Page 1

915SA 95 AFUE

LEGACY LINE SINGLE--STAGE

4--WAY MULTIPOISE

CONDENSING GAS FURNACE

Product Data

A11264

The 915S Multipoise Condensing Gas Furnace is part of the

Legacy Line product offering. Sporting a PSC blower motor and

an Annual Fuel Utilization Efficiency (AFUE) of 95.5%, this

single-stage gas furnace provides efficient comfort for

homeowners. This Legacy Line Gas Furnace also features 4-way

multipoise installation flexibility, and is available in nine model

sizes. The 915S can be vented for direct vent/two-pipe, ventilated

combustion air, or single-pipe applications. A BryantR Air

Conditioner or Heat Pump can be used to form a complete system.

All units meet California Air Quality Management District

emission requirements. These furnaces are approved for

Manufactured Housing (Mobile Home) applications. All sizes are

design certified in Canada.

STANDARD FEATURES

S 4-way multipoisedesign for upflow, downflow or horizontal

installation.

S Optional through-the-cabinet downflow venting.

S Installation flexibility with a 360-degree rotating elbow.

S Ideal condensing furnace height 35” cabinet: short enough for

taller coils, but still allows enough room for service.

S Silicon Nitride Perfect Lightt Hot Surface Igniter.

S Aluminized-steel primary heat exchanger.

S Stainless-steel condensing secondary heat exchanger.

S High-quality corrosion-resistant prepainted steel cabinet with

hemmed edges for safety.

S Factory-configured ready for upflow applications.

S Direct-vent/sealed combustion, single-pipe venting or ventilated

combustion air.

S PSC blower motor, single-speed inducer motor, and single-stage

gas valve.

S Self-diagnostics

S Approved for Twinning applications (42060 through 60120

sizes, only).

S Propane convertible (See accessory list).

S Approved for Manufactured Housing/Mobile Homeapplications

(except 140,000 Btuh input) with MH accessory kit.

S Convenient Air Purifier and Humidifier connections.

S Residential installations may be eligible for consumer financing

through the Retail Credit Program.

S Certified to leak 2% or less of nominal air conditioning CFM

delivered when pressurized to 1-inch water column with all

present air inlets, air outlets, and condensate drain port(s) are

sealed.

LIMITED WARRANTY*

S 10 year parts and lifetime heat exchanger limited warranty to the

original purchaser upon timely registration.

S Limited warranty period is five years for parts and twenty years

for the heat exchanger if not registered within 90 days of

installation.{

* For owner occupied, residential applications.

{Jurisdictions where warranty benefits cannot be conditioned on registra-

tion will receive registered limited warranty benefits.

Use of the AHRI Certified TM Mark indicates a

manufacturer’s participation in the program. For

verification of certification for individual products,

go to www.ahridirectory.org.

CERTIFIED

1

Page 2

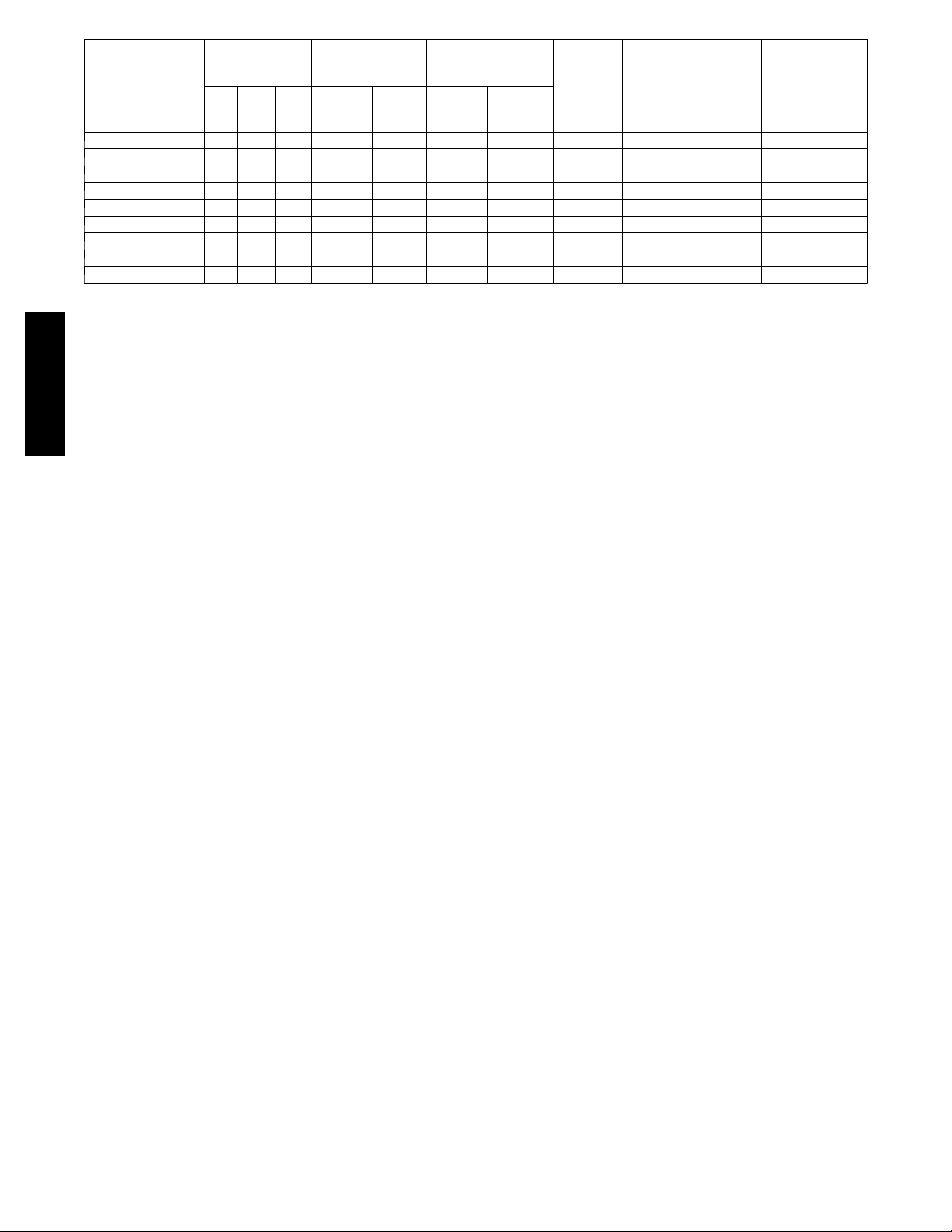

CASING

DIMENSIONS

SAP ORDERING

NO.

915SA30040S14 35 29.5 14.2 39,000 95.5% 820 0.10 625-905 1/2 - 4 123

915SA30060S14 35 29.5 14.2 58,000 95.5% 840 0.12 675-1130 1/2 - 4 127

915SA42060S17 35 29.5 17.5 58,000 95.5% 980 0.12 650-1420 1/2 - 5 144

915SA48080S17 35 29.5 17.5 78,000 95.5% 1040 0.15 810-1600 3/4 - 5 154

915SA60080S21 35 29.5 21.0 78,000 95.5% 1500 0.15 1225-2025 3/4 - 5 162

915SA42100S21 35 29.5 21.0 97,000 95.5% 1565 0.20 695-1565 3/4 - 5 169

915SA60100S21 35 29.5 21.0 97,000 95.5% 1520 0.20 1225-2145 3/4 - 5 169

915SA60120S24 35 29.5 24.5 117,000 95.5% 2065 0.20 1245-2065 3/4 - 5 186

915SA60140S24 35 29.5 24.5 135,000 95.5% 2100 0.20 1230-2100 3/4 - 5 190

† Capacity in accordance with DOE test procedures. See rating plate.

