Bryant 901KAX Installation, Start-up And Service Instructions Manual

Installation, Start-up

and Service Instruction

ELECTRONIC AIR CLEANER

NOTE: Read the entire instruction manual before starting the

installation.

SAFETY CONSIDERATIONS

Improper installation, adjustment, alteration, service, maintenance,

or use can cause explosion, fire, electrical shock, or other

conditions which may cause personal injury or property damage.

Consult a qualified installer, service agency, or your distributor or

branch for information or assistance. The qualified installer or

agency must use factory authorized kits or accessories when

modifying this product. Refer to the individual instructions packaged with the kits or accessories when installing.

Follow all safety codes. Wear safety glasses and work gloves.

Read these instructions thoroughly and follow all warning or

cautions attached to the unit. Consult local building codes and

National Electric Code (NEC) for special requirements.

Recognize safety information. This is the safety-alert symbol

When you see this symbol on unit or in instructions and manuals,

be alert to potential for personal injury.

Understand the signal word DANGER, WARNING, or CAUTION. These words are used with the safety-alert symbol. DANGER identifies the most serious hazards which willresultinsevere

personal injury or death. WARNING signifies a hazard which

could result in personal injury or death. CAUTION is used to

identify unsafe practices which would result in minor personal

injury or product and property damage. NOTE is used to highlight

suggestions that will result in enhanced installation, reliability, or

operation.

INTRODUCTION

Model 9011KAX Electronic Air Cleaner (EAC) is available in 3

sizes: 012 (300 to 1400 CFM), 016 (500 to 1800 CFM), and 020

(700 to 2000 CFM). (See Fig. 1.)

These plate-type air cleaners are designed for use with residential

and light commercial forced-air heating and/or cooling systems.

They may be installed in the vertical or horizontal section of a

typical return-air duct system. (See Fig. 2.)

These air cleaners are easily field-converted from right- to lefthand units. Cabinets are designed to support up to 400 pounds

when used in under-the-furnace applications.

A. Cabinet

The cabinet includes an electrical junction box and power safety

interlock, and houses the air cleaner components. These components are:

1. Mechanical pre-filters—Expanded aluminum mesh firststage filter that removes lint and large dust particles.

2. Cell assemblies—Cells consisting of combined ionizer

wires and collector plates.

Ionizer part of cell has tungsten wires that receive positive

charge and are mounted between grounded aluminum

channels supported by glazed ceramic insulators.

Collector part of cell consists of alternately charged collector plates.

901KAX

Cancels: II 901K-12-3 II 901K-12-4

10-01-94

.

