Page 1

Installation, Start-Up

and Operating Instructions

657A

SINGLE PACKAGED

HEAT PUMP UNITS

Cancels: II 657A.24.4 II 657A.24.5

7–03

NOTE: Read the entire instruction manual before starting the

installation.

This symbol → indicates a change since the last issue.

TABLE OF CONTENTS

SAFETY CONSIDERATIONS.....................................................1

Introduction ....................................................................................2

RECEIVING AND INSTALLATION..........................................2

Check Equipment......................................................................2

IDENTIFY UNIT................................................................2

INSPECT SHIPMENT........................................................2

Provide Unit Support................................................................3

ROOF CURB & SLAB MOUNT.......................................3

Provide Clearances....................................................................4

Select and Install Ductwork .....................................................5

Rig and Place Unit....................................................................6

INSTALLATION ................................................................8

Connect Condensate Drain.......................................................9

Install Duct Connections ..........................................................9

CONFIGURING UNITS FOR DOWNFLOW (VERTI-

CAL) DISCHARGE-STANDARD UNITS (024–042)....11

CONFIGURING UNITS FOR DOWNFLOW (VERTI-

CAL) DISCHARGE-ECM UNITS (048–060).................13

Install Electrical Connection ..................................................14

HIGH-VOLTAGE & CONTROL-VOLTAGE CONNEC-

TIONS................................................................................14

SPECIAL PROCEDURES FOR 208-V OPERATION ...15

PRE-START-UP ..........................................................................15

START-UP...................................................................................17

CHECK FOR REFRIGERANT LEAKS..........................17

START UP AND MAKE ADJUSTMENTS....................18

CHECKING COOLING CONTROL OPERATION .......18

CHECKING HEATING CONTROL OPERATION........18

CHECKING AND ADJUSTING REFRIGERANT

CHARGE...........................................................................18

INDOOR AIRFLOW AND AIRFLOW ADJUST-

MENTS..............................................................................21

For 208/230v-PSC Blower Motor.....................................21

For 208/230v-ECM Blower Motor...................................21

COOLING SEQUENCE OF OPERATION.....................22

HEATING SEQUENCE OF OPERATION.....................23

MAINTENANCE.........................................................................23

AIR FILTER......................................................................24

UNIT TOP REMOVAL....................................................24

INDOOR BLOWER AND MOTOR................................24

OUTDOOR COIL, INDOOR COIL, AND CONDENSATE

DRAIN PAN......................................................................27

OUTDOOR FAN...............................................................28

ELECTRICAL CONTROLS AND WIRING ..................28

REFRIGERANT CIRCUIT...............................................29

INDOOR AIRFLOW ........................................................29

METERING DEVICE — ACUTROL DEVICE .............29

LIQUID LINE STRAINER ..............................................29

Troubleshooting............................................................................31

Start-UpChecklist........................................................................32

NOTE TO INSTALLER — Before the installation, READ THESE

INSTRUCTIONS CAREFULLY AND COMPLETELY. Also,

make sure the User’s Manual and Replacement Guide are left with

the unit after installation.

SAFETY CONSIDERATIONS

Installation and servicing of air-conditioning equipment can be

hazardous due to system pressure and electrical components. Only

trained and qualified personnel should install, repair, or service

air-conditioning equipment.

Untrained personnel can perform basic maintenance functions of

cleaning coils and filters. All other operations should be performed

by trained service personnel. When working on air-conditioning

equipment, observe precautions in the literature, tags, and labels

attached to the unit, and other safety precautions that may apply.

Follow all safety codes. Wear safety glasses and work gloves. Use

quenching cloth for unbrazing operations. Have fire extinguisher

available for all brazing operations. Consult a qualified installer or

service agency for information or assistance. The qualified installer or agency must use only factory-authorized kits or accessories when modifying this product.

C95002

Fig. 1—Unit 657A with Optional Base Rails

WARNING: Before performing service or maintenance

operations on system, turn off power to unit. Turn off

accessory heater power switch, if applicable. Electrical

shock can cause personal injury.

Recognize safety information. This is the safety-alert symbol .

When you see this symbol in instructions or manuals, be alert to

the potential for personal injury.

Understand the signal words DANGER, WARNING, CAUTION,

and NOTE. These words are used with the safety-alert symbol.

DANGER identifies the most serious hazards which will result in

—1—

Page 2

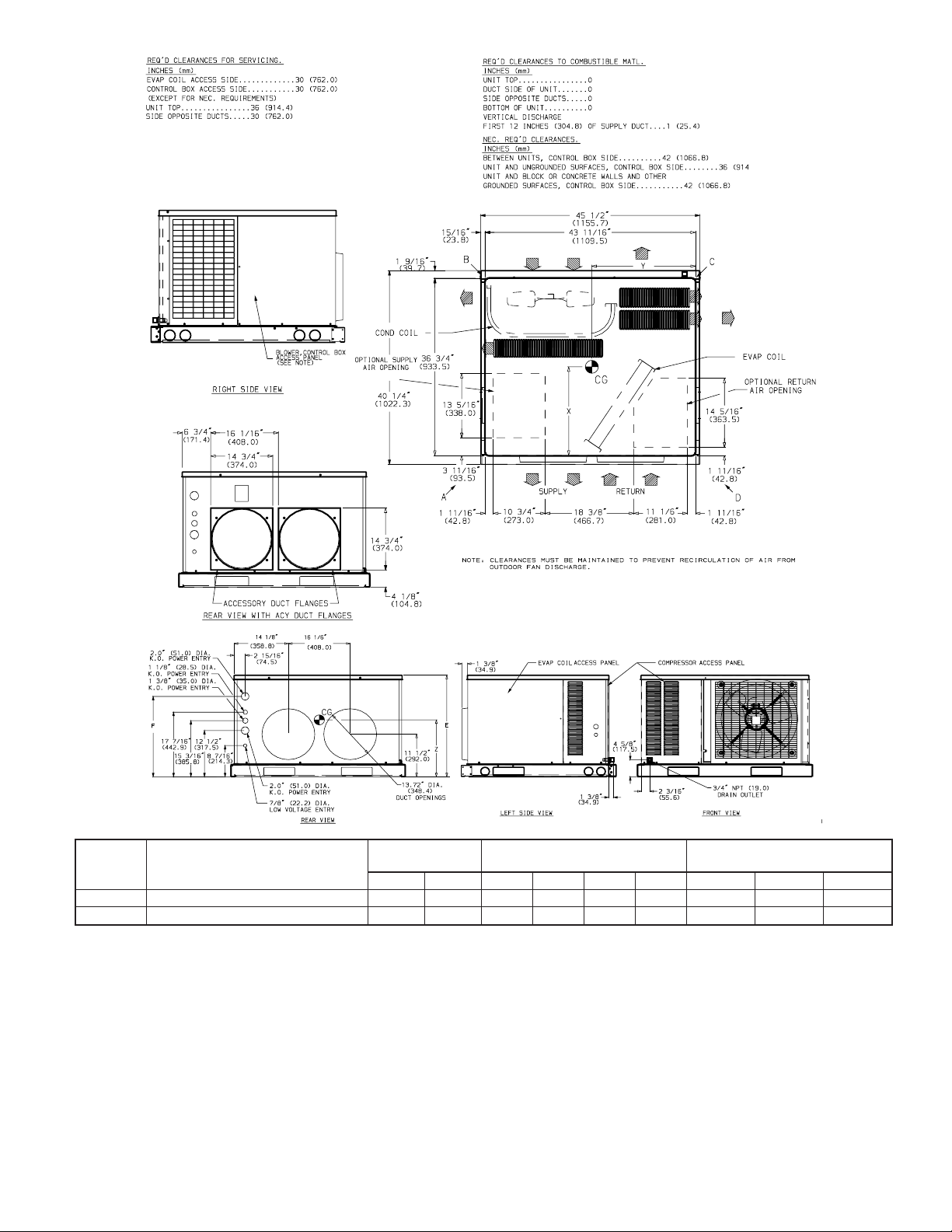

C95003

UNIT ELECTRICAL CHARACTERISTICS

657A024 208/230-1-60 257 117 57/26 69/31 75/34 56/25 20.4/519 21.1/540 11.2/286

657A030 208/230-1-60 288 131 56/25 87/40 74/34 71/32 20.3/518 21.5/547 11.2/286

UNIT WEIGHT

lb. kg A B C D X Y Z

CORNER WT

LB/KG

CENTER OF GRAVITY

IN/MM

Fig. 2— 657A024-030 Unit Dimensions (without base rails)

severe personal injury or death. WARNING signifies a hazard

which could result in personal injury or death. CAUTION is used

to identify unsafe practices which would result in minor personal

injury or product and property damage. NOTE is used to highlight

suggestions which will result in enhanced installation, reliability,

or operation.

These instructions cover minimum requirements and conform to

existing national standards and safety codes. In some instances,

these instructions exceed certain local codes and ordinances,

especially those that may not have kept up with changing residential construction practices. We require these instructions as a

minimum for a safe installation.

INTRODUCTION

The 657A units (see Fig. 1) are fully self-contained, and designed

for outdoor installation. See Figs. 2–5 for unit dimensions. All

units are shipped in a horizontal-discharge configuration for

installation on a ground-level slab. All units can be converted to

down-flow discharge configurations for rooftop applications. (See

Fig. 6 for roof curb dimensions.)

RECEIVING AND INSTALLATION

I. CHECK EQUIPMENT

A. IDENTIFY UNIT

The unit model number and serial number are stamped on the unit

identification plate. Check this information against shipping papers.

B. INSPECT SHIPMENT

Inspect for shipping damage while unit is still on shipping pallet.

If unit appears to be damaged or is torn loose from its anchorage,

have it examined by transportation inspectors before removal.