‡ Heating CFM at factory default blower motor heating tap settings.

ESP --- External Static Pressure

(IN.)

H D W (BTUH) AFUE CFM‡

RATED HEATING

OUTPUT†

HEATING AIRFLOW

Heating

ESP

(in. WC)

COOLING

CFM

@0.5ESP

(in WC)

MOTOR HP-SPEED

APPROX SHIP

WEIGHT (LB)

FEATURES AND BENEFITS

HYBRID HEATR Dual Fuel system — This system can provide

more control over your monthly energy bills by automatically

915SA

selecting the most economical method of heating. With HYBRID

HEAT, our system automatically switches between the gas furnace

and the single--stage electric heat pump as outside temperatures

change to maintain greater efficiency and comfort than with any

traditional single-source heating system. The heat pump also

delivers high-efficiency cooling in the summer.

Power Heatt Igniter — Bryant’s unique SiN igniter is not only

physically robust but it is also electrically robust. It is capable of

running at line voltage and does not require complex voltage

regulators as do other brands. This unique feature further enhances

the gas furnace reliability and continues Bryant’s tradition of

technology leadership and innovation in providing a reliable and

durable product.

Reliable Heat Exchanger Design — The aluminized steel,

clamshell primary heat exchanger was reengineered to achieve

greater efficiency out of a smaller size. The first two passes of the

heat exchanger are based on the current 80% product, a design

with more than ten years of field-proven performance and success.

These innovations, paired with the continuation of a crimped,

no-weld seam create an efficient, robust design for this essential

component.

The condensing heat exchanger, a stainless steel fin and tube

design, is positioned in the furnace to extract additional heat.

Stainless steel coupling box componentry between heat exchangers

has exceptional corrosion resistance in both natural gas and

propane applications.

4-Way Multipoise Design — One model for all applications –

there is no need to stock special downflow or horizontal models

when one unit will do it all. The new heat exchanger design allows

these units to achieve the certified AFUE in all positions.

Direct or Single-pipe Venting, or Optional Ventilated

Combustion Air — This furnace can be installed as a 2-pipe

(Direct Vent) furnace, in an optional ventilated combustion air

application, or in single-pipe, non-direct vent applications. This

provides added flexibility to meet diverse installation needs.

Sealed Combustion System — This furnace brings in combustion

air from outside the furnace, which results in especially quiet

operation. By sealing the entire combustion vestibule, the entire

furnace can be made quieter, not just the sound of the burners.

Monoport Burners — The burners are specially designed and

finely tuned for smooth, quiet combustion and economical

operation.

Bottom Closure — Factory--installed for side return; easily

removable for bottom return. The multi-use bottom closure can

also serve for roll-out protection in horizontal applications, and act

as the bottom closure for the optional return air base accessory.

Blower Access Panel Switch — Automatically shuts off 115-v

power to furnace whenever blower access panel is opened.

Quality Registration — Our furnaces are engineered and

manufactured under an ISO 9001 registered quality system.

Certifications — This furnace is CSA (AGA and CGA) design

certified for use with natural and propane gases. The furnace is

factory--shipped for use with natural gas. A CSA listed gas

conversion kit is required to convert furnace for use with propane

gas. The efficiency is GAMA efficiency rating certified. This

furnace meets California Air Quality Management District

emission requirements.

2

Page 3

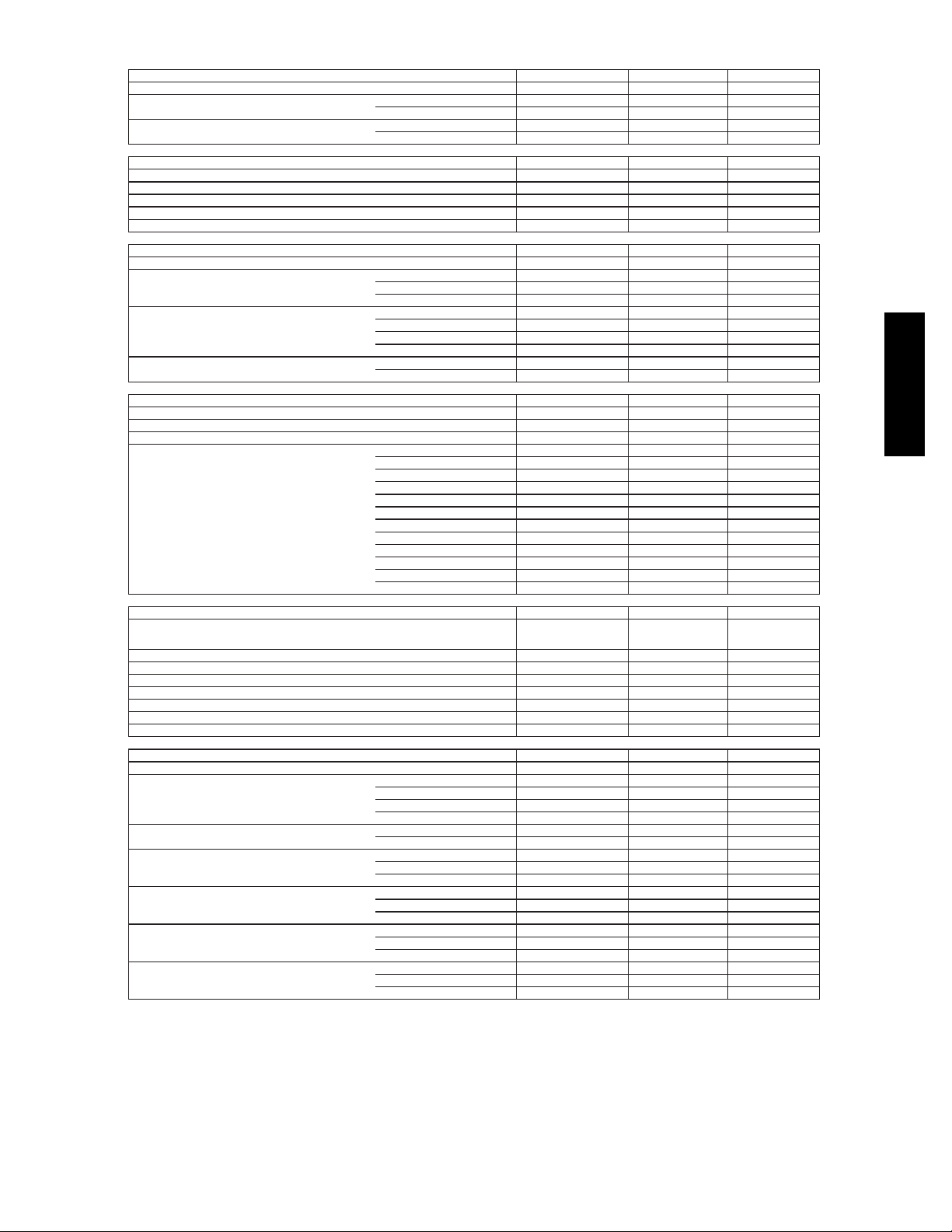

SPECIFICATIONS

Heating Capacity and Efficiency 30040 30060 42060 48080 60080 42100 60100 60120 60140

Input High

Output High

Efficiency AFUE % (ICS) 95.5 95.5 95.5 95.5 95.5 95.5 95.5 95.5 95.5

Certified Temperature

Rise Range ºF (ºC)

Airflow Capacity and Blower Data 30040 30060 42060 48080 60080 42100 60100 60120 60140

Certified External Static

Pressure (in. w.c.)

