Page 1

SINGLE-PACKAGE

Model 702B

ELECTRIC COOLING UNITS with

Puron® (R-410A) Refrigerant

UNIT 702B

Single-Package Products with

Energy-Saving Features and Puron® refrigerant.

• Low Sound Levels

• 12 SEER

• Variable Speed Blower Option

FEATURES/BENEFITS

One-piece cooling unit with optional electric heater, low

installation cost, dependable performance and easy

maintenance.

EFFICIENT OPERATION

High-efficiency design

Efficiency Ratio) of 12.0.

Puron® Environmentally Sound Refrigerant is Bryant’s unique

refrigerant designed to help protect the environment. Puron is an

HFC refrigerant which does not contain chlorine that can harm

the ozone layer. The most important advantage of Puron

refrigerant is that it has not been banned in future air

conditioning systems as the traditional refrigerant R-22 has

been. Puron refrigerant is in service in thousands of systems

proving highly reliable, environmentally sound performance.

Perfect Heat, Perfect Humidity™ featuring Variable Speed

Blower motors

You can expect up to 30 times better dehumidification; a SEER

boost of up to 12.7; economical constant fan for less than $30 a

year, which provides improved indoor air quality and more even

temperatures from room to room; and reduced indoor noise due

to lower air velocity. In addition, you’ll realize improved installation

flexibility with 3 different airflow choices for best overall comfort.

with a SEER (Seasonal Energy

provides better comfort and energy efficiency.

Sizes 024-060

2 To 5 Nominal Tons

Easy Installation— Factory-assembled package is a compact,

fully self-contained, electric cooling unit that is pre-wired, prepiped, and pre-charged for minimum installation expense . 702B

units are available in a variety of standard cooling sizes with

voltage options to meet residential and light commercial

requirements. Units are light weight, and install easily on a

rooftop or at ground-level. The hightech, composite base pan

eliminates rust problems associated with ground level

applications.

DURABLE, DEPENDABLE COMPONENTS

Scroll Compressors are designed for high efficiency. Each

compressor is hermetically sealed against contamination to help

promote longer life and dependable operation. Vibration isolation

provides quiet operation. Compressors have internal highpressure and overcurrent protection.

CONVERTIBLE DUCT CONFIGURATION —Unit is designed

for easy use in either downflow or horizontal applications. Each

unit is easily converted from horizontal to downflow.

Direct-drive multi-speed, PSC (permanent split capacitor)

blower motor

Direct-drive, PSC condenser-fan motors are designed to help

reduce energy consumption and provide for cooling operation

down to 40°F outdoor temperature. Motormaster® II low ambient

kit is available as a field-installed accessory.

Corporate thermostats include the Time Guard® II anti-short

cycle protection circuitry. If a non-Corporate thermostat without antishort cycle protection, is used the Time Guard II field installed antishort cycle kit is recommended.

Refrigerant system is designed to provide dependability. Liquid

refrigerant filter driers are used to promote clean, unrestricted

operation. Each unit lea ves the factory with a full Puron® refrigerant

charge. Refrigerant service connections are standard on the

suction and discharge lines for checking operating pressures .

Evaporator and condenser coils are computer-designed for

optimum heat transfer and cooling efficiency. The evaporator coil

is fabricated from copper tube and aluminum fins and is located

inside the unit for protection against damage. The condenser coil

is internally mounted on the top tier of the unit. Copper fin coils

and pre-coated fin coils are available from the factory by special

order. These coils are recommended in applications where

aluminum fins are likely to be damaged due to corrosion. The y are

ideal for seacoast applications.

High and Low Pressure Switches give added safety and reliability

to the compressor.

Low sound ratings ensure a quiet indoor and outdoor

environment with sound ratings as low as 72 dB.

(See page 3.)

is standard on all 702B models.

Copyright 2001 Bryant Corporation

Form No. PDS 702B.24.2

Page 2

Easy to service cabinets provide easy single-panel accessibility

to serviceable components during maintenance and installation.

The basepan with integrated drain pan provides easy ground le vel

installation with or without a mounting pad. Con venient handholds

are provided to manipulate the unit on the jobsite. A nesting feature

ensures a positive basepan to roof curb seal when the unit is roof

mounted. A con venient 3/4-in. wide perimeter flange makes fr ame

mounting on a rooftop easy.

Louvered Grille provides hail and vandalism protection for the

coil.

Downflow operation is easily provided in the field to allow vertical

ductwork connections. The basepan utilizes knockout style seals

on the bottom openings to ensure a positive seal in the horizontal

airflow mode.

Cabinets are constructed of heavy-duty , phosphated, zinc-coated

prepainted steel capable of withstanding 500 hours of salt spray.

Interior surfaces of the evapor ator and electric heater

compartments are insulated with cleanable semi-rigid insulation

board, which keeps the conditioned air from being affected by the

outdoor ambient temperature and provides improved indoor air

quality. (Conforms to American Society of Heating, Refrigeration

and Air Conditioning Engineers No. 62P.) The sloped drain pan

minimizes standing water in the drain, which is provided with an

external drain.

Standard metal duct covers with insulation come with the unit

and cover the horizontal duct openings. These can be left in place

if the unit is converted to downflow.

TABLE OF CONTENTS

Page

Features/Benefits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1,2

Model Number Nomenclature. . . . . . . . . . . . . . . . . . . . . . . . . . 3

ARI Capacities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Physical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Options and Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5,6

Base Unit Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7,8

Accessory Dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Selection Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Performance Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11-16

Typical Piping and Wiring. . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Application Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Electrical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19-20

Typical Wiring Schematics . . . . . . . . . . . . . . . . . . . . . . . . .21-24

Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Guide Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26, 27

—2—

Page 3

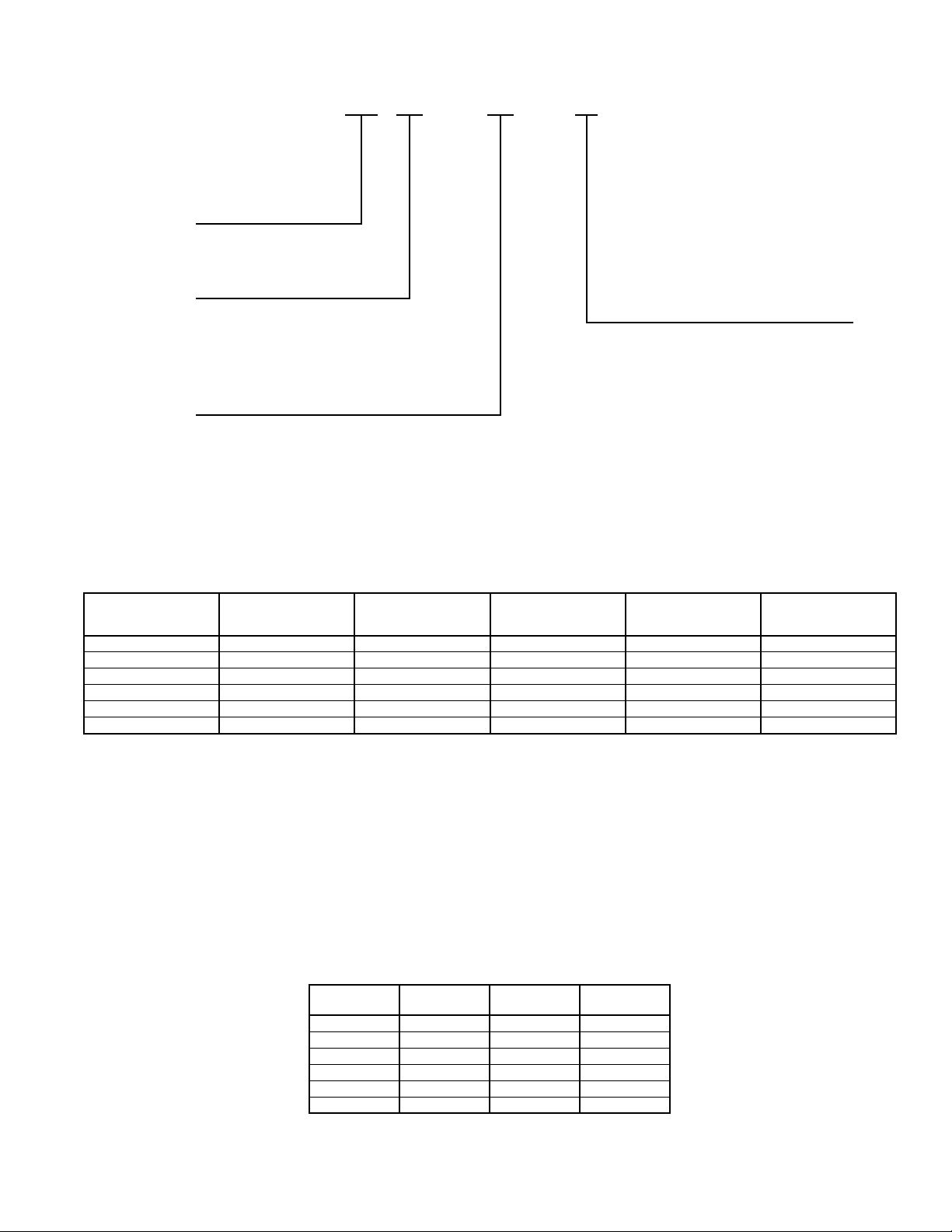

P

E

AL

CU

AD

BT

XT

CC

AC

CC

CU

VS

VT

VC

VU

Model number nomenclature

— Aluminum

— Copper

Model Number

702B – Single

Packaged Electric

Cooling

TT

Electrical Supply

N – *208/230-1-60

– 208/230-3-60

– 460-3-60

Nominal Cooling Capacity

024 – 2 ton

030 – 2.5 ton

036 – 3 ton

042 – 3.5 ton

048 – 4 ton

060 – 5 ton

702B N X 024

000 VS

Options

BT – AL evap, vinyl condens

– AL evap, CU condens

Options

– CU evap & condens

(None) – Wire Grille

– Louvered Grille

– Variable speed (VS) Unit

– Wire Grille and Vinyl-Coated Condenser

– VS, AL evap, vinyl condens

Coil Fin

– VS, AL evap, CU condens

– Louvered Grille and Vinyl-Coated Con-

– VS, CU evap & condens

denser Coil Fin

Only used if ordering an option

– Wire Grille, AL Evaporator and CU/CU

Condenser Coil

– Louvered Grille, AL Evaporator and CU/

CU con

*Variable speed units are only available

in 208/230-1-60 (N)

ARI* capacities

COOLING CAPACITIES AND EFFICIENCIES

UNIT

702B

024 2 800 24,000 12.0 72

030 2-1/2 1000 29,000 12.0 72

036 3 1200 35,000 12.0 72

042 3-1/2 1400 41,000 12.0 73

048 4 1600 48,000 12.0 78

060 5 1750 59,000 12.0 76

LEGEND

dB — Sound Levels (decibels)

db — Dry Bulb

SEER — Seasonal Energy Efficiency Ratio

wb — Wet Bulb

* Air Conditioning & Refrigeration Institute.

