Bryant 619PHA Series, 619PHAQ18XA3, 619PHAQ24XA3, 619PHAQ09XA3, 619PHAQ12XA3 Service Manual

!

619PHA

High Wall Ductless System

Sizes 09 to 24

Service Manual

TABLE OF CONTENTS

PAGE

SAFETY CONSIDERATIONS.......................................................1

INTRODUCTION............................................................................1

MODEL NUMBER NOMENCLATURE .......................................2

SPECIFICATIONS..........................................................................3

DIMENSIONS ................................................................................. 4

CLEARANCES................................................................................6

ELECTRICAL DATA ..................................................................... 7

WIRING...........................................................................................7

CONNECTION DIAGRAM............................................................ 8

WIRING DIAGRAM.......................................................................9

FAN AND MOTOR SPECIFICATIONS........................................11

REFRIGERATION CYCLE DIAGRAM........................................11

REFRIGERANT LINES..................................................................12

SYSTEM EVACUATION AND CHARGING...............................12

OPERATION MODES AND FUNCTIONS...................................13

ERROR DIAGNOSIS AND TROUBLESHOOTING WITHOUT ER-

ROR CODE...................................................................................... 20

QUICK MAINTENANCE BY ERROR CODE..............................24

TROUBLESHOOTING BY ERROR CODE.................................. 25

DIAGNOSIS AND SOLUTION......................................................27

DISASSEMBLY INSTRUCTIONS ................................................ 40

APPENDICES..................................................................................64

SAFETY CONSIDERATIONS

Installing, starting up, and servicing air-conditioning equipment can

be hazardous due to system pressures, electrical components, and

equipment location (roofs, elevated structures, etc.).

Only trained, qualified installers and service mechanics should install,

start-up, and service this equipment.

Untrained personnel can perform basic maintenance functions such as

cleaning coils. All other operations should be performed by trained

service personnel.

When working on the equipment, observe the precautions in the

literature and on tags, stickers, and labels attached to the equipment.

Follow all safety codes. Wear safety glasses and work gloves. Keep a

quenching cloth and fire extinguisher nearby when brazing. Use care

in handling, rigging, and setting bulky equipment.

Read this manual thoroughly and follow all the warnings or cautions

included in literature and attached to the unit. Consult local building

codes and National Electrical Code (NEC) for special requirements.

Recognize safety information. This is the safety-alert symbol .

When you see this symbol on the unit and in instructions or manuals,

be alert to the potential for personal injury. Understand these signal

words: DANGER, WARNING, and CAUTION.

These words are used with the safety-alert symbol. DANGER

identifies the most serious hazards which will result in severe personal

injury or death. WARNING signifies hazards which could result in

personal injury or death. CAUTION is used to identify unsafe

practices which may result in minor personal injury or product and

property damage. NOTE is used to highlight suggestions which will

result in enhanced installation, reliability, or operation.

WARNING

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in personal injury or death.

Before installing, modifying, or servicing the system, the main

electrical disconnect switch must be in the OFF position. There may

be more than 1 disconnect switch. Lock out and tag switch with a

suitable warning label.

WARNING

EXPLOSION HAZARD

Failure to follow this warning could

result in death, serious personal injury,

and/or property damage.

Never use air or gases containing oxygen

for leak testing or operating refrigerant

compressors. Pressurized mixtures of air

or gases containing oxygen can lead to

an explosion.

CAUTION

EQUIPMENT DAMAGE HAZARD

Failure to follow this caution may result in equipment damage or

improper operation.

Do not bury more than 36 in. (914 mm) of refrigerant pipe in the

ground. If any section of pipe is buried, there must be a 6 in. (152 mm)

vertical rise to the valve connections on the outdoor units. If more

than the recommended length is buried, refrigerant may migrate to the

cooler buried section during extended periods of system shutdown.

This causes refrigerant slugging and could possibly damage the

compressor at start-up.

INTRODUCTION

This service manual provides the necessary information to service,

repair, and maintain the indoor units. This manual has an appendix

with data required to perform troubleshooting. Use the Table of

Contents to locate a desired topic.

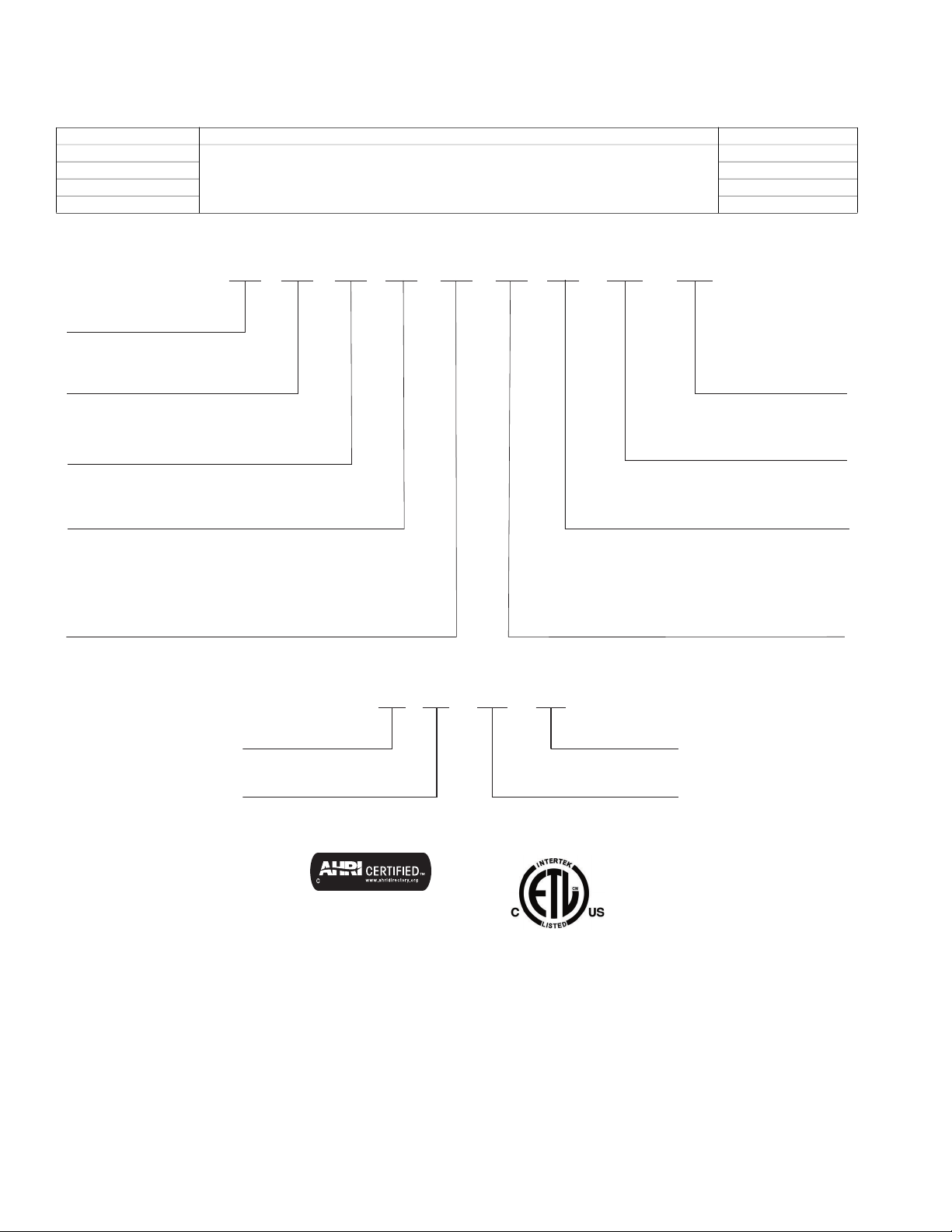

MODEL NUMBER NOMENCLATURE

619

P H A Q

09 X 3

619 = FAN COIL UNIT

P = MODEL

VOLTAGE

3 = 208/230-1-60

SYSTEM TYPE

H = HIGH WALL

MAJOR SERIES

X = NOT USED

NOMINAL CAPACITY

09 - 3/4 TON

12 - 1 TON

18 - 1.5 TONS

24 - 2 TONS

A

A = VARIATION

INDOOR FAN COIL TYPE

Q = HEAT PUMP

Week of Manufacture

Sequential Serial Number

V = ALL MODELSYear of Manufacture

Use of the AHRI Certified

TM Mark indicates a

manufacturer’s

participation in the

program For verification

of certification for individual

products, go to

www.ahridirectory.org.