—2—

Page 3

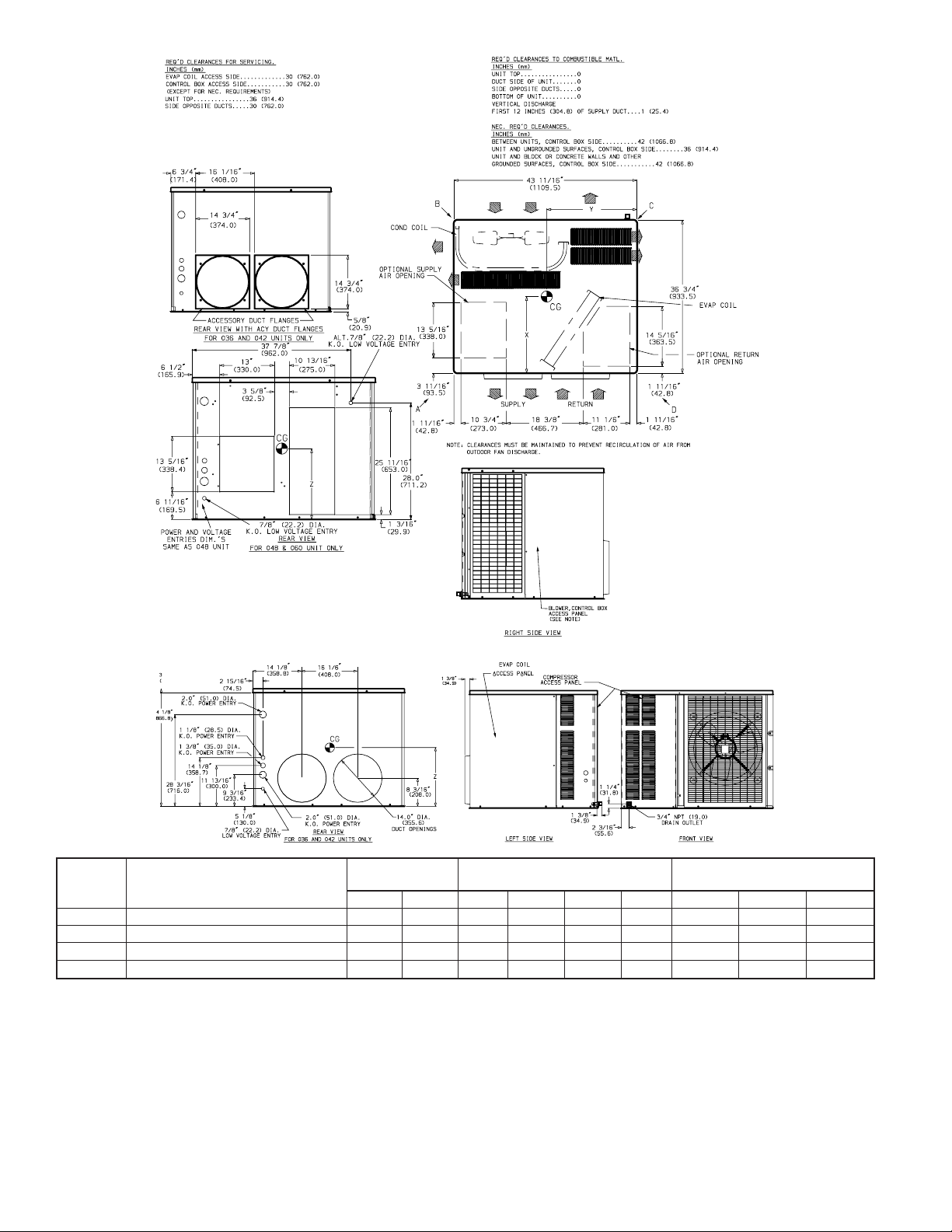

C95004

UNIT ELECTRICAL CHARACTERISTICS

657A024 208/230-1-60 277 126 62/28 74/34 80/36 61/28 20.2/515 21.3/541 13.8/351

657A030 208/230-1-60 308 140 61/28 92/42 79/36 76/35 20.2/514 21.5/547 13.8/351

UNIT WEIGHT

lb. kg A B C D X Y Z

CORNER WT

LB/KG

CENTER OF GRAVITY

IN/MM

Fig. 3— 657A024-030 Unit Dimensions (with base rails)

Forward claim papers directly to transportation company. Manufacturer is not responsible for any damage incurred in transit.

Check all items against shipping list. Immediately notify the

nearest distributor if any item is missing. To prevent loss or

damage, leave all parts in original packages until installation.

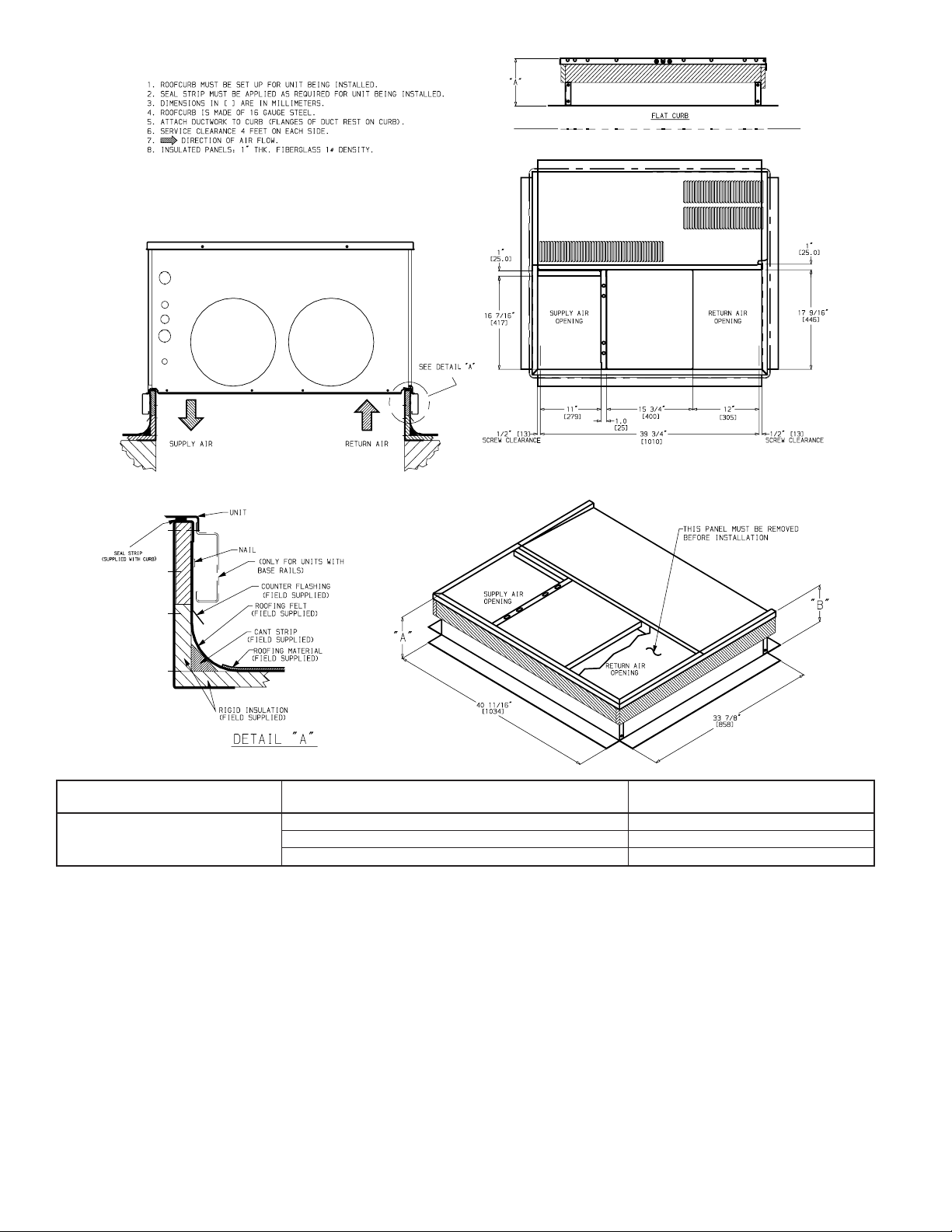

II. PROVIDE UNIT SUPPORT

A. ROOF CURB & SLAB MOUNT

ROOF CURB - Install accessory roof curb in accordance with

instructions shipped with curb (See Fig. 6). Install insulation, cant

strips, roofing, and flashing. Ductwork must be attached to curb.

IMPORTANT: The gasketing of the unit to the roof curb is

critical for a watertight seal. Install gasketing material supplied

with the roof curb. Improperly applied gasketing also can result in

air leaks and poor unit performance.

Curb should be level to within 1/4 in (See Fig. 8). This is necessary

for unit drain to function properly. Refer to accessory roof curb

installation instructions for additional information as required.

SLAB MOUNT - Place the unit on a solid, level concrete pad that

is a minimum of 4 in. thick with 2 in. above grade (See Fig. 10).

The slab should extend approximately 2 in. beyond the casing on

all 4 sides of the unit. Install a 6-in. gravel apron in front of

—3—

Page 4

UNIT ELECTRICAL CHARACTERISTICS

657A036 208/230-1-60 316 144 46/21 103/47 81/37 86/39 21.2/539 20.4/520 13.6/347

657A042 208/230-1-60 316 144 46/21 103/47 81/37 86/39 21.2/539 20.4/520 13.6/547

657A048 208/230-1-60 359 163 89/40 81/37 113/51 76/35 19.7/500 20.5/522 15.0/381

657A060 208/230-1-60, 373 170 92/42 85/39 116/53 80/36 19.6/499 20.6/523 15.0/381

UNIT WEIGHT

lb. kg A B C D X Y Z

CORNER WT

LB/KG

CENTER OF GRAVITY

IN/MM

Fig. 4— 657A036-060 Unit Dimensions (without base rails)

outdoor coil-air inlet to prevent obstruction of airflow by grass or

shrubs. Do not secure the unit to the slab except when required by

local codes.

III. PROVIDE CLEARANCES

The required minimum service clearances are shown in Fig. 2-5.

Adequate ventilation and outdoor air must be provided. The

outdoor fan pushes air through the outdoor coil and discharges it

through the louvers on the top cover, the decorative grille, and the

compressor access panel. Be sure that the fan discharge does not

recirculate to the outdoor coil. Do not locate the unit in either a

corner or under an overhead obstruction. The minimum clearance

under a partial overhang (such as a normal house overhang) is 48

in. above the unit top. The maximum horizontal extension of a

partial overhang must not exceed 48 in.

IMPORTANT: Do not restrict outdoor airflow. An air restriction

at either the outdoor-air inlet or the fan discharge may be

detrimental to compressor life.

Do not place the unit where water, ice, or snow from an overhang

or roof will damage or flood the unit. Do not install the unit on

carpeting or other combustible materials. Slab-mounted units

—4—

C95005

Page 5

C95006

UNIT ELECTRICAL CHARACTERISTICS

657A036 208/230-1-60 336 153 51/23 108/49 86/39 91/41 21.0/535 20.5/521 16.4/418

657A042 208/230-1-60 336 153 51/23 108/49 86/39 91/41 21.0/535 20.5/521 16.4/418

657A048 208/230-1-60 379 172 94/43 86/39 118/54 81/37 19.6/498.3 20.6/524 17.3/440

657A060 208/230-1-60, 393 179 97/44 90/41 121/55 85/39 19.5/497.3 20.6/524 17.3/440

UNIT WEIGHT

lb. kg A B C D X Y Z

CORNER WT

LB/KG

CENTER OF GRAVITY

IN/MM

Fig. 5— 657A036-060 Unit Dimensions (with base rails)

should be at least 4 in. above the highest expected water and runoff

levels. Do not use unit if it has been under water.

IV. SELECT AND INSTALL DUCTWORK

The design and installation of the duct system must be in

accordance with the standards of the NFPA (National Fire Protection Association) for installation of nonresidence-type air conditioning and ventilating systems, NFPA90A or residence type,

NFPA90B; and/or local codes and residence-type, NFPA90B;

and/or local codes and ordinances. Select and size ductwork,

supply-air registers and return-air grilles according to ASHRAE

(American Society of Heating, Refrigeration, and Air Condition-

ing Engineers) recommendations. The unit has duct flanges on the

supply- and return-air openings on the side of the unit. See Fig. 2-5

for connection sizes and locations. When designing and installing

ductwork, consider the following:

CAUTION: When connecting ductwork to units, do not

drill deeper than 1/2–in. in shaded area shown or coil may

be damaged.