A91465

Fig. 1—Model 31KAX

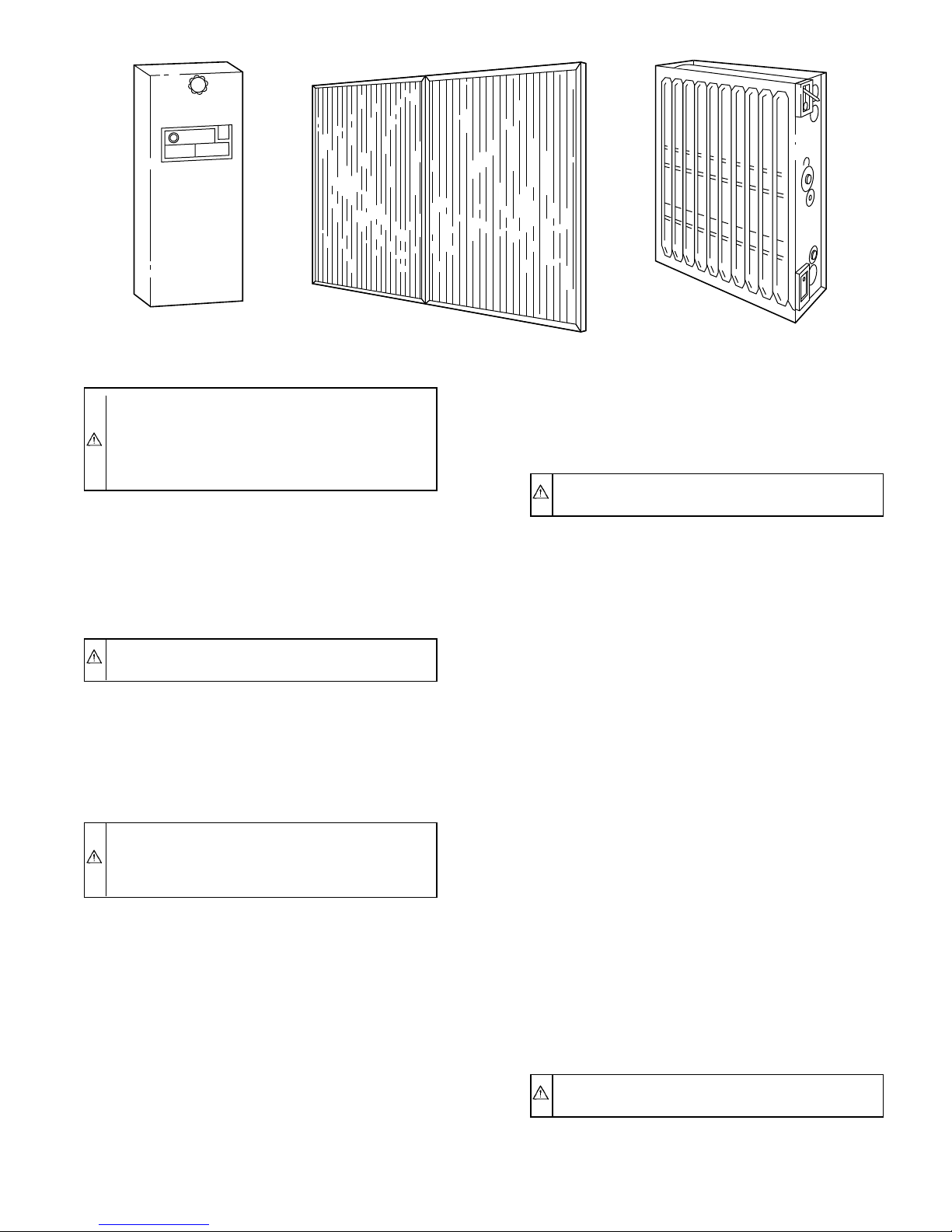

The EAC components are listed below and shown in Fig. 3.

1. Power door assembly.

2. Two pre-filters.

3. Cabinet containing 2 air-cleaning cell assemblies.

4. A parts bag including electrical bushing, plug buttons, wire

chase, and airflow label.

B. Power Door Assembly

The power door assembly consists of:

1. Unit operation light, ON-OFF switch, and door attachment

knob—all installed on door cover.

2. Door base plate contains a solid-state power pack that

converts 120vac to high voltage DC (a 240v Conversion

Kit, KEAVC0101240 is available). All wiring is mounted

internally. A line-voltage disconnect (male plug) and highvoltage buss bar are mounted on the base plate externally.

Four screws must be removed toexposethepower pack and

wiring.

The supply circuit to the power pack, which is wired across the

furnace blower motor, is controlled by an ON-OFF power switch.

With the power switch ON (assuming power door is in place and

blower motor is operating), 120vac ± 10 percent single-phase, 60

Hz power is applied to the power pack (240v conversion kit

transformer converts 240v to 120vac). Output of the power pack

assembly is approximately 7300vdc.

These Installation Instructions consist of the following:

Section I—Locating Unit

Section II—Installation

Section III-Electrical Connections

Section IV-Startup and Adjustments

Section V—Routine Maintenance and Service

—1—

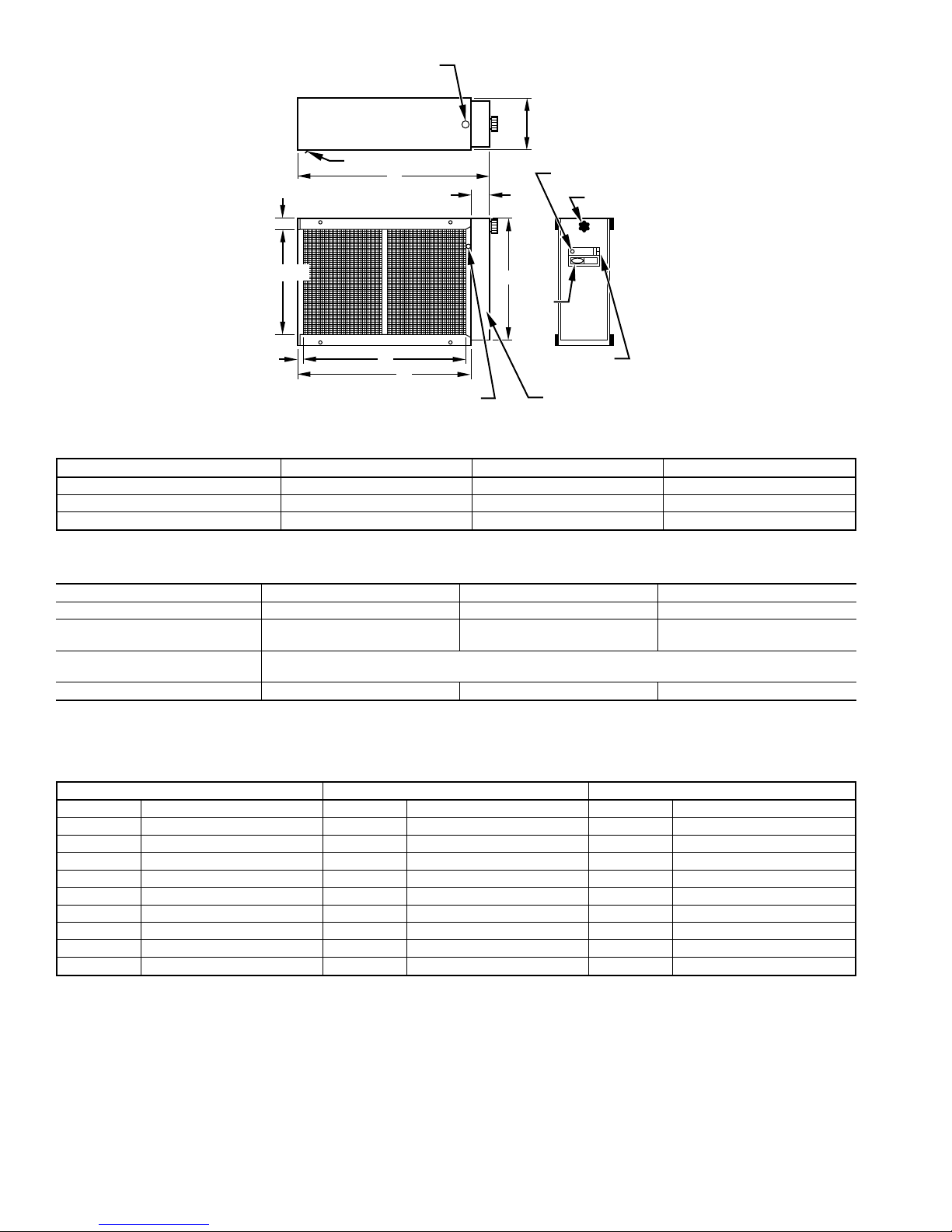

7

⁄8-IN. ELECTRICAL

ENTRANCE FOR DUCT

APPLICATION

8 1⁄2″

REAR MOUNTING FLANGE

A

1

⁄16″

2

16 7⁄8″

1″

C

B

ELECTRICAL ENTRANCE (5⁄8-IN. DIA)

FOR FURNACE APPLICATIONS

3″

21″

OPERATION

LIGHT

LOGO

REMOVABLE

POWER DOOR

KNOB

ON/OFF

SWITCH

A91466

MODEL A B C

901KAX012 24-3/4 21-3/4 19-1/2

901KAX016 27-1/4 24-1/4 22

901KAX020 31-1/2 28-1/2 26-1/4

Fig. 2—Dimensional Drawing

TABLE 1—COMPONENT INFORMATION

MODEL 901KAX012 901KAX016 901KAX020

Air Volume Range 300-1400 500-1800 700-2000

Electrical Data

(Input to power door)

Electrical Data

(Output To Collector Cell)

Approx Ship. Wt. 120v 50 54 57

Note: Using the EAC on air duct systems designed for airflows lower than 300 CFM for 012-size units, 500 CFM for 016-size units, or 700 CFM for 020-size units, is

not recommended.

120v, single phase, 60 Hz 120v, single phase, 60 Hz 120v, single phase, 60 Hz

120v—1.0 milliamps @ 7300vdc

TABLE 2—PRESSURE DROP AT VARIOUS AIRFLOWS

901KAX012 901KAX016 901KAX020

CFM Pressure Drop (In. wc) CFM Pressure Drop (In. wc) CFM Pressure Drop (In. wc)

300 0.005 500 0.010 700 0.010

400 0.010 600 0.025 800 0.013

600 0.020 800 0.020 1000 0.018

800 0.030 1000 0.028 1200 0.023

1000 0.050 1200 0.035 1400 0.030

1100 0.060 1400 0.045 1600 0.038

1200 0.065 1600 0.065 1800 0.045

1300 0.075 1700 0.070 1900 0.048

1400 0.085 1800 0.080 2000 0.050

See Service Guide, and Troubleshooting Flow Chart for supplementary information.