Airflow Delivery

@ Rated ESP (CFM)

Cooling Capacity (tons)

@ 400, 350 CFM/ton

Direct-Drive Motor Type Permanent Split Capacitor (PSC)

Direct-Drive Motor HP 0.5 0.5 0.5 0.75 0.75 0.75 0.75 0.75 0.75

Motor Full Load Amps 6.2 6.2 6.8 7.9 13.8 6.5 13.8 14.1 14.1

RPM Range 500-1150

Speed Selections 4 4 5 5 5 5 5 5 5

Blower Wheel Dia x Width in. 11 x 7 11 x 7 11 x 8 11 x 8 11 x 10 11 x 10 11 x 10 11 x 11 11 x 11

Air Filtration System Field Supplied

Filter Used for Certified Watt Data

Electrical Data 30040 30060 42060 48080 60080 42100 60100 60120 60140

Input Voltage Volts-Hertz-Phase 115-60-1

Operating Voltage Range Min-Max 104-127

Maximum Input Amps Amps 6.8 7.0 8.4 9.6 14.5 7.6 14.6 14.9 14.9

Unit Ampacity Amps 9.5 9.7 11.5 13.0 19.1 10.4 19.2 19.6 19.6

Minimum Wire Size AWG 14 14 14 14 12 14 12 12 12

Maximum Wire Length Feet 39 38 32 28 30 35 29 29 29

@ Minimum Wire Size (M) (11.9) (11.6) (9.8) (8.5) (9.1) (10.7) (8.8) (8.8) (8.8)

Maximum Fuse/Ckt Bkr

(Time-Delay Type Recommended)

Transfomer Capacity (24vac output) 40 VA

External Control Power Available Heating 27.9 VA

Heat

Heat

High Heat 40 - 70

(BTUH) 40,000 60,000 60,000 80,000 80,000 100,000 100,000 120,000 140,000

(BTUH) 39,000 58,000 58,000 78,000 78,000 97,000 97,000 117,000 135,000

(22 - 39)

Heating 0.10 0.12 0.12 0.15 0.15 0.20 0.20 0.20 0.20

Cooling 0.5 0.5 0.5 0.5 0.5 0.5 0.5 0.5 0.5

High Heat 820 840 980 1040 1500 1565 1520 2210 2190

Cooling 905 1130 1420 1600 2025 1565 2145 2065 2100

CFM/ton 2 2.5 3.5 4 5 4 5 5 5

CFM/ton 2.5 3 4 4.5 5.5 4.5 6 6 6

KGAWF1606UFR KGAWF1306UFR KGAWF1406UFR KGAWF1506UFR

Amps 15 15 15 15 20 15 20 20 20

Cooling 34.6 VA

40 - 70

(22 - 39)

40 - 70

(22 - 39)

40 - 70

(22 - 39)

40 - 70

(22 - 39)

40 - 70

(22 - 39)

40 - 70

(22 - 39)

40 - 70

(22 - 39)

45 - 75

(25 - 42)

915SA

Controls 30040 30060 42060 48080 60080 42100 60100 60120 60140

Gas Connection Size 1/2" - NPT

Burners (Monoport) 2 3 3 4 4 5 5 6 7

Gas Valve (Redundant) Manufacturer White Rogers

Minimum Inlet Gas pressure (in. wc) 4.5

Maximum Inlet Gas pressure (in. wc) 13.6

Gas Conversion Kit - Natural to Propane KGANP50011SP

Gas Conversion Kit - Propane to Natural KGAPN42011SP

Manufactured (Mobile) Home Kit KGAMH0601KIT N/A

Ignition Device Silicon Nitride

Limit Control 165 165 180 170 200 180 180 160 155

Heating Blower Control (Heating Off-Delay) Adjustable: 90, 120, 150, 180 seconds

Cooling Blower Control (Time Delay Relay) 90 seconds

Communication System none

Thermostat Connections Com24V,R,W,G,Y

Accessory Connections EAC (115vac); HUM (24vac)

3

Page 4

1 - 2

Family/Tier

91

91 - Legacy

92 - Preferred

98 - Evolution

3

Base Eff.

5

0 --- 90 AFUE

3 --- 93 AFUE

5 --- 95 AFUE

6 --- 96 AFUE

7 --- 97 AFUE

4

Htg. Stages

S

S - Single Stage

T - Two Stage

M - Modulating

MODEL NUMBER NOMENCLATURE

5

Major Series

A

Major Series

6 - 7

Clg. Cap.

30

24 - 800 CFM

30 - 1000 CFM

36 - 1200 CFM

42 - 1400 CFM

48 - 1600 CFM

54 - 1800 CFM

60 - 2000 CFM

66 - 2200 CFM

(@ 0.5” ESP)

Not all familes have these models.

8 - 10

Htg. Cap.

040

040=40,000 BTU

060=60,000 BTU

080=80,000 BTU

100=100,000 BTU

120=120,000 BTU

140=140,000 BTU

11

Motor

S

S - Standard

E - Energy Efficient

V - Variable Speed

14 - 14.2”

17 - 17.5”

21 - 21.0”

24 - 24.5”

12 - 13

Width

14

Voltage

Voltage

14

A

15

Features

--

L - Low NOx

16

Minor Series

A

A12042

915SA

FLAME

SENSOR

MANUAL RESET

ROLLOUT SWITCH

GAS VALVE

OPERATING INSTRUCTIONS

NOT SHOWN (LOCATED ON

MAIN FURNACE DOOR, SEE

OPERATING INSTRUCTIONS

INSIDE DOOR FIGURE).

ELECTRICAL JUNCTION

BOX (IF REQUIRED,

LOCATION MAY VARY)

BLOWER DOOR

SAFETY SWITCH

FURNACE COMPONENTS

HOT SURFACE

GAS BURNER

IGNITER

MANUAL RESET

ROLLOUT SWITCH

MAIN LIMIT SWITCH

(BEHIND GAS VALVE)

INDUCER MOTOR

ASSEMBLY

MEDIA CABINET

FURNACE

CONTROL

BOARD

RATING PLATE NOT SHOWN

(LOCATED ON BLOWER DOOR)

REPRESENTATIVE DRAWING ONLY, SOME MODELS MAY VARY IN APPEARANCE.

4

BLOWER AND

MOTOR

CAPACITOR/

POWER CHOKE

(IF USED)

A11408

Page 5

ACCESSORIES

y

Vent Kit - Through the Cabinet

Vent Terminal - Concentric

Vent Terminal Bracket

2-in.

3-in.

2-in.

3-in.