1. All units should have field-supplied filters or accessory

—5—

Page 6

ODS CATALOG NUMBER

Flat

Curb

CPRFCURB001A00 8 (203)

CPRFCURB002A00 11 (279)

CPRFCURB003A00 14 (356)

Fig. 6— Roof Curb Dimensions

filter rack installed in the return-air side of the unit.

Recommended sizes for filters are shown in Table 1.

2. Avoid abrupt duct size increases and reductions. Abrupt

change in duct size adversely affects air performance.

IMPORTANT: Use flexible connectors between ductwork and

unit to prevent transmission of vibration. Use suitable gaskets to

ensure weathertight and airtight seal. When electric heat is

installed, use fireproof canvas (or similar heat resistant material)

connector between ductwork and unit discharge connection. If

flexible duct is used, insert a sheet metal sleeve inside duct. Heat

resistant duct connector (or sheet metal sleeve) should extend

24-in. from electric heater element.

3. Size ductwork for cooling air quantity (cfm). The minimum

air quantity for proper electric heater operation is listed in

Table 2. Heater limit switches may trip at air quantities

below those recommended.

C95007

A

IN. (MM)

NOTE: A 90-degree elbow must be provided in the supply

ductwork to comply with UL (Underwriters’ Laboratories) codes

for use with electric heat.

4. Insulate and weatherproof all external ductwork. Insulate

and cover with a vapor barrier all ductwork passing through

conditioned spaces. Follow latest Sheet Metal and Air

Conditioning Contractors National Association

(SMACNA) and Air Conditioning Contractors Association

(ACCA) minimum installation standards for residential

heating and air conditioning systems.

5. Secure all ducts to building structure. Flash, weatherproof,

and vibration-isolate duct openings in wall or roof according to good construction practices.

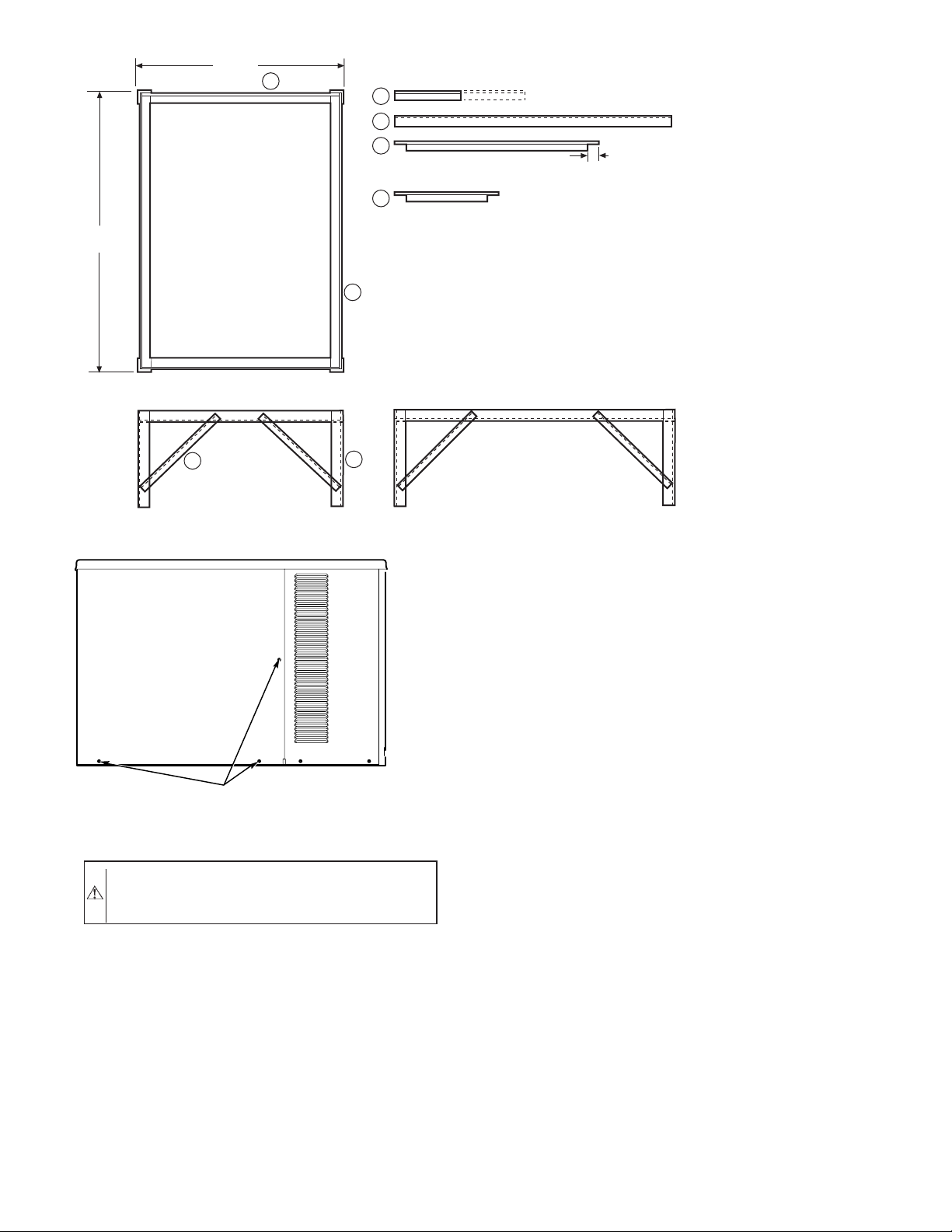

V. RIG AND PLACE UNIT

Use spreader bars or crate top when rigging the unit. The units

must be rigged for lifting as shown in Fig. 7. Use extreme caution

—6—

Page 7

CHART A CHART B

UNIT

SIZE

024 296 134 16.1 410 32.2 817 309 140 16.0 406 28.9 733

030 327 148 16.2 411 32.2 817 340 154 16.0 407 28.9 733

036 355 161 15.4 390 38.2 969 368 167 15.2 385 34.9 885

042 355 161 15.4 390 38.2 969 368 167 15.2 385 34.9 885

048 398 180 16.9 428 38.2 969 411 186 16.8 426 34.1 867

060 412 187 16.9 429 38.2 969 425 193 16.8 427 34.1 867

Max

Weight

LB KG IN MM IN MM LB KG IN MM IN MM

AB

Max

Weight

CD

Fig.7—657A RiggingInstructions

C95006

A

B

C

MAXIMUM ALLOWABLE

DIFFERENCE (in.)

A-B B-C A-C

1/4 1/4 1/4

Fig. 8—Unit Leveling Tolerances

to prevent damage when moving the unit. Unit must remain in an

upright position during all rigging and moving operations. The unit

must be level for proper condensate drainage; the ground-level pad

or accessory roof curb must be level before setting the unit in

place. When a field-fabricated support is used, be sure that the

support is level and that it properly supports the unit.

UNITS WITHOUT BASE RAILS-Accessory rigging brackets are

recommended to be used for rigging. Install brackets as follows:

C99065

—7—

Page 8

RETURN

AIR

INDOOR

THERMOSTAT

TOP COVER

Fig. 9—Typical Unit Installation

REAR SIDE OF UNIT

PAD

UNIT OUTLINE

933 mm

(36 3/4”)

1110 mm

(43 11/16”)

984 mm

(38 3/4”)

1161 mm

(45 11/16”)

FROM

POWER

SOURCE

DISCONNECT

PER NEC

SIDE

OF UNIT

WITH DUCT

CONNECTIONS

C95013

SIDE OF UNIT WITH

ACCESS PANELS FOR

CONTROL BOX AND

INDOOR BLOWER HOUSING

NOTES:

1. Extend

2. Provide a3-ft service clearance

gravel apron around pad.

6-in.

Fig.10—Typical Slab Layout

WARNING: Secure screws and paint protectors solidly

against unit base to hold lifting brackets in position.

Never use lifting brackets when the temperature is below

-10 F (-23 C). Never exceed 200 lbs per bracket of lifting

force. Never use lifting brackets for lifting other models

of air conditioning units. Lifting point should be directly

over the unit center of gravity. Failure to follow this

warning could result in personal injury or death.

1. Position brackets as close to the corners of unit as possible.

Be sure brackets are well outside of center of gravity (See

Fig. 2-5, and 7).

2. Position paint protectors and foam strips between screws

and painted surface of unit. Tighten screws until they make

contact with the paint protectors.

3. Secure device or hook of sufficient strength to hole in

bracket as shown in detail ’’C’’ of Fig. 7.

4. If wood top is available, use it for a spreader bar to prevent

straps from damaging unit. If wood top is not available, use

spreader bars of sufficient length.

at front and rear sides of unit.

C95039

UNITS WITH OPTIONAL BASE RAILS - Keep unit upright and

do not drop. Use spreader bars or top crate when rigging unit.

Rollers may be used to move unit across roof. Level unit for proper

condensate disposal. See Fig. 7 for additional information. Lifting

holes are provided in base rails as shown in Fig. 7, See Detail “A”

or “B-B”. Refer to rigging instructions on unit.

A. INSTALLATION

1. Position the lifting bracket assembly around the base of the

unit. Leave the top shipping skid on the unit to act as a

spreader bar. Be sure the strap does not twist.

2. Place each of the four (4) metal lifting brackets into the

rigging holds in the composite pan.

3. Tighten the ratchet strap unit tight. Lifting brackets should

be secure in the rigging holds.

4. Attach the clevis or hook of sufficient strength to hole in the

lifting bracket (See Fig. 7).

5. Attach safety straps directly to the field supplied rigging

straps or clevis clip. Do not attach the safety straps to the

lifting brackets.

6. Use the top of the unit as a spreader bar to prevent the

rigging straps from damaging the unit. If the wood top is not

available, use a spreader bar of sufficient length to not

damage the unit.

—8—

Page 9

959 mm

(37 3/4 in.)

3

1

2

3

305 mm (12 in.) TO 610 mm (24 in.) (4) REQ.

1010 mm

(39 3/4 in.) (2) REQ.

909 mm (35 3/4 in.) (2) REQ.

38 mm (1 1/4 in.)

1060 mm

(41 3/4 in.)

4

NOTES:

1. Material consistsof angle iron — 31.8 mm (1-1/4 in.) to 38 mm

2

4

1

2. We ldframetogether.

3. Pa int with z inc-rich paint (rust-proof).

406 mm (16 in.) (8) REQ.

(1-1/2 in.) commerical standard.

C95013

Fig. 11—Optional Heat Pump Mounting Frame

ACCESS PANEL

(REMOVE SCREWS)

Fig. 12—Indoor Coil Access Panel

WARNING: Lifting point should be directly over the

center of gravity for the unit. Failure to follow this

warning could result in personal injury or death.

VI. CONNECT CONDENSATE DRAIN

NOTE: When installing condensate drain connection be sure to

comply with local codes and restrictions.

Unit disposes of condensate through a 3/4-in. NPT fitting which

exits through the compressor access panel. See Fig. 2–5 (Front

View) for location of condensate connection.