† Rated in accordance with U.S. Government DOE Department of

Energy) test procedures and/or ARI Standard 210/240-94.

‡ Tested in accordance with ARI Standard 270-95 (not listed in ARI).

NOMINAL

TONS

STANDARD

CFM

702B WITH ICM FIOP RATINGS

UNIT

702B

024 24,000 10.7 12.7

030 29,000 10.7 12.7

036 35,000 10.6 12.5

042 41,000 10.7 12.5

048 48,000 10.5 12.3

060 59,000 10.4 12.3

**“A” Capacity- 80°F indoor db/67°F indoor wb & 95°F outdoor db.

“A”**

CAPACITY

NET COOLING

CAPACITIES

(Btuh)

NOTES:

1. Ratings are net values, reflecting the effects of circulating fan heat.

Ratings are based on:

Cooling Standard: 80°F db, 67°F wb indoor entering-air temperature and 95°F db outdoor entering-air temperature.

2. Before purchasing this appliance, read important energy cost and

efficiency information available from your retailer.

“A”**

EER

SEER

SEER†

SOUND

RATINGS‡

(dB)

—3—

Page 4

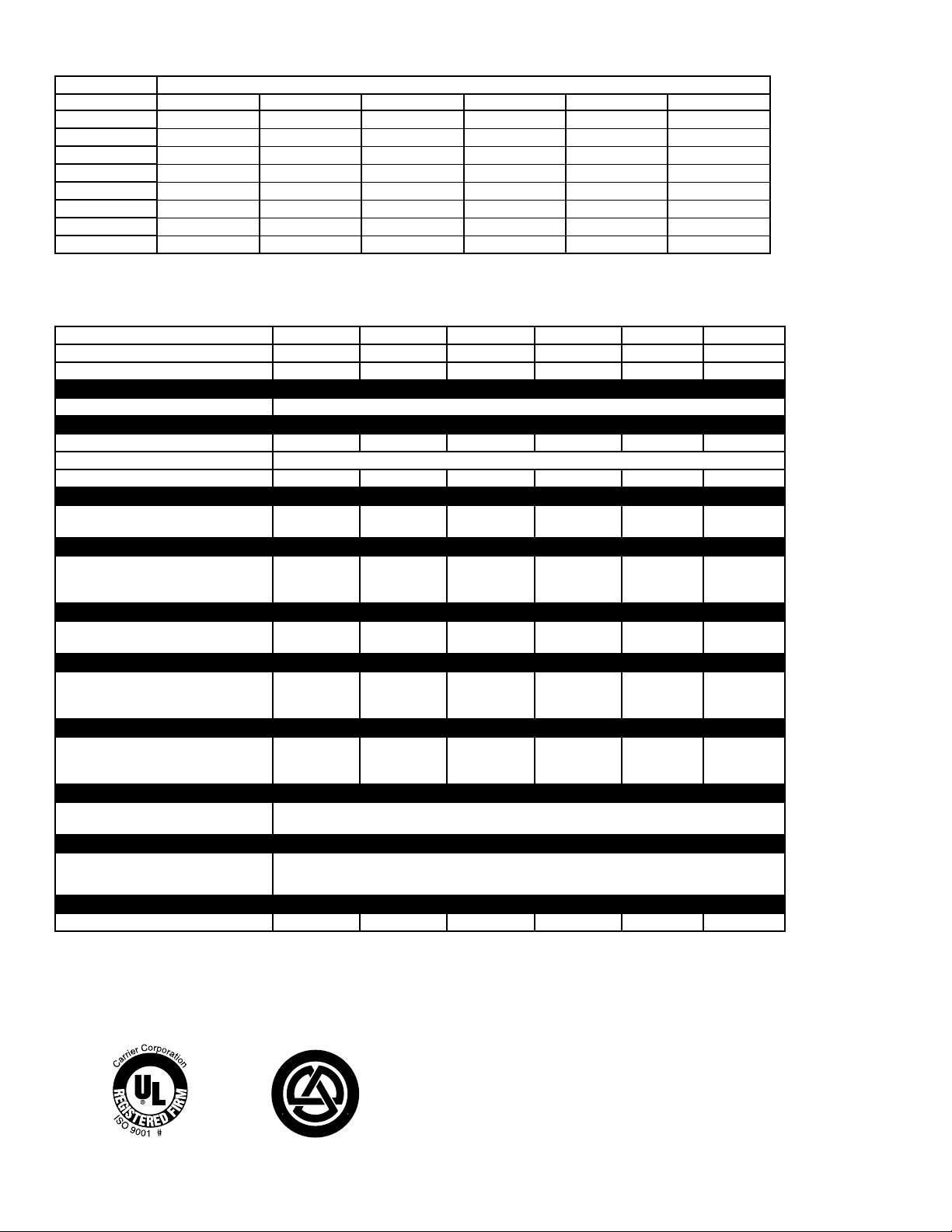

OUTDOOR SOUND: ONE-THIRD OCTAVE BAND DATA - DECIBELS

MODEL NO. 702B

Frequency (Hz) 024 030 036 042 048 060

63

125

250

500

1000

2000

4000

8000

44.8 48.0 50.0 49.1 51.4 53.7

60.4 58.2 60.4 63.9 65.2 62.6

58.3 59.2 61.6 65.2 69.7 65.9

64.8 65.8 66.9 67.9 72.7 70.6

66.9 67.7 67.8 66.7 72.9 71.6

64.3 64.8 64.6 63.8 69.8 68.2

59.8 61.8 60.7 60.2 65.8 65.8

51.8 53.6 52.8 50.7 57.9 58.3

PHYSICAL DATA

UNIT SIZE 702B 024 030 036 042 048 060

NOMINAL CAPACITY (ton)

OPERA TING WEIGHT (lb)

COMPRESSORS

Quantity

REFRIGERANT*

REFRIGERANT (R-410A) Quantity (lb.)

REFRIGERANT METERING DEVICE

ORIFICE ID (in.)

OUTDOOR COIL

Rows—Fins/in.

Face Area (sq ft)

OUTDOOR FAN

Nominal Airflow (Cfm)

Diameter

Motor Hp (Rpm)

OUTDOOR COIL

Rows—Fins/in.

Face Area (sq ft)

INDOOR BLOWER STANDARD

Nominal Airflow (Cfm)

Size (in.)

Motor (Hp)

EVAPORATOR BLOWER ICM FIOP ONLY

Nominal Airflow (Cfm)

Size (in.)

Motor (Hp)

HIGH-PRESSURE SWITCH (psig)

Cutout

Reset (Auto.)

LOSS-OF-CHARGE/LOW-PRESSURE SWITCH

(Liquid Line) (psig)

Cutout

Reset (Auto.)

RETURN-AIR FILTERS (In.)*

Throwaway

* Required filter sizes shown are based on the larger of the ARI (Air Conditioning & Refrigeration Institute) rated

cooling airflow or the heating airflow velocity of 300 ft/min for throwaway type or 450 ft/min for high-capacity

type. Air filter pressure drop for non-standard filters must not exceed 0.08 in. wg.

2 2-1/2 3 3-1/2 4 5

270 291 299 321 326 399

Scroll

5.0 5.5 6.9 9.0 9.5 10.0

Accurater® Piston

.057 .057 .065 .070 .073 .086

1—17

9.1

2350

22

1/8 (825)

3—15

3.7

800

10 x 10

1/4

800

10 x 10

1/2

1—17

12.7

2350

22

1/8 (825)

3—15

3.7

1000

10 x 10

1/4

1000

10 x 10

1/2

2—17

9.1

2350

22

1/8 (825)

3—15

3.7

1200

10 x 10

1/2

1200

10 x 10

3/4

2—17

12.3

2350

22

1/8 (825)

3—15

4.7

1400

11 x 10

3/4

1400

11 x 10

3/4

2—17

12.3

3300

22

1/4 (1100)

4—15

4.7

1600

11 x 10

3/4

1600

11 x 10

3/4

1/4 (1100)

11 x 10

11 x 10

610 ± 15

420 ± 25

20 ± 5

45 ± 10

20 x 20 x 1 20 x 20 x 1 20 x 24 x 1 24 x 30 x 1 24 x 30 x 1 24 x 30 x 1

2—17

16.4

3300

22

4—15

4.7

1750

1.0

1750

1.0

T

O

D

E

A

I

R

F

I

I

T

A

R

S

E

C

R

E

R

U

T

C

N

A

U

F

U

N

A

5

2

3

2

A

M

A

R

C

O

M

H

P

E

A

Y

R

A

T

I

I

S

L

T

Y

P

I

U

N

M

G

P

W

I

T

H

®

E

T

Q

N

U

E

I

P

M

0

4

2

D

T

A

R

N

A

D

—4—

Page 5

OPTIONS AND ACCESSORIES

Factory-installed options

Coil options

construction for refrigerant coils. Units are shipped standard with

copper tube/aluminum fin construction. See model number

nomenclature for coil options.

Electronic V ariable-Speed Motor — ICM Motors (Integrated

Control Motor) provide variable-speed operation to optimize

comfort levels year round. They are also more economical to

operate than standard motors.

Field-installed accessories

Economizer with Solid-State Controls and Barometric

Relief Dampers

Manual Air Damper (25% open)

Electric Heaters

Filter Rack

Flat Roof Curbs (8-in. and 14-in.)

Square-to-Round Duct Transition Kit

Thermostats

Crankcase Heater

Low Ambient Kit (Motormaster® II Control)

Solid-State Time Guard® II Device

Lifting Kit

Compressor Hard Start Kit

Economizer with solid-state controls and barometric relief

dampers

cooling and reduce compressor operation.

Manual outside air damper includes hood and filter rack with

adjustable damper blade for up to 25% outdoor air.

include copper/copper and vinyl-coated

includes filter racks and provide outdoor air during

Electric heaters provide heat in the unit when required. Each

package has a heater module that slides into the controls

compartment. Heater sizes range from 5.0 to 20.0 kW. The

electric heater design allows the use of a single-point power

supply for the entire unit, resulting in lower installed costs.

Flat roof curbs in both 8 in. and 14 in. sizes are a vailable f or roof

mounted applications.

Square-to-round duct transition kit enables 024-048 size

units to be fitted to 14 in. round ductwork.

Thermostats provide control for the system heating and cooling

functions. Thermostat models are av ailable in both programmab le

and non-programmable versions .