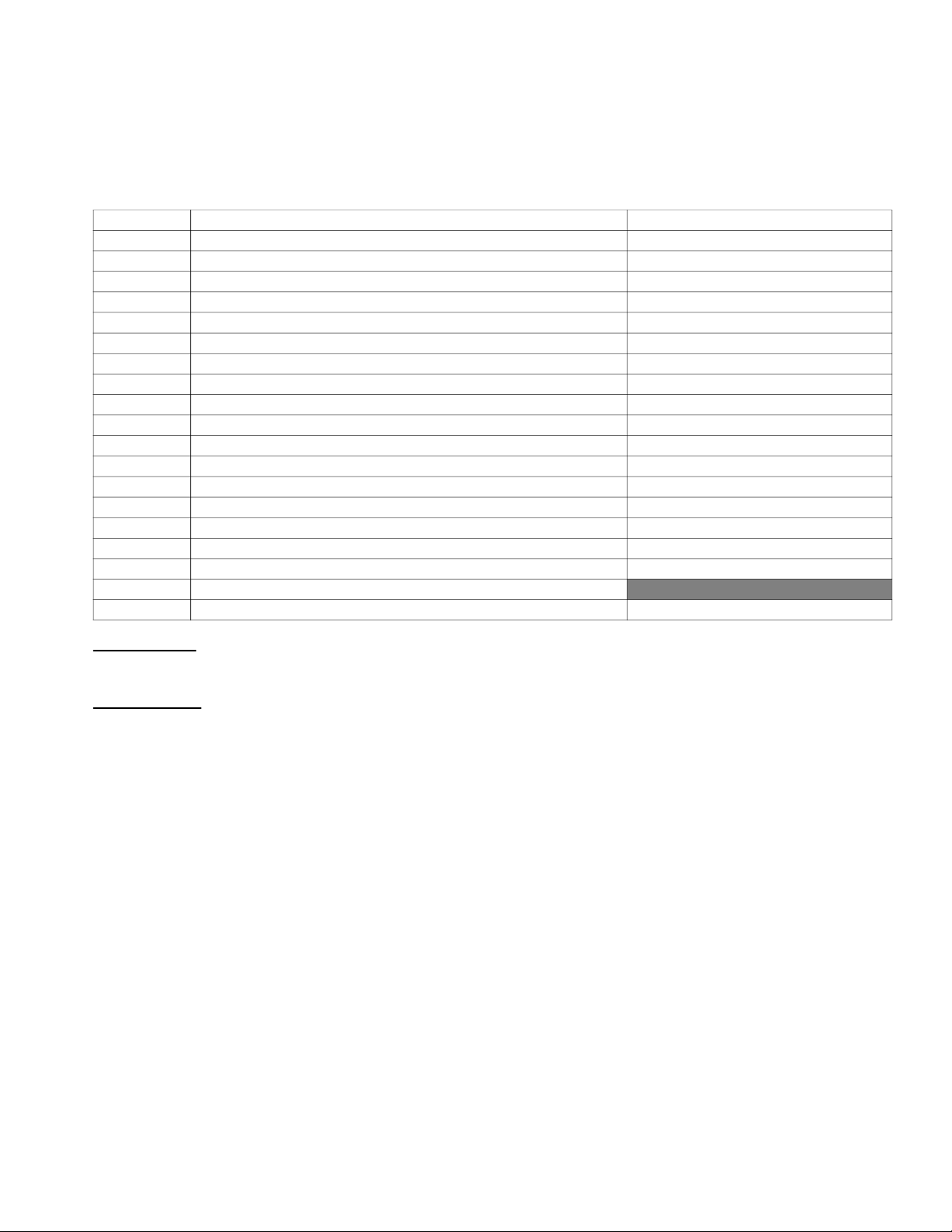

Table 1 —Unit Sizes

SYSTEMS TONS VOLTAGE/PH/HZ INDOOR MODEL

9

12 619PHAQ12XA3

18 619PHAQ18XA3

208-230/1/60

24 619PHAQ24XA3

INDOOR UNIT

619PHAQ09XA3

2 Specifications subject to change without notice. SM619PHA-03

12

19 10001

V

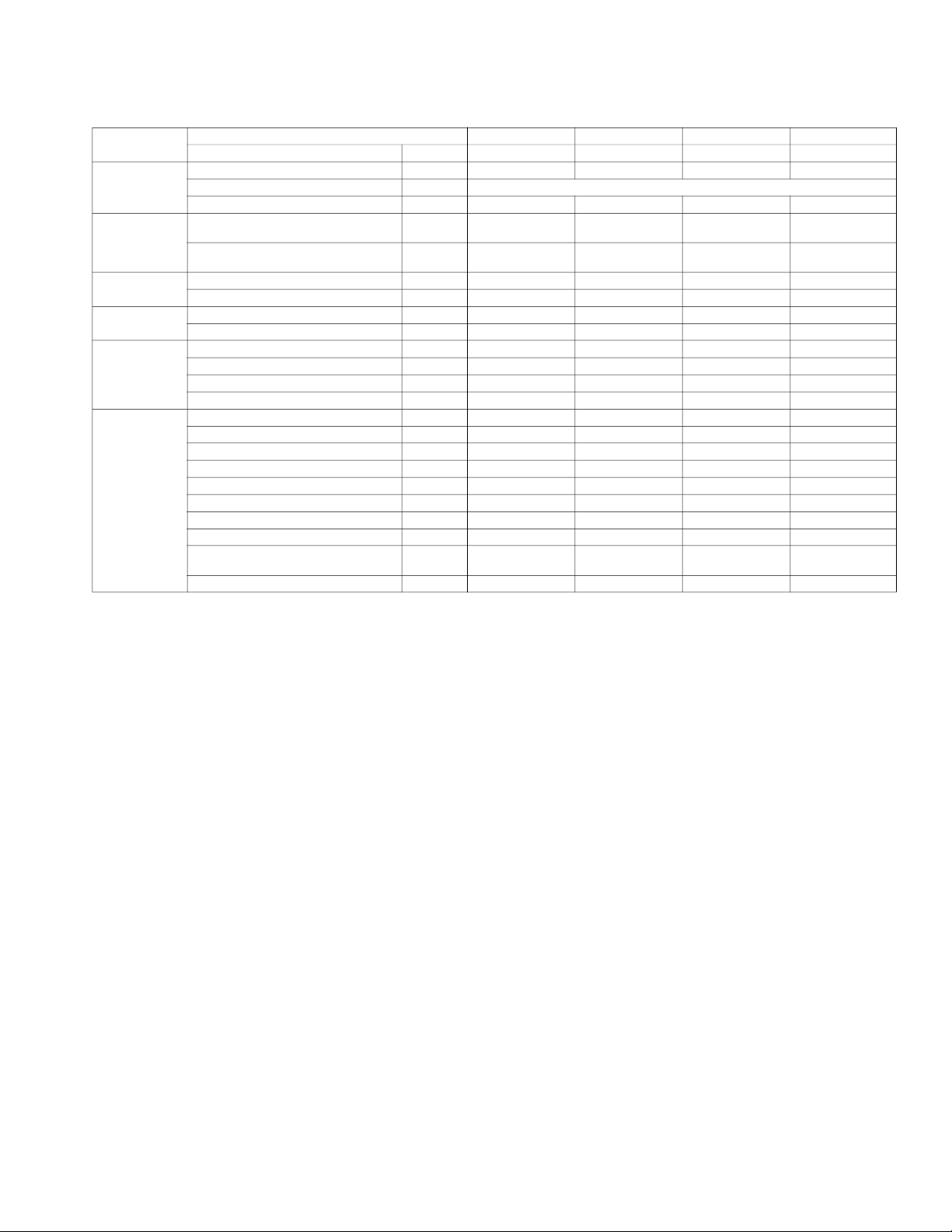

SPECIFICATIONS

SYSTEM

ELECTRICAL

CONTROLS

OPERATING

RANGE

PIPING

INDOOR COIL

INDOOR

Indoor Model

Voltage, Phase, Cycle V/Ph/Hz

Power Supply

MCA A.

Wireless Remote controller

(°F/°C Convertible)

Wired Remote controller

(°F/°C Convertible)

Cooling Indoor DB Min - Max °F (°C)

Heating Indoor DB Min - Max °F (°C)

Pipe Connection Size - Liquid in (mm)

Pipe Connection Size - Suction in (mm)

Face Area (sq. ft.) Sq. Ft.

No. Rows

Fins per inch

Circuits

Unit Width in (mm)

Unit Height in (mm)

Unit Depth in (mm)

Net Weight lbs (kg)

Number of Fan Speeds

Airflow (lowest to highest) CFM

Sound Pressure (lowest to highest) dB(A)

Air throw Data ft (m)

Moisture removal

Field Drain Pipe Size O.D. in (mm)

Table 2 — Specifications

SIZE 9 12 18 24

619PHAQ09XA3 619PHAQ12XA3 619PHAQ18XA3 619PHAQ24XA3

208/230-1-60 208/230-1-60 208/230-1-60 208/230-1-60

Indoor unit powered from outdoor unit

0.3 0.3 0.5 0.5

Standard Standard Standard Standard

Optional Optional Optional Optional

62~90 (17~32) 62~90 (17~32) 62~90 (17~32) 62~90 (17~32)

32~86 (0~30) 32~86 (0~30) 32~86 (0~30) 32~86 (0~30)

1/4 (6.35) 1/4 (6.35) 3/8” (9.52) 3/8” (9.52)

3/8 (9.52) 1/2 (12.7) 5/8” (15.9) 5/8” (15.9)

2.2 2.2 3.9 3.9

4 4 3 3

21 21 21 21

5 5 7 7

35.2 (895) 35.2 (895) 49.57 (1259) 49.57 (1259)

11.7 (298) 11.7 (298) 14.25 (362) 14.25 (362)

9.8 (248) 9.8 (248) 11.10 (282) 11.10 (282)

37.48 (17) 37.48 (17) 43.4 (19.7) 43.4 (19.7)

4 4 4 4

144/245/295/345 168/252/306/357 261/389/528/926 359/470/583/926

29/35.5/41.5/45.6 29/35.5/41.5/46.8 35.1/40.8/46.1/55.9 36.1/43.3/46.4/56.5

21.98 (6.7) 22.97 (7) 28.80 (8.7) 31.66 (9.65)

Pint/h

(L/h)

2.11 (1.0) 2.53 (1.2) 3.8 (1.8) 5.0 (2.39)

1 (25.4) 1 (25.4) 1 (25.4) 1 (25.4)

*Performance may vary based on the compatible outdoor units. See respective pages for performance data.

SM619PHA-03 Specifications subject to change without notice. 3

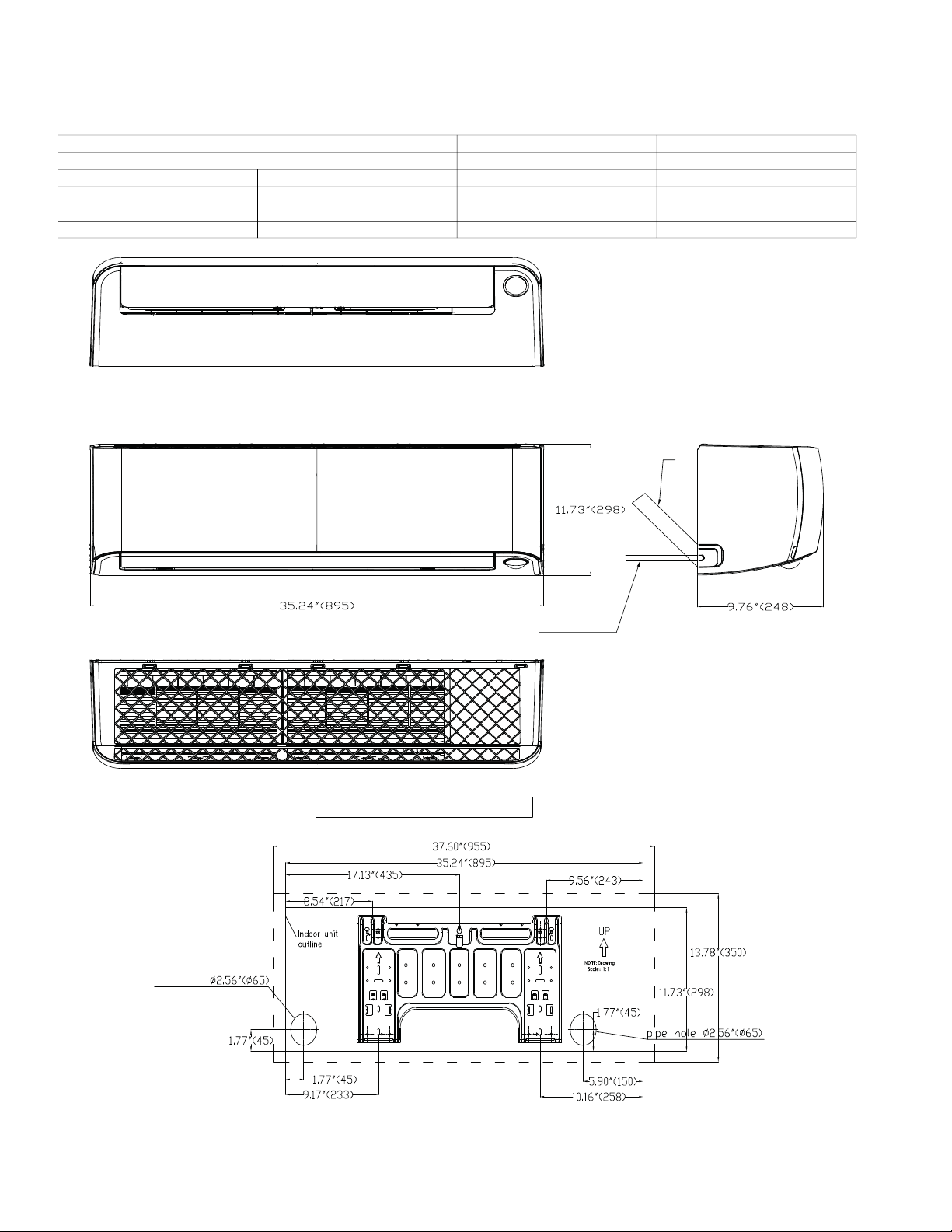

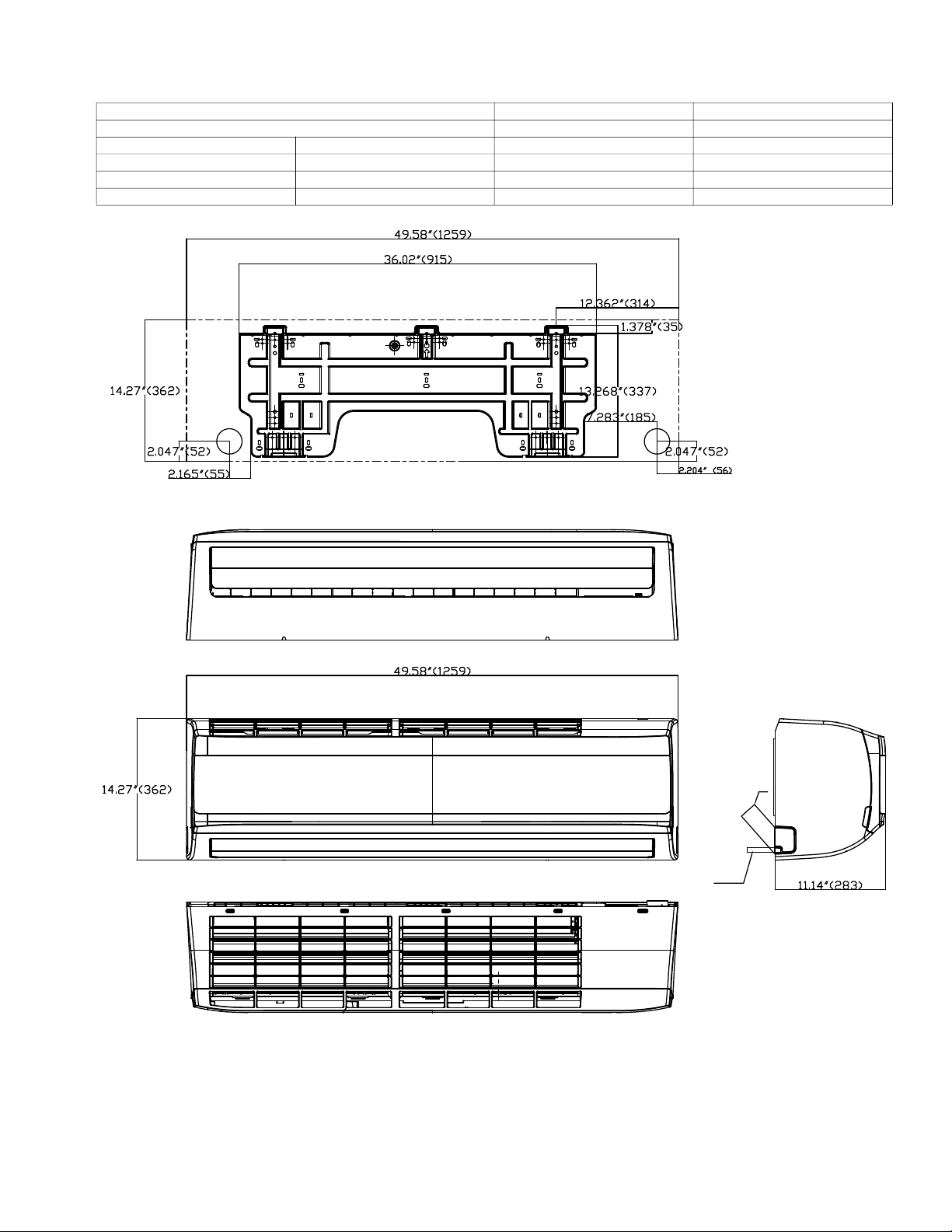

DIMENSIONS

Piping

Drain Hose

Drain Hose

Ø0.625"(16) L=25.20"(640)

Pipe hole

Units: Inch (mm)

Sizes 9K and 12K

Height In. (mm) 11.7 (298) 11.7 (298)

Width In. (mm) 35.2 (895) 35.2 (895)

Depth In. (mm) 9.8 (248) 9.8 (248)

Weight-Net Lbs (kg) 37.48 (17) 37.48 (17)

Table 3 — Dimension Sizes 09K and 12K

HIGH WALL UNIT SIZE 9K 12K

Voltage (208/230V) (208/230V)

Fig. 1 — Sizes 9K and 12K

NOTE: Drain adapter included with the indoor unit to allow the use of a 3/4 in. PVC Schedule 40 pipe where the actual

outside diameter is 1.05 in.