Condensate Drainage Accessories

Venting Accessories

Freeze Protect Kit - Heat Patch for Drain Trap

CPVC to PVC Drain Adapter - 1/2-in. CPVC to 3/4-in. PVC

Freeze Protect Kit - Heat Tape

Horizontal Trap Grommet for Direct Vent Applications

Condensate Neutralizer Kit

Ductwork Adapter Accessories

Furnace Base Kit for Combustible Floors

Coil Adapters Kits - Painted

Return Air Base (Upflow applications) - Painted

IAQ Device Duct Adapters (side return) - Painted

No Offset

Single Offsett

Double Offset

14.2-in. wide

17.5-in. wide

21-in. wide

24.5-in. wide

20-in IAQ to 16-in side return

24-in IAQ to 16-in side return

Gas Conversion Accessories

Mfg Home Kit - Single-stage

Gas Cnv Kit - Nat to LP; Single-stage

Gas Cnv Kit - LP to N at; Single-stage

Gas Orifice Kit

#42 Natural Gas

#43 Natural Gas

#44 Natural Gas

#45 Natural Gas

#46 Natural Gas

#47 Natural Gas

#48 Natural Gas

#54 LP

#55 LP

#56 LP

1.25 mm LP

1.30 mm LP

Control Accessories

Twinning Kit

Zone Perfect: 3-Zone System (HP only)

Zone Perfect: 3-Zone System (AC only)

Programmable Thermostat (HP or AC) / (AC only)

Non-Programmable Thermostat (HP or AC) / (AC only)

Non-Programmable Standard Screen Thermostat (HP or AC) / (AC only)

Programmable Thermostat (HP or AC) / (AC only)

Non-Programmable Thermostat (HP or AC) / (AC only)

IAQ Accessories

52X61sretliF"1rofnruteRediS-kcaRretliF

14.2-in. wide

Filter Rack - Bottom Return for 1" Filters

Filter Pack (6 pack) - Washable

EZ-Flex Filter

EZ-Flex Filter with End Caps

Cartridge Media Filter

EZ Flex Cabinet - Side or Bottom Return for 4" Filters

(Use FILCAB for 24" furnaces)

17.5-in. wide

21-in. wide

24.5-in. wide

16 x 25 x 1

24 x 25 x 1

16-in.

20-in.

24-in.

16-in.

20-in.

24-in.

16-in.

20-in.

24.in.

16-in.

20-in.

24-in.

Notes:

1. CSA requires that a termination kit be used. See latest PD for pipe and kit size selection. The qualified installer or agency must use only

factor

-author ized kits when modifyingthese furnaces.

2. Not for use with Concentric Vent Termination Kits.

3. Las t 2 digits of Part Number indicate filter s ize.

4. Las t 2 digits of Part Number indicate orifice size.

5. Choose IAQ/filter assembly appropriate for the designed system airflow and static pressure. Us e optional IAQ Device Duct Adapters as required.

6. Av ailable from Replacement Com ponents group.

7. Kit coming soon. Expected availability 2Q2012.

Part Number Used With Notes

KGADC0101BVC All 1

KGAVT0701CVT See Venting Tables 1

KGAVT0801CVT See Venting Tables 1

KGAVT0101BRA See Venting Tables 1, 2

KGAVT0201BRA See Venting Tables 1, 2

Part Number Used With Notes

KGAHT0201CFP All 7

KGAHT0101CFP All KGAAD0110PVC All KGACK0101HCK All DV Horizontal -

P908-0001 All 6

Part Number Used With Notes

KGASB0201ALL All -

KGADA0101ALL All -

KGADA0201ALL All -

KGADA0301ALL All -

KGARP0301B14 14.2" Wide Furnaces 7

KGARP0301B17 17.5" Wide Furnaces 7

KGARP0301B21 21" Wide Furnaces 7

KGARP0301B24 24.5" Wide Furnaces 7

KGAAD0101MEC 20"x25" IAQ Devices 7

KGAAD0201MEC 24"x25" IAQ Devices 7

Part Number Used With Notes

KGAMH0601KIT All, except 140k -

KGANP50011SP All -

KGAPN42011SP All -

KGAHA0150N42 All 4, 6

KGAHA0250N43 All 4, 6

KGAHA0350N44 All 4

KGAHA0450N45 All 4

KGAHA0550N46 All 4

KGAHA1550N47 All 4

KGAHA1650N48 All 4

KGAHA0650P54 All 4, 6

KGAHA0750P55 All 4

KGAHA0850P56 All 4, 6

KGAHA5750125 All 4, 6

KGAHA5750130 All 4, 6

Part Number Used With Notes

KGATW0701HSI

ZONEBB3ZHP01 All ZONEBB3ZAC01 All -

T2-PHP01 / T2-PAC01 All T2-NHP01 / T2-NAC01 All -

T2SNHP01 / T2SNAC01 All -

T1-PHP01 / T1-PAC01 All T1-NHP01 / T1-NAC01 All -

Part Number Used With Notes

KGAFR0801SRE All 5

KGBFR0401B14 14.2" W ide Furnaces 3, 5

KGBFR0501B17 17.5" W ide Furnaces 3, 5

KGBFR0601B21 21" Wide Furnaces 3, 5

KGAFR0701B24 24.5" W ide Furnaces 3, 5

KGAWF1306UFR All 5

KGAWF1506UFR All 5

EXPXXFIL0016 EZXCAB--1016 3, 5

EXPXXFIL0020 EZXCAB--1020 3, 5

EXPXXFIL0024 EZXCAB--1024 3, 5

EXPXXUNV0016 EZXCAB--1016 3, 5

EXPXXUNV0020 EZXCAB--1020 3, 5

EXPXXUNV0024 EZXCAB--1024 3, 5

FILXXCAR0016 FILCABXL1016 3, 5

FILXXCAR0020 FILCABXL1020 3, 5

FILXXCAR0024 FILCABXL2024 3, 5

EZXCABBB1016 All 5

EZXCABBB1020 All 5

FILCABXL0024 All 5

42060, 48080, 60080,

42100, 60100, 60120

915SA

-

5

Page 6

AIR DELIVERY -- CFM (BOTTOM RETURN WITH FILTER)