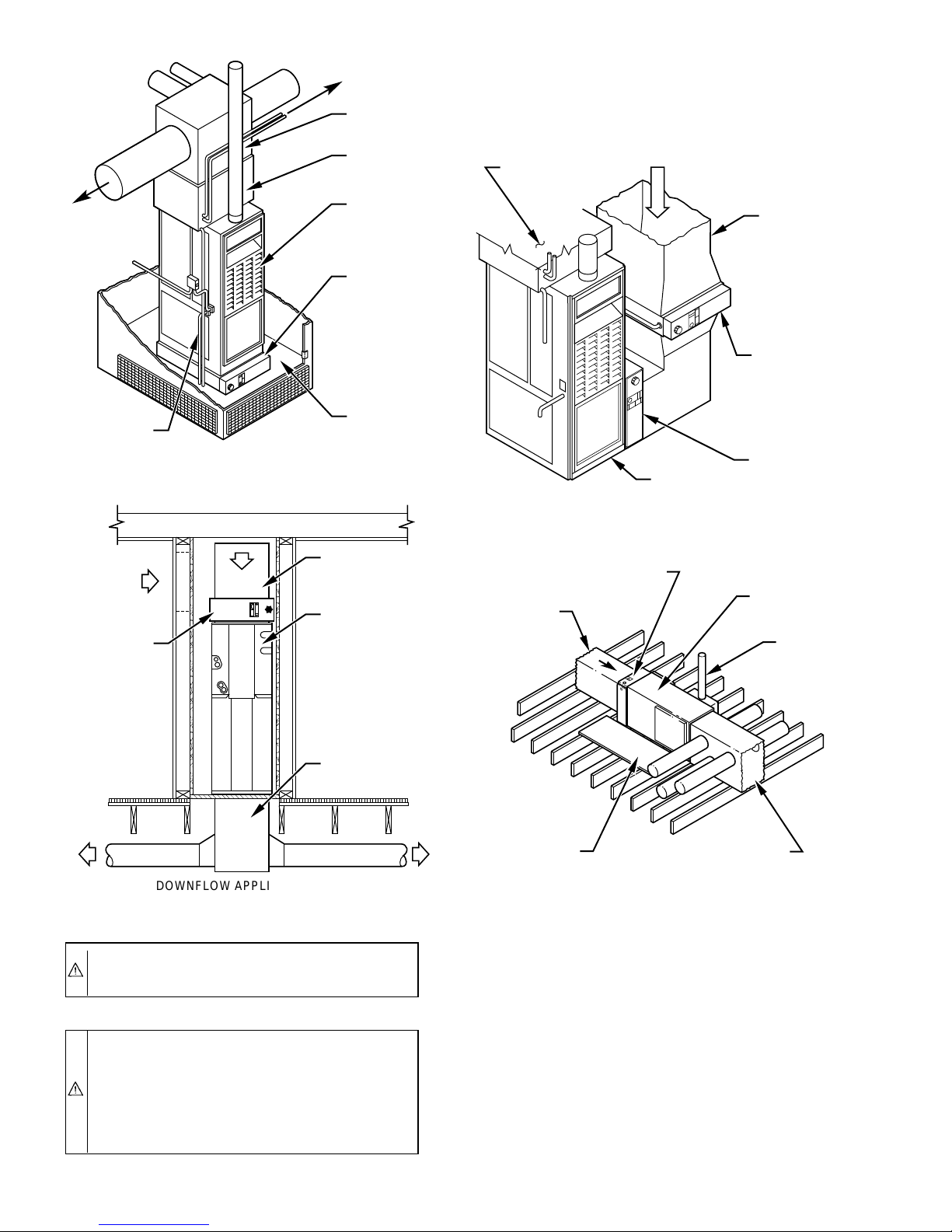

I. LOCATING UNIT

Fig. 4 shows the air cleaner in the return-air duct of various furnace

installations, with or without air conditioning. Other methods of

installing the unit are permissible if the design criteria outlined in

this section is observed.

A. A. Planning an Installation

When planning an installation, consider the following:

1. Air cleaner is approved only for indoor installation. If

outdoor installation is used, unit must be housed in weatherproof enclosure.