4 Specifications subject to change without notice. SM619PHA-03

Sizes 18K and 24K

Piping

Drain Hose

HIGH WALL UNIT SIZE 18K 24K

Height In. (mm) 14.25 (362) 14.25 (362)

Width In. (mm) 49.57 (1259) 49.57 (1259)

Depth In. (mm) 11.10 (282) 11.10 (282)

Weight-Net Lbs (kg) 43.4 (19.7) 43.4 (19.7)

Table 4 — Dimension Sizes 18K and 24K

Voltage (208/230V) (208/230V)

Fig. 2 — Sizes 18K and 24K

SM619PHA-03 Specifications subject to change without notice. 5

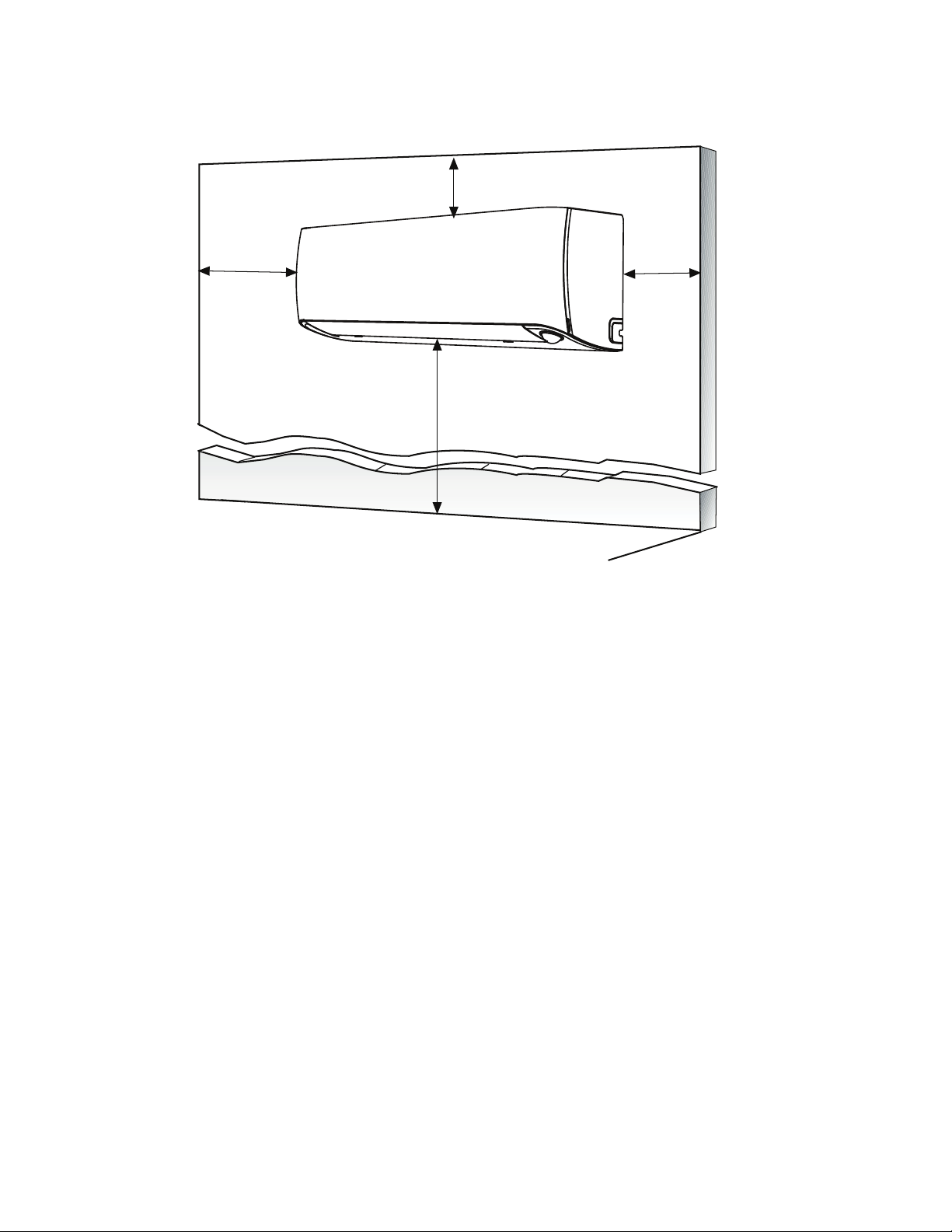

CLEARANCES

4.75 in

(12 cm)

min.

6 ft

(1.8m)

CEILING

FLOOR

5.9in. (15cm) min.

4.75 in

(12 cm)

min.

Fig. 3 — Indoor Unit Clearances

NOTE: The top clearance recommended for proper return airflow is 5.9 in (15cm). Reduction of this clearance may

decrease the performance of these units. This may be reduced to 3.2 in (80mm) as long as the right and left

clearances are achieved.

6 Specifications subject to change without notice. SM619PHA-03

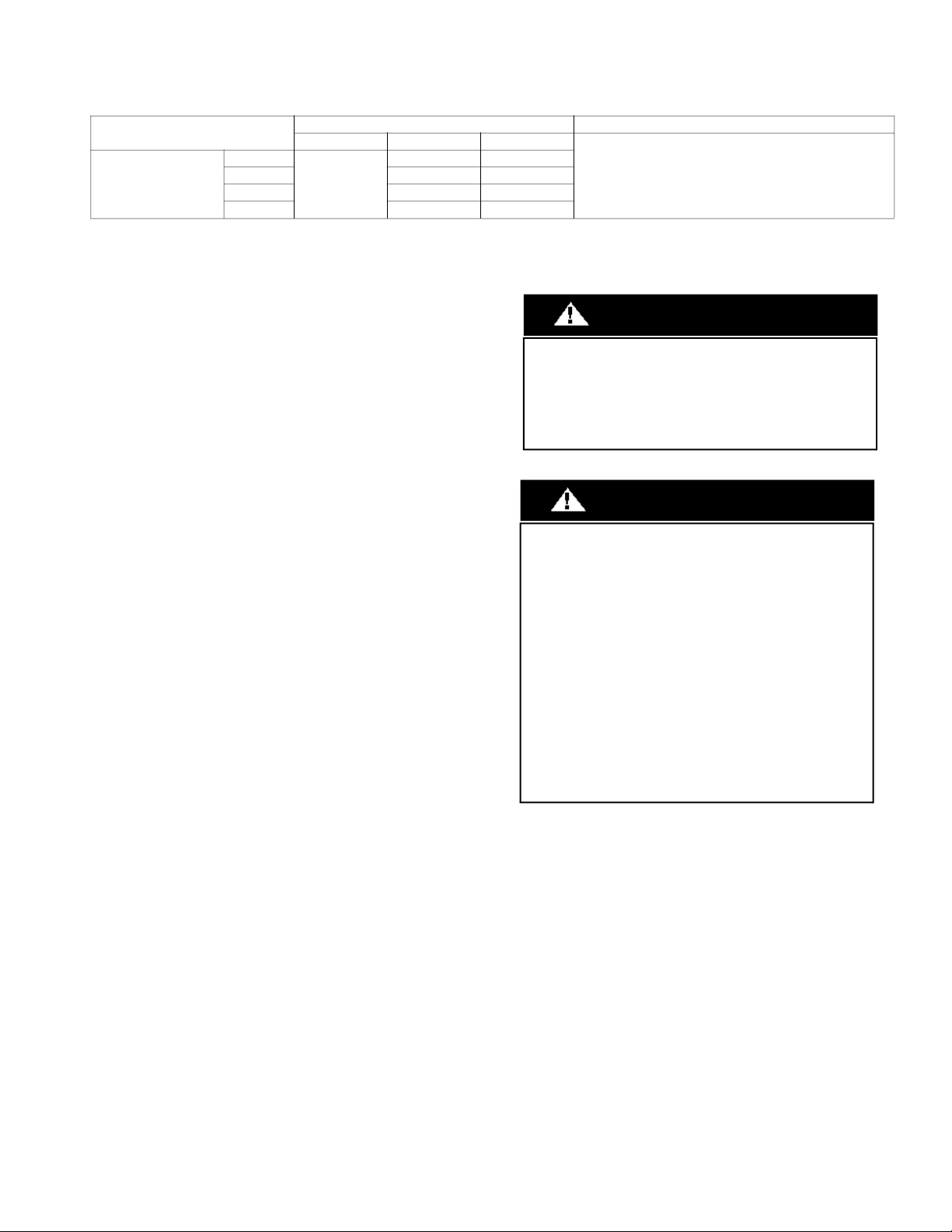

ELECTRICAL DATA

HIGH WALL UNIT SIZE

9K

Heat Pump Models

12K 0.34 0.027

18K 0.5 0.082

24K 0.5 0.082

WIRING

Table 5 — Electrical Data

INDOOR FAN MAX FUSE CB AMP

V-Ph-Hz FLA HP

0.34 0.027

208/230-1-60

Refer to outdoor unit installation instructions –

Indoor unit powered by the outdoor unit

All wires must be sized per NEC (National Electrical Code) or CEC

(Canadian Electrical Code) and local codes. Use the Electrical Data

table MCA (minimum circuit amps) and MOCP (maximum over

current protection) to correctly size the wires and the disconnect fuse

or breakers respectively.

Per the caution note, only stranded copper conductors with a 600 volt

insulation rating wire must be used.

Recommended Connection Method for Power and

Communication Wiring:

The main power is supplied to the outdoor unit. The field supplied

14/3 stranded wire with ground with a 600 volt insulation rating,

power/communication wiring from the outdoor unit to indoor unit

consists of four (4) wires and provides the power for the indoor unit.

Two wires are line voltage AC power, one is communication wiring

(S) and the other is a ground wire. Wiring between the indoor and

outdoor unit is polarity sensitive. The use of BX wire is NOT

recommended.

If installed in a high Electromagnetic field (EMF) area and

communication issues exists, a 14/2 stranded shielded wire can be

used to replace L2 and (S) between the outdoor unit and indoor unit

landing the shield onto ground in the outdoor unit only.

CAUTION

EQUIPMENT DAMAGE HAZARD

Failure to follow this caution may result in equipment damage

or improper operation.

Wires should be sized based on NEC and local codes.

CAUTION

EQUIPMENT DAMAGE HAZARD

Failure to follow this caution may result in equipment damage

or improper operation.

Be sure to comply with local codes while running wire from

the indoor unit to the outdoor unit.

Every wire must be connected firmly. Loose wiring may

cause the terminal to overheat or result in unit malfunction. A

fire hazard may also exist. Ensure all wiring is tightly

connected.

No wire should touch the refrigerant tubing, compressor or

any moving parts.

Disconnecting means must be provided and shall be located

within sight and readily accessible from the air conditioner.

Connecting cable with conduit shall be routed through the

hole in the conduit panel.