UNIT

SIZE

RETURN-AIR

CONNECTION

SPEED

TAPS

2

0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1.0

Black 1100 1055 1010 960 905 850 795 740 685 620

30040 SIDE/BOTTOM

Yellow 955 915 875 830 790 740 695 645 590 530

Blue 820 795 765 730 695 655 615 570 515 460

Red 730 710 680 655 625 595 555 515 465 400

Black 1340 1295 1245 1190 1130 1065 1005 895 815 725

30060 SIDE/BOTTOM

Yellow 1035 1010 980 945 910 865 795 730 665 605

Blue 845 825 810 785 755 710 670 625 570 515

5

Red

770 750 730 710 675 640 600 560 510 455

Black 1665 1615 1550 1485 1420 1345 1270 1190 1105 985

Yellow 1340 1320 1295 1260 1215 1165 1110 1045 925 850

42060 SIDE/BOTTOM

Orange 1050 1045 1035 1015 995 960 915 845 785 725

Blue 985 980 975 950 930 900 845 795 740 690

5

Red

735 720 700 675 650 620 595 560 520 480

Black 1870 1810 1740 1670 1600 1525 1440 1355 1270 1180

Yellow 1525 1495 1460 1415 1365 1305 1240 1170 1090 990

48080 SIDE/BOTTOM

915SA

Orange 1375 1355 1330 1300 1260 1210 1155 1090 1025 940

Blue 1045 1040 1030 1010 985 960 920 875 825 745

5

Red

880 865 850 835 810 785 750 715 665 605

Black 2390 2320 2230 2125 2025 1920 1825 1720 1600 1475

Yellow 2010 1970 1925 1875 1805 1730 1655 1560 1460 1350

Orange 1670 1660 1650 1620 1585 1550 1485 1410 1330 1225

Blue 1500 1500 1495 1485 1460 1425 1380 1320 1255 1165

60080

BOTTOM or

TWO-SIDES

3,4

Red 1270 1260 1255 1245 1225 1195 1160 1125 1065 1000

Black 1780 1735 1685 1625 1565 1495 1415 1325 1240 1145

Blue 1605 1565 1520 1465 1410 1340 1265 1190 1110 1020

42100 SIDE/BOTTOM

Yellow 1345 1310 1270 1225 1175 1120 1060 995 920 835

Orange51130 1090 1045 1000 945 895 840 775 715 635

5

Red

900 855 800 750 695 640 590 525 470 405

Black 2510 2420 2330 2240 2145 2040 1920 1805 1675 1520

Yellow 2030 2010 1970 1925 1870 1805 1725 1630 1525 1400

Orange 1655 1660 1650 1635 1615 1575 1520 1450 1360 1270

Blue 1520 1520 1520 1520 1500 1475 1430 1360 1290 1200

60100

BOTTOM or

TWO-SIDES

3,4

Red 1265 1255 1250 1240 1225 1205 1175 1135 1085 1025

Black 2470 2375 2280 2175 2065 1940 1820 1695 1580 1475

Blue 2275 2210 2125 2045 1945 1835 1715 1605 1500 1395

Yellow 1690 1685 1670 1640 1590 1525 1455 1385 1295 1210

Orange51460 1465 1450 1430 1400 1355 1315 1255 1185 1105

5

Red

1310 1300 1290 1265 1245 1210 1165 1120 1060 985

60120

BOTTOM or

TWO-SIDES

3,4

Black 2485 2395 2300 2200 2100 1985 1865 1750 1635 1520

60140

NOTE:

1. A filter is required for each return---air inlet. Airflow performance includes a 3/4---in. (19 mm) washable filter media such as contained in a factory ---authorized accessory filter rack. See accessory list. To determine airflow performance without this filter, assume an additional 0.1 in. w.c.. available external static

pressure.

2. Blower speed taps are not always in the same order. Factory default blower connections are as follows:

a. Heating airflow --- BLUE (also used for Continuous Fan)

b. Cooling airflow --- BLACK (enabled when the Y terminal is energized)

ADJUST THE BLOWER SPEED TAPS AS NECESSARY FOR THE PROPER AIR TEMPERATURE RISE FOR EACH INSTALLATION.

3. Airflows over 1800 CFM require bottom return, two --- side retur n, or bottom and side return. A minimum filter size of 20” x 25” (508 x 635 mm) is required.

4. For upflow applications, air entering from one side into both the side of the furnace and a return air base counts as a side and bottom return.

5. Highlighted areas indicate that this airflow range is beyond the range allowed for heating. THESE AIRFLOW RANGES MAY ONLY BE USED FOR COOL-

ING.

BOTTOM or

TWO-SIDES

3,4

Blue 2260 2190 2110 2020 1925 1825 1700 1600 1495 1385

5

Yellow

1660 1650 1635 1615 1580 1530 1475 1410 1320 1230

Orange51430 1445 1440 1420 1390 1355 1310 1245 1175 1085

5

Red

1285 1285 1260 1255 1230 1205 1165 1115 1055 975

EXTERNAL STATIC PRESSURE (IN. W.C.)

6

Page 7

MAXIMUM EQUIVALENT VENT LENGTH -- FT. (M)

Table 1 – Maximum Equivalent Vent Length -- Ft. (M)

0 to 4500 Ft. (0 to 1370 M) Altitude

NOTE: Maximum Equivalent Vent Length (MEVL) includes standard and concentric vent termination and does NOT include elbows.

Use Table 2 - Deductions from Maximum Equivalent Vent Length to determine allowable vent length for each application.

Unit Size

Altitude

FT (M)

0 to 2000

(0 to 610)

2001 to 3000

(610 to 914)

3001 to 4000

(914 to 1219)

4001 to 4500

(1219 to

1370)

NOTES: See notes at end of venting tables.

See Table 3 for altitudes over 4500 ft. (1370 M)

BTU/Hr

3

40,000

60,000 30 (9.1) 135 (41.1) 235 (71.6) 265 (80.8) NA

80,000 20 (6.1) 70 (21.3) 175 (53.3) 235 (71.6) 265 (80.8)

100,000 NA 25 (7.6) 110 (33.5) 235 (71.6) 265 (80.8)

120,000 NA NA 15 (4.6) 100 (30.5) 250 (76.2)

4

140,000

40,000 45 (13.7) 198 (60.4) 232 (70.7) NA NA

60,000 27 (8.2) 127 (38.7) 222 (67.7) 250 (76.2) NA

80,000 17 (5.2) 64 (19.5) 165 (50.3) 222 (67.7) 249 (75.9)

100,000 NA 22 (6.7) 104 (31.7) 223 (68.0) 250 (76.2)

120,000 NA NA 11 (3.4) 93 (28.3) 237 (72.2)

4

140,000

40,000 39 (11.9) 184 (56.1) 214 (65.2) NA NA

60,000 23 (7.0) 119 (36.3) 210 (64.0) 235 (71.6) NA

80,000 15 (4.6) 59 (18.0) 155 (47.2) 210 (64.0) 232 (70.7)

100,000 NA 19 (5.8) 98 (29.9) 211 (64.3) 236 (71.9)

120,000 NA NA 8 (2.4) 86 (26.2) 224 (68.3)

4

140,000

40,000 36 (11.0) 177 (53.9) 205 (62.5) NA NA

60,000 21 (6.4) 115 (35.1) 204 (62.2) 228 (69.5) NA

80,000 14 (4.3) 56 (17.1) 150 (45.7) 202 (61.6) 224 (68.3)

100,000 NA 17 (5.2) 94 (28.7) 205 (62.5) 229 (69.8)

120,000 NA NA NA 83 (25.3) 217 (66.1)

4

140,000

50 (15.2) 210 (64.0) 250 (76.2) NA

NA NA 10 (3.0) 90 (27.4) 210 (64.0)

NA NA NA 80 (24.4) 185 (56.4)

NA NA NA 79 (24.1) 158 (48.2)

NA NA NA 69 (21.0) 146 (44.5)

DIRECT VENT (2-PIPE) AND NON-DIRECT VENT (1-PIPE)

Vent Pipe Diameter (in.)

1-1/2 2 2-1/2 3 4

1

2

NA

915SA

Long

ELBOW CONFIGURATIONS VENT TERMINAL CONFIGURATIONS

Concentric

Medium

Mitered

Standard

A11580

7

Page 8

MAXIMUM EQUIVALENT VENT LENGTH -- FT. (M)

Table 2 – Deductions from Maximum Equivalent Vent Length -- Ft. (M)

Pipe Diameter (in): 1-1/2 2 2-1/2 3 4

Mitered 90º Elbow 8 (2.4) 8 (2.4) 8 (2.4) 8 (2.4) 8 (2.4)

Medium Radius 90º Elbow 5 (1.5) 5 (1.5) 5 (1.5) 5 (1.5) 5 (1.5)

Long Radius 90º Elbow 3 (0.9) 3 (0.9) 3 (0.9) 3 (0.9) 3 (0.9)

Mitered 45º Elbow 4 (1.2) 4 (1.2) 4 (1.2) 4 (1.2) 4 (1.2)

Medium Radius 45º Elbow 2.5 (0.8) 2.5 (0.8) 2.5 (0.8) 2.5 (0.8) 2.5 (0.8)

Long Radius 45º Elbow 1.5 (0.5) 1.5 (0.5) 1.5 (0.5) 1.5 (0.5) 1.5 (0.5)

Tee 16 (4.9) 16 (4.9) 16 (4.9) 16 (4.9) 16 (4.9)

Concentric Vent Termination NA 0 (0.0) NA 0 (0.0) NA

Standard Vent Termination 0 (0.0) 0 (0.0) 0 (0.0) 0 (0.0) 0 (0.0)

Venting System Length Calculations

The maximum length for each vent pipe (inlet or exhaust) equals the Maximum Equivalent Vent Length (MEVL) from Table 1 or Table 3

minus the number of elbows multiplied by the deduction for each elbow in Table 2.