Lifting kit, including 4 metal brackets that fit into the hand-holds,

a support strap and two safety straps, is available to assist in

lifting this product onto a roof application.

Crankcase heater provides anti-floodback protection for low-

load cooling applications.

Low-ambient kit (Motormaster II control) allows the use of

mechanical cooling down to outdoor temperatures as low as 0°F.

Solid-state Time Guard II device provides short-cycling

protection for the compressor. Not required with corporate

electronic thermostats.

Filter rack features easy installation, serviceability, and high-

filtering performance for vertical applications.

Compressor hard start kit assists compressor start-up by

providing additional starting torque on single phase units and

prolongs compressor motor life.

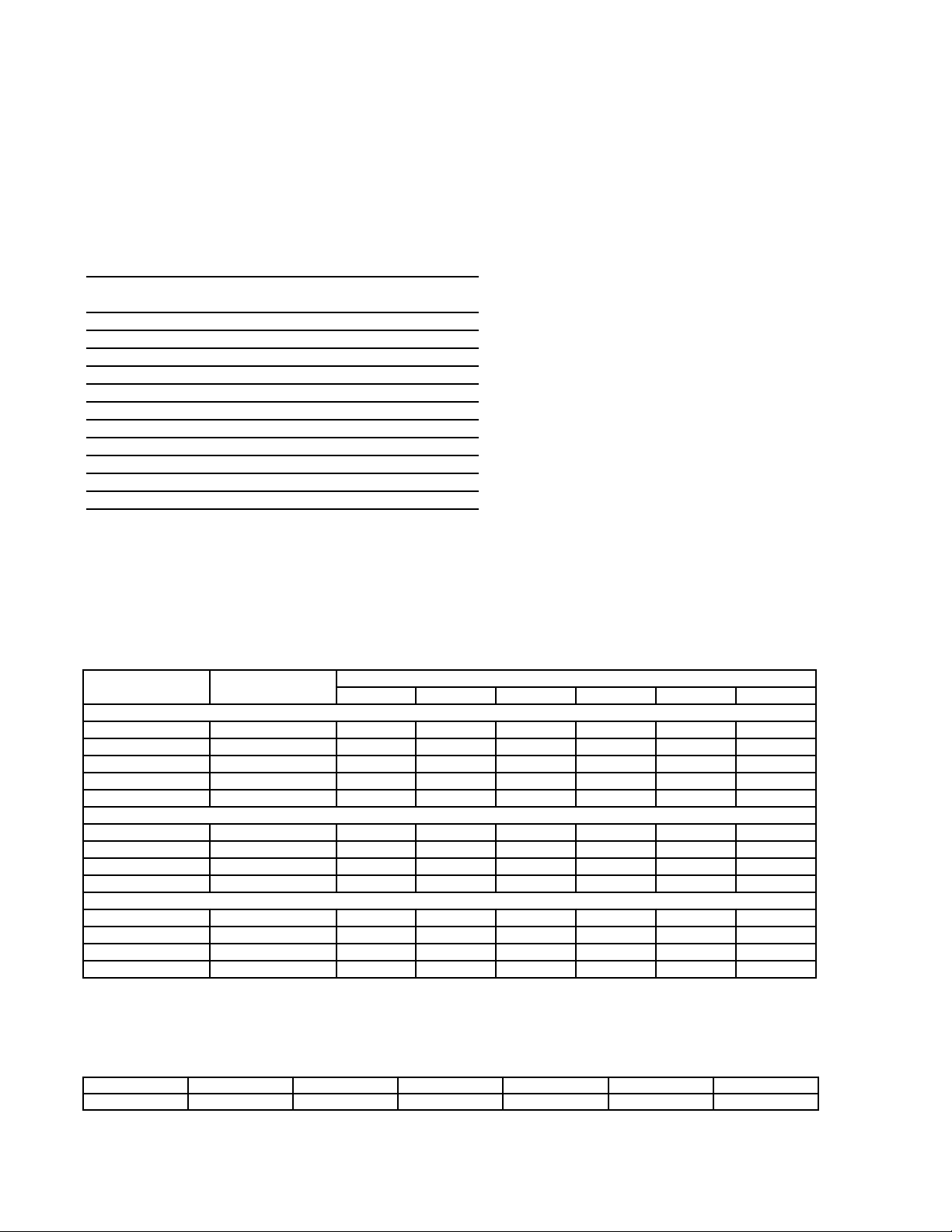

ELECTRIC HEATERS

ODS CATALOG

ORDERING NO.

CPHEATER052A00

CPHEATER069A00

CPHEATER065A00

CPHEATER051A00

CPHEATER053A00

CPHEATER055A00

CPHEATER056A00

CPHEATER057A00

CPHEATER059A00

CPHEATER060A00

CPHEATER061A00

CPHEATER062A00

CPHEATER063A00

LEGEND

ODS — Order Distribution System

NOTE: Electric heaters are rated at 240 v and 480 v. Refer to Multiplication Factors table for other voltages.

NOMINAL CAPACITY

(kW)

ELECTRIC HEATERS (208/230 — SINGLE PHASE — 60 Hz)

5.0 XXXXXX

7.5 XXXXXX

10.0 X X X X X X

15.0 X X X X X

20.0 X X X X

ELECTRIC HEATERS (208/230 — 3 PHASE — 60 Hz)

5.0 XXXXX

10.0 X X X X X

15.0 X X X X X

20.0 X X X X

ELECTRIC HEATERS (460 V — 3 PHASE — 60 Hz)

5.0 X X X X

10.0 X X X X

15.0 X X X X

20.0 X X X X

024 030 036 042 048 060

USED WITH SIZES

MINIMUM AIRFLOW FOR RELIABLE ELECTRIC HEATER OPERATION

UNIT 024 030 036 042 048 060

AIRFLOW

750 750 1250 1205 1500 1800

—5—

Page 6

ECONOMIZER

FILTER RACK MANUAL OUTSIDE AIR DAMPER

REPLACEMENT

PANEL

MANUAL OUTSIDE

AIR HOOD

DAMPER

BLADE

—6—

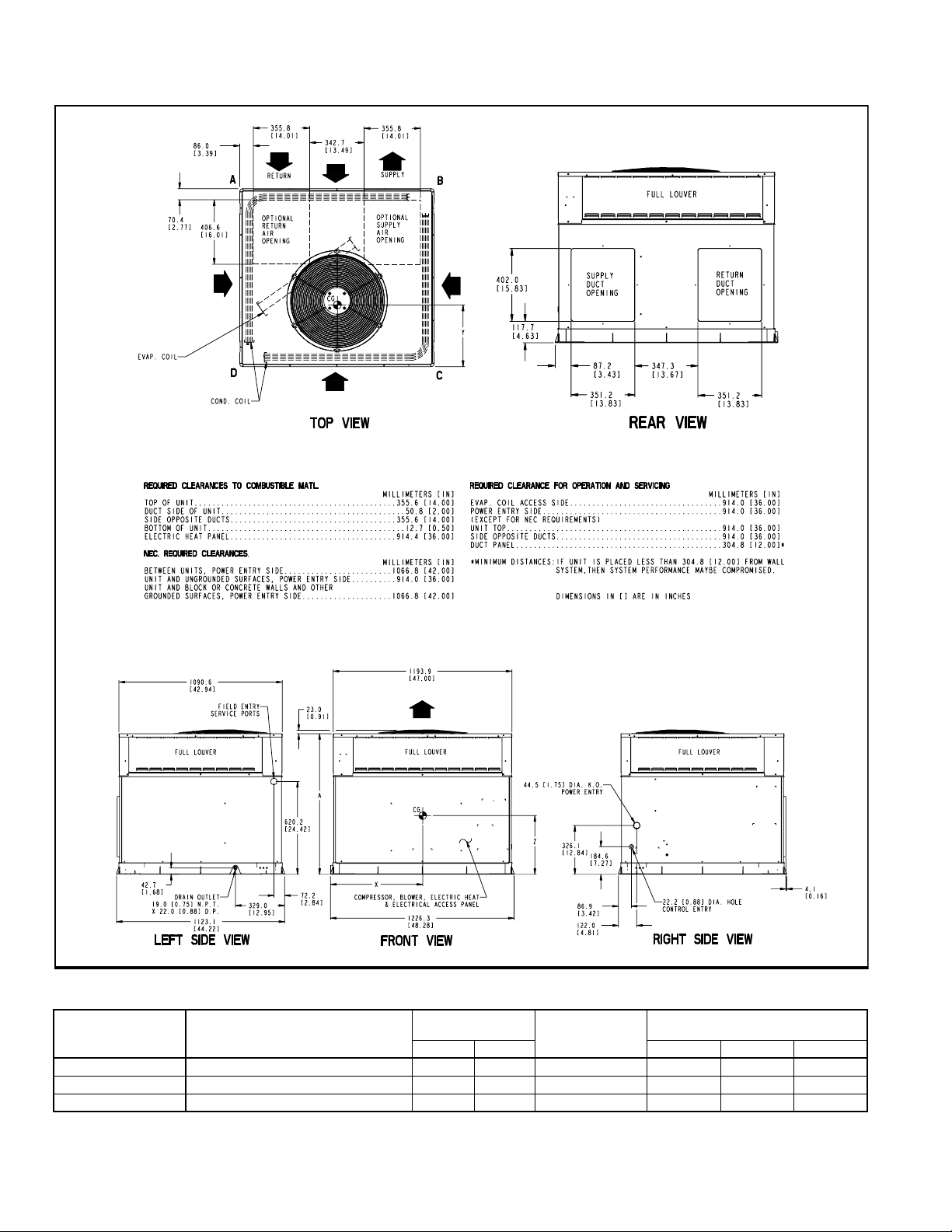

7

Page 7

BASE UNIT DIMENSIONS — 702B024-036

UNIT

702B024

702B030 208/230-1-60, 208/230-3-60 291 132.0 39.02 [991.1] 19.5 [495.3] 15.5 [393.7] 17.6 [447.0]

702B036 208/230-1-60, 208/230-3-60, 460-3-60 299 135.6 35.02 [889.5] 19.5 [495.3] 15.3 [387.4] 16.5 [419.1]

ELECTRICAL

CHARACTERISTICS

208/230-1-60 270 122.5 37.02 [940.3] 18.5 [469.9] 14.5 [368.3] 16.0 [406.4]

UNIT WEIGHT

lb kg X Y Z

UNIT HEIGHT

in. [mm]

“A”

CENTER OF GRAVITY

in. [mm]

702B 024-036 Dimensions

—7—

Page 8

BASE UNIT DIMENSIONS – 702B042-060

UNIT

702B042 208/230-1-60, 208/230-3-60, 460-3-60 321 146 38.98 [990.2] 20.5 [520.7] 16.8 [425.5] 16.6 [421.6]