SM619PHA-03 Specifications subject to change without notice. 7

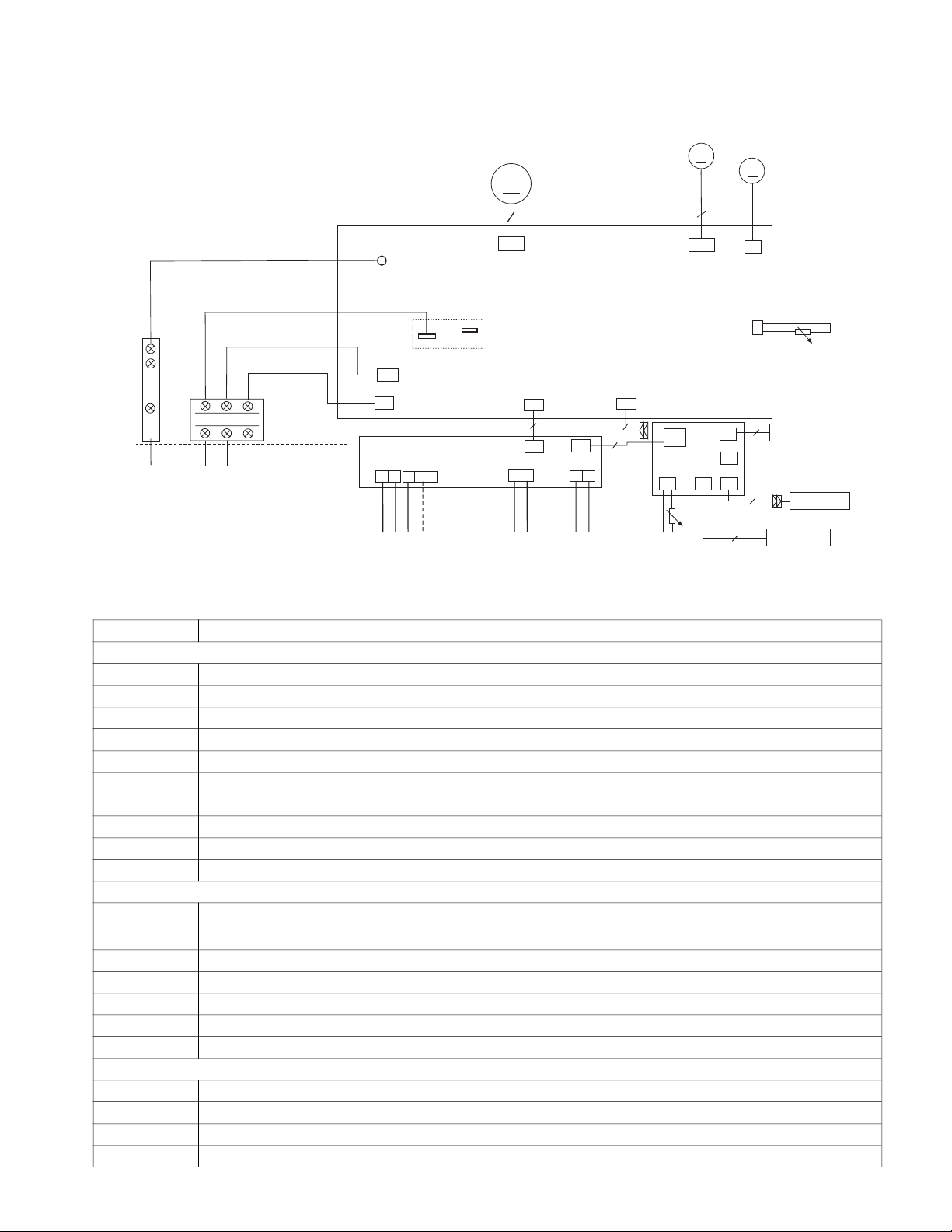

CONNECTION DIAGRAM

S

L1 L2

208/230-1-60

Main

Power Supply

L1

L2

S

L1

L2

CONNECTING CABLE

OUTDOOR TO INDOOR

Indoor Unit

Power Supply

208/230-1-60

Indoor

Signal

High

Voltage

GND

Ground

Power to

Indoor Unit

Indoor

Signal

High

Voltage

208/230-1-60

FIELD POWER SUPPLY

GND

208/230-1-60

208-230V Indoor Unit 208-230V Outdoor Unit

NOTES:

1. Do not use thermostat wire for any connection between the indoor and outdoor units.

2. All connections between the indoor and outdoor units must be as shown in Figure 4. The connections are polarity sensitive and improper wiring

will result in a fault code.

Fig. 4 — 208-230V

8 Specifications subject to change without notice. SM619PHA-03

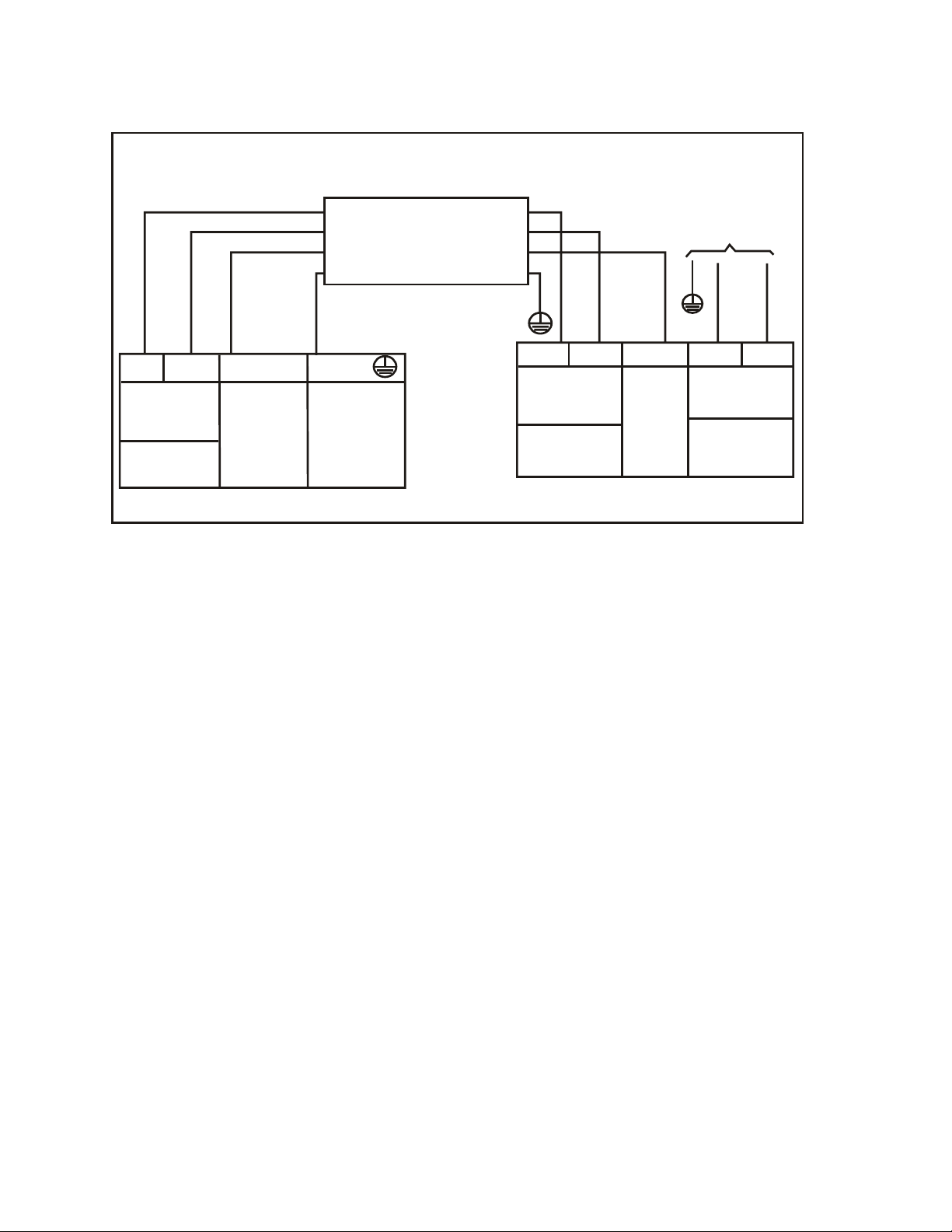

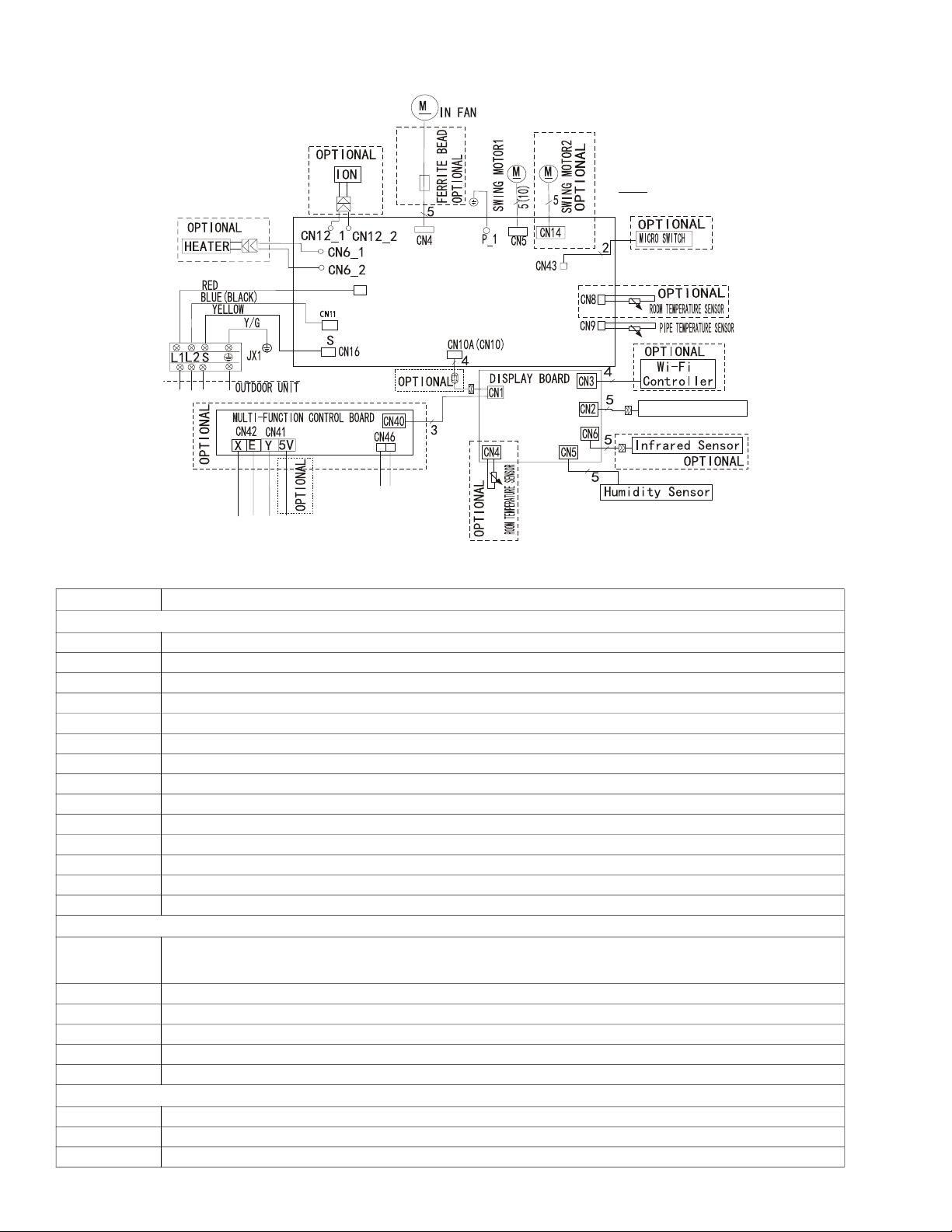

WIRING DIAGRAM

PIPE TEMPERATURE SENSOR

5

YELLOW

RED

M

CN20

SWING MOTOR2

INDOOR

FAN

M

5

CN3

N-IN

CN5

CN6

RY1

L-OUT

L-IN

BLUE(BLACK)

DISPLAY BOARD

CN10

MULTI-FUNCTION CONTROL BOARD

CN3

MAIN BOARD

CN2

CN4

CN1

CN40

CN43

CN32

2

CN42

CN41

CN45

CN46

X Y

E

12V/5V

To 485 Wire-controller

To Remote Switch

To Remote Alarm

4

3

- - - element is optional, the actual

shape shall prevail.