Standard vent terminations and concentric vent terminations count for zero deductions.

See Vent Manufacturers’ data for equivalent lengths of flexible vent piping.

DO NOT ASSUME that one foot of flexible vent pipe is equivalent to one foot of standard PVC vent pipe.

915SA

Example

A direct--vent 60,000 Btuh furnace installed at 2100 ft. (640 M) with 2--in.(51 mm) vent piping. Venting system includes, FOR EACH

PIPE, (3) 90_ long radius elbows, (2) 45_ long radius elbows and a concentric vent kit.

Maximum Equivalent Vent Length = 127 ft. (From Table 1)

Deduct (3) 90 long radius 3 x 3 ft. = - 9 ft. (From Table 2)

Deduct (2) 45 long radius 2 x 1.5 ft. = - 3 ft. (From Table 2)

No deduction for Concentric Vent Kit 0 ft. = - 0 ft. (From Table 2)

Maximum Vent Length = 115 ft. For EACH vent or inlet pipe

8

Page 9

MAXIMUM EQUIVALENT VENT LENGTH -- FT. (M) (CONTINUED)

Table 3 – Maximum Equivalent Vent Length -- Ft. (M)

4501 to 10,000 Ft. (0 to 1370 M) Altitude

NOTE: Maximum Equivalent Vent Length (MEVL) includes standard and concentric vent termination and does NOT include elbows.

Use Table 2 - Deductions from Maximum Equivalent Vent Length to determine allowable vent length for each application.

Altitude

FT (M)

5

Unit Size

1-1/2 2 2-1/2 3 4

40,000 33 (10.1) 171 (52.1) 196 (59.7)

4501 to 5000

(1370 to

1524)

60,000 20 (6.1) 111 (33.8) 198 (60.4) 221 (67.4) NA

80,000 13 (4.0) 54 (16.5) 146 (44.5) 195 (59.4) 216 (65.8)

100,000 NA 16 (4.9) 91 (27.7) 200 (61.0) 222 (67.7)

120,000 NA NA NA 80 (24.4) 211 (64.3)

4

140,000

NA NA NA 60 (18.3) 134 (40.8)

40,000 27 (8.2) 158 (48.2) 179 (54.6) NA NA

5001 to 6000

(1524 to

1829)

60,000 16 (4.9) 103 (31.4) 186 (56.7) 207 (63.1) NA

80,000 11 (3.4) 49 (14.9) 137 (41.8) 183 (55.8) 200 (61.0)

100,000 NA 12 (3.7) 85 (25.9) 188 (57.3) 208 (63.4)

120,000 NA NA NA 74 (22.6) 199 (60.7)

4

140,000

NA NA NA 50 (15.2) 109 (33.2)

40,000 21 (6.4) 145 (44.2) 162 (49.4) NA NA

6001 to 7000

(1829 to

2134)

60,000 13 (4.0) 96 (29.3) 174 (53.0) 194 (59.1) NA

80,000 NA 44 (13.4) 120 (36.6) 171 (52.1) 185 (56.4)

100,000 NA 10 (3.0) 79 (24.1) 178 (54.3) 195 (59.4)

120,000 NA NA NA 68 (20.7) 187 (57.0)

4

140,000

NA NA NA 41 (12.5) 87 (26.5)

40,000 15 (4.6) 133 (40.5) 146 (44.5) NA NA

7001 to 8000

(2134 to

2438)

60,000 10 (3.0) 89 (27.1) 163 (49.7) 181 (55.2) NA

80,000 NA 40 (12.2) 120 (36.6) 159 (48.5) 170 (51.8)

100,000 NA NA 73 (22.3) 167 (50.9) 182 (55.5)

120,000 NA NA NA 62 (18.9) 175 (53.3)

4

140,000

NA NA NA 32 (9.8) 63 (19.2)

40,000 10 (3.0) 121 (36.9) 130 (39.6) NA NA

8001 to 9000

(2438 to

2743)

60,000 7 (2.1) 82 (25.0) 152 (46.3) 168 (51.2) NA

80,000 NA 35 (10.7) 111 (33.8) 148 (45.1) 156 (47.5)

100,000 NA NA 67 (20.4) 157 (47.9) 170 (51.8)

120,000 NA NA NA 56 (17.1) 164 (50.0)

4

140,000

NA NA NA 23 (7.0) 42 (12.8)

40,000 5 (1.5) 110 (33.5) 115 (35.1) NA NA

9001 to

10,000

(2743 to

3048)

NOTES:

1. Use only the vent pipe sizes shown for each furnace. It is NOT necessary to choose the smallest diameter pipe possible for venting.

2. NA --- Not allowed. Pressure switch will not close, or flame disturbance may resul t.

3. Total equivalent vent lengths un der 10’ for 40,000 BTUH furnaces from 0 to 2000 ft. (0 to 610 M) above sea level require use of an outlet choke plate .

Failure to use an outlet choke when required may result in flame disturbance or flame sense lockout.

4. Not all furnace families include 140,000 BTUH input models.

5. Vent sizing for Canadian installations over 4500 ft (1370 M) above sea level are subject to acceptance by local authorities having jurisdiction.

6. Size both the combustion air and vent pipe independently, then use the larger size for both pipes.

7. Assume the two 45_ elbows equal one 90_ elbow. Wide radius elbows are desirable and may be required in some cases.

8. Elbow and pipe sections within the furnace casing and at the vent termination should not be included in vent length or elbow count.

9. The minimum pipe length is 5 ft. (1.5 M) linear feet (meters) for all applications.

10. Use 3---in. (76 mm) diameter vent termination kit for installations r equiring 4---in. (102 mm) diameter pipe.

60,000 NA 76 (23.2) 142 (43.3) 156 (47.5) NA

80,000 NA 31 (9.4) 103 (31.4) 137 (41.8) 142 (43.3)

100,000 NA NA 62 (18.9) 147 (44.8) 157 (47.9)

120,000 NA NA NA 51 (15.5) 153 (46.6)

4

140,000

NA NA NA 16 (4.9) 20 (6.1)

DIRECT VENT (2-PIPE) AND SINGLE-PIPE

NA

1

2

Vent Pipe Diameter (in.)