Condensate water can be drained directly onto the roof in rooftop

installations (where permitted) or onto a gravel apron in groundlevel installations. Install a field-supplied condensate trap at end of

condensate connection to ensure proper drainage. Make sure that

the outlet of the trap is at least 1-in. lower than the drain-pan

condensate connection to prevent the pan from overflowing. Prime

the trap with water. When using a gravel apron, make sure it slopes

C95014

away from the unit.

If the installation requires draining the condensate water away

from the unit, install a 2-in. trap using a 3/4-in. NPT connection

(See Fig. 18). Make sure that the outlet of the trap is at least 1-in.

lower than the unit drain-pan condensate connection to prevent the

pan from overflowing. Prime the trap with water. Connect a drain

tube using a minimum of 3/4-in. PVC, 3/4-in. CPVC, or 3/4-in.

copper pipe (all field supplied). Do not undersize the tube. Pitch

the drain tube downward at a slope of at least 1 in. for every 10 ft

of horizontal run. Be sure to check the drain tube for leaks. Prime

trap at the beginning of the cooling season start-up.

VII. INSTALL DUCT CONNECTIONS

The unit has duct flanges on the supply- and return-air openings on

the side and bottom of the unit. For downshot applications the

ductwork can be connected to the roof curb. See Fig. 2-5 for

connection sizes and locations.

IMPORTANT: Use flexible connectors between ductwork and

unit to prevent transmission of vibration. Use suitable gaskets to

ensure weathertight and airtight seal. When electric heat is

—9—

Page 10

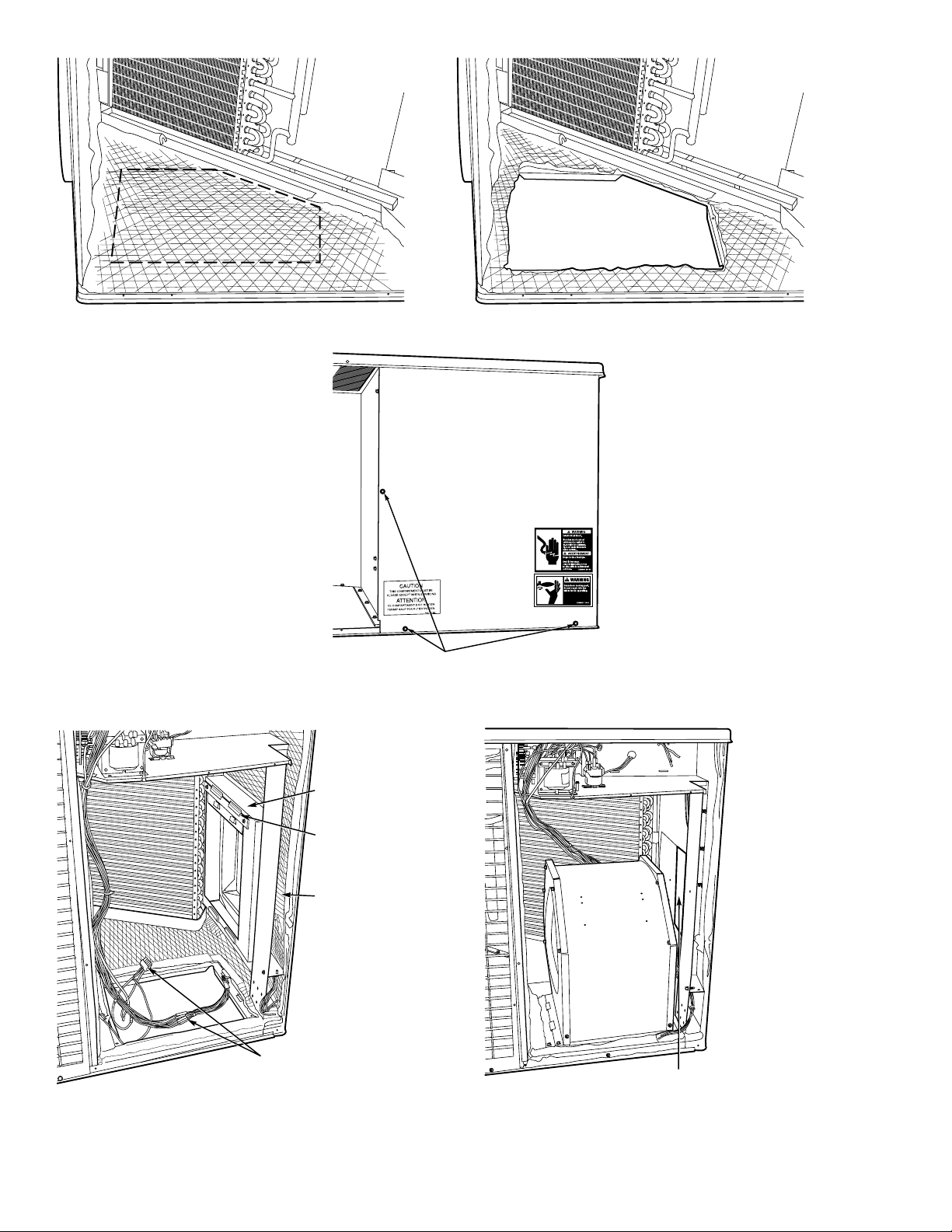

Fig. 13—Removing Insulation and Vertical Duct Cover

INDOOR BLOWER ACCESS PANEL

(REMOVE SCREWS)

Fig. 14—Indoor Blower Access Panel

C95015

C950016

BLOWER

SHELF

FILLER

BRACKET

RACEWA Y

PLUG ASSEMBLIES

HORIZONTAL DUCT OPENING

Fig. 15—Converting Blower Assembly to Vertical Airflow

—10—

C950010

Page 11

FILLER

BRACKET

REMOVE

Fig. 16—Blower Shelf and Housing

DEFROST

BOARD CONTACTOR RELAY

C95017

Fig. 17—Control Box Detail View

1” (25mm) MIN.

Fig. 18–Condensate Trap

installed, use fire proof canvas (or similar heat resistant material)

connector between ductwork and unit discharge connection. If

flexible duct is used, insert a sheet metal sleeve inside duct. Heat

resistant duct connector (or sheet metal sleeve) must extend 24-in.

from the unit discharge connection flange into the ductwork.

ACCESSORY DUCT FLANGE KIT INSTALLATION-

1. Mark hole locations (See instructions included in Flange

Kit).

CAUTION: Do not drill deeper than 1/2–in. into area

between round duct openings. Damage to refrigerant coil

could result.

2. At marked locations, drill holes using a no. 26 (.147-in.)

twist drill (See Fig. 19).

C95017

TRAP

OUTLET

2” (50mm) MIN.

C99013

3. Partially secure duct flanges using two of the no. 10, 1/2-in.

screws provided.

4. See the following caution. Using remaining holes in duct

flanges as templates, drill the remaining holes with the no.

26 (.147-in.) drill.

5. Fully secure the duct flanges using the remaining screws

provided.

NOTE: The finished kit installation accommodates a 14 3/4-in. x

14 3/4-in. duct.

A. CONFIGURING UNITS FOR DOWNFLOW (VERTICAL) DISCHARGE-STANDARD UNITS (024–042)

Units 024–042 (Units with PSC Indoor Blower Motors) are

shipped in a horizontal configuration. To convert a horizontal unit

for downflow (vertical) discharge, perform the following steps:

—11—

Page 12

TABLE 1—PHYSICAL DATA—UNIT 657A

UNIT SIZE 024 030 036 042 048 060

NOMINAL CAPACITY (ton) 2 2-1/2 3 3-1/2 4 5

OPERATING WEIGHT (lb.)

Without Base Rails

WIth Optional Rails

COMPRESSOR Scroll

REFRIGERANT (R-22)

Quantity (lb.)

REFRIGERANT METERING DEVICE Acutrol™ System

OUTDOOR COIL

Rows...Fins/in.

Face Area (sq. ft.)

OUTDOOR FAN

Nominal Cfm

Diameter (in.)

Motor Hp (Rpm)

INDOOR COIL

Rows...Fins/in.

Face Area (sq. ft.)

INDOOR BLOWER

Motor Type

Speeds

Nominal Airflow (Cfm)

Size (in.)

Motor Hp (RPM)

RETURN-AIR FILTERS (in.)

Throwaway

ECM-Electronic Computated Motor.

309

296

5.4 5.6 8.6 6.8 7.9 8.1

2...17

7.0

2200

20

1/4 (1100)

3...15

3.6

PSC

3

800

10x9

1/4 (1075)

24x24x1 24x24x1 24x30x1 24x30x1 24x30x1 24x30x1

340

327

2...17

7.0

2200

20

1/4 (1100)

3...15

3.6

PSC

3

1000

10x9

1/4 (1075)

368

355

2...17

8.7

2200

20

1/4 (1100)

4...15

4.5

PSC

3

1300

10x9

1/2 (1100)

368

355

2...17

8.7

2400

20

1/4 (1100)

4...15

4.5

PSC

3

1400

10x9

1/2 (1100)

411

398

2...17

8.7

2400

20

1/3 (1100)

4...15

4.5

ECM

Variable

1550

10x10

1.0 (Variable)

425

412

2...17

8.7

2400

20

1/3 (1050)

4...15

4.5

ECM

Variable

1800

10x10

1.0 (Variable)

19-1/2"

[495]

NOTES:

Do not drill more than 1/2-in into shaded area.

1.

Dimensions in [ ] are in mm.

2.

Fig. 19—Area Not To Be Drilled

WARNING: Before performing service or maintenance

operations on the system, turn off main power to unit and

install lockout tag or electrical shock could result.

1. Open all electrical disconnects and install lockout tag before

starting any service work.

2. Remove indoor coil access panel (See Fig. 12).

3. Locate lances in unit base insulation that are placed over the

perimeter of the vertical duct opening cover (See Fig. 13).

4. Using a straight edge and sharp knife, cut and remove the

insulation around the perimeter of the cover. Remove the

screws securing the cover to the unit base and slide out the

cover. Discard the cover.

5"

[127]

C95012

5. Remove indoor blower access panel (See Fig. 14).

6. Disconnect indoor-fan motor leads from indoor fan relay

and unit contactor (See Fig. 15). Carefully disengage wire

tie containing indoor-fan motor leads from the unit control

box (See Fig. 15 & 17).

7. Remove screws securing indoor blower housing to blower

shelf and carefully slide out blower housing. There is a filler

bracket attached to the blower shelf; remove this filler

bracket and retain for later use (See Fig. 16).

8. Locate lances in unit base insulation that are placed over the

perimeter of the vertical discharge opening cover (See Fig.

13).