702B048 208-230-1-60, 208/230-3/60, 460-3-60 326 148 38.98 [990.2] 19.5 [495.3] 17.6 [447.6] 18.0 [457.2]

702B060 208/230-1-60, 208/230-3-60, 460-3-60 399 181 42.98 [1091.7] 20.5 [520.7] 16.2 [412.8] 17.6 [447.0]

ELECTRICAL

CHARACTERISTICS

UNIT WEIGHT

lb kg X Y Z

UNIT HEIGHT

in. [mm]

“A”

CENTER OF GRAVITY

in. [mm]

702B 042-060 Dimensions

—8—

Page 9

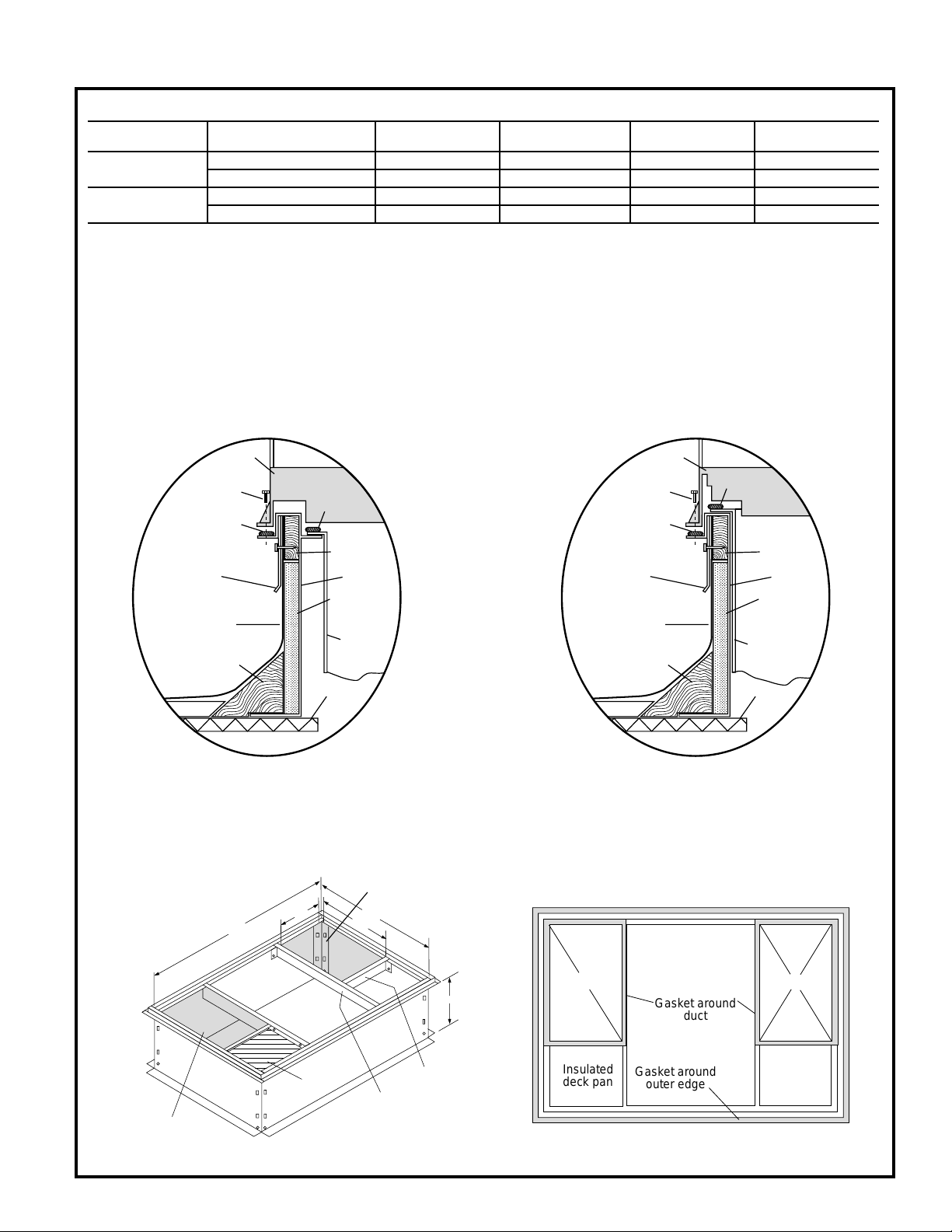

ACCESSORY DIMENSIONS

UNIT SIZE ODS CATALOG NUMBER

50GL024-036

50GL042-060

CPRFCURB006A00 8 [203] 11 [279] 16-1/2 [419] 28-3/4 [730]

CPRFCURB007A00 14 [356] 11 [279] 16-1/2 [419] 28-3/4 [730]

CPRFCURB008A00 8 [203] 16-3/16 [411] 17-3/8 [441] 40-1/4 [1022]

CPRFCURB009A00 14 [356] 16-3/16 [411] 17-3/8 [441] 40-1/4 [1022]

A

in. [mm]

B

in. [mm]

C

in. [mm]

D

in. [mm]

NOTES:

1. Roof curb must be set up for unit being installed.

2. Seal strip must be applied, as required, to unit being installed.

3. Dimensions in [ ] are in millimeters.

4. Roof curb is made of 16-gage steel.

5. Table lists only the dimensions, per part number, that have changed.

6. Attach ductwork to curb (flanges of duct rest on curb).

7. Insulated panels: 1-in. thick fiberglass 1 lb density.

8. Dimensions are in inches.

9. When unit mounting screw is used (see Note A), a retainer bracket must be used as well. This brack et must also be used when required by code

for hurricane or seismic conditions. This bracket is available through Micrometl.

HVAC unit

Screw

(NOTE A)

*Gasketing

outer flange

Flashing field

supplied

Roofing material

field supplied

Cant strip

field supplied

base

Gasketing

inner flange*

Wood nailer*

Roofcurb*

Insulation (field

supplied)

Duct work

field supplied

Flashing field

Roofing material

Screw

(NOTE A)

*Gasketing

outer flange

supplied

field supplied

Cant strip

field supplied

HVAC unit

base

Gasketing

inner flange*

Duct work

field supplied

Wood nailer*

Roofcurb*

Insulation (field

supplied)

Roof

*Provided with roofcurb

Roof Curb for Small Cabinet

Note A: When unit mounting screw is used,

retainer bracket must also be used.

B Typ .

Insulated

deck pan

Return opening

(B X C)

5

44

/16"

Supply opening

(B x C)

D

C Typ .

Long

Support

Short

Support

Roof

*Provided with roofcurb

Roof Curb for Large Cabinet

Note A: When unit mounting screw is used,

retainer bracket must also be used.

R/A

A

Gasket around

S/A

duct

Insulated

deck pan

Gasket around

outer edge

—9—

Page 10

702B Corner weights (In Pounds)

12

y

43

Small Base Large Base

Model 50GL 024

Corner Weight #1 76 84 85 71 78 85

Corner Weight #2 49 60 60 55 56 66

Corner Weight #3 57 61 64 85 80 108

Corner Weight #4 88 86 90 110 112 140

T otal W eight 270 291 299 321 326 399

SELECTION PROCEDURE (WITH EXAMPLE)

I Determine cooling and heating requirements at design

conditions:

Given:

Required Cooling Capacity (TC). . . . . . . . . . . 33,500 Btuh

Sensible Heat Capacity (SHC). . . . . . . . . . . . 24,500 Btuh

Required Heating Capacity . . . . . . . . . . . . . . 15,000 Btuh

Condenser Entering Air Temperature . . . . . . . . . . . . 95°F

Indoor-Air Temperature . . . . . . . . . . . 80°F edb, 67°F ewb

Evaporator Air Quantity . . . . . . . . . . . . . . . . . . . .1200 cfm

External Static Pressure. . . . . . . . . . . . . . . . . . . 0.2 in. wg

Electrical Characteristics . . . . . . . . . . . . . . . . . . .230-1-60

II Select unit based on required cooling capacity.

Enter Cooling Capacities table at condenser entering

temperature of 95°F. The 702B036 unit at 1200 cfm and

67°F ewb (entering wet bulb) will provide a total capacity of

35,000 Btuh and a SHC of 26,000 Btuh. Calculate SHC

correction, if required, using Note 4 under Cooling

Capacities tables.

III Select electric heat.

The required heating capacity is 15,000 Btuh (given).

Determine the electric heat capacity in kW.

15,000 Btuh

3414 Btuh/kW

Enter the Electric Heater Packages table for 208/240,

single-phase, 702B036 unit. The 5-kW heater at 240v most

= 4.4 kW of heat required

030 036 042 048 060

x

closely satisfies the heating required. To calculate kW at

208v, multiply the heater kW by multiplication factor 0.75

found in the Wattage Multiplication Factors table.

5 kW x 0.75 = 3.75 kW

3.75 kW x 3414 Btuh/kW = 12,802.50 Btuh

IV Determine fan speed and power requirements at design

conditions.

Before entering the air delivery tables, calculate the total

static pressure required. From the given, Filter Pressure

Drop table, and the Accessory Electric Heat Pressure Drop

table, find:

External static pressure 0.200 in. wg

Filter 0.130 in. wg

Total static pressure 0.330 in. wg

Enter the table for Wet Coil Air Delivery — (230 and 460 V.)

At 0.33 in. wg external static pressure and low speed, the

motor delivers 1228 cfm, and 440 watts.

V Select unit that corresponds to power source available.

The Electrical Data table shows that the unit is designed to

operate at 208/230-1-60.