This symbol indicates the

INDOOR UNIT

OUTDOOR UNIT

L2

S

ROOM TEMPERATURE SENSOR

SWING MOTOR3

M

CN8

L1

CN5

CN6

Motion Sensor

5

Humidity Sensor

5

4

Wi-Fi

Earth Ground

CN1 & CN1A

+12V &

GND

Display

Vertical Horizontal

S

DC - Fan

P1_1

Indoor Wiring Diagram

Sizes 09K to 12K

CODE PART NAME

CN 10 Display board port DC 12V

CN 6 Output DC 5V pipe sensor

CN 8 Output DC12V,Swing motor

CN 20 Output DC12V,Swing motor

CN 3 Output DC 310V,fan motor

P1_1 Earth Ground

L-IN Power Voltage: AC 208-230V

N-IN Power Voltage: AC 208-230V

CN 5 Output: DC 0-24V Communication port to outdoor

CN 32 Output: DC 12V function board

CN1

CN 3 Output: DC 5V WI-FI controller (optional)

CN 2 Output: DC 5V Wire controller (optional)

CN 6 Output: DC 3.3V Infrared sensor (optional)

CN 5 Output: DC 5V Humidity sensor

CN 4 Output: DC5V Room temperature sensor (optional)

CN42 & CN41 Output: DC 5V To CCM Comm.Bus or 485 Wire-controller

CN 40 Input: DC 5V Connect to display board

CN 43 Input: DC 12V Connect to main board

CN 46 Output: DC 5V To Remote Switch

SM619PHA-03 Specifications subject to change without notice. 9

Input: DC 12V

4 wires connect to main board

3 wires connect to multi-function control board

Fig. 5 — Wiring Diagram - Sizes 09K and 12K

MAIN BOARD

DISPLAY BOARD

MULTI-FUNCTION CONTROL BOARD

Sizes 18K to 24K

N

CN11

L-IN

CN 2

INDOOR UNIT

To Remote Switch

To CCM Comm.Bus or

OPTIONAL

Wire Controller

485 Wire-controller

Fig. 6 — Wiring Diagram - Sizes 18K and 24K

CODE PART NAME

MAIN BOARD

S (Cn16) Output:0-24VDC Communication port to outdoor

N(CN11) I nput:230VAC High Voltage N line from outdoor

L-IN (CN2) Input:230VAC High Voltage L line from outdoor

CN 6 Output:230VAC High Voltage Heater port (optional)

CN 12 Output:230V High Voltage Ion port (optional)

CN 4 Output:310VDC High Voltage Indoor DC fan

P_1 Output:0V Ground line welding on PCB

CN 5 Output:12VDC Swing motor 1

CN 14 Output:12VDC Swing motor2 (optional)

CN 43 Output:0-5VDC Micro switch (optional)

CN 44 Output:12VDC Plasma port (optional)

CN 8 Output:12VDC Room temperature sensor (optional)

CN 9 Output:12VDC Pipe temperature sensor

CN10A(CN10) Output:5VDC Connect to display board

DISPLAY BOARD

CN 1

CN 3 Output:5VDC Wi-Fi controller (optional)

CN 2 Output:5VDC Wire controller (optional)

CN 6 Output:3.3VDC Infrared sensor (operational)

CN 5 Output:5VDC Humidity sensor

CN 4 Output:12VDC Room temperature sensor (optional)

CN42&CN41 Output:5VDC To CCM Comm. Bus or 485 Wire-controller

CN40 Input:5VDC Connect to display board

CN 46 Output:5VDC To Remote Switch

10 Specifications subject to change without notice. SM619PHA-03

Input:5VDC

4 wires connect to main board

3 wires connect to multi-function control board

MULTI-FUNCTION CONTROL BOARD

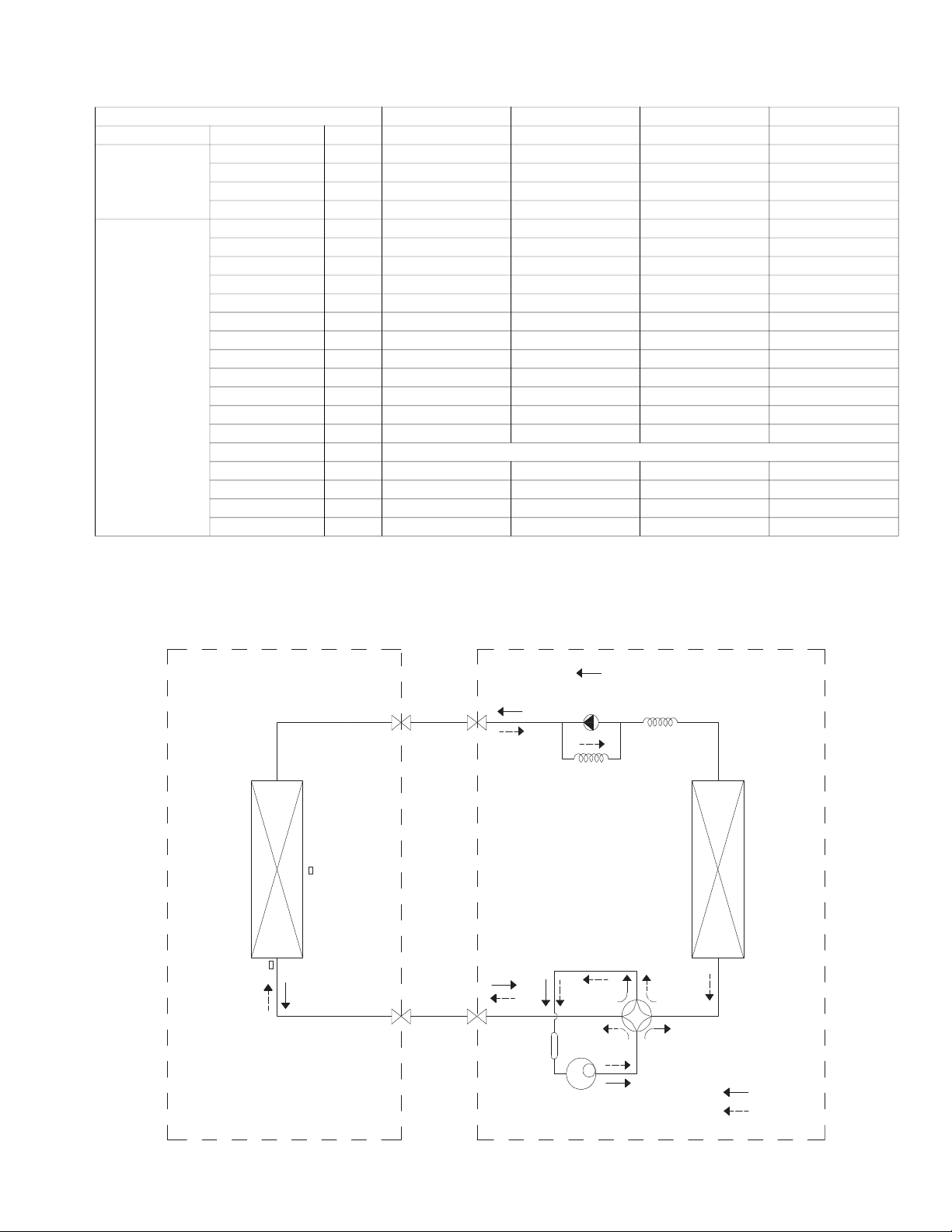

FAN AND MOTOR SPECIFICATIONS

LIQUID SIDE

GAS SIDE

HEAT

EXCHANGE

(EVAPORATOR)

HEAT

EXCHANGE

(CONDENSER)

COMPRESSOR

ïWAY VALV E

ïWAY VALV E

ïWAY VALV E

COOLING

HEATING

T2 Evaporator

temp. sensor

T1 Room temp.

sensor

ACCUMULATOR

CHECK VALVE

(Heating Model only)

CAPILLARY TUBE

Table 6 — Fan and Motor Specifications

HIGH WALL UNIT SIZE 9K 12K 18K 24K

(208/230V) (208/230V) (208/230V) (208/230V)

Material glass fiber+AS glass fiber+AS glass fiber+AS glass fiber+AS

HIGH WALL FAN

HIGH WALL

FAN MOTOR

Type GL-108*670-IN GL-108*670-IN GL-118*955-I GL-118*955-I

Diameter In (mm) 4.25 (108) 4.25 (108) 4.65(118) 4.65(118)

Height In (mm) 26.38 (670) 26.38 (670) 37.6(955) 37.6(955)

Model ZKFP-20-8-6-7 ZKFP-20-8-6-7 ZKFP-58-8-1-5 ZKFP-58-8-1-5

Volts V 208/230 208/230 208/230 208/230

Phase 1 1 1 1

Hertz 60 60 60 60

FLA 0.034 0.034 0.5 0.5

Type DC DC DC DC

Insulation class E E E E

Safe class IPX0 IPX0 IP40 IP40

Input W 50 50 58 58

Output W 20 20 60 60

Range of current Amps 0.023 0.023 0.1~0.48 0.1~0.48

Rated current Amps 0.023±10% 0.023±10% 0.65 0.65

Capacitor µF No Capacitor

Rated HP HP 0.027 0.027 0.082 0.082

Speed rev/min 1000/850/650 1050/900/650 1700/1660/1350 1700/1660/1350

Rated RPM rev/min 1000 1050 1700 1700

Max. input W 70 70 125 125

REFRIGERATION CYCLE DIAGRAM

ROODTUOROODNI

SM619PHA-03 Specifications subject to change without notice. 11

Fig. 7 — Heat Pumps

REFRIGERANT LINES

utdoor Unit

t

Gas Side

Liquid Side

A

B

C

D

Manifold Gage

500 microns

Lo

w pressure valve

High side valve

Low pressure hose

Charge hose

Vacuum

pump

Gas side valve

500

MINUTES

01234567

1000

1500

LEAK IN

SYSTEM

VACUUM

TIGHT

TOO WET

TIGHT

DRY SYSTEM

2000

MICRONS

2500

3000

3500

4000

4500

5000

CHECK FOR TIGHT, DRY SYSTEM

(IF IT HOLDS DEEP VACUUM)

EVACUATE TO 1500 MICRONS

EVACUATE TO 500 MICRONS MINIMUM (HOLD FOR 30 MINUTES)

RELEASE

CHARGE INTO SYSTEM BY OPENING

VALVES COMPLETELY

BREAK VACUUM WITH DRY NITROGEN TO 2 PSIG

EVACUATE TO 1000 MICRONS

BREAK VACUUM WITH DRY NITROGEN TO 2 PSIG

IMPORTANT: Both refrigerant lines must be insulated separately.

Table 2 on page 3 lists the pipe sizes for the indoor unit. Refer to the outdoor unit installation instructions for other allowed piping lengths and

refrigerant information.

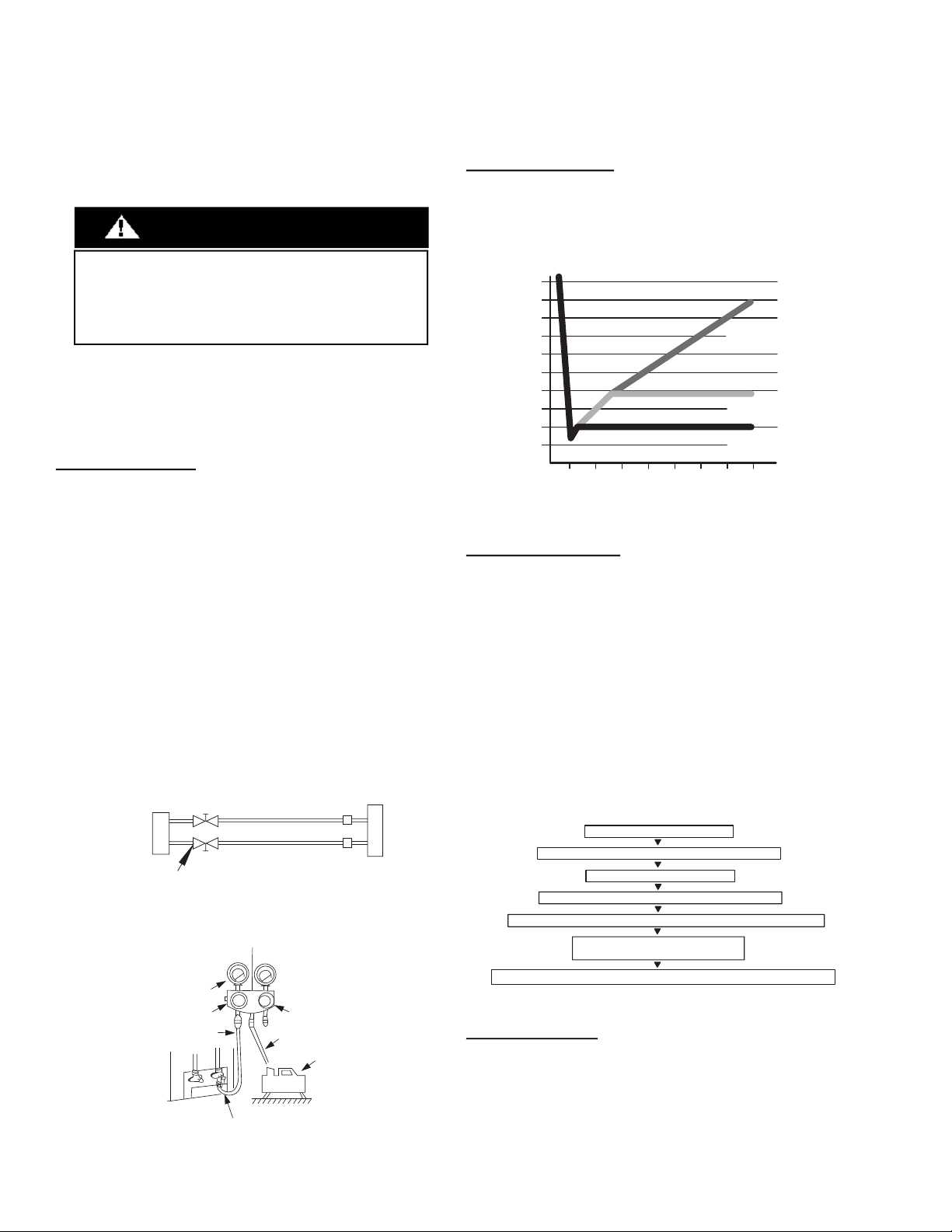

SYSTEM EVACUATION AND CHARGING

CAUTION

UNIT DAMAGE HAZARD

Failure to follow this caution may result in equipment damage

or improper operation.

Never use the system compressor as a vacuum pump.

Refrigerant tubes and indoor coil should be evacuated using the

recommended deep vacuum method of 500 microns. The alternate

triple evacuation method may be used if the following procedure is

followed. Always break a vacuum with dry nitrogen.

