Filter with End Caps - 20” (508 mm) EXPXXUNV0020 X X X X X

EZ-Flex Filter with End Caps - 24” (610 mm) EXPXXUNV0024 N/A X X X X

Filter Pack (6 pack) - Washable - 16x25x1 (406x635x25 mm) KGAWF1306UFR X X X X X

Filter Pack (6 pack) - Washable - 24x25x1 (610x635x25 mm) KGAWF1506UFR N/A X X X X

Controls

Programmable Relative Humidity Thermostat T6-PRH01-A X X X X X

Programmable Thermostat (HP or AC) T6-PHP01 X X X X X

Programmable Thermostat (AC only) T6-PAC01 X X X X X

Non-Programmable Relative Humidity Thermostat T6-NRH01 X X X X X

Non-Programmable Thermostat (HP or AC) T6-NHP01 X X X X X

Non-Programmable Thermostat (AC only) T6-NAC01 X X X X X

X = Used with this model furnace

N/A = Not used with this model furnace

4

INPUT

BTUH

40000 SIDE/BOTTOM

60000 SIDE/BOTTOM

80000 SIDE/BOTTOM

100000 SIDE/BOTTOM

120000

RETURN-AIR

SUPPLY

BOTTOM OR

TWO SIDES

AIR DELIVERY -- CFM (BOTTOM RETURN WITH FILTER)

SPEED

5(Gry) 1120 1080 1030 980 925 875 820 760 690 630

4(Yel) 880 845 810 780 740 710 680 640 615 570

3(Blu) 695 665 620 575 535 495 455 420 370 280

2(Org) 640 595 540 495 460 420 370 310 260 230

1(Red) 570 525 475 425 385 330 255 220 - -

5(Gry) 1720 1670 1620 1565 1505 1440 1375 1295 1220 1135

4(Yel) 1325 1285 1255 1220 1185 1145 1115 1075 1040 1000

3(Blu) 1010 970 925 875 835 785 745 690 660 620

2(Org) 1160 1115 1080 1045 1000 960 920 875 840 785

1(Red) 785 715 655 595 530 490 435 385 340 285

5(Gry) 1810 1770 1720 1665 1610 1540 1475 1400 1315 1235

4(Yel) 1535 1500 1475 1435 1405 1370 1340 1310 1245 1160

3(Blu) 1380 1340 1305 1270 1240 1200 1165 1130 1090 1050

2(Org) 1180 1130 1095 1060 1015 975 935 895 850 800

1(Red) 1100 1045 1010 970 920 885 845 790 745 690

5(Gry) 2040 1970 1885 1795 1720 1635 1540 1450 1360 1230

4(Yel) 1550 1505 1460 1415 1365 1325 1280 1230 1180 1135

3(Blu) 1780 1730 1690 1645 1610 1555 1481 1400 1310 1210

2(Org) 1345 1295 1250 1195 1155 1105 1055 1000 955 915

1(Red) 1390 1350 1295 1260 1200 1160 1105 1050 1010 965

5(Gry) 2275 2230 2185 2130 2055 1950 1825 1710 1610 1500

4(Yel) 1875 1820 1770 1720 1660 1600 1550 1505 1450 1390

3(Blu) 2170 2125 2075 2025 1975 1900 1790 1695 1590 1470

2(Org) 1475 1420 1350 1280 1215 1165 1105 1050 995 930

1(Red) 1625 1565 1505 1445 1385 1325 1275 1225 1170 1130

0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1

EXTERNAL STATIC PRESSURE (IN. W.C.)

*A filter is required for each r eturn --- air inlet. Airflow performance included 3/4 ---in. (19 mm) washable filter media such as con tained in factory --- a u t h o r i z e d

accessory filter rack. To determine airflow performance without this filter, assume an additional 0.1 in. W.C. available external static pressure.

--- Indicates unstable operating conditions.

5

Loading...

Loading...