NA

915SA

9

Page 10

MAXIMUM ALLOWABLE EXPOSED VENT LENGTHS INSULATION TABLE -- FT. (M)

Maximum Length of Uninsulated and Insulated Vent Pipe-Ft (M)

Single Stage

Furnace

Input

40000

Winter Design

Te m p ° F ( ° C )

20 (-10)

0 (-20)

-20 (-30)

-40 (-40)

Pipe

Length in

Ft. & M

11/2 2 21/2 3 4 11/2 2 21/2 3 4 11/2 2 21/2 3 4

Ft. 48 42 42 N/A N/A 50 122 111 N/A N/A 50 144 130 N/A N/A

M 14.6 12.8 12.8 N/A N/A 15.2 37.2 33.8 N/A N/A 15.2 43.9 39.6 N/A N/A

Ft. 25 19 17 N/A N/A 50 75 66 N/A N/A 50 90 79 N/A N/A

M 7.6 5.8 5.2 N/A N/A 15.2 22.9 20.1 N/A N/A 15.2 27.4 24.1 N/A N/A

Ft. 14 7 5 N/A N/A 50 52 45 N/A N/A 50 64 55 N/A N/A

M 4.3 2.1 1.5 N/A N/A 15.2 15.8 13.7 N/A N/A 15.2 19.5 16.8 N/A N/A

Ft. 7 0 0 N/A N/A 50 38 31 N/A N/A 50 48 40 N/A N/A

M 2.1 0.0 0.0 N/A N/A 15.2 11.6 9.4 N/A N/A 15.2 14.6 12.2 N/A N/A

No Insulatio n 3/8-in. (9.5 mm) Insulation 1/2-in. (12.7 mm) Insulation

Pipe Diameter-inches (mm) Pipe Diameter-inches (mm) Pipe Diameter-inches (mm)

(38) (51) (64) (76) (102) (38) (51) (64) (76) (102) (38) (51) (64) (76) (102)

915SA

60000

80000

100000

20 (-10)

0 (-20)

-20 (-30)

-40 (-40)

20 (-10)

0 (-20)

-20 (-30)

-40 (-40)

20 (-10)

0 (-20)

-20 (-30)

-40 (-40)

Ft. 30 61 61 54 N/ A 30 135 163 142 N/A 30 135 191 166 N/A

M 9.1 18.6 18.6 16.5 N/A 9.1 41.1 49.7 43.3 N/A 9.1 41.1 58.2 50.6 N/A

Ft. 30 31 30 23 N/ A 30 113 100 85 N/A 30 135 120 101 N/A

M 9.1 9.4 9.1 7.0 N/A 9.1 34.4 30.5 25.9 N/A 9.1 41.1 36.6 30.8 N/A

Ft. 24 17 15 7 N/A 30 81 70 57 N/A 30 98 85 70 N/A

M 7.3 5.2 4.6 2.1 N/A 9.1 24.7 21.3 17.4 N/A 9.1 29.9 25.9 21.3 N/A

Ft. 15 8 5 0 N/A 30 61 52 40 N/A 30 75 64 51 N/A

M 4.6 2.4 1.5 0.0 N/A 9.1 18.6 15.8 12.2 N/A 9.1 22.9 19.5 15.5 N/A

Ft. 20 70 78 70 60 20 70 175 183 154 20 70 175 215 181

M 6.1 21.3 23.8 21.3 18.3 6.1 21.3 53.3 55.8 46.9 6.1 21.3 53.3 65.5 55.2

Ft. 20 42 41 33 21 20 70 132 111 89 20 70 157 133 107

M 6.1 12.8 12.5 10.1 6.4 6.1 21.3 40.2 33.8 27.1 6.1 21.3 47.9 40.5 32.6

Ft. 20 25 23 14 1 20 70 94 77 57 20 70 113 94 71

M 6.1 7.6 7.0 4.3 0.3 6.1 21.3 28.7 23.5 17.4 6.1 21.3 34.4 28.7 21.6

Ft. 20 14 12 3 0 20 70 71 56 38 20 70 86 70 50

M 6.1 4.3 3.7 0.9 0.0 6.1 21.3 21.6 17.1 11.6 6.1 21.3 26.2 21.3 15.2

Ft. N/A 25 99 89 78 N/A 25 110 233 265 N/A 25 110 235 229

M N/A 7.6 30.2 27.1 23.8 N/A 7.6 33.5 71.0 80.8 N/A 7.6 33.5 71.6 69.8

Ft. N/A 25 55 46 33 N/A 25 110 145 117 N/A 25 110 173 140

M N/A 7.6 16.8 14.0 10.1 N/A 7.6 33.5 44.2 35.7 N/A 7.6 33.5 52.7 42.7

Ft. N/A 25 34 24 11 N/A 25 110 103 79 N/A 25 110 124 97

M N/A 7.6 10.4 7.3 3.4 N/A 7.6 33.5 31.4 24.1 N/A 7.6 33.5 37.8 29.6

Ft. N/A 23 20 11 0 N/A 25 95 77 55 N/A 25 110 94 70

M N/A 7.0 6.1 3.4 0.0 N/A 7.6 29.0 23.5 16.8 N/A 7.6 33.5 28.7 21.3

20 (-10)

0 (-20)

120000

-20 (-30)

-40 (-40)

20 (-10)

0 (-20)

140000

-20 (-30)

-40 (-40)

*Not all families have these models.

Ft. N/A N/A 15 99 86 N/A N/A 15 100 219 N/A N/A 15 100 250

M N/A N/A 4.6 30.2 26.2 N/A N/A 4.6 30.5 66.8 N/A N/A 4.6 30.5 76.2

Ft. N/A N/A 15 51 38 N/A N/A 15 100 130 N/A N/A 15 100 156

M N/A N/A 4.6 15.5 11.6 N/A N/A 4.6 30.5 39.6 N/A N/A 4.6 30.5 47.5

Ft. N/A N/A 15 28 14 N/A N/A 15 100 88 N/A N/A 15 100 108

M N/A N/A 4.6 8.5 4.3 N/A N/A 4.6 30.5 26.8 N/A N/A 4.6 30.5 32.9

Ft. N/A N/A 15 14 0 N/A N/A 15 85 62 N/A N/ A 15 100 79

M N/A N/A 4.6 4.3 0.0 N/A N/A 4.6 25.9 18.9 N/A N/A 4.6 30.5 24.1

Ft. N/A N/A 10 90 99 N/A N/A 10 90 210 N/A N/A 10 90 210

M N/A N/A 3.0 27.4 30.2 N/A N/A 3.0 27.4 64.0 N/A N/A 3.0 27.4 64.0

Ft. N/A N/A 10 61 47 N/A N/A 10 90 153 N/A N/A 10 90 183

M N/A N/A 3.0 18.6 14.3 N/A N/A 3.0 27.4 46.6 N/A N/A 3.0 27.4 55.8

Ft. N/A N/A 10 35 21 N/A N/A 10 90 104 N/A N/A 10 90 128

M N/A N/A 3.0 10.7 6.4 N/A N/A 3.0 27.4 31.7 N/A N/A 3.0 27.4 39.0

Ft. N/A N/A 10 20 NA N/A N/A 10 90 75 N/A N/A 10 90 94

M N/A N/A 3.0 6.1 NA N/A N/A 3.0 27.4 22.9 N/A N/A 3.0 27.4 28.7

10

Page 11

RETURN AIR TEMPERATURE

This furnace is designed for continuous return--air minimum temperature of 60_F(15_C) db or intermittent operation down to 55_F(13_C)

db such as when used with a night setback thermometer. Return--air temperature must not exceed 80_F(27_C) db. Failure to follow these

return air limits may affect reliability of heat exchangers, motors and controls.

80 / 27˚C

SUPPLY AIR

60

/ 16˚C

A10490

MINIMUM CLEARANCES TO COMBUSTIBLE MATERIALS

POSITION CLEARANCE

Rear 0(0mm)

Front (Combustion air openings in furnace and in structure) 1in.(25mm)

Required for service *24 in. (610 mm)

All Sides of Supply Plenum 1in.(25mm)

Sides 0(0mm)

Ve n t 0(0mm)

* Recommended

Top of Furnace 1in. (25mm)

915SA

COMBUSTION--AIR PIPE FOR NON--DIRECT (1--PIPE) VENT APPLICATION

FIELD-SUPPLIED

2-IN. (51 mm) DIA.

TIGHT RADIUS

PVC 90° ELBOW

FIELD-SUPPLIED

2-IN. (51 mm) DIA.