—10—

Page 11

702B024 COOLING PERFORMANCE TABLE

Temp (F)

Outdoor Air

Entering

Condenser

75

85

95

105

115

125

702B030 COOLING PERFORMANCE TABLE

Temp (F)

Outdoor Air

Entering

Condenser

75

85

95

105

115

125

TC 23.7 26.0 28.1 24.7 26.9 28.7 25.2 26.9 28.7

SHC 19.6 16.8 13.9 22.3 18.6 14.5 24.4 19.7 14.9

kW 1.74 1.76 1.78 1.88 1.90 1.91 2.04 2.09 2.11

TC 22.4 25.0 27.2 23.6 25.8 27.7 24.1 25.9 27.5

SHC 18.9 16.3 13.4 21.8 18.2 14.2 24.1 19.4 14.6

kW 1.91 1.96 1.97 2.07 2.09 2.11 2.22 2.29 2.30

TC 21.2 23.7 26.2 22.3 24.0 26.7 23.0 24.7 26.4

SHC 18.4 15.8 13.0 21.1 17.3 13.8 23.0 19.0 14.1

kW 2.11 2.17 2.21 2.25 2.25 2.35 2.40 2.52 2.52

TC 19.1 21.5 23.8 20.1 22.3 24.2 21.0 22.3 24.1

SHC 17.1 14.6 12.0 19.5 16.4 12.8 21.0 17.8 13.1

kW 2.37 2.45 2.47 2.52 2.61 2.61 2.68 2.81 2.81

TC 16.9 19.3 21.8 18.2 20.0 22.3 19.2 20.1 22.1

SHC 15.9 13.5 11.1 18.2 15.4 11.9 19.2 16.8 12.6

kW 2.73 2.82 2.89 2.88 3.01 3.02 3.07 3.21 3.23

TC 14.7 16.8 19.2 16.1 17.4 19.6 16.9 17.5 19.4

SHC 14.7 12.5 10.2 16.1 14.2 11.1 16.9 15.7 11.6

kW 3.16 3.28 3.38 3.34 3.46 3.51 3.54 3.68 3.72

TC 29.0 32.2 34.3 30.4 32.8 34.6 31.1 32.6 34.2

SHC 25.2 21.5 17.2 29.0 23.5 18.0 31.1 24.7 18.1

kW 2.11 2.14 2.15 2.28 2.32 2.33 2.46 2.58 2.59

TC 27.5 30.7 33.3 28.7 31.7 33.4 29.8 31.5 33.3

SHC 24.5 20.9 16.8 28.1 23.3 17.6 29.8 24.4 18.0

kW 2.34 2.38 2.44 2.52 2.60 2.62 2.68 2.87 2.84

TC 25.9 29.4 31.9 27.5 29.0 32.3 28.5 29.8 31.9

SHC 23.7 20.4 16.3 27.5 21.9 17.2 28.5 24.3 17.7

kW 2.58 2.65 2.67 2.78 2.75 2.85 2.95 3.09 3.12

TC 23.3 26.2 29.1 24.8 27.0 29.4 25.9 27.0 29.1

SHC 22.0 18.7 15.1 24.8 21.1 16.0 25.9 22.9 16.4

kW 2.90 3.00 3.01 3.07 3.19 3.20 3.31 3.43 3.47

TC 21.5 24.4 26.9 23.1 24.9 27.5 24.2 24.8 26.8

SHC 21.2 17.9 14.2 23.1 20.2 15.2 24.2 22.0 15.7

kW 3.14 3.28 3.33 3.39 3.49 3.48 3.62 3.74 3.79

TC 19.7 22.2 24.7 21.4 22.7 24.8 22.3 22.5 24.6

SHC 19.7 16.8 13.4 21.4 19.2 14.3 22.3 21.0 14.8

kW 3.55 3.69 3.70 3.78 3.86 3.89 4.00 4.10 4.10

62 67 72 62 67 72 62 67 72

62 67 72 62 67 72 62 67 72

See Legend and Notes on page 13.

PERFORMANCE DATA

STANDARD PSC INDOOR MOTOR

COOLING CAPACITIES

Evaporator Air—CFM/BF

600/0.08 800/0.10 1000/0.12

Evaporator Air—Ewb (F)

Evaporator Air—CFM/BF

750/0.08 1000/0.11 1250/0.15

Evaporator Air—Ewb (F)

—11—

Page 12

702B036 COOLING PERFORMANCE TABLE

Temp (F)

Outdoor Air

Entering

Condenser

75

85

95

105

115

125

702B042 COOLING PERFORMANCE TABLE

Temp (F)

Outdoor Air

Entering

Condenser

75

85

95

105

115

125

TC 35.2 38.7 41.6 36.6 39.8 41.9 37.3 39.5 41.5

SHC 30.3 25.5 20.7 34.0 28.0 21.6 37.3 29.3 21.6

kW 2.58 2.61 2.61 2.79 2.84 2.83 3.03 3.14 3.14

TC 32.9 36.9 39.9 34.8 37.9 40.2 35.5 37.7 39.8

SHC 28.7 24.8 20.1 33.3 27.4 21.0 35.5 28.8 21.1

kW 2.83 2.88 2.89 3.05 3.11 3.12 3.28 3.43 3.43

TC 31.0 34.9 37.9 32.4 35.0 38.3 33.8 35.7 37.8

SHC 27.9 24.0 19.3 30.8 26.0 20.3 33.8 28.0 20.5

kW 3.11 3.19 3.20 3.33 3.33 3.43 3.56 3.74 3.73

TC 27.9 31.5 34.3 29.3 32.2 34.6 30.7 32.0 34.0

SHC 26.0 22.2 17.7 28.3 24.8 18.6 30.7 26.5 18.7

kW 3.49 3.59 3.60 3.73 3.82 3.82 3.97 4.15 4.13

TC 25.5 28.8 31.4 27.5 29.4 31.5 28.3 29.2 31.0

SHC 24.7 21.0 16.5 27.5 23.4 17.5 28.3 25.2 17.6

kW 3.85 3.96 3.96 4.07 4.19 4.19 4.34 4.46 4.51

TC 22.2 24.6 27.0 24.0 25.0 27.0 24.5 24.8 26.3

SHC 22.2 19.1 14.8 24.0 21.5 15.8 24.5 23.0 15.8

kW 4.48 4.59 4.61 4.71 4.79 4.84 4.98 5.09 5.15

TC 40.9 44.6 48.1 42.3 45.8 49.1 43.1 45.9 48.8

SHC 35.2 29.5 23.4 39.8 32.4 24.6 43.1 34.4 25.1

kW 2.93 2.97 2.99 3.20 3.27 3.30 3.48 3.70 3.72

TC 38.8 42.7 46.3 40.4 43.8 47.1 41.5 43.9 46.9

SHC 34.2 28.7 22.8 39.0 31.7 24.0 41.5 33.8 24.5

kW 3.26 3.31 3.35 3.53 3.62 3.66 3.76 4.04 4.07

TC 36.5 40.7 44.2 38.1 41.0 45.0 39.8 41.6 44.7

SHC 33.1 27.8 22.0 38.1 30.4 23.3 39.8 33.0 23.9

kW 3.60 3.70 3.73 3.87 3.94 4.03 4.15 4.43 4.45

TC 31.9 35.8 39.4 33.9 36.8 40.0 35.5 36.5 39.8

SHC 30.3 25.3 20.0 33.9 28.5 21.3 35.5 30.7 22.1

kW 4.26 4.42 4.46 4.50 4.75 4.78 4.91 5.17 5.21

TC 28.6 32.0 35.6 30.8 32.9 36.0 32.2 32.7 35.5

SHC 28.6 23.6 18.6 30.8 26.9 20.0 32.2 29.1 20.6

kW 4.92 5.10 5.18 5.06 5.47 5.49 5.63 5.84 5.94

TC 25.3 28.4 32.0 27.8 29.1 32.1 29.0 28.9 31.3

SHC 26.6 21.8 17.1 27.8 25.1 18.5 29.0 27.2 19.0

kW 5.62 5.84 5.97 5.66 6.24 6.26 6.41 6.57 6.73

62 67 72 62 67 72 62 67 72

62 67 72 62 67 72 62 67 72

See Legend and Notes on page 13.

PERFORMANCE DATA

STANDARD PSC INDOOR MOTOR

COOLING CAPACITIES

Evaporator Air—CFM/BF

900/0.09 1200/0.13 1500/0.18

Evaporator Air—Ewb (F)

Evaporator Air—CFM/BF

1050/0.10 1500/0.13 1750/0.17

Evaporator Air—Ewb (F)

—12—

Page 13

702B048 COOLING PERFORMANCE TABLE

Temp (F)

Outdoor Air

Entering

Condenser

75

85

95

105

115

125

702B060 COOLING PERFORMANCE TABLE

Temp (F)

Outdoor Air

Entering

Condenser

75

85

95

105

115

125

TC 47.9 52.3 56.8 49.6 53.7 58.1 50.5 54.0 57.7

SHC 41.5 34.8 28.2 47.4 38.7 29.9 50.5 41.6 30.7

kW 3.38 3.43 3.48 3.68 3.78 3.82 4.01 4.23 4.27

TC 45.7 50.2 54.7 47.5 51.6 56.1 48.9 51.6 56.0

SHC 40.4 34.1 27.4 46.5 37.9 29.3 48.9 40.9 30.3

kW 3.77 3.80 3.86 4.03 4.16 4.21 4.36 4.63 4.68

TC 43.3 47.9 52.3 45.3 48.0 53.7 47.0 48.9 53.5

SHC 39.1 33.1 26.5 45.3 36.2 28.5 47.0 39.9 29.5

kW 4.15 4.23 4.28 4.41 4.46 4.63 4.78 5.07 5.11

TC 39.2 43.7 47.9 41.5 44.6 48.9 42.9 44.3 48.9

SHC 36.4 30.8 24.6 41.5 34.6 26.4 42.9 37.5 27.6

kW 4.67 4.79 4.82 4.93 5.14 5.19 5.34 5.60 5.66

TC 35.3 39.6 43.7 38.2 40.3 44.3 39.3 40.1 44.0

SHC 34.4 29.0 23.0 38.2 32.8 24.7 39.3 35.7 26.0

kW 5.32 5.50 5.54 5.65 5.85 5.89 6.06 6.27 6.36

TC 32.0 35.2 38.7 34.4 35.5 39.3 35.0 35.2 38.8

SHC 32.0 27.0 21.0 34.4 30.8 22.8 35.0 33.4 24.0

kW 6.16 6.31 6.34 6.47 6.63 6.69 6.89 7.04 7.16

TC 57.6 64.3 69.9 59.8 66.1 71.7 61.7 67.6 73.1 65.0 69.6 75.1

SHC 50.6 43.0 34.4 55.5 46.2 36.3 59.8 49.3 38.1 65.0 54.8 41.3

kW 4.63 4.69 4.75 4.67 4.71 4.78 4.68 4.73 4.80 4.70 4.75 4.84

TC 54.4 60.9 67.0 56.4 63.0 68.6 58.0 64.5 69.9 62.3 66.4 71.6

SHC 49.0 41.6 33.4 53.6 45.0 35.2 58.0 48.2 37.0 62.3 54.0 40.2

kW 5.06 5.17 5.21 5.10 5.17 5.23 5.14 5.18 5.26 5.17 5.21 5.29

TC 51.2 57.5 63.7 53.1 59.0 65.3 55.1 60.7 66.5 59.3 62.7 68.1

SHC 47.5 40.0 32.2 51.9 43.2 34.0 55.1 46.8 35.8 59.3 52.8 39.1

kW 5.54 5.68 5.72 5.58 5.64 5.74 5.64 5.69 5.76 5.68 5.71 5.79

TC 45.8 51.9 57.7 47.8 53.4 59.1 50.2 54.6 60.1 53.8 56.2 61.4

SHC 44.0 37.0 29.5 47.8 40.3 31.4 50.2 43.4 33.1 53.8 49.3 36.2

kW 6.17 6.35 6.39 6.23 6.36 6.41 6.30 6.37 6.42 6.36 6.38 6.44

TC 41.9 47.6 53.2 44.5 49.0 54.4 46.8 50.1 55.2 50.0 51.6 56.5

SHC 41.9 35.1 27.8 44.5 38.3 29.6 46.8 41.5 31.3 50.0 47.1 34.5

kW 6.75 6.94 6.98 6.83 6.95 6.99 6.82 6.95 7.01 6.94 6.95 7.03

TC 38.6 43.2 48.3 41.1 44.5 49.4 43.1 45.4 50.0 46.0 46.7 51.0

SHC 38.6 33.2 25.8 41.1 36.3 27.6 43.1 39.3 29.1 46.0 44.5 32.1

kW 7.36 7.64 7.67 7.58 7.64 7.68 7.63 7.64 7.69 7.64 7.65 7.71

62 67 72 62 67 72 62 67 72

1500/0.05 1750/0.06 2000/0.07 2500/0.08

62 67 72 62 67 72 62 67 72 62 67 72

1200/0.06 1600/0.08 2000/0.11

PERFORMANCE DATA

STANDARD PSC INDOOR MOTOR

COOLING CAPACITIES

Evaporator Air—CFM/BF

Evaporator Air—Ewb (F)