System Vacuum and Charge

Using Vacuum Pump

1. Completely tighten flare nuts on the line set at both the indoor and

outdoor units. DO NOT open the service valves on the outdoor unit

for the new installation or the replacement unit. Open the service

valves on the outdoor unit if repairs have been made to the

refrigerant sealed system. Connect the manifold gauge low pressure

hose to the charge port of the gas side service valve (see Fig. 8).

2. Connect the charge hose to the vacuum pump.

3. Fully open the low pressure valve of manifold gage (see Fig. 9).

4. Start the vacuum pump.

5. Evacuate using deep vacuum or triple evacuation method.

6. After evacuation is complete, fully close the pressure valve side of

manifold gage and stop the vacuum pump operation.

7. The factory charge contained in the outdoor unit is good for up to

25ft. (8 m) of line length. If vacuum is complete per Fig. 10 or 11,

open service valves to release factory charge into the system.

8. Disconnect the charge hose from the charge connection of the gas

side service valve.

9. Securely tighten the service valve caps.

O

Refrigerant

Indoor Uni

Deep Vacuum Method

The deep vacuum method requires a vacuum pump capable of pulling

a vacuum of 500 microns and a vacuum gage capable of accurately

measuring this vacuum depth. The deep vacuum method is the most

positive way of assuring a system is free of air and liquid water (see

Fig. 10).

Fig. 10 — Deep Vacuum Graph

Triple Vacuum Method

The triple evacuation method should be used. Refer to Fig. 9 and

proceed as follows:

1. Pump the system down to 1500 microns and allow the pump to

continue operating for an additional 15 minutes.

2. Close the service valves and shut off the vacuum pump.

3. Connect a dry nitrogen cylinder and regulator to the system and

break vacuum until the system reaches 2 psig.

4. Close the service valve and allow the system to stand for 1hr.

During this time, the dry nitrogen can diffuse throughout the system

absorbing moisture.

5. Pump the system down to 1000 microns.

6. Break the vacuum with dry nitrogen (2 psig).

7. Pump the system down to 500 microns.

8. Perform the hold test for 30 minutes.

Service Valve

Fig. 8 — Service Valve

12 Specifications subject to change without notice. SM619PHA-03

Fig. 9 — Manifold

Fig. 11 — Triple Evacuation Method

Final Tubing Check

IMPORTANT: Check to be certain factory tubing on both

indoor and outdoor unit has not shifted during shipment.

Ensure tubes are not rubbing against each other or any

sheet metal. Pay close attention to feeder tubes, making

sure wire ties on feeder tubes are secure and tight.

OPERATION MODES AND FUNCTIONS

Abbreviation

Table 7 — Unit Element Abbreviations

ABBREVIATION ELEMENT

T1 Indoor room temperature

T2 Evaporator Coil temperature

T3 Condenser Coil temperature

T4 Outdoor ambient temperature

Tsc Adjusted setting temperature

TP Compressor discharge temperature

Safety Features

Compressor Three-Minute Delay at Restart

Compressor functions are delayed for up to ten seconds upon the

first start-up of the unit, and are delayed for up to three minutes

upon subsequent unit restarts.

Automatic shutoff based on discharge temperature

If the compressor discharge temperature exceeds 226F (108C)

for nine seconds, the compressor ceases operation.

Automatic shutoff based on fan speed

If the indoor fan speed registers below 300RPM or over 1500RPM

for an extended period of time, the unit ceases operation and the

corresponding error code is displayed on the indoor unit.

Inverter module protection

The inverter module has an automatic shutoff mechanism based on

the unit’s current, voltage, and temperature. If automatic shutoff is

initiated, the corresponding error code is displayed on the indoor

unit and the unit ceases operation.

Display Function

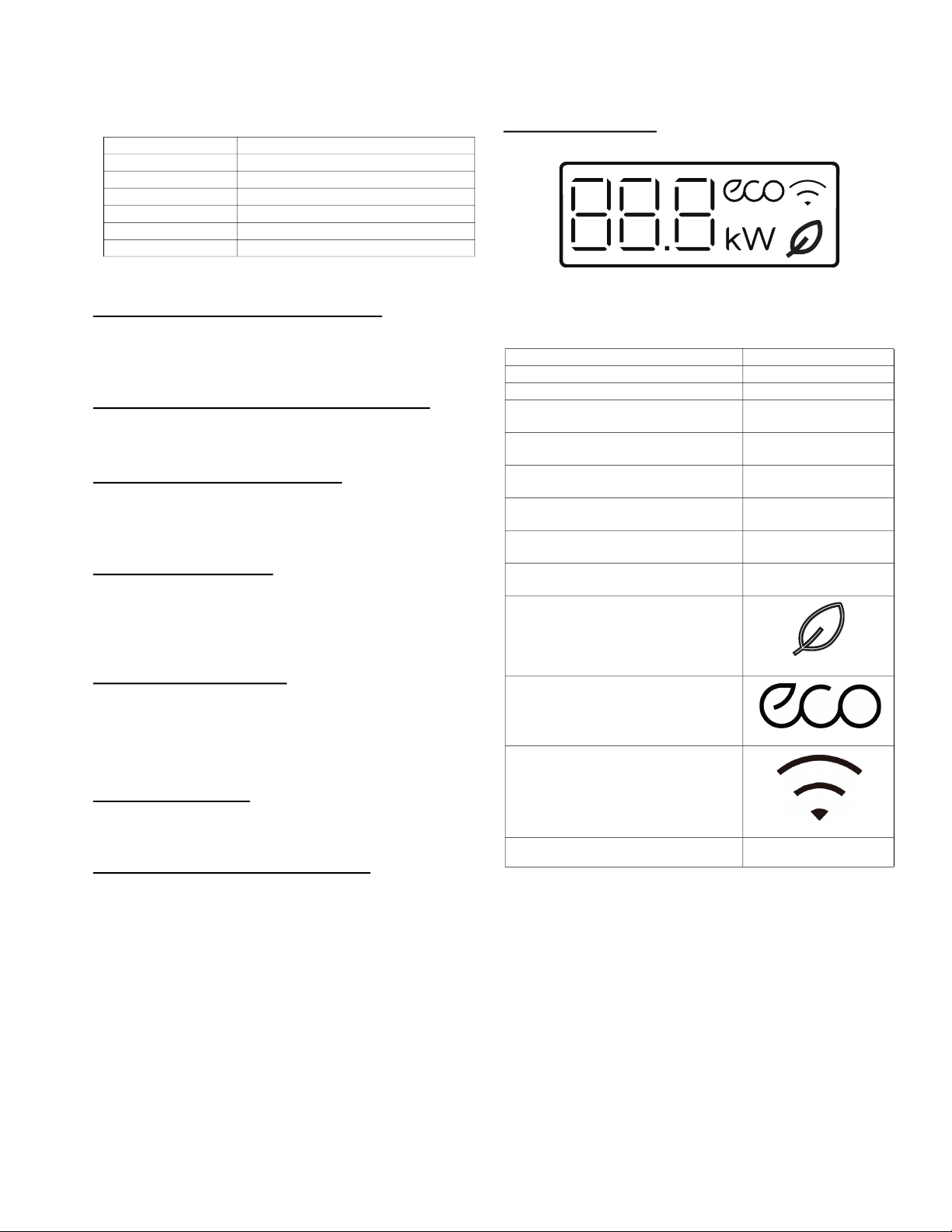

Unit Display Functions

Fig. 12 — Unit Display Functions

Table 8 — Unit Function Displays

FUNCTION DISPLAY

Temperature Set temperature value

Temperature (FAN and DRYING mode) Room temperature

Activation of Timer ON, Fresh, Swing,

Turbo, or Silent

Cancellation of Timer OFF, Fresh, Swing,

Turbo, or Silent

Defrost

Warming in heating mode

Self-clean

Heating in room temperature under

46°F (8°C) or 54°F (12°C)

Fresh (Not available on these systems)

ON(3S)

OF(3S)

dF

cF

SC

FP

Indoor fan delayed operation

• When the unit starts, the louver is automatically activated and the

indoor fan will operate after a period of setting time or when the

louver is in place.

• If the unit is in HEATING mode, the indoor fan is regulated by the

anti-cold wind function.

Compressor Preheating

Preheating is automatically activated when the T4 sensor is lower than

setting temperature.

Sensor redundancy and automatic shutoff

• If one temperature sensor malfunctions, the air conditioner

continues operation and displays the corresponding error code,

allowing for emergency use.

• When more than one temperature sensor malfunctions, the air

conditioner ceases operation.

ECO function

Wi-Fi Control

The current operation power

(Not available on these systems)

kW

SM619PHA-03 Specifications subject to change without notice. 13

FAN Mode

When the FAN mode is activated:

• The outdoor fan and compressor stop.

• Temperature control is disabled and the indoor room temperature

is displayed.

• The indoor fan speed can be set to 1%~100%, or AUTO.

• The louver operations are identical to those in COOLING mode.

• Auto fan: In FAN-ONLY mode, the AC operates the same as auto

fan in the COOLING mode with the temperature set at 75F

(24°C). (Tsc=75°F (24°C)).

COOLING Mode

Compressor control

Reach the configured temperature:

1. When the compressor runs continuously for less than 120 minutes.

• If the following conditions are satisfied, the compressor ceases

operation.

• While the calculated frequency (fb) is less than the minimum

limit frequency (FminC).

• While protective time is more than or equal to ten minutes.

• While T1 is lower than or equal to (Tsc-CDIFTEMP -1°F (-0.5°C)

NOTE: CDIFTEMP is the EEPROM setting parameter. It

is 4

°F (2°C).

2. When the compressor runs continuously for more than 120

minutes.

• If the following conditions are satisfied, the compressor ceases

operation.

• When calculated frequency (fb) is less than minimum limit

frequency (FminC).

• When protective time is more than or equal to ten minutes.

• When T1 is lower than or equal to (Tsc-CDIFTEMP).

NOTE: CDIFTEMP is the EEPROM setting parameter. It

is 4

°F (2°C).

3. If one of the following conditions is satisfied, regardless of time.

• Compressor running frequency is more than the test frequency.

• When the compressor running frequency is equal to the test

frequency, T4 is more than 59°F (15°C) or no T4 or T4 fault.

• Change setting temperature

• Turbo or sleep function on/off

• Various frequency limit shutdown occurs

Indoor Fan Control

1. In the COOLING mode, the indoor fan operates continuously. The

fan speed can be set to 1%-100%, or AUTO.

2. AUTO fan

• Descent Curve

• When T1-Tsc is lower than or equal to 6F (3.5C), fan speed

reduces to 80%;

• When T1-Tsc is lower than or equal to 2F (1C), fan speed

reduces to 60%;

• When T1-Tsc is lower than or equal to 1F (0.5C), fan speed

reduces to 40%;

• When T1-Tsc is lower than or equal to 0F (0C), fan speed

reduces to 20%;

• When T1-Tsc is lower than or equal to -1F (-0.5C), fan

speed reduces to 1%.

• Rise Curve

• When T1-Tsc is higher than 0F (0C), fan speed increases to

20%;

• When T1-Tsc is higher than 1F (0.5C), fan speed increases

to 40%;

• When T1-Tsc is higher than 2F (1C), fan speed increases to

60%;

• When T1-Tsc is higher than 3F (1.5C), fan speed increases

to 80%;

• When T1-Tsc is higher than 7F (4C), fan speed increases to

100%.

Outdoor Fan Control

• The outdoor unit runs at a different fan speed according to T4 and

the compressor running frequency.

• For different outdoor units, the fan speeds are different.

Condenser Temperature Protection

When the condenser temperature exceeds a configured value, the

compressor ceases operations.

Evaporator Temperature Protection

When the evaporator temperature drops below a configured value, the

compressor and outdoor fan ceases operations.

NOTE: CDIFTEMP is EEPROM setting parameter. It is

4

°F (2°C).

14 Specifications subject to change without notice. SM619PHA-03

HEATING Mode

“ ”

Compressor control

1. Reach the configured temperature:

• If the following conditions are satisfied, the compressor ceases

operation.

• While the calculated frequency (fb) is less than the minimum

limit frequency (FminC).

• When the protective time is more than or equal to ten minutes.

• When T1 is higher than or equal to Tsc+HDIFTEMP2.

NOTE: HDIFTEMP2 is the EEPROM setting parameter.

It is 4

°F (2°C).

• If one of the following conditions is satisfied, regardless of

time.

• Compressor running frequency is more than test frequency.

• When the compressor running frequency is equal to the test

frequency, T4 is more than 59°F (15°C) or no T4 or T4 fault.

• Change the setting temperature.

• TURBO or SLEEP function on or off.

2. When the current is higher than the predefined safe value, the surge

protection is activated, causing the compressor to cease

operations.

Indoor Fan Control

1. In the HEATING mode, the indoor fan operates continuously. The

fan speed can be set to 1%-100%, or muted.