9. Using a straight edge and sharp knife, cut the insulation

around the perimeter of the cover. Remove the screws

—12—

Page 13

14 11/16” (372)

13 3/4” (348)

3 3/4” (94)

9 11/16” (245)

0

21 9/16” (547)

11/32” DIA (8 Places/Holes)

11/16” (17) TYP

0 10 5/8” (270)

22-GAGE SHEET

METAL COVER (SEE ABOVE)

SEAL ALL FOUR CORNERS

WITH SILICONE SEALER

Fig. 20—Field-Fabricated Duct Cover

9/32” (7) TYP

19” (482)

4 ADHESIVE-BACKED SPONGE RUBBER

SEAL STRIPS-1/8” (3.2) THICK

1//2-IN. THICK, 1-lb. DENSITY FIBERGLASS INSULATION

WITH ALUMINUM FOIL BACKING; SECURE WITH ADHESIVE

31 3/16” (792)

1 3/4” (43) 0

C95019

TABLE 2—MINIMUM AIRFLOW FOR SAFE ELECTRIC HEATER

OPERATION (CFM)

SIZE

024 030 036 042 048 060

700 875 1225 1225 1400 1750

securing the cover to the unit base and slide out the cover.

Discard the cover. Install filler bracket removed in Step 7.

10. If unit ductwork is to be attached to vertical opening flanges

on the unit base (jackstand applications only), do so at this

time.

11. It is recommended that the unit base insulation around the

perimeter of the vertical opening be secured to the unit base

with aluminum tape to prevent the insulation from tearing

or bunching up when the blower housing is installed in the

vertical discharge position.

12. Orient blower housing for vertical airflow (blower motor

adjacent to horizontal duct opening) and slide into vertical

opening making sure the flanges on the blower side plates

engage the tabs in the unit base (See Fig. 15). Resistance

will be felt as the blower housing contacts the unit base

insulation; this can be overcome by applying a slight force

to the base of the blower. Continue sliding blower in until

hole in side plate flange aligns with the hole in the unit base.

Secure using screw removed in Step 7. Reconnect indoorfan motor leads and insert wire tie back into unit control

box.

13. Cover the horizontal duct openings. Duct covers can be

ordered as an accessory or field fabricated (See Fig. 20).

14. Reinstall the indoor coil and indoor blower access panels.

15. After completing unit installation, perform all safety checks

and power up unit.

B. CONFIGURING UNITS FOR DOWNFLOW (VERTICAL) DISCHARGE-ECM UNITS (048–060)

Units 048–060 (Units with ECM Indoor Blower Motors) are

shipped in a horizontal configuration. To convert a horizontal unit

for downflow (vertical) discharge, perform the following steps:

—13—

Page 14

WARNING: Before performing service or maintenance

operations on the system, turn off main power to unit and

install lockout tag or electrical shock could result.

1. Open all electrical disconnects and install lockout tag before

starting any service work.

2. Remove indoor coil access panel (See Fig. 12).

3. Locate lances in unit base insulation that are placed over the

perimeter of the vertical duct opening cover (See Fig. 13).

4. Using a straight edge and sharp knife, cut and remove the

insulation around the perimeter of the cover. Remove the

screws securing the cover to the unit base and slide out the

cover. Discard the cover.

5. Remove indoor blower access panel (See Fig. 14).

6. Disconnect the plug assemblies from the indoor-fan motor

(See Fig. 15 & 17).

7. Remove screws securing indoor blower housing to blower

shelf and carefully slide out blower housing. There is a filler

bracket attached to the blower shelf; remove this filler

bracket and retain for later use (See Fig. 16).

8. Locate lances in unit base insulation that are placed over the

perimeter of the vertical discharge opening cover (See Fig.

13).

9. Using a straight edge and sharp knife, cut the insulation

around the perimeter of the cover. Remove the screws

securing the cover to the unit base and slide out the cover.

Discard the cover. Install filler bracket removed in Step 6.

10. If unit ductwork is to be attached to vertical opening flanges

on the unit base (jackstand applications only), do so at this

time.

11. It is recommended that the unit base insulation around the

perimeter of the vertical opening be secured to the unit base

with aluminum tape to prevent the insulation from tearing

or bunching up when the blower housing is installed in the

vertical discharge position.

12. Remove screws securing the high-voltage raceway to duct

panel. Temporarily place raceway on top of unit until

blower housing is installed.

13. Orient blower housing for vertical airflow (blower motor

adjacent to horizontal duct opening) and slide into vertical

opening making sure the flanges on the blower side plates

engage the tabs in the unit base (See Fig. 15). Resistance

will be felt as the blower housing contacts the unit base

insulation; this can be overcome by applying a slight force

to the base of the blower. Continue sliding blower in until

hole in side plate flange aligns with the hole in the unit base.

Secure using screw removed in Step 6.

14. Reinstall the high-voltage raceway removed in Step 12.

15. Cover the horizontal duct openings. Duct covers can be

ordered as an accessory or field fabricated (See Fig. 20).

16. Reinstall the indoor coil and indoor blower access panels.

17. After completing unit installation, perform all safety checks

and power up unit.

VIII. INSTALL ELECTRICAL CONNECTION

WARNING: The unit cabinet must have an uninter-

rupted, unbroken electrical ground to minimize the possibility of personal injury if an electrical fault should

occur. This ground may consist of an electrical wire

connected to the unit ground lug in the control compartment, or conduit approved for electrical ground when

installed in accordance with NEC (National Electrical

Code) ANSI/NFPA (latest edition) and local electrical

codes. In Canada, follow Canadian Electrical Code CSA

(Canadian Standards Association) C22.1 and local electrical codes. Failure to adhere to this warning could result

in personal injury or death.

CAUTION: Failure to follow these precautions could

result in damage to the unit being installed:

1. Make all electrical connections in accordance with

NEC ANSI/NFPA (latest edition) and local electrical

codes governing such wiring. In Canada, all electrical

connections must be in accordance with CSA standard

C22.1 Canadian Electrical Code Part 1 and applicable

local codes. Refer to unit wiring diagram.

2. Use only copper conductor for connections between

field-supplied electrical disconnect switch and unit.

DO NOT USE ALUMINUM WIRE.

3. Be sure that high-voltage power to unit is within

operating voltage range indicated on unit rating plate.

4. Do not damage internal components when drilling

through any panel to mount electrical hardware, conduit, etc. On 3-phase units, ensure phases are balanced

within 2 percent. Consult local power company for

correction of improper voltage and/or phase imbalance.

A. HIGH-VOLTAGE & CONTROL-VOLTAGE CONNECTIONS

The unit must have a separate electrical service with a fieldsupplied, waterproof, disconnect switch mounted at, or within

sight from, the unit. Refer to the unit rating plate for maximum

fuse/circuit breaker size and minimum circuit amps (ampacity) for

wire sizing. See Table 3 for electrical data.

The field-supplied disconnect switch box may be mounted on the

unit over the high-voltage inlet hole when the standard power and

low-voltage entry points are used. See Fig. 21 for acceptable

location.

See unit wiring label and Fig. 23, 24 & 26-27 for reference when

making high voltage connections. Proceed as follows to complete

the high-voltage connections to the unit.

If the unit has an electric heater, a second disconnect may be

required. Consult the Installation Instructions provided with

the accessory heater for electrical service connections.

1. ROUTING POWER LEADS INTO UNIT-Use only copper

wire between disconnect and unit. The high-voltage leads

should be in a conduit until they enter the duct panel;

conduit termination at the duct panel must be watertight.

Run the high-voltage leads through the knockout on the

duct panel (see Fig. 21 for location and size). When the

leads are inside the unit, run leads up the high-voltage

raceway to the line wiring splice box (Fig. 22). For

single-phase units, connect leads to the black and yellow

wires (see Fig. 24 & 26-27).

2. CONNECTING GROUND LEAD TO WIRE-BINDING

SCREW - Refer to Fig. 22. Connect the ground lead to the

chassis using the wire-binding screw in the wiring splice

box.

—14—

Page 15

HIGH

VOLTAGE

POWER

ENTRY

(KNOCKOUT)

2 DIA.

1 1/8 DIA.

1 3/8 DIA.

2 DIA.

7/8 DIA.

CONTROL

POWER

ENTRY*

*Knockout on rectangular-duct panel units; entry hole on round-duct

panel units.

NOTE: For rectangular duct knockout sizes, see Fig. 2-9.

Fig. 21–Typical Duct Panel Knockouts

3. ROUTING CONTROL POWER WIRES - STD NONECM UNITS (24 v) -Form a drip-loop with the thermostat

leads before routing them into the unit. Route the thermostat

leads through grommeted hole provided in unit (see Fig. 21)

into unit control power splice box. Connect thermostat leads

to unit control power leads as shown in Fig. 23.

4. ROUTING CONTROL POWER WIRES - ECM UNITS

(24 v) - Remove knockout in the duct panel (see Fig. 21).

Remove the rubber grommet from the installer’s packet

(included with unit) and install it in the knockout opening.

Route thermostat wires through grommet providing a drip

loop at the panel. Connect low-voltage leads to the thermostat as shown in Fig. 23.

The Easy Select interface board is located in the return-air

section and is attached to the duct panel. The Easy Select

interface board is factory wired to the motor and factory

default selections are preset.

5. The unit transformer supplies 24-v power for complete

system including accessory electrical heater. Transformer is

factory wired for 230-v operation. If supply voltage is 208

v, rewire transformer primary as described in the Special

Procedures for 208-v Operation section.

NOTE: Do not use any type of power-stealing thermostat. Unit

control problems may result.

Use no. 18 American Wire Gage (AWG) color-coded, insulated

(35 C minimum) wires to make the control voltage connections

between the thermostat and the unit. If the thermostat is located

more than 100 ft. from the unit (as measured along the control

voltage wires), use no. 16 AWG color-coded, insulated (35 C

minimum) wires.

B. SPECIAL PROCEDURES FOR 208-V OPERATION

WARNING: Make sure that the power supply to the unit

is switched OFF and lockout tag installed before making

any wiring changes. Electrical shock can cause serious

injury or death.

C95036

6. Wrap the wire nut with electrical tape so that the metal

terminal cannot be seen.

NOTE: Indoor blower motor speeds may need to be changed for

208-v operation. Refer to Indoor Airflow and Airflow Adjustment

Section.

PRE-START-UP

WARNING: Failure to observe the following warnings

could result in serious personal injury:

1. Follow recognized safety practices and wear protective

goggles when checking or servicing refrigerant system.

2. Do not operate compressor or provide any electric

power to unit unless compressor terminal cover is in

place and secured.

3. Do not remove compressor terminal cover until all

electrical sources are disconnected.

4. Relieve and recover all refrigerant from system before

touching or disturbing anything inside terminal box if

refrigerant leak is suspected around compressor terminals.

5. Never attempt to repair soldered connection while

refrigerant system is under pressure.

6. Do not use torch to remove any component. System

contains oil and refrigerant under pressure. To remove

a component, wear protective goggles and proceed as

follows:

a. Shut off electrical power to unit.

b. Relieve and reclaim all refrigerant from system using

both high- and low-pressure ports.

c. Cut component connecting tubing with tubing cutter

and remove component from unit.

d. Carefully unsweat remaining tubing stubs when

necessary. Oil can ignite when exposed to torch

flame.

1. Disconnect the orange transformer-primary lead from the

contactor. See unit wiring label

2. Remove the wire nut from the terminal on the end of the red

transformer-primary lead.

3. Save the wire nut.

4. Connect the red lead to the contactor terminal from which

the orange lead was disconnected.

5. Using the wire nut removed from the red lead, insulate the

loose terminal on the orange lead.