Evaporator Air—CFM/BF

Evaporator Air—Ewb (F)

LEGEND

BF — Bypass Factor

Ewb — Entering Wet-Bulb

kW — Total Unit Power Input

SHC — Sensible Heat Capacity (1000 Btuh)

TC — Cooling Capacity (1000 Btuh)

PSC — Permanent Split Capacitor

NOTES:

1. Ratings are net; they account for the effects

of the evaporator-fan motor power and heat.

2. Direct interpolation is permissible. Do not extrapolate.

3. The following formulas may be used:

t=tⴚ

ldb edb

t = Wet-bulb temperature corresponding to enthalpy of air leaving

lwb

evaporator coil (h )

h=hⴚ

lwb ewb

Where: h = Enthalpy of air entering evaporator coil

sensible capacity (Btuh)

1.10 x cfm

lwb

total capacity (Btuh)

4.5 x cfm

ewb

4. The SHC is based on 80°F Edb (Entering dry bulb) air temperature

through Evaporator coil. Below 80°F Edb, subtract (Correction Factor x

CFM) from SHC. Above 80°F Edb, add (Correction Factor x CFM) to

SHC. Correction Factor = 1.10 x (1 + BF) x (Edb + 8)

—13—

Page 14

ECONOMIZER 1-in. FILTER PRESSURE DROP (in. wg)

UNIT 702B PRESSURE DROP

024-036 0.20

042-060 0.25

HEATER kW

RATING

240

480

Example: 20 kW (at 240v) heater on 230v

= 20.0 (.92 mult factor)

= 18.4 kW capacity at 230 v

PERFORMANCE DATA (CONT)

MULTIPLICATION FACTORS

VOLTAGE

DISTRIBUTION

200

208

230

240

440

460

480

MULTIPLICATION

FACTOR

.69

.75

.92

1.00

.84

.92

1.00

FILTER PRESSURE DROP (In. wg)

FILTER SIZE

20 X 20 X 1 0.05 0.07 0.08 0.10 0.12 0.13 0.14 0.15 ———————————

20 X 24 X 1 ————0.09 0.10 0.11 0.13 0.14 0.15 0.16 ————————

24 X 30 X 1 ———————0.07 0.08 0.09 0.10 0.11 0.12 0.13 0.14 0.15 0.16 0.17 0.18

500 600 700 800 900 1000 1100 1200 1300 1400 1500 1600 1700 1800 1900 2000 2100 2200 2300

CFM

ELECTRIC HEAT PRESSURE DROP TABLES

Small Cabinet: 024-036

STATIC

5 Kw 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.02 0.04 0.06 0.07

7.5 Kw 0.00 0.00 0.00 0.00 0.00 0.00 0.02 0.03 0.05 0.07 0.08 0.09

10 Kw 0.00 0.00 0.00 0.00 0.00 0.02 0.04 0.06 0.07 0.09 0.10 0.11

15 Kw 0.00 0.00 0.00 0.02 0.04 0.06 0.08 0.10 0.12 0.14 0.16 0.18

500 600 700 800 900 1000 1100 1200 1300 1400 1500 1600

CFM

Large Cabinet: 042-060

STATIC

5 Kw 0.00 0.00 0.00 0.01 0.02 0.03 0.04 0.05 0.06 0.07 0.08 0.09 0.10 0.11 0.12

7.5 Kw 0.00 0.00 0.01 0.02 0.03 0.04 0.05 0.06 0.07 0.08 0.09 0.10 0.11 0.12 0.13

10 Kw 0.00 0.00 0.01 0.02 0.03 0.04 0.05 0.06 0.07 0.08 0.09 0.10 0.11 0.12 0.13

15 Kw 0.00 0.02 0.03 0.04 0.05 0.06 0.07 0.08 0.09 0.10 0.11 0.12 0.13 0.14 0.15

20 Kw 0.02 0.03 0.04 0.05 0.06 0.07 0.08 0.09 0.10 0.11 0.12 0.13 0.14 0.15 0.16

1100 1200 1300 1400 1500 1600 1700 1800 1900 2000 2100 2200 2300 2400 2500

CFM

—14—

Page 15

WET COIL AIR DELIVERY — STANDARD 702B UNIT 024-060

230 AND 460 VOLT

External Static Pressure (in. wg)

Low

Med

High

Low

Med

High

Low

Med

High

Low

Med

High

Low

Med

High

Low

Med

High

Motor

Speed

Watts

CFM

Watts

CFM

Watts

CFM

Watts

CFM

Watts

CFM

Watts

CFM

Watts

CFM

Watts

CFM

Watts

CFM

Watts

CFM

Watts

CFM

Watts

CFM

Watts

CFM

Watts

CFM

Watts

CFM

Watts

CFM

Watts

CFM

Watts

CFM

0.0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1.0

281 282 281 278 276 ——————

833 776 702 638 554

———375 370 363 357 352 ———

———894 800 754 636 518 ———

—————468 457 444 431 423 —

—————884 802 697 467 397 —

246 244 243 241 ———————

910 806 749 680 ———————

343 339 336 332 328 322 317 ————

1148 1104 1028 958 850 782 645 ————

————441 432 421 410 400 ——

————1102 988 896 783 529 ——

— 470 458 445 430 415 399 384 ———

— 1350 1257 1240 1199 1107 1015 924 ———

——514 501 487 471 455 438 422 ——

——1338 1295 1288 1181 1111 968 813 ——

———646 636 626 614 602 589 ——

———1385 1268 1196 1159 1032 948 ——

— 625 614 605 593 574 549 518 485 454 —

— 1540 1510 1473 1396 1348 1288 1192 1124 1037 —

————726 695 661 625 591 561 540

————1648 1593 1530 1446 1352 1237 1114

———————790 766 742 713

———————1616 1492 1394 1283

— 588 577 572 566 556 539 517 491 ——

— 1514 1543 1467 1408 1374 1324 1237 1161 ——

— 756 738 719 699 676 650 623 596 572 555

— 1785 1765 1706 1628 1577 1503 1421 1357 1298 1253

————896 862 829 800 775 752 728

————1880 1804 1704 1547 1565 1406 1367

903 898 873 842 814 792 777 764 743 701 618

2190 2158 2081 2026 1958 1866 1822 1744 1678 1535 1377

— 1002 978 960 941 914 880 839 798 764 750

— 2389 2291 2216 2120 2020 1952 1852 1727 1617 1549

———1080 1080 1066 1041 1008 972 938 —

———2316 2181 2122 2101 2000 1802 1672 —

Unit

702B

024

030

036

042

048

060

NOTES:

1. Deduct 10% For 208v.

2. Deduct field-supplied air filter pressure drop to obtain external Static pressure available for ducting.

3. Air delivery values are without air filter.

4. Dashes indicate portions of table that are beyond the blower motor capacity or are not recommended.

—15—

Page 16

UNIT

SIZE

024

030

036

UNIT

SIZE

042

048

060

702B ICM FIOP DRY COIL AIRFLOW–SMALL CABINET

CFM ADJUST

PIN SELECT

EXTERNAL STATIC

PRESSURE RANGE

COOLING

COOLING

DEHUMIDIFY

COOLING

COOLING

DEHUMIDIFY

COOLING

COOLING

DEHUMIDIFY

702B ICM FIOP DRY COIL AIRFLOW–LARGE CABINET

CFM ADJUST

PIN SELECT

EXTERNAL STATIC

PRESSURE RANGE

COOLING

COOLING

DEHUMIDIFY

COOLING

COOLING

DEHUMIDIFY

COOLING

COOLING

DEHUMIDIFY

LO PIN NOM PIN HI PIN

0.0–0.4 0.4–0.7 0.7–1.0 0.0–0.4 0.4–0.7 0.7–1.0 0.0–0.4 0.4–0.7 0.7–1.0

800 725 — 885 805 730 990 930 855

715 670 — 715 695

1010 920 825 1105 1030 930 1255 1160 1050

890 845 795 890 865

1110 1025 970 1235 1175 1115 1400 1355 1280

990 960 910 990 975

LO PIN NOM PIN HI PIN

0.1–1.0 0.1–1.0 0.1–1.0

1100 1225 1410

980 980 1125

1260 1400 1610

1120 1120 1290

1575 1750 2010

1400 1400 1610

645 795 775 745

825 1010 980 925

940 1125 1110 1085

UNIT

SIZE

024 0.005

030 —

036

042

048

060

600 700 800 900 1000 1100 1200 1300 1400 1500 1600 1700 1800 1900 2000 2100

702B ICM FIOP WET COIL PRESSURE DROP

STANDARD CFM

0.007 0.010 0.012 0.015 ———————————

0.007 0.010 0.012 0.015 0.018 0.021 0.024 ————————

———0.019 0.023 0.027 0.032 0.037 0.042 0.047 ——————

————0.014 0.017 0.020 0.024 0.027 0.031 0.035 0.039 0.043 ———

——————0.027 0.032 0.036 0.041 0.046 0.052 0.057 0.063 0.068 —

—————————0.029 0.032 0.036 0.040 0.045 0.049 0.053

—16—

Page 17

ROOF-MOUNTING

CURB

SUPPLY-AIR

FLEXIBLE DUCT

TYPICAL PIPING AND WIRING

ROOF

RETURN-AIR

FLEXIBLE DUCT

CONCENTRIC DIFFUSER BOX

(FIELD-SUPPLIED)

TOP COVER

CEILING

C00023

INDOOR

THERMOSTAT

RETURN

AIR

FROM

POWER

SOURCE

—17—

DISCONNECT

PER NEC*

*NEC - NATIONAL ELECTRICAL CODE

C00063

Page 18

APPLICATION DATA

Condensate trap — A 2-in. condensate trap must be field

supplied.