2. AUTO fan

• Rise curve

• When T1-Tsc is higher than -3°F (-1.5°C), fan speed reduces

to 80%;

• When T1-Tsc is higher than 0°F (0°C), fan speed reduces to

60%;

• When T1-Tsc is higher than 1°F (0.5°C), fan speed reduces to

40%;

• When T1-Tsc is higher than 2°F (1°C), fan speed reduces to

20%.

•Descent curve

•When T1-Tsc is lower than or equal to 1°F (0.5°C), fan speed

increases to 20%;

• When T1-Tsc is lower than or equal to 0°F (0°C), fan speed

increases to 60%;

• When T1-Tsc is lower than or equal to -3°F (-1.5°C), fan

speed increases to 80%;

• When T1-Tsc is lower than or equal to -1.5°F (-3°C), fan

speed increases to 100%.

DEFROSTING Mode

• The unit enters defrosting mode according to changes in the

temperature value of T3, T4 as well as the compressor running

time.

• In the DEFROSTING mode, the compressor continues to run, the

indoor and outdoor motor will cease operation, the defrost light of

the indoor unit will turn on, and the symbol appears.

• If any one of the following conditions is satisfied, defrosting ends

and the machine switches to the normal HEATING mode:

• T3 rises above TCDE1C.

• T3 maintained above TCDE2C for 80 seconds.

• Unit runs for 15 minutes consecutively in the DEFROSTING

mode.

Evaporator Temperature Protection

• Off: Compressor stops.

• Decrease: Decrease the running frequency to the lower level per

20 seconds.

• Hold: Keep the current frequency.

• Resume: No limitation for frequency.

AUTO Mode

• This mode can be selected with the remote controller and the

setting temperature can be changed between 61°F~86°F

(16°C~30°C).

• In the AUTO mode, the machine selects the COOLING,

HEATING, AUTO-DRYING or FAN-ONLY mode on the basis

of T1,Ts, T4 and relative humidity.

• If the setting temperature is modified, the machine selects a new

running function.

DRY Mode

In the DRY mode, the air conditioner operates the same as auto fan in

the COOLING mode.

1. Mute function is active.

• All protections are activated and operate the same as they do

that in COOLING mode.

2. Low Room Temperature Protection

• If the room temperature is lower than 50°F (10°C), the

compressor ceases operations and does not resume until the

room temperature exceeds 54°F (12°C).

Outdoor Fan Control

•The outdoor unit runs at a different fan speed according to T4

and compressor running frequency.

• For different outdoor units, the fan speeds differ.

SM619PHA-03 Specifications subject to change without notice. 15

Forced Operation Function

• Forced COOLING Mode

The compressor and outdoor fan continues to run and the indoor

fan runs at rated speed. After running for 30 minutes, the air

conditioner switches to AUTO mode with a preset temperature

of 75°F (24°C).

• Forced AUTO Mode:

Forced auto mode operates the same as normal AUTO mode

with a preset temperature of 75°F (24°C).

•The unit exits the forced operation when it receives the following

signals:

• Switch on

• Switch off

• Timer on

• Timer off

• Changes in:

• Mode

• Fan Speed

• Setting Temperature

Timer Function

• The Timing range is 24 hours.

• Timer on. The machine turns on automatically when reaching the

setting time.

• Timer off. The machine turns off automatically when reaching the

setting time.

• Timer on/off. The machine turns on automatically when reaching

the setting “on” time, and then turns off automatically when

reaching the setting “off” time.

• Timer off/on. The machine turns off automatically when reaching

the setting “off” time, and then turns on automatically when

reaching the setting “on” time.

• The timer function will not change the AC current operation mode.

Suppose the AC is off now, it will not start up first after setting the

“timer off” function. And when reaching the setting time, the timer

LED will be off and the AC running mode has not been changed.

• The setting time is relative time.

• The AC will quit the timer function when it has malfunction.

Auto-Restart Function

• The indoor unit has an auto-restart module that allows the unit to

restart automatically. The module automatically stores the current

settings and, in the case of a sudden power failure, will restore

those setting automatically within 3 minutes after power returns.

• If there is a power failure while the unit is running, the compressor

starts 3 minutes after the unit restarts. If the unit was already off

before the power failure, the unit stands by.

46°F (8°C) Heating

In the HEATING mode, the temperature can be set to as low as 46°F

(8°C), preventing the indoor area from freezing if unoccupied during

severe cold weather.

ECO Function

• Used to enter the energy efficient mode.

•Under the COOLING mode, press ECO, the remote controller

adjusts the temperature automatically to 75°F (24°C), AUTO fan

speed to save energy (however only if the set temperature is less

than 75°F (24°C). If the set temperature is more than 75°F

(24°C) and 86°F (30°C), press ECO, the fan speed will change to

AUTO, the set temperature will remain unchanged.

• When AC receives signals, such as switch off, Turbo operation,

Silence operation, Self Clean operation, Forced COOLING

operation, mode setting, SLEEPING mode, or adjusting the set

temperature to less than 75°F (24°C), it will exit the ECO

operation.

• Operation time in ECO mode is 8 hours. After 8 hours the air

conditioner exits this mode.

• If there is a malfunctioning temperature sensor in, the air

conditioner will exit ECO mode.

• The indoor fan runs at auto fan when it enters the ECO mode. The

setting temperature and setting fan speed can be changed with the

remote controller.

Self Clean

• Press “Self Clean” when the unit is in the COOLING or

DRYING mode, the indoor unit runs at the low fan speed for 16

minutes then turn off.

• Self Clean keeps the indoor unit dry and prevents mold growth.

SLEEP Function

• The SLEEP function is available in COOLING, HEATING, or

AUTO modes.

• The operational process for sleep mode is as follows:

•When cooling, the temperature rises 2°F (1°C) (to not higher

than 86°F (30°C) every hour. After 2 hours, the temperature

stops rising and the indoor fan is fixed at low speed.

•When heating, the temperature decreases 2°F (1°C) (to not

lower than 61°F (16°C)) every hour.

•After 2 hours, the temperature stops decreasing and the indoor

fan is fixed at low speed. Anti-cold wind function takes

priority.

• The operating time for the SLEEP mode is 8 hours, after which,

the unit exits this mode and turns off.

• The timer setting is available in this mode.

Follow Me

• If you press “Follow Me” on the remote controller, the indoor unit

will beep. This indicates the “Follow Me” function is active.

• Once active, the remote controller will send a signal every 3

minutes, with no beeps. The unit automatically sets the

temperature according to the measurements from the remote

controller.

• The unit will only change modes if the information from the

remote controller makes it necessary, not from the unit’s

temperature setting.

• If the unit does not receive a signal for 7 minutes or you press

“Follow Me”, the function turns off. The unit regulates

temperature based on its own sensor and settings.

16 Specifications subject to change without notice. SM619PHA-03

Silence

Press SILENCE on the remote controller to enable the SILENCE

function. While this function is active, the indoor unit runs at faint

breeze (1% fan speed), which reduces noise to the lowest possible

level.

Occupancy Sensor (Sizes 09K-12K)

With the built-in infrared sensor, the indoor unit detects human

movement. The compressor operates in a low frequency if you leave

the room for 30 minutes. The compressor operates in a lower

frequency if you leave the room for 120 minutes, and resumes

automatically when you come back, which helps save energy.

Table 9 — Information Codes

DISPLAYED CODE EXPLANATION ADDITIONAL NOTES

T1 T1 T1 temperature

T2 T2 T2 temperature

T3 T3 T3 temperature

T4 T4 T4 temperature

TP TP TP temperature

Targeted Frequency FT Targeted Frequency

Actual Frequency TR Actual Frequency

Compressor Current dL N/A

Outdoor AC Voltage UO N/A

Indoor capacity test Sn N/A

Reserve -- Running mode

Outdoor Fan Speed Pr Outdoor fan speed

EXV opening angle LR EXV opening angle

Indoor fan speed IR Indoor fan speed

Indoor humidity HU N/A

Adjusted setting temperature TT N/A

Indoor dust concentrations DT N/A

WIFI signal strength IF N/A

GA algorithm frequency OT N/A

Information Inquiry

To enter information inquiry status, complete the following procedure

within ten seconds:

• Press LED 3 times.

• Press SWING 3 times. If successful, you will hear beeps for two

seconds.

• Use LED and SWING to cycle through the information displayed.

• Press LED to display the next code in the sequence.

• Press SWING to display the previous code.

Table 9 displays the information codes. The screen displays the code

for two seconds, then the information for 25 seconds.

SM619PHA-03 Specifications subject to change without notice. 17

TROUBLESHOOTING

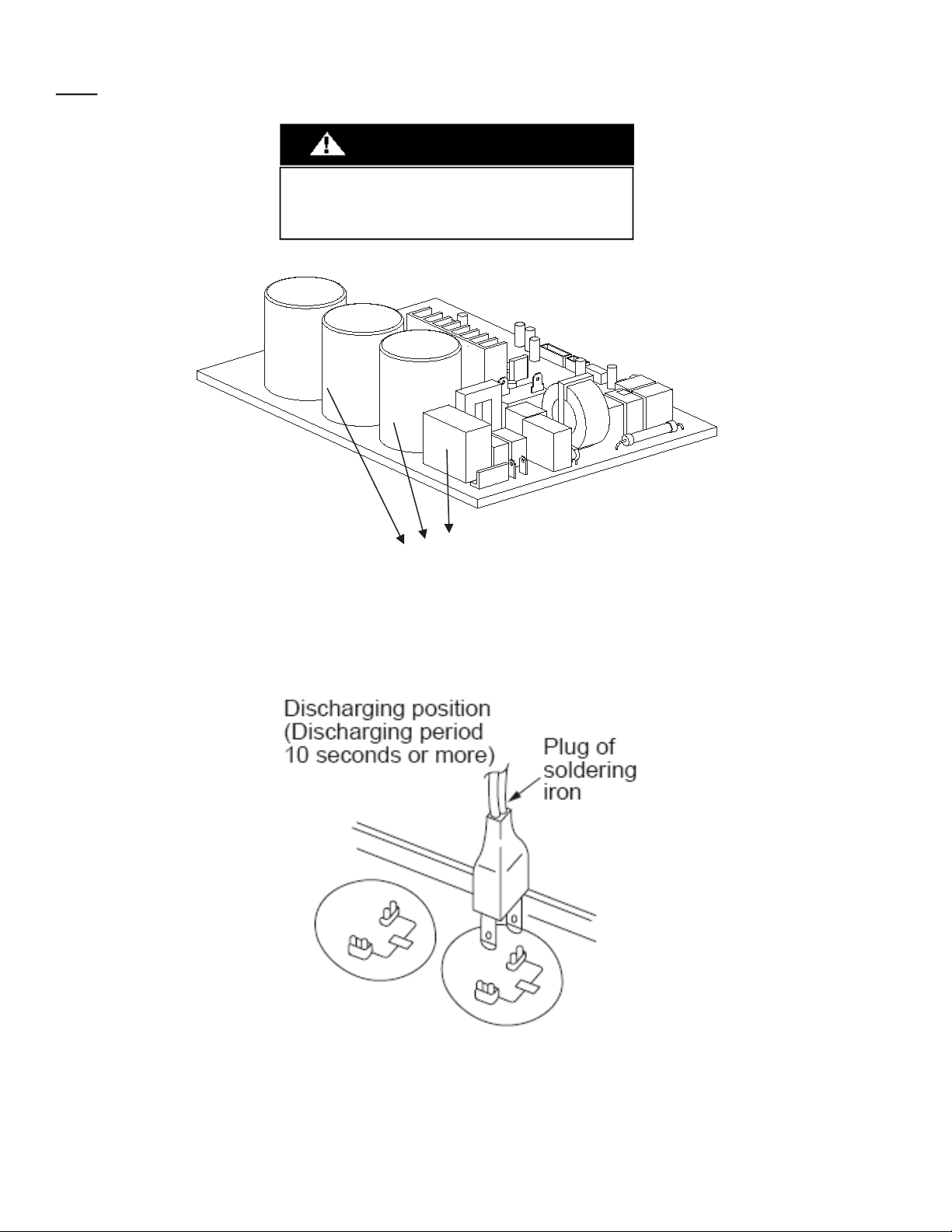

Electrolytic Capacitors

Safety

WARNING

UNIT DAMAGE HAZARD

Electricity remains in capacitors even when the power supply is off.

Ensure the capacitors are fully discharged before troubleshooting.

(HIGH VOLTAGE! CAUTION!)

Fig. 13 — Electrolytic Capacitors

For other models, please connect discharge resistance (approximately 100Ù 40W) or a soldering iron (plug) between the +, - terminals of the

electrolytic capacitor on the other side of the outdoor PCB.

Fig. 14 — Discharge Position

NOTE: Fig. 14 is for reference only. Actual appearances may vary.

18 Specifications subject to change without notice. SM619PHA-03

TROUBLESHOOTING (continued)

Error Display (Indoor Unit)

When the indoor unit encounters a recognized error, the indicator light flashes in a corresponding series, the timer display may turn on or

begin flashing, and an error code displays. These error codes are described in Table 10.