Proceed as follows to inspect and prepare the unit for initial

startup:

1. Remove access panel.

2. Read and follow instructions on all WARNING, CAUTION, and INFORMATION labels attached to, or shipped

with, unit.

3. Make the following inspections:

a. Inspect for shipping and handling damages such as

broken lines, loose parts, disconnected wires, etc.

—15—

Page 16

UNIT POWER

LEAD

UNIT LINE WIRE

SPLICE BOX

Fig. 22—Wiring Splice Boxes

WIRE-BINDING

SCREW

CONTROL POWER

SPLICE BOX

C95022

→

VOLTAGE

RANGE

UNIT

657A

SIZE

(–SERIES,

IF

USED)

024–311 208/230-1 187 253 11.2 56.0 1.4 2.0

024–321 208/230-1 187 253 12.1 54.0 1.4 2.0

030 208/230-1 187 253 15.0 73.0 1.4 2.6

036 208/230-1 187 253 16.0 88.0 1.2 2.6

042 208/230-1 187 253 20.0 104.0 1.4 3.1

048–301 208/230-1 187 253 26.4 129.0 2.1 7.2

048–311 208/230-1 187 253 20.8 109.0 2.1 7.2

060 208/230-1 187 253 32.1 169.0 2.1 7.2

(See legend following Electrical Data chart)

V-PH

(60 HZ)

Min Max RLA LRA FLA FLA kW FLA

COMPRESSOR OFM IFM

TABLE 3—ELECTRICAL DATA—657A

ELECTRIC

HEAT

3.75/5.00

5.60/7.50

7.50/10.0

3.75/5.00

5.60/7.50

7.50/10.0

3.75/5.00

5.60/7.50

7.50/10.0

11.30/15.0

3.75/5.00

5.60/7.50

7.50/10.0

11.30/15.0

3.75/5.00

5.60/7.50

7.50/10.0

11.30/15.0

15.0/20.0

3.75/5.00

5.60/7.50

7.50/10.0

11.30/15.0

15.0/20.0

3.75/5.00

5.60/7.50

7.50/10.0

11.30/15.0

15.0/20.0

3.75/5.00

5.60/7.50

7.50/10.0

11.30/15.0

15.0/20.0

18.1/20.8

27.1/31.3

36.1/41.7

18.1/20.8

27.1/31.3

36.1/41.7

18.1/20.8

27.1/31.3

36.1/41.7

54.1/62.0

18.1/20.8

27.1/31.3

36.1/41.7

54.1/62.0

18.1/20.8

27.1/31.3

36.1/41.7

54.1/62.0

72.2/83.3

18.1/20.8

27.1/31.3

36.1/41.7

54.1/62.0

72.2/83.3

18.1/20.8

27.1/31.3

36.1/41.7

54.1/62.0

72.2/83.3

18.1/20.8

27.1/31.3

36.1/41.7

54.1/62.0

72.2/83.3

SINGLE-POINT

POWER SUPPLY

Single-

Point

Wiring

MCA

40.3/43.4

51.0/56.5

62.5/69.5

41.4/44.5

52.2/57.7

63.7/70.7

45.3/48.8

56.6/61.8

67.9/74.8

90.4/100.3

48.3/51.7

56.6/61.8

67.9/74.8

90.4/100.3

52.1/55.5

63.3/68.6

74.6/81.6

97.1/107.0

119.8/133.7

65.2/68.3

75.9/81.4

87.4/94.4

110.2/120.4

131.8/145.9

58.2/61.3

68.9/74.4

80.4/87.4

103.2/113.4

124.8/138.9

72.0/75.5

83.3/88.5

94.6/101.5

117.1/126.9

139.6/153.5

Single-

Point

Max

Fuse

or

Ckt

Bkr

45/45

60/60

—

45/45

60/60

—

50/50

60/–

—

—

60/60

60/–

—

—

60/60

—

—

—

—

—

—

—

—

—

60/-

—

—

—

—

—

—

—

—

—

Single-

Point

MOCP

—

—

70/80

—

—

70/80

—

–/70

70/80

100/100

—

–/70

80/80

100/110

—

70/80

80/90

100/110

125/150

70/70

80/90

90/100

125/125

150/150

-/70

70/80

90/90

110/125

125/150

90/100

100/100

100/110

125/150

150/175

Heater

Only

DualPoint

Wiring

MCA

22.5/26.0

33.7/39.1

45.1/50.8

22.5/26.0

33.7/39.1

45.1/50.8

22.5/26.0

33.7/39.1

45.1/50.1

67.9/78.1

22.5/26.0

33.7/39.1

45.1/50.1

67.9/78.1

22.5/26.0

33.7/39.1

45.1/50.8

67.9/78.1

90.1/104.2

22.5/26.0

33.7/39.1

45.1/50.8

67.9/78.1

90.1/104.2

22.5/26.0

33.7/39.1

45.1/50.8

67.9/78.1

90.1/104.2

22.5/26.0

33.7/39.1

45.1/50.8

67.9/78.1

90.1/104.2

DUAL-POINT

POWER SUPPLY

(INCLUDING UNIT ONLY)

Heater

Only

Dual-

Heater

Point

Max

Fuse

or

Ckt

Bkr

25/30

35/40

50/60

25/30

35/40

50/60

25/30

35/40

50/60

—

25/30

35/40

50/60

—

25/30

35/40

50/60

—

—

25/30

35/40

50/60

—

—

25/30

35/40

50/60

—

—

25/30

35/40

50/60

—

—

100/110

100/110

100/110

100/110

Unit

Only

Only

Dual-

Dual-

Point

Point

MOCP

MCA

—

——17.4 25/25 —

—

——18.5 25/25 —

—

—

22.8 30/30 —

—

70/80

—

—

23.8 35/35 —

—

70/80

—

—

—

29.5 45/45 —

70/80

—

—

—

42.3 50/50 —

70/80

—

—

—

35.3 45/45 —

70/80

—

—

—

48.7 — 80/80

70/80

Unit

Only

Dual-

Point

Max

Fuse

or

Ckt

Bkr

Unit

Only

DualPoint

MOCP

b. Inspect for oil at all refrigerant tubing connections and

on unit base. Detecting oil generally indicates a refrigerant leak. Leak test all refrigerant tubing connections

using electronic leak detector, halide torch, or liquidsoap solution. If a refrigerant leak is detected, see Check

for Refrigerant Leaks section.

—16—

Page 17

LEGEND

FLA — Full Load Amps

LRA — Locked Rotor Amps

MCA — Minimum Circuit Amps

MOCP — Maximum Overcurrent Protection

RLA — Rated Load Amps

CKT BKR

NOTES:

1. In compliance with NEC (National Electrical Code) requirements

2. Minimum wire size is based on 60 C copper wire. If other than

3. Unbalanced 3-Phase Supply Voltage

—

Circuit Breaker

for multimotor and combination load equipment (refer to NEC

Articles 430 and 440), the overcurrent protective device for the

unit shall be Power Supply fuse. Canadian units may be

fuse or circuit breaker.

60 C wire is used, or if length exceeds wire length in table,

determine size from NEC.

Never operate a motor where a phase imbalance in supply voltage is greater than 2%.

the percentage of voltage imbalance.

% Voltage imbalance

= 100 x

max voltage deviation from average voltage

Use the following formula to determine

average voltage

®

EXAMPLE: Supply voltage is 460-3-60.

Determine maximum deviation from average voltage.

(AB) 457

(BC) 464

(AC) 457

Maximum deviation is 7 v.

Determine percent of voltage imbalance.

% Voltage Imbalance = 100 x

This amount of phase imbalance is satisfactory as it is below the

maximum allowable 2%.

IMPORTANT: If the supply voltage phase imbalance is

more than 2%, contact your local electric utility company

immediately.

AB = 452 v

BC = 464 v

AC = 455 v

Average Voltage =

452=5v

457=7v

455=2v

= 1.53%

457

=

= 457

7

452 + 464 + 455

3

1371

3

C99024

C

O

R

G

Y

E

W2

THERMOSTAT

AND SUBBASE

Fig. 23—Control-Voltage Connections

c. Inspect all field- and factory-wiring connections. Be sure

that connections are completed and tight.

d. Ensure electrical wiring does not contact refrigerant

tubes or sharp metal edges.

e. Inspect coil fins. If damaged during shipping and han-

dling, carefully straighten fins with a fin comb.

4. Verify the following conditions

a. Make sure that outdoor-fan blade is correctly positioned

in fan orifice. Leading edge of outdoor-fan blade should

be 2 in. back from inlet grille or 1/2–in. maximum from

the fan deck.

b. Make sure that air filter(s) is in place.

c. Make sure that condensate drain trap is filled with water

to ensure proper drainage.

d. Make sure that all tools and miscellaneous loose parts

have been removed.

5. Compressors are internally spring mounted. Do not loosen

or remove compressor hold-down bolts.

BRN

ORN

RED

GRN

YEL

WHT

UNIT CONTROL POWER

SPLICE BOX

C99056

6. Each unit (system) has 2 Schrader-type ports, one low-side

fitting located on the suction line, and one high-side fitting

located on the compressor discharge line. Be sure that caps

covering these Schrader fittings are tight.

START-UP

A. CHECK FOR REFRIGERANT LEAKS

Proceed as follows to locate and repair a refrigerant leak and to

charge the unit:

1. Locate leak and make sure that refrigerant system pressure

has been relieved and reclaimed from both high- and

low-pressure ports.

2. Repair leak following accepted practices. NOTE: Install a

filter drier whenever the system has been opened for repair.

3. Add a small charge of R-22 refrigerant vapor to system and

leak-test unit.

4. Recover refrigerant from refrigerant system and evacuate to

500 microns if no additional leaks are not found.

5. Charge unit with R-22 refrigerant, using a volumetriccharging cylinder or accurate scale. Refer to unit rating

plate for required charge. Be sure to add extra refrigerant to

compensate for internal volume of filter drier.

—17—

Page 18

GROUND

LEAD

GROUND LUG

(IN SLPICE BOX)

SINGLE-PHASE

CONNECTIONS

TO DISCONNECT

PER NEC

3-PHASE

CONNECTIONS

LEGEND

NEC – National Electrical Code

Field Wiring

Splice Connections

Fig. 24—High-Voltage Connections

1/2 IN. MAX

FR OM FAN DECK

MOTOR SHAFT

MOTOR

C95027

Fig. 25—Fan Blade Clearance

B. START UP AND MAKE ADJUSTMENTS

CAUTION: Complete the required procedures given in

the Pre-Start- Up section before starting the unit. Do not

jumper any safety devices when operating the unit. Do

not operate the compressor when the outdoor temperature

is below 40°F (unless accessory low-ambient kit is

installed). Do not rapid-cycle the compressor. Allow 5

minutes between “on” cycles to prevent compressor

damage.

C. CHECKING COOLING CONTROL OPERATION

Start and check the unit for proper cooling control operation as

follows:

1. Place room thermostat SYSTEM switch in OFF position.

Observe that blower motor starts when FAN switch is

placed in ON position and shuts down when FAN switch is

placed in AUTO position.