PVC PIPE

12” (300 mm) Minimum

A11487

11

Page 12

DOWNFLOW SUBBASE

LOCATING

TAB

11/

4-IN. TYP

PLENUM

OPENING

A

LOCATING

TAB

B

4

3

D

2

1

FACTORY-SUPPLIED

FIELD-INSTALLED

INSULATION

C

A97427

Assembled

DIMENSIONS (IN. / MM)

FURNACE

CASING WIDTH

915SA

17--- 1/2 (444.5)

21 (533.4)

24--- 1/2 (622.3)

*The plenum should be constructed 1/4 ---in. (6 mm) smaller in width and depth than the plenum dimensions shown above.

FURNACE IN DOWNFLOW

APPLICATION

Furnace with or without Cased Coil

Assembly or Coil Box

Furnace with or without Cased Coil

Assembly or Coil Box

Furnace with or without Cased Coil

Assembly or Coil Box

PLENUM OPENING* FLOOR OPENING

A B C D

15--- 1/8

(384.2)

18--- 5/8

(396.4)

22--- 1/8

(562.0)

19 (482.6)

19 (482.6)

19 (482.6)

16--- 3/4

(425.5)

20--- 1/4

(514.4)

23--- 3/4

(603.3)

Disassembled

20--- 3/8

(517.5)

20--- 3/8

(517.5)

20--- 3/8

(517.5)

1

2

3

4

A88207

HOLE NO. FOR

WIDTH

ADJUSTMENT

3

2

1

Concentric Vent Kit

A93086

A concentric vent kit allows vent and combustion--air pipes to

terminate through a single exit in a roof or side wall. One pipe

runs inside the other allowing venting through the inner pipe and

combustion air to be drawn in through the outer pipe.

Downflow Subbase

A88202

One base fits all furnace sizes. The base is designed to be installed

between the furnace and a combustible floor when no coil box is

used or when a coil box other than a Carrier cased coil is used. It is

CSA design certified for use with Carrier branded furnaces when

installed in downflow applications.

12

Page 13

23-5/8"

(600mm)

23-3/8”

(594mm)

MEDIA FILTER CABINET

A

25-5/8"

(651mm)

24-1/4”

(616mm)

Opening with Flanges Bent

23-1/8”

(588mm)

Opening

B Opening

Furnace Side

23-3/4”

(603mm)

Centerline Screw Slots

FIVE WIRE

THREE-WIRE

HEATING-ONLY

BLOWER DOOR SWITCH

BLK

WHT

115-V FIELD-

SUPPLIED

BLK

WHT

GND

AUXILIARY

J-BOX

DISCONNECT

GND

FURNACE

3

"

5

4

(146mm)

TYPICAL WIRING SCHEMATIC

NOTE 2

W

C

R

O

N

T

G

R

O

COM

L

Y

24-V

TERMINAL

BLOCK

WCR GY

NOTE 1

NOTES: Connect Y-terminal in furnace as shown for proper blower operation.

1.

2.

Some thermostats require a "C" terminal connection as shown.

3.

If any of the original wire, as supplied, must be replaced, use

same type or equivalent wire.

THERMOSTAT

TERMINALS

TWO

WIRE

Duct Side

Media Filter

Cabinet

16" (406mm)

20" (508mm)

24" (610mm)

A

17" (432mm)

21" (533mm)

25" (635mm)

FIELD 24-V WIRING

FIELD 115-, 208/230-, 460-V WIRING

FACTORY 24-V WIRING

FACTORY 115-V WIRING

FIELD-SUPPLIED

DISCONNECT

GND

CONDENSING

UNIT

B

16" (406mm)

20" (508mm)

24" (610mm)

208/230- OR

460-V

THREE

PHASE

208/230-V

SINGLE

PHASE

915SA

A11456

A11387

13

Page 14

915SA

DIMENSIONAL DRAWING

A11612

14

Page 15

GUIDE SPECIFICATIONS

General

System Description

Furnish a ______________________ 4--way multipoise gas--fired

condensing furnace for use with natural gas or propane (factory-authorized conversion kit required for propane); furnish cold air

return plenum; furnish external media cabinet for use with

accessory media filter or standard filter.

Quality Assurance

Unit will be designed, tested and constructed to the current ANSI Z

21.47/CSA 2.3 design standard for gas--fired central furnaces.

Unit will be third party certified by CSA to the current ANSI Z

21.47/CSA 2.3 design standard for gas--fired central furnaces. Unit

will carry the CSA Blue StarR and Blue FlameR labels. Unit

efficiency testing will be performed per the current DOE test

procedure as listed in the Federal Register.

Unit will be certified for capacity and efficiency and listed in the

latest AHRI Consumer’s Directory of Certified Efficiency Ratings.

Unit will carry the current Federal Trade Commission Energy

Guide efficiency label.

Delivery, Storage, and Handling

Unit will be shipped as single package only and is stored and

handled per unit manufacturer’s recommendations.

Warranty (for inclusion by specifying engineer)

U.S. and Canada only. Warranty certificate available upon request.

Equipment

Blower Wheel and PSC Blower Motor

Galvanized blower wheel shall be centrifugal type, statically and

dynamically balanced. Blower motor of PSC type shall be

permanently lubricated with sleeve bearings, of _______hp, and

have multiple speeds from 500--1150 RPM operating only when

115--VAC motor inputs are provided. Blower motor shall be direct

drive and soft mounted to the blower scroll to reduce vibration

transmission.

Filters

Furnace shall have reusable--type filters. Filter shall be ______ in.

(mm) X ________ in. (mm). An accessory highly efficient Media

Filter is available as an option. _____________ Media Filter.

Casing

Casing shall be of .030 in. thickness minimum, pre--painted

galvanized steel.

Draft Inducer

Draft inducer motor shall be single--speed design.

Motor

Primary Heat

Primary heat exchangers shall be 3--Pass corrosion--resistant

aluminized steel of fold--and--crimp sectional design and applied

operating under negative pressure.

Secondary Heat

Secondary heat exchangers shall be of a stainless steel

flow--through of fin--and--tube design and applied operating under

negative pressure.

Controls

Controls shall include a micro--processor--based integrated

electronic control board with at least 16 service troubleshooting

codes displayed via diagnostic flashing LED light on the control, a

self--test feature that checks all major functions of the furnace, and

a replaceable automotive--type circuit protection fuse. Multiple

operational settings available, including blower speeds for heating,

cooling, and continuous fan.

Exchangers

Exchangers

Operating Characteristics

Heating capacity shall be _________________ Btuh input;

______________ Btuh output capacity.

Fuel Gas Efficiency shall be __________AFUE.

Air delivery shall be ________________ cfm minimum at 0.50 in.

W.C. external static pressure.

Dimensions shall be: depth_________in. (mm); width

__________in. (mm); height___________in. (mm) (casing only).

Height shall be_________in. (mm) with A/C coil and

_________________in. (mm) overall with plenum.

Electrical Requirements

Electrical supply shall be 115 volts, 60 Hz, single--phase (nominal).

Minimum wire size shall be ________AWG; maximum fuse size

of HACR--type designated circuit breaker shall be _________

amps.

Special Features

Refer to section of the product data identifying accessories and

descriptions for specific features and available enhancements.

915SA

15

Page 16

915SA

E2012 Bryant Heating & Cooling Systems D 7310 W. Morris St. D Indianapolis, IN 46231 Printed in U.S.A. Edition Date: 01/12

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incur ring obligations.

16

Catalog No. PDS915SA--- 0 1

Replaces: NEW

Loading...

Loading...