Table 10 — Error Codes

DISPLAY ERROR INFORMATION SOLUTION

E0/EA Indoor unit EEPROM parameter error Page 27

E1 Indoor / outdoor units communication error Pages 28 - 29

E2 Zero crossing detection error diagnosis and solution Page 30

E3 The indoor fan speed is operating outside of the normal range Page 31

E4 Indoor room temperature sensor T1 is in open circuit or has short circuited Page 37

E5 Evaporator coil temperature sensor T2 is in open circuit or has short circuited Page 37

EB Communication error between the indoor PCB and display board Page 38

EF Occupancy Sensor module error Page 33

F0 Overload current protection Page 39

F1 Outdoor ambient temperature sensor T4 open circuit or short circuit Page 37

F2 Condenser coil temperature sensor T3 is in open circuit or has short circuited Page 37

F3 Compressor discharge temperature sensor TP open circuit or short circuit Page 37

F4 Outdoor unit EEPROM parameter error Page 27

F5 The outdoor fan speed is operating outside of the normal range Page 31

P0 IPM malfunction or IGBT over-strong current protection Page 40

P1 Over voltage or over low voltage protection Page 34

P2 High temperature protection of IPM module Page 35

P3 Outdoor ambient temperature is too low

P4 Inverter compressor drive error Page 36

For other codes

The display board may show a garbled code or a code undefined by the service manual. Ensure that this code is not a temperature reading.

Troubleshooting

Test the indoor unit using the remote control. If the unit display is working however will not respond to the remote, the indoor PCB

needs to be replaced. If there is no display after pressing LED and the unit responds, the display board needs to be replaced.

SM619PHA-03 Specifications subject to change without notice. 19

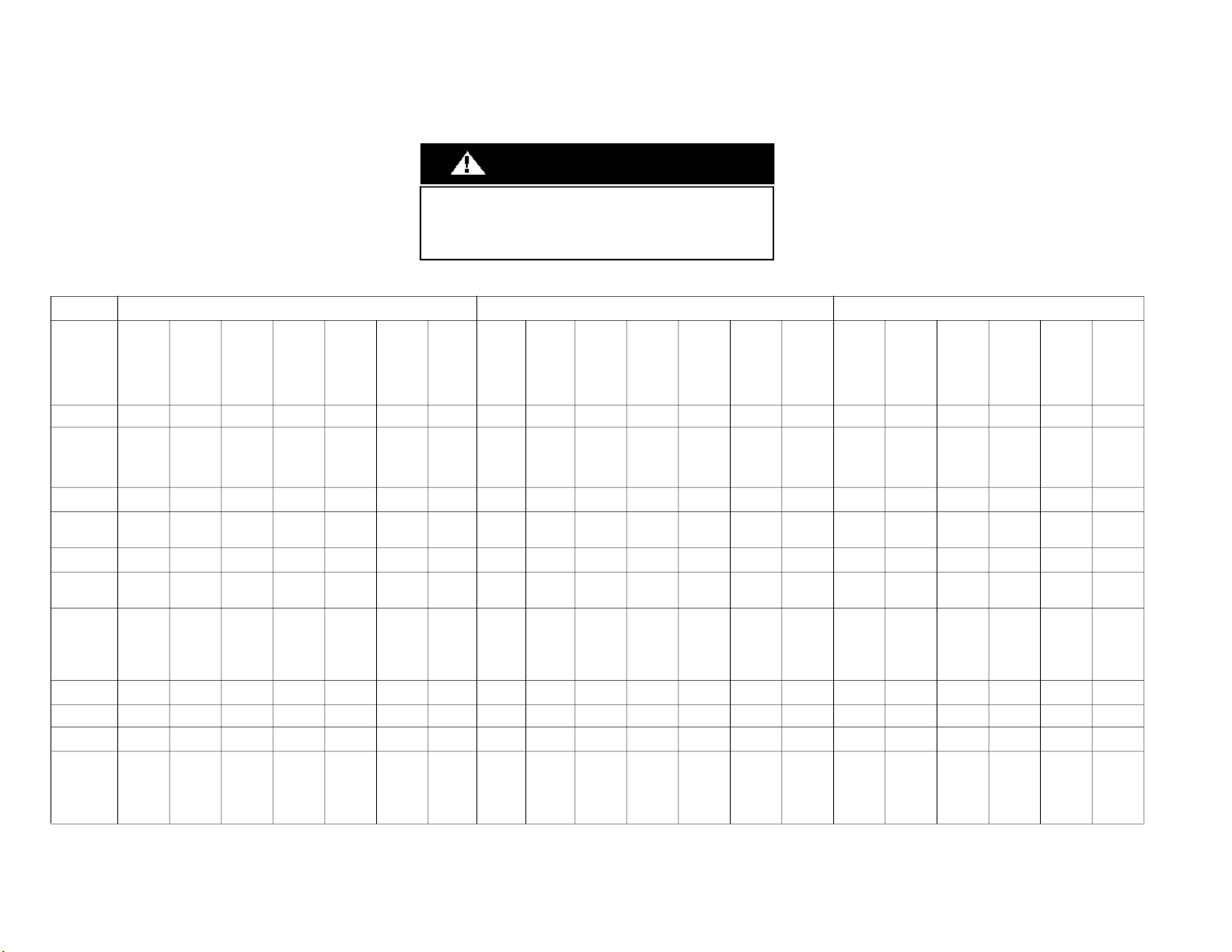

ERROR DIAGNOSIS AND TROUBLESHOOTING WITHOUT ERROR CODE

WARNING

UNIT DAMAGE HAZARD

Be sure to turn off unit before any maintenance to prevent damage or

injury.

Table 11 — Remote Maintenance

Remote

Maintenance

Possible causes

of trouble

Unit will not start

Operation is

erratic,

unpredictable or

unit is

unresponsive

Cannot set

desired temp.

Unit is on

but the wind is

not cold (hot)

Unit runs, but

shortly stops

The unit starts up

and stops often

Unit runs

continuously

however

insufficient

cooling

(heating)

Cool can not

change to heat

Unit is noisy

Unit emits

bad odor

Test method/

remedy

Power failure

Test voltage

The main

power tripped

☆ ☆ ☆ ☆

Close the

power switch

Electrical Circuit Refrigerant Circuit Others

Loose

connections

Inspect

connections

- tighten

Faulty

transformer

Change the

transformer

The setting

The voltage is

too high or

Test voltage

The remote

too low

control is

powered off

☆ ☆ ☆

☆ ☆ ☆ ☆

Replace the

battery of the

remote control

Broken

remote

control

☆ ☆

Replace

remote

control

Dirty

Dirty

condenser

air filter

☆ ☆ ☆ ☆ ☆ ☆ ☆ ☆

☆

Clean

or

replace

fins

Clean

higher/lower

setting temp.

The ambient

temp is

temp. is too

high/low when

than the

the mode is

room's

(cooling/

heating)

Adjust the

cooling/

heating

☆ ☆ ☆

Turn the

AC later

Fan mode

Adjust to

Cool mode

SILENCE

function is

activated

(optional

function)

Turn off

SILENCE

function.

Frosting and

defrosting

frequently

Turn the

AC later

Heavy load

condition

Check the

heat load

Interference

Loose hold

down bolts

and/or screws

Tighten bolts

or screws

Not air tight

☆ ☆

Close all

windows and

doors

Air inlet or

outlet of either

unit is blocked

Remove the

obstacles

from cell

phones

towers and

remote

boosters

☆

Reconnect the

power or

press ON/

OFF button on

remote control

to restart

Shipping

plates

remained

attached

Remove

them

20 Specifications subject to change without notice. SM619PHA-03

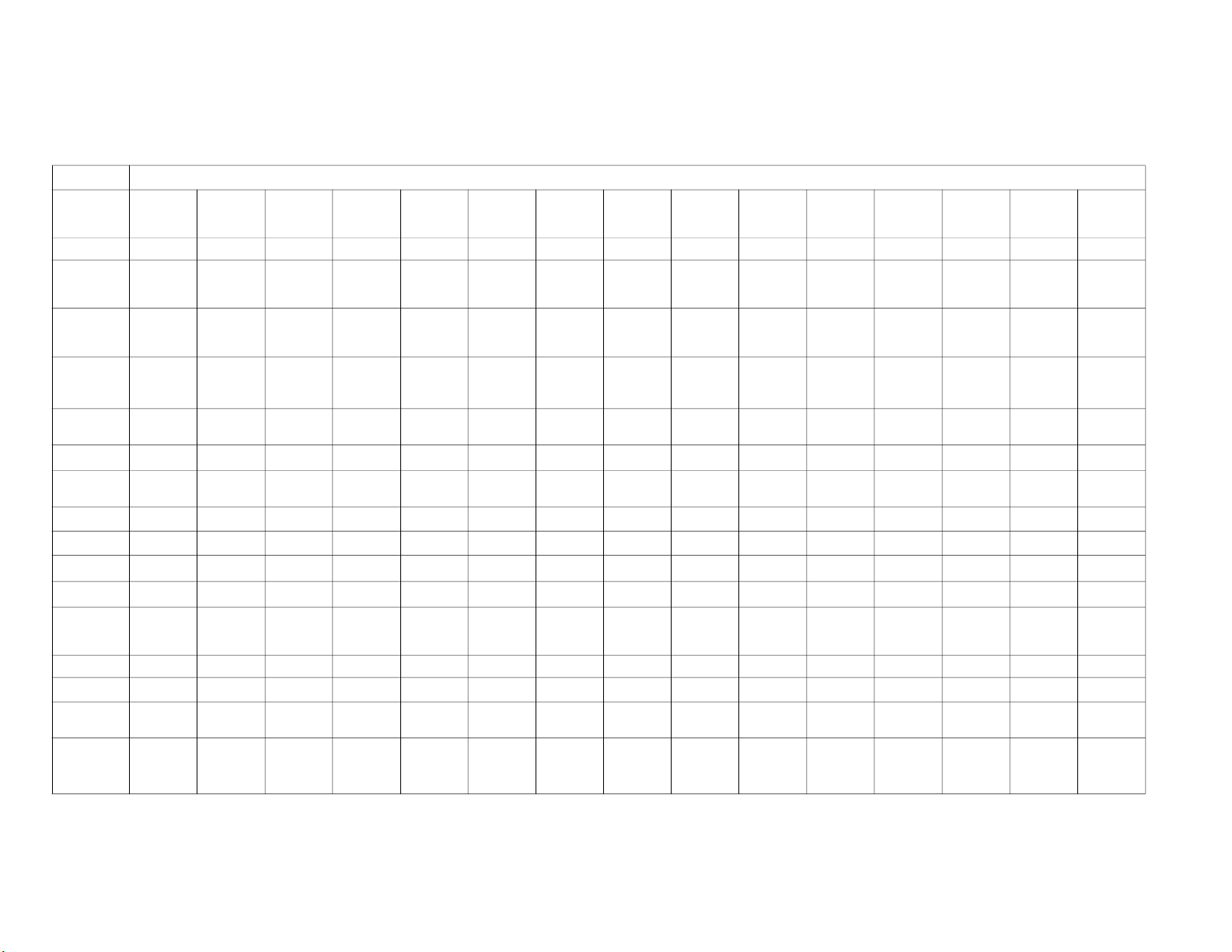

ERROR DIAGNOSIS AND TROUBLESHOOTING WITHOUT ERROR CODE (continued)

Table 12 — Field Maintenance

Field

Maintenance

Possible

causes

of trouble

Unit will not start

Compressor will

not start however

the fan runs

Compressor and

condenser

(outdoor) fan will

not start

Evaporator

(indoor)

fan will not start

Condenser

(outdoor) fan will

not start

Unit runs but

shortly stops

Compress or short

cycles due to

overload

High discharge

pressure

Low discharge

pressure

High suction

pressure

Low suction

pressure

Unit runs

continuously but

insufficient cooling

Too cool

Compressor is

noisy

Horizontal louver

can not revolve

Test method /

remedy

Power failure

☆ ☆

Test voltage

Blown fuse

or varistor

Inspect fuse

type & size

Loose

connections

☆ ☆ ☆ ☆

☆ ☆ ☆

Inspect

connections -

tighten

Shorted or

broken wires

Test circuits

with tester

Safety device

opens

☆ ☆ ☆ ☆ ☆

☆ ☆ ☆

☆ ☆ ☆ ☆

☆ ☆ ☆ ☆ ☆

Test continuity

of safety

device

Faulty

thermostat/

room temp

sensor

Test continuity

of thermostat /

sensor &

wiring

Wrong setting

place of temp

☆ ☆

Place the

temp. sensor

at the central

of air in- let

sensor

grille

Electrical Circuit

Faulty

transformer

Check control

circuit with

tester

Shorted or

open capacitor

Check

capacitor with

tester

Faulty

magnetic

contact for

compressor

☆ ☆

☆ ☆

Test continuity

of coil &

contacts

Faulty

magnetic

contact for fan

Test continuity

of coil &

contacts

Low voltage

Test voltage

Faulty

stepping motor

Replace the

stepping motor

Shorted or

grounded

compressor

Check

resistance with

Megger tester

Shorted or

grounded fan

motor

Check

resistance with

Megger tester

SM619PHA-03 Specifications subject to change without notice. 21

Loading...

Loading...