2. Place SYSTEM switch in COOL position and FAN switch

in AUTO position. Set cooling control below room temperature. Observe that compressor, outdoor fan, and indoor

blower motors start. Observe that compressor and outdoor

fan shut down when control setting is satisfied and that

indoor blower shuts down after fan time delay expires.

L1

L2

L3

BLK

YEL

BLU

NOTE: Use copper wire only.

3. When using an auto-changeover room thermostat, place

both SYSTEM and FAN switches in AUTO positions.

Observe that unit operates in heating mode when temperature control is set to “call for heating” (above room

temperature) and operates in cooling mode when temperature control is set to “call for cooling” (below room

temperature).

D. CHECKING HEATING CONTROL OPERATION

Start and check the unit for proper cooling control operation as

follows:

1. Place room thermostat SYSTEM switch in OFF position.

Observe that blower motor starts when FAN switch is

placed in ON position and shuts down when FAN switch is

placed in AUTO position.

2. Place SYSTEM switch in HEAT position and FAN switch

in AUTO position. Set cooling control above room temperature. Observe that compressor, outdoor fan, and indoor

blower motors start. Observe that compressor and outdoor

fan shut down when control setting is satisfied and that

indoor blower shuts down after fan time delay expires.

3. When using an auto-changeover room thermostat, place

both SYSTEM and FAN switches in AUTO positions.

Observe that unit operates in heating mode when temperature control is set to “call for heating” (above room

temperature).

4. If system is equipped with supplemental or emergency heat

(resistance heaters), observe that when thermostat is placed

in EMERGENCY HEAT mode and temperature control is

set above room temperature that heaters and indoor blower

come on. Observe that heaters shut off when control setting

is satisfied and that the indoor blower shuts off after fan

time delay expires.

E. CHECKING AND ADJUSTING REFRIGERANT

CHARGE

The refrigerant system is fully charged with R-22 refrigerant,

tested, and factory-sealed.

NOTE: Adjustment of the refrigerant charge is not required

unless the unit is suspected of not having the proper R-22 charge.

A superheat charging chart is attached to the outside of the

compressor access panel. The chart includes the required suction

line temperature at given suction line pressures and outdoor

ambient temperatures (See Table 13A-H and Fig. 30).

An accurate superheat, thermocouple- or thermistor-type thermometer, a sling psychrometer, and a gauge manifold are required

when using the superheat charging method for evaluating the unit

charge. Do not use mercury or small dial-type thermometers

because they are not adequate for this type of measurement.

C99057

—18—

Page 19

Fig. 26—Wiring Diagram–024 to 042 (208/230-60-1)

—19—

C95037

Page 20

Fig. 27—Wiring Diagram–048 to 060 (208/230-60-1 with ECM Indoor)

—20—

C95038

Page 21

TRANSFORMER CONTAINS A MANUAL

RESET OVERCURRENT PROTECTOR

IT WILL NOT AUTOMATICALLY RESET

DISCONNECT POWER AND INSTALL

LOCKOUT TAG PRIOR TO SERVICING

THIS COMPARTMENT MUST BE CLOSED

EXCEPT WHEN SERVICING

Fig. 28—Transformer Label

NOTE: Allow system to operate in the cooling mode for a

minimum of 10 minutes before checking or adjusting refrigerant

charge.

CAUTION: When evaluating the refrigerant charge, an

indicated adjustment to the specified factory charge must

always be very minimal. If a substantial adjustment is

indicated, an abnormal condition exists somewhere in the

cooling system, such as insufficient airflow across either

coil or both coils. Failure to adjust charge properly or

correct the abnormal conditions will cause damage to the

unit.

C95025

WARNING: Disconnect electrical power to the unit and

install lockout tag before changing blower speed. Electrical shock can cause serious injury or death.

Airflow can be changed by changing the lead connections of the

blower motor.

Unit 657A three-speed motors (024–042) are factory wired for low

speed operation.

G. For 208/230v-PSC Blower Motor

For color coding on the 208/230V motor leads, see Table 4.

Proceed as follows:

1. Remove caps from low- and high-pressure service fittings.

2. Using hoses with valve core depressors, attach low- and

high-pressure gauge hoses to low- and high-pressure service

fittings, respectively.

3. Start unit in Cooling mode and let unit run until system

pressures stabilize.

4. Measure and record the following:

a. Outdoor ambient-air temperature (°F db).

b. Indoor coil inlet-air temperature (°F wb).

c. Suction-tube temperature (°F) at low-side service fitting.

d. Suction (low-side) pressure (psig).

5. Using “Superheat Charging Charts” compare outdoor-air

temperature (°F db) with the Indoor coil air inlet temperature (°F wb) to determine desired system operating superheat temperature. See Table 13A–H and Fig. 30.

6. Using ’’Required Suction-Tube Temperature (F)’’ table,

compare desired superheat temperature with suction (lowside) operating pressure (psig) to determine proper suctiontube temperature. See Fig. 30.

7. Compare actual suction-tube temperature with proper

suction-tube temperature. Using a tolerance of ±3° F, add

refrigerant if actual temperature is more than 3° F higher

than proper suction-tube temperature, or remove refrigerant

if actual temperature is more than 3° F lower than required

suction-tube temperature.

NOTE: If the problem causing the inaccurate readings is a

refrigerant leak, refer to Check for Refrigerant Leaks section.

F. INDOOR AIRFLOW AND AIRFLOW ADJUSTMENTS

NOTE: For cooling operation, the recommended airflow is 350 to

450 cfm for each 12,000 Btuh of rated cooling capacity.

Table 8 shows cooling airflows at various external static pressures.

Table 9 shows Fan Only and Cooling modes for ECM units

(048-060). Refer to these tables to determine the airflow for the

system being installed.

NOTE: Be sure that all supply- and return-air grilles are open,

free from obstructions, and adjusted properly.

TABLE 4—COLOR CODING FOR 208/230–V MOTOR

LEADS

3-SPEED

black = high speed

blue = medium speed

red = low speed

To change the speed of the indoor fan motor (IFM), remove the fan

motor speed leg lead from the indoor fan relay (IFR) and replace

with lead for desired blower motor speed. Insulate the removed

lead to avoid contact with chassis parts.

H. For 208/230v-ECM Blower Motor

To configure the 657A 048-60 unit, move the 5 Easy Select board

wires to the terminals which control the airflow. Refer to the Easy

Select interface board (Fig. 29) located next to the terminal.

Perform the following steps for basic system configuration.

1. AUX HEAT RANGE (VIO) NOTE: If no heater is installed, this step can be omitted. The airflow for electric

heat is selected with the AUX HEAT RANGE terminals.

Refer to Table 2 and the installation instructions for electric

heaters for minimum airflow required for safe heater

operation. Refer to table below for the available airflows.

Each select pin is configured for a certain airflow. The

airflow will be supplied in the Heating mode on air

conditioners when electric heat is the primary heating

source. The preset factory default selection is the highest

airflow.

2. AC/HP SIZE (BLU) - The preset factory default selection

for AC/HP SIZE (air conditioner/heat pump) is set to 400

cfm/ton. The selection pins are configured for 350 cfm/ton

and 400 cfm/ton.

3. TYPE (ORN) - The TYPE is a preset factory default

selection. The preset factory default setting is AC for the

657A units. Default setting should not be altered.

4. AC/HP CFM ADJUST (BLK) - The preset factory default

selection is MED. Selections HI and LO will adjust the

airflow supplied for all operational modes (see table below).

The selection options allow installer to adjust airflow to

meet such individual needs as noise and static compensation, etc.

—21—

Page 22

TABLE 5—TERMINAL CONFIGURATION

TERMINAL 1234

Available

Airflow (CFM)

1365 1470 1680 1840

Y1

AUX HEAT

RANGE

VIO

1

BLU

BRN

BLK

GR Y

AC/HP SIZE

1

AC HPC HP

AC/HP CFM ADJUST

LO MED HI

AC/HP TIME DELAY

1 2 3 4

RED

2 3 4

2 3 4

TYPE

JW1 JW2

D4

D5

W3

W2

1

P2

JW3

JW 4

E

G

/W1

G

W2

Y/Y2

JW 5

D3

D1

D2

Y

C

R

O

Y1

/Y2

IFO

O

SEC-1

SEC-2

R1

L

R2

R3

F1

5

P1

1

L

5 AMP FUSE

Fig. 29—Easy Select Interface Board for Units 048-060 with ECM Blower Motor

TABLE 6—CFM ADJUST (PERCENT OF CFM)

MODE FAN ONLY COOLING HEATING

LO-Adjust

–15 –10 –10

C95024

HI-Adjust

15 10 10

5. AC/HP TIME DELAY (GRY) - Four motor operation delay

options are provided to customize system operation. See

listing below:

Unit Controls— All compressors have the following internalprotection controls.

1. High-Pressure Relief Valve - This valve opens when the

pressure differential between the low and high side becomes

excessive.

2. Compressor Overload - This overload interrupts power to

the compressor when either the current or internal temperature become excessive, and automatically resets when the

internal temperature drops to a safe level.

This overload may require up to 60 minutes (or longer) to

reset; therefore, if the internal overload is suspected of

being open, disconnect the electrical power to the unit and

check the circuit through the overload with an ohmmeter or

continuity tester.

I. COOLING SEQUENCE OF OPERATION

PSC BLOWER MOTOR UNITS (024–042)

NOTE: With the FAN switch in the ON position, 24-v is supplied

to the IFR through the G terminal on the thermostat. This voltage

energizes the coil of the contactor, closing the normally-open set of

contacts which provide continuous power to the indoor (evapora-

tor) fan motor (IFM). Moving the FAN switch back to the AUTO.

position, providing there is not a call for cooling, deenergizes the

IFR, opens the IFR contacts, and deenergizes the IFM. The FAN

switch in AUTO. position cycles upon a call for cooling.

On a call for cooling, 24 v is supplied to the compressor contactor

(C) and IFR simultaneously through the Y and G terminals of the

thermostat, respectively. On units with a compressor time delay

relay, there is a built-in, 5-minute (± 45 seconds) delay between

compressor starts. Energizing the contactor closes the normallyopen set of contacts supplying power to both the compressor and

outdoor (condenser) fan motor (OFM). Energizing the IFR closes

the normally-open set of contacts providing power to the IFM. On

the loss of the call for cooling, 24 v is removed from both the Y

and G terminals of the thermostat (providing the FAN switch is in

the AUTO. position), deenergizing both the contactor and IFR and

opening both the contacts supplying power to compressor/OFM

and IFM.

ECM BLOWER MOTOR UNITS (048–060)

Indoor Fan - With the fan switch in the ON position, 24-v is

supplied to the ECM motor through the ’’G’’ terminal on the

thermostat. This voltage provides continuous power to the indoor

(evaporator) fan motor (IFM). If the fan switch is moved back to

the AUTO position and there is not a call for heating or cooling,

24-v is removed from the ’’G’’ terminal and the indoor fan

—22—

Page 23

OPTION DESCRIPTION

30-Sec On/60-Sec Off Delay

Profile (Terminal 1)

No Delay Option

(Terminal 2)

30-Sec Off Delay

(Terminal 3)

45-Sec Off Delay

(Terminal 4)

TABLE 7—ECM BOARD PIN SELECTION

Used when it is desirable to allow system coils time to heat

up or cool down prior to airflow

Used for servicing or when other components are used to

perform the delay function

Preset factory setting for 657A units

Enhances system efficiency

remains energized for the delay timing. When the fan switch is in

AUTO, the fan cycles with either the call for heating or cooling.