1” MIN.

TRAP

OUTLET

2” MIN.

Ductwork — Secure downflow discharge ductw ork to roof curb.

For horizontal discharge applications, attach ductwork to unit

with flanges.

To convert a unit to downflow discharge — Units are

equipped with factory-installed inserts in the downflow openings.

Remove the inserts similar to removing an electrical knock-out.

Leave on duct covers to seal the hor izontal discharge openings

in the unit. Units installed in horizontal discharge orientation do

not require duct covers.

Maximum cooling airflow — To minimize the possibility of

condensate blow-off from the evaporator, airflow through the

units should not exceed 450 cfm/ton.

Minimum cooling airflow — The minimum cooling airflow is

350 cfm/ton.

Minimum cooling ambient operating temperature — All

standard units have a minimum ambient operating temper ature of

40°F. Units with the ICM Indoor Motor FIOP have a minimum

cooling outdoor operating temperature of 55°F. With accessory

low ambient temperature kit, units can operate at temperatures

down to 0°F.

Maximum operating outdoor air temperature — Maximum

outdoor operating air temperature for cooling is 125°F.

—18—

Page 19

ELECTRICAL DATA

UNIT

SIZE

702B

024 208/230-1-60 187 253 13.5 61.0 0.8 2.0

030

036

042

048

060

V-PH-Hz

208/230-1-60 187 253 14.7 73.0 0.8 2.1

208/230-3-60 187 253 9.6 63.0 0.8 2.1

208/230-1-60 187 253 15.4 83.0 0.8 3.6

208/230-3-60 187 253 12.2 77.0 0.8 3.6

460-3-60 414 506 5.1 35.0 0.8 1.9

208/230-1-60 187 253 18.6 105.0 0.8 4.1

208/230-3-60 187 253 13.8 88.0 0.8 4.1

460-3-60 414 506 6.3 39.0 0.8 2.0

208/230-1-60 187 253 20.5 109.0 1.6 4.1

208/230-3-60 187 253 14.7 91.0 1.6 4.1

460-3-60 414 506 6.5 46.0 0.9 2.0

208/230-1-60 187 253 27.6 158.0 1.6 6.2

208/230-3-60 187 253 18.1 137.0 1.6 6.2

460-3-60 414 506 9.0 62.0 0.9 3.2

VOLTAGE

RANGE

Min Max RLA LRA FLA FLA Nominal kW* FLA UNIT MCA

COMPRESSOR

*See Legend and Notes on page 20.

OUTDOOR

FAN MOTOR

INDOOR

FAN MOTOR ELECTRIC HEAT POWER SUPPLY

—19—

—/—

3.8/5.0

5.4/7.2

7.5/10.0

—/—

3.8/5.0

5.4/7.2

7.5/10.0

—/—

3.8/5.0

7.5/10.0

—/—

3.8/5.0

5.4/7.2

7.5/10.0

11.3/15.0

—/—

3.8/5.0

7.5/10.0

11.3/15.0

—/—

5.0

10.0

15.0

—/—

3.8/5.0

5.4/7.2

7.5/10.0

11.3/15.0

15.0/20.0

—/—

3.8/5.0

7.5/10.0

11.3/15.0

15.0/20.0

—/—

5.0

10.0

15.0

20.0

—/—‚

3.8/5.0

5.4/7.2

7.5/10.0

11.3/15.0

15.0/20.0

—/—

3.8/5.0

7.5/10.0

11.3/15.0

15.0/20.0

—/—

5.0

10.0

15.0

20.0

—/—

3.8/5.0

5.4/7.2

7.5/10.0

11.3/15.0

15.0/20.0

—/—

3.8/5.0

7.5/10.0

11.3/15.0

15.0/20.0

—/—

5.0

10.0

15.0

20.0

—/—

18.1/20.8

25.9/30.0

36.1/41.7

—/—

18.1/20.8

25.9/30.0

36.1/41.7

—/—

10.4/12.0

20.8/24.1

—/—

18.1/20.8

25.9/30.0

36.1/41.7

54.2/62.5

—/—

10.4/12.0

20.8/24.1

31.3/36.1

—/—

6.0

12.0

18.0

—/—

18.1/20.8

25.9/30.0

36.1/41.7

54.2/62.5

72.2/83.3

—/—

10.4/12.0

20.8/24.1

31.3/36.1

41.6/48

—/—

6.0

12.0

18.0

24.1

—/—

18.1/20.8

25.9/30.0

36.1/41.7

54.2/62.5

72.2/83.3

—/—

10.4/12

20.8/24.1

31.3/36.1

41.6/48

—/—

6.0

12.0

18.0

24.1

—/—

18.1/20.8

25.9/30.0

36.1/41.7

54.2/62.5

72.2/83.3

—/—

10.4/12.0

20.8/24.1

31.3/36.1

41.6/48

—/—

6.0

12.0

18.0

24.1

19.7/19.7

25.1/28.5

34.9/40.0

47.6/54.6

21.3/21.3

25.2/28.7

35.0/40.1

47.8/54.7

14.9/14.9

15.7/17.7

28.7/32.7

23.7/23.7

27.1/30.5

36.9/42.0

49.6/56.6

72.2/82.6

19.7/19.7

19.7/19.7

30.6/34.6

43.6/49.6

9.1

9.9

17.4

24.9

28.2/28.2

28.2/31.2

37.5/42.6

50.3/57.2

72.8/83.3

95.4/109.3

22.2/22.2

22.2/22.2

31.2/35.2

44.2/50.2

57.1/65.1

10.7

10.7

17.5

25.1

32.6

31.3/31.3

31.3/31.3

37.5/42.6

50.3/57.2

72.8/83.3

95.4/109.3

24.1/24.1

24.1/24.1

31.2/35.2

44.2/50.2

57.1/65.1

11.0

11.0

17.5

25.1

32.6

42.3/42.3

42.3/42.3

40.1/42.6

52.9/59.8

75.4/85.9

98.0/111.9

30.4/30.4

30.4/30.4

33.8/37.8

46.8/52.9

59.7/67.7

15.4

15.4

19.0

26.6

34.1

MAX FUSE

or CKT. BKR. MOCP

25/25

25/30

40/50

50/60

25/25

25/30

40/50

50/60

20/20

20/20

30/35

30/30

30/30

40/50

50/60

—

25/25

25/25

35/35

45/50

15

15

20

25

35/35

35/35

40/50

60/60

—

—

30/30

30/30

35/40

45/60

—

15

15

20

30

35

40/40

40/40

40/50

60/60

—

—

30/30

30/30

35/40

45/60

—

15

15

20

30

35

50/50

50/50

40/50

60/60

—

—

35/35

35/35

35/40

50/60

—

20

20

20

30

35

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

80/90

—

—

—

—

—

—

—

—

—

—

—

—

80/90

100/110

—

—

—

—

60/70

—

—

—

—

—

—

—

—

—

80/90

100/110

—

—

—

—

60/70

—

—

—

—

—

—

—

—

—

80/90

100/125

—

—

—

—

60/70

—

—

—

—

—

Page 20

702B WITH ICM FIOP ELECTRICAL DATA

UNIT

SIZE

702B

024 208/230-1-60 187 253 13.5 61.0 0.8 4.3

030 208/230-1-60 187 253 14.7 73.0 0.8 4.3

036

042 208/230-1-60 187 253 22.4 105.0 0.9 6.8

048

060

V-PH-Hz

208/230-1-60 187 253 16.9 83.0 1.6 6.8

208/230-1-60 187 253 20.5 109.0 1.6 6.8

208/230-1-60 187 253 27.6 158.0 1.6 9.1

VOLTAGE

RANGE

Min Max RLA LRA FLA FLA Nominal kw* FLA UNIT MCA

COMPRESSOR

OUTDOOR

FAN MOTOR

INDOOR

FAN MOTOR ELECTRIC HEAT

—/—

3.8/5.0

5.4/7.2

7.5/10.0

—/—

3.8/5.0

5.4/7.2

7.5/10.0

—/—

3.8/5.0

5.4/7.2

7.5/10.0

11.3/15.0

—/—

3.8/5.0

5.4/7.2

7.5/10.0

11.3/15.0

15.0/20.0

—/—

3.8/5.0

5.4/7.2

7.5/10.0

11.3/15.0

15.0/20.0

—/—

3.8/5.0

5.4/7.2

7.5/10.0

11.3/15.0

15.0/20.0

—/—

18.1/20.8

25.9/30.0

36.1/41.7

—/—

18.1/20.8

25.9/30.0

36.1/41.7

—/—

18.1/20.8

25.9/30.0

36.1/41.7

54.2/62.5

—/—

18.1/20.8

25.9/30.0

36.1/41.7

54.2/62.5

72.2/83.3

—/—

18.1/20.8

25.9/30.0

36.1/41.7

54.2/62.5

72.2/83.3

—/—

18.1/20.8

25.9/30.0

36.1/41.7

54.2/62.5

72.2/83.3

22.2/22.0

27.9/31.4

37.8/42.9

50.5/27.5

23.5/23.5

27.9/31.4

37.8/42.9

50.5/57.5

26.9/26.9

31.1/34.5

40/9/46.0

53.6/60.6

76.2/86.6

30.9/30.9

31.1/34.5

40.9/46.0

53.6/60.6

76.2/86.6

98.8/112.7

34.0/34.0

34.0/34.5

40.9/46.0

53.6/60.6

76.2/86.6

98.8/112.7

45.2/45.2

45.2/45.2

43.8/48.9

56.5/63.5

79.1/89.5

101.6/115.5

SINGLE POINT

POWER SUPPLY

MAX FUSE

or CKT. BKR. MOCP

30/30

30/35

40/50

60/60

30/30

30/35

40/50

60/60

35/35

35/40

50/50

60/–

—

40/10

40/40

50/50

60/–

—

—

40/40

40/40

50/50

60/–

—

—

60/60

60/60

50/50

60/–

—

—

100/125

100/125

110/125

—

—

—

—

—

—

—

—

—

—

—

–/70

80/90

—

—

—

–/70

90/90

—

—

—

–/70

90/90

—

—

—

–/70

90/90

ELECTRICAL DATA LEGEND

LEGEND

FLA — Full Load Amps

LRA — Locked Rotor Amps

MCA — Minimum Circuit Amps

MOCP — Maximum Overcurrent Protection

RLA

*Heater capacity (KW) based on heater voltage of 208v, 240v, & 480v.