2. Air cleaner may be placed in horizontal position on its right

or left side or in vertical position on its bottom or back. It

must be installed on inlet air side of heating and/or cooling

unit. Be sure that airflow through air cleaner is in same

direction as "airflow arrows" on cells.

—2—

POWER DOOR

ASSEMBLY

PRE-FILTERS CELL ASSEMBLY

Fig. 3—View of Major Components

CAUTION: Cabinets will support a maximum weight of

400 lbs when installed beneath a vertical furnace or

air-handling unit. When setting furnace on cabinet, do not

drop it into place. Position furnace correctly on cabinet to

prevent a corner from slipping down and damaging

cabinet.

3. Allow minimum 16-in. clearance in front of unit for

cleaning and maintenance.

4. Air outlets and returns must not be blocked with furniture,

drapes, or other objects.

5. Air cleaner should be installed where all air circulated by

system will pass through it.

CAUTION: Never use air cleaner to collect grease or

other flammable contaminants.

B. Humidifiers

An evaporative, supply-duct-mounted humidifier may be installed

without affecting the EAC. A bypass-type evaporative humidifier

should be installed so that the moist air does not contact the air

cleaner. When an atomizing-type humidifier is used, it should

always be installed in the supply-air system.

CAUTION: If an atomizing-type humidifier is installed

upstream from the air cleaner, the efficiency of the

electronic cells will be decreased by high humidity, salts,

and minerals. Service problems will result.

If bypass-type humidifier is installed upstream from the EAC, the

following precautions should be taken.

1. Humidifier must be installed as far from EAC as possible.

2. A standard, disposable furnace filter must be installed

between humidifier and EAC to trap water droplets and

mineral salts.

3. Electronic cells of air cleaner must be washed frequently to

prevent mineral deposit buildup.

C. Outdoor Air

When outdoor air is added to the return-air duct, sufficient heat

must be added to maintain the return-air temperature of 40°F

minimum or minimum specified by air handling equipment manufacturer. Temperatures lower than 40°F can cause ionizer wire

failure under certain conditions.

A91467

NOTE: The maximum operating temperature of the EAC is

125°F.

II. INSTALLATION

NOTE: See Fig. 4 for suggested installation positions.

CAUTION: Turn off all power to furnace or fan coil

before beginning installation.

Proceed as follows to install EAC:

1. Remove and discard existing furnace mechanical filters.

They are not required when using an EAC. Thoroughly

clean blower compartment of furnace.

2. Move ON-OFF switch to OFF and remove power door by

rotating knob (approximately 10 turns counterclockwise)

until door is free. Grasp power door by knob and remove it

from cleaner cabinet by pulling it towards you. This motion

disengages power supply connector.

3. Slide out pre-filters and air cleaner cells.

4. For size 016 EAC furnace side application, cut open return

knockout at the side of the furnace cabinet. For size 012 and

020, cut opening as shown in Fig. 5—Opening Detail.

5. In order to prevent air leakage, use foam tape provided to

attach air cleaner to side of furnace or system blower.

NOTE: The unit is shipped for furnace right side application. For

left side application, rotate rear mounting flange 180° by removing

4 screws in the back of the air cleaner. Be sure all 4 screws are in

place after the rotation. Relocate the junction box on the furnace to

the right side, if required.

6. Hook back flange into the opening. Use air cleaner cabinet

front support flange adjacent to the unit as template and drill

2 holes on furnace casing. (See Fig. 6.)

7. Secure the unit by screwing 2 provided screws into drilled

holes. (See Fig. 6.)

8. Prepare return-air duct for installation to unit. Return air

must use full cabinet opening. Duct should run straight into

unit.

CAUTION: Do not baffle any portion of the entering-air

side of the air cleaner.

NOTE: Baffles may be necessary in upflow applications.

(See Fig. 7.)

—3—

DOWNFLOW APPLICATION

RETURN AIR

PLENUM

FAN-COIL

UNIT

SUPPLY AIR

PLENUM

ELECTRONIC

AIR CLEANER

A91468

SUPPLY AIR

PLENUM

COOLING

COIL

UPFLOW

FURNACE

ELECTRONIC

AIR CLEANER

RETURN AIR

PLATFORM

GAS SUPPLY

UPFLOW APPLICATION

A91470

VENT

RETURN

AIR PLENUM

ELECTRONIC

AIR CLEANER

HORIZONTAL

FURNACE

SERVICE

PLATFORM

SUPPLY

AIR PLENUM

HORIZONTAL FURNACE APPLICATION

A91469

UPFLOW

FURNACE

3 TO 1

TRANSITION

DUCT WORK

ALTERNATE

AIR CLEANER

POSITION

AIRFLOW

ELECTRONIC

AIR CLEANER

COOLING

COIL

FURNACE SIDE APPLICATION

—4—

CAUTION: If flanged sheet metal ducts are metalscrewed to the unit casing, do not use screws longer than

1/2 in.