Cooling- On a call for cooling, 24 v is supplied to the compressor

contactor (C) and IFM simultaneously through the ’’Y’’ and ’’G’’

terminals of the thermostat. Energizing the contactor closes the

normally open set of contacts supplying power to both the

compressor and outdoor (condenser) fan motor (OFM). On the loss

of the call for cooling, 24 v is removed from the ’’Y’’ and ’’G’’

terminals of the thermostat, deenergizing the compressor and

OFM. The indoor fan remains energized for the delay timing.

NOTE: Once the compressor has started and then stopped, it

cannot be restarted again until 5 minutes have elapsed.

J. HEATING SEQUENCE OF OPERATION

PSC BLOWER MOTOR UNITS (024–042)

Heat Pump Heating - On a call for heat, thermostat makes circuits

R-Y and R-G. When compressor time delay (5 +/- 2 minutes) is

completed, a circuit is made to C, starting COMP and OFM.

Circuit R-G also energizes IFR and starts IFM after 1-sec. delay.

Should room temperature continue to fall, circuit R-W is made

through second-stage thermostat bulb. If optional electric heat

package is used, a relay is energized, bringing on first bank of

supplemental electric heat. When thermostat is satisfied, contacts

open, deenergizing contactor and relay; motors and heaters deenergize. The IFM may be controlled by a time-delay relay that will

extend IFM operation for a matter of sec.

Defrost Mode - Defrost board (DB) is a time and temperature

control, which includes a field-selectable time period between

checks for defrost (30, 50 or 90 minutes). Electronic timer and

defrost cycle start only when contactor is energized and defrost

thermostat (DFT) is closed.

Defrost mode is identical to Cooling mode, except outdoor-fan

motor stops and a bank of optional electric heat turns on to warm

air supplying the conditioned space.

Auxiliary Heating - If accessory electric heaters are installed, on

a call for heat, circuit R-W is made through the thermostat

contacts. Circuit R-G is made which energizes the IFR. If the

heaters are staged, then the thermostat closes a second set of

contacts W2 when second stage is required. When thermostat is

satisfied, contacts open, deenergizing the heater relay and the IFR.

ECM BLOWER MOTOR UNITS (048–060)

Heat Pump Heating - On a call for heat, thermostat makes circuits

R-Y and R-G. When compressor time delay (5 +/- 2 minutes) is

completed, a circuit is made to C, starting COMP and OFM.

Circuit R-G also energizes IFR and starts IFM after 1-sec. delay.

Should room temperature continue to fall, circuit R-W is made

through second-stage thermostat bulb. If optional electric heat

package is used, a relay is energized, bringing on first bank of

supplemental electric heat. At this time, the airflow (CFM) will be

either the AUX HEAT RANGE (VIO) setting or the AC/HP SIZE

(BLU) setting, whichever is greater. This may be a noticeable

change in airflow. When thermostat is satisfied, contacts open,

deenergizing contactor and relay; motors and heaters deenergize.

The IFM has a time delay relay that keeps the fan on for 30-sec.

Defrost Mode - Defrost board (DB) is a time and temperature

control, which includes a field-selectable time period between

checks for defrost (30, 50 or 90 minutes). Electronic timer and

defrost cycle start only when contactor is energized and defrost

thermostat (DFT) is closed.

Defrost mode is identical to Cooling mode, except outdoor-fan

motor stops and a bank of optional electric heat turns on to warm

air supplying the conditioned space.

Auxiliary Heating - If accessory electric heaters are installed, on

a call for heat, circuits R-W and R-G are made through the

thermostat contacts, energizing the heater relay and IFM. If the

heaters are staged, then the thermostat closes the second set of

contacts, W2, when the second stage is required. When the

thermostat is satisfied, contacts open, deenergizing the heater relay

and the IFM.

MAINTENANCE

To ensure continuing high performance, and to minimize the

possibility of premature equipment failure, periodic maintenance

must be performed on this equipment. This cooling unit should be

inspected at least once each year by a qualified service person. To

troubleshoot cooling of units, refer to tables at the back of the

book.

NOTE TO EQUIPMENT OWNER: Consult your local dealer

about the availability of a maintenance contract.

WARNING: The ability to properly perform maintenance on this equipment requires certain expertise, mechanical skills, tools, and equipment. If you do not

possess these, do not attempt to perform any maintenance

on this equipment other than those procedures recommended in the User’s Manual. FAILURE TO HEED

THIS WARNING COULD RESULT IN SERIOUS PERSONAL INJURY AND POSSIBLE DAMAGE TO THIS

EQUIPMENT.

WARNING: Failure to follow these warnings could

result in serious personal injury:

1. Turn off electrical power to the unit and install lockout

tag before performing any maintenance or service on

the unit.

2. Use extreme caution when removing panels and parts.

As with any mechanical equipment, personal injury

can result from sharp edges, etc.

3. Never place anything combustible either on, or in

contact with, the unit.

CAUTION: Errors made when reconnecting wires may

cause improper and dangerous operation. Label all wires

prior to disconnection when servicing.

The minimum maintenance requirements for this equipment are as

follows:

—23—

Page 24

TABLE 8—DRY COIL AIR DELIVERY (DEDUCT 10 PERCENT FOR 208V)*

HORIZONTAL AND DOWNFLOW DISCHARGE

UNIT 657A024-042

230 AND 460 VOLT

Unit

024 & 030

036

042

* Air delivery values are based on operating voltage of 230-v dry coil, without filter or electric heater. Deduct wet coil, filter and electric heater pressure drops to obtain static

pressure available for ducting.

NOTES:

1. Do not operate the unit at a cooling airflow that is less than 350 cfm for each 12,000 Btuh of rated cooling capacity. Indoor coil frosting may occur at airflows below this

point.

2. Dashes indicate portions of table that are beyond the blower motor capacity or are not recommended.

Motor

Speed

Low

Med

High

Low

Med

High

Low

Med

High

0.0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1.0

Watts 280 275 265 255 250 245 240 ————

Cfm820810755700660600560————

Watts 365 360 350 345 340 330 320 310 300 — —

Cfm 1025 1010 975 940 900 850 800 720 630 — —

Watts — — 490 480 470 460 445 430 410 390 380

Cfm — — 1300 1255 1200 1150 1080 1005 915 790 620

Watts 520 495 474 458 445 425 —————

Cfm 1375 1335 1290 1240 1200 1140 —————

Watts 575 560 535 510 480 460 440 425 — — —

Cfm 1520 1490 1450 1400 1380 1300 1200 1080 — — —

Watts ————650614575540510480—

Cfm————1560 1500 1380 1280 1170 1060 —

Watts 490 480 470 460 450 430 410 390 — — —

Cfm 1400 1380 1340 1300 1250 1200 1140 1070 — — —

Watts 590 580 560 545 525 505 480 450 420 — —

Cfm 1600 1560 1540 1470 1430 1360 1300 1220 1120 — —

Watts —————700670640600560500

Cfm—————1780 1670 1600 1480 1340 1100

External Static Pressure (in. wg)

TABLE 9—048 & 060 ECM AIRFLOW (CFM)

UNIT 657A

048 1400 1600

060 1750 2000

1. Inspect air filter(s) each month. Clean or replace when

necessary.

2. Inspect indoor coil, drain pan, and condensate drain at least

each cooling season for cleanliness. Clean when necessary.

3. Inspect blower motor and wheel for cleanliness and check

lubrication each heating and cooling season. Clean when

necessary.

4. Check electrical connections for tightness and controls for

proper operation each heating and cooling season. Service

when necessary.

5. Ensure electric wires are not in contact with refrigerant

tubing or sharp metal edges.

A. AIR FILTER

CAUTION: Never operate the unit without a suitable air

filter in the return-air duct system. Always replace the

filter with the same size as originally installed. See Table

1 for recommended filter sizes.

Inspect air filter(s) at least once each month and replace

(throwaway-type) or clean (cleanable-type) at least twice during

each heating and cooling season or whenever the filter(s) becomes

clogged with dust and lint.

B. UNIT TOP REMOVAL

NOTE: When performing maintenance or service procedures that

require removal of the unit top, be sure to perform all of the routine

maintenance procedures that require top removal, including coil

inspection and cleaning, and condensate drain pan inspection and

cleaning.

FAN ONLY

(CFM)

COOLING

(CFM)

Only qualified service personnel should perform maintenance and

service procedures that require unit top removal. Refer to the

following top removal procedures:

1. Remove 7 screws on unit top cover surface. (Save all

screws.)

2. Remove 4 screws on unit top cover flange. (Save all

screws.)

3. Lift top from unit carefully. Set top on edge and make sure

that top is supported by unit side that is opposite duct (or

plenum) side.

4. Carefully replace and secure unit top to unit, using screws

removed in Steps 1 and 2, when maintenance and/or service

procedures are completed.

C. INDOOR BLOWER AND MOTOR

NOTE: Motors without oilers are prelubricated. Do not attempt to

lubricate these motors.

For longer life, operating economy, and continuing efficiency,

clean accumulated dirt and grease from the blower wheel and

motor annually.

Lubricate the motor every 5 years if the motor is used intermittently (thermostat FAN switch in AUTO. position), or every 2

years if the motor is used continuously (thermostat FAN switch in

ON position).

—24—

Page 25

UNIT SIZE

024

030

036

042

048

060

TABLE 10—WET COIL PRESSURE DROP

AIRFLOW

(CFM)

600 0.039

700 0.058

800 0.075

900 0.088

900 0.088

1000 0.095

1200 0.123

1000 0.068

1200 0.088

1400 0.108

1600 0.123

1000 0.048

1200 0.069

1400 0.088

1600 0.102

1400 0.068

1550 0.073

1600 0.075

1800 0.088

1700 0.082

1900 0.095

2100 0.108

2300 0.123

PRESSURE DROP

(IN. WG)

TABLE 11—ACCESSORY ELECTRIC HEATER PRESSURE DROP (IN. WG)

HEATER

KW

600 800 1000 1200 1400 1600 1800 2000 2200

5–20 0.030 0.033 0.037 0.042 0.047 0.052 0.060 0.067 0.075

CFM

TABLE 12—FILTER PRESSURE DROP (IN. WG)

UNIT SIZE

024–036 24 x 24 x 1 — — 0.06 0.06 0.07 0.07 0.08 0.09 0.10 ——————————

042–060 24 x 30 x 1 — — — — — — — — 0.08 0.09 0.09 0.10 0.11 0.12 0.13 0.14 0.15 0.17 0.18

FILTER

SIZE

(IN.)

500 600 700 800 900 1000 1100 1200 1300 1400 1500 1600 1700 1800 1900 2000 2100 2200 2300

TABLE 13A—SUPERHEAT CHARGING TABLE, UNIT 024–311

TEMP (F)

AIR ENT

COND

65