If power distribution voltage to unit varies from rated heater voltage,

heater KW will vary accordingly.

Rated

—

Load Amps

NOTES:

1. In compliance with NEC (National Electrical Code) requirements

for multimotor and combination load equipment (refer to NEC

Articles 430 and 440), the overcurrent protective device for the

unit shall be Power Supply fuse. The CGA (Canadian Gas

Association) units may be fuse or circuit breaker.

2. Minimum wire size is based on 60 C copper wire. If other than

60 C wire is used, or if length exceeds wire length in table,

determine size from NEC.

3. Unbalanced 3-Phase Supply Voltage

Never operate a motor where a phase imbalance in supply voltage is greater than 2%.

the percentage of voltage imbalance.

Use the following formula to determine

% Voltage imbalance

= 100 x

max voltage deviation from average voltage

average voltage

®

EXAMPLE: Supply voltage is 460-3-60.

AB = 452 v

BC = 464 v

AC = 455 v

Average Voltage =

452 + 464 + 455

3

1371

=

3

= 457

Determine maximum deviation from average voltage.

(AB) 457

(BC) 464

(AC) 457

452=5v

457=7v

455=2v

Maximum deviation is 7 v.

Determine percent of voltage imbalance.

% Voltage Imbalance = 100 x

7

457

= 1.53%

This amount of phase imbalance is satisfactory as it is below the

maximum allowable 2%.

IMPORTANT: If the supply voltage phase imbalance is

more than 2%, contact your local electric utility company

immediately.

—20—

Page 21

TYPICAL WIRING SCHEMATIC — 208/230-1-60 SHOWN

—21—

Page 22

TYPICAL WIRING SCHEMATIC — 208/230-3-60 SHOWN

208/230-3-30

—22—

Page 23

TYPICAL WIRING SCHEMATIC — 460-3-60 SHOWN

—23—

Page 24

ICM FIOP WIRING SCHEMATIC — 208-230-1-60 SHOWN

—24—

Page 25

CONTROLS

SEQUENCE OF OPERATION

Cooling — When the system thermostat calls for cooling, 24 V

is supplied to the “Y” and “G” terminals of the thermostat. This

completes the circuit to the contactor coil (C) and indoor

(evaporator) fan time delay relay (TDR). The normally open

contacts of C close and complete the circuit to compressor motor

(COMP) and to outdoor (condenser) fan motor (OFM). Both

motors start instantly. The set of normally open contacts of TDR

close and complete the circuit through IFM. The IFM starts

instantly.

On the loss of the thermostat call for cooling, 24 v is removed

from both the “Y” and “G” terminals (provided the fan switch is in

the “AUTO” position) deenergizing the compressor contactor

and opening the contacts supplying power to compressor/OFM.

After a 60-second delay, the IFM shuts off. If the thermostat fan

selector switch is in the “ON” position, the IFM will run

continuously.

Heating — If accessory electr ic heaters are installed, on a call

for heat, circuit R-W is made through the thermostat contacts.

Circuit R-G is made which energizes the TDR. If the heaters are

staged, then the thermostat closes a second set of contacts

(W2) when second stage is required. When thermostat is

satisfied, contacts open, deenergizing the heater relay and the

TDR. After a 60-second delay, the IFM shuts off. If the

thermostat fan selector switch is in the “ON” position, the IFM will

run continuously.

NOTE: On units with a Time Guard® II device: once the

compressor has started and then stopped, it cannot be restarted

again until 5 minutes have elapsed.

ICM FIOP Models Only — The indoor blower operation with

a call for fan operation (G) in cooling mode will perform by the

on/off delay profile selected at start up on the easy select™

board.

—25—

Page 26

GUIDE SPECIFICATIONS

PACKAGED ELECTRIC COOLING UNITS

CONSTANT VOLUME APPLICATION

HVAC Guide Specifications

Size Range: 2 to 5 Tons, Nominal Cooling

Bryant Model Number: 702B

Part 1—General

SYSTEM DESCRIPTION

Outdoor rooftop or ground mounted, electric cooling unit

utilizing a hermetic compressor for cooling duty and optional electric heating. Unit shall discharge supply air vertically or horizontally as shown on contract drawings.

Condenser fan/coil section shall have a draw-thru design

with vertical discharge for minimum sound levels.

QUALITY ASSURANCE

A. Unit shall be rated in accordance with ARI Standards 210/

240-94 and 270-95.

B. Unit shall be designed in accordance with UL Standard

1995.

C. Unit shall be manufactured in a facility registered to ISO

9001 manufacturing quality standard.

D. Unit shall be UL listed and c-UL certified as a total package

for safety requirements.

E. Roof curb shall be designed to conform to NRCA Stan-

dards.

F. Insulation and adhesives shall meet NFPA 90A require-

ments for flame spread and smoke generation.

G. Cabinet insulation shall meet ASHRAE Standard 62P.

DELIVERY, STORAGE AND HANDLING

Unit shall be stored and handled per manufacturer’s rec-

ommendations.

Part 2 — Products

EQUIPMENT

A. General:

Factory-assembled, single-piece, cooling unit. Contained

within the enclosure shall be all factory wiring, piping, controls, refrigerant charge (R-410A), and special features required prior to field start-up.

B. Unit Cabinet:

1. Unit cabinet shall be constructed of phosphated, zinccoated, pre-painted steel capable of withstanding 500

hours of salt spray.

2. Normal service shall be through a single removable

cabinet panel.

3. The unit shall be constructed on a rust proof basepan

that has an externally trapped, integrated sloped drain

pan.

4. Evaporator fan compartment top surface shall be insulated with a minimum 1/2-in. thick, flexible fiberglass insulation, coated on the air side and retained by

adhesive and mechanical means. The evaporator wall

sections will be insulated with a minimum semi-rigid

foil-faced board capable of being wiped clean. Aluminum foil-faced fiberglass insulation shall be used in the

entire indoor air cavity section.

5. Unit shall have a field-supplied condensate trap.

C. Fans:

1. The evaporator fan shall be 3-speed, direct-drive, as

shown on equipment drawings, or factory installed optional variable speed motor and control.

2. Fan wheel shall be made from steel, and shall be doubleinlet type with forward curved blades with corrosion resistant finish. Fan wheel shall be dynamically balanced.

3. Condenser fan shall be direct drive propeller type with

aluminum blades riveted to corrosion resistant steel

spiders, be dynamically balanced, and discharge air

vertically.

D. Compressor:

1. Fully hermetic compressors with factory-installed vibration isolation.

2. Scroll compressors shall be standard on all units.

E. Coils:

Evaporator and condenser coils shall have aluminum

plate fins mechanically bonded to seamless copper tubes

with all joints brazed. (Copper/copper and vinyl-coated

construction available as option.) Tube sheet openings

shall be belled to prevent tube wear.

F. Refrigerant Metering Device:

Refrigerant metering device shall be of the single body

fixed orifice feed type.

G. Filters:

Filter section shall consist of field-installed, throwaway, 1in. thick fiberglass filters of commercially available sizes.

H. Controls and Safeties:

1. Unit controls shall be complete with a self-contained

low voltage control circuit.

2. Units shall incorporate an internal compressor protector that provides reset capability.

3. Unit shall provide High and Low/Loss-of-Charge Pressure Safety Protection.

I. Operating Characteristics:

1. Unit shall be capable of starting and running at 125°F

ambient outdoor temperature, exceeding maximum

load criteria of ARI Standard 210.

2. Compressor with standard controls shall be capable of

operation down to 40° F ambient outdoor temperature.

(55°F with ICM FIOP)

3. Unit shall be provided with 60-second fan time delay after the thermostat is satisfied (with standard indoor

blower motor).

4. On ICM FIOP-Fan on/off delay profile is selected (for

cooling) on the Easy Select™ Board.

J. Electrical Requirements:

All unit power wiring shall enter the unit cabinet at a single

location.

K. Motors:

1. Compressor motors shall be of the refrigerant-cooled

type with line-break thermal and current overload protection.

2. All fan motors shall have permanently lubricated bearings, and inherent, automatic reset, thermal overload

protection.

3. Condenser fan motor shall be totally enclosed.

L. Grille

1. Louvered Grille:

Louvered grille shall be standard on all units.

M. Special Features Available

1. ICM Indoor Blower FIOP:

Integral control motor shall be a factory installed option

for optimizing comfort levels in all operating modes and

—26—

Page 27

GUIDE SPECIFICATIONS continued

increasing system efficiency.

2. Coil Options:

Shall include factory-installed optional copper/cop-

per and vinyl-coated refrigerant coils.

3. Economizer:

a.Economizer controls capable of providing free cooling using outside air.

b. Equipped with low leakage dampers not to exceed

3% leakage, at 1.0 in. wg pressure differential.

c. Spring return motor shuts off outdoor damper on

power failure.

4. Flat Roof Curb:

Curbs shall have seal strip and a wood nailer for

flashing and shall be installed per manufacturer’s instructions.

5. Manual Outdoor Air Damper:

Package shall consist of damper, birdscreen, and

rainhood which can be preset to admit outdoor air for

year-round ventilation.

6. Thermostat:

To provide for one-stage heating and cooling in addi-

tion manual or automatic changeover and indoor fan

control.

7. Low Ambient Package:

Shall consist of a solid-state control and condenser

coil temperature sensor for controlling condenser-fan

motor operation, which shall allow unit to operate

down to 0° F outdoor ambient temperature.

8. Filter Rack Kit:

Shall provide filter mounting for downflow applica-

tions.

9. Square-To-Round Duct Transitions:

Shall have the ability to convert the supply and return

openings from rectangular to round. (024-048 only)

10. Compressor Protection (Time Guard® II Kit)

Solid-state control shall protect compressor by preventing “short cycling.”

11. Crankcase Heater:

Shall provide anti-floodback protection for low-load

cooling applications.

12. Electric heaters:

a. Electric heater shall be available as a field-

installed option.

b. Heater elements shall be open wire type, ade-

quately supported and insulated with ceramic

bushings.

c. Electric heater packages must provide single point

power connection capability.

13. Compressor Hard Start Kit:

Shall be available to give a boost to the compressor

motor at each start-up. (Single Phase only).

—27—

Page 28

SPECIFICATIONS SUBJECT TO CHANGE WITHOUT NOTICE

UNIT MUST BE INSTALLED IN ACCORDANCE

WITH INSTALLATION INSTRUCTIONS

Cancels: PDS 702B.24.1

Form: PDS 702B.24.2

© 2001 Bryant Heating & Cooling Systems, 7310 W. Morris St., Indpls., IN 46231 PRINTED IN U.S.A. Catalog No. 5270-202 5-01

—28—

Loading...

Loading...