CAUTION: Airflow across air cleaner must be uniform

for best results. Install turning vanes if air cleaner is

installed close to an elbow. Depending on size of furnace,

it may or may not be necessary to reduce ductwork on

leaving-air side of air cleaner. For any application,

maintain a 3-to-1 duct reduction ratio (3 in. of duct length

for every 1-in. of reduction in size).

A86134

Fig. 4—Typical Applications

9. Check airflow and component configuration. (See Fig. 8.)

10. Seal all joints on downstream side of air cleaner to prevent

infiltration of contaminated air.

III. ELECTRICAL CONNECTIONS

All wiring must comply with applicable local and national codes.

To determine best power wiring routing refer to Section A for

Internal Electrical Connections and Section B for External Electrical Connections.

NOTE: For general information a line to line wiring diagram is

provided. (See Fig. 9.)

FURNACE

KNOCKOUTS

1

⁄8 IN.

18 5⁄8″

17 1⁄4″

1

16

⁄4″

1

⁄4″

3

3

⁄4″

2

7

⁄16″

2

0

3

⁄4″

1

0

4 1⁄4″ 5 3⁄4″

5

DIA HOLE

REAR OF

25″

FURNACE

1

28

⁄2″

1

⁄8 IN.

DIA HOLE

1

⁄16″

18 5⁄8″

17 1⁄4″

1

16

⁄4″

3 1⁄4″

3

⁄4″

2

7

⁄16″

2

0

3

⁄4″

1

KNOCKOUTS

0

4 1⁄4″ 5 3⁄4″

1

5

⁄16″

FURNACE

1

⁄8 IN.

DIA HOLE

016012

1

⁄8 IN.

DIA HOLE

27 1⁄2″

28 1⁄2″

17

16 1⁄4″

REAR OF

FURNACE

7

2

⁄16″

1 3⁄4″

18 5⁄8″

1

15

10

3

2

FURNACE

KNOCKOUTS

1

⁄8 IN.

DIA HOLE

⁄4″

5

⁄8″

1

⁄2″

⁄4″

0

0

13

⁄16″

1 5⁄16″

3

⁄4 IN.

DIA HOLE

1

⁄8 IN.

DIA HOLE

020

27

1

⁄2″

28 1⁄2″

REAR OF

FURNACE

A91471

Fig. 5—Opening Detail

CAUTION: Be sure all incoming power is off before

beginning any procedures.

A. Internal Electrical Connections

Proceed as follows to make internal electrical connections.

1. With power door removed, remove junction box cover

adjacent to female plug on casing upper channel. (See Fig.

10.)

PLUG

BUSHINGS

SCREWS

FURNACE

OPENING

SCREWS

SCREWS

FLANGE

Fig. 6—Electronic Air Cleaner Installation

A89117

2. Install protective bushing from inside the air cleaner into the

upper hole on the side channel adjacent to the furnace. Be

sure bushing projects into furnace opening protecting wires

from sharp edges on cabinet opening.

3. Install protective bushing through top rail as shown in Fig.

10.

4. Plug unused hole on top of unit with plug provided in parts

bag.

5. Route power wires through bushing channel at top of

cabinet, down side channel, and through bushing in side

channel and into furnace opening. (See Fig. 10.)

6. Replace cover of junction box.

7. Install wire cover (provided in parts bag) under top flange

and secure to side channel with provided screw.

8. Connect power leads as follows:

a. Single Speed Furnaces—EAC is wired in parallel with

fan motor. (See Fig. 11.)

b. Multispeed Direct-Drive Motor—If the EAC is wired

to a multispeed direct-drive motor, it must be isolated by

a relay or sail switch. Use either air cleaner relay P/N

P283-1203 or sail switch P/N 69105D1. (See Fig. 12 or

13.)

c. Furnaces with Printed-Circuit Boards—EAC is wired

to furnace terminals EAC 1 and EAC 2. See Fig. 14 for

wiring connections.

9. Connect ground wire to base unit ground.

FURNACE

BAFFLES

ELECTRONIC

AIR CLEANER

A91472

Fig. 7—Installing Baffles if Needed

—5—

Loading...

Loading...